Page 1

Agilent E2251A

M-Module Carrier

Installation and Wiring Manual

Agilent 75000 Series C

Where to Find it - Online and Printed Information:

System installation (hardware/software)............VXIbus Configuration Guide*

Installing M-Modules onto M-Module Carrier..This Manual (Service-Trained Personnel only)

Installing M-Module Carrier into

VXI Mainframe..................................................This Manual (Service-Trained Personnel only)

M-Module configuration and wiring..................M-Module Hardware Manual

M-Module programming example (SCPI).........Agilent E2251A M-Module User’s Manual

M-Module programming example

(register-based)...................................................Agilent E2251A M-Module User’s Manual

VXIplug&play programming ............................VXIplug&play Online Help

VXIplug&play example programs .....................VXIplug&play Online Help

VXIplug&play function reference......................VXIplug&play Online Help

Soft Front Panel information.............. ................VXIplug&play Online Help

VISA language information. ...................... .... .....VISA User's Guide

*Supplied with Agilent Comm and Modules, Embedded Controllers, and VXLink.

*E2251-90002*

Manual Part Number: E2251-90002

Printed in Malaysia E0206

Page 2

Page 3

Contents

Agilent E2251A M-Module Carrier Installation and Wiring

Manual

AGILENT TECHNOLOGIES WARRANTY STATEMENT.....................................3

Safety Symbols.............................................................................................................4

WARNINGS.................................................................................................................4

WARNINGS (contd.) ...................................................................................................5

Declaration of Conformity............................................................................................6

M-Module Installation

Step 1. Remove the Carrier Shields............................................................................10

Step 2. Determine M-Module Layout ........................................................................11

Step 3. Set the Logical Address for each M-Module..................................................12

Guidelines for Determining Logical Addresses ..................................................12

Unused Slots on the Carrier ................................................ ................................12

Setting the Addresses ..........................................................................................13

Step 4. Install M-Modules onto the Carrier ...............................................................14

Step 5. Connect Field Wiring to Slot M4 & M5 M-Modules.....................................15

Step 6. Reattach the Carrier Shields...........................................................................16

Step 7. Install Carrier into C-Size VXI Mainframe....................................................17

Step 8. Connect Field Wiring to Front M-Modules....................................................18

Step 9. Installation / Operational Verification............................................................19

You Are Done .....................................................................................................19

Removing M-Modules from the Carrier.....................................................................20

(Edition 2)

M-Module Field Wiring Information

Assembling the M-Module Field Wiring Connector..................................................21

E2259A Double-Wide Breadboard M-Module Wiring Information.......................... 24

E2261A Quad RS-232 Interface Wiring Information.................................................26

E2270A 16-Channel Form A Switch Wiring Information .........................................28

E2271A 4x4 Matrix Switch Wiring Information........................................................29

E2272A Dual 8-to-1/Single 16-to-1 Relay Multiplexer Wiring Information............. 30

Configuring the E2272A .....................................................................................30

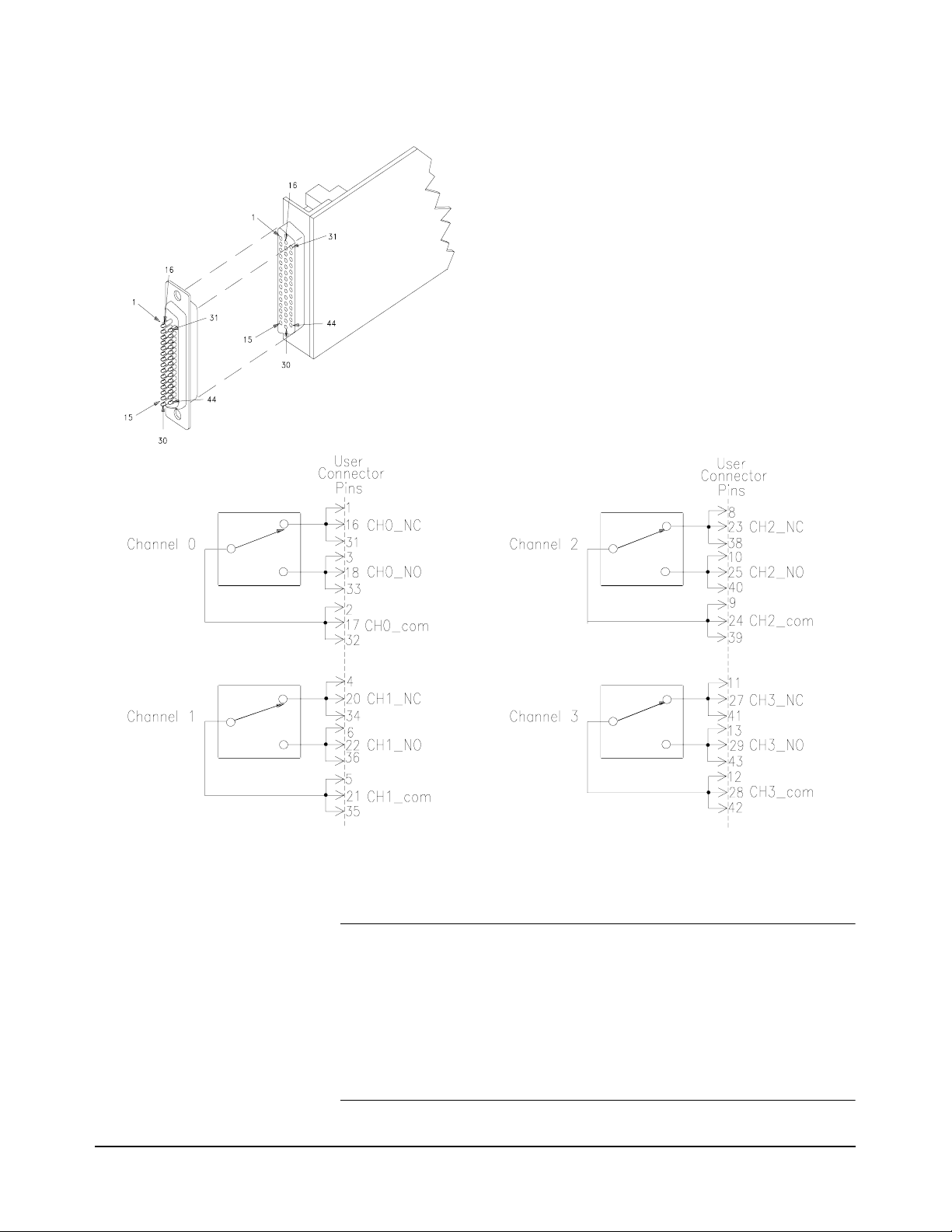

E2273A 8-Channel Form C Switch Wiring Information ........................................32

E2274A 4-Channel Power Relay Wiring Information ...............................................33

E2290A 16-Bit Digital I/O Wiring Information.........................................................34

E2291A 16-Channel Isolated Digital Output Wiring Information.............................35

Contents 1

Page 4

2 Contents

Page 5

Certification

Agilent Technologies, Inc. certifies that this product met its published specifications at the time of shipment from the factory. Agilent

Technologies further certifies that its calibration measurements are traceable to the United States National Institute of Standards and

Technology (formerly National Bureau of Standards), to the extent allowed by that organization's calibration facility, and to the

calibration facilities of other International Standards Organization members .

AGILENT TECHNOLOGIES WARRANTY STATEMENT

AGILENT PRODUCT: B-size and C-s i z e VX I modules DURATION OF WARRANTY: 1 year

1. Agilent warrants Agilent hardware, accessories and supplies against defects in material s and workmanship for the period specified

above. If Agilent receives notice of such defects during the warranty period, Agilent will, at its option, either repair or replace products

which prove to be def e ctive. Replacement products may be either new or like-new.

2. Agilent warrants that Agilent software will not fail to execute its programming instructions, for the period specified above, due to

defects in material and workmanship when properly installed and used. If Agilent receives notice of such defects during the warranty

period, Agilent will replace software media which does no t execu te its programm in g instr uctio ns du e to such defe cts.

3. Agilent does not warrant that the operation o f Agilent products will be interrup ted or error free. If Agilent is unable, within a reasonable

time, to repair or replace any product to a con dition as warrant ed, custome r will be entit led to a ref und of the pu rchase pri ce upon prompt

return of the product.

4. Agilent products may contain remanufactured parts equivalent to new in performance or may have been subject to incidental use.

5. The warrant y peri od begi ns on the d ate of deliver y or on the date o f install ation if install ed by A gilent. If custom er sch edul es or dela ys

Agilent installation more than 30 days after delivery, warranty begins on the 31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or inadequate maintenance or calibration, (b) software, interfacing, parts

or supplies not supplied by Agilent, (c) unauthorized modification or misuse, (d) operation outside of the published environmental

specifications for the product, or (e) improper site preparation or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTY OR CONDITION, WHETHER WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED AND AGILENT

SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OR CONDITIONS OF MERCHANTABILITY, SATISFACTORY

QUALITY, AND FITNESS FOR A PARTICULAR PURPOSE.

8. Agilent will be liable for damage to tangib le property per in cident up to the gre ater of $300,000 or the actual amoun t paid for t he pr oduct

that is the subject of the claim, and for damages for bodily injury or death, to the extent that all such damages are determined by a court

of competent jurisdiction to have been directl y caused by a defective Agilent product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS WARRANTY STATEMENT ARE CUSTOMER’S

SOLE AND EXLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO E VENT WILL AGILENT OR ITS SUPPL IERS BE

LIABLE FOR LOSS OF DATA OR FOR DIRECT, SP ECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST PROFIT OR

DATA), OR OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS

STATEMENT, EXCEPT TO THE EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE, REST RICT OR MODIFY AND ARE

IN ADDITION TO THE MANDATORY STATUTORY RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

U.S. Government Restricted Rights

The Software and Documentation have been developed entirely at private expense. They are delivered and licensed as "commercial

computer software" as defined in DFARS 252.227- 7013 (Oct 1988), DFARS 252.211-7015 (May 1991) or DFARS 252.227-7014 (Jun

1995), as a "commerci al item" as defined in FAR 2.101(a), or as "Restricted computer software" as defined in FAR 52.227-19 (Jun

1987)(or any equivalent agency regulation or contract clause), whichever is applicable. You have only those rights provided for such

Software and Documentation by the applicable FAR or DFARS clause or the standard software agreement for the product involved.

Agilent E2251A M-Module Carrier Installation Manual

Copyright © 1998-2006 Agilent Technologies, Inc. All Rights Reserved.

Edition 1

3

Page 6

or

Documentation History

All Editions and Updates of t his manu al and th eir creati on da te are list ed belo w. The first Edition of the m anual is Editi on 1. T he Ed ition

number increments by 1 whenever the manual is revised. Upd a tes, which are issued between Editions, contain replacement pages to

correct or add additional information to the current Edition of the manual. Whenever a new Edition is created, it will contain all of the

Update information for the previous E dition. Each new Edition or Update also inc ludes a revised co py of this doc umentation hi story page.

Edition 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .June 1997

Edition 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . February 1998

Safety Symbols

Instruction manual symbol affixed to

Instruction manual symbol affixed to

product. Indicates that the user must refer to

product. Indicates that the user must refer to

the manual for specific WARNING or

the manual for specific WARNING or

CAUTION information to avoid personal

CAUTION information to avoid personal

injury or damage to the product.

injury or damage to the product.

Indicates the field wiring te rminal th at must

be connected to eart h ground before

operating the equipment — protects against

electrical shock in case of fault.

WARNING

Alternating current (AC)

Direct current (DC).

Indicates hazardous voltages.

Calls attention to a procedure, practice, or

condition that could cause bodily injury or

death.

Frame or chassis ground terminal—typ ically

connects to the equipment's metal frame.

CAUTION

Calls attention to a procedure, practice, or

condition that coul d possibly cause damage to

equipment or permanent loss of data.

WARNINGS

The following gener al safety precautions must b e observed during all phases of operation, service, and repair of this product. Failure to

comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and

intended use of the product. Hewlett-Packar d Company assumes no liabilit y for the customer's failu re to comply with these requi rements.

Ground the equipment: For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth

ground must be provided from the mains power source to the product input wiring terminals or supplied power cable.

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gases or fumes.

For continued protection against fire, replace the line fuse(s) only with fu se(s) of the same voltage and curren t ratin g and type. DO NOT

use repaired fuses or short-circuited fuse holders.

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Procedures involving the removal of

covers or shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the

equipment sw itche d off. To av oid da ngerou s elec trical s hock , DO N OT per form pr ocedur es inv olving cover or shi eld removal unles s you

are qualified to do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into this product have been

impaired, either through physical damage, excessive moisture, or any other reason, REMOVE POWER and do not use the product until

safe operation can be verified by service-trained personnel. If necessary, return the product to an Agilent Technologies Sales and Service

Office for service and repair to ensure that safety features are maintained.

DO NOT service or adjust alone: Do not attempt internal service or adjustment unless another person, capable of rendering first aid and

resuscitation, is present.

DO NOT substitute parts or modify equipment: Because of th e dang er of int roduc ing ad ditiona l hazar ds, do not ins tall su bstitut e parts

or perform any unauthorized modification to the product. Return the product to an Agilent Technologies Sales and Service Office for

service and repair to ensure that safety features are maintained.

4

Page 7

WARNINGS (contd.)

In a cleanroom environment, some switch modules (such as the E2270A, 2271A, 2273A, etc) are capable of switching voltages that could

cause bodily injury or death to an operator. Special precautions must be adhered to (discussed below) when applying voltages in excess

of 60Vdc, 30Vac rms, or 42.4 Vac peak for a continuous, complex wavef orm.

Module connectors and test signal cables conn e cted to them must be made NO N- a cce ssi ble to an op era t or w ho ha s no t been tol d

to access them: It is a supervisor’s responsibility to advise an operator that dangerous voltages exist when the operator is instructed to

access connectors and cables carry in g t hese voltages. Making cables and connectors that carry hazardous voltages inaccessible is a

protective measure keeping an operator from inadvertant or unknowing contact with these harmful voltages. Cables and connectors are

considered inaccessible if a tool (e.g., scre wdriver, wrench, socket, etc.) or a key (equipment in a locked cabinet) is required to gain access

to them. Additionally, the operator cannot have access to a conductive surface connected to any cable conductor (High, Low, or Guard).

Assure the equipment un der test has a dequate insulatio n between the cable connections and any opera tor-accessible parts (doors,

covers, panels, shields, cases, cabinets, etc.): Verify there are multiple and sufficient protective means (rated for t he v ol tages you are

applying) to assure the operator will NOT come into contact with any energized conductor even if one of the protective means fails to

work as intended. For exam ple, th e inn e r side of a case, c a bine t, d oo r, c ove r, or p ane l c an be cov e red with an in sula tin g m ate ria l as well

as routing the test cables to the module’s front panel connectors through non-conduct ive, flexible conduit such as th at used in electrical

power distribution.

5

Page 8

SA

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name:

Agilent Technologies, Incorporated

Manufacturer’s Address: Measurement Product Generation Unit

815 14th ST. S.W.

Loveland, CO 80537 USA

Declares, that the product

Product Name:

Model Number:

C Size M Module Carrier

E2251A

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

and carries the CE Marking accordingly

Conforms with the following product standards:

EMC Standard

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1997 +A1:1997 / EN 55011:1998

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

Limit

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz

I cycle, 100%

[1]

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

Safety

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

UL 3111-1:1994

IEC 950(1991) + A1(1992) + A2(1993) + A3(1994)

EN 60950(1992) + A1(1992) + A2(1993) + A3(1994)

CSA C22.2#950(1995)

UL 1950(1995)

Supplemental Information:

[1]

The product was tested in a typical configuration with Agilent Technologies test systems.

September 5, 2000

Date Name

Quality Manager

Title

Authorized EU-representative: Agilent Technologies Deutschland GmbH, Herrenberger Straβe 130, D 71034 Böblingen, Germany

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Revision: A.03 Issue Date: 09/05/00

Page 9

Page 10

Page 11

M-Module Installation

This manual provides the following information:

•Installing M-Modules in the E2251A Carrier including:

-- Setting Logical Addresses

-- Attaching Field Wiring and Strain Relief

-- Installing RFI Dress Panels

•Installing the E2251A Carrier in a VXIbus Mainframe

• M-Module installation verification.

•Removing M-Modules from the Carrier.

For general information about the E2251A M-Module Carrier or for

M-Module programming information, refer to the E2251A M-Module

Carrier User’s Manual. For infor mation about speci fic M-Modules, refer to

that M-Module’s User’s Manual. VXIplug&play drivers, downloadable

SCPI drivers, and Soft front panels are avai la ble on t he CD ROM provided

with the Carrier and M-Modules. The E2251A does not support

MA-Modules.

WARNING SERVICE-TRAINED PERSONNEL ONLY. The information in this manual is for

service-trained personnel who are familiar with electronic cir cuit ry and are aware

of the hazards involved. To a void personal i njury or d amage to the i nstrument, do

not perform procedures in this manual or do any servicing unless you are

qualified to do so.

Caution All installation, wiring, and configuration procedures in this chapter are to be

done with power DISCONNECTED from the VXI mainframe and power

DISCONNECTED from any external wiring/cabling. To prevent equipment

damage, DISCONNECT the mainframe's power before installing any module into

the mainframe.

Caution STATIC ELECTRICITY. Static electricity is a major cause of component fai lure. To

prevent damage to the electrical components in the Carrier and the M-Modules,

observe anti-static techniques when installing or removing an M-Module from the

Carrier or installing or removing the Carrier from the VXI mainframe.

Caution Modules in Carrier slot M5 are restricted to 60Vdc, 30Vac

, or 42Vacpk.

rms

Caution Remove all packing material before installing Carrier in VXI mainframe.

9

Page 12

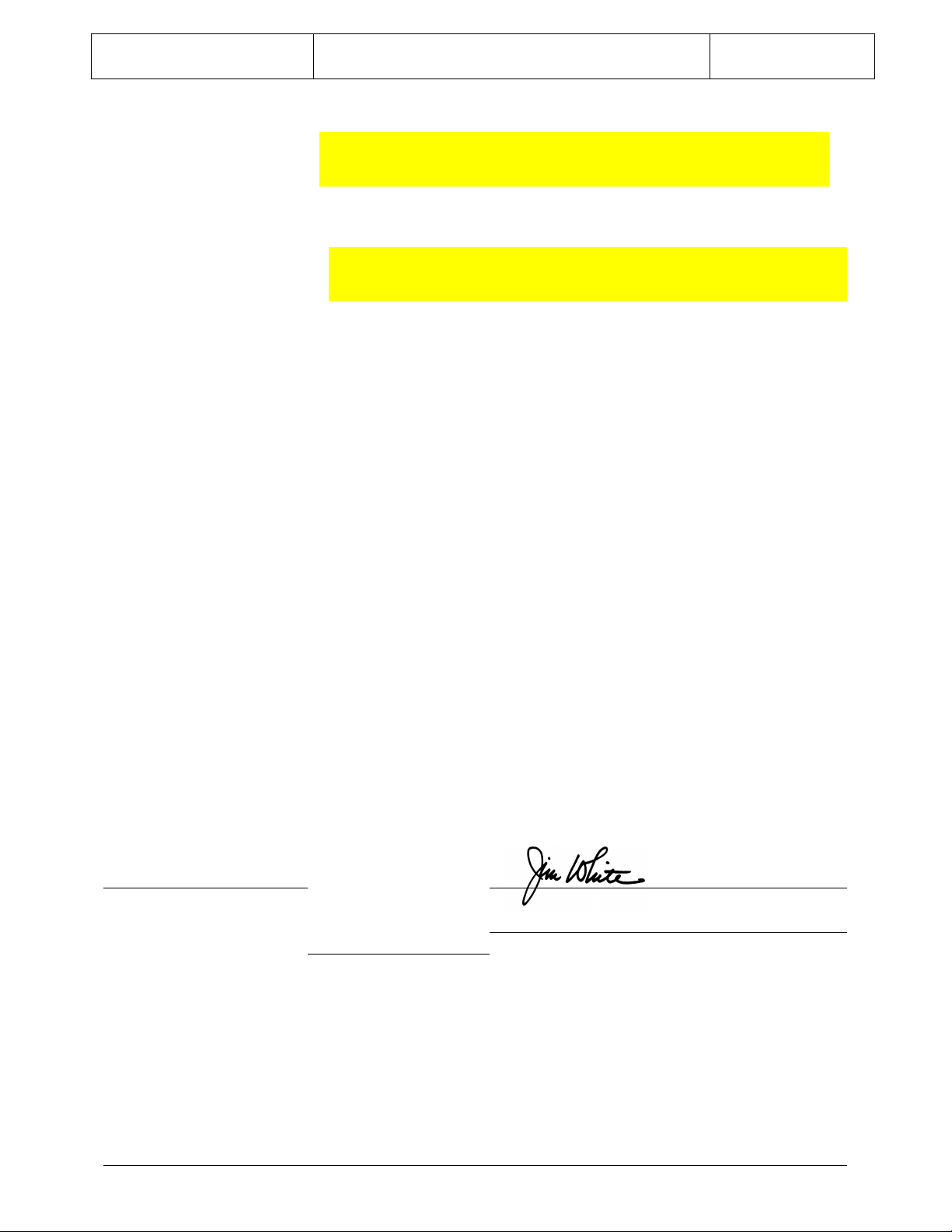

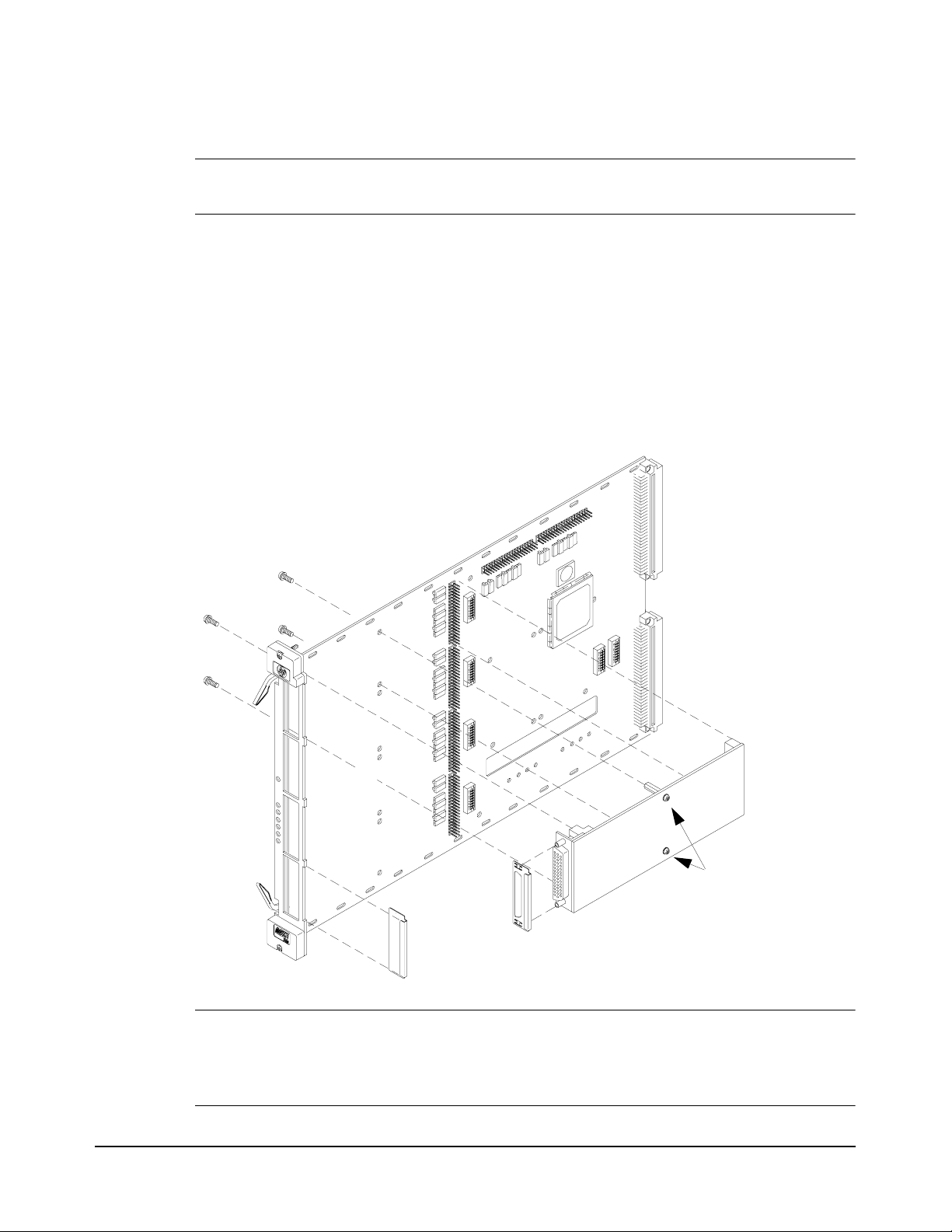

Step 1. Remove the Carrier Shields

1. Remove the four screws securing the Carrier top and bottom shield.

2. Remove the screw securing the PC board to the bottom shield.

3. Set the screws and shields aside for later re-assembly (Step 6).

M3X6

Panhead

Note Some earlier carriers did not have the scr ew sec uri ng t he PC bo ard to t he bot t om shie ld . Instead,

they had a fifth screw securing the top and bottom shields. Remove all five screws to

disassemble the Carrier.

10

Page 13

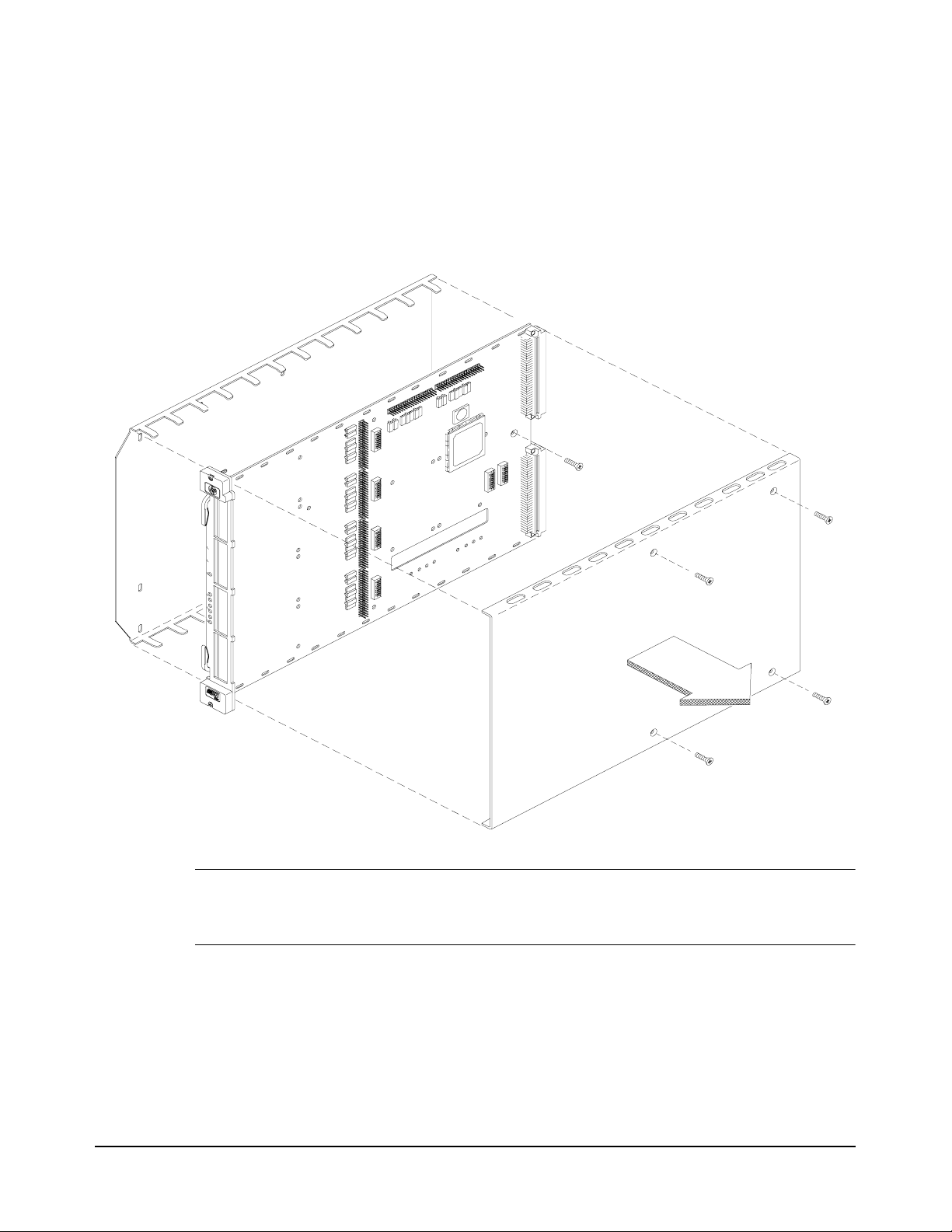

Step 2. Determine M-Module Layout

Up to 4 M-Modules

in front slots (neither

interior slot used)

Up to 5 M-Modules

(interior M-Modules

require external field

wiring)

6 M-Modules

(all slots used, interior

M-Modules do not require

external field wiring)

M

-

M

o

d

u

l

e

M

0

M

-

M

o

d

u

l

e

M

1

M

-

M

o

d

u

l

e

M

2

M

-

M

o

d

u

l

e

M

3

M

-

M

o

d

u

l

e

M

3

M

-

M

o

d

u

l

e

M

3

M

-

M

o

d

u

l

e

M

2

M

-

M

o

d

u

l

e

M

2

M

-

M

o

d

u

l

e

M

1

M

-

M

o

d

u

l

e

M

1

M

-

M

o

d

u

l

e

M

0

M-Module M4

M-Module M5

M-Module M4

M-Module M5

CAUTION: Modules in Carrier slot M5

are restricted to 60Vdc, 30Vac

rms

,

or 42Vac

pk

.

Strain Relief Plates

1. Identify the positions your M-Modules will occupy in the E2251A Carrier. The Carrier can hold up to

six M-Modules only if neither of the modules in the two interior slots (M4 & M5) require external

cabling. If one or both interior modules require external cabling, the bottom-front slot (M0) must be left

unused to accommodate the wiring; strain relief clamps are provided. The following figure shows the

common M-Module layouts.

11

Page 14

Step 3. Set the Logical Address for each M-Module

Each VXI module or M-Modul e in a VXI system must have a unique l ogical

address. The logica l address is used by the VXI resource manager t o identify

instruments. When t he logica l addres s of a module is set to a direct multiple

of 8 (such as 8, 16, 24, ... 256), that module is considered an “instrument”.

An instrument's seconda ry address (used to pro gram the module from GPIB)

is derived by dividing the instrument logical address by 8. For example, a

logical address of 24 is a secondary address of 03.

Guidelines for

Determining Logical

Addresses

Note Multiple-module Scanning Voltmeter or Switchbox instruments are not

Unused Slot s on th e

Carrier

The E2251A comes from the factory with the M-Module logical address

switches set to 0.

instructs the Carrier to ignore that slot and the Carrier does not report it to

the VXI system resource manager.

You must

in the E2251A Carrier.

If you are using an E1406 Command Module set M-Modul e add resses to a

multiple of 8 (i.e., 8, 16, 24, 32, . . . 256). Do not set any M-Modul e logical

address to the same value as any ot her M- Module or any o ther VXI mod ule

in the system. You can use up to 31 M- Modules (up to se ven Carr iers ) with

an E1406 Command Module or 255 M-Modules (up to 51 Carriers) with

embedded controllers, VXLink, or MXIbus controllers.

supported with M-Modules on the E2251A Carrier. Multiple-module

instruments can only be created using standard B- or C-size VXI modules.

Unused slots on the E2251A Carri er should hav e their lo gical addr ess set to

0 (zero). With the logical address set to 0, the Carrier disables the circuits

(interrupt, reserved memory, etc.) for that slot.

1

In the E2251A M-Module Carrier, logical address 0

set the logical address switches for each M-Module installed

1. Note that in a standard VXI system, logical address 0 is reserved for the VXIbus command module / resource

manager. On the E2251A Carrier however, logical address 0 causes the Carrier to disregard that M-Module

slot.

12

Page 15

Setting the

M-Module M2

M-Module M1

M-Module M3

M-Module M0

M-Module M4

M-Module M5

Logical Address

Switch for M3

Logical Address

Switch for M0

Logical Address

Switch for M4

Logical Address

Switch for M5

Addresses

As shown below, the E2251A has six logi ca l ad dress switch banks, one f or

each M-Module slot. You must set the logical address switches for each

M-Module installed in the E2251A Carrier.

A logical address switch bank contains eight individual switches. To

determine the logical address, add together the decimal values of the

switches that are set (posi tion 1 = set, 0 = not set). For example , in the figure

below, switches 4, 5, and 6 are set, t he other switch es are not set. Th e logical

address is the su m of t he decimal values of th e set switches: 16 + 32 + 64 =

112.

13

Page 16

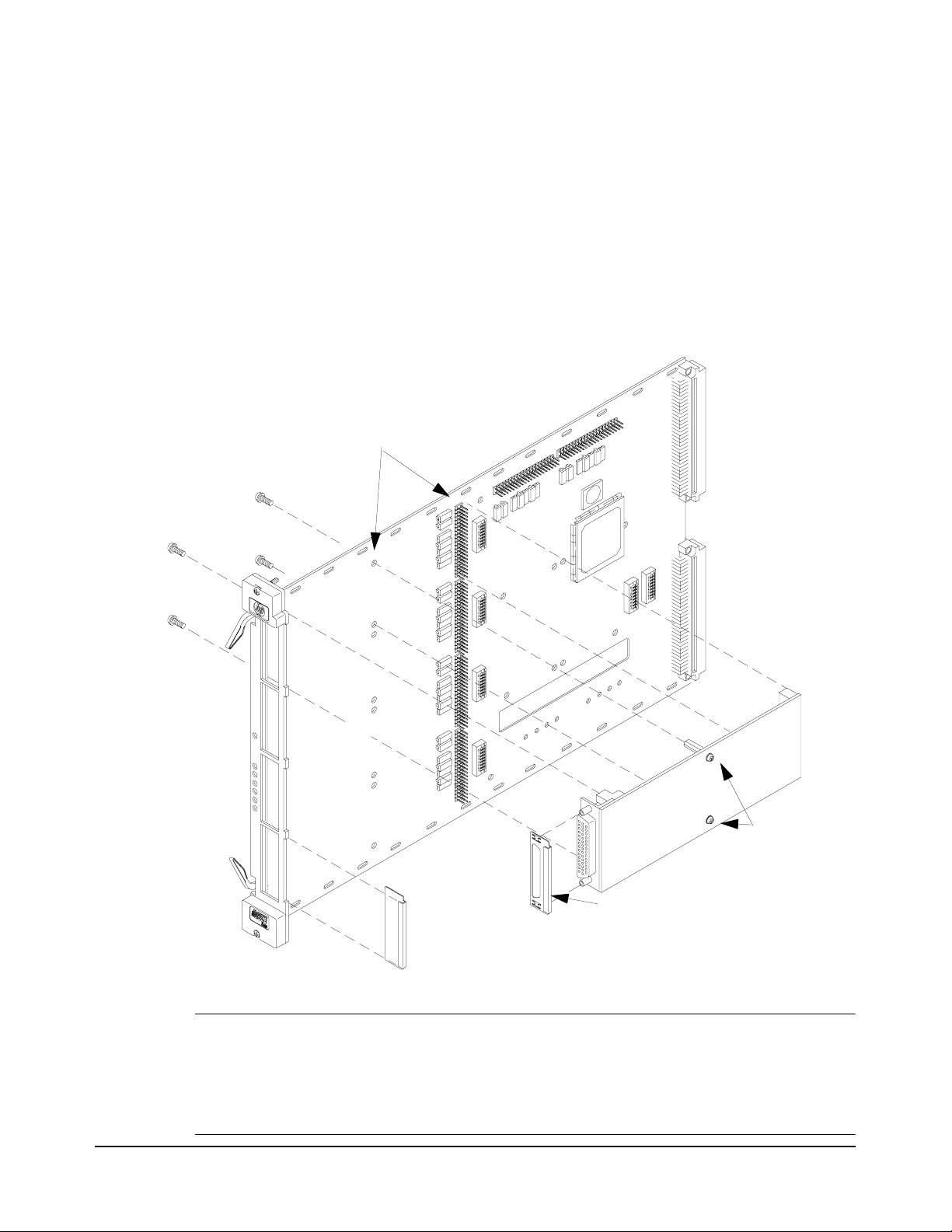

Step 4. Install M-Modules onto the Carrier

1. For internally-mounted M-Modules (slots M4 and M5) see Step 5, next page.

2. Install RFI Dress Panel (p.n. E2273-04301) on each of the front mounted M-Modules. Dress panels act

like a gasket and minimize RFI. Make certain the M-Module-to-Carrier connectors line up properly.

Make certain the M-Module standoffs are aligned over the screw mounting holes.

3. Secure each M-Module to the Carrier (from the back side) with four M3x5 mounting screws

(p.n. 0515-0372, with captive lock washer) supplied with M-Module. Open handles on Carrier to install

screws for slots M0 and M3 M-Modules.

4. Install blank Dress Panel (p.n. E2251-04301) over each unused front panel slot to minimize RFI.

2. Align M-Module on Carrier.

3. Secure M-Module with

four M3x6 screws.

0515-0430

Do not remove

these screws

if removing

M-Module.

1. Install E2273-04301

Dress Panel on M-Module.

4. Install E2251-04301 Blank

Dress Panels on Empty Slots.

If necessary, slightly crimp Dress Panel with pliers so it stays attached to Carrier front panel.

Caution Static Electricity. Use anti-static techniques when installing/removing M-Module.

Use care when installing M-Modules onto the carrier connectors. The Carrier and

M-Module connectors ARE NOT keyed; it is possibl e to misalign an M-Modul e and

connect it to the wrong connectors. APPLYING POWER TO A MISALIGNED

M-MODULE WILL DAMAGE OR DESTROY THE M-MODULE AND THE CARRIER.

14

Page 17

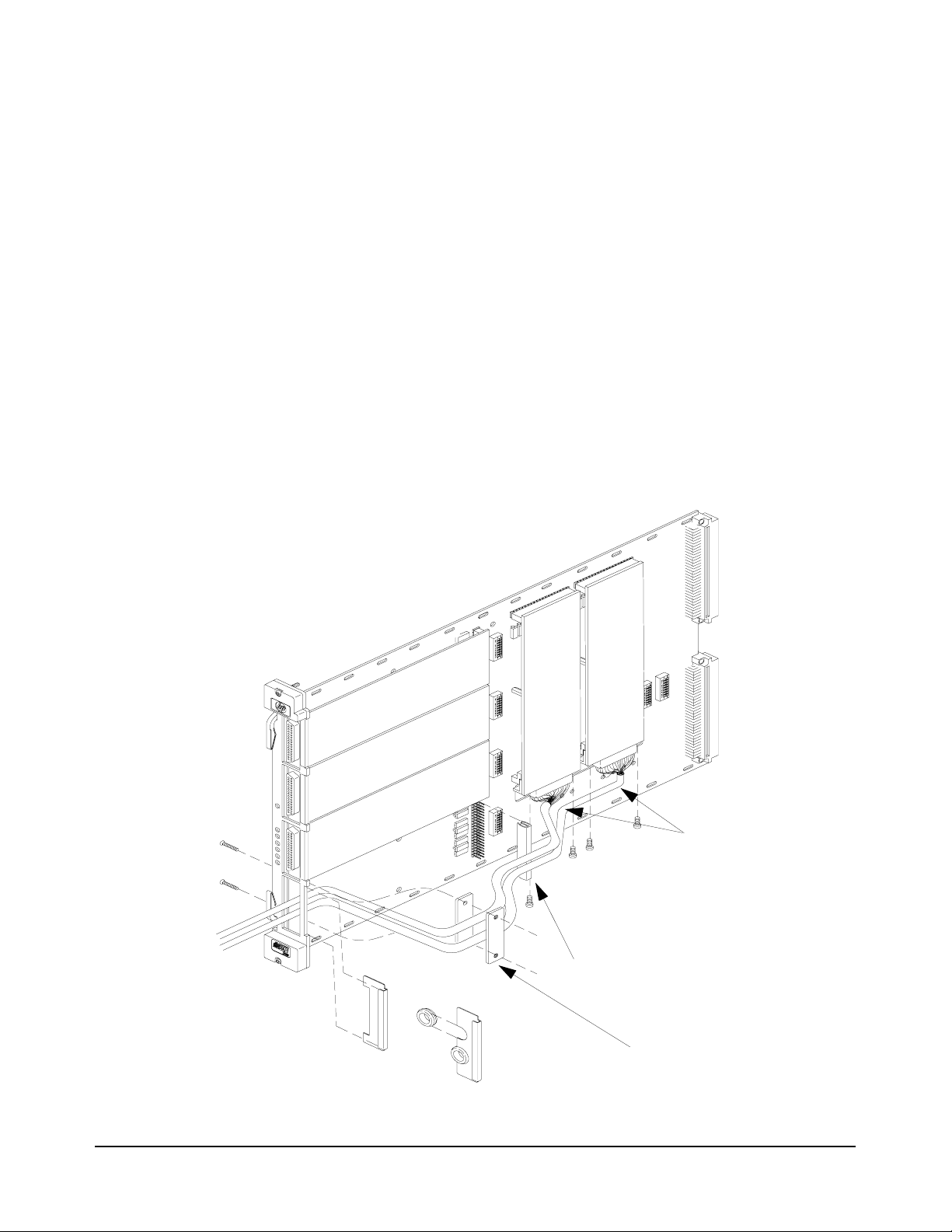

Step 5. Connect Field Wiring to Slot M4 & M5 M-Modules

If you installed M-Modules on either or both of the interior slots, the following instructions describe how to

secure the field wiring. If you did not install an M-Module in slots M4 or M5, skip this page and go to Step 6.

1. Cover the M0 2-row connector strip with provided Pin Protector/Cover (p.n. 1252-8273). This pin

protector protects the field wiring from chafing against the connector pins.

Note: Do not install the plastic cable hood (see page 21) on the field wiring connectors for the two internal

M-Modules. Do not install the RFI dress panels on the two interior M-Modules. If an RFI dress panel is

already installed on an M-Module, it must be removed. They are not needed and may interfere with

installatio n of the top shield.

2. Holes are provided in the Carrier for cable ties to secure the field wiring cables.

3. Install cable clamp plates (p.n. E 2251-01203) on top si de of PC boa rd. Secur e the cabl e clamp ( but do not

overtighten). Both clamps are required to prevent damage to PC board.

4. To minimize RFI, install a dress panel (p.n. E2251-04301) over the front panel M0 slot position. Have

the dress panel machined or punched to allow the cable to pass through. Machine the cut as small as

possible; large enoug h for the cab le and opt ional gro mmet (t o preve nt chaf ing) bu t ti ght to minimize RFI.

M3x20 Pan Head Screws

p.n. 0515-1410

2. Attach field wiring

5. Machine Dress Panel

for ribbon cable or

punch Dress Panel and add grommet for round cable.

3. Secure field wiring to

Carrier with wire ties

through holes provided

on Carrier.

to M-Modules

with 4-40 Pozidrive screws.

1. Place p.n. 1252-8273

Pin Protector over pins

to protect cable.

4. Install Cable Clamp.

Do not overtighten.

15

Page 18

Step 6. Reattach the Carrier Shields

1. Carefully place the place the PC boar d on t he bot tom Carrier shie ld. Align the mou nting holes an d secu re

with the mounting screw.

2. For modules mounted in the interior slots (M4 & M5), make certain their field wiring is not pinched.

3. Position the top shield and align the mounting holes. Install four screws securing the top and bottom

shields.

4. Attach supplied M-Module labels to the Carrier top shie ld and the RFI Dres s Panel to iden tify M-Modu le

installed in the Carrier.

M3X6

Panhead

Note Some earlier carriers did not have the scr ew sec uri ng t he PC bo ard to t he bot t om shie ld . Instead,

they had a fifth screw securing the top and bottom shields. Remove all five screws to

disassemble the Carrier.

16

Page 19

Step 7. Install Carrier into C-Size VXI Mainframe

1. Set the Carrier Extraction

2. Slide the Carrier into any slot

(except Slot 0) until the backplane

connectors touch.

3. Seat the Carrier

into the mainframe by

pushing in the extraction

levers.

4. Tighten the top and bottom screws

to secure the Carrier

to the mainframe.

Levers out.

Note: Do not push on the front

panel of the E2251A Carrier.

Doing so may bend the front panel.

WARNING To avoid possible electrical shock, make certain that power is removed from the

VXI mainframe, all field wiring, and external devices connected to the VXI

mainframe.

17

Page 20

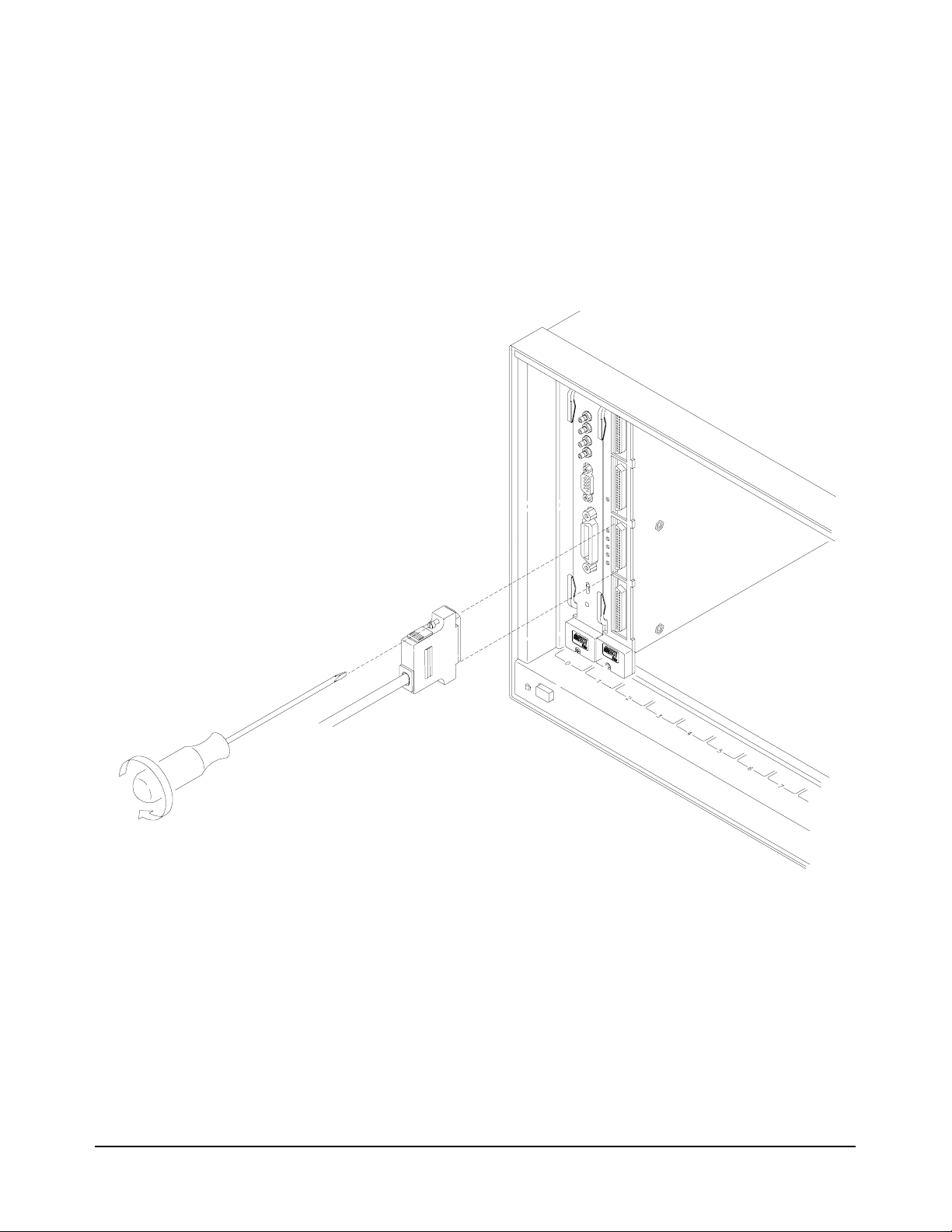

Step 8. Connect Field Wiring to Front M-Modules

1. Refer to “Assembling the M-Module Field Wiring Connec tor ” on page 21 for information on assembling

the connector and hood.

2. Attach assembled connector to M-Modules.

3. Tighten mounting screws to secure connector to the M-Module.

18

Page 21

Step 9. Installation / Operational Verification

1. Turn on the VXI mainframe and use the VXIplug&play Soft Front Panel s (SFP) to veri fy installat ion and

operation of the M-Modules. The SFPs are supplied on the CD ROM accompanying your M-Modules

and Carrier. The SFP is an MS Windows

M-Module over GP-IB or from an embedded controller. For systems with a GPIB-VXI Command

Module, such as the E1406, connect a GPIB cable between the computer’s I/O interface and the

Command Module. If the inst rument is not avail able, you can st ill run th e SFP with ‘li ve mo de’ di sable d.

Start the SFP by selectin g the LOGO a nd in str ument name in the VXIpnp program group . On li ne he lp is

available with the SFP.

You Are Done This concludes the M-Module Installation, Configuration, and Wiring

procedures for the E2251A M-Module Carrier. For Operating and

Programming information refer to the E2251A M-Module Carrier User’s

Manual. For information about specific M-Modules, refer to the respective

M-Module User’s Manual.

®

application that allows you to program an instrument or

19

Page 22

Removing M-Modules from the Carrier

WARNING To avoid possible hazardous electrical shock, remove power from the VXI

Mainframe, all field wiring, and external devices connected to the VXI mainframe.

1. Remove all field wiring connectors from the front-moun ted M-Module s of the E2251A. Refer to “Step 8.

Connect Field Wiring to Front M-Modules” on page 18 for general guidelines.

2. Remove the Carrier from the VXI Mainframe. Open the extraction levers to release the Carrier from the

mainframe. Refer to “Step 7. Install Carrier into C-Size VXI Mainframe” on page 17 for general

guidelines.

3. Follow instructions in “Step 1. Remove t he Carrier Shields” on p age 10 of this manual to remo ve t he to p

and bottom shields from the Carrier.

4. Refer to the figure below to remove M-Modules from the Carrier.

Remove these four screws

to remove M-Module from Carrier.

Do NOT remove

these two screws

from M-Modu le!

If moving M-Module to slot M4 or M5, remove

RFI Dress Panel from M-Module

Caution STATIC ELECTRICITY. Static electricity is a major cause of component fai lure. To

prevent damage to the electrical components in the Carrier and the M-Modules,

observe anti-static techniques when installing or removing an M-Module from the

Carrier or installing or removing the Carrier from the VXI mainframe.

20

Page 23

M-Module Field Wiring Information

The following section provides a brief, summary of the field wiring for each Hewlett-Packard M-module. It

includes a conne cto r pin-out table, a si mp li fi ed schematic, and a con nector drawing. For add it ional information

about a specific M-Module, refer to the respective M-Module’s User’s Manual.

Caution Do not exceed the voltage and current specifications for the indivi dual modules.

Caution All installation, wiring, and configuration procedures are to be done with power

DISCONNECTED from the VXI mainframe and power DISCONNECTED from any

external wiring/cabling.

WARNING To prevent electric shock, tighten all faceplate and mounti ng screws when

installing M-Modules on the Carrier and the field wiring connector mounting

screws.

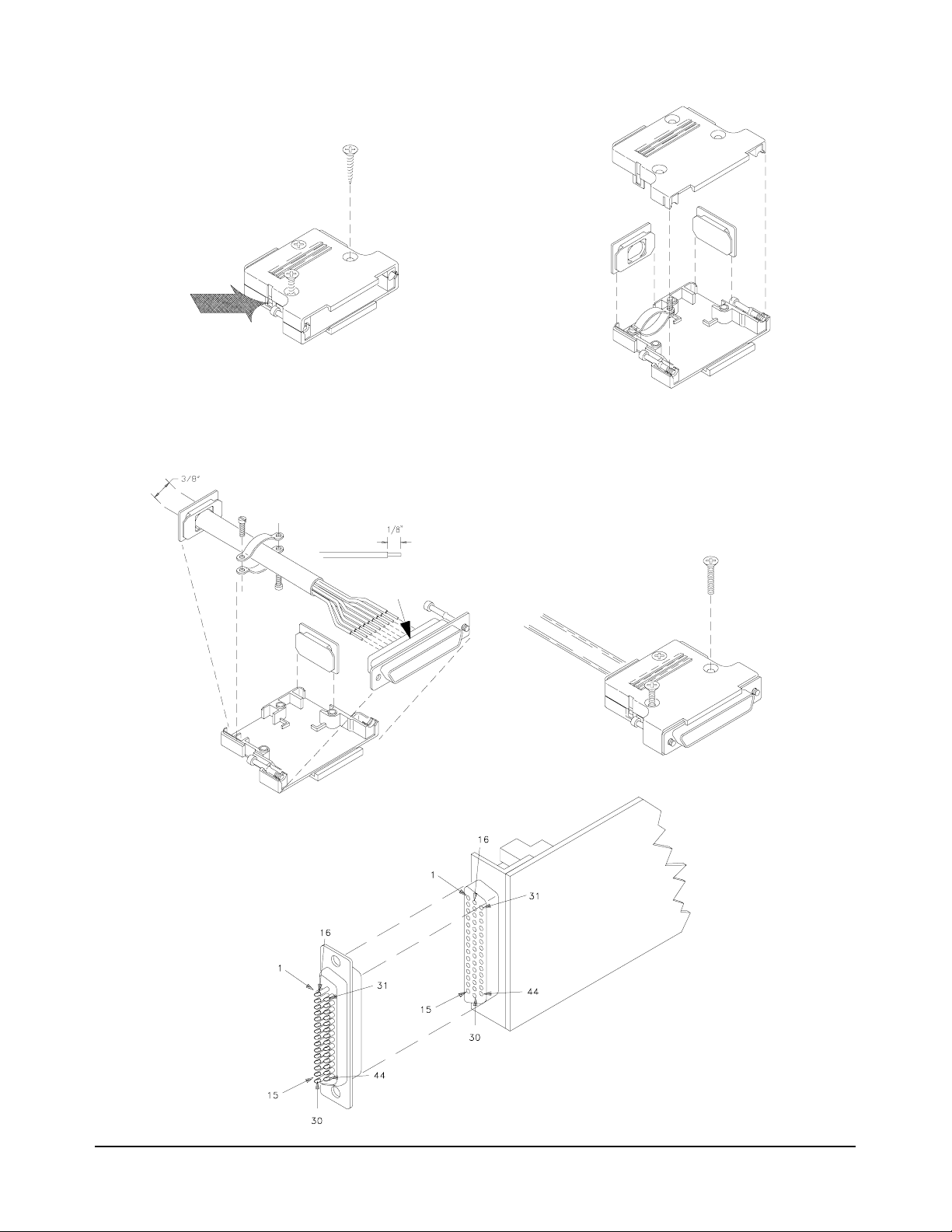

Assembling the M-Module Field Wiring Connector

Most M-Modules come supplied with a 44-p in co nnec tor and matching hood with strain reli ef (k it part number

E2251-01203). You must supply your own cable. The figure on the next page shows how to assemble the

connector and hood.

Note Do not assemble the hood to the connector for the two internally-mounted M-Modules. Strain

relief can be provided by wire ties through holes in the Carrier.

21

Page 24

22

Page 25

2. Release the latch on the

side of the hood.

3. Assemble bezel and

cable clamp before wiring

cable to connector.

1. If necessary, disassemble

the connector hood. Discard

the three self-tapping screws

supplied with the hood.

4. Wire cable to connector.

(24 AWG or smaller)

6. Assemble connector, cable

strain relief, and hood.

Use the supplied M3x12

machine screws.

5. Place connector and

connector screws on bottom shell.

23

Page 26

E2259A Double-Wide Breadboard M-Module Wiring Information

24

Page 27

E2259A

J102 Pinout Table

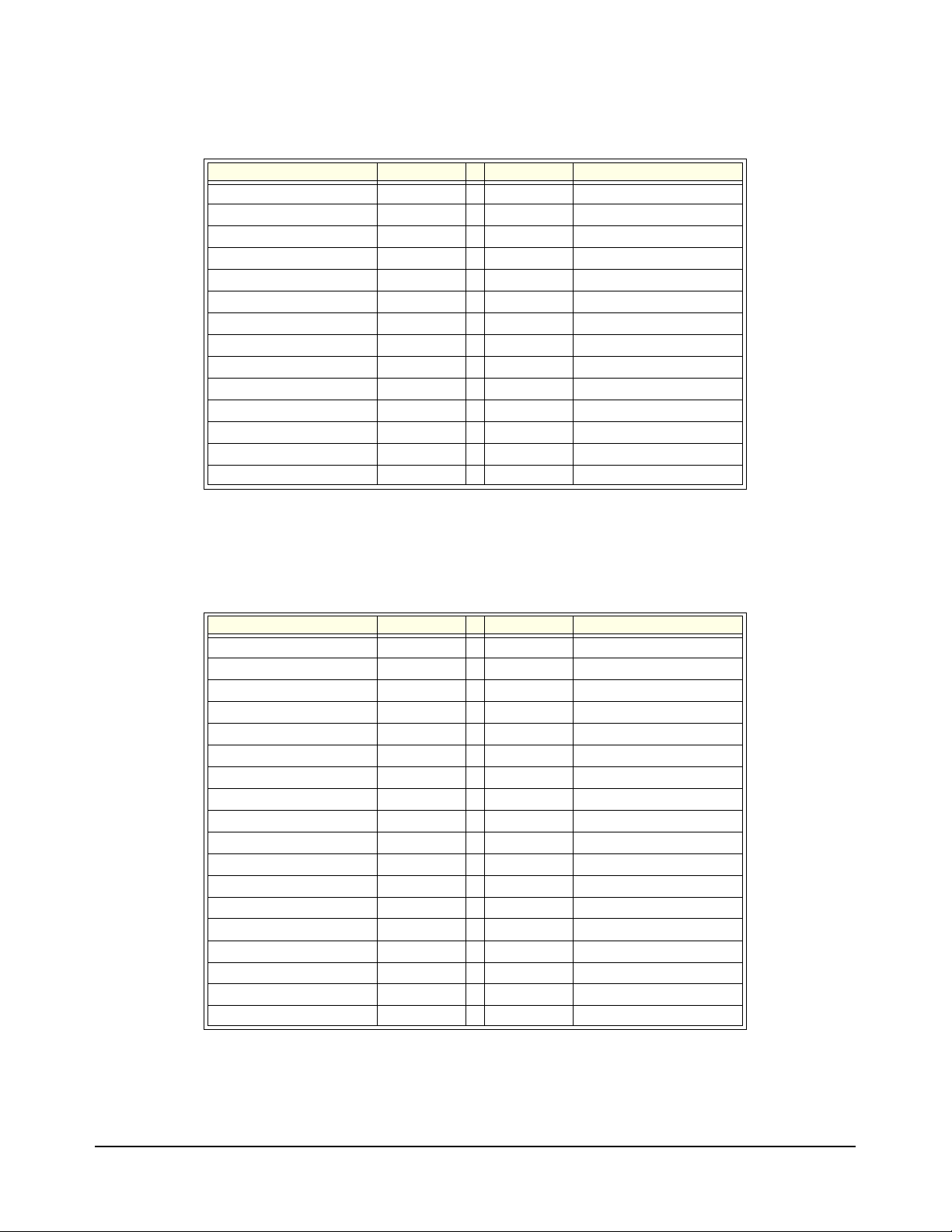

Description Pin Number Pin Number Description

RP712RP6

RP534RP4

RP356RP2

RP178RP0

WP7 9 10 WP6

WP5 11 12 WP4

WP3 13 14 WP2

WP1 15 16 WP0

Busy* 17 18 +5V dc

CRST 19 20 +5V dc

LAT* 21 22 +5V dc

EINT* 23 24 GND

CRST* 25 26 GND

DBEN* 27 28 GND

E2259A

J103 Pinout Table

Description Pin Number Pin Number Description

TR012TR1

TR234TR3

TR456TR5

TR678TR7

TR8 9 10 TR9

TR10 11 12 TR11

TR12 13 14 TR13

TR14 15 16 TR15

BC0 17 18 BC1

BC2 19 20 BC3

BC4 21 22 BC5

BC6 23 24 BC7

BC8 25 26 BC9

BC10 27 28 BC11

BC12 29 30 BC13

BC14 31 32 BC15

GND 33 34 GDN

Chassis GND 35 36 Chassis GND

25

Page 28

E2261A Quad RS-232 Interface Wiring Information

Serial Port 1

Serial Port 2

Serial Port 3

Serial Port 4

HP E2261A Quad Serial M-Module

Pin Name and Function

DTR Data Terminal Ready 1 5 9 13 4

TD Transmitted Data 2 6 10 14 3

RD Received Data 3 7 11 15 2

RTS Request to Send 16 20 24 28 7

CTS Clear to Send 17 21 25 29 8

DSR Data Set Ready 18 22 26 30 6

SG Signal Ground 4, 8, 12, 19, 23, 27 5

{

{

{

{

Port 1

Pin #s

Port 2

Pin #s

Port 3

Pin #s

Port 4

Pin #s

9-Pin Connector

Pin #

Chassis Connection

a. If you use a shielded cable, connect the shield to a chassis connector pin on the 44-pin

connector. Do not connect the other end of the shield.

a

31, 32, 33, . . . 43, 44 -

Note: If you use the optiona l E2261-6 1601 ca ble, you must remo ve the cab le hood i f you inst all t he E2261A in

either of the two internal slots of the E2251A Carrier. The figure on the next page shows the cable wiring for

making your own cable.

26

Page 29

Port 1

Port 2

Note: If you are using shielded cable,

connect the shield to pins 31 - 44

on the 44-pin M-Module connector

only. This connects the shield to the

VXI chassis (earth ground).

Port 3

Port 4

27

Page 30

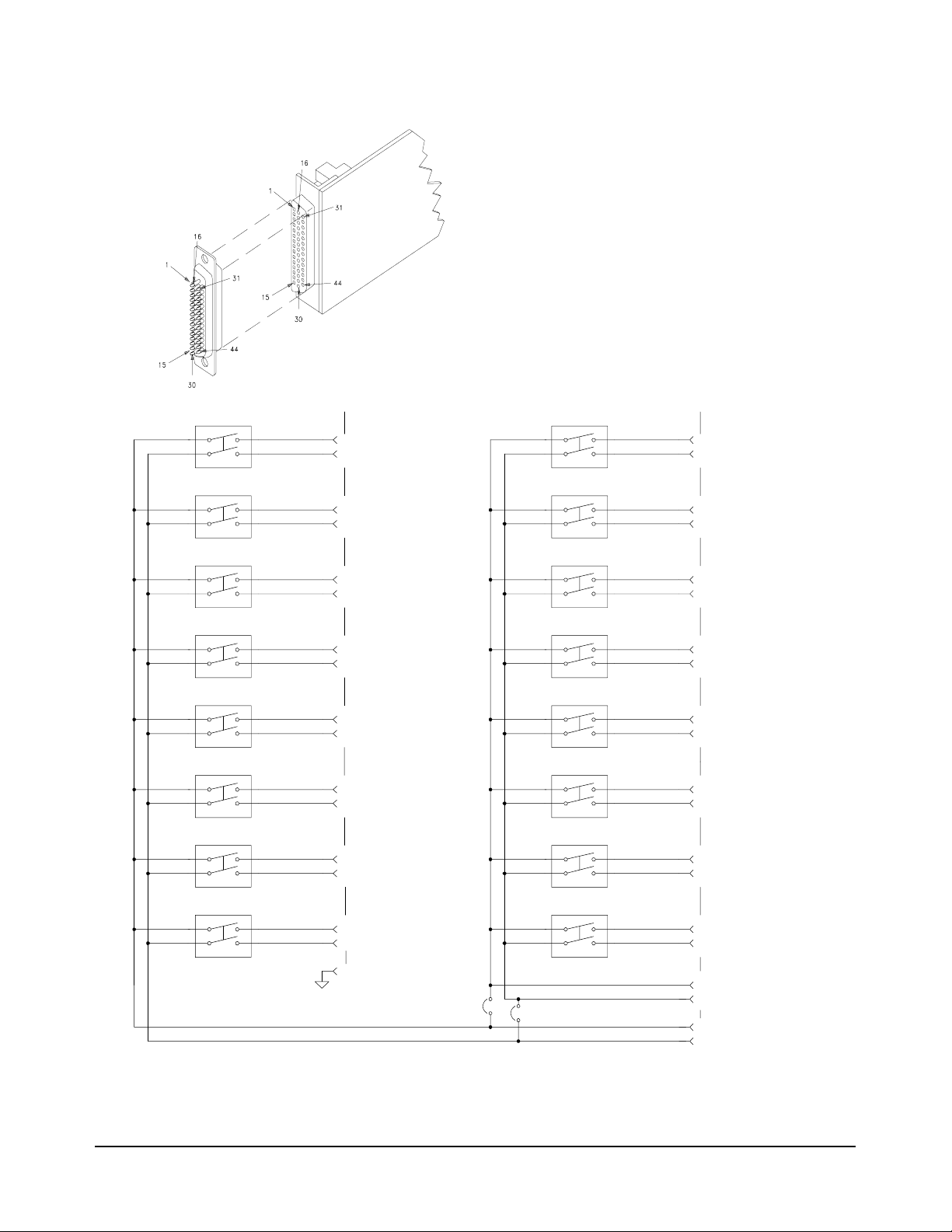

E2270A 16-Channel Form A Switch Wiring Information

MAXIMUM VOLTAGE/CURRENT: The maximum voltage

that may be applied to any connector on the E2270A,

E2271A, or E2272A is 200 VDC, 125 VA C rms, or 175 VAC

peak. These limits apply only if the product is installed

in a humidity-controlled (<60% RH) environment where

airborne contaminants and transients are controlled,

and there is NOT a relay connection made to power

mains. If these conditions CANNOT be maintaine d, then

the maximum voltage is 60 VD C, 48 VAC rms or 68 VAC

peak.

The maximum current (non-inductive) that may be applied to the E2270A, E2271A, or E2272A is:

Per Switch: 2 ADC, 2 AAC peak

User

Connector

Pins

Per M-Module: 8ADC, 8AAC peak

User

Connector

Pins

Channel 0

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

Channel 6

Channel 7

1 CH0_NO

16 CH0_COM

2 CH1_NO

17 CH1_COM

3 CH2_NO

18 CH2_COM

4 CH3_NO

19 CH3_COM

5 CH4_NO

20 CH4_COM

6 CH5_NO

21 CH5_COM

7 CH6_NO

22 CH6_COM

8 CH7_NO

23 CH7_COM

Channel 8

Channel 9

Channel 10

Channel 11

Channel 12

Channel 13

Channel 14

Channel 15

9 CH8_NO

24 CH8_COM

10 CH9_NO

25 CH9_COM

11 CH10_NO

26 CH10_COM

12 CH11_NO

27 CH11_COM

13 CH12_NO

28 CH12_COM

14 CH13_NO

29 CH13_COM

15 CH14_NO

30 CH14_COM

43 CH15_NO

44 CH15_COM

31 - 42

28

Page 31

E2271A 4x4 Matrix Switch Wiring Information

MAXIMUM VOLTAGE/CURRENT: The maximum voltage

that may be applied to any connector on the E2270A,

E2271A, or E2272A is 200 VDC, 125 VAC r ms, or 175 VAC

peak. These limits apply only if the product is installed

in a humidity-controlled (<60% RH) environment where

airborne contaminants and transients are controlled,

and there is NOT a relay connection made to power

mains. If these condi tions CANNOT be maintained, then

the maximum voltage is 60 VDC, 48 VAC rms or 68 VAC

peak.

The maximum current (non-inductive) that may be

applied to the E2270A, E2271A, or E2272A is:

Per Switch: 2 ADC, 2 AAC peak

Per M-Module: 8ADC, 8AAC peak

Channel 00 Channel 01 Channel 02 Channel 03

User Connector Pins

4 ROW_0_HI

20 ROW_0_LO

Channel 10 Channel 11 Channel 12 Channel 13

Channel 20 Channel 21 Channel 22 Channel 23

Channel 30 Channel 31 Channel 32 Channel 33

2 COL_0_LO

18 COL_0_HI

16 COL_1_LO

31 COL_1_HI

12 COL_2_LO

28 COL_2_HI

15 COL_3_LO

30 COL_3_HI

6 ROW_1_HI

22 ROW_1_LO

8 ROW_2_HI

24 ROW_2_LO

10 ROW_3_HI

26 ROW_3_LO

1, 3, 5, 7, 9, 11, 13, 14, 17,

19, 21, 23, 25, 27, 29, 32-44

User Connector Pins

29

Page 32

E2272A Dual 8-to-1/Single 16-to-1 Relay Multiplexer Wiring Information

MAXIMUM VOLTAGE/CURRENT: The maximum voltage

that may be applied to any connector on the E2270A,

E2271A, or E2272A is 200 VDC, 125 VAC r ms, or 175 VAC

peak. These limits apply only if the product is installed

in a humidity-controlled (<60% RH) environment where

airborne contaminants and transients are controlled,

and there is NOT a relay connection made to power

mains. If these condi tions CANNOT be maintained, then

the maximum voltage is 60 VDC, 48 VAC rms or 68 VAC

peak.

The maximum current (non-inductive) that may be

applied to the E2270A, E2271A, or E2272A is:

Per Switch: 2 ADC, 2 AAC peak

Per M-Module: 8ADC, 8AAC peak

Channel 0

User Connector Pins

Channel 8

1 CH0_HI

2 CH0_LO

User Connector Pins

25 CH8_HI

9 CH8_LO

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

Channel 6

Channel 7

18 CH1_HI

33 CH1_LO

17 CH2_HI

32 CH2_LO

16 CH3_HI

31 CH3_LO

22 CH4_HI

6 CH4_LO

21 CH5_HI

5 CH5_LO

20 CH6_HI

4 CH6_LO

19 CH7_HI

3 CH7_LO

Channel 9

26 CH9_HI

10 CH9_LO

Channel 10

27 CH10_HI

11 CH10_LO

Channel 11

28 CH11_HI

12 CH11_LO

Channel 12

13 CH12_HI

29 CH12_LO

Channel 13

15 CH13_HI

14 CH13_LO

Channel 14

30 CH14_HI

44 CH14_LO

Channel 15

43 CH15_HI

42 CH15_LO

30

34 - 41

Single/Dual Mux. Jumpers

8 MUXB_HI_COM

24 MUXB_LO_COM

23 MUXA_HI_COM

7 MUXA_LO_COM

Page 33

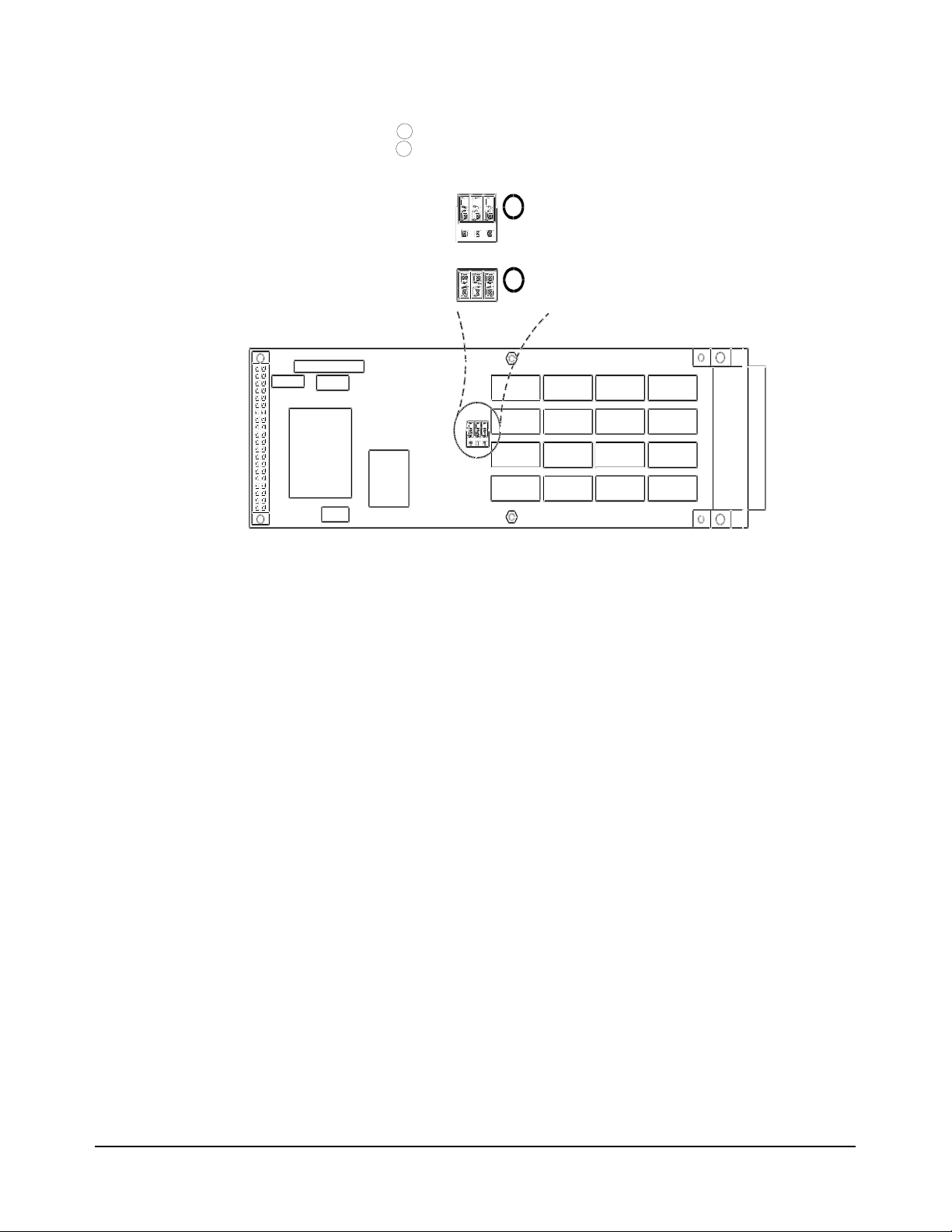

Configuring the

E2272A

The following figure shows the two jumper positions for the E2272A. In

position A , the M-Module is configured as a dual 8-to-1 multiplexer. In

position B , the M-Module is configured as a single 16-to-1 multiplexer.

A Du a l 8-to-1Multipl ex e rPo sitio n

B Single 16-to-1 Multiplexer Position

31

Page 34

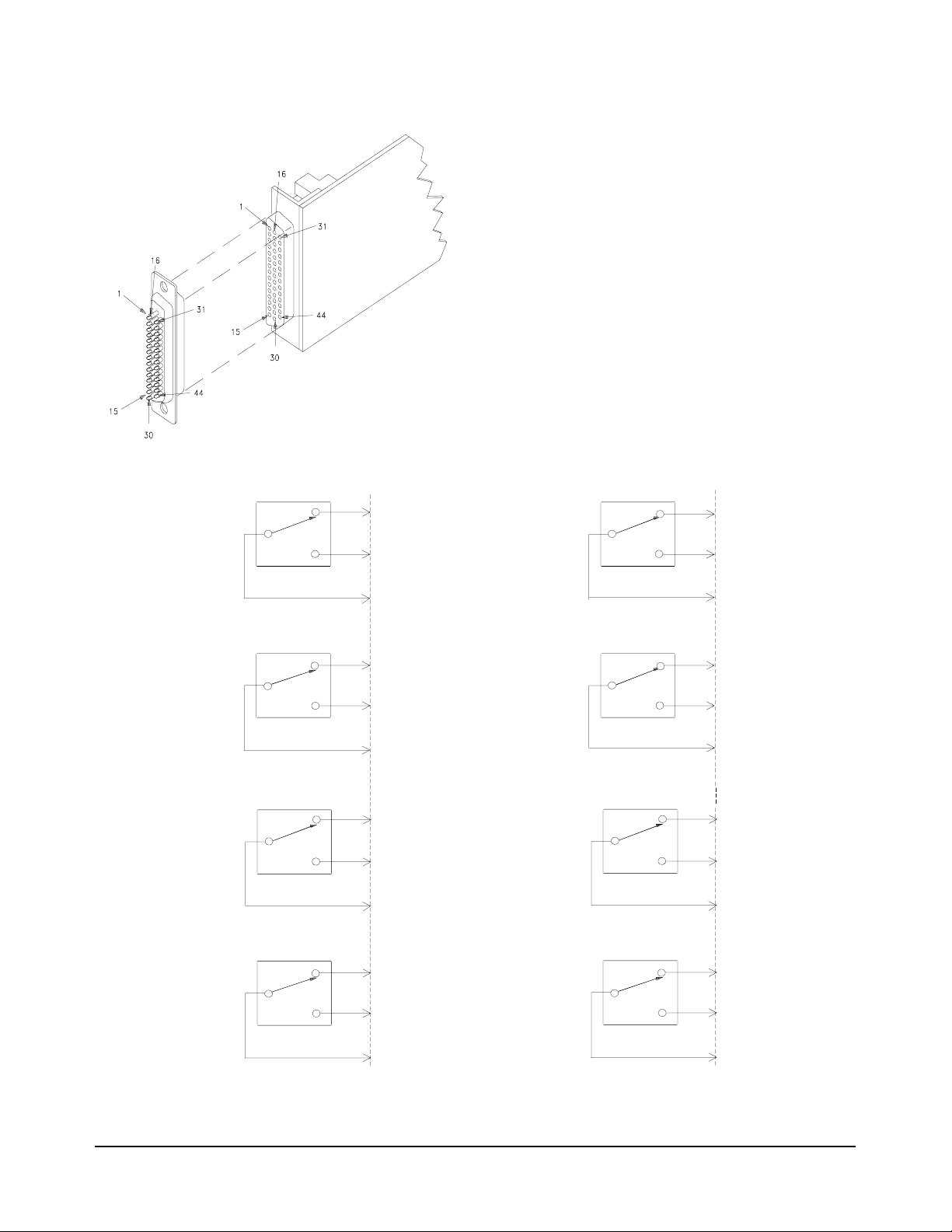

E2273A 8-Channel Form C Switch Wiring Information

MAXIMUM VOLTAGE/CURRENT: The maximum voltage

that may be applied to any connector on the E2273A is

200 VDC, 141 VAC rms, or 200 VAC peak. These limits

apply only if the product is installed in a humidity-controlled (<60% RH) environmen t w he re a irborne c ontam inants and transients are controlled, and there is NOT a

relay connection made to power mains. If these conditions CANNOT be maintained, then the maximum voltage is 60 VDC, 48 VAC rms or 68 VAC peak.

The maximum current (non-inductive) that may be

applied to the E2273A is 1 ADC, 1 AACpeak per switch.

Maximum power is 40W DC, 40VA AC per switch; 100W

DC, 100VA AC per M-Module.

Channel 0

Channel 1

Channel 2

User

Connector

Pins

1

CH0 NC

3

CH0 NO

2

CH0 com

5

7

CH1 NO

6

9

11

CH1 NC

CH1 com

CH2 NC

CH2 NO

Channel 4

Channel 5

Channel 6

User

Connector

Pins

16

18

17

20

22

21

24

26

CH4 NC

CH4 NO

CH4 com

CH5 NC

CH5 NO

CH5 com

CH6 NC

CH6 NO

32

Channel 3

NC = Normally Closed

NO = Normally Open

com = Common

10

13

15

14

CH2 com

CH3 NC

CH3 NO

CH3 com

Channel 7

CGND: Pin 4, 8, 12, 19, 23, 31 - 44

25

28

30

29

CH6 com

CH7 NC

CH7 NO

CH7 com

Page 35

E2274A 4-Channel Power Relay Wiring Information

MAXIMUM VOLTAGE/CURRENT: The maximum voltage

that may be applied to any connector on the E2274A is

125 VDC, 141 VAC rms, or 200 VAC peak. These limits

apply only if the product is installed in a humidity-controlled (<60% RH) environme nt w he re a irborne c ontam inants and transients are controlled, and there is NOT a

relay connection made to power mains. If these conditions CANNOT be maintained, then the maximum voltage is 60 VDC, 48 VAC rms or 68 VAC peak.

The maximum current (non-inductive) that may be

applied to the E2274A is 5 ADC, 5 AACpeak per switch.

Maximum power is 100W DC, 100VA AC, per switch;

300WDC, 300VA AC per M-module.

NC = Norma lly Closed

NO = Normally Open

com = Common

Caution All three connector pins for each relay contact must be

connected together in the field wiring for maximum current

capability. For example, for Channel 1, pins 1, 16, and 31 (for

NC contacts) must be wired toget her in t he field wiring, likewise

pins 3, 18, and 33 (for the NO contact ) and pins 2, 17, and 32 (for

channel common). You may need to run separate wires from

each connector pin and unite them at the device under test or in

your cable.

No Connection: Pins 7, 19, 26

CGND:Pins14,15,30,37,44

33

Page 36

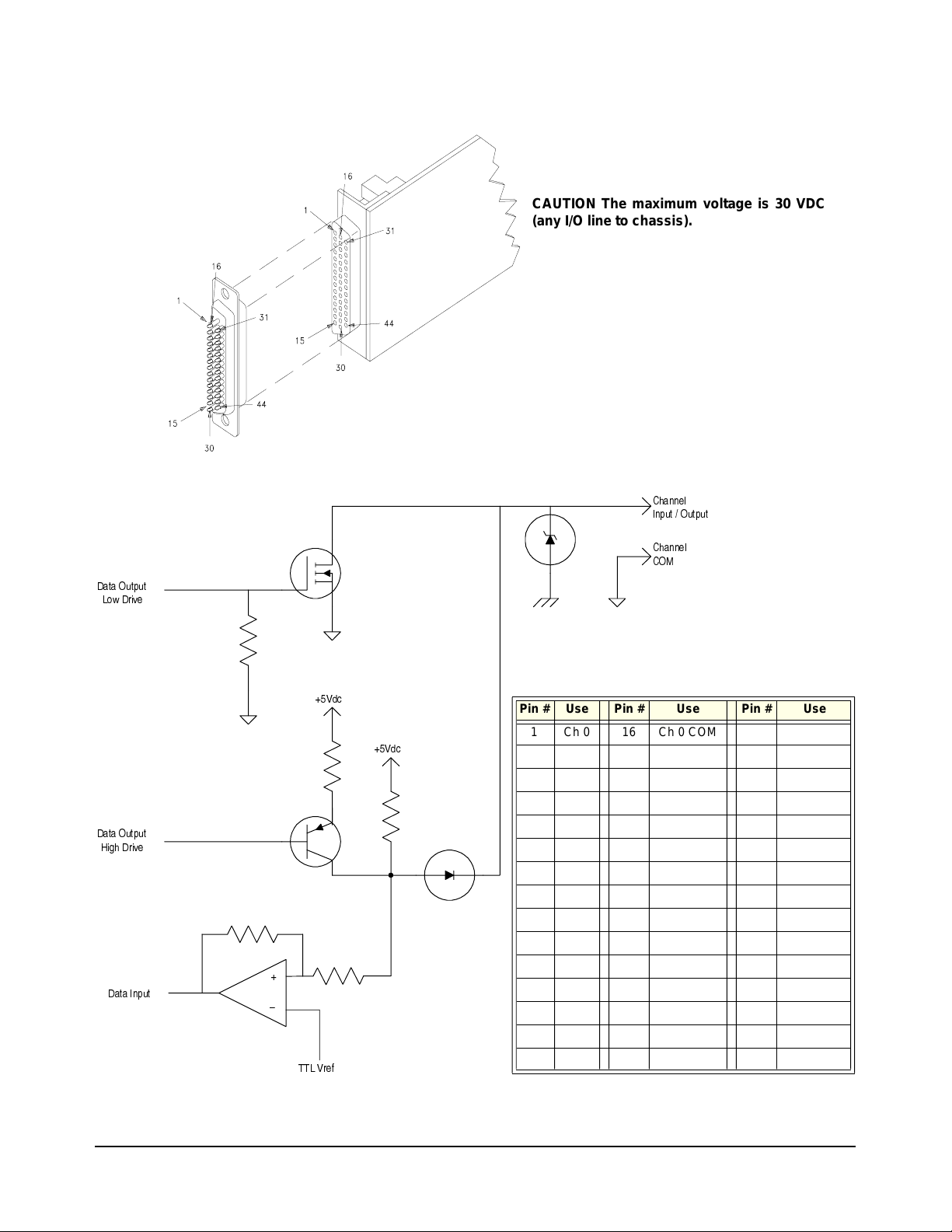

E2290A 16-Bit Digital I/O Wiring Information

CAUTION The maximum voltage is 30 VDC

(any I/O line to chassis).

%BUB 0VUQV U

-PX%SJWF

$IBOOFM

* O Q V U 0V UQ V U

$IBOOFM

$0.

%BUB 0VUQV U

)JHI%SJWF

%BUB * OQ V U

7ED

7ED

@

55- 7S F G

Pin # Use Pin # Use Pin # Use

1 Ch 0 16 Ch 0 COM 31 Chassis

2 Ch 1 17 Ch 1 COM 32 Chassis

3 Ch 2 18 Ch 2 COM 33 Chassis

4 Ch 3 19 Ch 3 COM 34 Chassis

5 Ch 4 20 Ch 4 COM 35 Chassis

6 Ch 5 21 Ch 5 COM 36 Chassis

7 Ch 6 22 Ch 6 COM 37 Chassis

8 Ch 7 23 Ch 7 COM 38 Chassis

9 Ch 8 24 Ch 8 COM 39 Chassis

10 Ch 9 25 Ch 9 COM 40 Chassis

11 CH 10 26 CH 10 COM 41 Chassis

12 CH 11 27 CH 11 COM 42 Chassis

13 Ch 12 28 Ch 12 COM 43 Ch 15

14 Ch 13 29 Ch 13 COM 44 Ch 15 COM

15 Ch 14 30 Ch 14 COM

34

Page 37

E2291A 16-Channel Isolated Digital Output Wiring Information

Note: User must supply +5Vdc to the module. You can supply up to

four isolated supplies (+5V

/TGND4) or they can be combined and one supply used. Refer

+5V

4

to the drawing below.

CAUTION The maximum collector-emitter

voltage is 36 VDC.

/TGND1, +5V2/TGND2, +5V3/TGND3,

1

ЌиззЮЬнил

ϴϾП

ߢ

Ќбϩ ϹϹ

Ќбϩ ϹϺ

Ќбϩ Ϲϻ

ОмЮл

Йвзм

ОмЮл

ЌиззЮЬнил

Йвзм

ϴϾП

Ќбϩ ϹϽ

Ќбϩ ϹϾ

Ќбϩ ϹϿ

ߣ

ϻϻ

Ͼ

ϻϹ

ϻϺ

ϺЁ

Ϻ

ϺϿ

ϺЀ

ϴϾП

Ќбϩ ϹЁ

Ќбϩ ϹЂ

Ќбϩ Ϻ Ϲ

ОмЮл

ЌиззЮЬнил

Йвзм

ߤ

ОмЮл

ЌиззЮЬнил

Йвзм

ϴϾП

Ќбϩ Ϻ ϻ

Ќбϩ Ϻ ϼ

Ќбϩ Ϻ Ͻ

ߥ

ϻЁ

ϺϽ

ϻЂ

ϼϹ

ϻϽ

ϺϹ

ϻϾ

ϻϿ

Ќбϩ Ϲϼ

ϼϺ

ϻϵϩ ϼϵ

НАЗЍ

ЙвзмϩзинϩомЮЭЃϩϽϵϩϺϺϵϩϺϾϵϩϺЂϵϩϻϼϵϩϻЀϵϩϼϽϵϩϽϺ

ϼϻϵϩ ϼϼ

ߢ

Ќбϩ ϹЀ

НАЗЍ

ߣ

ϼϾ

Ͽϵϩ Ѐϵ

ϼϿϵϩ ϼЀ

Ќбϩ Ϻ Ϻ

НАЗЍ

ϽϹ

Ёϵϩ Ђϵ

ϼЁϵϩ ϼЂ

ߤ

Ќбϩ Ϻ Ͼ

НАЗЍ

ߥ

ϽϽ

ϺϻϵϩϺϼϵ

Ͻϻϵ ϩ Ͻϼ

35

Page 38

36

Page 39

Index

E2251A Wiring and Installation Manual

Numerics

16-Channel Switch Wiring, 28

16-to-1 Relay Wiring, 30

4-Channel Power Relay Wiring, 33

4x4 Matrix Switch Wiring, 29

8-Channel Form C Relay Wiring, 32

8-to-1 Relay Wiring, 30

A

Address, Logical, 12

B

Bottom Shield, removing , 10

Bottom Shield, replacin g, 16

Breadboard, Wiring, 24

C

Cable

RS-232, 26

wiring RS-232, 26

Cables, connecting, 18

Carrier

installing into C-Size VXI Mainframe, 17

installing M-Modules onto, 14

removing M-Modules from, 20

slots, 11

Carrier, slots, 12

Caution

disconnect power, 9, 17

M-Module connector alignment, 14

Connect wiring to front M-Modules, 18

Connecting wiring to interior M-Modules, 15

Connector

assembly, 22

wiring, 22

E

Extraction levers, 17

E2259A Wiring Information, 24

E2261A Wiring Information, 26

E2270A Wiring Information, 28

E2271A Wiring Information, 29

E2272A Wiring Information, 30

E2273A Wiring Information, 32

E2274A Wiring Information, 33

E2290A Wiring Information, 34

E2291A Wiring Information, 35

F

Field Wiring Diagrams, 21

Form A Switch Wiring, 28

Form C Relay Wiring, 32

G

Guidelines for determini ng log ica l addr esses, 12

H

Hood, connector, 22

I

Install Carrier into C-Size VXI Mainframe, 17

Installation, verifying VXIplug&play, soft front

panels

, 19

Installing Carrier in Mainframe, 17

Installing Dress Panels, 15

Installing M-Modules, 14

Interior M-Modules, connecting wiring, 15

Interior slots, 11

Interior wiring, connecting, 15

Internal slots, 11

Isolated Digital Output Wiring, 35

D

Digital I/O Wiring, 34

Digital Output Wiring, 35

Dress Panels, 14, 15

Drivers

SCPI, 9

VXIplug&play, 9

L

labels, 16

Layout, M-Module, 11

Logical Address, 12

M

Mainframe, installing Carrier, 17

MA-Module Support, 9

Matrix Switch Wiring, 29

Index 37

Page 40

M-Module

position in Carrier, 11

removing from Carrier, 20

slots, 11

M-Module mating connectors, 15

M-Module Wiring Diagrams, 21

M-Modules

installing, 14

M-Modules, connecting interior wiring, 15

M-Modules, wiring front, 18

Module layout, 11

Multiple Module Instruments, 12

Multiplexer Wiring, 30

O

Operational Verification, 19

P

Placing M-Modules in Carrier, 11

Power Relay Wiring, 33

Power-on Test, 19

R

Removing M-Module from Carrier , 20

Removing shields, 10

Replacing Bottom Shield, 16

Replacing Top Shield, 16

RFI, minimizing, 14, 15

RS-232 Wiring, 26

V

Verify M-Module Installation, 19

VXI Mainframe, installing Carrier in, 17

VXIplug&play, 9

VXIplug&play driver, see CDROM

VXIplug&play function reference, see CDROM

VXIplug&play programs, see CDROM

VXIplug&play soft front panels, see CDROM

W

Wiring Diagrams, 21

Wiring front M-Modules, 18

Wiring Information

E2259A, 24

E2261A, 26

E2270A, 28

E2271A, 29

E2272A, 30

E2273A, 32

E2274A, 33

E2290A, 34

E2291A, 35

Wiring, connecting to interior M-Modules, 15

S

Scanning Voltmeter, 12

SCPI Drivers, 9

Serial Port Wiring, 26

Shields, removing, 10

Shields, replacing, 16

Slots in Carr ier, 12

Switchbox, 12, 12

T

Top Shield, removing, 10

Top Shield, replacing, 16

U

Unused slots in Carrier , 12

38 Index

Loading...

Loading...