Page 1

InSight™ Firmware Version 6.0

Cotton Harvest Insert

573

PN: 2002881 Rev.F

Page 2

InSight™ User Guide - Cotton Harvest Insert

ABOUT THIS INSERT

This Cotton Harvest Insert is designed to be included in the back of your current InSight User Manual,

immediately behind the Document Change Request Form.

Throughout this insert a number of cross-references are included which refer to other chapters of the

InSight Manual. To ensure that these cross-references accurately cite correct page numbers, please

ensure that the revision of this insert (the alphabet letter found at the bottom right-hand corner of the

page) matches the current revision of your InSight User Manual.

As with other chapters in the InSight User Manual, an index is provided at the back of this insert that

refers to terms found in this specific chapter.

574

PN: 2002881 Rev.F

Page 3

InSight™ User Guide - Cotton Harvest Insert

INSTALLATION

TYPICAL SYSTEM WIRING DIAGRAM

Yield monitor installation kits are specific to each supported picker model. Installation specific

instructions and diagrams are packaged with each kit.

575

PN: 2002881 Rev.F

Page 4

InSight™ User Guide - Cotton Harvest Insert

COTTON SETUP

COTTON HARVEST MENU

PN: 2002881 Rev.F

576

Page 5

InSight™ Firmware Version 6.0

COTTON SETUP TABS

CONFIGURATION

The Cotton Harvest setup pages contain all the necessary settings to configure the system for logging,

mapping, and rate control for planting operations. The combination of Configuration, Combine, Header,

Crop and Calibration are referred to as a Configuration within the InSight system.

Cotton Harvest Setup

Tab

Configuration

Picker

Crop

Calibration

Cotton Harvest configurations

Description

The Configuration Tab is where you can add and edit operating

configurations. For more information, see “Configuration” on

page 577.

The Picker Tab is where you can set up and configure additional

pickers. For more information, see “Picker Tab Buttons” on

page 584.

The Crop Tab is where you can add and edit crops. For more

information, see “Crop Tab Buttons” on page 593.

The Calibration Tab is where you can perform calibrations. For

more information, see “Calibration Tab” on page 599.

PN: 2002881 Rev.F

577

Page 6

InSight™ User Guide - Cotton Harvest Insert

CONFIGURATION TAB BUTTONS

The Configuration Tab is where cotton harvest configurations are made and displayed. Press the Setup

button and then the Cotton Harvest button to reach this screen.

• To see a Cotton Harvest Configuration Menu, see “Cotton Harvest Menu” on page 576.

• For required setup before this configuration can be used, see “Setup Tips” on page 17.

Cotton Configuration Tab

Button Description

Press to add a new cotton configuration. An on-screen wizard

will walk you through the setup process in a step-by-step

manner. New pickers can be created during the setup process.

For more detailed information, see “Adding A New

Configuration” on page 579.

Press to edit the name of a selected configuration. The onscreen keyboard will be displayed to complete the desired text

edits.

Press to remove a configuration. The picker will not be

deleted.

When deleting a configuration all regions and

harvest data logged with that configuration will be deleted!

Press to display and edit settings specific to a vehicle, picker

and controller combination. For more information, see

“Configuration Settings” on page 583.

578

PN: 2002881 Rev.F

Page 7

InSight™ Firmware Version 6.0

ADDING A NEW CONFIGURATION

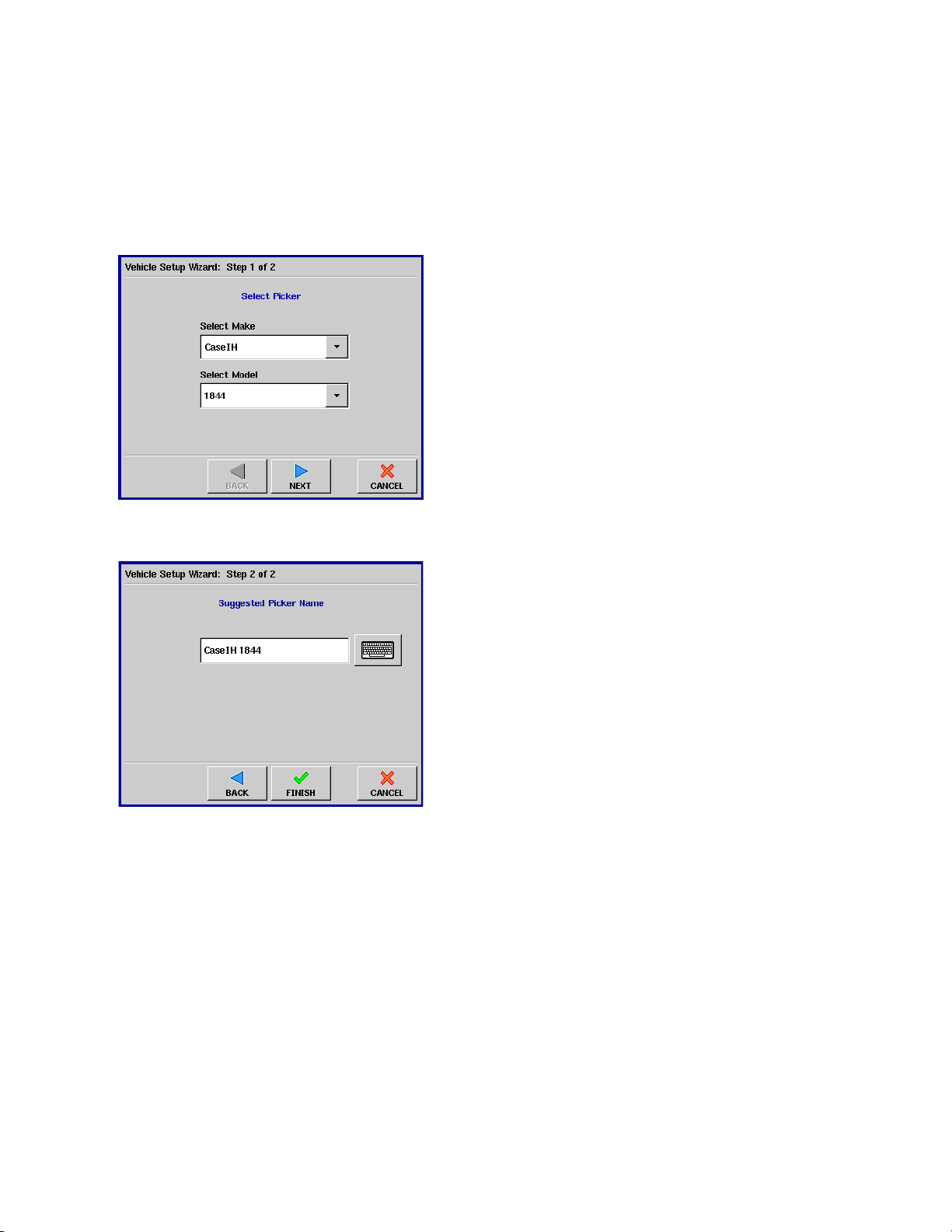

To add a new configuration press the Add button. The Configuration Setup Wizard appears, as shown

below.

Step 1: Select picker from Configuration

Setup Wizard

Press New to add a new picker or select an existing one from

the list. For detailed information, see “Adding A New Picker”

on page 586.

Press Next to continue.

Step 2: Select picker from Vehicle Setup

Wizard

Step 3: Enter suggested picker name

If you pressed New, the Vehicle Setup Wizard appears, as

shown at left. A list of all cotton pickers manufactured by

John Deere and Case IH which are supported by the InSight

monitor is provided in the Select Make and Select Model

drop-down menus. Select your make and model, then press

Next.

Use the keyboard button to edit the name of the picker.

Press Finish to continue, and you will return to the next

window in the Configuration Setup Wizard.

PN: 2002881 Rev.F

579

Page 8

InSight™ User Guide - Cotton Harvest Insert

ADDING A NEW CONFIGURATION (CONTINUED)

Auxiliary Step: Select Head Type (John

Deere vehicles only)

If you have entered in a John Deere make and model, you

will see an auxiliary step of the Configuration Setup Wizard.

Select either the inline or convention header type.

• The Inline head type configures the InSight monitor to

receive data from one sensor per row. Most current John

Deere pickers use this header type.

• The Conventional head type configures the InSight

monitor to receive data from two sensors per row. Some

older John Deere pickers use this head type.

After making your selection, press Next to continue.

Step 4: Enter Number of Rows and Full

Swath

Use the up and down arrows to enter the number of rows;

then use the numeric keypad to enter the full swath width

of the header. Press Next to continue.

580

PN: 2002881 Rev.F

Page 9

InSight™ Firmware Version 6.0

ADDING A NEW CONFIGURATION (CONTINUED)

Step 5: Enter header offset

If the header of your vehicle is mounted asymmetrically to

the vehicle’s center, you must enter in the offset distance.

At the Header Offset window shown at bottom left, you can

compensate for the distance between the center of the

vehicle and the center of the header’s swath. Use the

numeric keypad to enter this distance, and then use the

drop-down menu to enter the direction.

Press Next to continue.

Even after you have entered in the header offset

distance number here, you can still edit this number later.

For more information, see “Configuration Settings” on

page 583.

PN: 2002881 Rev.F

581

Page 10

InSight™ User Guide - Cotton Harvest Insert

ADDING A NEW CONFIGURATION (CONTINUED)

Step 6: Enter Sensor Configuration

The Sensor Configuration Window appears, showing the

rows being harvested. Press the checkboxes that correspond

to your sensor configuration. In the example at left, the

operator has selected four sensors on four rows.

In order to log data on the Run screen, you must

specify the correct sensor configuration. Otherwise, when

you attempt to set up an operating configuration at the

Run screen’s Field Operation Wizard, you will see an error

message stating that “The cotton flow sensor

configuration does not match the active picker.”

Step 7: Enter Ground Speed Source

Step 8: Enter Suggested Name for

Configuration

Select the ground speed source. If you will be using GPS as

the primary you will need to select a secondary source. Press

Next when finished.

Use the default name or enter in a new name for the

configuration.

Press Finish to complete the configuration process.

582

PN: 2002881 Rev.F

Page 11

InSight™ Firmware Version 6.0

CONFIGURATION SETTINGS

To access the Configuration Settings window, first highlight a configuration in the list and then press the

Configuration Settings button.

Configuration Settings window

Setting Description

The Header Offset shows the distance between the

centerline of the vehicle and the center of the header’s

swath. To change these settings, use the numeric keypad to

enter this distance, then use the drop-down menu to enter

the direction.

The Ground Speed Sensor area shows the primary and

secondary ground speed source.

The Active Rows area shows which rows are equipped with

sensors. If you wish to change these settings, press the

checkboxes that correspond to the number of sensors in your

configuration. In the example at left, the operator has

selected four sensors on four rows.

In order to log data on the Run screen, you must

specify the correct sensor configuration. Otherwise, when

you attempt to set up an operating configuration at the

Run screen’s Field Operation Wizard, you will see an error

message stating that “The cotton flow sensor

configuration does not match the active picker.”

PN: 2002881 Rev.F

583

Page 12

InSight™ User Guide - Cotton Harvest Insert

PICKER CONFIGURATION

PICKER TAB BUTTONS

The Picker Tab provides functionality for setting up and configuring additional pickers. This tab displays a

Picker List, which will show any pickers that have already been created. The Picker Tab also includes

functionality for Header Sensor and Distance calibrations, which must be performed prior to the start of

the cotton harvest season. To see a Cotton Configuration menu that includes information on the Picker

Tab, see “Cotton Harvest Menu” on page 576.

Picker Setup Tab

Button Description

The Add button allows you to add a new picker. A wizard will walk you

through setting up the picker. For detailed information, see “Adding A New

Picker” on page 586.

The Edit Name button allows you to edit the name of a picker in the list. To

edit, highlight the name of a picker in the list and then press this button. Use

the on-screen keyboard to edit the name.

The Remove button allows you to remove a picker. The configuration and any

regions and harvest data logged with it will be deleted.

When deleting a picker, any configurations using it will be

deleted. All regions and cotton harvest data logged with the configuration will

also be deleted!

584

The Picker Settings button allows you to view fan speed sensor settings. For

more information, see “Picker Settings” on page 587.

PN: 2002881 Rev.F

Page 13

PICKER TAB BUTTONS (CONTINUED)

Button Description

The Sensor Settings button opens the Sensor Settings window, where you can

edit the Low Signal Alarm and Zero Flow Threshold. For more information, see

“Sensor Settings” on page 588.

The GPS Offsets button allows you to specify the location of the GPS antenna

in relation to the vehicle. A wizard will walk you through these edits. For more

information, see “GPS Offsets” on page 589.

The Calibrate Distance button calibrates the radar, track or wheel speed

sensor. For more information, see “Calibrate Distance” on page 590.

InSight™ Firmware Version 6.0

The Calibrate Header Sensor button launches the Header Sensor Calibration

Wizard, which will walk you through calibrating the header sensor that turns

area logging on and off. For more information, see “Calibrating The Header

Sensor” on page 592.

PN: 2002881 Rev.F

585

Page 14

InSight™ User Guide - Cotton Harvest Insert

ADDING A NEW PICKER

To start the process of adding a new picker press the Add button. The Vehicle Setup Wizard appears, as

shown below.

Step1: Select Make and Model

Select the correct picker make and model from

the list boxes.

Press Next to continue.

Step 2: Edit Name

Use the keyboard button to edit the name of

the picker.

Press FINISH to complete the setup process.

586

PN: 2002881 Rev.F

Page 15

InSight™ Firmware Version 6.0

PICKER SETTINGS

The Cotton Picker Settings window contains fan speed sensor settings. To access this window, press the

Picker Settings button on the Picker Tab.

Cotton Picker Settings

Fan Speed Sensor Setting Description

The Use Fan Speed checkbox specifies that the fan speed

must be running at a minimum of 2,500 RPM before data

logging will begin. This box is checked by default.

This setting can be unchecked if you are having

problems with the fan speed sensor. When unchecked,

the InSight monitor will not require a minimum fan

speed for logging data. Instead, it will log data anytime

the Master Button is on Auto.

The pulses per revolution (pls/rev) setting is the number of

pulses generated for one revolution of the fan, and is preset for the factory-installed sensor on your machine. If you

replace a sensor, or believe the displayed fan speed to be

incorrect, you should verify this setting; and if necessary,

you can edit this number.

PN: 2002881 Rev.F

587

Page 16

InSight™ User Guide - Cotton Harvest Insert

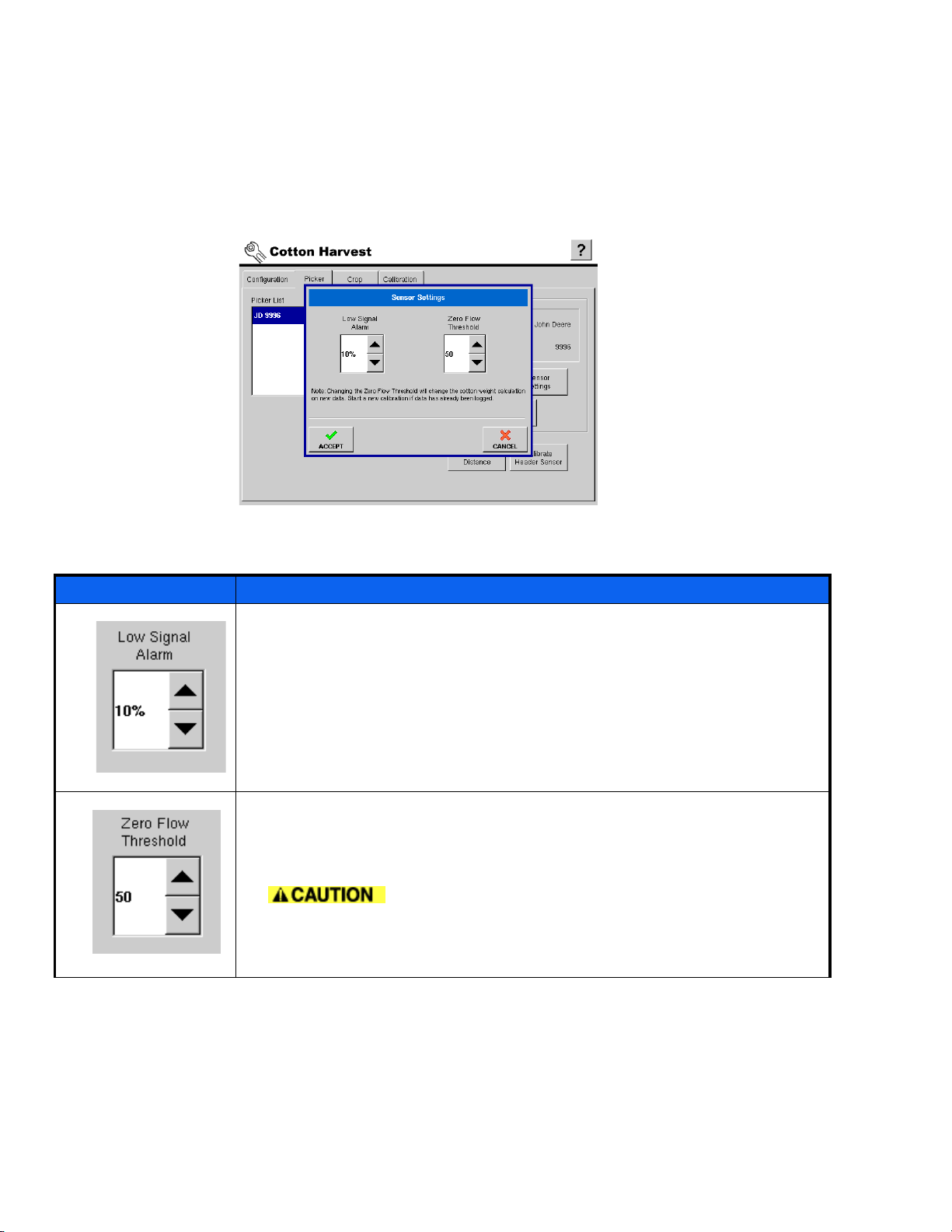

SENSOR SETTINGS

The Sensor Settings window contains values of settings that affect the operation of the picker’s cotton

flow sensors. You can access this window by pressing the Sensor Settings button on the Picker Tab.

Sensor Settings Window

Setting Description

The Low Signal Alarm box contains a percentage value that sets the threshold

for the sensors’ low signal strength alarm. Increasing this amount will make

the alarm threshold more sensitive; while decreasing it will make the alarm

threshold less sensitive. A setting of 0 will disable the low signal strength

alarm.

The Zero Flow Threshold box is a setting that compensates for the vibration of

the sensors inside the picker’s chutes.

Adjusting this value will change the current calibration.

The current calibration should be retired before changing this value. After

changing this value, you will need to perform a new calibration.

588

PN: 2002881 Rev.F

Page 17

InSight™ Firmware Version 6.0

GPS OFFSETS

After you complete the initial process of setting up a Picker, you must configure advanced GPS Offsets.

The GPS Offsets define where machine rear axle, hitch, and product placement is in relation to the GPS

antenna. These settings are used by mapping and product control. To do this, press the GPS Offsets

button, and the GPS Offsets window appears, as shown below.

Antenna Offsets

The Antenna Tab contains three different

settings. Accuracy when measuring for a specific

setting is essential to ensure proper machine

performance.

• Measure and enter the horizontal distance

from the rear axle to the position of the GPS

antenna. Select In Front or Behind from the list

box to indicate the position of the antenna in

relation to the rear axle.

• Measure and enter the horizontal distance

from the centerline of the vehicle to the position

of the GPS antenna. Select Left or Right to

indicate the position from the vehicle centerline.

• Measure and enter the vertical height of the

antenna above the ground.

Head Offset

The Head Tab allows you to enter in the distance

from the head attachment point to the rear axle.

Use the numeric keypad to enter in the distance

to the axle.

PN: 2002881 Rev.F

589

Page 18

InSight™ User Guide - Cotton Harvest Insert

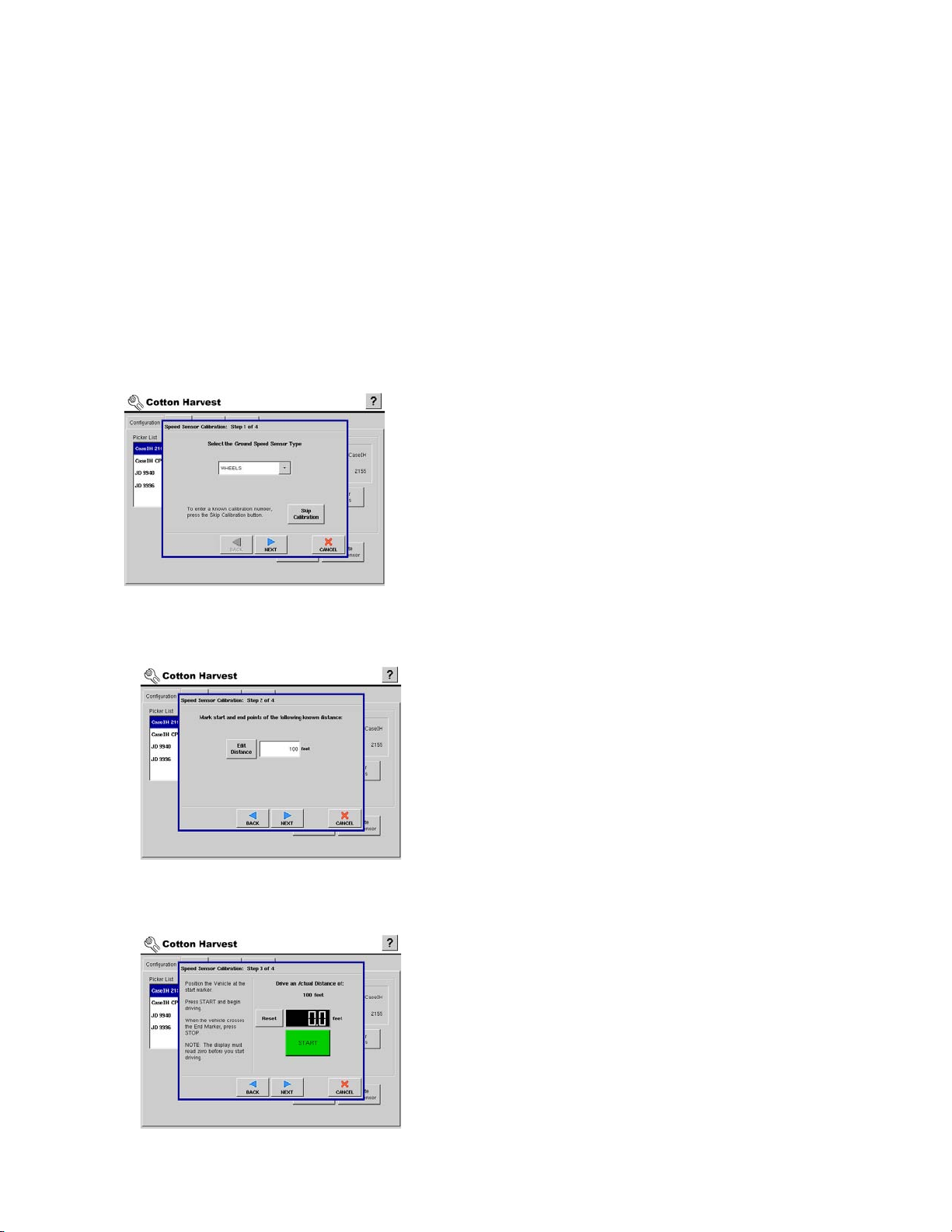

CALIBRATE DISTANCE

The following procedure describes a speed sensor calibration. Before beginning, keep in mind these two

tips:

• Before beginning the speed sensor calibration, you should mark a measured distance to drive. The

default distance currently in the InSight monitor (and the recommended distance) is 100 feet, or 50

meters if using metric measurements.

• For the most accurate results, this calibration should be performed in field conditions (not on gravel or

paved roads)

To begin, first select a Picker from the list and press the Calibrate Distance button to calibrate the radar,

track or wheel speed sensor.

Step 1: Select Speed Input

Select the sensor type to calibrate and press

NEXT to continue.

Step 2: Calibration Distance

Step 3: Start Driving Course

The system defaults to 100 feet (or, if using

metric, 50 meters) distance for calibration.

Press Edit Distance to change if needed. This

value must match the actual distance of the

course driven for calibration.

Press NEXT to continue.

Follow the on-screen directions and press START

to begin the calibration process.

590

PN: 2002881 Rev.F

Page 19

CALIBRATE DISTANCE (CONTINUED)

Step 4: Course Completed

Drive vehicle over the measured course and

press STOP.

Press NEXT to continue to final step.

Step 5: Calibration Completed

Press FINISH to complete calibration and store

the calculated value.

InSight™ Firmware Version 6.0

It is recommended that you run the

distance calibration twice to confirm an

accurate calibration.

Calibration settings can be manually

adjusted if desired by pressing Enter CAL

Number and making small changes to the

setting.

PN: 2002881 Rev.F

591

Page 20

InSight™ User Guide - Cotton Harvest Insert

CALIBRATING THE HEADER SENSOR

Prior to logging cotton data, you must calibrate the header sensor. Crops must be set up within the

system to proceed with the calibration routine. Select the correct header from the list and press the

Calibrate Header Sensor button, located on the Picker Tab.

Step 1: Read Instructions

Read the header sensor calibration instructions fully

before proceeding.

Press Next to start the calibration process.

Step 2: Set Max and Min

Step 3: Set Stop Height

Maximum and minimum header height settings.

1. Raise the header all of the way up and press Set Max.

2. Lower the header all of the way down and press Set

Min.

This determines the full operating range of the header.

Press Next to continue.

Raise or lower the header to the height where you

would like to have the area logging turn on and off.

Press Set Height.

The position relating to the Stop Height will be

represented as a percentage. (17% in the example to

the left).

Move the header above and below the Stop Height.

When below the Stop Height the dialog will indicate

Down, when above the Stop Height the dialog will

indicate UP.

To clear Min, Max, and Stop Height, press Reset.

592

If Reset is pressed, the sensor will

have to be calibrated!

PN: 2002881 Rev.F

Page 21

InSight™ Firmware Version 6.0

SETTING UP CROPS

CROP TAB BUTTONS

Crops and crop varieties are added and edited on the Crop Tab. The crop list shows all crops and varieties

that have been created and are available for use.

To see a Cotton Harvest Configuration Menu that includes detailed information on the Crop Tab, see

“Cotton Harvest Menu” on page 576.

Crops Setup Tab

Button Description

The Add Crop button allows you to add a new crop. A wizard will

walk you through setting up the crop. For detailed information

see “Adding A New Crop” on page 595.

Press the Add Variety button to add a new variety and associate

that variety with a crop type. For detailed information see “Adding

Additional New Varieties” on page 597.

The Edit Name button allows you to edit the name of a crop or

variety in the list. To edit, highlight the name of a crop or variety

in the list and then press this button. Use the on screen keyboard

to edit the name.

Press the Remove button to remove a crop or variety.

PN: 2002881 Rev.F

When a crop or variety is removed, all regions

and the logged harvest data relating to that crop or variety will

be deleted!

593

Page 22

InSight™ User Guide - Cotton Harvest Insert

CROP TAB BUTTONS (CONTINUED)

Button Description

The Crop Settings box displays the Lint Percentage and Bale Size

for the selected crop.

The Edit button allows you to change the values from the default.

To edit, highlight a crop in the crops list and press Edit.

Press the Edit Legend button to change the default legend for the

selected crop type. The Legend Settings that are made here will

affect all regions of that crop type. For additional information,

see “Edit Legend” on page 598 .

594

PN: 2002881 Rev.F

Page 23

InSight™ Firmware Version 6.0

ADDING A NEW CROP

To add a new crop press the Add Crop button. The Cotton Crop Wizard appears, as shown below.

Step 1: Edit Crop Name (optional)

The default name of Cotton appears in the

Suggested Name box. If necessary, use the

keyboard button to edit the name.

Press Next to continue.

Step 2: Add Varieties

Press Add to set up seed varieties for the crop

type.

Any seed varieties set up in the planting

setup will already be present in the list.

Press Finish. The Select Units window will appear

next.

PN: 2002881 Rev.F

595

Page 24

InSight™ User Guide - Cotton Harvest Insert

ADDING A NEW CROP (CONTINUED)

Step 3: Select Units

Step 4: Enter Variety Details

Select the units for the crop.

Press Next to continue.

Use the keyboard buttons to enter the

manufacturer and the variety or hybrid name.

The manufacturer name is optional.

Press Finish to complete setting up the seed

variety.

596

PN: 2002881 Rev.F

Page 25

InSight™ Firmware Version 6.0

ADDING ADDITIONAL NEW VARIETIES

To enter additional varieties, go to the Crop Tab and press the Add Variety button. The Variety Setup

Wizard appears, as shown below.

Step 1: Select A Crop

Select the planted units.

Press Next to continue.

Step 2: Enter Variety Details

Use the keyboard buttons to enter the

manufacturer and the variety name.

The manufacturer name is optional.

Press Finish to complete setting up the seed

variety.

PN: 2002881 Rev.F

597

Page 26

InSight™ User Guide - Cotton Harvest Insert

EDIT LEGEND

To access the Legend Settings window press the Edit Legend button.

Item Description

Press to edit average crop yield value.

Press to edit the legend range spacing value.

Selects the color scheme to use for the yield legend.

Press to reset legend to the system default.

598

Selects the number of ranges to display in the legend.

PN: 2002881 Rev.F

Page 27

InSight™ Firmware Version 6.0

COTTON CALIBRATION

CALIBRATION TAB

The Calibration Tab is where weight calibrations and Field Area calibrations are done. A weight

calibration must be completed after harvest has started. (For Header Sensor and Distance calibrations, see

“Picker Configuration” on page 584).

For a Cotton Configuration Menu that includes detailed information on the Calibration Tab, see “Cotton

Harvest Menu” on page 576.

Calibration Setup Tab

Settings Description

The Crop Type box lists the crop you are about to calibrate.

The Calibration drop-down menu lists all of the previous

calibrations that you have performed, and the date that these

calibrations were created.

The Field Area Calibration button will adjust the total area for

a field. For more information on the Field Area Calibration

button, see “Field Area Calibration” on page 601.

The Enter Weight button allows you to enter the measured

weight for a region. For more information, see “Entering Actual

Load Weights” on page 603.

PN: 2002881 Rev.F

599

Page 28

InSight™ User Guide - Cotton Harvest Insert

CALIBRATION TAB (CONTINUED)

Settings Description

The Show Calibration button allows you to view or manually

change the calibration numbers. To view the updated

calibration numbers, press the Show Calibration button after

you have performed a weight calibration. For more

information, see “Show Calibration” on page 602 and also

“Adding a New Calibration” on page 605.

The Move Regions button allows you to move a region from

one calibration to another. For more information, see “Moving

Regions Between Calibrations” on page 608.

After you have checked your calibration regions and entered

actual weights, you can perform the weight calibration. Check

the loads you wish to use in the calibration and then press the

Perform Calibration button. For more information, see

“Perform Calibration” on page 604.

600

PN: 2002881 Rev.F

Page 29

InSight™ Firmware Version 6.0

FIELD AREA CALIBRATION

To access the Area Calibration window, press the Field Area Calibration button. From here, you can

modify the field area that you have logged. To perform a Field Area Calibration, select the field that you

wish to calibrate and then press the numeric keypad button. Enter in the correct area and press Accept.

Area Calibration: Cotton window

Settings Description

The Field drop-down list shows all fields available for an area

calibration.

Inside the Area Adjustment section of the window, the Actual

Area numeric keypad allows you to enter a known field area,

shown in acres.

The Area Calibration section of the window shows the

percentage of measured area as a part of the user-entered

area. This percentage value will change if you change the Area

Adjustment.

PN: 2002881 Rev.F

601

Page 30

InSight™ User Guide - Cotton Harvest Insert

SHOW CALIBRATION

To view your current calibration settings, press the Show Calibration button. This displays the Weight

Calibration window, as shown below. From here, you can edit your current calibration number or create

a new calibration. For more information on weight calibrations, see “Entering Actual Load Weights” on

page 603.

Weight Calibration window

Settings Description

The Edit Calibration numeric keypad allows you to edit the

current calibration value you are using.

This calibration number should not be

changed if it has been providing accurate results. Changing it

will affect your previously-logged data.

The New Cal button retires the current calibration and starts a

new calibration. The New Cal button will not appear if you are

currently displaying a calibration that has been retired.

For more information on new calibrations, see “Adding a New

Calibration” on page 605.

By retiring your old calibration, you will not be able to

return to your old calibration, or add data to it. However, you

will still be able to move regions into previously-used

calibrations.

602

PN: 2002881 Rev.F

Page 31

ENTERING ACTUAL LOAD WEIGHTS

Step 1: Flag Region as Calibration Load

(if no data is already logged)

Step 2: Harvest a calibration weight load

Step 3: Press Enter Weight button

InSight™ Firmware Version 6.0

In order to create a weight calibration, you must

first have logged data to use for this calibration.

Thus, while you are at the Run screen and

logging data, press the Region button so that

the Region Selection window appears, as shown

at left. Check the checkbox titled Flag Region as

a Calibration Load.

You can flag a region as a calibration

load either before or after you have logged

data in the field.

Press Accept.

Beginning with an empty basket, harvest a

quantity of cotton that can be weighed later to

obtain an accurate weight. This may be a trailer,

basket or module.

When the calibration load has been collected,

switch to a new region to prevent adding

additional weight to a cal load.

Step 4: Perform Calibration

Return to the Calibration Tab in Cotton Harvest.

Press the Enter Weight button. The Enter

Calibration Weight window appears, as shown

at left. The Actual Weight appears in the

calculator portion at the right-hand side of the

window.

The monitor calibrates itself on the basis

of actual load weights you enter into it. You

obtain actual load weights by weighing the

monitor’s cotton load on accurate scales (as

found in a gin or calibrated weigh buggy).

Enter the actual measured weight, and press

Accept when finished.

• If you need to perform a weight calibration on

a second load, you may do so by repeating this

procedure.

• Otherwise, you may continue by pressing the

Perform Calibration button. This procedure is

described in “Perform Calibration” on page 604.

PN: 2002881 Rev.F

603

Page 32

InSight™ User Guide - Cotton Harvest Insert

PERFORM CALIBRATION

Assuming you have previously entered one or more actual load weights, perform a calibration using the

procedure below. (If not, see “Entering Actual Load Weights” on page 603).

Step 1: Check Calibration Load Checkboxes

The Cotton Weight Calibration box shows all the

regions that you specifically selected for

calibration regions. Here you may check or

uncheck regions that have an actual weight for

use in the calibration.

When you have checked the number of regions

you wish to use, press the Perform Calibration

button.

If you use multiple loads to obtain a

calibration, only select loads that have similar

error percentages. This will serve to create a

more accurate calibration.

Step 2: Perform Calibration

Step 3: Calibration Complete

The calibration may take a couple of seconds to

perform.

A window appears, stating “Linear Calibration

Complete.” This window displays the Average

Error and Maximum Error.

If you had only one weight calibration

entered in the Cotton Weight Calibration

box, the Average Error and Maximum Error

will both be 0, as there were no other weight

measurements to compare this calibration

with.

Press OK. When you return to the Run Screen,

the InSight monitor will now calculate cotton

yield using these new calibration numbers, and

previously-logged data will be updated using

the new calibration.

604

PN: 2002881 Rev.F

Page 33

InSight™ Firmware Version 6.0

ADDING A NEW CALIBRATION

After installing the system, you must calibrate the monitor for cotton weight before it will provide

accurate results. Each time you calibrate the monitor, it will automatically correct cotton yield data for all

regions associated with the active calibration. Performing a new calibration at the beginning of each

subsequent harvest season is not necessary, but is recommended. As you harvest, you may notice changes

in yield accuracy because of changes in field conditions or the variety being harvested. If you detect this

type of change, you can perform a new calibration using the following procedure.

Once you create a new calibration, there is no need to create additional crops

along with this new calibration, as the Retire Calibration and Move Region functionality eliminate any need

to create multiple cotton crops. The new calibration will be applied to the original cotton crop.

Step 1: Show Calibration Numbers

On the Harvest window, under the Calibration

tab, press the Show Calibration button. The

Weight Calibration window appears, as shown

at left.

Step 2: Start New Calibration

PN: 2002881 Rev.F

On the Weight Calibration Window, press the

New Cal button.

605

Page 34

InSight™ User Guide - Cotton Harvest Insert

ADDING A NEW CALIBRATION (CONTINUED)

Step 3: Retire Old Calibration

The Retire Calibration warning window appears,

as shown at left. Press the Yes button to retire

your old calibration.

not be able to return to your old calibration,

or add data to it. However, you will still be

able to move regions into previously-used

Step 4: Exit Weight Calibration window

Once this calibration is retired, the Weight

Calibration window reappears with the New

Calibration number showing, and the New Cal

button greyed out, as shown at left.

By retiring your old calibration, you will

calibrations.

The new calibration begins with the

same cal number as the previous calibration.

Press Exit to close this window.

606

PN: 2002881 Rev.F

Page 35

ADDING A NEW CALIBRATION (CONTINUED)

Step 5: New Calibration Appears

The new calibration now appears on the

Calibration drop-down menu. The calibration's

date of creation appears to the right of the

name.

• If the drop-down menu doesn’t appear, no

data has been previously logged.

• If no loads appear in the Cotton Weight

Calibration portion of this window, it is because

you have not checked loads specifically as

calibration loads.

All regions that have been marked as

cal loads will show only for the current

InSight™ Firmware Version 6.0

calibration.

Step 6: Perform new Weight Calibration

After you have created a new calibration, it is

recommended that you perform another weight

calibration. Refer to the procedure described in

“Entering Actual Load Weights” on page 603.

When you perform a weight calibration

on a second calibration, the data from the

first calibration is not affected.

PN: 2002881 Rev.F

607

Page 36

InSight™ User Guide - Cotton Harvest Insert

MOVING REGIONS BETWEEN CALIBRATIONS

If you have performed a cotton calibration that more accurately reflects your current conditions, you may

move previously-gathered cotton data from one calibration to another with the following procedure.

Press the Move Regions button, and the Move Region window appears, as shown below.

Step 1: Select Current Calibration Set

Two drop-down lists appear near the top of the

Move Region window. The left drop-down list

displays the Current Calibration Set, and the

right drop-down list displays the Destination

Calibration Set.

On the Current Calibration Set drop-down list,

use the down arrow to select the calibration

from where you wish to move data from. A tree

showing fields and regions used in that

calibration now appears.

Step 2: Select Destination Calibration Set

Step 3: Select Region to Move

On the Destination Calibration Set drop-down

menu, use the down arrow to select the

calibration to which you wish to move regions

to.

Return to the Destination Calibration Set tree. In

the tree showing underneath the Current

Calibration Set, press on the region or field that

you wish to move to the Destination Calibration

Set.

The region about to be moved is now

highlighted. Press the arrow in the middle of the

Move Region window to move the region.

608

PN: 2002881 Rev.F

Page 37

InSight™ Firmware Version 6.0

MOVING REGIONS BETWEEN CALIBRATIONS (CONTINUED)

Step 4: Region Moved to Destination Calibration Set

The moved region now appears in the

Destination Calibration Set. Press OK when you

are finished moving regions.

PN: 2002881 Rev.F

609

Page 38

InSight™ User Guide - Cotton Harvest Insert

RUN SCREEN OPERATION

RUN SCREEN BUTTONS

You must go to the Field button and accept a field, configuration, crop, and region. For detailed

information, see “Field Button - While Not Logging” on page 613 and “Field Button - While Logging” on

page 618. For a map of a generalized Run Screen, see “Run Screen Menu Tree” on page 559.

Settings Description

The Field button allows you to change fields. Press the Field button to view

Field Totals, if logging data. Otherwise if you not logging data, pressing the

Field button will bring up the Field Operation Wizard, which includes the Field

Totals button. For more information, see “Field Button - While Logging” on

page 618 and “Field Button - While Not Logging” on page 613.

The Region button allows you to change and name regions of the field, and

track and change varieties. For more information, see “Region Selection” on

page 615.

Press to access diagnostic information about the internal memory, display

information, CAN module information, and diagnostic information for harvest.

For more information see “System Button” on page 624.

Press to display information about the GPS. For more information, see “GPS

Diagnostics” on page 70.

The master button controls area logging. The number displayed is the position

of the head in the full range of motion that was set during calibration. When

the header is below the set stop height and the switch is set to Auto, the box

will be colored green and the area will be recorded. When the header is above

the set stop height and the button is set to Auto, the box will display the color

red and the area will not be logged.

610

PN: 2002881 Rev.F

Page 39

RUN SCREEN BUTTONS (CONTINUED)

Settings Description

When the master button is set to Off, it overrides the header sensor and the

area will not be logged. The box will remain colored red until the button is

pushed again to set it to Auto.

InSight™ Firmware Version 6.0

PN: 2002881 Rev.F

611

Page 40

InSight™ User Guide - Cotton Harvest Insert

RUN SCREEN MENU TABS

HARVEST TAB

The Harvest Tab is where the Cotton Harvest area is controlled. The fan speed is located in the center of

this tab, underneath the Run Screen. The master button allows you to turn area logging on and off. For

more details, see “Run screen buttons” on page 610.

FIELD NOTES TAB

For more information, see “Field Notes Tab” on page 79.

MAP TAB

For more information, see “Map Tab” on page 81.

612

PN: 2002881 Rev.F

Page 41

InSight™ Firmware Version 6.0

FIELD BUTTON - WHILE NOT LOGGING

The start of harvest in a field is accomplished by setting up a Field Operation at the Run Screen. This

process is similar regardless of the type of field operation currently taking place. Press the Field button,

and the Field Operation Wizard appears, as shown below.

This procedure assumes that you are not currently logging data in the field. If you are logging data

and you press the Field button, the Field Totals window appears. To see more information about the Field

Totals window and the Field Totals button, see “Field Button - While Logging” on page 618.

Step1: Select Grower, Farm, Field

At the Field Operation Wizard, choose the field

for harvest by making the proper selections

from the Grower, Farm, and Field list boxes.

If the Filter Fields by Farm check is cleared, the

system will display all fields in the Field list box

regardless of what farm the fields are

associated with.

Step 2: Choose Configuration

Press NEXT to continue.

Select the Operating Configuration that relates

to the equipment in use.

Press NEXT to continue.

PN: 2002881 Rev.F

613

Page 42

InSight™ User Guide - Cotton Harvest Insert

FIELD BUTTON - WHILE NOT LOGGING (CONTINUED)

Step 3: Choose Cotton as Crop Type

Select crop from the list box. Press the Finish

button.

Step 4: Select First or Second Pick (if necessary)

If you have selected a field where you have

previously logged cotton yield data, the InSight

monitor will ask you if you are logging data for

the first or second cotton pick. Select either First

Pick or Second Pick

After making this selection, you will return to

the Field Operation Wizard. Press Finish again

to complete the Field Operation portion of the

Field Operation Wizard.

614

PN: 2002881 Rev.F

Page 43

InSight™ Firmware Version 6.0

REGION SELECTION

You can use the Region Selection window to enable the InSight monitor to track varieties that you

planted earlier and are now harvesting. You can also use two types of variety tracking: Automatic Variety

Tracking and Automatic Region Changing. Automatic Variety Tracking tracks only varieties; hence the

operator must manually change to a new region. By contrast, the Automatic Region Changing feature

tracks both varieties and regions, so the InSight monitor changes the region automatically.

Tracking varieties and changing regions

The illustration at left shows how the InSight

monitor could track two different varieties. In

this example, when the cotton harvester reaches

the end of Variety 1, and the operator

maneuvers the vehicle to Variety 2, a message

appears that either a new variety has been

detected and the user is notified to change

regions (Automatic Variety Tracking,) or that a

variety has been detected and the InSight

monitor is automatically changing regions.

(Automatic Region Changing).

Selecting or creating New Region

These varieties must have been logged

in the InSight monitor during planting in

order for the monitor to reference them

during harvest.

To enable either Automatic Variety Tracking or

Automatic Region Changing, first access the

Region Selection window, by completing the

Field Operation Wizard under the Field button,

or press the Region button. The Region Selection

window appears, as shown in the following

picture.

To edit the name of a region, select it out of the

Region list and use the keyboard button.

Region Selection Window

PN: 2002881 Rev.F

615

Page 44

InSight™ User Guide - Cotton Harvest Insert

REGION SELECTION (CONTINUED)

Creating a New Region

Region List

Variety Tracking menu and Automatic Variety Tracking

To create a new region press the New button.

You will see a new region appear in the Region

list, with a numeric name shown in brackets, such

as <4>. You may use the keyboard button to

enter your own name for this new region.

If you would like to use this region in

the weight calibration, select the Flag Region

as Calibration Load check box. For more

information on calibration loads, see

“Entering Actual Load Weights” on page 603.

Variety Tracking List

If no variety map is present, then you can select a

variety from the Variety Tracking List, as shown

at left.

If you do not want to use the Automatic Variety

Tracking feature, press the Accept button now.

If you want to enable the Automatic Variety

Tracking feature, select only the Automatic

Variety Tracking check box, as shown below left.

(Do not select the Automatic Region Changing

checkbox).

A variety map for the current field and

crop must be present to enable Automatic

Variety Tracking.

616

Automatic Variety Tracking enabled

PN: 2002881 Rev.F

Page 45

REGION SELECTION (CONTINUED)

Automatic Region Changing

Variety Tracking messages

InSight™ Firmware Version 6.0

If you wish to enable the Automatic Region

Changing feature, select both the Automatic

Variety Tracking check box, and the Automatic

Region Changing check box, as shown at left.

Automatic Variety Tracking message

Automatic Region Changing message

If you have selected either the Automatic Variety

Tracking or Automatic Region Changing

features, you will see one of the messages at left

as you harvest your field.

• If you have selected Automatic Variety

Tracking, the message above left tells you that

the InSight monitor has detected a different

variety, and that you should manually change

the region.

• If you have selected Automatic Region

Changing, the message below left tells you that

the InSight monitor has detected a different

variety, and that the monitor is automatically

changing to a different region.

PN: 2002881 Rev.F

617

Page 46

InSight™ User Guide - Cotton Harvest Insert

FIELD BUTTON - WHILE LOGGING

Field Totals window

If the Field button is pressed while logging data

a dialog box shows field totals, as shown at left.

This Field Totals box displays the following

information:

• Average Lint Yield

• Seed Cotton Weight

• Lint Weight

• Bales

• Area

• Container Level

• Area Completed

• Area Left

• Distance Traveled

• Productivity

• Operating Time

If you press the Field button when you

are not logging, the Field Operation Wizard

will appear. If this happens, press the Field

Totals button to view the Field Totals

window. For more information, see “Field

Button - While Not Logging” on page 613.

618

PN: 2002881 Rev.F

Page 47

InSight™ Firmware Version 6.0

DISPLAY ITEMS

The Display Items window can be accessed by pressing any one of the four display items that are active on

the Run screen - Lint Yield, Area, Ground Speed and Total Bales are the defaults.

Once the Display Items window is visible, press

the display item you would like to activate. That

item will now appear as one of the four

immediately displayed on the Run screen.

Button Description

The Lint Yield shows the instantaneous lint yield in pounds per acre

(kilograms per hectare).

The Average Lint Yield shows the lint yield averaged over an active region.

This yield number is shown in pounds per acre (kilograms per hectare).

The Area Per Hour setting shows the instantaneous productivity.

The Lint Yield (Bales) shows the instantaneous lint yield in bales per acre

(bales per hectare).

PN: 2002881 Rev.F

619

Page 48

InSight™ User Guide - Cotton Harvest Insert

Button Description

The Total Bales setting shows the number of bales picked in the active

region.

The Ground Speed setting shows the instantaneous ground speed.

The Seed Cotton Weight setting displays the total amount that is

harvested for the region - including lint, seed and trash. This setting is

shown in pounds (kilograms).

The Cotton Flow setting shows the instantaneous cotton flow in the

picker, in pounds per hour (kilograms per hour).

The Distance setting shows the total distance driven in the region, in feet

(meters).

The Lint Weight setting shows the total amount of lint harvested in the

active region, in pounds (kilograms).

The Area setting shows the area harvested for the region, in acres

(hectares).

620

PN: 2002881 Rev.F

Page 49

InSight™ Firmware Version 6.0

VIEWABLE MAPS

There are four different types of viewable maps in harvest. The maps are accessed by pressing the button

in the legend that is either labeled Bale Yield, Lint Yield, Seed Cotton Yield, or variety. The yield map

displays an “on-the-go” color yield map. To edit the legend see “Map Legend” on page 622.

Bale Yield

The Bale Yield displays the lint yield in bales per

acre (hectare).

Lint Yield

The Lint Yield displays the lint yield in pounds

per acre (kilograms per hectare).

Seed Cotton Yield

Reference Varieties

The Seed Cotton Yield displays the amount of all

material being harvested - including lint, seed

and trash. This amount is displayed in pounds per

acre (kilograms per hectare).

The variety map displays a background map of

varieties that were logged with the InSight

during planting. This map can be used by the

InSight monitor to track varieties during harvest.

This map is also known as the reference map.

This legend is not editable.

PN: 2002881 Rev.F

621

Page 50

InSight™ User Guide - Cotton Harvest Insert

MAP LEGEND

To edit any of the yield legend settings for average, spacing, colors, and ranges, press on the range

portion of the legend and the Legend Settings window appears, as shown below. This window allows you

to change the default legend for cotton harvest. This window displays the same buttons and drop-down

menus, whether the attribute is Bale Yield, Lint Yield, or Seed Cotton Yield. These legends can all be

edited, but the variety (reference) legend cannot be edited.

Legend Settings (shown for Seed Yield)

The example at left shows the window for Seed

Cotton Yield. Legend settings that are made

here will affect all regions.

At the left of the Legend Settings window is the

yield scale, the same as it appears on the

viewable map. Other settings are described in

the table below and on the following page.

Item Description

Press Average to edit the average legend value.

Press Range Spacing to edit the legend range spacing value.

Selects the color scheme to use for the yield legend.

Press Reset to Product Legend to reset legend to the product legend.

622

PN: 2002881 Rev.F

Page 51

InSight™ Firmware Version 6.0

Item Description

Use the up and down arrows to select the number of ranges to

display in the legend.

If the Automatic Legend check box is selected, the average will

automatically set itself to the field average and update as that field

average changes.

Press the Save as Product Legend check box to set the current legend

as the default legend for all regions of the same product. This will

also reset the legend settings under the Crop Tab. To reset to the

default values go to Setup, Cotton Harvest, Crop Tab and press the

Edit Legend button.

PN: 2002881 Rev.F

623

Page 52

InSight™ User Guide - Cotton Harvest Insert

TROUBLESHOOTING

SYSTEM BUTTON

By pressing the System button, you can view the System Information window, which contains information

about the memory, InSight Display, modules, and picker diagnostic information. At the System

Information window, press the Cotton Diagnostics Tab to view diagnostic information about the

different sensors on the picker. Technical support may request that you look at this window for help in

diagnosing problems. This window will display the following information:

• Flow Rate

• Fan Speed

• Ground speed

• Ground Speed Pulses

Flow Data

• Header Height (percentage)

• Header Status - Up, Down or NA (shown for

uncalibrated headers).

• Header Raw - Indicates a signal is coming from

the header sensor.

The Flow Data settings of the Cotton

Diagnostics Tab shows the flow rate of each

sensor.

• All of the sensor pairs you have configured are

labeled on the left-hand side of this table. Move

the scroll bar down to view all of your sensors.

• Each of the five detectors on each sensor are

labeled at the top of this table. Each sensor has

five detectors, as shown in the photograph

below left. A sensor pair includes both emitters,

which output light, as well as detectors, which

receive that light.

Signal Strength

624

To view the Signal Strength window,

press the Change View button, on the right-

hand side of the Cotton Diagnostics Tab.

The Signal Strength settings of the Cotton

Diagnostics Tab shows how much light is being

detected by the sensors. Larger units indicate

more light is being detected. If one or more of

these numbers equals 0, this indicates a faulty or

misaligned sensor.

To view the Flow Data window, press

the Change View button on the right-hand

side of the Cotton Diagnostics Tab.

PN: 2002881 Rev.F

Page 53

COTTON TROUBLESHOOTING TABLE

Problem Possible Cause Solution

InSight™ Firmware Version 6.0

Module LED light is

flashing red.

Module LED light is

solid red.

Module LED light is

flashing orange.

Module LED light is

not lit up.

The InSight monitor

is displaying a low

signal strength

warning.

Module does not

have firmware

properly installed.

Possible module

failure.

Power is being

supplied to the

module, but there is

no CAN bus

communication.

The module is not

receiving power.

Dirt or debris is

covering the lenses

on the emitter or

detector.

Sap from cotton is

smeared on lenses.

Reload firmware to the module through the

Upgrade button. To reload firmware to the

module, follow the same process as used when

upgrading firmware to the InSight monitor.

Contact Ag Leader Technical Support.

Check the CAN bus cables for bent or broken pins

at each connection. If you can see no physical cable

problem, contact Ag Leader Technical Support.

Check cables for disconnections, breaks or cuts in

the line.

Once per week, wipe the lenses clean to ensure the

best performance.

If defoliation is not complete before harvest

begins, sap from cotton plants may build up on the

lenses. To ensure accuracy, you may need to clean

the lenses with a non-ammonia based cleaner.

The InSight monitor

is displaying

inaccurate yields

(John Deere pickers

only).

Sensors are not

properly aligned.

The ground strap is

not installed

properly.

Check the alignment of the sensors by slightly

moving the emitter to see if signal strength

increases. As precise movements are needed, move

the emitter slowly and slightly.

John Deere pickers need ground straps installed on

their flow sensors to remove static buildup. Make

sure this ground strap is properly installed on the

picker and is also properly grounded. Check the

installation instructions for proper placement of

the cable.

PN: 2002881 Rev.F

625

Page 54

InSight™ User Guide - Cotton Harvest Insert

COTTON TROUBLESHOOTING TABLE (CONTINUED)

Problem Possible Cause Solution

The InSight monitor

is displaying

inaccurate yields (all

picker models).

Calibration was not

performed properly.

Speed reading is

inaccurate.

Area count is not

correct.

Cotton may snag on

loose or jagged

edges and give false

readings.

Excess light in chutes.

Change in field

conditions.

Check calibration loads to ensure that a minimum

of three loads were recorded and have an average

error below 5% and a maximum error below 10%.

If using GPS as your ground speed source, check the

signal to ensure that the InSight monitor is getting

DGPS. If using a ground speed sensor, perform a

ground speed calibration to verify speed accuracy.

See the Incorrect Area Count problem and solution

described under “Incorrect area count.” on page 627.

Remove any stringers. After installation, file any

jagged edges below the sensors or seal the edges

for a smooth finished edge.

Make sure the chutes are sealed properly and that

excess light is not reflecting into the chutes which

can cause false readings.

If a field condition change leads to incorrect yield

values, a new calibration may be needed to

continue recording accurate values. For more

information about retiring calibrations, see

“Adding a New Calibration” on page 605.

Monitor displaying

zero flow or zero

yield.

(see also following

page).

Fan speed is not

above 2500 RPM or

below 4000 RPM.

Module is not

communicating

properly.

Modules are not on

correct firmware.

Verify that the fan speed is above 2500 RPM and

below 4000 RPM. If the speed is above or below

this value, no yield will be recorded. For further

troubleshooting tips, see “Fan speed too high or too

low (RPM must be between 2400 and 4000).” on

page 627.

Check the module communication by going to the

Run screen and selecting the System button in the

upper right-hand corner. Select the CAN Tab and

verify that the speed module and all cotton flow

modules are detected in the CAN device list. If a

module is not shown on the list, then check the

modules to see if their indicator lights are flashing.

Check the firmware for modules by going to the

Run screen on the InSight monitor and selecting

the System button and CAN Tab. Make sure all the

modules and the InSight monitor itself are all on

the correct firmware. The current firmware is

available on the InSight Support web page at

www.agleader.com.

626

PN: 2002881 Rev.F

Page 55

InSight™ Firmware Version 6.0

COTTON TROUBLESHOOTING TABLE (CONTINUED)

Problem Possible Cause Solution

If you are using GPS as the ground speed source,

check the signal to make sure that the InSight

monitor is getting DGPS. If using a ground speed

sensor, check the cable and speed sensor. Verify

that a ground speed calibration was performed for

ground speed accuracy.

When the head is lowered, the Run screen’s Master

Switch should turn green and read “On”. When

you are raising and lowering the header, verify

that the header sensor is properly turning the area

count on and off.

Monitor displaying

zero flow or zero

yield.

(continued from

previous page).

The InSight monitor

is not recording

ground speed.

The Area Count is

not being triggered.

Fan speed too high

or too low (RPM

must be between

2400 and 4000).

Obstruction of

sensors.

Fan clutch is

disengaged.

Fan speed cable is

unplugged or

damaged.

Speed sensor is out

of alignment.

Speed sensor is

defective.

Header height sensor

is not turning off

when the head is

raised.

Verify that no debris is blocking emitters and

detectors. Remove any possible blockage that may

interfere with the signal.

Make sure the fan clutch is engaged and the fan

belt is rotating at the proper speed.

Visually inspect the cable for disconnections, cuts,

breaks, crimps or exposed wire that may interfere

with the signal being sent back to the InSight

monitor.

Check the speed sensor and magnet for alignment.

Adjust the sensor for proper alignment.

Replace the sensor.

Recalibrate the header sensor, or replace the

header sensor if it is defective.

Incorrect area count.

PN: 2002881 Rev.F

Swath width is

incorrect.

Ground speed is

incorrect.

Enter the correct swath width in the cotton harvest

setup. For more information, see “Step 4: Enter

Number of Rows and Full Swath” on page 580.

If using GPS for ground speed, check the signal to

see that the InSight is receiving DGPS. If using the

ground speed sensor, perform a ground speed

calibration to verify speed accuracy.

627

Page 56

InSight™ User Guide - Cotton Harvest Insert

628

PN: 2002881 Rev.F

Page 57

InSight™ Firmware Version 6.0

Index - Cotton

A

active rows 585

Add

Picker 588

add button 586

add crop button 595, 597

add new calibration 607, 609

add new configration 581

add varieties 599

add variety button 595, 599

adding new crop 597

adding new picker 588

antenna offset 591

area button 622

area count 629

automatic region changing 617, 618, 619

automatic variety tracking 617, 618, 619

average crop yield 600

average yield 624

B

button

add 586, 597, 595, 599, 622

calibrate distance 587, 592, 587, 594, 626,

580, 585, 580

distance 622

edit distance 592, 596, 586, 595, 601

field 612

gps offsets 587, 622

perform calibration 602, 586

region 612, 595

sensor settings 587, 602, 607, 612, 626

C

calibrate

distance 592

complete 593

header sensor 594

calibrate distance

edit distance 592

calibrate distance button 587, 592

calibrate header sensor button 587, 594

calibration 601

add new 607, 609

calibration tab 601

crop type 601

enter weight 601

perform calibration 602

show cal numbers 602

change view button 626

combine tab 586

configuration

add 580, 581

edit name 580

header offset 585

name 584

remove 580

sensors 584, 585

vehicle setup wizard 581

configuration settings button 580, 585

configuration setup wizard 581

configuration tab 580

conventional head type 582

cotton diagnostics 626

change view 626

flow data 626

signal strength 626

cotton harvest button 580

cotton picker settings 589

create new region 618

crop

add 595, 597

crop settings box 596

crops tab 595

add crop button 595

edit 596, 595

remove button 595

D

detectors 626

diagnostics 626

display items 621

area button 622

distance button 622

grain flow 622

distance button 622

E

edit configuration name 580

edit crop name 595

edit distance button 592

edit legend 596, 600

edit name button 595

edit picker name 586

enter Cal number 593

enter weight button 601

PN: 2002881 Rev.F

629

Page 58

InSight™ User Guide - Cotton Harvest Insert Index

F

fan speed 629

logging data 589

minimum 589

pls/rev 589

fan speed sensor settings 586, 589

Farm 615, 616

Field 615, 616

field button 612

not logging 615, 616

while logging 620

field notes tab 614

field operation wizard 615

flow 629

flow data 626

full swath 582

G

GPS

antenna 591

GPS offset

antenna 591

head 591

gps offsets 591

antenna height 591

head tab 591

gps offsets button 587

grain flow button 622

ground speed button 622

ground speed sensor 585

ground speed source 584

H

harvest

calibration 601

harvest tab 614

head offset 591

head type 582

conventional 582

inline 582

John Deere 582

header offset 583, 585

header raw 626

header sensor

calibration 594

reset all 594

stop height 594

header sensor calibration instructions 594

header status 626

I

inaccurate yield 627, 628

inline head type 582

installation

wiring diagram 577

L

LED light

not lit 627

orange 627

LEDlight

red 627

legend

edit 600

legend settings 600, 624

automatic legend 625, 600, 624

color 600, 624

range spacing 600, 624, 600, 625, 600, 624

save as product legend 625

lenses 627

low signal alarm 590

low signal strength 627

M

map

legend 624

reference varieties 623

map legend

edit 596

see also legend settings 624

map tab 614

maps 623

variety 623

O

operating configuration 615

P

perform calibration button 602

picker

adding new 588

calibrate distance 587, 592, 587

Case IH 581

configuration 586

fan speed sensor settings 589

gps offsets 587

John Deere 581

make 588

name 588

remove 586

630

PN: 2002881 Rev.F

Page 59

InSight™ Firmware Version 6.0

sensor settings 587, 586

vehicle setup wizard 588

picker settings button 586

picker tab 586

edit name button 586

R

range spacing 600, 624

reference varieties 623

region

create new 618

region button 612

region selection 617

remove button 595

remove crop 595

retire calibration 608

rows

active 585

number 582

sensors 585

run screen 612

area 612, 613, 612

field button 612, 614, 615

harvest tab 614

map tab 614, 612, 613, 612, 613

region button 612

system button 612

tabs 614

S

sensor

calibrate distance 592

sensor configuration 584

does not match 584, 585

error message 584, 585

rows 584

sensor information

detectors 626

sensor settings 590

low signal alarm 590

zero flow threshold 590

sensor settings button 587

setup

configuration 578

show cal numbers button 602, 607

signal strength 626

speed sensor calibration 592

stop height 594

stringers 628

swath width 582

system button 612, 626

system information 626

cotton diagnistics 626

flow data 626

header raw 626

signal strength 626

T

troubleshooting 626, 627

area count 629

fan speed 629

inaccurate yield 627, 628

low signal strength 627

zero flow 629

U

use fan speed 589

V

variety setup wizard 599

variety tracking 618, 619

varities

add new 599

viewable maps 623

W

wiring diagram 577

Y

yield 627, 628, 629

Z

zero flow 629

zero flow threshold 590

zero yield 629

PN: 2002881 Rev.F

631

Page 60

InSight™ User Guide - Cotton Harvest Insert Index

632

PN: 2002881 Rev.F

Loading...

Loading...