Page 1

Granular Strip-Till Control Module

Quick Reference Sheet

Section 1: Configuration Procedure

The following setup procedure describes how to configure a Strip Till Module for

a multiple product application. To begin this procedure, go to the Application Setup

Configuration Tab and press the Add button.

Note: In order for you to use this configuration at the Run screen, you must also

configure a vehicle, implement, controller and product(s). For more information on how

to configure these, consult the InSight User Manual.

Strip-Till Configuration (for multiple products)

STEPS ACTION

1

Select Equipment Configuration Type

The Operating Configuration Wizard appears. Select either Single Product Application, or

Multiple Product Application. As this particular procedure describes how to configure a

Multiple Product Application, we have chosen this setting.

Note: You must have purchased a Multi-Product unlock code from Ag Leader in order to use

the Multiple Product Configuration.

2

3

4

5

6

Select Vehicle

Use the drop-down menu to choose a vehicle, or press the New button to enter a new vehicle.

Press Next to continue.

Add Equipment for Multiple Product Configuration.

The Add Additional Application Equipment window appears. From here, you may add

additional equipment or controllers to your configuration. Add equipment by pressing the Add

button.

Note: If you choose to add additional equipment, add them in the same order as the implements

are attached.

Select Implement

Select an Implement from the drop-down list menu, or press the New button to create a new

implement. Press Next to continue.

Select Implement Attachment Method

Use the drop-down list to select an implement attachment method. Press Next to continue.

Enter Full Swath Width

Use the numeric keypad to enter the full swath width of the implement. Press Next to continue.

Part No. 2002831-42 Rev. C

1

Page 2

Strip-Till Configuration (for multiple products)

STEPS ACTION

7

8

9

10

11

12

13

Enter Number of Boom Sections

Use the up and down arrow keys to enter the number of sections of the implement. Press

Next to continue.

Enter Boom Section Widths from Left to Right

For implements with more than one boom section, the system will default to the appropriate

number of equal width boom sections. To edit any of the boom values, select the desired

section from the list and press the numeric keypad to enter in a new width. Press Next to

continue.

Enter Distance from Hitch to Application Point

Enter the distance from the hitch to the application point (from front to back) using the

numeric keypad. Press Next to continue.

Implement Setup Wizard

Press Next to continue.

Enter Implement Name

Use the keyboard button to enter a name for the implement. Press Finish

Select Operating Mode

Use the drop-down menu to select Rate Logging/Control; then press Next.

Select Controller

Press the New button to add a controller; then press Next

14

Select Controller Device and Device Type

Select DirectCommand from the Device drop-down list box. Scroll down on the Direct

Type list box and select Granular Strip-Till Control. Press Next to continue.

15

Select Controller Device and Device Type

Select DirectCommand from the Device drop-down list box. Scroll down on the Direct

Type list box and select Granular Strip-Till Control. Press Next to continue.

16

Enter Suggested Controller Name

A default name of DirectStripTill appears. Press Finish, or use the on-screen keyboard to

enter a new name, if desired

17

Select Controller Channel

Use the drop-down menu to select a controller channel, then press Next to continue.

18

Select Container

Use the drop-down menu to select a container, or press the New button to enter a new

container; then press Next to continue.

Part No. 2002831-42 Rev. C

2

Page 3

Strip-Till Configuration (for multiple products)

19

20

21

22

23

Enter Container Capacity and Units

The Container Setup Wizard appears. Use the numeric keypad to enter the container

capacity and the drop-down menu, located underneath, to enter units. Press Next to

continue.

Select Container Name and Location

Use the keypad to enter a Container Name, and the drop-down menu underneath to enter

a Container Location.

Enter a Suggested Configuration Name

Use the keypad to enter a different name for the configuration (if desired), and press

Next. A suggested name has been provided, based on your previous selections. If this

name does not fully describe the configuration, you may change it here.

Add Equipment for a Multiple Product Application

The Operating Configuration Wizard reappears. Because we specified that we were

configuring a multiple product application in the first step of this procedure, we are now

asked to add more equipment to our configuration. Repeat steps 3-21. When you have

repeated these steps and have come back to the Add Equipment window, press the Next

button; then press Finish.

Select Ground Speed Source

Select your ground speed source. If you will be using GPS as the primary you will need

to select a secondary source.

Note: The Ground Speed Sensor must be calibrated for accurate speed and area

calculations, under the Vehicle Tab. Press Next to continue.

24

Enter Suggested Configuration Name

Use the keypad to enter a suggested name for your configuration. A suggested name has

been provided, based on your previous selections. If this name does not fully describe the

configuration, you may change it here. Press Finish when complete.

Part No. 2002831-42 Rev. C

3

Page 4

Section 2: Strip Till Hardware Setup

Part No. 2002831-42 Rev. C

4

Page 5

Section 3: Setup Menu

Part No. 2002831-42 Rev. C

5

Page 6

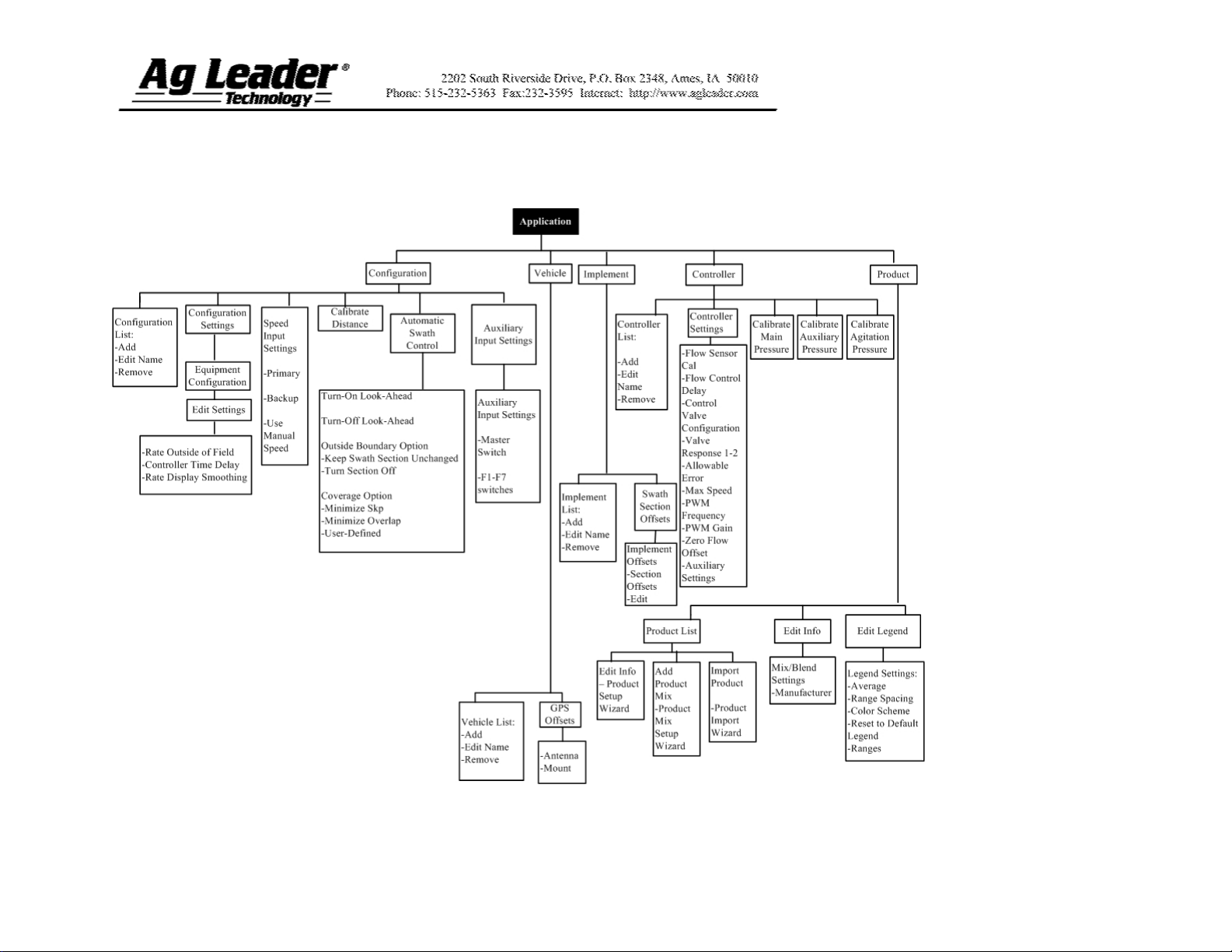

Section 3: Direct Command Menu Tree

Part No. 2002831-42 Rev. C

6

Page 7

Section 4: Run Screen Functionality

Part No. 2002831-42 Rev. C

7

Page 8

Section 5: Key Settings/Functionality

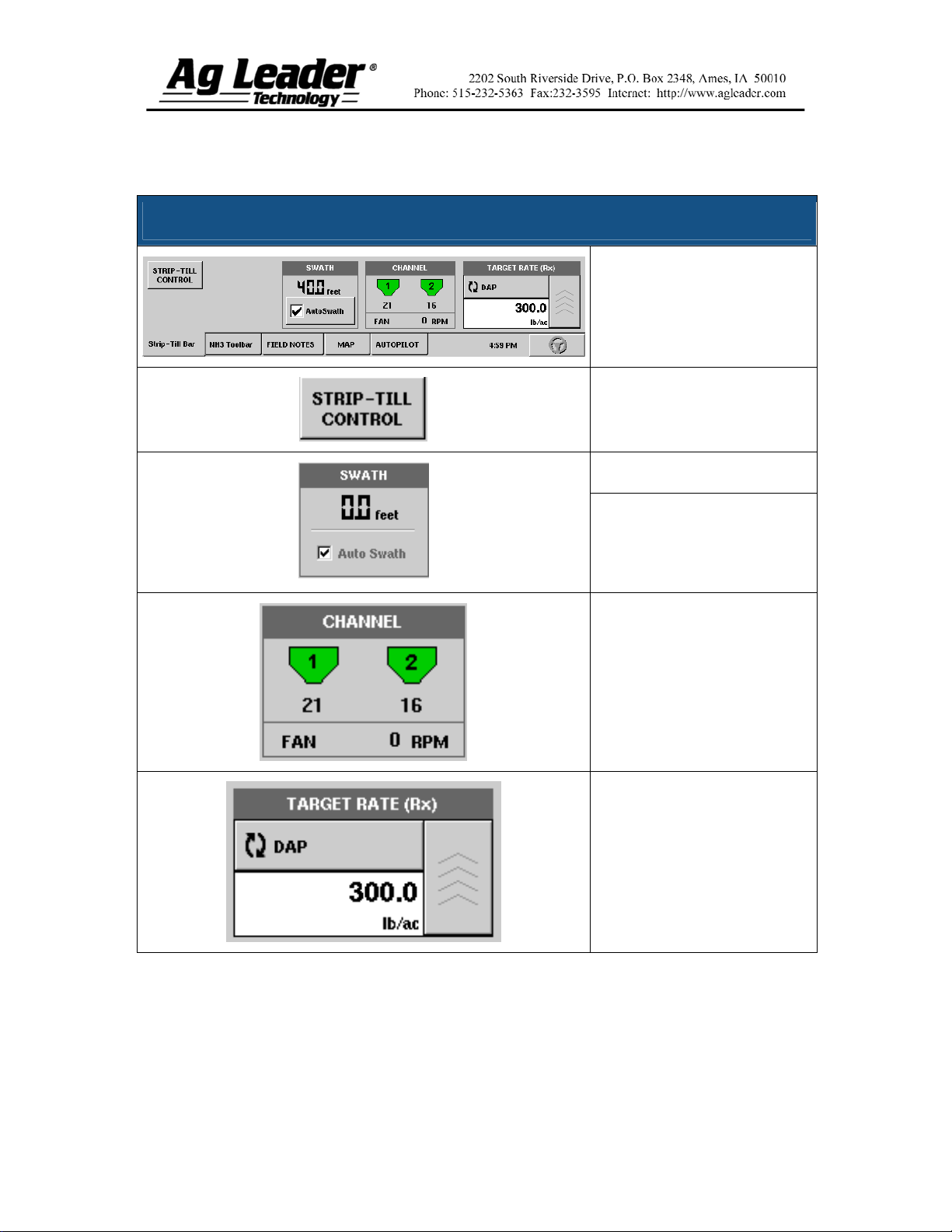

Strip Till Application Rate Control Tab

The Application Tab shown at

left is a typical configuration

for a Strip Till module.

Press to display the Strip Till

window and settings.

Displays active swath width.

The Auto Swath check box

allows the enable/disable of

the Automatic Swath Control

functionality.

Displays the status of the

product control channel. When

the fertilizer bin is grey no

product application is taking

place. When product is being

applied, the fertilizer bin icon

will turn green.

Displays the current target

application rate. Press the up

arrow button to go to the

Target Rate Application

window.

Part No. 2002831-42 Rev. C

8

Page 9

Strip Till Control Settings

Product Density:

This density value (shown in

pounds per cubic foot, or lb./ft.3),

is stored with each combination of

product and control channel. Use

the keypad to edit, if needed. Note:

For proper machine performance

and accuracy, you should check the

Product Density daily.

CFR 1:

This setting represents the volume

of product distributed on the field

with each revolution of the

metering circuit. This is shown in

Cubic Feet per Revolution

(ft.3/rev).

Caution: New products will have a

default CFR number the first time

they are used. You must either

manually enter or perform a CFR

calibration routine for each product

once that product is created,

otherwise misapplication will

occur.

Static CFR Calibration: Press the

Static CFR Calibration button to

perform an automated routine to

calibrate each metering circuit.

This calibration is performed

before applying in field conditions.

In-Field CFR Calibration: Press

the In-Field CFR Calibration

button to perform an automated

routine to adjust the calibration

number for the selected metering

circuit. This calibration is

performed if there is a difference

between the amount of product as

logged as compared to what was

actually applied.

Part No. 2002831-42 Rev. C

9

Page 10

Section 6: Strip Till Calibration

To perform the Static CFR Calibration, press the Static CFR Calibration button in the

Strip-Till Control Window.

Static CFR Calibration Procedure (Strip Till)

STEP

1

2

3 Enter Simulated Target Rate

4 Start Target Rate Countdown

5 Enter Actual Dispense Amount

ACTION

Read Static Calibration warning

A warning appears, advising to disable the blower fan circuit and prepare to catch any

product dispensed in an appropriate container. Press OK.

Select Metering Circuit to Calibrate

The CFR Calibration Wizard appears. Choose the desired channel to calibrate, and

press Next.

Enter Dispense Amount

Use the numeric keypad to enter the amount of product to be dispensed into the

container, and press Next.

Use the numeric keypad to enter a simulated target rate, shown in pounds per acres.

Press Next when finished.

Press the green Start button to begin the target rate countdown. As the countdown is

started, the button will turn red and state Stop. When the countdown is complete, press

the Next button.

Enter the actual dispense amount, in pounds.

Note: The CFR will be calculated from the actual product amount dispensed.

6 Calibration Complete

A message appears, stating that your calibration is complete, and showing the CFR

amount, in cubic feet per revolution.

Either:

Press the Repeat Calibration button, or

Press Finish.

Part No. 2002831-42 Rev. C

10

Loading...

Loading...