Page 1

Agilent 85225F

Performance Modeling System

Installation and User’s Guide

Agilent Technologies

Page 2

Notices

© Agilent Technologies, Inc. 2005

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

Acknowledgments

UNIX® is a registered trademark of the

Open Group.

Windows NT

mark of Microsoft Corporation.

Windows

istered trademarks of Microsoft Corporation.

®

is a U.S. registered trade-

®

and MS Windows are U.S. reg-

Manual Part Number

85225-90023

Edition

First edition, April 2005

Printed in USA

Agilent Technologies, Inc.

1400 Fountaingrove Parkway

Santa Rosa, CA 95403 USA

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, with out notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damage s in connection

with the furnishing, use, or performance of this document or of any

information contained he re in. Should

Agilent and the user ha v e a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

agency regulation or co ntract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencie s of t h e U .S . Gov ernment will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987) . U.S . Gov er nment users will receive no greater than

Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Technology Licenses

The hardware and/or sof tware describe d in

this document are furnished under a

license and may be used or copied only in

accordance wi t h the terms of such license.

Restricted Rights Legend

If software is for use in the performance of

a U.S. Government prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

Page 3

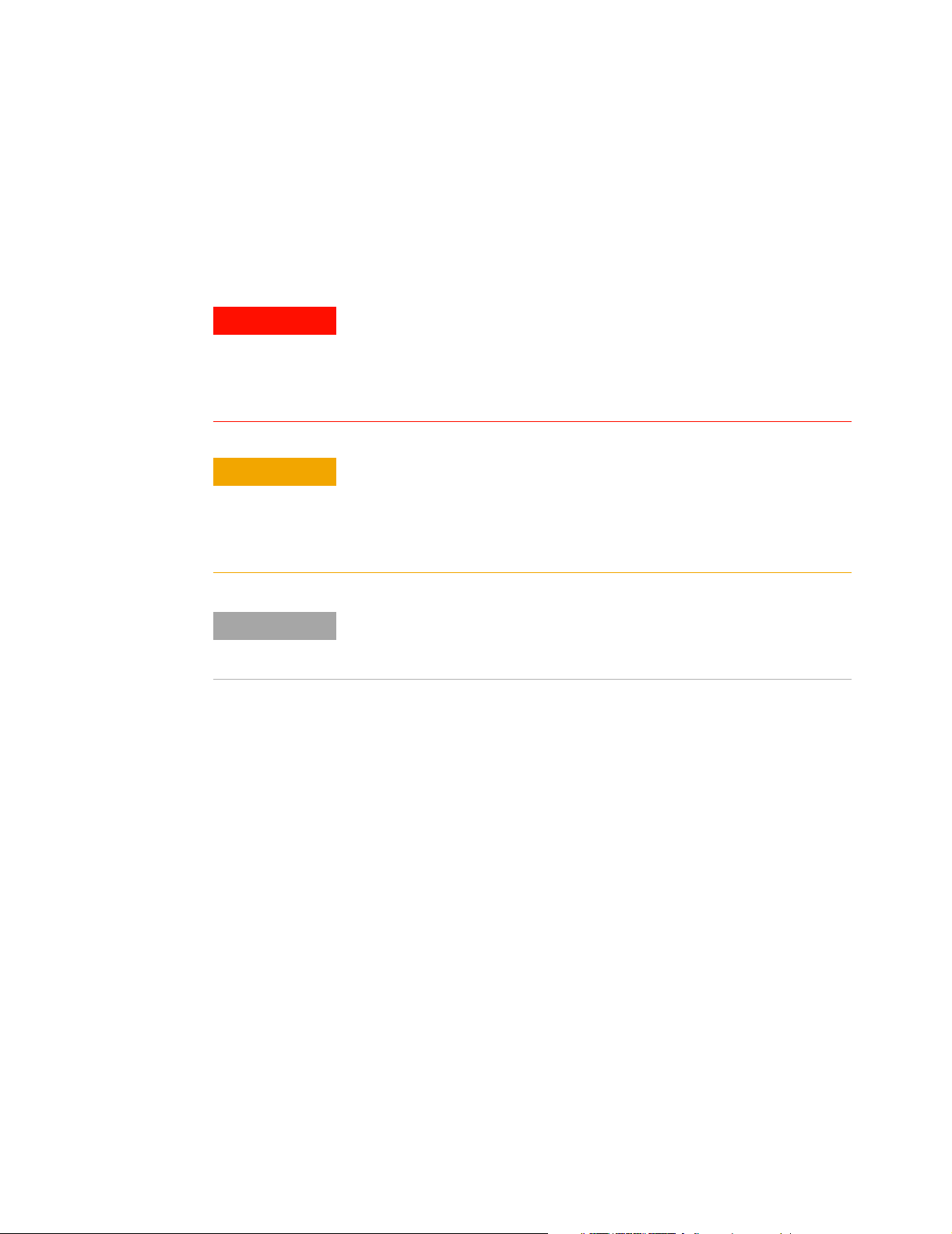

Safety and Regulatory Information

Warnings, Cautions, and Not es

This installation and user’s guide utilizes the following safety notations.

Familiarize yourself with each notation and its meaning before operating

the Agilent 85225F performance modeling system.

WARNING

CAUTION

NOTE

A WARNING notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like that, if not correctly performed or

adhered to, could result in personal injury or death. Do not proce ed

beyond a WARNING notic e unt il the indicated conditions are fully

understood and met.

A CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like that, if not correctly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

A NOTE calls the user’s attention to an important point or special

information within the text. It provides additional information or

instructions.

Installation and User’s Guide 3

Page 4

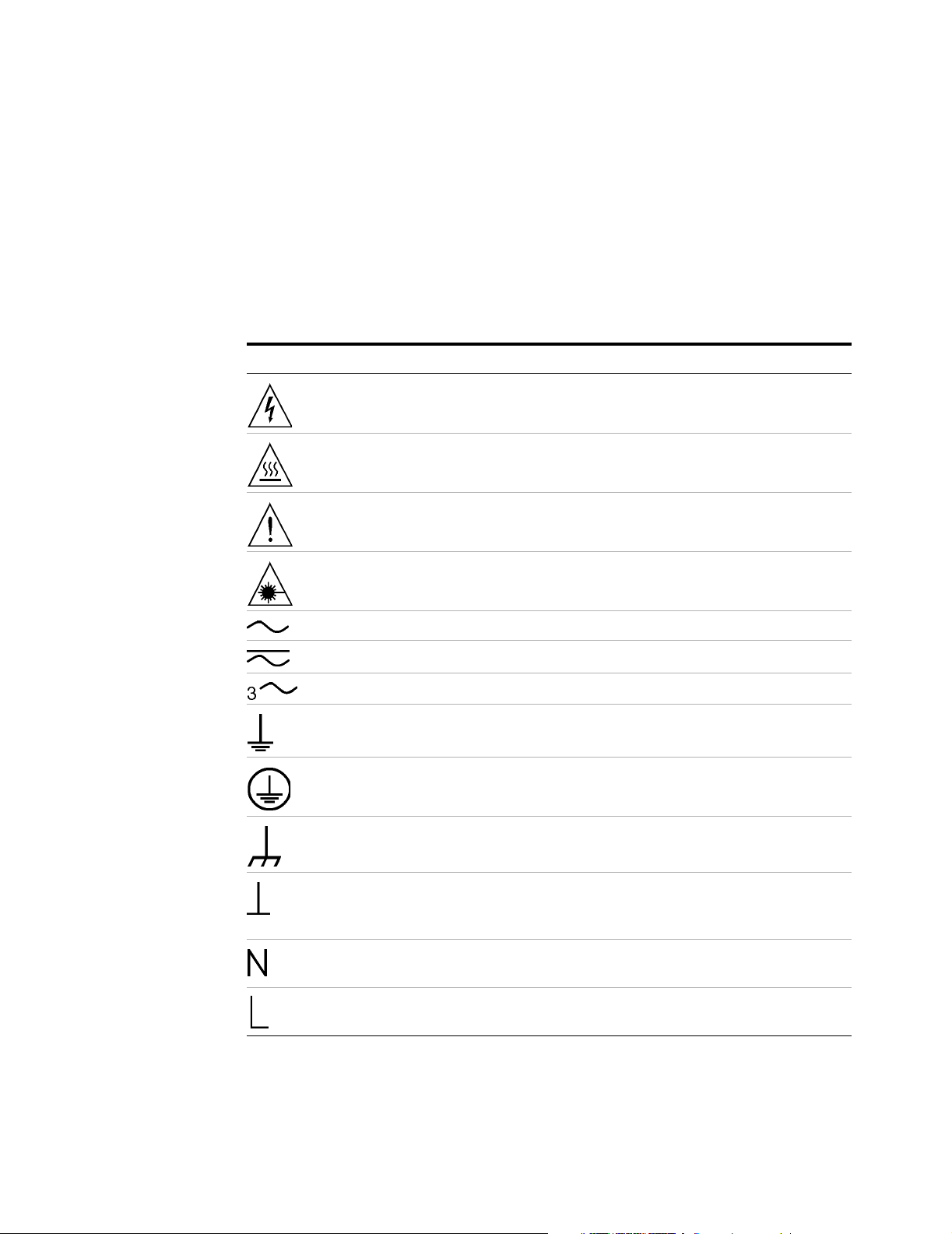

Safety Symbols and Instrument Markings

Symbols and markings in documentation and on instruments alert you to

potential risks, provide information about conditions, and comply with

international regulations. Table A defines the safety symbols and Table B

on page 5 defines the instrument markings you may find in the

documentation or on an instrument.

Table A Safety Symbols

Symbols Definition

Warning: risk of electric shock.

Warning: hot surface.

Caution: refer to instrument documen tat i on.

Laser radiation symbol: marked on pr oducts that have a laser

output.

Alternating current.

Both direct and alternating current.

Three-phase alternating current.

Earth (ground) terminal.

Protective earth (ground) terminal.

Frame or chassis terminal.

Terminal is at earth potential. Used for measurement and

control circuits designed to be operated with one terminal at

earth potential.

Terminal for neutral conductor on permanently installed

equipment.

Terminal for line conductor on permanently installed

equipment.

4 Installation and User’s Guide

Page 5

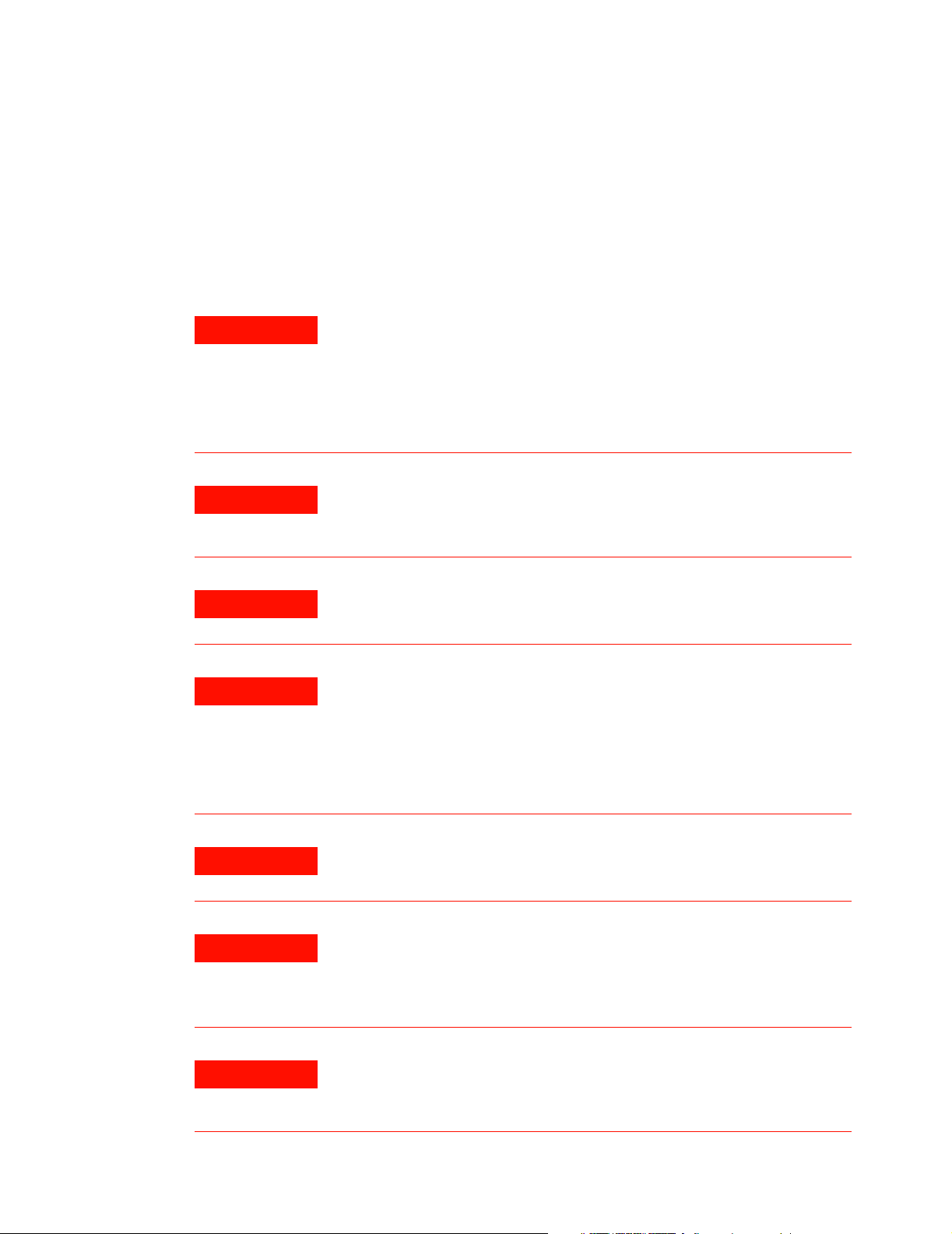

Table A Safety Symbols (continued)

Symbols Definition

Standby (supply). Units with this s ymb ol are not completely

disconnected from AC mains w hen this s witch is in th e stand by

position. To completely disconnect the unit from AC mains,

either disconnect the power cord, or have a qu alified/licensed

electrician install an external switch.

ON (supply). A switch with this symbol closes the instrument’s

power supply circuit, connecting it to the mains supply .

OFF (supply). A switc h with th is symbo l open s the instr umen t’s

power supply circuit, disconnecting it from the mains supply.

Table B Instrument Markings

Marking Definition

The instruction documentation symbol appears when it is

necessary for the user to refer to the instruction in the

documentation.

The CE mark is a registered trademark of the European

Community.

This product compli es with the WEEE Directiv e (2002/96/EC)

marking requirements. The affixed la bel indicates th at you must

not discard this electrical/el ectronic product in domestic

household waste. To return unwanted products, contact your

local Agilent Technologies office, or see www.agilent.com for

more information.

The CSA mark is a registered trademark of the

CSA-International.

N10149

ISM1-A This text indicates t hat the instrume nt is an In dustrial S cienti fic

ICES/NMB-001 This text indicates product compliance wi th the Canadian

The C-tick mark is a registered trademark of the Spectrum

Management Agency of Australia. This signifies compliance

with the Australian EMC Framework regulations under the

terms of the Radio Communications Act of 1992.

and Medical Group 1 Class A product (CISPER 11, Clause 4).

Interference-Causing Equipment Standard (ICES-001).

Operator Safety Requirements

The following general safety precautions must be observed during all

phases of operation of this system. Failure to comply with these

precautions or with specific warnings elsewhere in this manual violates

Installation and User’s Guide 5

Page 6

safety standards of design, manufacture, and intended use of the product.

Agilent Technologies, Inc. assumes no liability for the customer’s failure to

comply with these requirements.

For additional safety precautions, including precautions for making device

measurements in a floating ground configuration, see “To ensure your

safety while using the system" on page 76.

WARNING

WARNING

WARNING

This is a Safety Class 1 Product (provided with a protective earthing

ground incorporated in the mains supply cord). The mains plug shall

be inserted only in a socket outlet provided with a protective earth

contact. Any interruption of the protective conductor inside or

outside of the product is likely to make the product dangerous.

Intentional interruption is prohibited.

If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used only in a

normal condition (in which all means for protection are intact) only.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE. Do not operate

the instrument in the presence of flammable gases or flames.

WARNING

DO NOT REMOVE THE INSTRUMENT COVER. Operating personnel

must not remove instrument covers. Component replacement and

internal adjustments must be m a de only by qualified service

personnel. Instruments that appear damaged or defective should be

made inoperative and se cured against unintended operation until

they can be repaired by qualified service personnel.

WARNING

WARNING

WARNING

6 Installation and User’s Guide

Installing additional instrument s may dest abi l ize the rack cabinet.

Installing additional instruments into the ca bine t electrical system

could produce excessive leakage current. If the protective earth

conductor is interrupted or faulted, the user risks serious inj u ry or

death.

Prior to adding any additional instruments, review all wiring and

cooling capabilities to verify adeq uate design margins for nor mal and

under single fault conditions.

Page 7

Mains power

CAUTION

Ground the system

WARNING

WARNING

Before applying power

CAUTION

The mains cable shall be permanently connected to the premise circuit

breaker or connected using an agency approved twist-lock connector.

To minimize shock hazard, the rack cabinet must be connected to an

electrical protective earth ground. The power distribution unit (PDU)

must be connected to the AC power mains through a grounded power

cable, with the ground wire firmly connected to an electrical ground

(safety ground) at the power outlet.

Any interruption of the protective (grounding) conductor or

disconnection of the protective earth terminal will cause a potential

shock hazard that could result in personal injury.

Verify that the product is set to match the available line voltage, the

correct fuse is installed, and all safety precautions are taken. Before

applying power, note the product’s external markings described in

Table A, “Safety Symbols,” on page4 and Table B, “Instrument

Markings,” on page5.

CAUTION

CAUTION

CAUTION

Installation and User’s Guide 7

It is recommended that the premise wiring contain an adequate circuit

breaker for system protection.

To remove power from the cabinet, remove the mains supply from the

premise electrical supply.

Before switching on this system, make sure that the supply voltage is

in the specified range.

Page 8

CAUTION

Fuses and breakers

The front panel LINE switch disconnects the mains circuit from the

mains supply. Ho wev e r, the mains supply to the po wer d is tr ib ut io n u n it

remains energized.

WARNING

Before cleaning the system

WARNING

Overcurrent protection

CAUTION

For continued protection against fire hazard, use only fuses with the

required rated current, voltage, and specified type (normal blow ,

time delay). Do not use repaired fuses or short-circuited fuse

holders. Replace only with an identical fuse.

There are two resettable thermal bre a ke rs located on the power

strips. These are in the “hot” and “neutral” lines.

To prevent electrical shock, disconnect the system from mains before

cleaning. Use a dry (or slightly water-dampened) cloth to clean

external case parts. Do not atte mpt to clean internally.

If the power outlet strip breaker trips once, reset the breaker. If the

breaker trips twice, call a qualified/licensed electrician to service the

test system.

Statement of Compliance and Declaration of Conformity

This product has been designed and tested in accordance with accepted

industry standards, and has been supplied in a safe condition. The

documentation contains information and warnings that must be followed

by the user to ensure safe operation and to maintain the product in a safe

condition.

The Manufacturer’s Declaration of Conformity is available upon request.

Statement of CAN/CSA Compliance

This product has been designed and tested in accordance with

CAN/CSA- C22.2 No. 61010- 1 IEC.

8 Installation and User’s Guide

Page 9

Compliance with German Noise Requirements

This is to declare that this instrument is in conformance with the German

Regulation on Noise Declaration for Machines (Laermangabe nach der

Maschinenlaermrerordnung - 3.GSGV Deutschland).

Acoustic Noise Emission/Geraeuschemission

LpA <70 dB LpA <70 dB

Operator position am Arbeitsplatz

Normal position normaler Betrieb

per ISO 7779 nach DIN 45635 t.19

Compliance with Canadian EMC Requirements

This ISM device complies with Canadian ICES- 001. Cet appareil ISM est

conformé à la norme NMB du Canada.

IEC/EN 61000-4-2 Electrost atic Discharge Immunity Test

This system passes using criterion C where operator intervention may be

necessary to restart the measurement software operations.

IEC/EN 61326 Electrostat ic Di sc harg e and Surge Im muni t y Test

This system complies with the Electrostatic Discharge and Surge Immunity

requirements in the IEC/EN 61326 standard using Performance Criterion

C.

For Technical Assistance

To receive technical assistance, visit the online assistance web site, or call

the telephone number listed in Table 19 on page 107 appropriate to the

location of modeling system.

Installation and User’s Guide 9

Page 10

In This Guide...

1 Introducing the Agilent 85225F Performance Modeling System

2 Installing the System

3 Verifying System Functionality

This guide provides instruction on installing, verifying, and servicing the

system, as well as an introductory system overview and reference material.

This information is presented for use by the customer or an Agilent

Technologies field engineer.

This chapter provides a description of the system, its components,

integration, and characteristics.

Here you will find instruction on preparing the installation site, receiving

and inspecting the system (including a receiving checklist), installing the

worksurface, ensuring operator safety, connecting the bias networks, and

powering- on the system.

Turn here for instruction on choosing a level of system verification and

performing a post-installation functional verification test using a system

controller running IC- CAP software.

4 Servicing the System

This chapter includes instruction on troubleshooting the system, removing

and replacing system components, ordering replacement parts, and

acquiring additional assistance in solving measurement problems.

A Enhancing Measurement Accuracy

See this appendix for instruction on cleaning the system connections,

performing a system measurement calibration, and suggested intervals for

periodic component calibration.

B DC Subsystem Functional Verificat ion Tests

Turn here to find Agilent 4156C precision semiconductor parameter

analyzer and Agilent E5260A/70B high speed/precision parameteric

measurement mainframe functional verification tests that do not require

the IC- CAP software.

C RF Subsystem Functional Verification Tests

This appendix includes an Agilent E8364B PNA Series vector network

analyzer functional verification test that does not require the IC- CAP

software.

10 Installation and User’s Guide

Page 11

D CV Subsystem Functional Verification Tests

This appendix includes an Agilent 4284A precision LCR meter functional

verification test that does not require the IC- CAP software.

E Noise Subsystem Functional Verifi cation Tests

This appendix includes an Agilent 35670A dynamic signal analyzer

functional verification test that does not require the IC- CAP software.

F Understanding the Bias Networks

Here you will find features, characteristics, a schematic diagram, and

operational information on the bias networks.

G Network Analyzer Performance Specification Summary

See this appendix for a summary of the network analyzer’s performance

specifications.

For Additional

Information on...

Hardware

Additional information regarding instruments and accessories within the

system is provided in the individual instrument or accessory’s

documentation.

Software

IC- CAP software operating instructions and tutorials are provided in the

Agilent 85190D IC- CAP user’s guide.

Installation and User’s Guide 11

Page 12

Typeface

Conventions

This guide uses the following typeface conventions to describe various

aspects of a particular hardware or software user interface.

Hardware

Interface Examples in Body Text Examples in Procedural Text

and Tables

Front panel hardke ys

Front panel display

softkeys

Front or rear panel

connectors, instrument

markings

Data field entries

Keyboard keys

Press Preset

Press Cal

Press [MORE]

Press [Return]

RF/DC OUT connector

STIMULUS key group

Enter Calset

Enter 18

Press Ctrl+8

Press Enter

Press Preset

Press Cal

Press [MORE]

Press [Return]

RF/DC OUT connector

STIMULUS key group

Enter Calset

Enter 18

Press Ctrl+8

Press Enter

Software

Interface Examples in Body Te xt Examples in Procedural Text

and Tables

Screen buttons and

selections

Menu selections

Click Enter

Select Continuous

Choose Format > Small

Choose Cal > Full

Click Enter

Select Continuous

Choose Format > Small

Choose Cal > Full

Command and menu

names

Icon and window titles

The Save commands are in

the File menu.

The Model icons are in the

IC- CAP/Main window.

Program messages

Data field entries

Is the device conn ected?

Enter Calset

Enter 18

12 Installation and User’s Guide

The Save commands are in the

File menu.

The Model icons are in the

IC-CAP/Main window.

Is the device connected?

Enter Calset

Enter 18

Page 13

Contents

1 Introducing the Agilent 85225F Performance Modeling System

Performance Modeling System Configuration Overview 18

RF and DC Measurement System Configuration 19

Figure 1. System Block Diagram 19

The RF Subsystem 20

The DC Subsystem 20

The Bias Networks 21

Component Integration 22

Figure 2. System Components 23

Table 3.Front Panel System Connections, with Agilent 4156C 24

Figure 3.Front Panel Connections with Agilent 4156C 25

Table 4.Front Panel System Connections, with Agilent E5260A or E5270B 26

Figure 4.Front Panel Wiring Diagram with Agilent E5260A or E5270B 27

Table 5.Rear Panel System Connections with Agilent 4156C 28

Figure 5.Rear Panel Wiring Diagram with Agilent 4156C 29

Table 6. Rear Panel System Connections with Agilent E5260A or E5270B 30

Figure 6.Rear Panel Wiring with Agilent E5260A or E5270B 31

Figure 7.DC/RF Cabling Diagram - DC and RF Configuration 32

CV, RF, and DC Measurement System Configuration 33

Figure 8. System Block Diagram 33

The CV Subsystem 34

Component Integration 34

Figure 9. System Components 35

Table 7.Front Panel System Connections 36

Figure 10. Front Panel Wiring Diagram 37

Table 8.Rear Panel System Connections 38

Figure 11.Rear Panel Wiring Diagram 39

Figure 12. DC/RF Cabling Diagram - DC and RF Configuration 40

Figure 13.DC/RF Cabling Diagram - Parametric Configuration 41

The Low Leakage Switch Mainframe 42

Table 9.Rear Panel Connections, including Low Leakage Switch Mainframe 42

Figure 14. Rear Panel Wiring Diagram including Low Leakage Switch Mainframe 43

Figure 15.DC/RF Cabling Diagram - Parametric Configuration with Low Leakage Switch

Mainframe 44

Installation and User’s Guide 13

Page 14

1/f Noise, CV, RF, and DC Measurement System Configuration 45

Figure 16.System Block Diagram 46

Figure 17. 1/f Noise Measurement Block Diagram 47

Component Integration 48

Figure 18. System Components 49

Table 10.Front Panel System Connections 50

Figure 19. Front Panel Wiring Diagram 51

Tab le 11. Rear Panel System Connections 52

Figure 20.Rear Panel Wiring Diagram 53

Figure 21. DC/RF Cabling Diagram - DC and RF Configuration 54

Figure 22.DC/RF Cabling Diagram - Parametric Configuration 55

Instrument Control Interface 56

Tab le 12. GPIB Addresses 56

The LAN/GPIB Gateway 57

Figure 23.Rear Panel Wiring Diagram for LAN/GPIB Gateway 58

The System Controller 59

Table 13. Personal Computer Requirements 59

Table 14. UNIX Workstation Requirements 59

The Rack Cabinet 60

Performance Characteristics and Specifications 61

Table 15.Supplemental System Characteristics 61

Interference Standards 61

Performance Modeling System Performance Specifications 61

RF Subsystem Performance Specifications 62

DC Subsystem Specifications 62

Bias Network Characteristics 62

2 Installing the System

To prepare the installation site 64

Ta b le 16 . Environmen t al Requ ir em e nts 64

Table 17. Electrical Requirements 64

To receive the system 65

To unpack the shipment crate containing the rack cabinet 66

To verify the shipment 68

Tab le 18. Replaceable Parts 69

To install the work surface 74

To ensure your safety while using the system 76

Precautions for Performing Floating-Ground Measurements 78

To perform floating-ground measurements 78

14 Installation and User’s Guide

Page 15

Precautions for Avoiding Electrostatic Discharge 79

To connect the bias networks 80

Agilent 4156C Systems 80

Agilent 4156C Systems with Agilent 41501B Expander Box 82

Agilent E5260A/70B Systems 84

To switch on power to the system 87

To configure the LAN/GPIB gateway for functional verification 89

3 Verifying System Functionality

To choose a verification process 92

Understanding the System Functional Verification Test 94

Required Tools 94

Performing the System Functional Verification Test 95

If you encounter a problem 101

4 Servicing the System

To troubleshoot the system 104

To remove or replace a system component 105

To order replacement parts 106

To receive additional assistance 107

Ta b le 19. Contacting Agil ent Technologies 107

To package the system for transport 108

A Enhancing Measurement Accuracy

To enhance measurement accuracy 112

Understanding System Measurement Cal ibrati on 114

Required Tools 114

Performing a Coaxial System Measurement Calibration 115

If you encounter a problem 116

Periodic System Component Calibration 117

B DC Subsystem Functional Verification Test

Understanding the DC Subsystem Functional Verification Test 120

Required Tools 120

Performing the DC Subsystem Functional Verification Test 121

If you encounter a problem 121

Installation and User’s Guide 15

Page 16

If you encounter a problem 122

C RF Subsystem Functional Verification Test

Understanding the RF Subsystem Functional Verification Test 124

Required Tools 124

Performing the RF Subsystem Functional Verification Test 125

If you encounter a problem 127

D CV Subsystem Functional Verification Test

Understanding the CV Subsystem Functional Verification Test 130

Required Tools 130

Performing the CV Subsystem Functional Verification Test 131

If you encounter a problem 132

E 1/f Noise Subsystem Functional Verific ation Test

Understanding the 1/f Noise Subsystem Functional Verification Test 134

Required Tools 134

Performing the 1/f Noise Subsystem Functional Verification Test 135

If you encounter a problem 136

F Understanding the Bias Networks

Features 138

Characteristics 139

Table 20. 11612V Option K11/K21 Bias Network Characteristics 139

Operation 140

Figure 24. Bias Network Schematic 140

G Network Analyzer Performance Specification Summary

Network Analyzer System Performance 142

Maximum Output Power 142

Dynamic Range 142

Measurement Port Charact eristics 143

Measurement Uncertainty 143

Index

16 Installation and User’s Guide

Page 17

Agilent 85225F Perfor mance Model ing System

Installation and User’s Guide

1

Introducing the Agilent 85225F

Performance Modeling System

Performance Modeling System Configuration Overview 18

RF and DC Measurement System Configuration 19

CV, RF, and DC Measurement System Configuration 33

1/f Noise, CV, RF, and DC Measurement System Configuration 45

The System Controller 59

Performance Characteristics and Specifications 61

Related Topics “Installing the System" on page 63

“Network Analyzer Performance Specification Summary"on page 141

“Understanding the Bias Networks"on page137

Use this chapter to familiarize yourself with the measurement

configurations of the performance modeling system. This chapter

introduces the system by describing its operational theory, integration, and

performance.

Agilent Technologies

17

Page 18

1 Introducing the Agilent 85225F Performance Modeling System

Performance Modeling System Configuration Overview

The standard Agilent 85225F performance modeling system measures the

DC and RF performance of active and passive devices. You may configure

the Agilent 85225F performance modeling system to measure CV and 1/f

noise with the addition of optional instrumentation and IC-CAP 1/f noise

measurement modules.

For RF and DC performance measurement system configurations, see “RF

and DC Measurement System Configuration" on page 19.

For CV, RF, and DC performance measurement system configurations, see

“CV, RF, and DC Measurement System Configuration" on page 29.

For 1/f noise, CV, RF, and DC performance measurement system

configurations, see “1/f Noise, CV, RF, and DC Measurement System

Configuration" on page 45.

18 Installation and User’s Guide

Page 19

Introducing the Agilent 85225F Performance Modeling System 1

RF and DC Measurement System Configuration

In conjunction with a compatible controller running 85190-Series IC- CAP

software, the Agilent 85225F performance modeling system measures the

DC and RF performance of active and passive devices. The IC- CAP

software then extracts the device parameters and displays the results.

The Agilent 85225F performance modeling system is the integration of

rack- mounted RF and DC subsystems, bias networks, and a system

controller

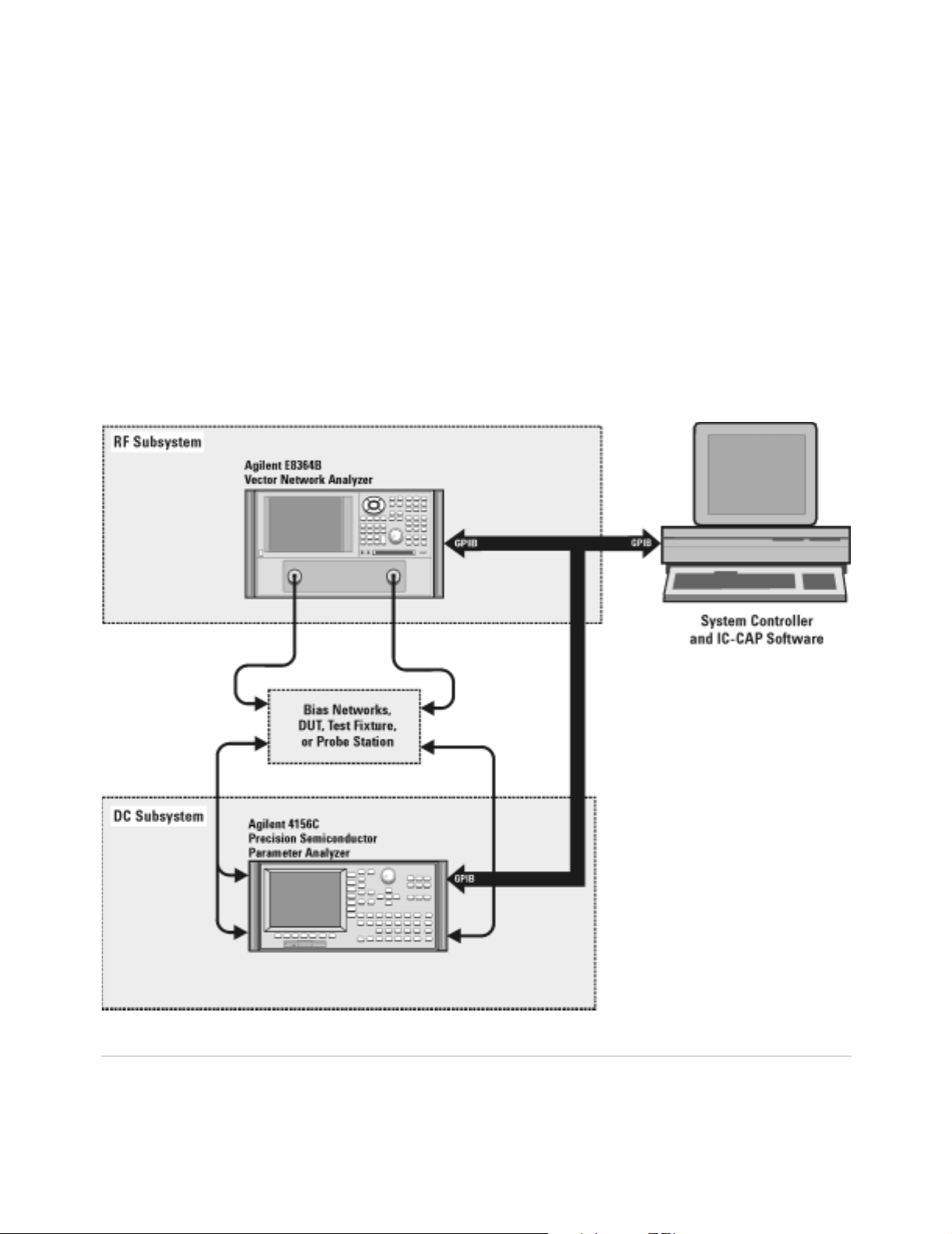

Figure 1 System Block Diagram

*

, as shown in Figure 1†.

* The system controller is not included and must be provided.

† This block diagram shows a system with an Agile nt 4156C as the DC subsystem. Other instrumentation may

be used. See “The DC Subsystem"on page 20.

Installation and User’s Guide 19

Page 20

1 Introducing the Agilent 85225F Performance Modeling System

The RF Subsystem

S- parameter device characterization is provided by the RF subsystem.

The RF subsystem contains the Agilent E8364B PNA Series vector network

analyzer.

Its integrated synthesizer supplies a swept or CW RF source signal from

10 MHz

The integrated test set separates the RF source signal into reference and

test signals, and provides RF connection via cables and adapters to the

external bias networks.

*

to 50 GHz.

The DC Subsystem

Precision DC characterization and bias for the S-parameter measurements

are provided by one of the following three DC subsystems.

The DC subsystem may contain one of the following three instruments.

Agilent 4156C Precision Semi conducto r Par a meter Analyzer

The Agilent 4156C precision semiconductor parameter analyzer provides

DC force (supply) and sense (measure) capability from its HRSMUs (high

resolution source/monitor units).

Optionally, the Agilent 4156C may be configured with a 41501B SMU PGU

expander is connected to and controlled by the 4156C via the expander

box interface. The 41501B provides a GNDU (active ground unit) and,

depending on option configuration, an HPSMU (high- power source/monitor

unit), two MPSMUs (medium- power source monitor units), and/or two

PGUs (pulse generator units).

The DC signals are routed through feedthrough panels via triaxial cables to

the bias networks.

Agilent E5260A 8-Slot High Speed Parametric Measurement Mainframe

The Agilent E5260A provides DC force (supply) and sense (measure)

capability from its plug- in source/monitor units.

The Agilent E5290A plug- in high speed high power source/monitor unit

provides up to 200 volts of potential and 1 amp of current to the device

under test.

The Agilent E5291A plug- in high speed medium power source/monitor unit

provides up to 100 volts of potential and 200 milliamps of current to the

device under test.

* Due to the minimum operating frequency of the bias networks, the performance modeling system low end

frequency range is 45 MHz.

20 Installation and User’s Guide

Page 21

Introducing the Agilent 85225F Performance Modeling System 1

Agilent E5270B 8-Slot Precision Parametric Measurement Mainframe

The Agilent E5270B provides DC force (supply) and sense (measure)

capability from its plug- in source/monitor units.

The Agilent E5280A plug- in high power source/monitor unit provides up

to 200 volts of potential and 1 amp of current to the device under test.

The Agilent E5281A plug- in medium power source/monitor unit provides

up to 100 volts of potential and 200 milliamps of current to the device

under test.

CAUTION

The Bias Networks

Exposing the bias networks to currents greater than 500 milliamps or voltages

greater than 40 volts will result in severe damage. Do not exceed these values

while using the bias networks. Remove the bias networks from the circuit if

greater voltages or currents are required.

The Agilent 11612V Option K11 and K21 bias networks combine the DC

and RF signals and apply them simultaneously to the device under test

(DUT). The bias networks are configured with 2.4 mm DC/RF output

connectors for connection to a DUT, a test fixture, or probe station, as

shown in Figure 21 on page 54.

Installation and User’s Guide 21

Page 22

1 Introducing the Agilent 85225F Performance Modeling System

Component Integration

System component integration is performed at the Agilent Technologies

factory. The individual components are placed into the rack, and the

required cabling is connected between the instruments.

After factory integration, the system is tested to verify functional

performance.

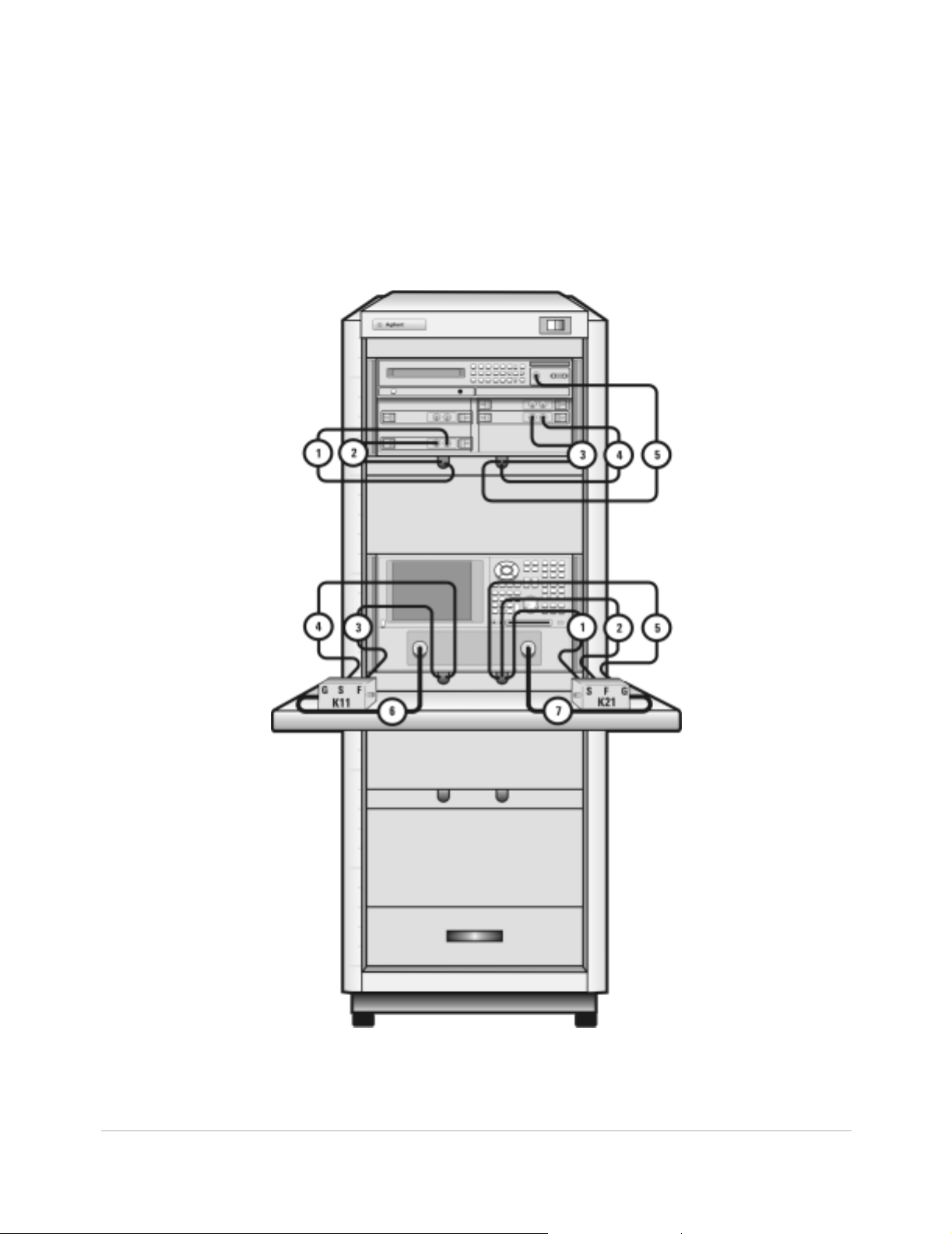

The Agilent 85225F performance modeling system includes the following

components, as shown in Figure 2 on page 23:

• Agilent E8364B PNA Series vector network analyzer

• Agilent 4156C precision semiconductor parameter analyzer (or

optionally Agilent E5260A or E5270B)

• Agilent 11612V Option K11 bias network (port 1)

• Agilent 11612V Option K21 bias network (port 2)

• Agilent 85133F flexible test port cable set

• Agilent E3661B 1.6 meter rack cabinet

• filler panels, feedthrough panels, work surface, cables, and adapters

For systems with Agilent 4156C, front panel connections are listed in

Table 3 on page 24 and illustrated in Figure 3 on page 25.

For systems with Agilent 4156C, rear panel connections are listed in

Table 5 on page 28 and illustrated in Figure 5 on page 29.

For systems with Agilent E5260A or E5270B, front panel connections are

listed in Table 4 on page 26 and illustrated in Figure 4 on page 27.

For systems with Agilent E5260A or E5270B, rear panel connections are

listed in Table 6 on page 30 and illustrated in Figure 6 on page 31.

22 Installation and User’s Guide

Page 23

Figure 2 System Components

Introducing the Agilent 85225F Performance Modeling System 1

Installation and User’s Guide 23

Page 24

1 Introducing the Agilent 85225F Performance Modeling System

Table 3 Front Panel System Connections, with Agilent 4156C

Component Information Connection Information

Designator Model

Number

1 16494A

Option 002

2 16494A

Option 002

3 16494A

Option 002

4 16494A

Option 002

5 16494A

Option 002

6 85133F Flexible test

7 85133F Flexible test

Description Connector

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

port cable

port cable

From

Type

2.4 mm E8364B PORT 1 RF IN 11612V K11

2.4 mm E8364B PORT 2 RF IN 11612V K21

Instrument

HRSMU1

HRSMU1

HRSMU2

HRSMU2

HRSMU3

Connector

Labeled

SENSE DC SENSE 11612V K11

FORCE DC FORCE 11612V K11

SENSE DC SENSE 11612V K21

FORCE DC FORCE 11612V K21

FORCE GNDU 11612V K21

T o Connector

Labeled

On

Instrument

24 Installation and User’s Guide

Page 25

Introducing the Agilent 85225F Performance Modeling System 1

Figure 3 Front Panel Connections with Agilent 4156C

Installation and User’s Guide 25

Page 26

1 Introducing the Agilent 85225F Performance Modeling System

Table 4 Front Panel System Connections, with Agilent E5260A or E5270B

Component Information Connection Information

Designator Model

Number

1 16494A

Option 002

2 16494A

Option 002

3 16494A

Option 002

4 16494A

Option 002

5 16493L

Option 002

6 85133F Flexibl e test

7 85133F Flexibl e test

Description Connector

Triaxial cable Triax BNC E5260A/70B

Triaxial cable Triax BNC E5260A/70B

Triaxial cable Triax BNC E5260A/70B

Triaxial cable Triax BNC E5260A/70B

Triaxial

GNDU cable

port cable

port cable

From

Type

Triax BNC E5260A/70B

2.4 mm E8364B PORT 1 RF IN 11612V K11

2.4 mm E8364B PORT 2 RF IN 11612V K21

Instrument

HPSMU1

HPSMU1

MPSMU3

MPSMU3

GNDU

Connector

Labeled

SENSE DC SENSE 11612V K21

FORCE DC FORCE 11612V K21

FORCE DC FORCE 11612V K11

SENSE DC SENSE 11612V K11

GNDU GNDU 11612V K21

To Connector

Labeled

On

Instrument

26 Installation and User’s Guide

Page 27

Introducing the Agilent 85225F Performance Modeling System 1

Figure 4 Front Panel Wiring Diagram with Agilent E5260A or E5270B

Installation and User’s Guide 27

Page 28

1 Introducing the Agilent 85225F Performance Modeling System

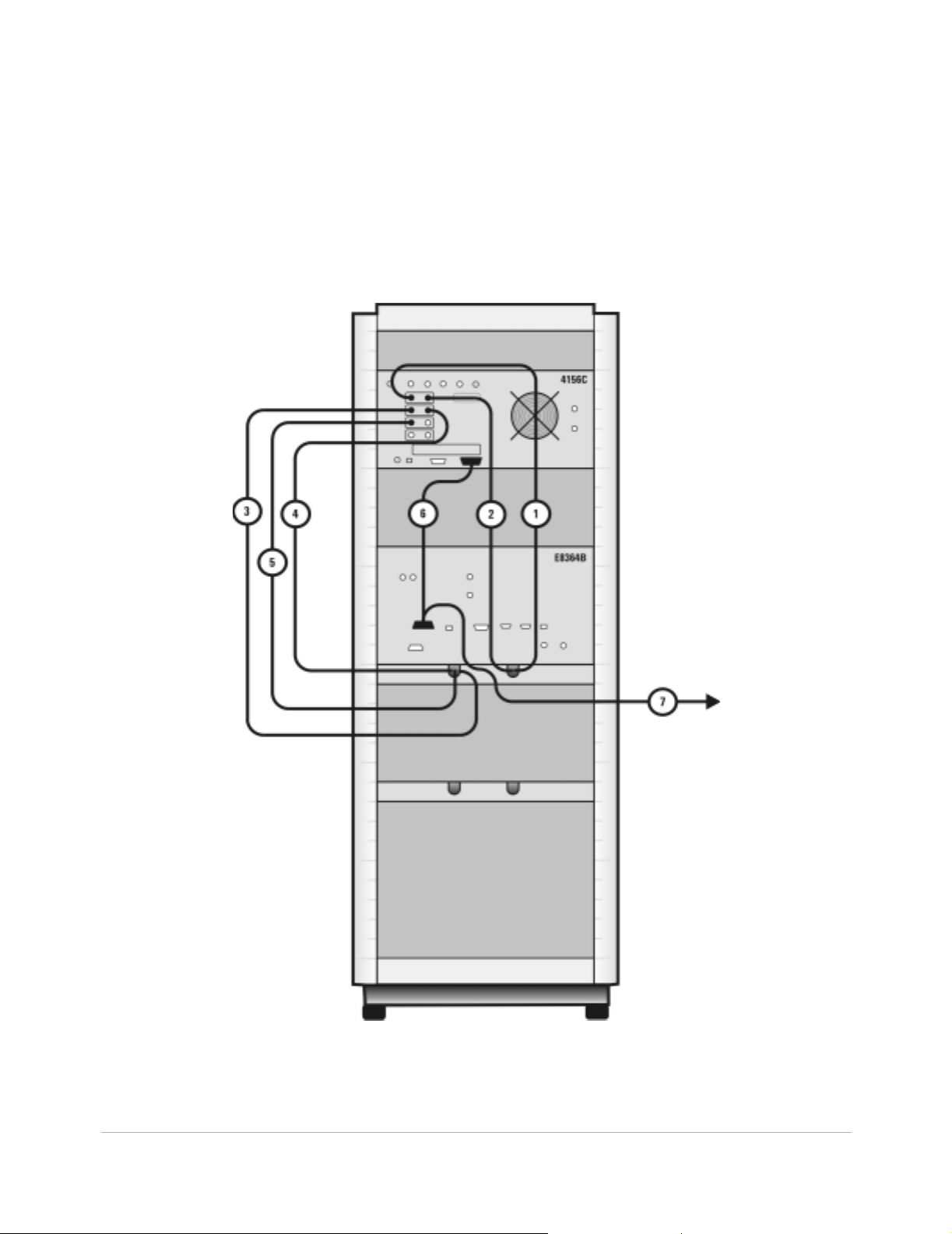

Table 5 Rear Panel System Connections with Agilent 4156C

Component Information Connection Information

Designator Model

Number

1 16494A

Option 002

2 16494A

Option 002

3 16494A

Option 002

4 16494A

Option 002

5 16494A

Option 002

6 10833D GPIB cabl e GPIB 4156C GPIB GPIB E8364B

7 10833C GPIB cable GPIB E8364B GPIB GPIB Controller

Description Connector

Type

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

NOTE

If the system does not include an Agilent 41501B SMU/PGU expander,

use the Agile nt 4156C HRSMU3 FORCE as the GND ( ground unit).

From

Instrument

HRSMU2

HRSMU2

HRSMU1

HRSMU1

HRSMU3

Connector

Labeled

FORCE DC FORCE 11612V K21

SENSE DC SENSE 11612V K21

FORCE DC FORCE 11612V K11

SENSE DC SENSE 11612V K11

FORCE GNDU 11612V K21

To Con nector

Labeled

On

Instrument

28 Installation and User’s Guide

Page 29

Introducing the Agilent 85225F Performance Modeling System 1

Figure 5 Rear Panel Wiring Diagram with Agilent 4156C

Installation and User’s Guide 29

Page 30

1 Introducing the Agilent 85225F Performance Modeling System

CV, RF, and DC Mea surement System Configuration

Table 6 Rear Panel System Connections with Agilent E5260A or E5270B

Component Information Connection Information

Designator Model

Number

1 10833A GPIB cable GPIB 4156C GPIB GPIB E8364B

2 10833C GPIB cable GPIB E8364B GPIB GPIB Controller

Description Connector

Type

From

Instrument

Connector

Labeled

To Connector

Labeled

On

Instrument

30 Installation and User’s Guide

Page 31

Introducing the Agilent 85225F Performance Modeling System 1

Figure 6 Rear Panel Wiring with Agilent E5260A or E5270B

Installation and User’s Guide 31

Page 32

1 Introducing the Agilent 85225F Performance Modeling System

Figure 7 DC/RF Cabling Diagram - DC and RF Configuration

Systems with Agilent 4156C

Systems with Agilent E5260A or E5270B

32 Installation and User’s Guide

Page 33

Introducing the Agilent 85225F Performance Modeling System 1

CV, RF, and DC Measurement System Configuration

With the addition of a precision LCR meter, the Agilent 85225F

performance modeling system measures the DC, RF, and CV performance

of active and passive devices. The IC- CAP software then extracts the

device parameters and displays the results.

The Agilent 85225F performance modeling system for CV, RF, and DC

measurement is the integration of rack-mounted RF, DC, and CV

subsystems, bias networks, and a system controller, as shown in Figure 8.

Figure 8 System Block Diagram

Installation and User’s Guide 33

Page 34

1 Introducing the Agilent 85225F Performance Modeling System

The CV Subsystem

The Agilent 4284A precision LCR meter provides a wide 20 Hz to 1 MHz

test frequency range and superior test- signal performance, allowing CV

testing to the most commonly- used test standards, such as IEC/MIL, and

under conditions that simulate the intended application.

Optionally, the system can be configured with the Agilent E5250A low

leakage switch mainframe. The Agilent E5250A is used for precise

parametric test. It improves measurement efficiency by eliminating the

need to manually change the probe positions on a manual probe station.

The E5250A is used to route signals from the DC and CV subsystems to

the probe card cable, and on to the probe card and probe station.

Component Integration

System component integration is performed at the Agilent Technologies

factory. The individual components are placed into the rack, and the

required cabling is connected between the instruments.

After factory integration, the system is tested to verify functional

performance.

The Agilent 85225F performance modeling system includes the following

components, as shown in Figure 18 on page 49:

• Agilent E8364B PNA Series vector network analyzer

• Agilent 4156C precision semiconductor parameter analyzer (or

optionally Agilent E5260A or E5270B)

• Agilent 11612V Option K11 bias network (port 1)

• Agilent 11612V Option K21 bias network (port 2)

• Agilent 4284A precision LCR meter

• Agilent 85133F flexible test port cable set

• Agilent E3661B 1.6 meter rack cabinet

• filler panels, feedthrough panels, work surface, cables, and adapters

System front panel connections are listed in Table 10 on page 50 and

illustrated in Figure 19 on page 51.

System rear panel connections are listed in Table 11 on page 52 and

illustrated in Figure 20 on page 53.

34 Installation and User’s Guide

Page 35

Figure 9 System Components

Introducing the Agilent 85225F Performance Modeling System 1

Installation and User’s Guide 35

Page 36

1 Introducing the Agilent 85225F Performance Modeling System

Table 7 Front Panel System Connections

Component Information Connection Information

Designator Model

Number

1 16494A

Option 002

2 16494A

Option 002

3 16494A

Option 002

4 16494A

Option 002

5 16494A

Option 002

6 85133F Flexibl e test

7 85133F Flexibl e test

8 16048D LCR meter

Description Connector

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial

GNDU cable

port cable

port cable

test cable

From

Type

Triax BNC 4156C

2.4 mm E8364B PORT 1 RF IN 11612V K11

2.4 mm E8364B PORT 2 RF IN 11612V K21

BNC 4284A UNKNOWN Test fixture

Instrument

HRSMU1

HRSMU1

HRSMU2

HRSMU2

HRSMU3

Connector

Labeled

FORCE DC FORCE 11612V K11

SENSE DC SENSE 11612V K11

FORCE DC FORCE 11612V K21

SENSE DC SENSE 11612V K21

FORCE GNDU 11612V K21

To Connector

Labeled

On

Instrument

or probe

station

36 Installation and User’s Guide

Page 37

Figure 10 Front Panel Wiring Diagram

Introducing the Agilent 85225F Performance Modeling System 1

Installation and User’s Guide 37

Page 38

1 Introducing the Agilent 85225F Performance Modeling System

Table 8 Rear Panel System Connections

Component Information Connection Information

Designator Model

Number

1 16494A

Option 002

2 16494A

Option 002

3 16494A

Option 002

4 16494A

Option 002

5 16494A

Option 002

6 10833D GPIB cable GPIB 4156C GPIB GPIB 4284A

7 10833D GPIB cable GPIB 4284A GPIB GPIB E8364B

8 10833C GPIB cable GPIB E8364B GPIB GPIB Controller

Description Connector

Type

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

From

Instrument

HRSMU1

HRSMU1

HRSMU2

HRSMU2

HRSMU3

Connector

Labeled

FORCE DC FORCE 11612V K11

SENSE DC SENSE 11612V K11

FORCE DC FORCE 11612V K21

SENSE DC SENSE 11612V K21

FORCE GNDU 11612V K21

To Connector

Labeled

On

Instrument

38 Installation and User’s Guide

Page 39

Figure 11 Rear Panel Wiring Diagram

Introducing the Agilent 85225F Performance Modeling System 1

Installation and User’s Guide 39

Page 40

1 Introducing the Agilent 85225F Performance Modeling System

Figure 12 DC/RF Cabling Diagram - DC and RF Configuration

40 Installation and User’s Guide

Page 41

Introducing the Agilent 85225F Performance Modeling System 1

Figure 13 DC/RF Cabling Diagram - Parametric Configuration

Installation and User’s Guide 41

Page 42

1 Introducing the Agilent 85225F Performance Modeling System

The Low Leakage Switch Mainframe

The Agilent E5250A is used for precise parametric test. It improves

measurement efficiency by eliminating the need to manually change the

probe positions on a manual probe station. The E5250A is used to route

signals from the 4156C and the 4284A to the probe card cable, and on to

probe card and probe station.

Table 9 Rear Panel Connections, including Low Leakage Switch Mainframe

Component Information Connection Information

Designator Model

Number

1 16494A

Option 002

2 16494A

Option 002

3 16494A

Option 002

4 16494A

Option 002

5 16048D LCR meter

6 10833D GPIB cable GPIB 4156C GPIB GPIB 4284A

7 10833D GPIB cable GPIB 4284A GPIB GPIB E8364B

8 10833D GPIB cable GPIB E8364B GPIB GPIB E5250A

9 10833C GPIB cable GPIB E5250A GPIB GPIB Controller

T1 1250-2405 BNC tee BNC 4284A HIpot/HIcur CV1 E5250A

T2 1250-2405 BNC tee BNC 4284A LOpot/LOcur CV2 E5250A

Description Connector

Type

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

BNC 4284A UNKNOWN T1 & T2 (CV1

test cable

From

Instrument

HRSMU1

HRSMU1

HRSMU2

HRSMU2

Connector

Labeled

SENSE SMU

FORCE SMU

FORCE SMU

SENSE SMU

To Connector

Labeled

INPUT 2

INPUT 1

INPUT 3

INPUT 4

& CV2)

On

Instrument

E5250A

E5250A

E5250A

E5250A

E5250A

42 Installation and User’s Guide

Page 43

Introducing the Agilent 85225F Performance Modeling System 1

Figure 14 Rear Panel Wiring Diagram including Low Leakage Switch Mainframe

Installation and User’s Guide 43

Page 44

1 Introducing the Agilent 85225F Performance Modeling System

Figure 15 DC/RF Cabling Diagram - Parametric Configuration with Low Leakage Switch Mainframe

44 Installation and User’s Guide

Page 45

Introducing the Agilent 85225F Performance Modeling System 1

1/f Noise, CV, RF, and DC Measurement System Configuration

With the addition of a dynamic signal analyzer and a precision LCR meter,

the Agilent 85225F performance modeling system measures the DC, RF,

CV, and 1/f noise performance of active and passive devices. The IC- CAP

software then extracts the device parameters and displays the results.

The Agilent 85225F performance modeling system is the integration of

rack- mounted RF and DC subsystems, a precision LCR meter, a dynamic

signal analyzer, bias networks, and a system controller, as shown in

Figure 16.

Installation and User’s Guide 45

Page 46

1 Introducing the Agilent 85225F Performance Modeling System

Figure 16 System Block Diagram

The 1/f Noise Subsystem

The Agilent 35670A dynamic signal analyzer (in conjunction with a

customer- furnished Stanford Model SR570 low noise amplifier) measures

the flicker noise (1/f noise) of active devices. Controlled by IC- CAP device

modeling software, the dynamic signal analyzer generates reliable 1/f noise

measurement data, which are analyzed and extracted in IC-CAP. Figure 17

shows the system configuration for 1/f noise measurements.

46 Installation and User’s Guide

Page 47

Figure 17 1/f Noise Measurement Block Diagram

Introducing the Agilent 85225F Performance Modeling System 1

Installation and User’s Guide 47

Page 48

1 Introducing the Agilent 85225F Performance Modeling System

Component Integration

System component integration is performed at the Agilent Technologies

factory. The individual components are placed into the rack, and the

required cabling is connected between the instruments.

After factory integration, the system is tested to verify functional

performance.

The Agilent 85225F performance modeling system includes the following

components, as shown in Figure 18 on page 49:

• Agilent E8364B PNA Series vector network analyzer

• Agilent 4156C precision semiconductor parameter analyzer with

optional Agilent 41501B SMU/PGU expander (or optionally Agilent

E5260A or E5270B)

• Agilent 11612V Option K11 bias network (port 1)

• Agilent 11612V Option K21 bias network (port 2)

• Agilent 4284A precision LCR meter

• Agilent 35670A dynamic signal analyzer

• Stanford Research SR 570 low noise current amplifier

• Agilent 85133F flexible test port cable set

• Agilent E3661B 1.6 meter rack cabinet

• filler panels, feedthrough panels, work surface, cables, and adapters

System front panel connections are listed in Table 10 on page 50 and

illustrated in Figure 19 on page 51.

System rear panel connections are listed in Table 11 on page 52 and

illustrated in Figure 20 on page 53.

*

* Customer supplied, not included with system.

48 Installation and User’s Guide

Page 49

Figure 18 System Components

Introducing the Agilent 85225F Performance Modeling System 1

Installation and User’s Guide 49

Page 50

1 Introducing the Agilent 85225F Performance Modeling System

Table 10 Front Panel System Connections

Component Information Connection Information

Designator Model

Number

1 16494A

Option 002

2 16494A

Option 002

3 16494A

Option 002

4 16494A

Option 002

5 16493L

Option 002

6 85133F Flexibl e test

7 85133F Flexibl e test

8 16048D LCR meter

Description Connector

Triaxial cable Triax BNC 41501B

Triaxial cable Triax BNC 41501B

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial

GNDU cable

port cable

port cable

test cable

From

Type

Triax BNC 41 501B GNDU GNDU 11612V K21

2.4 mm E8364B PORT 1 RF IN 11612V K11

2.4 mm E8364B PORT 2 RF IN 11612V K21

BNC 4284A UNKNOWN Test fixture

Instrument

HPSMU

HPSMU

HRSMU1

HRSMU1

Connector

Labeled

FORCE DC FORCE 11612V K11

SENSE DC SENSE 11612V K11

FORCE DC FORCE 11612V K21

SENSE DC SENSE 11612V K21

To Connector

Labeled

On

Instrument

or probe

station

9 8120-1839 Coaxial cable BNC 35670A CH1 Test fixture

or probe

station

50 Installation and User’s Guide

Page 51

Figure 19 Front Panel Wiring Diagram

Introducing the Agilent 85225F Performance Modeling System 1

Installation and User’s Guide 51

Page 52

1 Introducing the Agilent 85225F Performance Modeling System

Table 11 Rear Panel System Connections

Component Information Connection Information

Designator Model

Number

1 16494A

Option 002

2 16494A

Option 002

3 16494A

Option 002

4 16494A

Option 002

5 16493L

Option 002

6 10833A GPIB cable GPIB 4156C GPIB GPIB 4284A

7 10833A GPIB cable GPIB 4284A GPIB GPIB E8364B

8 10833A GPIB cable GPIB E8364B GPIB GPIB 35670A

9 10833C GPIB cable GPIB 4156C GPIB GPIB Controlle r

Description Connector

Type

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 4156C

Triaxial cable Triax BNC 41501B

Triaxial cable Triax BNC 41501B

GNDU cable Triax BNC 41501B GNDU GNDU 11612V K21

From

Instrument

HRSMU1

HRSMU1

HPSMU

HPSMU

Connector

Labeled

FORCE DC FORCE 11612V K11

SENSE DC SENSE 11612V K11

FORCE DC FORCE 11612V K21

SENSE DC SENSE 11612V K21

To Con nector

Labeled

On

Instrument

52 Installation and User’s Guide

Page 53

Figure 20 Rear Panel Wiring Diagram

Introducing the Agilent 85225F Performance Modeling System 1

Installation and User’s Guide 53

Page 54

1 Introducing the Agilent 85225F Performance Modeling System

Figure 21 DC/RF Cabling Diagram - DC and RF Configuration

54 Installation and User’s Guide

Page 55

Introducing the Agilent 85225F Performance Modeling System 1

Figure 22 DC/RF Cabling Diagram - Parametric Configuration

Installation and User’s Guide 55

Page 56

1 Introducing the Agilent 85225F Performance Modeling System

Instrument Control Interface

Instrument control interface is provided by a General Purpose Interface

Bus (GPIB) or LAN/GPIB gateway. GPIB addresses for programmable

system components are listed in Table 12.

Table 12 GPIB Addresses

Component GPIB Address

Agilent 34401A digital multime te r 9

Agilent 35670A dynamic signal analyzer 10

Agilent 4156C precision semiconductor parameter analyzer 19

Agilent 4284 A precision LCR meter 24

Agilent E5810A LAN/GPIB gateway 21

Agilent E8364B PNA Series vector network analyzer 16

*

Agilent E5250A low leakage switch mainframe 22

Agilent E5260A 8-slot high speed parametric measurement mainframe 19

Agilent E5270B 8-slot precision parametric measurement mainframe 19

* The 4156C default GPIB address 17 is sometimes used by other devices with a GPIB address at 16 (for example, an external display (set

to 17) to display the results generated by an instrument at address 16). Change the 4156C GPIB address to 19 using the procedure

described in step13 of “To switch on power to the system"on page 87 to ensure that IC-CAP can recognize the 4156C.

56 Installation and User’s Guide

Page 57

The LAN/GPIB Gateway

The Agilent E5810A LAN/GPIB gateway provides access to the system’s

GPIB instrumentation over an existing local area network. It allows the

use of SICL- or VISA- based applications designed for GPIB over the LAN

without modifying the application beyond a simple address change.

The gateway is a combination of hardware and SICL/VISA software. It

uses client/server technology to extend the standard remotely over the

LAN, allowing remote control from an alternative, more convenient, or

safer location.

Introducing the Agilent 85225F Performance Modeling System 1

Installation and User’s Guide 57

Page 58

1 Introducing the Agilent 85225F Performance Modeling System

Figure 23 Rear Panel Wiring Diagram for LAN/GPIB Gateway

58 Installation and User’s Guide

Page 59

Introducing the Agilent 85225F Performance Modeling System 1

The System Controller

A customer- furnished UNIX workstation or personal computer running

Agilent IC- CAP software controls the hardware via GPIB while making

device measurements, then stores, simulates, and optimizes device

parameters, using predefined or user- defined device models. Table 13 on

page 59 lists the personal computer requirements. Table 14 on page 59

lists the UNIX workstation requirements.

Table 13 Personal Computer Requirements

Parameter Requirement

Operating sys t em Microsoft Windows NT® 4.0- SP6a or Windows 2 000 Professional-SP3.

CPU Intel Pentium® class 200 MHz CPU or higher

Display Super VGA 800×600, 15 inch moni tor (1024×728 recommended)

Hard disk space 370 MB. It is recommended that you install IC-C AP software on your local drive.

Recommended file systems are FAT32 and NTFS. Novell file servers are not

supported. VFAT/FAT systems are not recommended for full installations.

*

RAM 128 megabytes (additional RAM will improve software perfor mance)

Virtual memory 300 megabytes

* Windows 95, 98, and ME are not supported.

† For NT 4.0 only: to avoid potential memory problems, ensure your virtu al memo ry space is always greater than your RAM space.

†

(Increased virtual memory may be required)

Table 14 UNIX Workstation Requirements

Parameter Requirement

HP UNIX Workstation SunOS Workstation

Operating system HP-UX 11.i with the following patches:

PHSS_24627 HP aC++, AA Runtime

Libraries (aCC A.03.33), PHSS_25718 LI BCL

Window manager HP VUE or CDE/X-Windows V.X11R5 Motif V.1.1/1.2 Open Windows 3.0, or CDE

RAM 128 megabytes (additional RAM will improve software performance)

Swap space 200 megabytes (additional swap space will improve software performance)

Hard disk 300 megabytes for minimum installation

500 megabytes for complete installation including online documentation and application

examples

SunOS 5.7, 5.8, and 5.9

(Solaris 7.0, 8.0, 9.0)

Display High resolution color only

Installation and User’s Guide 59

Page 60

1 Introducing the Agilent 85225F Performance Modeling System

The Rack Cabinet

The system is housed in a 1.6 meter rack cabinet. The cabinet provides

line power access, ventilation, mobility, and protection to the system

instrumentation.

A rack- mounted work surface is included for maximum flexibility and

convenience in making in- fixture or coaxial measurements. The work

surface can be removed to facilitate on- wafer measurements using a probe

station. The work surface is coated with antistatic material and connected

to chassis ground. Therefore, an antistatic mat is not required. For

installation instructions, see “To install the work surface" on page 74.

60 Installation and User’s Guide

Page 61

Introducing the Agilent 85225F Performance Modeling System 1

Performance Characteristics and Specifications

Supplemental characteristics are not specifications, but are provided in

Table 15 for your convenience.

Table 15 Supplemental System Characteristics

Characteristic Value

Line voltage 115 volts nominal (90 volts to 132 volts) or 220 volts nominal

(210 volts to 250 volts)

Line frequency 48 Hz to 66 Hz

Circuit breaker amper a ge rating 6 amps (115 volts), 3.5 amps (220 volts)

Rack weight capacity 818 kilograms (1800 pounds) maximum load ed

Rack external di m ensions 1620 mm high × 600 mm wide × 905 mm deep

Rack footprint (top view)

Interference Standards

The IEC/EN 61326- 1 and CISPR Publication 11 standards define the RFI

and EMI susceptibility of the performance modeling system.

Performance Modeling System Performance Specifications

The Agilent 85225F performance modeling system adheres to the

performance specifications of an Agilent E8364B PNA Series vector

network analyzer. Refer to Appendix G, “Network Analyzer Performance

Specification Summary,” starting on page 141.

Installation and User’s Guide 61

Page 62

1 Introducing the Agilent 85225F Performance Modeling System

RF Subsystem Performance Specifications

The overall performance of a network analyzer is dependent on the

individual instruments, system configuration, user- defined operating

conditions, measurement calibration, and cables.

For a specification summary, refer to Appendix G, “Network Analyzer

Performance Specification Summary,” starting on page 141.

In any high- frequency measurement, residual errors contribute

uncertainties to the results.

NOTE

When the system is configured with a probe station, microwave probes, on-wafer

calibration standards, or t est fixtures, additional uncertainties are contributed to the

measurement results. Refer to the manufacturer’s documentation for information on probe

station or test fixture characteristics.

DC Subsystem Specifications

Specifications for the Agilent 4156C precision semiconductor parameter

analyzer are listed in its user’s guide, chapter 7 of Volume 1, “General

Information.”

Specifications for the Agilent E5260A 8- slot high speed measurement

mainframe and Agilent E5270B 8- slot precision parametric measurement

mainframe are listed in its user’s guide, Chapter 2, “Introduction.”

Bias Network Characteristics

Table 20, “11612V Option K11/K21 Bias Network Characteristics,” on

page 139 lists the operational characteristics of the bias networks. For

detailed information, refer to Appendix F, “Understanding the Bias

Networks,” starting on page 137.

62 Installation and User’s Guide

Page 63

Agilent 85225F Perfor mance Model ing System

Installation and User’s Guide

2

Installing the System

To prepare the installation site 64

Environmental Requirements 64

Electrical Requirements 64

To receive the system 65

To unpack the shipment crate containing the rack cabinet 66

To verify the shipment 68

To install the work surface 74

To ensure your safety while using the system 76

Precautions for Performing Floating-Ground Measurements 78

Precautions for Avoiding Electrostatic Discharge 79

To connect the bias networks 80

To switch on power to the system 87

This completes the inst allat i on pro ce ss. To confirm the functional it y of t he

system, continue to Chapter3, “Verifying System Functionality,”

starting on page 91. 89

Related Topics “Introducing the Agilent 85 22 5F Perfo rma nce Mod el in g Syst em" on

page 17

Use this chapter to learn how to first prepare the installation site, and

then receive, unpack, install, and configure the system. This chapter

includes important information on operational safety, as well as

instruction on preparing the installation site, unpacking the system,

ensuring the completeness of the system shipment, installing the work

surface, performing final system configuration, and powering- on the

system.

Agilent Technologies

63

Page 64

2 Installing the System

To prepare the installation site

CAUTION

Follow these steps to prepare the site for system installation.

To prepare the installation site

Step Notes

1 Ensure that your installation site meets the

2 Ensure that your installation site meets the

Table 16 Environmental Requirements

Environmental Parameter System Requirement

Temperature +0°C to +45°C (+32 °F to +113°F)

Relative humidity Maximum 80% for temperatures up to 31°C

This product is designed for indoor use in Installation Category II

and Pollution Degree 2 per IEC 61010-1 and 664 respectively.

environmental requirem ents.

electrical requirements.

• Environmental requirements (temperature,

relative humidity, altitude, and clearance) are

listed in Table 16.

• Electrical requirements are listed in Table 17.

*†

decreasing linearly to 50% at 40°C

Altitude Up to 3000 meters (approximately 10000 feet)

Clearance (behind an d abo v e rac k)

* Install air conditioning and heating as needed to achieve the required ambient temperature range.

† Accuracy-enhanced measurement performance is specified at an ambient temperature range of

+25°C ±5°C. After calibration, hold the ambient temperature of the measurement environment to

±1°C of the ambient temperature at the time of calibration.

‡ Required to ensure the extractor fans can properly ventilate the system .

‡

15 centimeters (6 inches) minimum

Table 17 Electrical Requirements

Electrical Parameter System Requirement

Supply capability 100/120 volts, 2000 VA

200/240 volts, 2000 VA

Circuit sharing Do not connect air conditioning or

motor-operated equipment to the sa me ac

circuit supplying line voltage to the system.

64 Installation and User’s Guide

Page 65

To receive the system

Follow these steps to store, inspect, and confirm the system shipment.

To receive the system

Step Action Notes

Installing the System 2

1 Store and inspect the

shipment.

2 If the system is damaged,

notify appropriate parties.

a Keep the shipping containers toge ther ,

unopened, located in one area.

b Inspect the s hipping containers for

damage.

• If the shipment is damaged, contin ue to

step 2.

• If the shipment is verif i ed undamaged,

continue to the next section, “To unpack

the shipment crate containing the rack

cabinet" on page 66.

a Report the shipment damage to your

Agilent Technologies sales representative.

b Report the ship ment damage to the

shipping carrier.

c Provide all cartons and packaging material

for inspection by the shipping ca rrier .

• Keep all cartons and packaging

material until the entire shipment has

been verified undamaged and

complete, and the sy stem has passed

visual inspection and functional

verification.

• Agilent Technologies wi ll r ep ai r or

replace damaged equipment without

waiting for a claim settlement fr om the

shipping carrier.

Installation and User’s Guide 65

Page 66

2 Installing the System

To unpack the shipment crate containing the rack cabinet

The racked system is shipped upright secured to a pallet. Other system

components are shipped separately. Follow these instructions to unpack

and inspect the rack cabinet and the racked system components.

Required Tools

• 9/16 inch wrench or adjustable end wrench

• Prying tool to remove packaging clamps

WARNING

Always wear safety glasses when removing the clamps and other

packing materials fr om th e cra te .

CAUTION

Be careful not to bend the clamps while removing them from the

shipping crate. You may reuse the clamps when the system is

repacked.

To unpack the shipment crate containing the rack cabinet

Step Action Notes

1 Remove the outer packing

crate.

a Remove the clamps holding the packing

crate top cover in place.

b Remove the top cover and set it aside.

c Remove the clamps holding the first

packing crate wall in place.

d Insure that two other people are available

to hold the last two walls in place as the

last set of clamps is removed.

e Remove the other walls.

f Set the loading ramp panel aside for now.

• Which wall is removed first does not

matter.

• In double- rack crates, the heaviest wal l

is the loading ramp. In single-rack

crates, the loading ramp is shipped

inside the crate, plac ed on to p of th e

rack (it is a hinged asse mbly , shipped in

the folded position).

2 Remove the packaging

materials.

66 Installation and User’s Guide

a Remove the foam top cover.

b Remove the plastic wrapping from the

system.

Page 67

To unpack the shipment crate containing the rack cabinet (continued)

Step Action Notes

3 Unload the system a Remove the two brace bolts attaching the

side brace assembly to the bottom pallet.

b Remove the side brace assembly.

c Lift the hinged slat and remove the ramp

anchor bolt.

d Place one end of the ramp on the p allet

ramp ledge.

e Insert the ramp anchor bolt and fold down

the hinged slat.

f Fold down the ramp’s end flap.

• To secure the ramp, you may place long

wood screws through the ramp and

into the ramp ledge.

Installing the System 2

WARNING

A racked system is tall and top-heavy. It is easy to ti p the rack

over while moving it, which could result in injury or death.

Unloading the system safely requires the participation of four

persons exercising care so as not to topp l e the rac k cabi net . Do

not stand in front of the rack as it rolls down the ramp.

g Ensure that the rack cabinet leveling feet

are retracted and that the cabinet casters

are rolling freely.

h Roll the system down the ramp using

extreme care.

i Carefully roll the rack toward its prepared

place within the measurement

environment.

• In case the system must be moved in

the future, retain and reuse these

packing materials. You can also

purchase replacement packing

materials from Agilent Technologies.

Installation and User’s Guide 67

Page 68

2 Installing the System

To verify the shipment

Use Table 18 “System Receiving Checklist and Replaceable Parts” to:

• confirm the completeness of the shipment

• provide component part and model numbers required to order

All replacement items are available from Agilent Technologies. Part

numbers for replacement instrument subassemblies are listed in their

individual service manuals.

The majority of the system components are shipped preconfigured in the

system rack cabinet.

The PGUs (pulse generator units) and GNDU (active ground unit) are

factory- installed in the 41501B PGU expander.

With the exception of the bias networks, semi- rigid and SMU triaxial

cables, all other cables are connected at the factory.

replacement parts

NOTE

To verify the shipment

Step Action Notes

1 Verify that the serial

numbers on the rear panel

of the system inst rument s

match the serial numbers

listed in the shipping

documentation.

Other cables and accessories are shipped inside the rack-mounted storage drawer.

Compare the serial numbers liste d in the

shipping documents with the serial numbers

on the instrument’s rear panel serial number

labels.

• If an instrument serial number does not

match the shipping document, report

mismatched serial number to your

Agilent Technologies sales

representative.

• If all instrument serial numbers match

the shipping documents, continue to

step 2.

• For a list of support contacts, see “To

receive additional assistance" on

page107.

68 Installation and User’s Guide

Page 69

To verif y the shipme nt (con ti nu ed)

Step Action Notes

Installing the System 2

2 Complete the receiving

checklist.

3 If the system is

incomplete, report

missing item s to your

Agilent Technologies

sales representative.

1

Table 18 Replaceable Parts

Part or Model N umber Description

10833A GPIB cable, 1 meter

10833B GPIB cable, 2 meter

a Compare the Bill of Materials to the system

components received in the shipment.

b Verify the shipment is complete.

• If the shipment is confi rm ed incomplete,

go to step3.

• If you have confirmed the presence of all

system components, the receiving

process is complete. Proc ee d to the next

section “To ensure your safety while

using the system"on page76.

• Refer to the Bill of Materials included

with the shipment.

• For a list of support contacts, see “To

receive additional assistance" on

page107.

10833C GPIB cable, 4 meters

10833D GPIB cable, 0.5 meter

11612T Option K33 Mounting plates, bias networ ks to probe station

11612V Option K11 Bias netwo rk, port 1, 45 MHz to 50 GHz, 0.5 A

11612V Option K21 Bias netwo rk, port 2, 45 MHz to 50 GHz, 0.5 A

11900A Adapter, 2.4 mm (male-to-male)

11900B Adapter, 2.4 mm (female-to-female)

11900C Adapter , 2.4 mm (male-to-female)

1250-0080 Adapter, BNC, 50 ohm (female-female)

1250-1700 Adapter, coax

1250-2405C Adapter , BNC coaxial tee

1250-3231 Adapter, triaxial BNC (female to male)

16048D Test leads, 4 terminal pair, 1.98 meter

16493J Option 001 Interlock cable, 1.5 meter

16493L Option 001 G ND U c a bl e, 1.5 meter

Installation and User’s Guide 69

Page 70

2 Installing the System

Table 18 Replaceable Parts (continued)

Part or Model N umber Description

16494A Option 001 Triaxial cable, 1.5 meter

16494A Option 002 Triaxial cable, 3 meter

16494B Option 001 Kelvin triaxial cable, 1.5 meter

16494B Option 002 Kelvin triaxial cable, 3 meter

34401A Digital multimeter

35181M Storage drawer

35670A Dynamic signal analyzer

35670A Option AX4 Rack flange kit

35670A Option AY2 Two-input channel configuration

35670A Option AY6 Four-input channel configuration

35670A Option 1D4 Arbitrary source

41501B SMU/PGU expander with GNDU and cable

41501B Option 410 Add 41501B with high power SMU and cables

41501B Option 412 Add high power SMU, 2 PGUs, and cables

41501B Option 420 Add 2 medium power SMUs and cables

41501B Option 422 Add 2 medium power SMUs, 2 PGUs, and cables

41501B Option 902 Cable, power, Europe

41501B Option 903 Cable, power, US and Canada

4156C Precision semiconductor parameter analyzer

4156C Option 010 Delete all 4156C cables

4156C Option 020 Delete Windows controller for pa rameter analysis and

characterization

4156C Option 200 1.5 meter interlock, 4 coaxial, 4 triaxial cables

4156C Option 230 3.0 meter interlock, 4 coaxial, 4 triaxial cables

4284A Precision LCR meter

4284A Option 001 Add DC amplifier

4284A Option 006 Add 2 meter/4 meter cable operation

4284A Option 909 Rack mount kit

4284A Option ABA English documentation

4284A Option ABJ Japanese documentation

5063-9220 Rack mount kit with handles, 2-EIA

70 Installation and User’s Guide

Page 71

Table 18 Replaceable Parts (continued)

Part or Model N umber Description

5063-9221 Rack mount kit with handles, 3-EIA

5063-9222 Rack mount kit with handles, 4-EIA

5063-9223 Rack mount kit with handles, 5-EIA

5063-9224 Rack mount and handle kit, 6-EIA

5063-9225 Rack mount and handle kit, 7-EIA

8120-1396 Line power cord, 220V

8120-1839 Cable, BNC, 50 ohm, 24 inch

8120-1405 Line power cord, 120V

8120-1840 Cable, BNC, 48 inch

8120-2582 Cable

8120-5068 Cable

Installing the System 2

8490D Option 010 Attenuator, 2.4 mm coaxial, fixe d 10 dB, DC to 50 GHz

85043-20001 Ground stud

85043-20002 Shoulder screw

85043-80013 Anti-static mat kit

85056A Precision calibration kit, 2.4 mm

85056D Economy calibration kit, 2.4 mm

85106-60038 Work surface, 1 meter

85107-20004 Semi-rigid cable, 9 inc h, 2.4 mm (m-m)

85133F 2.4 mm flexible test port cable set

85225-90023 Agilent 85225F Performance Modeling System Installation and

User’s Guide

C2790AC Ballast, 30 pounds

E3661B Rack cabinet, 1.6 me ter

E3661B Option AW3 Power distributio n unit, 100/120 volts

E3661B Option AW5 Power distributio n unit, 220/240 volts

E3663AC Rail kit (2 rails per)

E3668B Feedthrough panel

E4470AZ Extractor fan, 100 to 120 volts

E4471AZ Extractor fan, 200 to 240 volts

E5250A Low leakage switch mainframe

Installation and User’s Guide 71

Page 72

2 Installing the System

Table 18 Replaceable Parts (continued)

Part or Model N umber Description

E5252A 10 x 12 switch mat rix

E5260A 8-slot high spe ed parametric measurement mainframe

E5260A Option 050 50 Hz line power frequency

E5260A Option 060 60 Hz line power frequency

E5260A Option ABA English documentation

E5260A Option ABJ Japanese documentation

E5290A High speed high power source mon i tor unit

E5291A High speed medium power source monitor unit

E5270B 8-slot parametric measurement solution

E5270B Option 050 50 Hz line power frequency

E5270B Option 060 60 Hz line power frequency

E5270B Option ABA English localization

E5270B Option ABJ Japanese localization

E5280A Precisio n high power source monitor unit

E5281A Precisio n medium power source monitor unit

E5286A High resolution source monitor unit

E5810A LAN/GPIB gateway

E5810A Option 100 Rack mount kit

E5810A Option AG6 I/O libraries client softw a re for MS Windows

E5810A Option ABJ Japanese documentation

E7731A Filler panel, 1-EIA unit

E7732A Filler panel, 2-EIA unit

E7733A Filler panel, 3-EIA unit

E7734A Filler panel, 4-EIA unit

E7735A Filler panel, 5-EIA unit

E7736A Filler panel, 6-EIA unit

E7737A Filler panel, 7-EIA unit

E8364B PNA Series vector network analyzer, 10 MHz to 50 GHz

E8364B Option 010 Time domain analysis capability

E8364B Option 014 Configurable test set