organic compounds per unit time

are purposely produced in order to

be screened against a variety of biological targets for drug detection.

Introduction

High sample throughput is particularly important in the pharmaceutical industry, for example, in

combinatorial chemistry and

metabolite studies. In combinatorial chemistry a large number of

An ideal instrument configuration

for high sample throughput comprises:

• an autosampler such as a standard HPLC autosampler for

2-ml vials or a sampler with

microtiter and deep-well plates,

• a high-pressure gradient pump

for lowest delay volume,

• a UV detector such as a diode

array detector or variable wavelength detector, and

• a mass selective detector for

additional mass and structural

information (optional).

Optimizing the Agilent 1100 Series

System for High Sample Throughput

Technical Note

Agilent Technologies

Innovating the HP Way

The limiting factor for high

throughput in such systems is the

speed of the HPLC analysis.

Standard HPLC cycle times from

injection to injection for gradient

analysis lie between 15 and 20 min

using columns of 100 to 200 mm in

length.

To significantly increase the sample throughput, cycle times must

be shortened. This can be

achieved using fast gradients with

short columns and high flow rates.

In the following example we

demonstrate how to optimize the

Agilent 1100 Series high-pressure

gradient system to obtain rapid

gradients and high sample

throughput. Hints are given on the

influence of chromatographic

parameters on cycle times, and on

how run times of less than two

minutes can be expected to affect

performance.

Equipment

All HPLC experiments were carried out on the Agilent 1100 Series

high-pressure gradient system

comprising:

• Agilent 1100 Series high-pressure

pump for lowest delay volume.

In this design each solvent is

pumped by its own pump

assembly, and mixing takes

place on the high-pressure side.

This means gradient changes

reach the column much faster

than in low-pressure gradient

systems where mixing takes

place on the low-pressure side.

• Agilent 1100 Series vacuum

degasser for optimum baseline

stability.

• Agilent 1100 Series autosampler

for sampling from 2-ml standard

vials.

• Optional Agilent 220 micro

plate sampler for flexible sampling from deepwell and/or

microtiter plates.

• Agilent 1100 Series thermostatted column compartment for

highest stability from 10 °C

below ambient up to 80 °C.

• Agilent 1100 Series diode array

detector with standard flow cell

(10-mm pathlength, 13-microliter volume).

• Optional Agilent 1100 Series

variable wavelength detector.

• Optional Agilent 1100 Series

LC/MSD module for mass and

structural information.

• Agilent ChemStation with 3D

HPLC single instrument software

for instrument control, data handling and sample tracking.

Compounds and chromatographic conditions

For our experiments we selected

the following compounds which

differ considerably in polarity:

• caffeine

• primidone

• phenacetin

• mandelic acid benzylester

• biphenyl

The chromatographic conditions

are listed next to the figures.

Optimization of chromatographic parameters

The following parameters have to

be adapted to obtain short cycle

times, sufficient resolution and

best performance over a wide

range of polarity:

• column length

• gradient

• flow rate

• delay volume

• data rate of detector

• column temperature

The aim was to achieve cycle

times of about 2 min and baseline

separation for all compounds.

Influence of column length on

run time

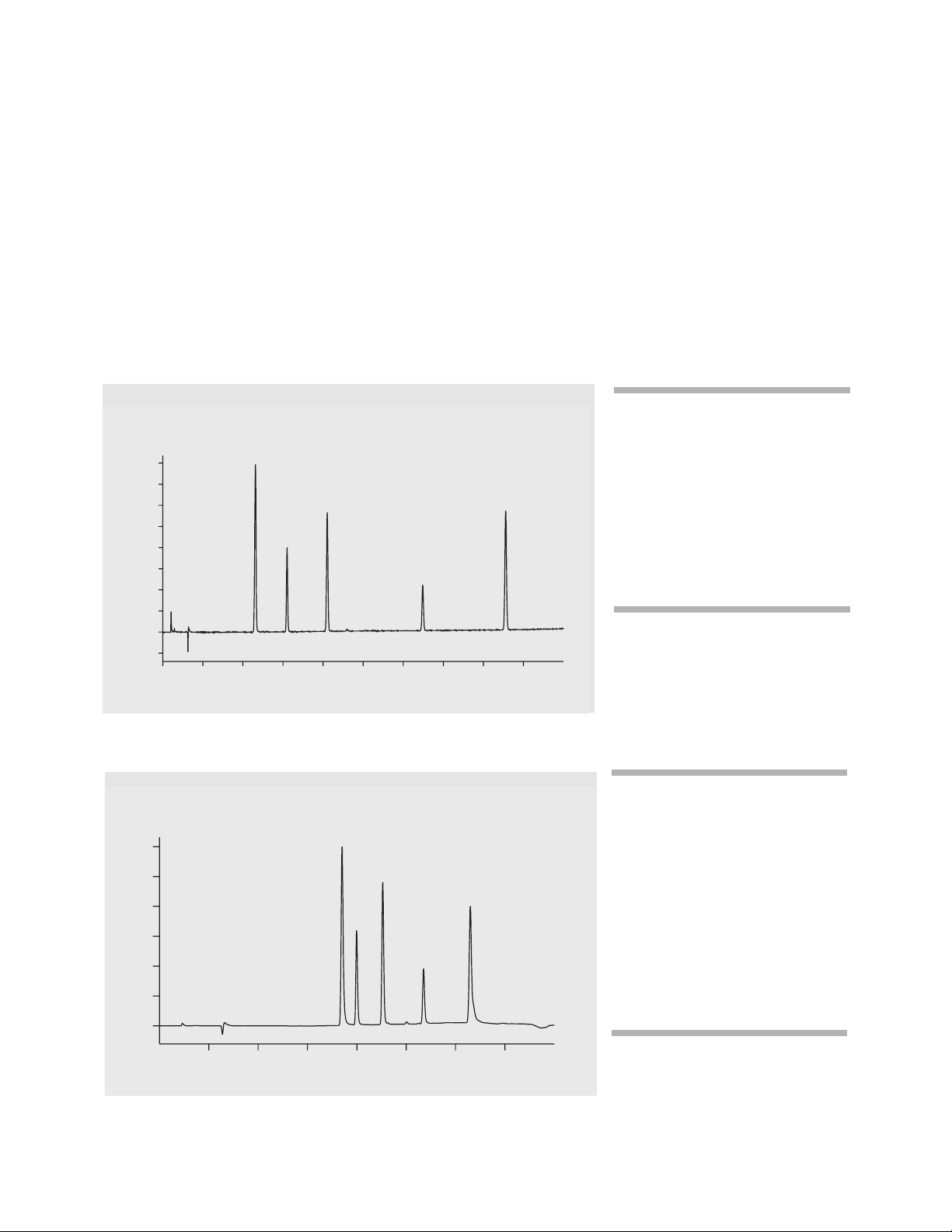

For a standard column with a

length of 100 mm and an id of

4.6 mm, run time cycles of about

15 min are good practice. In

figure 1, the compounds mentioned in the previous paragraph

were analyzed.

Cycle times of 14 min were

obtained with excellent resolution

for all compounds.

Shorter cycle times are obtained

using a short column. In figure 2,

the analysis of the same compounds is shown using a 50-mm

colum. Cycle times are down to

2.8 min and baseline separation

for all compounds is given, despite

decrease in resolution. Shortening

the column length was the principal step in achieving reduced

cycle times. The example on the

next page demonstrates how to

shorten the cycle even further.

Column 100 x 4.6 mm ODS

Hypersil, 5 µm

Flow rate 2 ml/min

Mobile phase A = water, B = ace-

tonitrile (ACN)

Gradient 5 % B to 95 % B in

12 min

to 5 % B in 13 min

Run time 13 min

Post run 1 min

Diode-array settings 210/8 nm,

ref. wavelength

360/100 nm

Injector volume 5 µl

Column temperature 50 °C

Figure 1

Analysis of selected compounds using a 100-mm column

Figure 2

Analysis of selected compounds using a 50-mm column

Column 50 x 4.6 mm Zorbax

SB-C18, 3.5 µm

Flow rate 2 ml/min

Mobile phase A = water, B = ace-

tonitrile (ACN)

Gradient 5 % B to 95 % B in

1 min

95 % up to 1.5 min

to 5 % B in min

Run time 2 min

Post run 0.8 min

Diode-array settings 210/8 nm,

ref. wavelength

360/100 nm,

response time 0.1 s

Injector volume 5 µl, autosampler in

bypass mode

Column temperature 50 °C

Absorbance

[mAU]

400

350

300

250

200

150

100

50

0

-50

0

Absorbance

[mAU]

1200

1000

800

600

400

200

0

1

2

3

2

1

1 Caffeine 4 Mandelic acid

2 Primidone benzylester

3 Phenacetin 5 Biphenyl

3

5

4

Time [min]

5

4

9

8

7

6

0.25

0.5

0.75

1

Time [min]

1.25

1.5

1.75

Influence of gradient on run

time

In order to achieve a good separation for the polar and the nonpolar compounds, a gradient from

5 to 95 % of the organic phase was

chosen. The evaluation of the

steepest possible gradient with

baseline separation for all compounds is shown in figure 3. The

flow rate was 2 ml/min.

As a result, the gradient from 5 to

95 % ACN in 1 min met the

demands of shortest run time and

baseline separation for all peaks.

Influence of flow rate on run

time

As well as the column length, the

flow rate can also be used to

shorten run times or achieve better cycle times. In figure 4, the

analysis of the selected compounds at 4 different flow rates is

shown using the gradient from

5 to 95 % ACN in 1 min.

Cycle time can be reduced from

3 min at a 1 ml/min flow rate,

down to 1.3 min at a flow rate of

4 ml/min. All peaks are baseline

separated, also at a flow rate of

4 ml/min. In the evaluation of peak

area counts, it is apparent that

there are about four times less

area counts in the 4-ml/min run

than in the 1-ml/min run.

Figure 3

Evaluation of gradient steepness

Figure 4

Analysis of selected compounds at four different flow rates

Absorbance

[mAU]

800

400

0

800

400

0

1200

800

400

0

0.5

0.5

0.5

5 % to 95 ACN in

1

1

1

1.5

1.5

1.5

Time [min]

2

2

2

2.5

5 % to 95 ACN in

2.5

5 % to 95 ACN in

2.5

3 min

3

2 min

3

1 min

3

Absorbance

[mAU]

1500

0

1000

0

800

0

600

0

0

0

0

0

1 ml/min

0.25

2 ml/min

0.25

3 ml/min

0.25

4 ml/min

0.25

0.5

0.5

0.5

0.5

0.75

0.75

0.75

0.75

1

1

1

1

Time [min]

1.25

1.25

1.25

1.25

1.5

1.5

1.75

2

Influence of high flow rates on

minimum detectable concentrations

If a high flow rate is run, peak

heights and area counts for UV

detection are reduced. Consequently, for UV detectors, which

are able to detect compounds in

the 0.1 ppm range, the compound

concentration in the analyzed

sample should be in the low ppm

or high ppt range to ensure that

the UV detector is able to “see”

the compounds. It must also be

taken into account that a mass

selective detector (MSD) cannot

handle flow rates of 4 ml/min. The

maximum flow rate range is about

1 to 1.5 ml/min. Optimum flow

rates for most MSD instruments

are about 0.5 ml/min. The column

eluent must therefore be split 1 to

10 for optimum conditions. The

MSD is able to detect masses in

the 100 ppt range. If the compound concentration of the evaluated sample is in the low ppb

range, the MSD should still be able

to detect the masses, even though

the column eluent has to be split

before entering the ion source.

Influence of delay volume on

run time

Modern high-pressure gradient systems, such as the Agilent 1100

Series, offer system delay volume

below 1 ml without modifying the

standard system. The Agilent 1100

Series also offers the possibility to

switch the Agilent 1100 Series

autosampler into bypass mode

after the sample has reached the

column. This is done using an

injector program saving another

300 µl of delay volume. In figure 5,

the effect when switching the

autosampler into bypass mode is

shown. The experiment was done

at a flow rate of 2 ml/min, with a

gradient of 5 to 95 % ACN in 1 min.

The following injector program

used was used:

1. DRAW 5 µl from sample

2. INJECT

3. WAIT 0.03 min

4. VALVE bypass

5. WAIT 1.75 min

6. VALVE mainpass

The wait time before the valve is

switched to the bypass position

depends on the injection volume,

according to the equation:

Wait time = 6 (injection volume +

5 µl)/flow rate.

The run time difference for the

last peak is about 0.16 min which

corresponds to a volume of 320 µl

at 2 ml/min. The influence of the

delay volume is not significant in

this case and the higher the flow

rate the lower the gain in time.

Influence of data rate on precision

Assuming that 20 to 30 data points

per peak are needed for a precise

measurement, the set data rate of

a response time of 0.1 s is sufficient for a peak width of 2 s. The

peak width is measured at peak

bottom (4 s). This peak width produces 20 data points. All peaks,

even those measured at a flow

rate of 4 ml/min, are broad enough

to produce at least 20 data points

per peak.

Influence of column temperature on run time

The influence of column temperature was tested for 50 °C and

25 °C at a 2 ml/ min flow rate,

using the gradient from 5 to 95 %

ACN in 1 min. The influence is low

in this case. The retention time

difference for the last peak is only

0.052 min.

Figure 5

Analysis of selected compounds at different delay volumes

Absorbance

[mAU]

1200

Agilent 1100 Series

800

autosampler in bypass mode

400

0

0.8

0.6

0.4

0.2

1200

Agilent 1100 Series

800

autosampler in mainpass mode

400

0

0.8

0.6

0.4

0.2

1.8

1.6

1.4

1.2

1

1.8

1.6

1.4

1.2

1

Time [min]

Results of optimization

process

The aim was to obtain cycle times

of about 2 min and baseline separation of all analyzed compounds.

This was achieved as shown in

figure 6.

The time the autosampler needs to

inject the next sample is sufficient

to equilibrate the system for the

start conditions.

Method performance was tested

over 10 runs and relative standard

deviations (rsd) are listed in

table 1. The injection volume was

5 µl. The precision of areas is

worse than normally expected in

HPLC. This is due to the low number of data points that can be

acquired at such narrow peak

width.

Compared to standard cycle times

of about 15 to 20 min, the cycle

time could be reduced by a factor

of 10.

Figure 6

Optimized chromatogram for high throughput and cycle run times below 1.5 min

Compound Precision of retention time Precision of areas

Caffeine 0.30 2.60

Primidone 0.29 2.58

Phenacetin 0.19 2.51

Madelic acid benylester 0.16 2.58

Biphenyl 0.06 2.32

Table 1

Precision of rentention times and areas

Column 50 x 4.6 mm Zorbax

SB-C18, 3.5 µm

Flow rate 4 ml/min

Mobile phase A = water, B = ace-

tonitrile (ACN)

Gradient 5 % B to 95 % B in

1 min,

95 % until 1.09 min

to 5 % B at 1.1 min

Run time 1.2 min

Post run time needed to inject

the next sample

Diode-array settings 210/8 nm,

ref. wavelength

360/100 nm,

response time 0.1 s

Injector volume 5 µl, autosampler in

bypass mode

Column temperature 50 °C

Absorbance

[mAU]

800

600

400

200

0

0

0.25

0.5

Time [min]

0.75

1

Conclusions

High-sample throughput in an

HPLC system can be achieved by

optimizing the cycle times from

injection to injection using short

columns, high flow rates and steep

gradients. Such an HPLC system

should include a high-pressure

gradient pump. These pumps have

low delay volumes and gradient

changes almost immediately affect

the column. The column length

should be 50 mm or less, and the

internal diameter should be

approximately 4.6 mm. Start and

end concentration of the gradient

composition should be selected

such that it has an impact on all

compounds. Otherwise the unaffected compounds tend to

broaden, especially at higher injection volumes. The gradient slope

should be as steep as possible,

however, peak resolution is the

limiting factor. A high flow rate of

approximately 2 to 4 ml/min is

recommended in order to further

reduce run times and equilibration

times. The data rate must be set as

high as possible to guarantee at

least 20 to 30 data points per peak.

If all parameters are optimized,

the sample throughput can be

increased at least by a factor of 10

with good precision for retention

times and areas.

Literature Reference

Wolfgang K. Goetzinger and

James N.Kyranos, “Fast gradient

RP-HPLC for high throughput

quality control analysis of spatially

addressable combinatorial

libraries” American Laboratory,

pp 27-37, April 1998.

For the latest information and services visit

our world wide web site:

http://www.agilent.com/chem

Agilent Technologies

Innovating the HP Way

Copyright © 1998 Agilent Technologies

All Rights Reserved. Reproduction, adaptation

or translation without prior written permission

is prohibited, except as allowed under the

copyright laws.

Publication Number 5968-0467E

Loading...

Loading...