Page 1

Operating and Service Manual

Agilent Technologies

85037A/B

Precision Detectors

Serial Numbers

This manual applies directly to Agilent 85037A/B detectors with serial

number 00101 and above.

Part Number: 85037-90013

Printed in USA

November 2001

Supersedes June 1993

© Copyright 1992–1993, 2001 Agilent Technologies, Inc.

Page 2

Notice.

The information contained in this document is subject to change without notice.

Agilent Technologies makes no warranty of any kind with regard to this material,

including but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. Agilent shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing, performatnce, or use of this

material.

Hewlett-Packard to Agilent Technologies Transition

This documentation supports a product that previously shipped under the

Hewlett-Packard company brand name. The brand name has now been changed to Agilent

Technologies. The two products are functionally identical, only our name has changed. The

document still includes references to Hewlett-Packard products, some of which have been

transitioned to Agilent Technologies.

ii

Page 3

Certification

AgilentTechnologies certies that this product met its published

specications at the time of shipment from the factory. Agilent

further certies that its calibration measurements are traceable to the

United States National Institute of Standards and Technology,to

the extent allowed by the Institute's calibration facility, and to the

calibration facilities of other International Standards Organization

members.

Warranty

This Agilent instrument pro duct is warranted against defects in

material and workmanship for a perio d of one year from date of

shipment. During the warranty p eriod, Agilent will, at its option,

either repair or replace pro ducts which prove to be defective.

For warranty service or repair, this product must be returned to a

service facility designated by Agilent. Buyer shall prepay shipping

charges to Agilent and Agilent shall pay shipping charges to return

the pro duct to Buyer. However, Buyer shall pay all shipping charges,

duties, and taxes for pro ducts returned to Agilen

t from another

country.

AgilentTechnologies warrants that its software and rmware

designated by Agilent for use with an instrument will execute

its programming instructions when prop erly installed on that

instrument. Agilent does not warrant that the operation of the

instrument, or software, or rmware will b e uninterrupted or

error-free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied

software or interfacing, unauthorized modication or misuse,

operation outside of the environmental specications for the

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED.

HEWLETT-PACKARD SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE

AND EXCLUSIVE REMEDIES. HEWLETT-PACKARD SHALL

NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER

BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL

THEORY.

iii

Page 4

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Agilent products.

For any assistance, contact your nearest Agilent Technologies Sales

and Service Oce.

Safety Notes

Caution

Warning

The following safety notes are used throughout this manual.

Familiarize yourself with each of the notes and its meaning before

operating this instrument.

Caution

denotes a hazard. It calls attention to a pro cedure that, if

not correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed b eyond a

caution

sign

until the indicated conditions are fully understood and met.

Warning

denotes a hazard. It calls attention to a procedure which, if

not correctly performed or adhered to, could result in injury or loss

of life. Do not proceed beyond a

warning

note until the indicated

conditions are fully understood and met.

Instruction

Manual

The

instruction manual

symbol. The product is marked with

this symbol when it is necessary for the user to refer to the

instructions in the manual.

L

iv

Page 5

Contents

1. General Information

Introduction . . . . . . . . . . . . . . . . . . 1-1

Product Description . . . . . . . . . . . . . 1-1

Instruments Covered by This Manual . . . . . . 1-1

Accessories . . . . . . . . . . . . . . . . . . 1-2

Equipment Required but Not Supplied . . . . . . 1-2

Recommended Test Equipment. . . . . . . . . 1-2

Reection or Transmission Measurements . . . . 1-2

AC Detection . . . . . . . . . . . . . . . . 1-2

Specications and Supplemental Characteristics . . 1-2

2. Installation

Safety Considerations . . . . . . . . . . . . . . 2-1

Initial Inspection . . . . . . . . . . . . . . . . 2-1

Preparation for Use . . . . . . . . . . . . . . . 2-2

Electrostatic Discharge (ESD) . . . . . . . . . 2-2

Static-Safe Workstation . . . . . . . . . . . 2-2

Static-Safe Practices . . . . . . . . . . . . 2-2

Power Requirements . . . . . . . . . . . . . 2-3

Cable Lead Identication . . . . . . . . . . . 2-3

Mating Connectors . . . . . . . . . . . . . . 2-3

Connecting an 85037A/B . . . . . . . . . . . 2-3

Mating a Precision 3.5 mm Connector to an SMA

Connector . . . . . . . . . . . . . . . 2-4

Electrical Performance . . . . . . . . . . 2-4

Operating Environment.. . . . . . . . . . . . 2-6

Storage and Shipment. . . . . . . . . . . . . . 2-6

Environment. . . . . . . . . . . . . . . . . 2-6

Packaging . . . . . . . . . . . . . . . . . . 2-6

Returning a Detector for Service . . . . . . . . . 2-7

3. Operation

Operating Theory . . . . . . . . . . . . . . . 3-1

AC Detection . . . . . . . . . . . . . . . . 3-1

DC Detection . . . . . . . . . . . . . . . . 3-1

Features . . . . . . . . . . . . . . . . . . . . 3-2

Connector Torque Values . . . . . . . . . . . . 3-2

Operator's Check. . . . . . . . . . . . . . . . 3-3

Operating Mo des and Sp ecications . . . . . . . 3-3

Dynamic Accuracy . . . . . . . . . . . . . . 3-3

Frequency Response . . . . . . . . . . . . . 3-3

Measurement System Conguration . . . . . . . . 3-4

Contents-1

Page 6

DC Detection Measurements . . . . . . . . . . . 3-5

Enabling the DC Detection Mo de . . . . . . . 3-5

Making Accurate DC Measurements . . . . . . 3-5

Operation . . . . . . . . . . . . . . . . . 3-5

Zeroing an 85037A/B . . . . . . . . . . . . 3-5

AC Detection Measurements . . . . . . . . . . . 3-6

Making Accurate AC Measurements . . . . . . 3-6

Characterizing the Detector (Performing a Power

Calibration) . . . . . . . . . . . . . . . . 3-7

4. Performance Tests

Introduction . . . . . . . . . . . . . . . . . . 4-1

Equipment Required . . . . . . . . . . . . . 4-1

Return Loss at a Nominal010 dBm . . . . . . . 4-2

Description . . . . . . . . . . . . . . . . . 4-2

Procedure . . . . . . . . . . . . . . . . . . 4-3

Frequency Response at a Nominal010 dBm . . . . 4-5

Description . . . . . . . . . . . . . . . . . 4-5

Procedure . . . . . . . . . . . . . . . . . . 4-6

Conguring the System . . . . . . . . . . . . 4-6

Measuring the Source . . . . . . . . . . . . . 4-7

Measuring the Detector . . . . . . . . . . . . 4-7

Computing the Maximum Error . . . . . . . . 4-8

Dynamic Power Accuracy . . . . . . . . . . . . 4-10

Description . . . . . . . . . . . . . . . . . 4-10

Procedure . . . . . . . . . . . . . . . . . . 4-10

First Alternate Dynamic Power Accuracy . . . . . 4-11

Description . . . . . . . . . . . . . . . . . 4-11

Second Alternate Dynamic Power Accuracy . . . . 4-12

Description . . . . . . . . . . . . . . . . . 4-12

Procedure . . . . . . . . . . . . . . . . . . 4-12

Contents-2

5. Adjustments

Introduction . . . . . . . . . . . . . . . . . . 5-1

Coarse Zero Adjustment. . . . . . . . . . . . . 5-2

Description . . . . . . . . . . . . . . . . . 5-2

Procedure . . . . . . . . . . . . . . . . . . 5-2

Feedthrough Nulling Adjustment.. . . . . . . . 5-3

Description . . . . . . . . . . . . . . . . . 5-3

Procedure . . . . . . . . . . . . . . . . . . 5-3

6. Replaceable Parts

Introduction . . . . . . . . . . . . . . . . . . 6-1

Ordering Parts . . . . . . . . . . . . . . . . . 6-1

Page 7

7. Service

Error Messages . . . . . . . . . . . . . . . . . 7-1

Repair . . . . . . . . . . . . . . . . . . . . 7-1

Replacing the Detector . . . . . . . . . . . . 7-2

Removing the Covers . . . . . . . . . . . . . 7-2

Replacing the Cable Assembly (W1) . . . . . . 7-3

A. Caring for Connectors

Visual Inspection . . . . . . . . . . . . . . . . A-1

Cleaning . . . . . . . . . . . . . . . . . . A-1

Mechanical Inspection . . . . . . . . . . . . . A-2

Index

Contents-3

Page 8

Figures

2-1. Example of a Static-Safe Workstation . . . . . . 2-2

2-2. Using Precision 7 mm Connectors . . . . . . . 2-3

2-3. SMA and 3.5 mm Connector Cross-Sections and

SWR Performance . . . . . . . . . . . . . 2-5

3-1. Detector Features . . . . . . . . . . . . . . 3-2

3-2. Typical Measurement Setup . . . . . . . . . . 3-4

4-1. Return Loss Setup . . . . . . . . . . . . . . 4-2

4-2. Frequency Response Test Setup . . . . . . . . 4-5

4-3. Frequency Response Graph . . . . . . . . . . 4-9

4-4. Dynamic Power Accuracy Test Setup . . . . . . 4-11

4-5. First Alternate Dynamic Power Accuracy Test Setup 4-11

4-6. Second Alternate Dynamic Power Accuracy Test

Setup . . . . . . . . . . . . . . . . . . 4-12

5-1. Coarse Zero/Feedthrough Nulling Adjustment . . 5-2

5-2. Coarse Zero Adjustment. . . . . . . . . . . . 5-3

5-3. Feedthrough Nulling Adjustment. . . . . . . . 5-4

6-1. Detectors and Cable Marker Kit . . . . . . . . 6-2

6-2. Mo dule Exchange Program . . . . . . . . . . 6-4

7-1. Removing the Detector Covers . . . . . . . . . 7-2

7-2. Cable Connections . . . . . . . . . . . . . . 7-4

Tables

Contents-4

1-1. Agilent 85037A Standard1. . . . . . . . . . . 1-3

1-2. Agilent 85037B Specications1. . . . . . . . . 1-4

1-3. Supplemental Characteristics . . . . . . . . . 1-5

1-4. Recommended Test Equipment. . . . . . . . . 1-6

4-1. Return Loss EquipmentTable . . . . . . . . . 4-3

4-2. Frequency Response EquipmentTable . . . . . . 4-6

4-3. Worksheet . . . . . . . . . . . . . . . . . . 4-9

4-4. Additional Equipment . . . . . . . . . . . . 4-12

4-5. Test Record for 85037A . . . . . . . . . . . . 4-13

4-6. Test Record for 85037A Option 001 . . . . . . . 4-17

4-7. Test Record for 85037B . . . . . . . . . . . . 4-21

6-1. Miscellaneous Parts . . . . . . . . . . . . . . 6-2

6-2. Replaceable Parts and Accessories . . . . . . . 6-3

6-3. Contacting Agilent . . . . . . . . . . . . . . 6-5

Page 9

General Information

1

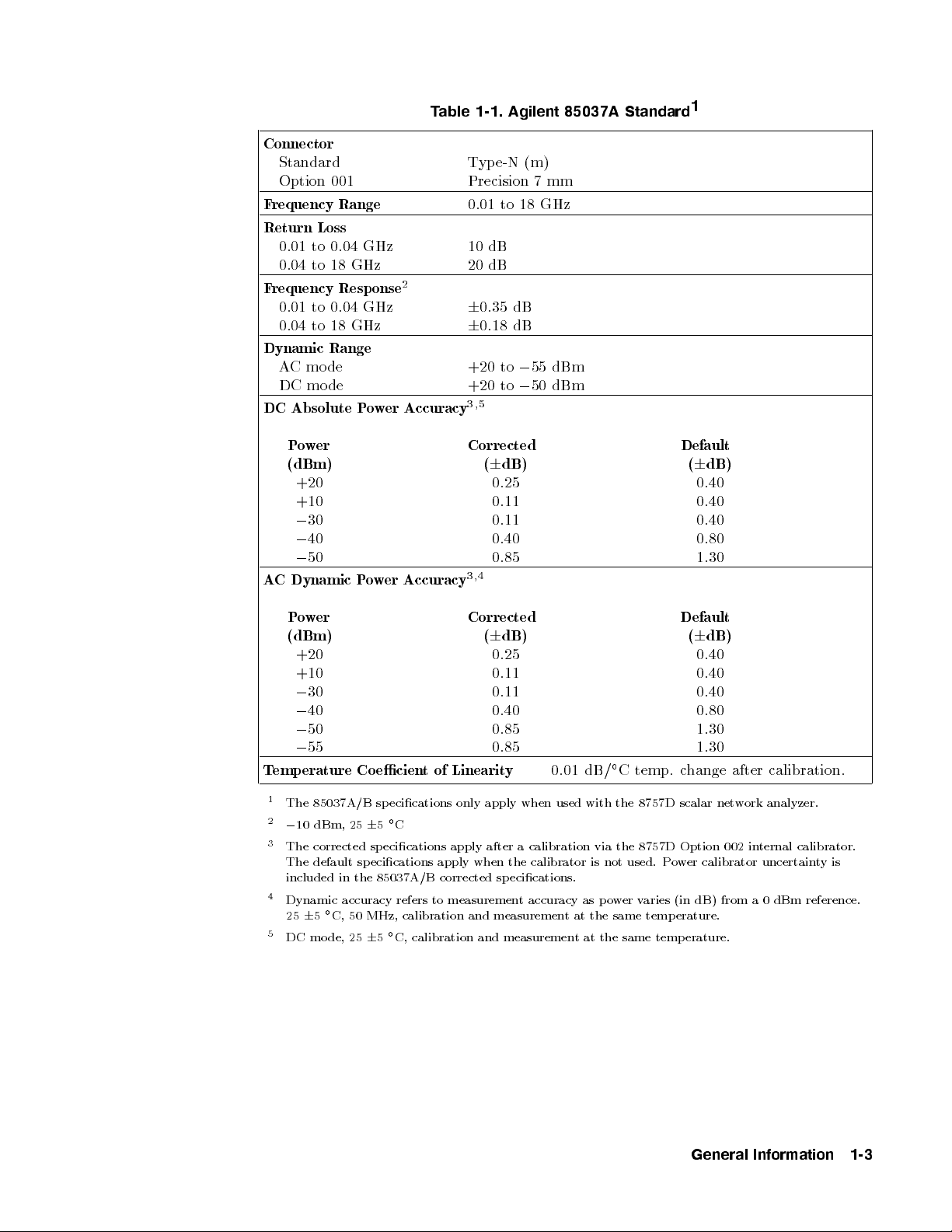

Introduction

Product Description

This manual contains information on operating, testing, and servicing

the Agilent 85037A and 85037B precision detectors. Figure 6-1 shows

the detectors and the supplied cable marker kit.

The Agilent 85037A/B precision detectors are specically designed

for use with an Agilent 8757D scalar network analyzer and are

not compatible with the Agilent 8757A/C/E, 8756, or 8755 scalar

network analyzers. These dual0diode detectors may be used in

either AC or DC detection modes. For improved power measurement

accuracy versus frequency, each Agilent 85037 series precision

detector includes detector specic frequency response data, stored in

an internal EEPROM, which is automatically read by the 8757D.

When used in conjunction with the 8757D's internal p ower calibrator

(Option 002), these detectors provide the maximum absolute power

measurement accuracy.

Agilent Detector Connector Type

85037A Type-N (m)

85037A Option 001 Precision 7 mm

85037B Precision 3.5 mm (m)

Instruments Covered by

This Manual

Each detector has a unique serial number. The contents of this

manual apply directly to detectors with serial numbers listed on the

title page.

General Information 1-1

Page 10

Accessories

Equipment Required

but Not Supplied

Table 6-2 lists accessories available for use with these detectors.

Recommended Test

Equipment

Reflection or

Transmission

Measurements

AC Detection

Table 1-4 lists the equipment required to test the detectors. You

may substitute any equipment that meets the indicated critical

specications.

Reection and transmission measurements require the following

equipment:

One or more detectors.

An Agilent 8757D scalar network analyzer.

One

of the following:

A directional bridge.

A directional coupler.

Asweep oscillator or synthesized sweeper.

For ratio measurements use:

Apower splitter or dual directional coupler.

AC detection requires the equipment listed ab ove,

plus

either a signal

source capable of 27.778 kHz squarewave amplitude modulation, or

an external modulator.

Specifications and

Supplemental

Characteristics

1-2 General Information

Table 1-1 and Table 1-2 list detector specications which are the

performance standards or limits against whichyou can test the

device.

Table 1-3 lists supplemental (typical, non-warranted) detector

characteristics.

Page 11

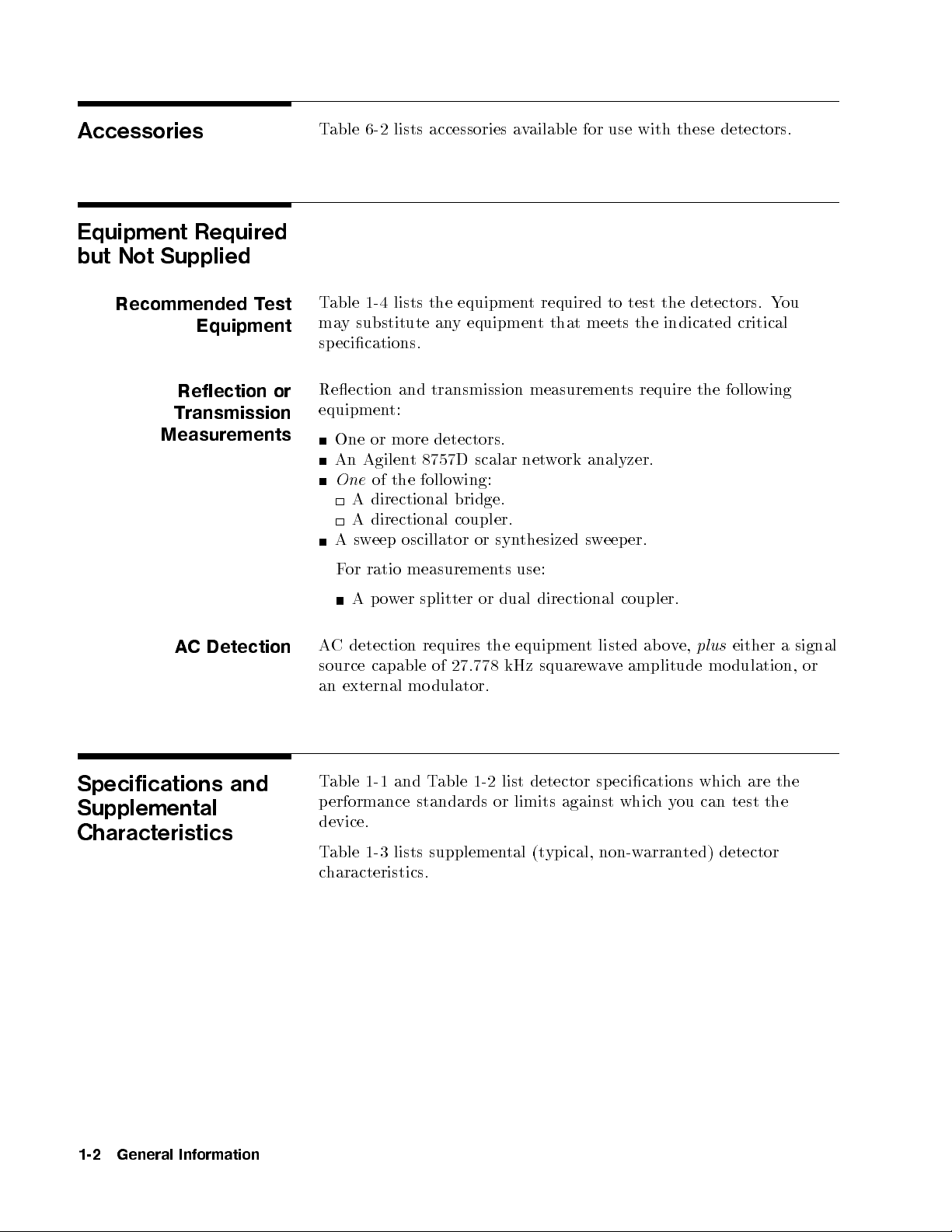

Table 1-1. Agilent 85037A Standard

Connector

Standard Type-N (m)

Option 001 Precision 7 mm

Frequency Range

0.01 to 18 GHz

Return Loss

0.01 to 0.04 GHz 10 dB

0.04 to 18 GHz 20 dB

Frequency Response

0.01 to 0.04 GHz

0.04 to 18 GHz

2

6

0.35 dB

6

0.18 dB

Dynamic Range

ACmode +20 to055 dBm

DC mode +20 to050 dBm

DC Absolute Power Accuracy

3,5

Power Corrected Default

(dBm) (6dB) (6dB)

+20 0.25 0.40

+10 0.11 0.40

0

30 0.11 0.40

0

40 0.40 0.80

0

50 0.85 1.30

AC Dynamic Power Accuracy

3,4

1

Power Corrected Default

(dBm) (6dB) (6dB)

+20 0.25 0.40

+10 0.11 0.40

0

30 0.11 0.40

0

40 0.40 0.80

0

50 0.85 1.30

0

55 0.85 1.30

Temp erature Co ecient of Linearity

1

The 85037A/B sp ecications only apply when used with the 8757D scalar network analyzer.

2

0

10 dBm, 2565C

3

The corrected sp ecications apply after a calibration via the 8757D Option 002 in

The default sp ecications apply when the calibrator is not used. P

0.01 dB/C temp. change after calibration.

ternal calibrator.

ower calibrator uncertaintyis

included in the 85037A/B corrected sp ecications.

4

Dynamic accuracy refers to measurement accuracy as power varies (in dB) from a 0 dBm reference.

2565C, 50 MHz, calibration and measuremen t at the same temperature.

5

DC mo de, 2565

C, calibration and measurement at the same temperature.

General Information 1-3

Page 12

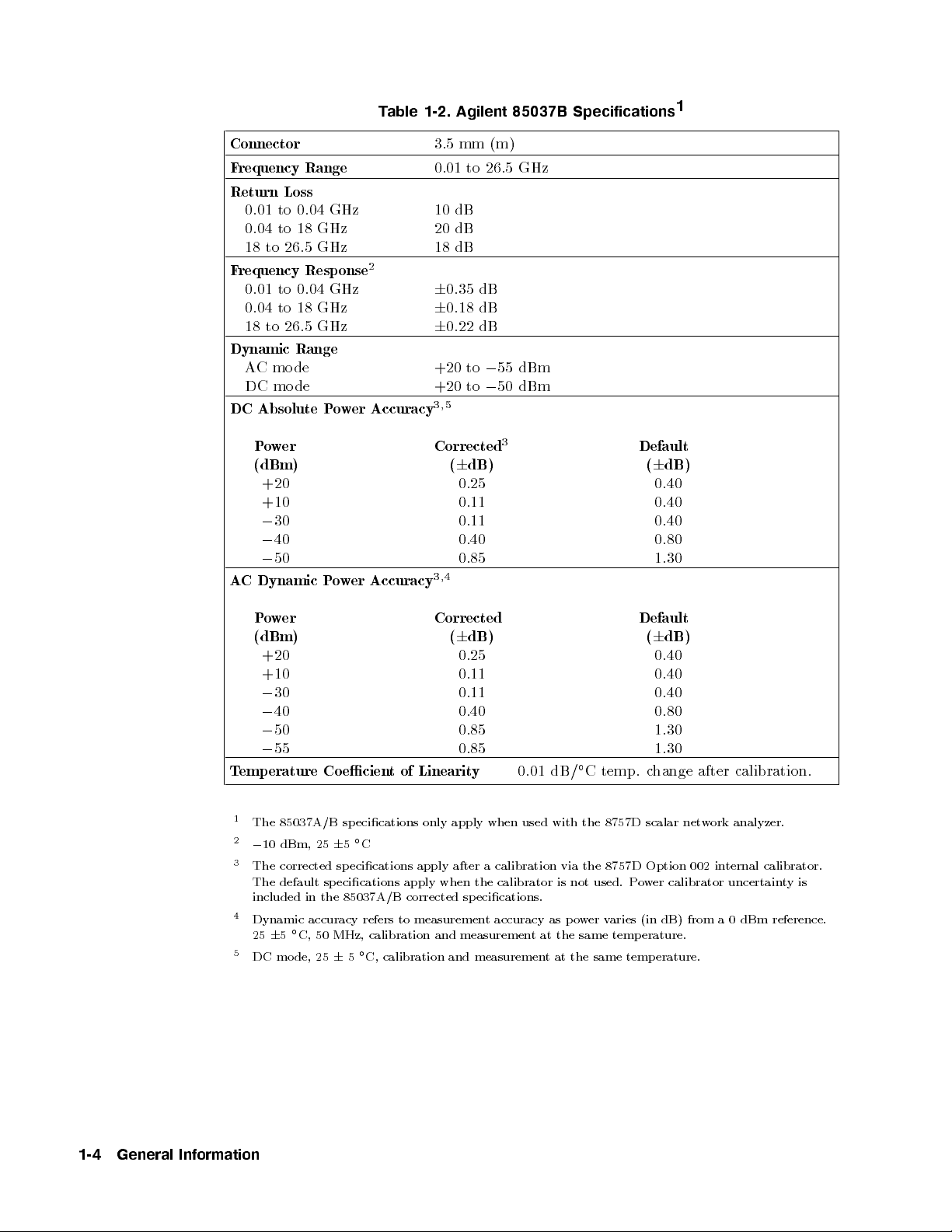

Table 1-2. Agilent 85037B Specifications

1

Connector

Frequency Range

3.5 mm (m)

0.01 to 26.5 GHz

Return Loss

0.01 to 0.04 GHz 10 dB

0.04 to 18 GHz 20 dB

18 to 26.5 GHz 18 dB

Frequency Response

0.01 to 0.04 GHz

0.04 to 18 GHz

18 to 26.5 GHz

2

6

0.35 dB

6

0.18 dB

6

0.22 dB

Dynamic Range

ACmode +20 to055 dBm

DC mode +20 to050 dBm

DC Absolute Power Accuracy

Power Corrected

3,5

3

(dBm) (6dB) (6dB)

+20 0.25 0.40

+10 0.11 0.40

0

30 0.11 0.40

0

40 0.40 0.80

0

50 0.85 1.30

AC Dynamic Power Accuracy

3,4

Default

Power Corrected Default

(dBm) (6dB) (6dB)

+20 0.25 0.40

+10 0.11 0.40

0

30 0.11 0.40

0

40 0.40 0.80

0

50 0.85 1.30

0

55 0.85 1.30

Temp erature Co ecient of Linearity

1

The 85037A/B sp ecications only apply when used with the 8757D scalar network analyzer.

2

0

10 dBm, 2565C

3

The corrected sp ecications apply after a calibration via the 8757D Option 002 in

The default sp ecications apply when the calibrator is not used. P

0.01 dB/C temp. change after calibration.

ternal calibrator.

ower calibrator uncertaintyis

included in the 85037A/B corrected sp ecications.

4

Dynamic accuracy refers to measurement accuracy as power varies (in dB) from a 0 dBm reference.

2565

C, 50 MHz, calibration and measuremen t at the same temp erature.

5

DC mode, 2565

C, calibration and measurement at the same temperature.

1-4 General Information

Page 13

Table 1-3. Supplemental Characteristics

Cable Length

Weight

Net 0.24 kg (0.5 lb)

Shipping 1 kg (2.2 lb)

RF Connector Mechanical Tolerances

Type-N male

Recession of the male center conductor 0.207 to 0.210 in

Precision 7 mm

Recession of the center conductor

Collet resilience After you depress the collet, it must spring back out.

Precision 3.5 mm

Recession of the male center conductor 0 to 0.003 in

1

Because a typ e-N gage calibration blo ck zeros the gage at a 0.207 inch oset, the gage displa

0.000 to 0.003 inches.

2

With the center conductor collet removed.

(85037A)

(85037A Option 001)

2

(85037B)

1.22m (48 in)

1

0 to 0.003 in

ys a 0.207 to 0.210 inch oset as

General Information 1-5

Page 14

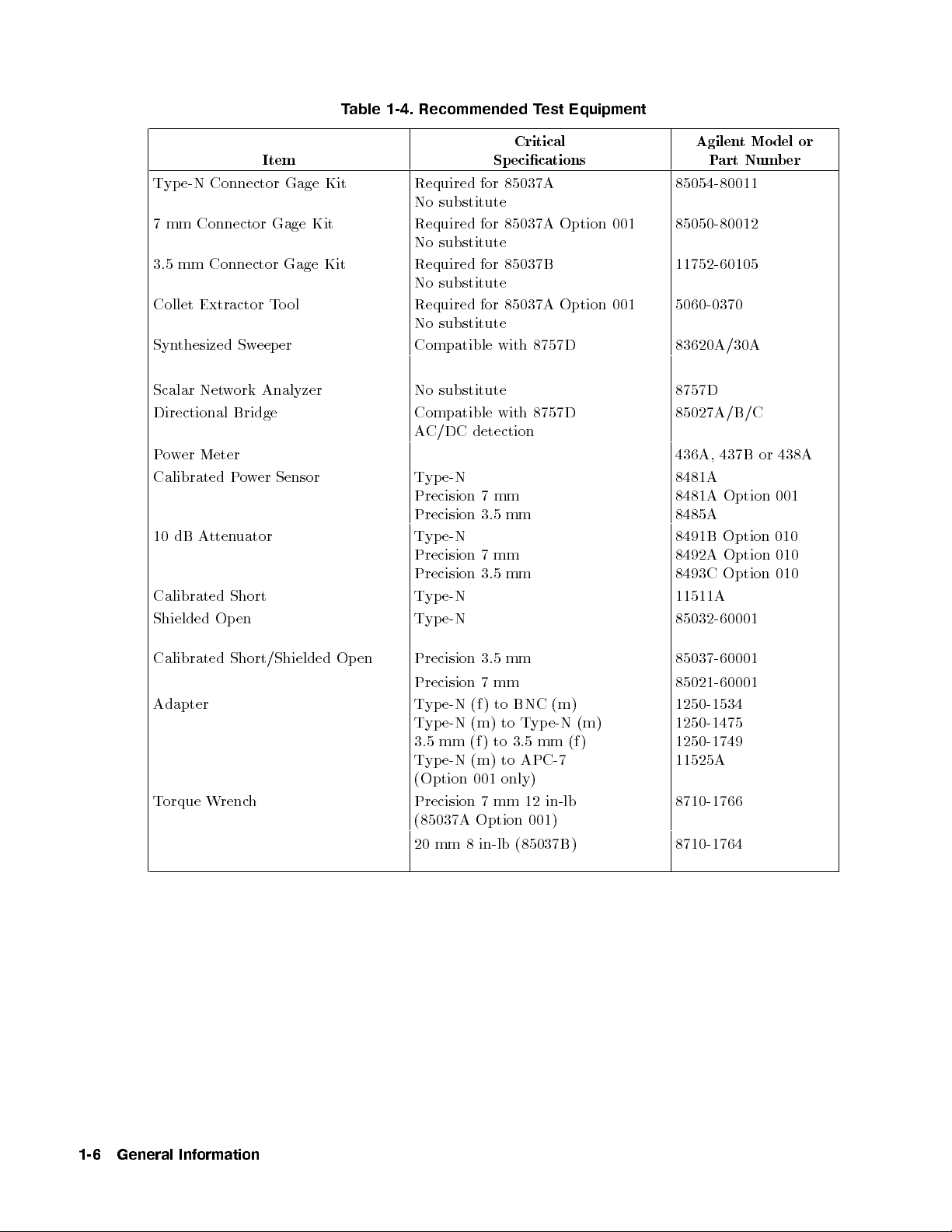

Table 1-4. Recommended Test Equipment

Critical

Item

Specications

Type-N Connector Gage Kit Required for 85037A

Agilent Model or

Part Number

85054-80011

No substitute

7 mm Connector Gage Kit Required for 85037A Option 001

85050-80012

No substitute

3.5 mm Connector Gage Kit Required for 85037B

11752-60105

No substitute

Collet Extractor Tool Required for 85037A Option 001

5060-0370

No substitute

Synthesized Sweeper Compatible with 8757D 83620A/30A

Scalar Network Analyzer No substitute 8757D

Directional Bridge Compatible with 8757D

85027A/B/C

AC/DC detection

Power Meter 436A, 437B or 438A

Calibrated Power Sensor Type-N

Precision 7 mm

Precision 3.5 mm

10 dB Attenuator Type-N

Precision 7 mm

Precision 3.5 mm

8481A

8481A Option 001

8485A

8491B Option 010

8492A Option 010

8493C Option 010

Calibrated Short Type-N 11511A

Shielded Open Type-N 85032-60001

Calibrated Short/Shielded Open Precision 3.5 mm 85037-60001

Precision 7 mm 85021-60001

Adapter Type-N (f ) to BNC (m)

Type-N (m) to Type-N (m)

3.5 mm (f ) to 3.5 mm (f )

Type-N (m) to APC-7

1250-1534

1250-1475

1250-1749

11525A

(Option 001 only)

Torque Wrench Precision 7 mm 12 in-lb

8710-1766

(85037A Option 001)

20 mm 8 in-lb (85037B) 8710-1764

1-6 General Information

Page 15

Installation

2

Safety

Considerations

Initial Inspection

There are no hazardous voltages in this detector.

1. Check the shipping container and packaging material for damage.

2. Check that the shipment is complete.

3. Check connector, cable, and detector body for mechanical damage.

4. Check the detector electrically:

Either make a measurement or test to specications. (See Chapter

3, \Operation" or Chapter 4, \Performance Tests.")

If any of the following conditions exist, notify your nearest Agilent

oce:

incomplete shipment

mechanical damage or defect

failed electrical test

If you nd damage or signs of stress to the shipping con

cushioning material, keep them for the carrier's inspection. Agilent

does not wait for a claim settlement before arranging for repair or

replacement.

tainer or the

Installation 2-1

Page 16

Preparation for Use

Caution

Electrostatic Discharge

(ESD)

Do not subject the detector to mechanical shock.

ESD can damage the highly sensitive microcircuits in this device;

charges as low as 100 V can destroy a detector.

ESD damage occurs most often as you connect or disconnect a

device. Use this detector at a static-safe workstation and wear a

grounding strap.

Never

touch the input connector center contacts or

the cable contact pins.

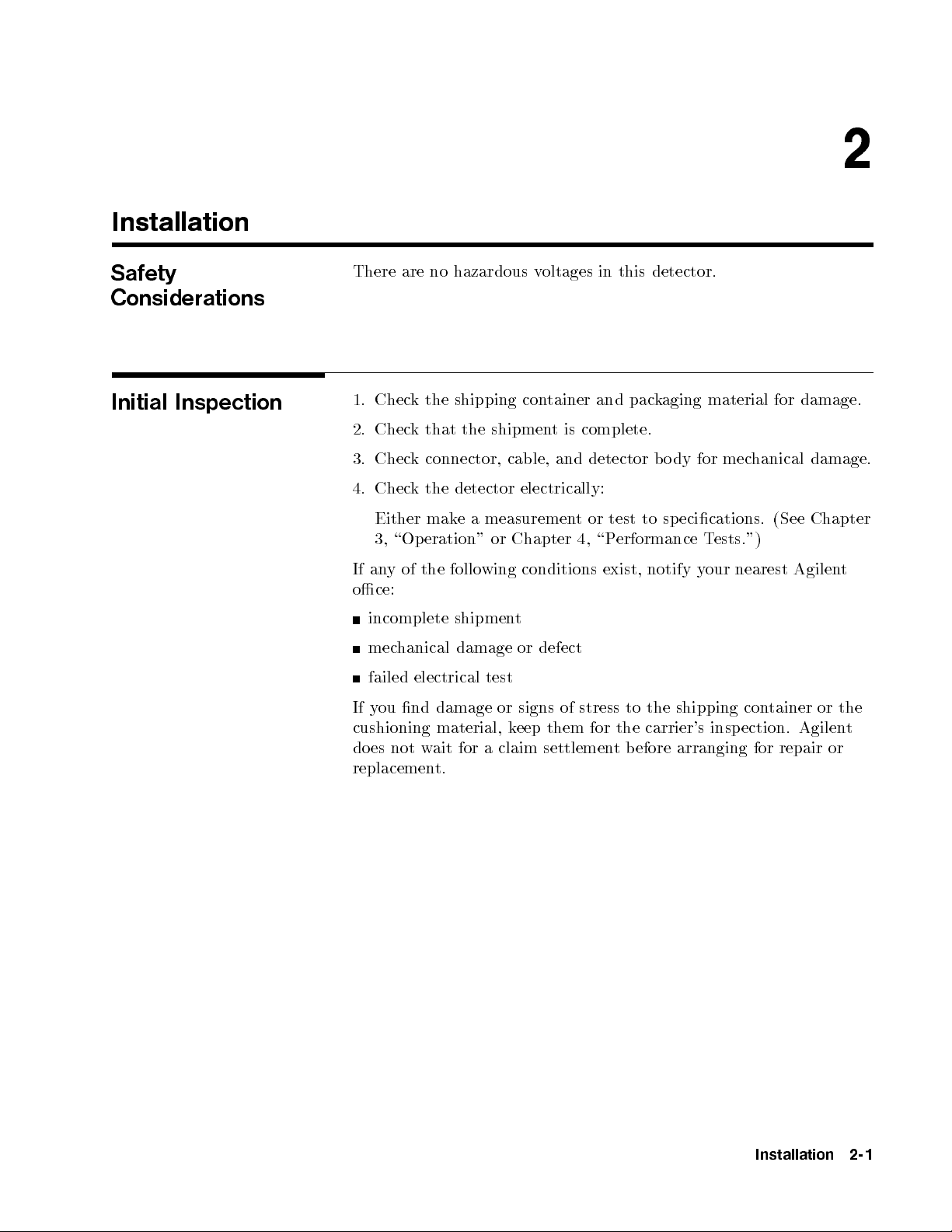

Static-Safe

Workstation

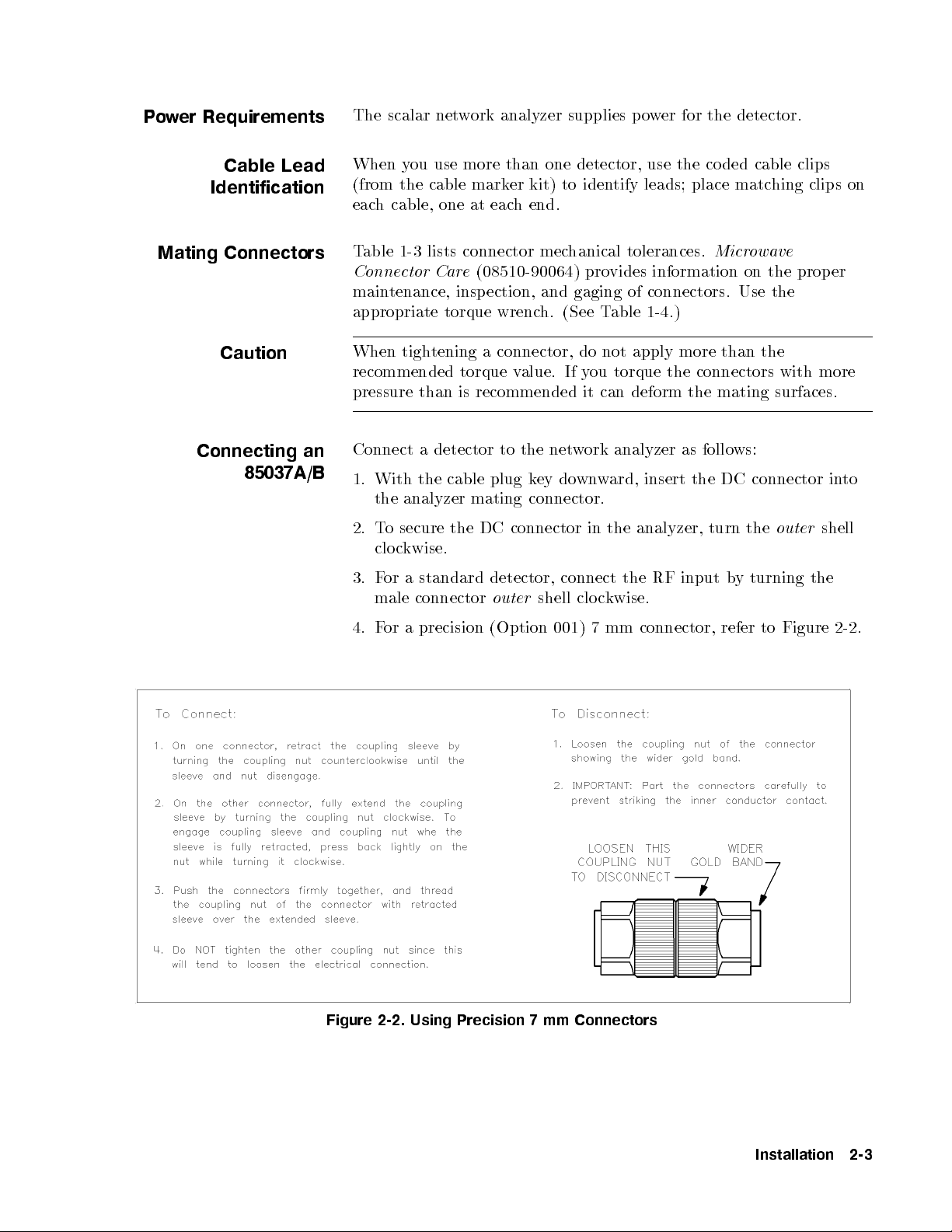

Figure 2-1 illustrates a static-safe station using twotypes of ESD

protection that you can use either together or separately.

A conductive table mat and wrist-strap combination.

A conductive oor mat and heel-strap combination.

2-2 Installation

Figure 2-1. Example of a Static-Safe Workstation

Static-Safe

Practices

Before cleaning, insp ecting, or making a connection to a

static-sensitive device or test port, ground yourself as far as

possible from the test p ort.

Discharge static electricity from a device b efore connecting it:

Touch the device briey (through a resistor of at least 2 M) to

either the outer shell of the test port, or another exposed ground.

This discharges static electricit y and protects test equipmen

circuitry.

t

Page 17

Power Requirements

The scalar network analyzer supplies power for the detector.

Cable Lead

Identification

Mating Connectors

Caution

Connecting an

85037A/B

When you use more than one detector, use the coded cable clips

(from the cable marker kit) to identify leads; place matching clips on

each cable, one at each end.

Table 1-3 lists connector mechanical tolerances.

Connector Care

(08510-90064) provides information on the proper

Microwave

maintenance, inspection, and gaging of connectors. Use the

appropriate torque wrench. (See Table 1-4.)

When tightening a connector, do not apply more than the

recommended torque value. If you torque the connectors with more

pressure than is recommended it can deform the mating surfaces.

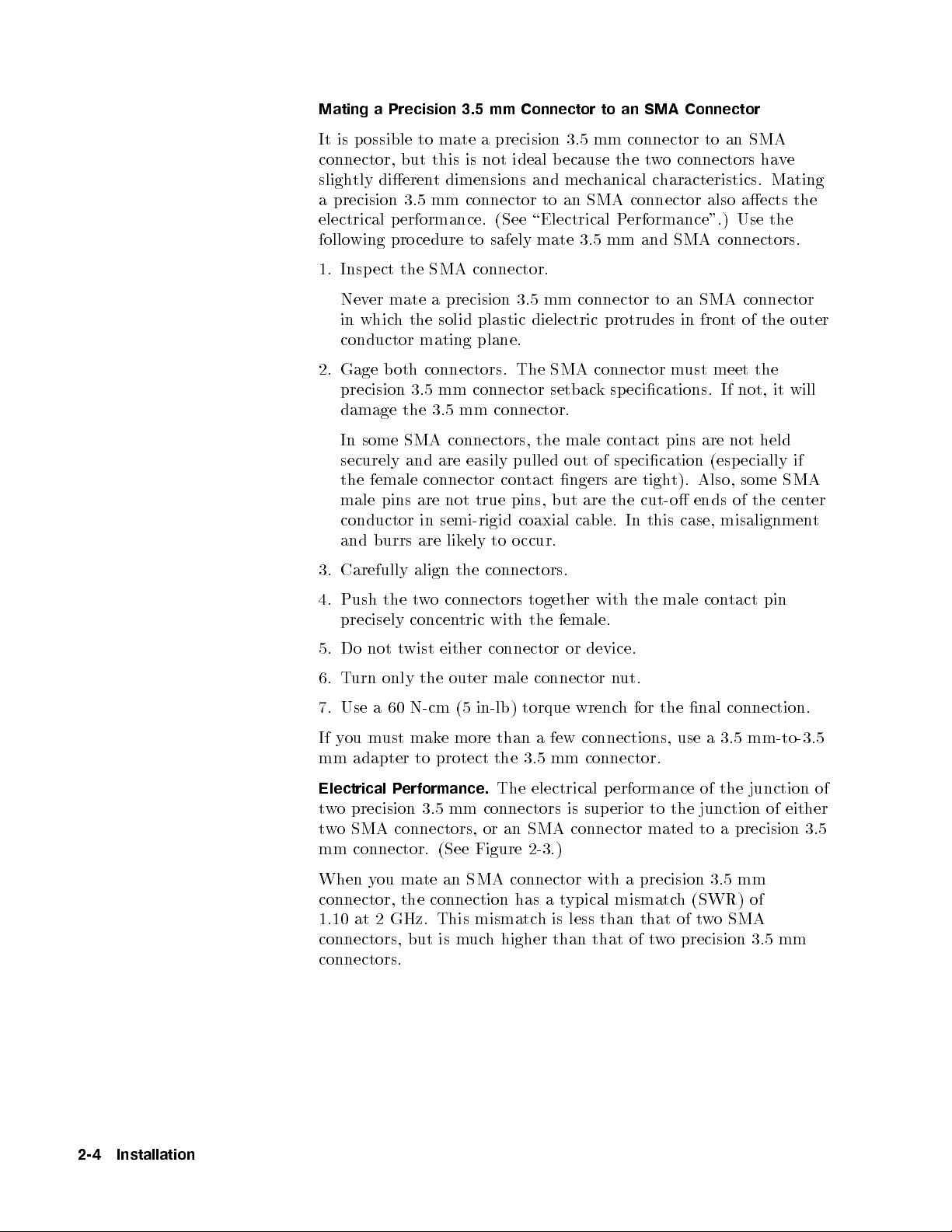

Connect a detector to the network analyzer as follows:

1. With the cable plug key downward, insert the DC connector into

the analyzer mating connector.

outer

2. To secure the DC connector in the analyzer, turn the

shell

clockwise.

3. For a standard detector, connect the RF input b

male connector

outer

shell clo ckwise.

y turning the

4. For a precision (Option 001) 7 mm connector, refer to Figure 2-2.

Figure 2-2. Using Precision 7 mm Connectors

Installation 2-3

Page 18

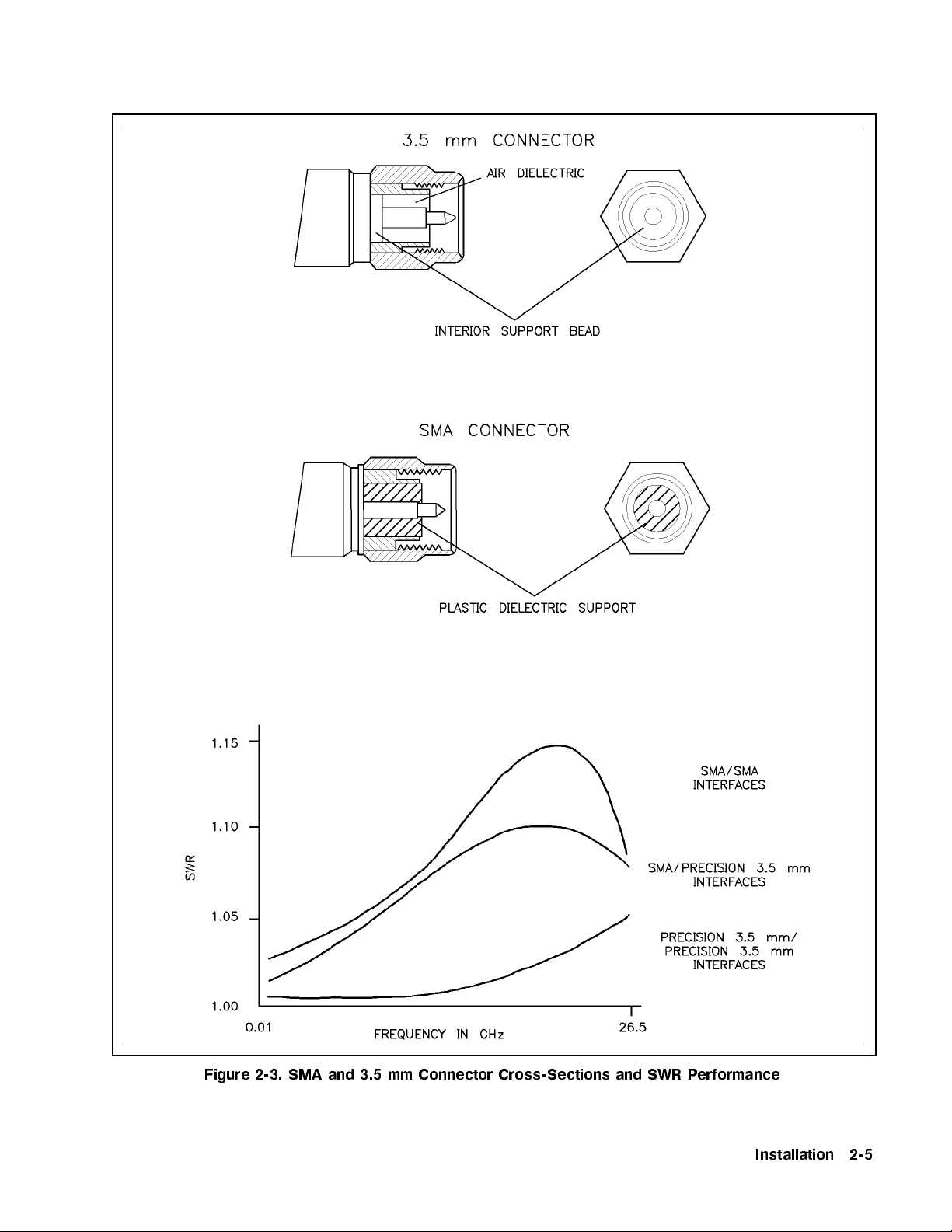

Mating a Precision 3.5 mm Connector to an SMA Connector

It is possible to mate a precision 3.5 mm connector to an SMA

connector, but this is not ideal because the two connectors have

slightly dierent dimensions and mechanical characteristics. Mating

a precision 3.5 mm connector to an SMA connector also aects the

electrical performance. (See \Electrical Performance".) Use the

following procedure to safely mate 3.5 mm and SMA connectors.

1. Insp ect the SMA connector.

Never mate a precision 3.5 mm connector to an SMA connector

in which the solid plastic dielectric protrudes in front of the outer

conductor mating plane.

2. Gage both connectors. The SMA connector must meet the

precision 3.5 mm connector setback specications. If not, it will

damage the 3.5 mm connector.

In some SMA connectors, the male contact pins are not held

securely and are easily pulled out of sp ecication (especially if

the female connector contact ngers are tight). Also, some SMA

male pins are not true pins, but are the cut-o ends of the cen

ter

conductor in semi-rigid coaxial cable. In this case, misalignmen

and burrs are likely to o ccur.

t

3. Carefully align the connectors.

4. Push the two connectors together with the male contact pin

precisely concentric with the female.

5. Do not twist either connector or device.

6. Turn only the outer male connector nut.

7. Use a 60 N-cm (5 in-lb) torque wrenc

h for the nal connection.

If you must make more than a few connections, use a 3.5 mm-to-3.5

mm adapter to protect the 3.5 mm connector.

Electrical Performance.

The electrical performance of the junction of

two precision 3.5 mm connectors is superior to the junction of either

two SMA connectors, or an SMA connector mated to a precision 3.5

mm connector. (See Figure 2-3.)

When you mate an SMA connector with a precision 3.5 mm

connector, the connection has a typical mismatch (SWR) of

1.10 at 2 GHz. This mismatch is less than that of two SMA

connectors, but is much higher than that of two precision 3.5 mm

connectors.

2-4 Installation

Page 19

Figure 2-3. SMA and 3.5 mm Connector Cross-Sections and SWR P

erformance

Installation 2-5

Page 20

Operating

Environment

Temperature

Humidity

: Up to 95%. Protect the detector from temperature

: 0C to +55C.

extremes, which can cause condensation.

Storage and

Shipment

Environment

Packaging

Altitude

: Up to 7,620m (25,000 ft).

Store or ship the detectors in environments within the follo wing

limits:

Temperature:0

Humidity

: Up to 95%. Protect the detector from temperature

25C to +75C.

extremes which can cause condensation.

Altitude

: Up to 7,620m (25,000 ft).

Containers and materials identical to those used in factory-packaging

are available. Contact your local Agilent oce for information. If you

package the detector using commercially available material, follow

these instructions:

1. Wrap the detector in heavy paper.

2. Use a strong shipping container that has a double-wall carton of

at least 350-pound test material.

3. Provide a rm cushion that prevents movement inside the

container.

4. Use a 5 to 7 cm (3 to 4 inch) layer of shock-absorbing material

around all sides of the detector.

5. Seal the shipping container securely.

6. Mark the shipping container

FRAGILE

.

2-6 Installation

Page 21

Returning a

Detector for Service

If you ship the detector to a Agilent oce or service center ll out a

blue service tag (provided at the back of this manual), and include

the following information:

1. Company name and address.

Do not

cannot be returned to a P.O. b ox.

2. A technical contact person with a complete phone number.

3. The complete model and serial number of the detector.

4. The type of service required (calibration, repair).

5. Any other information, such as failure condition or cause, that

could expedite service.

When you make an inquiry, either by mail or by telephone, refer to

the detector by both mo del number and full serial number.

use an address with a P.O. boxnumber because products

Installation 2-7

Page 22

Page 23

Operation

3

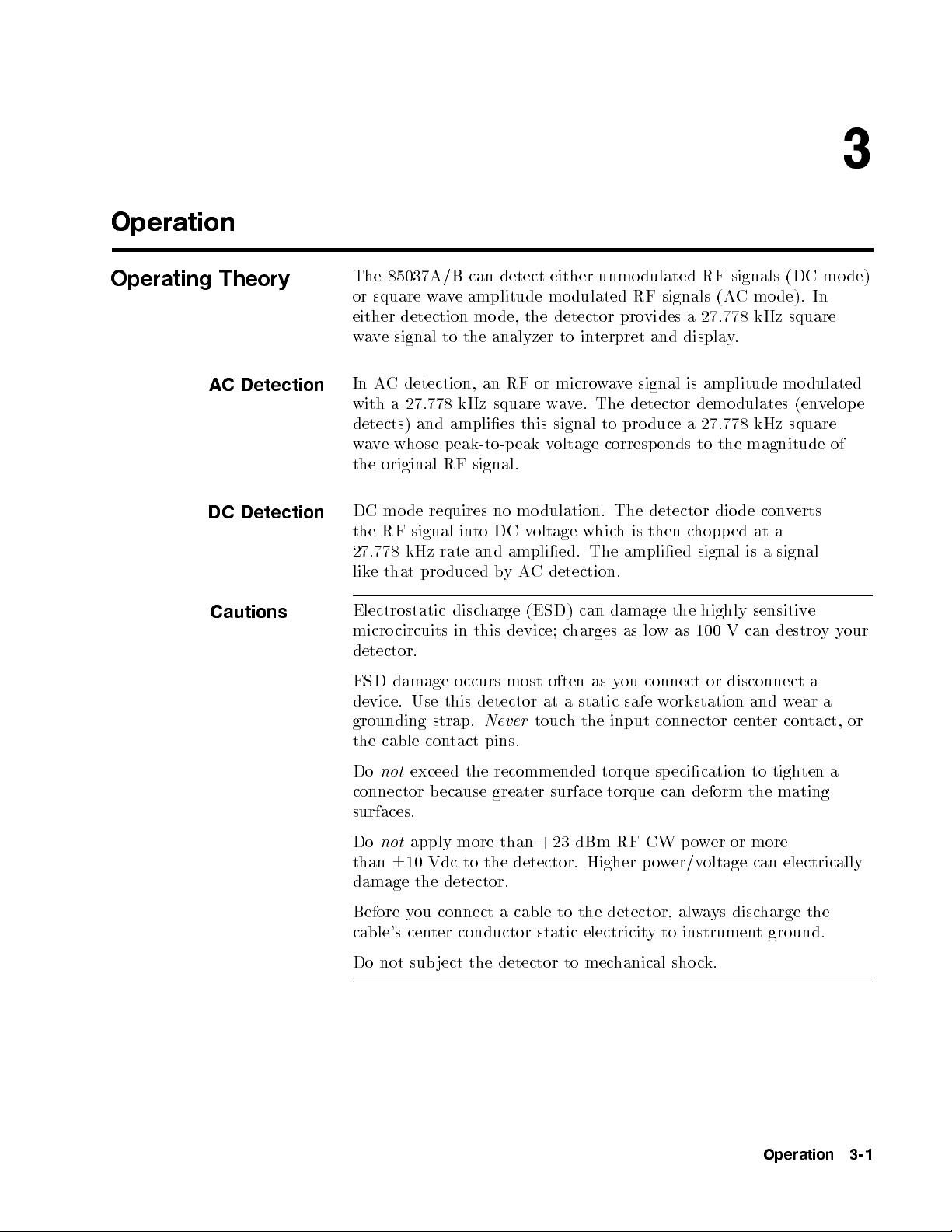

Operating Theory

AC Detection

DC Detection

Cautions

The 85037A/B can detect either unmodulated RF signals (DC mo de)

or square wave amplitude modulated RF signals (AC mo de). In

either detection mode, the detector provides a 27.778 kHz square

wave signal to the analyzer to interpret and display.

In AC detection, an RF or microwave signal is amplitude mo dulated

with a 27.778 kHz square wave. The detector demodulates (envelope

detects) and amplies this signal to produce a 27.778 kHz square

wave whose peak-to-peak voltage corresponds to the magnitude of

the original RF signal.

DC mo de requires no modulation. The detector dio de con

verts

the RF signal into DC voltage which is then chopped at a

27.778 kHz rate and amplied. The amplied signal is a signal

like that pro duced byAC detection.

Electrostatic discharge (ESD) can damage the highly sensitive

microcircuits in this device; charges as low as 100 V can destroyyour

detector.

ESD damage occurs most often as you connect or disconnect a

device. Use this detector at a static-safe workstation and wear a

grounding strap.

Never

touch the input connector center contact, or

the cable contact pins.

Do

not

exceed the recommended torque sp ecication to tighten a

connector b ecause greater surface torque can deform the mating

surfaces.

Do

not

apply more than +23 dBm RF CW power or more

than610 Vdc to the detector. Higher power/voltage can electrically

damage the detector.

Before you connect a cable to the detector, always discharge the

cable's center conductor static electricity to instrument-ground.

Do not subject the detector to mechanical shock.

Operation 3-1

Page 24

Features

Connector Torque

Values

Figure 3-1. Detector Features

Tighten the 85037A type-N connector nger-tight only.

Tighten the 85037A Option 001 with a torque wrenc

h, part number

8710-1766 set at 13.8 cm-kg (12 in-lb).

Tighten the 85037B with a torque wrench part number 8710-1764

set at 9.2 cm-kg (8 in-lb).

3-2 Operation

Page 25

Operator's Check

See \Characterizing the Detector" in this chapter for a procedure

that allows you to quickly check the detector. This pro cedure can b e

used as a daily check.

Operating Modes

and Specifications

Dynamic Accuracy

Frequency Response

The Agilent 85037 series precision detectors have built-in corrections

for both frequency range and dynamic accuracy. These corrections

are used to enhance the measurement capability of the detector. The

following text explains how the corrections are made. Additional

information regarding detector operation is available in the

Scalar Network Analyzer Operating Manual

.

8757D

The dynamic accuracy and absolute power accuracy of the detector is

measured at the factory. Approximately 150 correction constants are

then calculated and stored in the EEPROM of each detector. This

provides a default correction and is sucient to guarantee the default

dynamic accuracy specications. To obtain maximum performance,

the detector must b e connected to the 50 MHz calibrator output

of the 8757D Option 002 and then characterized using the built-in

correction routine in the 8757D. Once this is done, the detector will

meet the enhanced (corrected) sp ecication for dynamic accuracy for

both AC and DC measurements. This characterization will remain

valid until the detector is unplugged. For optimal p erformance

however, the detector must b e recharacterized if its temperature

changes by more than65

C.

The 85037 uses built-in correction factors to provide the best possible

frequency response. The numb er of correction factors will vary

with each detector, but is typically 25. These correction factors are

determined at the factory and are stored within the EEPROM of the

detector. If the 8757D is used with the system interface, then the

analyzer will automatically determine the proper correction factor to

use; no user intervention is required. If the 8757 system interface

is not being used, then the frequency related correction factors

will be determined from the start/stop labels. These labels can be

entered into the 8757 by pressing

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

STOP LABEL

) and then entering the start (or stop) frequency.

4

SYSTEM

NNNNNNNNNNNNNNNNNNNN

5

LABELS

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

START LABEL

(or

Operation 3-3

Page 26

However, if the frequency the detector sees is dierent from what is

being swept (for example, when using a mixer or multiplier), then the

user must manually enter the correct detector frequencies as follows:

Measurement

System

Configuration

1. Press

2.

3.

4.

5.

6.

7.

Select

Select

Select

Select

Select

Select

4

5

.

CAL

NNNNNNNNNNNNNN

MORE

.

NNNNNNNNNNNNNNNNNNNNNNNNNN

DET FREQ

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

DET A,B,C or R

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Start Freq

and use the keypad to enter a value.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Stop Freq

and use the keypad to enter a value.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

DET FREQ ON

.

.

Figure 3-2 shows a typical measurement setup. AC detection mode,

the turn-on state of the 8757D analyzer, do es not require an

y special

setup to initiate a measurement. DC detection mo de, however,

requires that you press specic analyzer keys in the correct order.

3-4 Operation

Figure 3-2. Typical Measurement Setup

Page 27

DC Detection

Measurements

DC detection oers absolute p ower measurement capability and the

ability to characterize oscillators and modulation sensitive devices.

Enabling the DC

Detection Mode

Remember

Making Accurate DC

Measurements

1. On the analyzer, press

4

PRESET

5

.

2. Connect the detector.

3. Enable DC mode:

NNNNNNNNNNNNNNNNNNNNNNN

Press

4

SYSTEM

5

and select

MODE DC

.

NNNNNNNNNNNNNNNNNNNNNNN

Selecting the

MODE DC

softkey also turns o the source square

wave mo dulation.

You must enable the DC mode to access the DC-sp ecic softkeys.

To make DC-mo de measurements as shown in Figure 3-2,you

must use an 85027 directional bridge capable of b oth AC and DC

detection.

Operation

Before accurate DC measurements can be made, two quick routines

must be performed; a DC zero and a dynamic po

wer characterization.

(This is referred to as a power calibration on the 8757 and on other

annotations.) The DC zero will improve accuracy below035 dBm.

The dynamic characterization will provide the improved (corrected)

power accuracy specication on the 8787D Option 002 only

Measurements can be performed without this c

haracterization (such

.

as on instruments without Option 002), however only the default

dynamic accuracy specications of the detector are guaran

teed. This

characterization includes a DC zero so it is not necessary to perform

the zero before performing the c

haracterization.

Zeroing an 85037A/B

When making DC{mode measurements, you must p erform a zeroing

operation to compensate for the eects of DC drift and temp erature

uctuations. This is not required in AC detection. The zeroing

operation eliminates small DC voltages present in the detector that

would otherwise cause amplitude measurement errors at lowpower

levels (035 dBm and below). Zeroing also establishes the displayed

noise level (the system noise o or) with no RF signal applied. A

DC zero should be performed at least once every half-hour once the

system has stabilized. A DC zero should be performed more often

as the system warms up, or if the temp erature is changing. The

autozero function is provided to automatically perform DC zeros

periodically when the system interface is used.

Operation 3-5

Page 28

Note

Before you zero the detector, remove

all

RF signals from the detector

input. Even a small RF signal present during zeroing produces

measurement errors.

The 8757D analyzer has three types of zeroing:

Autozero

NNNNNNNNNNNNNNNNNNNNNNN

AUTOZRO

turns o the source RF signal output and

automatically zero es the detector.

Repeat

Autozero

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

REPT AZ ON/OFF

selected intervals.

automatically repeats autozero at

NNNNNNNNNNNNNNNNNNNN

Manual Zero

MANUAL

is similar to power meter zeroing. First you

must either physically remove the detector from the

RF signal or turn the RF signal o, then you select

NNNNNNNNNNNNNNNNNNNN

MANUAL

to perform the zero.

Note

AC Detection

Measurements

Making Accurate AC

Measurements

See the analyzer documentation for more information on these

softkeys.

AC detection is the preferred metho d for the ma jorit

yof

measurements as it oers greater sensitivity. It also oers

immunity to noise and drift with time and temperature. A

C

detection amplitude measurements require a mo dulation envelope.

The envelope is provided through a 27.778 kHz square wave

amplitude mo dulation of the RF test signal. T

vary depending on the source. Figure 3-2 illustrates a t

est set connections

ypical

measurement setup with an Agilent 8360 synthesized sweeper

supplying the 27.778 kHz mo dulation.

Accurate AC measurements depend heavily on the envelope of

the amplitude modulated RF signal. In addition, to obtain the

specied dynamic accuracy,acharacterization of the detector (a

power cal) must rst be performed. Without this characterization,

only the default dynamic accuracy is guaranteed. Performing the

characterization will calibrate the detector in

both

AC and DC

modes. See \Characterizing the Detector" in this chapter.

3-6 Operation

The RF signal must be squarewave modulated at a rate within 20

Hz of 27.778 kHz. The amplitude ratio of the on portion to the

o portion of the envelop e must be at least 30 dB and the ratio of

on-time to o-time should b e within 5% of 50/50. Most Agilent

sources provide this capability.Ifyour 8757D scalar network analyzer

is equipped with the Option 002 p ower calibrator, you can obtain the

best power measurement accuracy by following this procedure.

Page 29

Characterizing the

Detector (Performing

aPower Calibration)

To obtain the b est accuracy, and to meet the \corrected" dynamic

accuracy sp ecications, each detector must be characterized on the

8757D input on which it will be used. The characterization routine

simultaneously corrects b oth AC

and

DC measurements. This

routine is also useful as an operator's check to ensure the detector

is operating properly. Only the 8757D with an Option 002 p ower

calibrator have this capability.

Detector characterization begins at +20 dBm and decreases in 1 dB

increments down to035 dBm. To reduce measurement time, p ower

steps are larger than 1 dB at lower p ower levels. Correction values

will be generated over this range if the detector is op erational. It

will also correct for any loss in the detector up to ab out 50 dB. For

example, lets assume a DC detector has a dynamic range of +20 to

0

50 dBm. A 30 dB attenuator is then placed on the detector and a

characterization is performed. Upon completion, the detector will b e

characterized from +20 to020 dBm. Applying a 0 dBm signal to

the detector/pad combination will result in a 0 dBm reading; not a

0

30 dBm reading which is what the detector itself is actually seeing.

A loss of more than about 50 dB ma

y result in an error message

being displayed on the analyzer. This could occur if the detector is

defectiveorifyou simply forgot to connect the detector under test to

the Power Cal Output of the 8757D.

Upon completion of this routine, the dynamic range of the detector

will be displayed; verify that it is correct for the current detection

mode, taking into accountany attenuation due to added pads or

other devices, or due to inherent loss, such as in a directional bridge

whichtypically has 12.5 dB of loss.

Tocharacterize the detector (perform a power cal), connect the

detector to the desired input of the 8757D. Connect the RF input of

the detector to the calibrator output. Make sure the analyzer has

been on and the detector connected for at least 30 minutes.

1. Press

2.

3.

4.

5.

Select

Select

Select

Select

4

5

.

CAL

NNNNNNNNNNNNNN

MORE

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

POWER CAL

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

DET A,B,C or R

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

START CAL

.

.

A complete characterization for one detector takes ab out 60 seconds.

Once characterized, do

not

unplug the detector from the analyzer or

you will have to p erform another characterization. This is b ecause

the 8757 automatically recalibrates itself when it senses a detector

has b een removed or connected to the detector inputs. Ho

the analyzer

can

be turned o and on again without losing this

wever,

information. Perform the characterization at least once per day and

more often if the temp erature varies by more than65

C.

Operation 3-7

Page 30

Page 31

Performance Tests

4

Introduction

Equipment Required

Note

Use the procedures in this chapter to test the detector's electrical

performance to the sp ecications listed in Chapter 1. None of these

tests require access to the detector's interior. To completely test each

detector, three tests are required:

1. return loss

2. dynamic accuracy (AC and DC uncorrected)

3. frequency response

Preceding each test is an equipment table that lists which equipment

you will need for that particular test. You may substitute any

equipment that meets the indicated critical specications. Refer to

Table 1-4.

Before you perform a performance test, gage the input connector

on the detector and enter the results in the test record at the

end of \Performance Tests." For descriptive illustrations dening

connector tolerances, see

08510-90064).

Microwave Connector Care

(part number

Performance Tests 4-1

Page 32

Return Loss at a

Nominal010 dBm

Description

The return loss of the 85037 can b e measured using the test system

described in this pro cedure. The test setup is calibrated using an

open/short to minimize frequency response and phasing errors. Then

the detector under test (DUT) is connected to the

bridge, and its return loss is measured on the 8757D.

The three main sources of error in these measurements come from:

1. bridge directivity

2. source match of the bridge

3. dynamic accuracy of the 8757D

The rst twovary with frequency while dynamic accuracy varies

with the measured return loss amplitude. Use the corresponding,

connector-compatible Agilent directional bridge, Agilent 85027/A/B

or C.

test port

of the

4-2 Performance Tests

Figure 4-1. Return Loss Setup

Page 33

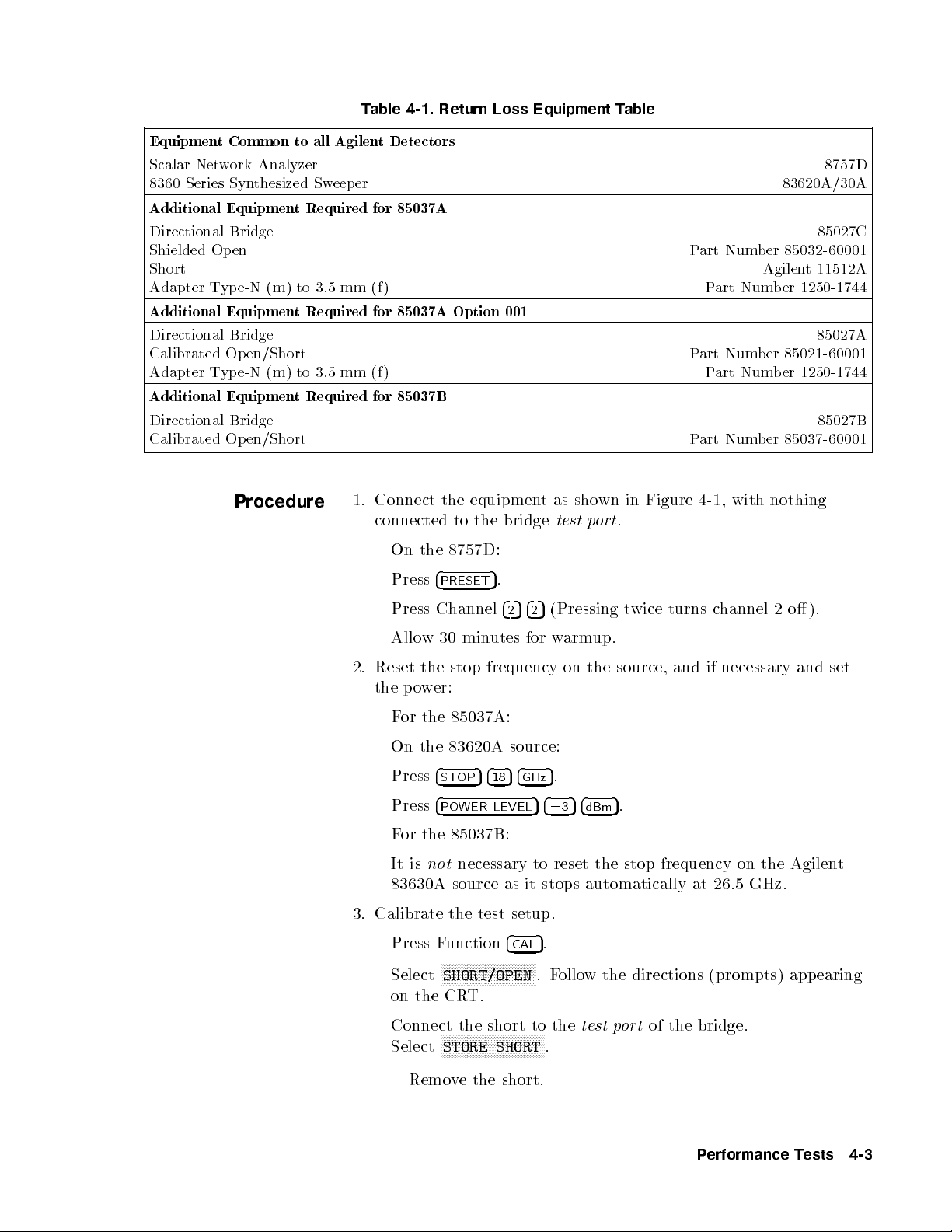

Table 4-1. Return Loss Equipment Table

Equipment Common to all Agilent Detectors

Scalar Network Analyzer 8757D

8360 Series Synthesized Sweeper 83620A/30A

Additional Equipment Required for 85037A

Directional Bridge 85027C

Shielded Open Part Number 85032-60001

Short Agilent 11512A

Adapter Type-N (m) to 3.5 mm (f ) Part Number 1250-1744

Additional Equipment Required for 85037A Option 001

Directional Bridge 85027A

Calibrated Open/Short Part Number 85021-60001

Adapter Type-N (m) to 3.5 mm (f ) Part Number 1250-1744

Additional Equipment Required for 85037B

Directional Bridge 85027B

Calibrated Open/Short Part Number 85037-60001

Procedure

1. Connect the equipment as shown in Figure 4-1, with nothing

connected to the bridge

test port

.

On the 8757D:

Press

4

PRESET

Press Channel

5

.

4

5

(Pressing twice turns channel 2 o ).

2542

Allow 30 minutes for warmup.

2. Reset the stop frequency on the source, and if necessary and set

the power:

For the 85037A:

On the 83620A source:

Press

Press

4

STOP541854GHz

4

POWER LEVEL540

5

.

354dBm

5

.

For the 85037B:

It is

not

necessary to reset the stop frequency on the Agilen

t

83630A source as it stops automatically at 26.5 GHz.

3. Calibrate the test setup.

Press Function

4

CAL

5

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Select

SHORT/OPEN

.Follow the directions (prompts) appearing

on the CRT.

Connect the short to the

Select

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

STORE SHORT

.

Remove the short.

test port

of the bridge.

Performance Tests 4-3

Page 34

Connect the open to the

Select

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

STORE OPEN

test port

.

Remove the open.

The CRT will display:

SHORT/OPEN CAL SAVED IN CH1 MEM

of the bridge.

.

Note

Press Function

4

DISPLAY

5

.

NNNNNNNNNNNNNNNNNNNNNNNNNN

Select

MEAS-MEM

.

4. On the 8757D:

Connect the detector under test to the

Press Function

Press

4

CURSOR

4

SCALE54554dB

5

. Use the cursor to nd the highest trace value

5

.

test port

of the bridge.

(the worst case measurement), in each specication range.

Write eachvalue in the test record.

If more frequency resolution is needed at the lo

w end of the

frequency range, repeat the preceeding procedure using a stop

frequency of 50 MHz.

This completes the procedure for measuring return loss.

4-4 Performance Tests

Page 35

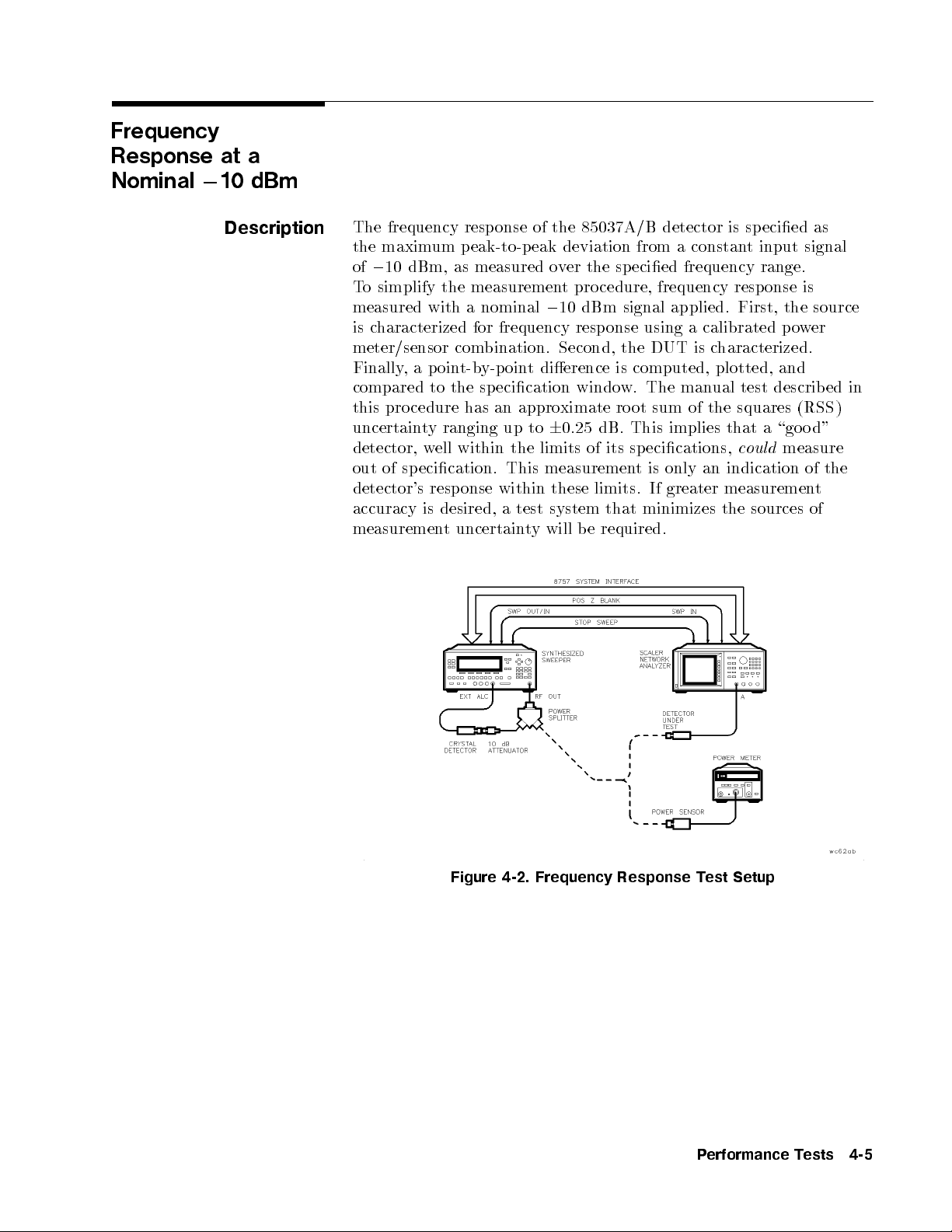

Frequency

Response at a

Nominal010 dBm

Description

The frequency response of the 85037A/B detector is specied as

the maximum p eak-to-peak deviation from a constant input signal

of010 dBm, as measured over the sp ecied frequency range.

To simplify the measurement procedure, frequency resp onse is

measured with a nominal010 dBm signal applied. First, the source

is characterized for frequency response using a calibrated power

meter/sensor combination. Second, the DUT is characterized.

Finally, a p oint-by-point dierence is computed, plotted, and

compared to the specication window. The manual test described in

this pro cedure has an approximate root sum of the squares (RSS)

uncertainty ranging up to60.25 dB. This implies that a \go od"

detector, well within the limits of its specications,

out of specication. This measurement is only an indication of the

detector's response within these limits. If greater measuremen

accuracy is desired, a test system that minimizes the sources of

measurement uncertainty will be required.

could

measure

t

Figure 4-2. Frequency Response Test Setup

Performance Tests 4-5

Page 36

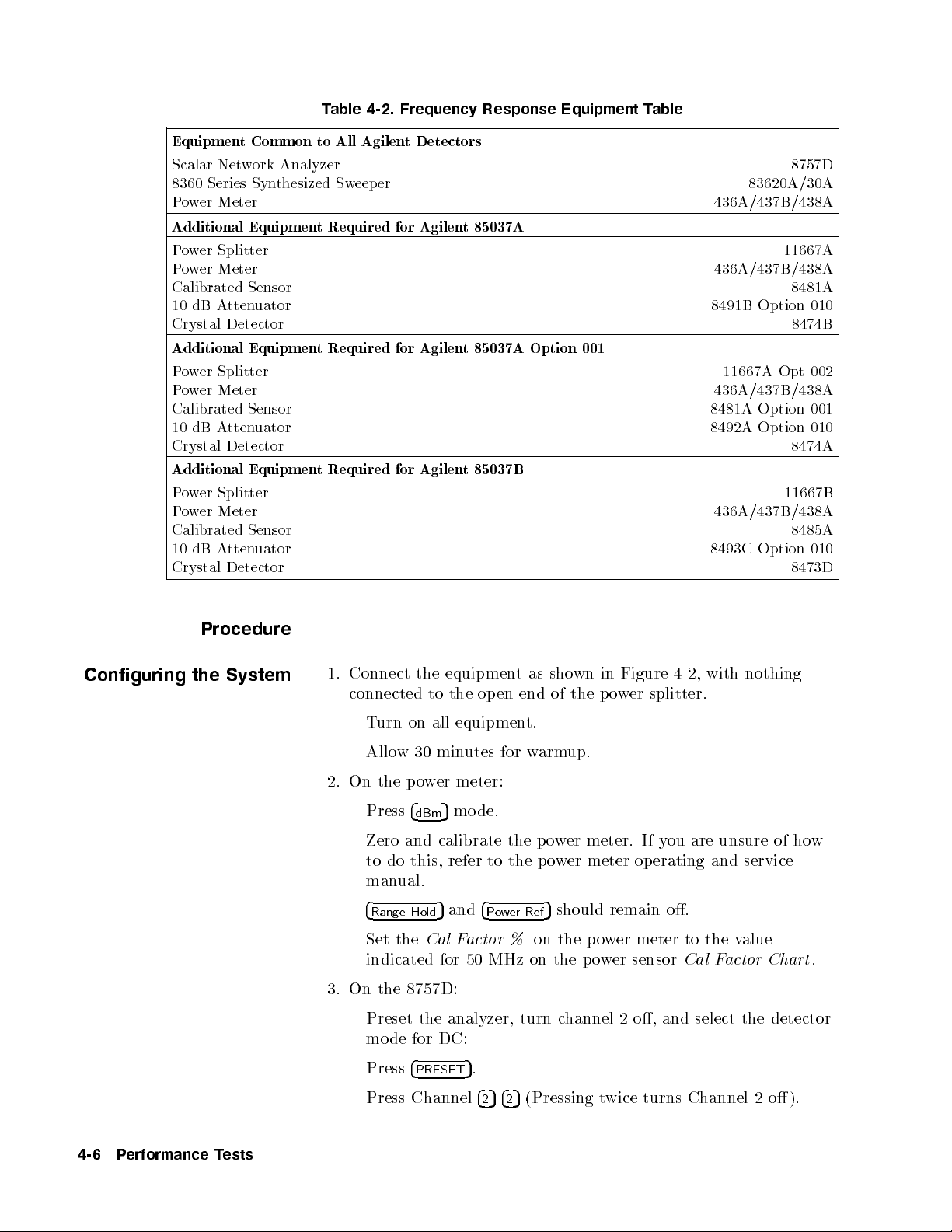

Table 4-2. Frequency Response Equipment Table

Equipment Common to All Agilent Detectors

Scalar Network Analyzer 8757D

8360 Series Synthesized Sweeper 83620A/30A

Power Meter 436A/437B/438A

Additional Equipment Required for Agilent 85037A

Power Splitter 11667A

Power Meter 436A/437B/438A

Calibrated Sensor 8481A

10 dB Attenuator 8491B Option 010

Crystal Detector 8474B

Additional Equipment Required for Agilent 85037A Option 001

Power Splitter 11667A Opt 002

Power Meter 436A/437B/438A

Calibrated Sensor 8481A Option 001

10 dB Attenuator 8492A Option 010

Crystal Detector 8474A

Additional Equipment Required for Agilent 85037B

Power Splitter 11667B

Power Meter 436A/437B/438A

Calibrated Sensor 8485A

10 dB Attenuator 8493C Option 010

Crystal Detector 8473D

Procedure

Configuring the System

1. Connect the equipment as shown in Figure 4-2, with nothing

connected to the open end of the po

wer splitter.

Turn on all equipment.

Allow 30 minutes for warmup.

2. On the power meter:

Press

4

5

mode.

dBm

Zero and calibrate the power meter. If you are unsure of how

to do this, refer to the power meter op erating and service

manual.

4

Range Hold

Set the

indicated for 50 MHz on the power sensor

5

and

4

Power Ref

Cal Factor %

5

should remain o.

on the p ower meter to the value

Cal Factor Chart

3. On the 8757D:

Preset the analyzer, turn channel 2 o, and select the detector

mode for DC:

Press

4

PRESET

5

.

.

4-6 Performance Tests

Press Channel

4

2542

5

(Pressing twice turns Channel 2 o ).

Page 37

Press Instrument State

4

SYSTEM

5

.

NNNNNNNNNNNNNNNNNNNNNNN

Select

MODE DC

.

4. On the source:

Press

4CW545054

MHz

5

.

Connect the power meter/sensor to the output of the splitter.

Press

Press

NNNNNNNNNNNNNNNNNNNNNNN

4

5

Ext Det

ALC

4

POWER LEVEL540

NNNNNNNNNNNNNN

MORE

1054dBm

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Coupling Factor

5

and, if necessary, adjust the

41054dB5

power level for a power meter reading within60.05 dB of

0

10 dBm.

.

Measuring the Source

Measuring the Detector

Do not

readjust the p ower level for the remainder of this test.

5. On the source:

Press

4CW5

and enter the test frequencies as shown on the work

sheet.

For example:

4

CW54.0154GHz

5

.

6. Using the Cal Factor Chart on the Power Sensor:

a. Set the

Cal Factor %

on the power meter to the value

indicated for the test frequency as needed. (Use the nearest

frequency value.)

b. Note the reading on the power meter.

c. Record this value onto the worksheet Table 4-3 under the

\Source Power" column.

7. Repeat steps 5 and 6 using, at minim

um, the test frequencies

noted on the work sheet.

8. Disconnect the power meter/sensor.

9. With the detector still disconnected from the source, zero the

detector:

Press

4

5

on the 8757D.

CAL

Select

4

DC DET ZERO

5

.

NNNNNNNNNNNNNNNNNNNNNNNNNN

Select

AUTOZERO

.

When the zero is complete, the display will indicate:

AUTO ZERO COMPLETE

.

Performance Tests 4-7

Page 38

10. Connect the detector to the power splitter.

On the 8757D:

Computing the

Maximum Error

Press Function

11. On the source:

Press

4CW5

only the test frequencies used in steps 5 through 7.

12. Note and record on the worksheet (under the \Measured Power"

column) the value indicated by the 8757D cursor display.

13. Repeat this step until all of the same frequency points have been

measured.

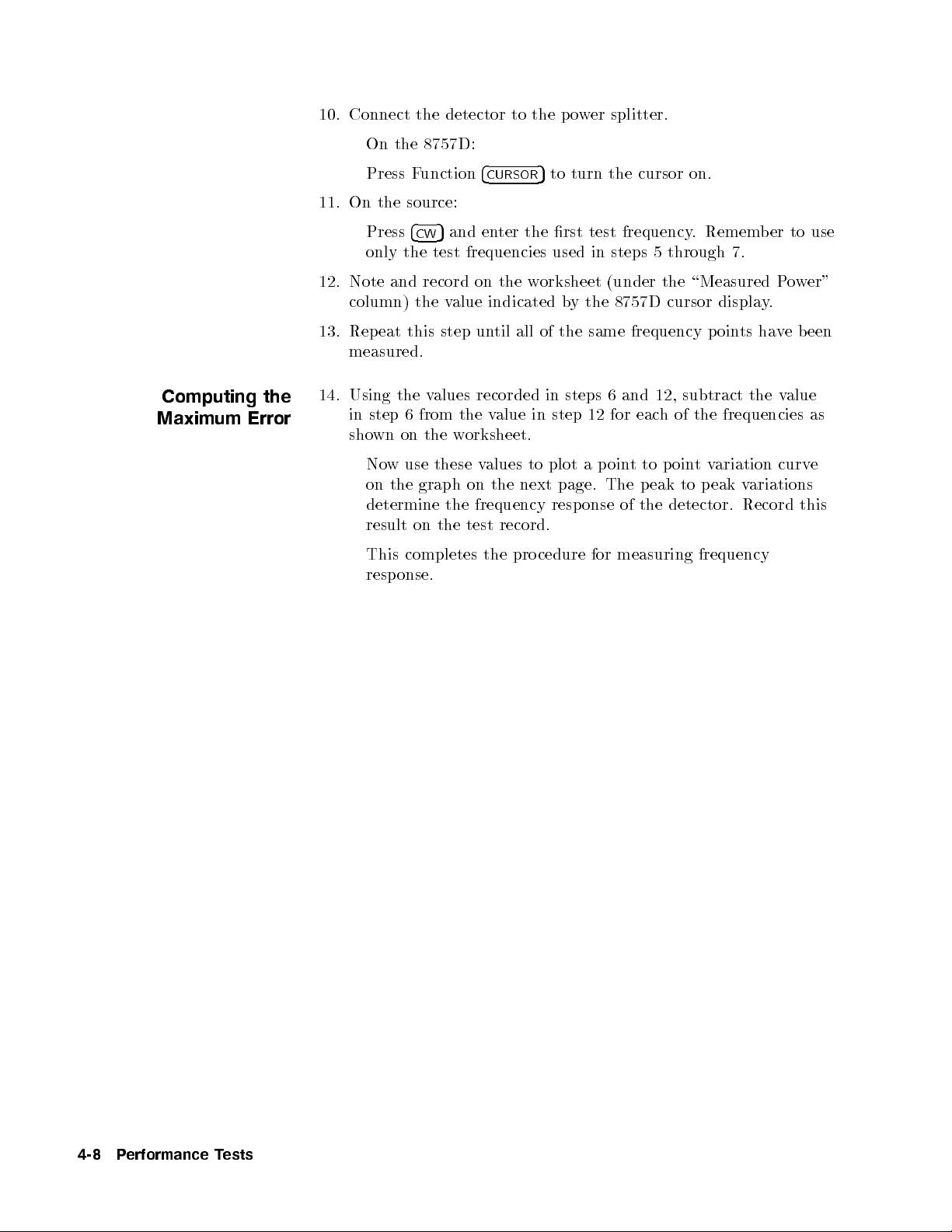

14. Using the values recorded in steps 6 and 12, subtract the value

in step 6 from the value in step 12 for each of the frequencies as

shown on the worksheet.

Now use these values to plot a poin

on the graph on the next page. The peak to peak v

determine the frequency response of the detector. Record this

result on the test record.

This completes the procedure for measuring frequency

response.

4

CURSOR

and enter the rst test frequency. Remember to use

5

to turn the cursor on.

t to p ointvariation curve

ariations

4-8 Performance Tests

Page 39

Figure 4-3. Frequency Response Graph

Table 4-3. Worksheet

Recommended Test Frequencies

Frequency

in GHz

0.01

0.04

0.10

2

6

10

14

16

18

20

22

24

26.5

Measured Power

(dBm)

Source Power

(dBm)

Meas Power minus

Source Power (dB)

Performance Tests 4-9

Page 40

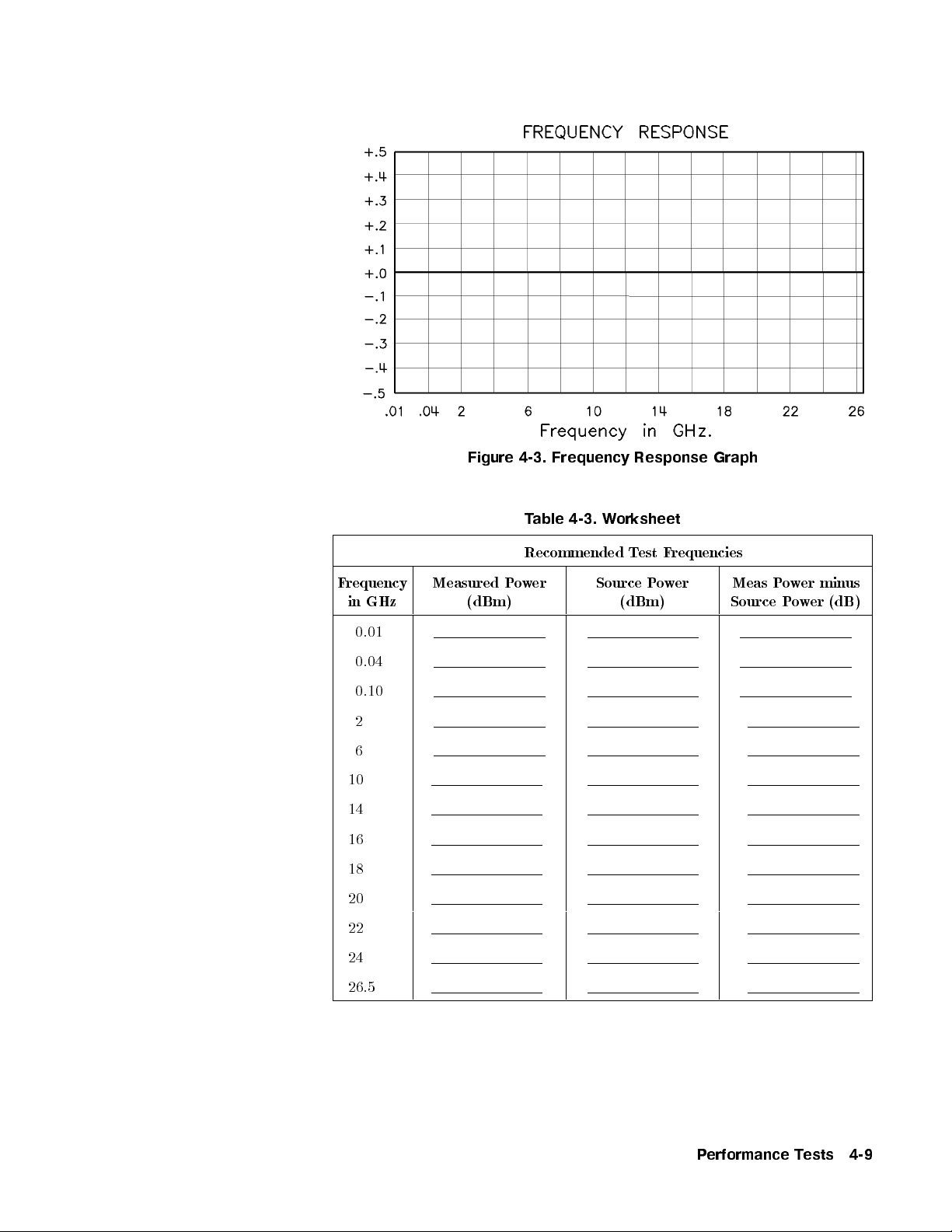

Dynamic Power

Accuracy

Description

Procedure

The dynamic power accuracy of the 85037A/B is dependent upon the

raw (uncorrected) resp onse of the detector, the correction routine

of the 8757D analyzer, and the accuracy of the 8757D Option 002

calibrator. The accuracy of the calibrator is assumed to b e within

specications. This can be checked by following the performance test

procedure in the 8757D manual. The correction routine is xed and

cannot vary, so it is also assumed to b e accurate. The high accuracy

of the 85037A/B is only guaranteed after performing the built-in

characterization routine (a power cal) in the 8757D. Once this is

done, p erforming any dynamic accuracy tests using the same 8757D

calibrator is ineectual because the only error that will be seen will

be due to measurement rep eatability and any possible temperature

drift. Therefore, to verify the dynamic accuracy of the 85037A/B,

only the raw, uncorrected performance is measured. Once this has

been veried, the corrected dynamic accuracy,by design, must b e

within sp ecication. Indep endentverication of both corrected and

uncorrected specications can be performed b

two alternative setups shown in Figure 4-5 or Figure 4-6. T

y using either of the

esting of

the raw dynamic accuracy performance is the only test required. The

manual test procedure follows.

1. Connect the equipment as shown in Figure 4-4. If the sw

eeper is

on, turn it o.

2. Allow equipmenttowarm up for 30 minutes.

3. Disconnect the detector.

4. Press

4

PRESET

5

.

5. Reconnect the detector to input A, this forces default correction.

6. Press Channel

7. Press

8.

9.

Select

Press

4054

dBm

4

SYSTEM

NNNNNNNNNNNNNN

MORE

4

CAL

5

425425

5

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SWEEP MODE

NNNNNNNNNNNNNN

5

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MORE

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

DET OFFSET

START MEAS

(Pressing twice turns Channel 2 o ).

NNNNNNNNNNNNNNNNN

CW ON

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MEASURE DET OFS

NNNNNNNNNNNNNNNNN

DET A

. Read the oset value. Note this number

as the reference value.

10. Press

4

CAL

5

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

PRIOR MENU

4

1954dBm

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

START MEAS

.

11. Read the oset value shown on the 8757D and subtract from

this the reference value in step 9. Record the results on the test

record card under Dynamic Accuracy AC Mo de.

12. Repeat steps 10 and 11 at the p o

wer levels shown on the test

record.

4-10 Performance Tests

Page 41

First Alternate

Dynamic Power

Accuracy

13. Verify the noise oor in AC mo de.

Press:

4

AVG

NNNNNNNNNNNNNNNNNNNN

5

AVG ON

4

CURSOR

5

and record the average noise oor as displayed by the cursor

reading.

14.

Press

4

PRESET54SYSTEM

NNNNNNNNNNNNNNNNNNNNNNN

5

MODE DC

.

15. Repeat steps 6 through 12 for DC mo de. The detector should be

rezeroed between the030 and040 dBm steps.

Figure 4-4. Dynamic Power Accuracy Test Setup

Description

Figure 4-5. First Alternate Dynamic Power Accuracy Test Setup

This setup is for p erforming independentverication of dynamic

accuracy in 10 dB increments up to 0 dBm in DC mode.

Performance Tests 4-11

Page 42

Second Alternate

Dynamic Power

Accuracy

Description

Figure 4-6. Second Alternate Dynamic Power Accuracy Test Setup

Procedure

This setup is for p erforming independen

accuracy in 10 dB increments up to +20 dBm in DC mode.

Table 4-4. Additional Equipment

Function Generator Agilent 8116A

50 MHz Bandpass Filter 08757-80027

1. Set the 8757D for CW, DC mo de, cursor on.

2. Set the step attenuator to 20 dB.

3. Adjust the 8116 for a 50 MHz sinew

for a cursor reading of 0.0 dBm.

4. Adjust the step attenuator in 10 dB steps and compare the 8757D

cursor reading with the calculated applied power determined

by the calibrated step attenuator. The 20 dB step on the step

attenuator becomes the reference. The other steps are relativeto

this 20 dB value.

5. The detector should b e rezero ed bet

steps.

tverication of dynamic

ave and adjust the amplitude

ween the030 and040 dBm

4-12 Performance Tests

Page 43

Table 4-5. Test Record for 85037A

Test Facility Report Number

Date

Customer

Tested by

Model Ambient temperature

C

Serial Number Relativehumidity %

Options

Special Notes

Performance Tests 4-13

Page 44

Table 4-5. Test Record for 85037A (2 of 3)

Model Report Number Date

Test Equipment Used Model Number Trace Numb er Cal Due Date

1.

2.

3.

4.

5.

6.

7.

8.

4-14 Performance Tests

Page 45

Table 4-5. Test Record for 85037A (3 of 3)

Serial Number: Report Number: Date:

Test

Description Specication

Return Loss at a Nominal010 dBm

0.01 to 0.04 GHz 10 dB

0.04 to 18 GHz 20 dB

Frequency Resp onse at a Nominal010 dBm

0.01 to 0.04 GHz

0.04 to 18 GHz

6

6

Dynamic Power Accuracy

AC Mo de uncorrected

+19 dBm

+10 dBm

0

30 dBm

0

40 dBm

0

50 dBm

6

6

6

6

6

0.35 dB

0.18 dB

0.4 dB

0.4 dB

0.4 dB

0.8 dB

1.3 dB

Measured

Results

Measurement

Uncertainty

6

1.0 dB

6

2.4 dB

6

0.18 dB

6

0.25 dB

6

0.2 dB

6

0.13 dB

6

0.22 dB

6

0.30 dB

6

0.36 dB

1

Noise Floor

Dynamic Power Accuracy

DC Mode uncorrected

+19 dBm

+10 dBm

0

30 dBm

0

40 dBm

0

50 dBm

1

Using the equipment and procedures do cumen

0

6

6

6

6

6

ted in this manual.

55 dBm

0.4 dB

0.4 dB

0.4 dB

0.8 dB

1.3 dB

6

0.2 dB

6

0.13 dB

6

0.22 dB

6

0.3 dB

6

0.36 dB

Performance Tests 4-15

Page 46

4-16 Performance Tests

Page 47

Table 4-6. Test Record for 85037A Option 001

Test Facility Report Number

Date

Customer

Tested by

Model Ambient temperature

C

Serial Number Relativehumidity %

Options

Special Notes

Performance Tests 4-17

Page 48

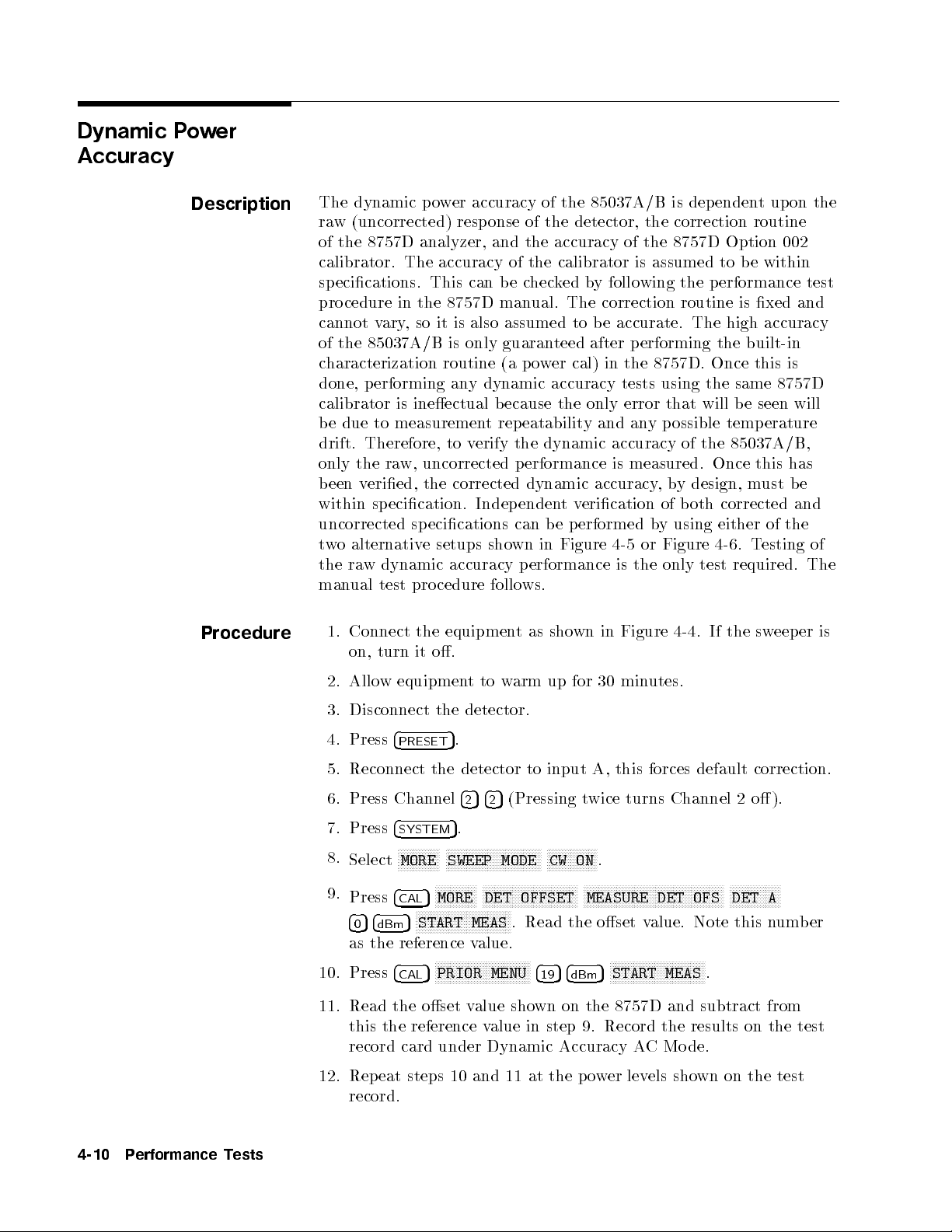

Table 4-6. Test Record for 85037A Option 001 (2 of 3)

Model Report Number Date

Test Equipment Used Model Number Trace Numb er Cal Due Date

1.

2.

3.

4.

5.

6.

7.

8.

4-18 Performance Tests

Page 49

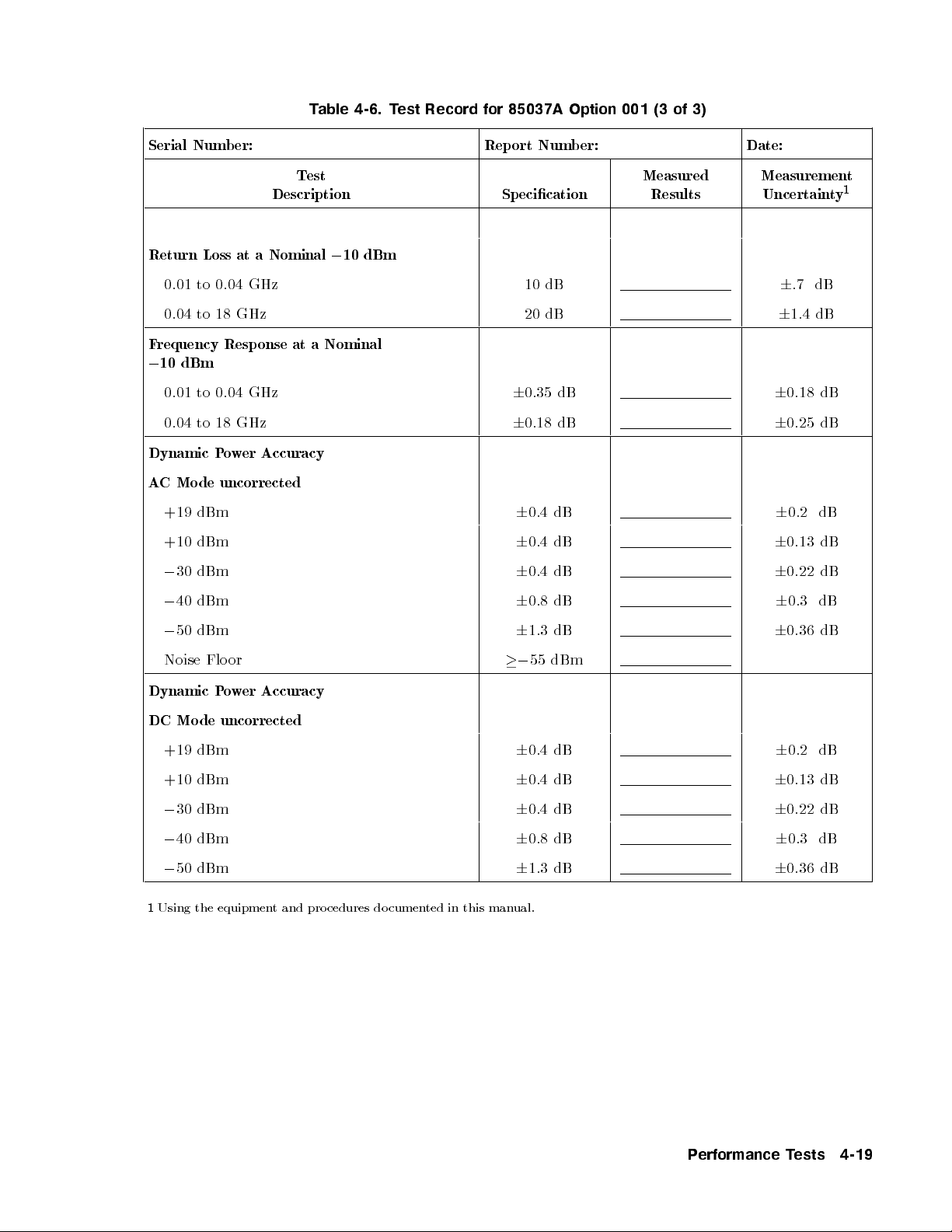

Table 4-6. Test Record for 85037A Option 001 (3 of 3)

Serial Number: Report Number: Date:

Test

Description Specication

Return Loss at a Nominal010 dBm

0.01 to 0.04 GHz 10 dB

0.04 to 18 GHz 20 dB

Frequency Resp onse at a Nominal

0

10 dBm

0.01 to 0.04 GHz

0.04 to 18 GHz

6

6

Dynamic Power Accuracy

AC Mo de uncorrected

+19 dBm

+10 dBm

0

30 dBm

0

40 dBm

6

6

6

6

0.35 dB

0.18 dB

0.4 dB

0.4 dB

0.4 dB

0.8 dB

Measured

Results

Measurement

Uncertainty

6

.7 dB

6

1.4 dB

6

0.18 dB

6

0.25 dB

6

0.2 dB

6

0.13 dB

6

0.22 dB

6

0.3 dB

1

0

50 dBm

Noise Floor

Dynamic Power Accuracy

DC Mode uncorrected

+19 dBm

+10 dBm

0

30 dBm

0

40 dBm

0

50 dBm

1

Using the equipment and procedures do cumented in this manual.

6

0

6

6

6

6

6

1.3 dB

55 dBm

0.4 dB

0.4 dB

0.4 dB

0.8 dB

1.3 dB

6

0.36 dB

6

0.2 dB

6

0.13 dB

6

0.22 dB

6

0.3 dB

6

0.36 dB

Performance Tests 4-19

Page 50

4-20 Performance Tests

Page 51

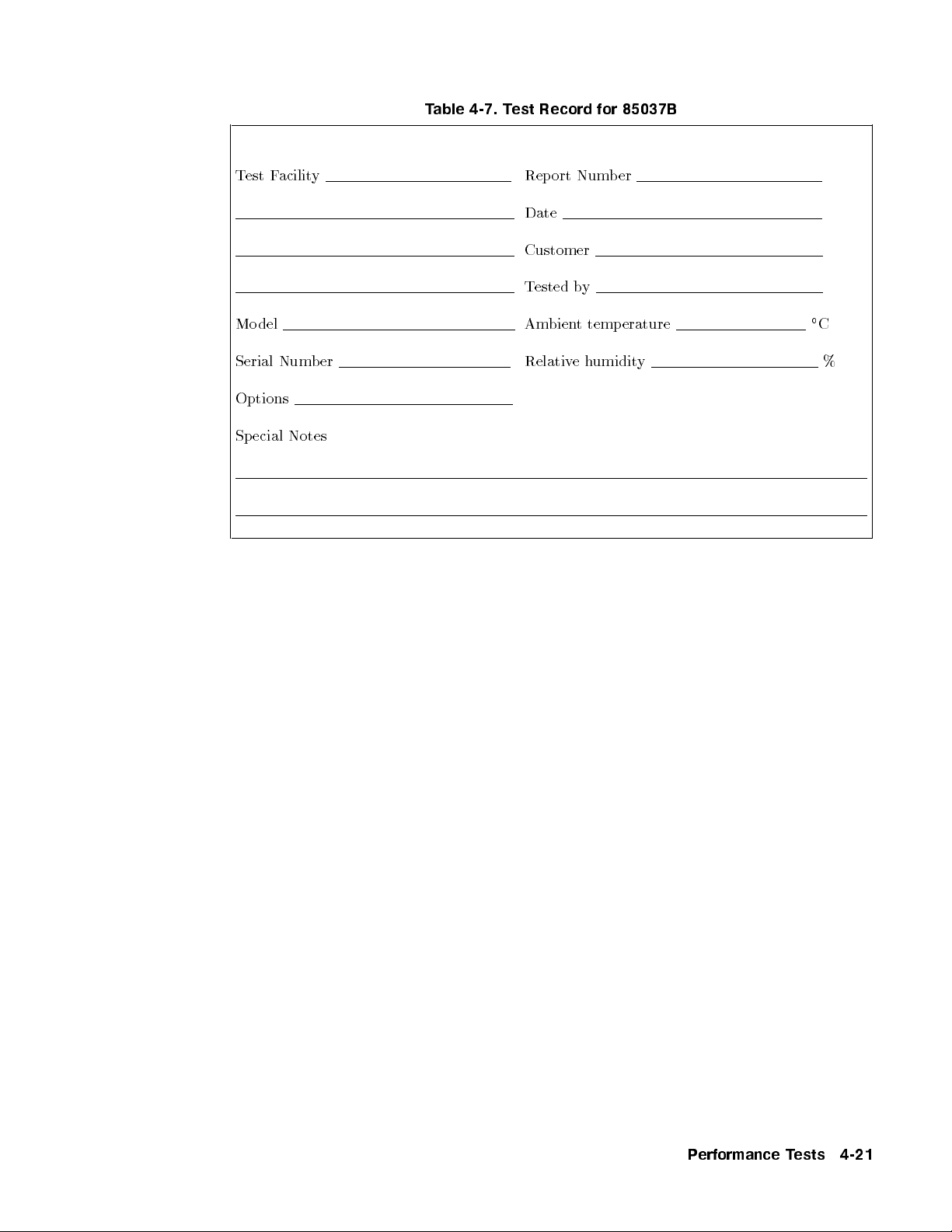

Table 4-7. Test Record for 85037B

Test Facility Report Number

Date

Customer

Tested by

Model Ambient temperature

C

Serial Number Relativehumidity %

Options

Special Notes

Performance Tests 4-21

Page 52

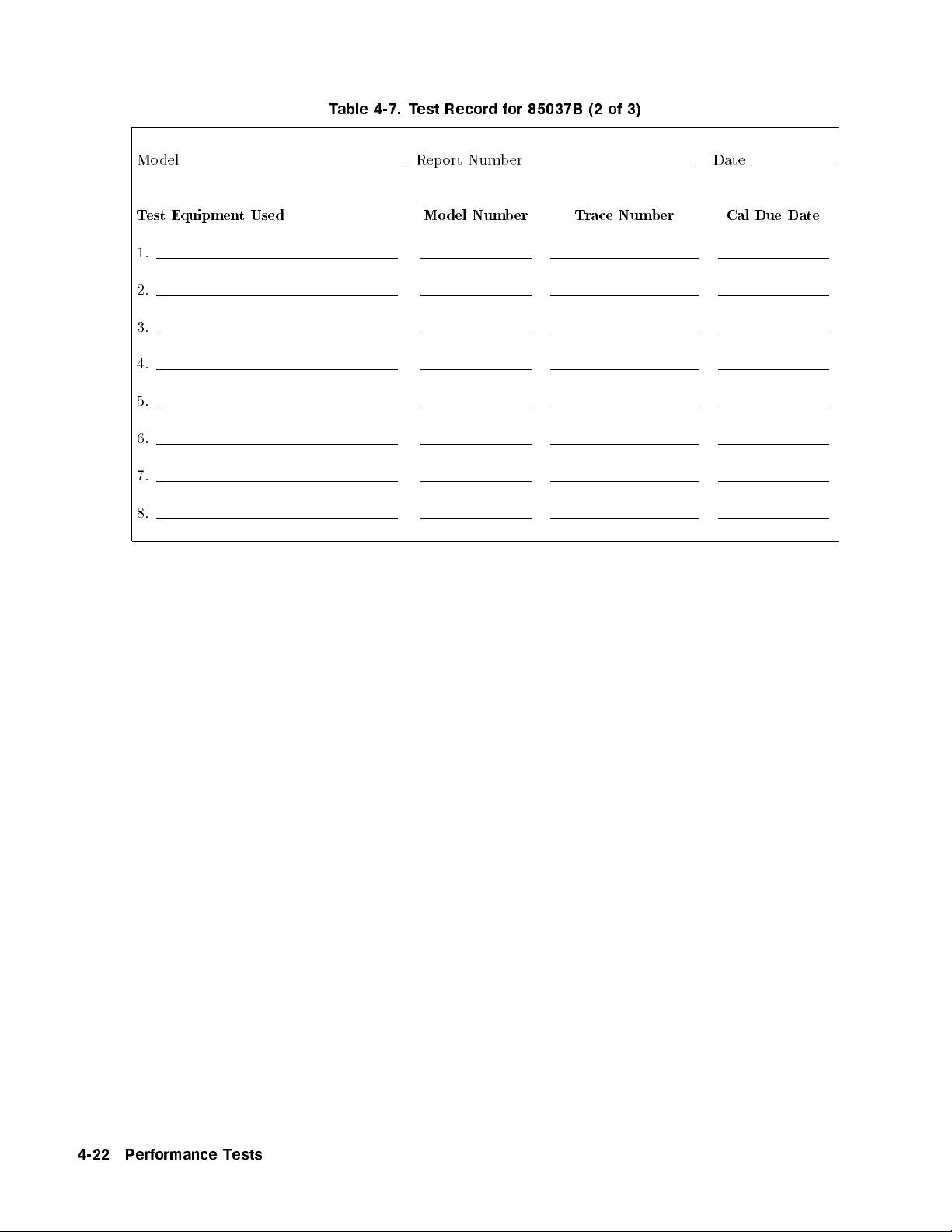

Table 4-7. Test Record for 85037B (2 of 3)

Model Report Number Date

Test Equipment Used Model Number Trace Numb er Cal Due Date

1.

2.

3.

4.

5.

6.

7.

8.

4-22 Performance Tests

Page 53

Table 4-7. Test Record for 85037B (3 of 3)

Serial Number: Report Number: Date:

Test

Description Specication

Return Loss at a Nominal010 dBm

0.01 to 0.04 GHz 10 dB

0.04 to 18 GHz 20 dB

18 GHz to 26.5 GHz 18 dB

Frequency Resp onse at a Nominal010 dBm

0.01 to 0.04 GHz

0.04 to 18 GHz

18 GHz to 26.5 GHz

6

6

6

Dynamic Power Accuracy

AC Mo de uncorrected

+19 dBm

+10 dBm

0

30 dBm

6

6

6

0.35 dB

0.18 dB

0.22 dB

0.4 dB

0.4 dB

0.4 dB

Measured

Results

Measurement

Uncertainty

6

0.7 dB

6

1.4 dB

6

2.0 dB

6

0.18 dB

6

0.25 dB

6

0.3 dB

6

0.2 dB

6

0.13 dB

6

0.22 dB

1

0

40 dBm

0

50 dBm

Noise Floor

6

6

0

Dynamic Power Accuracy

DC Mode uncorrected

+19 dBm

+10 dBm

6

6

0 dBm + 0.4 dB

0

30 dBm

0

40 dBm

0

50 dBm

1

Using the equipment and procedures do cumented in this manual.

6

6

6

0.8 dB

1.3 dB

55 dBm

0.4 dB

0.4 dB

0.4 dB

0.8 dB

1.3 dB

6

0.3 dB

6

0.36 dB

6

0.2 dB

6

0.13 dB

6

0.22 dB

6

0.22 dB

6

0.3 dB

6

0.36 dB

Performance Tests 4-23

Page 54

Page 55

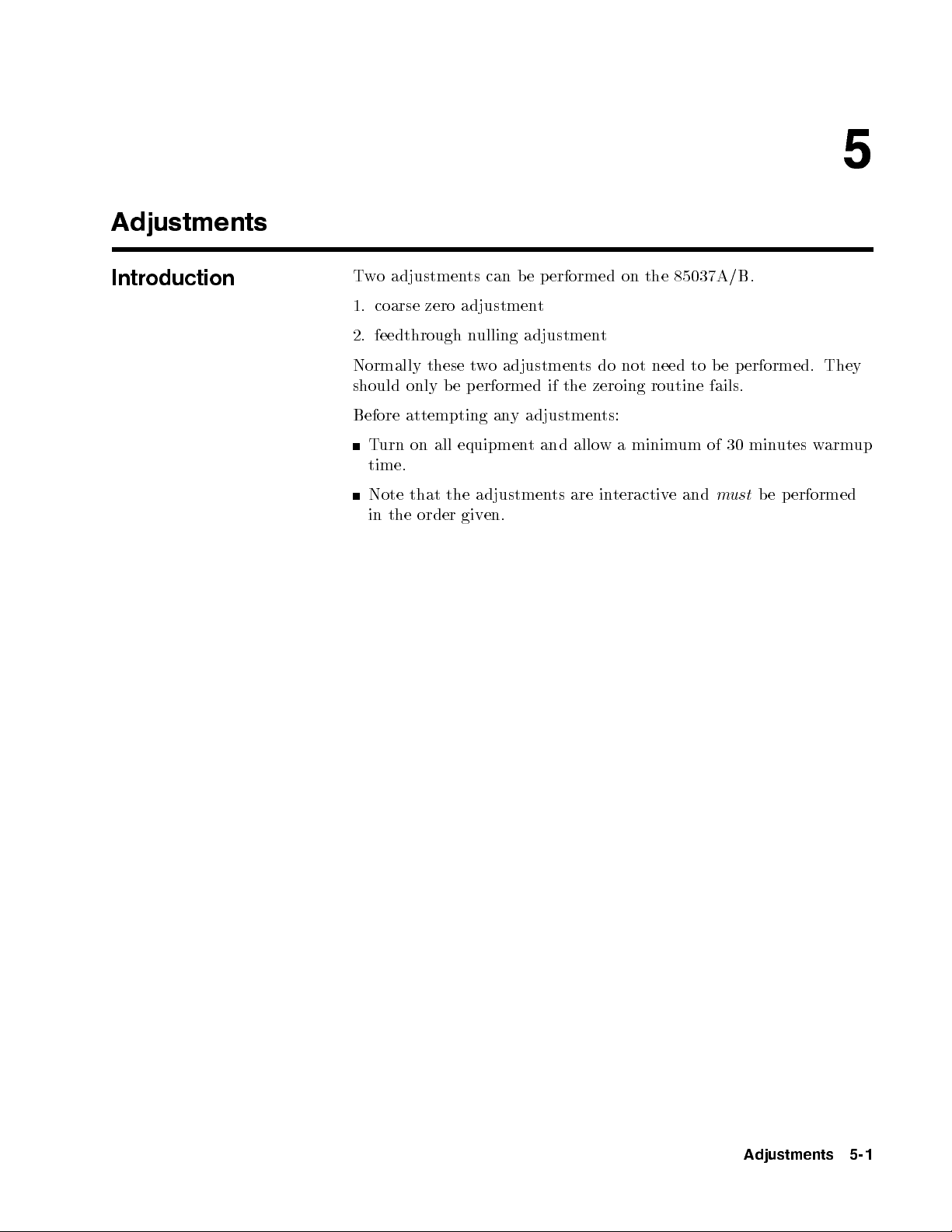

Adjustments

5

Introduction

Two adjustments can b e performed on the 85037A/B.

1. coarse zero adjustment

2. feedthrough nulling adjustment

Normally these two adjustments do not need to be p erformed. They

should only be performed if the zeroing routine fails.

Before attempting any adjustments:

Turn on all equipment and allow a minimum of 30 minutes warmup

time.

Note that the adjustments are interactive and

in the order given.

must

be performed

Adjustments 5-1

Page 56

Coarse Zero

Adjustment

Description

Procedure

The coarse zero adjustment centers the detector's DC preamp input

oset voltage within the built-in automatic zero routine's range.

This is accomplished by adjusting for the lowest overall indication of

noise on the 8757D. When the level is minimized, it indicates that

the range has been properly centered. Remove the detector's outer

covers and metal housing to allow access for making the adjustments.

(Refer to \Removing the Covers" at the beginning of Chapter 7,

\Service.")

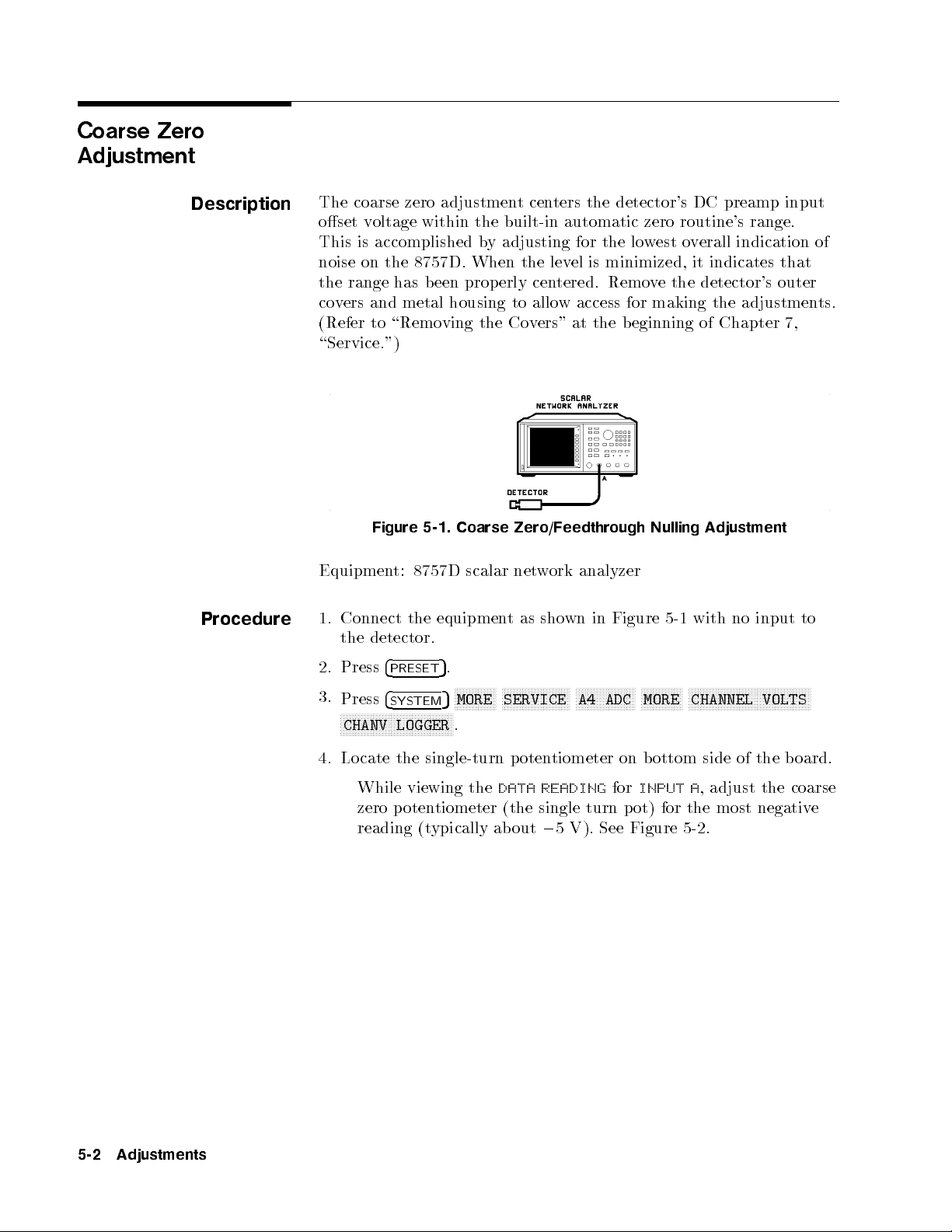

Figure 5-1. Coarse Zero/Feedthrough Nulling Adjustment

Equipment: 8757D scalar network analyzer

1. Connect the equipment as shown in Figure 5-1 with no input to

the detector.

2. Press

3.

4

PRESET

Press

4

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SYSTEM

5

CHANV LOGGER

.

NNNNNNNNNNNNNN

5

MORE

.

NNNNNNNNNNNNNNNNNNNNNNN

SERVICE

NNNNNNNNNNNNNNNNNNNN

A4 ADC

NNNNNNNNNNNNNN

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MORE

CHANNEL VOLTS

4. Locate the single-turn potentiometer on bottom side of the board.

While viewing the

DATA READING

for

INPUT A

, adjust the coarse

zero potentiometer (the single turn pot) for the most negative

reading (typically about05 V). See Figure 5-2.

5-2 Adjustments

Page 57

Feedthrough Nulling

Adjustment

Figure 5-2. Coarse Zero Adjustment

Description

Procedure

The feedthrough nulling is adjusted for best DC accuracy b elo

0

45 dBm. This is accomplished by adjusting for the

overall indication of noise on the 8757D. When the lev

highest

el of noise is

w

maximized, it indicates that the feedthrough is nulled.

Equipment: 8757D scalar network analyzer

Perform the following steps in order.

Connect the equipment as shown in Figure 5-1.

On the 8757D:

1. Press

2. Press Channel

3.

Press

4

PRESET

4

SYSTEM

5

.

425425

NNNNNNNNNNNNNN

5

(Pressing twice turns Channel 2 o ).

MORE

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SWEEP MODE

NNNNNNNNNNNNNNNNN

CW ON

to place the 8757D in

CW mo de.

NNNNNNNNNNNNNNNNNNNNNNN

4. Press

5.

6.

Press

Press

4

SYSTEM

5

MODE DC

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

4

5

SMOOTH ON

SPCL

4

SCALE54554dB

.

.

5

.

7. If necessary, use the arrows keys to moveupor down to set the

reference line to the center of the screen. (This will be 4 divisions

up from the bottom of the CRT screen.)

8.

9.

Press

Press

4

5

REF

4

CURSOR

NNNNNNNNNNNNNNNNNNNNNNNNNN

REF POSN

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

CRSR0>REF LVL

.

Adjustments 5-3

Page 58

10.

Press

4

CAL

indicates

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

DC DET ZERO

:REMOVE RF FROM DC DETECTORS.

NNNNNNNNNNNNNNNNNNNN

MANUAL

. The display

If you have connected

the detector to an RF output, disconnect it.

Press

NNNNNNNNNNNNNN

CONT

.

11.

When the routine is complete the display indicates: MANUAL

ZERO COMPLETED.

12. Lo cate the Feedthrough Null multi-turn p otentiometer which

is on the top side of the PC board, (the same side as the cable

wires). Adjust it one half turn (either direction). See Figure 5-3.

13. Repeat steps 9 through 12 until turning the Feedthrough Null

potentiometer in either direction will only

decrease

the displayed

noise. If the overall noise level is less (lower on the screen) than

the beginning value noted, reverse the direction of adjustment.

Continue adjusting until the noise level displayed is

maximized

.

5-4 Adjustments

Figure 5-3. Feedthrough Nulling Adjustment

Page 59

Replaceable Parts

6

Introduction

Ordering Parts

This section provides replaceable parts and ordering information.

To order a part listed in the replaceable parts Table 6-2, quote the

Agilent part number, indicate the quantity required and address the

order to your nearest Agilent oce.

Replaceable Parts 6-1

Page 60

To request information on a part that is not listed in the replaceable

parts table, include the instrument mo del number and a description

of the part and its function. Address the inquiry to the nearest

Agilent oce.

Figure 6-1. Detectors and Cable Marker Kit

Table 6-1. Miscellaneous Parts

Item

# Description and Quantity

1 Plastic half-b ody cover (2) 85025-40006

2 Lab el: warning max input (1) 85037-80003

Label: electrostatic sensitive (1) 85037-80002

3 Cable assembly (1) 85025-60003

4 Screw M2.5 x 0.45; 4 mm-LG (2) 0515-0972

5 Lo ckwasher 2.5 mm (2) 2190-0583

6 Cable marker kit (1) 5061-1044

Agilent

Part

Number

6-2 Replaceable Parts

Page 61

Table 6-2. Replaceable Parts and Accessories

Part Description Agilent Model or

Part Number

Rebuilt/Exchange Assemblies

85037A Type-N 85037-69006

85037A Option 001 7mm 85037-69007

85037B 3.5 mm 85037-69008

Accessories

Connector Gage Kits Type-N 85054-80011

7mm 85050-80012

3.5 mm 11752-60106

Collet Extractor Tool For 85037A Option 001 5060-0370

Adapters Type-N (f ) to BNC (m) 1250-1534

Type-N (m) to Type-N (m) 1250-1475

3.5 mm (f ) to 3.5 mm (f ) 1250-1749

Type-N (m) to APC-7 11525A

(Option 001 only)

APC-3.5 (f ) to N (m) 1250-1744

Extension Cables 7.6 meter (25 foot) 11679A

61 meter (200 foot) 11679B

Connector Care Manual 08510-90064

Replaceable Parts 6-3

Page 62

6-4 Replaceable Parts

Figure 6-2. Module Exchange Program

Page 63

By internet, phone, or fax, get assistance with all your test &

measurement needs.

Table 6-3. Contacting Agilent

Online Assistance:

www.agilent.com/find/assist

United States

(tel) 1 800 452 4844

Canada

(tel) 1 877 894 4414

(fax) (905) 206 4120

Europe

(tel) (31 20) 547 2323

(fax) (31 20) 547 2390

Japan

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

Latin America

(tel) (305) 269 7500

(fax) (305) 269 7599

Australia

(tel) 1 800 629 485

(fax) (61 3) 9210 5947

New Zealand

(tel) 0 800 738 378

(fax) 64 4 495 8950

Asia Pacic

(tel) (852) 3197 7777

(fax) (852) 2506 9284

Replaceable Parts 6-5

Page 64

Page 65

Service

7

Caution

Error Messages

Repair

This pro duct is susceptible to damage from electrostatic discharge

(ESD). When you p erform any of the following procedures, wear a

grounded static-strap and work at a static-safe workstation.

The message

EEPROM read failed -- A (B,C or R)

Indicates that

the EEPROM calibration constants are either corrupted or unable

to be read from the detector. The problem could be in either the

detector or the 8757D. Try another detector to isolate the cause.

If the detector appears to be the cause of the problem, then the

detector needs to have the calibration constants regenerated at the

factory. Refer to \Returning a Detector for Service" in Chapter 2,

\Installation."

These detectors have only one repairable item:

The cable assembly.

If the detector fails electrically, order an exchange detector:

Remember

1. See the Replaceable parts, Table 6-2 , for the part number that

matches the model that you are replacing:

85037A

85037A Option 001 or

85037B.

2. Follow \The Module Exchange Program" instructions in

Figure 6-2.

To receive exchange credit, you

must

return the failed assembly to

Agilent in the exchange assembly box.

Service 7-1

Page 66

Repair

Replacing the Detector

Removing the Covers

1. Remove the plastic covers from the existing detector. (See

\Removing the Covers.")

2. Install the covers on the replacement detector.

3. Perform an operator's check. (See \Operator's Check" in

Chapter 3.)

4. If the replacement is a restored exchange detector, return the

defective detector using the packing material supplied.

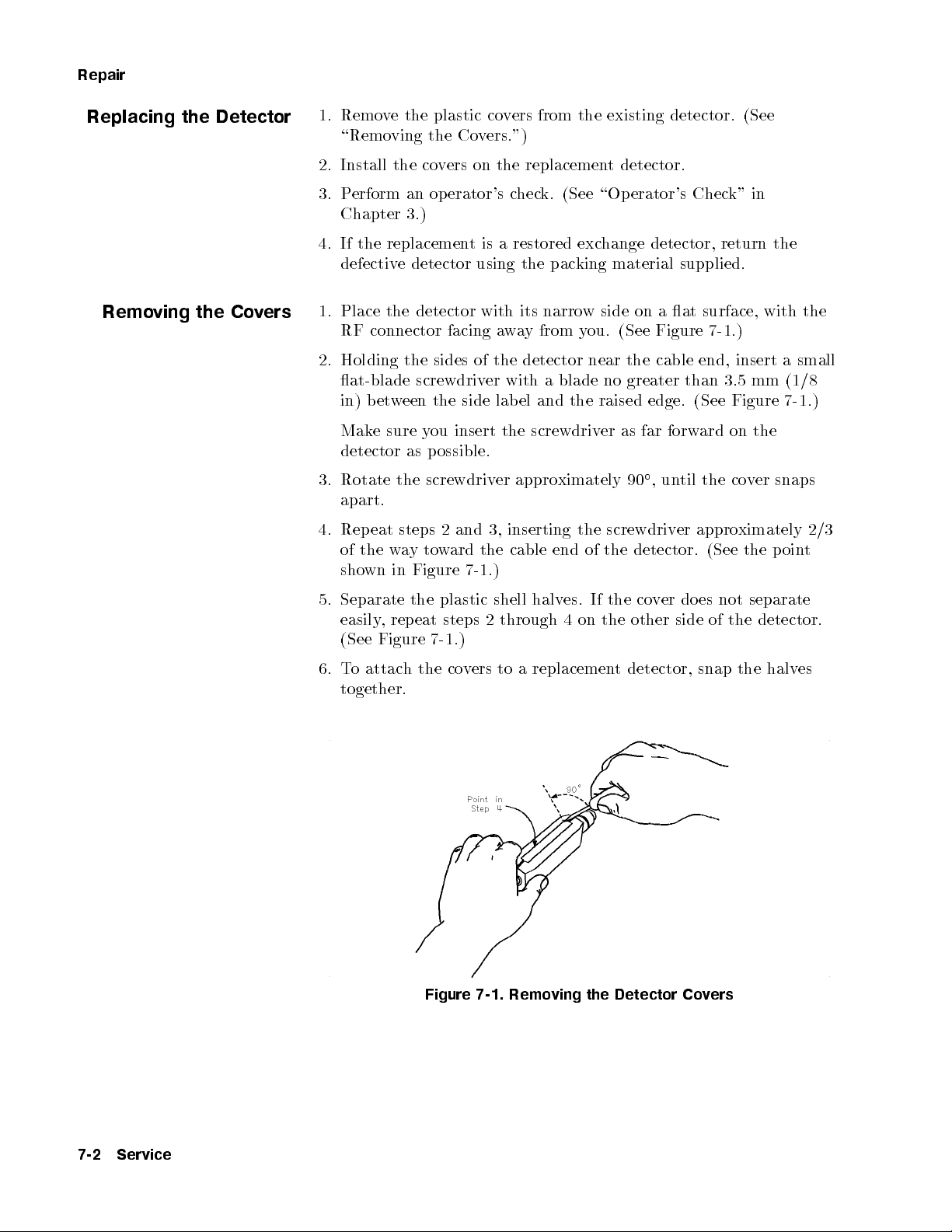

1. Place the detector with its narrow side on a at surface, with the

RF connector facing away from you. (See Figure 7-1.)

2. Holding the sides of the detector near the cable end, insert a small

at-blade screwdriver with a blade no greater than 3.5 mm (1/8

in) between the side label and the raised edge. (See Figure 7-1.)

Make sure you insert the screwdriver as far forward on the

detector as possible.

3. Rotate the screwdriver approximately 90

,until the cover snaps

apart.

4. Rep eat steps 2 and 3, inserting the screwdriv

of the waytoward the cable end of the detector. (See the p oin

er approximately 2/3

t

shown in Figure 7-1.)

5. Separate the plastic shell halves. If the cover do es not separate

easily, repeat steps 2 through 4 on the other side of the detector.

(See Figure 7-1.)

6. To attach the covers to a replacement detector, snap the halves

together.

Figure 7-1. Removing the Detector Covers

7-2 Service

Page 67

Repair

Replacing the Cable

Assembly (W1)

Caution

1. Remove the plastic covers from the detector. (See \Removing the

Covers.")

2. Remove the two screws at the cable end of the metal housing.

3. Slide the metal housing away from the RF connector, completely

exposing the printed circuit (PC) assembly.

4. Unsolder all cable wires from the PC assembly.

5. With the PC assembly facing up, carefully secure the detector

frame in a vice. Do not grip the PC assembly.

Do not over-tighten the vice; you can bend the frame.

6. Using a 7/16 inch op en-ended wrench, unscrew the cable hex nut.

7. Remove the old cable assembly.

8. Remove the metal housing from the cable.

9. Carefully slide the metal housing onto the new cable

assembly, making sure that you do not cover the adjustment

potentiometers.

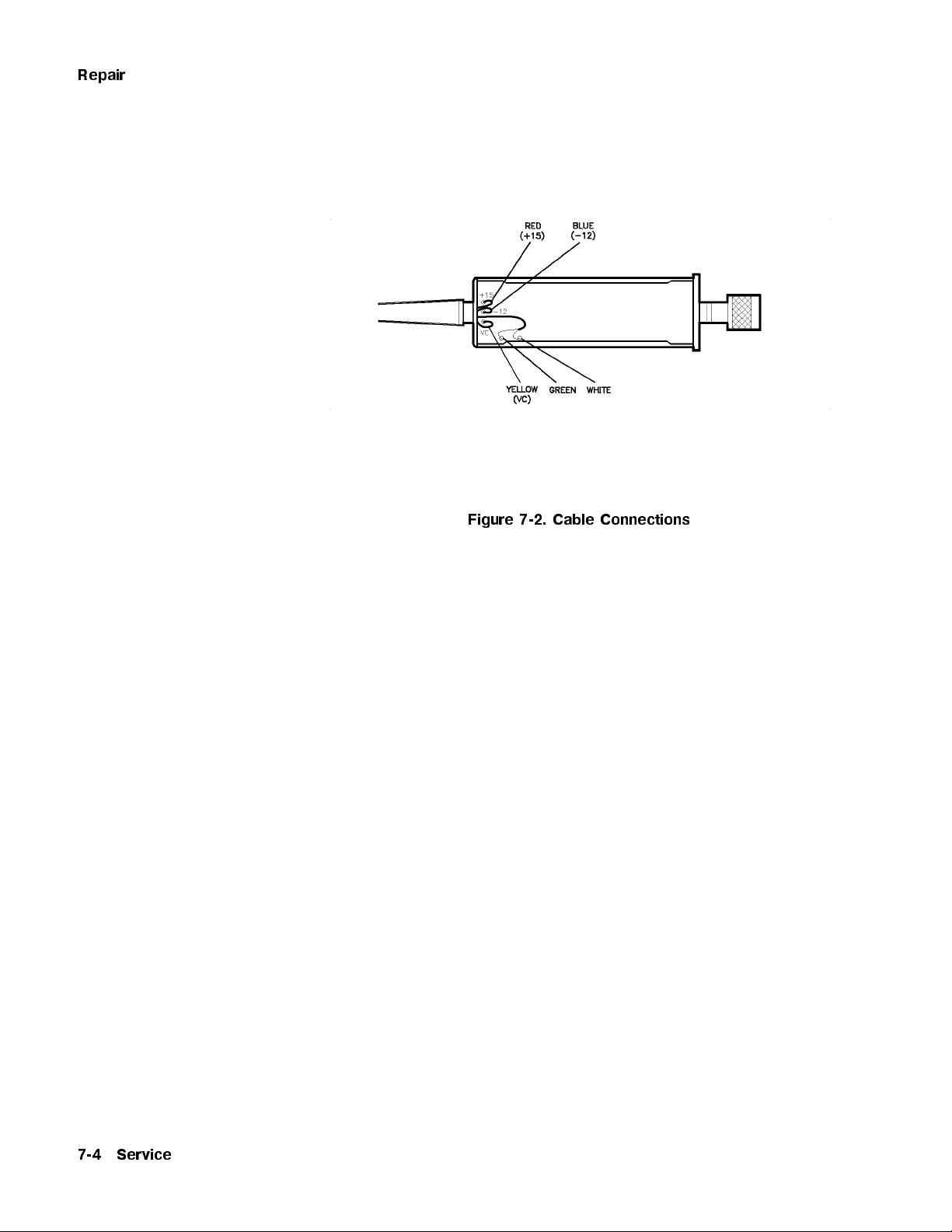

10. Solder the new cable wires to the PC assem

7-2.)

bly. (Refer to Figure

11. Ensure that all cable wires are securely connected to the

assembly.

12. Slide the metal housing over the PC assembly.

13. Using the screws removed in step 2, secure the metal housing to

the frame.

14. Snap the covers back on.

Service 7-3

Page 68

Repair

Figure 7-2. Cable Connections

7-4 Service

Page 69

Caring for Connectors

This appendix provides a brief introduction to the fundamentals of