Page 1

Agilent Technologies

E1563A 2-Channel Digitizer

E1564A 4-Channel Digitizer

User’s Manual

Manual Part Number: E1563-90004

Printed in U.S.A. E0501

Page 2

Page 3

Contents

E1563A/E1564A Digitizers User’s Manual

Front Matter....................................................................................................................... 9

Agilent Technologies Warranty Statement ................................................................... 9

U.S. Government Restricted Rights............................................................................. 9

Documentation History............................................................................................... 10

Safety Symbols .......................................................................................................... 10

Warnings .................................................................................................................... 10

Declaration Of Conformity.......................................................................................... 11

Chapter 1 - Configuring the Digitizer Modules ........................................................... 13

Using This Chapter .................................................................................................... 13

Digitizers Description ................................................................................................. 13

General Information ............................................................................................ 13

Front Panel Features .......................................................................................... 14

Warnings and Cautions.............................................................................................. 17

Configuring the Digitizers ........................................................................................... 19

Adding RAM to the Module ................................................................................. 19

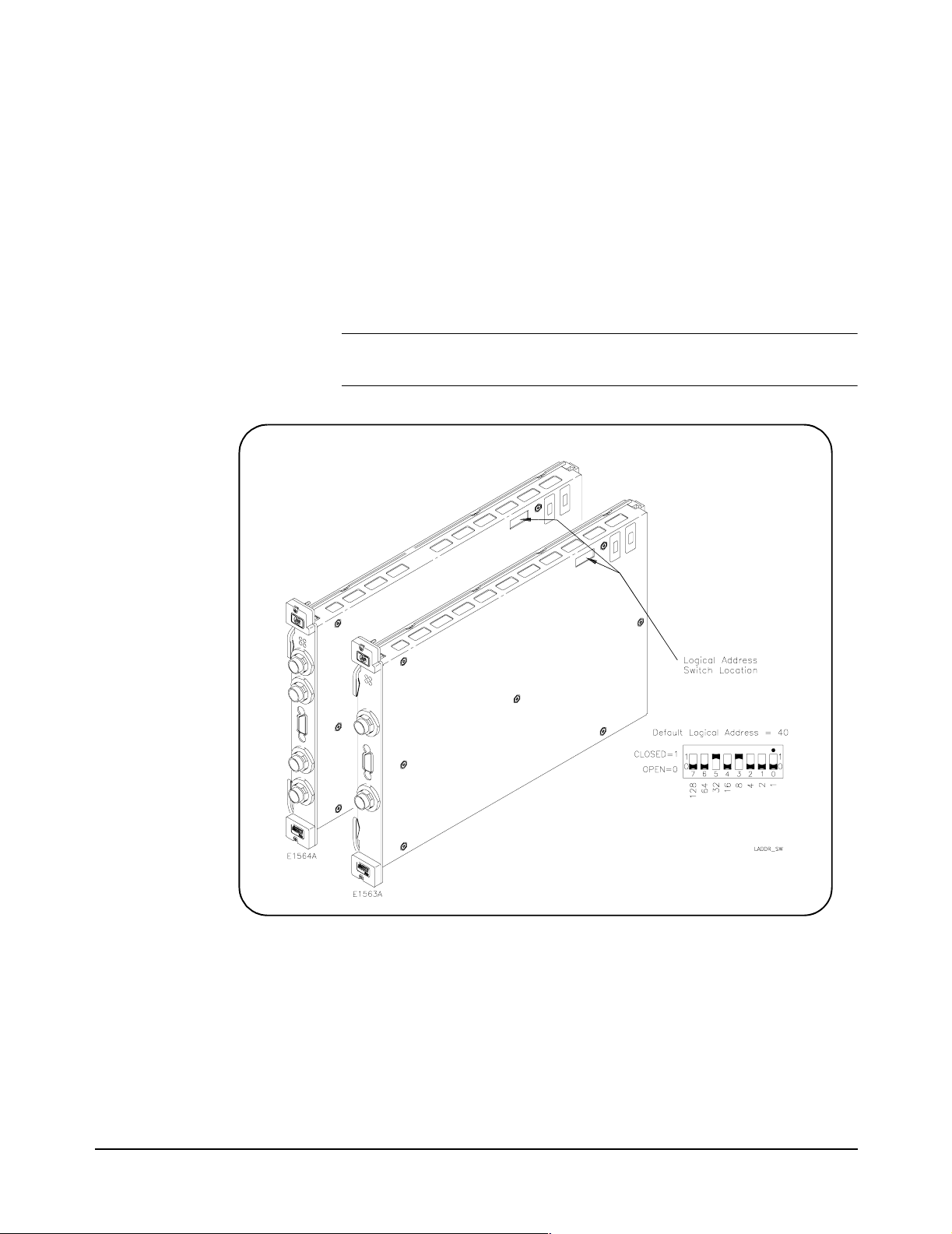

Setting the Logical Address Switch .................................................................... 21

Setting the Interrupt Line .................................................................................... 21

Installing the Digitizer in a Mainframe ................................................................. 22

User Cabling Considerations ..................................................................................... 23

Input Terminal Port Connector Cables ................................................................ 23

Trigger Input Port Cables .................................................................................... 24

3-Wire and 2-Wire Input Cabling Considerations ............................................... 24

Cable Connector Assembly ................................................................................ 27

Initial Operation .......................................................................................................... 30

Chapter 2 - Using the Digitizers ................................................................................... 33

Using this Chapter ..................................................................................................... 33

Digitizers Operation ................................................................................................... 33

Digitizer Block Diagram ...................................................................................... 33

Channel Block Diagram ...................................................................................... 34

Pre-Trigger/Post-Trigger Block Diagram ............................................................. 35

Power-on/Reset States ....................................................................................... 35

Input Overload Condition .................................................................................... 36

Triggering the Digitizers ............................................................................................. 37

Trigger Sources .................................................................................................. 37

Using Internal Triggering .................................................................................... 37

Using External Triggering ................................................................................... 38

Master-Slave Operation ...................................................................................... 38

Digitizers Application Examples................................................................................. 42

Introduction ......................................................................................................... 42

Making Digitizer Measurements ......................................................................... 43

3

Page 4

Chapter 3 - Digitizers Command Reference ................................................................ 45

Using This Chapter .................................................................................................... 45

Command Types........................................................................................................ 45

SCPI Command Reference........................................................................................47

ABORt ........................................................................................................................ 48

CALCulate.................................................................................................................. 49

CALCulate:LIMit:FAIL? ....................................................................................... 49

CALCulate:LIMit:LOWer:DATA ........................................................................... 50

CALCulate:LIMit:LOWer:DATA? ......................................................................... 50

CALCulate:LIMit:LOWer[:STATe] ........................................................................ 51

CALCulate:LIMit:LOWer[:STATe]? ...................................................................... 51

CALCulate:LIMit:UPPer:DATA ............................................................................ 51

CALCulate:LIMit:UPPer:DATA? .......................................................................... 52

CALCulate:LIMit:UPPer[:STATe] ......................................................................... 52

CALCulate:LIMit:UPPer[:STATe]? ....................................................................... 53

CALibration ................................................................................................................ 54

CALibration:DAC:VOLTage ................................................................................ 54

CALibration:DAC:VOLTage? .............................................................................. 55

CALibration:DATA? ............................................................................................. 55

CALibration:GAIN ............................................................................................... 55

CALibration:SOURce .......................................................................................... 57

CALibration:SOURce? ........................................................................................ 58

CALibration:STATe .............................................................................................. 58

CALibration:STATe? ............................................................................................ 58

CALibration:STORe ............................................................................................ 59

CALibration:VALue ............................................................................................. 59

CALibration:VALue? ...........................................................................................60

CALibration:ZERO .............................................................................................. 60

CALibration:ZERO:ALL? .................................................................................... 61

DIAGnostic ................................................................................................................. 63

DIAGnostic:DAC:GAIN ....................................................................................... 63

DIAGnostic:DAC:OFFSet ................................................................................... 64

DIAGnostic:DAC:OFFSet:RAMP ........................................................................ 64

DIAGnostic:DAC:SOURce .................................................................................. 65

DIAGnostic:DAC:SOURce:RAMP ...................................................................... 65

DIAGnostic:INTerrupt:LINE ................................................................................. 66

DIAGnostic:INTerrupt:LINE? ............................................................................... 66

DIAGnostic:MEMory:SIZE .................................................................................. 66

DIAGnostic:MEMory:SIZE? ................................................................................ 67

DIAGnostic:PEEK? ............................................................................................. 67

DIAGnostic:POKE .............................................................................................. 69

DIAGnostic:SHORt ............................................................................................. 70

DIAGnostic:SHORt? ........................................................................................... 70

DIAGnostic:STATus? .......................................................................................... 70

FORMat .....................................................................................................................72

FORMat[:DATA] .................................................................................................. 72

FORMat[:DATA]? ................................................................................................ 72

INITiate.......................................................................................................................73

INITiate:CONTinuous ......................................................................................... 73

INITiate:CONTinuous? ....................................................................................... 74

INITiate[:IMMediate] ........................................................................................... 74

4

Page 5

INPut ..........................................................................................................................75

INPut:FILTer[:LPASs]:FREQ ............................................................................... 75

INPut:FILTer[:LPASs]:FREQ? ............................................................................. 75

INPut:FILTer[:LPASs][:STATe] ............................................................................. 76

INPut:FILTer[:LPASs][:STATe]? ........................................................................... 76

INPut[:STATe] ..................................................................................................... 76

INPut[:STATe]? ................................................................................................... 76

OUTPut ...................................................................................................................... 77

OUTput:TTLT<n>:SOURce ................................................................................ 77

OUTPut:TTLT<n>:SOURce? .............................................................................. 77

OUTPut:TTLT<n>[:STATe] .................................................................................. 78

OUTPut:TTLT<n>[:STATe]? ................................................................................ 78

SAMPle ...................................................................................................................... 79

SAMPle:COUNt .................................................................................................. 79

SAMPle:COUNt? ................................................................................................ 80

SAMPle[:IMMediate] ...........................................................................................80

SAMPLe:PRETrigger:COUNt ............................................................................. 80

SAMPle:PRETrigger:COUNt? ............................................................................ 81

SAMPle:SLOPe ..................................................................................................82

SAMPle:SLOPe? ................................................................................................82

SAMPle:SOURce ............................................................................................... 82

SAMPle:SOURce? ............................................................................................. 83

SAMPle:TIMer .................................................................................................... 84

SAMPle:TIMer? ..................................................................................................84

[SENSe:] .................................................................................................................... 85

[SENSe:]DATA? ..................................................................................................85

[SENSe:]DATA:ALL? .......................................................................................... 87

[SENSe:]DATA:COUNt? ..................................................................................... 88

[SENSe:]DATA:CVTable? ................................................................................... 88

[SENSe:]ROSCillator:EXTernal:FREQuency ...................................................... 89

[SENSe:]ROSCillator:EXTernal:FREQuency? ....................................................89

[SENSe:]ROSCillator:SOURCe .......................................................................... 90

[SENSe:]ROSCillator:SOURce? ......................................................................... 90

[SENSe:]SWEep:OFFSet:POINts ...................................................................... 91

[SENSe:]SWEep:OFFSet:POINts? .................................................................... 91

[SENSe:]SWEep:POINts .................................................................................... 91

[SENSe:]SWEep:POINts? .................................................................................. 91

[SENSe:]VOLTage[<channel>][:DC]:RANGe ...................................................... 92

[SENSe:]VOLTage[<channel>][:DC]:RANGe? .................................................... 92

[SENSe:]VOLTage[<channel>][:DC]:RESolution? .............................................. 92

STATus....................................................................................................................... 93

Status System Registers ...................................................................................... 93

STATus:OPERation:CONDition? ........................................................................ 95

STATus:OPERation:ENABle ............................................................................... 95

STATus:OPERation:ENABle? ............................................................................. 95

STATus:OPERation[:EVENt]? ............................................................................ 96

STATus:PRESet ................................................................................................. 96

STATus:QUEStionable:CONDition? ................................................................... 96

STATus:QUEStionable:ENABle .......................................................................... 96

STATus:QUEStionable:ENABle? ........................................................................ 96

STATus:QUEStionable[:EVENt]? ........................................................................ 96

5

Page 6

SYSTem .....................................................................................................................97

SYSTem:ERRor? ................................................................................................ 97

SYSTem:VERSion? ............................................................................................ 97

TEST.......................................................................................................................... 98

TEST:ERRor? ..................................................................................................... 98

TEST:NUMBer? .................................................................................................. 98

TEST:TST[:RESults]? ....................................................................................... 103

TRIGger ................................................................................................................... 104

TRIGger[:IMMediate] ........................................................................................ 104

TRIGger:LEVel ................................................................................................. 104

TRIGger:LEVel? ............................................................................................... 105

TRIGger:MODE ................................................................................................ 105

TRIGger:MODE? .............................................................................................. 106

TRIGger:SLOPe[<n>] ....................................................................................... 106

TRIGger:SLOPe[<n>]? ..................................................................................... 107

TRIGger:SOURce[<n>] .................................................................................... 107

TRIGger:SOURce[<n>]? .................................................................................. 108

IEEE 488.2 Common Commands Quick Reference ................................................ 109

*CLS ................................................................................................................. 110

*ESE and *ESE? .............................................................................................. 110

*ESR? ............................................................................................................... 111

*IDN? ................................................................................................................ 111

*OPC ................................................................................................................ 111

*OPC? .............................................................................................................. 112

*RST ................................................................................................................. 112

*SRE and *SRE? .............................................................................................. 113

*STB? ............................................................................................................... 113

*TST? ............................................................................................................... 114

*WAI .................................................................................................................. 114

SCPI Commands Quick Reference.......................................................................... 115

Appendix A - Digitizers Specifications ...................................................................... 119

Appendix B - Register-Based Programming ............................................................. 121

About This Appendix ................................................................................................ 121

Register Programming vs. SCPI Programming........................................................ 121

Addressing the Registers ......................................................................................... 121

The Base Address ............................................................................................ 122

Register Offset .................................................................................................. 123

Register Descriptions ............................................................................................... 124

WRITE Registers .............................................................................................. 124

READ Registers .............................................................................................. 125

ID Register ........................................................................................................ 126

Device Type Register ....................................................................................... 126

Status/Control Register ..................................................................................... 126

A24 Offset Register .......................................................................................... 128

FIFO High Word/Low Word Registers .............................................................. 128

Interrupt Control Register ................................................................................. 129

Interrupt Source Register ................................................................................. 130

CVTable Channel 1 Register ............................................................................ 130

CVTable Channel 2 Register ............................................................................ 130

CVTable Channel 3 Register ............................................................................ 131

6

Page 7

CVTable Channel 4 Register ............................................................................ 131

Samples Taken High Byte Register .................................................................. 131

Samples Taken Low Word Register ................................................................. 131

Calibration Flash ROM Address Register ......................................................... 131

Calibration Flash ROM Data Register .............................................................. 132

Calibration Source Register .............................................................................. 132

Cache Count Register ...................................................................................... 132

Range, Filter, and Channel 1, 2 Connect Register ........................................... 133

Range, Filter, and Channel 3, 4 Connect Register ........................................... 133

Trigger/Interrupt Level Channel 1 Register ....................................................... 134

Trigger/Interrupt Level Channel 2 Register ....................................................... 135

Trigger/Interrupt Level Channel 3 Register ....................................................... 135

Trigger/Interrupt Level Channel 4 Register ....................................................... 136

Sample Period High Byte Register ................................................................... 136

Sample Period Low Word Register .................................................................. 136

Pre-Trigger Count High Byte Register .............................................................. 136

Pre-Trigger Count Low Word Register ............................................................. 137

Sample Count High Byte Register .................................................................... 137

Sample Count Low Word Register ................................................................... 137

Trigger Source/Control Register ....................................................................... 137

Sample Source/Control Register ......................................................................138

Programming Examples........................................................................................... 140

Appendix C - Digitizers Error Messages ................................................................... 145

Execution Errors ......................................................................................................145

Self-Test Errors ........................................................................................................ 149

Calibration Errors ..................................................................................................... 149

Zero Calibration ................................................................................................ 149

Gain Calibration ................................................................................................ 149

Appendix D - Digitizers Verification Tests ................................................................ 151

Introduction .............................................................................................................. 151

Types of Tests ................................................................................................... 151

Recommended Test Equipment ....................................................................... 151

Test Conditions ................................................................................................. 152

Recording Your Test Results ............................................................................ 152

Performance Verification Test Programs .......................................................... 152

Functional Verification Test ...................................................................................... 153

Functional Test

Procedure ......................................................................................................... 153

Performance Verification Tests................................................................................. 154

Zero Offset Verification Test ............................................................................. 154

Noise Verification Test ...................................................................................... 155

Gain Verification Test ........................................................................................ 156

Filter Bandwidth Verification Test ...................................................................... 157

Performance Test Record ........................................................................................ 158

7

Page 8

Appendix E - Digitizers Adjustments ......................................................................... 163

Introduction .............................................................................................................. 163

Closed-Cover Electronic Calibration ................................................................. 163

Calibration Intervals ..........................................................................................163

Adjustment Procedures............................................................................................ 164

Adjustment Conditions ...................................................................................... 164

General Procedure ........................................................................................... 164

Zero Adjustment....................................................................................................... 165

E1563A Gain Adjustment ......................................................................................... 166

E1564A Gain Adjustment ......................................................................................... 167

Index ............................................................................................................................. 169

8

Page 9

AGILENT TECHNOLOGIES WARRANTY STATEMENT

AGILENT PRODUCT: E1563A 2-Channel Digitizer and E1564A 4-Channel Digitizer DURATION OF WARRANTY: 3 years

1. Agilent Technologies warrants Agilent hardware, accessories and supplies against defects in materials and workmanship for the period

specified above. If Agilent receives notice of such defects during the warranty period, Agilent will, at its option, either repair or replace

products which prove to be defective. Replacement products may be either new or like-new.

2. Agilent warrants that Agilent software will not fail to execute its programming instructions, for the period specified above, due to

defects in material and workmanship when properly installed and used. If Agilent receives notice of such defects during the warranty

period, Agilent will replace software media which does not execute its programming instructions due to such defects.

3. Agilent does not warrant that the operation of Agilent products will be uninterrupted or error free. If Agilent is unable, within a

reasonable time, to repair or replace any product to a condition as warranted, customer will be entitled to a refund of the purchase price

upon prompt return of the product.

4. Agilent products may contain remanufactured parts equivalent to new in performance or may have been subject to incidental use.

5. The warranty period begins on the date of delivery or on the date of installation if installed by Agilent. If customer schedules or delays

Agilent installation more than 30 days after delivery, warranty begins on the 31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or inadequate maintenance or calibration, (b) software, interfacing, parts

or supplies not supplied by Agilent, (c) unauthorized modification or misuse, (d) operation outside of the published environmental

specifications for the product, or (e) improper site preparation or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTY OR CONDITION, WHETHER WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED AND AGILENT

SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OR CONDITIONS OF MERCHANTABILITY, SATISFACTORY

QUALITY, AND FITNESS FOR A PARTICULAR PURPOSE.

8. Agilent will be liable for damage to tangible property per incident up to the greater of $300,000 or the actual amount paid for the product

that is the subject of the claim, and for damages for bodily injury or death, to the extent that all such damages are determined by a court

of competent jurisdiction to have been directly caused by a defective Agilent product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS WARRANTY STATEMENT ARE CUSTOMER’S

SOLE AND EXLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL AGILENT OR ITS SUPPLIERS BE

LIABLE FOR LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST PROFIT OR

DATA), OR OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS

STATEMENT, EXCEPT TO THE EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE, RESTRICT OR MODIFY AND ARE

IN ADDITION TO THE MANDATORY STATUTORY RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

U.S. Government Restricted Rights

The Software and Documentation have been developed entirely at private expense. They are delivered and licensed as "commercial

computer software" as defined in DFARS 252.227- 7013 (Oct 1988), DFARS 252.211-7015 (May 1991) or DFARS 252.227-7014 (Jun

1995), as a "commercial item" as defined in FAR 2.101(a), or as "Restricted computer software" as defined in FAR 52.227-19 (Jun

1987)(or any equivalent agency regulation or contract clause), whichever is applicable. You have only those rights provided for such

Software and Documentation by the applicable FAR or DFARS clause or the Agilent standard software agreement for the product

involved.

E1563A 2-Channel Digitizer and E1564A 4-Channel Digitizer User’s Manual

Copyright © 1997, 1998, 2001 Agilent Technologies, Inc. All rights reserved.

Edition 4

9

Page 10

Documentation History

All Editions and Updates of this manual and their creation date are listed below. The first Edition of the manual is Edition 1. The Edition

number increments by 1 whenever the manual is revised. Updates, which are issued between Editions, contain replacement pages to

correct or add additional information to the current Edition of the manual. Whenever a new Edition is created, it will contain all of the

Update information for the previous Edition. Each new Edition or Update also includes a revised copy of this documentation history page.

Edition 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . October, 1997

Edition 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . April, 1998

Edition 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . March, 2001

Edition 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . May, 2001

Safety Symbols

Instruction manual symbol affixed to

Instruction manual symbol affixed to

product. Indicates that the user must refer to

product. Indicates that the user must refer to

the manual for specific WARNING or

the manual for specific WARNING or

CAUTION information to avoid personal

CAUTION information to avoid personal

injury or damage to the product.

injury or damage to the product.

Indicates the field wiring terminal that must

be connected to earth ground before

operating the equipment — protects against

electrical shock in case of fault.

WARNING

Alternating current (AC)

Direct current (DC).

Warning. Risk of electrical shock.

Calls attention to a procedure, practice, or

condition that could cause bodily injury or

death.

or

Frame or chassis ground terminal—typically

connects to the equipment's metal frame.

CAUTION

Calls attention to a procedure, practice, or

condition that could possibly cause damage to

equipment or permanent loss of data.

WARNINGS

The following general safety precautions must be observed during all phases of operation, service, and repair of this product. Failure to

comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and

intended use of the product. Agilent Technologies assumes no liability for the customer's failure to comply with these requirements.

Ground the equipment: For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth

ground must be provided from the mains power source to the product input wiring terminals or supplied power cable.

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gases or fumes.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type. DO NOT

use repaired fuses or short-circuited fuse holders.

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Procedures involving the removal of

covers or shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the

equipment switched off. To avoid dangerous electrical shock, DO NOT perform procedures involving cover or shield removal unless you

are qualified to do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into this product have been

impaired, either through physical damage, excessive moisture, or any other reason, REMOVE POWER and do not use the product until

safe operation can be verified by service-trained personnel. If necessary, return the product to Agilent for service and repair to ensure that

safety features are maintained.

DO NOT service or adjust alone: Do not attempt internal service or adjustment unless another person, capable of rendering first aid and

resuscitation, is present.

DO NOT substitute parts or modify equipment: Because of the danger of introducing additional hazards, do not install substitute parts

or perform any unauthorized modification to the product. Return the product to Agilent for service and repair to ensure that safety features

are maintained.

10

Page 11

DECLARATION OF CONFORMITY According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name: Agilent Technologies, Incorporated

Manufacturer’s Address:

815 - 14

th

ST. S.W.

Loveland, CO 80537

USA

Declares, that the product

Product Name: 2-Channel and 4-Channel Digitizers

Model Number: E1563A/E1564A

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

(including 93/68/EEC) and carries the CE Marking accordingly

Conforms with the following product standards:

EMC Standard

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

CISPR 22:1997 / EN 55022:1998

CISPR 24

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

The product was tested in a typical configuration with Agilent Technologies test systems.

Safety

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

UL 3111-1: 1994

IEC 60950: 1991+A1+A2+A3+A4 / EN 60950: 1992+A1+A2+A3+A4+A11

20 March 2001

Date

Limit

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz I cycle, 100%

Dips: 30% 10ms; 60% 100ms

Interrupt > 95%@5000ms

Class A

Ray Corson

Product Regulation Program Manager

Authorized EU-representative: Agilent Technologies Deutschland GmbH, Herrenberger Stra>e 130, D 71034 Böblingen, Germany

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Revision: B.02 Issue Date: 20 March 2001 Document E9850A.DOC

.

11

Page 12

Notes:

12

Page 13

Configuring the Digitizer Modules

Using This Chapter

This chapter provides guidelines to configure the E1563A and E1564A

modules and to verify successful installation. Chapter contents are:

• Digitizers Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

• Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

• Configuring the Digitizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

• User Cabling Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

• Initial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Digitizers Description

The E1563A (2-channel) and E1564A (4-channel) Digitizers are 800

kSample/second (14-bit resolution) digitizers capable of handling both

continuous and transient voltages up to 256V. You cannot upgrade an

E1563A 2-Channel Digitizer to an E1564A 4-Channel Digitizer.

Chapter 1

General Information Both the E1563A and E1564A digitizers are register-based instruments that

can be programmed at the register level (see Appendix C) or at a higher

level using SCPI or VXIplug&play drivers.

The digitizers are ideal for measurements in electomechanical design

characterization, particularily in environments with high levels of electrical

noise and for characterizing electronic and mechanical transient waveforms.

The E1563A 2-Channel Digitizer has a fixed 25 kHz input filter per channel

that can be enabled. The E1564A 4-Channel Digitizer has four selectable

input filters per channel (1.5 kHz, 6 kHz, 25 kHz and 100 kHz) that can be

enabled.

The E1564A 4-Channel Digitizer has a calibration bus output (High, Low and

Guard) and a programmable short. The E1563A 2-Channel Digitizer does

not have a calibration bus output. However, a programmable short is

provided for each channel. An external calibration source must be provided

for calibration.

Both digitizers use PC SIMM memory. Memory sizes that are supported are

4, 8, 16, 32, 64 and 128 Mbytes. The large memory can easily capture

transients or act as FIFO to allow continuous digitizing while unloading data

with block mode transfers.

Configuring the Digitizer Modules 13Chapter 1

Page 14

All channels sample simultaneously. The sample can be from an internal

clock derived from the internal time base or it can come from an external

source. Triggering can be set up for several sources with programmable pre

and post trigger reading counts. External time base, trigger and sample

inputs are provided on the front panel “D” subminiature connector.

Continuous voltages in a test setup where the user has access to module

connectors and test signal cable ends are restricted to 60 Vdc, 30 Vac rms,

or 42.4 Vac peak of a continuous, complex waveform. Continuous voltages

in test setups where the module connectors and the test signal cables

connected to them are made non-accessible are 256 Vdc, 240 Vdc floating,

or 256 Vac peak.

Transient voltages are permitted providing the maximum amount of charge

transferred into a human body that contacts the voltage under normal

conditions, does not exceed 45

(opens channel input relay) follow.

Range Voltage Input Condition Vmax

62 mV to 4V High or Low to Guard >20V

16V to 256V Low to Guard >40V

mCoulombs (45 mA-s). Overload voltages

Front Panel

Features

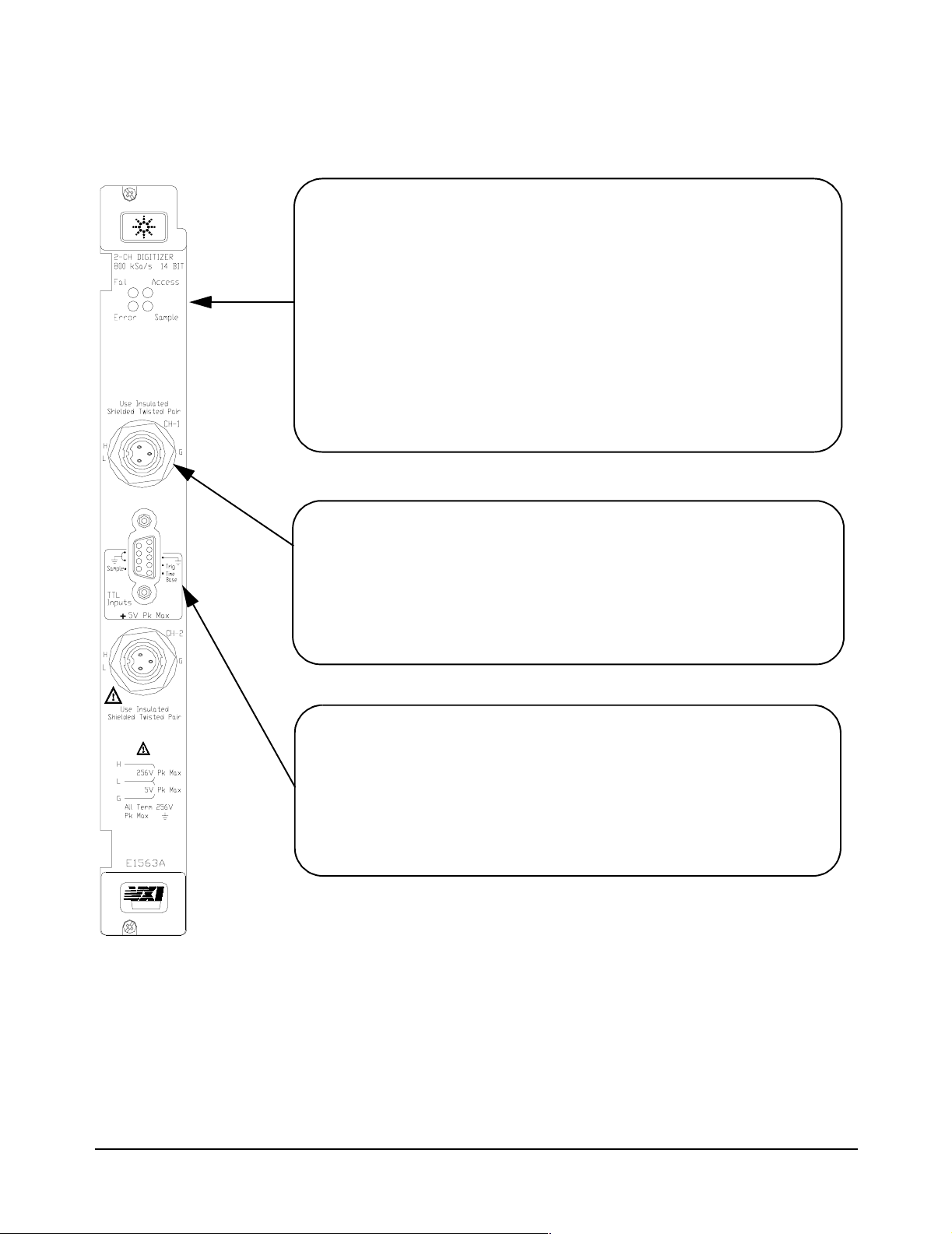

Figure 1-1 shows the front panel features for the E1563A 2-Channel

Digitizer. Figure 1-2 shows the front panel features for the E1564A

4-Channel Digitizer.

14 Configuring the Digitizer Modules Chapter 1

Page 15

Front Panel Indicators

Failed LED: Illuminates momentarily during digitizer power-on.

Access LED: Illuminates when the backplane is communicating with the

digitizer.

Error LED: Illuminates only when an error is present in the digitizer’s driver

error queue. The error can result from improperly executing a command

or the digitizer being unable to pass self-test or calibration.

Sample LED: Illuminates while the digitizer samples the input for a

measurement. Typically blinks for slow sample rates and is on

steady-state for high sample rates.

User Input Terminals

The E1563A Digitizer front panel contains two female connectors for user

inputs. Mating male connectors are supplied with the module. However,

the user must provide the input cable and connect the male connector to

the cable. See "User Cabling Considerations" for recommended

user-supplied cables.

plug&play

External Trigger Input

The front panel contains a 9-pin D-subminiature connector for external

(TTL) trigger inputs. The user must provide an appropriate input cable to

the external trigger input. The E1563A 2-Channel Digitizer does not have

a calibration bus output. However, a programmable short is provided for

each channel. An external calibration source must be provided for

calibration.

Figure 1-1. E1563A 2-Channel Digitizer Front Panel

Configuring the Digitizer Modules 15Chapter 1

Page 16

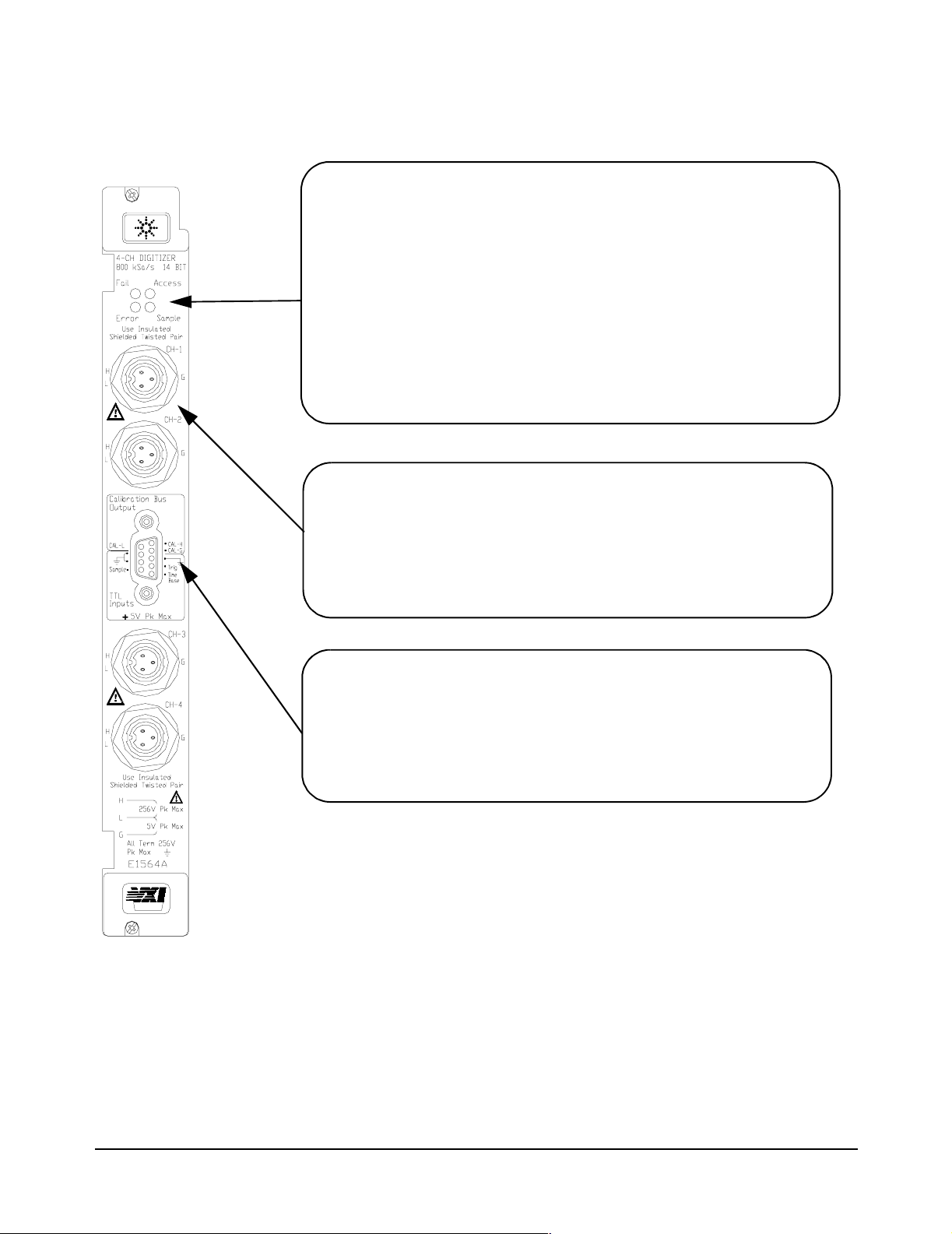

Front Panel Indicators

Failed LED

Access LED: Illuminates when the backplane is communicating with the

: Illuminates momentarily during digitizer power-on.

digitizer.

Error LED: Illuminates only when an error is present in the digitizer’s driver

error queue. The error can result from improperly executing a command

or the digitizer being unable to pass self-test or calibration.

Sample LED: Illuminates while the digitizer samples the input for a

measurement. Typically blinks for slow sample rates and is on

steady-state for high sample rates.

User Input Terminals

The E1564A Digitizer front panel contains four female connectors for user

inputs. Mating male connectors are supplied with the module. However,

the user must provide the input cable and connect the male connector to

the cable. See "User Cabling Considerations" for connecting

user-supplied cables.

plug&play

External Trigger Input/Calibration Bus Output

The front panel contains a 9-pin D-subminiature connector for external

(TTL) trigger inputs and for calibration bus outputs. The E1564A

4-Channel Digitizer has a calibration bus output (High, Low and Guard)

and a programmable short. The user must provide the the appropriate

cable to the external trigger input/calibration bus output.

Figure 1-2. E1564A 2-Channel Digitizer Front Panel

16 Configuring the Digitizer Modules Chapter 1

Page 17

Warnings and Cautions

WARNING DANGEROUS VOLTAGES. The E1563A and E1564A Digitizers are

capable of measuring voltages up to 256V maximum. Voltage levels

above the levels specified for accessible connectors or cable ends

could cause bodily injury or death to an operator. Special precautions

must be adhered to (discussed below) when applying voltages in

excess of 60 Vdc, 30 Vac rms or 42.4 Vac peak for a continuous,

complex waveform.

WARNING MODULE CONNECTORS MUST NOT BE OPERATOR-ACCESSABLE.

Module connectors and test signal cables connected to them must be

made NON-accessible to an operator who has not been told to access

them. It is a supervisor’s responsibility to advise an operator that

dangerous voltages exist when the operator is instructed to access

connectors and cables carrying these voltages.

Making cables and connectors that carry hazardous voltages

inaccessible is a protective measure keeping an operator from

inadvertent or unknowing contact with these harmful voltages.

Cables and connectors are considered inaccessible if a tool

(e.g., screwdriver, wrench, socket, etc.) or a key (equipment in a

locked cabinet) is required to gain access to them. Additionally,

the operator cannot have access to a conductive surface connected

to any cable conductor (High, Low or Guard).

WARNING ADEQUATE INSULATION IS REQUIRED. Assure the equipment under

test has adequate insulation between the cable connections and any

operator-accessible parts (doors, covers, panels, shields, cases,

cabinets, etc.).

Verify there are multiple and sufficient protective means (rated for the

voltages you are applying) to assure the operator will NOT come into

contact with any energized conductor even if one of the protective

means fails to work as intended.

For example, the inner side of a case, cabinet, door, cover or panel

can be covered with an insulating material as well as routing the

test cables to the module’s front panel connectors through

non-conductive, flexible conduit such as that used in electrical

power distribution.

WARNING TIGHTEN MOUNTING SCREWS. Tighten the faceplate mounting

screws after installing the module in the mainframe to prevent

electric shock in case of equipment or field wiring failure.

Configuring the Digitizer Modules 17Chapter 1

Page 18

CAUTION OVERVOLTAGE PROTECTION. To prevent equipment damage,

do not connect this equipment to mains or to any signal directly

derived from mains. Short-term temporary overvoltages must be

limited to 500V or less.

To prevent equipment damage in case of an overvoltage condition,

do not connect this equipment to any voltage source which can

deliver greater than 2A at 500V in the case of a fault. If such a fault

condition is possible, insert a 2A fuse in the input line.

CAUTION CLEANING THE MODULE. Clean the outside surfaces of this

module with a cloth slightly dampened with water. Do not attempt

to clean the interior of this module.

18 Configuring the Digitizer Modules Chapter 1

Page 19

Configuring the Digitizers

This section gives guidelines to configure the digitizers, including:

• Adding RAM to the Module

• Setting the Logical Address Switch

• Setting the Interrupt Line

• Installing the Digitizer in a Mainframe

Adding RAM to the

Module

Selecting a RAM Although most commercially available PC SIMM RAM will work with the

You can increase the size of RAM on your Digitizer module by purchasing

PC SIMM memory and installing it on the module after you remove the

standard 4 Mbyte SIMM shipped with your digitizer. Both FPM (Fast Page

Mode) and EDO (Extended Data Out) are supported.

Digitizer, there are some that are physically too large and will make contact

with the top shield when installed. A standard 72 SIMM specifies the length

(L) or keying but does not specify the depth (D). Certain depths are too large

and not compatible.

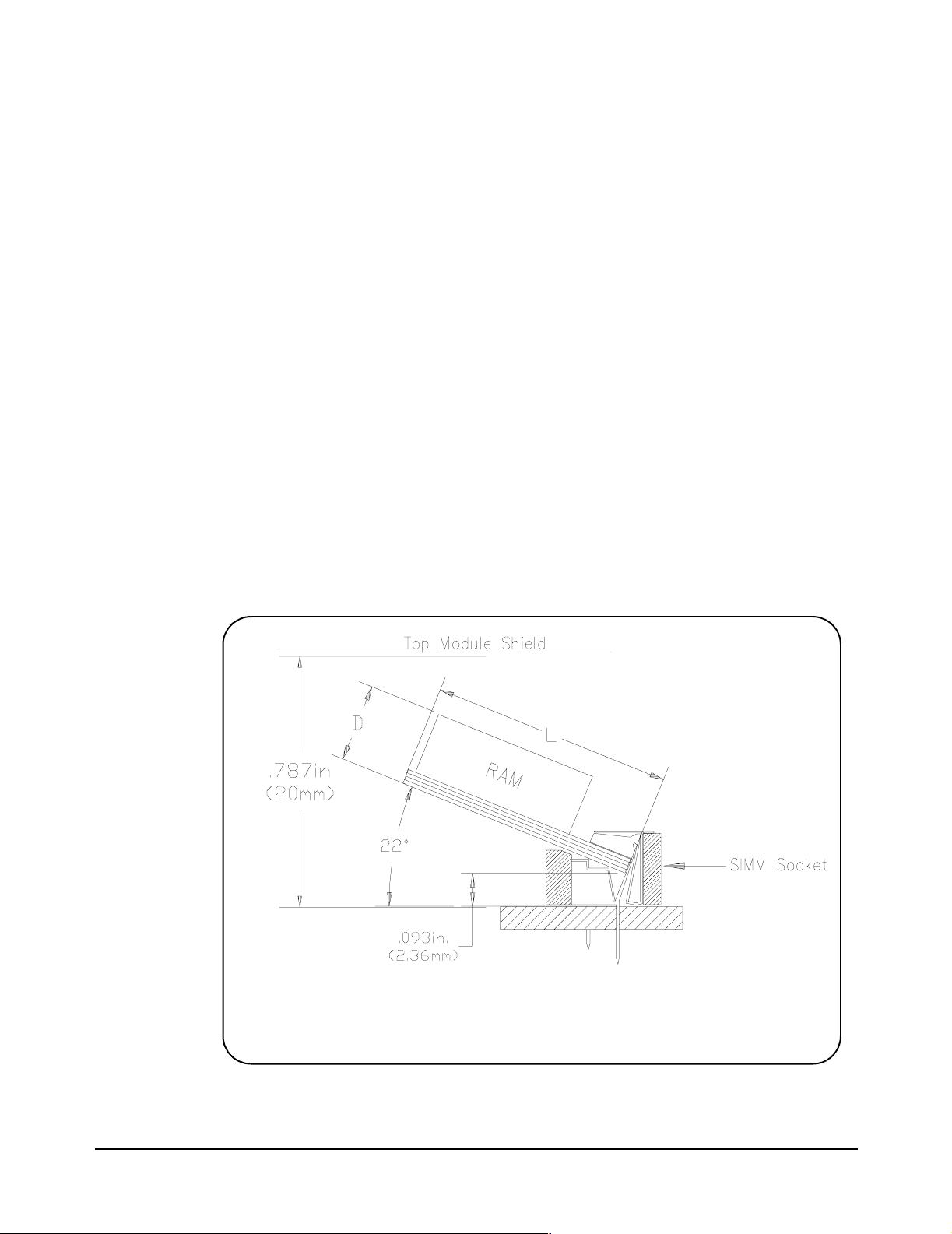

The E1563/E1564 has about 17.6 mm of space from the bottom of the

SIMM RAM inserted in the socket to the top module shield (see Figure 1-3).

You must verify that the SIMM RAM you purchase for replacement on the

module has a depth (D) that will clear the top module shield. You can use

the 4 Mbyte SIMM RAM you remove as a guide, as well as the dimensions

in Figure 1-3, when purchasing your upgrade RAM .

L = 1.25in (31.77mm) max for D = 0.18, where D is from PC board lower side

where it rests on the bracket. D does not include the height of chips mounted

on the lower side of the board.

Figure 1-3. Adding RAM to the Module

Configuring the Digitizer Modules 19Chapter 1

Page 20

RAM Installation

Procedure

NOTE It is important that you retain the 4 Mbyte SIMM you remove from the

1 Disconnect any field wiring from the module and remove power from

the mainframe before proceeding.

2 Remove the module from the mainframe and remove the top shield

from the module.

3 Remove the 4 Mbyte SIMM from the PC board by first spreading the

tabs at the ends of the SIMM connector. Store this SIMM in an

anti-static bag and save this part.

Digitizer. If you return your Digitizer to Agilent for repair or exchange, you

must return it in the same configuration as it was shipped to you. You must

remove the large memory SIMM and replace it with the standard 4 Mbyte

SIMM shipped with the product.

4 Add your replacement SIMM to the module’s RAM socket.

5 Reinstall the module’s top shield.

6 Note the new memory configuration by checking the appropriate box

on the module’s top shield.

7 Set the “CALIBRATION CONSTANTS” switch and the “FLASH”

switch to the “Write Enable” position.

8 Install the module in the mainframe and apply power.

9 Set the new RAM memory size by sending

DIAGnostic:MEMory:SIZE <size>.

10 Query the memory size to verify the setting by sending

DIAGnostic:MEMory:SIZE?

11 Remove mainframe power, remove the module and set the

“CALIBRATION CONSTANTS” and “FLASH” switches back to the

“Read Only” position.

12 Reinstall the module in the mainframe.

WARNING TIGHTEN THE FACEPLATE SCREWS. Tighten the faceplate mounting

screws to prevent electric shock in case of equipment or field wiring

failure.

20 Configuring the Digitizer Modules Chapter 1

Page 21

Setting the Logical

Address Switch

NOTE When using an E1406A as the VXIbus resource manager with SCPI

The E1563A and E1564A Digitizers are shipped from the factory with logical

address 40. Valid logical address are from 1 to 254 for static configuration

(the address you set on the switch) and address 255 for dynamic

configuration. The E1563A and E1564A do not support dynamic

configuration of the address.

If you install more than one digitizer, each module must have a different

logical address. If you use a VXIbus command module, the logical address

must be a multiple of eight (e.g., 32, 40, 48, 56, etc.). Each instrument must

have a unique secondary address which is the logical address divided by

eight. See Figure 1-4 for guidelines to set the Logical Address Switch.

commands, the digitizer’s address switch value must be a multiple of 8.

Setting the Interrupt

Line

Figure 1-4. Setting the Logical Address Switch

The E1563A and E1564A Digitizers are VXIbus interrupters. You can

specify which interrupt line (1 through 7) the interrupt is transmitted. The

interrupt line is specified using DIAGnostic:INTerrupt:LINE. You can query

the active interrupt line using DIAGnostic:INTerrupt:LINE?. The default is no

interrupt line enabled at power-up. You specify “0” if you do not want an

interrupt. Resetting the module does change the interrupt line setting and

you must reset your interrupt setting.

Configuring the Digitizer Modules 21Chapter 1

Page 22

Installing the

Digitizer in a

Mainframe

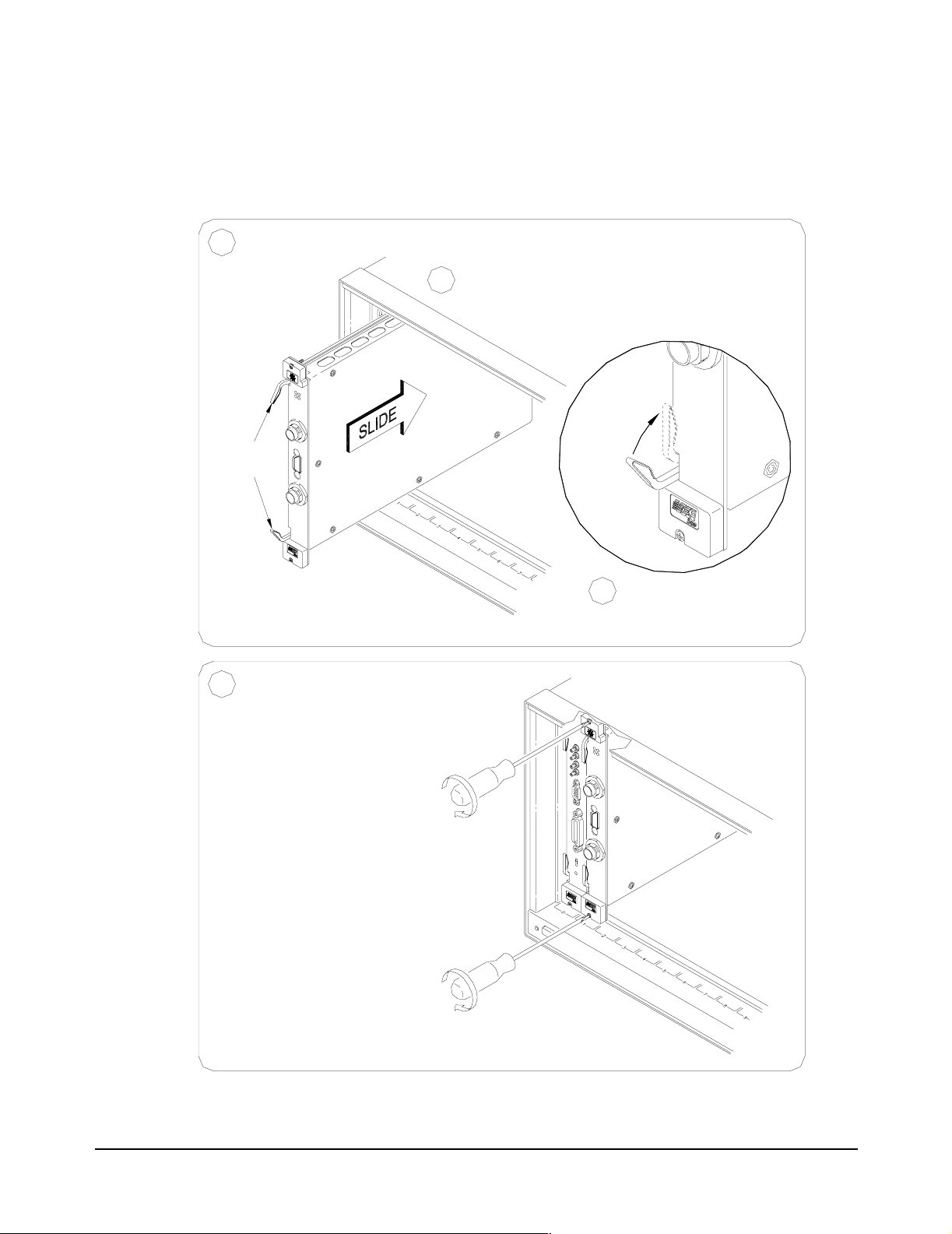

Set the extraction levers out.1

Extraction

Levers

The E1563A or E1564A Digitizer can be installed in any slot (except slot 0)

in a C-size VXIbus mainframe. See Figure 1-5 for the procedure to install the

Digitizer in a mainframe.

Slide the E1563/E1564 into any slot

2

(except slot 0) until the backplane

connectors touch.

4

Tighten the top and bottom screws

to secure the digitizer module

to the mainframe.

NOTE: The extraction levers will not

seat the backplane connectors on older

VXIbus mainframes. You must manually

seat the connectors by pushing in the

module until the module's front panel is

flush with the front of the mainframe. The

extraction levers may be used to guide or

remove the digitizer.

To remove the digitizer from the mainframe,

reverse the procedure.

Seat the digitizer into

3

the mainframe by pushing

in the extraction levers.

Figure 1-5. Installing the Digitizer in a Mainframe

22 Configuring the Digitizer Modules Chapter 1

Page 23

User Cabling Considerations

This section gives guidelines to select and configure user-supplied cables

for connection to the Input Terminals and to the External Trigger

Input/Calibration Bus Output Terminals.

Input Terminal Port

Connector Cables

E1563A Digitizer. The E1563A Digitizer front panel includes two Switchcraft®

EN3™ Mini Weathertight Connectors (female) (CH-1 and CH-2). See Figure

1-1. Mating Switchcraft® Cord Connectors (male) are supplied with the

module. However, the user must provide the cable and assemble the

connector to the cable end. Recommended shielded, twisted-pair cable in

the following table have an outside dimension compatible with the cord

connector.

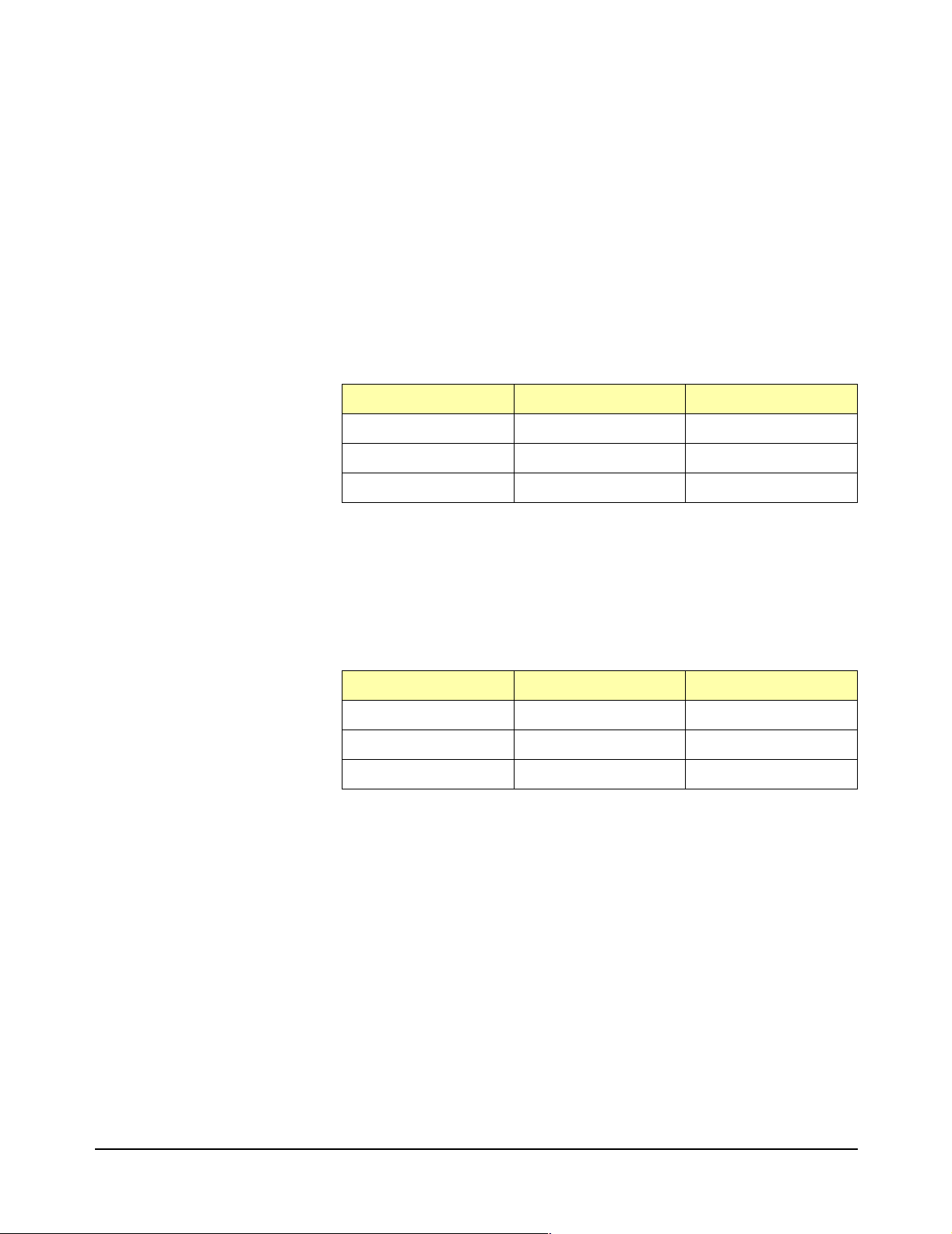

Wire gauge Belden® cable P/N Alpha® cable P/N

20 AWG (7x28) 8762 none

22 AWG (7x30) 9462 5481C

24 AWG (7x32) 8641 5491C

E1564A Digitizer. The E1564A Digitizer front panel contains four

Switchcraft® EN3™ Mini Weathertight Connectors (female) (CH-1 through

CH-4). See Figure 1-2. Mating Switchcraft® Cord Connectors (male) are

supplied with the module. However, the user must provide the cable and

assemble the connector to the cable end. Recommended shielded,

twisted-pair cable in the following table have an outside dimension

compatible with the cord connector.

Wire gauge Belden® cable P/N Alpha® cable P/N

20 AWG (7x28) 8762 none

22 AWG (7x30) 9462 5481C

24 AWG (7x32) 8641 5491C

Configuring the Digitizer Modules 23Chapter 1

Page 24

Trigger Input Port

Cables

SAMPle:SOURce EXT

The user must supply a standard cable to the External Trigger Input port

(E1563A) or to the External Trigger Input/Calibration Bus Output port

(E1564A).

E1563A Digitizer. The E1563A front panel contains a 9-pin D-subminiature

connector with the pin-outs and associated SCPI commands shown in

Figure 1-6 (do not make any connections to the top two pins).

TRIGger:SOURce EXT

ROSCillator:SOURce EXT

Figure 1-6. E1563A External Trigger Input Port

E1564A Digitizer. The E1564A front panel contains a 9-pin D-subminiature

connector with the pin-outs and associated SCPI commands shown in

Figure 1-7.

CAL:SOURce INT

SAMPle:SOURce EXT

Figure 1-7. E1564A External Trigger Input/Calibration Bus Output Port

3-Wire and 2-Wire

Input Cabling

Considerations

CAL:SOURce INT

TRIGger:SOURce EXT

ROSCillator:SOURce EXT

The E1563A and E1564A Digitizers provide a three-terminal input system

(High, Low and Guard) in which an unavoidable and undesirable current is

injected from chassis ground to the Guard terminal. Dependent on whether

you measure on a low-voltage range or a high-voltage range, the way you

connect the Guard terminal may or may not introduce a measurement error

due to this current. This section describes some considerations you can

take to use the Guard terminal properly to minimize measurement error.

24 Configuring the Digitizer Modules Chapter 1

Page 25

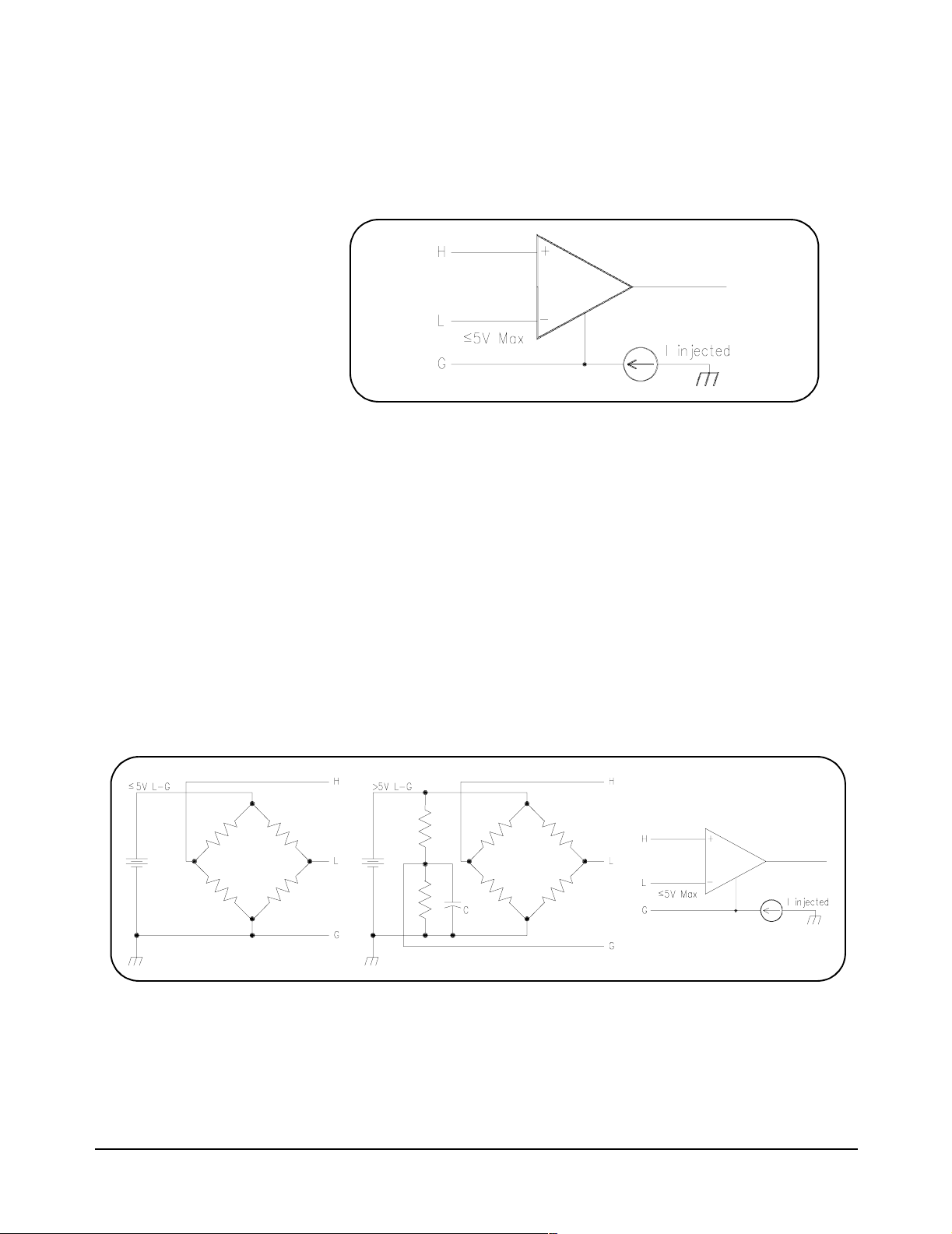

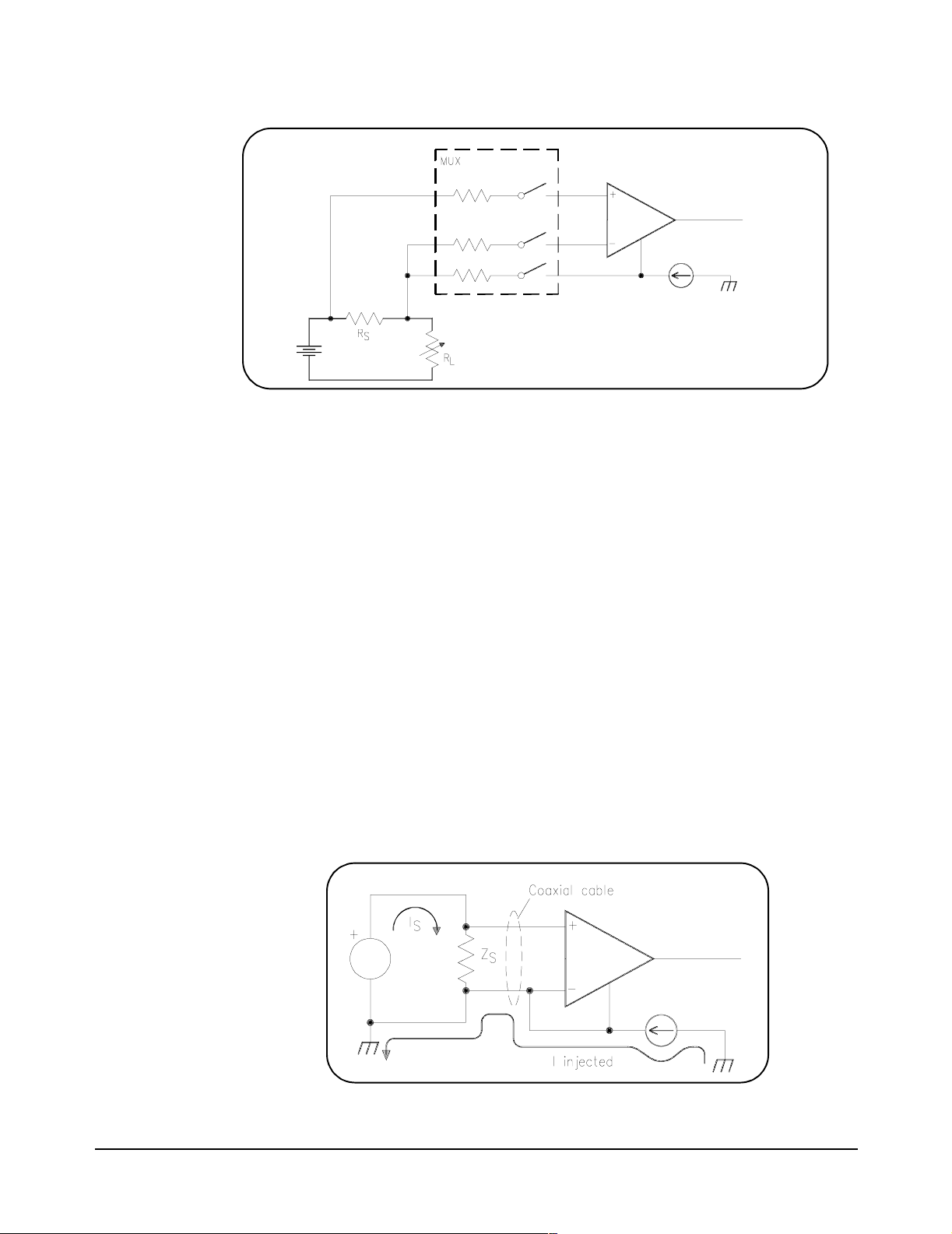

Digitizer Input Model Figure 1-8 shows the input model for the digitizer. Maximum voltage

between Low and Guard is 5V. Exceeding this limitation will not damage

your digitizer but will generate invalid data for any measurement taken.

In general, 3-Wire cabling is recommended, but 2-Wire cabling is supported

for some switching applications.

Figure 1-8. Digitizer Input Model

Three-Wire Connections This section shows two examples of connecting the input using a three-wire

connection. Both example connections can be made using shielded,

twisted-pair connectors.

For the first example, Figure 1-9 shows one way to make connections for a

bridge measurement where the L-to-G voltage is £ 5V and the L-to-G

voltage exceeds 5V. A “Wagner ground” is used to satisfy the L-to-G

restriction of £ 5V and to make a Guard connection point that minimizes

measurement error due to the digitizer’s injected current. A capacitor is

added to the Wagner ground to provide a signal path to ground to minimize

common mode voltages.

For the second example, Figure 1-10 shows one way to measure the voltage

across a small current sensing resistor where the input to the digitizer is

switched through a multiplexer switch module.

Figure 1-9. Example: Three-Wire Connections (Bridge)

Configuring the Digitizer Modules 25Chapter 1

Page 26

.

Figure 1-10. Example: Three-Wire Connections (Voltage Measurements)

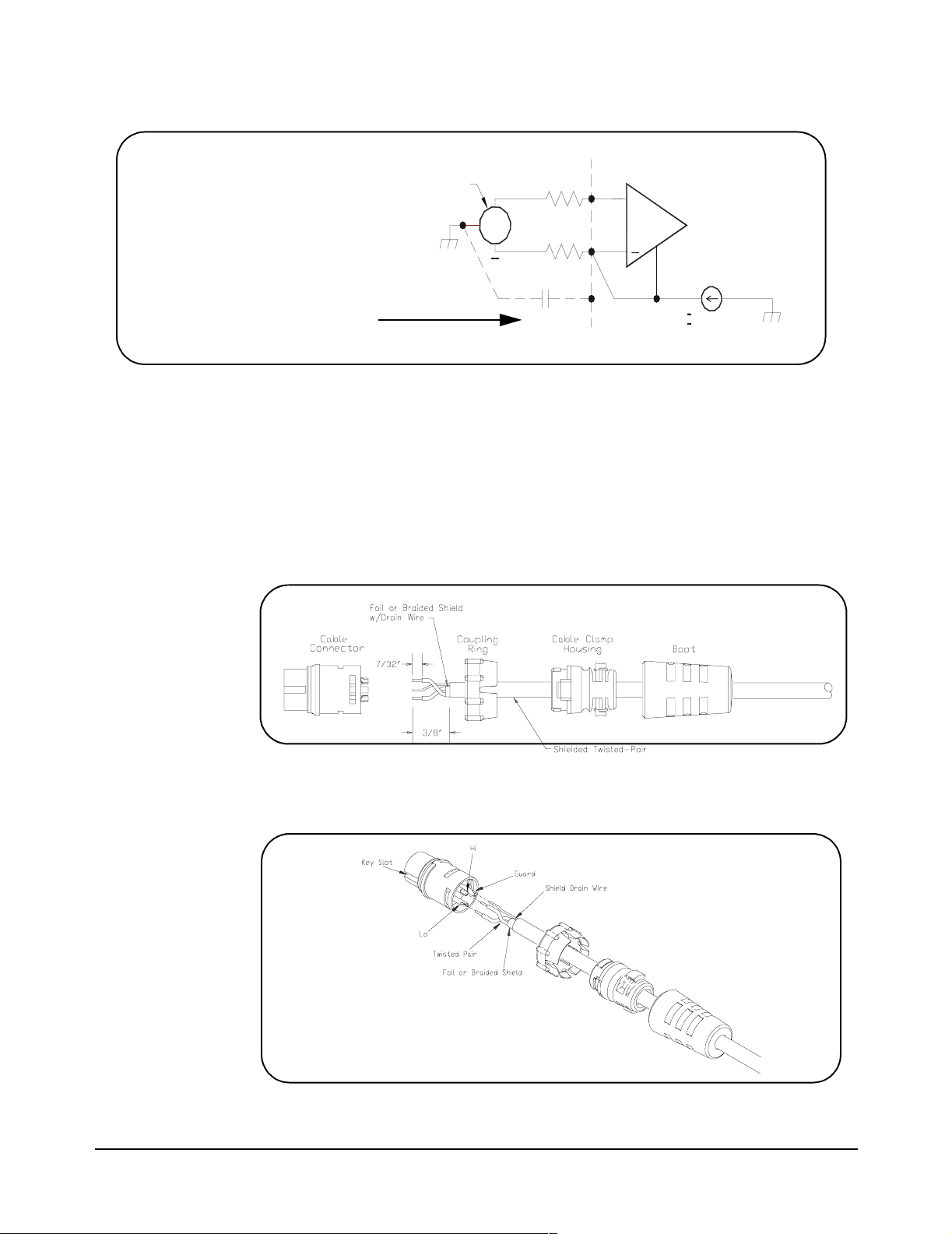

Two-Wire Connections When Low and Guard are connected together at the digitizer’s input on a

low-voltage range (4V and below), the injected current is directed to flow

through the source impedance (in a floating source) and the resultant

voltage drop will introduce a measurement error.

The resultant voltage drop through the source impedance can be a

significant error on low-voltage ranges where the voltage of interest is small.

It is not as significant an error on high-voltage ranges because the error

introduced is not a significant part of a larger voltage and the percent of error

is less significant.

Measurement error can increase significantly when you connect Low to

Guard at the digitizer’s input AND use switches to switch input signals to the

digitizer. Some switches have input protection resistors (usually 100W) in

series with the switch. The digitizer’s injected current now generates a

voltage drop across this resistor in addition to the voltage drop generated

across the source impedance. Even with a grounded source, an error

voltage is generated across the switches current limiting resistor.

Two examples of two-wire connections follow. For the first example, Figure

1-11 shows a typical connection using coaxial cable. For the second

example, Figure 1-12 shows connections for a differential source.

Figure 1-11. Example: Two-Wire Connections (Coaxial Cable)

26 Configuring the Digitizer Modules Chapter 1

Page 27

Add 100 pF capacitor if low-level

25 kHz noise from injected current

is present.

Figure 1-12. Example: Two-Wire Connections (Differential Source)

Differential

Source

100 pF

50

+

50

25 KHz From

Switching Supply

I Injected

+

Cable Connector

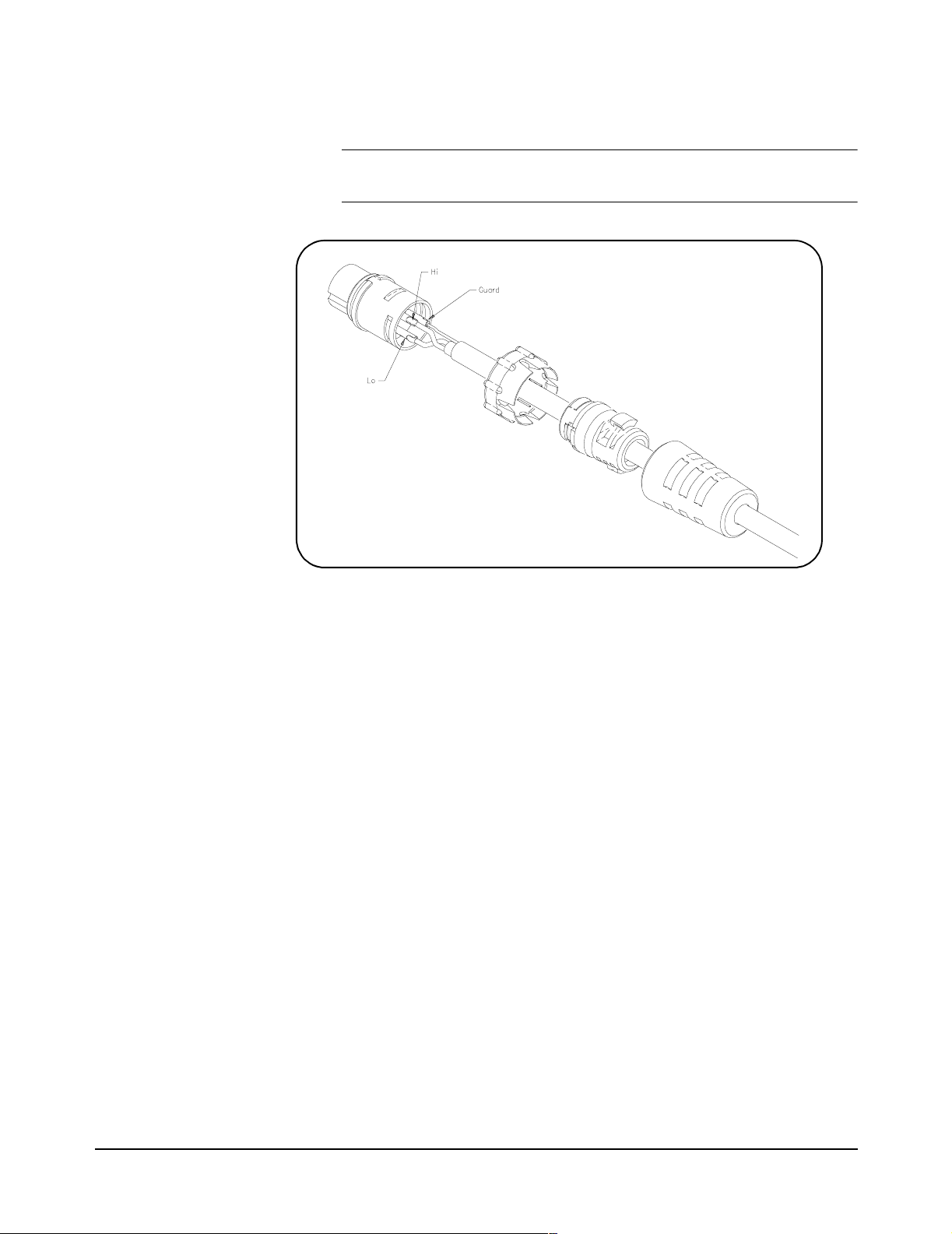

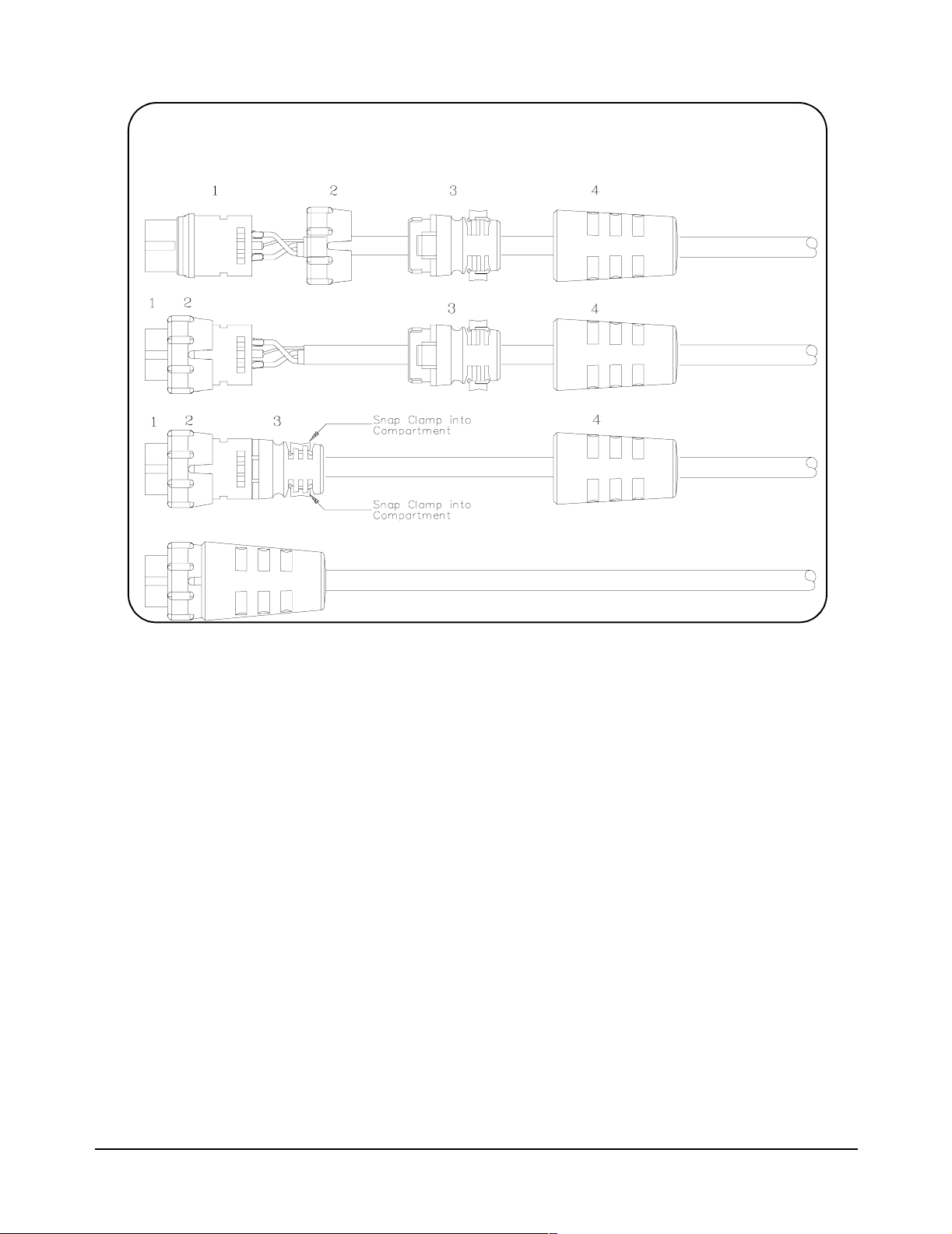

Assembly

Step 1 Strip cable as shown and feed the end of the cable through the boot, cable

Step 2 Orient the HI, LO and Guard conductors with the corresponding pins.

This section gives guidelines to connect user-supplied cables to the cable

connector supplied with the E1563A and E1564A Digitizers. See "Terminal

Port Connector Cables" for recommended user-supplied cables.

clamp housing, and coupling ring in the order and position shown. The

coupling ring can also be inserted onto the cable connector from the front.

Configuring the Digitizer Modules 27Chapter 1

Page 28

Step 3 Solder conductors to pins.

CAUTION AVOID EXCESSIVE HEAT. Excessive heat on the connector

terminals can cause damage to the connector.

Step 4 Assemble the connector.

A. Align coupling ring’s tabs with cable connector’s side notches and push

the coupling ring onto the cable connector.

B. Push the cable clamp housing forward until it locks into the connector

body and snap the two clamps into their compartments to secure the cable.

C. Push the boot all the way forward to seat tightly onto the cable clamp

housing.

28 Configuring the Digitizer Modules Chapter 1

Page 29

Cable Coupling Cable Clamp Boot

Connector Ring Housing

Step 5 Mate the cable connector to the User Input Terminal Port.

1 Hold the cable connector by the rubber boot and align the notched

key slot with the key on the left side of the instrument’s front panel

connector. Insert the cable connector just enough to encounter

insertion resistance and stay in place.

2 Grasp the coupling ring and slowly rotate it clockwise, while you

gently push the connector toward the panel mount, until the notches

on the coupling ring drop into the front panel connector detents.

3 Continue rotating until you feel the coupling ring ride over the locking

“bump” which secures the connector to the instrument’s front panel

connector.

Configuring the Digitizer Modules 29Chapter 1

Page 30

Initial Operation

NOTE This discussion applies only to Standard Commands for Programmable

NOTE The E1563A or E1564A Digitizer may have experienced temperature

To program the E1563A or E1564A Digitizer using Standard Commands for

Programmable Instruments (SCPI), you must select the interface address

and SCPI commands to be used. Information about using SCPI commands

is presented in Chapter 3.

Programming a digitizer using SCPI requires that you select the controller

language (C, C++, BASIC, Visual Basic, etc.), interface address and SCPI

commands to be used.

Instruments (SCPI) programming. The example program listed is written

using Virtual Instrument Software Architecture (VISA) function calls.

VISA allows you to execute on VXIplug&play system frameworks that

have the VISA I/O layer installed (visa.h “include” file).

extremes during shipment that can affect its calibration. It is recommened

you perform a zero offset calibration upon receipt using CAL:ZERO

<channel>:ALL? for each channel to meet the accuracy specifications

in Appendix A. See Appendix E for the zero adjustment procedure.

Example: Initial Operation

This C program verifies communication between the controller, mainframe

and digitizer. It resets the module (*RST), queries the identity of the module

(*IDN?) and queries the module for system errors.

#include <stdio.h>

#include <visa.h>

/*** FUNCTION PROTOTYPE ***/

void err_handler (ViSession vi, ViStatus x);

void main(void)

{

char buf[512] = {0};

#if defined(_BORLANDC_) && !defined(_WIN32_)

_InitEasyWin();

#endif

ViStatus err;

ViSession defaultRM;

ViSession digitizer;

/* Open resource manager and digitizer sessions */

viOpenDefaultRM (&defaultRM);

viOpen(defaultRM, “

GPIB-VXI0::9::40”,VI_NULL,VI_NULL, &digitizer);

30 Configuring the Digitizer Modules Chapter 1

Page 31

/* Set the timeout value to 10 seconds. */

viSetAttribute (digitizer, VI_ATTR_TMO_VALUE, 10000);

/* Reset the module. */

err = viPrintf(digitizer, “*RST\n”);

if (err<VI_SUCCESS) err_handler (digitizer, err);

/* Query for the module’s identification string. */

err = viPrintf(digitizer, “*IDN?\n”);

if (err<VI_SUCCESS) err_handler (digitizer, err);

err = viScanf(digitizer, “%t”, buf);

if (err<VI_SUCCESS) err_handler (digitizer, err);

printf (“Module ID = %s\n\n”, buf);

/* Check the module for system errors. */

err = viPrintf(digitizer, “*SYST:ERR?\n”);

if (err<VI_SUCCESS) err_handler (digitizer, err);

err = viScanf(digitizer, “%t”, buf);

if (err<VI_SUCCESS) err_handler (digitizer, err);

printf (“System error response = %s\n\n”, buf);

viClose (digitizer); /* close the digitizer session */

} /* end of main */

/*** Error handling function ***/

void err_handler (ViSession digitizer, ViStatus err)

{

char buf[1024] = {0};

viStatusDesc (digitizer, err, buf); /* retrieve error description */

printf (“ERROR = %s\n”, buf);

return;

}

Configuring the Digitizer Modules 31Chapter 1

Page 32

Notes:

32 Configuring the Digitizer Modules Chapter 1

Page 33

Using this Chapter

This chapter gives guidelines to use the E1563A and E1564A Digitizers,

including:

Digitizers Operation

This section shows block diagram operation for the E1563A and E1564A

Digitizers, including digitizer block diagrams, power-on/reset states, and

input overload conditions.

Chapter 2

Using the Digitizers

• Digitizers Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

• Triggering the Digitizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

• Digitizers Application Examples . . . . . . . . . . . . . . . . . . . . . . . .42

Digitizer Block

Diagram

Figure 2-1 shows a block diagram of the E1564A 4-Channel Digitizer.

The E1563A 2-Channel Digitizer has the same internal structure without

channels 3 and 4. TRIG:LEVel <channel> signals drive the internal trigger

inputs, LEVel1 drives INT1, LEVel2 drives INT2, etc.

Figure 2-1. Digitizer Block Diagram

Using the Digitizers 33Chapter 2

Page 34

Channel Block

Diagram

Figure 2-2 is a block diagram of an individual channel and the

interconnections between channels. The sample signal goes to all channels.

The commands beneath the diagram show the SCPI commands used to

program each section of a channel. In this case, all the commands are

written for channel 4. See Chapter 3 for a full description of the commands

illustrated here.

RANGE SELECTION:

INPut4:STATe ON | 1 | OFF | 0

VOLTage4:DC:RANGe <range>

FILTER SETTING:

INPut4:FILTer:LPASs:FREQ <freq>

INPut4:FILTer:LPASs:STATe ON | 1 | OFF | 0

Figure 2-2. Digitizer Channel Block Diagram

QUERY LAST READING (current value):

SENSe:DATA:CVTable? (@4)

LIMIT and LEVEL COMPARISON:

CALCulate4:LIMit:LOWer:DATA <value>

CALCulate4:LIMit:LOWer:STATe ON | 1 | OFF | 0

or

CALCulate4:LIMit:UPPer:DATA <value>

CALCulate4:LIMit:UPPer:STATe ON | 1 | OFF | 0

or

TRIGger:SOURce INTernal4

TRIGger:LEVel4 <voltage>

TRIGger:SLOPe4 POS | 1 | NEG | 0

34 Using the Digitizers Chapter 2

Page 35

Pre-Trigger/

Post-Trigger Block

Diagram

Figure 2-3 illustrates relationship of pre-trigger readings and post-trigger

readings with the trigger event. See Chapter 3 for a full description of the

commands illustrated here.

Figure 2-3. Pre-Trigger/Post-Trigger Block Diagram

Power-on/Reset

States

Parameter Power-on/Reset State Parameter Power-on/Reset State

DIAG:INTerrupt:LINE interrupt line #1 VOLT4:RANGe 256V (channel 4 range)

FORMat:DATA ASCii VOLT1:RESolution 7.8125 mV (channel 1 res)

INPut1:FILTer:FREQ 0 (no filter on channel 1 ) VOLT2:RESolution 7.8125 mV (channel 2 res)

INPut2:FILTer:FREQ 0 (no filter on channel 2 ) VOLT3:RESolution 7.8125 mV (channel 3 res)

INPut3:FILTer:FREQ 0 (no filter on channel 3 ) VOLT4:RESolution 7.8125 mV (channel 4 res)

INPut4:FILT:FREQ 0 (no filter on channel 4 ) SAMPle:COUNt 1 (one sample)

INPut1:STATe ON (channel 1 input state) SAMPle:PRETrigger:COUNt 0 (no pretrigger samples)

INPut2:STATe ON (channel 2 input state) SAMPle:SLOPe POSitive

INPut3:STATe ON (channel 3 input state) SAMPle:SOURce TIMer (internal time base)

INPut4:STATe ON (channel 4 input state) SAMPle:TIMer 1.3 µsec

Table 2-1 describes all power-on and reset states for the digitizer. The reset

state after executing *RST is the same as the power-on state.

Table 2-1. Power-on and Reset States.

OUTPut:TTLT0-7:SOURce TRIGger (all TTLTrigger

lines)

TRIGger:LEVel1 -256V (channel 1 level)

Using the Digitizers 35Chapter 2

Page 36

Table 2-1. Power-on and Reset States.

Parameter Power-on/Reset State Parameter Power-on/Reset State

OUTPut:TTLT0-7:STATe OFF (all TTLTrigger lines) TRIGger:LEVel2 -256V (channel 2 level)

ROSCillator:SOURce INTernal TRIGger:LEVel3 -256V (channel 3 level)

SWEep:POINts 1 (one sample) TRIGger:LEVel4 -256V (channel 4 level)

SWEep:OFFSet:POINts 0 (no pretrigger samples) TRIGger:SOURce1 IMMediate (source 1

not ch 1)

VOLT1:RANGe 256V (channel 1 range) TRIGger:SOURce2 HOLD (source 2 not ch 2)

VOLT2:RANGe 256V (channel 2 range) TRIGger:SLOPe1 POSitive (slope 1 not ch 1)

VOLT3:RANGe 256V (channel 3 range) TRIGger:SLOPe2 POSitive (slope 2 not ch 2)

Input Overload

Condition

NOTE Relays open at approxiately 260V. If this happens, you must reprogram the

Overload voltages may occur which will open the channel input relay

disconnecting the input signal from the channel. Overload voltage by range

is shown in the following table.

Range Voltage Input Condition Vmax

62 mV to 4V High or Low to Guard >20V

16V to 256V Low to Guard >40V

The overload is reported both when the readings are retrieved and when the

next measurement is initiated. If an overload occurred, an error message is

returned when data is retrieved informing you that the data is questionable

(Overload detected - data questionable)

when you initiate the next measurement

re-connect of input relays).

. An error message is also returned

(Overload detected - attempting

input range to close by executing INP <channel> ON.

36 Using the Digitizers Chapter 2

Page 37

Triggering the Digitizers

This section describes digitizer triggering, including:

• Trigger Sources

• Using Internal Triggering

• Using External Triggering

• Master/Slave Operation

Trigger Sources Triggering digitizer readings across all input channels is accomplished

with one or both of the two trigger sources (TRIGger:SOURce1 and

TRIGger:SOURce2). The trigger event can be different for each source.

For example, SOURce1 can be EXT and SOURce2 can be TTLT0. Use

TRIG:SOURce<n> to set the trigger source event options which can be

OFF | BUS | EXT | HOLD | IMMEDIATE | INTernal1-4 | TTLT0-7.

You must execute TRIG:SOURce<n> two times to set both trigger sources

(TRIG:SOUR1 and TRIG:SOUR2). At power-up and after resetting the

module with *RST, TRIG:SOUR1 defaults to IMM and TRIG:SOUR2

defaults to HOLD. The number of readings set by SAMPle:COUNt are

taken after the trigger event occurs.

NOTE Do not confuse TRIG:SOUR1 as being associated with only channel 1

(as well as TRIG:SOUR2 with only channel 2). Both sources are common

to ALL channels and the “1” and “2” are not channel designators but

“source” designators.

Using Internal

Triggering

Using SCPI or VXIplug&play, you can trigger internally from a voltage

level from any channel. The trigger level is set using TRIG:LEVel<channel>

<voltage> for the channel you want to generate the trigger event. You then

set the trigger source to trigger internally from that channel using

TRIG:SOURce<n>INT<channel>. For example, to trigger from a 11.5V

level on channel 2, send VOLT2:RANG 16; TRIG:LEV2 11.5;

TRIG:SOUR INT2. Figure 2-1 shows the relationship of the trigger level to

the internal trigger source.

Each channel has a level compare circuit that compares the input signal to

the value set by the TRIG:LEVel<channel> command. This level initiates a

trigger when the input signal equals or exceeds the value set by TRIG:LEVel

This means the trigger can occur at a value other than the value set by the

TRIG:LEVel command.

For example, assume a trigger level of 0V on a ramp from -1V to +1V.

The first samples may be negative values close to zero. These values will

not cause a trigger because they do not equal or exceed the trigger level

value yet. The next sample may be a positive value greater than the trigger

level. The trigger compare circuit (see Figure 2-4) detects this level is equal

to or greater than the trigger level value set and a trigger is generated.

It was not, however, generated at the exact trigger level value set by the

TRIG:LEVel command.

Using the Digitizers 37Chapter 2

Page 38

Figure 2-4. Trigger Level Compare Circuit Operation

Using External

Triggering

Master-Slave

Operation

Master-Slave

Synchronization

You can provide an external trigger common to all channels. The external

trigger connection is on the digitizer’s External Trigger Input D-subminiature

connector “Trig” pin. You set this input as the trigger source for all channels

using TRIGger:SOURce<n> EXT. Use TRIGger:SLOPe<n> POSitive |

NEGative to set which signal edge will trigger.

The E1563A and E1564A Digitizers can be configured in a master-slave

configuration. This configuration allows a master module and one or more

slave modules to have their measurements synchronized. Synchronization

occurs when all channels trigger from the same trigger event and all

channels sample from one sample signal.

The sample synchronization signal is always generated by the master.

The TTL trigger event can be generated by either the master module or any

of the slave modules. This allows a slave module (as well as the master

module) to use one of the four internal trigger sources or their external

trigger source to trigger a measurement.

Both the trigger signal and the sample signal are placed on the VXI

backplane TTL trigger (TTLT) lines where the master module and all slave

modules receive the signals simultaneously. TTL trigger lines are used in

pairs between the master and slave(s) where one TTL trigger line carries the

sample signal and the other carries the trigger signal. The next section

describes how these TTL trigger lines are paired.

TRIGger:MODE is used to configure Digitizers for master-slave operation.