Page 1

DirectCommand™ Liquid Control Module

Quick Reference Guide

The following procedure describes the complete process of configuring a liquid

DirectCommand control system. To begin, go to the Configuration Tab, press the Add

button, and the Operating Configuration Wizard appears.

Note: In order for you to use this configuration at the Run screen, you must configure a vehicle,

implement, controller and product(s). For more information on how to configure these, consult

the InSight User Manual.

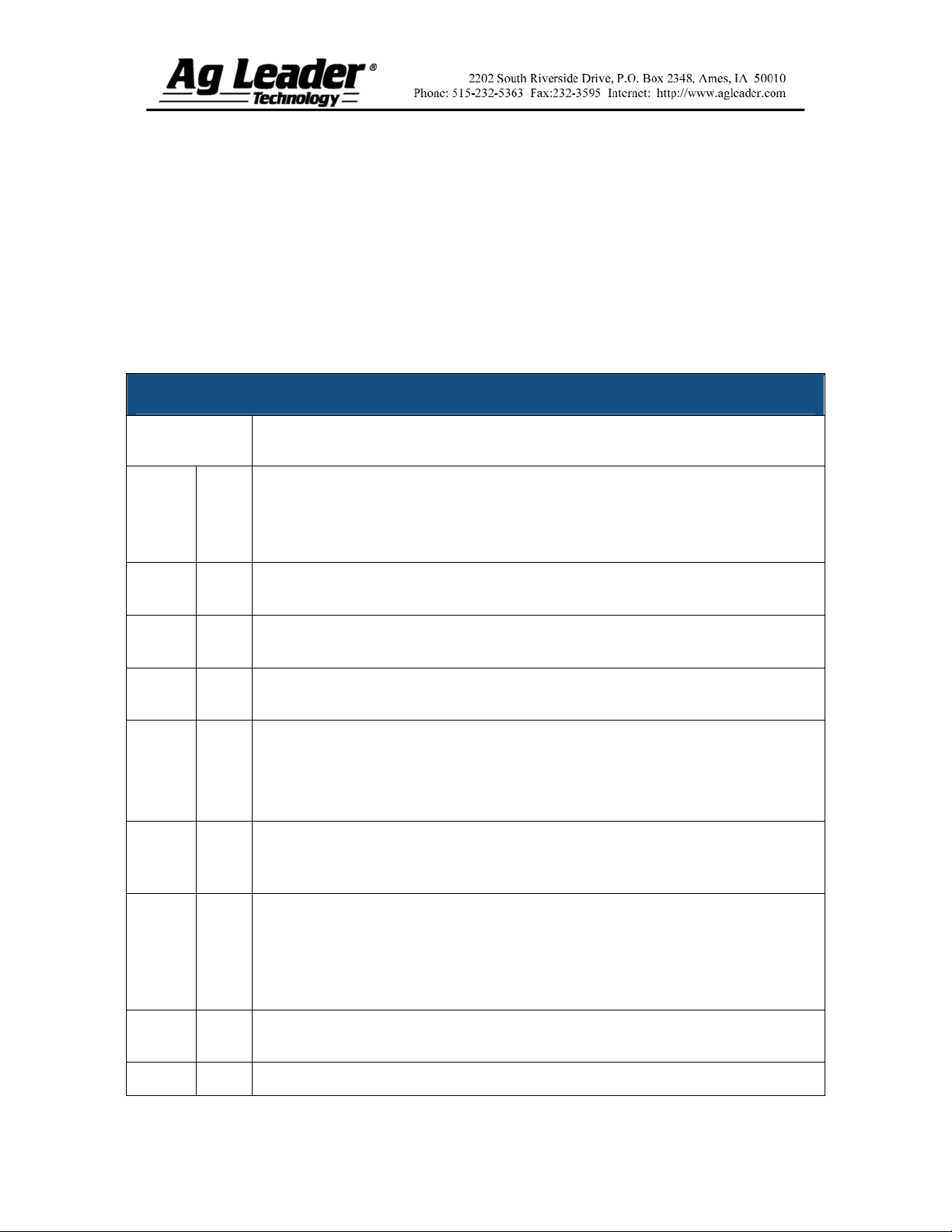

Section 1: Application Setup

Application Configuration

STEPS ACTION

1 a

1 b

1 c

Select the Equipment Configuration Type (Single- or Multi-Product). Press

Next.

Note: Multi-Product will be available only if this feature is unlocked in the

display.

Select a vehicle from the drop-down list, then press Next and proceed to Step

2a. If your vehicle is not listed, press the New button and proceed to Step 1d.

The Vehicle Setup Wizard appears. Choose the correct Vehicle Type from the

drop-down list and press Next.

1 d

1 e

1 f

2 a

2 b

2 c

Use the keyboard buttons to enter in the name of your vehicle’s make and

model. Press Next.

If you selected a Self-Propelled Sprayer, you must enter a full swath width,

number of boom sections and section widths. Press Next.

Note: This step is skipped if you are using a Tractor, ATV, or Pickup Truck.

Note: Individual boom widths must equal the total.

Enter a Vehicle Name. The vehicle’s default name is the Make and Model you

entered in step 1e. If necessary, edit that name by pressing the keyboard button

and typing the preferred name. Press Finish.

The Implement Setup Wizard appears. Select the desired implement from the

drop down list; then press Next and proceed to step 3a. If your implement is not

listed, press New and proceed to step 2b.

Note: This step does not apply if you have a Self-Propelled Sprayer. Instead,

proceed to step 3a on the following page.

Use the drop-down menu to select the correct Implement Attachment Method

and press Next.

Use the numeric keypad to enter the appropriate swath width and press Next.

Part No. 2002831-38 Rev. B

1

Page 2

Application Configuration (continued)

STEPS ACTION

2 d

2 e

2 f

2 g

3 a

3 b

Use the up and down arrow buttons to enter in the number of boom sections.

Press Next.

The section numbers and swath widths of the sections are displayed in the next

window. If necessary, adjust the boom widths by pressing on the section number

and use the numeric keypad to enter the actual measured width of the boom

section. Repeat the process for every boom section until each is correct. Press

Next when complete.

Note: Individual boom widths must equal the total.

Press the numeric keypad to enter the distance from hitch to application point.

When complete, press Next.

Caution: The distance settings must be measured accurately for the

AutoSwath™ feature to work properly.

Enter an implement name by using the keyboard button to type in the preferred

name. When complete, press Finish.

The Operating Configuration Wizard reappears, and you are asked to select an

Operating Mode. Use the drop-down menu to select Rate Logging/Control and

press Next.

Select the desired DirectCommand controller configuration from the list and

continue to step 4, or press New if the desired controller is not listed.

3 c

3 d

3 Notes

The Controller Setup Wizard appears. Select DirectCommand from the drop

down list. Under the Direct Type list, select Liquid Product Control. Press

Next.

Enter the Flow Meter Calibration Number by using the numeric keypad to set

the pulses per gallon. (This usually is tagged on the flow meter). Press Next.

For more information regarding Dickey-john Flow meters or Dickey-

john heat exchangers, see the Appendix for Dickey-john Flow Meter

Calibrations on page 19.)

Raven flow meter tags represent pulses per 10 gallons. Divide the

calibration number by 10 before entering into the display.

Tee Jet flow meter calibration numbers represent pulses per liter. To

convert the number, multiply the value found on the flow meter by 3.79

to find the pulses per gallon needed for the InSight display.

Mid-Tech flow meters sometimes have a cable with a module. The

calibration number found on this cable is in pulses/gal divided by 16.

The InSight display should bypass this module and plug directly into the

flow meter. If that is the case then multiply the calibration number by

16 before entering into the InSight display.

Part No. 2002831-38 Rev. B

2

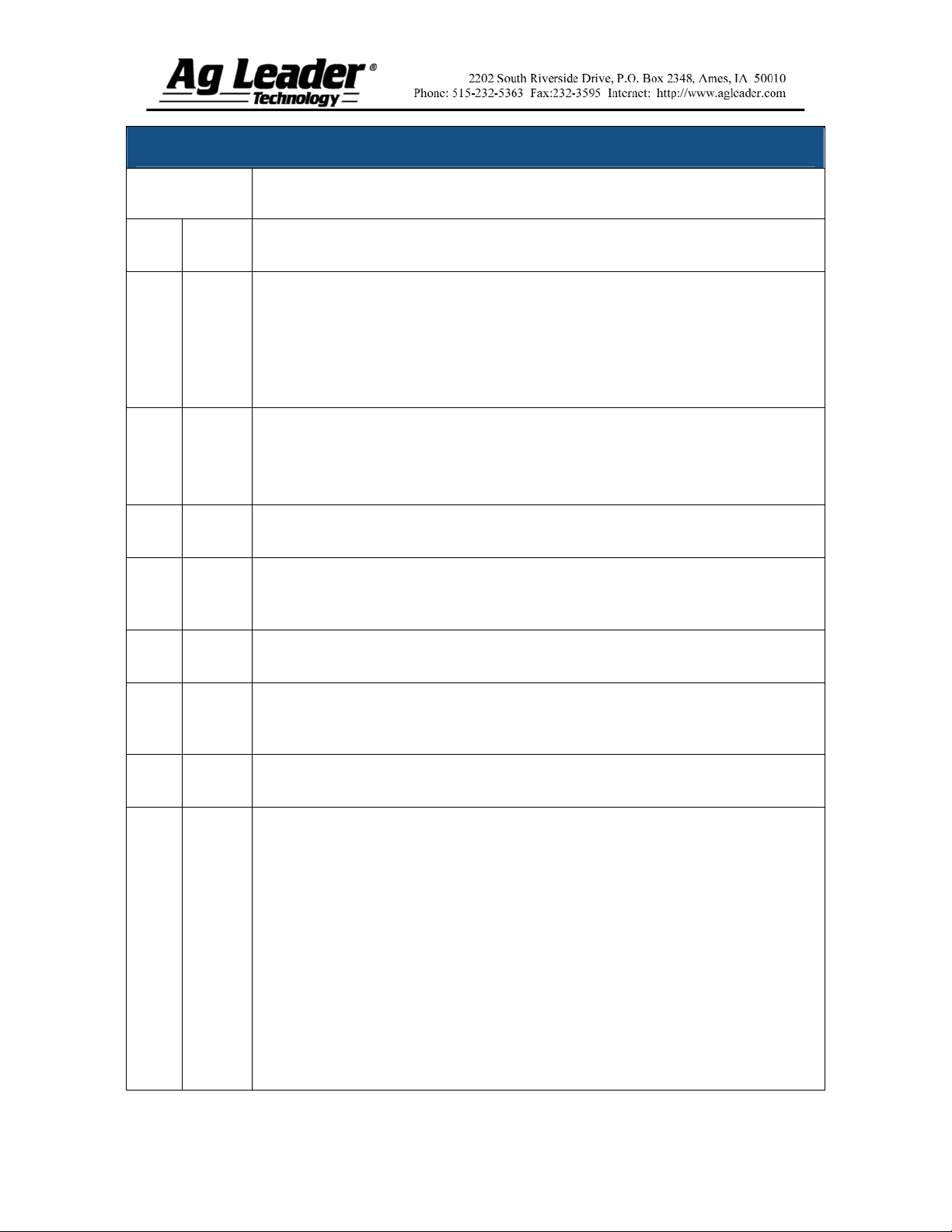

Page 3

Application Configuration (continued)

STEPS ACTION

3 e

3 f

3 g

3 h

4

5 a

5 b

Enter a controller name. A default name of DirectLiquid appears. If you would

like to change this name, press the keyboard button, enter a new name and press

Finish.

The Operating Configuration Wizard reappears. Select a container from the

drop-down list, or press the New button to create a new container.

The Container Setup Wizard appears. Enter a container capacity and units, then

press Next.

Enter a container name and location. Press Finish.

The Operating Configuration Wizard reappears. Select a primary and backup

Ground Speed Source. In most cases GPS is the primary speed source with

Radar serving as backup. If you are using a backup radar speed source it is

recommended that you calibrate it before the season begins. When finished,

press Next.

Note: Ground Speed calibrations are completed under the Calibrate Distance

button on the Application Setup Configuration window.

The Configuration name defaults to a name based on your previous

configuration settings. To edit the name, press the keyboard button and type a

new name.

Press Finish to complete the wizard and to save the configuration into the

InSight display.

Part No. 2002831-38 Rev. B

3

Page 4

Section 2: Configuration Settings

Additional settings are necessary for proper operation. To adjust these settings, first

highlight the desired configuration from the Configuration Window and press the

Configuration Settings button. When the Equipment Configuration window appears,

highlight the configuration in the list and press the Edit Settings button.

Note: Many of these settings have already been set through the Configuration Settings

Wizard during the Application setup process.

Configuration Settings

SETTING DESCRIPTION

Rate Outside

of Field

Minimum

Flow Setting

Rate Display

Smoothing

Controller

Time Delay

Set to Zero if you want rate outside field to be zero.

Set to Last Good if you want rate to be the last rate used at the time the

vehicle is detected outside the field. This is useful when experiencing

problems with the vehicle being falsely detected outside of the field

during the outside pass.

Set to Rx default if you want the product to be applied at the

prescription’s default rate setting.

This setting is used to maintain a consistent spray pattern. The display will not

allow flow to drop below the entered setting. Set to flow at the lowest operating

pressure for the selected spray tips with all sections on. When spraying with one

or more boom sections off, the system automatically reduces the minimum flow

setting according to the reduced spray width. To adjust this setting, select the

keyboard button and enter the desired numeric value.

When checked, this setting works to keep the displayed actual rate constant on

the run screen if the actual flow is within 10% of the target rate.

This compensates for any latency in the control system when changing between

different product flow rates during variable rate application. The typical setting

range for this is 0-1 seconds.

Speed Input Settings

After making changes to the Configuration Settings, check your ground speed source.

This setting is made in the wizard on step 4 on page 3, but may be adjusted if needed.

Note: You may use the manual speed option when GPS and radar are not available or for

testing of the application equipment. When this box is checkmarked then the InSight

display uses the entered speed to override any other speed source selections you have

made.

Part No. 2002831-38 Rev. B

4

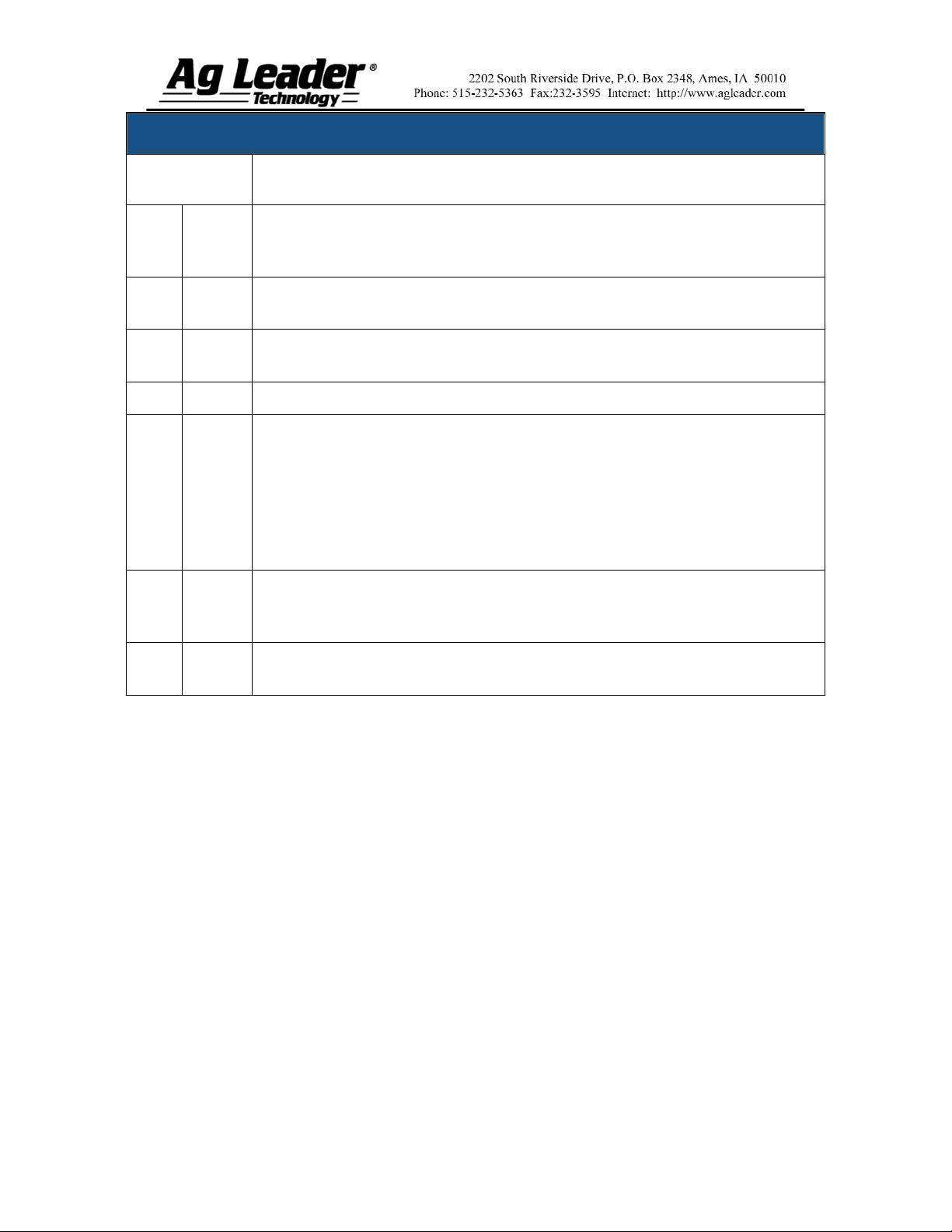

Page 5

Section 3: AutoSwath™ Control

Setting Defaults

AutoSwath™ Control Setting Defaults

STEPS ACTION

1 a

b

c

d

The default for the Turn-On Look Ahead is set to 1 second. If you need to adjust

the default, press the keyboard button to change this setting. Increasing this

setting causes the boom sections to turn on sooner. Press Accept when finished.

The default for the Turn-Off Look Ahead is set to 0 seconds. If you need to

adjust the default, press the keyboard button to change this setting. Increasing it

causes the boom section to turn off sooner. Press Accept when finished.

In the Outside Boundary Option box there is an option to have the booms shut

off outside of the field boundary or to keep swath section unchanged. This

setting should normally be checkmarked to ensure that the booms shut off

outside the boundary.

Press the Accept button to save your AutoSwath Settings.

Section 4: Auxiliary Input Settings

The Auxiliary Input Settings feature, (also called “Switch Mapping”) allows you to

specify which switch input controls the boom sections of your implement.

Note: If using an Ag Leader foot pedal, set the master switch to External 2.

Part No. 2002831-38 Rev. B

5

Page 6

Section 5: Vehicle Settings

To adjust Vehicle Settings, first press the Vehicle Tab. Follow the steps below.

Vehicle Settings

STEPS ACTION

1 a

1 b

1 c

1 d

1 e

1 f

2

Select the appropriate vehicle from the list and press the GPS Offsets button.

Select the Antenna tab.

Important: You must measure the distances entered in these steps for the

AutoSwath control to work accurately.

Press the keyboard button next to the Antenna Location from Rear Axle

keyboard button. Enter the distance from the GPS antenna to the Rear axle of the

vehicle.

Use the drop-down list to the right of the Antenna Location from Rear Axle

keyboard button to select the antenna location as either In Front or Behind the rear

axle of the vehicle.

Select the keyboard button next to the Antenna Location from Centerline

keyboard button. Enter the distance from the GPS antenna to the center of the

vehicle.

Use the drop-down list to the right of the Antenna Location from Centerline

keyboard button to adjust the offset as either Left or Right.

Select the keyboard button next to the Antenna Height from Ground keyboard

button. Enter the distance from the GPS antenna to the ground.

Note: To configure a self-propelled vehicle, proceed with step 2a. For all other

vehicles, skip to step 3a

2 a

2 b

2 c

2 d

Select the Mount tab.

Press the keyboard button next to the Dispensing Location from Rear Axle

setting. Use the numeric keyboard button to enter the distance from the rear axle

to the boom.

Use the drop-down list to the right of the Dispensing Location keyboard button to

select the dispensing location as either In Front or Behind the rear axle of the

vehicle.

When finished, press Exit and proceed to operation.

Part No. 2002831-38 Rev. B

6

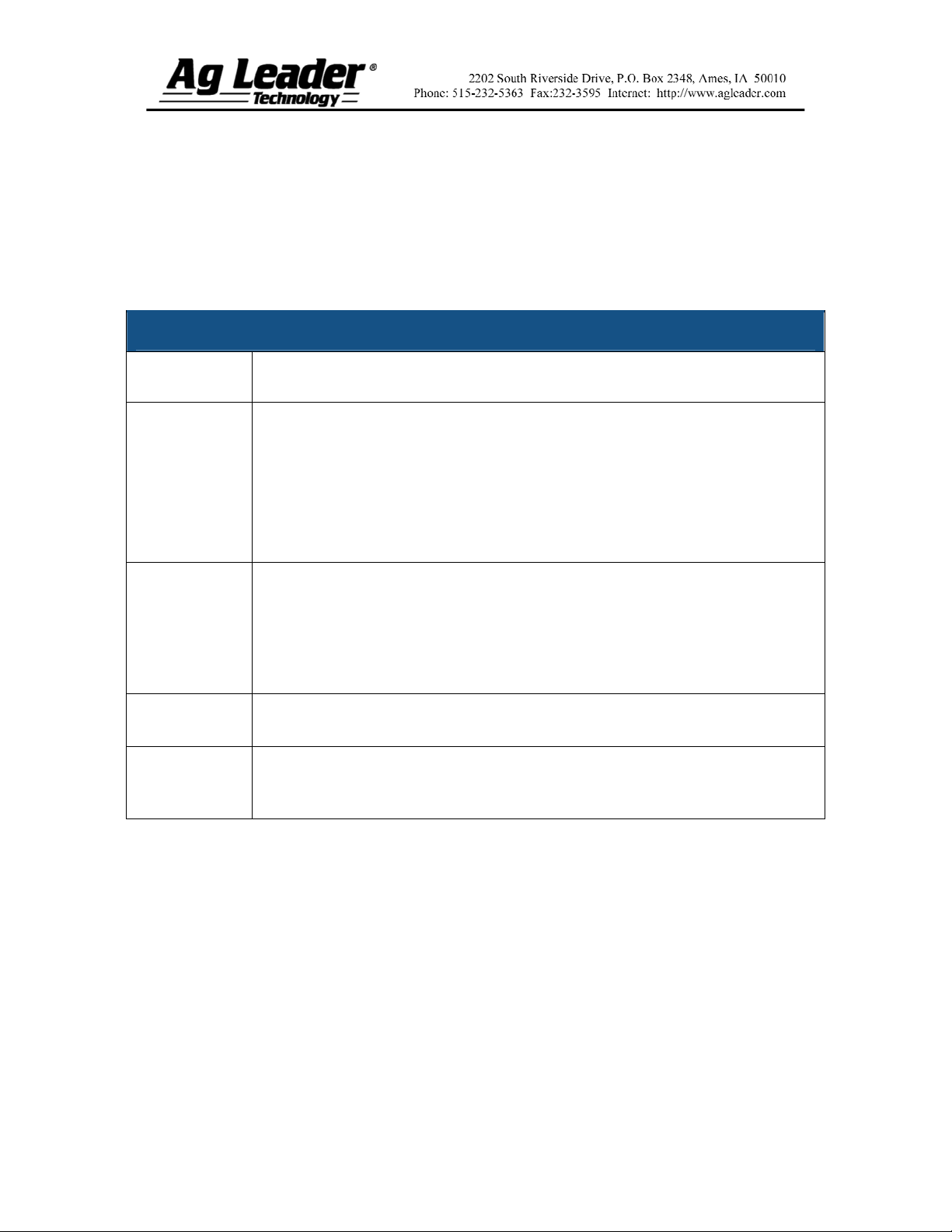

Page 7

Vehicle Settings (continued)

STEPS ACTION

3 a

3 b

3 c

3 d

3 e

3 f

Select the Hitch tab.

Select the keyboard button next to the Rear Draw Bar setting. Enter the

distance from the rear axle to the rear drawbar on the vehicle.

Select the keyboard button next to the Rear 3-Point Hitch setting. Enter the

distance from the rear axle to the rear 3-point hitch on the vehicle

Select the keyboard button next to the Front Draw Bar setting. Enter the

distance from the rear axle to the front drawbar on the vehicle.

Select the keyboard button next to the Front 3-Point Hitch setting. Enter the

distance from the rear axle to the front 3-point hitch on the vehicle.

When finished, press Exit and proceed to operation.

Section 6: Controller Settings

To adjust Controller Settings, first press the Controller Tab, then highlight the

DirectLiquid controller from the Controller List and press the Controller Settings

button. Follow the instructions below.

Controller Settings

STEPS ACTION

1 a

1 b

1 c

1 d

Verify that the Flow Meter Calibration Number is correct.

Press the Flow Control Delay button to enter a delay setting.

Note: This setting is a delay for the control valve to adjust after the flow is turned

on. Press Accept when finished.

Close flow control valve when rate off. Check this setting if you have a control

system with no section valves. If you have an anhydrous heat exchanger that uses

the flow control valve to shutoff flow (does not have separate on/off valve) check

mark this setting. Not checking this setting leaves the flow control valve in its last

position when the section valves are shut off.

Use the arrows on the right hand side of the Allowable Error setting to change the

setting. A 2% error setting is recommended. The InSight will stop adjusting the

control valve when the actual rate is within this percentage error of the target rate.

Part No. 2002831-38 Rev. B

7

Page 8

Controller Settings (continued)

STEPS ACTION

1 e

1 f

1 g

1 h

2

2 a

2 b

Use the drop-down menu to select the Control Valve Configuration that your

machine is using. For further description of these Control Valve Configuration

Options, see page 9.

Note: If you select a servo type configuration continue on to step 1f. If you select a

PWM type configuration then skip to step 2.

Use the arrow buttons on the right hand side of the Valve Response 1 to change to

the appropriate setting from your kit’s installation instructions.

Use the arrows on the right hand side of the Valve Response 2 to change to the

appropriate setting from your kit’s installation instructions.

Press the Response Threshold button to enter the response threshold needed for

your control valve. The appropriate values are included in your kit’s installation

instructions.

Note: The higher the threshold value the slower the rate will change. By contrast,

the lower the value, the faster the rate will change.

Note: Only use Step 2 if you selected PWM 12-Volt or PWM Ground for your

control valve configuration in Step 1e.

Select the PWM Frequency button to enter the appropriate frequency.

Select the PWM Gain button to enter the appropriate value found for your PWM

valve.

Note: A larger gain value will cause the system to make more aggressive rate

changes, a lower value will slow the rate response. Press Accept.

2 c

Select the Zero Flow Offset button to enter the appropriate setting shown in your

kit’s installation instructions. Press Accept.

Part No. 2002831-38 Rev. B

8

Page 9

Section 7: Liquid Control Valve

Configuration Options

Liquid Product Control Valve Configuration Options

Control Method Description

Rate control is achieved through actuating a butterfly or ball valve

In-line Servo

Bypass Servo

PWM 12 Volt

Pump Servo

found in the solution line that goes to the booms. When the valve

opens, the flow increases and when the valve closes, the flow

decreases.

Rate control is achieved through actuating a butterfly or ball valve

found in the return line to the solution tank. When the valve opens,

the flow decreases and when the valve closes the flow increases.

Rate control is achieved through speed changes to the solution pump.

The PWM 12 Volt setting is programmed to pulse the power to an

electric solenoid valve used to adjust the hydraulic flow to the

solution pump.

Rate control is achieved through speed changes to the solution pump.

The pump servo setting is programmed to control an electric motor

used to actuate a hydraulic valve to adjust the hydraulic flow to the

solution pump.

PWM Ground:

Calibrated Reflow

Rate control is achieved through speed changes to the solution pump.

The PWM ground setting is programmed to pulse the ground to an

electric solenoid vale used to adjust the hydraulic flow to the solution

pump.

Three-way boom valves are used to return product back to the tank in

the off state. The returned flow is calibrated with adjustment at each

valve. Calibration is required any time the nozzles are changed.

Part No. 2002831-38 Rev. B

9

Page 10

Section 8: Operation

To adjust Vehicle Settings, first press the Vehicle Tab, then follow the steps below.

Operation

STEPS ACTION

1

2

2 a

2 b

Press the Run button (located on the lower right hand side of the

display) to enter your main operating screen.

Press the Field button to select which grower and field you will be

logging to, the operating configuration being used and the product being

applied.

Select the appropriate Grower, Farm, Field, Operating Configuration,

Product and Instance from the lists. If your item is not listed, refer to the

appropriate section in this guide to set it up. Press Finish.

Note: The only reason to change the instance of operation is for the

second application in a field using the same product and configuration

as the first time.

If data has not been logged to the current field, a window to select the

Region will appear. The name may be edited by pressing the keyboard

button. Press Accept when finished.

Note: When applying fertilizers, you can select the controlling units

desired in this menu. For example, when applying Anhydrous Ammonia

controlling units can be set to pounds of NH

Nitrogen.

or actual pounds of

3

Part No. 2002831-38 Rev. B

10

Page 11

Section 9: Selecting a Target Rate

Target Rate Screen Item Descriptions

To open the Target Rate window, press the Target Rate button, (shown at left), which

appears at the bottom right-hand side of the Run screen. The Target Rate window will

appear for all target rates being applied. To return to the Run screen, press the Down

Chevron button.

Product

Application

Rate

Product

Target

Actual

Flow Rate

Rate

Control

The Product Application Rate settings, shown at the left of the Target Rate window, lists

the Product, Target Rate, Actual Rate, and Flow Rate of the product.

The Product lists the name of the product being applied.

The Target Rate is the amount of product that you wish to apply.

Note: In some conditions, the Target Rate may increment more quickly than the Actual

Rate.

The Flow Sensor returns the actual rate of the product that you are applying.

Note: In some conditions, the Actual Rate may increment slower than the Target Rate, or

its numeric values may vary before matching the Target Rate.

The Flow Rate is shown in units per minute.

The Rate Control buttons allow you to enter the specific rate applied.

The Manual Valve Control button allows operators to specify the position of the control

valve. Operators use this option to prime the system before application or clean out the

equipment at the end of the day.

The Rate 1 and Rate 2 settings represent preset application rates that allow operators to

quickly change between desired target rates for each individual product.

The Target Rate Increment button allows operators to specify the increase or decrease

amounts used when Rate 1 or Rate 2 is selected. Use the numeric keypad to enter the

desired increment.

The Increase and Decrease buttons allow Product Application Rate to be changed

Part No. 2002831-38 Rev. B

according to the Target Rate Increment. In using manual valve control, the increase and

decrease buttons allow the position of the control valve to be defined by the operator.

11

Page 12

Section 10: Control Settings

Descriptions

Liquid Servo Settings Description

Setting

Name

Valve

Response 1

Valve

Response 2

Allowable

Error

Default

Setting

100%

24%

2%

Setting Description Setting Characteristics

Determines the speed of

the servo valve when

product control error

exceeds the Response

Threshold setting.

Determines the speed of

the servo valve when

product control error is

less than the Response

Threshold setting.

Determines the percent of

error that is allowed prior

to the product control

system making any flow

rate corrections.

Decreasing the value will cause the servo

valve to run slower.

Decreasing the value will cause the servo

valve to run slower.

2%-3% is the normal dead band setting range.

-Too low of a setting value can cause the

product control system to continually hunt for

the target application rate.

-Too high of a setting will cause excessive

product application error.

Response

Threshold

Part No. 2002831-38 Rev. B

3

Determines where the

control system switches

between using Valve

Response 1 or Valve

Response 2 speed setting.

Leaving all other valve control settings at the

default value and making a small adjustment

to this setting is usually all that is required to

fine-tune system performance.

-Decreasing this value will have the overall

effect of speeding up servo valve response.

-Increasing this value will have the overall

effect of slowing servo valve response.

12

Page 13

PWM Valve Control Settings Description

Setting Name Default Value Description

The frequency that the PWM control valve is pulsed

PWM Frequency 100

Gain 800

Zero Offset 30

Allowable Error 2%

at. Typical settings range from 100-125.

Note: See PWM valve manufacturer information for

recommended settings.

This setting determines how aggressively the control

valve responds when making rate change

adjustments. The higher the value the more

aggressive the system response is.

This setting represents the maximum duty cycle that

is sent to the control valve without producing any

hydraulic flow from the PWM valve. Using too high

of a Zero Offset value can cause the product control

system to not properly shut off.

Note: See the PWM valve manufacturer’s

information for recommended settings.

2%-3% is the normal dead band setting range.

Too low of a setting value can cause the

product control system to continually hunt

for the target application rate.

Too high of a setting will cause excessive

product application error.

Part No. 2002831-38 Rev. B

13

Page 14

Section 11: Standard DirectCommand

Setup

Part No. 2002831-38 Rev. B

14

Page 15

Section 12: Setup Menu

Part No. 2002831-38 Rev. B

15

Page 16

Section 13: DirectCommand Menu Tree

Part No. 2002831-38 Rev. B

16

Page 17

Section 14: Run Screen Functionality

Part No. 2002831-38 Rev. B

17

Page 18

Section 15: Key Settings/

Functionality

Application Rate Control Tab

The Application Tab shown at

left is a typical configuration

for a Liquid Control module.

The pressure indicators include

information on the Main

Pressure, Agitation Pressure,

and Auxiliary Pressure.

Press the AutoSwath button to

enable the AutoSwath feature.

The boom indicators show the

active and inactive sections

used on a liquid

DirectCommand configuration.

Displays the current target

application rate. Press the up

arrow button to go to the

Target Rate Application

window.

The Master Switch Indicator

shows if the master switch is

on (green) or off (red). The

master switch is shown in the

F1 position on the Auxiliary

Input Settings window.

Part No. 2002831-38 Rev. B

18

Page 19

Appendix: Dickey-john Flow Meter Calibrations

Note: The flow sensor constant is stamped on the Dickey-john flow meter. Refer to the

Dickey-john manual for information on the density setting.

Flow meter calibration for Anhydrous Ammonia (NH3)

Use the following formula for flow meter calibration for Dickey-john reading pounds of

anhydrous ammonia.

Flow sensor constant (pulses/in3) x 1728 (in3/ft3) x 5.11 (lbs. of anhydrous/gal.)

Density (lbs. of anhydrous/ft.3)

Flow meter calibration for nitrogen (N)

Use the following formula for flow meter calibration for Dickey-john reading pounds of

Nitrogen.

Flow sensor constant (pulses/in3) x 1728 (in3/ft3) x 4.22 (lbs. of Nitrogen/gal.)

Density (lbs. of Nitrogen/ft.3)

Part No. 2002831-38 Rev. B

19

Loading...

Loading...