Page 1

Agilent

Specifying Calibration

Standards for the Agilent 8510

Network Analyzer

Application Note 8510-5B

Discontinued Product Information

— For Support Reference Only —

Information herein, may refer to products/services no longer supported.

We regret any inconvenience caused by obsolete information. For the

latest information on Agilent’s test and measurement products go to:

www.agilent.com/find/products

In the US, call Agilent Technologies at 1-800-829-4444

(any weekday between 8am–5pm in any U.S. time zone)

World-wide Agilent sales office contact information is available at:

www.agilent.com/find/contactus

Page 2

2

3

3

3

4

5

5

7

7

8

9

9

9

11

12

12

12

14

14

15

16

16

17

17

17

18

18

18

18

19

19

19

19

19

20

20

20

21

21

22

22

22

23

23

26

29

Introduction

Measurement errors

Measurement calibration

Calibration kit

Standard definition

Class assignment

Modification procedure

Select standards

Define standards

Standard number

Standard type

Open circuit capacitance: C0, C1, C2and C

3

Short circuit inductance: L0, L1, L2and L

3

Fixed or sliding

Terminal impedance

Offset delay

Offset Z

0

Offset loss

Lower/minimum frequency

Upper/maximum frequency

Coax or waveguide

Standard labels

Assign classes

Standard classes

S11A,B,C and S22A,B,C

Forward transmission match/thru

Reverse transmission match/thru

Isolation

Frequency response

TRL Thru

TRL Reflect

TRL Line

Adapter

Standard class labels

TRL options

Calibration kit label

Enter standards/classes

Verify performance

User modified cal kits and Agilent 8510 specifications

Modification examples

Modeling a thru adapter

Modeling an arbitrary impedance

Appendix A

Calibration kit entry procedure

Appendix B

Dimensional considerations in coaxial connectors

Appendix C

Cal coefficients model

Table of contents

Known devices called calibration standards

provide the measurement reference for network analyzer error-correction. This note

covers methods for specifying these standards and describes the procedures for their

use with the Agilent Technologies 8510 network analyzer.

The 8510 network analyzer system has the

capability to make real-time error-corrected

measurements of components and devices

in a variety of transmission media.

Fundamentally, all that is required is a set

of known devices (standards) that can be

defined physically or electrically and used

to provide a reference for the physical interface of the test devices.

Agilent Technologies supplies full calibration

kits in 1.0-mm, 1.85-mm, 2.4-mm, 3.5-mm,

7-mm, and Type-N coaxial interfaces. The

8510 system can be calibrated in other interfaces such as other coaxial types, waveguide

and microstrip, given good quality standards that can be defined.

The 8510’s built-in flexibility for calibration

kit definition allows the user to derive a

precise set of definitions for a particular set

of calibration standards from precise physical measurements. For example, the characteristic impedance of a matched impedance

airline can be defined from its actual physical dimensions (diameter of outer and inner

conductors) and electrical characteristics

(skin depth). Although the airline is

designed to provide perfect signal transmission at the connection interface, the dimensions of individual airlines will vary

somewhat—resulting in some reflection due

to the change in impedance between the test

port and the airline. By defining the actual

impedance of the airline, the resultant

reflection is characterized and can be

removed through measurement calibration.

The scope of this product note includes a

general description of the capabilities of the

8510 to accept new cal kit descriptions via

the MODIFY CAL KIT function found in the

8510 CAL menu. It does not, however,

describe how to design a set of physical

standards. The selection and fabrication of

appropriate calibration standards is as varied as the transmission media of the particular application and is beyond the scope of

this note.

Page 3

3

Introduction

This product note covers measurement calibration

requirements for the Agilent 8510B/C network

analyzer. All of the capabilities described in this

note also apply to the Agilent 8510A with the

following exceptions: response & isolation calibration; short circuit inductance; class assignments

for forward/reverse isolation, TRL thru, reflect,

line and options; and adapter removal.

Measurement errors

Measurement errors in network analysis can be

separated into two categories: random and systematic errors. Both random and systematic errors are

vector quantities. Random errors are non-repeatable measurement variations and are usually

unpredictable. Systematic errors are repeatable

measurement variations in the test setup.

Systematic errors include mismatch and leakage

signals in the test setup, isolation characteristics

between the reference and test signal paths, and

system frequency response. In most microwave

measurements, systematic errors are the most significant source of measurement uncertainty. The

source of these errors can be attributed to the signal separation scheme used.

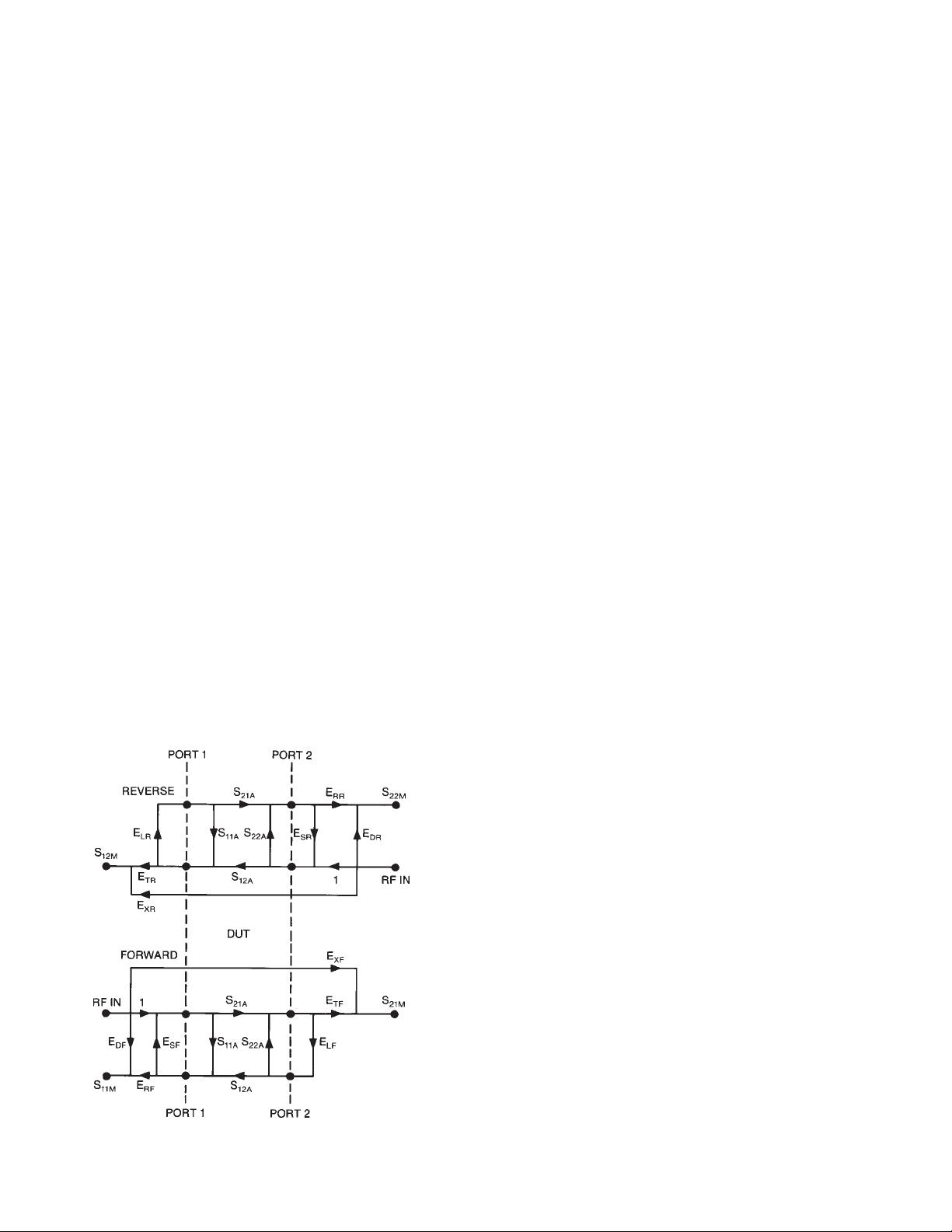

The systematic errors present in an S-parameter

measurement can be modeled with a signal flowgraph. The flowgraph model, which is used for error

correction in the 8510 for the errors associated with

measuring the S-parameters of a two port device, is

shown in the figure below.

The six systematic errors in the forward direction

are directivity, source match, reflection tracking,

load match, transmission tracking, and isolation.

The reverse error model is a mirror image, giving a

total of 12 errors for two-port measurements. The

process of removing these systematic errors from

the network analyzer S-parameter measurement is

called measurement calibration.

E

DF

, EDR-Directivity ELF, ELR-Load Match

ESF, ESR-Source Match ETF, ETR-Trans. Tracking

ERF, ERR-Refl. Tracking EXF, EXR-Isolation

Measurement calibration

A more complete definition of measurement calibration using the 8510, and a description of the

error models is included in the 8510 operating and

programming manual. The basic ideas are summarized here.

A measurement calibration is a process which

mathematically derives the error model for the

8510. This error model is an array of vector coefficients used to establish a fixed reference plane of

zero phase shift, zero magnitude and known

impedance. The array coefficients are computed by

measuring a set of “known” devices connected at a

fixed point and solving as the vector difference

between the modeled and measured response.

Figure 1. Agilent 8510 full 2-port error model

Page 4

4

The array coefficients are computed by measuring

a set of “known” devices connected at a fixed point

and solving as the vector difference between the

modeled and measured response.

The full 2-port error model shown in Figure 1 is

an example of only one of the measurement calibrations available with the 8510. The measurement

calibration process for the 8510 must be one of

seven types: RESPONSE, RESPONSE & ISOLATION,

Sll1-PORT, S221-PORT, ONE PATH 2-PORT, FULL

2-PORT, and TRL 2-PORT. Each of these calibration

types solves for a different set of the systematic

measurement errors. A RESPONSE calibration

solves for the systematic error term for reflection or transmission tracking depending on the

S-parameter which is activated on the 8510 at the

time. RESPONSE & ISOLATION adds correction

for crosstalk to a simple RESPONSE calibration.

An S11l-PORT calibration solves for the forward

error terms, directivity, source match and reflection tracking. Likewise, the S221-PORT calibration

solves for the same error terms in the reverse

direction. A ONE PATH 2-PORT calibration solves

for all the forward error terms. FULL 2-PORT and

TRL 2-PORT calibrations include both forward and

reverse error terms.

The type of measurement calibration selected by

the user depends on the device to be measured

(i.e., 1-port or 2-port device) and the extent of

accuracy enhancement desired. Further, a combination of calibrations can be used in the measurement of a particular device.

The accuracy of subsequent test device measurements is dependent on the accuracy of the test

equipment, how well the “known” devices are modeled and the exactness of the error correction

model.

Calibration kit

A calibration kit is a set of physical devices called

standards. Each standard has a precisely known or

predictable magnitude and phase response as a

function of frequency. In order for the 8510 to use

the standards of a calibration kit, the response of

each standard must be mathematically defined and

then organized into standard classes which correspond to the error models used by the 8510.

Agilent currently supplies calibration kits with

1.0-mm (85059A), 1.85-mm (85058D), 2.4-mm

(85056A/D/K), 3.5-mm (85052A/B/C/D/E), 7-mm

(85050B/C/D) and Type-N (85054B) coaxial connectors. To be able to use a particular calibration

kit, the known characteristics from each standard

in the kit must be entered into the 8510 nonvolatile memory. The operating and service manuals for each of the Agilent calibration kits contain

the physical characteristics for each standard in

the kit and mathematical definitions in the format

required by the 8510.

Waveguide calibration using the 8510 is possible.

Calibration in microstrip and other non-coaxial

media is described in Agilent Product Note 8510-8A.

Page 5

5

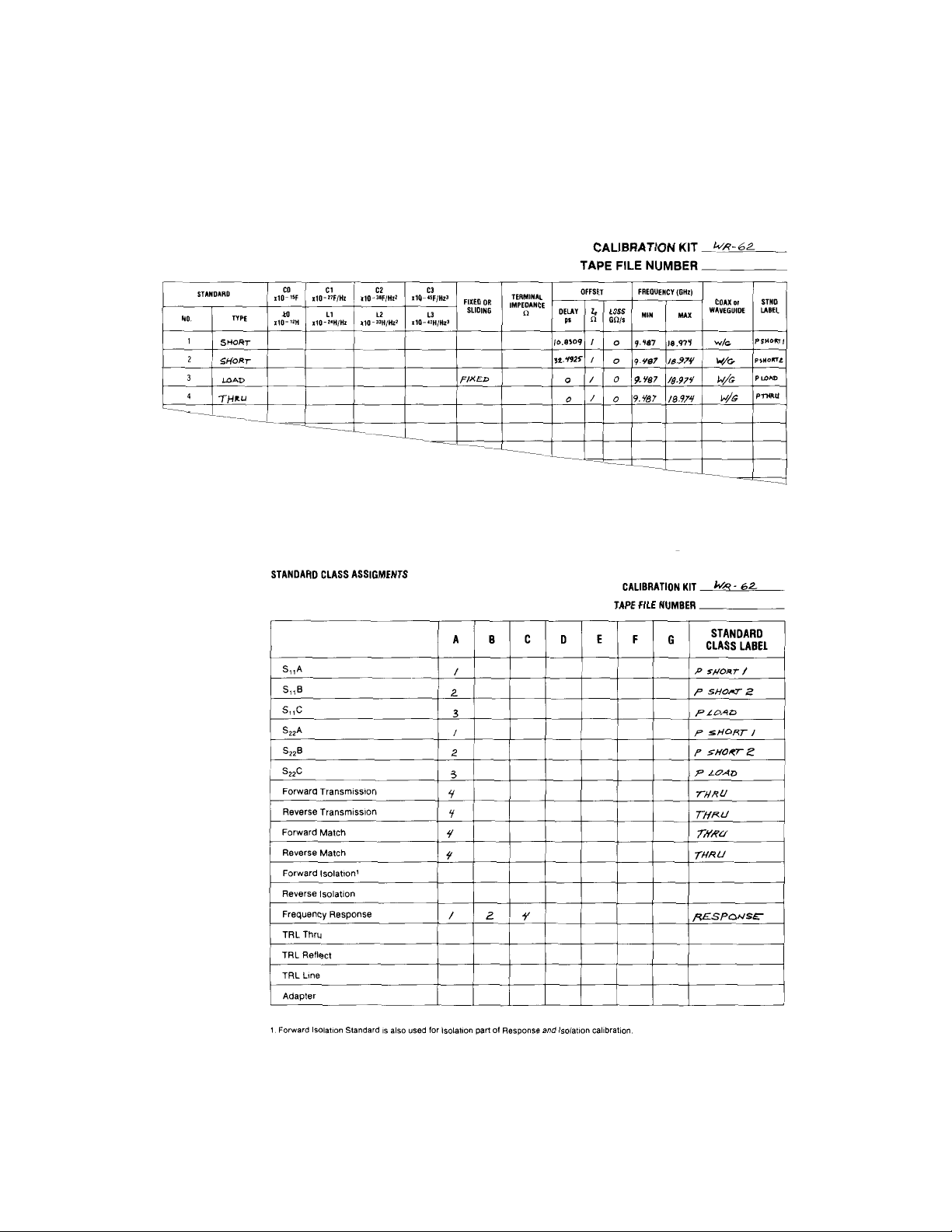

Standard definition

Standard definition is the process of mathematically modeling the electrical characteristics (delay,

attenuation and impedance) of each calibration

standard. These electrical characteristics can be

mathematically derived from the physical dimensions and material of each calibration standards or

from its actual measured response. A standard

definition table (see Table 1) lists the parameters

that are used by the 8510 to specify the mathematical model.

Class assignment

Class assignment is the process of organizing calibration standards into a format which is compatible with the error models used in measurement

calibration. A class or group of classes correspond

to the seven calibration types used in the 8510.

The 17 available classes are identified later in this

note (see Assign classes).

Page 6

6

Table 1. Standard definitions table

Table 2. Standard class assignments

Page 7

7

Modification procedure

Calibration kit modification provides the capability

to adapt to measurement calibrations in other connector types or to generate more precise error

models from existing kits. Provided the appropriate standards are available, cal kit modification

can be used to establish a reference plane in the

same transmission media as the test devices and at

a specified point, generally the point of device connection/insertion. After calibration, the resultant

measurement system, including any adapters

which would reduce system directivity, is fully corrected and the systematic measurement errors are

mathematically removed. Additionally, the modification function allows the user to input more precise physical definitions for the standards in a

given cal kit. The process to modify or create a cal

kit consists of the following steps:

1. Select standards

2. Define standards

3. Assign classes

4. Enter standards/classes

5. Verify performance

To further illustrate, an example waveguide calibration kit is developed as the general descriptions

in MODIFY CAL KIT process are presented.

Select standards

Determine what standards are necessary for calibration and are available in the transmission

media of the test devices.

Calibration standards are chosen based on the following criteria:

• A well defined response which is mechanically

repeatable and stable over typical ambient temperatures and conditions. The most common

coaxial standards are zero-electrical-length

short, shielded open and matched load terminations which ideally have fixed magnitude and

broadband phase response. Since waveguide

open circuits are generally not modelable, the

types of standards typically used for waveguide

calibration are a pair of offset shorts and a fixed

or sliding load.

• A unique and distinct frequency response. To

fully calibrate each test port (that is to provide

the standards necessary for S

11

or S221-PORT

calibration), three standards are required that

exhibit distinct phase and/or magnitude at each

particular frequency within the calibration

band. For example, in coax, a zero-length short

and a perfect shielded open exhibit 180 degree

phase separation while a matched load will provide 40 to 50 dB magnitude separation from

both the short and the open. In waveguide, a

pair of offset shorts of correct length provide

phase separation.

• Broadband frequency coverage. In broadband

applications, it is often difficult to find standards that exhibit a known, suitable response

over the entire band. A set of frequency-banded

standards of the same type can be selected in

order to characterize the full measurement

band.

• The TRL 2-PORT calibration requires only a single precision impedance standard—a transmission line. An unknown high reflection device

and a thru connection are sufficient to complete

this technique.

Page 8

8

Define standards

A glossary of standard definition parameters used

with the Agilent 8510 is included in this section.

Each parameter is described and appropriate conversions are listed for implementation with the

8510. To illustrate, a calibration kit for WR-62 rectangular waveguide (operating frequency range

12.4 to 18 GHz) will be defined as shown in Table

1. Subsequent sections will continue to develop

this waveguide example.

The mathematical models are developed for each

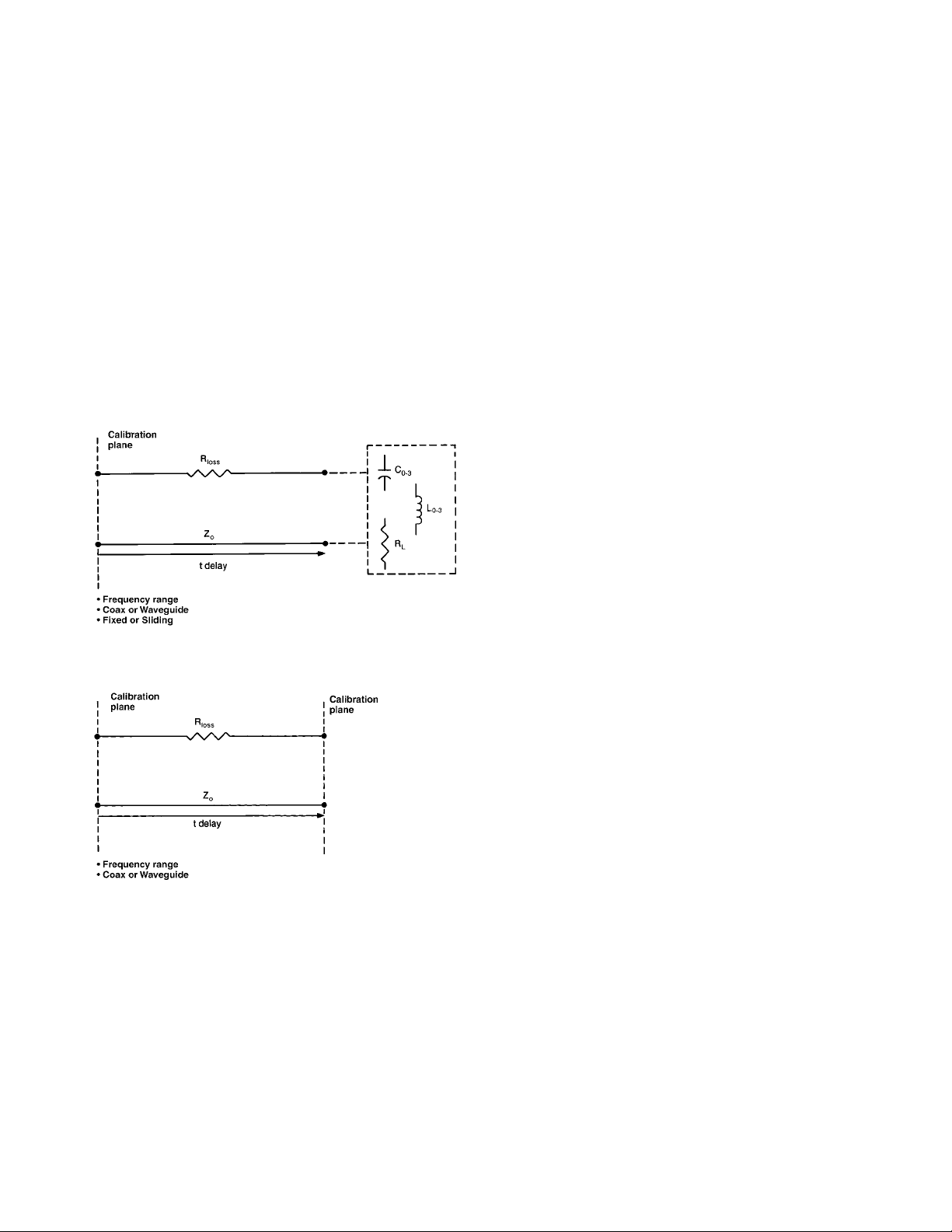

standard in accordance with the standard definition parameters provided by the 8510. These standard definition parameters are shown in Figure 2.

Figure 2. Standard definition models

Model for reflection standard

(short, open, load or arbitrary

impedance)

Model for transmission

standard (Thru)

Page 9

9

Each standard is described using the Standard

Definition Table in accordance with the 1- or 2port model. The Standard Definition table for a

waveguide calibration kit is shown in Table 1. Each

standard type (short, open, load, thru, and arbitrary impedance) may be defined by the parameters as specified below.

• Standard number and standard type

• Fringing capacitance of an open, or inductance

of a short, specified by a third order polynomial

• Load/arbitrary impedance, which is specified as

fixed or sliding

• Terminal resistance of an arbitrary impedance

• Offsets which are specified by delay, Z0, R

loss

• Frequency range

• Connector type: coaxial or waveguide

• Label (up to 10 alphanumeric characters)

Standard number

A calibration kit may contain up to 21 standards

(See Table 1). The required number of standards

will depend on frequency coverage and whether

thru adapters are needed for sexed connectors.

For the WR-62 waveguide example, four standards

will be sufficient to perform the FULL 2-PORT calibration. Three reflection standards are required,

and one transmission standard (a thru) will be sufficient to complete this calibration kit.

Standard type

A standard type must be classified as a “short”

“open,” “load”, “thru,” or “arbitrary impedance.”

The associated models for reflection standards

(short, open, load, and arbitrary impedance) and

transmission standards (thru) are shown in Figure 1.

For the WR-62 waveguide calibration kit, the four

standards are a

1

/8λλ and 3/8λ λ offset short, a fixed

matched load, and a thru. Standard types are

entered into the Standard Definition table under

STANDARD NUMBERS 1 through 4 as short, short,

load, and thru respectively.

Open circuit capacitance: C0, C1, C2and C

3

If the standard type selected is an “open,” the C

0

through C3coefficients are specified and then used

to mathematically model the phase shift caused by

fringing capacitance as a function of frequency.

As a reflection standard, an “open” offers the

advantage of broadband frequency coverage, while

offset shorts cannot be used over more than an

octave. The reflection coefficient (Γ = pe-je) of a

perfect zero-length-open is 1 at 0° for all frequencies. At microwave frequencies however, the magnitude and phase of an “open” are affected by the

radiation loss and capacitive “fringing” fields,

respectively. In coaxial transmission media, shielding techniques are effective in reducing the radiation loss. The magnitude (p) of a zero-length

“open” is assigned to be 1 (zero radiation loss) for

all frequencies when using the Agilent 8510

Standard Type “open.”

Page 10

10

It is not possible to remove fringing capacitance,

but the resultant phase shift can be modeled as a

function of frequency using C

0

through C3(C0+C

l

x

f + C

2

x

f2+ C

3

x

f3,with units of F(Hz), C0(fF),

C1(10

-27

F/Hz), C2(10

-36

F/Hz2) and C3(10

-45

F/Hz3),

which are the coefficients for a cubic polynomial

that best fits the actual capacitance of the “open.”

A number of methods can be used to determine the

fringing capacitance of an “open.” Three techniques, described here, involve a calibrated reflection coefficient measurement of an open standard

and subsequent calculation of the effective capacitance. The value of fringing capacitance can be calculated from the measured phase or reactance as a

function of frequency as follows.

C

eff

– effective capacitance

∆∅ – measured phase shift

f – measurement frequency

F – farad

Z0 – characteristic impedance

X – measured reactance

This equation assumes a zero-length open. When

using an offset open the offset delay must be

backed-out of the measured phase shift to obtain

good C0through C3coefficients.

This capacitance can then be modeled by choosing

coefficients to best fit the measured response

when measured by either method 3 or 4 below.

1. Fully calibrated 1-Port–Establish a calibrated

reference plane using three independent standards

(that is, 2 sets of banded offset shorts and load).

Measure the phase response of the open and solve

for the capacitance function.

2. TRL 2-PORT–When transmission lines standards

are available, this method can be used for a complete 2-port calibration. With error-correction

applied the capacitance of the open can be measured directly.

3. Gating–Use time domain gating to correct the

measured response of the open by isolating the

reflection due to the open from the source match

reflection and signal path leakage (directivity).

Figure 3 shows the time domain response of the

open at the end of an airline. Measure the gated

phase response of the open at the end of an airline

and again solve for the capacitance function.

tan( )

∆∅

2

2πfZ

0

1

2πfX

C

eff

==

Page 11

11

Note

In some cases (when the phase response is linear

with respect to frequency) the response of an open

can be modeled as an equivalent “incremental”

length.

This method will serve as a first order approximation only, but can be useful when data or standards for the above modeling techniques are not

available.

For the waveguide example, this parameter is not

addressed since opens cannot be made valid standards in waveguide, due to the excessive radiation

loss and indeterminant phase.

Short circuit inductance L

0

, L1, L2and L

3

If the standard type selected is a ‘short,’ the L

0

through L3coefficients are specified to model the

phase shift caused by the standard’s residual

inductance as a function of frequency. The reflection coefficient of an ideal zero-length short is 1 at

180° at all frequencies. At microwave frequencies,

however, the residual inductance can produce

additional phase shift. When the inductance is

known and repeatable, this phase shift can be

accounted for during the calibration.

Figure 3. Time domain response of open at the end of

an airline

2πf (∆length)

c

∆∅(radians) =

Page 12

The inductance as a function of frequency can be

modeled by specifying the coefficients of a thirdorder polynomial (L0+ L

1

x

f + L

2

x

f2+ L

3

x

f3),

with units of L0(nH), L1(10

-24

H/Hz),

L2(10

-33

H/Hz2) and L3(10

-42

H/Hz3).

For the waveguide example, the inductance of the

offset short circuits is negligible. L0through L3are

set equal to zero.

Fixed or sliding

If the standard type is specified to be a load or an

arbitrary impedance, then it must be specified as

fixed or sliding. Selection of “sliding” provides a

sub-menu in the calibration sequence for multiple

slide positions and measurement. This enables calculation of the directivity vector by mathematically

eliminating the response due to a non-ideal terminal impedance. A further explanation of this technique is found in the Measurement Calibration

section in the Agilent 8510 Operating and

Programming manual.

The load standard #4 in the WR-62 waveguide calibration kit is defined as a fixed load. Enter FIXED

in the table.

Terminal impedance

Terminal impedance is only specified for “arbitrary

impedance” standards. This allows definition of

only the real part of the terminating impedance in

ohms. Selection as the standard type “short,”

“open,” or “load” automatically assigns the terminal impedance to be 0, ∞ or 50 ohms respectively.

The WR-62 waveguide calibration kit example does

not contain an arbitrary impedance standard.

Offset delay

If the standard has electrical length (relative to the

calibration plane), a standard is specified to have

an offset delay. Offset delay is entered as the oneway travel time through an offset that can be

obtained from the physical length using propagation velocity of light in free space and the appropriate permittivity constant. The effective

propagation velocity equals . See Appendix B

for a further description of physical offset lengths

for sexed connector types.

Delay (seconds) =

= precise measurement of offset length in meters

εr = relative permittivity (= 1.000649 for coaxial

airline or air-filled waveguide in standard lab

conditions)

c = 2.997925 x 108m/s

In coaxial transmission line, group delay is constant over frequency. In waveguide however, group

velocity does vary with frequency due to dispersion as a function of the cut-off frequency.

√

ε

r

c

12

c

√

ε

r

Page 13

13

The convention for definition of offset delay in

waveguide requires entry of the delay assuming no

dispersion. For waveguide transmission line, the

Agilent 8510 calculates the effects of dispersion as

a function of frequency as follows:

fco= lower cutoff frequency

f = measurement frequency

Note

To assure accurate definition of offset delay, a

physical measurement of offset length is recommended.

The actual length of offset shorts will vary by manufacturer. For example, the physical length of a

1

/8 λ offset depends on the center frequency chosen.

In waveguide this may correspond to the arithmetic or geometric mean frequency. The arithmetic

mean frequency is simply (F1+ F2)/2, where F1and

F2are minimum and maximum operating frequencies of the waveguide type. The geometric mean

frequency is calculated as the square root of F1x

F2. The corresponding (λg) is then calculated from

the mean frequency and the cutoff frequency of the

waveguide type. Fractional wavelength offsets are

then specified with respect to this wavelength.

For the WR-62 calibration kit, offset delay is zero

for the “thru” (std #4) and the “load” (std #3). To

find the offset delay of the 1/8 λ and 3/8 λ offset

shorts, precise offset length measurements are necessary. For the 1/8 λ offset short, l = 3.24605 mm,

εr= 1.000649, c = 2.997925 x 108m/s.

Delay =

(3.24605 x 10-3m) (√1.000649)

= 10.8309 pS

2.997925 x 108m/s

For the 3/8 λ offset short, I = 9.7377 mm, εr= 1.000649,

c = 2.997925 x 108m/s.

Delay =

(9.7377 x 10

-3

m) (√1.000649)

= 32.4925 pS

2.997925 x 10

8

m/s

Offset Z

0

Offset Z0is the characteristic impedance within the

offset length. For coaxial type offset standards,

specify the real (resistive) part of the characteristic impedance in the transmission media. The characteristic impedance in lossless coaxial

transmission media can be calculated from its

physical geometry as follows.

Actual delay =

Linear delay

1 - (fco/f)

2

Page 14

14

µr= relative permeability constant of the medium

(equal to 1.0 in air)

εr= relative permittivity constant of the medium

(equal to 1.000649 in air)

D = inside diameter of outer conductor

d = outside diameter of inner conductor

The 8510 requires that the characteristic impedance of waveguide transmission line is assigned to

be equal to the SET Z0.

The characteristic impedance of other transmission media is not as easily determined through

mechanical dimensions. Waveguide impedance, for

example, varies as a function of frequency. In such

cases, normalized impedance measurements are

typically made. When calibrating in waveguide, the

impedance of a “matched” load is used as the

impedance reference. The impedance of this load is

matched that of the waveguide across frequency.

Normalized impedance is achieved by entering SET

Z0and OFFSET Z0to 1 ohm for each standard.

Offset Z0equal to system Z0(SET Z0) is the

assigned convention in the 8510 for matched waveguide impedance.

Offset loss

Offset loss is used to model the magnitude loss due

to skin effect of offset coaxial type standards only.

The value of loss is entered into the standard definition table as gigohms/second or ohms/nanosecond at 1 GHz.

The offset loss in gigohms/second can be calculated from the measured loss at 1 GHz and the physical length of the particular standard by the

following equation.

where:

dB

lOSS

|1 GHz =measured insertion loss at 1 GHz

Z0= offset Z

0

= physical length of the offset

The 8510 calculates the skin loss as a function of

frequency as follows:

Note: For additional information refer to

Appendix C.

For all offset standards, including shorts or opens,

enter the one way skin loss. The offset loss in

waveguide should always be assigned zero ohms by

the 8510.

1

Z0 = = 59.9585

2π

µ

ε

D

In

()

d

µr

εr

D

In

()

d

Offset loss =

Offset loss

GΩ

()

s 10 loge(10) e

1 GHz

GΩ

() ()

s

Offset loss

=

dB

loss

GΩ

1 GHz C Z

s

1GHz

0

r

f(GHz)

X

Page 15

15

Therefore, for the WR-62 waveguide standard definition table, offset loss of zero ohm/sec is entered

for all four standards.

Lower/minimum frequency

Lower frequency defines the minimum frequency at

which the standard is to be used for the purposes

of calibration.

Note

When defining coaxial offset standards, it may be

necessary to use banded offset shorts to specify a

single standard class. The lower and upper frequency parameters should be used to indicate the

frequency range of desired response. It should be

noted that lower and upper frequency serve a dual

purpose of separating banded standards which

comprise a single class as well as defining the overall applicable frequency range over which a calibration kit may be used.

In waveguide, this must be its lower cut-off frequency of the principal mode of propagation.

Waveguide cutoff frequencies can be found in most

waveguide textbooks. The cutoff frequency of the

fundamental mode of propagation (TE10) in rectangular waveguide is defined as follows.

f =

c

2a

c = 2.997925 x 1010cm/sec.

a = inside width of waveguide, larger dimension in cm

As referenced in offset delay, the minimum frequency is used to compute the dispersion effects in

waveguide.

For the WR-62 waveguide example, the lower cutoff

frequency is calculated as follows.

f =

c = 2.997925 x 1010cm/s

= 9.487 GHz

2a 2 x 1.58 cm

c = 2.997925 x 1010cm/s

a = 1.58 cm

The lower cut-off frequency of 9.487 GHz is entered

into the table for all four WR-62 waveguide standards.

Page 16

16

Upper/maximum frequency

This specifies the maximum frequency at which

the standard is valid. In broadband applications, a

set of banded standards may be necessary to provide constant response. For example, coaxial offset

standards (i.e., 1/4 λ offset short) are generally spec-

ified over bandwidths of an octave or less.

Bandwidth specification of standards, using minimum frequency and maximum frequency, enables

the 8510 to characterize only the specified band

during calibration. Further, a submenu for banded

standards is enabled which requires the user to

completely characterize the current measurement

frequency range. In waveguide, this is the upper

cutoff frequency for the waveguide class and mode

of propagation. For the fundamental mode of propagation in rectangular waveguide the maximum

upper cutoff frequency is twice the lower cutoff

frequency and can be calculated as follows.

F(upper) = 2 x F(lower)

The upper frequency of a waveguide standard may

also be specified as the maximum operating frequency as listed in a textbook.

The MAXIMUM FREQUENCY of the WR-62 waveguide cal kit is 18.974 GHz and is entered into the

standard definition table for all four standards.

Coax or waveguide

It is necessary to specify whether the standard

selected is coaxial or waveguide. Coaxial transmission line has a linear phase response as

Waveguide transmission line exhibits dispersive

phase response as follows:

where

Selection of WAVEGUIDE computes offset delay

using the dispersive response, of rectangular waveguide only, as a function of frequency as

This emphasizes the importance of entering “fco” as

the LOWER FREQUENCY.

Selection of COAXIAL assumes linear response of

offset delay.

∅(radians)

2πᐉ

λ

2πf(delay)

==

∅(radians)

2πᐉ

=

λg

λg

=

λ

1-(λ/λco)2

Delay (seconds)

Linear delay

=

1-(fco/f)2

Page 17

17

Note

Mathematical operations on measurements (and

displayed data) after calibration are not corrected

for dispersion.

Enter WAVEGUIDE into the standard definition

table for all four standards.

Standard labels

Labels are entered through the title menu and may

contain up to 10 characters. Standard Labels are

entered to facilitate menu driven calibration.

Labels that describe and differentiate each standard should be used. This is especially true for

multiple standards of the same type.

When sexed connector standards are labeled, male

(M) or female (F), the designation refers to the test

port connector sex—not the connector sex of the

standard. Further, it is recommended that the label

include information carried on the standard such

as the serial number of the particular standard to

avoid confusing multiple standards which are similar in appearance.

The labels for the four standards in the waveguide

example are; #1-PSHORT1, #2-PSHORT2, #3-PLOAD,

and #4-THRU.

Assign classes

In the previous section, define standards, the

characteristics of calibration standards were

derived. Class assignment organizes these stan-

dards for computation of the various error models

used in calibration. The Agilent 8510 requires a

fixed number of standard classes to solve for the n

terms used in the error models (n = 1, 3, or 12).

That is, the number of calibration error terms

required by the 8510 to characterize the measurement system (1-Port, 2-Port, etc.) equals the number of classes utilized.

Standard Classes

A single Standard Class is a standard or group of

(up to 7) standards that comprise a single calibration step. The standards within a single class are

assigned to locations A through G as listed on the

Class Assignments table. It is important to note

that a class must be defined over the entire frequency range that a calibration is made, even

though several separate standards may be required

to cover the full measurement frequency range. In

the measurement calibration process, the order of

standard measurement within a given class is not

important unless significant frequency overlap

exists among the standards used. When two standards have overlapping frequency bands, the last

standard to be measured will be used by the 8510.

The order of standard measurement between different classes is not restricted, although the 8510

requires that all standards that will be used within

a given class are measured before proceeding to

the next class. Standards are organized into specified classes which are defined by a Standards

Class Assignment table. See Table 2 for the class

assignments table for the waveguide calibration kit.

Page 18

18

S11A,B,C and S22A,B,C

S

11

A, B,C and S22A,B,C correspond to the S11and

S22reflection calibrations for port 1 and port 2

respectively. These three classes are used by the

Agilent 8510 to solve for the systematic errors;

directivity, source match, and reflection tracking.

The three classes used by the 7-mm cal kit are

labeled “short,” “open,” and “loads.” “Loads” refers

to a group of standards which is required to complete this standard class. A class may include a set

of standards of which there is more than one

acceptable selection or more than one standard

required to calibrate the desired frequency range.

Table 2 contains the class assignment for the WR62 waveguide cal kit. The

1

/8 λ offset short (stan-

dard #1) is assigned to S11A. The 3/8 λ offset short

(standard #2) is assigned to S11B. The matched

load (standard #3) is assigned to S11C.

Forward transmission match and thru

Forward Transmission (Match and Thru) classes

correspond to the forward (port 1 to port 2) transmission and reflection measurement of the

“delay/thru” standard in a FULL 2-PORT or ONEPATH 2-PORT calibration. During measurement

calibration the response of the “match” standard is

used to find the systematic Load Match error term.

Similarly the response of the thru standard is used

to characterize transmission tracking.

The class assignments for the WR-62 waveguide cal

kit are as follows. The thru (standard #4) is

assigned to both FORWARD TRANSMISSION and

FORWARD MATCH.

Reverse transmission match and thru

Reverse Transmission (Match and Thru) classes

correspond to the reverse transmission and reflection measurement of the “delay/thru” standard.

For S-parameter test sets, this is the port 2 to port 1

transmission path. For the reflection/transmission

test sets, the device is reversed and is measured in

the same manner using the forward transmission

calibration.

The class assignments for the WR-62 waveguide cal

kit are as follows. The thru (Standard #4) is

assigned to both REVERSE TRANSMISSION and

REVERSE MATCH.

Isolation

Isolation is simply the leakage from port 1 to port 2

internal to the test set.

To determine the leakage signals (crosstalk), each

port should be terminated with matched loads

while measuring S

21

and S12.

The class assignments for forward and reverse isolation are both loads (standard #3).

Frequency response

Frequency Response is a single class which corresponds to a one-term error correction that characterizes only the vector frequency response of the

test configuration. Transmission calibration typically uses a “thru” and reflection calibration typically uses either an “open” or a “short.”

Note

The Frequency Response calibration is not a simple frequency normalization. A normalized

response is a mathematical comparison between

measured data and stored data. The important difference is, that when a standard with non-zero

phase, such as an offset short, is remeasured after

calibration using Frequency Response, the actual

phase offset will be displayed, but its normalized

response would display zero phase offset (measured response minus stored response).

Therefore, the WR-62 waveguide calibration kit class

assignment includes standard #1, standard #2, and

standard #4.

Page 19

19

TRL Thru

TRL Thru corresponds to the measurement of the

S-parameters of a zero-length or short thru connection between port 1 and port 2. The Thru, Reflect

and Line classes are used exclusively for the three

steps of the TRL 2-PORT calibration. Typically, a

“delay/thru” with zero (or the smallest) Offset

Delay is specified as the TRL Thru standard.

TRL Reflect

TRL Reflect corresponds to the S

11

and S22measurement of a highly reflective 1-port device. The

Reflect (typically an open or short circuit) must be

the same for port 1 and 2. The reflection coefficient magnitude of the Reflect should be close to 1

but is not specified. The phase of the reflection

coefficient need only be approximately specified

(within ± 90 degrees).

TRL Line

TRL Line corresponds to the measurement of the

S-parameters of a short transmission line. The

impedance of this Line determines the reference

impedance for the subsequent error-corrected

measurements. The insertion phase of the Line

need not be precisely defined but may not be the

same as (nor a multiple of pi) the phase of the

Thru.

TRM Thru

Refer to “TRL Thru” section.

TRM Reflec

Refer to “TRL Reflec” section.

TRM Match

TRM Match corresponds to the measurement of the

S-parameters of a matched load. The input reflection of this Match determines the reference impedance for the subsequent error-corrected

measurements. The phase of the Match does not

need to be precisely defined.

Adapter

This class is used to specify the adapters used for

the adapter removal process. The standard number of the adapter or adapters to be characterized

is entered into the class assignment. Only an estimate of the adapter’s Offset Delay is required

(within ± 90 degrees). A simple way to estimate

the Offset Delay of any adapter would be as follows. Perform a 1-port calibration (Response or

S

11

1-PORT) and then connect the adapter to the

test port. Terminate the adapter with a short circuit and then measure the Group Delay. If the

short circuit is not an offset short, the adapter’s

Offset Delay is simply l/2 of the measured delay.

If the short circuit is offset, its delay must be subtracted from the measured delay.

Modifying a cal set with connector compensation

Connector compensation is a feature that provides

for compensation of the discontinuity found at the

interface between the test port and a connector.

The connector here, although mechanically compatible, is not the same as the connector used for

the calibration. There are several connector families that have the same characteristic impedance,

but use a different geometry. Examples of such

pairs include:

3.5 mm / 2.92 mm

3.5 mm / SMA

SMA / 2.92 mm

2.4 mm / 1.85 mm

The interface discontinuity is modeled as a

lumped, shunt-susceptance at the test port reference plane. The susceptance is generated from a

capacitance model of the form:

C=C

0

+ C

1

x

f + C

2

x

f2+ C

3

x

f

3

where f is the frequency. The coefficients are provided in the default Cal Kits for a number of typically used connector-pair combinations. To add

models for other connector types, or to change the

coefficients for the pairs already defined in a Cal

Kit, use the “Modifying a Calibration Kit” procedure in the “Calibrating for System Measurements”

chapter of the 8510 network analyzer systems

Operating and Programming Manual (part number

08510-90281). Note that the definitions in the

default Cal Kits are additions to the Standard

Class Adapter, and are Standards of type “OPEN.”

Page 20

20

Each adapter is specified as a single delay/thru

standard and up to seven standards numbers can

be specified into the adapter class.

Standard Class labels

Standard Class labels are entered to facilitate

menu-driven calibration. A label can be any userselected term which best describes the device or

class of devices that the operator should connect.

Predefined labels exist for each class. These labels

are

S11A, S11B, S11C, S22A, S22B, S22C, FWD TRANS,

FWD MATCH, REV TRANS, REV MATCH,

RESPONSE, FWD ISOLATION, REV ISOLATION,

THRU, REFLECT, LINE, and ADAPTER.

The class labels for the WR-62 waveguide calibration kit are as follows; S11A and S22A–PSHORT1;

S11B and S22B–PSHORT2; S11C and S22C–PLOAD;

FWD TRANS, FWD MATCH, REV TRANS and REV

MATCH–PTHRU; and RESPONSE–RESPONSE.

TRL options

When performing a TRL 2-PORT calibration, certain options may be selected. CAL Z is used to

specify whether skin-effect-related impedance variation is to be used or not. Skin effect in lossy

transmission line standards will cause a frequencydependent variation in impedance. This variation

can be compensated when the skin loss (offset

loss) and the mechanically derived impedance

(Offset Z0) are specified and CAL Z0: SYSTEM Z

0

selected. CAL Z0: LINE Z0specifies that the impedance of the line is equal to the Offset Z0at all

frequencies.

The phase reference can be specified by the Thru

or Reflect during the TRL 2-PORT calibration. SET

REF: THRU corresponds to a reference plane set by

Thru standard (or the ratio of the physical lengths

of the Thru and Line) and SET REF: REFLECT corresponds to the Reflect standard.

LOWBAND FREQUENCY is used to select the minimum frequency for coaxial TRL calibrations. Below

this frequency (typically 2 to 3 GHz) full 2-port

calibrations are used.

Note

The resultant calibration is a single cal set

combining the TRL and conventional full 2-port

calibrations. For best results, use TRM calibration

to cover frequencies below TRL cut-off frequency.

Calibration kit label

A calibration kit label is selected to describe the

connector type of the devices to be measured. If a

new label is not generated, the calibration kit label

for the kit previously contained in that calibration

kit register (CAL 1 or CAL 2) will remain. The predefined labels for the two calibration kit registers

are:

Calibration kit 1 Cal 1 Agilent 85050B

7-mm B.1

Calibration kit 2 Cal 2 Agilent 85052B

3.5-mm B.1

Page 21

21

Again, cal kit labels should be chosen to best

describe the calibration devices. The “B.1” default

suffix corresponds to the kit’s mechanical revision

(B) and mathematical revision (1).

Note

To prevent confusion, if any standard definitions

in a calibration kit are modified but a new kit label

is not entered, the default label will appear with

the last character replaced by a “*”. This is not the

case if only a class is redefined without changing a

standard definition.

The WR-62 waveguide calibration kit can be

labeled simply – P BAND.

Enter standards/classes

The specifications for the Standard Definition

table and Standard Class Assignments table can be

entered into the 8510 through front panel menudriven entry or under program control by an external controller. The procedure for entry of standard

definitions, standard labels, class assignments,

class labels, and calibration kit label is described

in Appendix A.

Note

DO NOT exit the calibration kit modification

process without saving the calibration kit definitions in the appropriate register in the 8510.

Failure to save the redefined calibration kit will

result in not saving the new definitions and the

original definitions for that register will remain.

Once this process is completed, it is recommended

that the new calibration kit should be saved on

tape.

Verify performance

Once a measurement calibration using a particular

calibration kit has been generated, its performance

should be checked before making device measurements. To check the accuracy that can be obtained

using the new calibration kit, a device with a well

defined frequency response (preferably unlike any

of the standards used) should be measured. It is

important to note that the verification device must

not be one of the calibration standards. Calibrated

measurement of one of the calibration standards is

merely a measure of repeatability.

A performance check of waveguide calibration kits

is often accomplished by measuring a zero length

short or a short at the end of a straight section of

waveguide. The measured response of this device

on a polar display should be a dot at 1 ∠ 180°. The

deviation from the known is an indication of the

accuracy. To achieve a more complete verification

of a particular measurement calibration, (including

dynamic accuracy) accurately known verification

standards with a diverse magnitude and phase

response should be used. NBS traceable or Agilent

standards are recommended to achieve verifiable

measurement accuracy. Further, it is recommended that verification standards with known but different phase and magnitude response than any of

the calibration standards be used to verify performance of the 8510.

Page 22

22

User modified cal kits and Agilent 8510

specifications

As noted previously, the resultant accuracy of the

8510 when used with any calibration kit is dependent on how well its standards are defined and is

verified through measurement of a device with

traceable frequency response.

The published Measurement Specifications for the

8510 Network Analyzer system include calibration

with Agilent calibration kits such as the 85050B.

Measurement calibrations made with user defined

or modified calibration kits are not subject to the

8510 performance specifications although a procedure similar to the standard verification procedure

may be used.

Modification examples

Modeling a “thru” adapter

The MODIFY CAL KIT function allows more precise

definition of existing standards, such as the “thru.”

For example, when measuring devices with the

same sex coaxial connectors, a set of “thru” standards to adapt non-insertable devices on each end

is needed. Various techniques are used to cancel

the effects of the “thru” adapters. However, using

the modify cal kit function to make a precise definition of the “thru” enables the 8510 to mathematically “remove” the attenuation and phase shift due

to the “thru” adapter. To model correctly a “thru”

of fixed length, accurate gauging (see OFFSET

DELAY) and a precise measurement of skin-loss

attenuation (see OFFSET LOSS) are required. The

characteristic impedance of the “thru” can be

found from the inner and outer conductor diameters and the permittivity of the dielectric (see OFFSET Z0).

Modeling an arbitrary impedance standard

The arbitrary impedance standard allows the user

to model the actual response of any one port passive device for use as a calibration standard. As

previously stated, the calibration is mathematically

derived by comparing the measured response to

the known response which is modeled through the

standard definition table. However, when the

known response of a one-port standard is not

purely reflective (short/open) or perfectly matched

(load) but the response has a fixed real impedance,

then it can be modeled as an arbitrary impedance.

A “load” type standard has an assigned terminal

impedance equal to the system Z

0

. If a given load

has an impedance which is other than the system

Z0, the load itself will produce a systematic error in

solving for the directivity of the measurement system during calibration. A portion of the incident

signal will be reflected from the mismatched load

and sum together with the actual leakage between

the reference and test channels within the measurement system. However, since this reflection is

systematic and predictable (provided the terminating impedance is known) it may be mathematically

removed. The calibration can be improved if the

standard’s terminal impedance is entered into the

definition table as an arbitrary impedance rather

than as a “load.”

A procedure similar to that used for measurement

of open circuit capacitance (see method #3) could

be used to make a calibrated measurement of the

terminal impedance.

Page 23

23

Appendix A

Calibration kit entry procedure

Calibration kit specifications can be entered into

the Agilent 8510 using the 8510 disk drive, a disk

drive connected to the system bus, by front panel

entry, or through program control by an external

controller.

Disk procedure

This is an important feature since the 8510 can

internally store only two calibration kits at one

time while multiple calibration kits can be stored

on a single disk.

Below is the generic procedure to load or store calibration kits from and to the disk drive or disk

interface.

To load calibration kits from disk into the

Agilent 8510

1. Insert the calibration data disk into the 8510

network analyzer (or connect compatible disk drive

to system bus).

2. Press the DISC key; select STORAGE IS:

INTERNAL or EXTERNAL; then press the following

display softkeys:

LOAD

CAL KIT 1-2

CAL KIT 1 or CAL KIT 2 (This selection determines

which of the 8510 non-volatile registers that the

calibration kit will be loaded into.)

FILE #_ or FILE NAME (Select the calibration kit

data to load.)

LOAD FILE.

3. To verify that the correct calibration kit was

loaded into the instrument, press the CAL key. If

properly loaded, the calibration kit label will be

shown under “CAL 1” or “CAL 2” on the CRT display.

To store calibration kits from the Agilent 8510 onto a disk

1. Insert an initialized calibration data disk into

the 8510 network analyzer or connect compatible

disk drive to the system bus.

2. Press the DISC key; select STORAGE IS:

INTERNAL or EXTERNAL; then press the following

CRT displayed softkeys:

STORE

CAL KIT 1-2

CAL KIT 1 or CAL KIT 2 (This selection determines

which of the 8510 non-volatile calibration kit registers is to be stored.)

FILE #_ or FILE NAME (Enter the calibration kit

data file name.)

STORE FILE.

3. Examine directory to verify that file has been

stored. This completes the sequence to store a calibration kit onto the disk.

To generate a new cal kit or modify an existing

one, either front panel or program controlled entry

can be used.

In this guide, procedures have been given to define

standards and assign classes. This section will list

the steps required for front panel entry of the standards and appropriate labels.

Page 24

24

Front panel procedure: (P-band waveguide example)

1. Prior to modifying or generating a cal kit, store

one or both of the cal kits in the 8510’s nonvolatile memory to a disk.

2. Select CAL menu, MORE.

3. Prepare to modify cal kit 2: press MODIFY 2.

4. To define a standard: press DEFINE STANDARD.

5. Enable standard no. 1 to be modified: press 1,

X1.

6. Select standard type: SHORT.

7. Specify an offset: SPECIFY OFFSETS.

8. Enter the delay from Table 1: OFFSET DELAY,

0.0108309, ns.

9. Enter the loss from Table 1: OFFSET LOSS, 0,

X1.

10. Enter the Z0from Table 1: OFFSET Z0, 50, X1.

11. Enter the lower cutoff frequency: MINIMUM

FREQUENCY, 9.487 GHz.

12. Enter the upper frequency: MAXIMUM FREQUENCY, 18.97 GHz.

13. Select WAVEGUIDE.

14. Prepare to label the new standard: PRIOR

MENU, LABEL STANDARD, ERASE TITLE.

15. Enter PSHORT 1 by using the knob, SELECT

LETTER soft key and SPACE soft key.

16. Complete the title entry by pressing TITLE

DONE.

17. Complete the standard modification by pressing STANDARD DONE (DEFINED).

Standard #1 has now been defined for a

1

/8 λ P-band

waveguide offset short. To define the remaining

standards, refer to Table 1 and repeat steps 4 -17.

To define standard #3, a matched load, specify

“fixed.”

The front panel procedure to implement the class

assignments of Table 2 for the P-band waveguide

cal kit are as follows:

1. Prepare to specify a class: SPECIFY CLASS.

2. Select standard class S11A.

3. Inform the 8510 to use standard no. 1 for the

S11A class of calibration: l, X1, CLASS DONE

(SPECIFIED).

Page 25

25

4. Change the class label for S11A: LABEL CLASS,

S11A, ERASE TITLE.

5. Enter the label of PSHORT 1 by using the knob,

the SELECT soft key and the SPACE soft key.

6. Complete the label entry procedure: TITLE

DONE, LABEL DONE.

Follow a similar procedure to enter the remaining

standard classes and labels as shown in the table

below:

Finally, change the cal kit label as follows:

1. Press LABEL KIT, ERASE TITLE.

2. Enter the title “P BAND.”

3. Press TITLE DONE, KIT DONE (MODIFIED). The

message “CAL KIT SAVED” should appear.

This completes the entire cal kit modification for

front panel entry. An example of programmed

modification over the GPIB bus through an external controller is shown in the Introduction To

Programming section of the Operating and Service

manual (Section III).

Standard Standard Class

class numbers label

S11B 2 PSHORT 2

S11C 3 PLOAD

S22A 1 PSHORT 1

S22B 2 PSHORT 2

S22C 3 PLOAD

FWD TRANS 4 THRU

FWD MATCH 4 THRU

REV TRANS 4 THRU

REV MATCH 4 THRU

RESPONSE 1,2,4 RESPONSE

Page 26

26

Appendix B

Dimensional considerations in coaxial

connectors

This appendix describes dimensional considerations and required conventions used in determining the physical offset length of calibration

standards in sexed coaxial connector families.

Precise measurement of the physical offset length

is required to determine the OFFSET DELAY of a

given calibration standard. The physical offset

length of one and two port standards is as follows.

One port standard–Distance between “calibration

plane” and terminating impedance.

Two port standard–Distance between the Port 1

and Port 2 “calibration planes.”

The definition (location) of the “calibration plane”

in a calibration standard is dependent on the

geometry and sex of the connector type. The “calibration plane” is defined as a plane which is perpendicular to the axis of the conductor coincident

with the outer conductor mating surface. This mating surface is located at the contact points of the

outer conductors of the test port and the calibration standard.

To illustrate this, consider the following connector

type interfaces:

7-mm coaxial connector interface

The “calibration plane” is located coincident to

both the inner and outer conductor mating surfaces as shown. Unique to this connector type is

the fact that the inner and outer conductor mating

surfaces are located coincident as well as having

hermaphroditic (sexless) connectors. In all other

coaxial connector families this is not the case.

3.5-mm coaxial connector interface

The location of the “calibration plane” in 3.5-mm

standards, both sexes, is located at the outer conductor mating surface as shown.

Type-N coaxial connector interface

The location of the “calibration plane” in Type-N

standards is the outer conductor mating surfaces

as shown below.

Note

During measurement calibration using the Agilent

85054 Type-N Calibration Kit, standard labels for

the “opens” and “shorts” indicate both the standard type and the sex of the calibration test port.

The sex (M or F) indicates the sex of the test port,

NOT the sex of the standard. The calibration plane

in other coaxial types should be defined at one of

the conductor interfaces to provide an easily verified reference for physical length measurements.

Page 27

27

Female type-N

Male type-N

7 mm Coaxial connector

Type-N coaxial connector interface

The location of the “calibration plane” in Type-N standards is the outer conductor mating surfaces as shown below.

Note: 1.0mm, 1.85mm and 2.4mm connectors not shown, but similar to 3.5mm calibration planes.

Page 28

28

Page 29

29

Appendix C

Cal coefficients model

Offset devices like offset shorts and offset opens can

be modeled by the following signal flow graph :

Figure 1 Signal flow graph model of offset devices

The offset portion of the open or short, is modeled

as a perfectly uniform lossy air dielectric transmission line. The expected coefficient of reflection, Γ,

of the open or short then can be solved by signal

flow graph technique.

Equation 1

The terms Zo, and are related to the cal

coefficients - Offset Zo, Offset Loss, and Offset

Delay - as follows:

Recall that

Equation 2

L ≈ L +

0

R

ω

Page 30

30

Their first order approximations, R is small and G=0, are:

Equation 3

Since

Equation 4

For coaxial devices

Page 31

31

then:

Equation 5

Equation 6

If the Offset delay=0, then the coefficient of reflection,

Γ = ΓL.

Page 32

www.agilent.com/find/emailupdates

Get the latest information on the products and

applications you select.

Agilent Email Updates

www.agilent.com

Agilent Technologies’ Test and Measurement

Support, Services, and Assistance

Agilent Technologies aims to maximize the value you

receive, while minimizing your risk and problems. We

strive to ensure that you get the test and measurement

capabilities you paid for and obtain the support you

need. Our extensive support resources and services

can help you choose the right Agilent products for

your applications and apply them successfully. Every

instrument and system we sell has a global warranty.

Two concepts underlie Agilent’s overall support policy:

“Our Promise” and “Your Advantage.”

Our Promise

Our Promise means your Agilent test and measurement

equipment will meet its advertised performance

and functionality. When you are choosing new equipment, we will help you with product information,

including realistic performance specifications and

practical recommendations from experienced test

engineers. When you receive your new Agilent equipment, we can help verify that it works properly and

help with initial product operation.

Your Advantage

Your Advantage means that Agilent offers a wide

range of additional expert test and measurement

services, which you can purchase according to your

unique technical and business needs. Solve problems

efficiently and gain a competitive edge by contracting

with us for calibration, extra-cost upgrades, out-ofwarranty repairs, and onsite education and training,

as well as design, system integration, project management, and other professional engineering services.

Experienced Agilent engineers and technicians worldwide can help you maximize your productivity, optimize

the return on investment of your Agilent instruments

and systems, and obtain dependable measurement

accuracy for the life of those products.

For more information on Agilent Technologies’

products, applications or services, please contact

your local Agilent office.

Phone or Fax

United States: Korea:

(tel) 800 829 4444 (tel) (080) 769 0800

(fax) 800 829 4433 (fax) (080) 769 0900

Canada: Latin America:

(tel) 877 894 4414 (tel) (305) 269 7500

(fax) 800 746 4866 Taiwan:

China: (tel) 0800 047 866

(tel) 800 810 0189 (fax) 0800 286 331

(fax) 800 820 2816 Other Asia Pacific

Europe: Countries:

(tel) 31 20 547 2111 (tel) (65) 6375 8100

Japan: (fax) (65) 6755 0042

(tel) (81) 426 56 7832 Email: tm_ap@agilent.com

(fax) (81) 426 56 7840

Contacts revised: 09/26/05

The complete list is available at:

www.agilent.com/find/contactus

Product specifications and descriptions in this

document subject to change without notice.

© Agilent Technologies, Inc. 2001, 2004, 2006

Printed in USA, July 13, 2006

5956-4352

www.agilent.com/find/agilentdirect

Quickly choose and use your test equipment

solutions with confidence.

Agilent Direct

Agilent

Open

www.agilent.com/find/open

Agilent Open simplifies the process of connecting

and programming test systems to help engineers

design, validate and manufacture electronic products. Agilent offers open connectivity for a broad

range of system-ready instruments, open industry

software, PC-standard I/O and global support,

which are combined to more easily integrate test

system development.

Loading...

Loading...