Page 1

Page 2

Page 3

Precision Farming System

PF3000

Operators Manual

Page 4

Page 5

PF3000

1-1

Ag Leader Technology

General

Welcome

System Upgrades

Limited Warranty

Welcome to the Ag Leader Technology family. Ag Leader Technology is

dedicated to the development of advanced, yet practical and cost-effective

tools for grain production. Above all, however, we are dedicated to meeting

your needs for support of existing products and development of product

improvements.

We want to hear from you! Feel free to call any time to discuss:

• Operational problems with your system

• Features you don’t like about your system

• Features you would like added to your system

We will do our best to ensure that you are happy with your current system

and that it is upgraded in the future to better meet your needs.

Ag Leader Technology will periodically provide free operating program

upgrades that will improve the performance of your PF3000.

To receive free upgrades and new product news, you must send in or fax

(515-232-3595) the Registration Form that is at the beginning of the

operator’s manual. Our mailing address is:

Ag Leader Technology

2202 South Riverside Drive

P.O. Box 2348

Ames, IA 50010

Internet http://www.agleader.com

Ag Leader Technology will repair or replace at no charge any component of

the PF3000 system that fails during normal service on the equipment model

that the system was intended for use within two years from the date of first

use.

Warranty is not provided for damage resulting from abuse, neglect,

accidents, vandalism, acts of nature, or any other causes that are outside the

normal, intended use of the PF3000 system.

April 2002

Page 6

General

1-2

Service

Copyright Notice

Proprietary

Technology Notice

PF3000

Ag Leader Technology

Ag Leader Technology shall not be liable for indirect, incidental, or

consequential damages to the dealer, end user, or third parties arising from

the sale, installation, or use of the PF3000 system.

If you have a problem with your system, call your Ag Leader Technology

dealer or call us directly at the phone number below. If we determine you

have a hardware failure, we will ship replacement hardware immediately.

Our mailing address and phone numbers are:

Ag Leader Technology

2202 South Riverside Drive

P.O. Box 2348

Ames, IA 50010

Phone: 515-232-5363

Fax: 515-232-3595

Note: Return failed hardware to us by UPS (preferred) or US mail.

Ag Leader Technology has copyrighted (1998) the contents of this

manual and the operating program for the PF3000 system. No reproductions

of this material may be made without first obtaining the consent of Ag

Leader Technology.

The PF3000 system has patents on its design and operational features.

Copying features of this system relating to measurement and calculation of

grain flow and weight, or organization of field and load data may result in

patent infringement.

April 2002

Page 7

PF3000

1-3

Ag Leader Technology

General

General

Description

Fields and Loads

Keypad

The PF3000 is a universal monitor/controller for crop production that is

GPS compatible. It can be transferred from a combine to a tractor or other

vehicles easily. In the combine it functions as a yield monitor and

accurately measures and records acres, moisture, grain weight, bushels, and

yield on-the-go. In the tractor or sprayer it connects to a sprayer or planter

controller and monitors and controls the application rate. The PF3000 also

can record data for field boundaries, tile lines or where a hybrid is planted.

The PF3000 has its own internal memory for recording field and load data.

GPS data, however, is not recorded in the internal memory, but must be

logged to a memory card.

The PF3000 must be setup and calibrated to record accurate information.

NOTE: The Grass Seed version of the PF 3000 is setup and

calibrated using the same procedures as for grain harvest. Where

there are differences between the harvest of grain verses grass seed

they will be noted.

All the information recorded by the PF3000 must be recorded in a field and

load. The operator must manually select or change the field and load on the

PF3000 during field operation. A load is used to subdivide a field into

smaller sections. The monitor load is not associated with the combine tank,

wagon, or truck load. It is recommended to use different loads for different

hybrids or varieties or field conditions (like a wet hole).

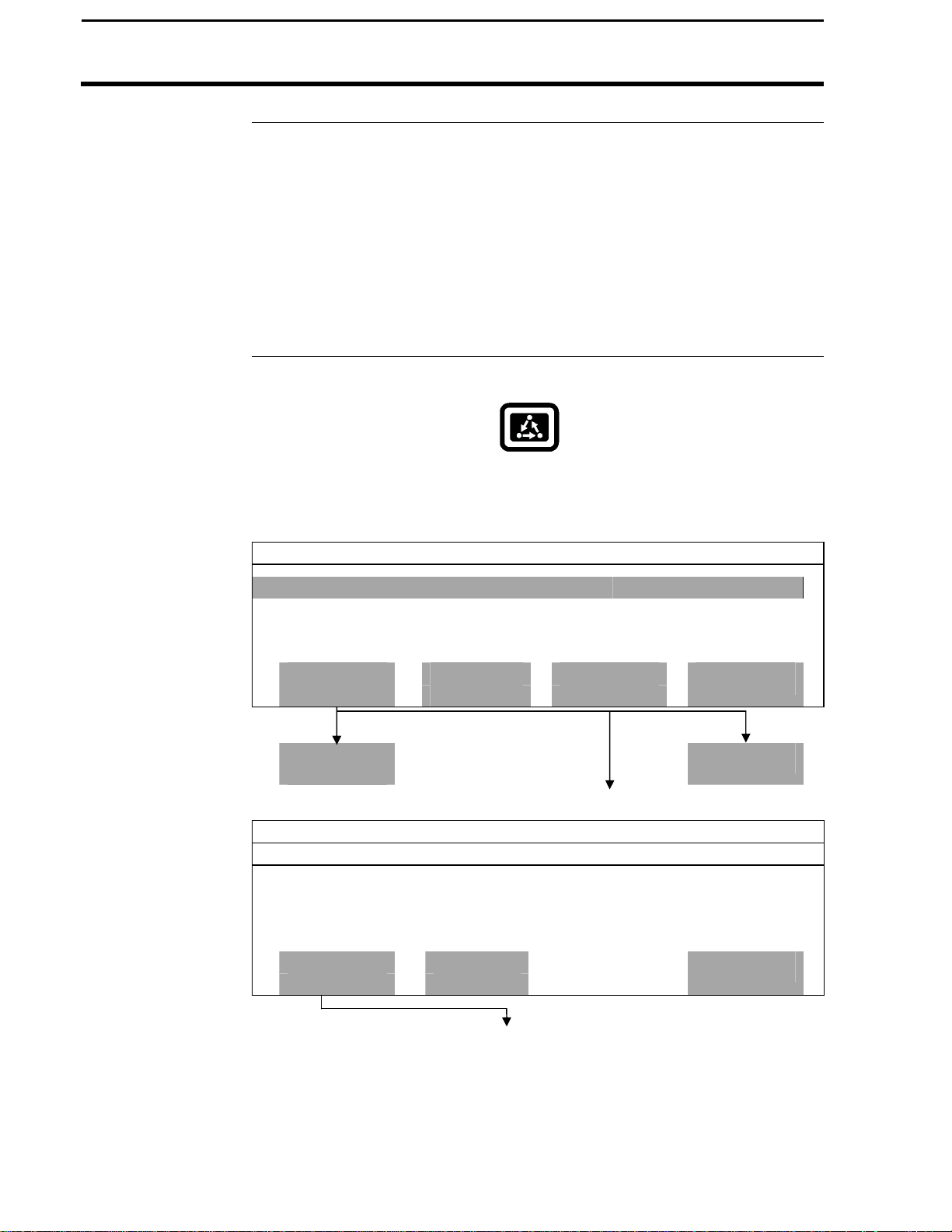

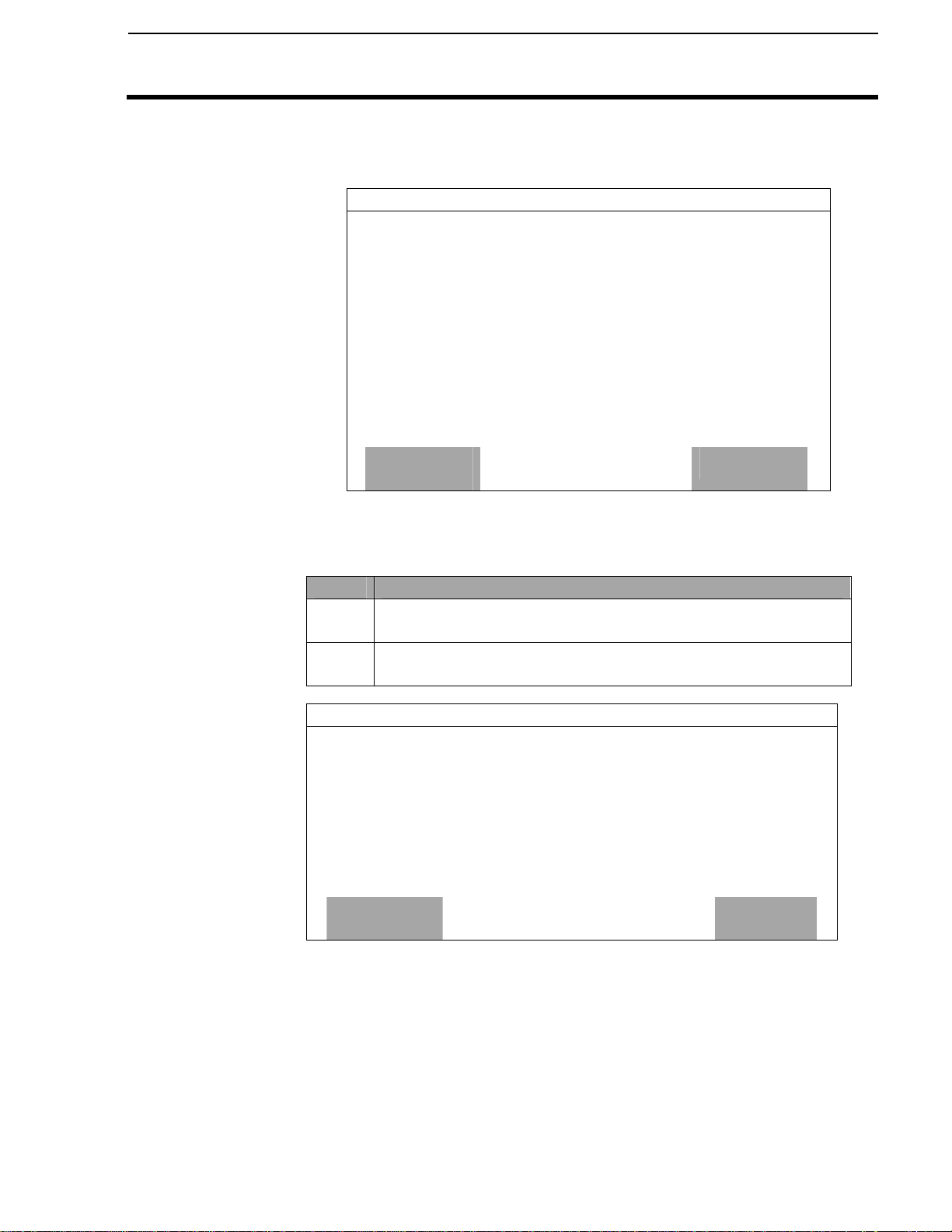

The monitor has “soft” keys which do not have labels on the keys to identify

the function of the key. The labels for the keys will appear on the display

screen next to the key. However, there are four major groups of the keys:

arrow keys, display selection keys, menu key, menu selection keys.

April 2002

Page 8

General

1-4

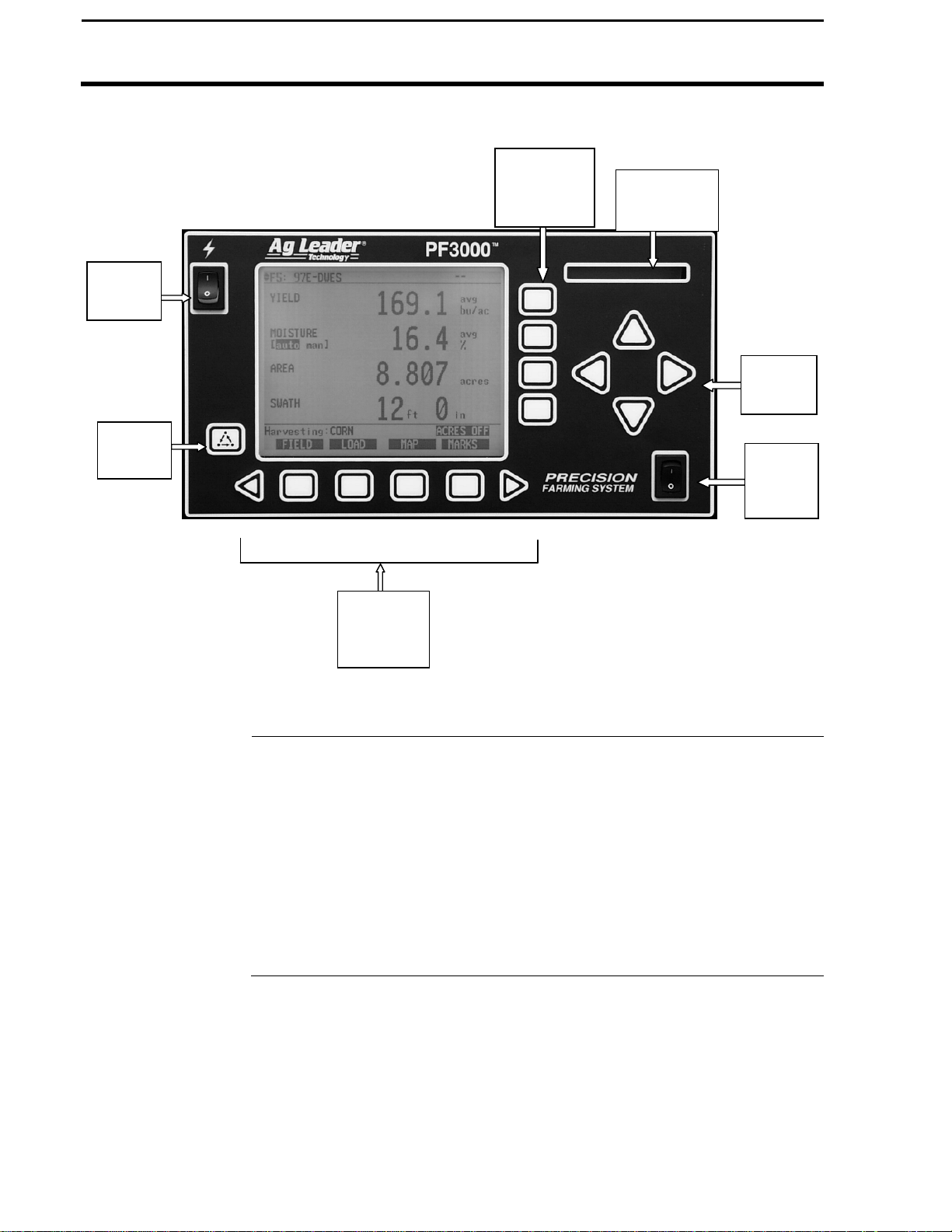

Switch

Power

Switch

Menu

Key

Ag Leader Technology

PF3000

Display

Selection

Keys

Memory

Card Slot

Arrow

Keys

Area

Count

Arrow Keys

Menu

Selection

Keys

Figure 1: Front panel of the PF3000

The UP, DOWN, LEFT and RIGHT ARROW keys on the right side of the

keypad are used to select and change a setting. The bottom LEFT and

RIGHT ARROW keys are only used to view more menu or display items.

They are never used to select or change a setting.

On the main operating screen, you will see an up and down arrow symbol

that will either be beside the field or load or to the right of one of the display

lines. This symbol indicates what item the UP or DOWN ARROW keys

will change if pressed.

April 2002

Page 9

PF3000

1-5

Ag Leader Technology

Display and

Display Selection

Keys

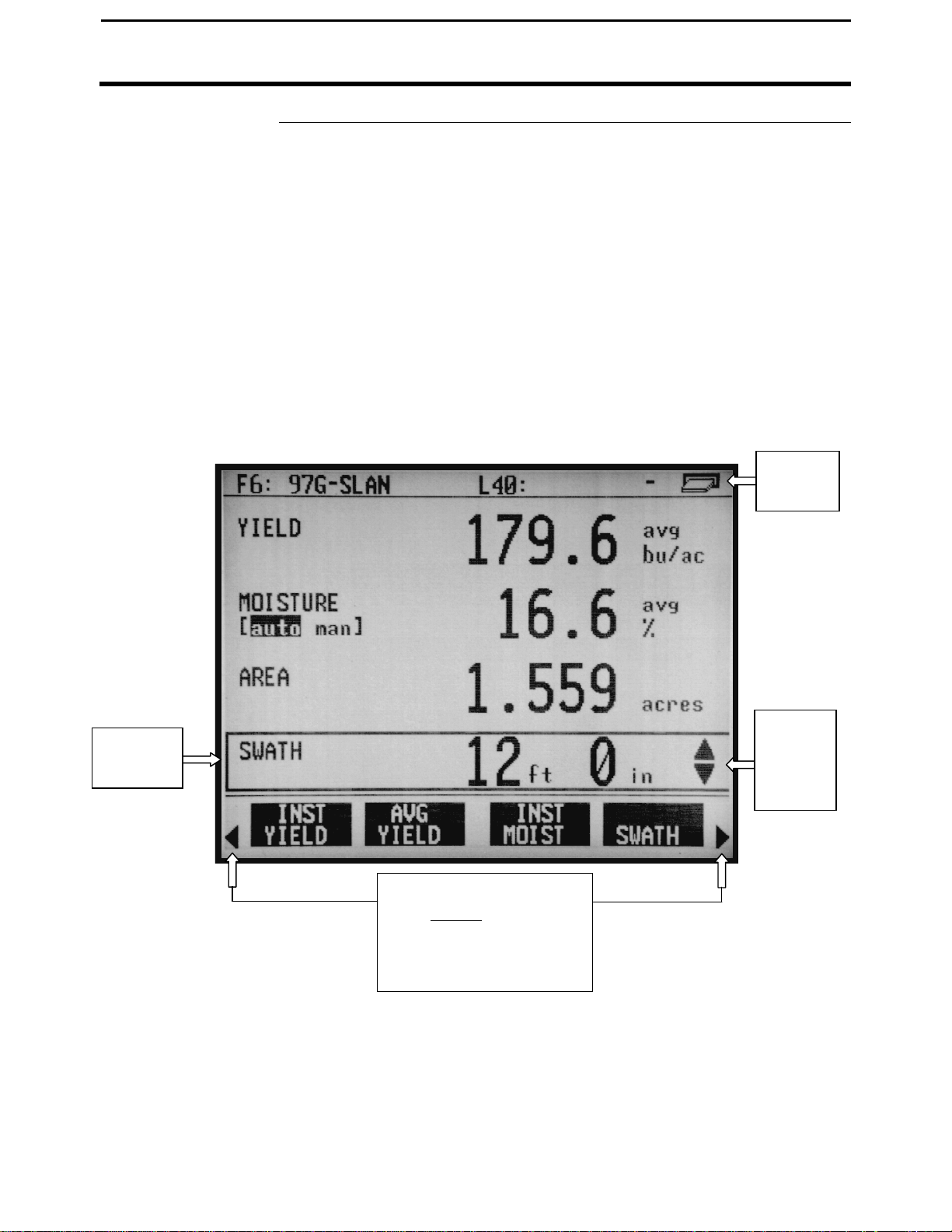

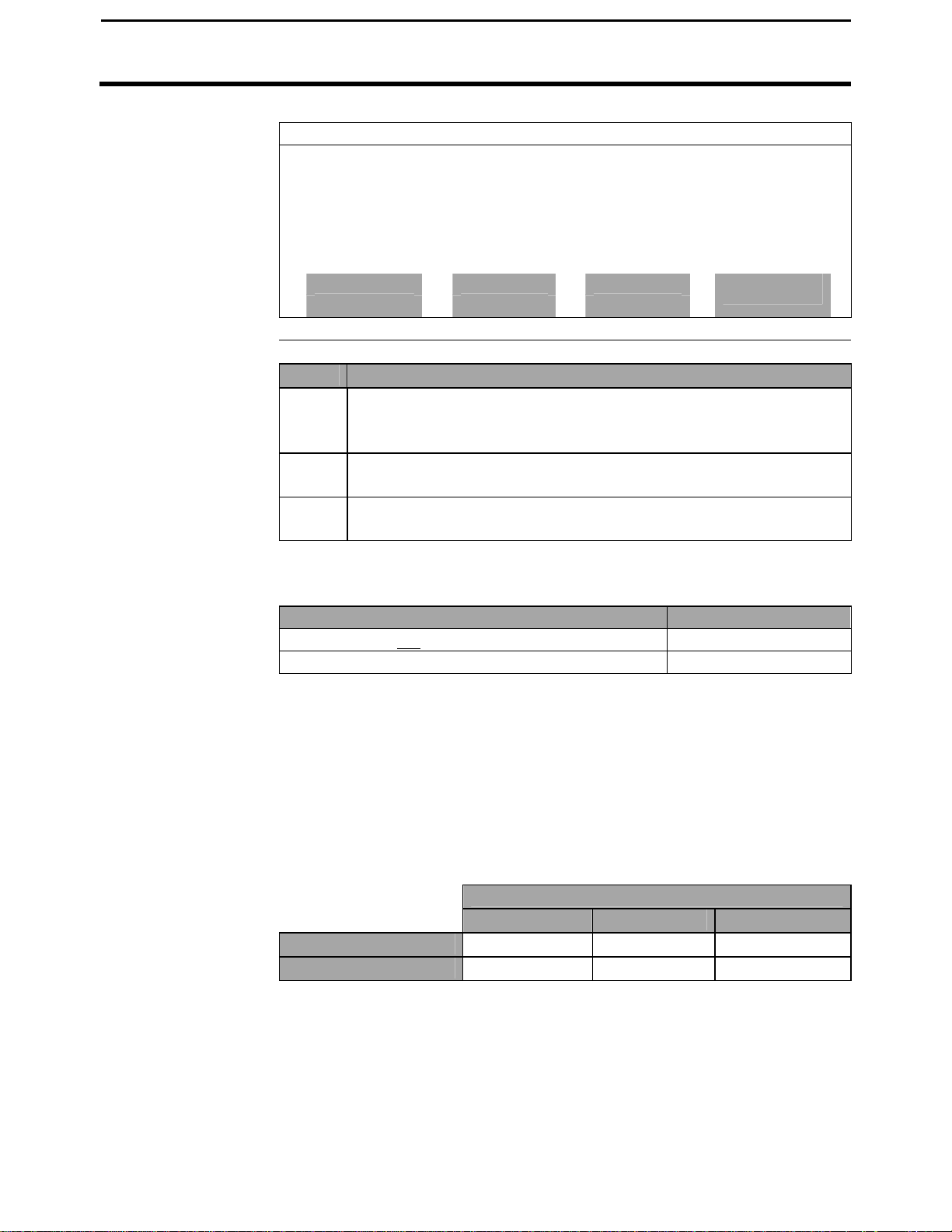

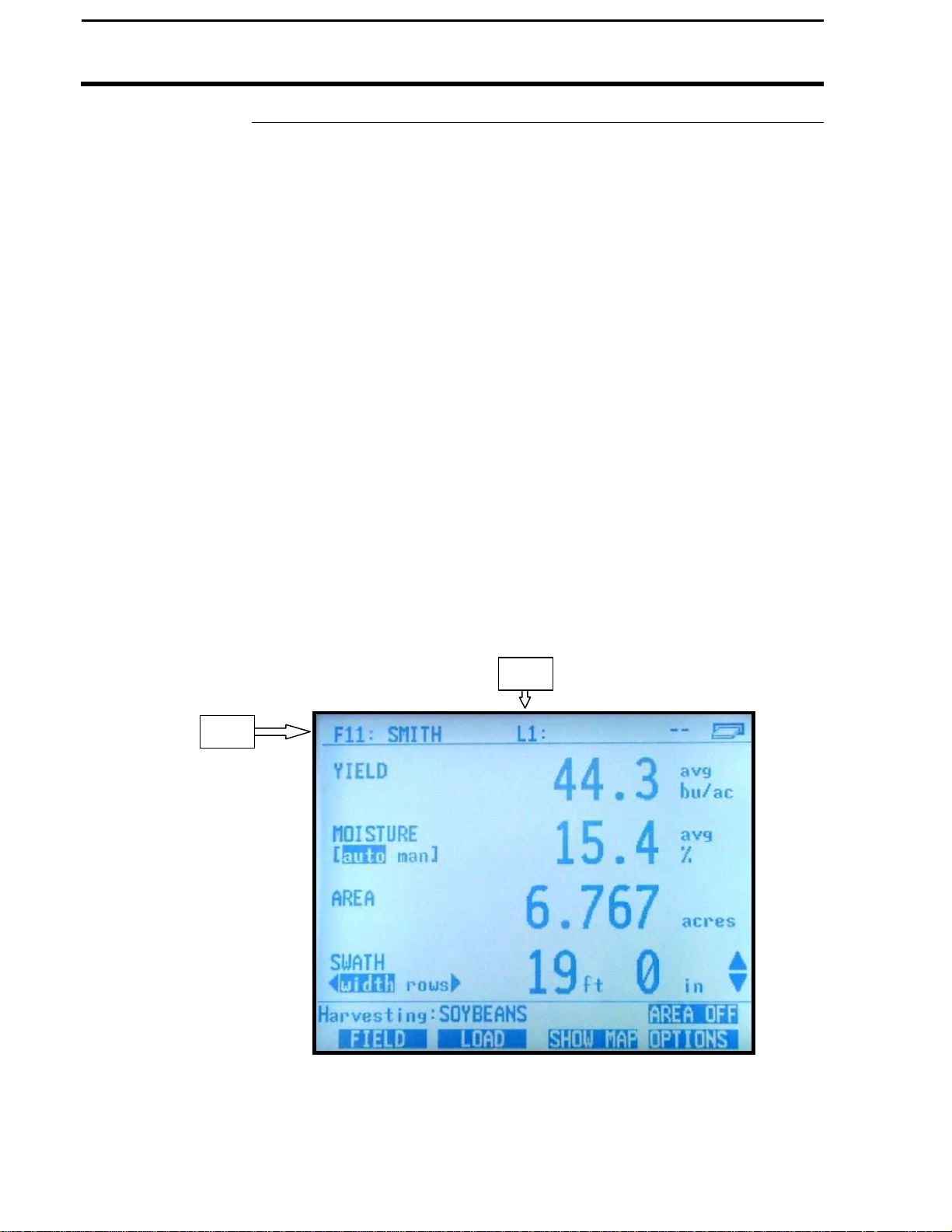

The PF3000 has four display lines for viewing items on the main operating

screen. You can choose which items you see on the display and the position

that the items appear on the display.

To change a display item on a display line you must select the line. The four

display selection keys to the right of the display each select a display line. A

rectangular box surrounds the display line to show that it is selected.

When the display line is selected the four menu items on the bottom change

and show items you can select for display. Press a key below one of the

four display items to put a different display item in place of the selected

display item. There are more than four display items to choose for viewing.

Press the bottom LEFT or RIGHT ARROW keys to scroll to the right or left

and view other display items on the bottom.

General

Card

Symbol

Selection

Box

Up and

Down

Arrow

Symbol

When arrows present,

press bottom arrow keys

to display additional

menu or display items

Figure 2: Main operating screen

When some display items (like swath) are selected, an up and down arrow

April 2002

Page 10

General

1-6

Menu Key

Ag Leader Technology

PF3000

symbol will appear on the right of the display line. This indicates you can

change the setting of the item with the UP or DOWN ARROW keys. After

you have made the change you must press the key to the right of the display

line to deselect the line.

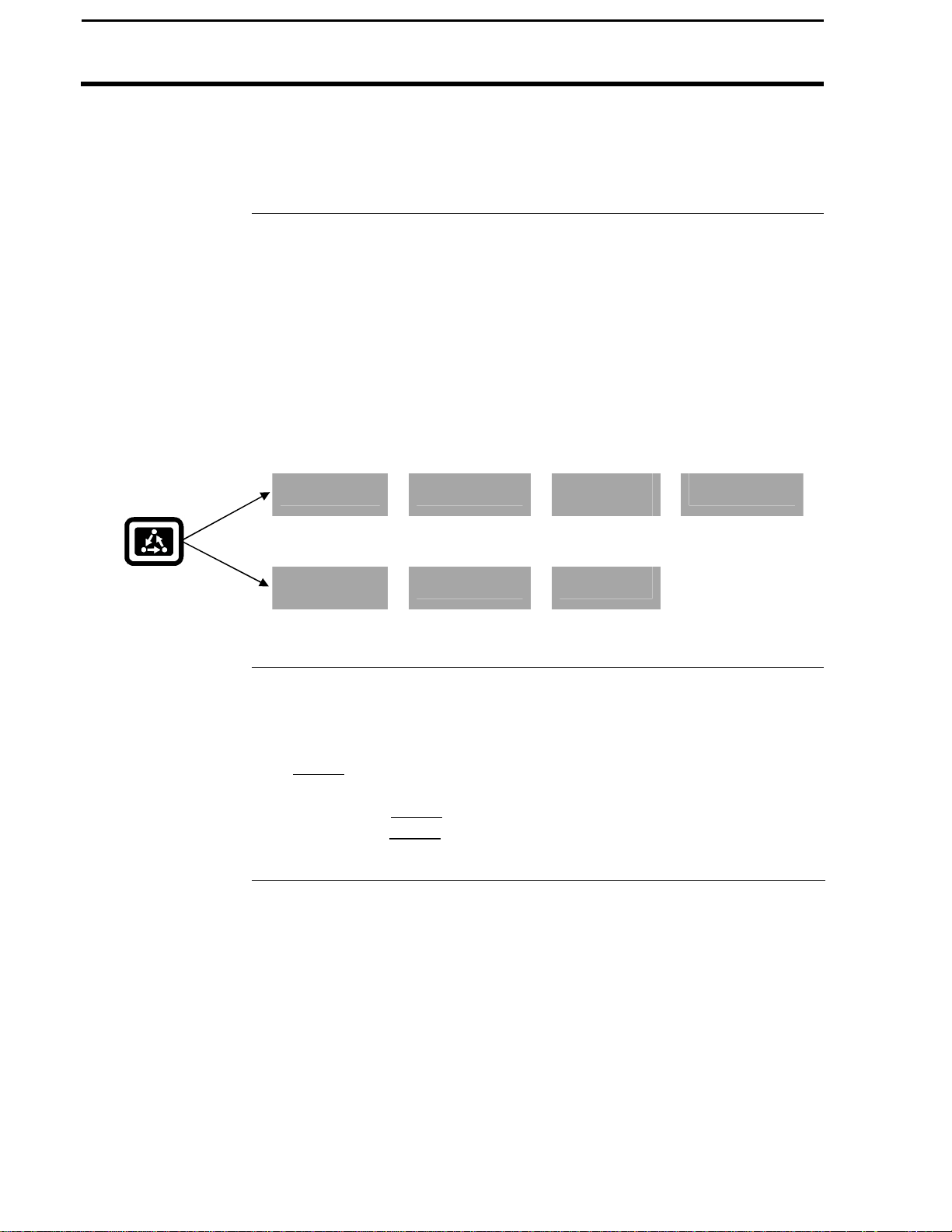

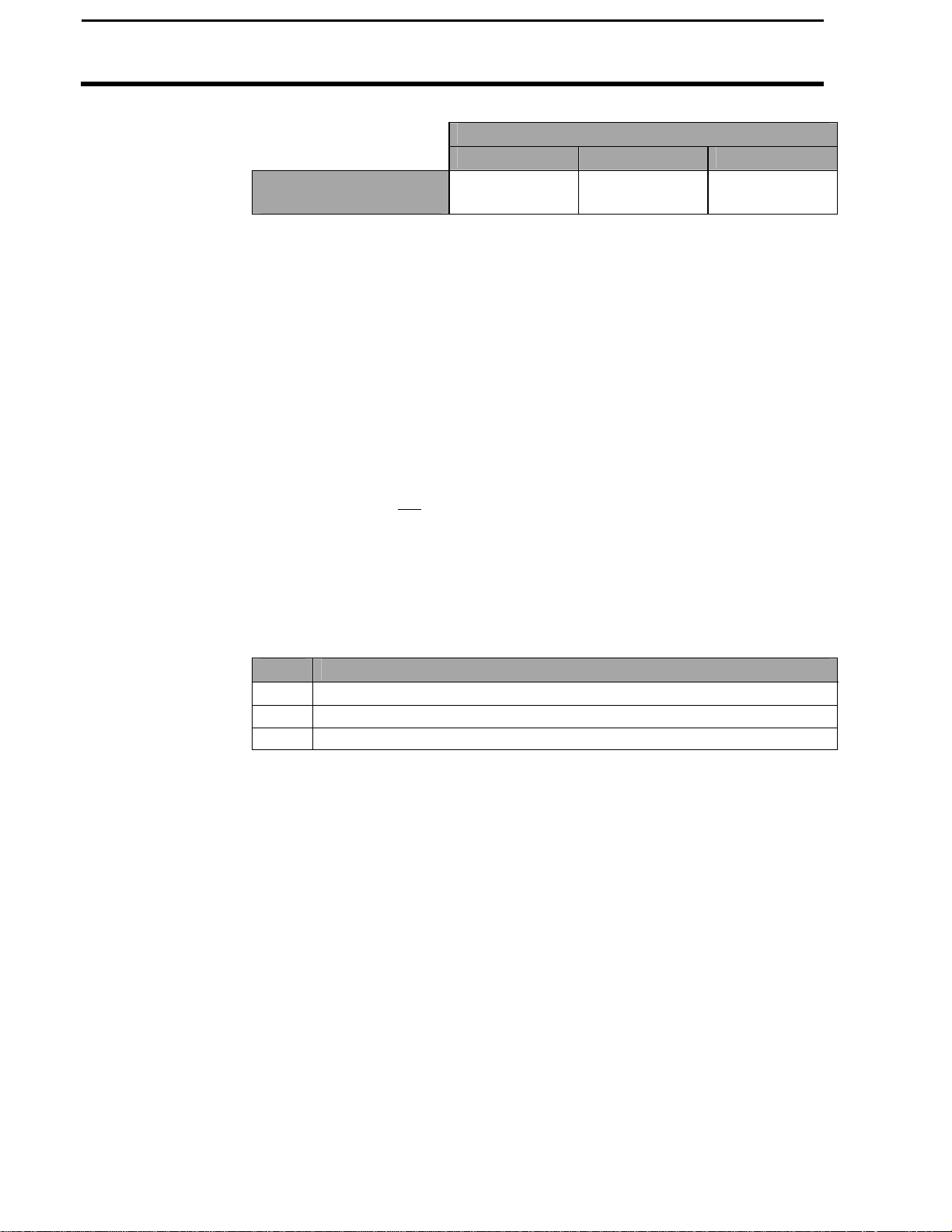

The MENU key switches the menus on the bottom of the display. There are

two main menus that you can view by pressing the MENU key. They are

shown below.

It is recommended to display the FIELD, LOAD, MAP, and OPTIONS

menu during normal operation of the monitor, unless you are marking and

therefore need to display marks on the bottom.

Main Menus:

FIELD

LOAD

SHOW

MAP

OPTIONS

Menu Selection

Keys

CAL

SETUP

DIAG

The name above the four menu selection keys on the bottom of the display

will change depending on what you are doing on the monitor.

The bottom RIGHT and LEFT ARROW keys are used to view additional

menu or display items. If you see a right and left arrow symbol on the

display above the bottom RIGHT and LEFT ARROW keys, this indicates

you can press the bottom RIGHT and LEFT ARROW keys to view more

menu or display items. Refer to Figure 2.

April 2002

Page 11

PF3000

1-7

Ag Leader Technology

Area Count Switch

The area count switch manually turns on and off area counting. When the

switch is in the up position area is counting. When the switch is in the

down position, area is not counting. The monitor will display either “AREA

ON” or “AREA OFF” on the bottom right corner of the display to indicate

the status of area couting.

General

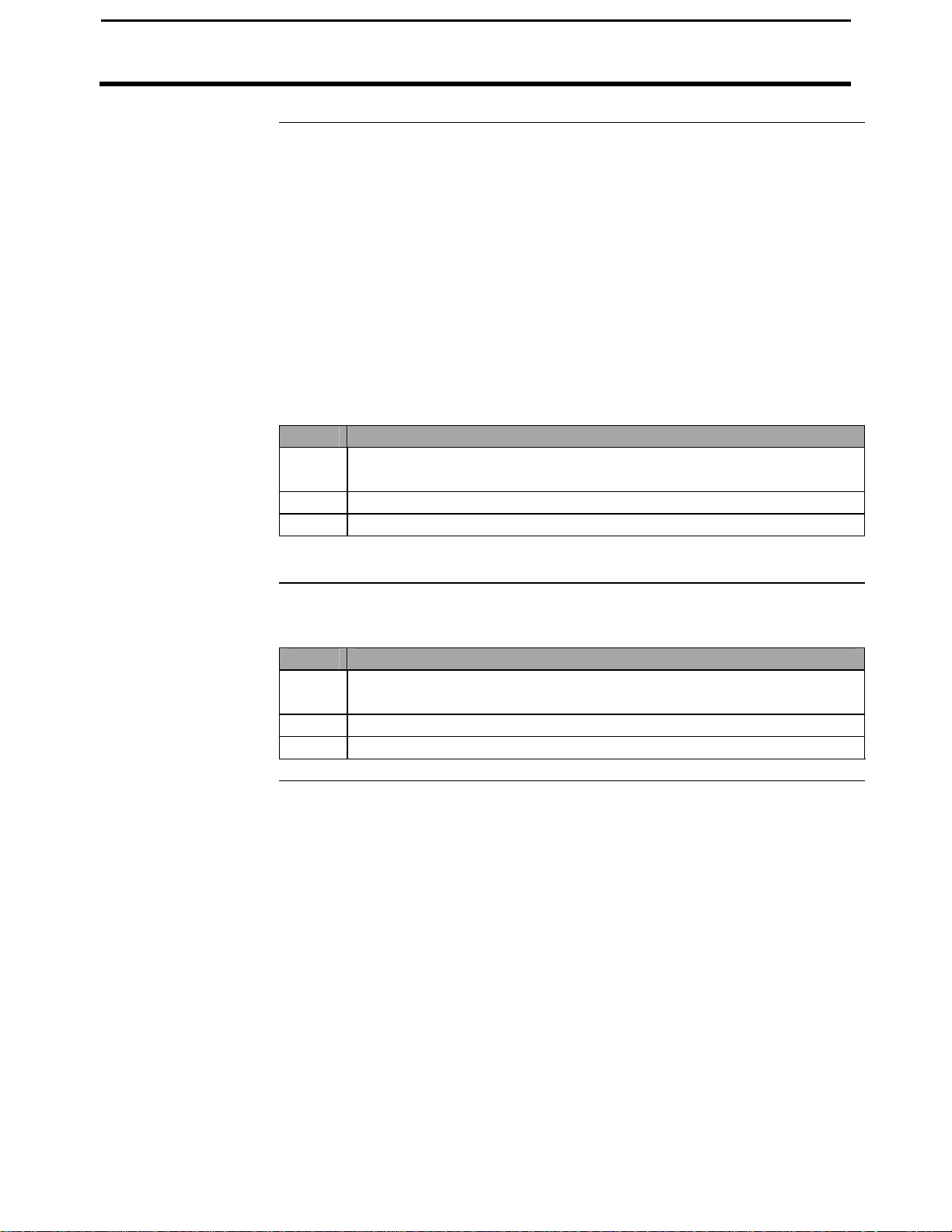

Connectors

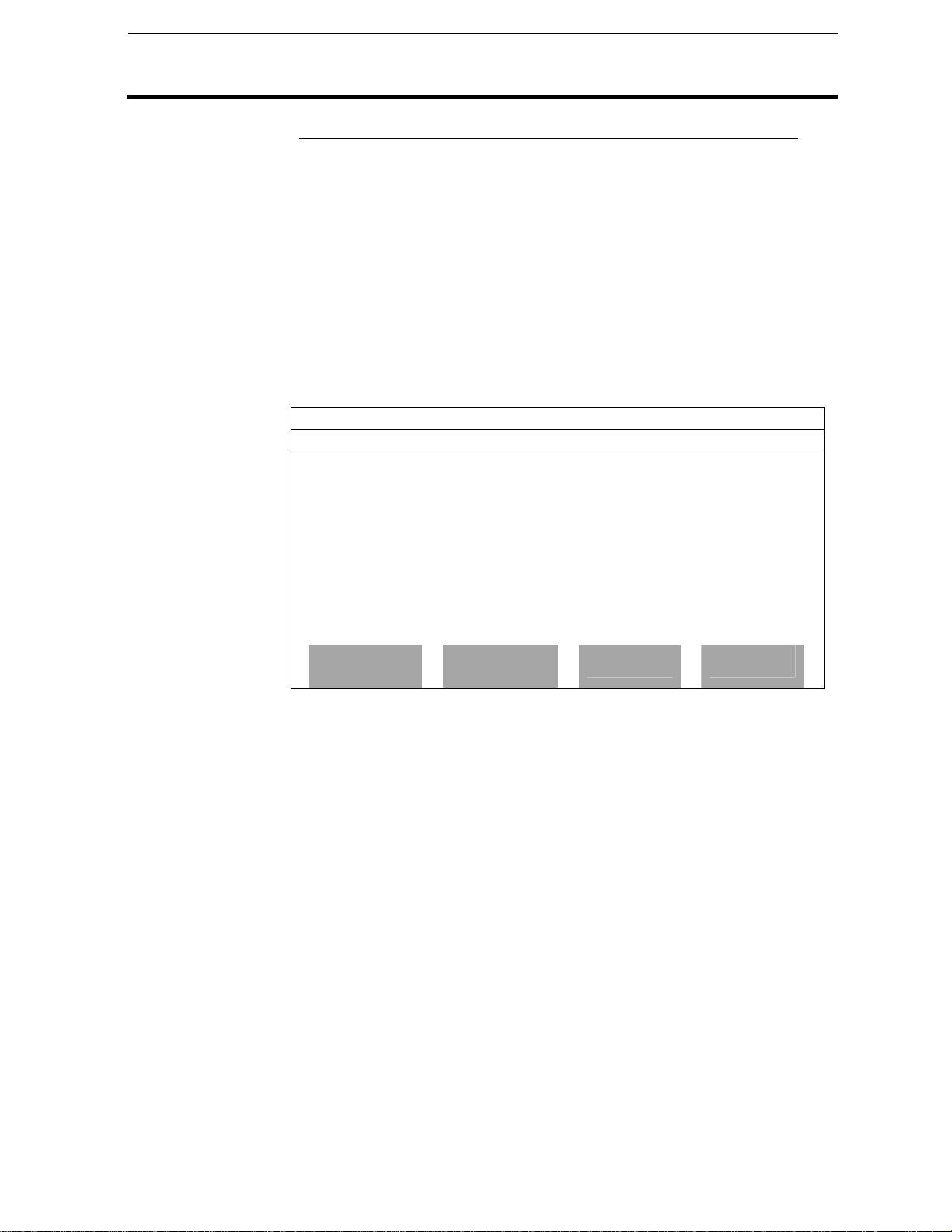

The PF3000 has four connectors on the bottom side of the console. The

large 25-pin connector is for power and sensor connections. The three 9-pin

ports (Port 1, Port 2, Port 3) are for connecting to a GPS receiver, planter or

fertilizer or sprayer controller or any other GPS compatible device.

25-Pin Connector

Port 3 Port 2 Port 1

Figure 3. PF3000 Connectors

April 2002

Page 12

General

1-8

Grain Flow Sensor

PF3000

Ag Leader Technology

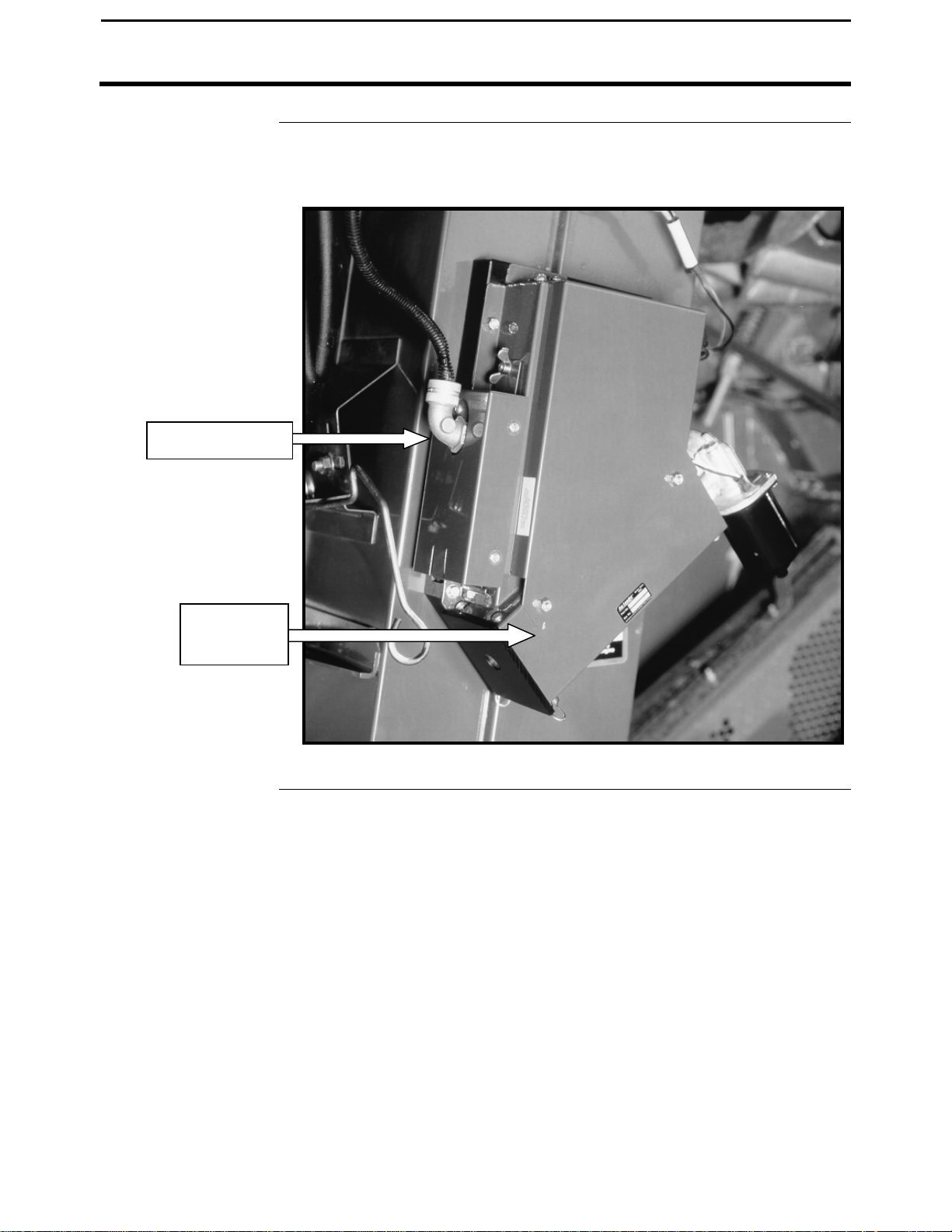

Below is an example of a grain flow sensor. Your grain flow sensor may

look different, depending on which combine model you have. On all

combines, the grain flow sensor installs on top of the clean grain elevator.

The grain flow sensor measures the grain weight in pounds as you harvest.

The clean grain paddles throw the grain, as the paddles rotate around the top

sprocket, toward the grain flow sensor. The flow sensor measures the grain

weight when the grain strikes the flow sensor impact plate.

NOTE: The flow sensor for grass seed harvest function in the same

manner as the grain flow sensor. The grass seed flow sensor differs

only in appearance.

Grain Flow

Sensor

Figure 4: Grain flow sensor

April 2002

Page 13

PF3000

1-9

Ag Leader Technology

Moisture Sensor

Moisture Sensor

Below is an example of the moisture sensor mounted on the side of a clean

grain elevator. The moisture sensor is installed in the elevator mount kit.

General

Elevator

Mount Kit

Figure 5: Moisture sensor

April 2002

Page 14

General

1-10

Header Height

Sensor

Header Sensor

PF3000

Ag Leader Technology

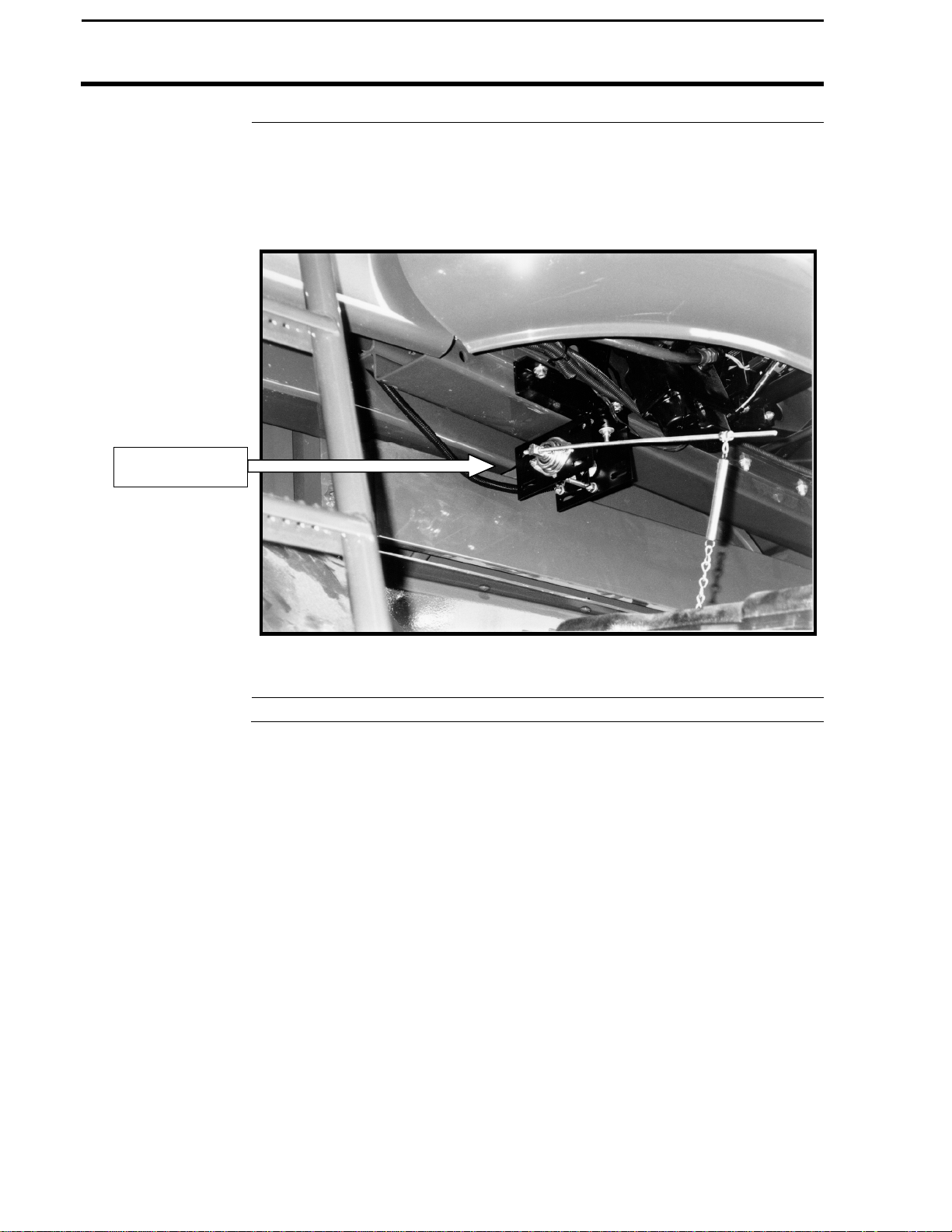

Below is an example of a header height sensor installed underneath a

combine cab. The header height sensor tells the monitor the position of the

combine head so that when the head is raised on the end rows, the monitor

stops counting area.

Figure 6: Header height sensor

* * *

April 2002

Page 15

Page 16

Setup Overview

2-2

Important Notices

Section Contents

Using Power

Supply

PF3000

Ag Leader Technology

The PF3000 must be set up before field operation, but before you begin the

setup procedures, read the following notices:

• The PF3000 is a software upgradeable monitor. Ag Leader Technology

will periodically offer free operating program upgrades to increase the

capabilities of the PF3000. To receive the program upgrade, you

must send in the registration form found at the beginning of the

operator’s manual.

• If you plan to make yield maps on your own computer, you will need to

use a mapping program that can process files created by the PF3000.

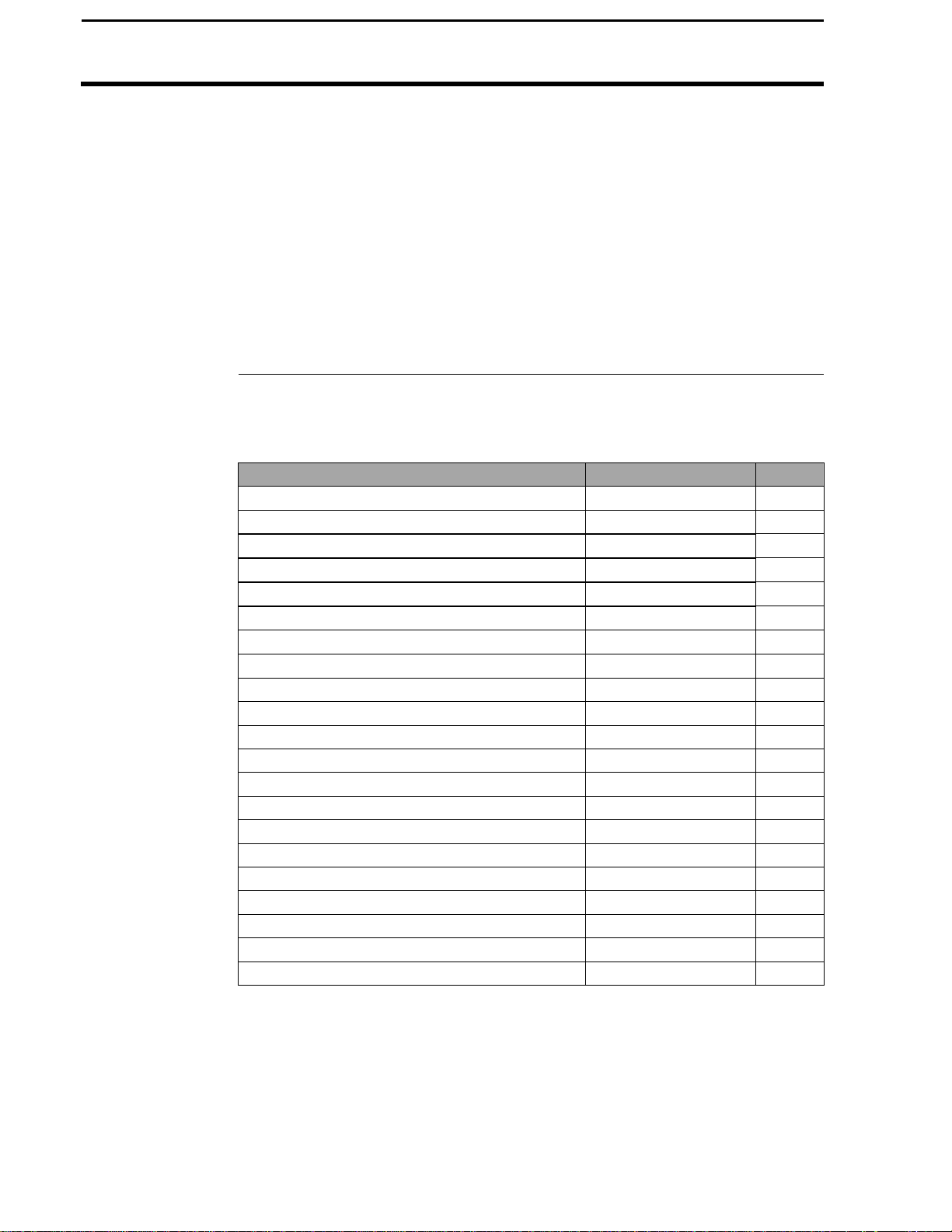

This setup section contains instructions for the following items. The

operating modes that the instructions pertain to are also listed.

Item Operating Mode Page

Console Setup All 2-6

Card Setup All 2-8

Creating, Naming Fields and Loads All 2-12

Marker Setup All 2-17

GPS Setup All 2-19

Vehicle Setup Harvest 2-30

Grain Setup Harvest 2-34

Swath Setup Harvest 2-39

Swath Setup Site Verification 2-41

Vehicle Site Verification 2-42

Controller Setup Application Rate 2-44

Raven Controller ( with Serial Ports) Application Rate 2-44

Mid-Tech Controller Application Rate 2-49

DICKEY-john Land Manager Application Rate 2-55

DICKEY-john Seed Manager Application Rate 2-61

Rawson Accu-Rate/Accu-Plant Application Rate 2-65

New Leader Mark III/Mark IV Application Rate 2-73

Flexicoil Flexcontrol Application Rate 2-79

Hiniker 8605 Application Rate 2-85

Teejet 844 Application Rate 2-90

Flowmeter Controller Application Rate 2-95

The PF3000 console does not need to be in the vehicle to set it up. You can

use the provided power supply (plugs into 120v outlet) to power up the

April 2002

Page 17

PF3000

2-3

Ag Leader Technology

console inside your home or shop.

Setup Overview

April 2002

Page 18

Page 19

PF3000

2-3

Setup Overview

Ag Leader Technology

Order of Keys

(Harvest Mode)

Press the MENU key until you see the following keys on

the display.

SUMMARY

Press the SETUP key to view the

following setup menu items.

All Modes

CAL

SETUP

DIAG

SETUP

OPTIONS

PRESS TO EXIT

SWATH

LOAD

GPS

MARKS

VEHICLE

MAP

GRAIN

CONSOLE

Press the bottom LEFT or RIGHT ARROW keys to

switch between and view the setup menu items

shown above.

CARD

MEMORY

April 2002

Page 20

Setup Overview

2-4

Mode)

PF3000

All Modes

Order of Keys

(Site Verification

Ag Leader Technology

Press MENU key

the display.

CAL

SETUP

Press the SETUP key to view

Until you see the following keys on the

DIAG

the following setup menu items.

SETUP

OPTIONS

PRESS TO EXIT

SWATH

VEHICLE

MAP

MARKS

CONSOLE

CARD

MEMORY

Press the bottom LEFT or RIGHT ARROW keys to

switch between and view the setup menu items

shown above.

LOAD

GPS

April 2002

Page 21

PF3000

2-5

Setup Overview

Ag Leader Technology

Order of Keys

(Application Rate

Mode)

Press the MENU key until you see on the following keys on

the display.

CAL

Press the SETUP key to view the

All Modes

SETUP

DIAG

following setup menu items.

SETUP

OPTIONS

PRESS TO EXIT

APP.RATE

CONFIG

CONSOLE

Press the bottom LEFT or RIGHT ARROW keys to

MARKS

MEMORY

CARD

GPS

switch between and view the setup menu items

shown above.

* * *

LOAD

MAP

April 2002

Page 22

Console Setup

2-6

Changing a Setting

PF3000

All Modes

Ag Leader Technology

Introduction

The console settings are general settings that apply to all operating modes

and uses of the PF3000.

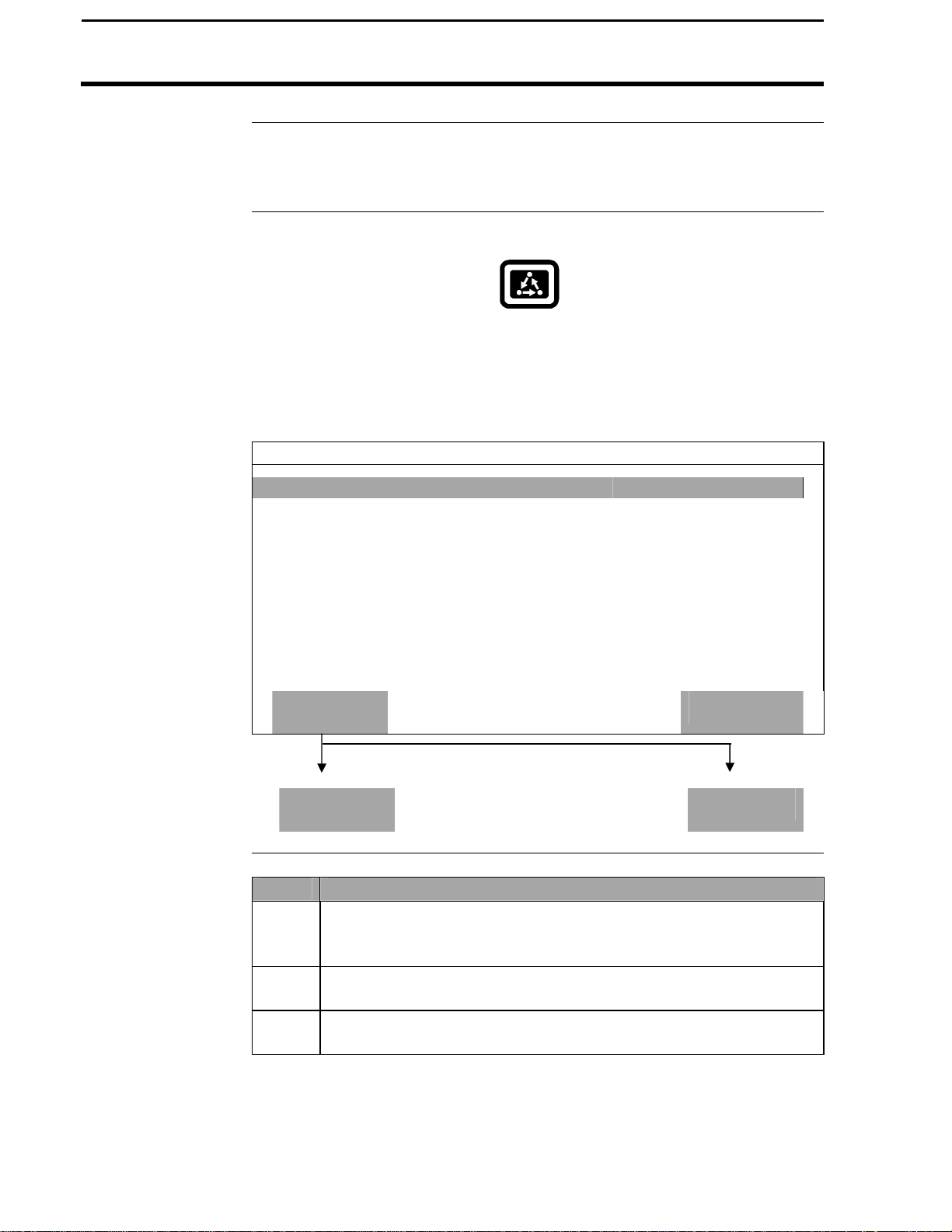

Console Setup

Screen

To view the console setup screen press the:

MENU key

SETUP key

bottom RIGHT ARROW key

CONSOLE key

Example of console setup screen:

CONSOLE SETUP

Operating Mode GRAIN HARVEST

Month/Day/Year 08/15/1998

Time 1:15 PM

Serial Number 980034

Box Cal 770

Voltage Cal 490

GPS Check Sum ON

Field Marker Input INTERNAL

EDIT

ACCEPT

EXIT

CANCEL

Step Action

1 Use the UP or DOWN ARROW keys to select the item you want

to change. The item is selected when a black filled rectangular

box surrounds the entire line.

2 Press the EDIT key and then use the UP or DOWN ARROW keys

to change the number or setting.

3 Once you have changed a setting press the ACCEPT key. Press

the EXIT key once you have made all the settings.

April 2002

Page 23

PF3000

2-7

Voltage calibration

Console Setup

Ag Leader Technology

Adjust Display

Brightness

Operating mode

Operating Program

Firmware

Serial number,

Box calibration,

GPS Check Sum

Field Marker

To adjust the display back lighting, scroll down to "Display brightness" and

press EDIT key. Use the UP or DOWN ARROW keys to adjust the screen

brightness and press the ACCEPT key.

The PF3000 has the following operating modes: Grain Harvest, Grass Seed

Harvest, Cotton Harvest, HarvestMaster™, Application Rate and Site

Verification. Upon changing the operating mode you should make sure all

setup items for that operating mode are correct.

To switch modes, you must install that modes operating firmware. The

exception is Site Verification Mode. Site Verification is available with all

other modes. See "Updating Operating Program" instructions in the

Operation Section of this manual to load different firmware. All firmware

versions are on the CD that that came with the monitor or on the web at

www.agleader.com.

The serial number, box calibration number and voltage calibration number

can be found on the bottom side of the monitor. These numbers should be

set correctly from the factory.

GPS Check Sum setting is used to enable or disable data string error

checking. Normally set to ON.

If you are... Select

Marking field points with the PF3000’s internal

marker selection keys.

Marking field points with an external Ag Leader

Field Marker.

All Modes

INTERNAL

EXTERNAL

* * *

April 2002

Page 24

Card Setup

2-8

PF3000

All Modes

Ag Leader Technology

Introduction

If you are using the GPS receiver, all the GPS data must be logged to a

memory card. If you are not using a GPS receiver, you do not need a card.

The memory card must be formatted with a DOS format. Cards rarely need

to be formatted since they are usually DOS formatted before they are

shipped. If formatting is required, format the card in your PC before using.

IMPORTANT:

You must copy memory to every log file you create and log to before

you read the card into your computer.

Card Setup Screen

To view the card setup screen press the:

MENU key

SETUP key

CARD key

Example of card setup screens:

CARD SETUP

Logging Device MEMORY CARD

Logging Interval 1 second

Log file 98081501.YLD

CARD FILES

EDIT

ACCEPT

COPY TO SHOW ALL

EXIT

CANCEL

FILES ON CARD

FILE NAME SIZE LAST MODIFIED

98081502.YLD 130 KB 08/15/1998

98081501.YLD 128 KB 08/15/1998

98073001.YLD 130 KB 07/30/1998

FILE ERASE

OPTIONS ALL

EXIT

April 2002

Page 25

PF3000

2-9

Changing a Setting

Card Setup

Ag Leader Technology

All Modes

FILES OPTIONS

File Name 98081501.YLD

File Size 132640 bytes

Last Modified 13:42

Date 08/15/1998

COPY TO RESTORE ERASE

FILE FILE FILE

EXIT

Step Action

1 Use the UP or DOWN ARROW keys to select the item you want

to change. The item is selected when a black filled rectangular box

surrounds the entire line.

2 Press the EDIT key and then use the UP or DOWN ARROW keys

to change the number or setting.

3 Once you have changed a setting press the ACCEPT key. Press

the EXIT key once you have made all the settings.

Logging Device

If you are using the GPS receiver with the PF3000 you must use a memory

card to save the instantaneous GPS data.

If you... Select

NOTE: In Application Rate mode, if the PF3000 is controlling application

Do not have a GPS receiver. NONE

Do have a GPS receiver. MEMORY CARD

rate, but you don’t want to log actual rate to card set to NONE.

Logging Interval

This setting determines how often the GPS information is saved to the

memory card. It also affects how large an area each GPS record will

represent on a map and how many logging hours are available before the

memory card becomes full.

There are three possible settings for the logging interval.

1, 2 or 3 Seconds

3 mph

5 mph

.

The recommended setting is either two or three seconds.

Distance Traveled (ft)

1 sec 2 sec 3 sec

4.4 8.8 13.2

7.3 14.6 21.9

April 2002

Page 26

Card Setup

2-10

PF3000

All Modes

Log File

Ag Leader 32MB ATA

Logging Hours Available/Logging Interval

1 sec 2 sec 3 sec

400 800 1200

Ag Leader Technology

Flash Card

NOTE: The logging hours available can vary from the numbers shown above

due to the number of separate files that can be stored on the card.

The PF3000 requires a log file to store data on a memory card. The log file

will always have a “.yld” extension and be named with the date the file was

created. Example: 98081502.yld, second file created on 08/15/98.

IMPORTANT: You must copy memory to every log file you create and

log to before you read the card into your computer. The monitor

automatically copies data to the log file every time it is shut off.

Using the Ag Leader ATA FLASH card a new log file must be created for

each day. You can not add to an old log file after a new file has been created

but you can store multiple log files on one card.

In order to log instantaneous GPS data or copy field and load data to a

memory card, a log file must be selected. Every time you turn on the monitor,

the monitor will prompt you to select or create a log file. Refer to the steps

below to select or create a log file after the monitor has been turned on.

Step Action

1 Select Log File and press the EDIT key.

2 Select a log file or press CREATE FILE key to create a new log file.

3 With the desired file selected, press the ACCEPT key.

NOTE: After you read all the log files on your card into your computer (and

make backup copies of files), it is recommended to erase the log file(s) on the

card.

April 2002

Page 27

PF3000

2-11

Card Setup

Ag Leader Technology

Copying Data to

Log File

To copy memory to log files that are not set as the current log file, press the

SHOW FILES key and select one of the log files. Press the FILE OPTIONS

key and press the COPY TO FILE key. At the card setup screen, press the

COPY TO CARD key to copy memory to the file set as the log file (this is the

same copy to card function that automatically occurs when monitor is shut

off).

Restoring from

File

You can restore field and load data into the monitor’s memory from a log file

on a memory card.

IMPORTANT: It is dangerous to restore memory from a card because

the current data in the monitor will be replaced with the data on card.

Step Action

1 Press the SHOW ALL FILES key. Select the log file and press the

FILE OPTIONS key. Press the RESTORE FILE key.

2 Press the RESTORE key again if you really want to restore the data.

3 Press the EXIT key once you are finished.

Erasing File

You can erase individual log files from a memory card

Step Action

1 Press the SHOW ALL FILES key. Select the log file and press the

FILE OPTIONS key. Press ERASE FILE key.

2 Press the ERASE key again if you really want to erase the file.

3 Press the EXIT key once you are finished.

* * *

All Modes

April 2002

Page 28

Creating, Naming Fields, Loads

2-12

PF3000

All Modes except App Rate

Recommendations

All the information recorded by the PF3000 must be recorded in a field and

load. The field and load that the monitor is set on is located on the top line

of the display on the main operating screen.

Fields

You should at least create all the fields and name them before you begin to

use the PF3000. The monitor will use the same set of fields you create for

each operating mode (harvest mode, application rate mode, site verification)

of the monitor. You can create and name your fields using any operating

mode. You should choose field names that you can use year after year.

Loads

It also recommended to create and name loads within fields before you use

the PF3000. Each operating mode of the PF3000 will have its own set of

loads for each field.

Definition:

Load: A load is used to subdivide a field into smaller sections. The

NOTE: If using Application Rate Mode, refer to the Controller

Setup instructions on how to create and change fields. Refer to this

section for how to name fields and loads.

monitor load is not associated with the combine tank, wagon, or

truck load.

Ag Leader Technology

Load

Field

April 2002

Page 29

PF3000

2-13

Creating and

Creating, Naming Fields, Loads

Ag Leader Technology

All Modes except App Rate

Step Action

Naming Fields

1

Press the MENU key until the following is displayed on

the bottom of the display.

FIELD

LOAD

SHOW

MAP

OPTIONS

F1: DG

2 Press the FIELD key twice to view the screen below.

ACTIVE FIELD

F1:

PRESS TO EDIT NAME

SELECT GRAIN

SOYBEANS

ACCEPT

Step Action

3

Naming Field

With the line displaying the field number selected (rectangular box

surrounds line), press the RIGHT ARROW key to move the cursor to

the right to enter a name. Use the UP or DOWN ARROW keys to scroll

through letters, numbers and other characters. After you have set the

character, move the cursor to the right by pressing the RIGHT ARROW

key and set a new character. You can enter up to an 8-character name.

Press the ACCEPT key once you have entered a name.

4

Setting Grain (harvest mode) or Site Type (Site Verification Mode)

To set the grain or site type for the field you must select the line

displaying the grain or site type. Press the key to the right of the line

displaying the grain or sit type to select the line. Use the UP or DOWN

ARROW keys to set the setting. Press the ACCEPT key twice, once to

accept the grain or site type, once to accept the field.

CANCEL

April 2002

Page 30

Creating, Naming Fields, Loads

2-14

PF3000

All Modes except App Rate

Step Action

5

NOTE: You can have more than one grain or site type in a field.

To enter more than one grain or site type, press the FIELD key twice so that the

field is displayed in large text. Select the line displaying grain or site type and

change the setting. Press the ACCEPT key twice, once to accept the new grain

or site type and once to accept the field. The monitor will create a separate set

of loads (which are renumbered beginning with load one) for each grain or site

type in a field.

L3 L3

Grass Seed types

ANNUAL RYE

PERENNIAL RYE

FESCUE

ORCHARD GRASS

CRIMSON CLOVER

MEADOW FOAM

WHITE CLOVER

BENT GRASS

Creating Fields

Press the UP ARROW key to scroll through all the fields. Once you

scroll past the last field, “Create New Field” will be displayed. Name

the field and set the grain or site type, then with “Create New Field”

displayed above the field number press the ACCEPT key to create the

new field.

6 Repeat Step 5 and create and name all your fields.

Example of load organization when two grain types are in one field in

harvest mode:

F10 L1 F10 L1

Corn Soybeans

L2

Harvest grain types

SOYBEANS

CORN

WHEAT

OATS

RYE

BARLEY

SORGHUM

POPCORN

EDIBLE BEANS

CORN 2

CANOLA

RICE

SUNFLOWERS

CORN 3

CORN 4

OPT GRAIN 1

Ag Leader Technology

L2

Site Verification types

PLANTING 1

PLANTING 2

PLANTING 3

SPRAYING 1

SPRAYING 2

SPRAYING 3

FERTILIZER 1

FERTILIZER 2

FERTILIZER 3

OPT SITE 1

OPT SITE 2

OPT SITE 3

OPT SITE 4

OPT SITE 5

OPT SITE 6

OPT SITE 7

April 2002

Page 31

PF3000

2-15

Creating and

Creating, Naming Fields, Loads

Ag Leader Technology

All Modes except App Rate

Step Action

Naming Loads

1

Press the MENU key until the following is displayed on

the bottom of the display.

F1: L1:

2 Press the LOAD key twice to view the screen below.

DG

FIELD

LOAD

SHOW

MAP

OPTIONS

ACTIVE LOAD

L1:

PRESS TO EDIT NAME

SELECT GRAIN

SOYBEANS

ACCEPT

Step Action

3

Naming Load

With the line displaying the load number selected (rectangular box

surrounds line), press the RIGHT ARROW key to move the cursor to

the right to enter a name. Use the UP or DOWN ARROW keys to

scroll through letters, numbers and other characters. After you have

set the character, move the cursor to the right by pressing the RIGHT

ARROW key and set a new character. You can enter up to an 8character name. Press the ACCEPT key once you have entered a

name.

CANCEL

April 2002

Page 32

Creating, Naming Fields, Loads

2-16

PF3000

All Modes except App Rate

Changing Fields

and Loads

Step Action

4

Creating Loads

Press the UP ARROW key to scroll through all the loads in the field

for the grain type. Once you scroll past the last load, “Create New

Load” will be displayed above the load number and name. Name the

load and set the grain type, then with “Create New Load” displayed

above the load number press the ACCEPT key to create the new

load.

5 Repeat step 4 and create and name all your loads.

Note: Refer to Load Setup to change grain, product or site type for an

existing load.

Changing Field

Press the FIELD key to display current field. Press the UP or DOWN

ARROW keys to scroll through the fields. Press the ACCEPT key to

change to the different field.

Changing Load

Press the LOAD key to display the current load. Press the UP or DOWN

ARROW keys to scroll through the loads. Press the ACCEPT key to change

to the different load.

Ag Leader Technology

* * *

April 2002

Page 33

PF3000

2-17

Marker Setup

Marker Setup

Ag Leader Technology

Introduction

If you are using an external Field Marker ignore the instructions below. The

All Modes

marker setup screen is only used for making settings for the Internal marker

selection keys.

IMPORTANT:

If you are using the external field marker, make sure that under the

CONSOLE key you set Field Marker to EXTERNAL.

To view the marker setup screen press the:

Screen

MENU key

SETUP key

OPTIONS key

MARKS key

Example of marker setup screen:

MARKER SETUP

MARK NAME TYPE

MARK 1 WEEDS CONTINUOUS

MARK 2 ROCKS SPOT

MARK 3 TILE CONTINUOUS

MARK 4 WET SPOT SPOT

EDIT EDIT

NAME TYPE

ACCEPT

EXIT

CANCEL

April 2002

Page 34

Marker Setup

2-18

Changing a Setting

PF3000

All Modes

Step Action

1 Use the UP or DOWN ARROW keys to select the mark. The mark

is selected when a black filled rectangular box surrounds the entire

line.

2 Press the EDIT NAME key to rename an existing mark. Use the

UP or DOWN ARROW keys to change a character in the name.

Use the LEFT or RIGHT ARROW keys to move the cursor over

another character within the name. Press the ACCEPT key after

you have changed the name.

3 Press the EDIT TYPE key to set the mark for continuous or spot

marking. Use the UP or DOWN ARROW keys to change the

setting. Press the ACCEPT key after you have changed the setting.

4 Press the EXIT key once you have made all the settings.

Continuous marking

Set the marking type to continuous if the item in the field you are marking

requires you to make several marks in a row (for example: marking large

weed patches or tile lines).

When you press a mark key that is set for continuous marking, the mark will

remain on until you press the mark key again to turn off the mark.

Spot marking

Set the marking type to spot if the item in the field you are marking requires

just one mark (for example: marking a rock or tile hole).

When you press a mark key that is set for spot marking, the mark will

remain on only for a few seconds and then will automatically go off.

* * *

Ag Leader Technology

April 2002

Page 35

PF3000

2-19

GPS Setup

Ag Leader Technology

Introduction

The GPS 4100 or integrated GPS of the PF3000 require no initial setup to

begin fieldwork. The PF3000 will display a “D” or “G” on the top right

hand corner of the display to indicate a GPS signal. A “D” indicates that

you have a differential signal. A “G” indicates that you have a GPS

signal and you GPS receiver are tracking four or more satellites. A lower

case “g” indicates that you have a GPS signal but your GPS receiver is

tracking only three satellites. Your GPS receiver must track four or more

satellites to get an elevation reading. You may wish to use the GPS to

show your ground speed, which requires changing the ground speed

sensor settings. Refer to Primary and Secondary Speed Sensor under

Vehicle Setup in the PF3000 Operator’s manual for instructions.

The following provides information to change factory settings on the

integrated GPS:

All Modes

Beacon Selection

The settings for beacon selection are Auto range, Auto Power and

Manual.

• Auto Range: This is the default setting. In this setting the receiver

keeps a record of the closest three beacons within the receivers range.

It then selects a beacon based on the ranking of the beacon in memory.

• Auto Power: The receiver keeps a record of the three strongest

beacons in its range. It then selects a beacon based on the ranking of

the available beacons.

• Manual: Allows you to input frequencies for two beacons.

To change Beacon Selection complete the following steps:

Step Action

1 Press Menu key on PF3000 until SETUP is displayed and

press SETUP.

2 Press bottom left or right arrow key until GPS is

displayed and press GPS key.

April 2002

Page 36

GPS Setup

2-20

PF3000

All Modes

Ag Leader Technology

GPS SETUP

NMEA MESSAGE

GPS INPUT/OUTPUT

BEACON DIFFERNTIAL

SATELLITE DIFFERNTIAL

LIGHTBAR

GUIDANCE

EDIT

EXIT

Step Action

3 From the GPS SETUP screen scroll down to BEACON

DIFFERNTIAL and press EDIT key. Use up or down

arrow keys to set mode.

4 After setting Auto Power mode, push ACCEPT key and

then EXIT.

BEACON SETUP

Mode: Auto Power

Channel 0 Frequency AUTO

Channel 1 Frequency AUTO

ACCEPT

April 2002

EXIT

Page 37

PF3000

2-21

GPS Setup

Ag Leader Technology

BEACON SETUP

Mode: Manual

Channel 0 Frequency 300.0

Channel 1 Frequency 300.0

ACCEPT

Step Action

5 If you are setting to Manual push ACCEPT key then use

down arrow key to scroll to Channel 0 Frequency and

press EDIT key. Use the up or down arrow key to set

desired frequency and press ACCEPT key. Scroll down

to Channel 1 Frequency and press EDIT key. Use up or

down arrow keys to set desired frequency and press

ACCEPT key.

6 Press the EXIT key two times to return to operating

screen.

All Modes

EXIT

April 2002

Page 38

GPS Setup

2-22

PF3000

All Modes

Ag Leader Technology

Satellite Selection

If you will be using the satellite differential option then do the following

depending on which service provider you select.

Step Action

1 Press Menu key on PF3000 until SETUP is displayed,

press SETUP key.

2 Press bottom left or right arrow key until GPS is

displayed and press GPS key.

3 At the GPS SETUP screen scroll down to Satellite

Differential with down arrow key and press EDIT.

GPS SETUP

NMEA MESSAGE

GPS INPUT/OUTPUT

BEACON DIFFERNTIAL

SATELLITE DIFFERENTIAL

LIGHTBAR

GUIDANCE

EDIT

EXIT

April 2002

Page 39

PF3000

2-23

GPS Setup

Ag Leader Technology

SATELLITE DIFFERENTIAL SETUP

Differential Source Satellite

Differential Provider Omnistar

Satellite Frequency 0000.0000

Satellite Baud Rate 0000

Provider User Code 0

OMNISTAR Code 00000000000000000000000000

WAAS Selection

If you are going to use the WAAS option complete the following:

ACCEPT

All Modes

CANCEL

Step Action

1 Press Menu key on PF3000 until SETUP is displayed, press

SETUP key.

2 Press bottom left or right arrow key until GPS is displayed and

press GPS key. You should now see the screen shown below.

GPS SETUP

NMEA MESSAGE

GPS/PORT CONFIGURATION

BEACON DIFFERENTIAL

SATELLITE DIFFERENTIAL

LIGHTBAR

GUIDANCE

EDIT

EXIT

April 2002

Page 40

GPS Setup

2-24

PF3000

All Modes

Ag Leader Technology

Step Action

3 At the GPS SETUP screen scroll down to Satellite Differential

Mode with down arrow key and press EDIT. You should now

see the screen shown below.

SATELLITE DIFFERENTIAL SETUP

Differential Source WAAS

Differential Provider

Satellite Frequency 0000.0000

Satellite Baud Rate 0000

Provider User Code 0

OMNISTAR Code 000000000000000000000000

Subscription Expiration 00/00/0000

EDIT

EXIT

Step Action

4 At the SATELLITE DIFFERENTIAL SETUP screen

Differential Source will be highlighted, press EDIT key and

use UP or DOWN ARROW key until WAAS is displayed and

press ACCEPT key.

5 Now press EXIT key to return to GPS SETUP screen, press

EXIT key again to return to the main operating screen.

April 2002

Page 41

PF3000

2-25

GPS Setup

Ag Leader Technology

If you will

be using…

Omnistar At SATELLITE DIFFERENTIAL SETUP screen

SATELLITE DIFFERENTIAL SETUP

Oministar Satellite Beacon Frequencies:

Eastern USA 1556.825

Central USA 1554.497

Western USA (1) 1551.429

Western USA (2) 1551.489

Australia 1558.510

Europe 1531.230

South America (1) 1541.705

South America (2) 1541.715

Custom (1) 0000.0

Custom (2) 0000.0

ACCEPT

All Modes

Then…

Differential Source will be highlighted, press EDIT key and

use up or down arrow key until Satellite is displayed and

press ACCEPT key. Scroll down to Differential Provider

and press EDIT key. Use the UP or DOWN ARROW key

until Omnistar is displayed and press ACCEPT key. Scroll

down to Satellite Frequency and press EDIT key. Use the

UP or DOWN ARROW key to select your region and press

ACCEPT key. If you will be using a custom frequency

with this provider, scroll down to Custom (1) and push

EDIT NAME key. Use the UP or DOWN and LEFT or

RIGHT ARROW keys to name this frequency. Push EDIT

VALUE key and use the UP or DOWN and LEFT or

RIGHT ARROW keys to enter the frequency. Push

ACCEPT key. Your customized frequency should appear

as the Satellite Frequency.

CANCEL

April 2002

Page 42

GPS Setup

2-26

digit code.

PF3000

All Modes

Ag Leader Technology

SATELLITE DIFFERENTIAL SETUP

Oministar Satellite Beacon Frequencies:

Eastern USA 1556.825

Central USA 1554.497

Western USA (1) 1551.429

Western USA (2) 1551.489

Australia 1558.510

Europe 1531.230

South America (1) 1541.705

South America (1) 1541.705

Custom (1) 0000.0

Custom (2) 0000.0

ACCEPT

If you will

EDIT

NAME

EDIT

VALUE

Then…

CANCEL

be using…

Omnistar Call the Omnistar subscription number (713-785-5850 in

the USA) and give them the number to the right of the GPS

serial number. Omnistar will then give you a 24Key the code into the right of Omnistar Code using UP and

DOWN ARROW keys. Once the code is entered, press

ACCEPT key to send the code to the unit. Now press

EXIT key to return to GPS SETUP screen, press EXIT key

to return to operating screen. After 30 minutes, the

receiver should start receiving corrections and display a

“D” in the upper right hand corner of the PF3000.

April 2002

Page 43

PF3000

2-27

GPS Setup

Ag Leader Technology

SATELLITE DIFFERENTIAL SETUP

Differential Source Satellite

Differential Provider RACAL

Satellite Frequency 1553.345000

Satellite Baud Rate 1200

Provider User Code 8111

OMNISTAR Code 00000000000000000000000000

ACCEPT

All Modes

CANCEL

April 2002

Page 44

GPS Setup

2-28

PF3000

All Modes

If you will

Then…

Ag Leader Technology

be using …

RACAL At SATELLITE DIFFERENTIAL SETUP screen

Differential Source will be highlighted press EDIT key

and use UP or DOWN ARROW key until Satellite is

displayed and press ACCEPT key. Scroll down to

Differential Provider and press EDIT key. Use the UP

or DOWN ARROW key until RACAL is displayed and

press ACCEPT key. Scroll down to Satellite Frequency

and press EDIT key. Use the UP or DOWN ARROW

key to select your region and press ACCEPT key. If you

will be using a custom frequency with this provider,

scroll down to Custom (1) and push EDIT NAME key.

Use the UP or DOWN and LEFT or RIGHT ARROW

keys to name this frequency. Push EDIT VALUE key

and use the UP or DOWN and LEFT or RIGHT

ARROW keys to enter the frequency. Push ACCEPT

key. Your customized frequency should appear as the

Satellite Frequency.

SATELLITE DIFFERENTIAL SETUP

RACAL Satellite Beacon Frequencies:

North American East 1553.345

North American Mntn 1554.350

North American West 1556.225

Australia 1558.525

Europe 1531.210

South Africa 1552.640

Custom (1) 0000.0

Custom (2) 0000.0

Custom (3) 0000.0

Custom (4) 0000.0

ACCEPT

CANCEL

April 2002

Page 45

PF3000

2-29

GPS Setup

Ag Leader Technology

SATELLITE DIFFERENTIAL SETUP

RACAL Satellite Beacon Frequencies:

North American East 1553.345

North American Mntn 1554.350

North American West 1556.225

Australia 1558.525

Europe 1531.210

South Africa 1552.640

Custom (1) 0000.0

Custom (2) 0000.0

Custom (3) 0000.0

Custom (4) 0000.0

If you will

ACCEPT

Then…

EDIT

NAME

EDIT

VALUE

be using …

RACAL Call the RACAL subscription number (713-784-4482 in the

USA) and give them the number to the right of the GPS

serial number. RACAL will activate a code for the serial

number that was given. After the serial number is called in,

press the EXIT key to return to operating screen. Within 15

to 30 minutes the receiver should start receiving corrections

from RACAL. A “D” should appear in the upper right hand

corner of the PF3000.

SATELLITE DIFFERENTIAL SETUP

Differential Source Satellite

Differential Provider RACAL

Satellite Frequency 1553.345000

Satellite Baud Rate 1200

Provider User Code 8111

OMNISTAR Code 00000000000000000000000000

ACCEPT

***

CANCEL

CANCEL

All Modes

April 2002

Page 46

Vehicle Setup

2-30

PF3000

Harvest Mode

Ag Leader Technology

Introduction

For each operating mode, there are different items to setup in the vehicle

setting screen. Below are the setup items for the harvest mode. Refer to

your Initial Calibration Sheet to make the correct settings.

Vehicle Setup

Screen

To view the vehicle setup screen press the:

MENU key

SETUP key

bottom RIGHT ARROW key

VEHICLE key

Example of vehicle setup screen:

VEHICLE SETUP

Elevator pulses / revolution 1 Pulses

Sprocket teeth 8 Teeth

Combine scale factor 1.0

Area count stop beeps 20 Beeps

Expand grain below dry % NO

Sensor calibration 1400

T1 10

T2 5

T3 8

Primary speed sensor WHEELS

Secondary speed sensor ---------

Speed sensor pulses / 100 ft 2000 Pulses

EDIT

ACCEPT

EXIT

CANCEL

April 2002

Page 47

PF3000

2-31

Changing a Setting

pulses/revolution

Vehicle Setup

Ag Leader Technology

Step Action

Elevator

Sprocket teeth

Combine scale

factor

1 Use the UP or DOWN ARROW keys to select the item you want

to change. The item is selected when a black filled rectangular

box surrounds the entire line.

2 Press the EDIT key and then use the UP or DOWN ARROW keys

to change the number or setting.

3 Once you have changed a setting press the ACCEPT key. Press

the EXIT key once you have made all the settings.

Refer to the Initial Calibration Sheet for the correct setting for your

combine.

Refer to the Initial Calibration Sheet for the correct setting for your

combine.

Refer to the Initial Calibration Sheet for the correct setting for your

combine.

IMPORTANT:

• Never change the scale factor during harvest. Doing so will cause

the monitor to lose calibration accuracy and you will have to set the

monitor on different grain types and recalibrate every grain type.

• All of your calibration loads and data loads must be harvested using

the same scale factor setting otherwise you will have severe

calibration problems that possibly can not be corrected.

Harvest Mode

April 2002

Page 48

Vehicle Setup

2-32

Expand grain below

PF3000

Harvest Mode

Area count stop

beeps

Dry %

Sensor calibration

T1, T2, T3

Ag Leader Technology

This setting is for the number of times the monitor beeps when the head is

raised at the end of a pass and the monitor stops counting area.

NOTE: The recommended setting is 20. Set this number high enough so

that after the head is raised at the end of a pass, the beeps continue until the

combine is completely turned around and the head is lowered to start the

new pass. This gives the operator an audible signal that the head is

lowered enough to begin counting area again.

If you select . . . Then . . .

No, You prevent the monitor from adding bushels to grain

that is dryer than the dry percent moisture by which dry

bushels are calculated. This calculates all yields in terms

of actual bushels available for you to sell.

(Recommended setting).

Yes, The monitor shows a yield comparison of all loads at the

dry percent moisture. This increases the bushels of the

grain harvested below the dry percent moisture to

account for moisture lost because of excessive dryness

of the grain.

NOTE: This setting applies to all loads and grains in the monitor. It can be

changed from NO to YES and vice-versa at any time.

Refer to the Initial Calibration Sheet for the correct setting for your

combine.

NOTE: If you replace the flow sensor, you must change this setting to the

value of the new sensor calibration number of the new flow sensor.

Refer to the Initial Calibration Sheet for the correct setting for your

combine.

April 2002

Page 49

PF3000

2-33

Vehicle Setup

Ag Leader Technology

Primary and

Secondary speed

sensor

Speed sensor pulses

/ 100 ft.

The monitor has four different primary speed settings. They are listed

below.

Ground Speed Sensor Primary Speed Sensor

Speed sensor on transmission WHEEL

Speed sensor on tracks TRACK

Radar gun RADAR

GPS receiver GPS

If you choose GPS as your primary speed sensor, you need to set the

secondary speed sensor to WHEEL, TRACK, or RADAR. If the GPS signal

is lost, the monitor will use the secondary speed sensor. If you do not

choose GPS as your primary speed sensor you can not set the secondary

speed sensor.

It is not recommended that you change this setting. This number is the

distance calibration number that is set when you perform a distance

calibration for WHEEL, TRACK or RADAR. Refer to the calibrating

distance instructions in the Calibration section. You must calibrate distance

for a WHEEL, TRACK or RADAR setting for accurate ground speed.

NOTE: If you want to use a radar gun, contact an Ag Leader Technology

dealer and purchase a special adapter cable for your radar gun.

* * *

Harvest Mode

April 2002

Page 50

Grain Setup

2-34

Screen

PF3000

Harvest Mode

Grain Setup

Ag Leader Technology

NOTE: Grass Seed monitors are setup using the same

procedures as Grain.

To view the grain setup screen press the:

MENU key

SETUP key

GRAIN key

Example of grain setup screen:

GRAIN SETUP

GRAIN NAME TYPE

GRAIN 1 SOYBEANS Low Flow

GRAIN 2 CORN Hi Flow

GRAIN 3 WHEAT Low Flow

GRAIN 4 OATS Low Flow

EDIT EDIT

NAME SETTINGS

ACCEPT

EXIT

CANCEL

April 2002

Page 51

PF3000

2-3

5

Changing a Setting

Grain Setup

Ag Leader Technology

Harvest Mode

Step Action

1 Use the UP or DOWN ARROW keys to select the grain. The grain

is selected when a black filled rectangular box surrounds the entire

line.

2 Press the EDIT SETTINGS key to move to another screen and

change the settings for the selected grain. Refer to the screen

below.

3 Press the EDIT NAME key to rename an existing grain (can not

rename SOYBEANS, CORN, or WHEAT). Use the UP or

DOWN ARROW keys to change a character in the name. Use the

LEFT or RIGHT ARROW keys to move the cursor over another

character within the name. Once you have changed the grain name

press the ACCEPT key.

4 Press the EXIT key once you have made all the settings.

Example of grain settings screen:

GRAIN SETTINGS: CORN

Dry lbs / bu 56 lb / bu

Dry moisture 13.0 %

Moisture offset 4.7 %

Stop height 54

M1 400

S1 50

EDIT

ACCEPT

EXIT

CANCEL

April 2002

Page 52

Grain Setup

2-36

Scale Factor

S1

PF3000

Harvest Mode

Dry lbs / bu

Dry moisture

Moisture offset

Stop Height

M1

Setting Initial C

Numbers

Ag Leader Technology

This setting is the pounds / bushel value that the monitor uses to calculate

bushels. You can change this setting for all grains except corn (56 lbs / bu),

soybeans (60 lbs / bu) and wheat (60 lbs / bu).

This setting is the moisture value that the monitor uses to calculate dry

bushels.

Example:

Corn – 15%

Soybeans – 13%

For grass seed the recommended setting is 1. Settings are 1, 10, 100.

Refer to the Initial Calibration Sheet for the correct setting. Do not readjust

the moisture offset number after you have performed a moisture calibration.

This setting determines how high the combine head must be raised to make

the monitor stop counting area. This number can be automatically set under

the CAL, STOP HGT key.

Refer to the Initial Calibration Sheet for the correct setting.

Refer to the Initial Calibration Sheet for the correct setting.

The 11 C Numbers, C1 through C11 determine the pounds of grain that the

monitor calculates. The C numbers initially should be set to the same values

that appear on your Initial Calibration Sheet, but they will change and

become more accurate after you have calibrated.

Do not change the C numbers after you have calibrated.

You only need to set the C11 number to its initial value. When you set the

C11 number, the C2-C10 numbers will automatically change to the correct

value. Do not set the C1 number. It is adjusted automatically when you do

a vibration calibration.

April 2002

Page 53

PF3000

2-37

Changing C11

Grain Setup

Ag Leader Technology

Step Action

1 You must display the weight calibration screen.

Press the following keys to view the weight calibration screen:

MENU key

CAL key

WEIGHT key

2 Refer to the screens on the next page and press the UP or DOWN

ARROW keys to set a grain type that you will harvest. Press the

SHOW CAL NUMBERS key.

3 Use the DOWN ARROW key to select C11 number (a line is

selected when the entire line is surrounded by a black filled box).

4 Press the EDIT key. Use the UP or DOWN ARROW keys to set

the correct number according to the Initial Calibration Sheet.

Press the ACCEPT key.

5 Press the EXIT key once to return to the previous screen. Repeat

steps 2-4 and set C11 for all the grain types you will harvest.

6 Press the EXIT key twice to return to the main operating screen.

NOTE: You may not be able to set C11 to the exact number that is on the

Initial Calibration Sheet. C2-C10 numbers also may not exactly agree with

the Initial Calibration Sheet. If this is the case, set C11 as close to the

initial number as possible.

Harvest Mode

April 2002

Page 54

Grain Setup

2-38

GRAIN CALIBRATION

PF3000

Harvest Mode

SELECT GRAIN:

SOYBEANS

ENTER

WEIGHT

GRAIN CALIBRATION: SOYBEANS

EDIT

ACCEPT

SHOW CAL

LOADS

CALIBRATION NUMBERS

C1 0

C2 250

C3 500

C4 750

C5 1000

C6 1250

C7 1500

C8 1750

C9 2000

C10 2250

C11 2500

CAL

ON/OFF

PERFORM

* * *

Ag Leader Technology

SHOW CAL

NUMBERS

CAL

EXIT

EXIT

CANCEL

April 2002

Page 55

PF3000

2-39

The swath setup screen is used to set the permanent, full swath of your head.

Swath Setup

Swath Setup

Ag Leader Technology

Harvest Mode

Introduction

Do not adjust the swath setting on this screen when you encounter a partial

swath while harvesting. Refer to the Swath Setting instructions in

Operation Section and select swath as a display item and set a partial swath.

To view the swath setup screen press the:

Screen

SWATH SETUP

SOYBEANS 24 12 in 24 ft 0 in

CORN 8 30 in 20 ft 0 in

WHEAT 24 12 in 24 ft 0 in

OATS 24 12 in 24 ft 0 in

EDIT EDIT

# ROWS SPACING

MENU key

SETUP key

SWATH key

Example of swath setup screen:

GRAIN # ROWS SPACING FULL SWATH

ACCEPT

CANCEL

EXIT

April 2002

Page 56

Swath Setup

2-40

PF3000

Harvest Mode

Ag Leader Technology

Changing a Setting Step Action

1 Use the UP or DOWN ARROW keys to select the grain. The grain

is selected when a black filled rectangular box surrounds the entire

line.

2 Press the EDIT # ROWS key to change the number of rows. Use

the UP or DOWN ARROW keys to change the number. Press the

ACCEPT key after you have changed the number.

3 Press the EDIT SPACING key to change the row spacing. Use the

UP or DOWN ARROW keys to change the number. Press the

ACCEPT key after you have changed the number.

4 Press the EXIT key once you have made all the settings.

Recommendations for Row Crop Heads:

• For row crops, set your row space to the planted row spacing and your

number of rows to the number of total rows of your combine head.

Recommendations for Cutting Platform Heads:

Row Crops

• For row crops, set your row space to the planted row spacing and your

number of rows to the number of total rows your cutting platform will

cut.

Non-rowed crops

• Set the swath in the monitor to one foot less than the actual swath width

of the head because you can rarely maintain a constant full swath while

harvesting.

Example: If your cutting platform head is 20 actual feet, set the

monitor’s swath to 19 feet by setting the row space to 12 inches and the

number of rows to 19.

• Set the monitor on a row space of 12 inches and a number of rows that

adds up to the correct swath. Setting the row space to 12 inches for

cutting platforms allows you to reduce the cutting swath by easier-to-see

one-foot increments when you are harvesting a partial swath

Refer to the Swath Setting instructions in the Operation Section for more

information about partial swath.

* * *

April 2002

Page 57

PF3000

2-41

Screen

Swath Setup

Ag Leader Technology

Introduction

Swath Setup

Recommendations

The swath setup screen is used to set the permanent, full swath of your

application equipment. Do not adjust the swath setting on this screen when

you encounter a partial swath in the field. Refer to the Swath Setting

instructions in Operation Section and select swath as a display item and set

a partial swath.

NOTE: If you do not want to count area, you do not need to set the

swath.

Refer to the swath setup instructions for harvest mode for instructions on

viewing the swath setup screen and setting the swath.

To enter a swath setting, you must enter a number of rows setting and a row

spacing setting for the product you are applying.

Application equipment that uses row units

If your application equipment is applying the product with row units, then

enter the number of rows and row spacing of the application equipment.

Application equipment that uses boom sections

If your application equipment is applying the product using boom sections

enter the width of the boom section in inches for the row spacing setting.

Enter the total number of booms for the number of rows setting. If your

boom sections are not all the same width, enter twelve inches for the row

spacing setting and a number rows setting that makes the total swath equal

the full swath of the application equipment.

Application equipment that uses a spreader mechanism

If your application equipment is applying the product using a spreading

mechanism enter twelve inches for the row spacing setting and a number

rows setting that makes the total swath equal the full swath of the

application equipment.

Site Verification Mode

* * *

April 2002

Page 58

Vehicle Setup

2-42

PF3000

Site Verification Mode

Ag Leader Technology

Introduction

For each operating mode, there are different items to setup in the vehicle

setting screen. Below are the setup items for the site verification mode.

Vehicle Setup

Screen

To view the vehicle setup screen, press the MENU key, SETUP key and

VEHICLE key to view the following:

VEHICLE SETUP

TRACTOR

TRUCK

ATV

OPTIONAL 1

OPTIONAL 2

OPTIONAL 3

OPTIONAL 4

ACCEPT EDIT EDIT

VEHICLE NAME SETTINGS

Use the UP or DOWN ARROW key select a vehicle type. Press EDIT

CANCEL

NAME key. Use the UP or DOWN ARROW key to name the vehicle type

and press SAVE NAME key.

To edit vehicle settings press EDIT SETTINGS key to view the following:

VEHICLE SETUP

Primary speed sensor WHEELS

Secondary speed sensor -------- Speed sensor pulses / 100 ft 2000 Pulses

Area count stop beeps 20 Beeps

Area Count STANDARD

Stop height 8

EDIT

ACCEPT

EXIT

CANCEL

April 2002

Page 59

PF3000

2-43

Vehicle Setup

Ag Leader Technology

Area count stop

beeps

Primary and

Secondary speed

sensor

Press the UP or DOWN ARROW key to scroll down to highlight a setting

and press the EDIT key to change a setting, then press ACCEPT key. After

making changes, press EXIT key.

Choose the vehicle you want to use and press ACCEPT VEHICLE key.

This setting is for the number of times the monitor beeps when the monitor

stops counting area at the end of a pass.

The monitor has four different primary speed settings. They are listed

below.

Ground Speed Sensor Primary Speed Sensor

Speed sensor on transmission WHEEL

Speed sensor on tracks TRACK

Radar gun RADAR

GPS receiver GPS

Site Verification Mode

***

April 2002

Page 60

Raven Controller (with Serial Port)

2-44

PF3000

Application Rate Mode

Cable attachment

for Raven

controllers with

serial ports

Setup for Raven

controllers with

serial ports

ATV Battery Power Cable

(p.n. 2000497-2)

The Raven Serial Cable enables the PF3000 to control the rate. It also

provides swath width (based on the number of booms on), actual rate

and area count status (based on Master Switch) information to the PF.

Complete the following steps to set up for Raven – Sidekick, 440, 450,

460, 660, 700, 710, 750, 760 controllers with serial ports.

A separate configuration of settings should be created for every product

applied. A maximum of 16 different configurations can be created. The

screen below illustrates two configurations set up for a Raven 440.

1. Press SETUP key. Press APP RATE CONFIG key. A screen

similar to the one below should appear.

Ag Leader Technology

NOTE: If your Raven console has a serial port, it

will be on the back of the console. It is a nine-pin

rectangular computer port. The Raven 750 and

760 serial port is built-in the main wiring harness.

Not all Ravens consoles have a serial port.

PF3000

Port 3

Raven Serial Cable (p.n. 2000944)

Raven Console

Cable attachment from Raven console to monitor

April 2002

Page 61

PF3000

2-45

Raven Controller (with Serial Port)

Ag Leader Technology

APP RATE CONFIG

PRODUCT CONTROLLER CHANNEL

Treflan 440 Rate 1

Roundup 440 Rate 1

EDIT

SETTINGS

Press CREATE NEW key to set up a new configuration or

select an existing configuration and press the EDIT

SETTINGS key. A new screen appears with the following

settings. Select each setting and press EDIT key to change the

settings.

Controller Make: Set to RAVEN. This setting can not be

changed once the configuration is used by one or more fields.

Controller Model: Set to the Raven model you have. For

example: 440 or 460 etc. This setting can not be changed once

the configuration is used by one or more fields.

Product: Press EDIT key. You can select an existing product

and press ACCEPT key or create a new product by pressing

CREATE NEW key. Press EDIT NAME key and enter name

of product. Use Left or Right Arrow keys to select a character.

Use Up or Down Arrow key to change the character. To erase

a character in the name, highlight that character and use UP or

DOWN ARROW key to scroll to the blank space between "9"

and "A". Set every character and press ACCEPT key twice.

Units: Usually set to GALLONS. Set to Units/Acre of

application.

Ground Speed Sensor: Set primary speed sensor to GPS.

SERIAL is not recommended. RADAR is an option but you

will need additional cabling to connect the radar to your

monitor. All Ag Leader GPS except GPS 1000 will work for

ground speed.

Application Rate Mode

CREATE

NEW

DELETE

Note: This setting affects all configurations.

EXIT

April 2002

Page 62

Raven Controller (with Serial Port)

2-46

PF3000

Application Rate Mode

Ag Leader Technology

App Distance From GPS: Set to distance between where

product exits applicator and position of GPS antenna on

vehicle. Example: If spray boom is 20 feet behind GPS

antenna set to 20 feet back. Press DOWN ARROW key to set

feet back, UP ARROW key to set feet forward.

Full Swath: Ignore setting. Swath automatically comes from

serial port of Raven. The swath on the PF automatically

changes as boom sections are turned ON or OFF.

Tgt Units: Contrler Units: Normally set to 1:1.0000. This

ratio is used to convert the units in a target file (.tgt) to the

units of application.

Example: Tgt file in pints/ac of Treflan, Raven applies based

on gallons/ac. If tank mix is 1 pint of Treflan / 10 gallon

water, then set to 1:10.0000. The PF will read the pints/acre

rate out of the tgt file, multiply it by ten to convert it to

gallons/ac and send that rate to the Raven console as the rate

to be applied.

Target Rate Increment: Determines increment value by

which you can change the manual target rate with each press

of Up or Down arrow keys. Choices are 0.1, 1.0, 10.0, 100.0,

500.0, 1000.0, 5000.0 or 10000.0.

Actual Rate Scale Factor: This setting is required to prevent

data loss in the log file (YLD file) when the units/sec of

application get above 3. Use the chart below for setting. The

rate actually applied and rate displayed on PF is unaffected by

this setting. When the log file is mapped in Ag Leader's SMS

mapping program, the mapped actual rate will be 1/10th of the

real rate if the Actual Rate Scale Factor is 0.100. If it is

0.010, the mapped actual rate will be 1/100th the real rate.

The mapped actual rate can be scaled back up in SMS. The

summary actual rate in SMS is unaffected by this setting.

April 2002

Page 63

PF3000

2-47

Raven Controller (with Serial Port)

Ag Leader Technology

Avg. Speed Swath Application Rate between Scale Factor

0-25 mph 0-80 ft 0-10 units/ac

0-10 mph 0-80 ft 11-100 units/ac

11-15 mph 0-50 ft 11-100 units/ac

11-15 mph 51-80 ft

16-25 mph 0-80 ft 11-100 units/ac

0-25 mph 0-80 ft 101-500 units/ac

0-10 mph 0-80 ft 501-1000 units/ac

11-15 mph 0-50 ft 501-1000 units/ac

11-15 mph 51-80 ft

16-25 mph 0-80 ft 501-1000 units/ac

0-25 mph 0-80 ft 1001+ units/ac

2. If you have a 440, 450, or 460 ignore this step, otherwise press

CONTRLER SETTINGS key. Set the following:

Controller Channel: Set to channel of Raven to record or

control rate.

Controller Operating Mode: Set to liquid or granular,

whichever type the Raven console is controlling.

3. Press EXIT key to return to screen with ADVANCED

SETTINGS key on bottom. Press the ADVANCED

SETTINGS key.

Target Rate Outside Field: This only pertains to using a

.tgt prescription file.

Set to ZERO if want rate outside field to be zero.

Set to USE LAST if want rate to be the last rate used at

the time the vehicle is detected outside the field. This is

useful when the vehicle is being falsely detected outside

of the field during the outside pass.

Set to TGT DEFAULT if want rate outside field to be the

default rate stored in the .tgt prescription file.

Controller Time Delay: Set to 3 seconds. This is delay of

controller to change application equipment to new rate + 2

seconds.

Application Rate Mode

1.000

1.000

1.000

11-100 units/ac

0.100

0.100

0.100

0.100

0.100

501-1000 units/ac

0.010

0.010

0.010

April 2002

Page 64

Raven Controller (with Serial Port)

2-48

PF3000

Application Rate Mode

4. This completes all the settings for one configuration. Press

EXIT key twice to return to screen showing all configurations

or press EXIT key 3 times and menu key to return to main

operating system.

Activating

Configuration and

Setting .tgt

Prescription File

Settings for Raven.

Additional

Instructions

5. Exit back to main screen.

Under Data Menu key, set Baud = 9600, Trig = 1, Unit = sec,

Dlog = ON. To turn the rate change alarm OFF set Rate = OFF.

On some Ravens the Dlog setting has to be reset when the console

is turned ON.

For more information on setting Target Rate, display items, creating

and using .tgt prescription files and logging actual rate see the

Operation Section in this manual.

Ag Leader Technology

Actual Rate Units: Ignore this setting.

Log Actual Rate: Set to YES to log actual rate to card. Set

to No, otherwise.

a) Press FIELD key twice.

b) Select appropriate field and press VIEW CONFIG key.

c) Select appropriate product/controller configuration and

press ACTIVE ON/OFF key to check it as active. (All

other configs must be unchecked first).

d) If you will be using a .tgt prescription file. Press EDIT

TGT FILE key, otherwise press EXIT key and skip to

step f.

e) Select .tgt file. Press VIEW INFO key to ensure it is

the correct one. After exiting view info screen, press

ACCEPT key. Press EXIT key.

Press ACCEPT key to accept field.

April 2002

Page 65

PF3000

2-49

Mid-Tech Controller

Ag Leader Technology

Cable attachment

for Mid-Tech

controllers that

are connected to

Data-Link

consoles

ATV Battery

Power Cable

(p.n. 2000497-2)

PF3000

Cable attachment from Mid-Tech console to monitor

The Mid-Tech Data-Link console provides a serial cable connection

between the PF and Ag Logix or the TASC controller. The serial cable

enables the PF3000 to control and record the rate. It also provides swath

width (based on the number of booms on), ground speed, actual rate and

area count status (based on Master Switch) information to the PF3000.

Application Rate Mode

Port 3

Data-Link

April 2002

Page 66

Mid-Tech Controller

2-50

PF3000

Application Rate Mode

Setting up MidTech controllers

that are connected

to Data-Link

consoles

Complete the following steps to set up for Ag Logic, TASC 6000,

6100, 6200, 6300, 6500, 6600 with Data Link.

A separate configuration of settings should be created for every

product applied. A maximum of 16 different configurations can be

created. The screen below illustrates two configurations set up for a

Mid-Tech.

1. Press SETUP key. Press APP RATE CONFIG key. A screen

similar to the one below should appear.

APP RATE CONFIG

PRODUCT CONTROLLER CHANNEL

Treflan TASC 6100 Carrier

Roundup TASC 6100 Carrier

Ag Leader Technology

EDIT

SETTINGS

Press CREATE NEW key to set up a new configuration or select

CREATE

NEW

DELETE

EXIT

an existing configuration and press the EDIT SETTINGS key. A

new screen appears with the following settings. Select each

setting and press EDIT key to change the settings.

Controller Make: Set to MIDTECH. This setting can not be

changed once the configuration is used by one or more fields.

Controller Model: Set to the MIDTECH model you have. For

example: TASC 6100 etc. This setting can not be changed once

the configuration is used by one or more fields.

Product: Press EDIT key. You can select an existing product and

press ACCEPT key or create a new product by pressing CREATE

NEW key. Press EDIT NAME key and enter name of product.

Use Left or Right Arrow keys to select a character. Use Up or

Down Arrow key to change the character. To erase a character in

the name, highlight that character and use UP or DOWN ARROW

key to scroll to the blank space between "9" and "A". Set every

character and press ACCEPT key twice.

April 2002

Page 67

PF3000

2-51

Mid-Tech Controller

Ag Leader Technology

Units: Set to Units/Acre of application. Set to GALLONS

if applying liquid. Set to POUNDS if applying granular

product.

Ground Speed Sensor: Set primary speed sensor to

SERIAL. The monitor will get ground speed from the

serial cable connection to the Mid-Tech. Leave the

secondary speed sensor set to WHEEL and do not change

the Speed Sensor Pulses/100 ft. Also do not perform a

distance calibration using wheel selection. No calibration

is needed when primary speed is set to SERIAL.

App Distance From GPS: Set to distance between where

product exits applicator and position of GPS antenna on

vehicle. Example: If spray boom is 20 feet behind GPS

antenna set to 20 feet back. Press DOWN ARROW key to

set feet back, UP ARROW key to set feet forward.

Full Swath: Ignore setting. Swath automatically comes

from serial port of Mid-Tech. The swath on the PF

automatically changes as boom sections are turned ON or

OFF.

Tgt Units: Contrler Units: This only pertains to using a

.tgt prescription file. Normally set to 1:1.0000. This ratio

is used to convert the units in a target file (.tgt) to the units

of application.

Target Rate Increment: Determines increment value by

which you can change the manual target rate with each

press of Up or Down arrow keys. Choices are 0.1, 1.0,

10.0, 100.0, 500.0, 1000.0, 5000.0 or 10000.0.

Application Rate Mode

Note: This setting affects all configurations.

Example: Tgt file in pints/ac of Treflan, Mid-Tech

applies based on gallons/ac. If tank mix is 1 pint

of Treflan / 10 gallon water, then set to 1:10.0000.

The PF will read the pints/acre rate out of the .tgt

file, multiply it by ten to convert it to gallons/ac

and send that rate to the Mid-Tech console as the

rate to be applied.

April 2002

Page 68

Mid-Tech Controller

2-52

PF3000

Application Rate Mode

Avg. Speed Swath Application Rate between Scale Factor

0-25 mph 0-80 ft 0-10 units/ac

0-10 mph 0-80 ft 11-100 units/ac

11-15 mph 0-50 ft 11-100 units/ac

11-15 mph 51-80 ft

16-25 mph 0-80 ft 11-100 units/ac

0-25 mph 0-80 ft 101-500 units/ac

0-10 mph 0-80 ft 501-1000 units/ac

11-15 mph 0-50 ft 501-1000 units/ac

11-15 mph 51-80 ft

16-25 mph 0-80 ft 501-1000 units/ac

0-25 mph 0-80 ft 1001+ units/ac

2. Press CONTRLER SETTINGS key. Set the following:

3. Press EXIT key to return to screen with ADVANCED

SETTINGS key on bottom. Press the ADVANCED

SETTINGS key.

Ag Leader Technology

Actual Rate Scale Factor: This setting is required to prevent

data loss in the log file (YLD file) when the units/sec of

application get above 3. Use the chart below for setting. The

rate actually applied and rate displayed on PF is unaffected by

this setting. When the log file is mapped in Ag Leader's SMS

mapping program, the mapped actual rate will be 1/10th of the