Page 1

Agilent 75000 SERIES C

Agilent E1445A

Arbitrary Function Generator

Service Manual

Serial Numbers

This manual applies directl y to instruments with se ria l numbers

prefixed with 3144A.

Copyright© Ag il en t T echnologies, Inc . 1992-2005

Manual Part Number: E1445-90011 Printed: Novemb er 2005 Edition 2

Printed in U.S.A. E1105

Page 2

Page 3

Chapter 1 - General Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Inspection/Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Shipping Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

AFG Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

AFG Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

AFG Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

AFG Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2 - Verification Tests

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Test Conditions/Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Verification Test Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Command Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ref In/Marker Out Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Start Arm In Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Start Arm In Test (cont’d) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Gate In Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Output Relay Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operation Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Test 2-1: DC Zeros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Test 2-2: DC Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Test 2-3: DC Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Test 2-4: AC Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Test 2-5: AC Flatness - 250 kHz Filter . . . . . . . . . . . . . . . . . . . . . . . . 49

Test 2-6: AC Flatness - 10 MHz Filter . . . . . . . . . . . . . . . . . . . . . . . . 52

Test 2-7: Frequency Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Test 2-8: Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Test 2-9: Total Harmonic Distortion . . . . . . . . . . . . . . . . . . . . . . . . . 64

Test 2-10: Spurious/Non-Harmonic Distortion . . . . . . . . . . . . . . . . . . . . 69

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

AFG Test Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Measurement Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Test Accuracy Ratio (TAR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Contents

Agilent E1445A Service Manual Contents 1

Page 4

Chapter 3 - Ad ju stments

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Recommended Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Calibration Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Defeating Calibration Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

DC Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

AC Flatness Adjustment Procedure - 250 kHz Filter . . . . . . . . . . . . . . . . . . . 93

AC Flatness Adjustment Procedure - 10 MHz Filter . . . . . . . . . . . . . . . . . . . 94

Skew DAC Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Chapter 4 - Replaceable Parts

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Exchange Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Chapter 5 - Service

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Service Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Troubleshoot in g Te c hniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Identifying the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Testing the Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Removing BNC Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Repair/Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Soldering Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Post-Repair Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

2 Conten ts Agilen t E1 44 5A Service Manua l

Page 5

Certification

Agilent Technologies certifies that this product met its published specifications at the time of shipment from the factory. Agilent Technologies further certifies that its calibration measurements are traceable to the United States National Institute of Standards and Technology (form er ly National Bureau of Standar ds), to the exte nt al lo w ed by that organi zati on’s calibrati on f acility, and to the calib rat i on

facilities of other International Standards Organization members.

Warranty

This Agilent Technologies product is w ar ra nt ed against def ects in mater ia l s and workmans hi p fo r a period of three years from date of

shipment. Du ra ti on and conditi ons of w ar ra nt y for this product may be supers eded when the pr oduct is integr ated into (bec om es a part

of) other Agil ent products. Duri ng t he warranty per io d, Ag il e nt Technolog ie s will, at its opt i on, either repair or replace pr oducts whic h

prove to be def ec t ive.

For warrant y service or rep ai r, t his product mu st be r et ur ned to a service fa cility designated by Agi le n t Technologies. Buyer shall prepay shippin g charges to Agil en t a nd A gi lent shall pay shipping char ges to return the prod uct to Buyer. How ever, Buyer shal l pay all

shipping ch arges, duties, and taxes for pr oducts returned t o A gilent from another count ry.

Agilent warrants that its software and firmware designated by Agilent for use with a product will execute its programming instructions

when proper l y in st al led on that pro duct. Agilent does not warrant th at the operatio n of th e product, or softw a re, or firmware w ill be uninterru pt ed or er ro r free.

Limitation Of Warranty

The foregoi ng w ar ra nt y shall not apply t o defects res ul ting from imprope r or in adequate mai nt enance by Buyer, Buyer-sup pl ie d pr oducts or interfa ci ng, unautho rized modificat i on or misuse, operation outside o f the environmen ta l specificati ons for the product, or improper site pr eparation or ma i nt enance.

The design and implementation of a ny ci r cui t on this produc t is the sol e responsibi l ity of the Buyer. A gi le nt does not warrant the

Buyer’s circuitry or malfunctions of Agi le nt pro ducts that resul t fr om th e B uyer’s circuitr y. In addition, Agil ent does not warrant any

damage th at occurs as a resu lt of the B uyer’s circuit or a ny defects tha t r es ul t f rom Buyer-suppli ed products.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. Agilent SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES. Agilent SHALL NOT BE LIABLE

FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Notice

The inform at i on contained i n th is document is s ubj ect to change w i t hout not ice. Agilen t Technologies MAKES NO WA R R A N TY OF

ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Agilent shall not be liable for errors contained herein or

for incident al or consequential dam ages in connect i on w i t h th e fu rni shing, perfo rmance or use of th is m at erial. This document contains

proprietar y in for m at i on w hich is protect ed by copyright. All rights are reserved. No part of this docum ent may be photocopied, reproduced, or translated to anot her language w i thout the prio r wr it t en consent of A gi le nt T echnologies, Inc. Agilen t as sum es no responsibility for the use or reliability of its software on equipment that is not furnished by Agilent.

U.S. Government Restricted Rights

The Softwa re and Document at ion have bee n developed en tirely at private expense . They are deliver ed and license d as "comme rc ia l

computer sof t w ar e" as defined in DFA R S 252.227- 7013 (Oct 1988), DFARS 25 2. 211-7015 (May 1991) or DFARS 252. 227-7014 (Jun

1995), as a "com m ercial ite m" as defined in F AR 2.1 01(a), or as "Re stri cted comput er sof tware" as def in ed i n FA R 52. 227-19 (Jun

1987)(or any e qui valent agenc y re gul at ion or contrac t cl ause), whiche ver is applicabl e. You have onl y th ose ri ght s provided for s u ch

Software and Document ation by the applicable FA R or DFA R S clause or th e A gilent standard softwa re agr eement for the product involved.

Agilent E1445A Arbitrary Function Generator Service Manual

Copyright © 1992-2005 Agi l ent Technologies, Inc. All Rights Reserved.

Edition 2

Agilent E1445A Service Manual 3

Page 6

Printing H is tory

The Printing H i story shown belo w list s al l Editions and Up dat es of this manua l and t he printing date (s ). T he fi rs t pri nt in g of the manual is Edition 1. The Edition number increments by 1 whenever the manual is revised. Updates, which are issued between Editions,

contain replacement pages to correct the current Edition of the manual. Updates are numbered sequentially starting with Update 1.

When a new Edition is created, it contains all the Update information for the previous Edition. Each new Edition or Update also includes a re vi se d copy of this print ing history pag e. Ma ny pr oduct updates or re vi si ons do not require m anual chang es and, conversely,

manual correction s m ay be done with out accomp anying product changes. Th erefore, do not expect a one-t o -o ne correspon dence between product updates and manual updates.

Edition 1 (P ar t Num ber E1445-90010). . . . . . . . . . . . . . . . . . . . September 1992

Edition 2 (P ar t Num ber E1445-90011). . . . . . . . . . . . . . . . . . . . September 1996

Safety Symbols

Instructi on m anual symbol affixed to prod uct. Indicates that the user must refer to the

manual for specific WARNING or CAUTION information to avoid personal injury

or damage t o t he pr oduct.

Alternating current (AC).

Direct current (DC).

Indicates the field wiring terminal that must

be connec t ed t o earth ground bef or e operating the equipm ent—protects agains t el ectrical shock in case of fault.

or

Frame or chassis ground terminal— typically connects to the equipment’s metal

frame.

WARNING

CAUTION

Indicate s ha zardous volta ges.

Calls at te nt i on t o a procedure, pr actice, or

condition that could cause bodily i nj ury o r

death.

Calls at te nt i on t o a procedure, pr actice, or condition that could possibl y ca use damage to

equipme nt or pe rm anent loss of dat a.

WARNINGS

The following general safety precautions must be obse rv ed during all phases of op er ati on, service, and re pai r of this product.

Failure to com p l y w i th t hese precautions or with sp ec i fi c w arnings else w here in this m anual violates saf et y st andards of des ign,

manufac ture, and int ended use of the produc t. A gi le n t Te chnologies assume s no l i ab i l it y for the customer’s fai lure to com p l y

with thes e requir em ents.

Ground the equipm en t: For Safety Class 1 equipment ( equipment ha vi ng a pr otective ea rt h t er minal), an uni nterruptib le sa fe ty earth

ground must be provided from t h e m a ins power source to the product input wiring ter minals or supplied power cable.

DO NOT operate the product in an explosiv e atmosphere or in the presence of flammabl e gases or fum es.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type.

DO NOT use re pai r ed fuses or short -c i rc ui te d fuse holders.

Keep away from live circuits: Operati ng personnel mu st not re m ove equipment covers or shields . P roc edures involv in g th e re moval

of covers or shi el ds are for use by service-train ed personnel onl y. U nder certain cond it i ons, dangerous voltages may exi st even with the

equipmen t s w itched off. To avoid dangerous e le ct r ic al shock, DO NOT perform procedures involving cover or shie ld removal unless

you are qualif ie d t o do so.

DO NOT operat e damaged equipmen t: Whe n e ver it is possible that the sa fe ty prot e ct ion features bui l t in t o t hi s pr oduct have been impaired, eit he r t hr ough physical damage, exc es si ve moisture, or any other reas on, R EMOVE POW ER and do not use the pr oduct until

safe opera tion can be verified by service- trained pers onnel. If necess ary, return the pr oduct to an Agi l ent Technologies Sales an d Ser vice Office for service and repair to ensure that safety features are maintained.

DO NOT ser vice or adjus t alone: Do not at te m pt internal service or adj us tm ent unless a not her person, ca pable of render in g fi rs t ai d

and resuscitation, is present.

DO NOT substitute par ts or modi fy equi pm e nt: Because of the danger of introducing additional hazards, do not instal l substitute

parts or perfo rm any unauthoriz ed modifica t io n to the product. R et ur n the product to an A gilent Technologies Sal es and Service Office

for service and repair to ensure that safety features are maintained.

4 Agilent E1445A Service Manual

Page 7

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name:

Manufacturer’s Address:

Agilent Technologies, Incorporated

815 – 14th St. SW

Loveland, Colorado 80537

USA

Declares, that the product

Product Name:

Model Number:

Arbitrary Function Generator

E1445A

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

(including 93/68/EEC) and carries the CE Marking accordingly.

Conforms with the following product standards:

EMC Standard

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

Limit

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz I cycle, 100%

Dips: 30% 10ms; 60% 100ms

Interrupt > 95%@5000ms

The product was tested in a typical configuration with Agilent Technologies test systems.

Safety

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

UL 3111-1: 1994

1 June 2001

Date

Ray Corson

Product Regulations Program Manager

Authorized EU-representative: Agilent Technologies Deutschland GmbH, Herrenberger Straβe 130, D 71034 Böblingen, Germany

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Revision: B.01 Issue Date: 1 June 2001 Document E1445A.DOC

Page 8

Notes

6 Agilent E1445A Service Manual

Page 9

Page 10

Page 11

Chapter 1

General Information

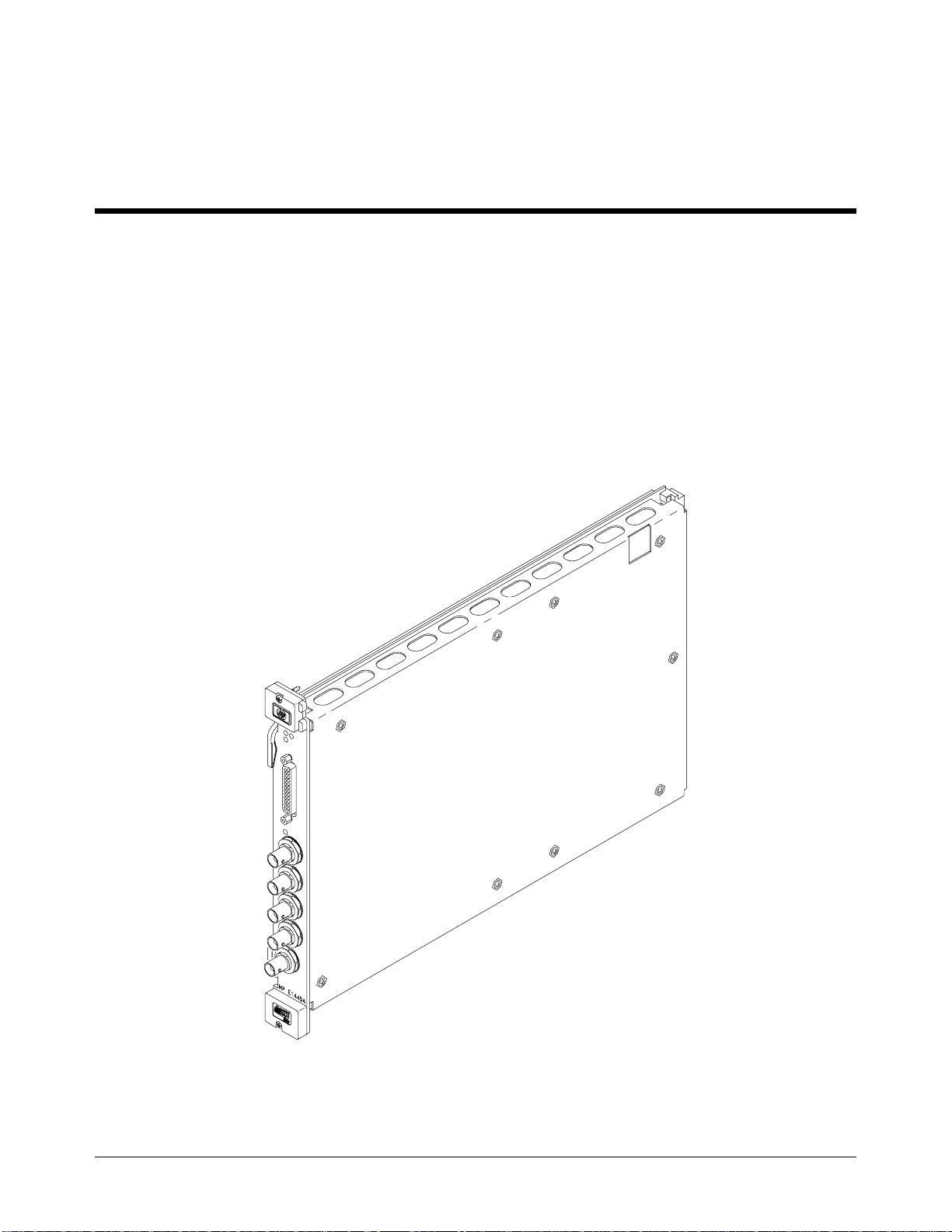

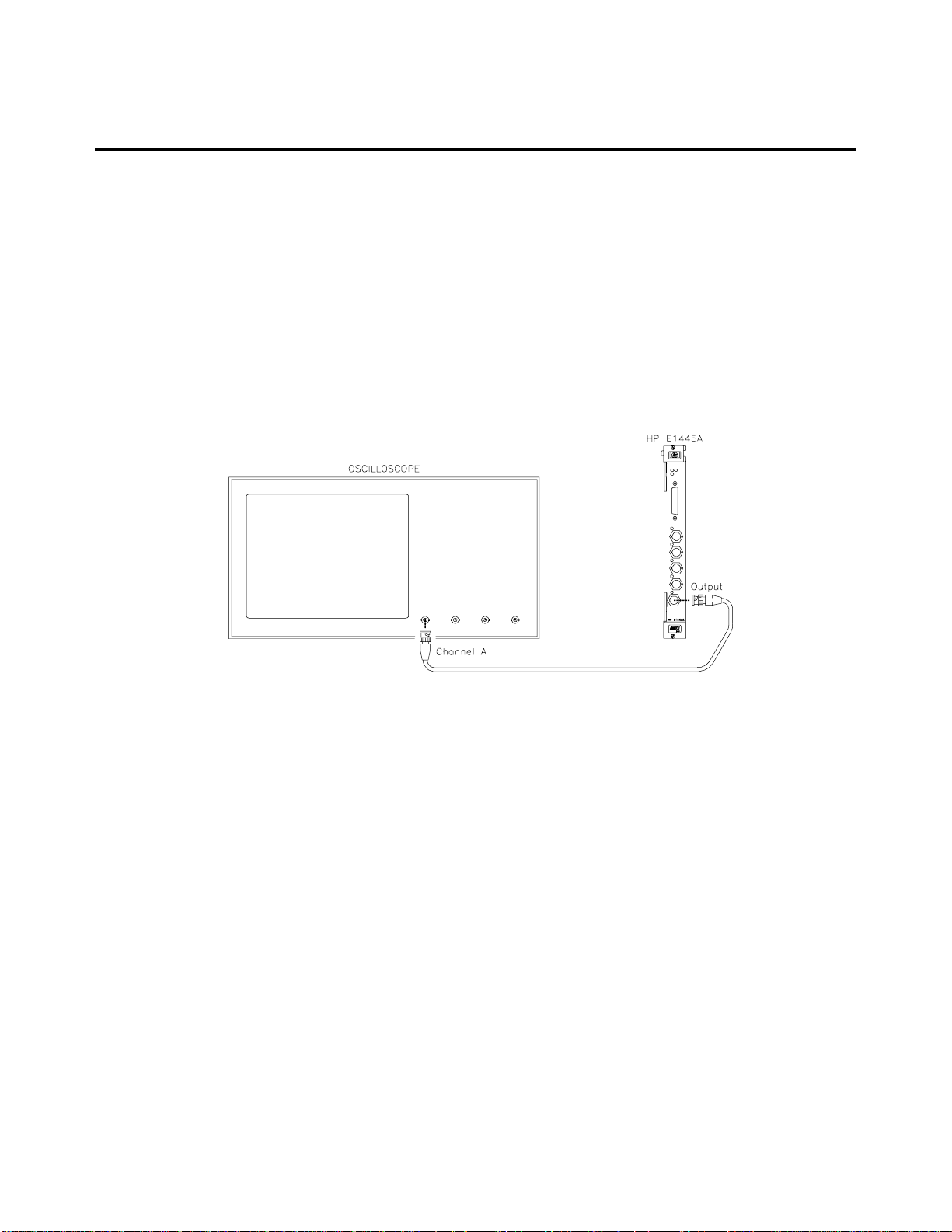

Introduction This manual co nta ins information required to test, trouble shoot, and repa ir

the Agilent E144 5A C-Siz e VXI Arbit rary Func tion Generator (AFG). See

the Agilent E1445A User’s Manual for additional informa ti on. Fi gur e 1-1

shows the Agile nt E1445A. This chapter inc ludes the followi ng se c ti ons:

• Introduction

• Safety Considerat ions

• Inspection/Shipping

• Environment

• AFG Description

• Recommended Test Equi pm en t

Figure 1-1. E1445A Arbitrary Function Generator

Agilent E1445A Service Manual General Information 9

Page 12

Safety

Considerations

This product is a Safet y Cl as s I instrument that i s provided with a protect ive

earth terminal when installed in the mainframe. The mainframe, AFG, and

all related documentat ion should be reviewed for familiarizat ion with safety

markings and instructions before opera ti on or se rv ic e .

Refer to the WARNINGS page (page 4) in this manual for a summary of

safety information. Safety information for preventive maintenance, testing,

and service follows and is also found throughout this manual.

Warnings and

Cautions

WARNING

This section cont ai ns W AR N INGS which must be followed for your

protection and CAUTIONS whi c h mus t be followed to avoid dama ge to the

equipment whe n pe rforming instrume nt maintenanc e o r repa ir .

SERVICE-TRAINED PERSONNEL ONLY. The information in this

manual is for service-trained personnel who are familiar with

electronic circuitry and are aware of the hazards involved. To

avoid personal injury or damage to the instrument, do not

perform procedures in this manual or do any servicing unless

you are qualified to do so.

CHECK MAINFRAME POWER SETTINGS. Before applying

power, verify t h at th e m ai n f ra m e se t ti n g m a tc hes the li ne

voltage and that the correct fuse is installed. An uninterruptible

safety earth ground must be provided from the main power

source to t he suppl ie d po we r co r d set .

GROUNDING REQUIREMENTS. Interruption of the protective

(grounding) conductor (inside or outside the mainframe) or

disconnecting the protective earth terminal will cause a

potential shock hazard that could result in personal injury.

(Grounding one conductor of a two-conductor outlet is not

sufficient protection.)

IMPAIRED PROTECTION. Whenever it is likely that instrument

protection has been impaired, the mainframe must be made

inoperative and be secu r ed against any u n intende d o p e rat i o n .

REMOVE POWER IF POSSIBLE. Some procedures in this

manual may be performed with power supplied to the

mainframe whil e p ro t e ct iv e covers ar e removed. Energy

available at many points may, if contacted, result in personal

injury. (If maintenance can be performed without power applied,

the power should be removed.)

10 General Information Agilent E1445A Service Manual

Page 13

WARNING

USING AUTOTRANSFORMERS. If the mainframe is to be

energized via an autotransformer (for vol tage reduction) make

sure the common terminal is connected to neutral (that is, the

grounded side of the main’s supply).

CAPACITOR VOLTAGES. Capacitors inside the mainframe may

remain charged even when the mainframe has been

disconnected from its source of supply.

USE PROPER FUSES. For continued protection against fire

hazard, replace the line fuses only with fuses of the sa me

current rating and type (such as normal blow, time delay, etc.).

Do not use repaired fuses or short-circuited fuseholders.

CAUTION

Static electricity is a major cause of component failure. To prevent

damage to the electrical components in the AFG, observe anti-static

techniques whenever working on the AFG.

Agilent E1445A Se rvice Man ual General Inform ation 11

Page 14

Inspection/

Shipping

This section de sc ri be s initial (in co ming) inspection and shipping guidelines

for t he AFG.

Inspection

WARNING

Initial

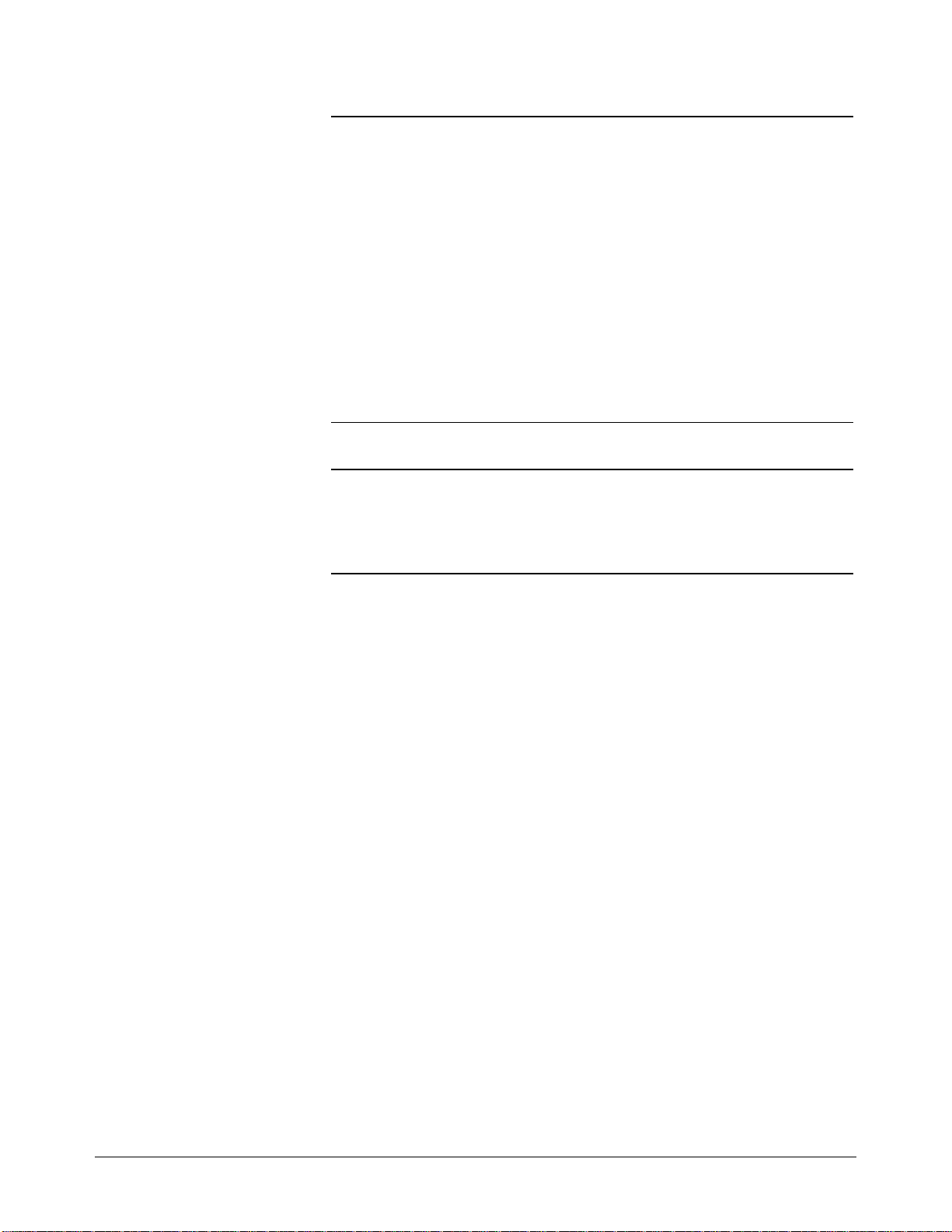

Use the steps in F igure 1-2 as guidelines to perform initial inspe c tion of

the AFG.

To avoid possible hazardous electrical shock, do not perform

electrical tests if there are signs of shipping damage to the

shipping container or to the instrument.

Figure 1-2. Initial (Incoming) Inspec tion Guidelines

12 General Information Agilent E1445A Service Manual

Page 15

Shipping

Guidelines

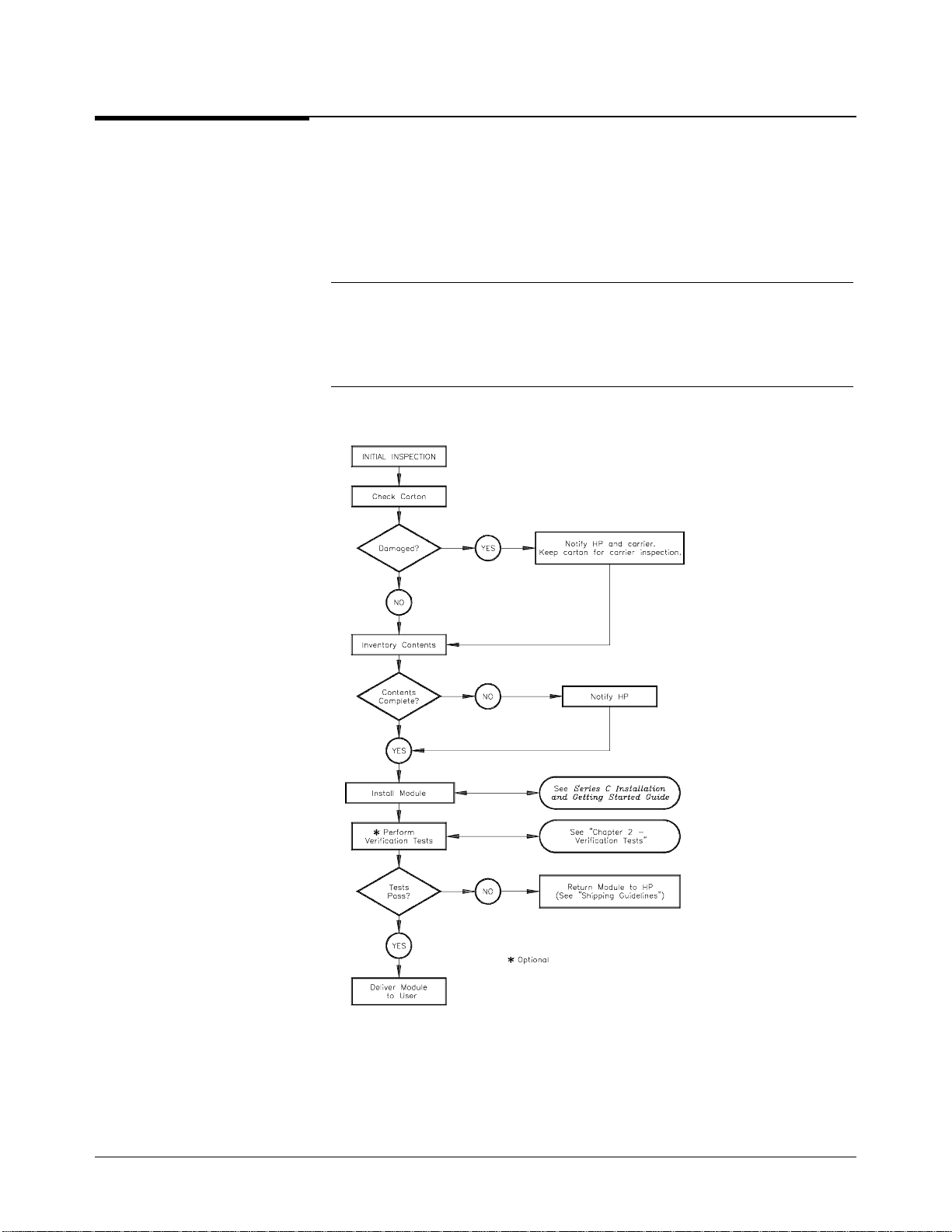

Follow the step s in Figure 1-3 to retu rn the AFG to an Agilent Technologies

Sales and Support Offi ce or Ser vi ce Center.

1. Prepare the module

• Remove user wiring from terminal bloc k

• Attach tag to module th at identifies :

• Owner

• Model Number/Serial Number

• Service Required

• Place tagged devi ce in approved anti-static bag

2. Package the module

• Place packag ed mod ule in shipping carton*

• Place 75 to 100 mm (3 to 4 in ch es) of

shock-abs orbi ng material ar ound the module

• Seal the shipping c ont ai ne r s ecurely

• Mark the shipping container FRAGI LE

3. Ship the module to Agi lent Technologie s

• Place address lab el on s hip ping carton

• Send carton to Agilent Technologies

* We recommend that you use the same shipping materials as those used in factory packaging (available from

Agilent Technologies). For other (commerc ia l ly-available ) sh ipp ing ma te ri a ls, use a double-wall carton with

minimum 2.4 M Pa (350 psi) test.

Figure 1-3. Packaging/Shipping Guidelines

Agilent E1445A Se rvice Man ual General Inform ation 13

Page 16

Environment The recommended oper at in g env ironment for the Agilent E1445A

Agilent

AFG is:

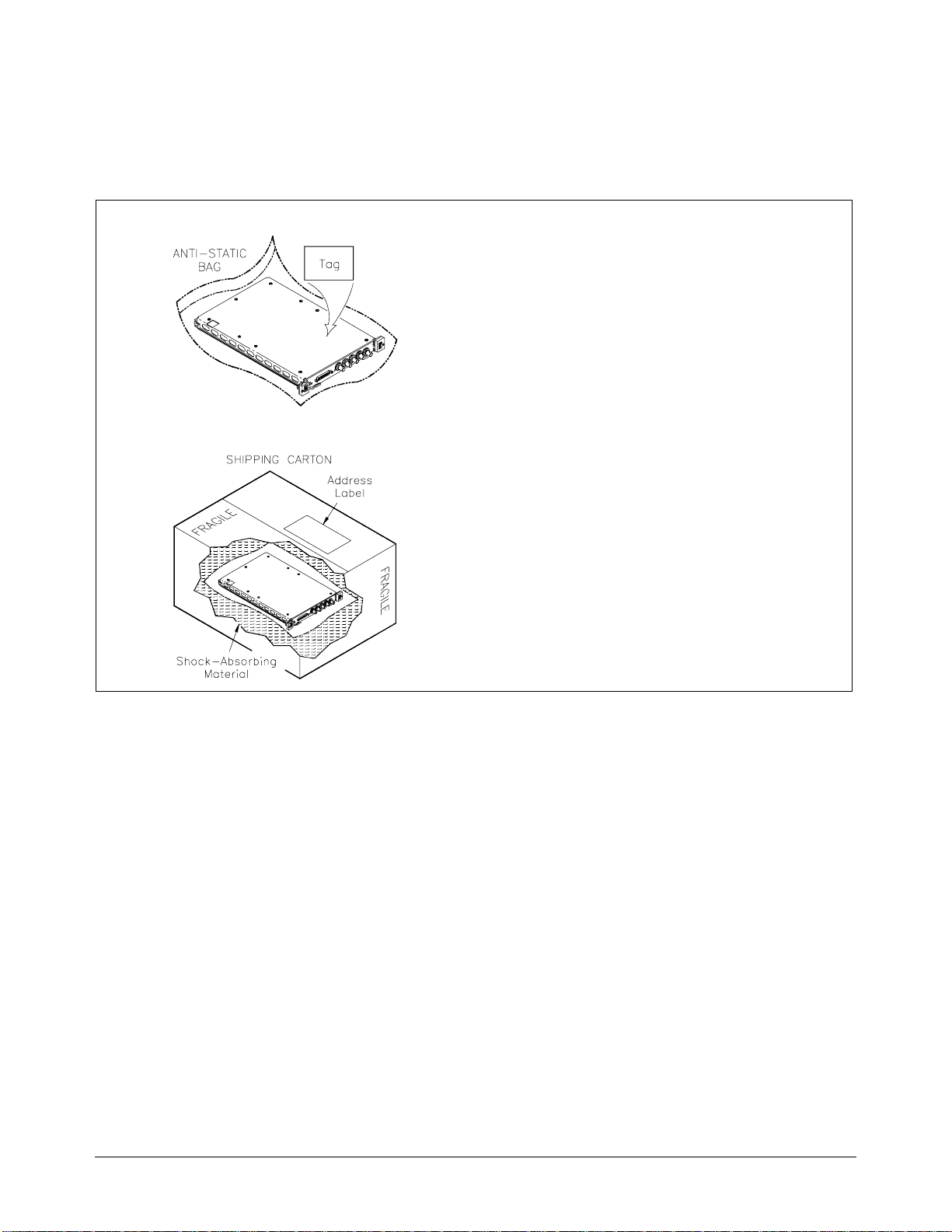

Environment Temperature Humidity

Operating 0

Storage and

Shipment

AFG

Description

Specifications

Options

AFG

AFG

o

C to +55oC <65% relative (0oC to +40oC)

o

-40

C to +75oC <65% relative (0oC to +40oC)

The Agilent E1445A Ar bi tr a ry Function Generator is a VXIbus C -size ,

message-based instrument. The AFG can operate in a C-size VXIbus

mainframe usi ng a n Agi le nt E1405/E1406 Command Module a nd St a nda r d

Commands for Programmable Instruments (SCPI).

The AFG has 13 bits of resol ution (including sign). It uses a sequen cer

architecture, with 256K points of Segment storage and 32K point s of

Sequence storage. The AFG has two internal timebases, 40 MHz and

(app roximate l y) 42 .9 MHz.

AFG specificatio ns a re li sted in Appendix A of the Agi le nt E1445A User’s

Manual. These specifications are the performance standards or limits

against which the instru m ent may be teste d.

Arbitrary Waveform Ge ne rat ion Software for HP 9000 Serie s 30 0

computers c an be order e d as Opti on 005.

AFG

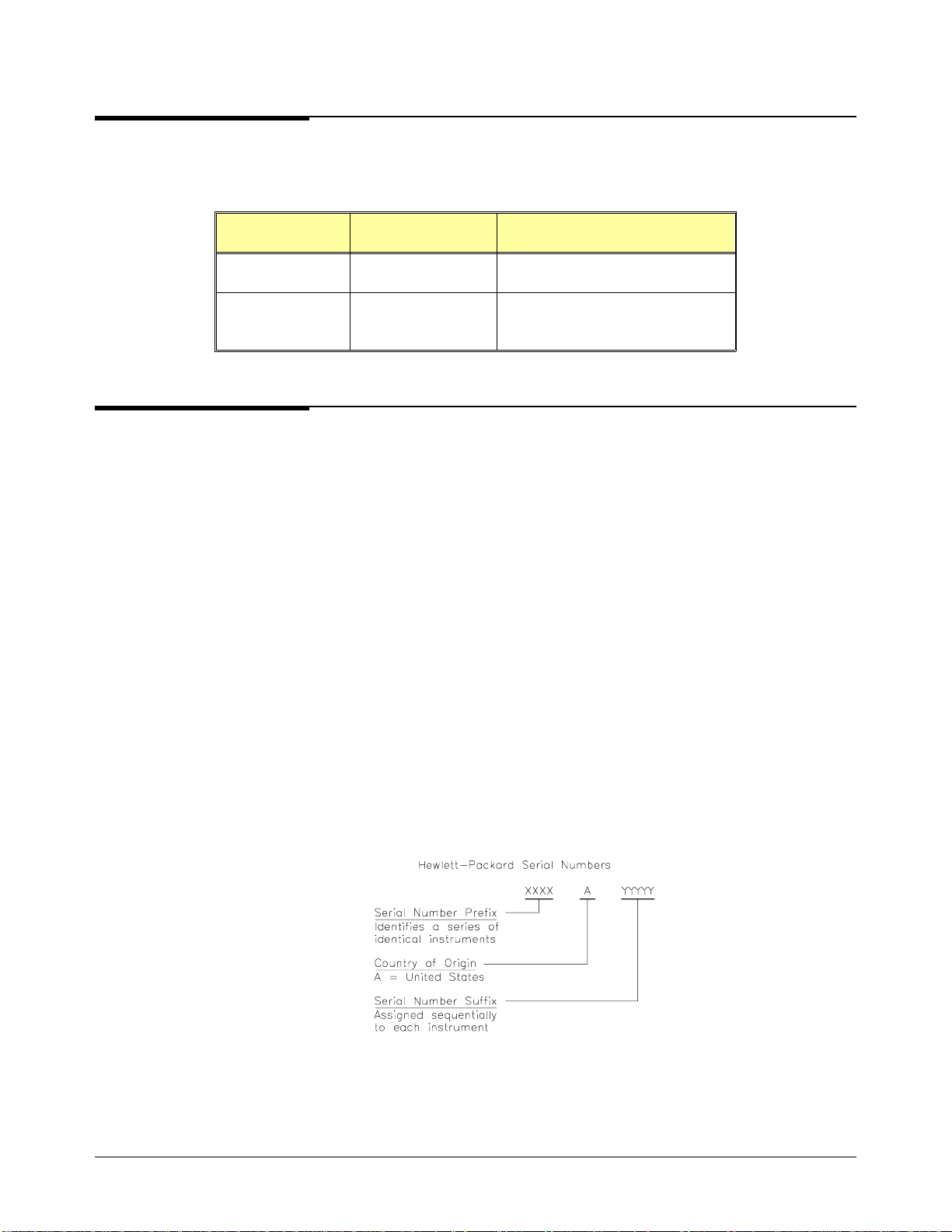

Serial Numbers

Figure 1-4 shows Agil en t Te chnologies’ serial num be r str uc ture . AFG’s

cove red by t h is man ual ar e iden tified by a s erial number pr efix listed on th e

title page.

Figure 1-4. Agilent Serial Numbers

14 General Information Agilent E1445A Service Manual

Page 17

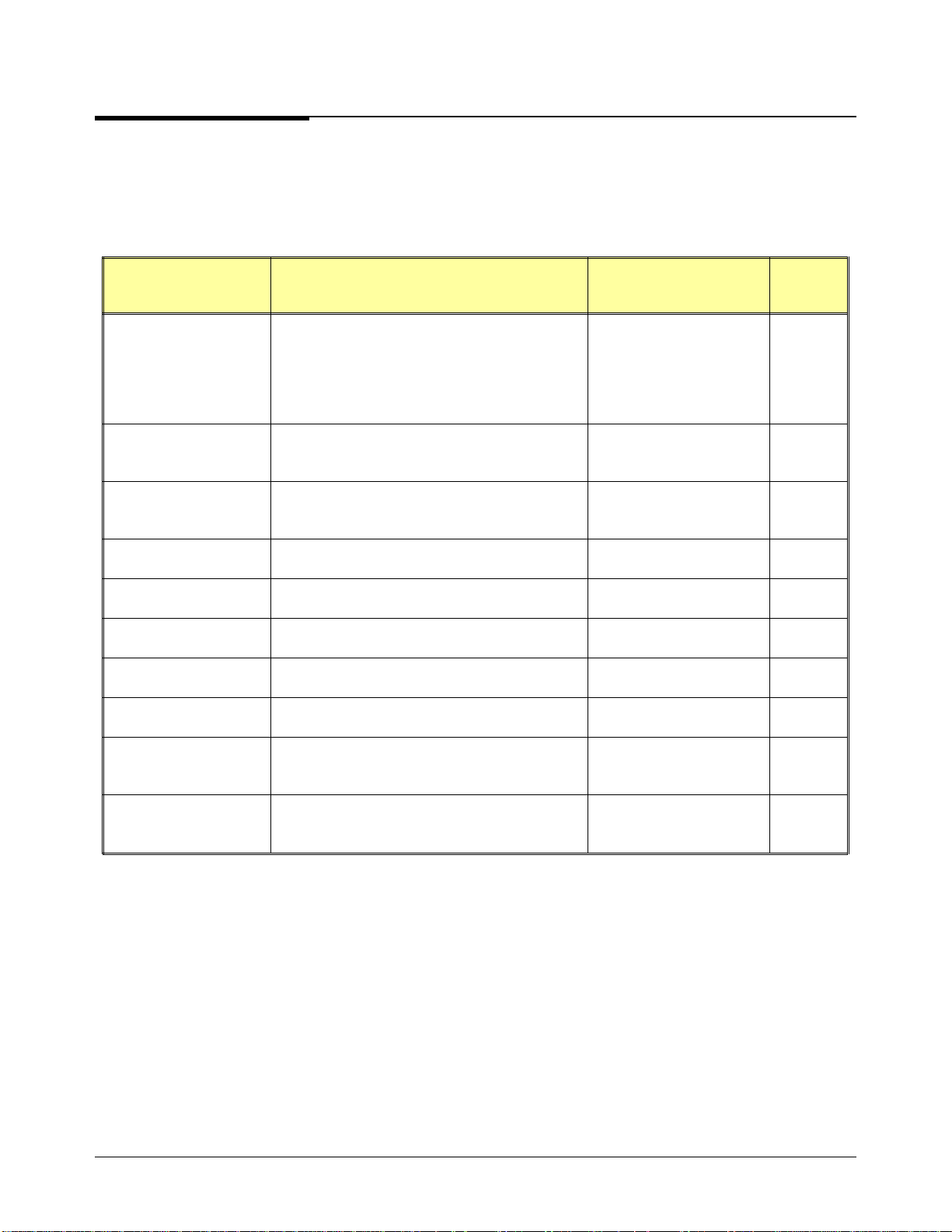

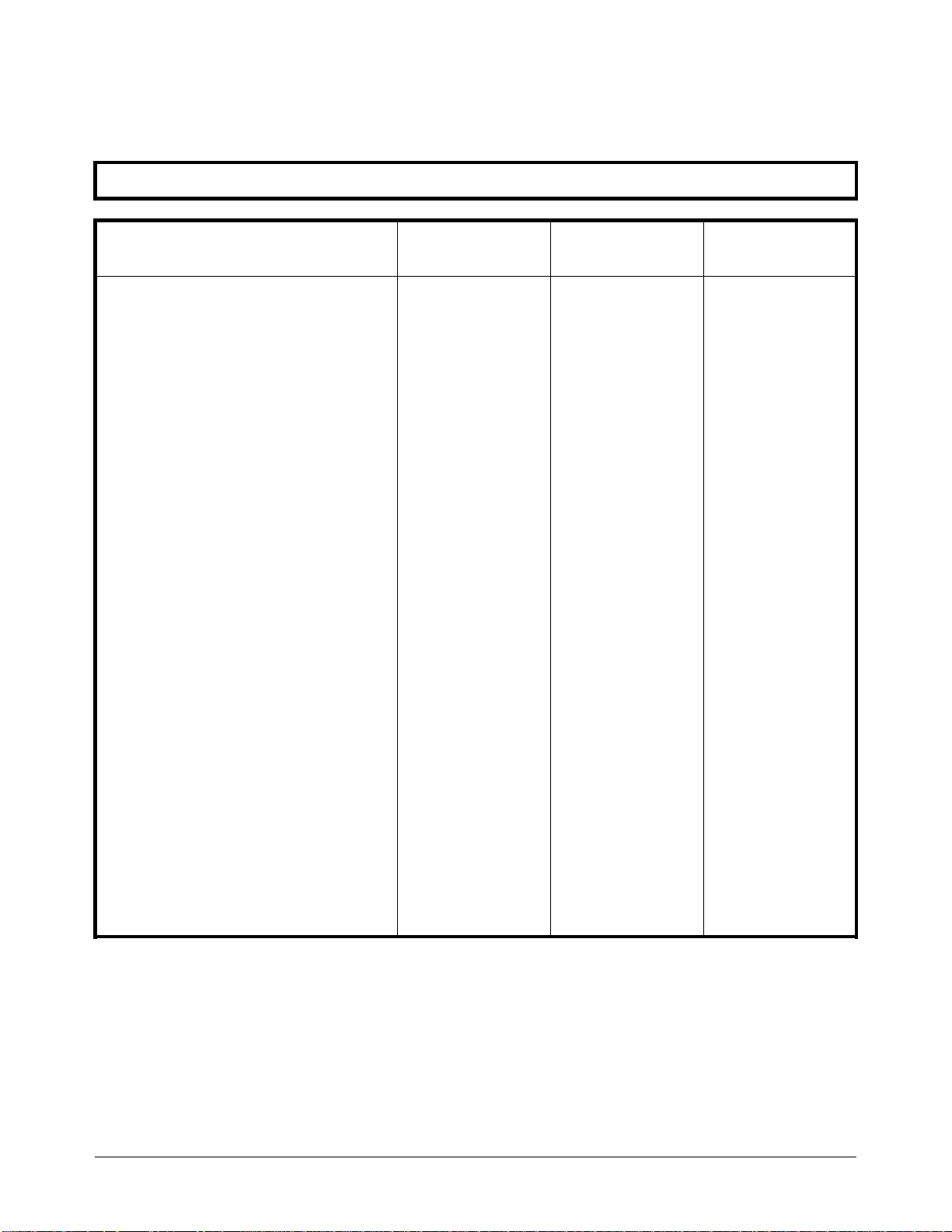

Recommended

Test Equipment

Table 1-1 list s the te st equipment recommended f or te sting, adjusting, and

servicing the AFG. Essential requirements for each piece of test equipment

are described in the Requirements col um n .

Table 1-1. Recommended Test Equipment

Instrument Requirements Recommended

Model

Controller, GP-IB GP-IB compatibility as defined by IEEE

Standard 488-1988 and the identical

ANSI Standard MC1.1: SH1, AH1, T2,

TE0, L2, LE0, SR0, RL0, PP0, DC0,

DT0, and C1, 2, 3, 4, 5.

Mainframe Compatible with AFG Agilent E1401B/T or

Command Module 10 MHz Clk Out

TTL compatible Trig Out

Digital Multimeter DCV, ACV, 4-wire ohms w/offset comp Agilent 3458A O,P,A

Power Meter Frequency Range: 400 kHz - 10.8 MHz Agilent 8902A O,P,A

Power Sensor Frequency Range: 400 kHz - 10.8 MHz Agilent 11722A O,P,A

Counter Frequency Range: 100 Hz - 45 MHz Agilent 5334A/B O,P

Spectrum Analyzer Frequency Range: 100 kHz - 150 MHz Agilent 8566B O,P,A

HP 9000 Series 300

or

IBM Compatible PC

with HP BASIC

E1421B

Agilent E1405B or

Agilent E1406A

Use*

F,O,P,

A,T

F,O,P,

A,T

F,O,P,

A,T

Oscilloscope General Purpose

Bandwidth: 20 MHz

50 Ω feed-thru

termination

* F = Functional Verification, O = Operation Verification Tests, P = Performance Verification

Tests, A = Adjustments, T = Troubleshooting

50 ±0.10 Ω

Agilent 54111D F

Agilent 11048C O,P,A

Agilent E1445A Se rvice Man ual General Inform ation 15

Page 18

16 General Information Agilent E1445A Service Manual

Page 19

Chapter 2

Verification Tests

Introduction The three levels of test procedures described in this chapter are use d to

verify that the Agilen t E1445A:

• is fully functional (Fu nctional Verific a tion)

• meets selected testable specifications (Operation Verification)

• meets all testable specifications (Performance Verification)

WARNING

Test Conditions/

Procedures

Performance

Test Record

Do not perform any of the following verification tests unless

you are a qualified, service-trained technician and have read the

WARNINGS and CAUTIONS in Chapter 1.

See Table 1-1 for test equipment requ ir em e nts. You should complete the

Performance Verification tests at least once a year. For heavy use or severe

operating environments, perform the tests more often.

Before performing these tests, allow the AFG to warm up for at least one hour .

The temperature should be within

recent calibration), and between 18

The verificati on te sts assume that th e per son performing the te sts

understands how to operate the mainframe, the AFG, and specified test

equipment. T he te st pr oc e dur e s do not sp e cify equipment settin gs f or tes t

equipment, except in gener al terms. It is assumed that a qualified,

service-trained technicia n w ill se le c t a nd c onne c t the c ab le s, adap t ers, a n d

probes required f or the test.

The resul t s o f each Perf o rmance Verifi catio n t est m ay be recorded in Tabl e

2-11, Agilent E1445A Performance Test Recor d. This form can be copied.

o

±5

C of T

o

C and 28oC.

(the temperature of the most

cal

Verification Test

Examples

Each verificatio n te st proc e dur e include s a n e xa mpl e program that performs

the test. All exa mple programs a ssume the followin g co nf igur a tion:

• Controller is an HP 9000 Series 200/300 compu te r

• Programming language is HP BASIC

• AFG address is 70910

Agilent E1445A Service Manual Verification Tests 17

Page 20

Command Coupling Many of the AFG SCPI commands are value-coupled. In order to prevent

"Settings C onflict" errors, co uple d c o m ma nds must be sent con tiguously by

placing them in th e same program line, or by suppr e ssi ng the e nd- of - line

terminator . (Fo r m or e in fo rm a tion on command co upling and syntax, see

Chapter 1 of the Agilent E1445A User’s Manual). In HP BAS IC, the

end-of-line ter minator can be suppressed by linking th e commands with a

semi-colon (;) and a colon (:), as illustra te d below:

ROSC:SOUR INT1;

:TRIG:S OU R INT1

In the Example programs, these commands would appear as follows:

OUTPUT 70910;"ROSC:SOUR:INT1;";

OUTPUT 70910;":TRIG:SOUR:INT1"

Functional

Verification

NOTE

NOTE

The purpose of these te sts is to verify that the AFG is fun ctioni ng pr ope r ly

and that all front pa nel inputs and ou tputs are working . No a tte mpt is made

to verify that the A F G is me e ting specificati ons. Functional Ver ific a tion for

the AFG include s the f ollowing tests:

• Self-Test

• Ref In/Marker Out Test

• Start A r m I n Test

• Gate In Test

• Output Rela y Te st

For a quick functiona l ch eck of the AFG, per form only the Self-Test.

An example program tha t perfor m s al l of the Functional Verification tests is

included at the end of this section . An Agilen t E1405/E1406 Comma nd

Module is requir e d for this pr ogram.

Some of the tests use the "TRI G OUT" port of the Comma nd M odule. This

port uses negati ve logic, i.e., the hi gh v oltage is a logical 0 and the low

voltage is a logical 1.

18 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 21

Functional Ve rification: Self-Test

Description

The AFG self-test performs the following internal checks:

• internal interrupt lines

• waveform sele ct RAM

• segmen t se quence RAM

• waveform segment RAM

• DDS/NCO operation

• sine wave generation

• arbitrary waveform generation

• marker generation

• waveform cycle and arm counters

• sweep timer

• frequency-shift keying

• stop trigger

• DC analog paramete rs (amplitude, o ffset, attenuato rs , filters,

calibration DACs)

Test Procedure

1. Remove any connections to the AF G front panel .

2. Reset the AFG:

*RST;*CLS Reset AFG and clear

status registers

Execute the AFG self-test:

3.

*TST? Self-test command

Read the result. A "0" indicates that the test passed. A "1" indicates a

4.

failure. Read the error que ue using the SYST:ERR ? command until

the error message is "No error".

Agilent E1445A Service Manual Verification Tests 19

Page 22

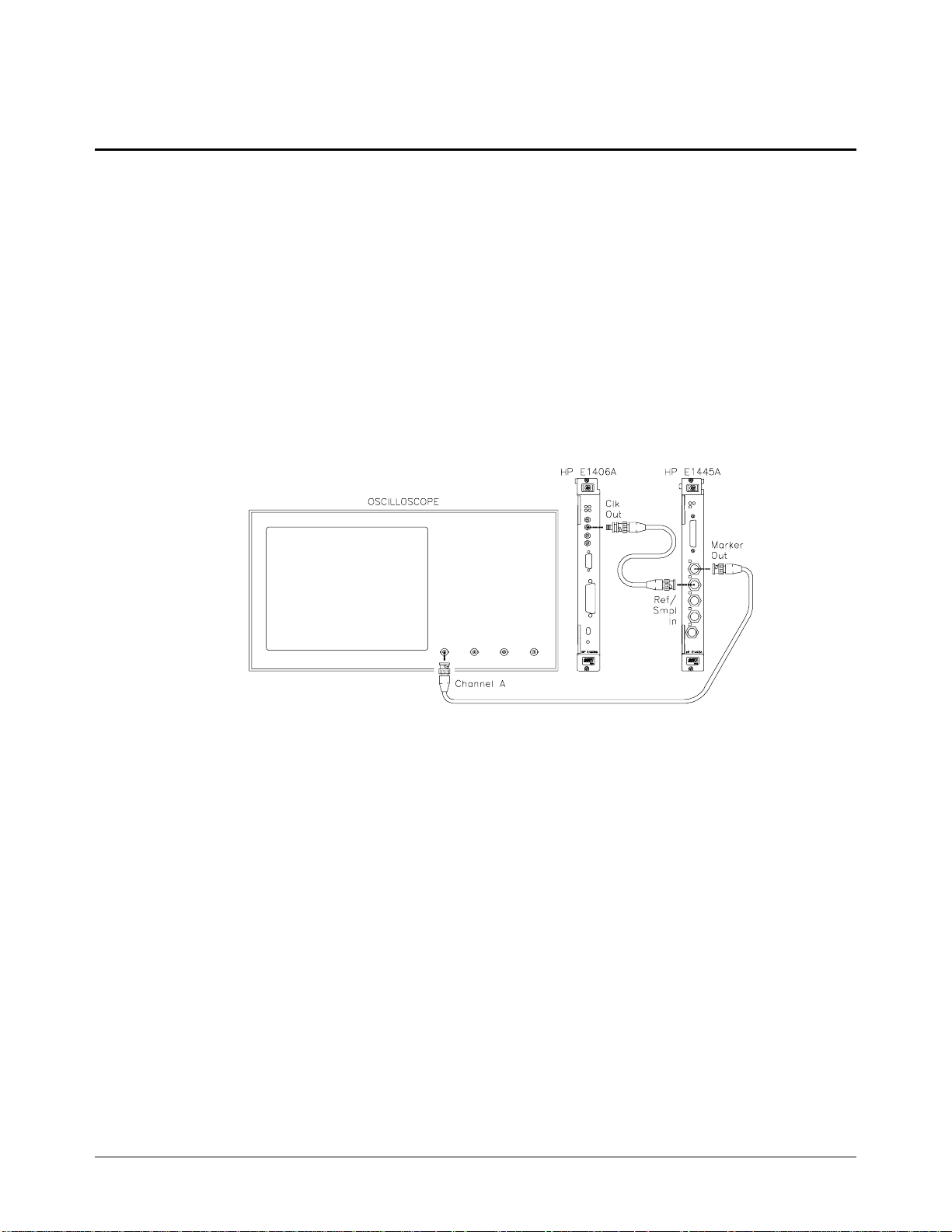

Funct ional Verification: Ref In/Marker Out Test

Description

The purpose of thi s te st is to check the Ref /S a mple In and Marker Ou t por ts.

An external ref e renc e is c onne cted to the Ref/S a mple In port and sent to the

Marker Out port.

Test Procedure

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

2.

Set up equipme nt a s shown in Fi gur e 2-1 :

status registers

Figure 2-1. Ref/Sample In Test Setup

3. Set up the AFG to output the external ref ere nc e to the "Marker Out"

port:

ROSC:SOUR EXT External ref osci ll ato r

MARK:FEED "ROSC" Marker sour ce is RO SC

INIT:IMM Initiate

Verify that the scope shows a 10 MH z squa rewave .

4.

20 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 23

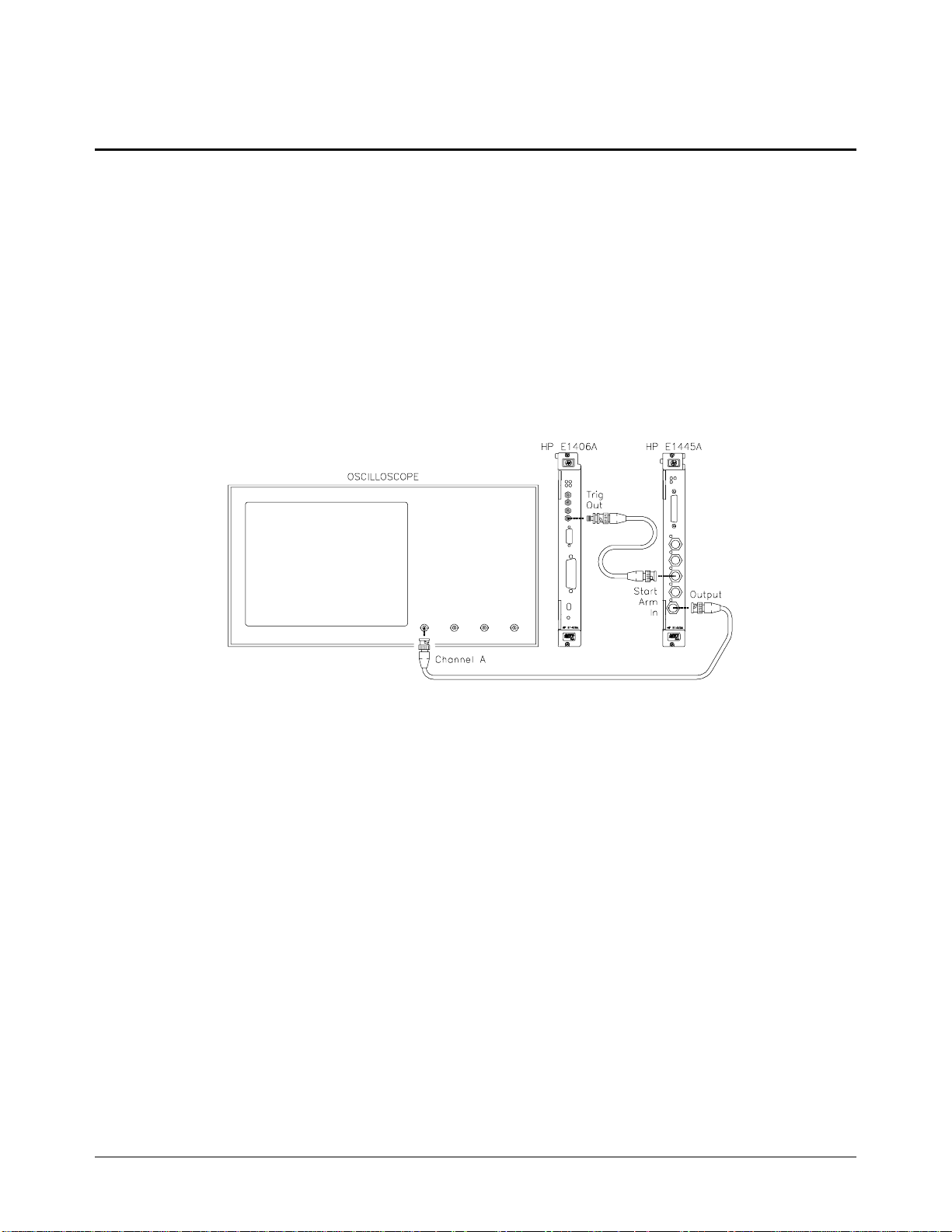

Functional Verification: Start Arm In Test

Description

The purpose of this test is to check the Start Arm In port. The "TRIG OUT"

port of the Command Module is used to send a Sta r t Arm signal to the AFG.

Test Procedure

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

Set up equipme nt a s shown in Fi gur e 2-2 :

2.

status registers

Figure 2-2. Start Arm In Test Setup

3. Send the following comm a nds to the Command Module to output 0 V

to the "Trig Out" port:

*RST

OUTP:EXT:STAT ON

OUTP: EX T :SOUR IN T

OUTP:EXT:LEV 1

Agilent E1445A Service Manual Verification Tests 21

Page 24

Functional Verification: Start Arm In Test (cont’d)

Test Procedure

(cont’d)

4. Set up the AFG to output a 1 MHz sinewav e, w ith an external S ta rt

Arm source:

FREQ 1E6; Set fre q to 1 MHz

:VOLT 4VPP Set AFG amplitude

ARM:LAY2:SO UR EXT External Star t Arm

INIT:IMM Initiate

Verify that no signal appears on the scope. Send the following

5.

command to th e Co mm a nd Module to provide a Sta r t Arm signal to

the AFG:

OUTP:EXT:LEV 0

Verify that a 1 MHz sinewave appea r s on the sc ope.

6.

source

22 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 25

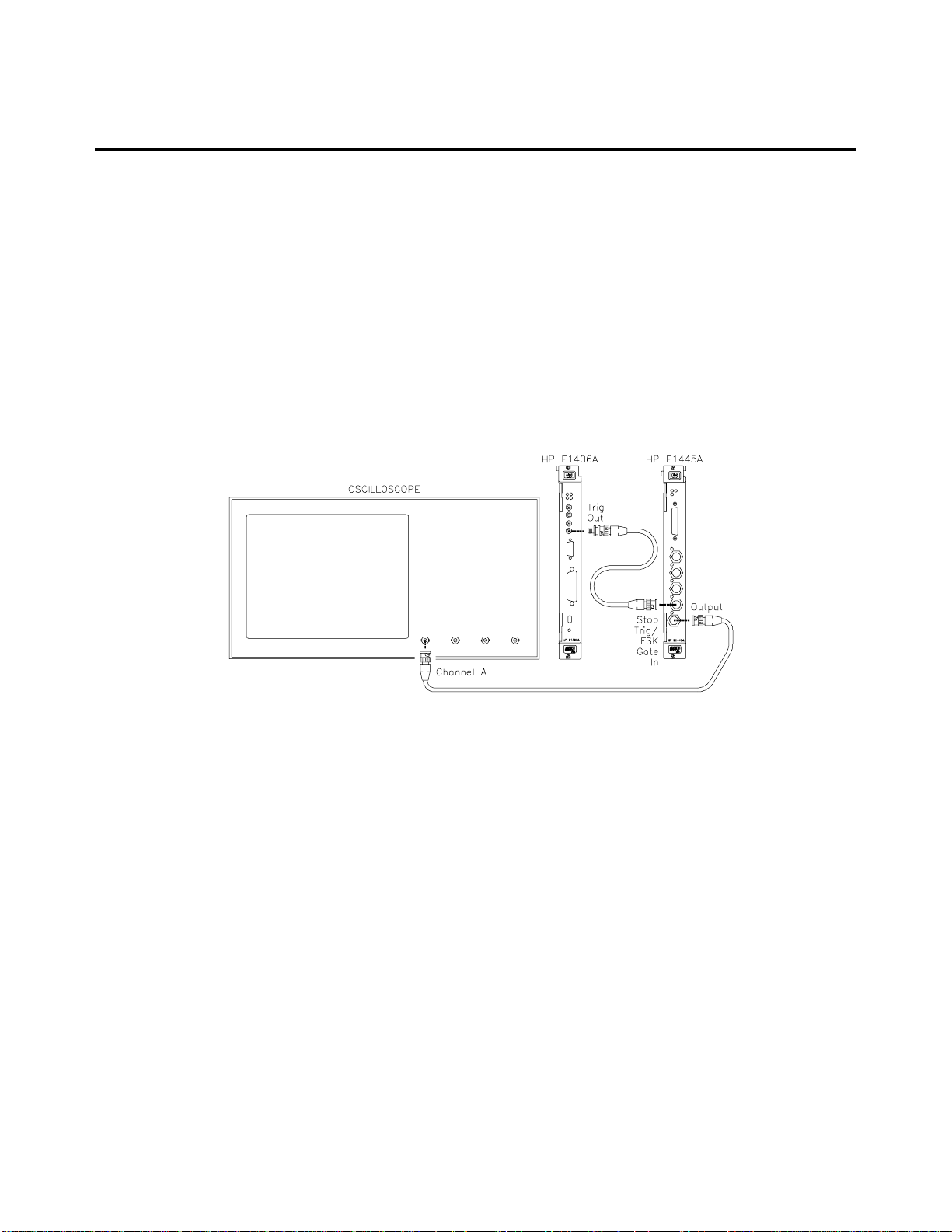

Functional Ve rification: G ate In Test

Description

The purpose of thi s te st is to check the gating function. The "TRIG OUT"

port of the Command Module is use d to gate the output .

Test Procedure

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

Set up the equipm e nt a s shown in Figure 2-3.

2.

status registers

Figure 2-3. Gate In Test Setup

3. Send the following comm a nds to the Command M odule to enable the

"Trig Out" port:

*RST

OUTP:EXT:STAT ON

OUTP: EX T :SOUR IN T

Agilent E1445A Service Manual Verification Tests 23

Page 26

Functional Verification: Gate In Test (cont’d)

Test Procedure

(cont’d)

4. Set up the AFG to output a 1 MHz sinewave with an external gate

source:

TRIG:GATE:SOUR EXT; External gate source

:TRIG:GATE:ST AT O N; Enable gate

:FREQ 1E6; Set fre q to 1 MHz

:VOLT 4VPP Set AFG amplitude

INIT:IMM Initiate

Send the follow i ng c o mm and to the Comma nd Module to set th e

5.

level at the "Trig Out" por t to 5 V. Verify that the scope shows a 1

MHz sinewave.

OUTP:EXT:LEV 0

Send the follow i ng c o mm and to the Comma nd Module to set th e

6.

level at the "Trig Out" port to 0 V. Verify that the scope shows a DC

signal.

OUTP:EXT:LEV 1

24 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 27

Funct ional Ve rifica tion: Output Relay Test

Description

The purpose of this te st is to check the output r e la y.

Test Procedure

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

Set up equipme nt a s shown in Fi gur e 2-4 :

2.

status registers

Figure 2-4. Output Relay Test Setup

3. Set up the AFG to output a 1 MHz sinewave:

FREQ 1E6; Set fre q to 1 MHz

:VOLT 4VPP Set AFG amplitude

INIT:IMM Initiate

Verify that a 1 MHz sinewave appea r s on the sc ope.

4.

5. Disable the Output relay:

OUTP OFF

Verify that no signal appears on the scope.

6.

Agilent E1445A Service Manual Verification Tests 25

Page 28

Functional Verification

Example Progr am

This program pe rfor ms the Functional Verification Tests for the AF G . An Agilent E1405/E1406 Comm an d

Module is requir e d f or this te st.

10! RE-STORE "FUNC_TEST"

20 COM @Afg,@Cmd_mod,INTEGER Done

30 !

40 !--- ------- S e t u p I/O pa ths ---------50 ASSIGN @Afg TO 7091 0

60 ASSIGN @Cmd_mod TO 70900

70 !

80 !---------- Initialize AFG & Comm and M odule ---------90 Reset_afg

100 !

110 !Set up Command M odule ’ TRI G O UT’ port

120 OUTPUT @Cmd_m od;"*RST"

130 OUTPUT @Cmd_mod;"OUTP:EXT:STAT ON"

140 OUTPUT @Cmd_mod;"OUTP:EXT:SOUR INT"

150 !

160 !---------- Perform tests ---------170 CLEAR SCREEN

180 PRINT "Agilent E1445A FUNCTIONAL VERIFICATION TESTS"

190 PRINT

200 !

210 !Oscilloscope settings

220 PRINT "Set scope t o: 2 V/di v, . 02 usec/div"

230 PRINT

240 Wait_for_cont

250 !

260 CALL Self_test !Self-Test

270 CALL Ref_in !Ref In/Marker Out Test

280 !

290 !Oscilloscope settings

300 CLEAR SCREEN

310 PRINT "Set scope t o: 2 V/div, . 2 usec/div"

320 PRINT

330 Wait_for_cont

340 !

350 CALL Start_arm !Start Arm In Test

360 CALL Gate_in !Gate In Test

370 CALL Output_ relay !Output Relay Test

380 !

390 Quit: !

400 Reset_afg

410 CLEAR SCREEN

420 DISP "Functional Tes ts compl et ed. "

430 END

(Continued on ne xt pa ge )

26 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 29

Functional Verification

Example Program (cont’d)

450 !---------- Subprogram s ---------460 SUB Reset_afg

470 COM @Afg,@Cmd_mod,INTEGER Done

480 OUTPUT @Afg ;"* RS T; *CLS" !Reset AFG and clear Status re gi ster

490 WAIT 1

500 SUBEND

510 !

520 SUB Self_test

530 COM @Afg,@Cmd_mod,INTEGER Done

540 DIM Message$[255]

550 !

560 Reset_afg

570 !

580 CLEAR SCREEN

590 PRINT "SELF-TEST"

600 PRINT

610 !

620 !Test connections

630 PRINT "Remove any connections from the E1445A front panel."

640 PRINT "Press ’Conti nue’ t o in itiat e Sel f -Te st."

650 PRINT

660 Wait_for_cont

670 !

680 !Perform test

690 OUTPUT @Afg;"*TST?" !Self -test command

700 ENTER @Afg;Result !Get result

710 !

720 IF Result=0 THEN

730 PRINT "Self-test passed."

740 ELSE

750 PRINT "Self-test failed."

760 PRINT "The following err or (s) occurred:"

770 REPEAT

780 OUTPUT @Afg;"SYST:ERR?" !Check for errors

790 ENTER @Afg;Message$

800 PRINT " "&Message$

810 UNTIL POS(Message$,"No error")

820 END IF

830 Wait_for_cont

840 SUBEND

850 !

860 SUB Ref_in

870 COM @Afg,@Cmd_mod,INTEGER Done

880 !

(Continued on ne xt pa ge )

Agilent E1445A Service Manual Verification Tests 27

Page 30

Functional Verification

Example Program (cont’d)

890 Reset_afg

900 !

910 CLEAR SCREEN

920 PRINT "REF IN/MARKER OUT TEST"

930 PRINT

940 !

950 !Test connections

960 PRINT "Connect Scope to ’Marker Out’ on the E1445A."

970 PRINT "Connect Command Module ’Clk Out’ to ’Ref/Sample In’ on the E14 45A."

980 PRINT

990 Wait_for_cont

1000 !

1010 !Perform test

1020 OUTPUT @Afg;"ROSC:SOUR EXT" !External ref osc source

1030 OUTPUT @Afg;"MARK:FEED ""ROSC""" !Marker source is ’ROSC’

1040 OUTPUT @Afg;"INIT:IMM" !Initiate

1050 !

1060 PRINT "Verify th at the scope shows a 10 MHz squarewave."

1070 Wait_for_cont

1080 SUBEND

1090 !

1100 SUB Start_arm

1110 COM @Afg,@Cm d_m od,INTEGER Don e

1120 !

1130 Reset_afg

1140 !

1150 CLEAR SCREEN

1160 PRINT "START ARM TEST"

1170 PRINT

1180 !

1190 !Test connecti ons

1200 PRINT "Connect Sco pe t o th e E1445A Output."

1210 PRINT "Connect Com m and Module ’Trig Out’ to ’Start A rm In’ on th e E1445A."

1220 PRINT

1230 Wait_for_cont

1240 !

1250 !Set Command Mo dul e’s ’ TR IG OUT’ to 0V (E1405 uses neg logic )

1260 OUTPUT @Cmd_m od ;"O UTP :E XT: LEV 1"

1270 !

1280 !Perform test

1290 OUTPUT @Afg;"FREQ 1E6;"; !Set freq to 1 MHz

1300 OUTPUT @Afg;":VOLT 4VPP" !Set amplitude

1310 OUTPUT @Afg;"ARM:LAY2:SOUR EXT" !Start Arm source is EXT

1320 OUTPUT @Afg;"INIT:IMM" !Initiate

1330 !

(Continued on ne xt pa ge )

28 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 31

Functional Verification

Example Program (cont’d)

1340 PRINT "Verify th at no signal appears on the scope. "

1350 PRINT "Press ’Con tinu e’ to se nd a STA RT A RM . "

1360 PRINT

1370 Wait_for_cont

1380 !

1390 !Set ’TRIG OUT’ to 5V

1400 OUTPUT @Cmd_m od ;"O UTP :E XT: LEV 0"

1410 !

1420 PRINT "Verify th at the scope shows a 1 MHz sinewa ve. "

1430 Wait_for_cont

1440 SUBEND

1450 !

1460 SUB Gate_in

1470 COM @Afg,@Cm d_m od,INTEGER Don e

1480 !

1490 Reset_afg

1500 !

1510 CLEAR SCREEN

1520 PRINT "GATE IN TEST"

1530 PRINT

1540 !

1550 !Test connecti ons

1560 PRINT "Connect Sco pe t o th e E1445A Output."

1570 PRINT "Connect Com m and Mod ul e ’Trig O ut ’ to ’St op Tr ig/F SK /Ga te In’ on the E1445A."

1580 PRINT

1590 Wait_for_cont

1600 !

1610 !Perform test

1620 OUTPUT @Afg;"TRIG:GATE:SOUR EXT;"; !Gate source is EXT

1630 OUTPUT @Afg;":TRIG:GATE:STAT ON;"; !Enable gate

1640 OUTPUT @Afg;":FREQ 1E6;"; !Set freq to 1 MHz

1650 OUTPUT @Afg;":VOLT 4VPP" !Set amplitude

1660 OUTPUT @Afg;"INIT:IMM" !Initiate

1670 !

1680 PRINT "Verify th at the sig nal di splayed on the scope toggl es bet w een"

1690 PRINT "a 1 MHz sine w ave an d a D C signal at 1 secon d in te rva ls."

1700 !

1710 ON KBD ALL CALL Key_press

1720 DISP "Press an y key t o continue"

1730 !

1740 Done=0

1750 !Send pulses to ’T RIG O U T’ B NC unt il a ke y is pres sed

(Continued on ne xt pa ge )

Agilent E1445A Service Manual Verification Tests 29

Page 32

Functional Verification

Example Program (cont’d)

1760 REPEAT

1770 OUTPUT @Cmd_m od; " O UTP :E XT: LEV 1"

1780 WAIT 1

1790 OUTPUT @Cmd_m od; " O UTP :E XT: LEV 0"

1800 WAIT 1

1810 UNTIL Done

1820 OFF KBD

1830 SUBEND

1840 !

1850 SUB Output_ relay

1860 COM @Afg,@Cm d_m od,INTEGER Don e

1870 !

1880 Reset_afg

1890 !

1900 CLEAR SCREEN

1910 PRINT "OUTPUT RELAY TEST"

1920 PRINT

1930 !

1940 !Test connecti ons

1950 PRINT "Connect Sco pe t o th e E1445A Output."

1960 PRINT

1970 Wait_for_cont

1980 !

1990 !Perform test

2000 OUTPUT @Afg;"FREQ 1E6;"; !Set freq to 1 MHz

2010 OUTPUT @Afg;":VOLT 4VPP" !Set amplitude

2020 OUTPUT @Afg;"INIT:IMM" !Initiate

2030 !

2040 PRINT "Verify th at the scope shows a 1 MHz sinewa ve. "

2050 PRINT "Press ’Con tinu e’ to disa bl e th e E1445A output."

2060 PRINT

2070 Wait_for_cont

2080 !

2090 OUTPUT @Afg;"OUTP OFF" !Open Output relay

2100 PRINT "Verify th at no signal appears on the scope. "

2110 Wait_for_cont

2120 SUBEND

2130 !

(Continued on ne xt pa ge )

30 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 33

Functional Verification

Example Program (cont’d)

2140 SUB Key_press

2150 COM @Afg,@Cm d_m od,INTEGER Don e

2160 Done=1

2170 DISP

2180 SUBEND

2190 !

2200 SUB Wait_for_ cont

2210 DISP "Press ’Cont inue’ when ready"

2220 PAUSE

2230 DISP

2240 SUBEND

Agilent E1445A Service Manual Verification Tests 31

Page 34

Operation

Verification

Operation Verification is a subset of the Performan ce Ve rifi cati on te sts that

follow. For the AFG, Opera tion Verification consists of the fo llow ing tests:

• DC Accuracy

• AC Accuracy

• Total Harmonic Dis tortion

Performance

Verification

The procedures in this section are used to test the AFG’s electrical

performance using the spe c ifica tions in Appendix A of the Agilent E1445A

User’s Manual as the performance standards. These tests are suitable for

incoming inspe c tion, troublesho oting, and preventive mainten an ce. Th e

results of the Perf o rma n c e Verif ic a tion tests should be recorded in the

Performance Test Recor d (Table 2-11).

Performance Verification includes the following tests:

Test # Test Name

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

DC Zeros

DC Accuracy

DC Offset

AC Accuracy

AC Flatness - 250 kHz filter

AC Flatness - 10 MHz filter

Frequency Accuracy

Duty Cycle

Total Harmonic Distortion

Spurious/Non-harmonic Distortion

32 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 35

Test 2-1: DC Zeros

Description

Equipment Setup

The purpose of thi s te st is to verify that the AFG me e ts it s spe c if ic at ions for

DCV accuracy for an output of zero volts. An arbitrary waveform

consisting of zer os is used. The amplitude is va r ie d in or de r to te st e a ch

attenuator.

• Connect equipm e nt as shown in Figure 2-5

• Set DMM to: DCV, 100 mV range

Figure 2-5. Equipment Setup for Test 2-1 thru Test 2-4

Test Procedure

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

status registers

Delete all sequence s and segment s from memory :

2.

LIST:SSEQ:DEL:ALL Delete all sequence s

LIST:SEGM:DEL:ALL Delete all segments

Agilent E1445A Service Manual Verification Tests 33

Page 36

Test 2-1: DC Zeros (cont’d)

Test Procedure

(cont’d)

3. Creat e a user-defined waveform made up of zeros:

4.

LIST:SEGM:SEL ZE ROS Select segment name

LIST:SEGM:DEF 8 # of segment points

LIST:SEGM:VOLT 0,0,0,0,0,0,0,0 Segment list

LIST:SSEQ:SEL DC _ZERO S Select sequence name

LIST:SSEQ:D EF 1 # of segments

LIST:SSEQ:SEQ ZEROS Sequence list

Set up the AFG to output the waveform defined above:

ROSC:SOUR CLK10; Select 10 MHz clock

:VOLT MAX; Set amplitude

:OUTP:LOAD INF ; Infinite load

:FUNC USER Select user waveform

FUNC:USER DC_ZEROS Select sequence

INIT:IMM Initiate waveform

Perform steps 5 - 7 for each amplitude listed in Table 2-1:

5. Set the AFG output filter as specified in Ta ble 2- 1. Use th e

appropriate command(s) below:

OUTP:FILT OFF Disable filter

or

OUTP:FILT:FREQ 250KHZ Select 250 kHz filte r

OUTP:FILT ON Enabl e filter

or

OUTP:FILT:FREQ 10MHZ Select 10 MHz filter

OUTP:FILT ON Enabl e filter

Set the AFG output amplitude:

6.

VOLT <amplitude> Se t ampl it ude

where <amplitude> is the value specified in Table 2-1.

7. Trigger the DMM and record the reading in Table 2-11.

34 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 37

Test 2-1: DC Zeros (cont’d)

Test Procedure

(cont’d)

Table 2-1. DC Zeros Test Points

Attenuation

(dB)

0

.99

1

2

4

8

13

14

30

0

.99

1

2

4

8

13

14

30

Amplitude

(volts)

10.23750

9.13469

9.12416

8.13192

6.45941

4.07560

2.29187

2.04263

0.32372

10.23750

9.13469

9.12416

8.13192

6.45941

4.07560

2.29187

2.04263

0.32372

Filter Test Limits

(volts)

None

None

None

None

None

None

None

None

None

250 kHz

250 kHz

250 kHz

250 kHz

250 kHz

250 kHz

250 kHz

250 kHz

250 kHz

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0044

0 ± 0.0044

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0044

0 ± 0.0044

10 MHz

10 MHz

10 MHz

10 MHz

10 MHz

10 MHz

10 MHz

10 MHz

10 MHz

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0220

0 ± 0.0044

0 ± 0.0044

.99

13

14

30

0

1

2

4

8

10.23750

9.13469

9.12416

8.13192

6.45941

4.07560

2.29187

2.04263

0.32372

Agilent E1445A Service Manual Verification Tests 35

Page 38

Test 2-1: DC Zeros (cont’d)

Example Progr am

This program perform s the DC Zero s te st. An arbit rar y wave fo rm, con sisting of zeros, is used with va rious

amplitudes to test a variety of attenuator and filter combin at ion s .

10! RE-STORE "DC_ZEROS"

20 COM @Afg

30 DIM Attn(1:9),Vout(1:9)

40 !

50 !---------- Set up I/O path and reset AFG ---------60 ASSIGN @Afg TO 70910

70 OUTPUT @Afg;"*RST;*CLS" !Reset AFG

80 !

90 !---------- Initialize variables ---------100 DATA 0,.99,1,2, 4,8, 13, 14, 30

110 READ Attn(*) !Read in attenuations

120 !

130 DATA 10.2375,9. 13469,9.12416,8. 13192,6.45941,4. 0756

140 DATA 2.29187,2. 04263,0.32372

150 READ Vout(*)

160 !

170 !---------- Set up DMM ---------180 PRINT "Set up DMM:"

190 PRINT

200 PRINT " Function -- DCV"

210 PRINT " Range -- 100 mV"

220 PRINT

230 PRINT "Connect D M M HI and LO t o AFG O ut put. "

240 DISP "Press ’Conti nue’ when ready"

250 PAUSE

260 CLEAR SCREEN

270 !

280 !---------- Set u p A F G ---------290 OUTPUT @Afg;"*RST" !Reset AFG

300 OUTPUT @Afg; "LIST:SSEQ:DEL:ALL " !Delete all sequenc es

310 OUTPUT @Afg;"LIST:SEGM:DEL:ALL" !Delete all segments

320 WAIT .5

330 OUTPUT @Afg;"ROSC:SOUR CLK10;"; !10MHZ clock

340 OUTPUT @Afg;":VOLT MAX;"; !MAX output

350 OUTPUT @Afg;":OUTP:LOAD INF;"; !Infinite load

360 OUTPUT @Afg;":FUNC USER" !User waveform

370 !

380 CALL Def_seq_zeros !Define wa vef or m

390 OUTPUT @Afg;"FUNC:USER DC_ZEROS" !Select sequence

400 OUTPUT @Afg;"INIT:IMM"

410 !

420 !---------- Perform te s t ------ ---430 PRINT "ATTEN","FILTER","AMPLITUDE"

(Continued on ne xt pa ge )

36 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 39

Test 2-1: DC Zeros (cont’d)

Example Program (cont’d)

440 PRINT

460 FOR Filter=0 TO 2

470 SELECT Filter

480 CASE 0 !No filter

490 OUTPUT @Afg;"OUTP:FILT OFF"

500 Filter$="NONE"

510 CASE 1 !250KHZ filter

520 OUTPUT @Afg;"OUTP:FILT: FREQ 250KH Z"

530 OUTPUT @Afg;"OUTP:FILT ON"

540 Filter$="250 kHz"

550 CASE 2 !10MHZ filter

560 OUTPUT @Afg;"OUTP:FILT:FREQ 10MHZ"

570 OUTPUT @Afg;"OUTP:FILT ON"

580 Filter$="10 MHz"

590 END SELECT

600 !

610 FOR I=1 TO 9 !Loop through atten ’s

620 OUTPUT @Afg;":VOLT "&VAL$(Vout(I)) !Set AFG amplitude

630 PRINT Attn(I),Filter$,Vout(I)

640 !

650 DISP "Record DMM reading, the n pre ss ’C ont inue’ "

660 PAUSE

670 DISP

680 NEXT I !Next attenuation

690 PRINT

700 NEXT Filter !Next filter

710 !

720 OUTPUT @Afg;"*RST;*CLS" !Reset AFG

730 END

740 !

750 SUB Def_seq_zer o s

760 COM @Afg

770 OUTPUT @Afg;"LIST:SEGM:SEL ZEROS" !Segment name

780 OUTPUT @Afg;"LIST:SEGM:DEF 8" !Segment length

790 OUTPUT @Afg;"LIST :SEGM : VO LT 0, 0,0, 0, 0, 0,0, 0" !Voltage points

800 !

810 OUTPUT @Afg;"LIST :SSEQ :S EL D C_ZEROS" !Sequence name

820 OUTPUT @Afg;"LIST:SSEQ:DEF 1" !# of segments

830 OUTPUT @Afg;"LIST:SSEQ:SEQ ZEROS" !Segment list

840 SUBEND

Agilent E1445A Service Manual Verification Tests 37

Page 40

Test 2-2: DC Accuracy

Description

Equipment Setup

Test Procedure

The purpose of thi s te st is to verify that the AFG me e ts it s spe c if ic at ions for

DC accuracy.

• Connect equipm e nt as shown in Figure 2-5

• Set DMM to DCV, autorange

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

status registers

Set up the AFG to output a DC signal:

2.

FUNC DC; Select DC waveform

:OUTP:LOAD INF ; Infinite load

:VOLT MAX Set amplitude

Perform steps 3 - 5 for each amplitude listed in Table 2-2:

3. Set up the AFG output filter as specified in Table 2-2. Use the

appropriate command(s) below:

OUTP:FILT OFF Disable filter

or

OUTP:FILT:FREQ 250KHZ Select 250 kHz filte r

OUTP:FILT ON Enabl e filter

or

OUTP:FILT:FREQ 10MHZ Select 10 MHz filter

OUTP:FILT ON Enabl e filter

Set the AFG output amplitude:

4.

VOLT <amplitude> Se t ampl it ude

where <amplitude> is the value specified in Table 2-2.

5. Trigger the DMM and record the reading.

38 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 41

Test 2-2: DC Accuracy (cont’d)

Test Procedure

(cont’d)

Table 2-2. DC Accuracy Test Points

Amplitude

(volts)

10.2375

5.0

0.0

-5.0

-10.24

10.2375

-10.24

10.2375

-10.24

Example Progr am

This program pe rfor m s the D C Ac curacy test.

10! RE-STORE "DC_LEVELS"

20 DIM Vout(1:9),Filter(1:9)

30 !

40 !---------- Set up I/O path and reset AFG ----------50 ASSIGN @Afg TO 70910

60 OUTPUT @Afg;"*RST;*CLS" !Reset AFG

70 !

80 !---------- Initialize variables ---------90 DATA 10.2375,5.0,0, -5 .0,-10. 24,10.2375,-10.24,10.2375,-10.24

100 READ Vout(*)

110 !

120 DATA 0,0,0,0,0,1,1,2,2

130 READ Filter(*)

140 !

150 !--------- - Set up DMM ---------160 CLEAR SCREEN

170 PRINT "Set up DMM:"

180 PRINT

190 PRINT " Function -- DCV"

200 PRINT " Range -- AUTO"

210 PRINT

220 PRINT "Connect DMM HI and LO to AFG Output."

230 DISP "Press ’Continue’ w hen r eady "

240 PAUSE

250 CLEAR SCREEN

Filter Test Limits

(volts)

None

None

None

None

None

250 kHz

250 kHz

10 MHz

10 MHz

10.2375 ± 0.0512

5.0 ± 0.0355

0.0 ± 0.0205

-5.0 ± 0.0355

-10.24 ± 0.0512

10.2375 ± 0.0512

-10.24 ± 0.0512

10.2375 ± 0.0512

10.24 ± 0.0512

Agilent E1445A Service Manual Verification Tests 39

Page 42

Test 2-2: DC Accuracy (cont’d)

Example Program (cont’d)

270 !--------- - Set up AFG ---------280 OUTPUT @Afg;"*RST" !Reset AFG

290 WAIT .5

300 OUTPUT @Afg;"FUNC DC;"; !DC function

310 OUTPUT @Afg;":OUTP:LOAD INF;"; !Infinite load

320 OUTPUT @Afg;":VOLT MAX" !MAX output

330 !

340 !---------- Perform test ---------350 PRINT "FILTER","AMPLITUDE"

360 PRINT

370 !

380 FOR I=1 TO 9

390 SELECT Filter(I)

400 CASE 0

410 OUTPUT @Afg;"OUTP:FILT OFF" !No filter

420 Filter$="NONE"

430 CASE 1

440 OUTPUT @Afg;"OUTP:FILT:FREQ 250KHZ" !250kHz filter

450 OUTPUT @Afg;"OUTP:FILT ON"

460 Filter$="250 kHz"

470 CASE 2

480 OUTPUT @Afg;"OUTP:FILT:FREQ 10MHZ" !10MHz filter

490 OUTPUT @Afg;"OUTP:FILT ON"

500 Filter$="10 M Hz"

510 END SELECT

520 !

530 OUTPUT @Afg;"VOLT "&VAL$(Vout(I)) !Set amplitude

540 PRINT Filter$,Vout(I)

550 !

560 DISP "Record DMM reading, then press ’Continue’ "

570 PAUSE

580 DISP

590 NEXT I

600 !

610 OUTPUT @Afg;"*RST;*CLS" !Reset AFG

620 END

40 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 43

Test 2-3: DC Offset

Description

Equipment Setup

Test Procedure

The purpose of thi s te st is to verify that the AFG me e ts it s spe c if ic at ions for

DC offset accuracy.

• Connect equipm e nt as shown in Figure 2-5

• Set DMM to DCV, autorange

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

status registers

Delete all sequence s and segment s from memory :

2.

LIST:SSEQ:DEL:ALL Delete all sequence s

LIST:SEGM:DEL:ALL Delete all segments

Create a user-defined wave form made up of zeros:

3.

LIST:SEGM:SEL ZE ROS Select segment name

LIST:SEGM:DEF 8 # of segment points

LIST:SEGM:VOLT 0,0,0,0,0,0,0,0 Segment list

LIST:SSEQ:SEL DC _ZERO S Select sequence name

LIST:SSEQ:D EF 1 # of segments

LIST:SSEQ:SEQ ZEROS Sequence list

Set up the AFG to output the waveform defined above:

4.

ROSC:SOUR CLK10; Select 10 MHz clock

:OUTP:LOAD INF ; Infinite load

:VOLT MAX; Set amplitude

:FUNC USER Select user waveform

FUNC:USER DC_ZEROS Select sequence

INIT:IMM Initiate waveform

Agilent E1445A Service Manual Verification Tests 41

Page 44

Test 2-3: DC Offset (cont’d)

Test Procedure

(cont’d)

Perform steps 5 - 7 for eac h offset listed in Table 2- 3:

5. If necessary, change the AFG output amplitude:

6. Set AFG offset voltage:

7. Trigger the DMM and record the reading.

VOLT:OFFS 0; Set offset to 0

:VOLT <amplitude> Set amplitude

where <amplitude> is the value specified in Table 2-3.

VOLT:OFFS <offset> Set offset

where <offset> is the valu e sp ecif ie d in Table 2-3.

Table 2-3. DC Offset Test Points

Offset

(volts)

9.755

4.000

-4.000

-9.755

2.000

-2.000

Amplitude

(volts)

2.29189

2.29189

2.29189

2.29189

0.40756

0.40756

Test Limits

(volts)

9.755 ± 0.1196

4.0 ± 0.0620

-4.0 ± 0.0620

-9.755 ± 0.1196

2.0 ± 0.0244

-2.0 ± 0.0244

42 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 45

Test 2-3: DC Offset (cont’d)

Example Progr am

This program performs the DC Offset Test .

10! RE-STORE "DC_OFFSET"

20 COM @Afg

30 DIM Offset(1:6)

40 !

50 !---------- Set up I/O path and reset AFG ---------60 ASSIGN @Afg TO 70910 !AFG I/O path

70 OUTPUT @Afg;"*RST;*CLS" !Reset AFG

80 !

90 !---------- Initialize variables ---------100 DATA 9.755,4.0,- 4. 0,-9.755,2.0,-2.0

110 READ Offset(*) !Read in offsets

120 !

130 Vout_old=0 !Initialize

140 !

150 !---------- Set up DMM ---------160 CLEAR SCREEN

170 PRINT "Set up DMM:"

180 PRINT

190 PRINT " Function -- DCV"

200 PRINT " Range -- AUTO"

210 PRINT

220 PRINT "Connect D M M HI and LO t o AFG O ut put. "

230 DISP "Press ’Conti nue’ when ready"

240 PAUSE

250 CLEAR SCREEN

260 !

270 !---------- Set u p A F G ---------280 OUTPUT @Afg;"*RST" !Reset AFG

290 OUTPUT @Afg; "LIST:SSEQ:DEL:ALL " !Delete all sequenc es

300 OUTPUT @Afg;"LIST:SEGM:DEL:ALL" !Delete all segments

310 WAIT .5

320 OUTPUT @Afg;"ROSC:SOUR CLK10;"; !10MHz clock

330 OUTPUT @Afg;":OUTP:LOAD INF;"; !Infinite load

340 OUTPUT @Afg;":VOLT MAX;"; !MAX output

350 OUTPUT @Afg;":FUNC USER" !User waveform

360 !

370 CALL Def_seq_zeros !Define sequence of zer os

380 OUTPUT @Afg;"FUNC:USER DC_ZEROS" !Select sequence

390 !

400 !---------- Perform te s t ------ ---410 PRINT "AMPLITUDE" , " OFF S ET"

420 PRINT

430 !

(Continued on ne xt pa ge )

Agilent E1445A Service Manual Verification Tests 43

Page 46

Test 2-3: DC Offset (cont’d)

Example Program (cont’d)

440 FOR I=1 TO 6

450 IF I<=4 THEN

460 Vout=2.2919

470 ELSE

480 Vout=.40756

490 END IF

500 !

510 IF Vout<>Vout_old THEN

520 !Set offset to zero before changing am pl itu de

530 OUTPUT @Afg;":VOLT:OFFS 0;";

540 OUTPUT @Afg;":VOLT "&VAL$(Vout)&";";

550 END IF

560 !

570 OUTPUT @Afg;":VOLT:OFFS "&VAL$(Offset(I))!Set offset

580 PRINT Vout,Offset(I)

590 !

600 DISP "Record DMM readin g, then pre ss ’C ont inue’ "

610 PAUSE

620 DISP

630 Vout_old=Vout

640 NEXT I !Next attenuation

650 !

660 OUTPUT @Afg;"*RST;*CLS" !Reset AFG

670 END

680 !

690 SUB Def_seq_zer o s

700 COM @Afg

710 OUTPUT @Afg;"LIST:SEGM:SEL ZEROS" !Segment name

720 OUTPUT @Afg;"LIST:SEGM:DEF 8" !Segment length

730 OUTPUT @Afg;"LIST :SEGM : VO LT 0, 0,0, 0, 0, 0,0, 0" !Voltage points

740 !

750 OUTPUT @Afg;"LIST :SSEQ :S EL D C_ZEROS" !Sequence name

760 OUTPUT @Afg;"LIST:SSEQ:DEF 1" !# of segments

770 OUTPUT @Afg;"LIST:SSEQ:SEQ ZEROS" !Segment list

780 SUBEND

44 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 47

Test 2-4: AC Accuracy

Description

Equipment Setup

Test Procedure

The purpose of thi s te st is to verify that the AFG me e ts it s spe c if ic at ions for

AC accuracy at 1 kHz.

• Connect equipm e nt as shown in Figure 2-5

• Set DMM to ACV, autorange

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

status registers

Set up the AFG to output a 1 kHz sinewave:

2.

FREQ 1E3; Set fre q to 1 kHz

:VOLT MAX; Set to max amplitude

:OUTP:LOAD INF Infinite load

CAL:STAT:AC OFF AC corrections off

INIT:IMM Initiate waveform

Perform steps 3 - 5 for e ac h amplitude and filte r listed in Table 2-4:

3. Set up AFG output filter as specified in Table 2-4. Use the

appropriate command(s) below:

OUTP:FILT OFF Disable filter

or

OUTP:FILT:FREQ 250KHZ Select 250 kHz filte r

OUTP:FILT ON Enabl e filter

or

OUTP:FILT:FREQ 10MHZ Select 10 MHz filter

OUTP:FILT ON Enabl e filter

Agilent E1445A Service Manual Verification Tests 45

Page 48

Test 2-4: AC Accuracy (cont’d)

Test Procedure

(cont’d)

4. Set the AFG output amplitude:

VOLT <amplitude>VRMS Set amplitude

where <amplitude> is the value specified in Table 2-4.

5. Trigger the DMM and record the reading.

Table 2-4. AC Accuracy Test Points

Amplitude

(volts rms)

7.2390

6.4500

5.7500

4.5660

2.8818

1.4444

0.2290

7.2390

7.2390

Filter Test

Limits

±(dB)

None

None

None

None

None

None

None

250 kHz

10 MHz

0.10

0.15

0.15

0.15

0.15

0.15

0.15

0.10

0.10

46 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 49

Test 2-4: AC Accuracy (cont’d)

Example Progr am

This program performs the AC Accuracy Test.

10! RE-STORE "AC_LEVELS"

20 DIM Vout(1:9),Filter(1:9 )

30 !

40 !---------- Set up I/O path and reset AFG ---------50 ASSIGN @Afg TO 70910

60 OUTPUT @Afg;"*RST;*CLS" !Reset AFG

70 !

80 !---------- Initialize variables ---------90 DATA 7.239,6.45,5. 75,4. 566,2.8818,1.4 444, . 229,7.239,7.239

100 READ Vout(*)

110 !

120 DATA 0,0,0,0,0, 0,0, 1, 2

130 READ Filter(*)

140 !

150 !---------- Set up DMM ---------160 CLEAR SCREEN

170 PRINT "Set up DMM:"

180 PRINT

190 PRINT " Function -- ACV"

200 PRINT " Range -- AUTO"

210 PRINT

220 PRINT "Connect D M M HI and LO t o AFG O ut put. "

230 DISP "Press ’Conti nue’ when ready"

240 PAUSE

250 CLEAR SCREEN

260 !

270 !---------- Set u p A F G ---------280 OUTPUT @Afg;"*RST" !Reset AFG

290 WAIT .5

300 OUTPUT @Afg;"FREQ 1E3;"; !Set freq to 1 kHz

310 OUTPUT @Afg;":VOLT MAX;"; !MAX amplitude

320 OUTPUT @Afg;":OUTP:LOAD INF" !Infinite load

340 OUTPUT @Afg;"CAL:STAT:AC OFF" !AC corrections off

350 OUTPUT @Afg;"INIT:IMM" !Initiate

360 WAIT .5

370 !

380 !---------- Perform te s t ------ ---390 PRINT "FILTER","AMPLITUDE"

400 PRINT

410 !

(Continued on ne xt pa ge )

Agilent E1445A Service Manual Verification Tests 47

Page 50

Test 2-4: AC Accuracy (cont’d)

Example Program (cont’d)

420 FOR I=1 TO 9

430 SELECT Filter(I)

440 CASE 0

450 OUTPUT @Afg;"OUTP:FILT OFF" !No filter

460 Filter$="NONE"

470 CASE 1

480 OUTPUT @Afg;"OUTP:F ILT: FR EQ 250KH Z" !250 kHz filter

490 OUTPUT @Afg;"OUTP:FILT ON"

500 Filter$="250 kHz"

510 CASE 2

520 OUTPUT @Afg;"OUTP:FILT:FREQ 10MHZ" !10 MHz filter

530 OUTPUT @Afg;"OUTP:FILT ON"

540 Filter$="10 MHz"

550 END SELECT

560 OUTPUT @Afg;":VOLT "&VAL$(Vout(I))&"VRMS" !Set amplitude

570 PRINT Filter$,Vout(I)

580 WAIT .5

590 !

600 DISP "Record DMM readin g, then pre ss ’C ont inue’ "

610 PAUSE

620 DISP

630 NEXT I

640 !

650 OUTPUT @Afg;"*RST;*CLS" !Reset AFG

660 END

48 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 51

Test 2-5: AC Flatness - 250 kHz Filter

Description

The purpose of thi s te st is to verify that the AFG me e ts it s spe c if ic at ions for

AC flatness with the 250 kHz filter enabled.

Equipment Setup

• Connect equipm e nt as shown in Figure 2-6

• Set DMM to ACV, autorange

Test Procedure

Figure 2-6. Equipment Setup for Test 2-5 and Test 2-6

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

Set up the AFG to output a 24 dBm sinewa ve with the 250 kHz filter

2.

enabled:

VOLT 24DBM; Set amplitude

:OUTP:LOAD 50 50 ohm load

OUTP:FILT:FREQ 250KHZ 250 kHz filter

OUTP:FILT ON Enabl e filter

INIT:IMM Initiate waveform

status registers

Agilent E1445A Service Manual Verification Tests 49

Page 52

Test 2-5: AC Flatness - 250 kHz Filter (cont’d)

Test Procedure

(cont’d)

3. Set the AFG output to the reference frequency (1 kHz):

FREQ 1000 Set frequency

Measure the amplitude with the DMM and c onvert the reading to

4.

dBm. Note the resul t fo r us e in ste p 6:

Reference Level (dBm) = 20 × log ïReading (volts)ï+13.0103

Perform steps 5 - 6 for eac h frequency lis te d in Table 2- 5:

5. Set the AFG output:

FREQ <frequency> Set frequency

where <frequency> is the value spe cified in Table 2-5.

6. Measure the amplitude with the DMM and convert the reading to

dBm. Calculate and record the error relative to the reference level

calculated in step 4:

Reading (dBm) = 20 × log ïReading (volts)ï+13.0103

Error (dB) = Reading (dBm) − Reference Level (dBm )

50 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 53

Test 2-5: AC Flatness - 250 kHz Filter (cont’d)

Test Procedure

(cont’d)

Table 2-5. AC Flatness Test Points - 250 kHz Filter

Frequency

(Hz)

10E3

20E3

30E3

40E3

50E3

60E3

70E3

80E3

90E3

100E3

110E3

120E3

130E3

Test Limits*

±(dB error)

0.05 dB

0.05 dB

0.05 dB

0.05 dB

0.05 dB

0.05 dB

0.05 dB

0.05 dB

0.05 dB

0.05 dB

0.10 dB

0.10 dB

0.10 dB

Frequency

(Hz)

140E3

150E3

160E3

170E3

180E3

190E3

200E3

210E3

220E3

230E3

240E3

250E3

Test Limits*

±(dB error)

0.10 dB

0.10 dB

0.10 dB

0.10 dB

0.10 dB

0.10 dB

0.10 dB

0.10 dB

0.10 dB

0.10 dB

0.10 dB

0.10 dB

* Error relative to 1 kHz

Example Progr am

See the AC Flatness Adjustment procedure (Cha pte r 3) for an ex am ple pr ogra m that performs the AC Flatne ss

Test (change line 180 to:

Mode$="M" ).

Agilent E1445A Service Manual Verification Tests 51

Page 54

Test 2-6: AC Flatness - 10 MHz Filter

Description

The purpose of thi s te st is to verify that the AFG me e ts it s spe c if ic at ions for

AC flatness with the 10 MHz filter enable d.

Equipment Setup

• Connect equipm e nt as shown in Figure 2-6

• Set DMM to ACV, autorange

Test Procedure

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

Set up the AFG to output a 24 dBm sinewa ve with the 10 MHz filter

2.

enabled:

VOLT 24DBM; Set amplitude

:OUTP:LOAD 50 50 ohm load

OUTP:FILT:FREQ 10MHZ 10 MHz filter

OUTP:FILT ON Enabl e filter

INIT:IMM Initiate waveform

status registers

Set AFG output to the reference frequency (1 kHz):

3.

FREQ 1000 Set frequency

Measure the amplitude with the DMM, c onve rt the r eadi ng to dBm,

4.

and note the reading for future reference:

Reference Level (dBm) = 20 × log ïReading (volts)ï+13.0103

Set the AFG to the crossover frequency (lowest frequency that the

5.

Power Meter can measure):

FREQ 1E 5 Set frequency

Measure the amplitude with the DMM and note the reading for future

6.

reference.

52 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 55

Test 2-6: AC Flatness - 10 MHz Filter (cont’d)

Test Procedure

(cont’d)

7. Set up the Power Meter:

Units - Watts

Power Range - auto

Reference Oscillator - ON

NOTE

Follow the Pow er Mete r m anufacture r’ s instructions for per forming an

autocalibration and correcti ng for the power sens or.

8. Connect the equipment a s shown in Fi gur e 2-7 :

Figure 2-7. Equipment Setup for Test 2-6

9. Set the Power Meter expected frequency to the crossover frequency

(100 kHz). Measure the AFG output power and convert the reading

to volts:

Reading (volts) =(

√

ïReading (watts) ï × 50 )

Agilent E1445A Service Manual Verification Tests 53

Page 56

Test 2-6: AC Flatness - 10 MHz Filter (cont’d)

Test Procedure

(cont’d)

10. Calculat e th e co r rec ti on f actor that will be use d to r e fer e nc e the

Power Meter to the DMM:

Correction Factor =

DMM reading at 100 kHz (step 6)

Power Meter reading at 100 kHz (step 9)

Repeat 11 - 14 for each frequ e n cy in Table 2- 6:

11. Set the AFG output to the freque nc y spe c ifie d in Table 2- 6. If the

frequency is less than 10.8 MHz , us e th e following comma nd:

FREQ <frequency>

where <frequency> is the value spe cified in Table 2-6. If the

frequency is 10.8 MHz , use the fo llowing register comm an ds to se t

the output freque nc y:

DIAG:POKE #HE000A1,8,0

DIAG:POKE #HE000A3,8,126

DIAG:POKE #HE000A5,8,95

DIAG:POKE #HE000A7,8,64

DIAG:POKE #HE0008D,8,0

Set the Power Meter expected frequency to the AFG output frequency.

12.

13. Measure the am plitude with the Pow e r Meter, convert the reading to

volts, and mul tipl y by the c orrec tion factor.

Reading (volts) =(

Corrected Reading (volts) = Reading (volts) × C.F. (step 10)

Convert the reading to dBm. Calculate and record the error relative

14.

√

ïReading (watts) ï × 50 )

to the referenc e le ve l c a lc ula te d in step 4:

Reading (dBm) = 20 × log ïCorrected Reading (volts)ï +13. 0103

Error (dB) = Reading (dBm) − Reference Level (dBm )

54 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 57

Test 2-6: AC Flatness - 10 MHz Filter (cont’d)

Test Procedure

(cont’d)

Table 2-6. AC Flatness Test Points - 10 MHz Filter

Frequency

(Hz)

400E3

800E3

1.2E6

1.6E6

2.0E6

2.4E6

2.8E6

3.2E6

3.6E6

4.0E6

4.4E6

4.8E6

5.2E6

5.6E6

Test Limits*

±(dB error)

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

Frequency

(Hz)

6.0E6

6.4E6

6.8E6

7.2E6

7.6E6

8.0E6

8.4E6

8.8E6

9.2E6

9.6E6

10.0E6

10.4E6

10.8E6

Test Limits*

±(dB error)

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

0.2 dB

* Error relative to 1 kHz

Example Progr am

See the AC Flatness Adjustment procedure (Cha pte r 3) for an ex am ple pr ogra m that performs the AC Flatne ss

Test (change line 180 to:

Mode$="M" ).

Agilent E1445A Service Manual Verification Tests 55

Page 58

Test 2-7: Frequency Accuracy

Description

The purpose of thi s te st is to verify that the AFG me e ts it s spe c if ic at ions for

frequency accura cy.

Equipment Setup

• Connect equipm e nt as shown in Figure 2-8

• Set Counter to: Fr eque nc y, 50Ω input impe da nc e

Test Procedure

Figure 2-8. Equipment Setup for Test 2-7

1. Reset the AFG:

*RST;*CLS Reset AFG and clear

status registers

Perform steps 2 - 6 for ea c h entry listed in Table 2-7:

2. Abort the waveform if it ha s be e n pr ev iously initiated:

ABORT

56 Verificat ion Tes ts Agilent E1445A Serv ice Manu al

Page 59

Test 2-7: Frequency Accuracy (cont’d)

Test Procedure

(cont’d)

3. Set reference oscilla tor to INT1 or INT2, as specified in Tabl e 2-7:

ROSC:SOUR INT1 Set ref osc to INT1

or

ROSC:SOUR INT2 Set ref osc to INT2

Set marker source to "ROSC" or "TRIG", as specified in Table 2-7:

4.

NOTE

MARK:FEED "ROSC"

or

MARK:FEED "TRIG" Set marker source to

If the marker source is "TRIG", use the following commands to

5.

Set marker sourc e to

"ROSC"

"TRIG"

output a squarewav e (otherwise, skip this step ):

FUNC SQU; Select squarewave

:FREQ2 <frequency>; Set AFG frequency

:TRIG:S OU R INT2 Set trig source

INIT:IMM Initiate

where <frequency> is the value given in the "Squarewave

Frequency" column of Table 2-7.

If the marker source is "TRIG", the marker output frequency will be four

times the frequ ency of the squarewave, since it takes four points to produce

a squarewave. See Ta ble 2- 7 for the expected freque nc ie s.

6. Measure frequency with the Counter and record the reading in Table

2-11.

Agilent E1445A Service Manual Verification Tests 57

Page 60

Test 2-7: Frequency Accuracy (cont’d)

Test Procedure

(cont’d)

Table 2-7. Frequency Accuracy Test Points

Ref Oscillator

Source

INT1

INT2

INT2

INT2

INT2

Marker

Source

"ROSC"

"ROSC"

"TRIG"

"TRIG"

"TRIG"

*Add aging rate of ±20 ppm /ye a r

Example Progr am

This program perform s the Fre que ncy Ac c ur acy Te st.

10! RE-STORE "OSC_FREQ"

20 DIM Freq(1:5)

30 !

40 !---------- Set up I/O path and reset AFG ---------50 ASSIGN @Afg TO 70910

60 OUTPUT @Afg;"*RST;*CLS" !Reset AFG

70 !

80 !---------- Initialize variables ---------90 DATA 42.94967E6, 40E6, 20 E 6, 13.3333E6,305.176

100 READ Freq(*)

110 !

120 !---------- Set u p C o unte r - --------130 CLEAR SCREEN

140 PRINT "Set up Count er:"

150 PRINT

160 PRINT " Function -- Frequenc y"

170 PRINT " Input Impedan ce -- 50 ohm s"

180 PRINT

190 PRINT "Connect t he Counter to ’Marker Out ’ on the E1 445A. "

200 PRINT

210 DISP "Press ’Conti nue’ "

220 PAUSE

230 CLEAR SCREEN

240 !

Squarewave

Frequency (Hz)

----------

----------

5.0 E6

3.333 E3

76.294

Test Limits

(Hz)*

42.94967 E6 ± 0.005%

40 E6 ± 0.005%

20 E6 ± 0.005%