Page 1

Agilent 75000 Series B

Agilent E1364A

16-Channel Form C Switch Module

Service Manual

Serial Numbers

This manual a pplies direct ly to instrum en ts w ith serial nu mbers

prefixed with 2934A a nd hi ghe r .

Copyright © Agi lent Technologi es, Inc . 1991- 2005

*E1364-90012*

E1364-90012

E1105

Manual Part Number : Ε1364−90012 Printed November, 2005, Edition 3

Printed in U.S.A.

Page 2

Page 3

Contents

Agilent E1364A Switch Module Service Manual

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reader Comment Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

WARNINGS and CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inspection/Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Shipping Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 2. Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Test Conditions and Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Verification Test Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operation Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Switch Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Measurement Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Test Accuracy Ratio (TAR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 3. Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Replaceable Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Agilent E1364A Switch Module Service Manual Contents 3

Page 4

Chapter 4. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Service Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Troubleshoot in g Te c hniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Identifying the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Testing the Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Repair and Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Soldering Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Post-Repair Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Appendix A. Verification Tests - C Programs . . . . . . . . . . . . . . . . . . . . . . . . . 47

Functional Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Performance Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Example: Closed Channel Resistance Test . . . . . . . . . . . . . . . . . . . . . . 48

Example: DC Isolation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Appendix B. Backdating Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4 Contents Agilent E1364A Switch Module Service Manual

Page 5

Certification

Agilent Technologies, Inc. certifies that this product met its published specifications at the time of shipment from the factory. Agilent

Technologies further certifies that its calibration measurements are traceable to the United States National Institute of Standards and

Technol ogy ( for m er l y N at i onal Bureau of Sta ndards), to the extent allow ed by that organization’ s c al i bration faci l ity, and to the cali br ation facilities of other International Standards Organization members.

Warranty

This Agile nt Technolog ie s pr oduct is warra nted against defects in materials an d w ork m anship for a period of one year from da t e of

shipment. Du ra ti on and conditi ons of warranty fo r t hi s pr oduct may be superseded when the produ ct is in te gr at ed into (becomes a part

of) other Agil ent products. Du ring t h e wa rr anty period, Ag ilent Technol ogies will, at its option, ei ther repair or replace produ cts which

prove to be def ec t ive.

For warrant y service or rep ai r, this product mu st be returned to a service fa ci l it y de si gnated by A gi le nt Technolo gi es. Buyer shall prepay shippin g charges to Agil ent and Agilent shall pay shi ppi ng charges to re tu rn t he product to Buyer. However, B uyer shall pay all

shipping ch arges, dutie s, and taxes for products return ed t o A g i l ent fr om another cou nt ry.

Agilent warrants that its software and firmware designated by Agilent for use with a product will execute its programming instructions

when proper l y in st al led on that product. Agile nt does not warra nt th at the operatio n of t he product, or s oftw are, or firmware will be uninterru pt ed or er ro r free.

Limitation Of Warranty

The foregoi ng w ar ra nt y shall not appl y t o defects resulting from improper or inade quate maintenance by B uyer, Buyer-sup pl ie d pr oducts or interfa ci ng, unautho rized modific at i on or m is use, operation outside of t he e nvi ronmental specificati ons for the produc t, or improper site pr eparation or ma i ntenance.

The design and implem entation of a ny ci r cui t on t h i s pr oduc t is the sole res ponsibility of th e B uyer. Agilent does not warrant the

Buyer’s circuitry or malfunctions of Agilent produc ts th at re sul t fr om th e B uyer’s circuitry. In addition, A gi l ent does not warrant any

damage th at occurs as a result of the Buye r’ s ci rcuit or any de fe ct s t hat result from B uyer-suppli ed p rod uct s.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES. AGILENT TECHNOLOGIES

SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Notice

The inform at i on contained i n th is doc ument is subj ect to change w i t hout notice. AGI L EN T TECHNOLOGIES MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Agilent shall not be liable for errors

containe d herein or for incidental or c onsequential damages in connection w ith the furnishing, perfor m ance or use of this material.

This document contai ns proprieta ry informatio n w hi ch i s pr ot ected by copy right. All rights are re served. No par t of th is document

may be photocopied, reproduced, or translated to another language without the prior written consent of Agilent Technologies, Inc.

Agilent assumes no responsibility for the use or reliability of its software on equipment that is not furnished by Agilent.

U.S. Government Restricted Rights

The Softwa re and Document ation have bee n developed entirely at pr ivate expe nse . T hey are delive red and licensed as "commercial

computer software" as def in ed i n D FA R S 252.227-7013 (Oct 1988), DFAR S 252.211-7015 (M ay 1991) or DFA RS 252. 227-7014

(Jun 1995), as a " co mmercial i te m " as de fi ned in FAR 2.101( a) , or as "Restricted computer so ftw ar e" as defined in FAR 52.227-19 (J u n

1987) (or any equivalent agency regulation or contract clause), whichever is applicable. You have only those rights provided for such S oftware and Docume ntation by the applicable FAR or DFARS clause or the Agilent standard software agreem ent for t he product involved.

E1364A 16-Channel Form C Sw i tc h Se rvi c e Manual

Copyright © 1991-2005 Agi l ent T echnologies, Inc. All Righ ts R es erved.

Edition 3

Page 6

Documentation History

All Editions and Updates of this manual and their creation date are listed below. The first Edition of the manual is Edition 1. The Edition numbe r increments b y 1 w henever the ma nual is revised. Updates , whi ch are issued between E di t ions, contai n r epl acement pages

to correct or add additional information to the current Edition of the manual. Whenever a new Edition is created, it will contain all of

the Update i nformatio n for th e pr evi ous Edition. Each new Ed it i on or U pdate also inc l udes a revised copy of this doc um entation hi story page.

Edition 1 (P ar t Num ber E1364 -90 010). . . . . . . . . . . . . . . . . . . . November 1991

Edition 2 (P ar t Num ber E1364-90011). . . . . . . . . . . . . . . . . . . . . . . . April 1996

Edition 3 (P ar t Num ber E1364 -90 012). . . . . . . . . . . . . . . . . . . . November 2005

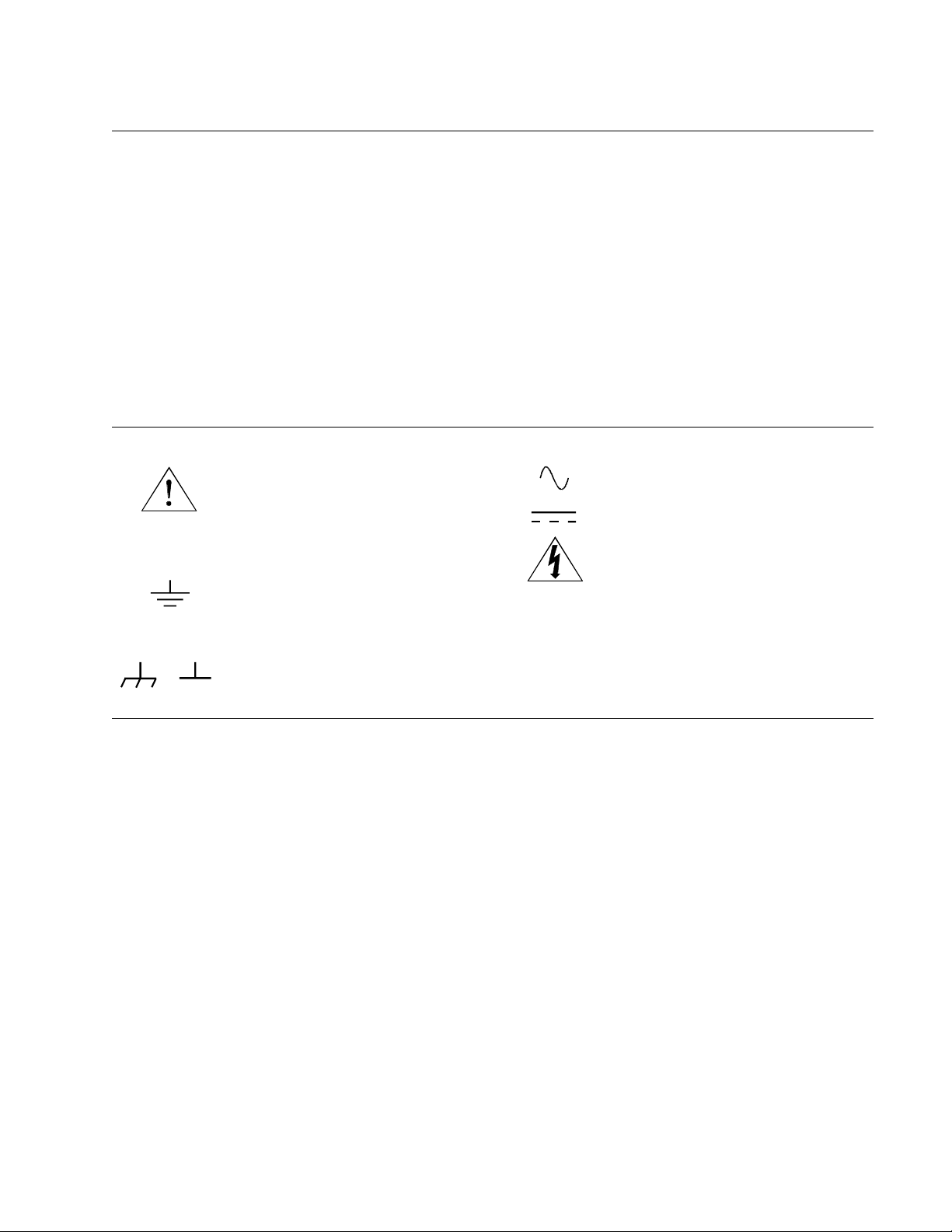

Safety Symbols

Instructi on m anual sym bol af fi xed to product. Indicates that the user must refer to the

manual for specific WARNING or CAUTION information to avoid personal injury

or damage t o t he pr oduct.

Alternating current (AC).

Direct current (DC).

Indicates the field wiring terminal that must

be connec t ed t o earth ground bef ore operating the equipm ent—protects against electrical shock in case of fault.

or

Frame or chassis ground t er m i n al —typically connects to the equipment’s metal

frame.

WARNING

CAUTION

Indicate s ha zardous vol ta ge s.

Calls at te nt i on t o a procedure, practice, or

condition that could cause bodily i njury or

death.

Calls at te nt i on t o a procedure, practice, or c ondition that could possibl y cause dam age to

equipme nt or pe rm anent loss of dat a.

WARNINGS

The following general safety pr ec aut io ns m us t be obse rved during all phases of operation, service, an d re pai r of this p rod uct .

Failure to com p l y w i th t hese precaut i ons or with spec i fi c warnings el se w h e re in this manua l vi ol at es safety standards of des ig n ,

manufacture, and intended use of the product. Agilent Technologies Inc. assumes no liability for the customer’s failure to comply with t hese requ ir em ents.

Ground the equipm en t: For Safety Clas s 1 eq ui pment (equipment havi ng a protectiv e earth termi n al ) , a n uni nt erruptible safety earth

ground must be provided from t he m ains power source to the prod uct input wiri ng t er m i nals or suppli ed power cable.

DO NOT operate the product in an explosiv e atmosph er e or in the pr es ence of flam m a bl e gases or fum es.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type.

DO NOT use re pai r ed fuses or short -c i rcuited fuse hol ders.

Keep away from live circuits: Operating pe rs onnel must not re m ove equipment covers or shields. Procedures involvin g th e re m oval

of covers or shi el ds are for use by se rv ic e- trained pers onnel only. Under certain conditions, dangerous vol ta ge s m ay exist even with the

equipmen t s w itched off. To avoi d dangerous ele ct rical shock, DO NOT pe rf orm procedure s involving cove r or shi eld removal unl ess

you are qualif ie d t o do so.

DO NOT operat e damaged equipmen t: Whenever it i s pos si bl e that the sa fe ty prot ection features built int o this product have been impaired, eit he r t hr ough physical damage, excessive mo is t ure , or any other reas on, R E M O V E POWER and do not use the product unt il

safe opera tion can be verifi ed by service- t rained personnel. If nece ss ar y, ret ur n t he product to an Agilent Technologies Sal es and Service Office for service and repair to ensure that safety features are maintained.

DO NOT ser vice or adjus t al one: Do not at te m pt internal se rvi ce or adjustment unless another pers on, capable of rendering firs t ai d

and resuscitation, is present.

DO NOT substitute par ts or modi fy equi pm e nt: Because of the danger of introducing addi tional hazar ds , do n ot ins t al l substitute

parts or perfo rm any unauthoriz ed modification to the pro duct. Return t he pr oduct to an Agi l ent T echnologies Sales an d Ser vice Office

for service and repair to ensure that safety features are maintained.

Page 7

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name:

Manufacturer’s Address:

Agilent Technologies, Incorporated

815 – 14th St. SW

Loveland, Colorado 80537

USA

Declares, that the product

Product Name:

Model Number:

VXI B-Size 16 Channel Form C Switch

E1364A

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

(including 93/68/EEC) and carries the CE Marking accordingly.

Conforms with the following product standards:

EMC Standard

CISPR 11:1990 / EN 55011:1991

IEC 801-2:1991 / EN 50082-1:1992

IEC 801-3:1984 / EN 50082-1:1992

IEC 801-4:1988 / EN 50082-1:1992

The product was tested in a typical configuration with Agilent Technologies or Hewlett-Packard Company test

systems.

Limit

Group 1 Class A

4kV CD, 8kV AD

3 V/m

0.5kV signal lines, 1kV power lines

Safety

IEC 1010-1:1990+A1:1992 / EN 61010-1:1993

Canada: CSA C22.2 No. 1010.1:1992

UL 1244

5 June 2001

Date

Ray Corson

Product Regulations Program Manager

Authorized EU-representative: Agilent Technologies Deutschland GmbH, Herrenberger Straβe 130, D 71034 Böblingen, Germany

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Revision: B.01 Issue Date: 5 June 2001 Document E1364A.DOC

Page 8

Page 9

Page 10

Page 11

Introduction

Chapter 1

General Information

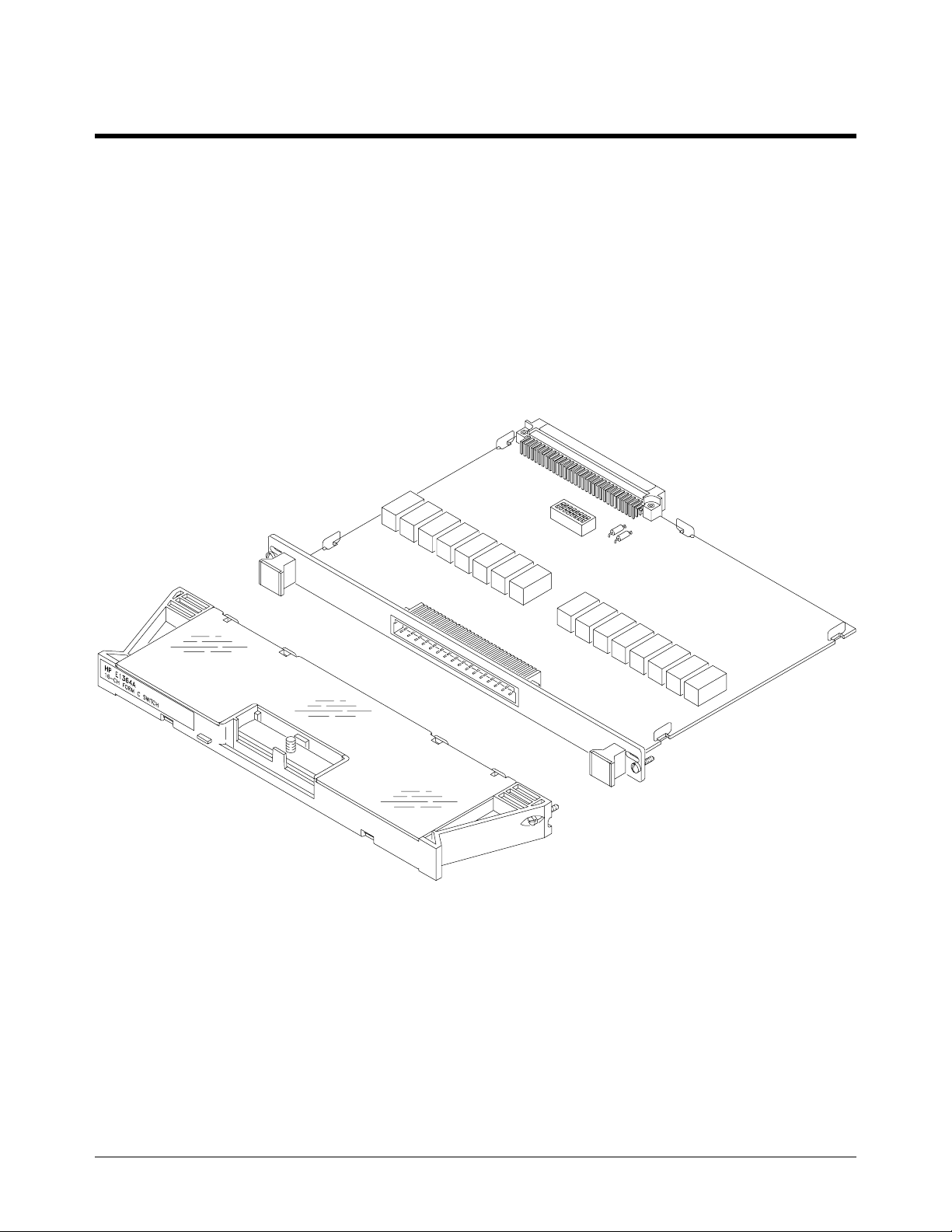

This manual co nta ins information required to test, troubleshoot , and r e pa ir

the Agilent E1364A B-Size VXI Form C Switch. See the Agilent E1364A

User’s Manual for ad dit ional informa ti on. Fig ur e 1-1 shows the E1364A

Switch Modul e.

Figure 1-1. Agilent E1364A Form C Switch Module

Chapter 1 General Information 11

Page 12

Safety Considerations

This product is a Saf ety Class I instrume nt tha t is provided wit h a prote c ti ve

earth terminal when installed in the mainframe. The mainframe, switch, and

all related documentation should be reviewed for familiarization with safety

markings and i nstructions be f ore operation or serv ice .

Refer to the WARNINGS on page 6 in this manual for a summary of safety

information. Safety information for preventive maintenance, testing, and

service foll ows a nd is also found throughout this ma nual.

WARNINGS and

CAUTIONS

WARNING SERVICE-TRAINED PERSONNEL ONLY. The information in this

This section cont ai ns W AR N INGS which must be followed for your

protection and CAUTIONS whi c h mus t be followed to avoid dama ge to the

equipment whe n pe rforming instrume nt maintena nc e or re pa ir .

manual is for service-trained personnel who are familiar with

electronic circuitry and are aware of the hazards involved. To

avoid personal injury or damage to the instrument, do not

perform procedures in this manual or do any servicing unless

you are qualified to do so.

CHECK MAINFRAME POWER SETTINGS. Before applying

power, verif y th at the mainf r a me se t ti n g ma tc h e s the line

voltage and that the correct fuse is installed. An uninterruptible

safety earth ground must be provided from the main power

source to t he suppl ie d po we r co rd set.

GROUNDING REQUIREMENTS. Interruption of the protective

(grounding) conductor (inside or outside the mainframe) or

disconnecting the protective earth terminal will cause a

potential shock hazard that could result in personal injury.

(Grounding one conductor of a two-conductor outlet is not

sufficient protection.)

IMPAIRED PROTECTION. Whenever it is likely that instrument

protection has been impaired, the mainframe must be made

inoperative and be se cured against any u n intende d op e rat ion.

REMOVE POWER IF POSSIBLE. Some procedures in this

manual may be performed with power supplied to the

mainframe while prote ct ive cove rs are removed. Ene rgy

available at many points may, if contacted, result in personal

injury. (If maintenance can be performed without power applied,

the power should be removed.)

12 General Information Chapter 1

Page 13

WARNING USING AUTOTRANSFORMERS. If the mainframe is to be

energized via an autotransf or mer (for voltage reduction) make

sure the common terminal is connected to neutral (that is, the

grounded side of the main’s supply).

CAPACITOR VOLTAGES. Capacitors inside the mainframe may

remain charged even when the mainframe has been

disconnected from its source of supply.

USE PROPER FUSES. For continued protection against fire

hazard, replace the line fuses only with fuses of the same

current rating and type (such as normal blow, time delay, etc.).

Do not use repaired fuses or short-circuited fuseholders.

CAUTION Static electricity is a maj o r ca u se o f co mp onent fa il u re . T o

preven t damage to t he electrical comp onents in th e switch,

observe anti-static techniques whenever working on the switch.

Chapter 1 General Information 13

Page 14

Inspection/Shipping

This section c ont ai ns initial (i nc omi ng) inspection and shipping guide lines

for the E1364A Switc h Module.

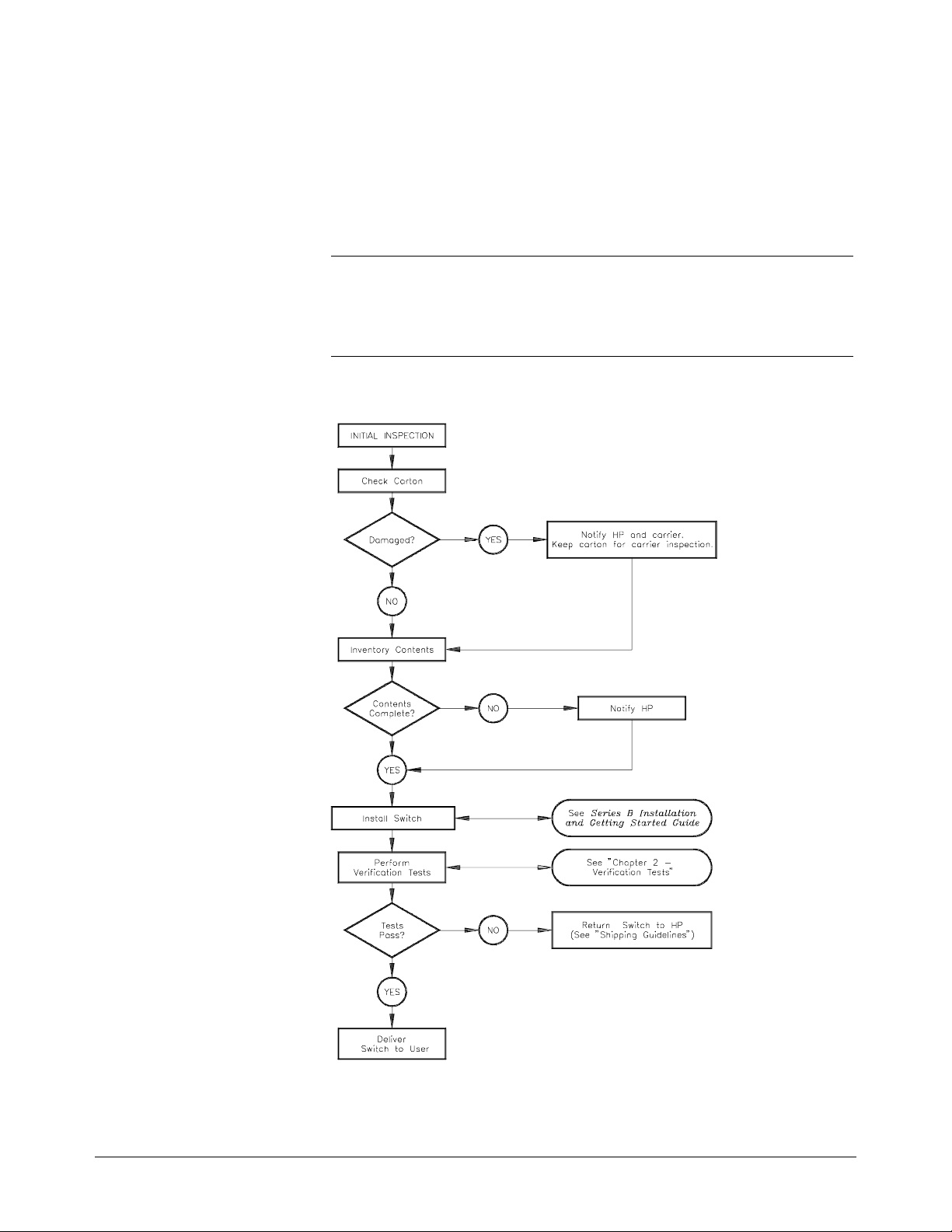

Initial Inspection Use the steps in F igure 1-2 as guidelines to perfor m initial in spe c ti on of the

switch modul e.

WARNING To avoid possible hazardous electrical shock, do not perform

electrical tests if there are signs of shipping damage to the

shipping container or to the instrument.

Figure 1-2. Initial (Incoming) Inspection Guidelines

14 General Information Chapter 1

Page 15

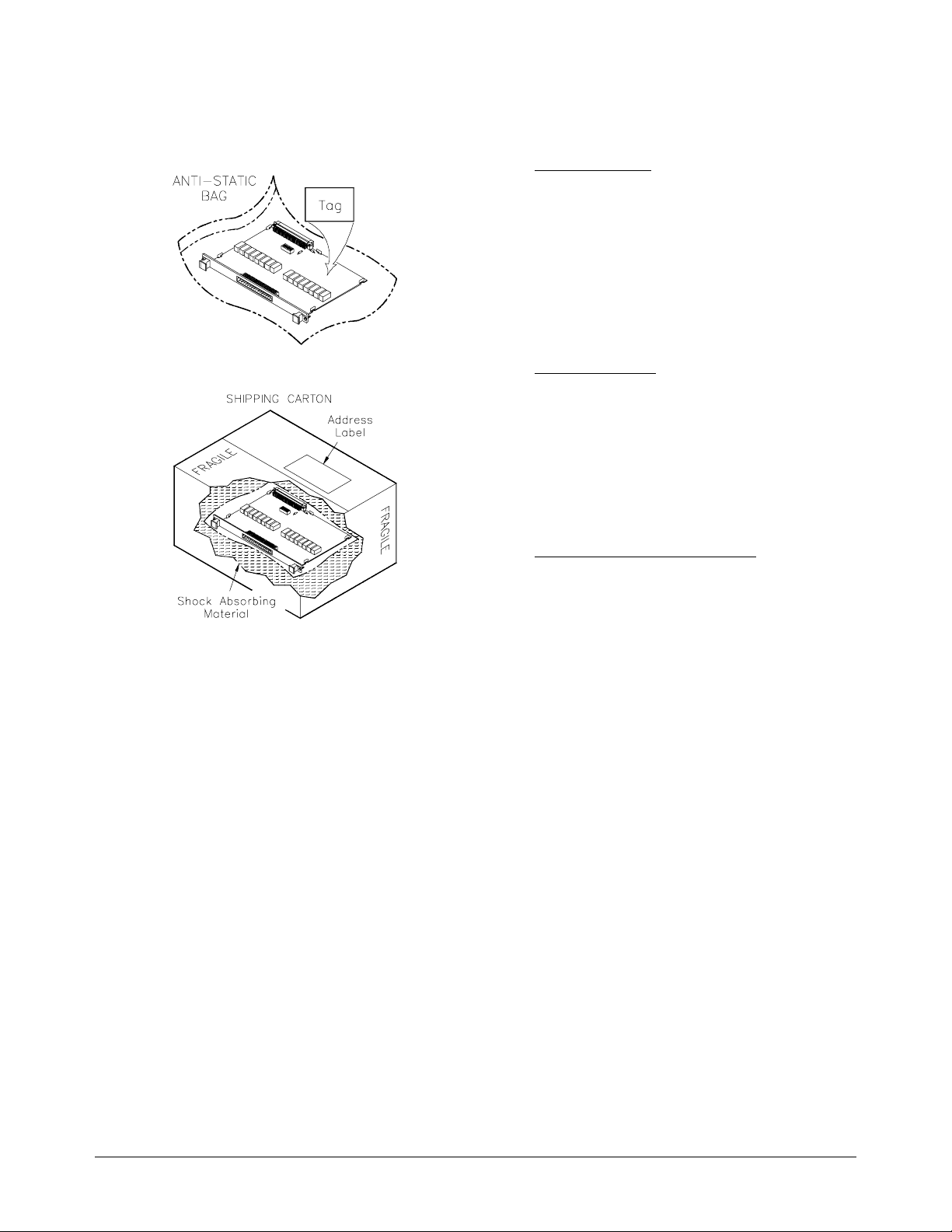

Shipping Guidelines Follow the step s in F igure 1-3 to return the E1364A Switch Mod ule

to an Agilent Te ch nol ogies Sales and Suppor t Office or Serv ic e Ce nte r.

1. Prepare the Switch

• Remove user wiring from termi na l mo dule.

• Attach ta g to switch that identi f ie s :

– Owner

– Model Number/Serial Number

– Service Required

• Place tagged device in approved anti-static

bag.

2.

Pack age the Switc h

• Place packaged switch in shipping carton.*

• Place 75 to 100 mm (3 to 4 inches) of

shock-absorbi ng material around t he

module.

• Seal the shippi ng c ontainer securely.

• Mark the shipping container FRAGILE.

3.

Ship the Switch to Hewlett-Packard

• Place address lab el on shi pping carton.

• Send carton to Agilent Technologies .

* We recommen d tha t you use the sam e sh ipping mater ia ls as t hose use d in factory packa ging (avail ab le from

Agilent). For othe r (commercially available) shippi ng materials, use a double-walled carton with minimum 2. 4

MPa (350 psi) te st .

Figure 1-3. Packaging/Shipping Guidelines

Chapter 1 General Information 15

Page 16

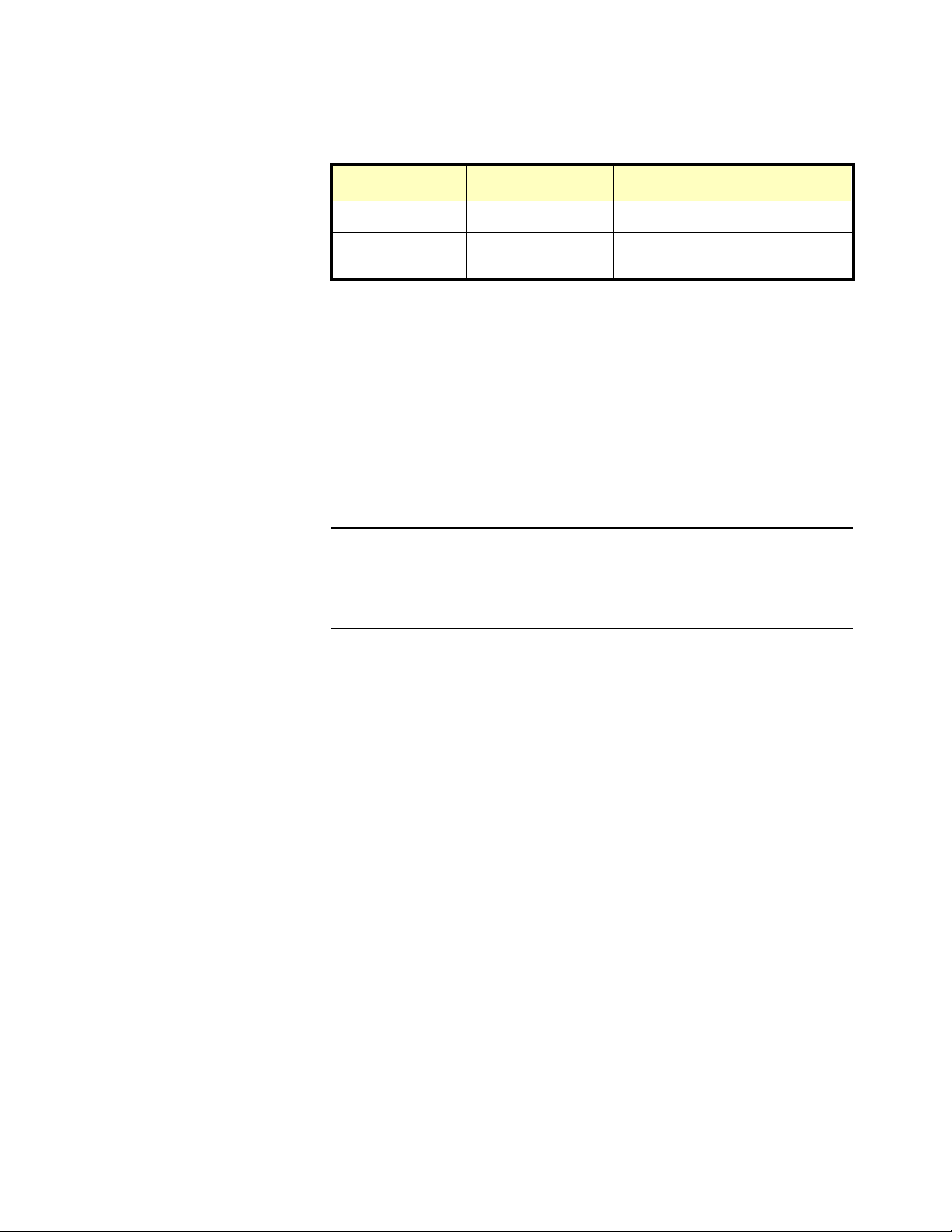

Environment

The recommended operating environment for the E1364A Switch Module

is:

Switch Description

The Agilent E1364A Switch Modu le is a n "instrument " in the slots of a

VXIbus mainframe . As su ch , i t is ass ign ed an er ro r queu e, input and outp ut

buffers, and a status register. The switch has 16 channe ls of Form C relays.

Each channel in cl ude s a rel ay with com mo n (C) , no rma lly open (NO), and

normally close d ( N C) co nta c ts .

Environment Temperature Humidity

Operating 0oC to + 5 5oC <65% relative (0oC to + 4 0oC)

Storage and

Shipment

o

-40

C to +75oC <65% relative (0oC to + 4 0oC)

NOTE Instruments are bas ed o n the logical addre sse s of the plug-in modules. See

Switch

Specifications

Switch Serial

Numbers

Chapter 1 of the E1364A User’s Manual to set the logical address of the

switch mod u le .

Switch module spe ci fic a tions are listed in Appendix A of th e E1364A

User’s Manual. These specifications are the performance standards or limits

against which the instr ument may be tested.

Switches cover e d by this manual a re identifie d by a seri al number prefix

listed on the title page. Agilent uses a two-part serial number in the form

XXXXAYYYYY, where XXXX is the serial prefix, A is the country of

origin (A=USA), and YYYYY is the serial suffix. The serial number prefix

identifi e s a ser ie s of identical instruments. T he se ri a l number suffix is

assigned sequentially to each instrument.

The serial number plate is located on the backplane connector. If the serial

number prefix o f your instrument is gre a te r tha n the one liste d on the title

page, a Manual Upda te (as re quired) will expla in ho w to a da pt this manual

to your instrument.

Switch Options There are no electrical or mechanical options available for the E1364A

Switch Modul e.

16 General Information Chapter 1

Page 17

Recommended Test Equipment

Table 1-1 lists the test equi pme nt recommended f or testing, adju st ing, and

servicing the E1364A Switch Modul e. Essential requirements for each piece

of test equipment are descr ibed in the "Re quirements" c olumn.

Table 1-1. Recomm e nde d Te st Equipment

Instrument Requirements Recommended Model Use*

Controller, GP-IB GP-IB compat ibi lity as defined by

Main fram e Compa tible with switch

Digital Multimeter

IEEE Standard 488-1978 and the

identical ANSI St andard MC1.1:

SH1, AH1, T2, TE0, L2, LE 0, S R0,

RL0, PP0, DC0, D T0, and C1, 2, 3,

4, 5.

Use the E1403 B A/B- to-C- size

Adapter to inst all a B-size module in

a C-size E14XX mainframe.

2-wire ohms (up to 1 GΩ)

4-wi re ohms

* F = Functional Verificat i on, O = O per at ion Verif icat i on Tes ts ,

P = Performance Verificat ion Tests, T = Troubleshoo ting

HP 9000 Series 300

or

IBM compatible PC with HP

BASIC

E1300A, E1301 A,

E1302A (requires E1306A**)

E1400B/T (requir es E1405A/B

or E1406B**),

E1401B/T (requ ires E1405A/B

or E1406B**),

E1421B (requires E1405A/B

or E1406B**)

** or an embedded controller or

VXLink in place of a command

module.

3458A

34401A

F,O,

P,T

F,O,

P,T

O,P,T

Chapter 1 General Information 17

Page 18

Notes

18 General Information Chapter 1

Page 19

Introduction

Chapter 2

Verification Tests

The three levels of test procedures described in this chapter are used to

verify that the E1364A Switch Mo dul e:

• is fully function al (Func tional Verification)

• meets selected testable specifications (Operation Verification)

• meets all testable specifications (Performance Verification)

Test Condit ions

and Procedur es

Performance Test

Record

Verificat ion Test

Examples

See Table 1-1 for te st e quipment requir e me nts. You should com plete the

Performance Verification tests at least once a year. For heavy use or severe

operating environments, pe rform the tests mor e of te n.

The verificati on tests assume tha t the pe rs on pe r form ing the tests

understands ho w to ope r a te the ma i nf rame, the switch, a nd spe c if i ed te st

equipment . The te st pr oc e dure s do not specify equipment settings for test

equipment, except in general terms. It is assumed that a qualified,

service-trained technician will select and connect the cables, adapters, and

probes required f or the te st.

The results of each Performance Verification test may be recorded in

Table 2-1, "Agilen t E1364A Performance Test Recor d. " You may make a

copy of this for m, if de sired.

Each verification test proced ur e inc ludes an example progr a m that performs

the test. All example programs assume the following conf iguration:

• Controller is an HP 9000 Ser ies 200/300 compu ter

• Programming la nguage is BASIC

• Switch address is 7 0915

• Switch card number is 1

• DMM is an 3458A

Chapter 2 Verification Tests 19

Page 20

Functional Verification

The Functiona l Ve rif ica ti on Te st for the E1364A sw it ch con sists of sending

*IDN? command and chec king the respons e. Thi s te st can be used at any

the

time to verify that the switch is connec ted properly and is r e sponding to

basic commands .

Procedure 1. Verify tha t the switc h is installed in the main f ram e a nd t h a t the

mainframe has passed its power-on test.

2. Send the

following).

3. The switch mo dule should retur n the f oll owing string (revision

number may vary):

*IDN? command to t he sw it ch module (see e xa mpl e

HEWLETT-PACKARD,SWITCHBOX,0,A.06.00

NOTE If the pri ma r y ad dr ess se tting, secondary address set ti ng, or interface se le c t

code is set incor rectl y, the switch will not r espond. Verify proper ad dr ess

selection bef or e tro ubleshooting.

Example An exampl e follows which uses an HP 9000 S eri es 300 c omputer with

HP BASIC and a switch addr ess of 70915.

10 DIM A$[80]

20 OUTPUT 70915;"*IDN?" !Send the ID co m mand

30 ENTER 70915;A$ !Get response

40 PRINT A$

50 END

Operation Verification

The procedures in this section are used to provide a high confidence that the

switch module is meeting published specifications. The Operation

Verification tests are a subset of the Performance Verification tests and are

suitable for checkout after performing repairs.

Operation Verification is performed by completing the Closed-Channel

Resistan ce Te st as described in the Performa nce Verific at ion test

procedures. Th is test is usually sufficien t to verify tha t t h e switch module is

meeting its specifications.

20 Verification Tests Chapter 2

Page 21

Performance Verification

The procedures in this section are used to test the switch modul e ’s el ectrical

performance using the specificati ons in Appe ndix A of the E1364A User’s

Manual as the performance standards. These tests are suitable for incoming

inspecti on, tr oubleshooti ng, a nd pr e ve n ti ve ma intenance .

Test Fixture A test fi xture is required for the following t es ts. It is r e co mmended that you

order an extra terminal module (aka "terminal bloc k" ) to use a s a tes t

fixture, so tha t you do not have to re-wire the termina l module each time

these tests a re per f or me d. T he te rminal module pa rt number is

E1364-80001.

Figures 2-1(a) and 2-1(b) show how the test fixt ur e sh ould be wired.

Perform the following steps to wire the test fixture:

– Short all NO (Normally Open) lines t oge ther.

– Short all NC (Normally Cl ose d) lines togethe r .

– Short all C (Common) lin es together.

Figure 2-1(a). Agilent E1364A Test Fixture Schematic

Chapter 2 Verification Tests 21

Page 22

Figure 2-1(b). Agilent E1364A Test Fixture

22 Verification Tests Chapter 2

Page 23

Test 2-1: Closed-Channel Resistance Test

The purpose of this test is to verify that all relay contacts meet the

closed-chann el resi st an ce spe c if i cation for the switch module. If the

closed-c h ann el resist ance of any contact i s greater than 3 .5

should be replaced.

Normally Open

Contacts 1. Hardware Connections

Ω, th e relay

Figure 2-2. Closed-Channel Resistance (NO channels)

2. Equipment Setup

• Set DMM to: 4-wire ohms, au tor a nge .

• Send *RST to the switch to open all NO contacts.

3. Closed-Cha nne l Reading (channe l 00)

• Send CLOS (@100) to the switch to cl ose c ha nne l 00.

• Trigger the DMM and record the reading.

4. Open-Channel Reading (channel 00)

• Send OPEN (@100) to the switch to open c ha nne l 00.

• Trigger the DMM and verify that an open cir c ui t is indicated

5. Closed- and Open -Channel Readings ( c ha nne ls 01- 15)

(>10

8

Ω).

• Repeat steps 3 and 4 fo r channe ls 01 through 15 . Use

CLOS (@ccnn) and OPEN (@ccnn), where

cc

= switch card nu mbe r (0 1- 99, le ad ing zero not necess ary)

nn = channel number (00-15)

Chapter 2 Verification Tests 23

Page 24

Normally Closed

Contacts 1. Hardware Connections

Figure 2-3. Closed-Channel Resistance (NC Channels)

2. Equipment Setup

• Set DMM to: 4-wire ohms, au tor a nge .

• Send *RST to the switch.

• Send CLOS (@100:115) to the switch to open all NC contacts.

3. Closed-Cha nne l Reading (channe l 00)

• Send OPEN (@100) to the switch to close channel 00.

• Trigger the DMM and record the reading.

4. Open-Channel Reading (channel 00)

• Send CLOS (@100) to the switch to ope n ch anne l 00.

• Trigger the DMM and verify that an open cir c ui t is indicated

5. Closed- and Open -Channel Readings ( c ha nne ls 01- 15)

(>10

8

Ω).

• Repeat steps 3 and 4 fo r channe ls 01 through 15 . Use

CLOS (@ccnn) and OPEN (@ccnn), wh ere

cc = switch card number (01-99, leading zero not necessary)

nn = channel number (00-15)

24 Verification Tests Chapter 2

Page 25

Example:

Closed-Channel

Resistance Test

This example performs the Closed-Channel Resistance Test for all

Normally Open and Normally Closed contacts.

10 ! RE-STORE "CONTACT_RES"

20 ASSIGN @Switch TO 70915

30 ASSIGN @Dmm TO 722

40 !

50 OUTPUT @Switch;"*RST" !Open all NO contacts

60 OUTPUT @Dmm;"PRESET NORM;TRIG HOLD"

70 OUTPUT @Dmm;"FUNC OHMF"

80 !

90 !--------------- NORMALLY OPEN C ONT ACT S --------------100 DISP "Connect DMM to NO and C lines of E1364A (4-wire

connection)"

110 PAUSE

120 DISP

130 PRINT "Contact Resistance -- Normally Open Contacts"

140 PRINT

150 !

160 FOR I=0 TO 15

170 !Closed-channel resistance (NO contacts)

180 OUTPUT @Switch;"CLOS (@"&VAL$(100+I)&")"

190 OUTPUT @Dmm;"TRIG SGL"

200 ENTER @Dmm;Rdg

210 PRINT "Channel "&VAL$(I)&" (closed): "&VAL$(Rdg)

220 !

230 !Open-channel resistance (NO contacts)

240 OUTPUT @Switch;"OPEN (@"&VAL$(100+I)&")"

250 OUTPUT @Dmm;"TRIG SGL"

260 ENTER @Dmm;Rdg

270 PRINT "Channel "&VAL$(I)&" (open): "&VAL$(Rdg)

280 PRINT

290 NEXT I

300 !

310 !--------------- NORMALLY CLO SED CONTACT S --- ---- -------320 DISP "Connect DMM to NC and C lines of E1364A (4-wire

connection)"

330 PAUSE

340 DISP

350 PRINT "Contact Resistance -- Normally Closed Contacts"

360 PRINT

370 !

Continued on Next Page

Chapter 2 Verification Tests 25

Page 26

380 OUTPUT @Switch;"CLOS (@100:115)" !Open all NC contact s

390 FOR I=0 TO 15

400 !Closed-channel resistance (NC contacts)

410 OUTPUT @Switch;"OPEN (@"&VAL$(100+I)&")"

420 OUTPUT @Dmm;"TRIG SGL"

430 ENTER @Dmm;Rdg

440 PRINT "Channel "&VAL$(I)&" (closed): "&VAL$(Rdg)

450 !

460 !Open-channel resistance (NC contacts)

470 OUTPUT @Switch;"CLOS (@"&VAL$(100+I)&")"

480 OUTPUT @Dmm;"TRIG SGL"

490 ENTER @Dmm;Rdg

500 PRINT "Channel "&VAL$(I)&" (open): "&VAL$(Rdg)

510 PRINT

520 NEXT I

530 !

540 END

26 Verification Tests Chapter 2

Page 27

Test 2-2: DC Isolation Test

This test ve ri f ie s that sufficie nt DC isolat ion exists betw e e n va ri ous points

on the switch module. The DMM use d should be capa ble of me a sur ing up to

at least 1 G

">R

If the DMM is a 3458A, for exam pl e, the reading shoul d be wri tt e n as ">1. 2

G

Normally Open to

Common 1. Hardware Connections

max

Ω".

", where R

Ω. If the DMM indicates an overload, record the reading as

is the highest resistance that the DMM can measure.

max

Figure 2-4 . D C Is ola tion Test (NO C ha nne ls to Common)

2. Equipment Setup

• Set DMM to: 2-wire ohms, 1 G Ω rang e.

• Send *RST to the switch to open all NO contacts.

3. DC Isolation Reading

• Trigger the DMM and record the reading.

Chapter 2 Verification Tests 27

Page 28

Normally Closed to

Common 1. Hardware Connections

Figure 2-5. DC Isolation Test (NC Channels to Common)

2. Equipment Setup

• Set DMM to: 2-wire ohms, 1 G Ω rang e.

• Send *RST to the switch.

• Send the CLOS (@100:115) command to the switch to open all NC

contacts.

3. DC Isolation Reading

• Trigger the DMM and record the reading.

28 Verification Tests Chapter 2

Page 29

Normally Open to

Chassis 1. Hardware Connections

Figure 2-6. DC Isolation Test (NO Channels to Chassis)

2. Equipment Setup

• Set DMM to: 2-wire ohms, 1 G Ω rang e.

• Send *RST to the switch.

• Send the CLOS (@100:115) command to the switch to close all NO

contacts.

3. DC Isolation Reading

• Trigger the DMM and record the reading.

Chapter 2 Verification Tests 29

Page 30

Normally Closed to

Chassis 1. Hardware Connections

Figure 2-7. DC Isolation Test (NC Channels to Chassis)

2. Equipment Setup

• Set DMM to: 2-wire ohms, 1 G Ω rang e.

• Send *RST to the switch to close all NC contacts.

3. DC Isolation Reading

• Trigger the DMM and record the reading.

30 Verification Tests Chapter 2

Page 31

Example: DC

Isolation Test

This example performs the DC Isolation Test for Normally Open and

Normally Closed channels to both Common and chassis (earth ground).

10 !RE-STORE "DC_ ISOL"

20 ASSIGN @Switch TO 70915

30 ASSIGN @Dmm TO 722

40 !

50 OUTPUT @Dmm;"PRESET NORM;TRIG HOLD"

60 OUTPUT @Dmm;"FUNC OHM;RANGE 1E9"

70 !

80 !---------------NORMALLY OPEN TO COM MO N -- ------------90 DISP "Connect DMM HI and LO to E1364A NO and C lines"

100 PAUSE

110 DISP

120 !

130 OUTPUT @Switch;"*RST" !Open all NO contacts

140 WAIT 1

150 OUTPUT @Dmm;"TRIG SGL"

160 ENTER @Dmm;Rdg

170 !

180 PRINT "DC Isolation -- Normally Open Channels to Common"

190 PRINT "R = "&VAL$(Rdg)

200 PRINT

210 !

220 !---------------NORMALLY CLOSED TO COMMON--------------230 DISP "Connect DMM HI and LO to E1364A NC and C lines"

240 PAUSE

250 DISP

260 !

270 OUTPUT @Switch;"CLOS (@100:115)" !Open all NC contacts

280 WAIT 1

290 OUTPUT @Dmm;"TRIG SGL"

300 ENTER @Dmm;Rdg

310 !

320 PRINT "DC Isolation -- Normally Closed Channels to Common"

330 PRINT "R = "&VAL$(Rdg)

340 PRINT

350 !

360 !---------------NORMALLY OPEN TO CHASSIS--------------370 DISP "Connect DMM HI and LO to E1364A NO line and mainframe

chassis"

380 PAUSE

390 DISP

400 !

Continued on Next Page

Chapter 2 Verification Tests 31

Page 32

410 OUTPUT @Dmm;"TRIG SGL"

420 ENTER @Dmm;Rdg

430 !

440 PRINT "DC Isolation -- Normally Open Channels to Chassis"

450 PRINT "R = "&VAL$(Rdg)

460 PRINT

470 !

480 !---------------NORMALLY CLOSED TO CHASSIS--------------490 DISP "Connect DMM HI and LO to E1364A NC line and mainframe

chassis"

500 PAUSE

510 DISP

520 !

530 OUTPUT @Switch;"OPEN (@100:115)" !Close all NC contacts

540 WAIT 1

550 OUTPUT @Dmm;"TRIG SGL"

560 ENTER @Dmm;Rdg

570 !

580 PRINT "DC Isolation -- Normally Closed Channels to Chassis"

590 PRINT "R = "&VAL$(Rdg)

600 !

610 END

32 Verification Tests Chapter 2

Page 33

Performance Test Record

Table 2-1, "Performance Test Reco rd for th e E1 364A S w it ch Module," is a

form you may copy a nd use to record performan ce ve rif ica tion test result s

for the switch module. Pages 3 and 4 of Table 2-1 show switch accuracy,

measurement uncertainty (M.U.), and test accuracy ratio (TAR) values.

Switch Accuracy Accuracy is defined for closed-channel contact resistance and DC isolation

using the specific a ti ons in Appendix A of the E136 4A Use r’s Manual. The

closed-chann el resi stance and DC isolat ion specificati ons are single-sided,

meaning th at the r e is an uppe r limit OR a lower limit, but not both. In Table

2-1, either the "Minim um" or "Ma ximum" col umn will be blank fo r a

single-side d te st.

Measurement

Uncertainty

Closed-Channel

For the performance verification tests in this manual, the measurement

uncertainties are based on 90-day accuracy specifications for the 3458A

Digital Multimeter. The calculations are shown below.

Conditions:

Resistance Test

– 4-wire ohms function

– 10 Ω range

– 90- da y spec ifi cat ion s

– Worst-case reading = 3.5 Ω

M.U. = 15ppm of Reading + 5ppm of Range

= 15 x 10

= 1.03 x 10

-6

DC Isolation Test Conditions:

– 2-wire ohms function

– 1 GΩ range

– 90- da y spec ifi cat ion s

– Worst-case reading = 1.2 GΩ (highest resistance that can be

measured with the 3458A)

⋅ 3.5 + 5 x 10-6 ⋅ 10 (Ω)

-4

Ω

Test Accuracy

Ratio (TAR)

M.U. = 0.5% of Readin g + 10ppm of Ran ge

= 0.005 ⋅ 1.2 x 10

= 6 x 10

Test Accuracy Ra tios are not define d for single-sided meas ur em e nts, so all

closed-channel resi st an ce a nd DC i sol ation measurements have "NA" (Not

Applicable) in the TAR column.

6

Ω

9

+ 10 x 10-6 ⋅ 1 x 109 (Ω)

Chapter 2 Verification Tests 33

Page 34

Table 2-1. Performance Test Record for the E1364A Swit ch Mod ul e (Page 1 of 4)

Test Facility:

Name______ ________________________ ________

Address____________________________ ________

City/State___________________________________

Phone______________________________________

Model _______ ____ ____________ ____ __________

Serial No.________ _________________________

Options____________________________________

Firmware Rev.___ ___________________________

Special Note s:

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

Report No.____ ______________________________

Date__________________ ____________________

Customer___ ____________ ____________ _______

Tested by_______ ___________________________

Ambient tempera tu re_ ____ __________________

Relative humidit y___________________________%

Line frequency__ ____________ ____ _________ Hz

(nominal)

o

C

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

34 Verification Tests Chapter 2

Page 35

Table 2-1. Performance Test Record for the E1364A Switch Module (Page 2 of 4)

Model ________ ____ ____________ ____ __ Report No. ____________________ Date _________________

Test Equipment U sed :

Description Model No. Trace No. Cal Due Date

1. _______________________________

2. _______________________________

3. _______________________________

4. _______________________________

5. _______________________________

6. _______________________________

7. _______________________________

8. _______________________________

9.________________________________

10._______________________________

11._______________________________

12._______________________________

13._______________________________

14._______________________________

15._______________________________

16._______________________________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

17._______________________________

18._______________________________

19._______________________________

20._______________________________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

Chapter 2 Verification Tests 35

Page 36

Table 2-1. Performance Test Record for the E1364A Swit ch Mod ul e (Page 3 of 4)

Model ______ ____ ____________ ____ ____ Report No. _____________________________ Date_____________

Test

No.

2-1. Closed-Channel Resistance Test (Values in ohms)

Test

Description Minimum*

Measured

Reading Maximum

Normally Open (NO) Contacts

Channel 00

Channel 01

Channel 02

Channel 03

Channel 04

Channel 05

Channel 06

Channel 07

Channel 08

Channel 09

Channel 10

Channel 11

Channel 12

Channel 13

Channel 14

Channel 15

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

Normally Closed (NC) Contacts

Channel 00

Channel 01

Channel 02

Channel 03

Channel 04

Channel 05

Channel 06

Channel 07

Channel 08

Channel 09

Channel 10

Channel 11

Channel 12

Channel 13

Channel 14

Channel 15

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

Meas

Uncert TAR

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

1.03E-4

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

*Single-si de d spe c if ica tion -- Minimu m doe s not apply.

36 Verification Tests Chapter 2

Page 37

Table 2-1. Performance Test Record for the E1364A Swit ch Mod ul e (Page 4 of 4)

Model ____________________________ Report No. _____________________ Date______________

Test

No.

2-3. DC Isolation Test (Values in ohms)

Test

Description Minimum

NO to Common

NC to Common

NO to chassis

NC to chassis

1E8

1E8

1E8

1E8

____________

____________

____________

____________

*Single-si de d spe c if ica tion -- Maximum does not apply.

Measured

Reading Maximum*

Meas

Uncert TAR

6.0E6

6.0E6

6.0E6

6.0E6

NA

NA

NA

NA

Chapter 2 Verification Tests 37

Page 38

Notes

38 Verification Tests Chapter 2

Page 39

Introduction

Chapter 3

Replaceable Parts

This chapter contains information for ordering replaceable parts for the

E1364A Switch Modules with serial num be r 2934A10370 and higher.

The tables provide the following informat ion:

• Table 3-1 list s as se mbly and termina l module part nu mbers for the

E1364A Switch Module.

• Table 3-2 list s the Ref e rence Des ignators for the switch module.

Ordering

Information

To order a part list ed in Table 3-1, speci fy the Agilent part numbe r an d the

quantity req uir e d. Send the order to your near e st Agi le nt Te ch nologies

Sales and Support Office.

If your E1364A Switch Module has a serial numbe r prior to 2934A10370,

see Appendix B, "B ackdating Info rma ti on, " f or repl a cea bl e par ts

information.

Replaceable Parts Lists

See the Parts Locat or Dia gra ms ( Fi gur e s 3-1 a nd 3- 2) fo r lo cat ions of

replaceable parts.

Table 3-1. E1364A Replaceable Parts (serial number 2934A10370 and higher)

Reference

Designator

BRK1-BRK2

F1

F2

J1

LBL1

LBL2

Part

Number

E1364-66201 1 COMPONENT ASSEMBLY

0050-2183

2110-0936

2110-0936

1252-1591

E1300-84308

E1300-84312

Qty Part Description

2

1

1

1

1

1

BRKT-PNL MNT

FUSE 4A 125V SMT

FUSE 4A 125V SMT

CONNECTOR-RA PL, 48P

LBL LOGO B SIZE

LBL-LOGO VXI B SIZE

RELAY-ARMATURE HiR, Low E

K100-K115

MP1-2

P1

SCR1-2

SCR3-4

SHD1

SW1

0490-1912

1400-1546

1252-1596

0515-0444

0515-1968

E1300-80601

3101-3142

E1364-80001 1 TERMINAL MODUL E

E1364-66510

E1300-8440111

16

BRACKET PC BOARD HOLDER; BLACK; EXTRUDED

2

CONNECTOR-POST TYPE 2.54-PIN-SPCG 96-CONTACT

1

SCREW- X 8MM-LG -HD

2

SCR PHM 2.5 X 11 TX

2

SHIELD SAFETY

1

SWITCH-DIP 8 - 1A SMTV

1

TERMINAL CARD 16-CH GP RLY SWITCH

TERMINAL CARD, CASE ASSY

Chapter 3 Replaceable Parts 39

Page 40

Table 3-2. Reference Designa tors

A assembly PCB printed circuit boar d

BRK bracket PNL panel

C capacitor R resistor

CR diode RP resistor pack

LBL label RVT rivet

Ffuse SCRscrew

J electrical connector (jack) SHD shield

JM jumper SW switch

K rel ay T B terminal block (module)

MP mechanical part U integ rated circuit

P electrical connector (plug)

Figure 3-1. E1364A Mechanical Replaceable Parts

40 Replaceable Parts Chapter 3

Page 41

Figure 3-2. E1364A Terminal Block Replaceable Parts

Chapter 3 Replaceable Parts 41

Page 42

Notes

42 Replaceable Parts Chapter 3

Page 43

Introduction

WARNING Do not perform any of the service procedures shown unless

Chapter 4

Service

This chapter contains service information for the Agilent E1364A Switch

Module, including trou ble shooting tech niques and repai r and m ai ntenance

guidelines.

you are a qu a li f ied, serv ic e- t rained te ch nicia n, and have r ea d

the WARNINGS and CAUTIONS in Chapter 1.

Equipment

Required

Equipment r e qui red f or switch trouble shooting and re pa ir is listed in

Table 1-1, "Reco mm en de d Te st Equipment ." Any eq uipment that sat isfies

the requirem en ts given in the ta bl e m ay be su bstituted. To a void damage to

the screw head slots, use a T8 Torx drive r to r emove the front panel ha ndl es .

Service Aids See Chapter 3, "Replaceable Parts," or Appendix B, "Backdati ng

Information," for descriptions and locations of E1364A replaceable parts,

depending on the serial number of your switch module. Schematic

Diagrams are available at the back of this manual. Service notes, manual

updates, and service literature for the switc h ma y be av ai la ble through

Agilent. For infor ma t ion, contact your ne a rest Agilent Techno logies Sales

and Support Office.

Chapter 4 Service 43

Page 44

Troubleshooting Techniques

To troubleshoot an E 1364A Switch Module pr obl em , you should first

identify the problem and then isolate the cause to a replaceable part. See

Chapter 3, "Replaceable Parts," or Appendix B, "Bac kda ting Information,"

for descriptions and locations of replaceable parts, depending on the serial

number of your switch module.

Identi fy in g th e

Problem

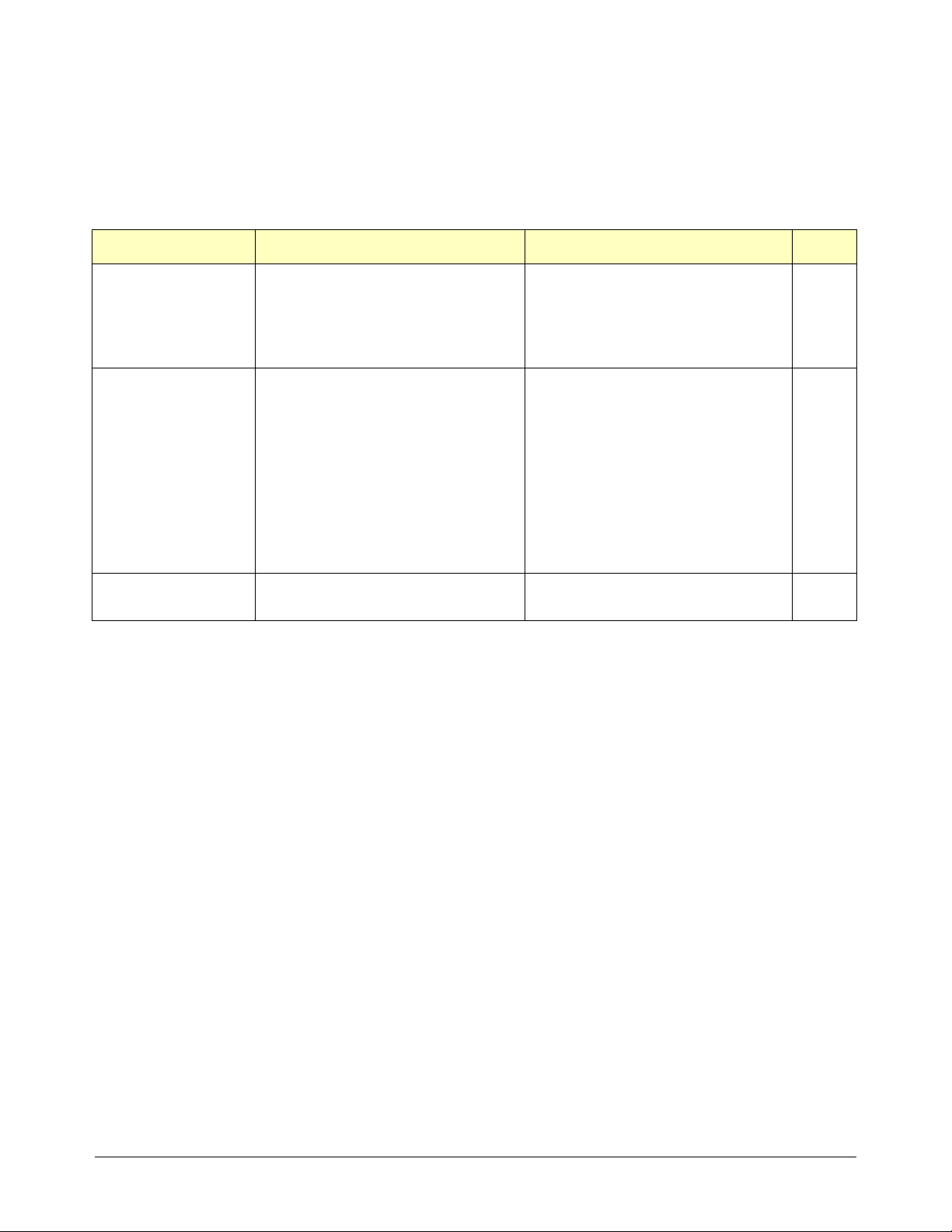

Problem Type Symptom Possible Solutions

Operator Errors Non-zero error co de in res ponse to

Catastrophic

Failures

Performance

Out of

Specification

Table 4-1 lists some common problems, along with symptoms and possible

solutions. If the pr oblem persists, pe rform component-le ve l troubleshoo ting

using the component locator and schematics.

Table 4-1. Agilent E1364A Tests/Checks

the SYST:ERR? command.

Switch not responding to commands. Check logical address setting.

Switch failin g Clo sed- cha nnel

Resistance Test (Test 2-1).

See Appendix C of the

E1364A User’ s M anual for Switch

errors and causes.

See Appendix B of the

E1300A/E1301A or E130 2A U se r’ s

Manual for addi tion al

information on opera to r errors.

See "Testing the Ass em bly" in this

chapter.

Check user wiring and test

connections.

Replace relays that correspond to

the channels that are fail ing. For

example, if channe l 15 fails, rep lace

relay K115.

If most of the chann els are near

or above the test limit (3.5 Ω),

replace the entire module (part

number E1364-66 201).

Switch failing DC Isolation Test

(Test 2-2).

Check user wiring and test

connections.

Clean the printed ci rcuit board.

44 Service Chapter 4

Page 45

Testing the

Assembly

You can use the tests and checks in Table 4-2 to isolate the problem. See

Figure 3-1 in Cha pte r 3 or Figur e B-1 in Appendix B for locati ons of

replaceable p art s, dep ending on the ser ia l n umber of your switch module.

Table 4-2. E1364A Tests/Checks

Test/Check Reference Designator Check:

Heat Damage - - - - - - - - - - Discolored PC boards

Switch/Jumper

Settings

Switch PCA F1, F2

JM13, JM14 , ..., JM 26

SP1

P1, J1

K100, K101, ..., K115

Damaged insulation

Evidence of arci ng

IRQ Level setting

LADDR setting

Fuse continu ity

Connector cont acts

Relay contact resistance

Checking for Heat Damage

Inspect the switch for signs of a bnormal intern ally generated he a t such as

discolored printed circui t boa r ds or c omponents, dam a ge d insulation , or

evidence of arc in g . If ther e is dama ge , do not operate the switch until you

have correcte d the problem.

Checking Switch es /Jum pers

Verify that the logical addre ss se tt ing is set corre ct ly (factory set a t 120).

Verify that the interrupt priority jumpers are set correctly (factory set at

level 1). See the E1364A User’s Manual for information.

Checking the Switch PCA

Use the replaceable parts locator (Figure 3-1 or B-1, depending on the

serial number of your sw it c h module) to che c k the f ollowing:

• Verify that fuses F1 and F2 are go od.

• Check the closed-channel resistance of all relays using the procedure

in Chapter 2. Replace any bad relays.

• Check connecto rs P1 and J1 f or da ma ge .

NOTE If the preceding steps fail to isolate the problem, use the schematics

included with this manual to perform compone nt-level tro ubl es hooting.

Chapter 4 Service 45

Page 46

Repair and Maintenance Guidelines

This section provides guidelines for repairi ng a nd ma intainin g the E1364A

Switch Modul e, including:

• ESD precautions

• Solderin g pr inted circuit boards

• Post-repair sa fet y ch ecks

ESD Precautions Electrostatic discharge (ESD) ma y da m ag e st a tic sensitive de vices in the

E1364A Switch Mo dule. This damage c an range fro m sl ight parameter

degradation to catastrophi c failure. When handling switch a sse mblies,

follow th es e gu ide lines to av oid damagin g sw itch compo ne nts:

• Always use a static-free work station with a pad of

conducti ve rub be r or si milar materia l whe n ha ndling

switch components.

• If a device requir e s sol d e ring, be sur e the as se mbly is

placed on a pad of conduc tive material . Also, be sur e that

you, the pad, and the soldering iron ti p are grounded to

the assembly.

Solde rin g Pr in te d

Circuit Boards

Post-Repair

Safety Checks

Some of the components on the etched circuit boards in the switch have

plated throu gh- holes that allow a sol de r path to both side s of the insulatin g

material. Sol de ring c a n be done from ei ther side of the boa rd with equ al ly

good result s. Wh en soldering to any ci rcuit board, kee p in mind the

following gui de li ne s:

• Avoid unnecessary component unsoldering and soldering.

Excessive replacement can result in damage to the circuit

board and/or ad ja c en t c omponents.

• Do not use a high-power sol de ring iron on etched circ ui t

boards, as exces sive heat may lift a conductor or damage

the board.

• Use a suction devic e or woode n toothpick t o rem ove

solder from co mponent mount ing holes. When using a

suction de vic e , be sure that the equipment is properly

grounded.

After making repa i rs to the E1364A Switch Module, inspect t he sw it ch for

any signs of abnormal internal ly generated hea t, suc h a s discolored pri nte d

circuit boar ds or co mponents, dam aged insulation, or evidenc e of arcing.

Determine and correct the cause of the condition. Then per fo rm the

Functional Ve r ific a ti on Te st described in Cha pter 2 to verify tha t t he switch

is function a l.

46 Service Chapter 4

Page 47

Verification Tests - C Programs

Functional Verification Test

This program is designed to do the Fun ct io na l Ve rif ica ti on Te st found in

Chapter 2, "Verifi cation Tests. "

Example This example sends a *IDN? command to the switch. This test can be used

to verify tha t t he sw it ch is c onne c te d pr operly and is re sponding to a basic

command.

#include <stdio.h>

#include <sicl.h>

Appe ndix A

#define ADDR "hpib7,9,15" /* Address of device */

main ()

{

INST id; /* Define id as an instrum e nt */

char a[256] = {0}; /* Result variabl e */

id = iopen (ADDR); /* Open instrument session */

ipromptf(id, "*IDN?\n", "%t", a); /* Self test com mand */

printf("\n %s", a); /* Print resul t * /

getchar(); /* Pause */

iclose (id); /* Close instrument session */

}

Appendix A Example C Programs 47

Page 48

Performance Verification Tests

These programs are designed to do the Performance Verification Tests

found in Chapte r 2, " V eri fi c ation Tests."

Example:

Closed Channel

Resistance Test

This example performs the Closed-Channel Resistance Test for all

Normally Open and Normally Closed contacts.

/* Closed-channel Resistance Test E1364A */

#include <stdio.h>

#include <sicl.h>

#define ADDR "hpib7,9,15"

#define DMM "hpib7,22"

void main (void)

{

INST id, dm;

char reading[256] = {0}; /* Resu lt variable */

int channel, i;

/* Define id and dm as an instrument */

/* Address of devi c e */

#if defined(__BORLANDC__) && !defined(__WIN32__)

_InitEa syWin() ;

#endif

ionerror(I_ERROR_EXIT);

id = iopen (ADDR);

dm = iopen (DMM);

iprintf (id, "*RST\n");

iprintf (dm, "PRESET NORM;TRIG HOLD\n");

iprintf (dm, "FUNC OHMF\n");

printf ("\n\nConnect DMM to NO and C lines of E1364A (4-wire

connection)");

getchar ();

printf ("\n\nContact Resistance -- Normally open contacts\n");

for (i = 0; i <= 15; i++)

{

channel = 100 + i;

/* Open instrument session */

48 Example C Programs Appendix A

Page 49

iprintf (id, "CLOS (@%u)\n", channel);

ipromptf (dm, "TRIG SGL\n", "%t", reading);

printf ("\n Channel %u (closed): %s", i, reading);

iprintf (id, "OPEN (@%u)\n", channel);

ipromptf (dm, "TRIG SGL\n", "%t", reading);

printf ("\n Channel %u (open): %s", i, reading);

}

printf ("\n\nConnect DMM to NC and C lines of E1364A (4-wire

connection)");

getchar ();

iprintf (id, "CLOS (@100:115)\n");

printf ("\n\nContact Resistance -- Normally closed contacts\n");

for (i = 0; i <=15; i++)

{

channel = 100 + i;

iprintf (id, "OPEN (@%u)\n", channel);

ipromptf (dm, "TRIG SGL\n", "%t", reading);

printf ("\n Channel %u (closed): %s", i, reading);

iprintf (id, "CLOS (@%u)\n", channel);

ipromptf (dm, "TRIG SGL\n", "%t", reading);

printf ("\n Channel %u (open): %s", i, reading);

}

iclose (id);iclose (dm);

}

/* Close instrument session */

Appendix A Example C Programs 49

Page 50

Example: DC

Isolation Test

This example performs the DC Isolation Test for Normally Open and

Normally Closed channels to both Common and chassis (earth ground).

/* DC Isolation Test E1364A */

#include <stdio.h>

#include <sicl.h>

#define ADDR "hpib7,9,15"

#define DMM "hpib7,22"

void main (void)

{

INST id, dm;

char reading[256] = {0}; /* Result va riable */

int channel, i;

#if defined(__BORLANDC__) && !defined(__WIN32__)

_InitEasyWin();

#endif

ionerror(I_ERROR_EXIT);

id = iopen (ADDR);

dm = iopen (DMM);

iprintf (dm, "PRESET NORM;TRIG HOLD\n");

iprintf (dm, "FUNC OHM;RANGE 1E9\n");

printf ("\n\nConnect DMM HI and LO to E1364A NO and C lines");

getchar ();

iprintf (id, "*RST\n");

ipromptf (id, "*OPC?\n", "%t", reading);

ipromptf (dm, "TRIG SGL\n", "%t", reading);

printf ("\nDC Isolation -- Normally Open Channels to Common");

printf ("\n R = %s", reading);

/* Define id and dm as an instrument */

/* Address of device */

/* Open instrument session */

printf ("\n\nConnect DMM HI and LO to E1364A NC and C lines");

getchar ();

iprintf (id, "CLOS (@100:115)\n");

ipromptf (id, "*OPC?\n", "%t", reading);

ipromptf (dm, "TRIG:SGL\n", "%t", reading);

printf ("\nDC Isolation -- Normally Closed Channels to Common");

printf ("\n R = %s", reading);

50 Example C Programs Appendix A

Page 51

printf ("\n\nConnect DMM HI and LO to E1364A NO line and

mainframe chassis");

getchar ();

ipromptf (dm, "TRIG SGL\n", "%t", reading);

printf ("\nDC Isolation -- Normally Open Channels to Chassis");

printf ("\n R = %s", reading);

printf ("\n\nConnect DMM HI and LO to E1364A NC line and

mainframe chassis");

getchar ();

iprintf (id, "OPEN (@100:115)\n");

ipromptf (id, "*OPC?\n", "%t", reading);

ipromptf (dm, "TRIG SGL\n", "%t", reading);

printf ("\nDC Isolation -- Normally Closed Channels to Chassis");

printf ("\n R = %s", reading);

iclose (id);

iclose (dm);

}

/* Close instrume nt session */

Appendix A Example C Programs 51

Page 52

Notes

52 Example C Programs Appendix A

Page 53

Introduction

Appendix B

Backdating Information

This chapter contains information for ordering replaceable parts for the

Agilent E1364A Switch Modules wit h seri al numbers prior to 2934A10370.

• Table B-1 lists the assembly and termin al module part numbe r s fo r

the E1364A Swit ch Module.

• Table B-2 list s the Reference De signators for the switch mo dule.

Ordering

Information

To order a part liste d in Ta ble B-1, specify the Agilent part number and the

quantity req uir e d. Send the order to your ne arest Agilent Tec hnologies Sales

and Support Office.

If your E1364A Swit c h Module has a serial number of 2934A1037 0 an d

higher, refer to Chapter 3 for replaceable parts ordering information.

Replaceable Parts List

See Figures B-1 and B-2 or the Component Lo c ator (in the back of this

manual) for locations of replaceable parts.

Table B-1. Agilent E1364A Replaceable Parts

Reference

Designator

BRK1-BRK2

F1

F2

J1

K0-K15

LBL1

LBL2

Part

Number

E1364-66201 1 COMPONENT ASSEMBLY

0050-2183

2110-0712

2110-0665

1252-1591

0490-1651

E1300-84308

E1300-84312

Qty Part Description

2

1

1

1

16

1

1

PRIMARY COMPONENTS

CASTING-ZN P.C. BOARD HOLDER

FUSE- SUBMINIATURE 4A 125V NTD AX

FUSE- SUBMINIATURE 1A 125V NTD AX UL CSA

CONNECTOR-POST TYPE 5.08-PIN-SPCG 48-CONTACT

RELAY 2C 12VD C-CO IL 3A 220 V DC

LBL LOGO B SIZE

LBL-LOGO VXI B SIZE

MP1-2

P1

SCR1-2

SCR3-4

SHD1

SW1

1400-1546

1252-1596

0515-0444

0515-1968

E1300-80601

3101-3066

2

BRACKET PC BOARD HOLDER; BLACK; EXTRUDED

1

CONNECTOR-POST TYPE 2.54-PIN-SPCG 96-CONTACT

2

SCREW- X 8MM-LG -HD

2

SCR PHM 2.5 X 11 TX

1

SHIELD SAFETY

1

SWITCH-DIP ROCKER 8-1A 0.15A 30VDC

Appendix B Backdating Information 53

Page 54

Reference

Designator

C1 0180-3 899 1 CAPACITOR-FXD 220uF +-2 0% 50 V AL-ELCT LT

C2 0160-3 334 2 CAPACITOR-FXD 0.01uF +-10% 50 V CER X7R

C9 0160-4 801 1 CAPACITOR-FXD 100p F +-5 % 100 V CER C0G

C11 0160-3334 CAPACITOR-FXD 0.01uF +-10% 50 V CER X7R

C17 0160-4835 10 CAPACITOR-FXD 0.1uF +-10% 50 V CER X7R

C38-C42 0160-4835 CAPACITOR-FXD 0.1uF +-10% 50 V CER X7R

C44 0180-1746 1 CAPACITOR-FXD 15uF +-10% 20 V TA

C45-C48 0160-4835 CAPACITOR-FXD 0.1uF +-10% 50 V CER X7R

CR1 1902-0557 1 DIODE-ZENER 24V 5% PD=1W IR=5UA

CR2 1901-1098 1 DIODE-SWITCHI NG 1N4150 50V 200MA 4NS

JM15-JM16 7175-0057 2 RESISTOR 0 MFS

LBL1 7121-7148 1 LABEL-INFORMATION .25-IN-WD .9-IN-LG

LBL2 9320-5333 1 LBL-LNE-PTR; .625- IN- W D X .25- IN -LG

PNL1 E1364-00202 1 PNL-RR RLY MUXR

R1 075 7-0 465 1 RESISTOR 100K +-1% . 125W TF TC = 0+- 100

R2 075 7-0453 1 RESISTOR 30.1K +- 1% .125W TF TC=0+-100

R9 075 7-0 417 1 RESISTOR 562 +-1% .125W TF TC=0+-100

R10 0698-3451 1 RESISTOR 133K +-1% .125W TF TC=0+-100

RP1-RP4 1810-0265 4 NETWORK-RES 16-DIP 680 .0 OHM X 8

RP25-RP26 1810-0279 3 NETWORK-RES 10-SI P 4. 7K O HM X 9

RP32 1810-0279 NETWO R K- RE S 10-SIP 4. 7K O HM X 9

RVT1-RVT2 0361-1231 2 RIVET-SEMITUB OVH .099D I A . 36LG

RVT3-RVT4 0361-1294 2 RIVET-SEMITUB OVH .099D I A . 328L G

RVT5-RVT6 0361-1295 2 RIVET-SEMITUB OVH .095D I A . 406L G

U1-U4 1858-0069 4 TRANSISTOR ARRAY 18-PIN PLASTIC DIP

U5 1820-4057 1 IC BUFFER TTL/F NAND QUAD 2-INP

U6 182 0-6 731 1 IC GATE-ARRAY CM O S

U7-U8 1820-3079 2 IC DCDR CMOS/74HC BIN 3-TO-8-LINE

U9 1820-3081 1 IC FF CMOS/74HC D-TYPE POS-EDGE-TRIG

U10-U11 1820-3975 2 IC DRIVER CMOS/74HC LINE OCTL

U12 1820-4590 1 IC MV CMOS/74HC MONOSTBL RETRIG DUAL

U15 1820-4147 1 IC LCH CMOS/74HCT TRANSPARENT OCTL

U16 1820-3714 2 IC TRANSCEIVER TTL/ALS BUS OCTL

U17-U18 1820-3631 2 IC COMPARATOR CMOS/74HCT MAGTD 8-BIT

U19 1820-3664 1 IC GATE CMOS/HCT NAND QUAD 2-INP

U20 1820-4242 1 IC SCHMITT-TRIG CMOS/74HCT INV HEX

U21-U22 1820-4643 2 IC GATE CMOS/74HCT NOR QUAD 2-INP

Part

Qty Part Description

Number

ADDITIONAL COMPONENTS

3050-0082 2 WASHER-FL NM NO. 4 .1 16- IN-I D .18 8-IN- O D

54 Backdating Information Appendix B

Page 55

Reference

Designator

U25-U26 1820-5424 2 IC DRIVER CMOS/74HCT LINE OCTL

U30 1820-4152 2 IC FF CMOS/74HCT D-TYPE POS-EDGE-TRIG

U35 1820-3714 IC TRANSCEIVER TTL/ALS BUS OCTL

U38 1820-4152 IC FF CMOS/74HCT D-TYPE POS-EDGE-TRIG

Part

Qty Part Description

Number

E1364-80001 1 E1364A TERMINAL MODULE

E1364-66510 1 TERMINAL C ARD 16- CH GP RLY S W I TCH

E1300-84401 1 TERMINAL CARD, CASE ASSEMBLY

Table 3-2. E1364A Re ferenc e Desi gna tors

Agilent E1364A Reference Designators

A assembly P electrical connector (plug)

BRK bracket PCB printed circuit board

C capacitor PNL panel

CR diode R resistor

LBL label RP resistor pack

F fuse RVT rivet

J electrical connector (jack) SCR screw

JM jumper SHD shield

K relay SW switch

LBL label TB terminal block

MP mechanical part U integrated circuit

Appendix B Backdating Information 55

Page 56

Figure B-1. E1364A Component Assembly Parts

56 Backdating Information Appendix B

Page 57

Figure B-2. E1364A Terminal Module Replaceable Parts

Appendix B Backdating Information 57

Page 58

Page 59

Page 60

Copyright © Agilent Technologies, Inc. 1991-2005

Loading...

Loading...