Page 1

Product Bulletin

Release Date: April 2002

Instructions for Initial Startup of Ag Leader Lightbar

Beginning April 1, 2002, the instructions for initial startup of the Ag Leader Lightbar

have changed slightly. These changes apply to all Lightbars with the model number of

21A that are used in conjunction with an PF Series monitor (PF3000, PF3000 PRO and

PFavantage) running version 4.20 and lower. This model number can be found on the

serial number tag on the bottom the Lightbar and should read AgGPS 21A Lightbar.

If the Ag Leader Lightbar does not have this model number, this product bulletin can be

disregarded and the instructions detailed in the Lightbar Manual should be followed as

usual.

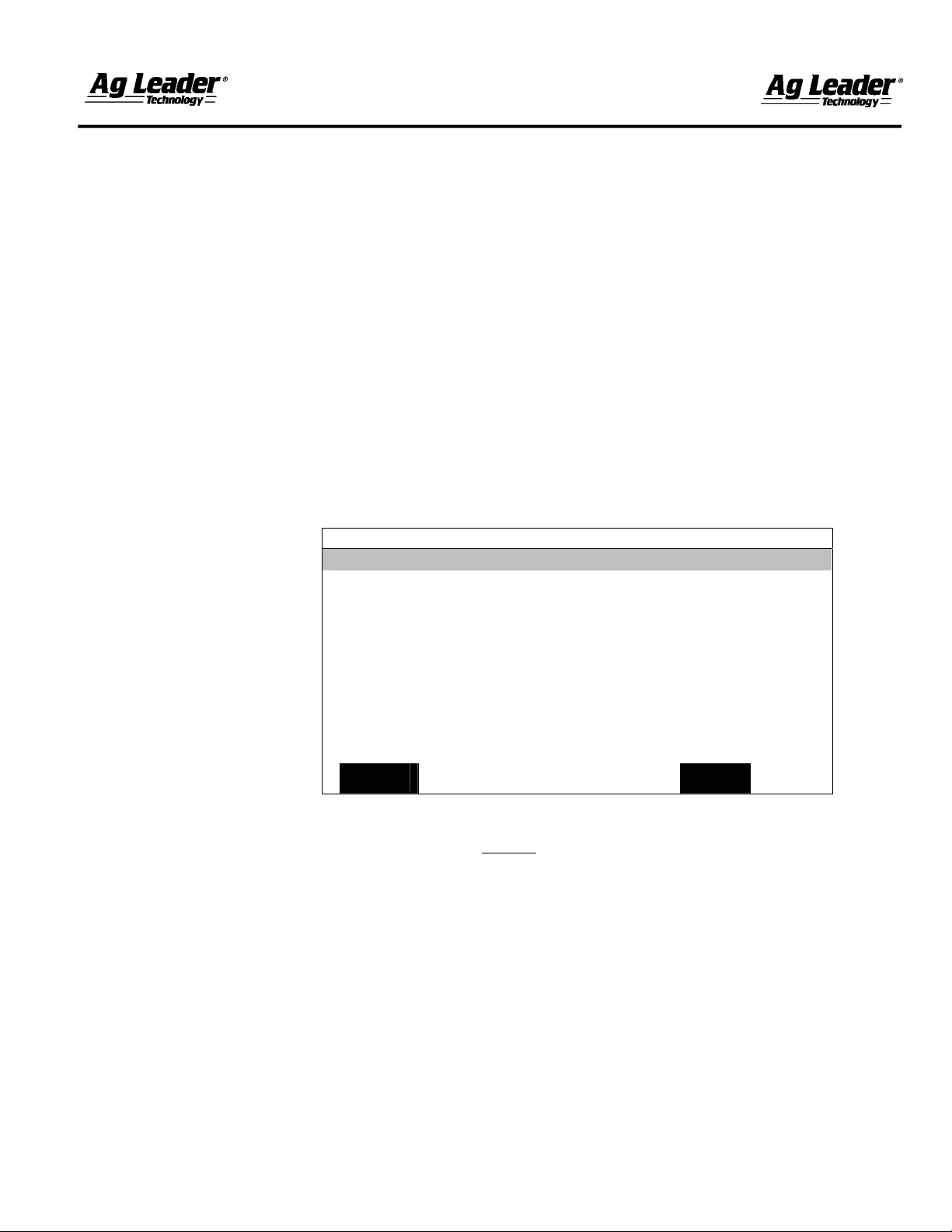

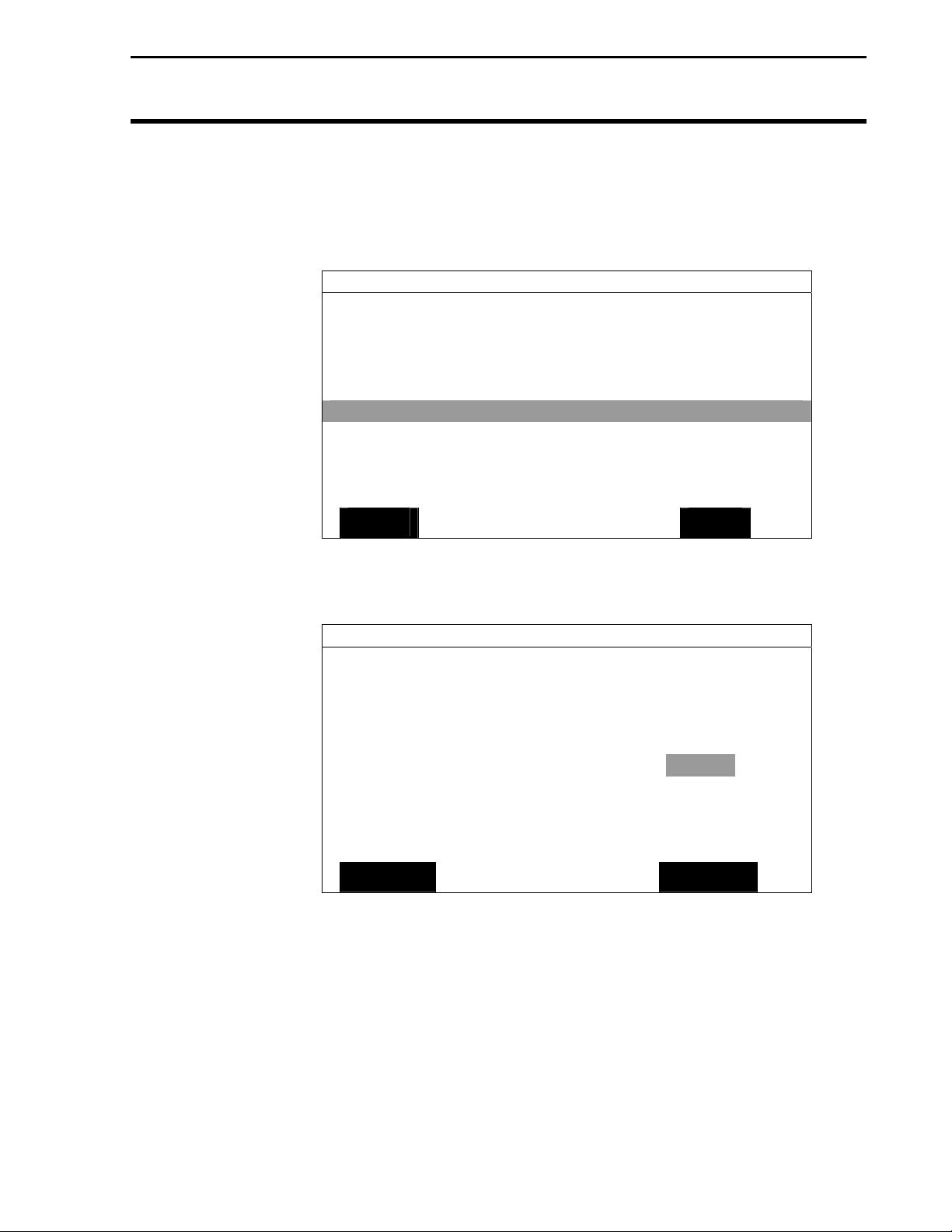

1. Before hooking the Lightbar to the GPS unit, the Lightbar Status setting must be

turned ON in the PF monitor. To turn on the Lightbar, press the MENU button until

you see SETUP on the bottom of the screen and press this button. Locate and press

the GPS button (may need to scroll left or right) on the bottom of the screen. A

screen similar to the one pictured below should now be displayed.

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 1.0 ft

End Distance --- ft

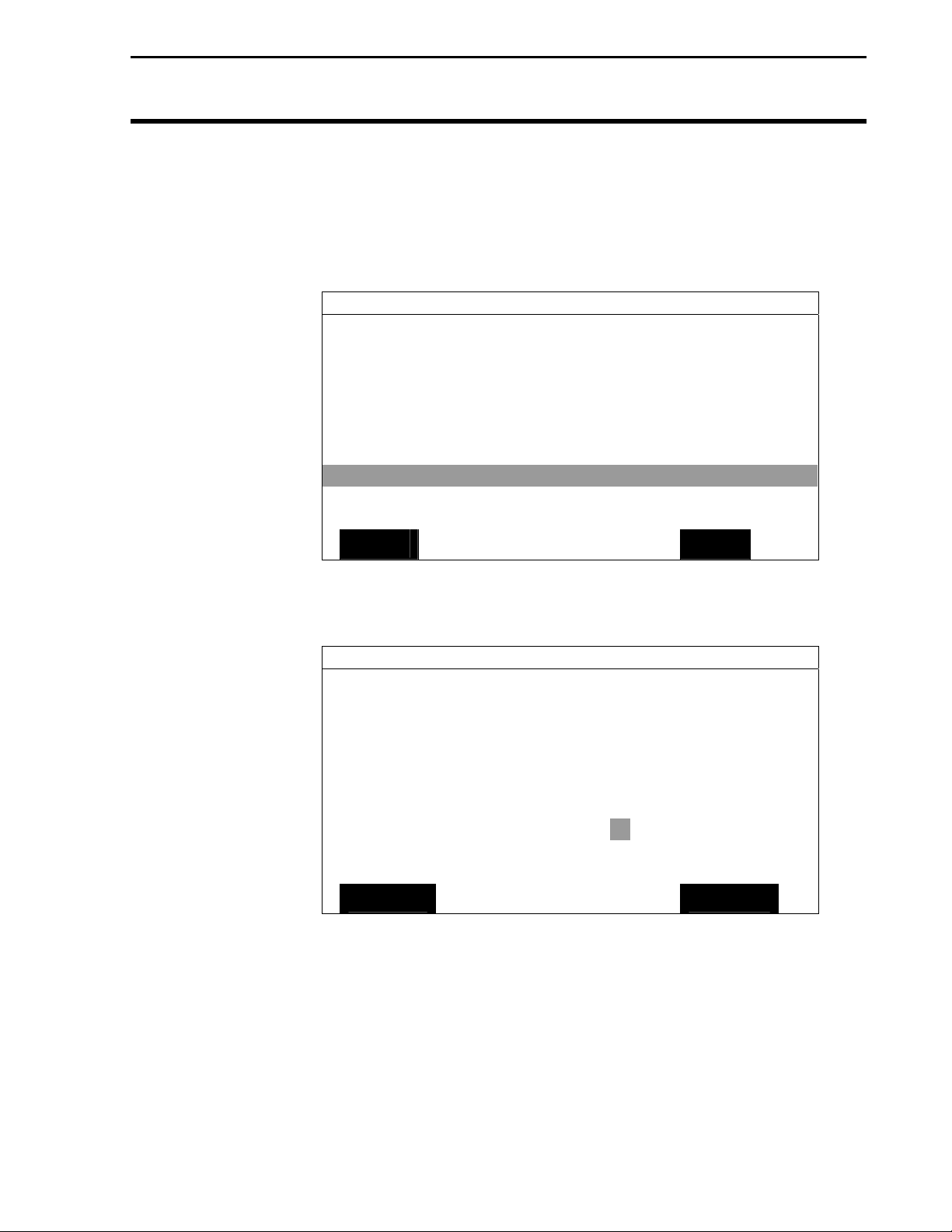

2. Lightbar status should now be highlighted. Press the EDIT button and use the up or

down arrow to change this setting to ON (Do Not

time).

3. Now plug the Lightbar into the GPS connection.

4. After plugging in the Lightbar, press ACCEPT on the PF monitor. The Lightbar

should now be ready for operation. Refer to the Lightbar Manual for additional setup

and operational instructions.

If you see EZ-Guide displayed on the Lightbar or it prompts you for a swath width, the

process was not completed correctly and should be tried again. It is important to plug the

Lightbar in first, before you press the Accept button. If you still encounter problems,

please contact your local Ag Leader dealer or our Tech Support department at (515) 2325363 ext. 1.

EDIT

EXIT

press the ACCEPT button at this

February 2003

Page 2

Page 3

Light Bar

INSTALLATION

AND

GENERAL INSTRUCTIONS

February 2003 Rev.3 3000135

Page 4

Page 5

Light Bar

Ag Leader Technology

Important Notices

Before beginning installation of your Light Bar, please take the time to

thoroughly read these instructions. Signal words (CAUTION,

IMPORTANT, and NOTE) are provided to draw attention to

information that is important for the safe/correct installation and

operation of this product.

• CAUTION--will alert you to situations that will impact the physical

safety of you or others.

• IMPORTANT—will alert you to the potential for damage to the

product or loss of data.

• NOTE--will provide you with additional information to simplify a

procedure or clarify a process.

After completing installation of the Light Bar we recommend that you

place these instructions in the Options Section of your PF monitor

Operator’s Manual to prevent their loss.

To receive upgrade/update information of this product you must send

in or fax the Registration Form. Refer to the Registration Form for

address and fax number.

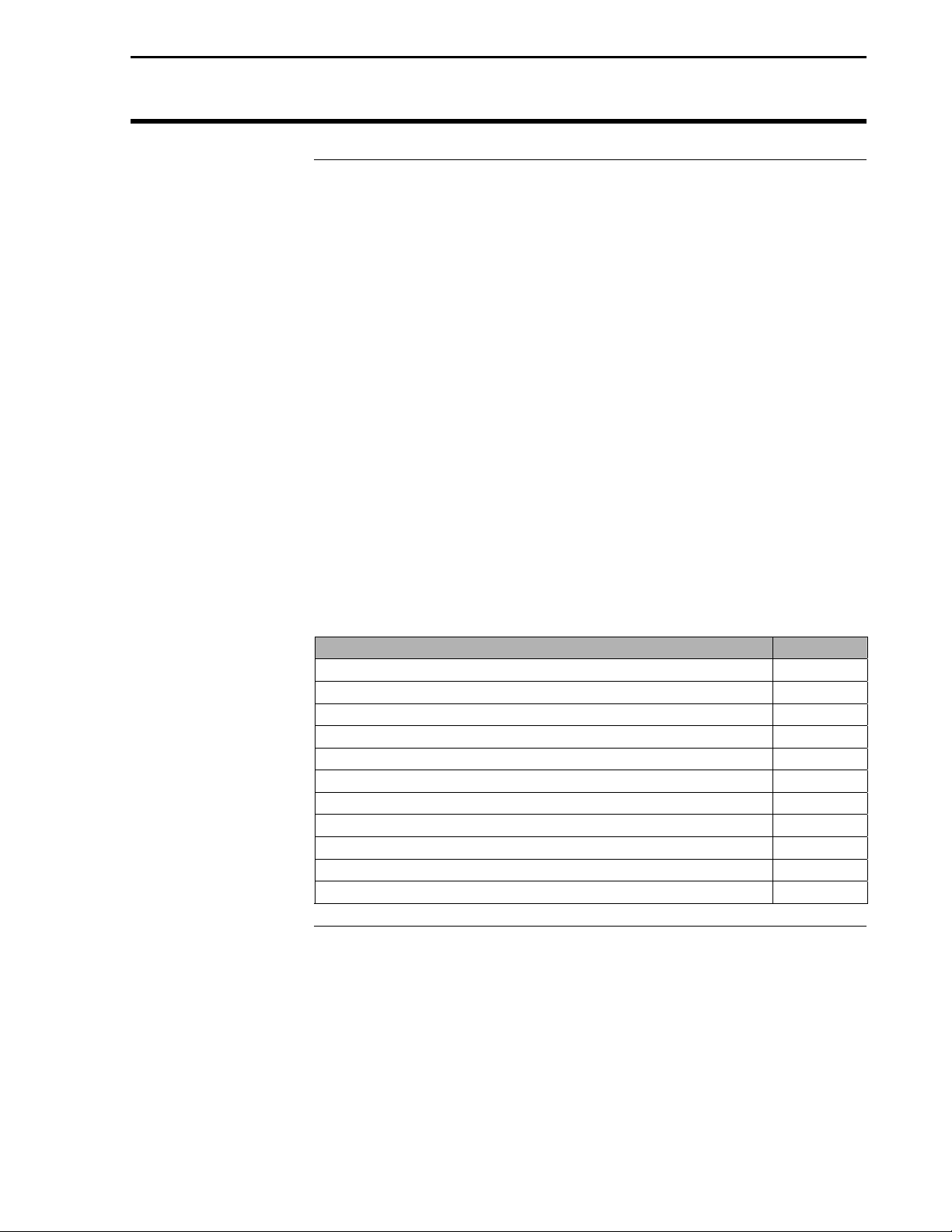

Installing Light Bar 2

General Information 5

Explanation of GPS/Light Bar Screen 5

Explanation of GPS/Guidance Screen 8

General Operation 13

Following a Curved Line 13

Using Headlands 13

Using Light Bar with PF Series monitors 13

PF monitor Setup for Light Bar 31

PF monitor Pro Setup for Guidance 40

Parts List 51

Contents

Item Page

***

February 2003 Rev.3 3000135

1

Page 6

Installation

Installing Light

Bar

Light Bar

Ag Leader Technology

IMPORTANT: The Light Bar must be mounted inside the cab

of your vehicle. The Light Bar is not resistant to weather

elements on the outside of the vehicle and could be damaged if

mounted outside of the cab.

1. Determine a location on the dash or ceiling to mount the Light Bar.

The Light Bar should be positioned within your peripheral vision.

2. Use an upright position for dash mounting and inverted for ceiling

mounting.

NOTE: Mounting the Light Bar on the ceiling inverts the Light Bar

text and requires a SETUP change.

3. Mounting the Light Bar bracket may be done by using three

methods: Dual-Lock strips, mounting hardware or the Optional

Suction cup. Select one of the methods below to mount the

bracket.

a. Bracket mounting with Dual-Lock strips:

(1) Clean the surface of the mounting location with

provided alcohol swabs.

(2) Remove the peel off strip from the Dual-Lock strip

on the back of the Light Bar bracket.

Do not touch the adhesive surface of the strip.

(3) Press the Light Bar bracket to the mounting location

determined in Step 1. Press the bracket firmly or

gently pound on the bracket to bond the adhesive

strip.

NOTE: The two additional Dual-Lock strips are for

replacement of the bracket strip or to add additional

mounting locations in the cab.

b. Bracket mounting with hardware:

(1) Using the mounting bracket as a template, mark the

three bracket holes for the position you determined

in Step 1.

(2) Use a 3/16-in. drill bit to drill the holes.

2

February 2003 Rev.3 3000135

Page 7

Light Bar

Ag Leader Technology

NOTE: Use the screws, nuts and washers for plastic or

soft materials or self-tapping screws for sheet metal.

Refer to diagram in hardware bag.

4. Attach Light Bar to bracket.

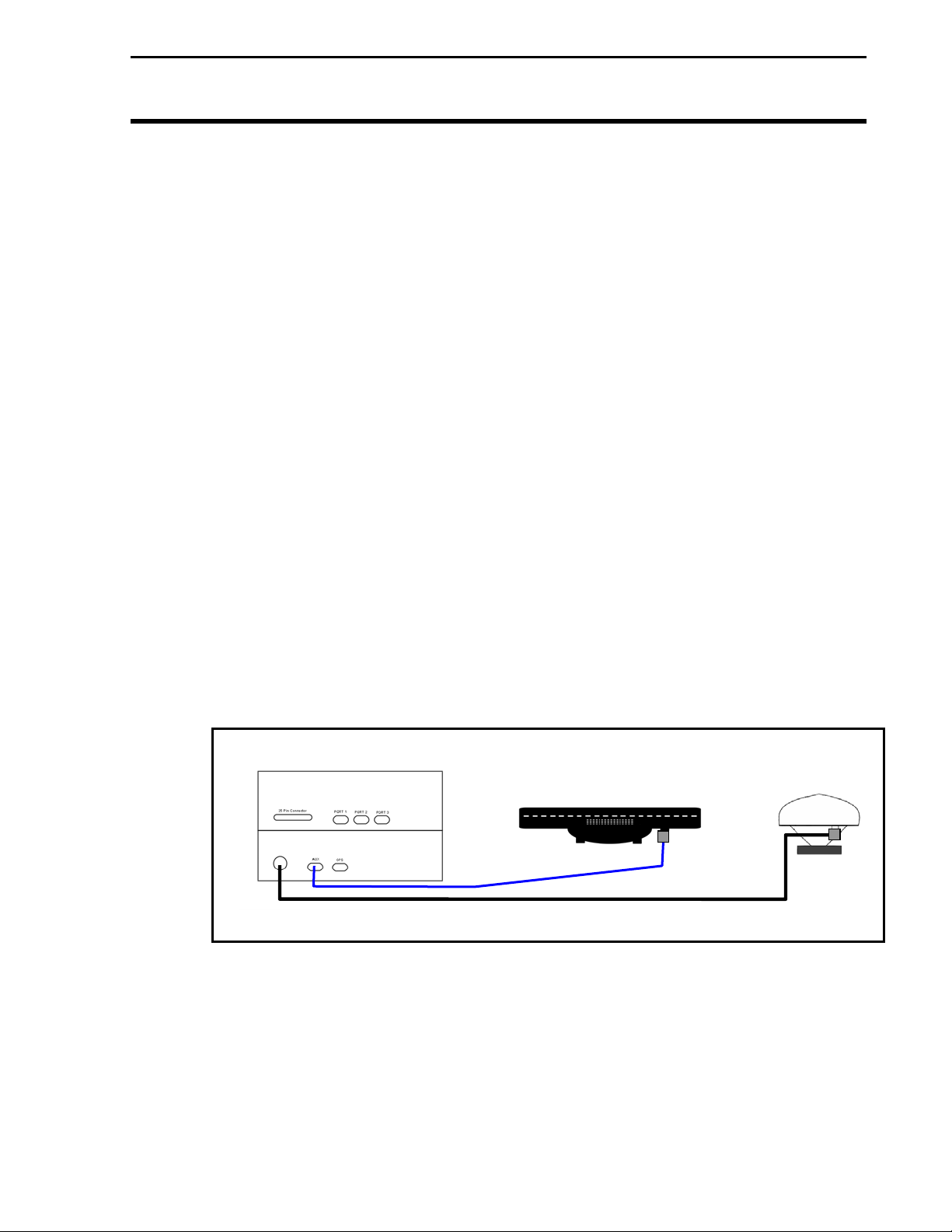

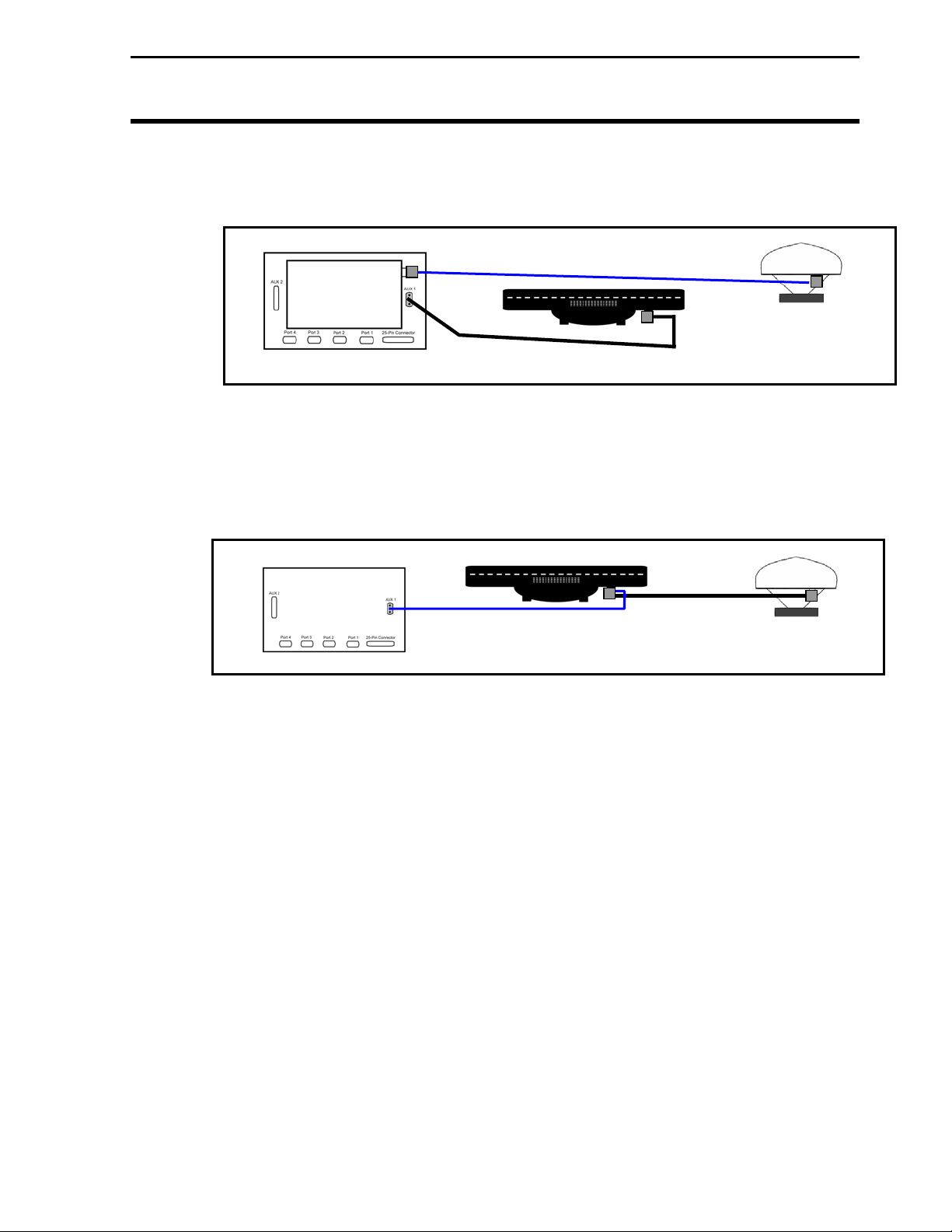

5. Attach cable to Light Bar and run to the AUX port of the Add-On

GPS3050 or 3100.

NOTE: If you are attaching the Light Bar to a PF3000 Pro or PFadvantage, attach the Light Bar cable to the AUX 1 port.

Figure 1. Light Bar cable connections to PF3000 with Add-On GPS

Installation

(3) Attach bracket with screws, nuts and washers

provided.

c. Bracket Mounting with optional suction cup:

NOTE: The Optional Suction cup is ordered

separately from the Lightbar Kit.

(1) Attach suction cup to bracket with 1/4 inch nut

(NOT provided).

(2) Refer to suction cup instructions to mount.

Ferbruary 2003 Rev.3 3000135

3

Page 8

Installation

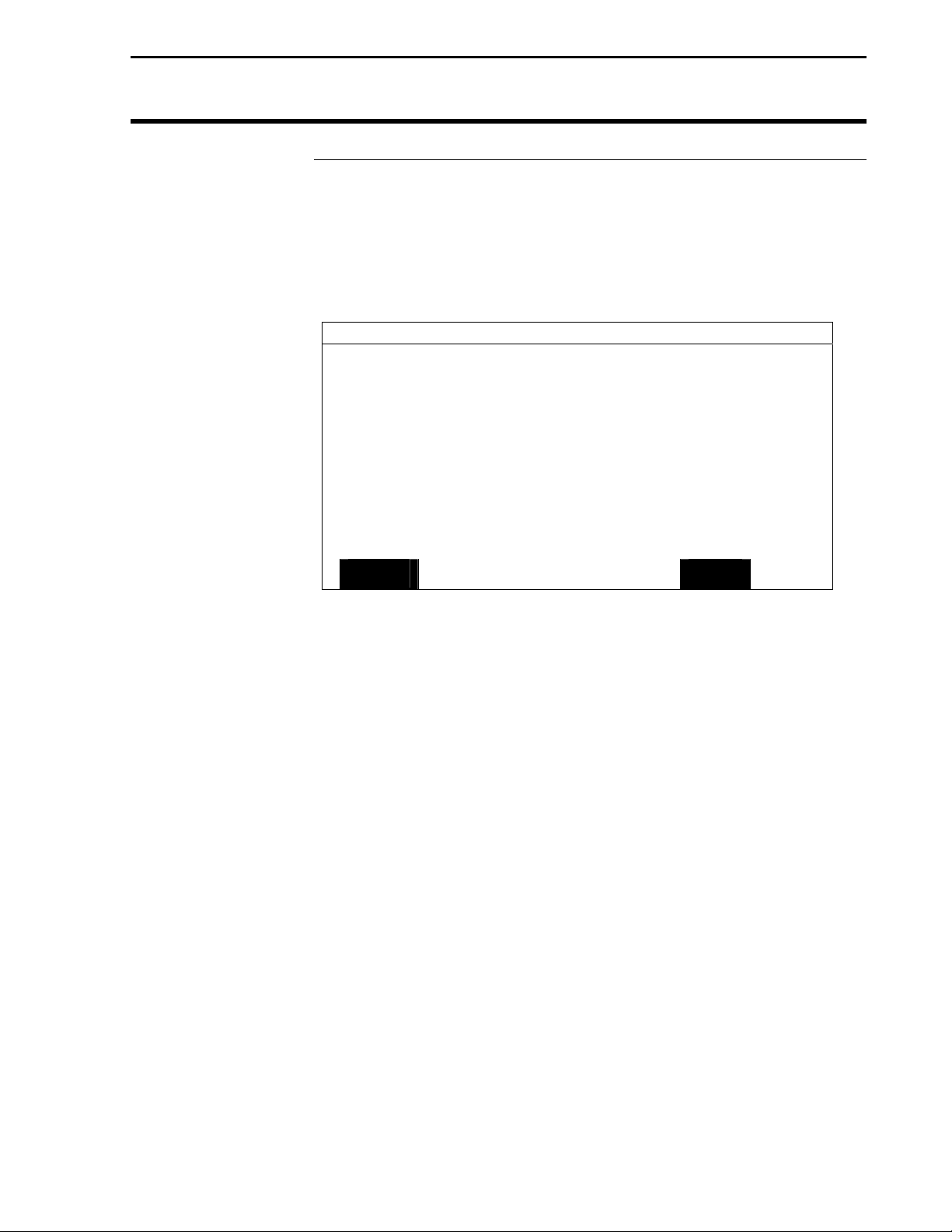

Figure 3. Light Bar cable connections to PF3000 Pro or PFadvantage with “all-

Light Bar

Ag Leader Technology

Figure 2. Light Bar cable connections to PF3000 Pro with integrated GPS

in-the-antenna” GPS 4100

4

February 2003 Rev.3 3000135

Page 9

Light Bar

Ag Leader Technology

General

Information

Explanation of

GPS/Lightbar

Screen

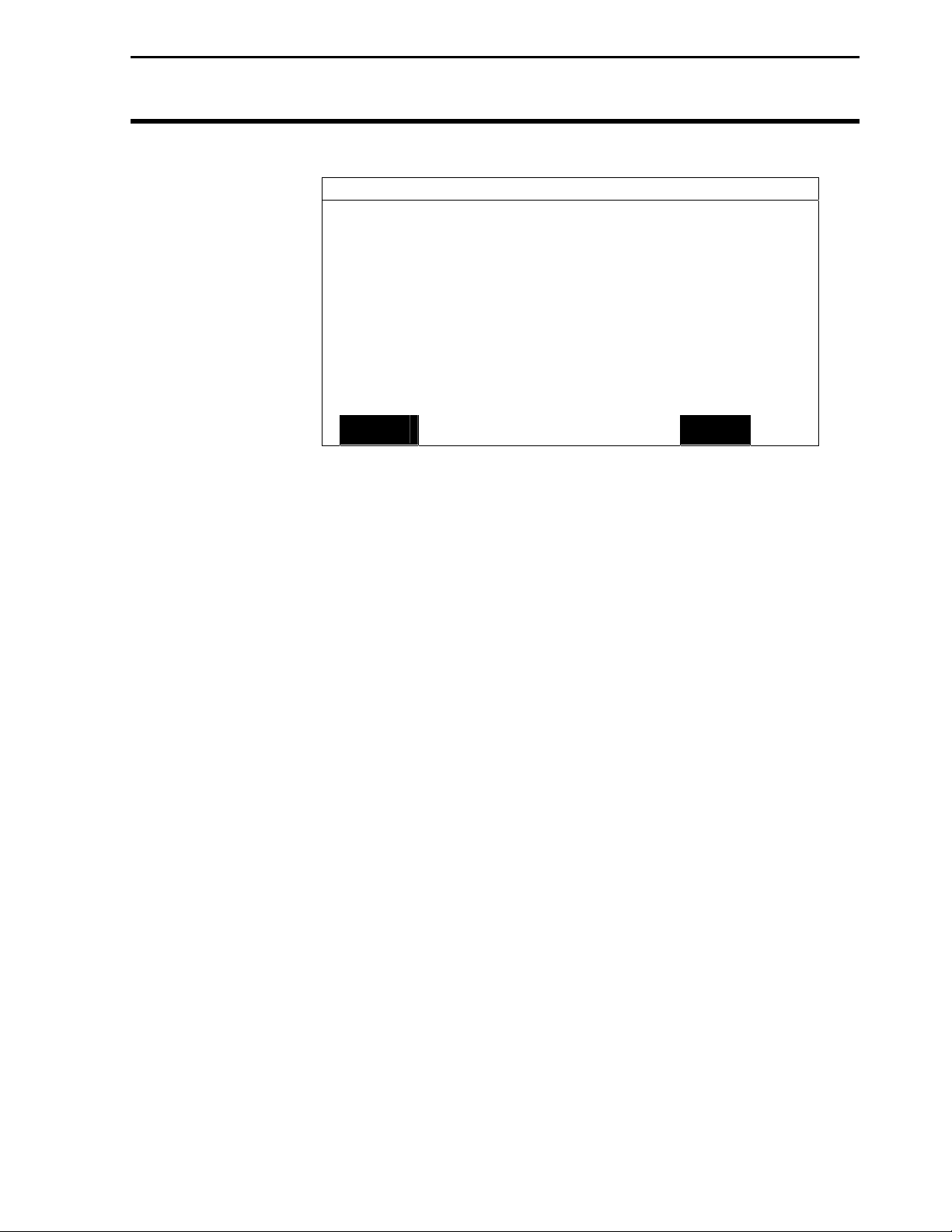

Use the following information to determine your requirements to setup the PF Series monitor for your Light Bar.

NOTE: The Add-On GPS3050/3100, or GPS 4100 are the only

receivers that can operate the Ag Leader Light Bar.

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 1.0 ft

End Distance --- ft

EDIT

Use Figure 4 to note the location of items on the screen.

NOTE: The Light Bar may be used in GRAIN HARVEST,

APPLICATION RATE or SITE VERIFICATION modes. Refer to

Console Setup in the Setup Section of the PF monitor Operators

Manual.

Lightbar Status: ON signifies that power is being sent to the light

bar.

Mounting Position: Ceiling mounting of the lightbar requires that it

be inverted. This setting will allow the text to be inverted also.

Brightness (1-5): This setting (1 = dim, 5 = bright) allows you to

determine the brightness of the LED on the lightbar.

Figure 4

General Information

EXIT

February 2003 Rev.3 3000135

5

Page 10

General Information

Text Mode: Provides the following selection to monitor (See

Figure 2 for location of text items)

Pass # & Error - Provides the pass number and error

from the center of the swath.

No Text – No text is displayed on the screen

Demo – Used for demonstration only, cycles power on

and off

Pass & Speed – Provides pass number and ground speed

Ground Speed – Displays ground speed only

Light Bar

Ag Leader Technology

Approach LED

Text Display Area

Guidance LED

Figure 5

Heading Error – Displays the degree error for the

heading from the center of the swath

Cross – TRK Error – Displays the error between current

position and swath

True Heading – Displays the actual degree heading from True

North

End Line Dist(ance) – Displays the distance from the

end of a pass (decreasing)

Start Line Dist(ance) – Displays the distance from the

start of a pass (increasing)

6

February 2003 Rev.3 3000135

Page 11

Light Bar

Ag Leader Technology

and magnitude of the correction, more

arrows indicate a sharper turn. For

curved modes only.

Sensitivity: This setting sets the sensitivity for the PAUSE function.

It only affects the large center LED of the Light Bar.

The large LED changes color as you approach headlands,

or the Pause/Resume point.

NOTE: LED sensitivity should be set larger as

ground speed increases

LED Spacing Mode: Use the Linear or Scaled settings to set the

spacing interval of the lightbar LED’s.

line. i.e. a setting of one foot off line from the

center of the swath will be represented by one

LED. The second LED will represent two feet

etc.

Scaled – Sets the first 10 LED’s each side of the

lightbar on a linear scale. The outer 7 LED’s on

each side are scaled to represent an end value

setting.

LED Spacing: This setting establishes LED spacing distance. If the

setting is 3 feet, the LED slides one unit to the left or

right for every 3 feet off line.

NOTE: The smaller the LED spacing the more precise

guidance the lightbar will provide.

End Distance: This setting is used when in Scaled for LED Spacing

Mode. You cannot set an end value smaller than the

LED spacing multiplied by 17 (there are 17 LEDs on

each side of the lightbar.

General Information

Pass # - Displays the current pass number for that field

Curve Arrows – Displays arrows indicating the direction

GPS Status – Displays GPS and Differential information on the text screen

Linear - Set the light bar to show off-line distance on a

February 2003 Rev.3 3000135

7

Page 12

General Information

Explanation of

GPS/Guidance

Screen

Use Figure 6 to note the location of items on the screen.

NOTE: The Light Bar may be used in GRAIN HARVEST,

APPLICATION RATE or SITE VERIFICATION modes. Refer to

Console Setup in the Setup Section of the PF monitor Operator’s

Manual.

Pattern: Determines which guidance pattern is driven.

None: Configures straight line guidance parallel to the

beginning and end of the first swath driven.

Curve Spiral: Use this curve setting to drive spirals or

closed rings.

Curve: Activates last curve following. Positions are

logged during current swath. The next swath is

parallel to the previous swath driven.

Skip Pass: Provides parallel guidance in a racetrack pattern

with a user specified swath skip. This setting is

for equipment with a large turn radius.

A+ Heading: Allows establishing a reference line from True North

Light Bar

Ag Leader Technology

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset +20.0 ft

Pass Skips 2

Units Displayed English

Contour Log Interval SWATH CHANGE

EDIT

Figure 6

EXIT

8

February 2003 Rev.3 3000135

Page 13

Light Bar

Ag Leader Technology

Headland Type: Determines the type of headland used.

None: In this mode, swath lengths are

infinite. The center LED remains one color,

never changing to indicate end of swath.

C-Clamp: Field ends are sprayed as headlands so

parallel passes may be used with minimal

overlap.

Curved: Logs irregular boundary shapes for

guidance.

Closed: Defines headlands with a series of user

entered points. The last point connects to

the first point to form a closed loop.

A-B End Zones: A & B points mark the center of

the boundary swath. (See Figure

Look-Ahead: The value that allows the system to predict future error.

This accounts for system delays, including operator

response time. 3 seconds is the default setting.

Display Mode: Determines which direction from the center of the

light bar the LEDs light indicate off-line error.

Show Error: Displays the extent and direction of the

error between current position and

swath line. Steer vehicle to "pull"

lights back to center of the lightbar.

Show Correction: Displays the extent and direction

of the necessary correction to

match the swath line. Steer

vehicle by "chasing" lights left or

right.

Swath Direction: This setting determines whether the swath is

manually or automatically incremented.

General Information

4) When the system is inside the

boundary area the center LED

illuminates green. The center

LED glows red when beyond the

boundary area.

February 2003 Rev.3 3000135

9

Page 14

General Information

Auto: Automatically increments in the direction

turned after the first swath. The swath

increments when the vehicle turns more than

110 degrees.

Right: Swaths are manually incremented to the

right of the A-B line.

Left: Swaths are manually incremented to the left

of the A-B line.

Snap: Automatically increments swath

number to the closest swath. (Not availabe

with Pass Skip and Curve following.) This is

the default setting.

Swath Width: Adjust in .5 ft increments from 1 to 999 ft. Set the

swath width to 1 ft less than the actual swath width to

reduce skip. Set the swath width 1 ft more than the

actual swath to reduce overlap.

Antenna Offset: The distance from the antenna, ahead or behind the

spray boom so that guidance information is

referenced to the spraying boom instead of the

antenna. It is adjusted in .5 ft increments from 0 to

100 ft. The antenna must be placed along the

vehicle’s centerline. Negative numbers are used for

a boom in front of the antenna, positive numbers are

for a boom behind the antenna.

Pass Skips: Adjusted in 0 to 99.

Units Displayed: Determines whether Metric or US Standards

(English) are used. The default is Metric.

Contour Log Interval: The settings are Swath Change and Heading

Change. Heading change is the default and

recommended setting. With the Contour Log

Interval set to Heading Change a reference

point will be logged whenever the heading

changes slightly.

Light Bar

Ag Leader Technology

10

February 2003 Rev.3 3000135

Page 15

Light Bar

Ag Leader Technology

Approach LED

Action

Figure 7. Headland Approach LED Action for AB ENDZONE

Green

Figures 7 through 9 show the action of the lightbar LED for different

patterns and headland types.

B

A

Figure 8. Headland Approach LED Action for Curved

RED

GREEN

RED

Green

Operator sees

Approach LED

change colors near

headland boundary

General Information

Red

Orange

Orange

Headland: Vehicle centerline on

last headland pass

Red

February 2003 Rev.3 3000135

11

Page 16

General Information

RED

Figure 9. Headland approach LED action for closed circuit

GREEN

GREEN

Light Bar

Ag Leader Technology

REDRED

RED

***

12

February 2003 Rev.3 3000135

Page 17

Light Bar

Ag Leader Technology

General Operation

Following a Curved

Line

Using Headlands

Using Light Bar

with PF Series

monitors

The following are general operation information to aid you in the use

of the Light Bar.

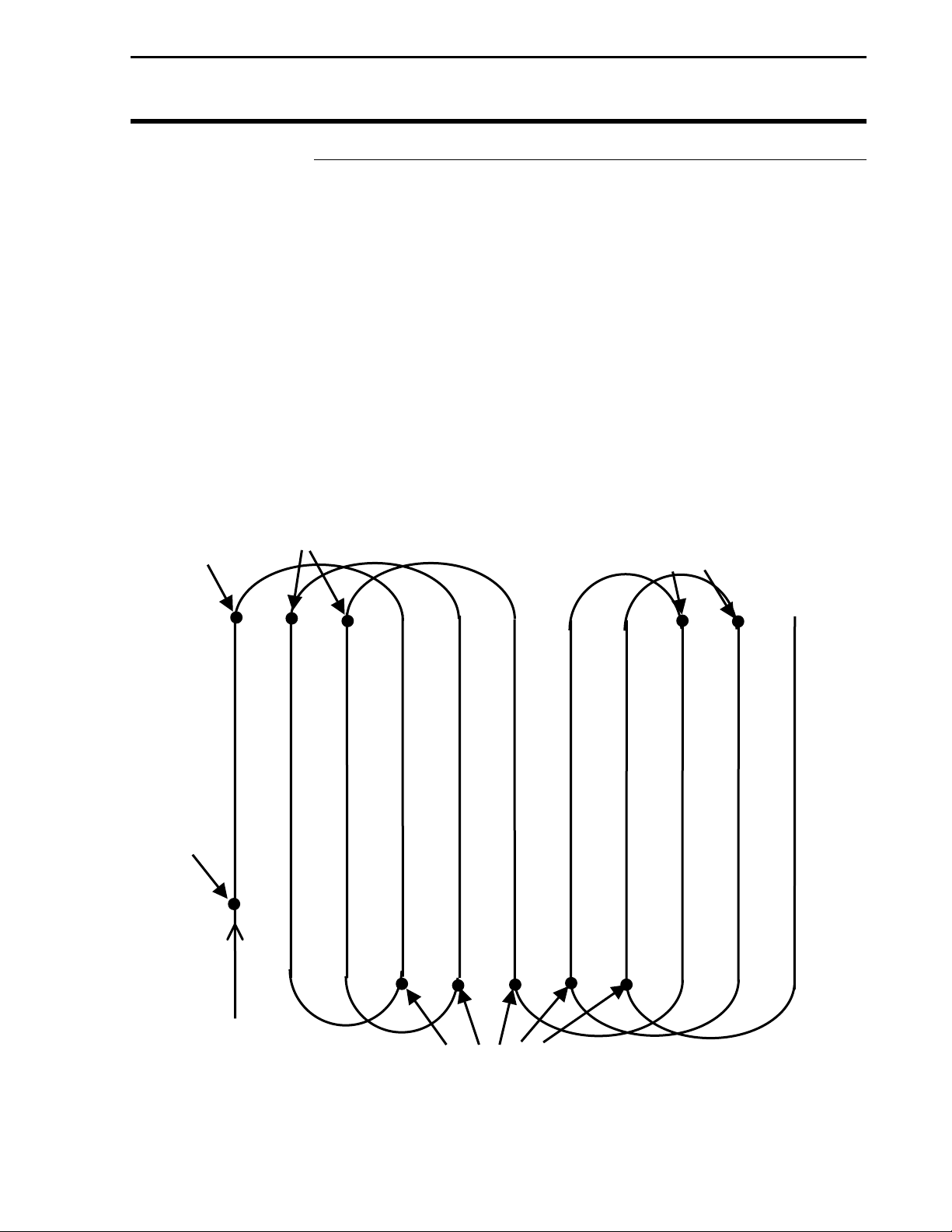

When using curve following pattern, guidance is provided parallel to

the previously driven swath.

While driving a swath, the GPS receiver records the swath location.

When the swath is incremented, positions logged are offset in the turn

direction. Guidance begins down the offset positions. Meanwhile,

new positions are logged for the current swath. When the swath

increments, the new positions are offset and guidance begins down the

next swath. The cycle repeats until guidance is reset.

Because of limited memory capacity, only the positions representing

the current and next swath are stored. Positions representing previous

swaths are deleted.

To help operators anticipate upcoming turns; a turn signal has been

added to the Light Bar. As turns approach, the lightbar illuminates in

the turn direction. The more LEDs illuminated, the sharper the turn.

The turn signal indicates a swath turn at twice the look-ahead distance.

By default, the turn signal occurs six seconds before the turn is

required.

Headlands specify field zones that have specific meaning. In some

applications, it may be an area where chemical application is not

desired. In other applications, the headland can be used to turn

equipment and move to the next swath. Its most simple function might

be to indicate the end of swath.

Power up the PF monitor.

Press the MENU key until OPTIONS is displayed and press OPTIONS

key.

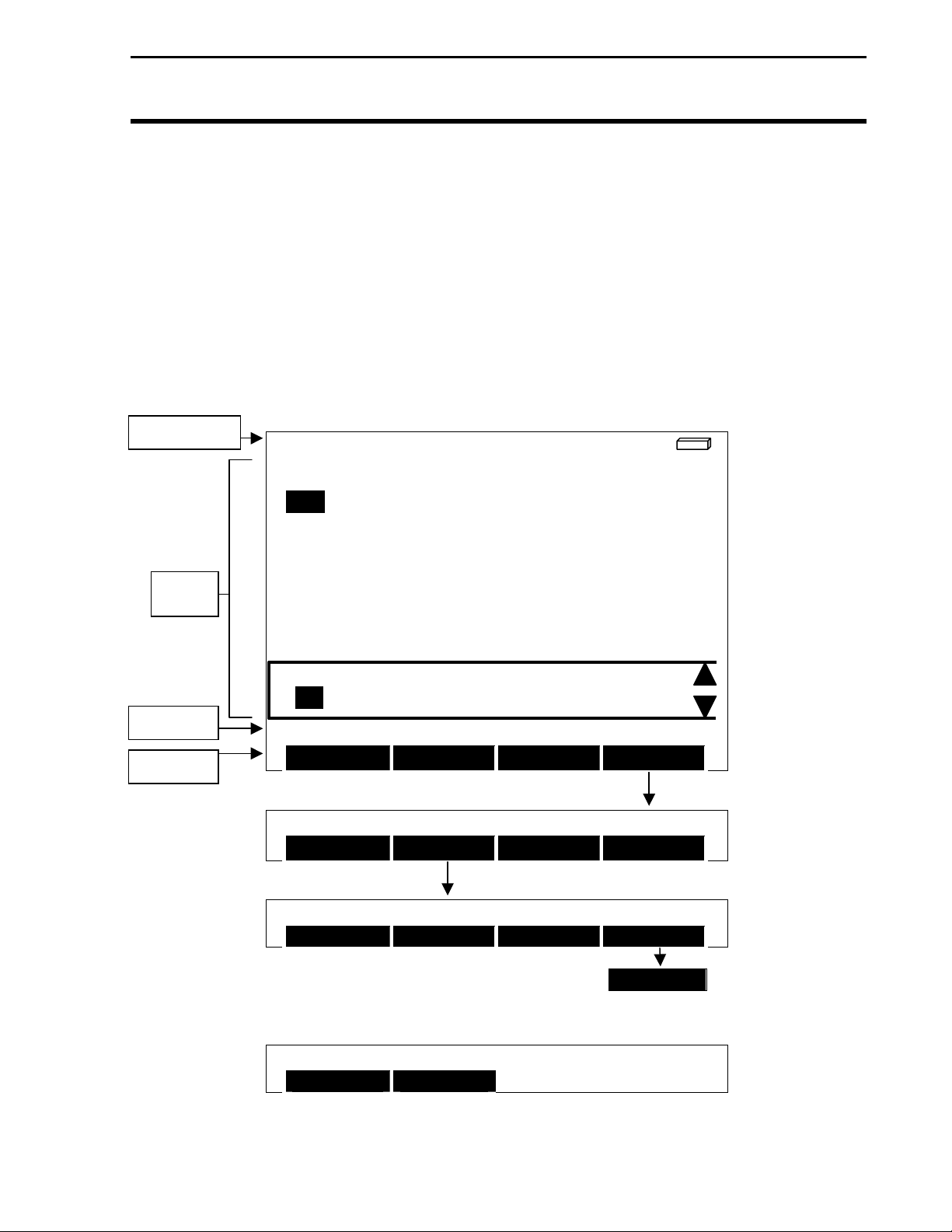

Under OPTIONS press the LIGHTBAR key. (See Figure 10)

The key settings perform the following functions:

SET A: Sets the beginning of the first swath.

SET B: Sets the end of the first swath.

General Operation

February 2003 Rev.3 3000135

13

Page 18

General Operation

<

<

Screen Info Line

F1: HOME 40 L1: ENDS DG >

Light Bar

Ag Leader Technology

headland points are cleared.

Pause: Used to leave the field in mid swath. Press once to

disable guidance. Leave the swath. The system guides

back to the pause location. Press this key again to

resume swathing.

ADD/STRT: Adds a point to the headland or starts logging

headland points.

CLR/STOP: Deletes the last point entered from the headland

or stops logging headland points.

Reset: Resets Guidance to begin a new field. Pattern and

TARGET

[auto man]

TOTAL SEEDS

Active

Display

AREA

PASS NUMBER

< left right >

Status Line

Menu Line

OPTIONS SELECTIONS

LIGHTBAR

Application: CORN 1 AREA ON

FIELD LOAD SHOW MAP OPTIONS

Application: CORN 1 AREA ON

MARKS LIGHTBAR NAV BoUNDARY

Application: CORN 1 AREA ON

SET A SET B RESET PAUSE

PRESS < > TO GET ADDITIONAL SELECTIONS

Application: CORN AREA ON

ADD/STRT CLR/STOP

300125

Figure 10

160

10.1

A-B

bu/ac

sds

acres

>

RESUME

>

3 Rev.3 3000135

14

February

200

Page 19

Light Bar

Ag Leader Technology

Basic A-B Parallel

Swathing using

AUTO or Snap

Use this type of pattern when no headlands are required and the field is

going to be driven in a straight parallel swath pattern. Refer to the PF

monitor Setup for Guidance Section on page 23 for the procedures to

set the following:

Pattern: Set to NONE

Headland Type: Set to NONE

Swath Direction: Set to AUTO or SNAP

Look – Ahead, Display Mode, Swath Width and Units Display should

be established to your preference or situation.

Before making your first pass:

Press MENU key until OPTIONS is displayed and press OPTIONS

key.

Press the LIGHTBAR key.

Press the RESET key to clear all points in memory.

NOTE: Before working in a new field, you should reset the system

to clear previous field information.

When you begin your first pass, press SET A key. (See Figure 11.)

At the end of the first pass press SET B key.

NOTE: SET B cannot be set without first setting SET A.

General Operation

February 2003 Rev.3 3000135

15

Page 20

General Operation

Ag Leader Technology

Light Bar

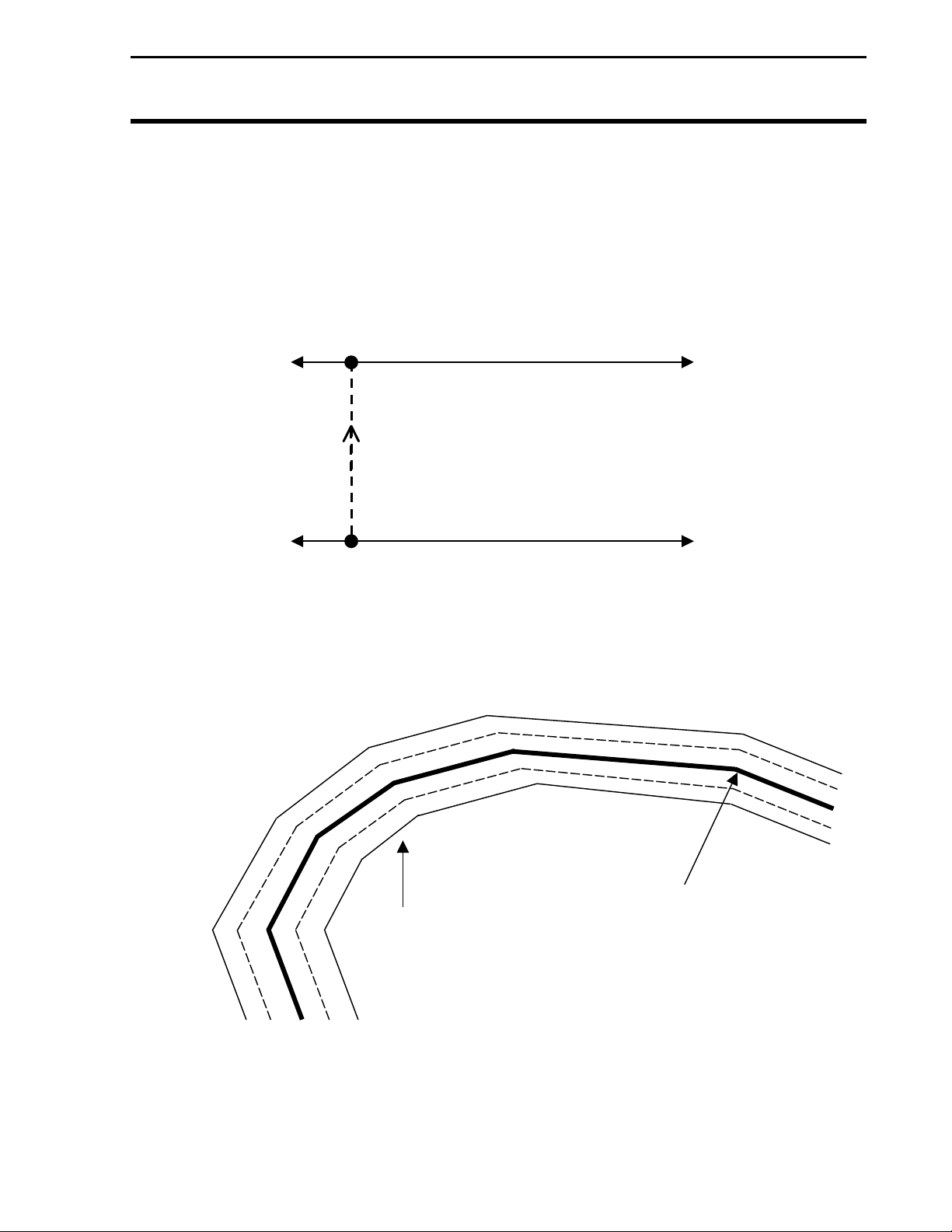

Set B

Set A

Direction of Travel

Figure 11.

Basic A-B Parallel Swathing with Auto or Snap to swath increment.

NOTE: You may manually override Auto or Snap by using the UP or DOWN ARROW

keys. Using the manual override will not change the setting of Auto or Snap. The system

will default back to Auto or Snap after overriding.

IMPORTANT: In order to use the UP or DOWN ARROW, the Lightbar pass

number must be displayed on the screen of the PF monitor.

16

February 2003 Rev.3 3000135

Page 21

Light Bar

Ag Leader Technology

Set B

Set turn

direction to

left or right

of A-B

reference

line

Set A

Direction of Travel

IMPORTANT: In order to use the UP or DOWN ARROW,

number must be displayed on the screen of the PF monitor.

UP

ARROW

UP

ARROW

UP

ARROW

Basic A-B Parallel Swathing with Manual Increment

To use Manual Increment:

Have Lightbar Pass Number item displayed on the PF monitor screen.

Set swath direction under GPS/Guidance to left or right of A-B line.

At the Set B spot, of the current swath, press the UP ARROW to increase

your pass number and down arrow to decrease the pass number.

UP

ARROW

UP

ARROW

Figure 12

UP

ARROW

UP

ARROW

General Operation

UP

ARROW

UP

ARROW

the Lightbar pass

February 2003 Rev.3 3000135

17

Page 22

General Operation

C-Clamp Pattern

Light Bar

Ag Leader Technology

This pattern may be used in a field you want to work in a parallel A-B

pattern. The ends of the fields are sprayed as headlands so the parallel

A-B passes are made with minimal overlap in the headland zones.

Pattern: Set to None

Headland pattern: Set to C-Clamp

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

IMPORTANT: In order to use the UP or DOWN ARROW,

the Lightbar pass number must be displayed on the screen of

the PF Monitor.

18

Figure 13. Straight Parallel pattern with C-clamp headland.

February 2003 Rev.3 3000135

Page 23

Light Bar

p

Ag Leader Technology

C-Clamp PatternCurve Following

Figure 13a. Curved Following pattern with C-clamp headland.

Use this pattern when working an irregularly shaped field. Guidance in

curve following mode is always based on the previous swath after the

initial A-B line is established. The ends of the fields are sprayed as

headlands so the parallel curved passes are made with minimal overlap in

the headland zones.

Pattern: Curved

Headland pattern: Set to C-Clamp

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

IMPORTANT: In order to use the UP or DOWN ARROW,

the Lightbar pass number must be displayed on the screen of

the PF Monitor.

CLR/

Sto

Set A

Set B

Add/

Start

Up Arrow

General Operation

Up

Arrow

Up Arrow

Red

Orange

Orange

Red

Up Arrow Up Arrow Up Arrow

Up

Arrow

February 2003 Rev.3 3000135

19

Page 24

General Operation

Double Curved

Headland, Straight

Pattern

Figure 14. Straight Parallel Pattern with a double curved headland.

Light Bar

Ag Leader Technology

This pattern may be used in a field you want to work in a parallel A-B

pattern. The ends of the fields are sprayed as headlands so the parallel

A-B passes are made with minimal overlap in the headland zones.

Pattern: Set to None

Headland pattern: Set to Curved

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

IMPORTANT: In order for this pattern to function properly

the Lightbar pass number must be displayed on the screen of

the PF monitor.

18

March 2001 Rev.1 3000135

Page 25

Light Bar

Ag Leader Technology

Straight Parallel

Swathing with A-B

Endzone Headlands

Set B

Set A

Basic Straight Parallel Swathing with A-B Endzones as the headland type

Use this pattern when headlands are required at both ends of a

rectangular field and the field is driven in a straight parallel swath

pattern. Headland locations are determined by the A and B points on

the A-B reference line. Headlands are generated perpendicular to the

A-B line at both ends of the field. The A-B points mark the center of

the headlands at either end of the field.

The Approach LED illuminates green when the vehicle is inside the

headlands boundary. The Approach LED changes to red upon crossing

the headland boundary.

Pattern: Set to NONE.

Headland pattern: Set to A-B Endzone.

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

General Operation

Approach LED Color

Red

Green

Red

Figure 15.

May 2001 Rev.2 3000135

19

Page 26

General Operation

A

r

Straight Parallel

Swathing with

Closed Circuit

Headland

ADD/STRT

ADD/STRT

Set B

Basic Straight Parallel Swathing with a single Closed Circuit Headland

Light Bar

Ag Leader Technology

Use this pattern when headlands are required, the ends of the field are

irregularly shaped, and the field is driven in a straight parallel swath

pattern. The headland location is determined by the position of the

headland points along the outside field boundary. Headlands are

generated one swath width along the field boundary according to the

manually entered headland points. The system automatically closes the

headland boundary by connecting the first and last headland point.

The Approach LED illuminates green when the vehicle is inside the

headland boundary. The Approach LED changes to red upon crossing

the headland boundary.

Pattern: Set to NONE.

Headland pattern: Set to Closed Circuit.

Direction of Travel

Set A

1/2 Swath Width

Figure 16

ADD/STRT

ADD/STRT

Red

Green

Red

pproach LED

Colo

20

May 2001 Rev.2 3000135

Page 27

Light Bar

A

Ag Leader Technology

Straight Parallel

Swathing with

Curved Headlands

Basic Straight Parallel Swathing with a single Curved Headland

Use this pattern in an irregularly shaped field that is still worked in a

parallel straight pattern. The irregularly shaped boundary can be

recorded as a sprayed headland using curved headlands, so the

following straight parallel passes can be made with minimal overlap

into the headland zone.

The Light Bar will prompt you to Set B after you press ADD/STRT

when beginning the circuit, ignore this message. Continue to the end

of the circuit and press CLR/STOP. Then press Set A and resume

following Light Bar prompts to begin parallel swathing.

The Approach LED illuminates green when the unit is inside the

headland boundary. As the unit approaches the edge of the headland

boundary the Approach LED changes to orange within 1/2 swath width

of the sprayed headland edge and to red upon crossing the headland

edge.

NOTE: If you pass beyond the outer orange band in this mode, the

Approach LED changes back to Green (See Figure 15).

Pattern: Set to None.

Headland pattern: Set to Curved.

Figure 17

General Operation

1/2 Swath

DD/STRT

Approach LED

May 2001 Rev.2 3000135

23

Page 28

General Operation

A

Parallel A-B on

Center Pivots

Light Bar

Ag Leader Technology

Use this pattern for spraying crops that are irrigated with a center pivot

when only sections of the entire circle are to be sprayed or worked.

This pattern is typically used where more than one type of crop is

irrigated by one pivot and no (or minimal) furrows exist.

The Approach LED illuminates green when inside the headland

boundary. When approaching the edge of headland boundary the

Approach LED changes to orange within 1/2 swath width of the

sprayed edge and to red upon crossing the headland edge.

Pattern: Set to NONE.

Headland pattern: Set to Curved.

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

ADD/STRT

Set B

Figure 18.

Straight Parallel swathing with Curved Headlands

pproach

LED Color

Red

Orange

Green

Green

Set A

CLR/STOP

24

May 2001 Rev.2 3000135

Page 29

Light Bar

Ag Leader Technology

A + Pattern

Set the angle from true north that you want to swath. As you

begin to make your first pass, press Set A. When you get to the

end of your first pass, turn into your next pass and the lightbar

will guide you on the reverse angle you set.

Pattern: Set to A+ Heading.

Headland pattern: Set to None.

Baseline heading: 315 degrees (Example)

Below is an example of the settings an operator may choose to

establish the desired heading across a field.

Figure 19. A+ Swath pattern

General Operation

Direction of travel

at 315 degrees

May 2001 Rev.2 3000135

25

Page 30

General Operation

Curve Following

Set B

Set A

Light Bar

Ag Leader Technology

Use this pattern when working an irregularly shaped field. Guidance in

curve following mode is always based on the previous swath after the

initial A-B line is established.

Pattern: Set to Curve.

Headland pattern: Set to curved (this happens by default with this

pattern setting).

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

IMPORTANT: In order for this pattern to function

properly the Lightbar pass number must be displayed on

the screen of the PF monitor.

Set B or UP ArrowSet B or UP Arrow

Set B

or UP

Arrow

Figure 20. Curve Pattern

Set B

or UP

Arrow

Set B

or UP

Arrow

24

February 2003 Rev.3 3000135

Page 31

Light Bar

Ag Leader Technology

Curve Following on

Pivots

Use this pattern for crops that are irrigated with a center pivot. It is

typically used on center pivots where crops irrigated by the pivot have

furrows around the center of the circle or when the pivot tracks become

difficult to navigate.

Pattern: Set to Curved.

Headland pattern: Set to None

Figure 21. Curve Pattern – Center Pivot

General Operation

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

IMPORTANT: In order for this pattern to function

properly the Lightbar pass number must be displayed on

the screen of the PF monitor.

Set B

Set B or UP Arrow

Set B or UP Arrow

Set A

May 2001 Rev.2 3000135

25

Page 32

General Operation

Curve Following

with Curved

Headlands

Press

ADD/STRT

UP Arrow

Figure 22. Curve Pattern with Curved Headlands

Light Bar

Ag Leader Technology

Use this pattern when headlands are required on all sides of a field that

is irregularly shaped. Double headland passes and curved swath lines

can also be implemented in this mode. Guidance in Curve Following

mode is always based on the previous swath after the initial A-B line is

established.

The Approach LED illuminates green when inside the headland

boundary. When approaching the edge of a headland boundary, the

Approach LED changes to orange within 1/2 swath width of the

sprayed edge and to red upon crossing the headland edge.

Pattern: Set to Curve.

Headland pattern: Set to Curved.

IMPORTANT: In order for this pattern to function properly the

Lightbar pass number must be displayed on the screen of the PF

monitor.

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

Set B or UP Arrow

Set B or UP Arrow

CLR/STOP

Set B or UP Arrow Set B or UP Arrow

Set B or UP Arrow

26

February 2003 Rev.3 3000135

Page 33

Light Bar

y

y

Ag Leader Technology

Spiral

Set A

Use this pattern when the operating pattern within a field dictates

continuous application from the center out or outside in. Using the

curved guidance spiral pattern, a field can be worked continuously and

completely using no headlands.

This pattern is not recommended for fields under 10 acres. Fields with

long runs may cause erratic behavior. The more contour to a swath the

better this pattern will perform. At the start of a new guided pass, it

may take a short period of time for the lightbar to determine your

location and guidance pattern.

Pattern: Set to Curved Spiral.

Headland Pattern: Set to None.

Up Arrow Ke

General Operation

IMPORTANT: In order to use the UP or DOWN ARROW,

the Lightbar pass number must be displayed on the screen

of the PF monitor.

NOTE: Depending on the direction that your want to spiral,

you increment the pass in the following manner:

Up Arrow =Right, Down Arrow = Left

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

Up Arrow Ke

Figure 23. Curved Spiral Pattern

May 2001 Rev.2 3000135

29

Page 34

General Operation

ARRO

ARRO

Skip with No

Headlands

Set B

Set A

Press UP

Figure 24. Parallel swathing with Pass Skips

Light Bar

Ag Leader Technology

Use this pattern when the equipment being used to work a field

requires a larger turning radius than the standard parallel A-B pattern

allows. Skip enables the operator to specify the number of swaths to

skip between passes and provides racetrack guidance across the field

accordingly.

Pattern: Set to Skip Pass.

Headland Pattern: Set to None.

IMPORTANT: In order for this pattern to function

properly the Lightbar pass number must be displayed on

the screen of the PF monitor.

NOTE: Before working in a new field, you should reset the

system to clear previous field information.

W KEY

Press UP

ARROW key

Press UP

W key

30

February 2003 Rev.3 3000135

Page 35

Light Bar

Ag Leader Technology

Using In-Field

Guidance

LED Sensitivity

Figure 25. Approach LED Sensitivity with Pause/Resume Point

The Pause/Resume feature disables lightbar guidance in mid-swath.

You can leave the swath, navigate back to the work location and resume

swathing.

By pressing the pause/resume key, you can leave the current swath.

When restarting, the lightbar provides guidance to help align the vehicle

with the swath that was active when guidance was paused. To use the

lightbar to find the active swath:

The LED illuminates green when the vehicle is within the

Approach LED sensitivity setting of the pause.

When the LED turns green, press resume to continue. See

Figure 25 for an example.

General Operation

Pass Direction

Approach LED

Sensitivity

Red

Amber

Pause/Resume Point

Green

Amber

Red

***

May 2001 Rev.2 3000135

31

Page 36

PF3000 or PF3000 Pro Setup for Light Bar

PF Series monitors Setup for Lightbar

1. Power up the PF monitor.

2. Press MENU key until SETUP is displayed and select SETUP.

3. Press the left or right arrow keys to select GPS.

4. At the GPS Setup screen, use the up or down arrow key to scroll

down until Light Bar is highlighted and press EDIT key. (Figure

26)

GPS SETUP

NEMA MESSAGES

GPS/PORT CONFIGURATION

BEACON DIFFERENTIAL

SATELLITE DIFFERENTIAL

LIGHT BAR

GUIDANCE

EDIT

Figure 26.

Light Bar

Ag Leader Technology

EXIT

30

March 2001 Rev.1 3000135

Page 37

Light Bar

Ag Leader Technology

5. With the Lightbar Status line highlighted, press EDIT key. (Figure

27) Change the lightbar status to ON or OFF and press ACCEPT

key. (Figure 28)

GPS/LIGHTBAR

Lightbar Status OFF

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

EDIT

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

ACCEPT

PF3000 or PF3000 Pro Setup for Light Bar

Figure 27.

Figure 28.

EXIT

CANCEL

March 2001 Rev.1 3000135

31

Page 38

PF3000 or PF3000 Pro Setup for Light Bar

Ag Leader Technology

Light Bar

6. Scroll down to Mounting Position and press EDIT key (Figure 29).

Use the up or down arrow key to select “Dash” or “Ceiling”

mounting and press ACCEPT key. (Figure 30) Selecting ceiling

mount will invert the text

GPS/LIGHTBAR

Lightbar Status OFF

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

EDIT

EXIT

Figure 29.

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

ACCEPT

CANCEL

Figure 30.

32

March 2001 Rev.1 3000135

Page 39

Light Bar

Ag Leader Technology

PF Monitor Setup for Light Bar

7. Scroll down to Brightness and press EDIT key. (Figure 31) Use

the up or down arrow key to select the lightbar display brightness

from 1 (dimmest) to 5 (brightest) and press ACCEPT key. (Figure

32)

GPS/LIGHTBAR

Lightbar Status OFF

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

EDIT

EXIT

Figure 31.

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

ACCEPT

CANCEL

Figure 32.

March 2001 Rev.1 3000135

33

Page 40

PF3000 or PF3000 Pro Setup for Light Bar

Ag Leader Technology

Light Bar

8. Use the down arrow key to scroll down until Text Mode is

highlighted (Figure 33) and press EDIT key. Use the up or down

arrow key to select one of the following and press ACCEPT key

(Figure 34):

Pass # and Error Cross-TRK Error

No Text True Heading

Curve Arrows Demo

End Line Dist Pass & Speed

Start Line Dist Ground Speed

Pass # Heading Error

GPS Status

GPS/LIGHTBAR

Lightbar Status OFF

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

EDIT

EXIT

Figure 33.

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

ACCEPT

CANCEL

Figure 34.

34

March 2001 Rev.1 3000135

Page 41

Light Bar

Ag Leader Technology

PF Monitor Setup for Light Bar

9. Scroll down to Proximity Sensitivity and press EDIT key. (Figure

35) Use the up or down arrow key to select a setting from 1 to 99 ft

and press ACCEPT key. (Figure 36)

GPS/LIGHTBAR

Lightbar Status OFF

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

EDIT

EXIT

Figure 35.

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

ACCEPT

CANCEL

Figure 36.

March 2001 Rev.1 3000135

35

Page 42

PF Monitor Setup for Light Bar

Ag Leader Technology

Light Bar

10. Scroll down to LED Spacing Mode and press EDIT key. (Figure

37) Use the up or down arrow key to select "Linear" or "Scaled"

and press ACCEPT key (Figure 38).

GPS/LIGHTBAR

Lightbar Status OFF

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

EDIT

EXIT

Figure 37.

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

ACCEPT

CANCEL

Figure 38.

36

March 2001 Rev.1 3000135

Page 43

Light Bar

Ag Leader Technology

PF Monitor Setup for Light Bar

11. Scroll down to LED Spacing and press EDIT key. (Figure 39) Use

the up or down arrow keys to select a setting from 0.1 to 9.9 ft and

press ACCEPT key. (Figure 40)

GPS/LIGHTBAR

Lightbar Status OFF

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

EDIT

EXIT

Figure 39.

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

ACCEPT

CANCEL

Figure 40.

March 2001 Rev.1 3000135

37

Page 44

PF Monitor Setup for Light Bar

Ag Leader Technology

Light Bar

12. Scroll down to End Distance and press EDIT key. (Figure 41) If

SCALED is used, the first 10 LED’s are normal spacing and the

remaining LED distance represents the difference to the end

distance. Enter that value and press ACCEPT key. (Figure 42)

GPS/LIGHTBAR

Lightbar Status OFF

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

EDIT

EXIT

Figure 41.

GPS/LIGHTBAR

Lightbar Status ON

Mounting Position Dash

Brightness (1-5) 5

Text Mode PASS # & ERROR

Proximity Sensitivity 25 ft

LED Spacing Mode LINEAR

LED Spacing 5.0 ft

End Distance --- ft

ACCEPT

CANCEL

Figure 42.

13. Press EXIT key to return to GPS Setup screen.

***

38

March 2001 Rev.1 3000135

Page 45

Light Bar

Ag Leader Technology

PF Series monitor

Setup for

Guidance

1. At the GPS Setup screen, scroll down to Guidance and press EDIT

key. (Figure 43)

Figure 43.

PF3000 or PF3000 Pro Setup for Guidance

GPS SETUP

GPS/PORT CONFIGUREATION

BEACON DIFFERENTIAL

SATELLITE DIFFERENTIAL

EDIT

NEMA MESSAGES

LIGHT BAR

GUIDANCE

EXIT

March 2001 Rev.1 3000135

39

Page 46

PF3000 or PF3000 Pro Setup for Guidance

2. With Pattern highlighted, press EDIT key. (Figure 44) Use the up

or down arrow keys to select one of the following and press

ACCEPT key (Figure 45):

None

A+ Heading

Curve Spiral

Curve

Skip Pass

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

EDIT

Figure 44.

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

Figure 45.

Light Bar

Ag Leader Technology

EXIT

CANCEL

40

March 2001 Rev.1 3000135

Page 47

Light Bar

Ag Leader Technology

3. Scroll down to Headland Type and press EDIT key. (Figure 46)

Use the up or down arrow key to select one of the following and

press ACCEPT key (Figure 47):

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

EDIT

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

PF3000 or PF3000 Pro Setup for Guidance

None C-Clamp Curved

Closed Circuit A-B End Zones

Figure 46.

Figure 47.

EXIT

CANCEL

March 2001 Rev.1 3000135

41

Page 48

PF Monitor Setup for Guidance

4. Scroll down to Look – Ahead and press EDIT key. (Figure 48)

Use the up or down arrow key to select from 0 to 9 seconds and

press ACCEPT key. (Figure 49)

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

EDIT

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

Light Bar

Ag Leader Technology

EXIT

Figure 48.

CANCEL

Figure 49.

42

March 2001 Rev.1 3000135

Page 49

Light Bar

Ag Leader Technology

5. Scroll down to Display Mode and press EDIT key. (Figure 50)

Use the up or down arrow key to select “Show Correction” or

“Show Error” and press ACCEPT key. (Figure 51)

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

EDIT

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

PF Monitor Setup for Guidance

Figure 50.

Figure 51.

EXIT

CANCEL

March 2001 Rev.1 3000135

43

Page 50

PF Monitor Setup for Guidance

6. Scroll down to Swath Direction and press EDIT key. (Figure 52)

Use the up or down arrow key to select one of the following and

press ACCEPT key (Figure 53):

AUTO LEFT

RIGHT SNAP (Default)

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

EDIT

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

Light Bar

Ag Leader Technology

EXIT

Figure 52.

CANCEL

Figure 53.

44

March 2001 Rev.1 3000135

Page 51

Light Bar

Ag Leader Technology

7. Scroll down to Swath Width and press EDIT key. (Figure 54) Use

the up or down arrow key to set swath width from 0.1 to 100.0 ft

and press ACCEPT key (Figure 55).

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

EDIT

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

PF Monitor Setup for Guidance

Figure 54.

Figure 55.

EXIT

CANCEL

March 2001 Rev.1 3000135

45

Page 52

PF Monitor Setup for Guidance

8. Scroll down to Antenna Offset and press EDIT key. (Figure 56)

Use the up or down arrow key to set Antenna Offset from –100 to

+100 ft and press ACCEPT key. (Figure 57)

NOTE: Antenna Offset could be a negative number if your spray

boom is mounted in front of the antenna. Positive numbers indicate

a boom mounted behind the antenna.

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

EDIT

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

Light Bar

Ag Leader Technology

EXIT

Figure 56.

CANCEL

Figure 57.

46

March 2001 Rev.1 3000135

Page 53

Light Bar

Ag Leader Technology

9. Scroll down to Pass Skips and press EDIT key. (Figure 58) Use

the up or down arrow key to set Pass Skip from 0 to 99 and press

ACCEPT key. (Figure 59)

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

EDIT

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

PF Monitor Setup for Guidance

Figure 58.

Figure 59.

EXIT

CANCEL

March 2001 Rev.1 3000135

47

Page 54

PF Monitor Setup for Guidance

10. Scroll down to Units Displayed and press EDIT key. (Figure 60)

Use the up or down arrow key to set English or Metric and press

ACCEPT key. (Figure 61)

GPS/GUIDANCE

Pattern NONE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

EDIT

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

Light Bar

Ag Leader Technology

EXIT

Figure 60

CANCEL

Figure 61

48

March 2001 Rev.1 3000135

Page 55

Light Bar

Ag Leader Technology

PF Monitor Setup for Guidance

11. Scroll down to Contour Log Interval and press EDIT key. (Figure

62) Use the up or down arrow key to set Swath Change or Heading

Change and press ACCEPT key. (Figure 63)

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

CANCEL

Figure 62.

GPS/GUIDANCE

Pattern CURVE

Headland Type CURVED

Look – Ahead 3 SEC

Display Mode SHOW CORRECTION

Swath Direction Auto

Swath Width 60.0 ft

Antenna Offset 20.0 ft

Pass Skips 15

Units Displayed English

Contour Log Interval HEADING CHANGE

ACCEPT

CANCEL

Figure 63.

12. Press the EXIT key twice to return to the main operating screen.

***

February 2003 Rev.3 3000135

51

Page 56

Parts List

Ag Leader Technology

Light Bar

Parts List – Light Bar

Part Name/Description Part No. Quantity

Light Bar System 3001469 1

Light Bar Cable, 12 ft 2000933 1

Light Bar, Ag Leader 3000126 1

Manual – Ag Leader Light Bar 3000135 1

Light Bar Installation Kit 3000506 1

Dual-Lock – Type 170 (Window Side) 3 in. 2000052 3

Dual-Lock – Type 400 (Monitor Side) 3 in. 2000053 1

Alcohol Swab Pack 2002811 4

Grey Plastic Cable Clamps 2002812 6

Cable Tie – 6 in. black 2002817-6 10

Optional Suction Cup is ordered separately from the Light Bar

3-inch Suction Cup for Lightbar 3001475 1

50

March 2001 Rev.1 3000135

Page 57

Light Bar

Owners Registration

You will NOT receive upgrade/update information of this

product if you are not registered.

Return this sheet in the enclosed postage – paid envelope or

fax.

(Outside the USA 011) – 515-232-3595

Ag Leader Technology

2202 South Riverside Drive

P.O. Box 2348

Ames, Iowa 50010

Name:__________________________________________________________________

Street Address:___________________________________________________________

City, State, Country:_______________________________________________________

Postal or USA ZIP code:____________________________________________________

Phone # (including Country code or USA area code):_____________________________

Mobile Phone #:______________________ FAX #:_____________________

Email address:_________________________________________________

Ag Leader Dealer:______________________________________________

Dealer Address:___________________________________________________________

Intended Use (Please circle all that apply): Combine Sprayer Planter ATV

Other, please specify___________________________________________

Light Bar Serial #_____________________

PF monitor Serial #________________________

Add-On GPS3050 Serial #_______________

Add-On GPS3100 Serial #_______________

Add-On GPS 4100 Serial #_______________

Page 58

Page 59

Light Bar

Ag Leader Technology

Summary of Changes for 3000135

Revision 1 Completed April 2001. Incorporated two new patterns and the setup for them.

Incorporated three new drawings to illustrate correct cable attachment. Corrected

typographical errors in previous editions.

Revision 2 Completed May 2001: Incorporated change at the suggestion of customer.

See CR NO. CR051001-0128

Revision 3 Completed February 2003: Incorporated changes for v1.70 GPS firmware.

Reworked Fig. 13 added Fig. 13a.

Revision Page

May 2001 Rev.2 3000135

Loading...

Loading...