Page 1

Calibration Guide

Agilent Technologies ESA Spectrum Analyzers

This manual provides documentation for the following instruments:

Agilent ESA-E Series

E4402B (9 kHz - 3.0 GHz)

E4404B (9 kHz - 6.7 GHz)

E4405B (9 kHz - 13.2 GHz)

E4407B (9 kHz - 26.5 GHz)

and

Agilent ESA-L Series

E4411B (9 kHz - 1.5 GHz)

E4403B (9 kHz - 3.0 GHz)

E4408B (9 kHz - 26.5 GHz)

Manufacturing Part Number: E4401-90493

Supersedes E4401-90475

Printed in USA

March 2005

© Copyright 2000-2005 Agilent Technologies, Inc.

Page 2

Notice

The information contained in this document is subject to change

without notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent

Technologies shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

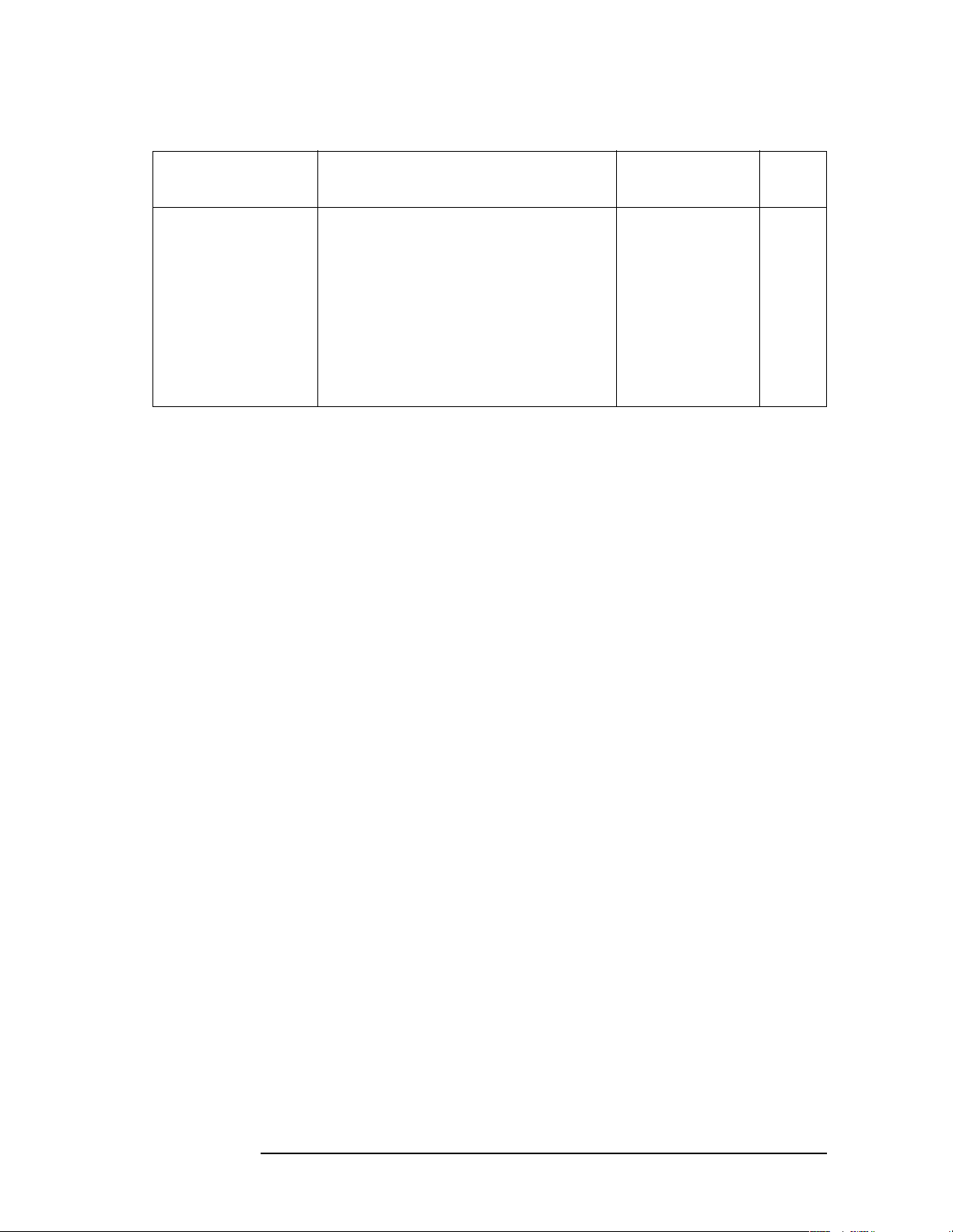

The following safety symbols are used throughout this manual.

Familiarize yourself with the symbols and their meaning before

operating this instrument.

WAR NING Warning denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could result in

injury or loss of life. Do not proceed beyond a warning note

until the indicated conditions are fully understood and met.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution sign

until the indicated conditions are fully understood and met.

WAR NING This is a Safety Class 1 Product (provided with a protective

earthing ground incorporated in the power cord. The mains

plug shall only be inserted in a socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor inside or outside of the product is likely to make the

product dangerous. Intentional interruption is prohibited.

WAR NING If this product is not used as specified, the protection provided

by the equipment could be impaired. This product must be used

in a normal condition (in which all means for protection are

intact) only.

CAUTION Always use the three-prong ac power cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord may

cause product damage.

CAUTION This instrument has autoranging line voltage input, be sure the supply

voltage is within the specified range.

2

Page 3

Where to Find the Latest Information

Documentation is updated periodically. For the latest information about

Agilent ESA Spectrum Analyzers, including firmware upgrades and

application information, please visit the following Internet URL:

http://www.agilent.com/find/esa.

3

Page 4

4

Page 5

Contents

1. Calibrating

Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2. Performance Verification Tests

Tests included in this section: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1. 10 MHz Reference Output Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2. 10 MHz High-Stability Frequency Reference Output Accuracy: Agilent E4401B, E4402B,

E4404B, E4405B, and E4407B (Option 1D5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3. Frequency Readout and Marker Frequency Count Accuracy: Agilent E4401B, E4402B,

E4403B, and E4411B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4. Frequency Readout and Marker Frequency Count Accuracy: Agilent E4404B, E4405B,

E4407B, and E4408B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5. Frequency Span Accuracy: Agilent E4401B and E4411B . . . . . . . . . . . . . . . . . . . . . . . . 55

6. Frequency Span Accuracy:

Agilent E4402B, E4403B, E4404B, E4405B, E4407B, and E4408B . . . . . . . . . . . . . . . . . 59

7. Noise Sidebands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8. Noise Sidebands - Wide Offsets: Agilent E4402B, E4404B, E4405B and E4407B . . . . 70

9. System-Related Sidebands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10. Residual FM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

11. Sweep Time Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

12. Display Scale Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13. Input Attenuation Switching Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

14. Reference Level Accuracy: Agilent E4401B and E4411B . . . . . . . . . . . . . . . . . . . . . . 107

15. Reference Level Accuracy: Agilent E4402B,

E4403B, E4404B, E4405B, E4407B, and E4408B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

16. Resolution Bandwidth Switching Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

17. Absolute Amplitude Accuracy (Reference Settings): Agilent E4401B and E4411B . . 129

18. Absolute Amplitude Accuracy (Reference Settings): Agilent E4402B, E4403B, E4404B,

5

Page 6

Contents

E4405B, E4407B, and E4408B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

19. Overall Absolute Amplitude Accuracy: Agilent E4401B and E4411B . . . . . . . . . . . .143

20. Overall Absolute Amplitude Accuracy: Agilent E4402B, E4403B, E4404B, E4405B,

E4407B, and E4408B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

21. Resolution Bandwidth Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

22. Frequency Response: Agilent E4401B and E4411B . . . . . . . . . . . . . . . . . . . . . . . . . . .162

23. Frequency Response, Agilent E4402B and E4403B . . . . . . . . . . . . . . . . . . . . . . . . . . .172

24. Frequency Response, Agilent E4404B, E4405B, E4407B, and E4408B . . . . . . . . . . .187

25. Frequency Response (Preamp On): Agilent E4401B . . . . . . . . . . . . . . . . . . . . . . . . . .213

26. Frequency Response (Preamp On): Agilent E4402B . . . . . . . . . . . . . . . . . . . . . . . . . .221

27. Frequency Response (Preamp On): Agilent E4404B, E4405B, and E4407B . . . . . . . .231

28. Other Input-Related Spurious Responses: Agilent E4401B and E4411B . . . . . . . . . . .244

29. Other Input-Related Spurious Responses: Agilent E4402B, E4403B, E4404B, E4405B,

E4407B, and E4408B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .249

30. Spurious Responses: Agilent E4401B and E4411B . . . . . . . . . . . . . . . . . . . . . . . . . . .255

31. Spurious Responses: Agilent E4402B and E4403B . . . . . . . . . . . . . . . . . . . . . . . . . . .263

32. Spurious Responses: Agilent E4404B, E4405B, E4407B, and E4408B . . . . . . . . . . . .273

33. Gain Compression: Agilent E4401B, E4402B, E4403B, and E4411B . . . . . . . . . . . . .290

34. Gain Compression: Agilent E4404B, E4405B, E4407B, and E4408B . . . . . . . . . . . . .294

35. Displayed Average Noise Level: Agilent E4401B and E4411B . . . . . . . . . . . . . . . . . .299

36. Displayed Average Noise Level: Agilent E4402B and E4403B . . . . . . . . . . . . . . . . . .309

37. Displayed Average Noise Level: Agilent E4404B and E4405B . . . . . . . . . . . . . . . . . .316

38. Displayed Average Noise Level: Agilent E4407B and E4408B . . . . . . . . . . . . . . . . . .323

39. Residual Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .330

40. Fast Time Domain Amplitude Accuracy: Agilent E4401B, E4402B, E4404B, E4405B,

and E4407B (Option AYX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .333

41. Tracking Generator Absolute Amplitude and Vernier Accuracy: Agilent E4401B and

E4411B (Option 1DN or 1DQ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .335

6

Page 7

Contents

42. Tracking Generator Absolute Amplitude and Vernier Accuracy: Agilent E4402B,

E4403B, E4404B, E4405B, E4407B, and E4408B (Option 1DN) . . . . . . . . . . . . . . . . . . . 340

43. Tracking Generator Level Flatness: Agilent E4401B and E4411B (Option 1DN or 1DQ)

343

44. Tracking Generator Level Flatness:

Agilent E4402B, E4403B, E4404B, E4405B, E4407B, and E4408B (Option 1DN) . . . . 350

45. Tracking Generator Harmonic Spurious Outputs: Agilent E4401B and E4411B

(Option 1DN or 1DQ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

46. Tracking Generator Harmonic Spurious Outputs: Agilent E4402B, E4403B, E4404B,

E4405B, E4407B, and E4408B (Option 1DN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

47. Tracking Generator Non-Harmonic Spurious Outputs: Agilent E4401B and E4411B (Op-

tion 1DN or 1DQ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

48. Tracking Generator Non-Harmonic Spurious Outputs: Agilent E4402B, E4403B,

E4404B, E4405B, E4407B, and E4408B (Option 1DN) . . . . . . . . . . . . . . . . . . . . . . . . . . 370

49. Tracking Generator LO Feedthrough: Agilent E4402B, E4403B, E4404B,

E4405B, E4407B, and E4408B(Option 1DN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

50. Gate Delay Accuracy and Gate Length Accuracy: Agilent E4401B, E4402B, E4404B,

E4405B, and E4407B (Option 1D6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

51. Gate Mode Additional Amplitude Error: Agilent E4401B, E4402B, E4404B, E4405B,

and E4407B (Option 1D6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

52. First LO OUTPUT Power Accuracy (Option AYZ only) . . . . . . . . . . . . . . . . . . . . . . 387

53. IF INPUT Accuracy (Option AYZ only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

54. Comms Frequency Response (Option BAC or BAH) . . . . . . . . . . . . . . . . . . . . . . . . . 394

58. GSM Phase and Frequency Error (Options BAH and B7E) . . . . . . . . . . . . . . . . . . . . . 406

59. Comms Absolute Power Accuracy (Options BAC or BAH) . . . . . . . . . . . . . . . . . . . . 409

3. Performance Verification Test Records

Agilent E4401B Performance Verification Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Agilent E4402B Performance Verification Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . 450

7

Page 8

Contents

Agilent E4403B Performance Verification Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . .479

Agilent E4404B Performance Verification Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . .495

Agilent E4405B Performance Verification Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . .525

Agilent E4407B Performance Verification Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . .557

Agilent E4408B Performance Verification Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . .596

Agilent E4411B Performance Verification Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . .617

4. If You Have a Problem

What You’ll Find in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .636

Before You Call Agilent Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .637

How to Return Your Analyzer for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .640

8

Page 9

1Calibrating

9

Page 10

Calibrating

Calibration verifies that the analyzer performance is within all

specifications. It is time consuming and requires extensive test

equipment. Calibration consists of all the performance tests. For a

complete listing of the performance tests, see the performance

verification tests table for your specific analyzer.

Allow the analyzer to warm up in accordance with the temperature

stability specifications before performing the tests in this chapter.

None of these test procedures involve removing the cover of the

analyzer.

10 Chapter 1

Page 11

Calibrating

Calibration Cycle

Calibration Cycle

The performance tests in chapter 2 should be used to check the analyzer

against its specifications once every year. Specifications are listed in the

Specifications Guide.

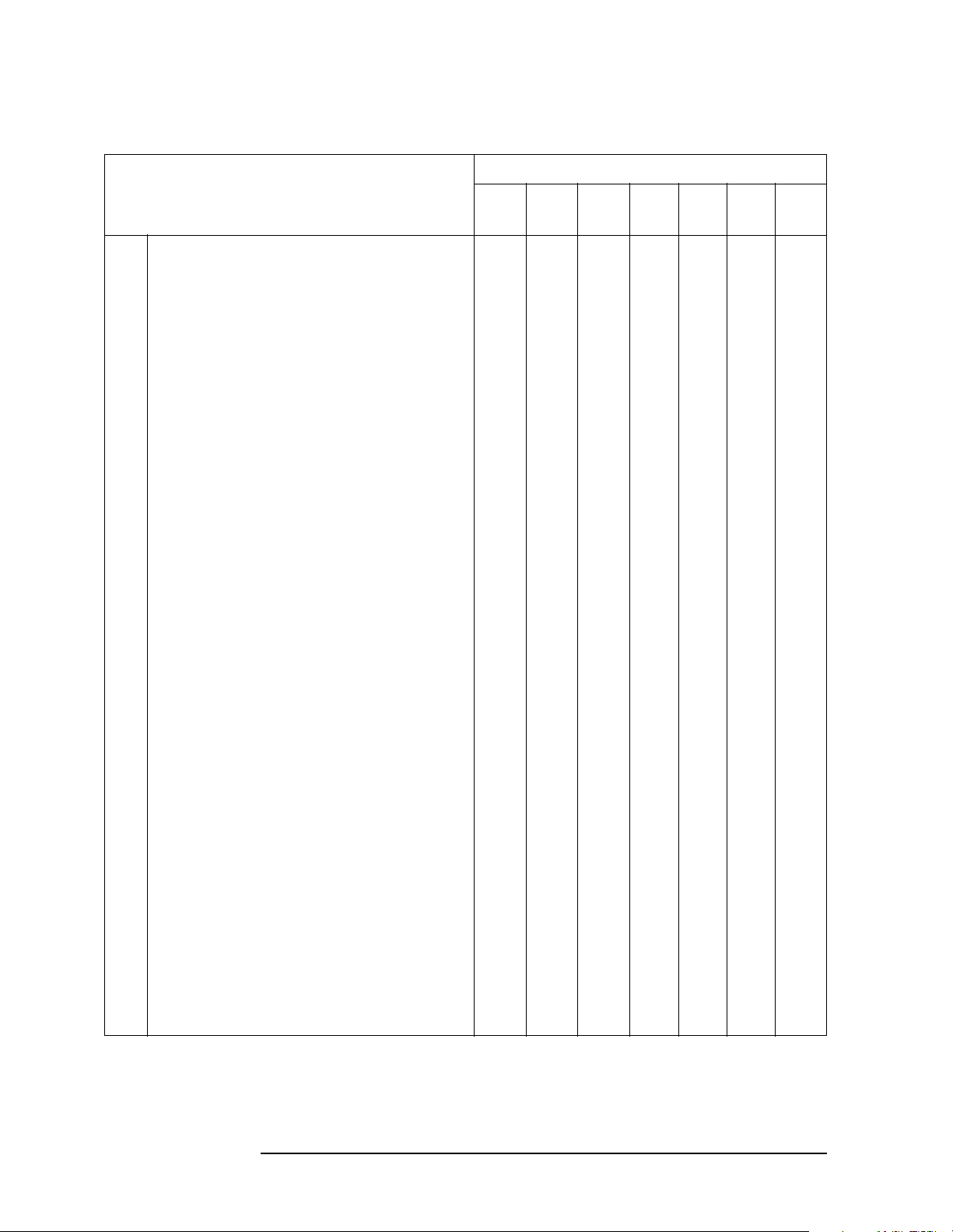

Performance Verification Test Tables

The tables on the following pages list the performance tests in Chapter

2 , “Performance Verification Tests,” required for each model number.

Perform all the tests marked with a dot in the “Std” (standard) column.

If any options are installed in the analyzer, also perform all tests

marked with a dot in the appropriate option column.

Chapter 1 11

Page 12

Calibrating

Calibration Cycle

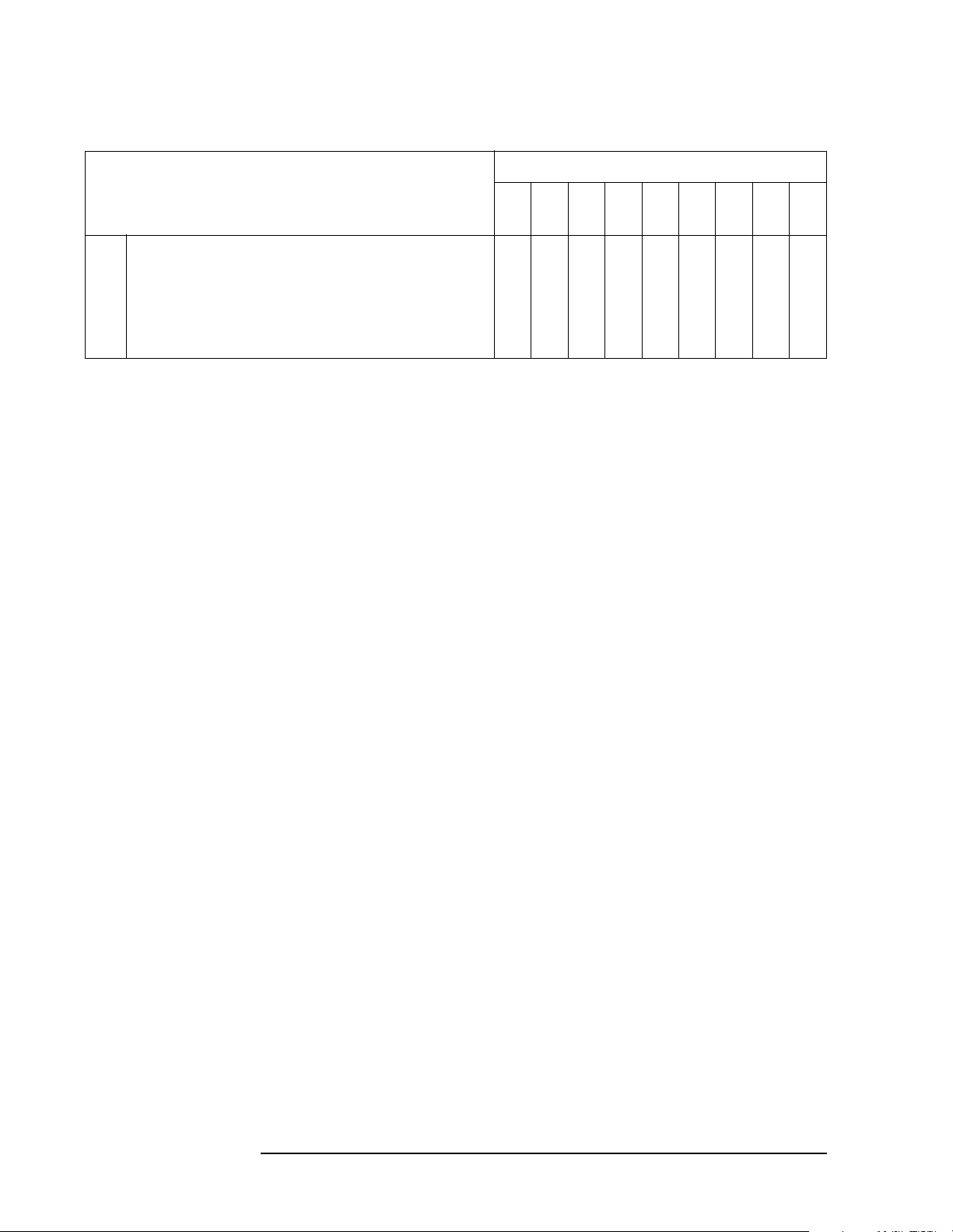

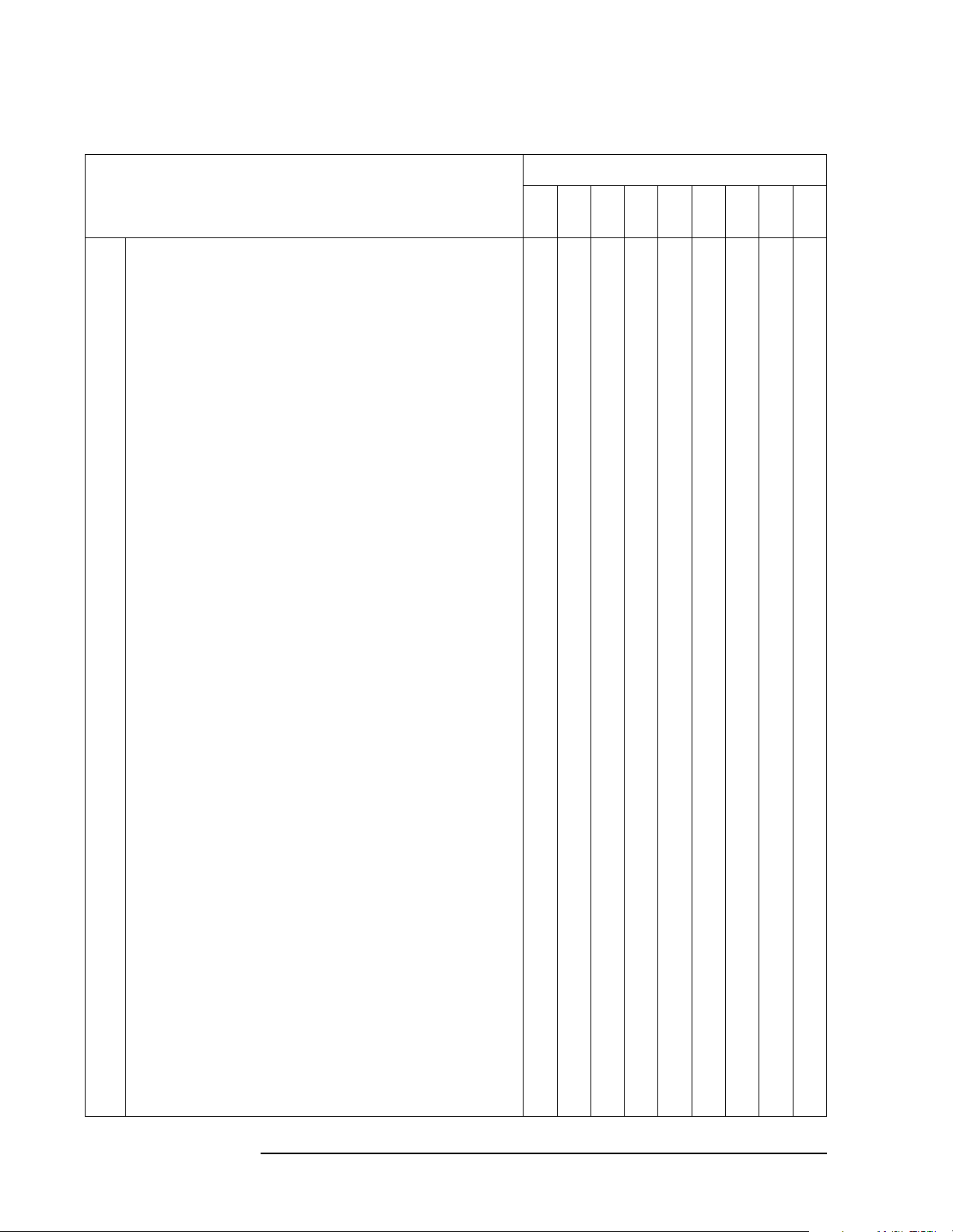

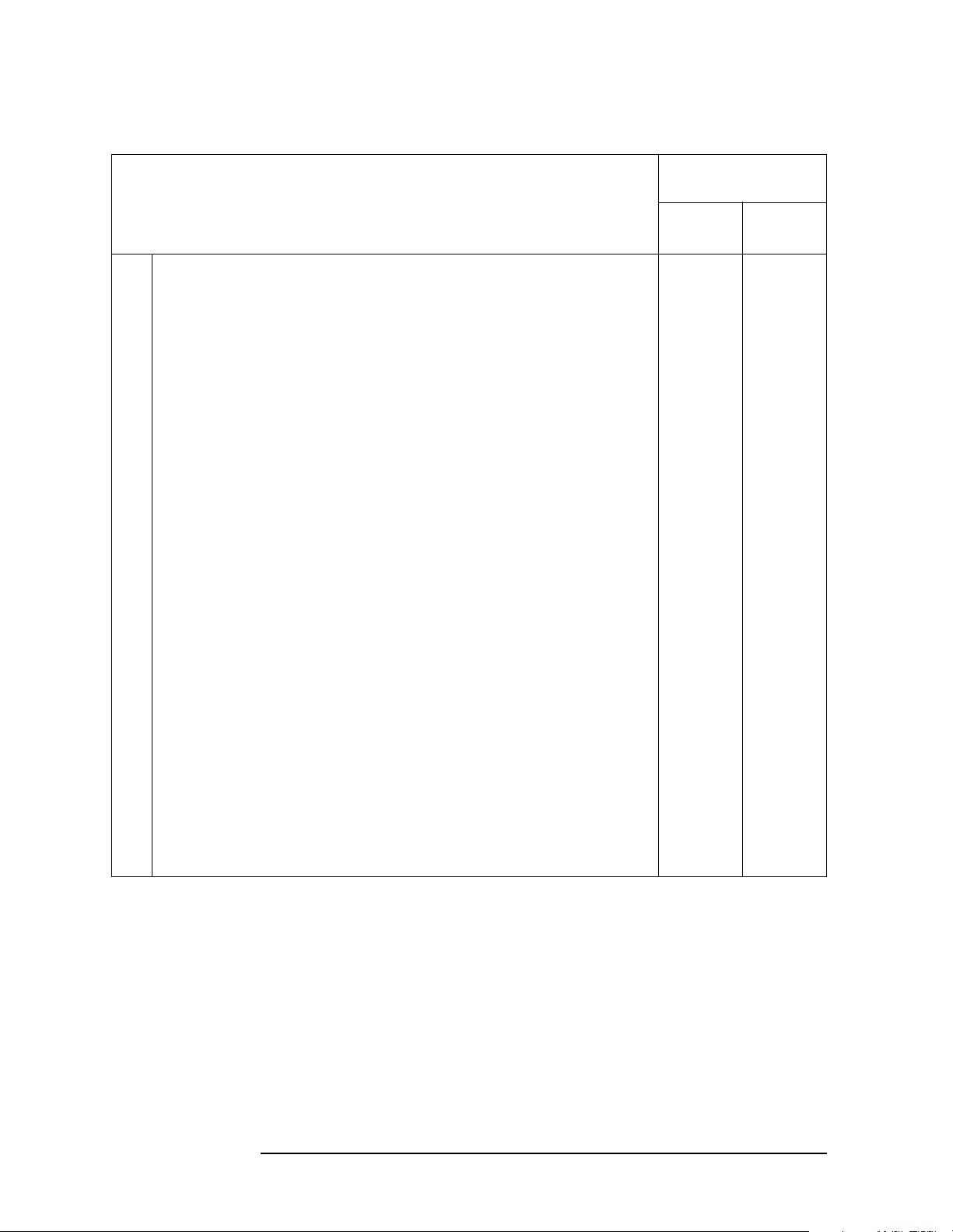

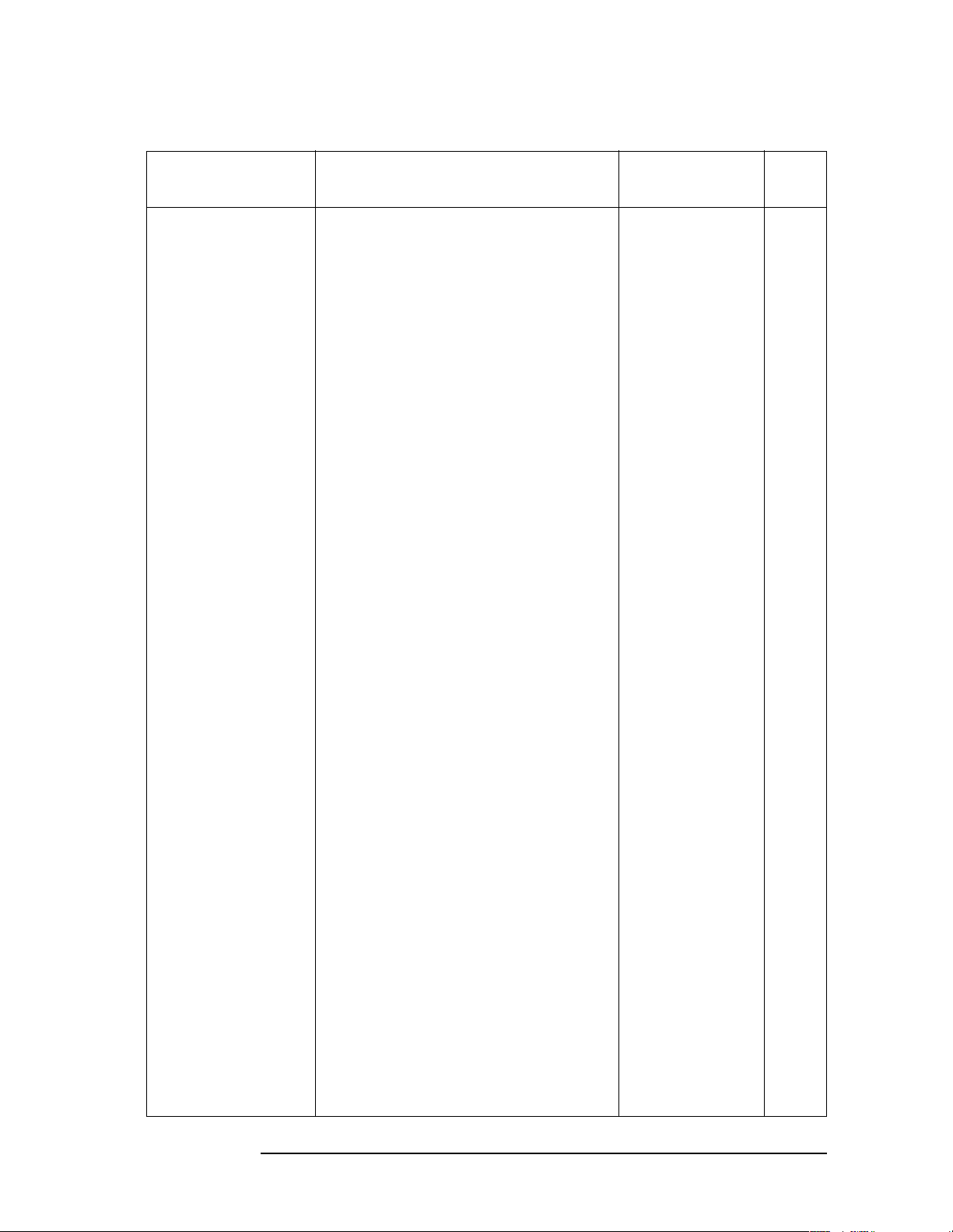

Table 1-1 Agilent E4401B Performance Verification Tests

Calibration for Instrument Option:

Performance Test Name

Stda1DN

1.

10 MHz Reference Output Accuracy

2. 10 MHz High-Stability Frequency Reference

Output Accuracy

3. Frequency Readout and Marker Frequency

Count Accuracy

5. Frequency Span Accuracy •

7. Noise Sidebands •

9. System-Related Sidebands •

10. Residual FM •

11. Sweep Time Accuracy •

12. Display Scale Fidelity •

13. Input Attenuation Switching Uncertainty •

14. Reference Level Accuracy •

16. Resolution Bandwidth Switching Uncertainty •

17. Absolute Amplitude Accuracy (Reference

Settings)

19. Overall Absolute Amplitude Accuracy •

21. Resolution Bandwidth Accuracy •

22. Frequency Response •

25. Frequency Response (Preamp On) •

28. Other Input-Related Spurious Responses •

30. Spurious Responses •

33. Gain Compression •

35. Displayed Average Noise Level •

39. Residual Responses •

40. Fast Time Domain Amplitude Accuracy •

41. Tracking Generator Absolute Amplitude and

Vernier Accuracy

43. Tracking Generator Level Flatness • •

45. Tracking Generator Harmonic Spurious

Outputs

47. Tracking Generator Non-Harmonic Spurious

Outputs

50. Gate Delay Accuracy and Gate Length

Accuracy

51. Gate Mode Additional Amplitude Error •

a. Perform these tests for all E4401B analyzers.

b. Perform this test only on analyzers not equipped with Option 1D5.

b

•

•

•

••

••

••

1DQ

1DS

1D5

•

1D6

•

AYX

12 Chapter 1

Page 13

Calibrating

Calibration Cycle

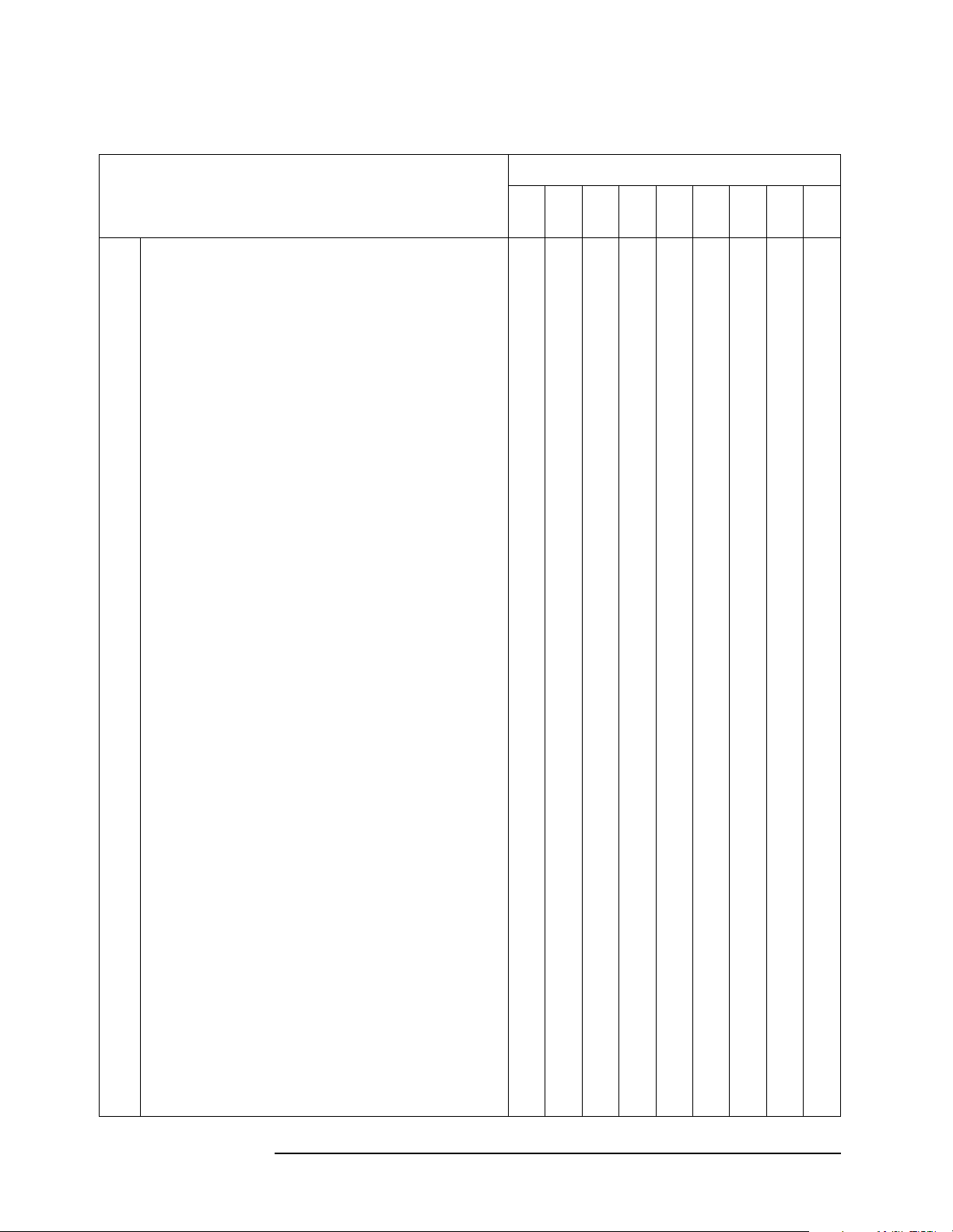

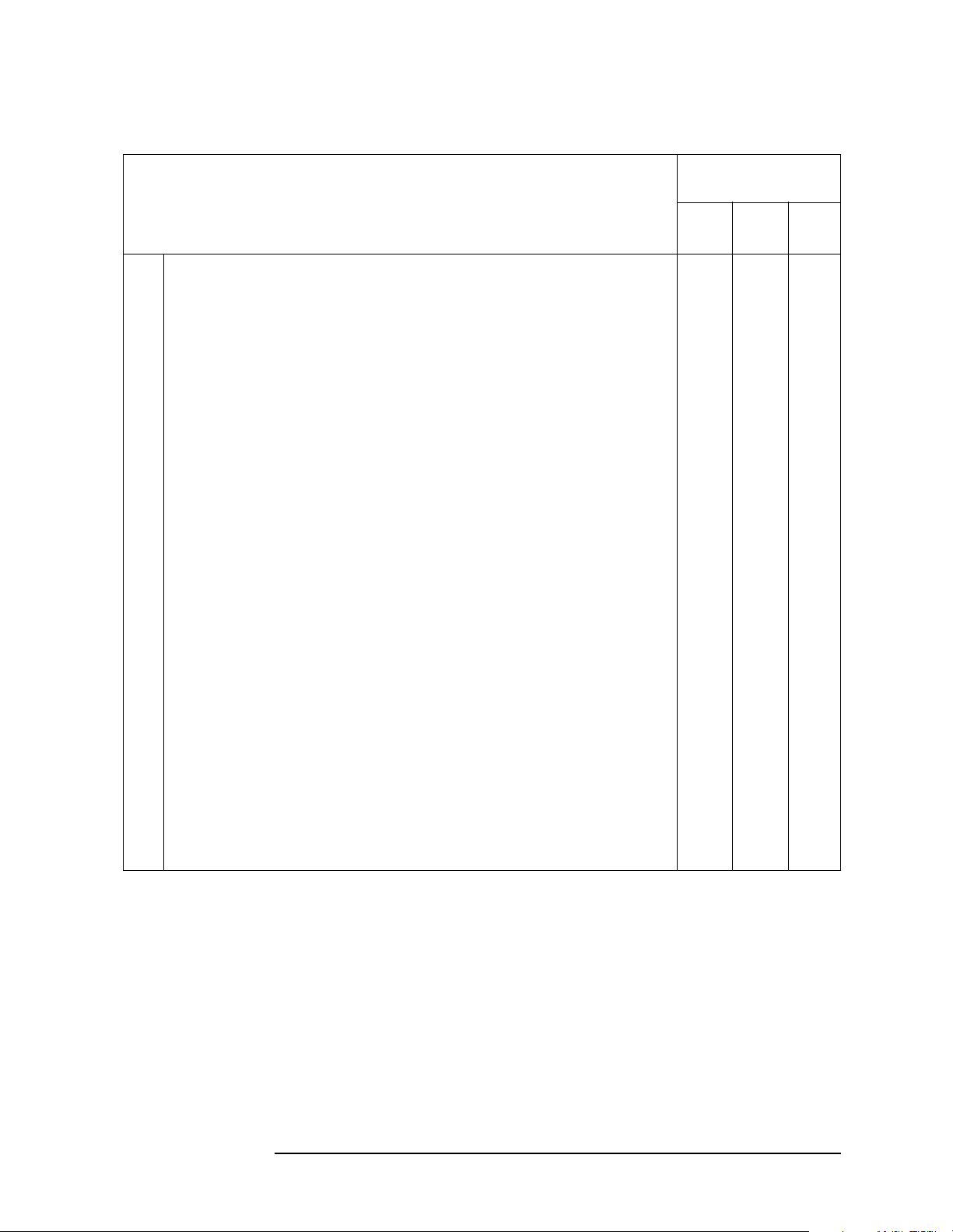

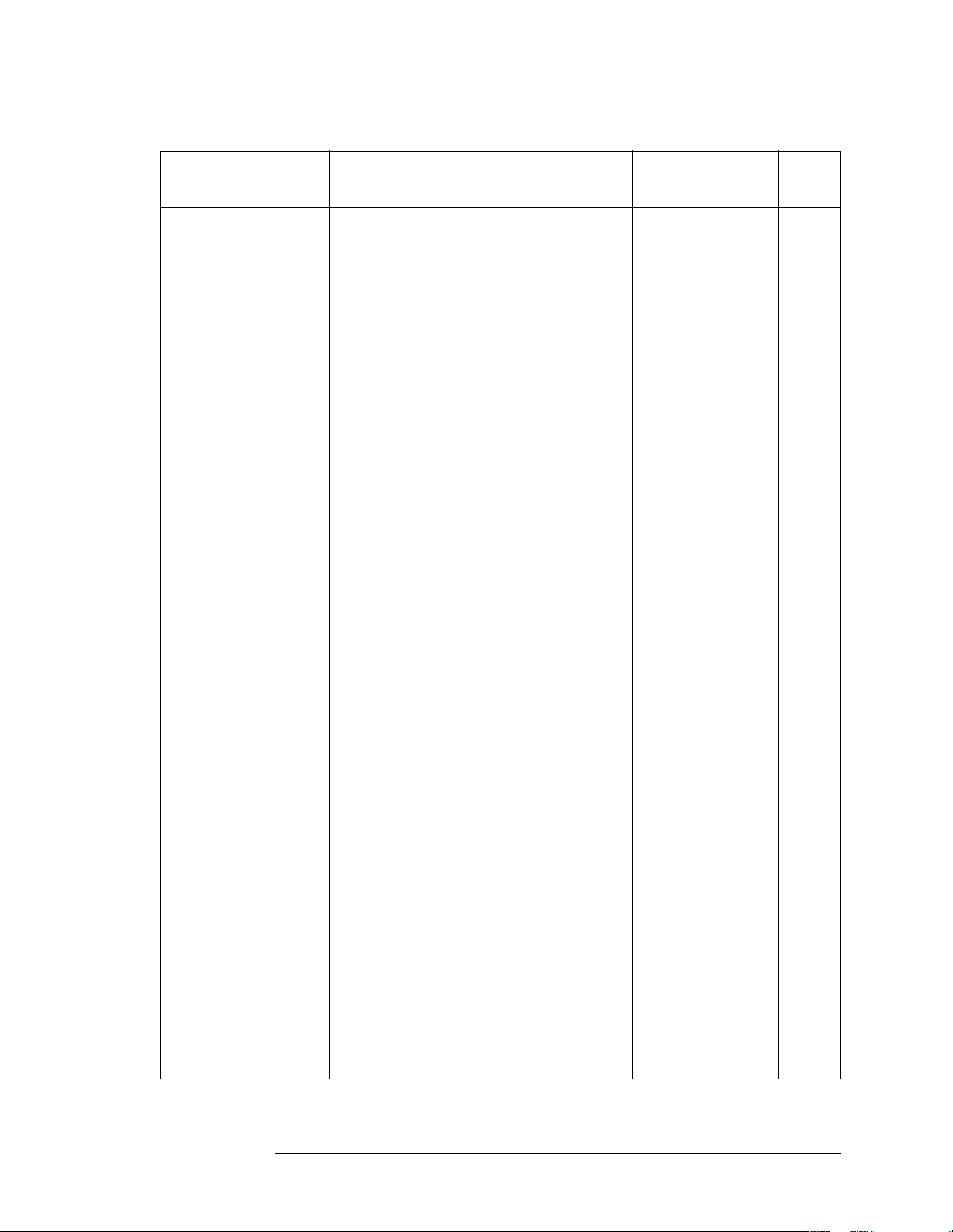

Table 1-2 Agilent E4402B Performance Verification Tests

Calibration for Instrument Option:

Performance Test Name

1.

10 MHz Reference Output Accuracy

2. 10 MHz High-Stability Frequency Reference Output

Accuracy

3. Frequency Readout and Marker Frequency Count

Accuracy

6. Frequency Span Accuracy •

7. Noise Sidebands •

8. Noise Sidebands - Wide Offsets •

9. System-Related Sidebands •

10. Residual FM •

11. Sweep Time Accuracy •

12. Display Scale Fidelity •

13. Input Attenuation Switching Uncertainty •

15. Reference Level Accuracy •

16. Resolution Bandwidth Switching Uncertainty •

18. Absolute Amplitude Accuracy (Reference Settings) •

20. Overall Absolute Amplitude Accuracy •

21. Resolution Bandwidth Accuracy •

23. Frequency Response •

26. Frequency Response (Preamp On) •

29. Other Input-Related Spurious Responses •

31. Spurious Responses •

33. Gain Compression •

36. Displayed Average Noise Level •

39. Residual Responses •

40. Fast Time Domain Amplitude Accuracy •

42. Tracking Generator Absolute Amplitude and Vernier

Accuracy

44. Tracking Generator Level Flatness •

46. Tracking Generator Harmonic Spurious Outputs •

48. Tracking Generator Non-Harmonic Spurious Outputs •

49. Tracking Generator L.O. Feedthrough •

50. Gate Delay Accuracy and Gate Length Accuracy •

51. Gate Mode Additional Amplitude Error •

54. Comms Frequency Response • •

55.

(This test has been deleted.)

b

a

•

•

Std

1D5

1DS

1DN

•

1D6

AYX

BAC

•

B7E

BAH

Chapter 1 13

Page 14

Calibrating

Calibration Cycle

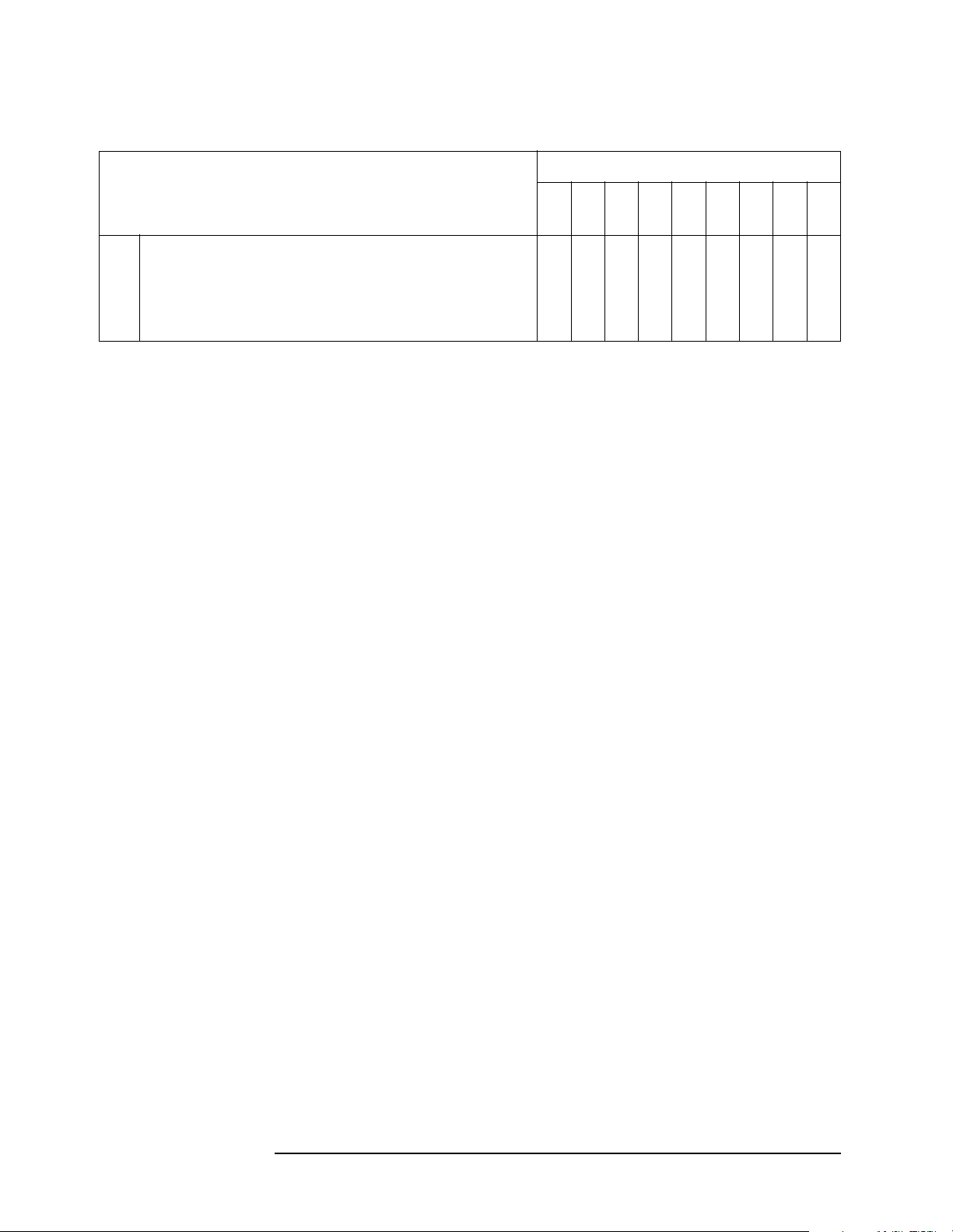

Table 1-2 Agilent E4402B Performance Verification Tests

Calibration for Instrument Option:

Performance Test Name

1D5

Stda1DN

56.

(This test has been deleted.)

57.

(This test has been deleted.)

58.

GSM Phase and Frequency Error

59. Comms Absolute Power Accuracy (Options BAC or

BAH)

a. Perform these tests for all E4402B analyzers.

b. Perform this test only on analyzers not equipped with Option 1D5.

c. Perform this test only on instruments having Option BAH, GSM Measurement Personality.

c

1DS

1D6

AYX

BAC

BAH

••

B7E

•

14 Chapter 1

Page 15

Calibrating

Calibration Cycle

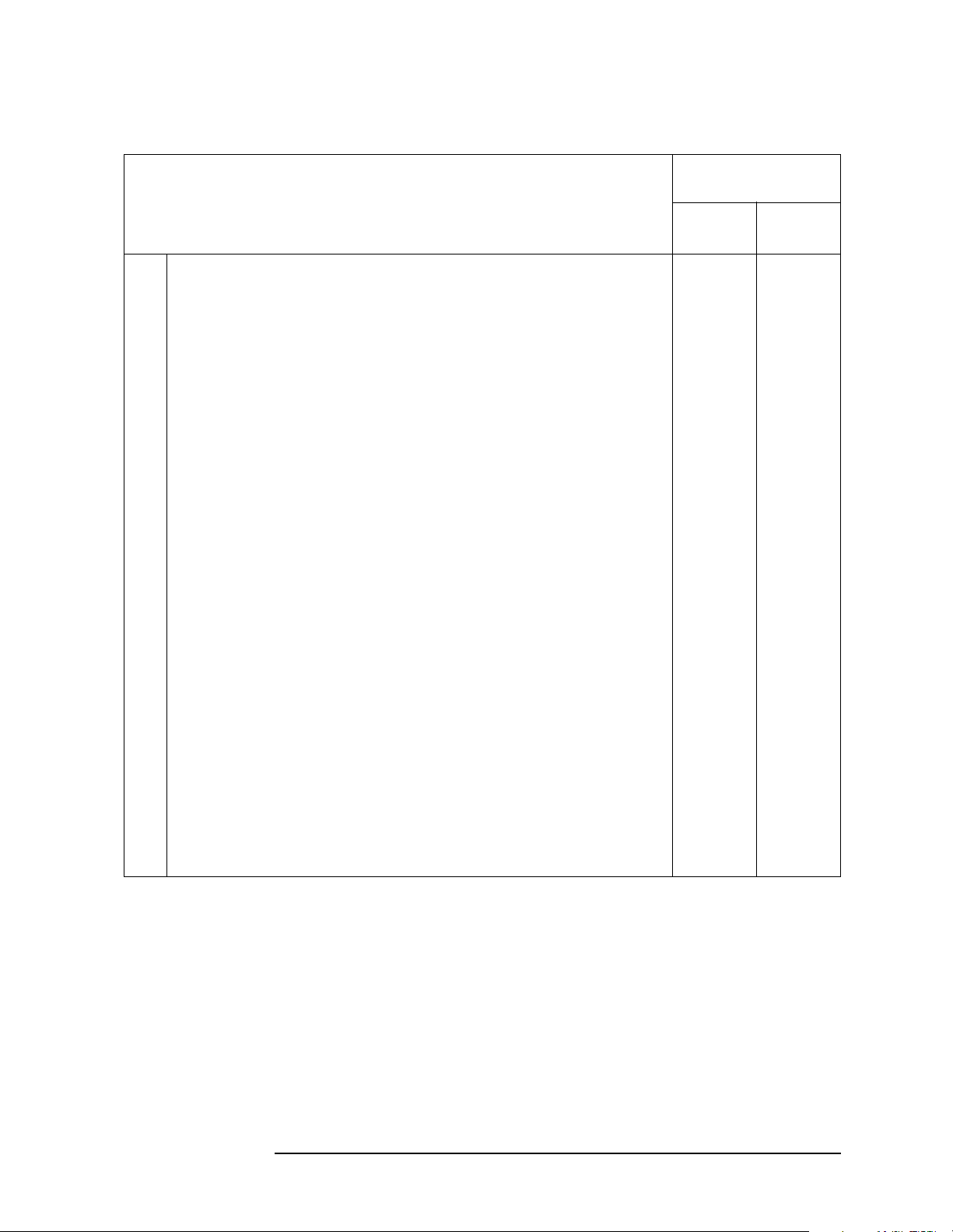

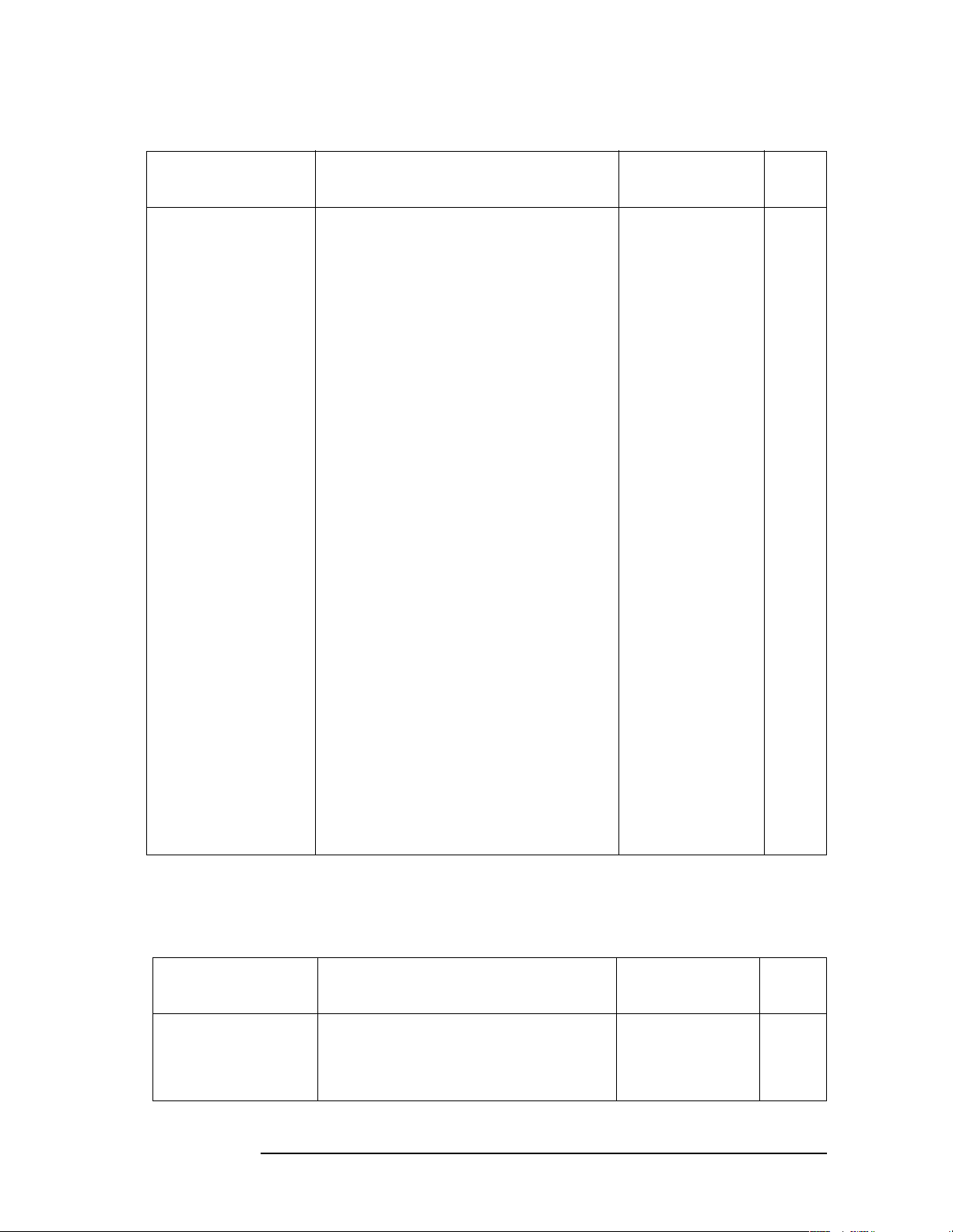

Table 1-3 Agilent E4403B Performance Verification Tests

Calibration for

Performance Test Name

1. 10 MHz Reference Output Accuracy •

3. Frequency Readout and Marker Frequency Count Accuracy •

6. Frequency Span Accuracy •

7. Noise Sidebands •

9. System-Related Sidebands •

10. Residual FM •

11. Sweep Time Accuracy •

12. Display Scale Fidelity •

13. Input Attenuation Switching Uncertainty •

15. Reference Level Accuracy •

16. Resolution Bandwidth Switching Uncertainty •

18. Absolute Amplitude Accuracy (Reference Settings) •

20. Overall Absolute Amplitude Accuracy •

21. Resolution Bandwidth Accuracy •

23. Frequency Response •

29. Other Input-Related Spurious Responses •

31. Spurious Responses •

33. Gain Compression •

36. Displayed Average Noise Level •

39. Residual Responses •

42. Tracking Generator Absolute Amplitude and Vernier Accuracy •

44. Tracking Generator Level Flatness •

46. Tracking Generator Harmonic Spurious Outputs •

48. Tracking Generator Non-Harmonic Spurious Outputs •

49. Tracking Generator L.O. Feedthrough •

Instrument Option:

a

Std

1DN

a. Perform these tests on all E4403B analyzers.

Chapter 1 15

Page 16

Calibrating

Calibration Cycle

Table 1-4 Agilent E4404B Performance Verification Tests

Perform anc e Test Name

1.

10 MHz Reference Output Accuracy

b

2. 10 MHz High-Stability Frequency Reference Output

Calibration for Instrument Option:

1D5

Stda1DN

1DS

1D6

•

•

AYX

BAC

Accuracy

4. Frequency Readout and Marker Frequency Count

•

Accuracy

6. Frequency Span Accuracy •

7. Noise Sidebands •

8. Noise Sidebands - Wide Offsets •

9. System-Related Sidebands •

10. Residual FM •

11. Sweep Time Accuracy •

12. Display Scale Fidelity •

13. Input Attenuation Switching Uncertainty •

15. Reference Level Accuracy •

16. Resolution Bandwidth Switching Uncertainty •

18. Absolute Amplitude Accuracy (Reference Settings) •

20. Overall Absolute Amplitude Accuracy •

21. Resolution Bandwidth Accuracy •

24. Frequency Response •

27. Frequency Response (Preamp On) •

29. Other Input-Related Spurious Responses •

32. Spurious Responses •

34. Gain Compression •

37. Displayed Average Noise Level •

39. Residual Responses •

40. Fast Time Domain Amplitude Accuracy •

42. Tracking Generator Absolute Amplitude and Vernier

•

Accuracy

44. Tracking Generator Level Flatness •

46. Tracking Generator Harmonic Spurious Outputs •

48. Tracking Generator Non-Harmonic Spurious Outputs •

49. Tracking Generator L.O. Feedthrough •

50. Gate Delay Accuracy and Gate Length Accuracy •

51. Gate Mode Additional Amplitude Error •

54. Comms Frequency Response • •

55.

(This test has been deleted.)

B7E

BAH

16 Chapter 1

Page 17

Calibrating

Table 1-4 Agilent E4404B Performance Verification Tests

Calibration Cycle

Perform anc e Test Name

56.

(This test has been deleted.)

57.

(This test has been deleted.)

58.

GSM Phase and Frequency Error

c

Calibration for Instrument Option:

1D5

Stda1DN

1DS

1D6

AYX

BAC

59. Comms Absolute Power Accuracy (Options BAC or BAH) • •

a. Perform these tests on all Agilent E4404B analyzers.

b. Perform this test only on analyzers not equipped with Option 1D5.

c. Perform this test only on instruments having Option BAH, GSM Measurement Personality.

B7E

BAH

•

Chapter 1 17

Page 18

Calibrating

Calibration Cycle

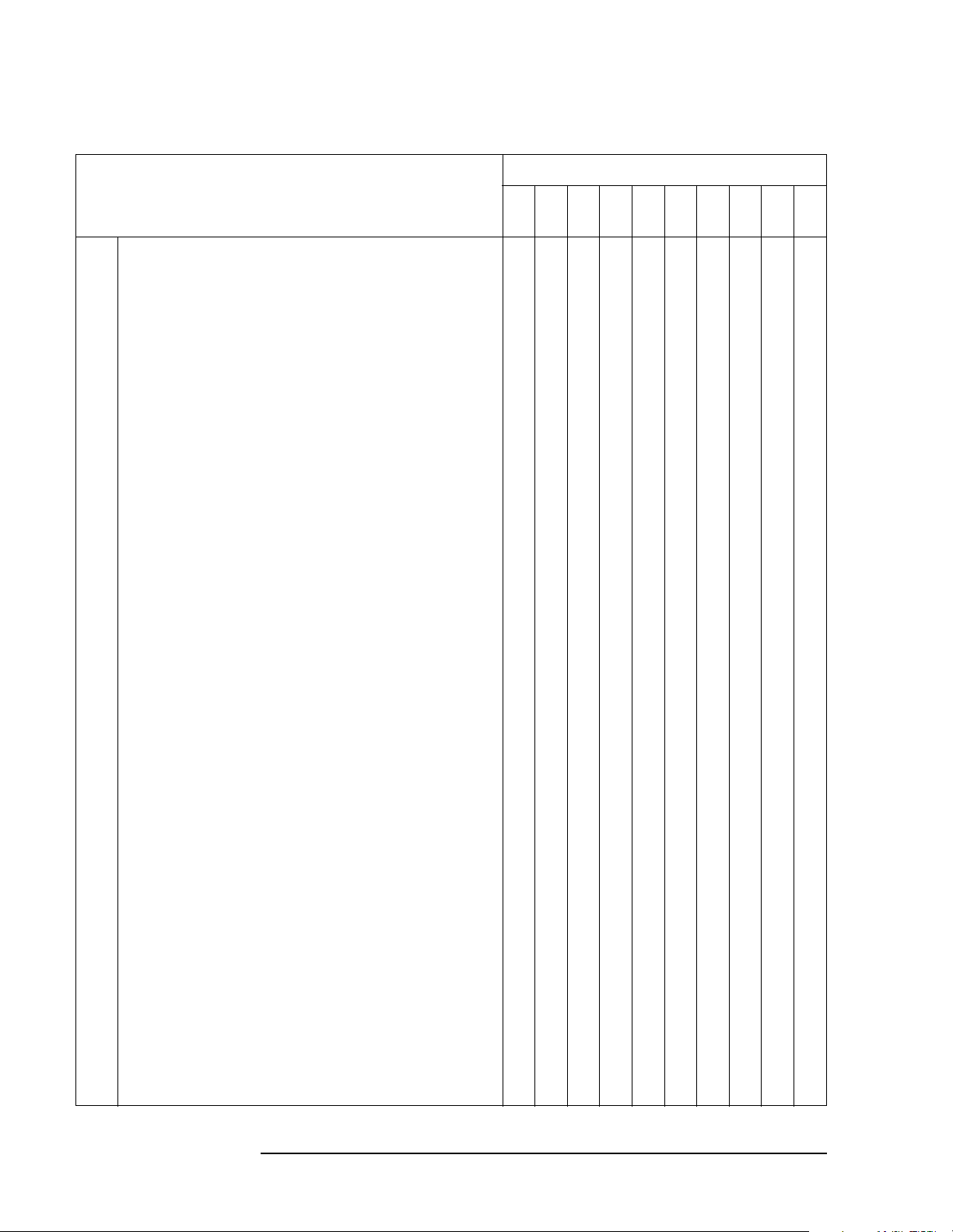

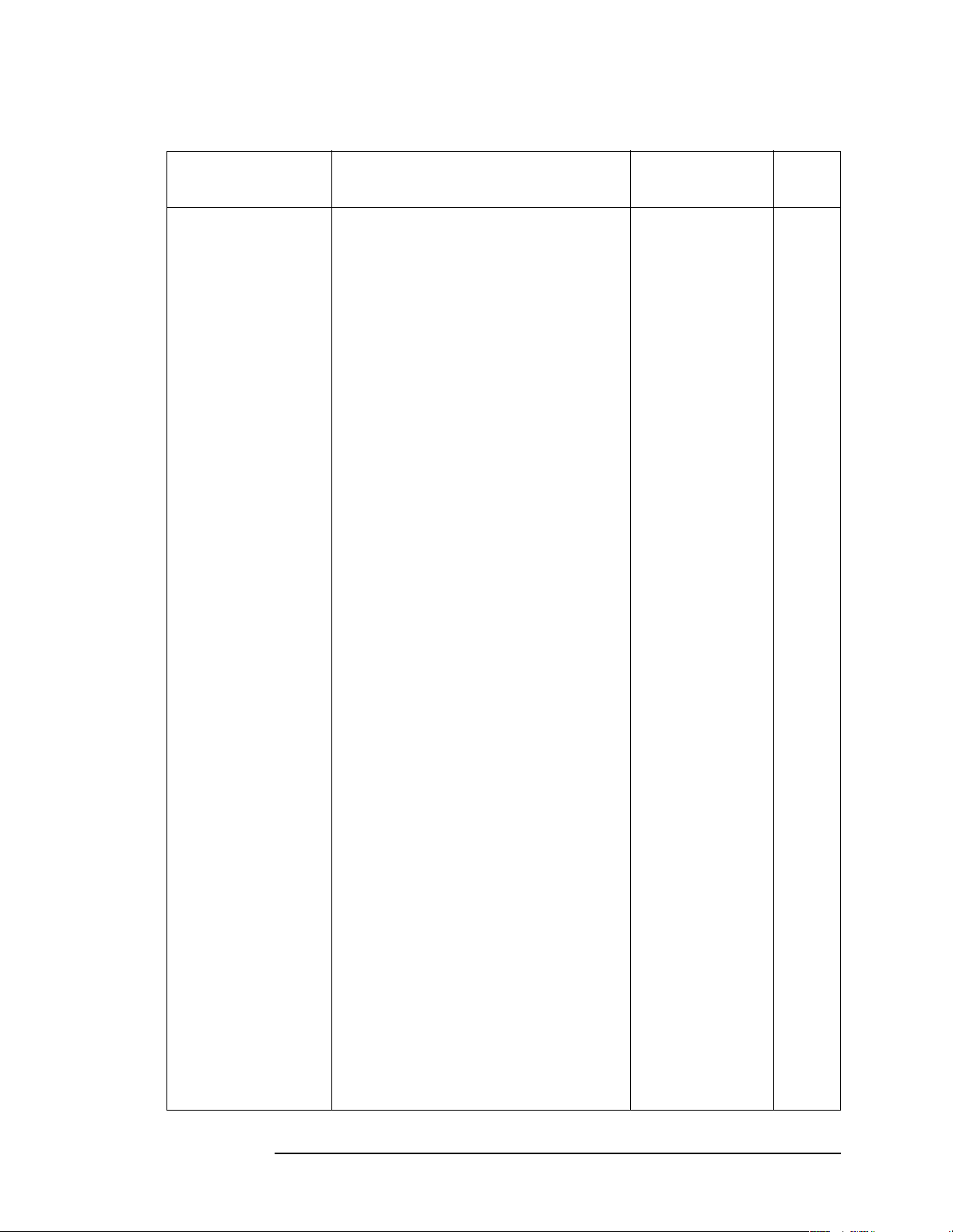

Table 1-5 Agilent E4405B Performance Verification Tests

Calibration for Instrument Option:

Performance Test Name

1.

10 MHz Reference Output Accuracy

2. 10 MHz High-Stability Frequency Reference Output

Accuracy

4. Frequency Readout and Marker Frequency Count

Accuracy

6. Frequency Span Accuracy •

7. Noise Sidebands •

8. Noise Sidebands - Wide Offsets •

9. System-Related Sidebands •

10. Residual FM •

11. Sweep Time Accuracy •

12. Display Scale Fidelity •

13. Input Attenuation Switching Uncertainty •

15. Reference Level Accuracy •

16. Resolution Bandwidth Switching Uncertainty •

18. Absolute Amplitude Accuracy (Reference Settings) •

20. Overall Absolute Amplitude Accuracy •

21. Resolution Bandwidth Accuracy •

24. Frequency Response •

27. Frequency Response (Preamp On) •

29. Other Input-Related Spurious Responses •

32. Spurious Responses •

34. Gain Compression •

37. Displayed Average Noise Level •

39. Residual Responses •

40. Fast Time Domain Amplitude Accuracy •

42. Tracking Generator Absolute Amplitude and Vernier

Accuracy

44. Tracking Generator Level Flatness •

46. Tracking Generator Harmonic Spurious Outputs •

48. Tracking Generator Non-Harmonic Spurious Outputs •

49. Tracking Generator L.O. Feedthrough •

50. Gate Delay Accuracy and Gate Length Accuracy •

51. Gate Mode Additional Amplitude Error •

54. Comms Frequency Response • •

55.

(This test has been deleted.)

b

•

•

a

Std

1D5

1DS

1DN

•

1D6

AYX

BAC

•

B7E

BAH

18 Chapter 1

Page 19

Calibrating

Calibration Cycle

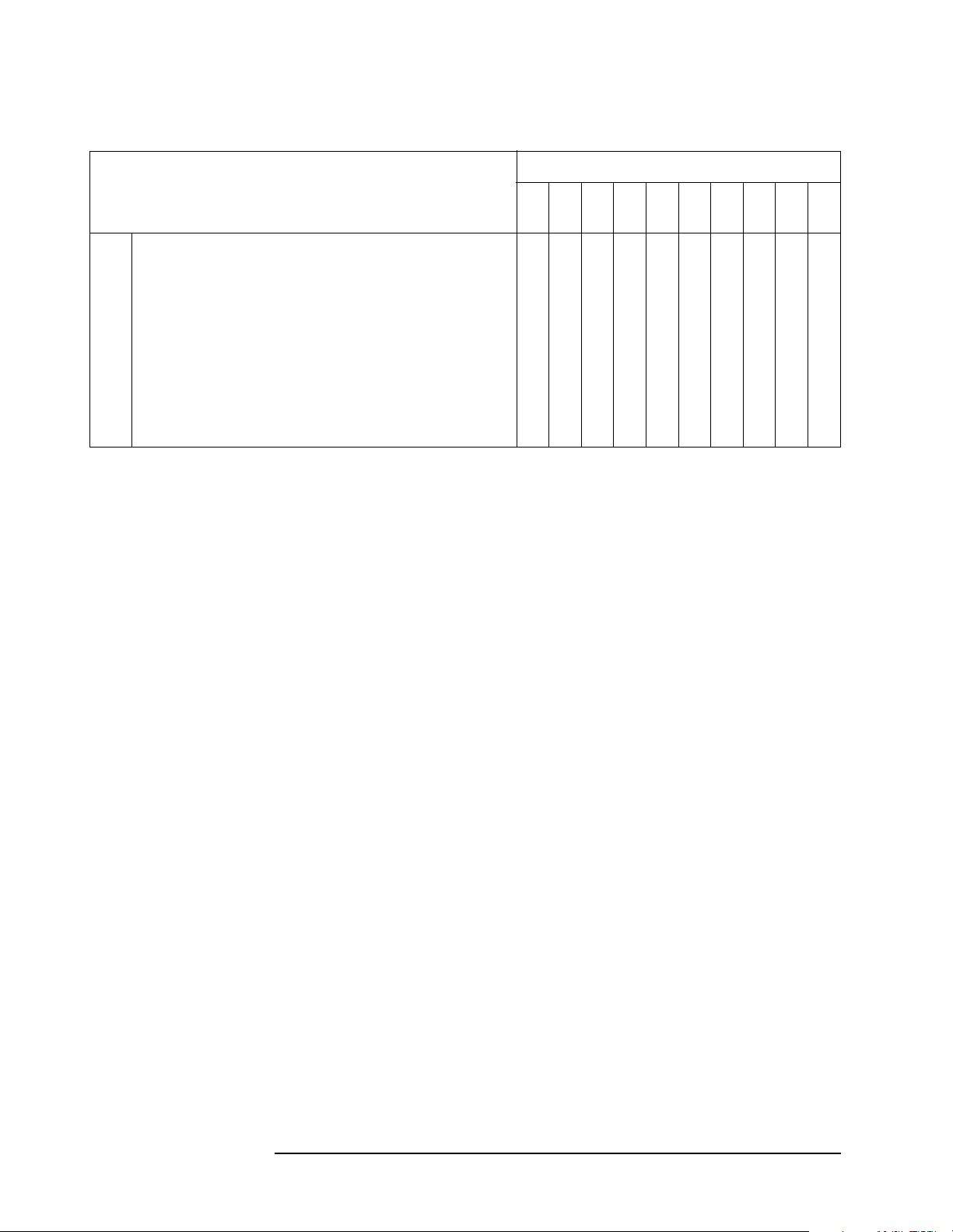

Table 1-5 Agilent E4405B Performance Verification Tests

Calibration for Instrument Option:

Performance Test Name

1D5

Stda1DN

56.

(This test has been deleted.)

57.

(This test has been deleted.)

58.

GSM Phase and Frequency Error

59. Comms Absolute Power Accuracy (Options BAC or BAH) • •

a. Perform these tests on all E4405B analyzers.

b. Perform this test only if the analyzer is not equipped with Option 1D5.

c. Perform this test only on instruments having Option BAH, GSM Measurement Personality.

c

1DS

1D6

AYX

BAC

B7E

BAH

•

Chapter 1 19

Page 20

Calibrating

Calibration Cycle

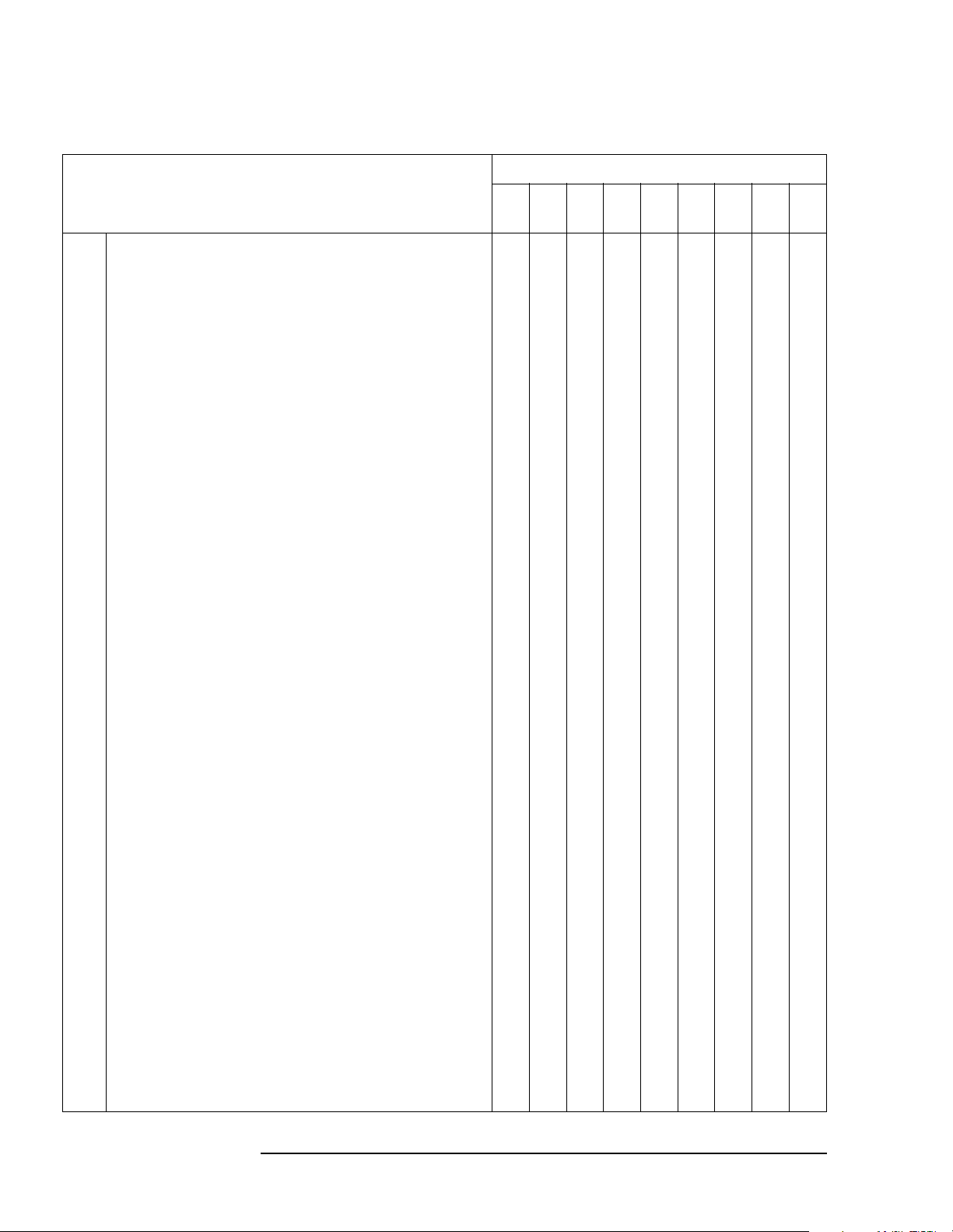

Table 1-6 Agilent E4407B Performance Verification Tests

Calibration for Instrument Option:

Performance Test Name

1.

10 MHz Reference Output Accuracy

b

2. 10 MHz High-Stability Frequency Reference Output

Accuracy

4. Frequency Readout and Marker Frequency Count

Accuracy

6. Frequency Span Accuracy •

7. Noise Sidebands •

8. Noise Sidebands - Wide Offsets •

9. System-Related Sidebands •

10. Residual FM •

11. Sweep Time Accuracy •

•

•

a

Std

1DS

1DN

•

1D5

1D6

AYX

BAC

AYZ

BAH

B7E

12. Display Scale Fidelity •

13. Input Attenuation Switching Uncertainty •

15. Reference Level Accuracy •

16. Resolution Bandwidth Switching Uncertainty •

18. Absolute Amplitude Accuracy (Reference Settings) •

20. Overall Absolute Amplitude Accuracy •

21. Resolution Bandwidth Accuracy •

24. Frequency Response •

27. Frequency Response (Preamp On) •

29. Other Input-Related Spurious Responses •

32. Spurious Responses •

34. Gain Compression •

38. Displayed Average Noise Level •

39. Residual Responses •

40. Fast Time Domain Amplitude Accuracy •

42. Tracking Generator Absolute Amplitude and Vernier

•

Accuracy

44. Tracking Generator Level Flatness •

46. Tracking Generator Harmonic Spurious Outputs •

48. Tracking Generator Non-Harmonic Spurious Outputs •

49. Tracking Generator L.O. Feedthrough •

50. Gate Delay Accuracy and Gate Length Accuracy •

51. Gate Mode Additional Amplitude Error •

20 Chapter 1

Page 21

Calibrating

Table 1-6 Agilent E4407B Performance Verification Tests

Calibration for Instrument Option:

Performance Test Name

52. First LO OUTPUT Power Accuracy

53. IF Input Accuracy •

a

Std

1DN

1D5

1DS

1D6

AY X

Calibration Cycle

BAC

AYZ

•

BAH

B7E

54. Comms Frequency Response •

55.

(This test has been deleted.)

56.

(This test has been deleted.)

57.

(This test has been deleted.)

58.

GSM - Phase and Frequency Error

c

59. Comms Absolute Power Accuracy (Options BAC or BAH)

a. Perform these tests on all E4407B analyzers.

b. Perform this test only on analyzers not equipped with Option 1D5.

c. Perform this test only on instruments having Option BAH, GSM Measurement Personality.

•

•

••

Chapter 1 21

Page 22

Calibrating

Calibration Cycle

Table 1-7 Agilent E4408B Performance Verification Tests

Calibration for

Performance Test Name

1. 10 MHz Reference Output Accuracy •

4. Frequency Readout and Marker Frequency Count Accuracy •

6. Frequency Span Accuracy •

7. Noise Sidebands •

9. System-Related Sidebands •

10. Residual FM •

11. Sweep Time Accuracy •

12. Display Scale Fidelity •

13. Input Attenuation Switching Uncertainty •

15. Reference Level Accuracy •

16. Resolution Bandwidth Switching Uncertainty •

18. Absolute Amplitude Accuracy (Reference Settings) •

20. Overall Absolute Amplitude Accuracy •

21. Resolution Bandwidth Accuracy •

24. Frequency Response •

29. Other Input-Related Spurious Responses •

32. Spurious Responses •

34. Gain Compression •

38. Displayed Average Noise Level •

39. Residual Responses •

42. Tracking Generator Absolute Amplitude and Vernier Accuracy •

44. Tracking Generator Level Flatness •

46. Tracking Generator Harmonic Spurious Outputs •

48. Tracking Generator Non-Harmonic Spurious Outputs •

49. Tracking Generator L.O. Feedthrough •

Instrument Option:

a

Std

1DN

a. Perform these tests on all E4408B analyzers.

22 Chapter 1

Page 23

Calibrating

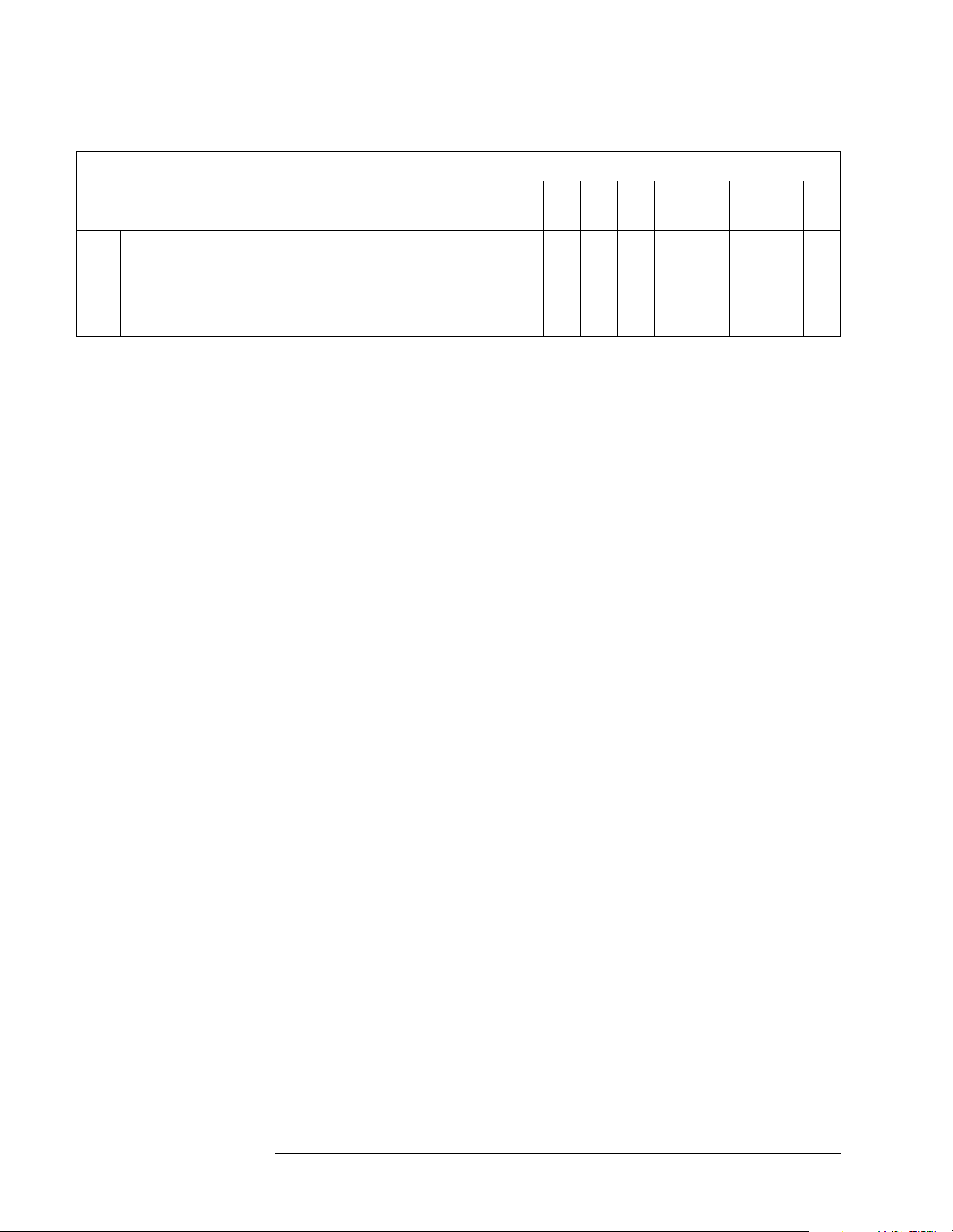

Table 1-8 Agilent E4411B Performance Verification Tests

Performance Test Name

Calibration Cycle

Calibration for

Instrument Option:

Stda1DN

1. 10 MHz Reference Output Accuracy •

3. Frequency Readout and Marker Frequency Count Accuracy •

5. Frequency Span Accuracy •

7. Noise Sidebands •

9. System-Related Sidebands •

10. Residual FM •

11. Sweep Time Accuracy •

12. Display Scale Fidelity •

13. Input Attenuation Switching Uncertainty •

14. Reference Level Accuracy •

16. Resolution Bandwidth Switching Uncertainty •

17. Absolute Amplitude Accuracy (Reference Settings) •

19. Overall Absolute Amplitude Accuracy •

21. Resolution Bandwidth Accuracy •

22. Frequency Response •

28. Other Input-Related Spurious Responses •

30. Spurious Responses •

33. Gain Compression •

35. Displayed Average Noise Level •

39. Residual Responses •

41. Tracking Generator Absolute Amplitude and Vernier Accuracy • •

43. Tracking Generator Level Flatness • •

45. Tracking Generator Harmonic Spurious Outputs • •

47. Tracking Generator Non-Harmonic Spurious Outputs • •

1DQ

a. Perform these tests on all E4411B analyzers.

Chapter 1 23

Page 24

Calibrating

Before You Start

Before You Start

This brief procedure should be performed before starting the

performance verification tests:

1. Switch the analyzer on and let it warm up for five minutes.

2. If the analyzer is an Agilent E4402B, E4403B, E4404B, E4405B,

E4407B, or E4408B, connect a cable from AMPTD REF OUT to the

50 Ω Input.

3. Press

alignments to finish.

4. Read the remainder of this section before you start any of the tests,

and make a copy of the Performance Verification Test Record

described below in "Recording the test results."

System, Alignments, Align Now, All, and wait for the auto

Recording the test results

Performance verification test records, for each analyzer, are provided in

the chapter following the tests.

Each test result is identified as a TR Entry in the performance tests

and on the performance verification test record. We recommend that

you make a copy of the performance verification test record, record the

test results on the copy, and keep the copy for your calibration test

record. This record could prove valuable in tracking gradual changes in

test results over long periods of time.

Performing Self-Alignment

Perform a complete self-alignment at least once per day, or if the

analyzer fails a verification test. To perform a self-alignment, press

System, Alignment, Align Now, All. The instrument must be up to

operating temperature in order for this test to be valid. If the analyzer

continuously fails one or more specifications, complete any remaining

tests and record all test results on a copy of the test record. Then refer

to Chapter 4 , “If You Have a Problem,” for instructions on how to solve

the problem.

24 Chapter 1

Page 25

Calibrating

Periodic verification of operation

The analyzer requires periodic verification of operation. Under most

conditions of use, you should test the analyzer at least once a year with

the complete set of performance verification tests.

Test equipment you will need

The following tables list the recommended test equipment for the

performance tests. The tables also list recommended equipment for the

analyzer adjustment procedures which are located in the Agilent ESA

Spectrum Analyzers Service Guide. Any equipment that meets the

critical specifications given in the table can be substituted for the

recommended model.

Table 1-9 Recommended Test Equipment

Before You Start

Equipment

Digital Multimeter Input Resistance

DVM Test Leads For use with HP/Agilent 3458A Digital

Universal Counter Frequency Range: 10 MHz ±

Frequency Standard Frequency: 10 MHz

Critical Specifications for Equipment

Substitution

≥10 megohms

Accuracy: ±10 mV on 100 V range

Multimeter

Time Interval Range: 25 ms to 100 ms

Single Trigger Operation

Range: 2.5 Vdc to –2.5 Vdc

External Reference Input

Gate Time:

Frequency Resolution: 0.01 Hz

Timebase Accuracy

(Aging): <1

≥10 seconds

−9

×10

/day

100 Hz

Recommended

HP/Agilent Model

3458A P,A,T

34118B T

53132A P,A,T

5071A P,A

Use

a

Chapter 1 25

Page 26

Calibrating

Before You Start

Table 1-9 Recommended Test Equipment

Equipment

Critical Specifications for Equipment

Substitution

Oscilloscope Bandwidth: dc to 100 MHz

Vertical Scale Factor of 0.5 V to 5 V/Div

Two channels

Minimum Timebase Setting: <100 ns

Digitizing display with pulse width and

time interval measurement functions

Delta –T measurement accuracy in

200 ns / div: <450 ps

Power Meter Compatible with HP/Agilent 8480

series power sensors.

dB relative mode.

Resolution: 0.01 dB

Reference Accuracy: ±1.2%

RF Power Sensor

(2 required)

Frequency Range: 100 kHz to 3 GHz

Maximum SWR:

1.60 (100 kHz to 300 kHz)

1.20 (300 kHz to 1 MHz)

1.1 (1 MHz to 2.0 GHz)

1.18 (2.0 GHz to 3.0 GHz)

Amplitude range: –25 dBm to 10 dBm

Recommended

HP/Agilent Model

54820A T

E4419B P,A,T

8482A P,A,T

Use

a

Microwave Power

Sensor

Power Sensor, Low

Power

Synthesized Signal

Generator

Frequency Range: 50 MHz to 26.5 GHz

Maximum SWR:

1.15 (50 MHz to 100 MHz)

1.10 (100 MHz to 2 GHz)

1.15 (2 GHz to 12.4 GHz)

1.20 (12.4 GHz to 18 GHz)

1.25 (18 GHz to 26.5 GHz)

Amplitude range: –25 dBm to 0 dBm

Frequency Range: 50 MHz to 3.0 GHz

Amplitude Range: –20 dBm to –70 dBm

Maximum SWR:

1.4 (10 MHz to 30 MHz)

1.15 (30 MHz to 3.0 GHz)

Frequency Range: 100 kHz to

1500 MHz

Amplitude Range: –35 to 16 dBm

SSB Noise: <–120 dBc/Hz at 20 kHz

offset

8485A P,A,T

8481D P,A,T

8663A P,A

26 Chapter 1

Page 27

Calibrating

Table 1-9 Recommended Test Equipment

Before You Start

Equipment

Wide Offset

Phase Noise

Signal Generator

Signal Generator

(Option BAH)

Spectrum Analyzer,

Microwave

Critical Specifications for Equipment

Substitution

Frequency Range: 1 GHz ±1 MHz

Amplitude Range: 0 dBM

±5 dB

Phase Noise:

<−131 dBc/Hz typical @ 100 kHz offset

<−145 dBc/Hz typical @ 1 MHz offset

<−147 dBc/Hz typical @ 5 MHz offset

<−149 dBc/Hz typical @ 10 MHz offset

Frequency Range: 900 MHz to

1800 MHz

Amplitude Range: –30 to 0 dBm

Phase Error: <0.5

°

Frequency Error: <2.5 Hz

Frequency Range: 100 kHz to 7 GHz

Relative Amplitude Accuracy:

100 kHz to 3.0 GHz: <±1.8 dB

Frequency Accuracy: <±10 kHz at 7

GHz

Recommended

HP/Agilent Model

8665B P

E4433B

Option UN8, 1E5

8563E P,T

Use

P

a

Synthesized

Sweeper

(2 required)

Frequency Range:

E4407B or E4408B: 10 MHz to

26.5 GHz

All others: 10 MHz to 13.2 GHz

Frequency Accuracy (CW): ±0.02%

Leveling Modes: Internal and External

Modulation Modes: AM

Power Level Range: –40 to 16 dBm

Function Generator Frequency Range: 0.1 Hz to 15 MHz

Frequency Accuracy: ±0.02%

Waveform: Triangle, Square, Sine

Attenuator/Switch

Driver

Compatible with HP/Agilent 8494G

and 8496G Programmable step

attenuators

83630/40/50B

83620/30/B

40/50B

33120A or

3325B

11713A P

P, A ,T

P, A ,T

Chapter 1 27

Page 28

Calibrating

Before You Start

Table 1-9 Recommended Test Equipment

Equipment

Attenuator, 1 dB

Step

Attenuator, 10 dB

Step

Attenuator, 10 dB

Fixed

Attenuator, 6 dB

Fixed (2 required)

Critical Specifications for Equipment

Substitution

Attenuation Range: 0 to 11 dB

Frequency Range: 50 MHz ±1 MHz

Connectors: Type-N female

Calibrated at 50 MHz with accuracy of

1 to 11 dB attenuation: ±0.010 dB.

Attenuation Range: 0 to 110 dB

Frequency Range: 50 MHz ±1 MHz

Connectors: Type-N female

Calibrated at 50 MHz with accuracy of:

0 to 40 dB attenuation: ±0.020 dB

50 to 100 dB attenuation: ±0.065 dB

110 dB attenuation: ±0.075 dB

Nominal attenuation: 10 dB

Frequency Range: dc to 3 GHz

Connectors: Type-N(m) and Type-N(f)

Nominal attenuation: 6 dB

Frequency Range: 50 MHz

±1 MHz

VSWR: <1.1: 1 at 50 MHz

Recommended

HP/Agilent Model

8494A/G P

8496A/G P

8491A

Option 010

8491A

Option 006

Use

P

P

a

Attenuator, 20 dB

Fixed

Attenuator

Interconnect Kit

Nominal attenuation: 20 dB

Frequency Range: 100 kHz to 3 GHz

VSWR: <1.2: 1 at

≤3 GHz

Mechanically and electrically connects

HP/Agilent 8494A/G and HP/Agilent

8496A/G

a. P = Performance Test, A = Adjustment, T = Troubleshooting

Table 1-10 Recommended Accessories

Equipment

Directional Bridge Frequency Range: 5 MHz to 3 GHz

Critical Specifications for Accessory

Substitution

Directivity: >40 dB

Coupling factor: 16 dB nominal

Insertion Loss: 2 dB maximum

8491A

Option 020

11716 Series

Recommended

HP/Agilent Model

86205A P

P

Use

a

28 Chapter 1

Page 29

Calibrating

Table 1-10 Recommended Accessories

Before You Start

Equipment

Power Splitter

(for E4401B/

02B/03B/11B)

Power Splitter

(for E4404B/

05B/07B/08B)

Directional Coupler

(for E4404B/05B/

07B/08B)

Termination, 50

Ω

(2 required for

Option 1DN)

Critical Specifications for Accessory

Substitution

Frequency Range: 9 kHz to 13.2 GHz

Insertion Loss: 6 dB nominal

Output Tracking: <0.25 dB

Equivalent Output SWR: <1.22:1

Frequency Range: 9 kHz to 26.5 GHz

Insertion Loss: 6 dB nominal

Output Tracking: <0.25 dB

Equivalent Output SWR: <1.22:1

Frequency Range: 2 GHz to 15 GHz

Directivity: >16 dB

Max.VSWR: 1.35:1

Transmission Arm Loss: <1.5 dB

(nominal)

Coupled Arm Loss: ~ 10 dB (nominal)

Impedance: 50

Ω nominal

Connector: Type-N (m)

Recommended

HP/Agilent Model

11667A P,A

11667B

87300B

909A P,T

Use

a

Termination, 50

Termination, 75

Ω Impedance: 50 Ω (nominal) Connector:

Ω

(Option 1DQ, 1DP)

50 MHz Low Pass

Filter

300 MHz Low Pass

Filter

1 GHz Low Pass

Filter

BNC (m)

Impedance: 75

Ω (nominal) (2 required

for Option 1DQ) (1 required for

Option 1DP)

Cutoff Frequency: 50 MHz

Rejection at 65 MHz:

Rejection at 75 MHz:

>40 MHz

>60 dB

Cutoff Frequency: 300 MHz

Rejection at >435 MHz:

>45 dB

Cutoff Frequency: 1 GHz

Rejection at >2 GHz:

>60 dB

11593A P,A

909E

P, T

Option 201

0955-0306 P

0955-0455 P

0955-0487 P

Chapter 1 29

Page 30

Calibrating

Before You Start

Table 1-10 Recommended Accessories

Equipment

1.8 GHz Low Pass

Filter (for

Critical Specifications for Accessory

Substitution

Cutoff Frequency: 1.8 GHz

Rejection at >3 GHz:

>45 dB

E4404/5/7/8B)

4.4 GHz Low Pass

Filter (for

Cutoff Frequency: 4.4 GHz

Rejection at >5.5 GHz: >42 dB

E4404/5/7/8B)

a. P = Performance Test, A = Adjustment, T = Troubleshooting

Recommended

HP/Agilent Model

0955-0491

(2 required)

9135-0005 or

360D

(2 required)

Use

P

P

a

30 Chapter 1

Page 31

Calibrating

Table 1-11 Recommended Adapters

Before You Start

Recommended

Critical Specifications for Adapter Substitution

HP/Agilent

Use

Model

BNC (m) to BNC (m) 1250-0216 P,T

BNC tee (f,m,f) 1250-0781 A,T

Type-N (f) to APC 3.5 (f) 1250-1745 P,A,T

Type-N (f) to BNC (m) 1250-1477 P,T

Type-N (f) to BNC (m), 75

Ω (2 required for Option 1DQ)

1250-1534 P,A,T

(1 required for Option 1DP)

Type-N (m) to BNC (f) (4 required) 1250-1476 P,A,T

Type-N (m) to BNC (m) (2 required) 1250-1473 P,T

Type-N (m) to BNC (m), 75

Ω (Option 1DP) 1250-1533 P,A,T

Type-N (m) to Type-N (m) 1250-1472 P,T

Type-N (m) to Type-N (m) 1250-1475 P,A,T

Type-N (f) to Type-N (f), 75

Type-N (f), 75

Ω, to Type-N (m), 50 Ω (Option 1DP) 1250-0597 P,A,T

Ω (Option 1DP) 1250-1529 P,A,T

a

Type-N (m) to SMA (m) 1250-1636 P

50 to 75

Ω Minimum Loss

11852B P,A,T

Frequency Range: dc to 1.5 GHz

Insertion Loss: 5.7 dB, nominal (Option 1DP)

Type N(f) to Type N(f) 1250-0777

Type N(f) to BNC(f), 75 ohm (Option 1DP only) 1250-1535

Type N (m) to APC 3.5 (f) (3 required) 1250-1744

APC 3.5 (f) to APC 3.5 (f) 1250-1749

Dual Banana to BNC (f) 1251-2277 P,A,T

Type N (m) to BNC (f) (2 required) 1250-0780

a. P = Performance Test, A = Adjustment, T = Troubleshooting

Chapter 1 31

Page 32

Calibrating

Before You Start

Table 1-12 Recommended Cables

Recommended

Critical Specifications for Cable Substitution

HP/Agilent

Use

Model

Frequency Range: dc to 1 GHz

Length:

≥122 cm (48 in)

10503A P,A,T

Connectors: BNC (m) both ends (4 required)

Type-N, 62 cm (24 in) 11500C P,T

Type-N, 152 cm (60 in) (2 required) 11500D P,A,T

Frequency Range: dc to 310 MHz

10502A P,T

Length: 23 cm (9 in)

Connectors: BNC (m) both ends

BNC, 75

Cable, Test

Length:

Ω, 30 cm (12 in) (Option 1DP) 5062-6452 P,A,T

85680-60093 T

≥91 cm (36 in)

Connectors: SMB (f) to BNC (m) (2 required)

APC 3.5 Cable

8120-4921 P,A,T

Frequency: 9 kHz to 26.5 GHz

Connectors: APC 3.5 (m)

Length: >92 cm (36 in) (2 required)

a

a. P = Performance Test, A = Adjustment, T = Troubleshooting

32 Chapter 1

Page 33

2 Performance Verification Tests

These tests verify the electrical performance of the analyzer. Allow the

analyzer to warm up in accordance with the temperature stability

specifications before performing the tests.

33

Page 34

Performance Verification Tests

Tests included in this section:

Tests included in this section:

1. 10 MHz Reference Output Accuracy

2. 10 MHz High-Stability Frequency Reference Output Accuracy:

Agilent E4401B, E4402B, E4404B, E4405B, and E4407B (Option

1D5)

3. Frequency Readout and Marker Frequency Count Accuracy:

Agilent E4401B, E4402B, E4403B, and E4411B

4. Frequency Readout and Marker Frequency Count Accuracy:

Agilent E4404B, E4405B, E4407B, and E4408B

5. Frequency Span Accuracy: Agilent E4401B and E4411B

6. Frequency Span Accuracy: Agilent E4402B, E4403B, E4404B,

E4405B, E4407B, and E4408B

7. Noise Sidebands

8. Noise Sidebands - Wide Offsets: Agilent E4402B, E4404B, E4405B

and E4407B

9. System-Related Sidebands

10. Residual FM

11. Sweep Time Accuracy

12. Display Scale Fidelity

13. Input Attenuation Switching Uncertainty

14. Reference Level Accuracy: Agilent E4401B and E4411B

15. Reference Level Accuracy: Agilent E4402B, E4403B, E4404B,

E4405B, E4407B, and E4408B.

16. Resolution Bandwidth Switching Uncertainty

17. Absolute Amplitude Accuracy (Reference Settings): Agilent

E4401B and E4411B

18. Absolute Amplitude Accuracy (Reference Settings): Agilent

E4402B, E4403B, E4404B, E4405B, E4407B, and E4408B

19. Overall Absolute Amplitude Accuracy: Agilent E4401B and

E4411B

20. Overall Absolute Amplitude Accuracy: Agilent E4402B, E4403B,

E4404B, E4405B, E4407B, and E4408B

21. Resolution Bandwidth Accuracy

22. Frequency Response: Agilent E4401B and E4411B

34 Chapter 2

Page 35

Performance Verification Tests

Tests included in this section:

23. Frequency Response, Agilent E4402B and E4403B

24. Frequency Response, Agilent E4404B, E4405B, E4407B, and

E4408B

25. Frequency Response (Preamp On): Agilent E4401B

26. Frequency Response (Preamp On): Agilent E4402B

27. Frequency Response (Preamp On): Agilent E4404B, E4405B, and

E4407B

28. Other Input-Related Spurious Responses: Agilent E4401B and

E4411B

29. Other Input-Related Spurious Responses: Agilent E4402B,

E4403B, E4404B, E4405B, E4407B, and E4408B

30. Spurious Responses: Agilent E4401B and E4411B

31. Spurious Responses: Agilent E4402B and E4403B

32. Spurious Responses: Agilent E4404B, E4405B, E4407B, and

E4408B

33. Gain Compression: Agilent E4401B, E4402B, E4403B, and

E4411B

34. Gain Compression: Agilent E4404B, E4405B, E4407B, and

E4408B

35. Displayed Average Noise Level: Agilent E4401B and E4411B

36. Displayed Average Noise Level: Agilent E4402B and E4403B

37. Displayed Average Noise Level: Agilent E4404B and E4405B

38. Displayed Average Noise Level: Agilent E4407B and E4408B

39. Residual Responses

40. Fast Time Domain Amplitude Accuracy: Agilent E4401B,

E4402B, E4404B, E4405B, and E4407B (Option AYX)

41. Tracking Generator Absolute Amplitude and Vernier Accuracy:

Agilent E4401B and E4411B (Option 1DN or 1DQ)

42. Tracking Generator Absolute Amplitude and Vernier Accuracy:

Agilent E4402B, E4403B, E4404B, E4405B, E4407B, and E4408B

(Option 1DN)

43. Tracking Generator Level Flatness: Agilent E4401B and E4411B

(Option 1DN or 1DQ)

44. Tracking Generator Level Flatness: Agilent E4402B, E4403B,

E4404B, E4405B, E4407B, and E4408B (Option 1DN)

45. Tracking Generator Harmonic Spurious Outputs: Agilent

E4401B and E4411B (Option 1DN or 1DQ)

Chapter 2 35

Page 36

Performance Verification Tests

Tests included in this section:

46. Tracking Generator Harmonic Spurious Outputs:

Agilent E4402B, E4403B, E4404B, E4405B, E4407B, and E4408B

(Option 1DN)

47. Tracking Generator Non-Harmonic Spurious Outputs:

Agilent E4401B and E4411B (Option 1DN or 1DQ)

48. Tracking Generator Non-Harmonic Spurious Outputs:

Agilent E4402B, E4403B, E4404B, E4405B, E4407B, and E4408B

(Option 1DN)

49. Tracking Generator LO Feedthrough: Agilent E4402B, E4403B,

E4404B, E4405B, E4407B, and E4408B(Option 1DN)

50. Gate Delay Accuracy and Gate Length Accuracy:

Agilent E4401B, E4402B, E4404B, E4405B, and E4407B (Option

1D6)

51. Gate Mode Additional Amplitude Error: Agilent E4401B,

E4402B, E4404B, E4405B, and E4407B (Option 1D6)

52. First LO OUTPUT Power Accuracy (Option AYZ only)

53. IF INPUT Accuracy (Option AYZ only)

54. Comms Frequency Response (Option BAC or BAH)

55. This Test Has Been Deleted (Modulation Accuracy

− Rho)

56. This Test Has Been Deleted (CDMA Modulation Accuracy

EVM)

57. This Test Has Been Deleted (CDMA Code Domain Power)

58. GSM Phase and Frequency Error (Options BAH and B7E)

59. Comms Absolute Power Accuracy (Options BAC or BAH)

−

36 Chapter 2

Page 37

Performance Verification Tests

Tests included in this section:

Calibration

To perform calibration:

1. Run all performance verification tests listed in Column 1 of Table 2-1

that are applicable to the analyzer being calibrated and the installed

options. Refer to the Performance Verification test tables in

Chapter 1 for a list of the tests that are applicable to the analyzer

being calibrated.

2. If any of the performance verification tests fail, perform the

appropriate calibration adjustments listed in Column 2 of Table 2-1

which corresponds to the failure.

3. Repeat all of the performance verification tests listed in Column 1 of

Table 2-1 if any calibration adjustments were made in step 2. This

will confirm that there is no interaction between adjustments which

could negatively impact analyzer performance.

Table 2-1 lists the performance verification tests and adjustments

needed for calibration. The performance tests are located in the

following pages of this chapter. Adjustment information is located in the

service guide.

Chapter 2 37

Page 38

Performance Verification Tests

Tests included in this section:

Table 2-1 Calibration Requirements

Tes t

1. 10 MHz Reference Output

2. 10 MHz High-Stability Frequency

3. Frequency Readout and Marker

4. Frequency Readout and Marker

5. Frequency Span Accuracy None

6. Frequency Span Accuracy None

7. Noise Sidebands None

8. Noise Sidebands - Wide Offsets None

9. System-Related Sidebands IF Amplitude

10. Residual FM None

11. Sweep Time Accuracy None

Performance Verification Tests Calibration Adjustments

#

10 MHz Frequency Reference

Accuracy

Reference Output Accuracy

Frequency Count Accuracy

Frequency Count Accuracy

Adjustment

10 MHz Frequency Reference

Adjustment

None

None

12. Display Scale Fidelity IF Amplitude

13. Input Attenuation Switching

Uncertainty

14. Reference Level Accuracy IF Amplitude

15. Reference Level Accuracy IF Amplitude

16. Resolution Bandwidth Switching

Uncertainty

17. Absolute Amplitude Accuracy

(Reference Settings)

18. Absolute Amplitude Accuracy

(Reference Settings)

19. Overall Absolute Amplitude

Accuracy

20. Overall Absolute Amplitude

Accuracy

21. Resolution Bandwidth Accuracy IF Amplitude

22. Frequency Response Frequency Response

50 MHz Amplitude Reference

IF Amplitude

None

None

Frequency Response Adjustment

None

23. Frequency Response Frequency Response

38 Chapter 2

Page 39

Table 2-1 Calibration Requirements

Performance Verification Tests

Tests included in this section:

Tes t

24. Frequency Response Frequency Response

25. Frequency Response (Preamp On) Frequency Response

26. Frequency Response (Preamp On) Frequency Response

27. Frequency Response (Preamp On) Frequency Response

28. Other Input-Related Spurious

29. Other Input-Related Spurious

30. Spurious Responses None

31. Spurious Responses None

32. Spurious Responses None

33. Gain Compression None

34. Gain Compression None

35. Displayed Average Noise Level Frequency Response

Performance Verification Tests Calibration Adjustments

#

None

Responses

None

Responses

36. Displayed Average Noise Level Frequency Response

37. Displayed Average Noise Level Frequency Response

38. Displayed Average Noise Level Frequency Response

39. Residual Responses None

40. Fast Time Domain Amplitude

Accuracy

41. Tracking Generator Absolute

Amplitude and Vernier Accuracy

42. Tracking Generator Absolute

Amplitude and Vernier Accuracy

43. Tracking Generator Level Flatness Tracking Generator ALC and

44. Tracking Generator Level Flatness Tracking Generator ALC and

45. Tracking Generator Harmonic

Spurious Outputs

46. Tracking Generator Harmonic

Spurious Outputs

None

Tracking Generator ALC and

Tracking Generator Frequency Slope

Tracking Generator ALC and

Tracking Generator Frequency Slope

Tracking Generator Frequency Slope

Tracking Generator Frequency Slope

None

None

Chapter 2 39

Page 40

Performance Verification Tests

Tests included in this section:

Table 2-1 Calibration Requirements

Tes t

47. Tracking Generator Non-Harmonic

48. Tracking Generator Non-Harmonic

49. Tracking Generator L.O.

50. Gate Delay Accuracy and Gate

51. Gate Mode Additional Amplitude

52. First LO OUTPUT Power Accuracy LO Power

53. IF INPUT Accuracy IF INPUT Correction

54. Comms Frequency Response Frequency Response Error Correction

55. Deleted None

56. Deleted None

Performance Verification Tests Calibration Adjustments

#

None

Spurious Outputs

None

Spurious Outputs

LO Power

Feedthrough

None

Length Accuracy

None

Error

57. Deleted None

58. GSM Phase and Frequency Error None

59. Comms Absolute Power Accuracy IF Amplitude Adjustment

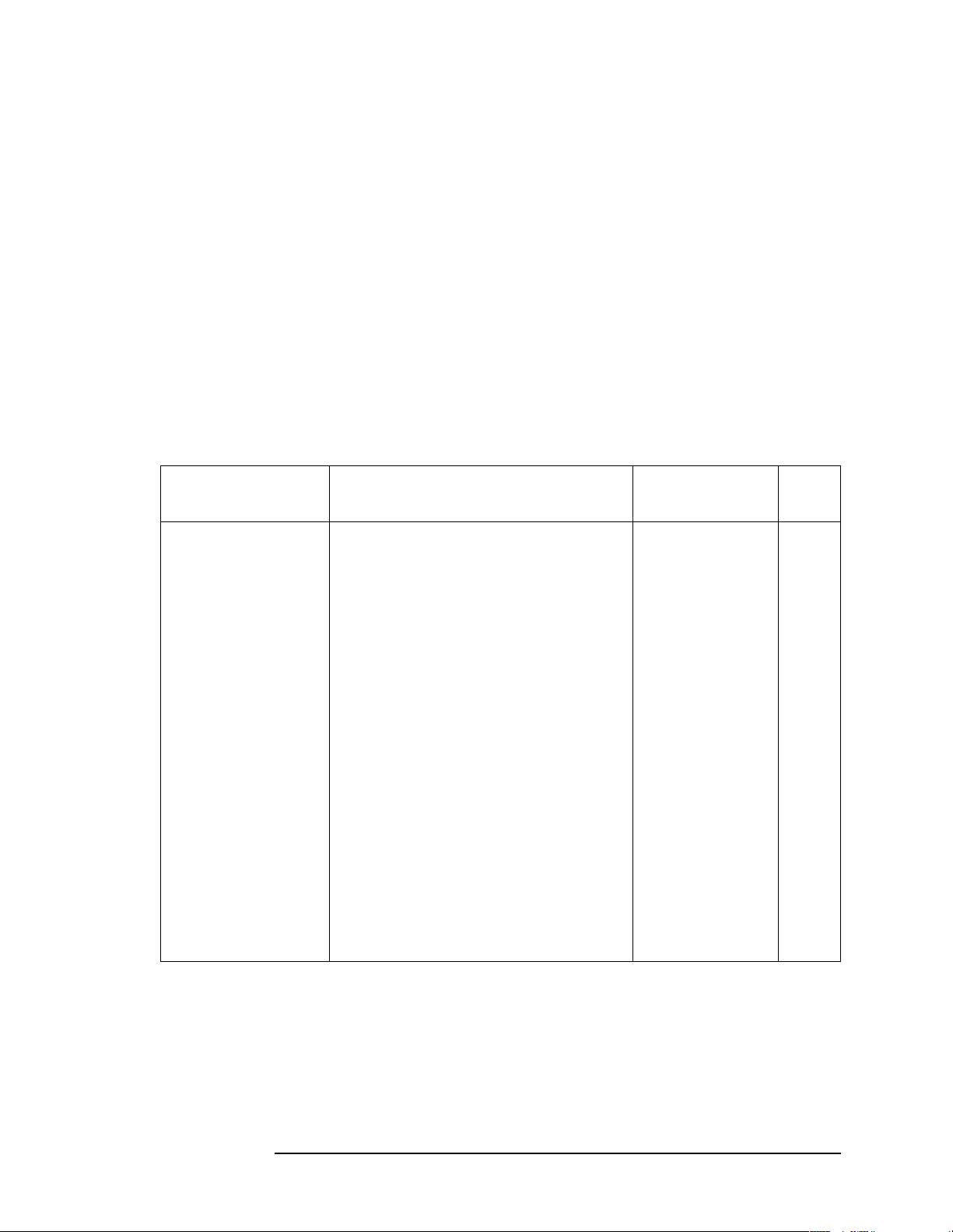

Manual use of Agilent 8494G and Agilent 8496G Attenuators

with the Agilent 11713A

When using the programmable versions of the 1 dB and 10 dB step

attenuator (Agilent 8494G and Agilent 8496G), the Agilent 11713A

Attenuator/ Switch Driver must be used to control the attenuators. The

Agilent 8494G 1 dB step attenuator should be connected as Attenuator

X and the Agilent 8496G 10 dB step attenuator should be connected as

Attenuator Y.

Use Table 2-2 to determine which of the Attenuator X and Attenuator Y

settings are use to set the step attenuators to the desired value. In the

columns labeled Attenuator X and Attenuator Y, a “1” indicates that

section is on (the LED in the button will be lit), while a “0” indicates

that section is off. For example, if the 1 dB step attenuator should be set

to 2 dB and the 10 dB step attenuator should be set to 60 dB, sections 2,

6, and 7 should be on (lit) and all other sections should be off.

40 Chapter 2

Page 41

Performance Verification Tests

Tests included in this section:

Table 2-2 Agilent 11713A Settings for Agilent 8494G and Agilent 8496G

1 dB

Step

Atten

(dB)

0 0000 0 0000

1 1000 10 1000

2 0100 20 0100

3 1100 30 1100

4 0010 40 0010

5 1010 50 1010

6 0110 60 0110

7 1110 70 1110

8 0011 80 0011

9 1011 90 1011

10 0111 100 0111

11 1111 110 1111

Attenuator X 10 dB

Step

1234 5678

Atten

(dB)

Attenuator Y

Chapter 2 41

Page 42

Performance Verification Tests

1. 10 MHz Reference Output Accuracy

1. 10 MHz Reference Output Accuracy

The setability is measured by changing the settings of the

digital-to-analog converter (DAC), which controls the frequency of the

timebase. The difference in frequency for each DAC step is calculated

and compared to the specification.

The related adjustment for this performance verification test is the

“10 MHz Reference Frequency Adjustment.”

Equipment Required

Universal counter (Instructions are for Agilent 53132A. For Agilent

5316B, refer to its user documentation.)

Frequency standard

Cable, BNC, 122-cm (48-in) (2 required)

Figure 2-1 10 MHz Reference Test Setup

Procedure

1. Connect the equipment as shown in Figure 2-1. The frequency

standard provides the reference for the universal counter.

2. Check that the analyzer is not in external reference mode. If

Ext Ref appears on the screen, the analyzer is in external reference

mode. If the analyzer is in external reference mode, disconnect the

external reference.

3. Ensure that the analyzer has been on and in internal frequency mode

for at least five minutes before proceeding.

4. Set the universal counter controls as follows:

a. Press

b. Press any one of the arrow keys until TIME is displayed.

c. Press

42 Chapter 2

Gate & ExtArm.

Gate & ExtArm again. Using the arrow keys, set the time to

Page 43

10 s.

Performance Verification Tests

1. 10 MHz Reference Output Accuracy

d. Press

e. On Channel 1, press

f. On Channel 1, press

g. On Channel 1, press

Enter.

50 Ω/1 MΩ until the LED is lit.

x10 Attenuator until the LEd is extinguished.

AC/DC until the LED next to DC is

extinguished.

h. On Channel 1, press

i. On Channel 1, press

100 kHz Filter until the LED is extinguished.

Trigger/Sensitivity until Auto Trig is

displayed.

j. Use the arrow keys to toggle to off.

k. Press

Freq & Ratio.

5. Wait for the universal counter reading to stabilize. Record the

universal counter reading in Table 2-3 as Counter Reading 1 with

0.1 Hz resolution.

6. Set the analyzer by pressing the following keys:

System, Alignments, Timebase, Fine

7. Record the number in the active function block of the analyzer in

Table 2-3 as Timebase Fine.

8. Press the

↑ (up arrow) key on the analyzer.

9. Wait for the frequency counter reading to stabilize. Record the

frequency counter reading in Table 2-3 as Counter Reading 2 with

0.1 Hz resolution.

10.Press the

↓ (down arrow) key on the analyzer 2 times.

11.Wait for the frequency counter reading to stabilize. Record the

frequency counter reading in Table 2-3 as Counter Reading 3 with

0.1 Hz resolution.

12.Press

initial values. Press the

Preset on the analyzer to return the DAC settings to their

Factory Preset softkey, if it is displayed.

13.Subtract Counter Reading 1 from Counter Reading 2 and record the

difference in Table 2-3 as the Positive Frequency Change.

Positive Frequency Change Counter Reading 2 Counter Reading 1–=

14.Subtract Counter Reading 3 from Counter Reading 1 and record the

difference in Table 2-3 as the Positive Frequency Change.

Negative Frequency Change Counter Reading 1 Counter Reading 3–=

15.Of the Positive Frequency Change and negative frequency change

values recorded in Table 2-3, record the largest value in Table 2-3 as

Chapter 2 43

Page 44

Performance Verification Tests

1. 10 MHz Reference Output Accuracy

the maximum frequency change.

16.Divide the maximum frequency change by two and record the result

as the settability.

Table 2-3 10 MHz Reference Accuracy Worksheet

Description Measurement

Counter Reading 1 ___________ Hz

Timebase Fine DAC ___________ Hz

Counter Reading 2 ___________ Hz

Counter Reading 3 ___________ Hz

Positive Frequency Change ___________ Hz

Negative Frequency Change ___________ Hz

Maximum Frequency Change ___________ Hz

Settability ___________ Hz

44 Chapter 2

Page 45

Performance Verification Tests

2. 10 MHz High-Stability Frequency Reference Output Accuracy: Agilent E4401B, E4402B,

E4404B, E4405B, and E4407B (Option 1D5)

2. 10 MHz High-Stability Frequency Reference

Output Accuracy: Agilent E4401B, E4402B,

E4404B, E4405B, and E4407B (Option 1D5)

This test applies only to analyzers equipped with the high-stability

frequency reference, Option 1D5. If your analyzer does not have Option

1D5, perform the “10 MHz Reference Output Accuracy” test instead.

This test measures the warmup characteristics of the 10 MHz reference

oscillator. The ability of the 10 MHz oscillator to meet its warmup

characteristics gives a high level of confidence that it will also meet its

yearly aging specification.

The universal counter is connected to the 10 MHz REF OUT. After the

analyzer has been allowed to cool for at least 60 minutes, the analyzer

is powered on. A frequency measurement is made five minutes after

power is applied and the frequency is recorded. Another frequency

measurement is made 10 minutes later (15 minutes after power is

applied) and the frequency is recorded. A final frequency measurement

is made 60 minutes after power is applied. The difference between each

of the first two frequency measurements and the last frequency

measurement is calculated and recorded.

The related adjustment for this performance verification test is the

“10 MHz Reference Frequency Adjustment.”

Equipment Required

❏ Universal counter (Instructions are for Agilent 53132A. For Agilent

5316B, refer to its user documentation.)

❏ Frequency standard

❏ Cable, BNC, 122-cm (48-in) (2 required)

Figure 2-2 Frequency Reference Test Setup

Chapter 2 45

Page 46

Performance Verification Tests

2. 10 MHz High-Stability Frequency Reference Output Accuracy: Agilent E4401B, E4402B,

E4404B, E4405B, and E4407B (Option 1D5)

Procedure

The analyzer must have been allowed to sit with the power off for at

least 60 minutes before performing this procedure. This adequately

simulates a cold start.

1. Allow the analyzer to sit with the power off for at least 60 minutes

before proceeding.

2. Switch the power to the analyzer on. Record the Power On Time

below.

Power On Time___________

3. Connect the equipment as shown in Figure 2-2. The frequency

standard provides the reference for the universal counter.

Disconnect any cable to the 10 MHz REF INPUT of the analyzer.

4. Check that the analyzer is not in external reference mode. Ext Ref

will appear on the display if the analyzer is in external reference

mode. If the analyzer is in external reference mode, disconnect the

external reference.

5. Set the universal counter controls as follows:

a. Press

Gate & ExtArm.

b. Press any one of the arrow keys until TIME is displayed.

c. Press

Gate & ExtArm again. Using the arrow keys, set the TIME to

10s.

d. Press

Enter

e. On Channel 1, press 50 Ω/1 MΩ to light the LED next to 50 Ω.

f. On Channel 1, press

g. On Channel 1, press

AC/DC to extinguish the LED next to DC.

x10 Attenuator to extinguish the LED next to

x10 Attenuator.

h. On Channel 1, press

100 kHz Filter to extinguish the LED next to

100 kHz Filter.

i. On Channel 1, press

Trigger/Sensitivity until Auto Trig is

displayed.

j. Use the arrows keys to toggle to off.

k. Press

Freq & Ratio

6. Continue with the next step 5 minutes after the Power On Time

noted in step 2.

7. Wait for the universal counter reading to make at least two readings.

Record the universal counter reading in Table 2-3 as Counter

Reading 1 with 0.001 Hz resolution.

46 Chapter 2

Page 47

Performance Verification Tests

2. 10 MHz High-Stability Frequency Reference Output Accuracy: Agilent E4401B, E4402B,

E4404B, E4405B, and E4407B (Option 1D5)

8. Continue with next step 15 minutes after the Power On Time noted

in step 2.

9. Wait for the universal counter reading to make at least two readings.

Record the universal counter reading in Table 2-3 as Counter

Reading 2 with 0.001 Hz resolution.

10.Continue with next step 60 minutes after the Power On Time noted

in step 2.

11.Wait for the universal counter reading to make at least two readings.

Record the universal counter reading in Table 2-3 as Counter

Reading 3 with 0.001 Hz resolution.

12.Calculate the 5 Minute Warm-up Error (in ppm) by subtracting

Counter Reading 3 from Counter Reading 1 and dividing the result

by 10.

5 Minute Warm-up Error Counter Reading 1 Counter Reading 3–()10⁄=

NOTE Dividing the frequency by 10 is equivalent to dividing the difference

first by 10 MHz (to normalize the difference to the reference frequency)

and then multiplying by 1 x 106 to convert the result to

parts-per-million (ppm).

13.Record the 5 Minute Warm-up Error (in ppm) in the performance

verification test record as Test Record entry 1.

14.Calculate the 15 Minute Warm-up Error (in ppm) by subtracting

Counter Reading 3 from Counter Reading 2 and dividing the result

by 10.

15 Minute Warm-up Error Counter Reading 2 Counter Reading 3–()10⁄=

15.Record the 15 Minute Warm-up Error in the performance

verification test record as Test Record entry 2.

Table 2-4 10 MHz Reference Accuracy Worksheet

Description Measurement

Counter Reading 1 ___________ Hz

Counter Reading 2 ___________ Hz

Counter Reading 3 ___________ Hz

Chapter 2 47

Page 48

Performance Verification Tests

3. Frequency Readout and Marker Frequency Count Accuracy: Agilent E4401B, E4402B, E4403B, and E4411B

3. Frequency Readout and Marker Frequency

Count Accuracy: Agilent E4401B, E4402B,

E4403B, and E4411B

The frequency readout accuracy of the analyzer is tested with an input

signal of known frequency. By using the same frequency standard for

the analyzer and the synthesized sweeper, the frequency reference error

is eliminated.

There are no related adjustment procedures for this performance test.

Equipment Required

Synthesized sweeper

Adapter, Type N (f) to APC 3.5 (m)

Cable, Type N, 183 cm (72 in)

Cable, BNC, 122 cm (48 in)

Additional Equipment for 75 Ω Input

Pad, minimum loss

Adapter, Type N (f) to BNC (m), 75

Ω

Procedure

Figure 2-3 Frequency Readout and Marker Frequency Accuracy Test

Setup

This performance test consists of two parts:

“Part 1: Frequency Readout Accuracy”

48 Chapter 2

Page 49

Performance Verification Tests

3. Frequency Readout and Marker Frequency Count Accuracy: Agilent E4401B, E4402B,

E4403B, and E4411B

“Part 2: Marker Count Accuracy”

Perform “Part 1: Frequency Readout Accuracy” before “Part 2: Marker

Count Accuracy”.

Part 1: Frequency Readout Accuracy

1. Connect the equipment as shown in Figure 2-3. Remember to

connect the 10 MHz REF OUT of the analyzer to the 10 MHz REF

INPUT of the synthesized sweeper.

CAUTION Use only 75 Ω cables, connectors, or adapters on instruments with 75 Ω

inputs, or the input connector will be damaged.

2. Perform the following steps to set up the equipment:

a. Press

INSTRUMENT PRESET on the synthesized sweeper, then set

the controls as follows:

CW, 1.490 GHz (Agilent E4401B and E4411B)

CW, 1.5 GHz (Agilent E4402B and E4403B)

POWER LEVEL, –10 dBm

b. Press Preset on the analyzer. Press the Factory Preset softkey, if it

is displayed. Set the analyzer by pressing the following keys:

FREQUENCY, 1.5 GHz

SPAN, 20

MHz

3. Press Peak Search (or Search) on the analyzer to measure the

frequency readout accuracy.

4. Record the marker frequency reading in the performance verification

test record.

5. Repeat step 3 and step 4 above for the remaining spans listed in

Table 2-5.

Table 2-5 Frequency Readout Accuracy

Analyzer Span

(MHz)

Test Record Entry,

Actual

Marker Frequency

20 1)

10 2)

1 3)

Part 2: Marker Count Accuracy

Perform "Part 1: Frequency Readout Accuracy" before performing this

procedure.

1. Press

Chapter 2 49

Preset on the analyzer. Press the Factory Preset softkey, if it is

Page 50

Performance Verification Tests

3. Frequency Readout and Marker Frequency Count Accuracy: Agilent E4401B, E4402B,

E4403B, and E4411B

displayed. Set the analyzer to measure the marker count accuracy by

pressing the following keys:

FREQUENCY, 1.490 GHz (Agilent E4401B and E4411B)

FREQUENCY, 1.5 GHz (Agilent E4402B and E4403B)

SPAN, 10 MHz

BW/Avg

Freq Count, Marker Count (On)

Resolution (Man), 1 Hz

, Res BW, 100 kHz (Man)

2. Press Peak Search (or Search), then wait for a count be taken (it may

take several seconds).

3. Record the counter (Cntr1) frequency reading as Test Record entry 4

of the performance verification test record.

4. On the analyzer, press

5. Press

Peak Search (or Search), then wait for a count be taken (it may

SPAN, 1 MHz.

take several seconds).

6. Record the counter (Cntr1) frequency reading as Test Record entry 5

of the performance verification test record.

50 Chapter 2

Page 51

Performance Verification Tests

4. Frequency Readout and Marker Frequency Count Accuracy: Agilent E4404B, E4405B, E4407B, and E4408B

4. Frequency Readout and Marker Frequency

Count Accuracy: Agilent E4404B, E4405B,

E4407B, and E4408B

The frequency readout accuracy of the analyzer is tested with an input

signal of known frequency. By using the same frequency standard for

the analyzer and the synthesized sweeper, the frequency reference error

is eliminated.

There are no related adjustment procedures for this performance test.

Equipment Required

Synthesized sweeper

Adapter, Type N (m) to APC 3.5 (f)

Adapter, APC 3.5 (f) to APC 3.5 (f)

Cable, APC 3.5, 91 cm (36 in)

Cable, BNC, 122 cm (48 in)

Additional Equipment for Option BAB

Adapter, APC 3.5 (f) to APC 3.5 (f)

Figure 2-4 Frequency Readout and Marker Count Accuracy Test Setup

Chapter 2 51

Page 52

Performance Verification Tests

4. Frequency Readout and Marker Frequency Count Accuracy: Agilent E4404B, E4405B,

E4407B, and E4408B

Procedure

This performance verification test consists of two parts:

“Part 1: Frequency Readout Accuracy”

“Part 2: Marker Count Accuracy”

Perform “Part 1: Frequency Readout Accuracy” before “Part 2: Marker

Count Accuracy.”

Part 1: Frequency Readout Accuracy

1. Connect the equipment as shown in Figure 2-4. Remember to

connect the 10 MHz REF OUT of the analyzer to the 10 MHz REF

INPUT of the synthesized sweeper.

Option BAB only: Use the APC 3.5 adapter to connect the cable to

the analyzer input.

2. Perform the following steps to set up the equipment:

a. Press

INSTRUMENT PRESET on the synthesized sweeper, then set

the controls as follows:

CW, 1.5 GHz

POWER LEVEL

, –10 dBm

b. Press Preset on the analyzer. Press the Factory Preset softkey, if it

is displayed. Set the analyzer by pressing the following keys:

FREQUENCY, 1.5 GHz

20 MHz

SPAN,

3. Press Peak Search (or Search) on the analyzer to measure the

frequency readout accuracy.

4. Record the marker (Mkr1) frequency reading in the performance

verification test record as indicated in Table 2-6.

5. Change to the next analyzer span setting listed in

Table 2-6.

6. Repeat step 3 through step 5 for each analyzer frequency and span

setting and synthesized sweeper CW frequency setting listed in

Table 2-6 for the analyzer being tested.

Table 2-6 Frequency Readout Accuracy

Synthesized

Sweeper CW

Frequency

(MHz)

1500 20 1.5 1)

52 Chapter 2

Analyzer

Span

(MHz)

Analyzer

Center

Frequency

(GHz)

Test

Record

Entry

Frequency

(GHz)

Page 53

4. Frequency Readout and Marker Frequency Count Accuracy: Agilent E4404B, E4405B,

Table 2-6 Frequency Readout Accuracy

Performance Verification Tests

E4407B, and E4408B

Synthesized

Sweeper CW

Frequency

(MHz)

1500 10 1.5 2)

1500 1 1.5 3)

4000 20 4.0 4)

4000 10 4.0 5)

4000 1 4.0 6)

9000 20 9.0 7)

9000 10 9.0 8)

9000 1 9.0 9)

16000 20 16.0 10)

Analyzer

Span

(MHz)

Stop here for Agilent E4404B.

Stop here for Agilent E4405B.

Analyzer

Center

Frequency

(GHz)

Frequency

Test

Record

Entry

(GHz)

16000 10 16.0 11)

16000 1 16.0 12)

21000 20 21.0 13)

21000 10 21.0 14)

21000 1 21.0 15)

Part 2: Marker Count Accuracy

Perform "Part 1: Frequency Readout Accuracy" before performing this

procedure.

1. Press

Preset on the analyzer. Press the Factory Preset softkey, if it is

displayed. Set the analyzer to measure the marker count accuracy by

pressing the following keys:

FREQUENCY, 1.5 GHz

, 20 MHz

SPAN

BW/Avg

Freq Count, Marker Count (On)

Resolution (Man)

2. Press

, Res BW, 100 kHz (Man)

Peak Search (or Search), then wait for a count be taken (it may

take several seconds).

3. Record the counter (Cntr1) frequency reading in the performance

Chapter 2 53

Page 54

Performance Verification Tests

4. Frequency Readout and Marker Frequency Count Accuracy: Agilent E4404B, E4405B,

E4407B, and E4408B

verification test record as indicated in Table 2-7.

4. Repeat step 2 and step 3 for each analyzer center frequency and

span setting and synthesized sweeper CW frequency setting listed in

Table 2-7 for the analyzer being tested.

Performance verification test “Frequency Readout Accuracy and

Marker Count Accuracy” is now complete.

Table 2-7 Marker Count Accuracy

Synthesized Sweeper

CW Frequency

MHz GHz MHz Test Record

1500 1.5 20 16)

1500 1.5 1 17)

4000 4.0 20 18)

4000 4.0 1 19)

9000 9.0 20 20)

9000 9.0 1 21)

16000 16.0 20 22)

16000 16.0 1 23)

21000 21.0 20 24)

Analyzer

Center

Frequency

Stop here for Agilent E4404B.

Stop here for Agilent E4405B.

Analyzer

Span

Counter

Frequency

(Cntr1)

Entry

21000 21.0 1 25)

54 Chapter 2

Page 55

Performance Verification Tests

5. Frequency Span Accuracy: Agilent E4401B and E4411B

5. Frequency Span Accuracy: Agilent E4401B

and E4411B

For testing each frequency span, two synthesized sources are used to

provide two precisely-spaced signals. The analyzer marker functions

are used to measure this frequency difference.

There are no related adjustment procedures for this performance test.

Equipment Required

Synthesized sweeper

Synthesized signal generator

Power splitter

Adapter, Type-N (m) to Type-N (m)

Adapter, Type-N (f) to APC 3.5 (f)

Cable, Type-N, 152-cm (60-in) (2 required)

Cable, BNC, 122-cm (48-in)

Additional Equipment for 75 Ω Input

Pad, minimum loss

Adapter, Type-N (f), to BNC (m), 75

Ω

Procedure

Full Span Frequency Span Readout Accuracy

1. Connect the equipment as shown in Figure 2-5. Note that the power

splitter is used as a combiner. The synthesized signal generator

provides the frequency reference for the synthesized sweeper.

2. Press

displayed.

3. Press

follows:

4. On the synthesized signal generator, set the controls as follows:

Preset on the analyzer. Press the Factory Preset softkey, if it is

PRESET on the synthesized sweeper and set the controls as

CW, 1350 MHz

POWER LEVEL

FREQUENCY, 150 MHz

AMPLITUDE

, –5 dBm

, 0 dBm

Chapter 2 55

Page 56

Performance Verification Tests

5. Frequency Span Accuracy: Agilent E4401B and E4411B

Figure 2-5 Frequency Span Readout Accuracy Test Setup

5. Adjust the analyzer center frequency, if necessary, to place the lower

frequency on the second vertical graticule line (one division from the

left-most graticule line).