Page 1

75000 SERIES B

Mainframes

E1300B and E1301B

User’s Manual

Copy ri ght © Agi lent Technologies, Inc., 1989, 1990, 1991, 2006

Manual Part Number: E1300-90005 Printed: February 2006 Edition 3

Microfiche Part Number: E1300-99005 Printed in U.S.A. E 0206

Page 2

Page 3

Certification

Agilent Technologies certifies that this product met its published specifications at the time of shipment from the factory. Agilent Technologies further certifies that its calibration measurements are traceable to the United States National Institute of Standards and Technology (form er ly National Bur eau of Standards ), to the ex te nt allowed by that orga nization’s cal ib rat i on f acility, and to the calibrat i on

facilities of other International Standards Organization members.

Warranty

This Agilent Technologies product is w ar ra nted against def ects in materia ls and workmanship for a period of three years f rom date of

shipment. Du ra ti on and conditions of warranty fo r t hi s pr oduct may be supers eded when the product is inte grated into (becomes a pa rt

of) other Agil ent products. Duri ng t he warranty per io d, Ag il ent Technologies will, at i ts opt i on, ei t her repair or repl ace products w hi ch

prove to be def ec t ive.

For warrant y service or repai r, t hi s pr oduct must be ret urned to a service facility designated by A gilent Technologies. Buye r shall prepay shippin g charges to Agilent and Agilent sh al l pay shipping c har ges to return the prod uct t o B uyer. However, Buyer shall pay all

shipping ch arges, duties, and taxes for products returned t o A gi lent from anot her country.

Agilent warrants that its software and firmware designated by Agilent for use with a product will execute its programming instructions

when proper l y in st al led on that pro duct. Agilent does not warrant th at th e operation of the product, or soft w a re, or firmware w ill be uninterru pt ed or er ro r free.

Limitation Of Warranty

The foregoi ng w ar ra nt y shall not apply t o defects resul ting from imprope r or in adequate maint enance by Buyer, Buyer-supp l ie d pr oducts or interfa ci ng, unauthori ze d modificati on or m is us e, operation outsi de of the environm ental specifi c ations for the pro duct, or improper site pr eparation or ma intenance.

The design and implementation of any ci rcuit on this pr oduc t is the sole responsibility of th e B uye r. A gi le nt does not warrant the

Buyer’s circuitry or malfunc tions of Agilent products that re sul t fr om th e B uye r’ s c ir cuitry. In additi on, A gi l ent does not warrant any

damage th at occurs as a resu lt of the Buyer’s ci r cui t or a ny defects tha t result from Buy er -s uppl i ed products.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. Agilent SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES. Agilent SHALL NOT BE LIABLE

FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Notice

The inform at i on contained i n th is document is subj ect to change w i t hout not ice. Agilen t Te chnologies MAKES NO WAR R A N TY OF

ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Agilent shall not be liable for errors contained herein or

for incident al or consequential damages in connect i on w i t h the furnishing, performance or us e of th is material. This document contains

proprietar y in for m at i on w hich is protect ed by copyright . Al l rights are reser ved. No part of this do cument may be phot ocopied, reproduced, or translated to anot her language without the pri or w r it t en consent of Agilent Technologies, Inc. A gi le nt assumes no responsibility for the use or reliability of its software on equipment that is not furnished by Agilent.

U.S. Government Restricted Rights

The Softwa re and Document at i on have been dev el oped entirely at pr iv ate expense. Th ey are delivered and license d as "comme rc ia l

computer sof t w ar e" as defined in DFA RS 252.227- 7013 (Oct 1988), DFARS 252.211-7015 (May 1991) or DFARS 252.227-70 14 (J un

1995), as a "com m ercial ite m " a s de fi ned in FAR 2.101( a) , or as "Restricted computer soft w ar e" as defined in FAR 52. 227-19 (Jun

1987)(or any e qui valent agenc y re gul at i on or contract cl ause), whiche ver is applicable . You ha ve only those right s provided for s uc h

Software and Documentation by the applicable FA R or DFA R S clause or th e A gi lent standa rd s oftw are agreem ent for the product in volved.

Agilent E 1300B and E1301B Mai nframes Servi ce Manual

Copyright © 1992-2006 Agilent Technologies, Inc. Al l Rights Reserved.

Edition 3 Rev 2

i

Page 4

Printing H is tory

The Printing H i st or y sh ow n below lists al l Editions and Up dat es of this manua l and t he pri nt i ng date(s). The firs t printing of the manual is Edition 1. The Edition number increments by 1 whenever the manual is revised. Updates, which are issued between Editions,

contain replacement pages to correct the current Edition of the manual. Updates are numbered sequentially starting with Update 1.

When a new Edition is created, it contains all the Update information for the previous Edition. Each new Edition or Update also includes a re vi sed copy of this pri nt ing history pag e. Many product updates or revisions do not require m anual chang es and, conversely,

manual correction s m ay be done with out accompany in g product chan ges . Therefore, do not expect a one-to-one corr espondence between product updates and manual upda t es.

Edition 1 (P ar t Number E1300 -90 001). . . . . . . . . . . . . . . . . . . . . . October 1989

Edition 2 (P ar t Number E1300 -90 002). . . . . . . . . . . . . . . . . . . . S ept ember 1990

Edition 3 (Part Number E1300-90005). . . . . . . . . . . . . . . . . . . . November 1991

Edition 3 Rev 2 (Part Number E1300-90005) . . . . . . . . . . . . . . . February 2006

Trademark Information

Microsoft ® and MS-DOS® ar e U . S. reg is t ered tradem ar ks of Mi crosoft Corporat ion. IBM® and PC-DOS® are U .S . r egi s te red trademarks of Inte rn ational Busi ness Machine s C or por ation. DEC® , V T 100® , and VT220® are register ed t ra demarks of Dig it a l Equipment Corpor at i on. WYSE® is a re gi st er ed trademar k or Wyse Technol ogy. WY-30 is a trademark of Wyse Technology.

Macinto sh® is a registe re d tr ademark of A ppl e C om puter Inc.

Safety Symbols

Instructi on m anual symbol af fi xed to product. Indicates that the user must refer to the

manual for specific WARNING or CAUTION information to avoid personal injury

or damage t o t he pr oduct.

Alternating current (AC).

Direct current (DC).

Indicates the field wiring terminal that must

be connec t ed t o earth ground bef or e operating the equipment—prot ects agains t el ectrical shock in case of fault.

or

Frame or chassis ground ter minal—ty pi cally connects to the equipment’s metal

frame.

WARNING

CAUTION

Indicate s ha zardous volta ges.

Calls at te nt i on t o a procedure, pr actice, or

condition that could ca use bodily injury or

death.

Calls at te nt i on t o a pr ocedure, prac tice, or condition that could possibly cause damage to

equipme nt or pe rm anent loss of dat a.

WARNINGS

The following general safety prec aut io ns m ust be observed duri ng al l phas es of operation, servi ce , an d re pai r of this product.

Failure to com p l y w i th t hese precauti ons or with spec i fic w arnings else w h e re in this manua l viol ates safety standards of des ig n,

manufac ture, and int ended use of th e p roduct. Agi lent Techn ol ogies assum es no liabil it y fo r the custom er’s failure to comply

with thes e requirements.

Ground the equipm en t: For Safety Class 1 equipment (equipment ha vi ng a pr ot ective earth terminal), an uninterru ptible safety ear th

ground must be provided from t he m ains power sour ce to the product i nput w i ri ng t er m i nal s or supplied po w er cab le .

DO NOT operate the product in an explosive atmosphere or in the pr esence of flammable gases or fume s.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type.

DO NOT use re pai red fuses or sho rt-circuited fu se holders.

Keep away from live circuits: Operating personnel mu st not re m ove equipment covers or shields. Procedure s i nvolving the rem oval

of covers or shi el ds are for use by service-train ed personnel only. U nder certain conditions, dangerous volta ges may exist even with the

equipmen t s w it c hed off. To avoid da ngerous electrical shock , DO N O T perform procedures involving cover or shie ld removal unless

you are qualif ie d t o do so.

DO NOT operat e damaged equipment: Whenever it i s pos si bl e that the safe ty prot ection featur es built into t hi s pr oduct have been i m paired, eit her through phys ic al damage, exc es si ve moisture, or an y other reason, R EMOVE POWE R and do not use the pr oduc t until

safe opera tion can be verified by service- t ra ined personnel . If ne ce ssary, return t he pr oduct to an Agilent Techno l ogi es Sales and Ser vice Office for service and repair to ensure that safety features are maintained.

DO NOT ser v i ce or adjust alon e: Do not at te m pt internal service or adjustment unles s another pers on, capable of rend er in g fi rs t ai d

and resuscitation, is present.

DO NOT substitute par ts or modi fy equipm ent: Because of th e danger of introducing additional hazards, do not instal l substitute

parts or perfo rm any unauthoriz ed modificat ion to the produc t. R et ur n the product to an A gi lent Technologies Sale s and Service Office

for service and repair to ensure that safety features are maintained.

ii

Page 5

Declara tion of Conformit y

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Agilent Tech nol ogies, Inc.

Loveland Manufacturing Cent er

Manufacturer’s Address: 815 14th Street S .W.

Loveland, Col ora do 80537

declares, that the product:

Product Name: 75000 Series B V X I Mai nframe

Model Number: Agilent E1300B/E1301B

Product Options: All

conforms to the following Product Standards:

Safety: IEC 1010-1:1990+A2:1996/EN61010-1:1993

Canada: CSA 556 B

UL 3111

EMC: CISPR 11:1990/ EN55011:1991: Gr oup 1, Cl ass A

EN61000-3-2:1995: Class A

EN50082-1:1992

IEC 801-2:1991: 4kV CD, 8kV A D

IEC 801-3:1984: 3V /m

IEC 801-4:1988: 0. 5kV Signal Lines, 1kV P ower Line

ENV50141:1993/prEN50082-1:1995: 3Vrms

ENV50142:1994/prEN50082-1:1995: 1kV CM, .5kV DM

EN61000--4- 8:1 993/prEN50082- 1:1 995: 3A/m

EN61000-4-1 1:1 994/prEN50082- 1:1 995: 30%, 10ms:60% , 100ms

Conforms with the following European Directives: The product herewith compl ie s w it h th e re quirements of the

Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC and carries the "CE" marking accordingly.

May 7, 2001

Ray Corson, Product Regulation s Progr am Man age r

European contact: Your loca l Agi le nt Te c hnologies Sale s and Service Office or A gi le nt Te c hnologies GmbH,

Department HQ-TRE, Herre nberger Straße 130, D -71034 Böblingen, G e rm any (FAX +49-70 31-14-3143).

iii

Page 6

Agilent 75000 Series B Documentation

Manual Descriptions Installation and Getting Starte d Guide. Contains s tep-by-step ins tructions for

all aspects of plug-in module and mainframe installation. This guide also

contains introductory programming information and examples.

Agilent E1300B/E1301B Mainframe User’s Manual. Contains programmi ng

information f or the mai nframe, front panel operation information (for the

Agilent E1301B mainframe), and general programming information for

instruments installed in the mainframe.

Plug-In Module User’s Manuals. Contains plug-in module programmi ng and

configuration information. Thes e m anuals contai ns examples for the most-used

module f unc tions, and a complete TMSL command reference for the plug-i n

modu le.

Installation and Getting

Started Gu ide

Instrument Appli cations* Using the Mainframe front panel or pacer

Plug-in Module User’s

Manuals

* For Scanning Voltmeter Applications, refer to the Agilent E1326A/E1411A 5 1/2 Digit

Multimeter User’s Manual.

Suggested Sequence for Using the Manuals

Mainframe User’s

Manuals

iv

Page 7

1

Related Documents A g ilent Instrument BA SIC User’s Handbook. Includes three books: Agilent

Inst rument BASIC Prog ramming Techniques , Ag ilent Instrument BASIC

Interfacing Techniques, and Agilent Instrument BASIC Language Referenc e.

Using Agilent Instrument BASIC with the E1405. Contains information on the

version of Agilent Ins trument Basic which can be i nstalled in ROM in your

E1405B Command Module.

Beginner’ s Guide to SCPI. Expl ains the fundamentals of programming

instrum e nts with Standard Commands for Programmab le Instrument s (SC P I).

We recommend this guide to anyone who is programming wi th TMSL for the

first time.

Tutorial Description of the General Purpose Interface Bus. Describes the

technical fundamentals of the General Purpose Interface Bus (GPIB). Thi s

book also includes g eneral information on IEEE 488.2 Common Commands.

We recommend this book to anyone who is programming w ith IEEE 488.2 for

the first time.

IEEE Standard 488.2-1987, IEEE Standard Codes, Formats, Protocols, and

Common Commands. Describes the underlying message formats and data ty pes

used in TMS L and defi nes Common Comm ands. You may find this document

usef ul if you need to know the precise definition of c ertain message formats,

data types, or Comm on Com mands. Available from: The Ins titute of Electrical

and Electronic Engineers, Inc.; 345 East 47th Street;

New York, NY 10017; USA

VXIbus System Specifications. Agilent part number E1400-90006.

The VMEbus Specification. Available from: VMEbus International Trade

Association; 10229 N. Scottsdale Road, Suite E; Scottsdale, AZ 85253; U.S.A.

v

Page 8

About this Manual

Manual Co ntent This manual shows how to use the Agilent E1300/E1301 Mainframe and how to

operate and program instruments within th e mainframe usi ng SCPI (Standard

Commands for Programmable Inst rum ents) commands an d IEEE 488.2

Common Commands. For installation and configuration i nformation refer to the

" Agilent 75000 Series B Installation and Getting Started Guide".

Chapter 1:

Getting Starte d

Chapter 2: Using the

Front Panel

Chapter 3: Using the Display

Terminal Interface

Chapter 4: Using the

Mainframe

Chapter 5: Downloading

Device Drivers

Chapter 6: Controlling

Instruments using GPIB

Chapter 7:

Command Reference

This chapter contains a mai n frame description, discusses the instrument

concept, and contains introductory programming ex am pl es.

This chapter describes how to use the Agilent E1301 mainframe’s front panel

keyboard and display to operate instruments in th e mainframe.

This chapter desc ribes ho w to use a displ ay termi n al to operate instruments in

the mainfram e.

This chapter shows how to use the mainframe’s Pacer, how to change the

primary GPIB address, and how to synchronize internal and external

instruments using the mainframe’s Trigger In and Even t Out ports.

This chapter contains information on downloading device drivers into

non-volatil e mem ory using both GPIB and RS-232 connections.

This chapter shows some general concepts for operating instruments in the

m ainframe u sing IEEE 488.2 Common Commands and the GPIB interface.

The command reference contains a detail ed descripti on of each System

Instrument command. It includes information on the choice of settings and

examples showing th e context in which the c o mmand i s used. It also c o ntains

c ommand references for the supported IEEE 488.2 Common Commands and

IEEE 488.1 GPIB Messages.

Appendix A: Specification This appendix contai ns a list of th e Mainframe’s operating specifications.

Appendix B:

Error Messag es

Appendix C: Conne c ting &

Configuring a Terminal

Appendix D: Sending Binary

Data Over RS-232

This appendix lists SCPI error codes and messages for the System Instrument,

and poss ible causes.

This appendix show s how to set-up a terminal for use with the Display Terminal

Interface described in Ch apter 3.

This Appendix contains information on transferring bi nary files over an RS-232

interface. It i ncludes information on how these files are coded f or transmi ssion.

vi

Page 9

1. G etting Started

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Mainframe Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Optional Mainframe Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Instrument Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Instrument Logical Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Instrument Secondary Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Unassigned Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Introductory Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2. Using the Front Panel

Using this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Front Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Using Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

A 60-Second Menu Tutorial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Using the System Instrument Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Using the Other Instrument Menus . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Executing Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Key Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Menu Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Display Control & Editing Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Instrument Control Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Other Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

In Case of Difficulty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Instrument Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Table of Contents

3. Using the Display Terminal Interface

Using this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Terminal Interface Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Using Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

A 60-Second Menu Tutorial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Using the System Instrument Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Using the Other Instrument Menus . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-11

Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Executing Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

General Key Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Menu and Menu Control Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Editing Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Instrument Control Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Other Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Table of Contents - 1

Page 10

Using Supported Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

The Supported Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Using the HP 700/22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Using the WYSEØ WY-30œ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Using Other Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

What “Not Supported” Means . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Testing Terminals for Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Using a Terminal Without Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -21

In Case of Difficulty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Instrument Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

4. Using the Mainframe

Using this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Using the Pacer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Changing the Primary GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Synchronizing Internal and External Instruments . . . . . . . . . . . . . . . . . . . . 4-3

Mainframe Data Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Using Mainframe Data Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Non-Volatile User Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Allocating a User Memory Segment . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Locating the NRAM segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Using :DOWNload and :UPload? to Access Data . . . . . . . . . . . . . . . . . . 4-9

Data Formats for :DOWNload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

5. Downloading Device Driv er s

About this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

What You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Download Program Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Editing the Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Downloading Drivers in MS-DOS Systems . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Downloading Drivers in GPIB Systems with IBASIC . . . . . . . . . . . . . . . . . . 5-7

Downloading Drivers in GPIB Systems with BASIC . . . . . . . . . . . . . . . . . . 5-8

Downloading Multiple Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Checking Driver Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Manually Downloading a Driverdown manual . . . . . . . . . . . . . . . . . . . . . . 5-10

Preparing Memory for Manual Downloading . . . . . . . . . . . . . . . . . . . . . 5-10

Manually Downloading Over GPIB . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Manually Downloading Over RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

6. Controlling Instrume n t s Using GPIB

About this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Programming Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Status System Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

The Status Byte Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Reading the Status Byte Register . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Service Request Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

2 - Table of Contents

Page 11

The Service Request Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Clearing the Service Request Enable Register . . . . . . . . . . . . . . . . . . . . 6-5

Standard Event Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Unmasking Standard Event Status Bits . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Reading the Standard Event Status Enable Register Mask . . . . . . . . . . . . . 6-7

Reading the Standard Event Status Register . . . . . . . . . . . . . . . . . . . . . 6-7

Operation Status Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Reading the Condition Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Unmasking the Operation Event Register Bits . . . . . . . . . . . . . . . . . . . . 6-8

Clearing the Operation Event Register Bits . . . . . . . . . . . . . . . . . . . . . . 6-9

Using the Operation Status Group Registers . . . . . . . . . . . . . . . . . . . . . 6-9

Clearing Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Interrupting an External Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Synchronizing an External Computer and Instruments . . . . . . . . . . . . . . . . . 6-12

7. System Instrument Command Reference

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Command Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Common Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

SCPI Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Linking Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

SCPI Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

ABORt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

DIAGnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

INITiate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

[SOURce] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

STATus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

SYSTem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

TRIGger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

VXI 7-54

Common Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-65

*CLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-66

*DMC < name_string> , < command_block> . . . . . . . . . . . . . . . . . . . 7-66

*EMC < enable> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-66

*EMC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-66

*ESE < mask> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-66

*ESE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-67

*ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-67

*GMC? < name_string> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-67

*IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-68

*LMC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-68

*LRN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-68

*OPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-69

*OPC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-69

*PMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-69

*PSC < flag> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-69

*PSC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-69

*RCL < state number> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-70

*RMC < name_string> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-70

*RST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-70

*SAV < state number> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-70

Table of Contents - 3

Page 12

*SRE < mask> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-70

*SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-71

*STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-71

*TRG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-71

*TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-71

*WAI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-71

GPIB Message Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-72

Go To Local (GTL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-72

Group Execute Trigger (GET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-72

Interface Clear (IFC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-72

Device Clear (DCL) or Selected Device Clear (SDC) . . . . . . . . . . . . . . . . 7-73

Local Lockout (LLO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-73

Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-74

Serial Poll (SPOLL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-74

Command Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-75

A. Specifications

Mainframe Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Pacer (50% duty cycle): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Real-time Clock: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Trigger Input: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Non-volatile added memory storage lifetime: . . . . . . . . . . . . . . . . . . . . . A-1

Slots: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

EMC, RFI, Safety : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Size: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Weight: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Cooling: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Humidity: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Operating temperature: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Storage temperature: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

SCPI Conformance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Switchbox Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Multimeter Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Counter Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

D/A Converter Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Digital I/O Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

System Instrument Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

B. Error Messages

4 - Table of Contents

Using This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Reading an Instrument’s Error Queue . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Error Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Command Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Execution Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Device-Specific Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Query Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Start-up Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Page 13

C. Connecting and Configuring a Display Ter minal

Using this Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Connecting a Terminal to the Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Configuring a Terminal for the Mainframe . . . . . . . . . . . . . . . . . . . . . . . . C-3

Starting with Default Mainframe Settings . . . . . . . . . . . . . . . . . . . . . . . C-3

Restoring the Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Configuring the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Trying it . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Configuring the Mainframe with Menus . . . . . . . . . . . . . . . . . . . . . . . . . C-4

D. Sending Binary Data Over RS-232

About this Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Formatting Binary Data for RS -232 Transmission . . . . . . . . . . . . . . . . . . . . D-1

Sending Binary Data Over RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Setting Up the Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Table of Contents - 5

Page 14

6 - Table of Contents

Page 15

Chapter 1

Getting Started

Usi ng Th i s Chapter This chapter describes the Agilent E1300B/E1301B Mainframe, defines the

instrument c on cept, and explain s how plug-in modul es are design ated as

instruments in th e mainframe. Thi s chapter also co n tains introducto ry

programming examples showing how to read and set the m ainframe’s c lock and

calendar. This chapter contains the following sections:

• Mainframe Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

• Instrument Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

• Introductory Programming Examples . . . . . . . . . . . . . . . . . . . . 1-4

1

Mainframe

Description

Optional Mainframe

Memory

The Agilent E1301B mainframe contains a front panel keyboard and display; the

Agilent E1300B has no keyboard or display. Otherwise, there is no conceptual

difference between the two mainframes. Both models provide a termi nal based

user interface (Displ ay Terminal Interface) through the built-in, or optional

plug-in s erial interfaces . The front panel keyboard and display are disc ussed in

Chapter 2 of this manual. The Display Terminal Interface is discussed in

Chapter 3.

The mainframe handles such high level operations as language translation of

IEEE-488.2 Common Commands and SCPI (Standard Commands for

Programmable Instruments) com m ands; module-to-module s ynchroniz ation;

and memory manag ement. When i nstalled in the mainframe, SCPI-compatible

register-based plug- in modules behave as independent instruments operating

under control of SCPI commands and Common Commands. Plug-i n m odules

that are not S C PI-compatible mus t b e programmed at a reg ister level (see the

VXI:REG:WRITE and VXI:REG:READ? commands in Chapter 5 of this

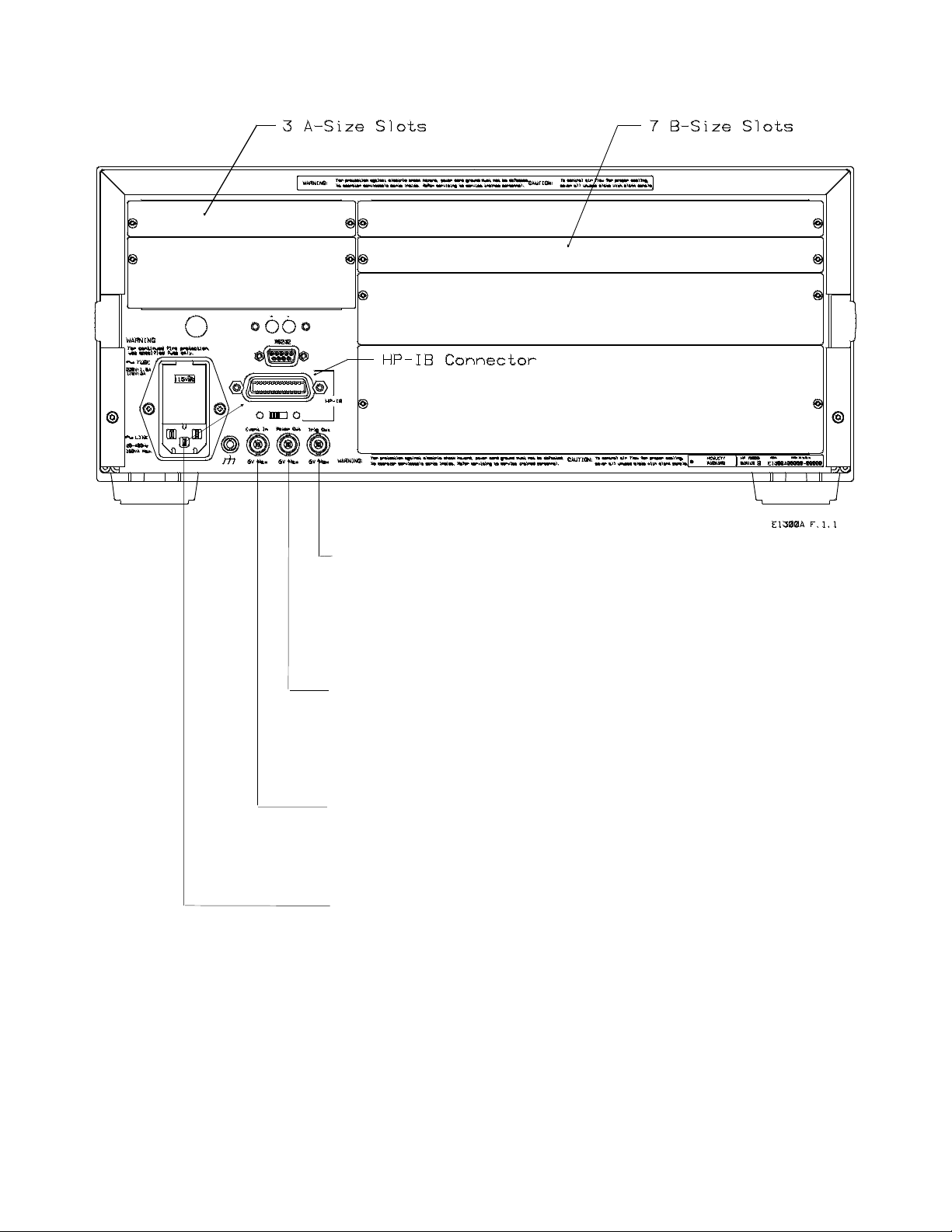

manual for more information). Figure 1-2 shows the E1300B/E1301B

Mainframe’s A- and B-size plug-in module slots, GPIB

and input/o utput ports.

The mainframe comes from the factory with 256 kBytes of non-volatile memory

(RAM) for reading storage. You c an install up to 2 MBytes of opti onal RAM.

The E1320A provides 500 kBytes while the E1321A provides 1 MByte of

memory. Optional RAM replaces the standard memory and is not in addition to

it (e. g. the mainframe with an optional 1 Mbyte module has 1Mbyte availab le).

*

connector, RS-232 port,

* GPIB is the implemen tation of IEEE Std 488.1-1978.

Getting Starte d 1-1

Page 16

Trig Out: Allows an instrument to o utput a negative-going pulse to indicate th e

GPIB

occurrence of som e event such as closing a c hannel on a Switchbox Instrument.

The signal levels are standard TTL (0V to 5V). This pulse can be used to

synchronize external equi pm en t to the instrument (see Ch apter 5 fo r examples).

You direc t th e pulse from the appropriate instrum en t to th e Trig Out port using

the OUTP:STAT ON command.

Pacer Out: Allows you to output a square wave signal to trigger or pace external

equipment such as scanners or voltmeters. Y ou c an c ontrol the period of the

square wave signal and the number of periods output. The si gnal levels are

standard TTL (0V to 5V). Refer to Chapters 4 and 5 for mo re informatio n o n

the Pacer.

Event In: Allows an instrument to be armed or triggered from an external

negative-going signal. The signal levels are stan dard TTL (0V to 5V). Use an

instrument’s ARM:SOUR:EXT command or the TRIG:SOUR:EXT command

to direct the Event In port to that ins trum ent .

RS-232: Serial interface provides a user interface usin g a terminal o r a

computer running terminal em ulator software. The user interface provides the

functionality of the E1301’s keyboard and display. If present, the optional

IBASIC interpreter can be configured to control the RS -232 port.

Figure 1-1. Mainframe Features

1-2 Getting Started

Page 17

1

Instrument

Definition

SC PI-compatible plug-in mo dules installed in th e mainframe are treated as

independent instruments each having a unique secondary GPIB address. As

shown in Figure 1-3, each ins trument is assi gned a dedicated error queue, input

and output buffers, st a tus regist e rs and, if applic a ble, dedicated mainfra me

memory space for reading s or data. An instrument may be composed of a single

plug-in module (such as a counter) or multiple pl ug-in modules (for a Switchbox

or Scanning Voltmeter Instrument). In addition, the mai nframe contains a

built-in instrument called the System Instrument which has a Pacer for timi ng

external devices. The System Instrument also can control the built-in RS-232, as

well as up to seven optional Agilent E1324A plug-in serial interfaces.

Figure 1-2. I nstrument Conc e pt

Getting Starte d 1-3

Page 18

Instrument Logical

Addresses

Instruments are identified by a logical address which directly relates to its GPIB

seco n dary address. Instruments com e from the fac tory with a pres et logical

address. You can chang e the factory setting during installati on (see the "Agi lent

75000 Series B Installation and Getting Started Guide" for instructions).

A single-module instrument must have its logical address set to an integer

multiple of 8 (0, 8, 16, 24, ... 240). In a multiple-module instrument, only one of

the modules has a logical address that is an integer multiple of 8. The other

modules in the multiple-module instrument must have consecutive logical

addresses . For example, in a Scanning Voltmeter, if the vo ltmeter module has a

logical address of 16, the other modules in that instrument must have logical

addresses of 17, 18, 1 9 and so on. The same applies to the System Instrument

who’s logical address fixed at 0. An E1324A plug-in serial interface controlled

by the System Instrument would be set to logical address 1. A second E1324A

would be set to logical address 2 and so on.

Instrument Secondary

Addresses

An instrument’s GPIB secondary address is simply the logical address divided

by 8 (for a multiple-module instrument, the lowest logical address divided by 8).

For example, an instrument with a logical address of 16 h as a secondary address

of 02. Th e secondary address allows acc ess to a particular instrument when

programming vi a GPIB. (The S ystem Instrument’s sec ondary address is 00 and

is the only address that cannot be changed).

Unassigned Modules An unassigned module in an E1300B/E1301B Mainframe is one that does not

have a logical address that is a multiple of 8 (8, 16, 24...240) and is not part of a

Sc anning Voltmeter or Switchbox configuration. You c an only program these

modul es at the register level using the VXI:WRITE and VXI:READ?

commands (see Chapter 5 of this manual for more information on these

commands).

1

Introductory

Programming

Examples

This section shows how to send SCPI and Common Commands to the

mai n frame’s System I nstrument and how to read data back . The fol lowing

assum es that y ou send the commands or read the data over GPIB. To send SCPI

commands or to read data, s pecify the:

• Computer’s GPIB in terface address

• Mainframe’s GPIB prim ary address

• Instrument’s GPIB secondary address

• SCPI comm and string or Common Comm and

1-4 Getting Started

For instruments in the mainframe, the primary address is the same as th e

mai n frame address (i.e., th e factory setting is 09). Th e instrument’s secondary

address is si mply the logical addres s divide d by 8 (e.g., logi cal addresses of 8, 16,

24, or 32, result in secondary addresses of 01, 02, 03, or 04, respectively).

Page 19

Example: Reading the Time This program reads an d prints the time from the System Instrument’s internal

clock. The computer used in the example is an Agilent Series 200/300 computer

with Agilent BAS I C as the program language. The computer in terfaces to the

mai n frame usin g the General Purpos e I n terface Bus (GPIB). Th e GPIB

interface selec t code is 7, the GPIB primary address is 09, and the GPIB

seco n dary address is 00 (System Instrument). Resu lting in a combined address

of 70900.

10 OUTPUT 70900;"*RST" Reset System Instrument using

Common Command

20 OUTPUT 70900;"SY S T :TIME?" Send SCP I query command to

return time

30 ENTER 70900; H,M,S Place hour in H, minutes in M,

se conds in S

40 PRINT H,M,S Print time

50 END

Typical response: + 16, + 15, + 30 (4:15:30 PM)

Example: Setting the Time Set the clock us ing the 24 hour hour,minute,second format. Execute the

following line to set the time to 14,00,00 (i.e., 2:00:00 PM).

SYST:TIME 14,00,00

Example: Reading the Date This program reads an d prin ts the date stored in the mainframe’s i nternal

calendar.

10 OUTPUT 70900;"SY S T:DATE?" Send SCPI query command to

return date

20 ENTER 70900; Y,M,D Place yea r in Y, month in M,

day in D

30 PRINT Y,M,D Print date

40 END

Typical response: + 1989, + 9, + 16 (September 16, 1989)

Example: Setting th e Date Set th e date using the YYYY,MM,DD format. Executing the following line sets

the date to 1990,1,13 (January 13, 1990).

SYST:DATE 1990,1,13

Getting Starte d 1-5

Page 20

1-6 Getting Started

Page 21

Chapter 2

Agilent

Us ing the Front Panel

Usi ng th i s Ch a p ter This chapter shows you how to use the Agilent E1301B Mainframe’s front panel

keyboard and display to operate instruments in th e mainframe. It contains the

following sections:

• Front Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

• Using Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

• Executing Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

• Key Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

• In Case of Difficulty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

• Instrument Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

1

Front Panel

Features

2-Line X 40 Character Display Menu Keys

Fig ure 2 -1 shows the f ront panel’s QWERTY keyboard and the dedicated key

groupings. The tutorials in this chapter show how to use most of the dedicated

keys. See “Key Descriptions” near the end of this chapter for a c omplete

des cription of eac h dedicat ed key.

Displa y Control and

Editing Key s

Instrument

Control Keys

QWERTY Keyboard

Figure 2-1. Front Panel Features

Using the Front Panel 2-1

Page 22

1

Using Menus You can access a System Ins trument menu and a variety of other instrument

menus (depending on install ed i nstruments) from the front panel. Thes e m enus

incorporate the most used functi ons but do not provide access to all of the

ins trument comm ands. If a particular functi on is not available from a menu, you

can type the corresponding command string and exec ute it from the f ront panel.

See “ Execu ting Commands” later in this chapter for more inf ormat ion.

When you select an ins trum en t, you are assigning the keyboard and dis play to

that instrument. Thi s means that any menu operation s, comm an ds executed or

recalled, errors displ ayed, etc. pertain only to that instrument. Front panel

operation of an ins trument i s independent from other instruments and

independent from the remote operation of the ins trument. To operate another

ins trument f rom the front panel, you must select that i nstrument.

Note: Typical instruments shown. Actual choices depend on installed instruments

A 60-Second Menu

Tutorial

Figure 2-2. Select an Instrument Menu

Following the power-on sequence or a system reset the display shows the Select

an instr ument menu (see Figure 2-2) whic h lets you select one of the instruments

listed.

The menu keys are located directly below the display. To select a displayed

menu choice, press the function key (f1 - f5) directly below the choice. This

chapter shows key labels in bold text.

• When there are more than five menu c ho ices, an arrow appears on the

right side of the display. Press More to dis pl ay the nex t group of choi ces.

By repeatedly pressing More you can dis play all groups of choic es. Af ter

you have dis pl ayed all groups of choices, pressing More again returns to

the fi rs t group of choi c es.

• When the display is requesting information (input prompt) such as Enter

the device’ s logical address, just type the inf o rmation and press Return.

If you press the wrong menu key and do not want to enter the

requested in format ion, you ca n es cape the input prom pt and stay at

the same menu level by pressing ESC or Prev Menu.

If you make an incorrect entry in response to an input prompt, the

top line of the display will show an error message. When this

happens, jus t select that menu choice agai n (f1 - f5 key s), re-type the

correct information, and pre ss Return.

2-2 Using the Front Panel

Page 23

• Press Prev Menu to return to the previous m enu within an instrum en t

GPIB

GPIB

GPIB

menu or escape from an input prompt. Press Select Instr to return to the

Select an Instrument menu. Note that when you l eave an i nstrument and

return later, you return to the same menu location you were w h en you

left. In addition, any other displayed information (instrument responses

or commands being entered) will also be displayed when you return.

• In additio n to th e menu keys, Clear Instr and Reset I nstr are helpfu l

when operating an inst rum en t. Clear Instr clears the instrument’s front

panel input and output buffers (remote buffers are not cl eared) and

returns to the top l evel o f the instrument menu. Press C lear Instr

whenever an instrument is busy, is not responding to front panel control,

or to abort a command being entered from the front panel. R eset Instr

clears all front panel and rem ote input and o utput buffers and reset s the

instrument.

Using the System

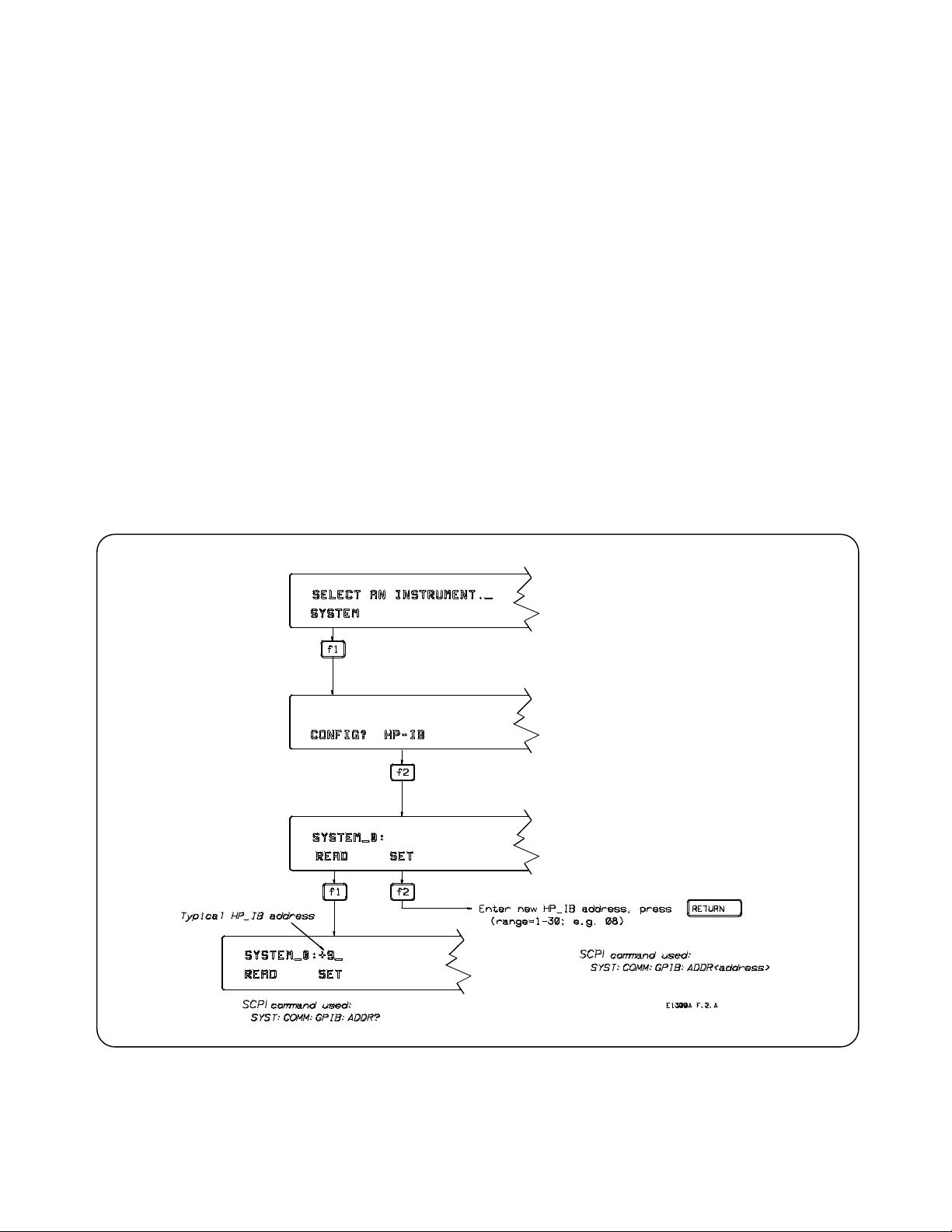

Instrument Menu

Ho w to Set or Read the System GPIB Address

The System Instrument menu allows you to:

• Set or read the system GPIB address

• Reset (reboot) the mainframe

• Display the logical addresses of installed instruments

• Display information about installed ins truments

Using the Front Panel 2-3

Page 24

Ho w to Reset the System

GPIB

GPIB

Note: The RESET menu selection is equivalent to the DIAG:BOOT command which has the same eff ect as cycling power to the mainframe.

Pressing Reset Instr from the System Instrument menu is equiva lent to executing the *RST c omm and which resets the S ystem Ins trument.

How to Display Logical Addresse s or Instrument Information

2-4 Using the Front Panel

Page 25

Using the Other

Instrument Menus

Selecting the Switchbox To select the Switchbox, press the function key (f1 - f5) directly below the word

The instrument menus allow you to access the most-used i nstrument functi ons

or to monitor an instrument (monitor mode) while it is being controll ed f rom

remote. We’ll use the Switchbox menu to show you how to use the instrument

menus. Menus are available for many but not all instruments. S ee “Instrument

Menu s”, later in th is chapter, for more information on a particular instrumen t ’s

menu. The Switchbox menu all ows you to:

• Open and Cl ose Channels

• Sc an C h an nels

• Displ a y Module Type and Des cription

• Monitor a Switchbox

• Reset a selected switch module

SWITCH in the “Select an instrument” menu. (If the “Select an instrument”

menu is not being di splayed press Select Instr.)

Note After you press the function key below the word SWITCH, the top line of the

display may show: “Select SWITCH at logical address: _” while the bottom line of

the display lists two or more logical addresses. This means more than one

Switchbox is installed in the mainframe. To select one of the Switchboxes, press

the function key directly below the corresponding logical address.

The charts on the followi ng pages show how to use the Switchbox menu. K eep

the following points in mind when using the menu:

• The card number identif ies a module within the Switchbox. The module

with the lowest logical address is always card number 01. The module

with the next successive l ogical address is card number 02 and so on.

• The @ character is required preceding a channel list when executing a

Switchbox command from the front panel or remote. When entering a

channel lis t in response to a menu prompt however, do not precede it

with th e @ character. Doi n g so causes a syntax error.

Using the Front Panel 2-5

Page 26

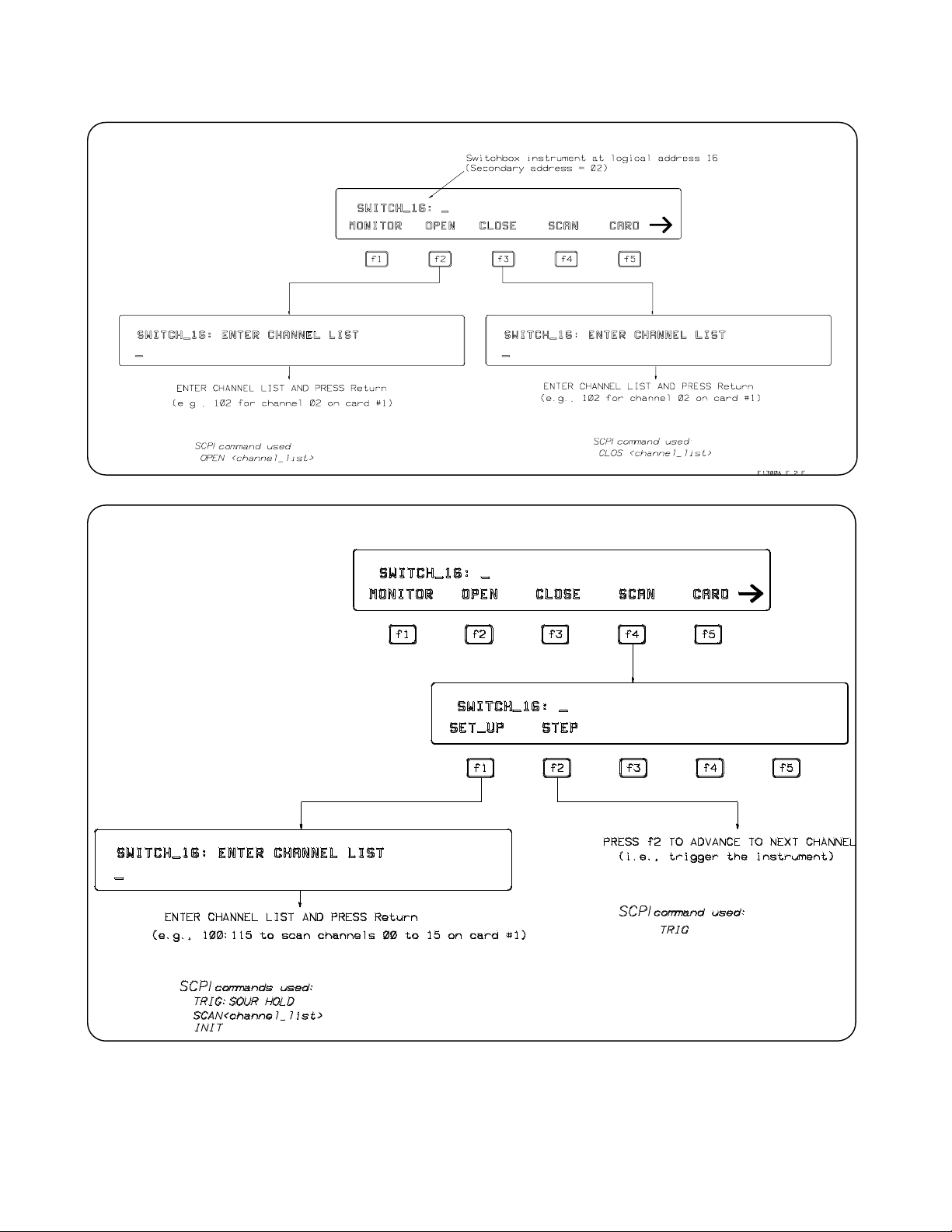

How to Open/Close Channels

How to Scan Channels

2-6 Using the Front Panel

Page 27

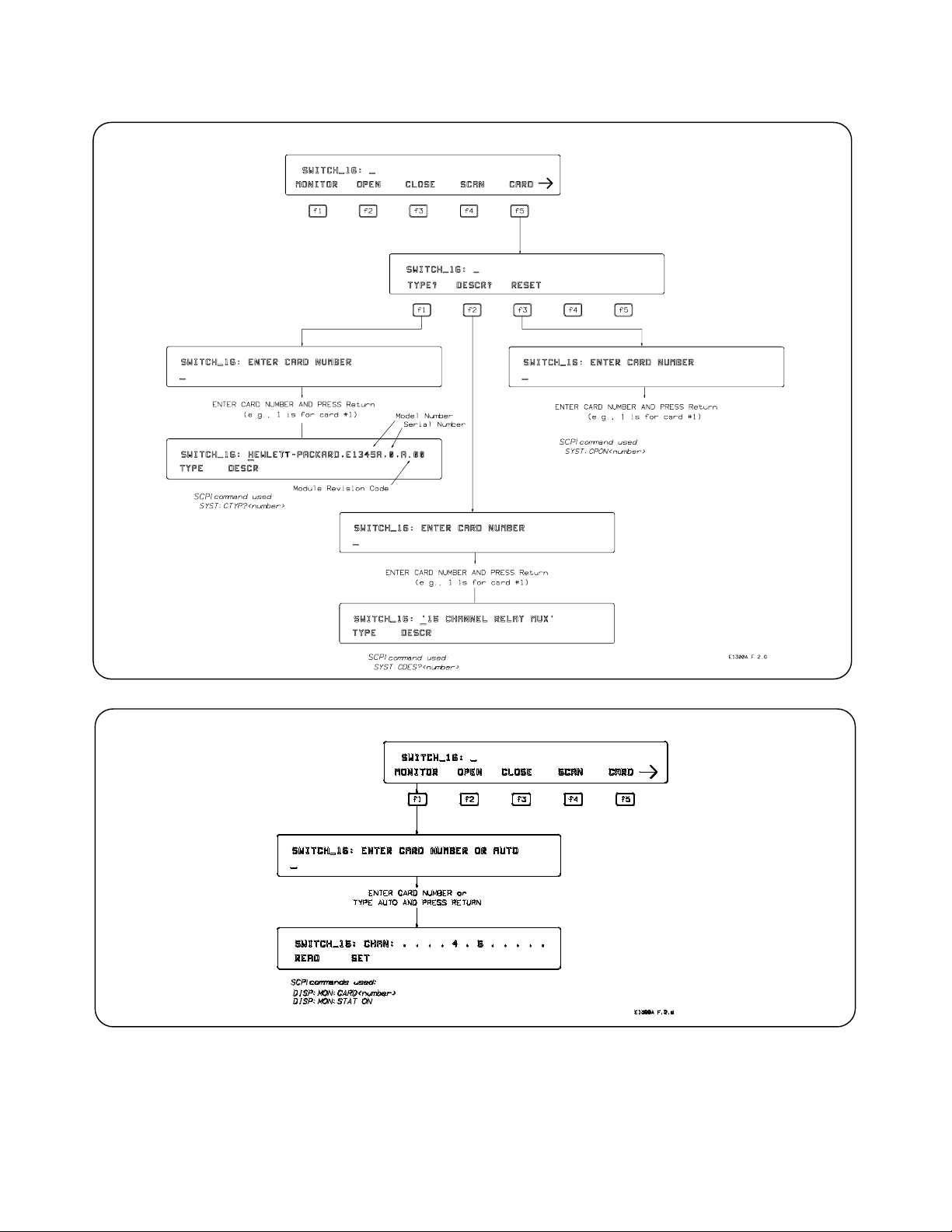

How to Display Monitor Type, Description, or Reset Module

How to Select Monitor Mode

Using the Front Panel 2-7

Page 28

Monitor Mode Monitor mode displays the status of an instrument while it is being controlled

from remote. Moni tor mode is usef ul for debuggi ng programs. You can place an

ins trument i n m onitor mode using front panel menus , or by executing the

DISP:MON:STAT ON command from the front panel or by remote. (Ex ec uting

the remote DISP:MON:STAT ON com mand is the onl y way to assign the

display/keyboard to an instrument from remote.) Pressing most f ront panel keys

will automatically exit monitor mode and return to the instrument menu.

However, you can use the left and right arrow keys in m onitor mode to view long

displays.

Note Enabling monitor mode slows instrument operations. If the timing or speed of

instrument operati o ns is critical (such as making multimeter readings at a

precise tim e interv al), you should not use monitor mode.

Table 2-8 shows the status annunciators that may appear in the bottom l ine of

the display in monitor mode. Some instruments also have device-specific

annunciators (see the plug -in module manual for more informati on).

Table 2-1. Monitor Mode Display Annunciators

A nnunc iator Description

mon Th e instrum e nt is in monitor mode

bsy The instrument is executing a command

err An error has occurred (see “Reading Error

Messages” belo w)

srq A service request has occurred

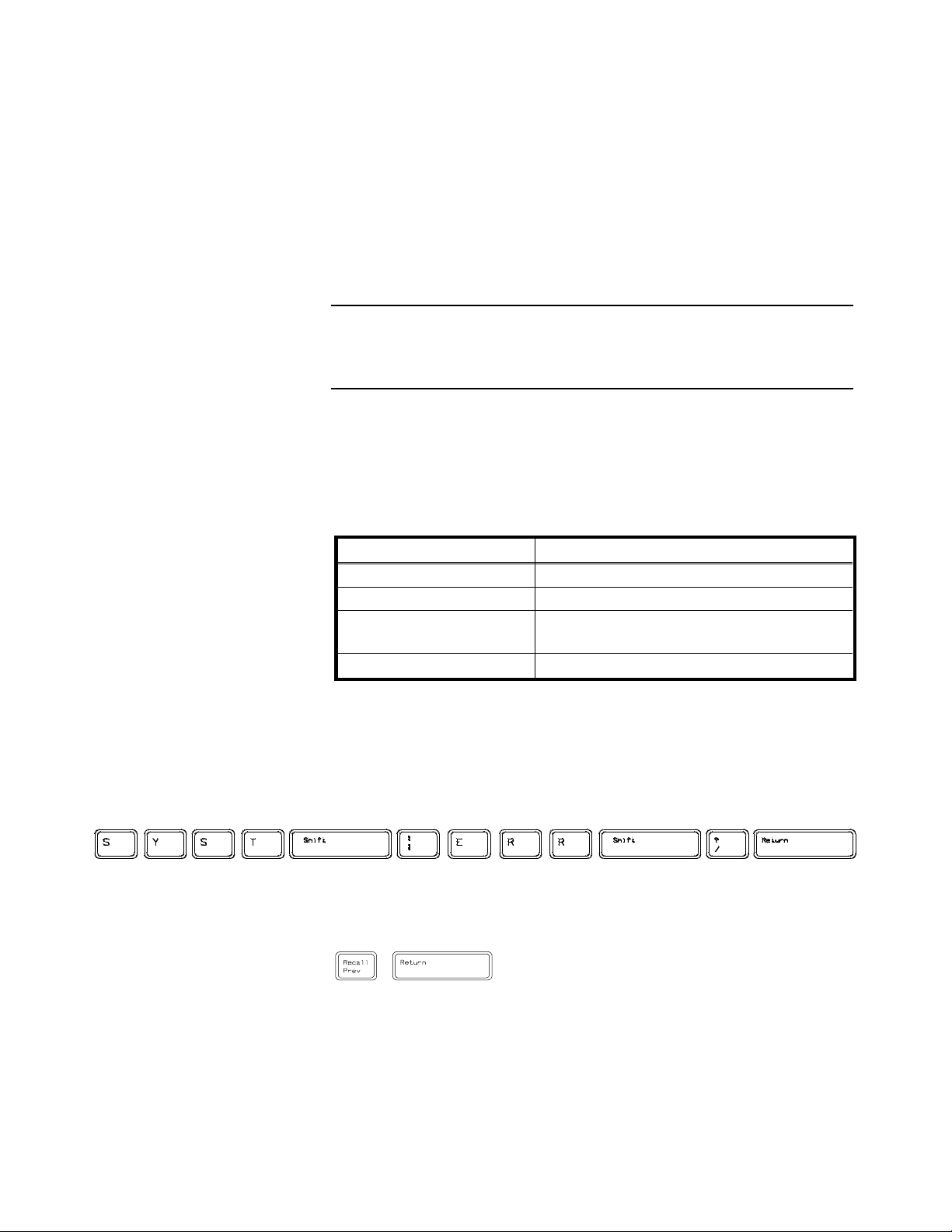

Reading Error Messages Whenever the display is showing the err annunciator, an error has occurred for

the instrument being monitored. You can read the error message, al though

doing so cancels moni to r m o de. To read an error message, press the follo wing

keys:

The error message will be displayed in the top line of the display. To see if

another error was logged, repeat the above keystrokes or press:

After you have read all the error messages, executing the SYST:ERR?

command causes the display to show : + 0 No error. After reading th e error

message(s), press f1 to return to moni to r m ode.

2-8 Using the Front Panel

Page 29

1

Executing

Commands

Fr om the front panel, you can type and execute IEEE 488.2 Common

Comman ds and SC PI C ommands for the instrument presently selected by the

Select an instrument menu. (How ever, you cannot execute a command when the

display is requesting that you input information.) This is particularly useful for

access ing functions not availabl e in an instrument’s menu. For exam pl e, the

System Instrument contai ns a Pacer that can be programmed to output a square

wave signal on the mainframe’s Pacer Out port. From the System Instrument

menu, you can program the Pacer to output 10 s quare w ave cycles with a period

of 1 second each by typing the following commands and pressi ng Return after

each command (see Chapter 3 f o r mo re informati on o n th e Pac er).

SOUR:PULS:COUN 10

SOUR:PULS:PER 1

INIT:IMM

TRIG:SOUR IMM

As another exampl e, after sel ec ting the Switchbox, suppose you must s et up and

execute a scan list with autom atic advan ce (automati c advance is n o t available

from the menu). You can do this by typing the f ollowing command string and

pressing Return (notice that by linking the commands to gether with a sem icolon

and colon you need press Return only once).

TR IG:SOUR IMM;:SCAN (@100:105);:INIT

Editing The display editing keys (shown on the following page) allow you to edit

user-en tered data or commands. When editing, the display is in insert mode.

That is, typed characters will be inserted into the string at the present cursor

position.

Using the Front Panel 2-9

Page 30

1

Key Descriptions Thi s section explains the function of each of the front panel’s dedicated keys. If

a key is not func tional in a particular si tuation, pressing that key does nothing

except to cause a beep. Users of the optional IBASIC interpreter shoul d refer to

their IBASIC manual set for additi onal editing functions.

Menu Ke ys

Selects the menu choice displayed directly above each key.

Returns to the Select an instr ument menu.

Returns to the previ ous menu lev el within an instrument menu or escapes from

an input prompt. When y ou reach the top of an i nstrument’s menu, pressi ng

Prev Menu does no th ing except to cause a beep.

The display can sho w a maximum o f five menu c h o ices at a time. W h en th ere are

more than five menu c h oices, an arrow appears on the right side of th e display.

Press More to display the next group of choi ces. By repeatedly pressing More

you can dis pl ay all groups of c hoices. After you have displayed all groups of

choices, pressing More again returns to the first group of c hoices.

Disp lay Control &

Editing Keys

Recalls the last command entered from the front panel. After recalling a

command, it can be edited or re-executed. You can recall from a stack of

prev iously executed comman ds by repeatedly pressing R ecall Prev. When you

reach the bottom o f the stack (the last line in th e bu ffer), press ing Recall Prev

does nothing except to cause a beep. Press ing Shift with Recall Prev recalls the

last SCPI command gen erated by a menu operation . For example, readi n g the

tim e u sing the menus (SYSTEM, TIME, READ) generates and executes the

SCPI com m and SYST:TIME?. A recalled command can be executed by

pressing the Return key. You can also edi t a recalled command before you

execute it.

Accesses commands in the opposite order to that of Recall Prev. Pressing Recall

Next does nothi ng until you have pressed Recall Prev at least twi ce.

Performs the same function as Prev Menu.

(Right arrow key.) Moves the c u rsor one character s pac e to th e right while

leaving characters i ntact. Use the ri ght arrow k ey to scroll displays that are

longer than the display size. Pres sing Sh i ft followed by the righ t arrow key

moves the cursor to the end of th e line. Pressing CTRL followed by the right

arrow key m oves the cursor 4 character s pac es to the right.

2-10 Using the Front Panel

(Left arrow key.) Moves the cursor one character space to the l eft while leaving

characters intact. Use the l eft and right arrow keys to scroll displays that are

longer than the display size. Pres sing Shift f ollowed by the left arrow key moves

Page 31

the cursor to the beginni ng of the li ne. Pressing CTRL followed by the left

arrow key m oves the cursor 4 character spaces to the left.

Erases the character at the presen t cursor position (fo r user-entered data only).

Erases the character to the left of the curso r (for user-en tered data onl y).

(Clear-to-end key .) Erases al l characters f rom the present cursor posi tion to the

end of the input line (for user-entered data only). Press ing Shift followed by the

cl ear- to -end key erases the en tire line and moves the cursor to the beginni n g of

the line.

Selects the upper-case alphabetic characters or the ch arac ter shown on the top

half of a key. You can either hold down Shift while pressing another key or press

and release Shift and then press another key.

Sets all alphabeti c keys to uppercase (capitals); does not aff ect the other keys.

To ret urn to lowercas e , press Caps Lock again.

Instrume nt C o ntro l

Keys

Other Keys

Resets only the selected instrument (equi valen t of ex ecutin g *RST). Rese t Instr

also clears the instrument’s front panel and remote input and output buffers.

R eset Instr is the only front panel key that can affect an ins trument being

operated from remote.

Clears the front panel input and output buffers (remote buffers are not cleared)

of th e selected instrument and returns to the to p level of the instrument m en u.

Press Clear Instr whenever an instrument is busy, is not responding to front

panel control, or to abort a command being entered from the front panel.

End of line. Enters your responses to menu prompts. Exec utes commands

entered from the front panel keyboard.

Selects al ternate key definitions. You can either hold down CT RL while pressing

another key or press and release CTRL and then press another k ey. Th ese

CTRL key sequences provide sho rt- cuts for some menu key sequences as well as

additional functions not directly av ailable from dedicated front panel keys. For

a complete lis t o f all CTRL key sequenc es see table 3-3 i n th e n ext chapter.

Using the Front Panel 2-11

Page 32

1

In Case of Diffi culty

Problem: Problem Cause/ Solu t io n :

Error -113 undefined header error occurs after entering

data in response to a menu prompt.

Following the power-on sequence or sy stem reset the

display shows:

Configuration errors. Select SYSTEM

Press a ny key to continue_

The display shows: "instrument in local lockout" .

Menus seem to work but nothing happens w hen I reach

the bottom level or try to execute a com mand.

Display cannot be removed from m onitor mode. Monitor mode was entered from remote

Display shows:

Can not connect to ins trument

Press a ny key to continue_

For some commands used by the menus, the data

entered is appended to a com mand header. For

example, if you enter "1" as the port number for a digital

I/O module, the command used is

DIG:HAND1:MODE NONE where HAND1 indicates

the port number. If your entry was invalid or incorrect,

error -113 occurs.

An unnassigned device (incorrect logical address) w as

detected, or the contents of non-volatile memory may

have been lost, If you cycle power or perform system

reset, the display will show the logical address of the

unassigned device. You can al so check the logical

addresses u sing the C ONFIG? -- LADDS branch of th e

System Instrument menu. Refer to Chapter 1 of thi s

manual for a discus sion of logical addresses and

unassigned devices.

The front panel has been locked-out (GPIB local

lockout). You can re-enable menu operation by

cancelling local lockout (from remote) or by cycling

mai n frame power.

(DISP:MON:STAT ON command) and the front panel

has also been lock ed out (GPIB local lockout). Either

cancel the l ocal l oc kout or ex ecute

DISP:MON:STAT OFF (from remote).

A hardware or software problem has oc c ured in the

ins trument prev enting it from responding to front panel

control.

After selecting an instrument the display shows:

busy.

Display shows:

Ins trument in use by another display.

Press a ny key to continue_

2-12 Using the Front Panel

The instrument is busy performing an operation. Press

Clear Instr to abort the instrument operations and

allow the front panel to access the instrument.

The instrument has al ready been selected f rom th e

Display Terminal Interface. An instrument can only be

“attached” to o ne display at a time. At the terminal,

return to the “Select instrument” menu. Th e instrument

can now be selec ted from the Front Panel.

Page 33

2

Instrument Menus This sec tion contains charts showing the s tructure and content for all front panel

ins trument menus . Als o shown in the charts are the SCPI or Common

Commands used and descriptions of menu-controlled instrument operations.

This section c ontains the f ollowing charts:

• S ystem Instrument Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

• Swi tc hbox Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

• S canning Voltmeter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

• Agilent E1326A 5 1/2 Digit Multimeter Menu . . . . . . . . . . . . . 2-20

• Agilent E1328A 4-Channel D/A Converter Menu. . . . . . . . . . 2-21

• Agilent E1330A Quad 8-Bit Digital I/O Menu. . . . . . . . . . . . . 2-22

• Agilent E1332A 4-Channel Counter/Totalizer Menu . . . . . . . 2-24

• Agilent E1333A 3-Channel Universal Counter Menu. . . . . . . 2-26

Using the Front Panel 2-13

Page 34

instruments

2-14 Using the Display Terminal Interface

the specified logical address. (Refer to the

Command R eference for details)

DEVICE logical address VXI:CONF:DLIS? < log_addr> Displays information about the device at

Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 User Entry Command(s ) Used Description

System Instrument Menu

Menu Levels and Content

SYSTEM CON FIG? L ADDS VXI:CONF:DLAD ? Displays lo gical addresses o f mainframe

1200 card number SYST:COMM:SER[n]:BAU D 1200 Sets the serial interface baud rate to 1200

2400 card number SYST:COMM:SER[n]:BAU D 2400 Sets the serial interface baud rate to 2400

9600 card number SYST:COMM:SER[n]:BAU D 9600 Sets the serial interface baud rate to 9600

19200 card number SYST:COMM:SER[n]:BAU D 19200 Sets the serial interface baud rate to 19200

SET 300 card number SYST:COMM:SER[n]:BAU D 300 Sets the serial interface baud rate to 300

SET GPIB address SYST:COMM:GPIB:ADDR < addre ss>

GP IB READ SYST:COMM:GPIB:ADD R? Displays GPIB address

RS232 BAUD READ card number SYST:COMM:SER[n]:BAU D? Read current baud rate

PARITY READ card number SYST:COMM:SER[n] :PAR? Read current parity type

OD D card n umber SYST:COMM:SER[n]:PAR ODD Sets the serial interface parity to odd

ONE card number SYST:COMM:SER[n]:PA R ONE Sets the serial interface parity to one

ZERO card number SYST:COM M:SER[n]:PAR ZERO Sets the serial interface parity to zero

NONE card n umber SYST:COMM:SER[n]:PAR NONE Sets the serial interface parity to none

SET EVEN card n umber SYST:COMM:SER[n]:PAR EVEN Sets the serial interface parity to even

BITS READ card number SYST:COMM:SER [n]:BITS? Read current data bit width

8 card n umber SYST:COMM:SER[n]:BITS 8 Sets the data width to 8 bits

SET 7 card number SYST:COMM:SER [n]:BITS 7 Sets the data width to 7 bits

PACE READ card numbe r SY ST:COMM:SER[n]:PAC E? Read current pacing typ e

NONE card number SYST:COMM:SER[n]:PACE NONE Disables XON/ XOFF software handshaking

SET X ON/ OFF card number SYST:COMM:SER[n]:PACE XON Enables XON/XOFF software handshaking

(continued on following page)

Page 35

se ttings into non-volatile storage.

Using the Display Terminal Interface 2-15

VXI:WRIT <laddr>,<reg>,<data> Write data to register in A16 address space.

reg_num, data

OFF card number SYST:COMM:SER[n] :CONT:DTR OFF Set DTR line to static -V

IBFULL ca rd number SYST:COMM:SER[n]:CONT :DTR IBF Set DTR for hardware handshaking

STANDRD card number SYS T:COMM:S ER[n] :CONT :DTR STAN DTR operates to RS-232 standard

OFF card number SYST:COMM:SE R[n]:CONT:RTS OF F Se t RTS line to static -V

IBFULL ca rd number SYST:COMM:SER[n]:CONT :RTS IBF Set RTS for hardware handshaking

STANDRD card number SYST:COMM:SER[ n] : CONT:RTS STAN RTS operat es to RS-232 standar d

stored in non-volatile memo ry

SET ON card number SYST:COMM:SER[n]:CONT:DTR ON Set DTR line to static + V

CONTROL DTR READ card number SYST:COMM:SER[n] :CONT:DTR? Read current setting for DTR line

(continued from previous page)

System Instrument Menu

Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 User Entry Command(s) Used Description

Menu Levels and Content

SET ON card number SYST: COM M: SER[ n]:CONT: RTS ON Set RTS li ne t o static + V

RTS READ card number SYST:COMM: S E R[n]:CONT:RTS? Read cur rent setti ng for RTS line

STORE card number DIAG:C OMM:SER[n]:STORE Store current serial communications

WRITE laddr,

DEBUG READ laddr, reg_num VXI:READ? < laddr> ,< reg> Read register in A16 address space.

SET time SYST:TIME < time> Set the system clock

TIME RE AD SYST:TIME? Read the current system clock

SET date SYST:DATE < date> Set the system calendar

DATE READ SYST:DATE? Read the current system calendar

RES ET DIAG:BOOT Resets mainframe using the configuration

Page 36

othe r number= fail)

2-16 Using the Display Terminal Interface

OPEN channel list † OPEN (@channel_list) Open channel(s)

CLOSE channel list † CLOS (@channel_list) Close channel(s)

SCAN SET_UP channel list † TRIG:SOUR HOLD;:SCAN <channel_list> ;:INIT Set up channels to scan

Level 1 Level 2 Level 3 User Entry Command( s ) Used Description

Switchbox Menu

Menu Levels and Content

SWITCH MONITOR card number ‡ or AUTO DISP:MON:CARD <card_number> ;STAT ON Monitor instrument operations

STEP channel list † TRIG Step to next channel in scan list

DESCR? card number ‡ SYST:CDES? < card_number> Display module description

RESET card number ‡ SYST:CPON < ca rd_number> Re turn module to power-on state

CARD TYPE? card number ‡ SYST:CTYP? < card_number> Display module ID information

TEST * TST? Runs self-test, displays result s (+ 0= pass; any

† Channel lists are of the form “ccnn” (single channel), “ccnn,cc nn” (two or more channels) or “ccnn:ccnn” (range of channels); where “cc” is the card number and “nn” is the channel

number. For example, to access channel 2 on card number 1 spec ify 102.

‡ The card number identifies a module within the Switchbox. The switch modu le with the lowest log i cal address is a lways ca rd number 01. The switch module with the next

succes sive logical address is ca rd number 02 and so on.

Page 37

Notes

Using the Front Panel 2-17

Page 38

DISP:MON:CHAN <channel_list>;STAT O N Monitor instrument ope rations

2-18 Using the Display Terminal Interface

for auto

E channel list † ME AS:TEMP? TC,E, < channel_lis t> Measure °C of E thermocouple on each channel

J channel list † MEAS:TEMP? TC,J, <channel_list> Measure °C of J thermoc ouple on each channel

K channel list † ME AS:TEMP? TC,K, < channel_list> Measure °C of K thermocouple on each channel

N14 channel list † MEAS:TEMP? TC,N14, <channel_list> Measure °C of N14 thermocouple on each channel

N28 channel list † MEAS:TEMP? TC,N28, <channel_list> Measure °C of N28 thermocouple on each channel

R cha nnel list † MEAS:TEMP? TC,R, < channel_list> Measure °C of R thermocouple on each channel

S channel list † ME AS:TEMP? TC,S, < channel_list> Measure °C of S thermocouple on each channel

T channel list † MEAS:TEMP ? TC,T, <channel_list> Measure °C of T thermocouple on e ach channel

5K channel list † MEAS:TEMP? THER,5000,< channel_list> Measure °C of 5k Ω thermistor on each channel

10K channel list † MEAS:TEMP? THER,10000,< channel_list> Measure °C of 10k Ω thermistor on each channel

392 cha nnel list † MEAS:TEMP? RTD,92,< channel_list> Measure °C of 392 RTD on each channel (4-wire)

POISSON chan nel list † MEAS:STR:HPO? < channel_list> Measure strain with Poisson half bridge

BENPOIS channel list † MEAS:STR:FBP? < channel_list>, Measure strain with Be nding Poiss on full bridge

POISSON chan nel list † MEAS:STR:FPO? < channel_list> Measure strain with Poisson full bridge

VDC channel list † MEAS:VOLT:DC? < channel_list> Measure DC voltage on each channel

VAC channel list † MEAS:VOLT:AC? <channel_list> Me asure AC voltage on each channel

Level 1 Level 2 Level 3 Level 4 User Entry Command( s ) Used Description

Scanning Voltmeter Menu

Menu Levels and Content

VOLTMTR MONITOR channel list † or 0

THERMIS 2252 channel list † MEAS:TEMP? THER,2252,< channel_list> Measure °C of 2252 Ω thermistor on each channel

OHM channel list † MEAS:RES? < channel_list> Measure 2-wire resistance on e ach channel

TEMP TCOUPL E B channel list † MEAS:TEMP? TC,B, <channel_list> Measure °C of B thermocouple on each channel

RTD 385 channel list † MEAS:TEMP? RTD,85,<channel_list> Measure °C of 385 R TD on each channel (4-wire)

HALF B ENDING c hannel list † MEAS:STR:HBE N? <channel_list> Measure strain with bending half bridge

STRAIN QUA RTER channel list † MEAS:STR:Q UAR? < channel_ list> Measure stra in with quarter bridge

FULL BENDING channel list † MEAS:STR:FBEN? < channel_list> Measure strain with bending full bridge

(continued on following page)

Page 39

number= f ail)

Using the Display Terminal Interface 2-19

UNSTRN channel list † MEAS:STR:UN ST? < channel_list> Measure bridge unstrained

DIAG COMPRES channel list † MEAS:STR:Q COM? < channel_list> Compression shunt diag nostic

Level 1 Level 2 Level 3 Level 4 User Entry Command( s ) Used Description

Scanning Voltmeter Menu

Menu Levels and Content

(continued from previous page)

TENSION channel list † MEAS:STR:QTEN? < c hannel_list> T ension shunt diagnostic

DESCR? card number ‡ SYST:CDES? < card_number> Displays module description

CARD TYPE? card num be r ‡ SYST:CTYP? < card_number> Displays module ID information

TEST * TST? Runs self-test, displays results ( + 0= pass; any ot her

† Channel lists are of the form “ccnn” (single channel), “ccnn,cc nn” (two or more channels) or “ccnn:ccnn” (range of channels); where “cc” is the card number and “nn” is the channel

number. For example, to access channel 2 on card number 1 spec ify 102.

‡ The card number identifies a module within the Switchbox. The switch modu le with the lowest log i cal address is a lways ca rd number 01. The switch module with the next

succes sive logical address is ca rd number 02 and so on.

Page 40

VDC MEAS:VOLT:DC? Measure DC volts

2-20 Using the Display Terminal Interface

VAC MEAS:VOLT:AC? Measur e AC volts

OHM MEAS:FRES? Measure 4-wire ohms

Level 1 Level 2 Level 3 Level 4 User Entry Command(s ) Used Description

Agilent E1326B/E1411B 5 1/2 Digit Multimeter (Standalone) Menu

Menu Levels and Content

VOLTMTR MONITOR DISP:MON:STAT ON Display instrument operations

5K MEAS:TEMP? FTH,5000 Measure °C of 5kΩ thermistor (4-w ire measur ement)

10K MEAS:TEMP? FTH,10000 Measure °C of 10kΩ thermistor (4-wire measurement)

392 MEAS:TEMP FRTD,92? Measure °C of 100Ω RTD with alpha = 392 (4-wire measurement)

RTD 385 MEAS:TEMP FRTD,85? Measure °C of 100Ω RTD with alpha = 385 (4-wire measurement)

TEMP THERMIS 2252 MEAS:TEMP? FTH,2252 Measure °C of 2252Ω thermistor (4-wire measurement)

TEST *TST? Run sel f-test, di spl ay results (0= pass; any other number = fai l)

† Channel lists are of the form “ccnn” (single channel), “ccnn,cc nn” (two or more channels) or “ccnn:ccnn” (range of channels); where “cc” is the card number and “nn” is the channel

number. For example, to access channel 2 on card number 1 spec ify 102.

‡ The card number identifies a module within the Switchbox. The switch modu le with the lowest log i cal address is a lways ca rd number 01. The switch module with the next

succes sive logical address is ca rd number 02 and so on.

Page 41

number= f ail)

Using the Display Terminal Interface 2-21

CHAN2 DISP:MON:CHAN 2;STAT ON Monitor instrument ope rations on c hannel 2

CHAN3 DISP:MON:CHAN 3;STAT ON Monitor instrument ope rations on c hannel 3

CHAN4 DISP:MON:CHAN 4;STAT ON Monitor instrument ope rations on c hannel 4

AUTO DISP:MON:CHAN AUTO;STAT ON Monitor instrument operations on active channel

Level 1 Level 2 Level 3 Level 4 User Entry Command(s) Used Description

Agilent E1328A 4-Channel D/A Converter Menu

Menu Levels and Content

D/A MONITOR CHAN1 DISP:MON:CHAN 1;STAT ON Monitor instrument ope rations on c hannel 1

CHAN2 voltage † VOL T2 < voltage> Output voltage on channel 2

CHAN3 voltage † VOL T3 < voltage> Output voltage on channel 3

CHAN4 voltage † VOL T4 < voltage> Output voltage on channel 4

OUTPUT VOLTAGE CHAN1 voltage † VOLT1 < voltage> Output voltage on channel 1