Page 1

Dear MyChron 3 Plus/Gold/Gold XG Owner

Your MyChron 3 Plus/Gold/Gold XG represents the newest generation of Aim

data acquisition systems for car/bike racing that provide the driver with a wide,

easy to use and multifunctional display.

MyChron 3 Plus/Gold/Gold XG monitors and displays RPM, four analog inputs

(temperatures and pressures for Plus version, temperature, pressures,

potentiometers, Lambda sond for Gold versions), speed, gear number and lap

(split) times. It has a backlight, which can be switched on during night racing, and

a huge internal flash memory (512 kbyte for Plus version and 2 Mbyte for Gold

ones) which guarantees the capacity to record up to 315 laps. The gauge is

equipped with an USB port, used to interface the instrument with a PC. The new

software Race Studio 2 will allow you to easily configure the instrument, to

download data to a PC and to analyse them. Finally, the internal lateral G-force

sensor (standard equipment for Gold CAR versions) or the external gyroscope

(optional equipment for Gold BIKE versions) will allow you the ability to create a

circuit map, in order to correlate your data to your track position.

Our Customer Service is available every day from 9 to 5 and at most all the major

races throughout the country to provide you with personal service. If you have any

questions, need help, or want to give us feedback, please call us or visit our

website www.aim-sportline.com

.

Thank you for your MyChron 3 Plus/Gold/Gold XG purchase.

1

Page 2

Table of contents

ETTING STARTED WITH MYCHRON 3 PLUS/GOLD/GOLD

G

HRON 3 PLUS/GOLD/GOLD XG AND ITS PARTS

MYC

XG.............................................4

.............................................................5

The Display...................................................................................................................6

The Keyboard................................................................................................................7

The alarm led and the gear display ..............................................................................8

The Speed sensor for CAR installations........................................................................9

The Speed sensor for BIKE installations ....................................................................10

The Temperature sensors............................................................................................10

The LAP receiver ........................................................................................................11

The LAP transmitter (Beacon) ....................................................................................12

OW TO INSTALL MYCHRON 3 PLUS/GOLD/GOLD

H

XG.......................................................14

Installing MyChron 3 Gold XG...................................................................................14

Installing the H2O thermocouple (thermoresistance) .................................................16

Installing the EGT thermocouple................................................................................16

Installing the under-spark thermocouple....................................................................18

Installing the “CAR” speed sensor.............................................................................19

Installing the “BIKE” speed sensor ...........................................................................21

How to power the gauge .............................................................................................21

How to sample the RPM .............................................................................................21

N TRACK

O

...........................................................................................................................22

Configuration functions ..............................................................................................22

Utility functions ..........................................................................................................37

Maintenance ...............................................................................................................42

HRON 3 PLUS/GOLD/GOLD XG AND THE COMPUTER

MYC

..................................................44

Software installation...................................................................................................45

Installing the USB drivers...........................................................................................48

USB drivers troubleshooting.......................................................................................52

ONFIGURATION VIA SOFTWARE

C

........................................................................................56

Creating a new configuration .....................................................................................57

Channels .....................................................................................................................60

Customize sensor ........................................................................................................62

Channels configuration...............................................................................................64

2

Page 3

Transmitting the configuration ...................................................................................67

Sensors calibration (Gold/Gold XG versions only) ....................................................67

Gear sensor calibration..............................................................................................69

Online visualization ....................................................................................................70

OW TO DOWNLOAD A TEST

H

Downloading a test .....................................................................................................72

Inserting the test in a database...................................................................................74

OW TO USE RACE STUDIO ANALYSIS

H

How to load a test.......................................................................................................78

How to plot a channel.................................................................................................81

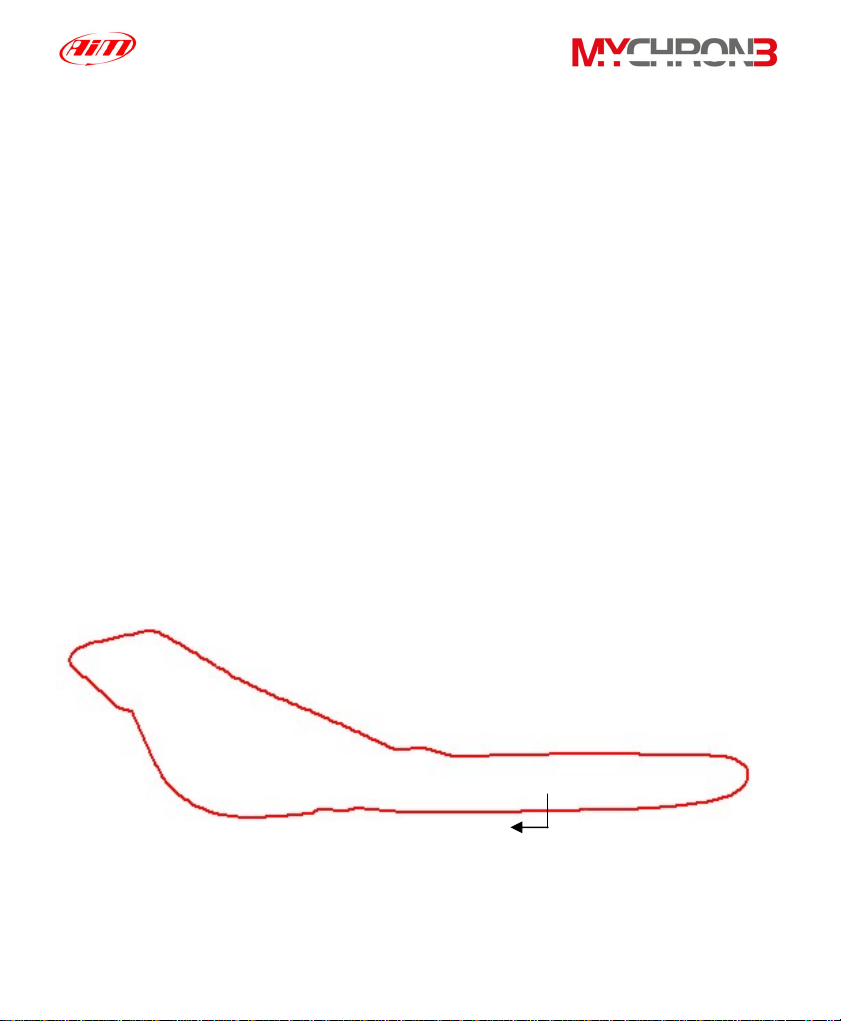

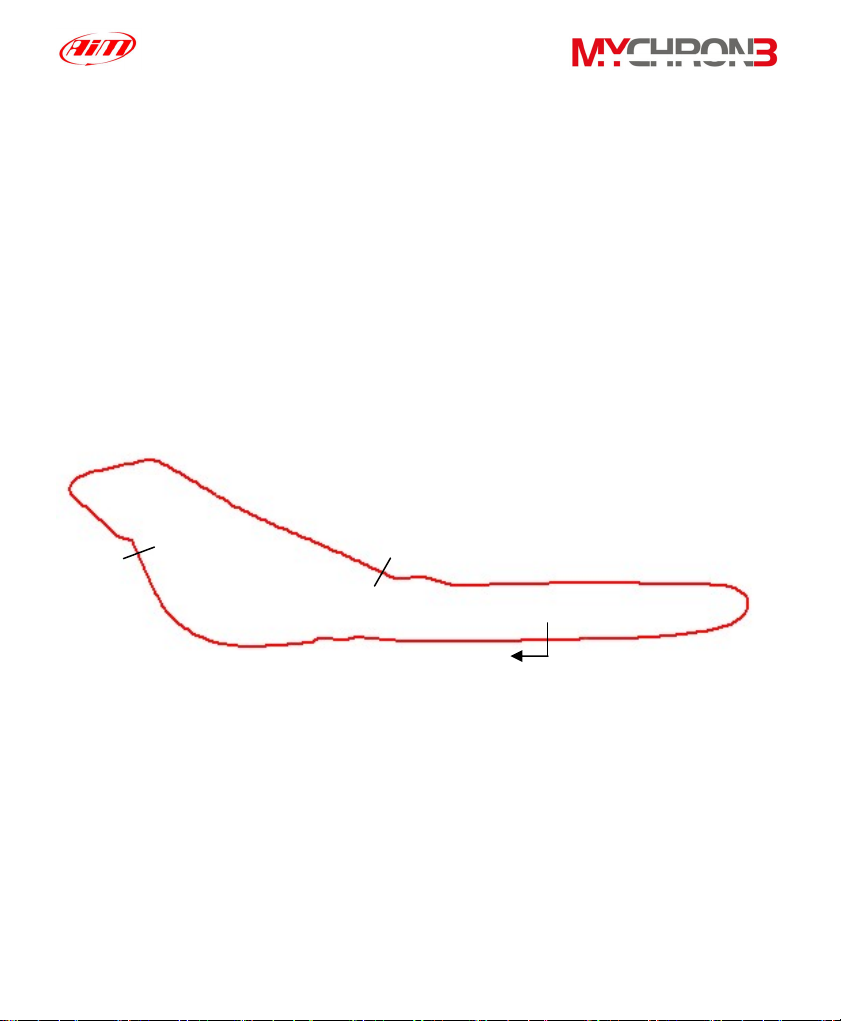

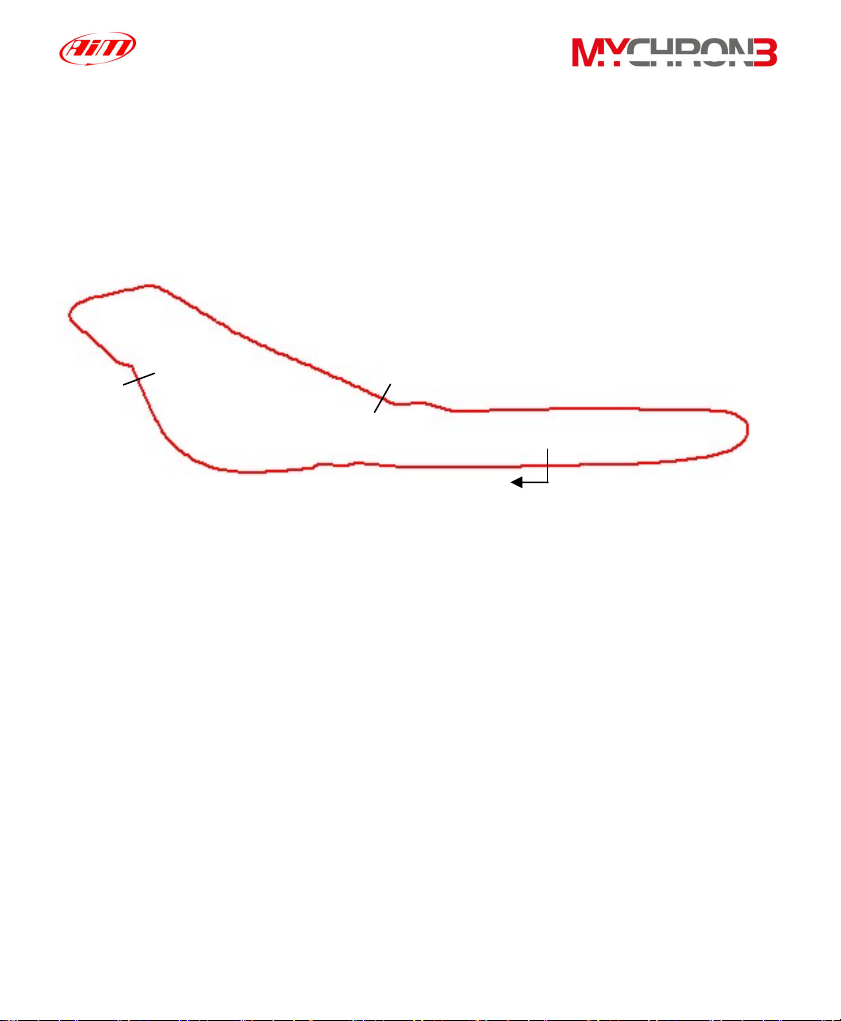

How to create your track map (Gold/Gold XG versions only)....................................83

Track map creation troubleshooting...........................................................................86

HRON 3 PLUS/GOLD/GOLD XG QUICK REFERENCE GUIDE

MYC

Configuration via keyboard ........................................................................................87

How to use MyChron 3 Plus/Gold/Gold XG...............................................................90

Configuration via software .........................................................................................90

...............................................................................................72

................................................................................77

..........................................87

3

Page 4

Getting Started with MyChron 3 Plus/Gold/Gold XG

Aim has developed and tested your MyChron 3 Plus/Gold/Gold XG to provide

precise and accurate results.

Here are the parts of your system:

• MyChron 3 Plus/Gold Display Unit. MyChron 3 Gold XG display unit and

Junction box.

• Gear tooth speed sensor (CAR installations) or magnetoresistive speed

sensor (BIKE installations).

• Temperature sensor: you may choose among Water thermocouple, Water

thermoresistance, Exhaust Gas Sensor or Under-spark thermocouple.

• Standard harness (available, on request, as specifications).

• RPM cable (only for MyChron 3 Gold XG).

• USB data download cable and Race Studio 2 CD-ROM.

Optional accessories:

• M5 inline fitting for water thermocouple/thermoresistance.

• External gyroscope for MyChron 3 Gold (BIKE installations).

• Oil/fuel pressure sensor.

• Linear and angular potentiometers (Gold versions only).

• Sensors’ extension cables.

• Optic lap receiver and transmitter.

4

Page 5

MyChron 3 Plus/Gold/Gold XG and its parts

Before installing MyChron 3 Plus/Gold/Gold XG, please read carefully these

installation instructions.

It is very important that your MyChron 3 Plus/Gold/Gold XG is correctly

installed to capture consistent and accurate data. Incorrect installation may

result in system malfunction.

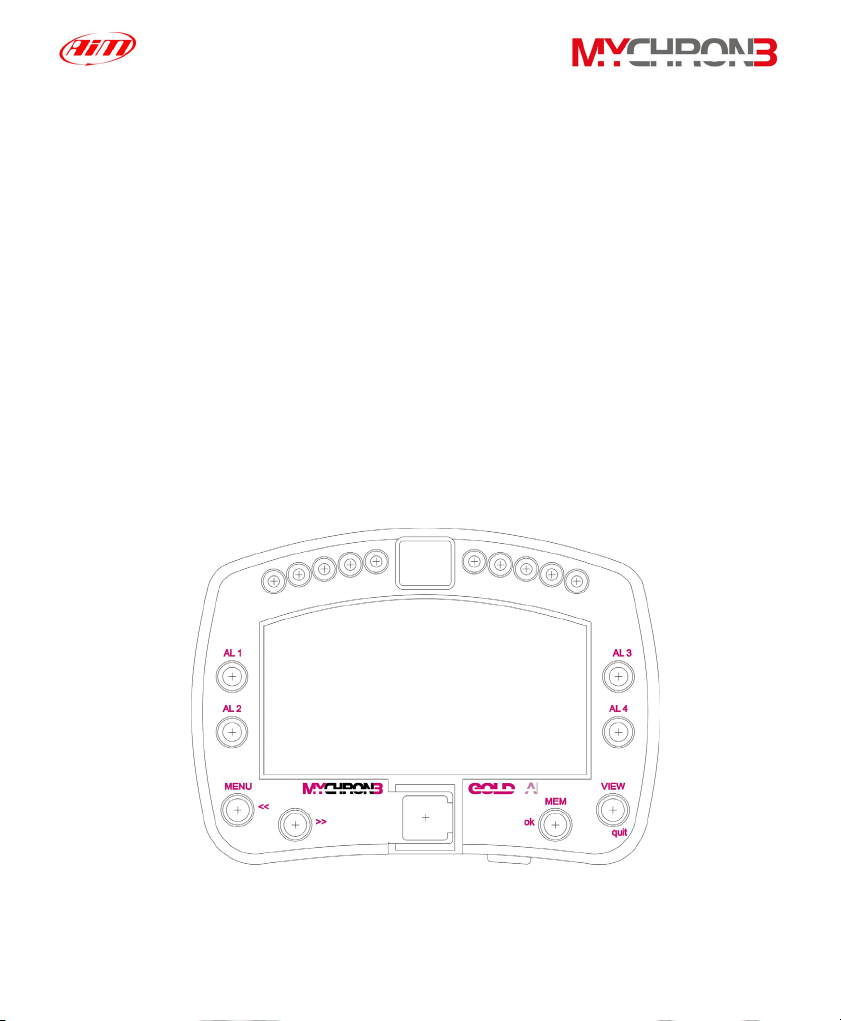

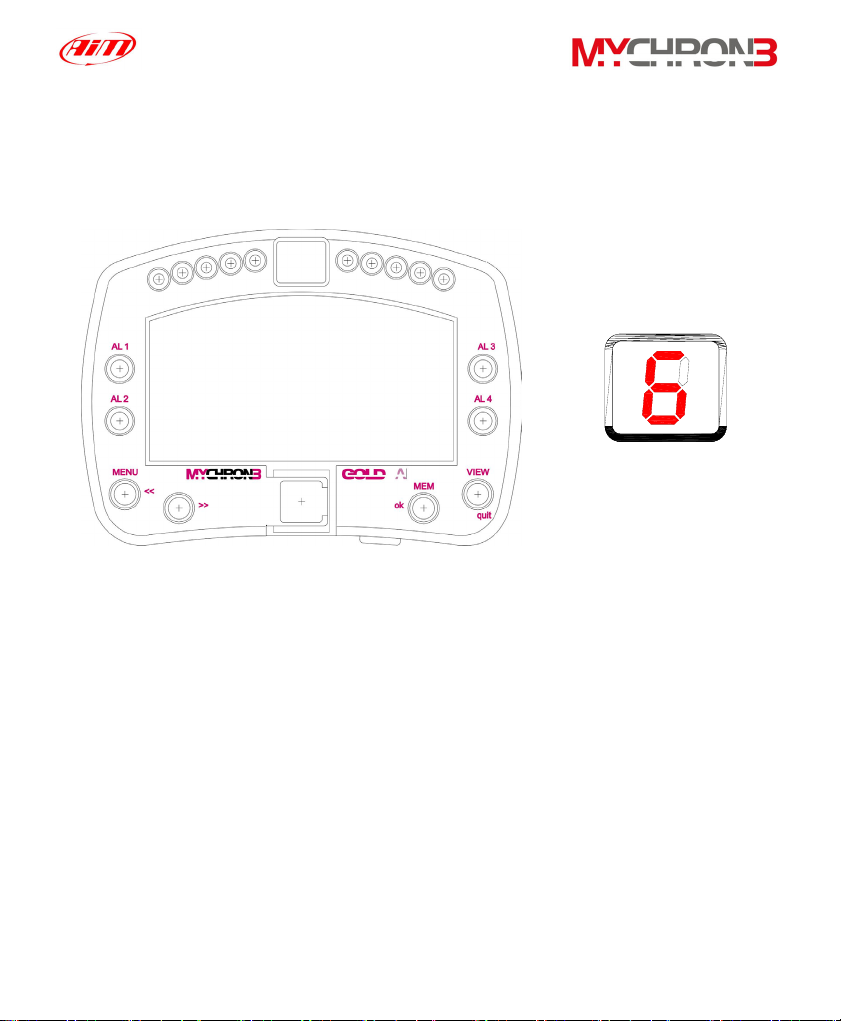

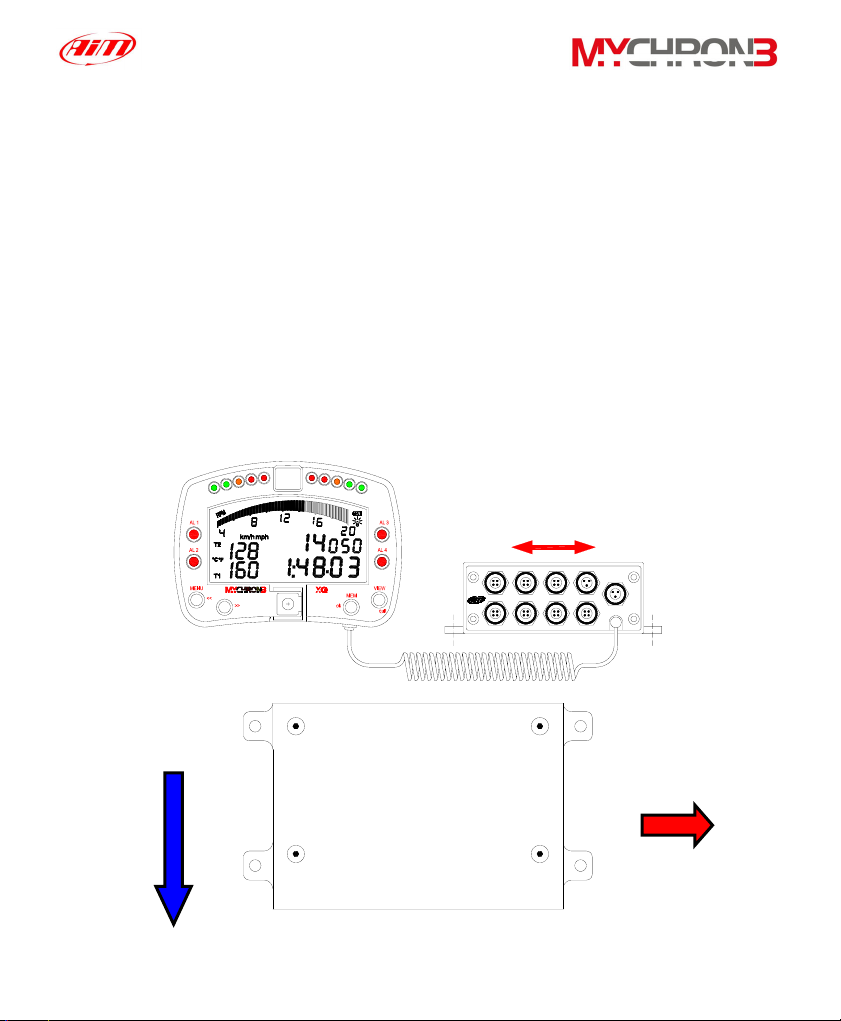

In the following drawing it is represented your MyChron 3 Gold display unit: in

the middle of the picture it is visible the wide display, in the lower part there is the

keyboard, on the left and on the right there are 4 coloured alarm led (labelled from

AL.1 to AL4) and, in the upper part, you can find the gear number display and 10

fully configurable RPM led.

In the following pages it will be described the different parts of MyChron 3

Plus/Gold/Gold XG system.

5

Page 6

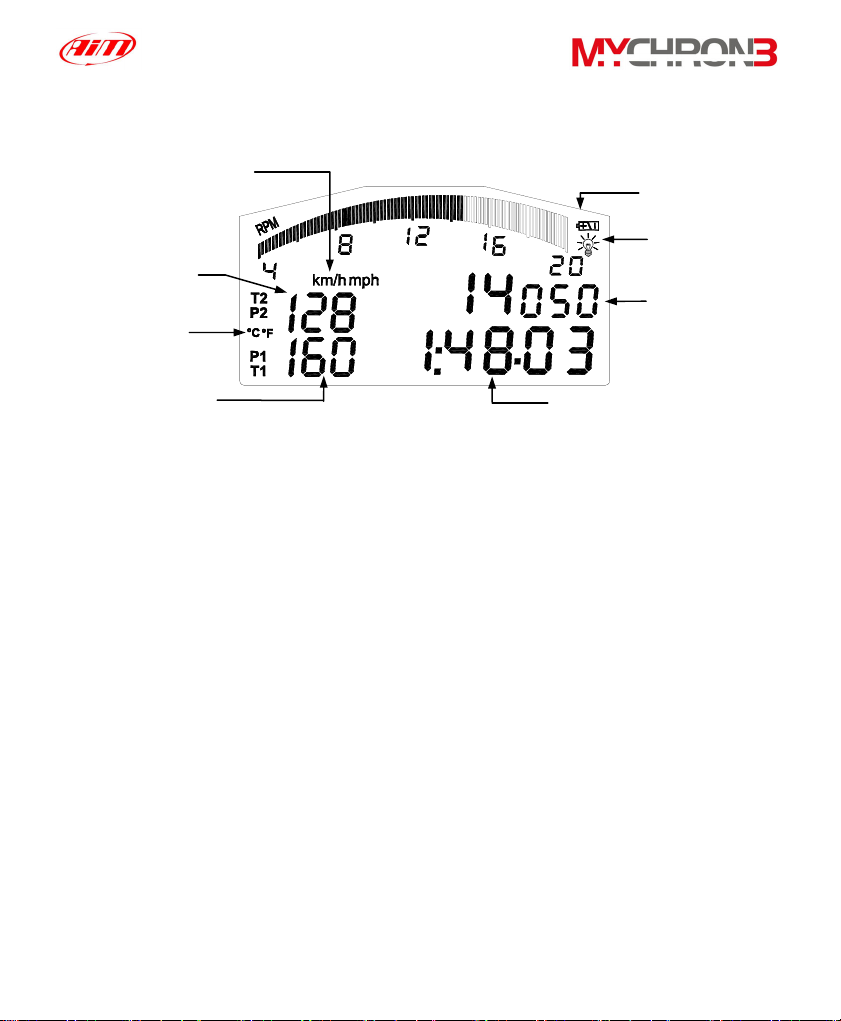

Speed measure

unit

Channels #2 and

#4

Temperature

measure unit

The Display

Low battery

warning

Night Vision

Configurable

display: RPM,

speed, battery

voltage

Channels #1 and

#3

Lap (split) time

The wide display with backlight shows RPM (graphical bar), temperature and

pressure analog inputs, test and lap number and, when the vehicle passes in front

of the beacon, it shows the Lap Time (or Split Time). It is also possible to

configure a second display page (using button VIEW) in order to see the RPM

digital value (as shown in the previous drawing), the vehicle speed (in km/h or

Mph) or the best lap time. When you are not running it is also possible to see the

battery voltage.

The display also shows some small icons, showing the configured Temperature

unit of measure (Celsius [°C] or Fahrenheit [°F]), the Speed unit of measure (km/h

or Mph), the current displayed measure (P1 → P4 for pressures, T1 → T2 for

temperatures, 1 → 4 for custom sensors) the backlight option and the Low Battery

Warning, that appears when the battery voltage is low.

6

Page 7

The Keyboard

MENU

<<

>>

The Keyboard is composed of four push-buttons and it is used to configure the

instrument, to recall recorded data and to clear the internal memory.

The four pushbuttons are used for:

MENU/<<

>>

MEM/OK

VIEW

The gauge automatically switches ON/OFF when the user switches on/off the

Used to enter configuration mode and to switch to previous

configuration option; also used to turn on/off backlight during a test.

Used in configuration to switch to next option; also used to switch

between the 4 analog inputs (temperatures and pressures).

Used to confirm a configuration, to retrieve recorded data and to

see the best lap time.

Used to exit configuration mode without saving, or to switch the

display from “digital RPM” value to “battery voltage”, to “best lap

time” or to “vehicle speed”.

USB

MEM

ok

VIEW

quit

car’s (bike’s) electric switchboard.

To run the system in DEMO MODE, while holding down button MENU/<< and >>,

press button VIEW.

In the middle of the keyboard, protected by a plastic cover, it is located the

instrument’s USB port (used to connect the instrument to a PC).

7

Page 8

The alarm led and the gear display

In the following picture it is reported a drawing of MyChron 3 Gold Car display

unit.

• The alarm led are placed on the left and right of the main display: on the

left there are the led 1 and 2 and, on the right, there are the led 3 and 4.

The four led are red colored.

• The RPM led are placed in the display unit upper part: this fully

configurable led turn on two-by-two, advising the driver to shift gear. The

4 external led (2 on the left and 2 on the right) are green colored, the 2

middle ones are orange colored and the 4 remaining ones are red

colored.

• The Gear display is placed in the middle of the RPM led. This digital

display shows the current gear number; the instrument is able to display

up to 9 gears.

8

Page 9

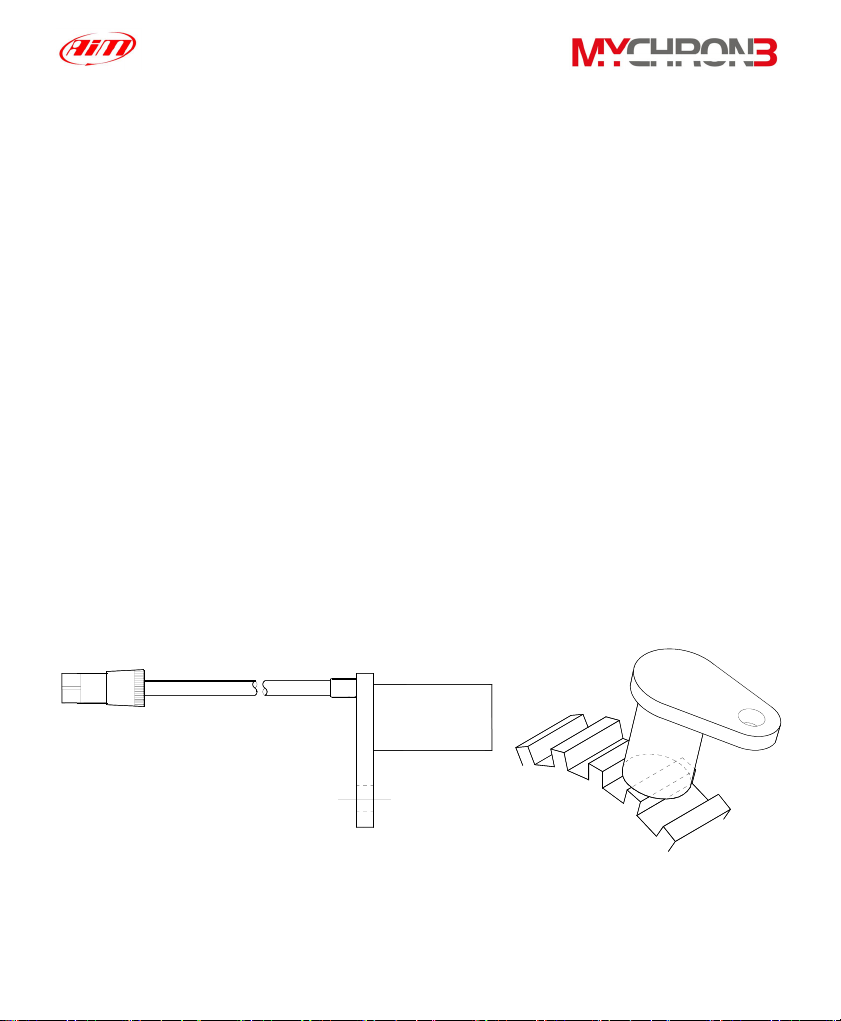

The Speed sensor for CAR installations

MyChron 3 Plus/Gold/Gold XG is equipped with a speed sensor, which allows

the pilot to measure vehicle’s speed.

The wheel speed sensor for gear tooth belongs to the “non contact” devices and it

needs a ferrous metal trigger to pass the sensor face.

The instrument’s measure range is included between 0.5 and 2 mm: the optimum

sensing distance is 1 mm.

Optimum sensor performance is dependent on the following variables, which

must be considered in combination: trigger material, geometry and speed, sensor

trigger gap, magnetic material in close proximity. Please refer to the “Installing the

CAR speed sensor” paragraph for further information.

The speed sensor is supplied with an 80 mm long cable.

In the following drawing you can see the gear tooth speed sensor side view (on

the left) and a 3D view (on the right).

9

Page 10

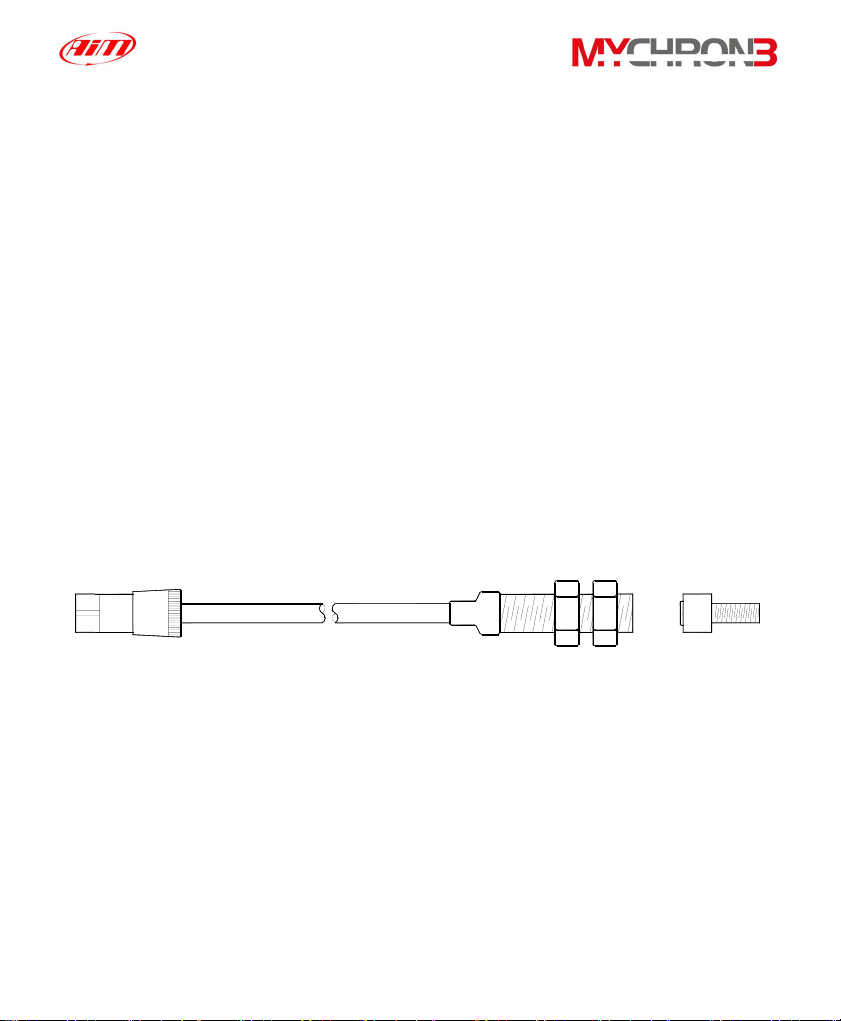

The Speed sensor for BIKE installations

The wheel speed sensor for bike installations belongs to the “magnetoresistive –

non contact” devices and it needs a magnetic metal trigger to pass the sensor

face.

The magnetoresistive speed sensor is a high sensing distance instrument: its

measure range goes from 8 to 15 mm and the optimum sensing distance is

10 mm.

Please refer to the “Installing the BIKE speed sensor” paragraph for further

information.

The speed sensor is supplied with a 1700 mm long cable.

In the following drawing you can see the bike speed sensor and, on the right, the

magnetic trigger (supplied together with the sensor).

The Temperature sensors

MyChron 3 Plus/Gold/Gold XG supports up to 4 temperature sensors. There are

4 types of temperature sensors that are available for selection or subsequent

purchase:

O - Water thermocouple or thermoresistance: M5 type.

1. H

2

2. EGT - Exhaust gas thermocouple.

3. CHT - Cylinder head thermocouple.

10

Page 11

1

2

3

All temperature sensors are supplied with a 0.25 m long connection cable.

Thermocouple or thermoresistance extension cables are available with lengths

included between 0.5 and 2 m and, on request, as specified dimensions.

The LAP receiver

The infrared lap receiver is used to recognise a signal, called “lap marker”,

emitted from an infrared transmitter (Beacon).

The Infrared receiver has to “see” the

transmitter placed on the trackside, so

remember to install it with the receiver

eye (the grey point in the photo on the

left) pointed to the beacon transmitter.

11

Page 12

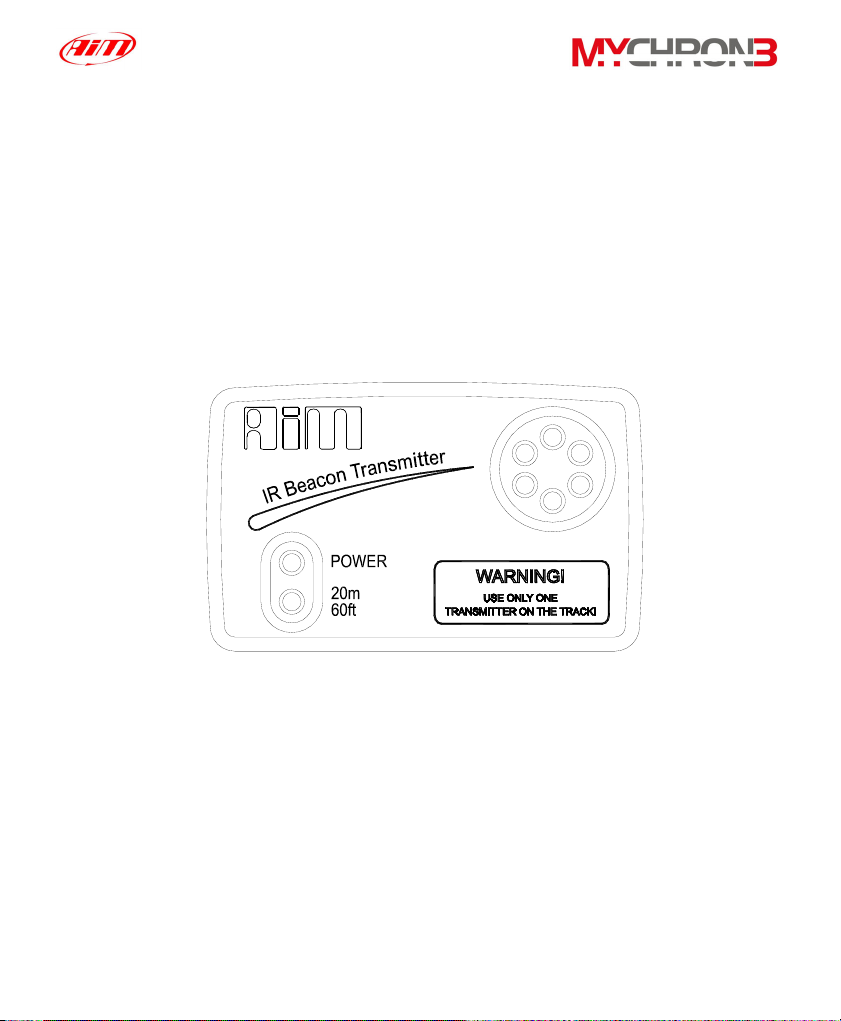

The LAP transmitter (Beacon)

The optical Beacon Transmitter has to be placed on the trackside to mark laps.

Ensure the infrared receiver eye faces the side of the track where the Beacon

has been placed, otherwise the system will not record lap time.

The Beacon transmitter is powered using 8 AA batteries or an external 12V power

cable. If you are using 8 AA batteries, unscrew the back cover of the Beacon

transmitter and place the battery pack into the transmitter casing.

The transmitter has two operating modes: Low power and High power. The Low

Power Mode has to be used when the track is less than 10 meters wide, while

the High Power mode has to be used when the track is wider than 10 meters.

To activate the High/Low Power function, please open the Beacon transmitter

with a corkscrew and place the clip (located directly below where the battery

pack is attached to the beacon transmitter board) either over one of the two

connectors (for low power mode) or over the two connectors (for high power

mode).

12

Page 13

When the Beacon transmitter operates in high power mode, both the power led

lights will light up when the transmitter is turned on.

Please, remember that, in High Power Mode, the transmitter has to be

powered by an external 12 Volts battery.

13

Page 14

How to install MyChron 3 Plus/Gold/Gold XG

Now you can start installing your MyChron 3 Plus/Gold/Gold XG on your

car/bike.

It is recommended to follow these instructions in order to preserve your

instrument and to capture consistent and accurate data.

We remind you that your MyChron 3 Plus/Gold/Gold XG is not equipped with

internal batteries, and so it needs to be powered by an external power source (the

car / bike battery).

The first installation step consists in mounting the Gauge in your car’s

(motorbike’s) cockpit. It is recommended to choose a place where the instrument

will not be in contact with oil or fuel, make sure that the gauge is not installed too

close to heat sources and protect the instrument from vibrations.

In order to correctly measure the lateral g-force using the internal accelerometer

(MyChron 3 Gold only), it is suggested to install the gauge with the display

perpendicular to the vehicle’s speed.

Installing MyChron 3 Gold XG

Your MyChron 3 Gold XG is composed of two separate objects (the display unit

and the Junction box) connected by a pig-tail cable.

It is recommended to choose a place where both the display unit and the Junction

box are not in contact with oil or fuel, make sure that the gauge is not installed too

close to heat sources and protect the instrument from vibrations.

14

Page 15

In particular, pay attention when installing the Junction box:

•

Avoid rigid connections between the Junction box and the chassis. It is

suggested to use anti-vibration mountings (Silent Blocks).

•

We remind you that your MyChron 3 Gold XG is not equipped with

internal batteries, and so it needs to be powered by an external power

source (i.e. the car battery).

•

In order to correctly measure the lateral g-force using the lateral

accelerometer (mounted inside the Junction box), it is suggested to install

the gauge with the Junction box’s front panel perpendicular to the car’s

speed, as shown in the following image.

Internal lateral accelerometer

CH1

CH3

CH2

CH4

Power IN

Speed

RPM

Beacon

GEAR

Speed

direction

Junction

Lateral

accelerometer

Box

15

Page 16

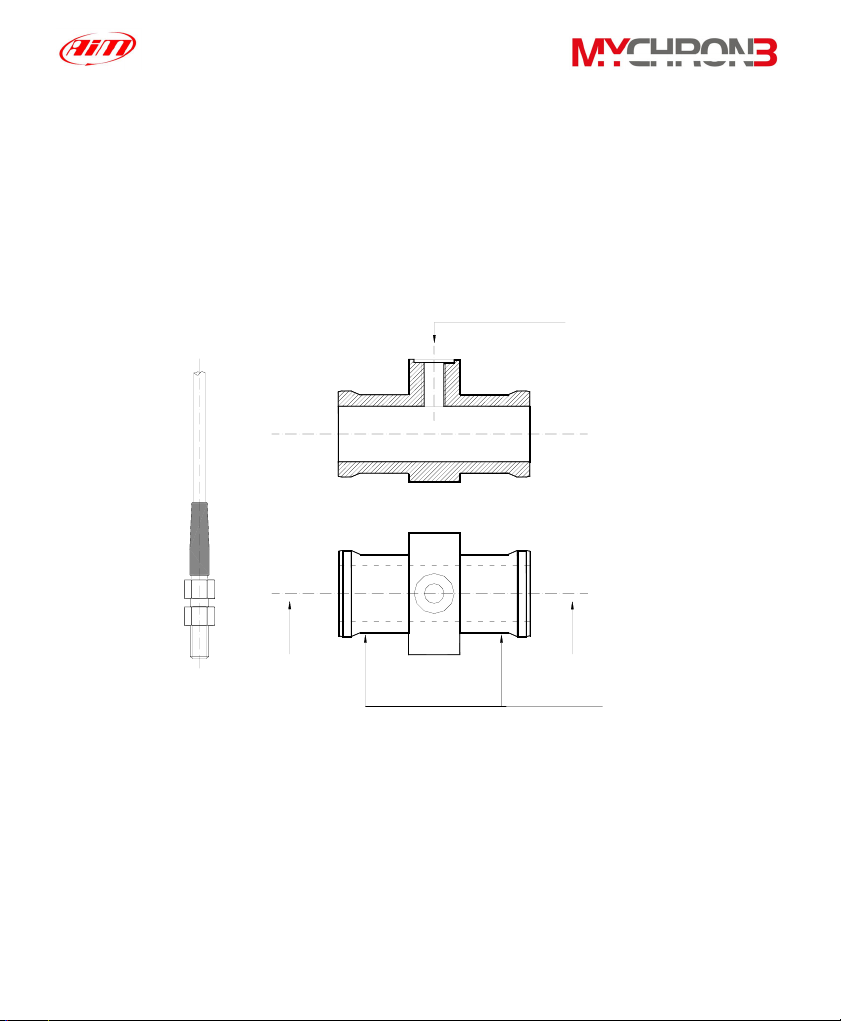

Installing the H2O thermocouple (thermoresistance)

The H

O thermocouple and the thermoresistance can be installed in the inline

2

water fitting (sold separately).

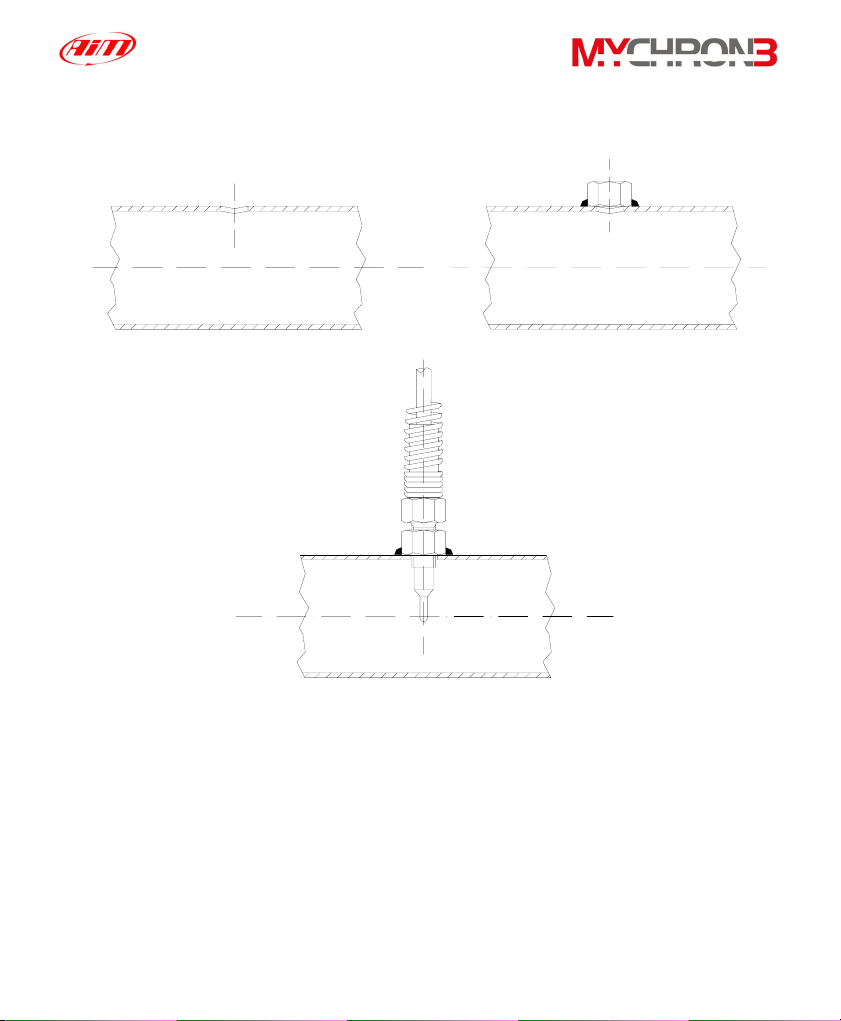

In the following drawing it is represented how to correctly install the water

thermocouple (thermoresistance) for the M5 type.

The water

thermocouple

SEZ A - A

A A

Water thermocouple

must be

placed here

Junction

must be

hanged here

with two

wiring wraps

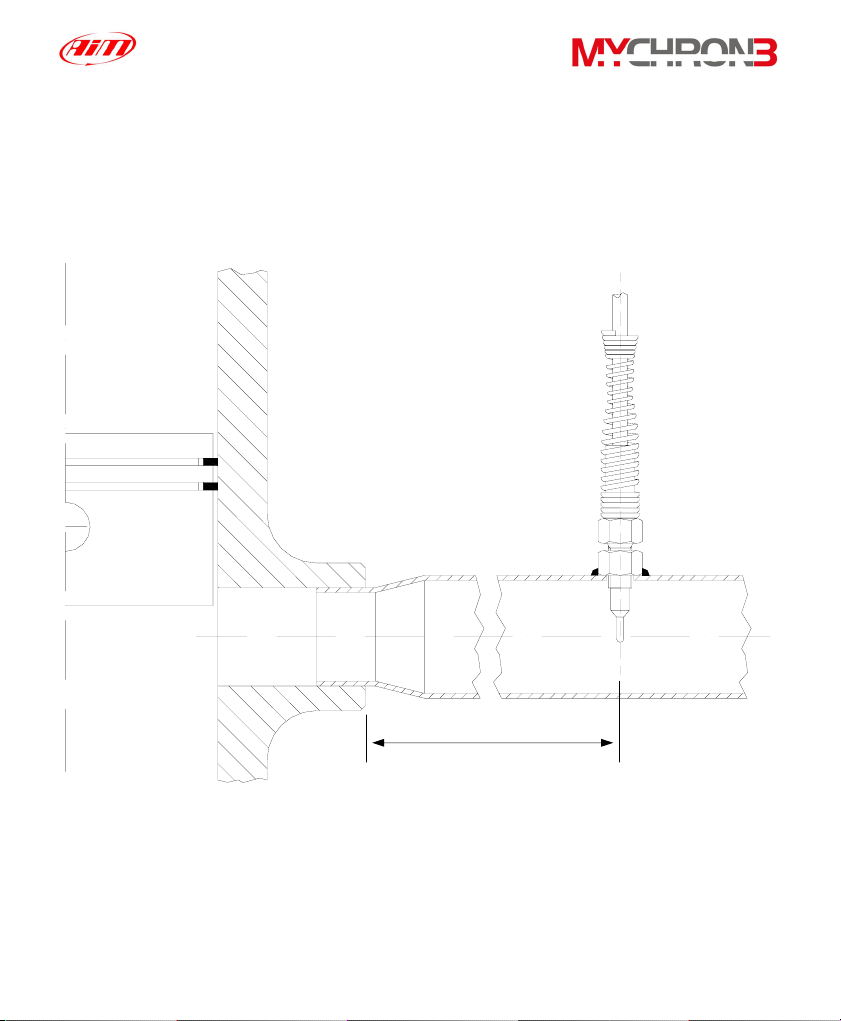

Installing the EGT thermocouple

The Exhaust Gas Thermocouple (EGT) should be positioned inside the exhaust

header pipe at a distance of 150 mm (5.9 inches) from the exhaust port.

16

Page 17

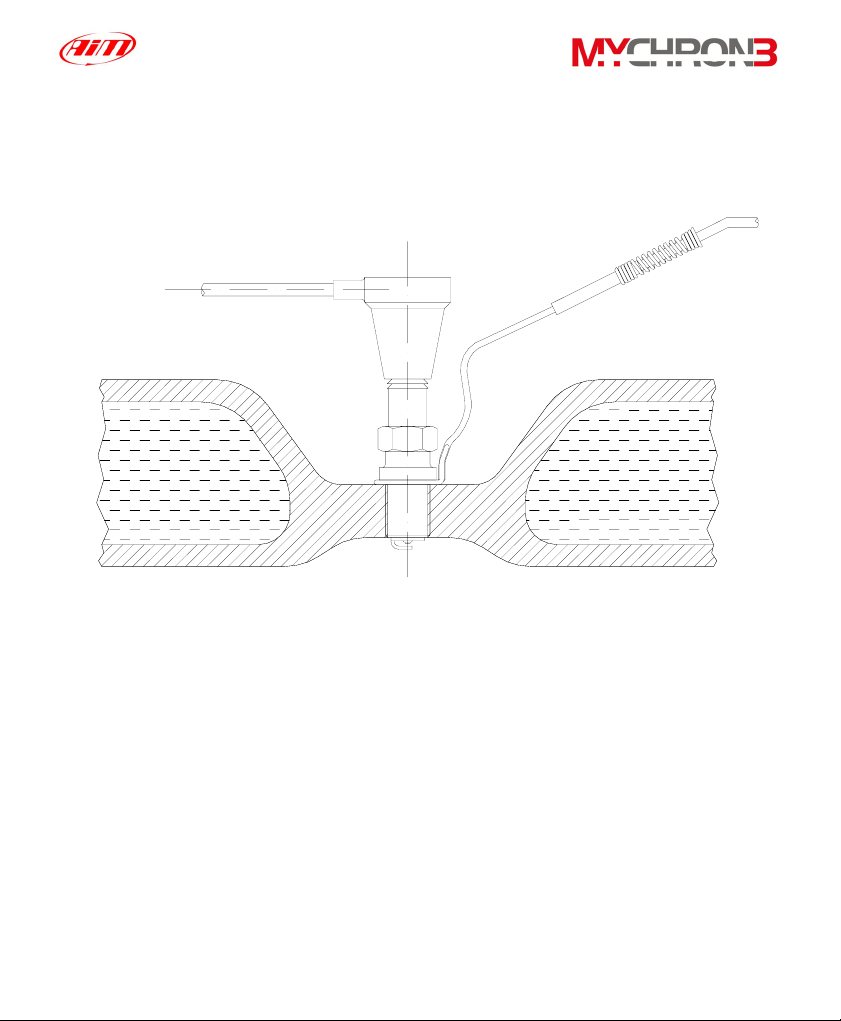

In the following drawing it is represented a correct installation of the EGT

thermocouple.

It is recommended that the probe be inserted between 25% and 50% inside the

exhaust gas header.

150 mm

To install the EGT thermocouple, please follow these instructions:

1. Make a 5 mm (0.2 inches) hole inside the exhaust header;

2. Weld the little nut to the exhaust header in the place where the hole has

been drilled;

17

Page 18

3. Connect the remaining part of the thermocouple and fix it to the exhaust

header by screwing it.

1 2

Weld

3

Installing the under-spark thermocouple

When using a Cylinder Head Thermocouple (CHT) sensor, always remove the

spark plug washer before inserting the spark plug into the sensor.

When tightening and loosening the spark plug, minimise movement of the sensor

to avoid damage.

18

Page 19

y

In the following drawing it is represented the correct installation of the under-spark

thermocouple.

CHT thermocouple

Spark

linder head

C

Installing the “CAR” speed sensor

The wheel speed sensor for phonic wheel belongs to the “non contact” devices

and it needs a ferrous metal trigger to pass the sensor face.

When mounting the sensor, please firmly install it on a self-made iron bracket and

make sure that the distance between the sensor and the phonic wheel is included

between 0.5 and 2 mm (1 mm is the optimum value). Once the sensor has been

installed, please plug the sensor’s Binder connector in your MyChron 3

Plus/Gold/Gold XG.

19

Page 20

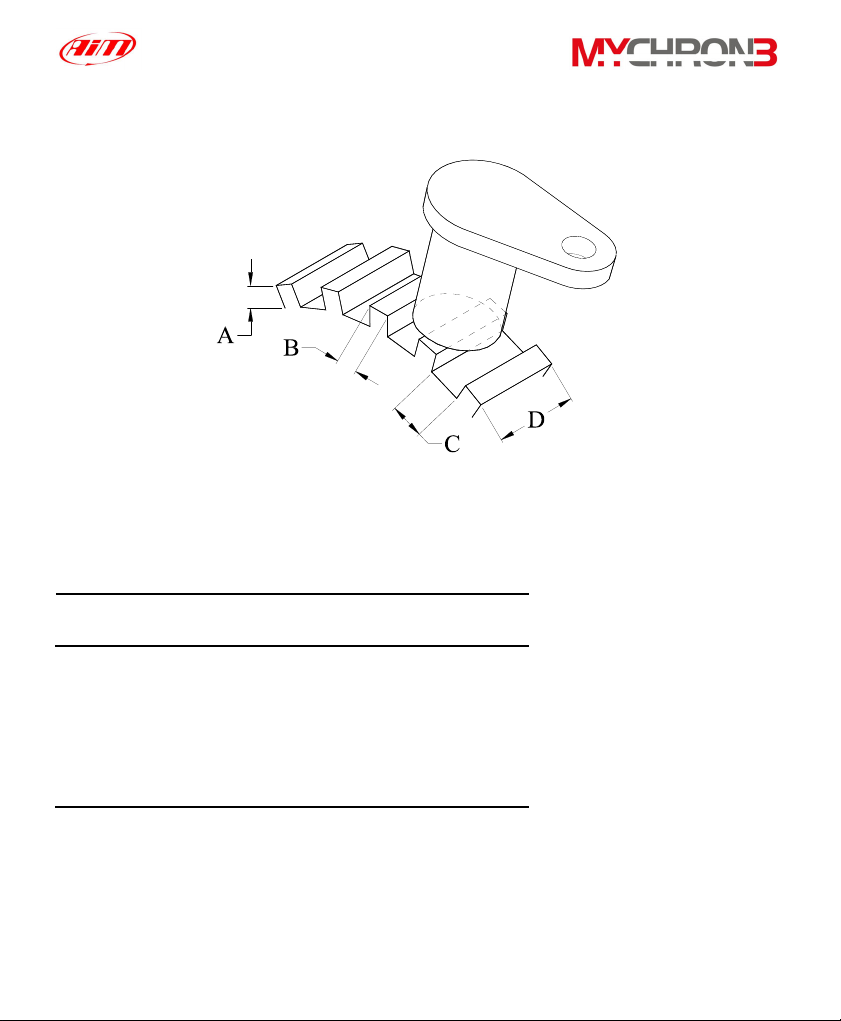

In the following drawing it is reported the speed sensor installation.

In the following table it is reported a short description of the minimum values for

the trigger dimensions A, B, C and D required for a correct sensor’s working.

Description Value (Minimum)

Tooth height (A) 5.06 mm

Tooth width (B) 2.54 mm

Tooth spacing (C) 10.16 mm

Thickness (D) 6.35 mm

In short, optimum sensor performance is dependent on the following variables,

which must be considered in combination: trigger material, geometry and speed,

sensor trigger gap, magnetic material in close proximity.

20

Page 21

Installing the “BIKE” speed sensor

The wheel speed sensor for bike installations belongs to the “magnetoresistive –

non contact” devices and it needs a magnetic trigger to pass the sensor face.

When mounting the sensor, please firmly install it on a self-made iron bracket and

make sure that the distance between the sensor and the magnetic trigger is

included between 15 and 8 mm (10 mm is the optimum value). Once the sensor

has been installed, please plug the sensor’s Binder connector in your MyChron 3

Gold.

How to power the gauge

The gauge must be powered by an external 9-15 VDC power source. Do not

exceed these limits.

Connect the red wire to the battery’s positive pole (+) and the black one to the

negative pole (-).

How to sample the RPM

The RPM signal may be sampled either from the ECU or from the coil.

• • The RPM signal sampled from the ECU is a square wave signal (from 8

up to 50 V);

The RPM signal sampled from the coil is a high voltage RPM input (from

150 to 400 V) and must not be connected on the “RPM from ECU” input

(this event may seriously damage the gauge).

It is also reminded to connect either the RPM signal from the coil or the

RPM signal from the ECU, NOT both (this event creates shortcuts).

21

Page 22

On track

As you power on your MyChron 3 Plus/Gold/Gold XG, some information is

displayed: here they are described in the same order as they appear:

AIM 1_xy

1.

MYC 3 PLUS/GOLD/GOLD XG CAR/BIKE

2.

Firmware version.

Instrument name.

Configuration functions

Before getting started, please configure your gauge in order to get correct

data from your system.

Enter CONFIGURATION MODE (push MENU/<< button) to set the parameters.

Buttons MENU/<< (back to previous option) and >> (forward to next option) are

used to scroll through the configuration menu.

To exit CONFIGURATION MODE and return to MAIN DISPLAY MODE, press

button VIEW.

The parameters you can set in CONFIGURATION MODE are here above

explained in the same order they appear by clicking the MENU/<< button.

22

Page 23

Night Vision

Clear test data

MyChron 3 Plus/Gold/Gold XG display can be set to

backlight display so that it is visible during night racing.

To set the Night Vision ON or OFF, press button MEM/OK

until you see

NIGHT VISION ON/OFF

and then push button MEM/OK. To return to main display

mode press button VIEW. When the Night Vision option is

activated, a light globe will be displayed in the display’s top

right corner.

To activate Night Vision mode during a test, it is enough to

press button MENU/<<.

The backlight setting is stored by the logger: each time the

logger is switched on, the setting used before switching off

the gauge is automatically restored

The “Clear test data” option clears the data stored in system’s

memory.

To run this function, after having entered the

CONFIGURATION MODE, push MENU/<< until you see

CLEAR TEST DATA

Then press button MEM/OK twice to erase data or press

VIEW to quit.

23

Page 24

Beacon

obscuring

time and

split’s number

These 2 functions are fundamental in order to acquire the

correct lap and split time.

The first function is used to set the Beacon’s obscuring time,

which is a time period during which the optic receiver, after

having acquired the lap marker, is “blind” and can’t detect

other lap markers.

The second function, instead, allows the user to set the track’s

split number. In fact, it is possible that a circuit is equipped

with more than one Beacon transmitter along the track:

additional transmitters than the first one installed on the

straight line give “split time”.

In the following paragraph, it is reported three examples of

obscuring time/split’s number configurations.

Example 1) The track is equipped with only one lap transmitter

Start/Finish

Lap time 1’ 25”

24

Page 25

• In this case you cannot acquire split times because the track is not

equipped with additional lap transmitters. It is recommended to set the

following values:

o Split’s number = 0;

o Beacon obscuring time: please set a time lower than your best

lap time. In this example, the best lap time is 1’ 25”: you should

set, for instance, 1’ 10”.

Example 2) The track is equipped with more than one lap transmitter but

you do not wish to capture split times

Intermediate 2:

Time 50”

Intermediate 1:

Time 30”

Start/Finish

Lap time 1’ 25”

• As the track is equipped with more than one transmitter and you do not

wish to capture split times, please set the following parameters:

o Split’s number = 0;

o Beacon obscuring time: please set a time lower than your best

lap time and greater than the time elapsed at the last

25

Page 26

intermediate before the finish line. In this example, you should

set a value included between 50” and 1’ 25”.

Example 3) The track is equipped with more than one lap transmitter and

you wish to capture split times

Intermediate 2:

Time 50”

Intermediate 1:

Time 30”

Start/Finish

Lap time 1’ 25”

• As the track is equipped with more than one transmitter and you wish to

capture split times, please set the following parameters:

o Split’s number = total number of lap transmitters installed on the

track excluded the one installed on the finish line. In this

example, set 2 split’s number.

o Beacon obscuring time: the obscuring time must be lower than

the minimum split time. In this example, as the minimum split

time elapsed is the one from the first intermediate to the second

one (split time 20”), please set the beacon obscuring time to 15”.

26

Page 27

To set the split’s number, after having entered the

CONFIGURATION MODE, push MENU/<< until you see

NUMBER OF SPLITS

Then push MEM/OK to enter EDIT MODE: use button

MENU/<< to change numbers and button >> to change digit.

The blinking number identifies the digit that can be edited.

Press button MEM/OK to save the changes or button VIEW to

discard the changes.

To set the Beacon obscuring time, after having entered the

CONFIGURATION MODE, push MENU/<< until you see

Obscuring time

Now push MEM/OK to enter EDIT MODE, then press button

MENU/<< until the correct number of splits appears on the

display’s lower right corner. The obscuring time can be set up

to a maximum value of 100 seconds.

Press button MEM/OK to save the changes or button VIEW to

Distance and

total time

discard the change

This function shows the total instrument working time (in hours

and minutes) and the distance covered by the vehicle (in km

or in miles) during a test.

To run this function press button MENU/<< until you see

TOTAL RUNNING

27

Page 28

To delete the total working time and the distance covered by

the vehicle, please press twice button MEM/OK; press VIEW,

instead, if you do not wish to delete these information.

It is reminded that this function computes only time and

distance corresponding to a single test: if you wish to know

the total distance covered by the vehicle, please run function

“Odometer”.

Odometer

Gears

calibration

This function computes the total distance covered by the

vehicle during all the tests made.

To run this function press button MENU/<< till you see

ODOMETER

Unlike the previous function, this parameter cannot be erased.

Your gauge is able both to detect the engaged gear by using

an on-board sensor (for those vehicles equipped with a sensor

installed inside the gearbox) or by calculating them (using an

algorithm based on engine’s RPM and Speed). If no sensor is

installed and the driver does not wish to see the gear number

on the display, the gauge allows the user to disable the gear

channel.

To run this function press button MENU/<< until you see

GEAR CALIBRATION

Press button NEXT/MEM to activate one of the gears

calibration functions here above described:

28

Page 29

GEAR computed

Gear is disabled

Gear with sensor

1) Compute gears

Once selected the “Gear computed” option, pressing button

MEM/OK, it will appear the following text:

Higher gear

Enter the higher gear number (up to 9) using button

MENU/<<; then press button MEM/OK to save the changes or

VIEW to discard them.

Once set the higher gear number, you have to run at least 2

track laps in order to let the gauge “learn” the threshold values

for the different gears.

It is strongly recommended to run these laps engaging all

gears. If a gear is not engaged during these “learning

laps”, the gauge will not be able to show all gears.

During these “learning laps”, no gear value will be shown.

Once finished the “learning laps”, return to the pit lane and,

before switching the gauge off, please ensure that the vehicle

is completely stopped (i.e. the speed value is 0). It is reminded

that there is no problem if you switch off the gauge together

with the engine (MyChron 3 Plus/Gold/Gold XG with firmware

1.55 or later).

29

Page 30

Case 1: if you turned off the engine and stopped the vehicle

without switching off the gauge, the red led AL 1 starts

blinking, informing the driver that the gauge is calculating the

threshold values.

Case 2: otherwise, if you switched off the gauge together with

the engine, the gear calculation procedure starts once you re-

switch on the gauge (the red led AL 1 blinks).

Once the red led AL 1 stops blinking, the gear calculation

procedure is completed: now you will be able to see the gear

value inside the gauge’s gear display.

If the gear values displayed do not correspond to the engaged

gears, please repeat the gear calibration procedure.

It is reminded that the threshold values are saved in the

gauge’s internal memory and the user will not have to

calculate them each time the gauge is switched on.

The algorithm is able to detect the engaged gear as it

calculates the engine’s RPM vs. speed ratio. If the speed is

acquired from a non-driving wheel, the algorithm may return

incorrect gear values.

The RPM vs. speed ratio is directly proportional to the

transmission/gearbox ratio and to the wheel circumference: if

one of them (or both) is changed, the gear calibration

procedure may have to be repeated.

30

Page 31

2) Gear is disabled

Select this option if you do not have a gear sensor installed

inside the gearbox or you do not wish to see the gear number.

3) Gear with sensor

Once selected the “Gear with sensor” option, you will see the

following sentence

INSERT GEAR

Meanwhile, in the gear display, you will see the gear number

blinking.

Please engage the “neutral gear” and then press button >> to

step to next gear calibration. The procedure to be followed is

similar to what has just been explained: you have to engage

the next gear and to press the >> pushbutton.

The gauge supports gearboxes with a gear number up to 9.

If your vehicle’s gearbox has a gear number lower than 9

(typical values are 5, 6 or 7 gears), once you have engaged

the last gear you have to press button MEM/OK to save the

current calibration.

To restart the calibration procedure, press button MENU/<<.

To disable the gear channel, press button MEM/OK when you

see the number 0 blinking in the gear display; it will also

appear the following sentence

GEAR IS DISABLED

To exit calibration mode without saving press button VIEW.

31

Page 32

Shift lights

configuration

This function allows the user to configure the 10 colored led

placed in the right upper part of the instrument’s display.

These led get switched on when the engine reaches a set

RPM value, indicating the pilot to shift gear.

To run this function, press button MENU/<< until you see

SHIFT LIGHT

By pressing button MEM/OK you will switch on the first led on

the left and the first one on the right, both green colored, and it

will appear the RPM value correspondent to that led lighting.

Press MEM/OK to enter EDIT MODE: use button MENU/<< to

change numbers and button >> to change digit. The blinking

digit identifies the digit that can be edited.

When the correct RPM value is displayed, press button

MEM/OK to save the changes and to step to second led

configuration; otherwise press button VIEW to quit without

saving.

The 10 led are colored in the following way: the first two on

the left and the first two on the right are green, the middle

ones are orange and the remaining ones led are red colored.

th

When the engine reaches the RPM value set for the 5

led, all

the 10 led will start flashing, advising the pilot to shift gear.

The RPM value can be set between 0 and 29999; if you set an

alarm value of 0, that led will be disabled.

32

Page 33

Wheel

circumference

Phonic

This function sets the wheel circumference (in mm or in

inches).

This parameter is fundamental to correlate the wheel’s

angular speed and the vehicle speed.

To run this function press button MENU/<< until you see

WHEEL CIRCUMFEREN

Then push MEM/OK to enter EDIT MODE: use button

MENU/<< to change numbers and button >> to change digit.

The blinking digit identifies the digit that can be edited.

The wheel circumference value can be set in a range included

between a minimum value of 0 and a maximum one of

9999 mm (0 and 399.99 inches).

When the correct circumference value has been set, press

button MEM/OK to save changes or press button VIEW to quit

without saving.

This option allows the user to set the phonic wheel’s teeth

wheel’s teeth

number

number in order to measure the wheel’s angular speed.

The speed sensor, passing by a gear tooth, generates an

electric pulse which gets acquired by the instrument: if the

phonic wheel is made up of just one tooth, the instrument will

measure one pulse per lap, while, if it is made up of more than

one tooth, the number of pulses per lap will be greater than

one.

33

Page 34

In order to capture the correct wheel’s angular speed, it is

necessary to set the correct teeth number.

To run this function press MENU/<< until you see

PULSES ON WHEEL

Then push MEM/OK to enter EDIT MODE: use button

MENU/<< to change numbers and button >> to change digit.

The blinking digit identifies the digit that can be edited.

This parameter is included between a minimum value of 0 and

a maximum of 199.

Press button MEM/OK to save the changes and button VIEW

to quit without saving.

Max RPM

value

This function sets the maximum scale for the graphical RPM

display and the maximum acceptable RPM value acquired by

your MyChron 3 Plus/Gold/Gold XG.

MyChron 3 Plus/Gold/Gold XG has seven levels for the

RPM scale: 8,000 / 10,000 / 12,000 / 16,000 / 20,000 / 22,000

and 25,000 RPM.

To run this function, after having entered the

CONFIGURATION MODE, push MENU/<< until you see

MAX RPM VALUE

Then push MEM/OK to enter EDIT MODE and use buttons

MENU/<< or >> to scroll between the seven standard RPM

values. When the required RPM value is displayed, press

button MEM/OK to save the changes or button VIEW to quit.

34

Page 35

Spark for Revs

Temperature

unit of

measure

This option represents the number of spark signals, acquired

from the coil or the ECU, per engine revolution.

To set the Spark for Revs, after having entered the

CONFIGURATION MODE, push MENU/<< until you see

SPARK FOR REVS

Then push MEM/OK to enter EDIT MODE and use buttons

MENU/<< or >> to scroll between six standard values: x1, x2,

/2, /3, /4 and /6. For instance, the correct value for a 4 strokes

4 cylinder engine is /2.

Press button MEM/OK to save the changes or button VIEW to

discard the changes.

This function sets the temperature’s unit of measure: the user

may choose between Celsius [°C] and Fahrenheit [°F]

degrees.

To run this function, after having entered the

CONFIGURATION MODE, push MENU/<< until you see

FAHRENHEIT/CELSIUS

Then push MEM/OK to enter EDIT MODE and use button

MENU/<< till you don’t see the proper Temperature unit of

measure, and confirm it pushing MEM/OK. Press button VIEW

to discard the changes.

The symbols °C or °F will appear on the left of the display.

35

Page 36

Speed unit of

measure

Pressure unit

of measure

This function sets the speed’s unit of measure; the user can

choose between km/h and Mph.

To run this function, after having entered the

CONFIGURATION MODE, push MENU/<< until you see

SPEED UNIT

Then push MEM/OK to enter EDIT MODE and use button

MENU/<< till you don’t see the proper unit of measure.

To confirm your choice push button MEM/OK; press button

VIEW to discard the changes.

This function sets the speed’s unit of measure; the user can

choose between Bar and PSI.

To run this function, after having entered the

CONFIGURATION MODE, push MENU/<< till you see

Pressure unit

Then push MEM/OK to enter EDIT MODE and use button

MENU/<< till you don’t see the proper unit of measure.

Message

language

To confirm your choice push button MEM/OK; press button

VIEW to discard the changes.

MyChron 3 Plus/Gold/Gold XG text can be displayed in

English, Italian, German or French.

To run this function, after having entered the

CONFIGURATION MODE, push MENU/<< until you see

MESSAGE LANGUAGE

36

Page 37

Firmware

Then push MEM/OK to enter EDIT MODE and use MENU/<<

or >> to change language.

Press button MEM/OK to save the changes or button VIEW to

discard the changes.

This function shows three numbers, which represent,

version

respectively, the firmware version, the firmware upgrade date

and the gauge’s serial number.

To run this function, after having entered the

CONFIGURATION MODE, push MENU/<< until you see

FIRMWARE version

The firmware management window is organized on two

different rows: in the upper one it is shown the firmware

version, on the left, and the firmware upgrade date, on the

right (dd/mm/yy). In the lower row, instead, it is shown the

gauge’s serial number.

Utility functions

Once configured your system, you are ready to manage the data acquired with

your gauge. MyChron 3 Plus/Gold/Gold XG records RPM, 4 analog inputs

(pressures or temperatures for Plus version, pressures, temperatures,

potentiometers, Lambda sond for the Gold/Gold XG ones), speed, gear number,

lateral g-force (Gold CAR and Gold XG versions) or Gyroscope (Gold BIKE

versions) at a maximum sampling rate of 200 Hertz (200 times per second) per

channel. These data can be retrieved at a later stage for analysis.

37

Page 38

MyChron 3 Plus/Gold/Gold XG segments data for a session as a test and each

test includes the laps completed in that session. To begin recording a new test

you may switch off your instrument and then switch it back on, or you may press

the MEM button: once you exit the “retrieve data from memory” function, your

MyChron 3 Plus/Gold/Gold XG will record data in a new test session.

Viewing data

MyChron 3 Plus/Gold/Gold XG will display “Test 01” or the

while driving

current test number if memory has not been cleared, and “Lap

001” once the infrared receiver passes the beacon transmitter.

If the system has been configured to capture back segments

using the number of splits option, the system will display “Split

Number x”, up to the number of splits selected. Once the

system records times for each split, the final segment is

displayed as a completed lap.

At the same time the system displays the time gap between the

current split time and the split time of the previous lap.

When the system records the best lap time for a test, the text

BEST LAP TIME

will appear on the display under the RPM graphical bar.

By pressing button VIEW it is possible to visualize, instead of

lap time, the RPM digital value or vehicle’s speed.

The four analog inputs are shown on the left of the display: the

system will display, as a default, channels number 1 and

number 2.

38

Page 39

By pressing button >> it is possible to shift your MyChron 3

Plus/Gold/Gold XG to another display page, where you can

see the other two analog inputs.

Moreover, together with the channel’s values, the display shows

two further information:

• an icon (T or P), to identify the sensor type: “T” stands

for “temperature sensor”, while “P” stands for “Pressure

sensor”. If you connected a temperature or pressure

“custom sensor” (please refer to paragraph “Customize

sensor”), the display will show the corresponding icon

(T or P). Otherwise, if you connected a generic “custom

sensor” (i.e. a custom sensor which does not belong to

the temperature/pressure sensors), no icon “T” or “P”

will be shown.

• A number (from 1 to 4), which identifies the sensor

number.

For instance, if you connected a temperature sensor on channel

1, a “generic custom sensor” on channel 2, a pressure sensor

on channel 3 and another temperature sensor on channel 4,

your MyChron 3 Plus/Gold/XG will show, in the first display

page, “T1” for channel 1 (it is the first temperature channel),

“1” for channel 2 (it is the fist “generic custom sensor”), “P1”

for channel 3 (it is the first pressure channel) and “T2” for

channel 4 (it is the second temperature channel).

39

Page 40

When the gauge is switched on, the display shows the last

selected measures during race time: for instance, if you were

visualizing speed, temperature 1 and temperature 2, the display

will show these channels. Moreover, the gauge saves the

backlight status (switched on or off) and restores the previously

saved status when the gauge was switched on.

Your gauge’s memory is divided into two separate parts. In the

first one it is stored the sampled channels and it has 45 minutes

(MyChron 3 Plus) or 3 hours (MyChron 3 Gold/Gold XG)

maximum storage time. In the second one it is only stored the

lap times, the split times and the maximum / minimum values of

speed, RPM and channels number 1 and 2 for each lap.

If during race the “sampled channels” memory fills up, the

following text will be displayed:

Measures mem full

The gauge will keep on recording the lap/split times and the

channels’ maximum/minimum values.

If, otherwise, the “maximum/minimum values” memory fills up,

the following text will be displayed:

Lap Memory full

The gauge will keep on recording the channels’ values.

When both memories are full, the following text will be

displayed:

Memory full

40

Page 41

In this situation, the data logger works only as a “dash” and

does not samples any more data. It is recommended to

download the data stored in the gauge’s memory and to clear it.

When a test is completed, the system displays the last lap number and last lap

time. Using button MEM/OK you will access the data stored in system’s memory.

Let’s now see how to retrieve data after the completion of a test.

Viewing data

To view the data for the lap with the best lap time, press

per best lap

time

MEM/OK while in general display mode.

The best lap time is displayed for the most recent test. The

lap time will be flashing, signaling that this is the best time for

the current test.

The instrument will also show the test and lap number and

the maximum values corresponding to channels number 1

and 2 for the current lap.

If button MEM/OK is pressed a second time, it will appear the

minimum values corresponding to channels number 1 and 2

and minimum RPM for the best lap.

If you press button VIEW in one of the two previously

described display pages, the display will show the maximum

values corresponding to speed and to channels number 1

and 2.

Press button VIEW again to quit replay mode or press button

MEM/OK to view the minimum values corresponding to speed and

to channels number 1 and 2.

41

Page 42

View other

completed

lap data

To view completed lap data, while in general display mode,

press button MEM/OK to view the best lap time. Then press

button MENU/<< to view a previous lap or button >> for a

following lap. If you have configured your MyChron 3

Plus/Gold/Gold XG to capture splits, buttons MENU/<< and

>> will also scroll through the split times within each lap.

To retrieve previous test data (when more than one test has

been recorded) press button MENU/<< until the required test

and lap details (or split details) appear on the display.

Buttons MEM/OK and VIEW will allow you to switch between

the different display pages, as previously described in the

“Viewing data per best lap time” paragraph.

Maintenance

Your MyChron 3 Plus/Gold/Gold XG does not require any special

maintenance.

Provided adequate care is taken with the display unit and components, the only

maintenance will be to upgrade the firmware when upgrades are released by

Aim (periodically check www.aim-sportline.com

).

Upgrading

the firmware

To upgrade the firmware, please visit to our website

www.aim-sportline.com

and download the latest firmware

version. The file you have to download is an EXE file, and it is

called “FIRMUP.EXE” (FIRMware UPgrade).

42

Page 43

Connect MyChron 3 Plus/Gold/Gold XG to your PC using the

USB cable furnished as equipment.

Now you can launch the FIRMUP file by double-clicking on it

and the system will automatically upgrade your instrument’s

firmware.

43

Page 44

MyChron 3 Plus/Gold/Gold XG and the computer

MyChron 3 Plus/Gold/Gold XG is equipped with an internal non volatile flash

RAM memory (512 kbyte for Plus version and 2 Mbyte for Gold/Gold XG ones)

which guarantees the capacity to record up to 315 laps and a total amount of 45

minutes (Plus version) or 3 hours (Gold/Gold XG ones) full analog inputs

record.

MyChron 3 Plus/Gold/Gold XG has been designed and developed to be

interfaceable with a PC: through an USB cable it is possible to connect the

gauge to a PC in order to both download the data stored in memory and

configure your instrument.

Aim reminds all MyChron 3 Plus/Gold/Gold XG owners that, for a correct,

complete and easier instrument configuration, it is absolutely

necessary to

use a PC and the software Race Studio 2.

This software has been properly developed by Aim in order to interface all its

products (Drack, EVO 3, MyChron 2, MyChron PRO, Dash ST1, MyChron 3

standard/Plus/Gold) with the PC.

It is reminded that the new software installation does not either cancel or

influence the functionalities of Race Studio 1. Once installed the program, the

user will be able to choose if to use the new software even with his old Aim

products (all supported by Race Studio 2) or if to keep on using the previous

program. It is also reminded that Aim newest products (MyChron 3, MyChron 3

Plus/Gold/Gold XG and Dash ST1) are only supported by Race Studio 2.

44

Page 45

In the following pages it will be shown how to install the software on your

PC and how to correctly configure your MyChron 3 Plus/Gold/Gold XG by

using a PC.

Software installation

Inside MyChron 3 Plus/Gold/Gold XG packaging you will find a CD containing

Race Studio 2, software properly developed to download and analyse the data

stored in your MyChron 3 Plus/Gold/Gold XG memory.

To install the software, insert the CD inside the CD-ROM drive: if the autorun

option is enabled (most of cases), the software installation will automatically

start, otherwise click twice on the SETUP icon.

st

The 1

installation language choice. Through a pop-up menu it will be possible to

choose the preferred language.

screenshot that will appear on your PC’s monitor concerns the

It is reminded that the installation language choice does not entail the software’s

working with only that language.

45

Page 46

If on your PC you have installed a previous version of Race Studio 2, it will

appear the following screenshot:

It is possible to choose whether to Remove the previous version or to Install the

new release. By choosing this second option, the software will automatically

uninstall the previous version and install the new one.

Otherwise, if you do not have older versions of Race Studio 2 on your PC, it will

appear the standard installation window:

46

Page 47

By using button Browse, it is possible to choose the software installation folder: if

you click on the Next button without choosing the installation folder, the software

will be installed in the default folder “X:\Program files\AIM”, where “X” represents

the Hard Drive in which you installed the operative system.

The following screenshot is the final one: please click on Finish button and, then,

run the program.

To run the program, click twice on Race Studio 2 icon, located directly on your

computer desktop, once the installation has finished.

To uninstall Race Studio 2 from your computer, please insert the CD-Rom

containing the software inside the CD-ROM drive and run the installation

procedure. It will appear a dialog box where the user will be allowed to “Remove

Race Studio 2” or to “Install a new release of Race Studio 2”. Please, select the

first option and press “Next” button: Race Studio 2 will be automatically

removed from your computer.

47

Page 48

If you wish to update Race Studio 2, please connect to our website

www.aim-sportline.com and go to “Download” page, where it is possible to

download the latest updates. To install the update, click twice on the downloaded

file and follow the instructions you see on your PC’s monitor.

Race Studio 2 program has been designed and developed to guarantee the

maximum working reliability and its proper working has been tested with

the following operative systems: Microsoft Windows 98 ™, Windows

2000 ™, Windows Me ™, Windows Xp ™. Microsoft Windows 95 ™,

Windows NT ™ and other operative systems (Linux, Unix, Macintosh ™)

are not supported.

If you have troubles during installation or normal working time, please check out

our website or contact Aim.

Installing the USB drivers

Please, read carefully these instructions in order to correctly install the

USB drivers: an incorrect installation may cause system’s malfunctions.

To connect your MyChron 3 Plus/Gold/Gold XG to the PC’s USB port, please

use the USB cable furnished as equipment.

When the PC and the instrument are switched off, connect your MyChron 3

Plus/Gold/Gold XG to the PC’s USB and then switch on both computer and

MyChron 3 Plus/Gold/Gold XG (it is suggested to switch on before the PC and

later on the gauge).

48

Page 49

During restart time, the operative system will recognize a new hardware and will

ask you to install the proper driver, driver that is included either in Race Studio 2

installation CD-ROM or in the “X:/Program files/AIM/USB_DRIVER” folder on

your PC”.

The driver file name is WDUSB522.inf.

In the following pages it will be reported two examples concerning the USB

drivers’ installation for the Microsoft Windows 98 ™, Microsoft Windows

2000 ™ and Microsoft Windows XP ™ operative systems.

How to install the USB Driver for Windows 98 ™:

1. Press [ Next ] button when the “Add new Hardware wizard” window

appears.

2. Select [ Search for the best driver for your device ] and press the [ Next ]

button again.

3. Place the Race Studio 2 disk in the computer’s CD-ROM drive if it is not

already there.

4. If the autorun option is enabled the system will try to install

Race Studio 2. As you have already installed it, please exit installation

menu. If the autorun option is enabled, go directly to next installation

step.

5. Place a check beside [ CD-ROM drive ] and click the [ Next ] button.

6. Click the [ Next ] button again.

7. The installation software has to search for WDUSB522.inf.

8. Click the [ Finish ] button once reached the end of the installation.

9. Restart the computer if prompted.

49

Page 50

How to install the USB Driver for Windows 2000 ™:

1. Press [ Next ] button when the “Found new Hardware wizard” window

appears.

2. Select [ Search for a suitable driver for my device ] and press the [ Next ]

button again.

3. Place a check beside [ Specify a location ] and click the [ Next ] button.

4. Browse the path until you find the driver file WdUSB522.inf located in

the directory X:\Program files\AIM\USB_DRIVER.

5. Click [ Next ] when the correct driver has been selected.

6. Click [ Yes ] if the “Digital Signature Not Found” window appears.

7. Click the [ Finish ] button once reached the end of the installation.

8. Reboot the system in order to install the Virtual Device driver.

9. Press [ Next ] button when the “Found new Hardware wizard” window

appears.

10. Select [ Search for a suitable driver for my device ] and press the [ Next ]

button again.

11. Place a check beside [ Specify a location ] and click the [ Next ] button.

12. Browse the directory path until you find the driver wd_virtual.inf, located

in the directory X:\Program files\AIM\USB_DRIVER, and then click [OK].

13. Click [ Next ] when the correct driver has been selected.

14. Click [ Yes ] if the “Digital Signature Not Found” window appears.

15. Click the [ Finish ] button once reached the end of the installation.

16. Restart the computer if prompted.

50

Page 51

How to install the USB Driver for Windows XP ™:

1. Press [ Next ] button when the “Found new Hardware wizard” window

appears.

2. Select [ Install from a list or specific location (Advanced) ] and press the

[ Next ] button again.

3. Place a check beside [ Include this location in the search ] and click the

[ Browse ] button.

4. Browse the path until you find the driver file WdUSB522.inf located in

the directory X:\Program files\AIM\USB_DRIVER.

5. Click [ Next ] when the correct driver has been selected.

6. Click [ Yes ] if the “Digital Signature Not Found” window appears.

7. Click the [ Finish ] button once reached the end of the installation.

8. Reboot the system in order to install the Virtual Device driver.

9. Press [ Next ] button when the “Found new Hardware wizard” window

appears.

10. Select [ Install from a list or specific location ] and press the [ Next ]

button again.

11. Place a check beside [ Include this location in the search ] and click the

[ Browse ] button.

12. Browse the directory path until you find the driver wd_virtual.inf, located

in the directory X:\Program files\AIM\USB_DRIVER, and then click [OK].

13. Click [ Next ] when the correct driver has been selected.

14. Click [ Yes ] if the “Digital Signature Not Found” window appears.

15. Click the [ Finish ] button once reached the end of the installation.

16. Restart the computer if prompted

51

Page 52

If the USB drivers have been correctly installed, when your MyChron 3

Plus/Gold/Gold XG is switched on, in your PC’s Device management window

(click Start \ Settings \ Control Panel \ System \ Device management) you will

find the voice HID (Human Interface Device) Class and, in subnode, AIM

logger, as shown in the following screenshot.

USB drivers troubleshooting

In this paragraph it will be described the possible solutions to the mostly common

USB drivers installation troubles encountered.

1. Once connected MyChron 3 Plus/Gold/Gold XG to a switched on PC,

the automatic USB drivers installation does not start:

52

Page 53

a. Control that the instrument is correctly plugged in the PC’s USB

port.

b. Verify that both PC and MyChron 3 Plus/Gold/Gold XG are

switched on.

c. If MyChron 3 Plus/Gold/Gold XG does not turn on, verify that

the external battery charge status is good.

d. If the instruments switches on but the automatic USB drivers

installation does not begin, try to plug the USB cable into another

USB port (if a second USB port is available).

e. If available, try to use another USB cable to plug MyChron 3

Plus/Gold/Gold XG in a PC’s USB port.

2. The automatic USB drivers installation starts but the USB driver is not

properly installed:

a. Control your PC’s Control Panel (click Start \ Settings \ Control

Panel \ System \ Device management): if you see a voice like

Unknown Peripheral or Unknown USB device with a yellow

question mark (or a red cross), please select that voice and

remove it (click the mouse right button and select the “Remove”

option). Then switch off your MyChron 3 Plus/Gold/Gold XG,

unplug the USB cable from the PC’s USB port, re-plug the USB

cable in the PC’s USB port and repeat the previously described

installation procedure.

53

Page 54

b. If you see a yellow question mark again, please select the voice

and, instead of removing it, click on the “Property” option; then

choose the “Driver” tab and finally select the “Driver Update”

option. It is now possible to repeat the installation procedure

described in the “How to install the USB Driver for Windows”

paragraph. Please remember to specify the correct path for the

USB drivers, which is the Race Studio 2 CD-ROM drive.

3. In case your PC has not been able to automatically recognize your

MyChron 3 Plus/Gold/Gold XG or the two procedures previously

described had not succeeded in solving your problems, you have to install

the driver manually as here above explained:

• Go to Control panel window.

• Select the “New Hardware” icon.

• Click twice button “Next”.

• Place a check beside “No, I want to select the hardware from list”.

54

Page 55

• Select “HID class” (or “Human Interface Device”).

• Specify the correct path for the USB driver (i.e. Race Studio 2 CD-

ROM drive).

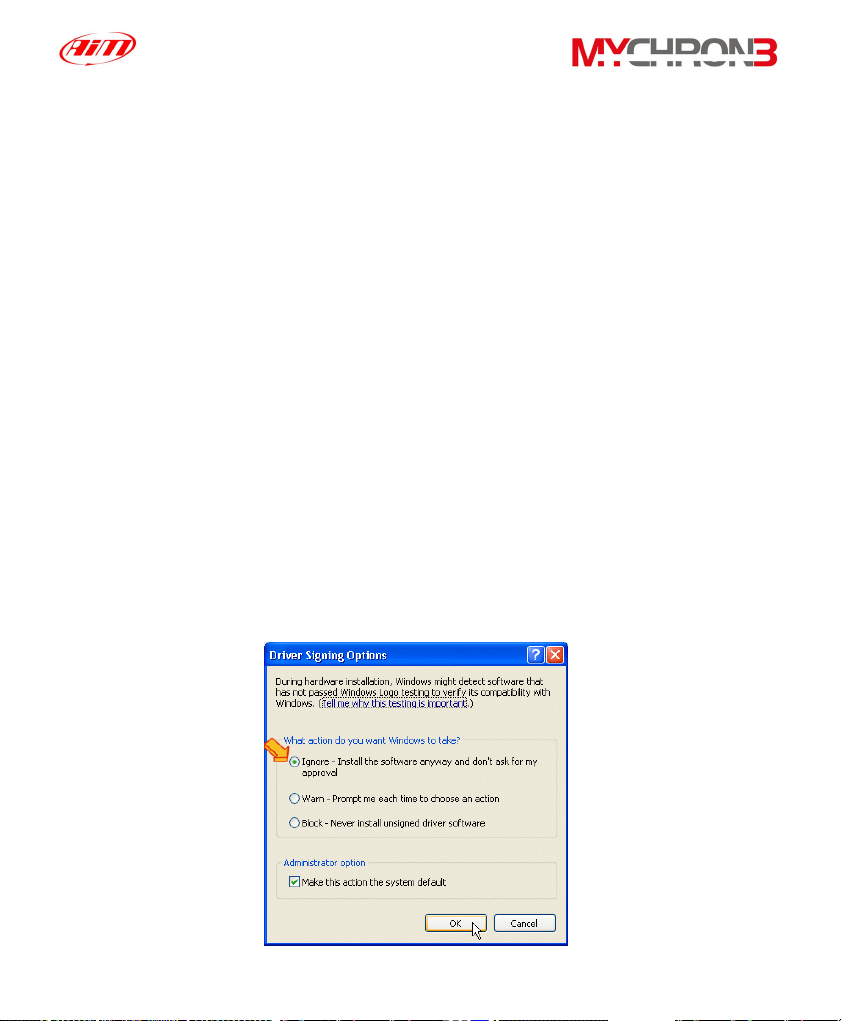

4. The USB driver WDUSB522 does not have a “digital signature”. In some

cases (very rare) Windows XP ™ or Windows 2000 ™ operative

systems have some default settings which do not allow the driver

WDUSB522 to be installed. These settings may be removed following this

procedure:

• Go to Control panel window.

• If you have a Windows XP ™ operative system, select the

“Performance and maintenance” option.

• Click the “System” button (both for Windows XP ™ and 2000 ™).

• Select the “Hardware” flag and, then, press button “Driver signing”.

• Select the “Ignore” option and press button “OK”, as showed in the

following image.

55

Page 56

Configuration via software

For a correct, complete and fast MyChron 3 Plus/Gold/Gold XG

configuration, it is absolutely

necessary to use a PC and the software Race

Studio 2.

The “via software configuration” allows the user to set some parameters that

cannot be set using the keyboard. For instance, the temperature sensors

(thermocouples, thermoresistances, VDO sensors) or the pressure ones, cannot

be set via keyboard and so, if you wish to measure temperature or pressure, you

have to configure your MyChron 3 Plus/Gold/Gold XG using Race Studio 2.

Moreover, if you bought a MyChron 3 Gold/Gold XG and you wish to measure

the lateral g-force (or the gyroscope input), in order to create a track map, you

have to autocalibrate the gauge via software.

Before starting the via software configuration, it is reminded to install Race

Studio 2 and the USB drivers, as mentioned in the previous chapter. It is

also reminded that, before configuring the instrument, you have to connect

it to a PC and to switch it on.

Once launched the program, by double-clicking on the Race Studio 2 icon on

your PC’s desktop or by selecting the Race Studio 2 shortcut in your PC’s Start

toolbar, it will appear the software’s main window, reported here above:

56

Page 57

On the left of the window you may see the icons corresponding to all the Aim

instruments supported by Race Studio 2: Dash ST1, MyChron 3 Plus/Gold,

MyChron 3, Evo 3, Drack, MyChron Pro, MyChron 2.

To select MyChron 3 Plus/Gold/Gold XG, please click on the corresponding

icon (as showed in the previous image).

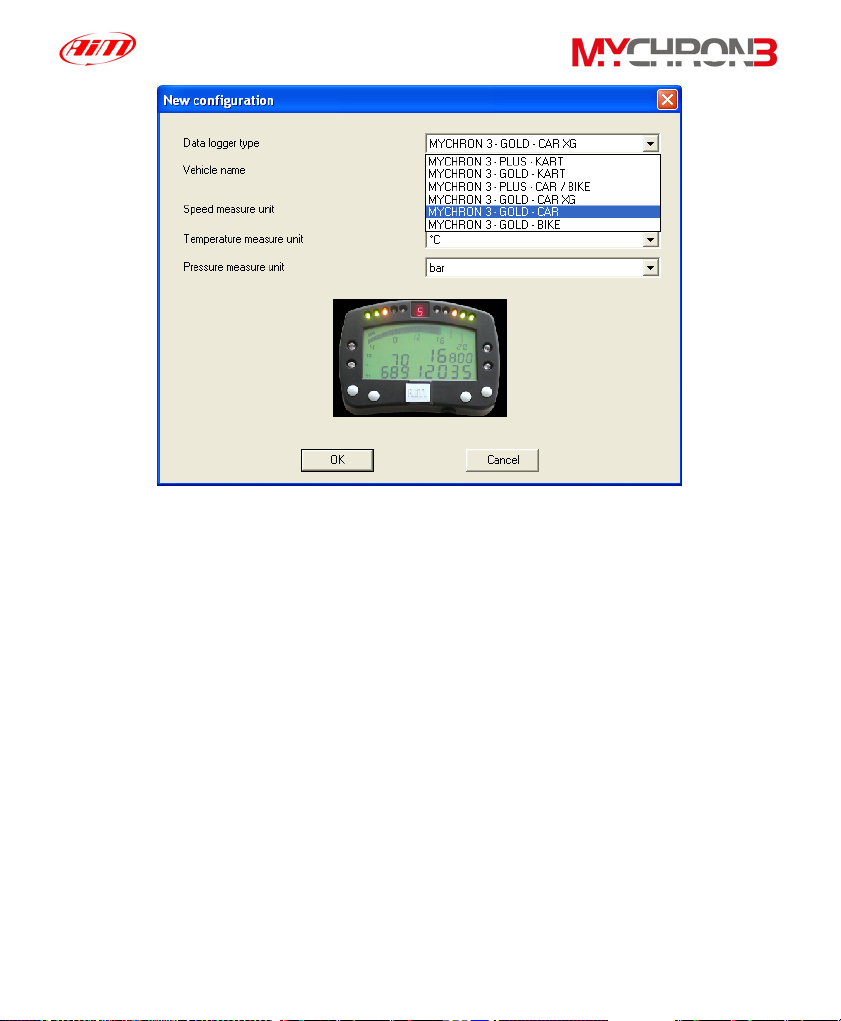

Creating a new configuration

It is now possible to configure the instrument: in order to start the configuration

procedure, please click on the Logger manager icon, located in Race Studio 2

toolbar. It will appear the following screenshot:

57

Page 58

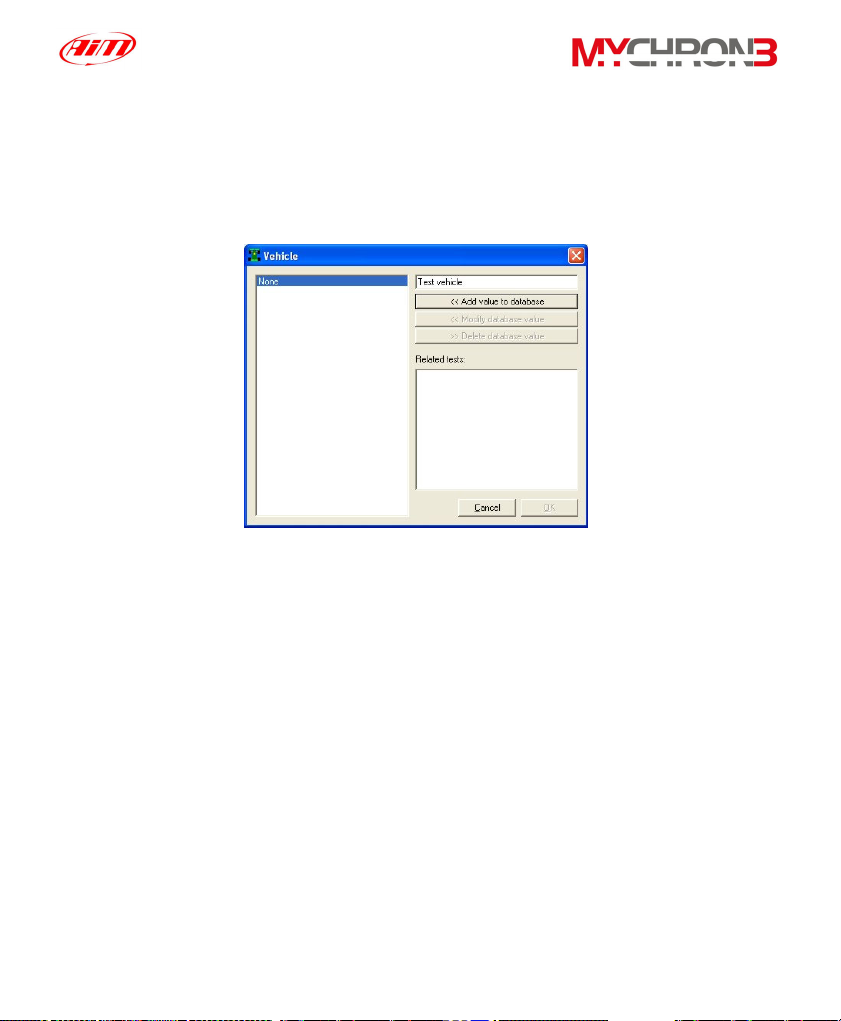

The user will have to set some parameters, listed here above:

• Data logger type: choose among MyChron 3 Plus/Gold/Gold XG and

Kart/Car/Bike. It is reminded NOT to select the KART version;

• Vehicle name;

• Speed unit of measure: choose between km/h and Mph;

• Temperature unit of measure: choose between °C and °F;

• Pressure unit of measure: choose between Bar and PSI.

Once filled all the boxes of the previous screenshot, click on the OK pushbutton to

save the settings. On your PC’s monitor it will appear the Logger manager main

window:

58

Page 59

Here above you can see a short description of all the pushbuttons that can be

used to configure your MyChron 3 Plus/Gold/Gold XG:

• General: with this pushbutton you activate the Logger manager main

window;

• Configuration: this pushbutton will open a very useful dialog box, where

the user is allowed to set the temperature and pressure alarm values,

the RPM shift light threshold values, the RPM and speed parameters

and the measure units;

• Channels: by using this option you may visualize the sensors installed

on your vehicle;

• Customize sensor: this pushbutton allows the user to customize a

sensor, setting the sensor’s calibration curve;

• Logger identification: this button allows the user to detect the

characteristics of the data logger connected to the PC;

• Transmit: once configured the data logger, the parameters have to be

transmitted to the instrument by clicking this button;

• Receive: if you connect to a PC a data logger of whom you do not know

the configuration, you may detect its configuration, by clicking the

Receive button, and to save it in the configuration’s database;

59

Page 60

• Online: the Online button allows the user to make a data acquisition

simulation, in order to verify if the new configuration is correct and if it

has been correctly transmitted to the data logger;

• Calibrate: this button allows the user to calibrate both the lateral

accelerometer and the gear sensor;

• New / Delete / Clone: these three buttons allows the user to create a

new configuration, to delete an old one or to clone an existing one;

• Import / Export: these 2 functions are used to export the selected

configuration (among the available ones) into a “.cfn” file or to import a

configuration (saved into a “.cfn” file) into the configuration database.

• Exit: this button is used to exit the “Logger manager” menu.

Channels

Clicking on the Channels pushbutton it will appear the following screenshot:

60

Page 61

In the window previously shown, it is possible to set the channels acquired by

your MyChron 3 Plus/Gold/Gold XG.

• Channels labelled as CH_1 ÷ 4 may be used to acquire a temperature or

a pressure input, if you are using a MyChron 3 Plus, or may be used to

sample temperature, pressure, potentiometer or Lambda sond, if you are

using a MyChron 3 Gold/Gold XG. The user may choose the sensor

among a long list of Aim standard sensors or, otherwise, may set a

custom sensor by selecting the “Custom sensor management” (see

Customize sensor paragraph).

• If your MyChron 3 is a Gold version one, you may also install an external

gyroscope (for BIKE installations), labelled as CH_7, which will allow you

to create the circuit map.

• Your MyChron 3 Gold/Gold XG (CAR versions) has an internal lateral g-

sensor, labelled as ACC_1, which will allow you to create the circuit map.

61

Page 62

Customize sensor

By using this function, the user can configure a “custom” sensor, setting the

sensor’s calibration curve. This option is very useful when the sensor (pressure,

temperature or other) installed on the vehicle does not appear in the default

sensors list.

It is reminded that the “Customize sensor” option is intended only for

expert users.

To enter this function, please press button Customize sensor: it will appear the

following screenshot:

62

Page 63

In the window’s left part there are three columns: in the first one it is possible to

insert the instrument’s output voltage (i.e. the abscissa values of the calibration

curve), while in the second one it is possible to insert the temperature/pressure

value corresponding to the previous voltage (i.e. the ordinate values of the

calibration curve). These values will be interpolated using a polynomial. In the

third column it is reported the “Curve Error”, i.e. the difference between the

computed curve and the experimental values.

To set how many experimental values you wish to use to create the calibration

curve, please place a check in the column besides the abscissa values.

In the window’s middle part it is reported both the sensor’s calibration curve and

the 5 coefficients (from a

to a4) of the interpolation polynomial. Please, use

0

button “Compute Curve” to refresh the calibration curve to apply any changes.

On the right of the calibration curve there are some boxes, where you can insert

the sensor name, the desired measure units and the sensor type (Temperature,

Pressure or Other).

Below these boxes there are some pushbuttons which allow the user to save or

delete a customized sensor.

In the window’s upper right corner you can see some default “custom” sensors. If

you wish to load one, please click twice on the sensor’s name.

Once correctly defined the new sensor, the user may exit Customization sensor

mode, by clicking on the OK pushbutton, and has to set the new sensor on the

desired channel (press button Channels and follow the instructions reported in the

channels paragraph).

63

Page 64

Channels configuration

Your MyChron 3 Plus/Gold/Gold XG is equipped with 14 fully configurable

coloured led; the 4 ones placed on the left and right of the display unit represent

the 4 analog inputs (temperatures and pressures) maximum alarms, while the

other 10 led in the upper part of the display are called Shift light.

By clicking on the Configuration icon it will appear the following screenshot:

• Wheel circumference: this function allows the user to set wheel

circumference (in mm or in inches); this value is fundamental to correlate

the wheel revolution speed and the vehicle speed.

64

Page 65

• Number of pulses per wheel revolution: this function allows the user to

set the number of pulses per wheel revolution (i.e. the phonic wheel

teeth number), in order to measure the wheel revolution speed. When

the sensor passes by a gear tooth, it generates an electric pulse if the

phonic wheel is made up of just one tooth, the instrument will measure

one impulse per lap, while, if it is made up of more than one tooth, the

number of pulses per lap will be greater than one.

• Configuring the Shift light led: in the window’s middle part it is possible to

set 5 RPM values, each one corresponding to a coloured led. The five led

progressively turn on in order to indicate the pilot to shift gear.

To set the proper RPM value, you have to modify the values in the

different boxes.

The 10 led are so coloured: the first two on the left and the first two on the

right are green coloured, the middle ones are orange coloured and the

last four are red. When the engine reaches the RPM value set in the 5

box, all the five led start blinking, informing the pilot to change gear.

th

If a value is set to 0, the corresponding led will be disabled.

• Number of pulses per engine revolution: this option represents the

number of pulses, acquired from the coil or from the ECU, per engine

revolution. The user may choose the multiply factor among these values:

/1, /2, /3, /4, /6 and *2. For instance, the correct value for a 4 strokes 4

cylinders engine is /2.

• Maximum RPM value: this option allows the user to set the Maximum

RPM value acquired by the instrument.

65

Page 66

• Configuring the 4 alarms led: the 4 alarms led may be configured as

Maximum alarms, Minimum alarms or both for the 4 analog inputs. This

means that led #1, for instance, may switch on when temperature 1

reaches a value greater and/or lower than a fixed value. It is reminded to

select the led number inside the “High led” menu if you wish to set a

Maximum alarm (max value 1999), otherwise, if you wish to set a

Minimum alarm (min value -99), select the led number inside the “Low

led” menu. If you do not wish to set an alarm, please choose the “None”

option.

• Configuring the unit of measure: the user can set the Speed (Km/h or

Mph), Temperature (°C or °F) and Pressure (Bar or PSI) unit of measure

• Gear sensor: the software allows you setting the gear sensor type.

Select “None” if you do not wish to see the gear number, select

“Potentiometer” if your vehicle is equipped with a gear sensor installed

inside the gearbox or select “Calculated” if you wish to use a software

algorithm to calculate the engaged gear. In this case, the “Higher gear

number” box will become enabled: please insert the gear number.

• Configuring the lap parameters: by setting these two parameters, the

user will be able to acquire the correct lap time and, if more than one

optic transmitter is available, the split times. For further information on

these parameters, please refer to the “Beacon obscuring time and split’s

number” paragraph reported in the “Configuration functions” paragraph.

• Language selection: the user may choose the display text language

among 6 different languages: Italian, English, German, Spanish, French

and Slovenian.

66

Page 67

Transmitting the configuration

It is recommended, before transmitting the configuration, to switch on the

instrument and to connect it to the PC’s USB port.

Once set all the parameters, it is necessary to transmit the configuration to the

instrument.

In order to transmit the configuration, you have to press the Transmit pushbutton

and the system, automatically, will download the configuration from the PC to the

instrument’s Flash memory.

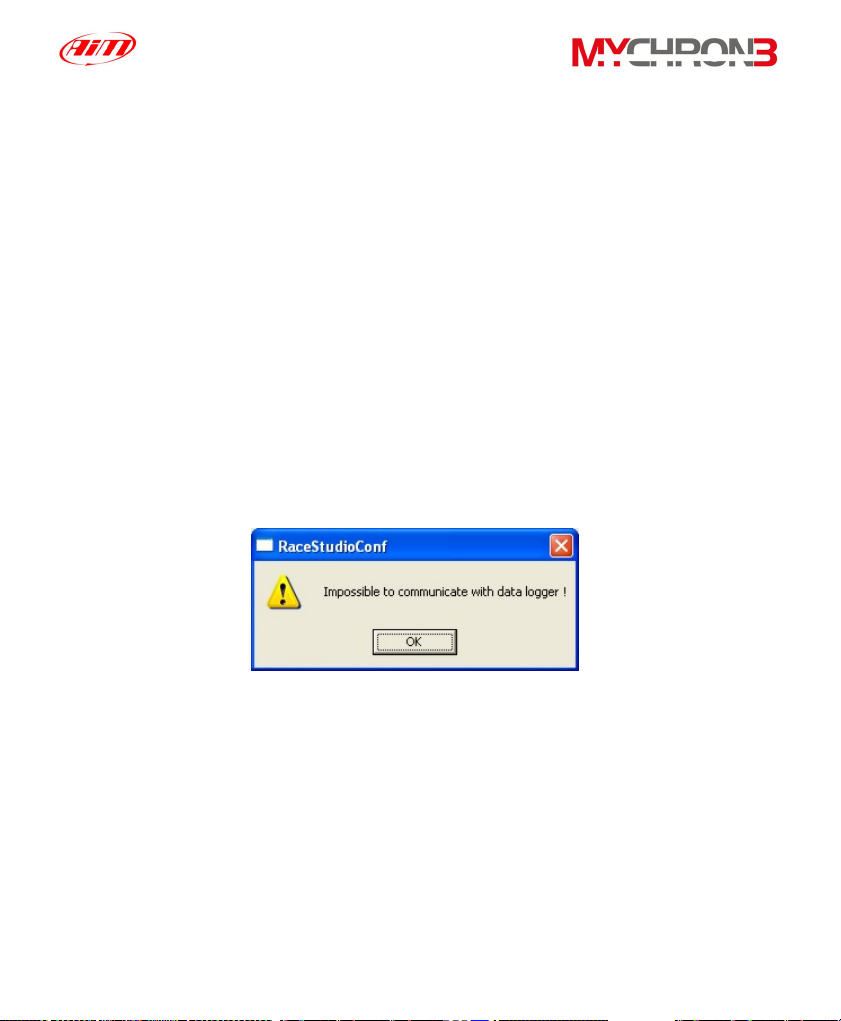

If the data logger is not correctly connected to the PC’s USB port or if the data

logger is switched off when transmitting the configuration, it will appear the

following screenshot on your PC’s monitor:

Please, ensure that the data logger is switched on and correctly connected to the

PC and then retry to transmit the configuration.

Sensors calibration (Gold/Gold XG versions only)

Once the configuration has been transmitted to the instrument, it is absolutely

necessary to autocalibrate the internal lateral g-sensor (or the Gyroscope) and

the “potentiometer distance”, and to calibrate the “mid zero potentiometer”, the

67

Page 68

“zero based potentiometer” and the gear sensor (for the gear sensor, please refer

to paragraph “Gear sensor calibration”).

In order to calibrate/autocalibrate, press button “Calibrate”: the following

screenshot will be prompted:

• The g-force sensor, the gyroscope and the “potentiometer distance” need

to be autocalibrated pressing button “Click here to autocalibrate all

sensors in the list”. Once autocalibrated, the “calibration status” will turn

from “To calibrate” in “Calibrated”.

In order to correctly autocalibrate the g-sensors (accelerometer and

gyroscope), it is suggested to keep the car as horizontal as possible and

to leave the bike on the prop-stand.

68

Page 69

• The “mid zero potentiometer”, the “zero based potentiometer” and the

gear sensor need to be calibrated. Press the button “Calibrate”

corresponding to the channel you wish to calibrate and follow the

instructions prompted on your PC’s monitor.

Once all the sensors have been calibrated, it is absolutely necessary to transmit

the calibration to the logger pressing button “Transmit calibration”.

It is reminded that the calibration/autocalibration procedure is fundamental

to acquire correct data.

Gear sensor calibration