Page 1

Operator Manual

Firmware Version 5.4

Ag Leader PN 4002083 Rev. M

Page 2

© 2014 Ag Leader Technology

2202 South Riverside Drive

Ames, Iowa 50010 USA

All Rights Reserved

Firmware Version 5.4

Page 3

Table of Contents

General

T

ABLE

OF

C

About this Manual

Introduction and Company Profile............................................................................1

Display......................................................................................................................1

Service......................................................................................................................1

System Uses ............................................................................................................2

System Features ......................................................................................................2

USB Flash Drive.......................................................................................................3

Color Touch Screen..................................................................................................3

CAN BUS Technology..............................................................................................3

Technical Specifications...........................................................................................3

System and Upgrades..............................................................................................4

Automated Module Firmware Upgrade.....................................................................4

Product Registration.................................................................................................4

Conventions Used In This Manual............................................................................4

Cautions and Warnings............................................................................................4

Cross-references and Web Links.............................................................................5

Viewing this Manual Online......................................................................................5

How to Find Information You’re Looking For............................................................5

Installation

Display Hardware.....................................................................................................7

Installation Instructions.............................................................................................7

Fuse Installation and Replacement..........................................................................9

Screen Icon Conventions .........................................................................................9

ONTENTS

Setup

Configuration

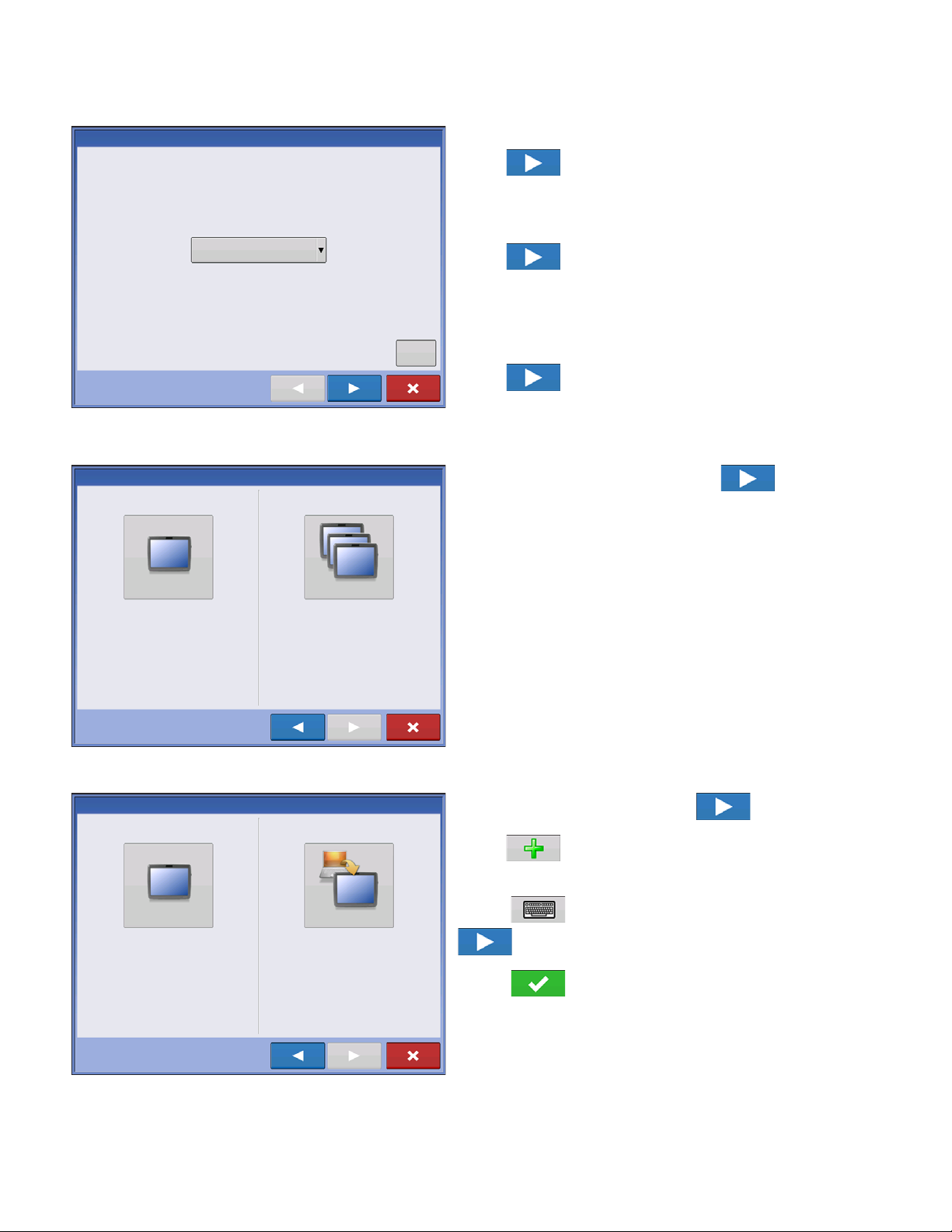

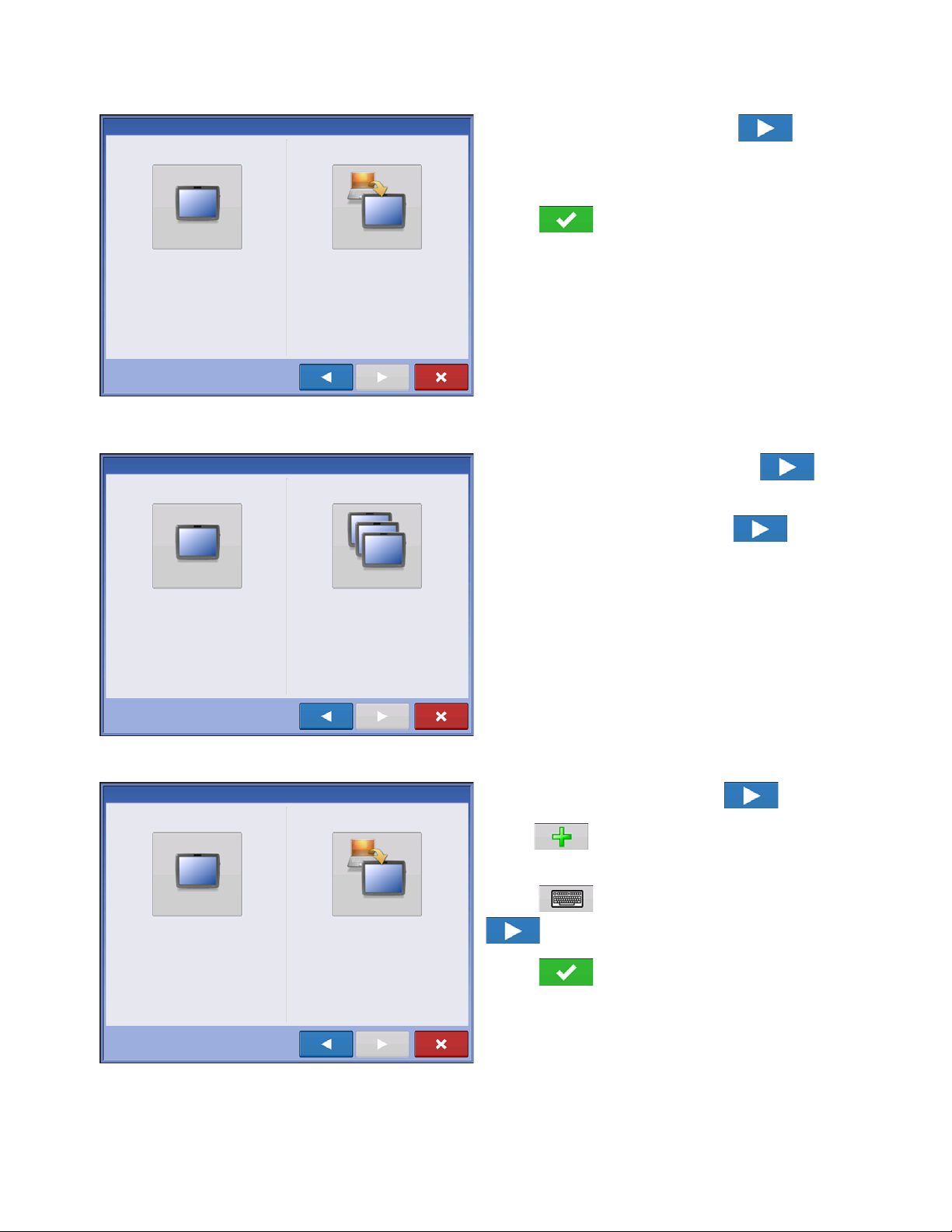

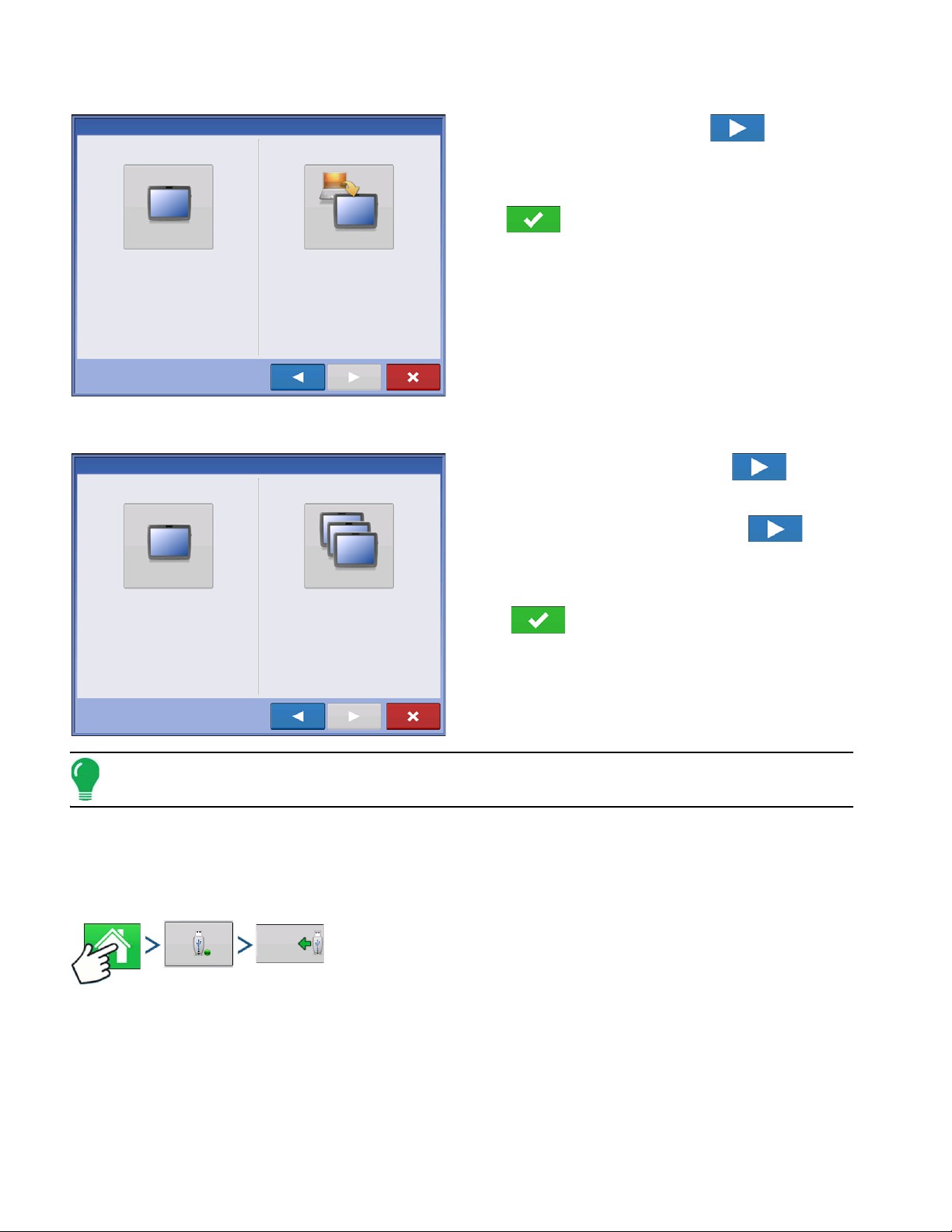

Initial Startup...........................................................................................................11

Advanced Options.............................................................................................11

Location Specific Setup.....................................................................................12

Single Display ...................................................................................................12

Multiple Display Setup - First Display................................................................13

Multiple Display Setup - Additional Display.......................................................14

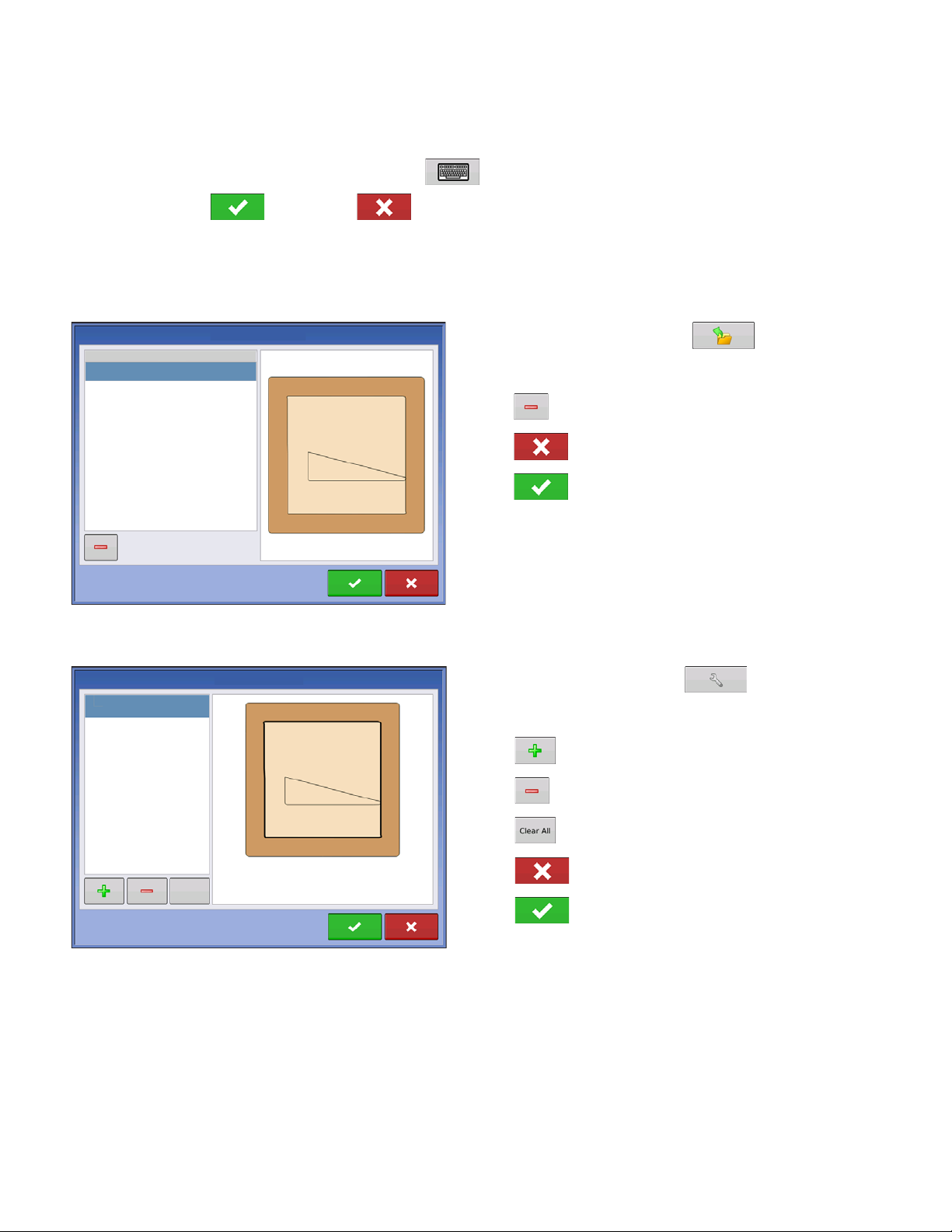

Import Setup Data ..................................................................................................14

Import Files .......................................................................................................14

Home Screen..........................................................................................................15

Setup buttons .........................................................................................................16

Display button.........................................................................................................16

General tab .......................................................................................................17

iii

Page 4

Display tab........................................................................................................18

Features tab ..................................................................................................... 18

Unlocking Features..................................................................................... 19

Advanced tab....................................................................................................19

Configuration button...............................................................................................21

Configuration tab.............................................................................................. 21

Product tab....................................................................................................... 22

Planting Settings......................................................................................... 23

Application Settings.....................................................................................23

Grain Harvest Settings................................................................................ 23

Management Setup

Configuration Selection .................................................................................... 25

All Modules Detected............................................................................. 25

Modules Missing....................................................................................25

Some Modules Not Detected................................................................. 26

Modules not the same as previously used............................................. 26

Events...............................................................................................................27

Setting mode (Traditional or Events Only) using Permissions.................... 27

Starting an Event.........................................................................................28

Managing Events ........................................................................................ 28

Management button..........................................................................................30

Grower/Farm/Field tab......................................................................................30

Grower ........................................................................................................ 30

Farm and Field. ........................................................................................... 31

Importing and Exporting Field Boundaries.................................................. 32

Season tab ....................................................................................................... 33

Users tab.......................................................................................................... 33

Add a User.................................................................................................. 34

User Setup button....................................................................................... 34

General tab............................................................................................ 35

Phone/Email tab .................................................................................... 35

Address tab............................................................................................35

Permissions......................................................................................................35

Operators.................................................................................................... 35

Managers................................................................................................... 35

Permission Level For Operators....................................................................... 36

Full Permission............................................................................................36

Basic Permission.........................................................................................36

Custom Permission.................................................................................... 37

Accessing Setup Menus...................................................................................39

Accessing USB.................................................................................................39

Forgotten Passwords........................................................................................39

Businesses tab................................................................................................ 40

Field Operations

Operator Selection............................................................................................43

Operator Log Out..............................................................................................44

Configuration Setup Screen...................................................................................44

iv Firmware Version 5.4

Page 5

Setup Event............................................................................................................45

Field Finder.......................................................................................................46

Field Operation Options....................................................................................46

Run screens ...........................................................................................................47

GPS Signal Indicator.........................................................................................49

Mapping Toolbox...............................................................................................50

Map Legend tab...........................................................................................51

Map Options ................................................................................................51

Legend Settings .....................................................................................52

Markers tab..................................................................................................53

Edit Markers...........................................................................................53

Field Tab......................................................................................................54

Boundary................................................................................................54

Boundary Settings..................................................................................55

Create Boundary....................................................................................55

Pause Boundary.....................................................................................55

Headlands.........................................................................................................56

Active Area ..................................................................................................56

Add a Headland...........................................................................................56

Headland Types.....................................................................................57

Load Headlands...........................................................................................58

Edit Headlands ............................................................................................58

Headland Alarm Settings.............................................................................59

Topography............................................................................................59

Setup Map Screen..................................................................................60

Video.................................................................................................................62

T

ABLE

OF

C

ONTENTS

Reports

Summary Report ....................................................................................................65

Date Range.......................................................................................................67

Field Notes........................................................................................................67

Smart Report™.......................................................................................................68

Create Reports..................................................................................................69

Smart Report Auto-Generation .........................................................................69

Control Channel Report Content.......................................................................71

View Reports.....................................................................................................72

View Map ..........................................................................................................72

External Drive

External Storage Operations..................................................................................73

Upgrade Firmware ............................................................................................73

Import Files .......................................................................................................73

.AGSETUP...................................................................................................73

.AGDATA.....................................................................................................74

Export Files.......................................................................................................74

.AGSETUP...................................................................................................74

.AGDATA.....................................................................................................74

Export Reports.............................................................................................75

Manage Files.....................................................................................................75

v

Page 6

Advanced Options............................................................................................ 75

Devices

Device Information.................................................................................................77

Devices.............................................................................................................77

Display Diagnostics.......................................................................................... 77

Settings

Equipment Settings ................................................................................................ 79

Implement Switch Settings (for Area Logging)............................................ 79

Equipment Configuration Settings for Rate Control.................................... 80

Speed Input Settings..............................................................................................80

Calibrate Distance............................................................................................ 81

Auxiliary Input ........................................................................................................ 82

Auxiliary Input Settings..................................................................................... 83

Auxiliary Input: Help..........................................................................................83

Auxiliary Input Diagnostics ...............................................................................83

AutoSwath..............................................................................................................84

Look-Ahead Settings...................................................................................85

Vehicle Offsets. ...................................................................................................... 85

Antenna Offsets tab..........................................................................................86

Hitch Tab Settings tab...................................................................................... 86

Mount Tab Settings (for some Application vehicles) ........................................ 86

Head Tab (for Harvest vehicles)....................................................................... 86

Swath Section Offsets......................................................................................86

Section Offsets............................................................................................87

Virtual Terminal

Common Terminology............................................................................................89

Auxiliary Assignment..............................................................................................91

VT Alarms and Trouble Codes............................................................................... 92

Task Controller.......................................................................................................93

Configuration Setup............................................................................................... 93

ISOBUS Settings ................................................................................................... 94

AgFiniti

Connecting to Wi-Fi Network.................................................................................95

Connecting to AgFiniti............................................................................................96

File Transfer........................................................................................................... 97

Importing and Exporting Files........................................................................... 97

Viewing Files .................................................................................................... 97

Export Settings.................................................................................................98

Importing a Prescription....................................................................................99

Importing a Variety Reference Map (Harvest Only)........................................ 100

Remote Support...................................................................................................100

Remote Support Permissions Options ........................................................... 100

GPS

vi Firmware Version 5.4

Page 7

GPS

GPS Button...........................................................................................................103

Setup....................................................................................................................103

GPS Settings...................................................................................................103

OmniSTAR Settings .............................................................................................105

OmniSTAR Settings — GPS 2500.......................................................................106

Serial Port Settings...............................................................................................107

GPS Information...................................................................................................109

GPS Information - General Tab ......................................................................109

Satellite Plot...............................................................................................111

GPS Information - Receiver Tab.....................................................................111

GPS Information - OmniSTAR Tab.................................................................112

RTK/NTRIP Information.............................................................................112

GPS Information - NTRIP................................................................................113

GPS Information for 2500 RTK.......................................................................113

2500 RTK Setup..............................................................................................114

Guidance

T

ABLE

OF

C

ONTENTS

Guidance

Guidance/Steering Control...................................................................................115

Setup....................................................................................................................115

Lightbar Settings...................................................................................................116

Setup....................................................................................................................116

Guidance Tab on Mapping Toolbox .....................................................................116

New Pattern..........................................................................................................117

Straight............................................................................................................117

Select Pattern............................................................................................117

Create AB line using 2 points ....................................................................117

Create AB line using Current Location and Heading.................................117

Create AB line using Current Location and Inputting Heading..................117

Adaptive Curve................................................................................................118

Select Pattern............................................................................................118

Create AB line using 2 points ....................................................................118

Identical Curve................................................................................................119

Select Pattern............................................................................................119

Create AB line using 2 points ....................................................................120

Pivot................................................................................................................120

Select Pattern............................................................................................121

Create AB line using driven path...............................................................121

SmartPath.......................................................................................................122

Select SmartPath.......................................................................................122

Inputting Paths into SmartPath..................................................................123

Cycle between Loaded Paths....................................................................123

Select a Previous SmartPath Pass............................................................124

SmartPath Guidance Options....................................................................124

AutoSave..............................................................................................................125

vii

Page 8

Manage Patterns..................................................................................................126

Spatial Sort .......................................................................................................... 126

Import Pattern ................................................................................................. 126

Export Pattern.................................................................................................126

Edit Pattern. .................................................................................................... 126

Remove Pattern/Remove All Patterns............................................................ 127

Reset Pattern..................................................................................................127

Pattern Groups.....................................................................................................127

Guidance Options................................................................................................ 128

Save ............................................................................................................... 128

Pause ............................................................................................................. 129

Remark A........................................................................................................ 129

Nudge............................................................................................................. 129

Shift ................................................................................................................ 130

Steering.......................................................................................................... 131

OnTrac Tuning................................................................................................131

Lightbar...........................................................................................................132

Tramlines........................................................................................................132

OnTrac2+

AutoSteer Setup Screen...................................................................................... 135

Vehicle................................................................................................................. 136

Setup Wizard..................................................................................................136

Manage Vehicle..............................................................................................137

Select..............................................................................................................137

Edit ................................................................................................................. 138

Delete............................................................................................................. 138

Export/Import.................................................................................................. 138

Export profile to a USB drive ............................................................... 139

Import profile to a USB drive................................................................ 139

Auto Calibrate...................................................................................................... 139

Adjust Lateral Offset..................................................................................140

Steering Adjust............................................................................................... 141

Steering Components..................................................................................... 142

OnTrac2 ECU............................................................................................142

Manual Steering Override......................................................................... 142

Remote Engage Switch............................................................................. 142

MDU. ......................................................................................................... 142

System Menu....................................................................................................... 143

System Health................................................................................................ 143

Manage Settings.............................................................................................144

Log Files....................................................................................................144

Database...................................................................................................145

Reset Factory Default ...............................................................................145

Accessories....................................................................................................145

Technician...................................................................................................... 146

Software Upgrade...........................................................................................146

GPS Diagnostics..................................................................................................146

Details.................................................................................................................. 147

viii Firmware Version 5.4

Page 9

Tillage

Create Tillage Configuration.................................................................................149

Configuration Setup..............................................................................................149

Load Configuration..........................................................................................150

Run Configuration.................................................................................................150

Planting

Create Planting Configuration

Create Equipment Configuration..........................................................................153

AutoSwath

Row Shutoff..........................................................................................................157

Configuration Setup ........................................................................................157

Row Shutoff Look-Ahead Numbers.................................................................157

Automatic AutoSwath Control...............................................................................158

Look-Ahead Settings .................................................................................158

Checking AutoSwath Performance for Row Shutoff .......................................159

Fixing Overplanting and Underplanting in AutoSwath.....................................160

T

ABLE

OF

C

ONTENTS

Rate Control

Hydraulic Seed Rate Control................................................................................161

Controller Settings for Hydraulic Seed Rate Motor Drives..............................161

Channel Tab settings.................................................................................162

Control Valve Settings - PWM..............................................................162

Control Valve Settings - Servo.............................................................163

Auxiliary Tab settings.................................................................................163

Hydraulic Seed Controller Settings for Specific Planters................................164

Hydraulic Seed Meter Calibration Numbers....................................................165

Stepper Seed Rate Control ..................................................................................166

Controller Settings for Stepper Seed Rate Motor Drives ................................166

Channel Tabs ............................................................................................167

Auxiliary Tab..............................................................................................167

Gear Ratio Calculations for Seed Rate Motors...............................................168

Gear Ratio Drawing - For Single Motor Drive............................................168

Gear Ratio Drawing - For Multiple Drive Combinations.............................169

Seed Ratio Calculation Example Procedure..............................................169

Gear Ratio Drawing Shaft Drives...............................................................170

Planter Options Screen ........................................................................................171

Priming Seed Rate Meters ...................................................................................171

Calibrating Seed Rate Meters ..............................................................................172

Rate Control: Map Screen....................................................................................173

Product Control Toolbox.......................................................................................173

Rate Control Settings......................................................................................174

Loading Prescriptions...........................................................................................175

Showing Prescriptions on the Map Screen.....................................................175

ix

Page 10

Troubleshooting................................................................................................... 176

Hydraulic Seed Control: Zero Flow Offset Variation....................................... 176

Hydraulic Seed Control: Zero Flow Offset Variation....................................... 177

Stepper Seed Control Meter Alarms............................................................... 177

Down Force

Modes of Operation ............................................................................................. 179

Create Equipment Configuration.......................................................................... 179

Setup Down Force Configuration......................................................................... 180

Calibrate Pressure Sensor...................................................................................183

Down Force Status .............................................................................................. 183

Bar Graphs on Run Screen............................................................................ 183

Planter Options Screen........................................................................................184

Planter Performance Screen................................................................................185

Down Force Diagnostics screen..........................................................................185

Down Force Alarm screens.................................................................................. 185

Seed Tube Monitor Module

Configuration Setup........................................................................................187

Seed Monitor Setup........................................................................................188

AutoConfig Procedure...............................................................................188

Seed Tube Sensor Configuration................................................................... 189

STMM Split-Row Configurations............................................................... 189

Planter Options ............................................................................................... 190

Seed Monitor Diagnostics............................................................................... 191

Seed Monitor Alarms......................................................................................191

Seed Monitor Thresholds ...............................................................................192

SeedCommand Map Screen Examples ......................................................... 192

Planting Map Screen - Zoom to Extent........................................................... 193

Planting Map Screen - Zoom Detail................................................................ 194

Legend Select.................................................................................................194

Legend Setup............................................................................................195

Advanced Seed Monitoring..................................................................................196

Bar Graph....................................................................................................... 196

Planter Performance screen........................................................................... 197

Row Performance screen..........................................................................198

Virtual Seed Trench........................................................................................199

KINZE Planter Monitor Module

KINZE Planter Configuration.....................................................................201

Ground Speed Settings ....................................................................... 202

Other Sensors......................................................................................202

EdgeVac.............................................................................................. 203

KINZE Sensor Configuration.....................................................................203

Muxbus Sensor Detection......................................................................... 203

Sensor Information .................................................................................... 205

KINZE Seed Monitor Alarms..................................................................... 206

KINZE Magnetic Coil Speed Sensor Calibration....................................... 206

KINZE EdgeVac Calibration......................................................................207

x Firmware Version 5.4

Page 11

KINZE Planter Monitor Options.......................................................................207

Seed Monitor Diagnostics...............................................................................208

KINZE Display Items on Equipment Tab.........................................................209

Planter Monitor Module screen..................................................................210

Troubleshooting....................................................................................................211

Alarms on KINZE Planter Monitor...................................................................211

Application

Liquid Rate Control

Create Configuration.......................................................................................215

Implement Offsets...........................................................................................217

Controller Settings...........................................................................................218

Creating Products ...........................................................................................219

CREATING SINGLE PRODUCTS.............................................................219

CREATING PRODUCT TEMPLATE .........................................................219

Load Configuration..........................................................................................221

Mix Calculator .................................................................................................223

Configuration Setup ........................................................................................225

Hardi Safe Track.............................................................................................226

Liquid Application Controller Settings .............................................................226

Control Valve Settings - PWM...................................................................228

Control Valve Settings - Servo, Calibrated Reflow and Ramsey Valve.....228

Calibrate Pressure.....................................................................................229

Fence Row Nozzle Indicators .........................................................................229

Load Configuration..........................................................................................230

Run Configuration...........................................................................................230

Application Map screen - Zoom to Detail........................................................231

Legend Select.................................................................................................231

Rate Control: Product Control Toolbox.................................................................232

Rate Control Settings......................................................................................233

Rate Control: Container Level.........................................................................234

Tank Fill.....................................................................................................234

Tank Empty................................................................................................234

Tank Partial Fill..........................................................................................234

Adjust Container Amount .....................................................................234

Tank Alarms...............................................................................................235

Loading Prescriptions...........................................................................................235

Showing Prescriptions on the Map Screen.....................................................236

Shape File Conversion.........................................................................................237

Liquid Application Diagnostics ........................................................................238

Troubleshooting DirectCommand Liquid Applications ....................................239

John Deere Specific Instructions..........................................................................241

Master Switch Input.........................................................................................241

Master Switch Usage......................................................................................241

Target Rate.....................................................................................................241

Data Collection................................................................................................241

T

ABLE

OF

C

ONTENTS

xi

Page 12

AutoSwath Boom Section Control.................................................................. 241

SprayStar Application Rate ............................................................................ 241

SprayStar Rinse Cycle ...................................................................................242

Control Valve Settings ......................................................................................... 242

Liquid Product Control Valve Configuration Options................................. 242

Servo Control Valve Settings (By Manufacturer)............................................ 243

Liquid Servo Settings Description................................................................... 247

Liquid PWM Control Valve Settings Description............................................. 247

Dickey-John NH3 Conversions....................................................................... 248

Conversion Formulas................................................................................ 248

Troubleshooting Serial Control Applications................................................... 248

Miscellaneous......................................................................................................249

Glossary of Application Settings..................................................................... 249

Configuration Settings............................................................................... 249

Speed Input Settings.................................................................................249

Automatic Swath Control Settings............................................................. 249

Auxiliary Input Settings..............................................................................250

Controller Settings.....................................................................................250

Fertilizer default Product Settings................................................................... 252

Application

ISOBUS Serial Application Rate Control

Enable Virtual Terminal and Task Controller....................................................... 253

Setup.................................................................................................................... 254

Status Screen ...................................................................................................... 256

Settings Screen....................................................................................................257

Manage Configurations ..................................................................................257

Alarm Settings......................................................................................................257

Diagnostics .......................................................................................................... 258

Injection

Create Configuration ...................................................................................... 259

Setup Configuration........................................................................................259

Rate Response Warning...................................................................... 259

Flow Monitor Warning.......................................................................... 260

Calibrating an Injection Pump................................................................... 260

Priming an Injection Pump........................................................................261

Load Configuration......................................................................................... 262

Run Configuration...........................................................................................262

Injection Diagnostics.......................................................................................263

Troubleshooting Direct Injection Configurations............................................. 263

Direct Injection: Pump Doesn’t Run.......................................................... 264

BATTERY POWER PIN OUTS............................................................................265

Direct Injection: Pump Runs Full Speed ................................................... 265

Digital Pump Speed Pin Outs .............................................................................. 265

Analog Speed Pin Outs........................................................................................266

xii Firmware Version 5.4

Page 13

Direct Injection: Application Error ..............................................................266

Direct Injection: Discharge Flow Sensor Error...........................................266

Discharge Flow Sensor Pin Outs..........................................................................267

Direct Injection: Inlet Restriction................................................................267

Vacuum Switch Pin Outs......................................................................................267

Controller Settings: Direct Injection Pump Calibration...............................267

Pump Calibration Setting......................................................................267

Rate Response Warning......................................................................268

Flow Monitor Warning ..........................................................................268

Field Notes.................................................................................................268

Setting Name and Description..............................................................268

Run Screen................................................................................................268

OptRx

Installation.......................................................................................................269

Checklist....................................................................................................269

Create Configuration.......................................................................................269

Crop Sensor Setup..........................................................................................270

Corn Settings............................................................................................270

North American Wheat Settings ...............................................................270

Europe Settings........................................................................................270

Sensor Setup.............................................................................................271

Application Rate Table....................................................................................271

Load Configuration..........................................................................................272

Run Configuration...........................................................................................273

Create an OptRx V.I. Reference Value...........................................................273

Determining where to scan a Reference Strip...........................................273

Scan a Reference Strip..............................................................................273

Crop Sensor Settings......................................................................................274

Glossary of OptRx Terminology......................................................................275

Troubleshooting OptRx Error Messages.........................................................276

T

ABLE

OF

C

ONTENTS

NORAC UC5

Norac Unlock...................................................................................................279

Create Configuration.......................................................................................279

Setup Configuration ........................................................................................280

Load Configuration..........................................................................................281

Run Configuration...........................................................................................282

Engage button ...........................................................................................282

Boom Height Control Options Button.........................................................282

Boom Height Control Options Screen........................................................283

Boom Height Diagnostics................................................................................283

Spreader

Create Configuration.......................................................................................285

Controller Settings...........................................................................................287

Spreader Control: PWM Control Valve......................................................288

Spreader Control: Servo Control Valve .....................................................289

Spreader Control: Spinner Tab..................................................................289

xiii

Page 14

Creating Products...........................................................................................290

CREATING SINGLE PRODUCTS............................................................ 290

CREATING DRY FERTLIZER BLENDS................................................... 291

Load Configuration......................................................................................... 292

Run Configuration...........................................................................................293

Automatic Spinner Control...................................................................................294

Spinner Spreader, with two-bin configuration...................................................... 294

Run Time Operations .....................................................................................294

Spreader Control screen...........................................................................295

Conveyor Rate Look-Up...................................................................... 295

Fan Frame & Feed Gate Actuator Settings ......................................... 296

Spreader Control: Routine Operations ................................................ 297

Spreader Control: Chain Oiler ............................................................. 297

Spreader Control: Static Calibration.................................................... 297

Spreader Control: In-Field Calibration................................................. 298

Troubleshooting DirectCommand Granular Applications ............................... 299

Troubleshooting Serial Control Applications................................................... 300

Strip Till

Create Strip Till Fertilizer Configuration.......................................................... 301

Create Air Seeder Configuration ....................................................................303

Controller Settings.......................................................................................... 306

Strip Till Control: Servo Control Valve....................................................... 306

Strip Till Control: PWM Control Valve....................................................... 307

Linear Actuator/Clutch Settings................................................................. 307

Actuator/Clutch Logic............................................................................... 309

Fertilizer Blend Setup................................................................................ 309

Load Configuration......................................................................................... 310

Run Configuration...........................................................................................310

Meter Prime...............................................................................................310

Run Time Operations .....................................................................................312

Strip-Till (Three-Bin Configuration)...................................................................... 312

Strip Till Control Screen............................................................................ 313

Static CFR Calibration Procedure for Hydraulic Drive systems........... 313

Static CFR Calibration Procedure for Ground Drive Systems............. 315

In-Field Calibration Procedure (Strip Till)............................................. 315

Strip Till Control: Auxiliary Tab.................................................................. 316

Troubleshooting DirectCommand Granular Applications ............................... 316

Troubleshooting Serial Control Applications................................................... 317

Fertilizer Default Product Settings.................................................................. 318

Harvest

Harvest Monitoring/Mapping

Display Preparation........................................................................................ 319

Vehicle Inspection .......................................................................................... 319

Create Configuration ...................................................................................... 319

xiv Firmware Version 5.4

Page 15

Configuration Setup ........................................................................................319

Calibration Sequence ................................................................................319

Calibrate Distance...........................................................................................320

Calibrate Header Sensor...........................................................................320

Input Header Offset ...................................................................................321

Vibration Calibration........................................................................................321

Temperature Calibration .................................................................................322

Moisture Calibration........................................................................................322

Manual Moisture Setting............................................................................323

Grain Weight Calibration.................................................................................323

Turn On/Off Auto Calibration...........................................................................324

AutoSwath Sensitivity Settings........................................................................324

Load Configuration..........................................................................................325

Run Configuration...........................................................................................325

Harvest Status Items.......................................................................................326

Harvest Diagnostic Button on Map Screen.....................................................327

Map Options....................................................................................................327

Map Screen: Flow Delay.................................................................................328

Region Selection: Options Screen..................................................................328

Tracking Varieties and Changing Regions......................................................328

Variety Tracking menu and Automatic Variety Tracking............................329

Automatic Variety Tracking ..................................................................329

Automatic Region Changing.................................................................329

In-Field Messages................................................................................329

Importing Variety Maps...................................................................................330

Importing Variety Map Procedure..............................................................330

Error Messages at Variety Map Import......................................................330

Grain Harvest Diagnostics....................................................................................331

T

ABLE

OF

C

ONTENTS

Claas Quantimeter

Create Configuration.......................................................................................333

Configuration Setup ........................................................................................333

Calibration Information....................................................................................334

Load Configuration..........................................................................................334

Manual Moisture Setting............................................................................335

Map Screen for CLAAS Quantimeter..............................................................336

Diagnostics for CLAAS Quantimeter...............................................................336

Diagnostics Screen for CLAAS Quantimeter.............................................336

Bridge Module......................................................................................337

Troubleshooting CLAAS Quantimeter Configurations.....................................337

Appendix

Appendix

System Diagrams Reference................................................................................339

Current File Formats.............................................................................................339

.AGSETUP......................................................................................................339

xv

Page 16

.AGDATA........................................................................................................339

Legacy File Formats ............................................................................................340

Prescription Map File Types...........................................................................340

Boundary and Guideline File Types ............................................................... 340

Image File Types............................................................................................340

System File Types.......................................................................................... 340

Module LED Diagnostic States............................................................................ 341

Company Warranty Statement............................................................................. 341

Unauthorized Access........................................................................................... 341

PROPRIETARY TECHNOLOGY NOTICE.......................................................... 342

COPYRIGHT NOTICE.........................................................................................342

SERVICE AND SUPPORT.................................................................................. 342

xvi Firmware Version 5.4

Page 17

GENERAL

GENERAL

ABOUT THIS MANUAL

INTRODUCTION AND COMPANY PROFILE

G

ENERAL

A

BOUT

THIS

ABOUT US

Welcome to the Ag Leader Technology family. Ag Leader Technology, Inc. is the global leader in yield

monitor and precision farming systems and is committed to meeting the present and future needs of the

agriculture industry by providing high quality products and first class customer support.

INNOVATION

Ag Leader Technology manufactures and sells products which support a wide array of precision farming

practices. These include grain yield monitoring, application rate control and monitoring, variable rate

fertilizer application, site-verification, GPS guidance and interface to Autosteer technologies.

COMPATIBILITY

Ag Leader Technology offers compatibility and supports integration of many different types and brands

of equipment used for precision farming. The latest equipment available is supported as well as older

series of combines, planters, sprayers, tillage equipment, etc.

QUALITY AND SUPPORT

Ag Leader Technology continues to provide the best customer support in the industry. Precision farming

doesn't come without questions. Ag Leader is committed to providing the most responsive,

knowledgeable and friendly technical support available. Our technical support team is available sevendays-a-week during peak seasons to answer your questions on the operation of Ag Leader products.

WE WANT TO HEAR FROM YOU!

M

ANUAL

Feel free to call and discuss:

• Operational questions about the display

• Features you would like to see implemented to improve the system or features you would like to see added

to the system to increase functionality

DISPLAY

The display is a full-featured, year-round hub of any precision farming operation. A full-color, highbrightness, high-resolution touchscreen display is easy to read and offers powerful, year-round precision

farming tools. Built-in manual guidance, full-screen mapping, planter and application control, yield

monitoring, real-time data logging and automated steering make up the core functionality of the display.

WARNING: Read manual completely before operating display. Understand and follow all operating and

safety instructions for proper use of this display . Failur e to use display properly could result in an impairment

of the safety features of this product.

SERVICE

There are no user-serviceable parts inside the display. Contact the manufacturer for a Return Material

Authorization (RMA).

1

Page 18

ph: (515) 232-5363

fax: (515) 232-3595

e-mail: support@agleader.com

CAUTION: This display has an internal lithium coin cell battery that is good for the life of the product and

does not need to be replaced. There is a risk of explosion if the battery is replaced by an incorrect type.

Dispose of used batteries according to the battery manufacturer’s instructions.

SYSTEM USES

• Manual Guidance

• ParaDyme™ and GeoSteer™ automated steering

• OnTrac2+™ Assisted Steering

• Planter DownForce Control

• Norac UC5

• Video Camera Inputs

• Mapping tillage operations

• Mapping and logging product application

• Mapping of all field boundaries, sub-boundaries, waterways and terraces

• Grain yield monitoring

• Variety logging

• Granular and liquid fertilizer application

• Liquid spray system control

• NH3 application control

• Application control of multiple bin spinner spreaders

SYSTEM FEATURES

• Sunlight-readable screen

• Rugged sealed enclosure

• Compatible with most NMEA GPS receivers

• DirectCommand and SeedCommand product con trol using industry- standard CAN-bus interface

• Adjustable volume control

• Perspective 3D View Map

• Report preview

• Automatic field selection

• Automated module firmware upgrade

• Advanced GPS Diagnostics

• USB media slot

• 28-pin plug compatible with other Ag Leader displays.

2 Firmware Version 5.4

Page 19

• 28-pin auxiliary connection

• RAM mount

G

ENERAL

A

BOUT

USB FLASH DRIVE

Display kits include a USB Flash Drive which you can use to save and transfer your data in and out of

the display.

COLOR TOUCH SCREEN

The display features a color touch screen display. The touch screen allows easy and intuitive navigation

through the screens on the display without the need for any external keypad or mouse devices. Here are

a few key things to remember if you are new to using a touch screen device:

• Do not use any sharp objects fo r running the touch screen device, this could result in damage to the

display. Using the tip of a finger is the recommended method of operating the display touch screen.

• Do not use any harsh chemicals to clean the touch screen. Using a dam p sof t cloth or an anti-st atic wipe

made specifically for cleaning computer displays is the correct way to cle an the screen and the

enclosure.

• The touch screen requires only a gentle touch of about half-second in duration to operate correctly. A

common mistake is to try to navigate too quickly through the system using firm taps instead of gentle

presses.

CAN BUS TECHNOLOGY

THIS

M

ANUAL

This system uses Controller Area Network (CAN) technology. CAN systems are comprised of individual

modules, each with their own high speed processor, connected through a high-speed communications

cable. CAN has many benefits, including greater ability to configure and expand the system,

compatibility, simpler installations with less wiring, and increased system dependability.

TECHNICAL SPECIFICATIONS

Do not exceed the specifications below:

• Storag e Temperature: -4 to +176 °F (-20 to +80 °C)

• Operating Temperature: 14 to +156 °F (-10 to +70 °C)

• Operating Input V oltage: 9 –16 V DC

• Max Current Rating: 4.0 amp

• Environmental Protection Rating: IP64

• No Protective Grounding required

• Use 150V minimum insulation rating for external circuits

CAUTION: Exceeding these specifications may result in degraded ope ration and/or damage to the disp lay.

3

Page 20

SYSTEM AND UPGRADES

Ag Leader Technology will periodically provide operating program updates that will improve the

performance of your display. Required software updates will be available free of charge for download

from www.agleader.com. On occasion, major releases will be made available that have significant

product feature additions or enhancements. These optional software updates may have an additional

fee associated with them.

AUTOMATED MODULE FIRMWARE UPGRADE

In the display, all display and module firmware upgrades are packaged in a single.fw2 file. The module

firmware files are stored internally in the display. A warning alerts you when a module upgrade is

required. You can upgrade all files in a single batch by using an upgrade screen. For more information,

see

“Advanced tab” on page 19.

PRODUCT REGISTRATION

When registering your Ag Leader Technology products by one of the following methods, you can elect to

receive notice of any new product updates or features.

Register by mail: Ag Leader Technology

2202 South Riverside Dr.

Ames, IA 50010

Register by Fax: 515-232-3595

Register at the Ag Leader Web site at http://www.agleader.com

CONVENTIONS USED IN THIS MANUAL

CAUTIONS AND WARNINGS

The operators manual uses the following text formatting schemes to call attention to information related

to simplifying system operation and proper operating practices to prevent accidental data loss. If in doubt

about the results of performing an action or deleting an item from the system, back up all system files to

the USB external drive prior to proceeding with the action.

Note: Provides informative tips to assist with system setup, calibration, and operation.

CAUTION: Indicates specific settings, calibrations, and procedures tha t must be followed for prop er system

performance and operation.

WARNING: Indicates specific instructions to avoid accidental loss of data and system configurations

settings.

4 Firmware Version 5.4

Page 21

G

ENERAL

CROSS-REFERENCES AND WEB LINKS

Throughout this manual, numerous cross-references are provided to other pages or sections. These

cross-references are always shown in blue, italic text; and list the title and page number as in the

following example: To find the information you’re looking for, see

For” on page 5

directly to the link.

Links to web sites are shown in blue, italicized, and underlined text, as in the fo llowing example: To view

the web site, go to: www.agleader.com.

. If you are viewing this manual in PDF format, you can click on this blue text and go

“How to Find Information You’re Looking

VIEWING THIS MANUAL ONLINE

This operators manual can be viewed online at Ag Leader’s Web site. To view an online version, go to

the Ag Leader Web site and click the Customer Support link. You will see a page titled “Product

Manuals.”

To view and/or print the Operators Manual online, you will need the Adobe Acrobat or Adobe Reader.

The Adobe Reader software comes pre-installed on most personal computers. If Adobe Reader is not

installed on your computer the program is available for download at no charge. A link to the Adobe

download site is located at the Ag Leader Web site.

A

BOUT

THIS

M

ANUAL

HOW TO FIND INFORMATION YOU’RE LOOKING FOR

What do you do if you cannot find the information that you’re looking for There are three different ways at

your disposal to find specific information quickly. These steps can include:

1. Look up the information in the Table of Contents.

2. Look up the information in the section indexes that are located at the end of each manual section

(Planting, Tillage, Application, and Harvest).

3. Use the Adobe Reader’s search function. While viewing this manual online in PDF format, press the

CTRL+F buttons on your keyboard. A search menu should appear, and from here, you may enter in a

search term.

5

Page 22

6 Firmware Version 5.4

Page 23

G

ENERAL

GENERAL

INSTALLATION

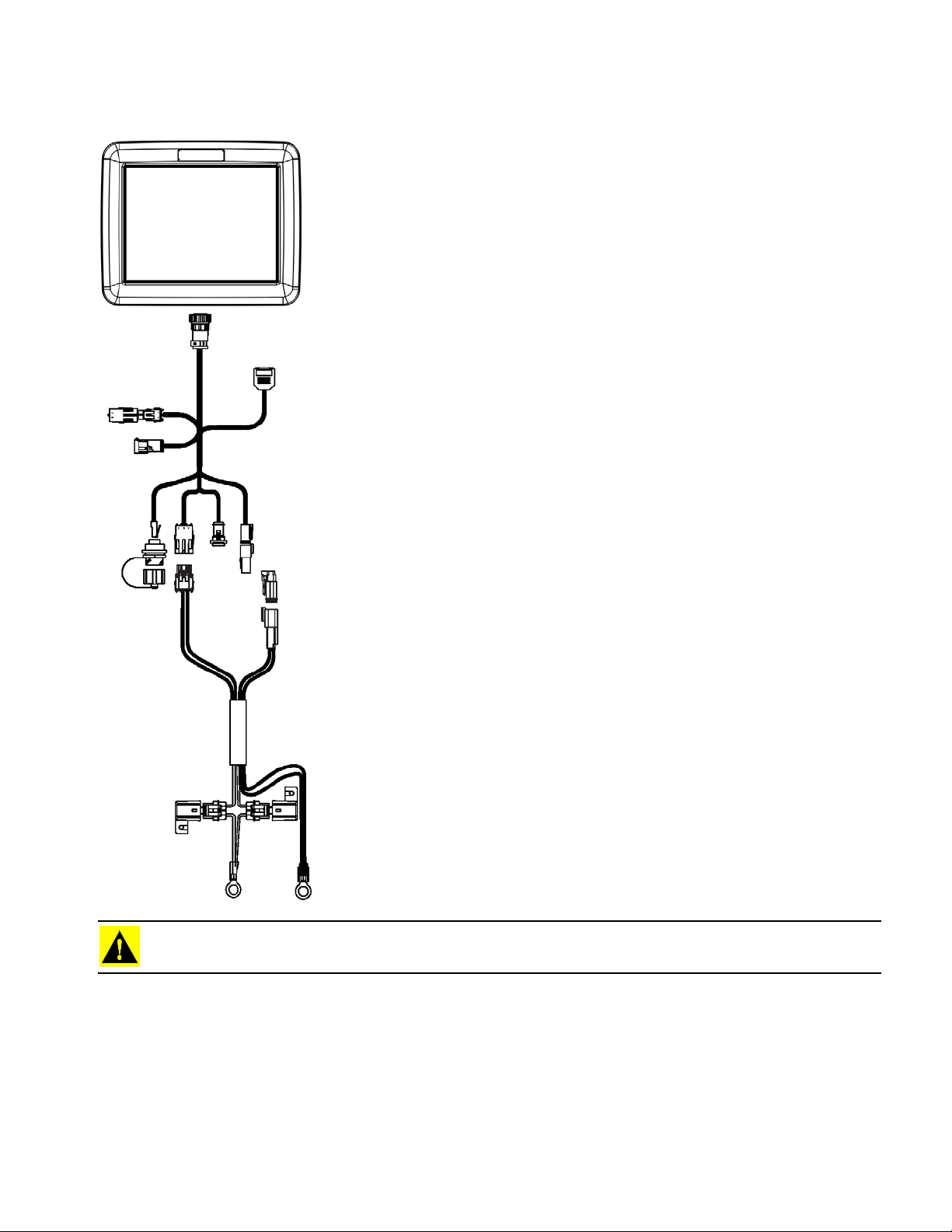

DISPLAY HARDWARE

• (A) USB media slot

Used for data transfer in and out of the display.

• (B) speaker

The built-in speaker is used for audible wa rnings. The volume

can be adjusted through the display setup routine.

• (C) RAM mount

• (D) Power/Reset switch

The Power/Reset switch is used for turning the display on and

off in installations where the system is connected to a

continuous power supply. If the display ever stops

responding, the manual power switch may be held in for five

seconds to restart the system. Only do this as a last resort, data loss could occur during times of improper

shutdown.

I

NSTALLATION

• (E) 28-pin auxiliary connection

Used for camera input.

• (F) 28-pin plug

The 28-Pin round connector contains CAN, RS-232 serial, and system power and ground connections. It is

compatible with other Ag Leader displays. Ether ne t f or ParaDyme and GeoSteer automated steering is

included in connection.

• (G) VGA video output

Can be used to connect to a video projector for demonstration purposes.

• (A) USB media slot

• Used for data transfer in and out of the display.

• (H) Light sensitivity sensor

Used to automatically dim the display during nighttime or low-light

situations.

• (I) Power light

The power light displays one of three st ates: When it is green the

display is on; when it pulses amber the display is in Standby M ode,

and when it is solid amber the display is running on battery power.

INSTALLATION INSTRUCTIONS

All machine installation and mounting kits are shipped with instructions specific to that kit. Instructions

include special details relating to mounting, wiring and display configuration.

7

Page 24

Mount the display to a secure support inside the vehicle cab. The following must be considered when

choosing a mounting location:

• The display must be readily accessible to the machine operator.

• The display must not obstruct the machine operator's normal driving view.

• The display must not interfere with or limit access to any of the existing machine controls.

• The CAN system cabling be routed and secured without interfering with existing machine controls.

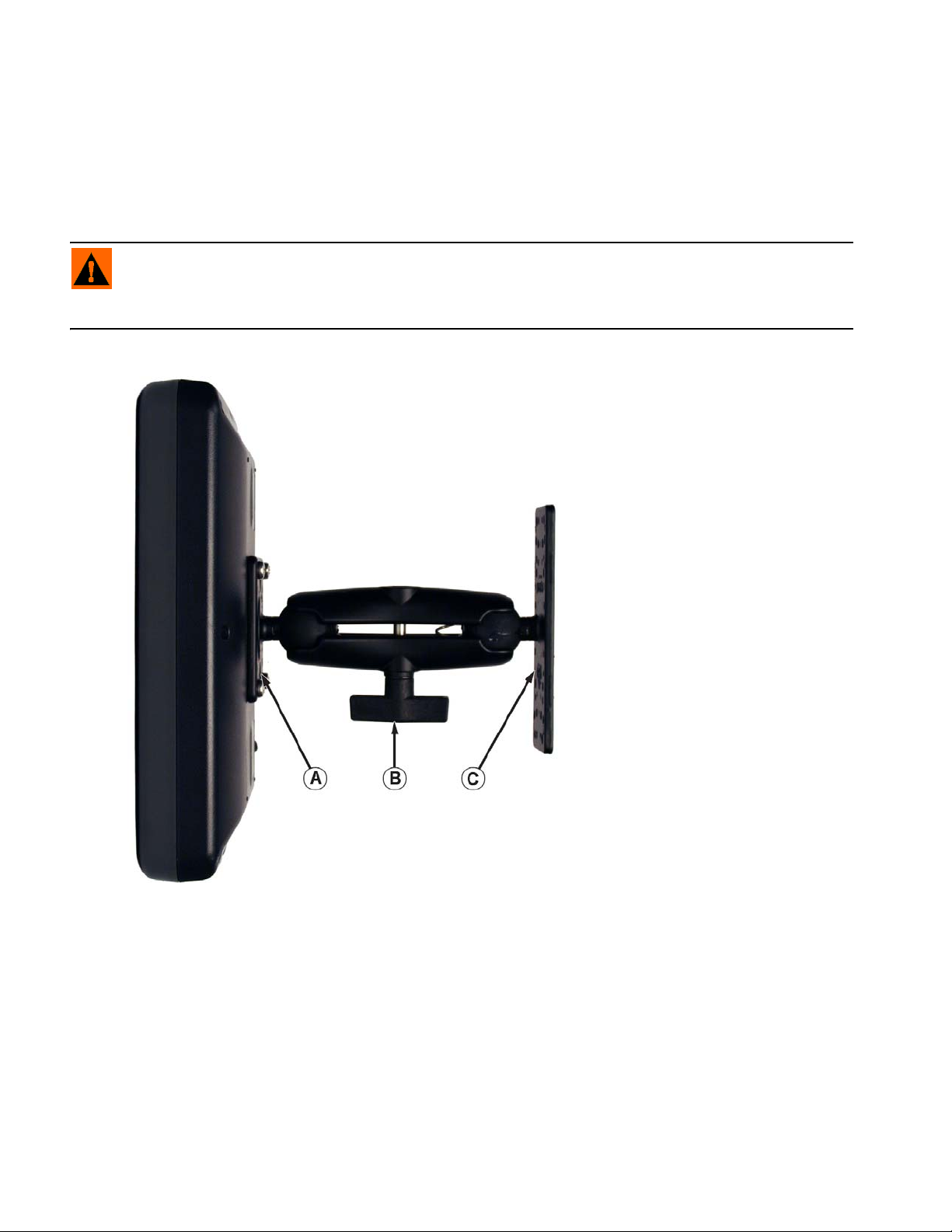

WARNING: If drilling holes is required during the mounting process, care must be taken to insure that

damage is not done to existing vehicle wiring, mechanical, or cab structure. Refer to vehicle manufacturer

documentation for specific details on your equipment. Follow all OEM instructions, cautions, and warnings

when working around equipment.

• (A) RAM Base

• (B) RAM Arm

• (C) Base

8 Firmware Version 5.4

Page 25

FUSE INSTALLATION AND REPLACEMENT

Fuse Type: Blade Style (ATO/ATC)

Rating:

Fuse Holder (orange wire) 5A, 250 VAC

Fuse Holder (pink wire) 15A, 250 VAC

G

ENERAL

I

NSTALLATION

CAUTION: The fuse is to be placed in the fuse holder in-line with the battery power cable and used with

display only.

SCREEN ICON CONVENTIONS

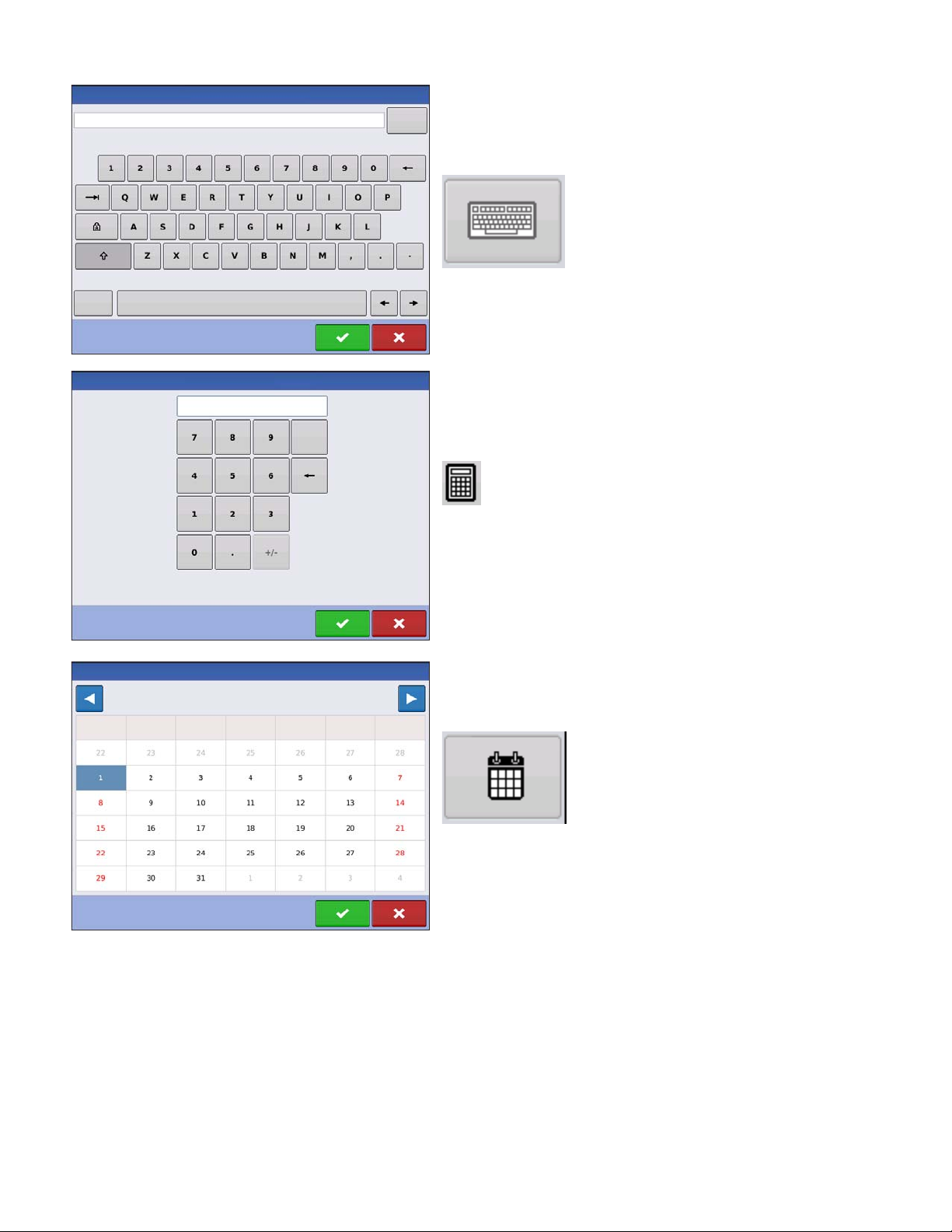

The following control buttons are made available for entering names and calibration values into the

system.

9

Page 26

An on-screen Keyboard is made available when

Symbols

Clear

All

Clear

Start Date

March 2015

Sunday

Monday

Tuesday

Wednesday Thursday Friday Saturday

appropriate for use during all setup processes. Press

the keyboard button to access the on-screen text entry

screen.

An on-screen Numeric Keypad is made available for

changing configuration settings and calibration

numbers. Press the keypad button to access the onscreen numeric entry screen.

An on-screen calendar is made available for changing

dates. Press the calendar button to access the

calendar screen.

10 Firmware Version 5.4

Page 27

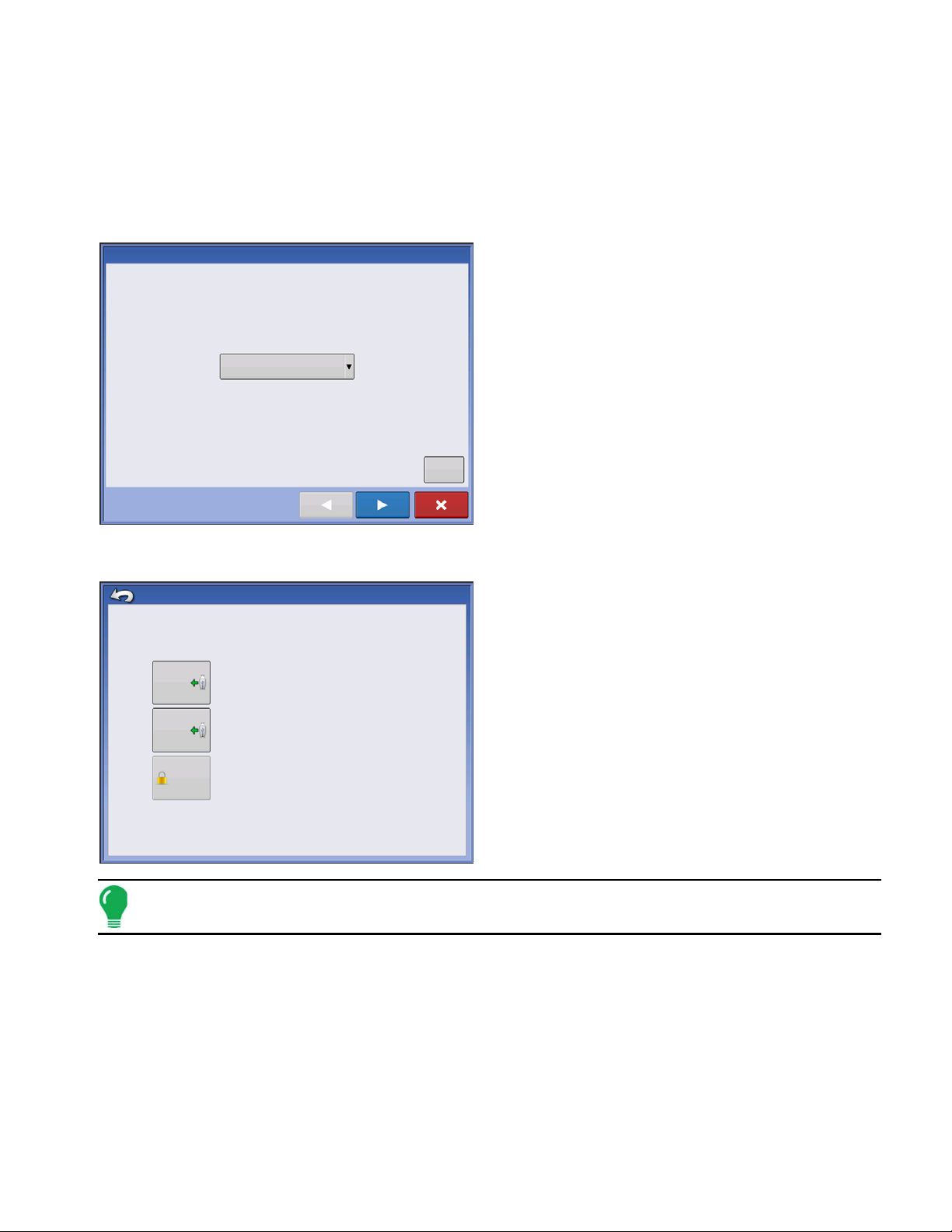

SETUP

Language Selection

Language

English / US

Advanced

Advanced Options

Restore

Upgrade

Restore data from a backup file (same display model only)

Upgrade the display firmware.

Unlock display features.

Features

Unlocks

SETUP