Page 1

User’s Guide

11970 SERIES

HARMONIC MIXERS

(K, A, Q, U, V, and W Models)

Manufacturing Part Number: 11970-90031

Supersedes 11970-90030

Printed in USA

October 2003

© Copyright 1992, 1999, 2001

−2003 Agilent Technologies, Inc.

Page 2

Notice

The information contained in this document is subje ct to change without notice.

Agilent Technologies makes no warranty of any kind with regard to this material,

including but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. Agilent Technologies shall not be liable for errors contained herein or

for incidental or consequential damages in connec tion with the furnishing , perfor mance, or

use of this material.

Certification

Agilent T echnologi es certifies that this product met its published specif ications at the ti me

of shipment from the factory. Agilent Technologies further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute’s calibration facility, and to the

calibration facilities of other International Standards Organization members.

Warranty

This Agilent T echnologies instrument pr oduct is warranted agains t defects in material and

workmanship for a period of one year from date of shipm ent. During the warranty period,

Agilent Technologies will, at its option, either repair or replace products which prove to be

defective.

For warranty service or repair, this product must be returned to a service facility

designated by Agilent Technologies. Buyer shall prepay shipping charges to Agilent

Technologies and Agilent Technologies shall pay shipping charges to return the product to

Buyer. However, Buyer shall pa y all shipping charges, duties, and taxes for products

returned to Agilent Technologies from another country.

Agilent Technologies warrants that its software and firmware designate d by Agilent

Technologies for use with an instrument will execute its programming instructions when

properly installed on that instrument. Agilent Technologies does not warrant that the

operation of the instrument, or software, or firmware will be uninterrupted or error-free.

2

Page 3

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to def ects resulting from improper or inadequate

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modification

or misuse, operation outside of the environmental specifications for the product, or

improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT TECHNOLOGIES

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AN D EXCLUSIVE

REMEDIES. AGILENT TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER

BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Assistance

Product maintenance agreements and other customer assis tance agreements are availa ble

for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales and Service Office

listed on page 77.

This guide uses the following conventions:

Instrument Key This represents a key physically l ocated on the ins trument, or a key with a

label that is determined by the instrument firmware.

Screen Text This indicates text displayed on the spectrum analyzer screen.

3

Page 4

4

Page 5

Contents

1. General Information

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mixers Covered by Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

11970 Series Harmonic Mixers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Spectrum Analyzer Retrofit Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Equipment Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Environmental Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. Operation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Mixer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Using a Conversion-Loss Data Disk with the ESA or PSA Series Analyzers . . . . . . . . . . . . . . . . . . . . . . . 21

Loading Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Viewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Using the Mixers with the E4407B Spectrum Analyzer (Option AYZ). . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Set up the equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Using the Mixers with the E4440A, E4446A, or E4448A

PSA Series Spectrum Analyzer (Option AYZ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Set up the equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Using the Mixers with the 856X Series Spectrum Analyzers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Set up the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Select the Frequency Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Save the average conversion-loss value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Signal Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Identify signals with the frequency-shift method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Identify signals in wide frequency spans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Using the Mixers with MMS Analyzers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Preliminary Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Conversion Loss Versus Frequency Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Using the Mixers with the 8566B Spectrum Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Set up the equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Amplitude Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Signal Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table of Contents

3. Performance Tests

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Performance Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Conversion Loss and Frequency Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

AVERAGE NOISE LEVEL TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5

Page 6

Contents

Table of Contents

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4. Service

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Circuit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6

Page 7

General Information

1 General Information

7

Page 8

General Information

Introduction

Introduction

The Agilent Models 11970K, 11970A, 11970Q, 11970U, 11970V and 11970W are

general-purpose harmonic mixers with very flat frequency re sponse characteristics and

low conversion loss. Collectively, they cover the frequency range of 18 to 110 GHz. The

11970K covers the 18 - 26. 5 GHz range; the 1197 0A, t he 26.5 - 40 GHz range; the 11970Q,

the 33 - 50 GHz range; the 11970U, the 40 - 60 GHz range; the 11970V, the 50 - 75 GHz

range; and the 11970W, the 75 - 110 GHz range.

The overall local oscillator (LO) frequency range of the 11970 Series Mixers is 3.0 to 6.1

GHz. Each of the mixers employs a different LO harmonic, and as a result has a different

optimum LO range within the overall LO range of the series.

The 11970 Series Mixers use the Agilent 11975A Amplifier to raise the LO power to their

required LO input level of 14 to 18 dBm. By taking advantage of the power leveling

capability of the 11975A, the mixers are able to achieve maximum measurement accuracy

(at optimum LO input level of 14.5 to 16 dBm).

A label on the end of each mixer shows a Conversion Loss Calibration table printed

General Information

especially for that part icular mixer. An 8-1/ 2 by 11-inch calibration table shi ppe d with th e

mixer provides a larger, easi er to read, version of th e same table shown on the label, plus a

graph which shows the conversion loss and reference level offset across the mixer’s

frequency range. This calibration table must be employed for absolute amplitude

measurements . Also supplied with each mixer are five screws (four required) for attaching

the mixer RF input flange to the waveguide.

Mixers Covered by Manual

Serial Numbers

Attached to your mixer, is a label which s hows both the mixer model number and its ser ial

number (two parts). The first four digits and the letter of the serial number are the serial

number prefix; the last five digits are the suffix. The contents of this manual apply to

mixers with the serial number prefixe s lis ted under “Serial Number Prefixes” on the title

page of this manual.

8 Chapter 1

Page 9

11970 Series Harmonic Mixers

Figure 1-1.

General Information

Introduction

General Information

Options

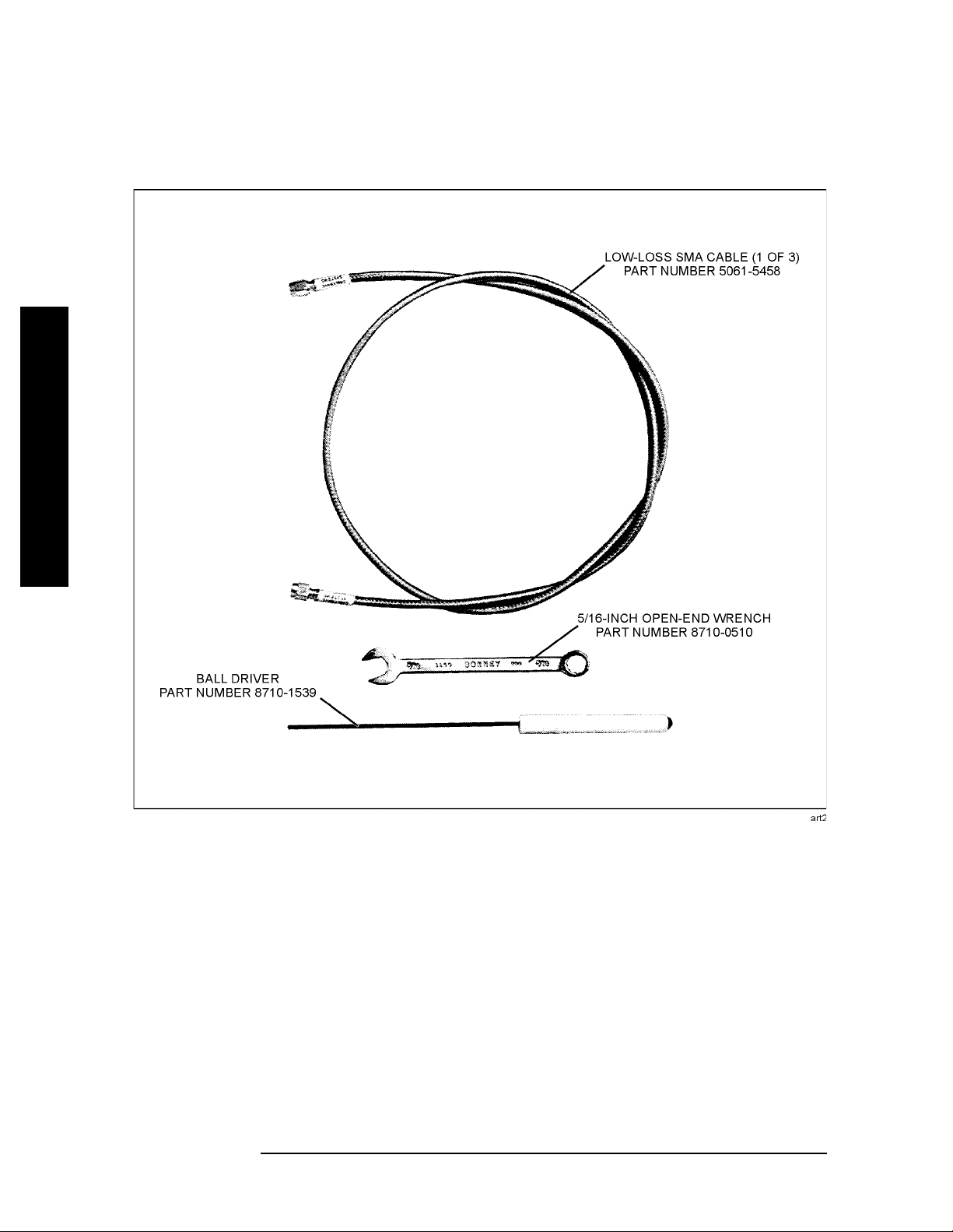

Option 009, shown in Figure 1-2. is a Mixer Connection Kit. It includes three low-loss SMA

cables (Part Number 5061-5458), one hex-head balldriver (Part Number 8710-1539) for

tightening the wave guide connector screws, and one 5/16-inch open-end wrench (Part

Number 8710-0510) for use on the SMA connectors.

Spectrum Analyzer Retrofit Requirements

• The 11970 Series Mixers are fully compatible with all 8566B Spectrum Analyzers.

• 856x Series portable spectrum analyzers with options 002 (tracking generator ) and 327

(no IF IN on front panel) do not have external mixing capability.

• 856x Series Portable Spectrum Analyzers require option 008, or FW date code

for signal id e n ti fication functional i ty.

• Agilent E4407B spectrum analyzers require option AYZ (LO Out and IF IN

connections).

• MMS analyzers using 11970 series mixers must have a front end model 70907A,

70907B, 7090 9A, or 70910A, a s well as a 70900A/B with f irmw ar e new eno ugh for tho se

modules:

Model FW Date Code:

(or newer)

≤ 920528,

70907A

70907B

70909A

70910A

-

860203

-

900314

-

910802

-

910802

Chapter 1 9

Page 10

General Information

Introduction

• PSA Series E4440A, E4446A, and E4448A spectrum analyzers require Option AYZ (LO

OUT and IF IN connectors). The E4443A and E4445A do not support external mixing.

Figure 1-2. Mixer Connection Kit, Option 009

General Information

10 Chapter 1

Page 11

General Information

Specifications

Specifications

Specifications for the 11970 Serie s Mixers are listed in Table 1-1. These are the performance

standards against which the mixers are tested (p erformance tests are provided in

3 ,“Performance Tests,”

). Typical or nominal operating values are listed in Table 1-2.

NOTE Supplemental characteristics are included only as additional information;

they are not specifications.

Chapter

Equipment Supplied

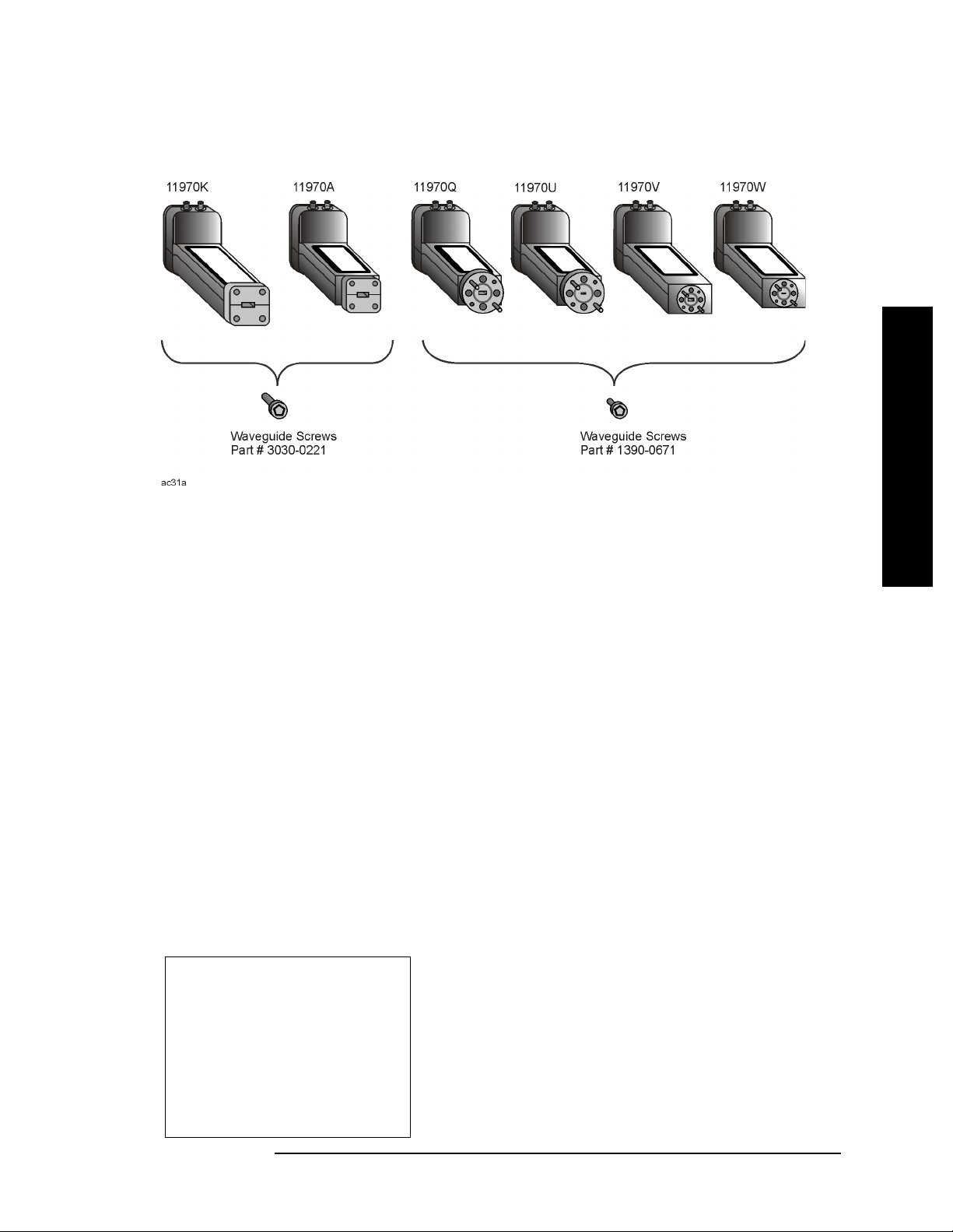

Waveguide Connector Screws

Five hex-head screws are supplied with each mixer. Four are required to make the mixer-to-waveguide

connection, one is a spare. Use ONLY the screws supplied t o attach the mixe r to the waveguid e. Because

of slight diffe rences in t he way the mixer s couple with the waveguide, the square-fl ange mixers (1 1970K

and 11970A) and the round-flange mixer (1970Q, 11970U, 11970V and 11970W) require different

screws.

If your mixer has a square waveguide flange, use four hex-head screws with Part Number

3030-0221. If it has a round waveguid e flange, use four hex-head captive screws with Part

Number 1390-0671. The special balldrive r hex scr ewdriver available in the Option 009

Mixer Connector Kit simplifies installation of the waveguide connector screws.

NOTE See Chapter 4 ,“Service,” for a list of replacement parts.

Environmental Limitations

The 11970 Series Mixers meet or exceed the environmental requirements of MIL-T-28800C, Type III,

Class 3, Style C. Specific environmental qualifications for the mixers are as follows:

Temperature, Non-operating: -40

o

C to 75oC

General Information

Temperature, Operating: 0

Relative Humidity: 95 ±5% (up to 30

o

C to 55oC

o

C)

Altitude, Non-operating: Less than 12,195 meters (40,000 ft.)

Altitude, Operating: Less than 3,048 meters (10,000 ft.)

Maximum Vibration Levels: 2 G’s at 5 to 2000 Hz

Maximum Shock: 30 G’s

Chapter 1 11

Page 12

General Information

Specifications

Table 1-1 11970 Series Specifications

NOTE

Unless otherwise stated, all specifications apply for an IF of 321.4 MHz and for RF input amplitudes of

less than -20 dBm.

GENERAL

LO Amplitude Range: 14 to 18 dBm

Calibration Accuracy: Maximum CW RF Input Level:

11970K/A/Q/U:

± 2.0 dB with LO amplitude r ange of 14.5 to 16 dBm

11970V/W:

± 2.2 dB with LO amplitude r ange of 14.5 to 16 dBm

11970K/A/Q/U:

± 3.0 dB with LO amplitude r ange of 16 to 18 dBm

General Information

11970V/W: ± 3.2 dB with LO amplitude range of 16 to

18 dBm

1

Bias Requirements: None

20 dBm (l00mW)

Maximum Peak Pulse Power:

24 dBm with < 1µsec pulse

Environmental:

Meets MIL-T-28800C, Type III, Class 3, Style C

IF/LO Connectors:

SMA female

(avg. power: + 20 dBm)

12 Chapter 1

Page 13

General Information

Specifications

Table 1-1 11970 Series Specifications

NOTE

Unless otherwise stated, all specifications apply for an IF of 321.4 MHz and for RF input amplitudes of

less than -20 dBm.

MODEL 11970K MODEL 11970A

RF Frequency Range:

18 - 26.5 GHz

LO Harmonic Number: 6 LO Harmonic Number: 8

LO Input Frequency Range:

2.95 - 4.36 GHz

Maximum Conversion Loss: 24 dB

8566B Noise Level at 1 kHz Bandwidth, and

14.5 to 16 dBm

LO Input Power:

Frequency Response at 14.5 to 16 dBm

LO Input Power: ±1.9 dB

Frequency Response at 14 to 18 dBm

LO Input Power: ±2.8 dB

RF Frequency Range:

33 - 50 GHz

LO Harmonic Number: 10

-105 dBm

MODEL 11970Q

RF Frequency Range:

26.5 - 40 GHz

LO Input Frequency Range:

3.27 - 4.96 GHz

Maximum Conversion Loss: 26 dB

8566B Noise Level at 1 kHz Bandwidth, and

14.5 to 16 dBm

LO Input Power: -102 dBm

Frequency Response at 14.5 to 16 dBm

LO Input Power: ±1.9 dB

Frequency Response at 14 to 18 dBm

LO Input Power: ±2.8 dB

MODEL 11970U

RF Frequency Range:

40 - 60 GHz

LO Harmonic Number: 10

General Information

LO Input Frequency Range:

3.27 - 4.97 GHz

Maximum Conversion Loss: 28 dB Maximum Conversion Loss: 28 dB

8566B Noise Level at 1 kHz Bandwidth, and

14.5 to 16 dBm

LO Input Power: -101 dBm

Frequency Response at 14.5 to 16 dBm

LO Input Power: ±1.9 dB

Frequency Response at 14 to 18 dBm

LO Input Power: ±2.8 dB

LO Input Frequency Range:

3.97 - 5.97 GHz

8566B Noise Level at 1 kHz Bandwidth, and

14.5 to 16 dBm

LO Input Power: -101 dBm

Frequency Response at 14.5 to 16 dBm

LO Input Power: ±1.9 dB

Frequency Response at 14 to 18 dBm

LO Input Power: ±2.8 dB

Chapter 1 13

Page 14

General Information

Specifications

Table 1-1 11970 Series Specifications

NOTE

Unless otherwise stated, all specifications apply for an IF of 321.4 MHz and for RF input amplitudes of

less than -20 dBm.

MODEL 11970V

RF Frequency Range:

50 - 75 GHz

LO Harmonic Number: 14 LO Harmonic Number: 18

LO Input Frequency Range:

3.55 - 5.33 GHz

Maximum Conversion Loss: 40 dB

8566B Noise Level at 1 kHz Bandwidth, and

14.5 to 16 dBm

LO Input Power: -92 dBm

Frequency Response at 14.5 to 16 dBm

General Information

LO Input Power: ±2.1 dB

Frequency Response at 14 to 18 dBm

LO Input Power: ±2.8 dB

RF Frequency Range:

75 - 110 GHz

LO Input Frequency Range:

4.15 - 6.09 GHz

Maximum Conversion Loss: 46 dB

8566B Noise Level at 1 kHz Bandwidth, and LO Input

Power: - 85 dBm

Frequency Response at 14.5 to 16 dBm

LO Input Power: ±3.0 dB

Frequency Response at 14 to 18 dBm

LO Input Power: ±4.0 dB

MODEL 11970W

2

1. The 11975A Amplifier, or a similar amplifier, can be used to provide sufficient LO power (14 to

18 dBm) to the mixers. Leveled power capability of 16 dBm, as is available with the 11975A, is necessary to achieve the maximum amplitude accuracy with the mixers. Assuming the 1 meter cables

supplied with the instrum ent are used , only the 85 66B LO ou tput requ ires ampl ificati on. Howe ver,

if longer or lower quality cables are used LO amplification may be necessary.

2. Typically ± 2.5 dB with LO supplied by 8566B Spectrum Analyzer, 11975A Amplifier set to

16 dBm, and P/N 5061-5458 SMA cables.

14 Chapter 1

Page 15

General Information

Specifications

Table 1-2 11970 Supplemental Characteristics

NOTE

Supplemental characteristics are included only as additional information; they are not specifications.

3 dB IF Bandwidth: DC to 1.3 GHz Odd Order Mixing Product Suppression:

11970K/A/Q/U: >20 dB

11970V/W: >15 dB

Spectrum Analyzer Absolute Amplitude

Accuracy (using calibration data with a 14.5 to

16 dBm LO):

11970K, 18 - 26.5 GHz: ±3.2 dB

11970A, 26.5 - 40 GHz: ±3.2 dB

11970Q, 33 - 50 GHz: ±3.2 dB

11970U, 40 - 60 GHz: ±3.2 dB

11970V, 50 - 75 GHz: ±3.4 dB

11970W: 75 - 110 GHz: ±3.4 dB

RF Input SWR:

11970K/A/Q/U: <2.2:1

11970V/W: <2.6:1

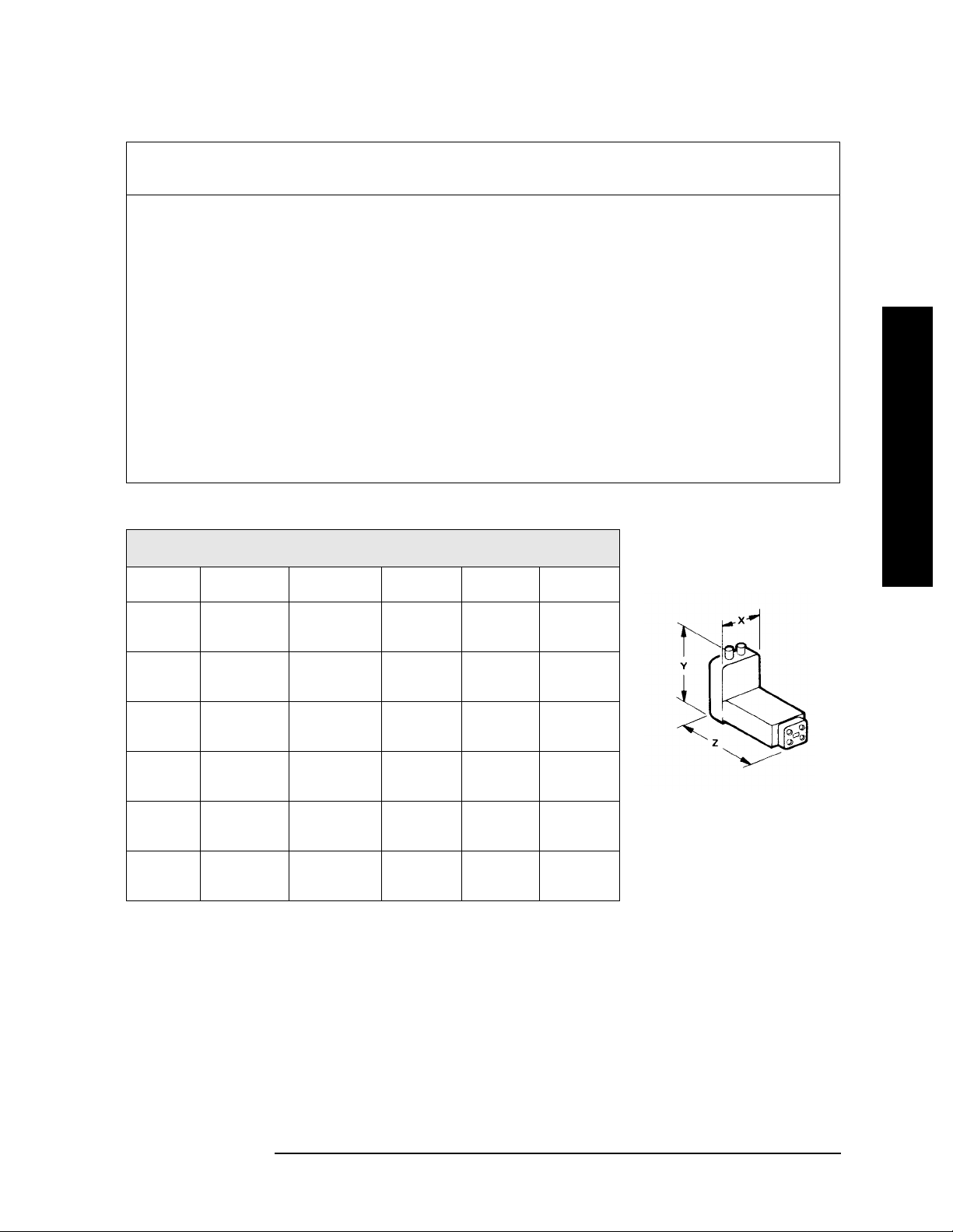

PHYSICAL CHARACTERISTICS

Model

11970K

Flange

UG-595/U

WR-42

11970A UG-599/U

WR-28

11970Q

UG-383/U

WR-22

1

Weight X Y

0.17 kg

0.36 lb

0.14 kg

0.32 lb

0.14 kg

0.32 lb

36 mm

1.4 in

36 mm

1.4 in

36 mm

1.4 in

Gain Compression Level (<1 dB):

11970K: -3 dBm

11970A: -5 dBm

11970Q: -7 dBm

11970U: -7 dBm

11970V: -3 dBm

11970W: -1 dBm

5061-5458 Cable Insertion Loss:

.8 dB at 2 GHz

1.1 dB at 6 GHz

Z

51 mm

2.0 in

51 mm

2.0 in

51 mm

2.0 in

90 mm

3.5 in

71 mm

2.8 in

76 mm

3.0 in

General Information

11970U

11970V UG-385/U

11970W

UG-383/U-M

WR-19

WR-15

UG-387/U-M

WR-10

0.14 kg

0.32 lb

0.14 kg

0.32 lb

0.14 kg

0.32 lb

36 mm

1.4 in

36 mm

1.4 in

36 mm

1.4 in

51 mm

2.0 in

51 mm

2.0 in

51 mm

2.0 in

1. Waveguide attachment screws enter blind holes in the flanges of the mixers.

Chapter 1 15

76 mm

3.0 in

76 mm

3.0 in

76 mm

3.0 in

Page 16

General Information

Specifications

General Information

16 Chapter 1

Page 17

2 Operation

Operation

17

Page 18

Operation

Introduction

Introduction

This section provides information on how to make effective use of the 11970 mixers.

Operating Precautions

Refer to the sections below for specific pa r ameters to follow prior to m i xer operation.

WARNING Do not exceed the maximum ratings listed below or permanent

damage to the mixer will result.

RF Input Power

Use the following parameters:

CW: No greater than 20 dBm

Pulse: No greater than 24 dBm at < 1 mSec

Average: No great e r th a n 20 dBm

LO Input Power

Make sure the LO input power is no greater than 20 dBm.

Electrostatic Discharge

When installing the mixer, you must always connect the SMA cables to the spectrum

analyzer and LO amplifier BEFORE connecting them to the mixer. This will minimize the

danger of an electrostatic discharge damaging the mixer diodes.

Operation

11975A ALC Switch

BEFORE using the 11975A Amplifier to increase the LO input power, set the amplifier

ALC switch to the ON position. When this switch is in the OFF position the LO power can

be greater than 20 dBm. This level of LO power can destroy the mixer diodes. The ALC

switch is on the amplifier rear panel.

Waveguide Protective Foam

Do not remove, displace, or damage the white, nonconductive foam installed in the ope n

end of the waveguide. Since the mixer is amplitude calibrated with this foam in place,

tampering with it affects the calibration.

18 Chapter 2

Page 19

Operation

Getting Started

Getting Started

The 11970 series of millimeter wave mixers ha ve no bias or back-s hort adjustment s. 11970

Mixers require an LO power of 14 to 18 dBm at the LO input. If the spectrum analyzer

used with the 11970 does not have sufficient LO power, an 11975A Amplifier or an

equivalent is required to increase this power.

CAUTION Before connecting the 11975A Amplifi er, set its rear panel ALC switch to ON.

Failure to do this can damage the mixer.

Mixer Connections

With the three SMA cables (Part Number 5061-5458, each) provided in the Option 009

Mixer Connection Kit, connect the 11970 Mixer, the spectrum analyzer, and the 11975A

Amplifier. An example connection for an 8566B Spectrum Analyzer is shown in Figure 2-1.

NOTE The example below shows an 8566B analyzer, other spectrum analyzers do

not require the amplifier and third SMA cable.

Figure 2-1. 11970 Mixer Connections

Leave the waveguide flange cap on whenever the mixer is not connected to a device under

test. This protects the flange mating s urface from scrat ches , which can degrade th e mixer’s

performance. Use an appropriate waveguide attenuator if the output power of the unit

under test exceeds the RF Input Power indicated in the specifications.

Operation

Chapter 2 19

Page 20

Operation

Getting Started

If you are using an 11970Q, 11970U, 11970V or 11970W Mixer, and the shoulder of its waveguide

flange is not properl y a ligned with th e flan ge of t he de vi ce unde r t est, amplit ude measure ment err ors ca n

result. To ensure proper alignment, tighten each of the four flange screws in turn by small amounts,

moving clockwise around the flange.

NOTE 11970K and 11970A Mixers require flange screws that are different from

those used with the 11970Q, 11970U, 11970V and 11970W; 11970K and

11970A use Part Number 3030-0221 (#4-40 hex head screw). 11970Q,

11970U, 11970V and 11970W use Part Number 1390-0671 (#4-40 hex head

captive sc re w ) .

Operation

20 Chapter 2

Page 21

Operation

Using a Conversion-Loss Data Disk with the ESA or PSA Series Analyzers

Using a Conversion-Loss Data Disk with the ESA or PSA

Series Analyzers

The conversion-loss data for your mixer can be quickly lo aded in the memory of an ESA or

PSA series analyzer from a floppy disk. The following process works with the floppy disk

provided by the factory with your new mixer, or with one that you have st ored the

correction data. This process eliminates the time consuming and sometimes error-prone

process of manually entering the data from a table.

Loading Data

1. Insert the conversion-loss data disk (fr om th e factory or your own) into the floppy drive

of the analyzer.

2. Press

3. Press

4. Press

5. Use the down arrow to select the file. The factory supplied disk has a file with the OTH

extension which places the data in the corrections set “other” location.

6. Press

analyzer.

File, then Load.

Type, More, then select Corrections.

Directory Select, highlight drive -A-, then press Directory Select again.

Load Now to load the conversion loss values into the correction table of the

Viewing Data

1. Press Amplitude, More, Corrections, Other (ON) and Edit to view the correction values.

2. Use the front-panel knob or up/down arrows to scroll through the lis t of correction

values.

Operation

Chapter 2 21

Page 22

Operation

Using the Mixers with the E4407B Spectrum Analyzer (Option AYZ)

Using the Mixers with the E4407B Spectrum Analyzer

(Option AYZ)

The Agilent Technologies E4407B spectrum analyzer contains an extensive menu of

functions that help with millimeter measure ments . The foll owing examples explain how to

connect external mixers to the spectrum analyzer, how to choose the ba nd of interest, how

to store and activate conversion-loss factors, and how to use the signal-identification

functions.

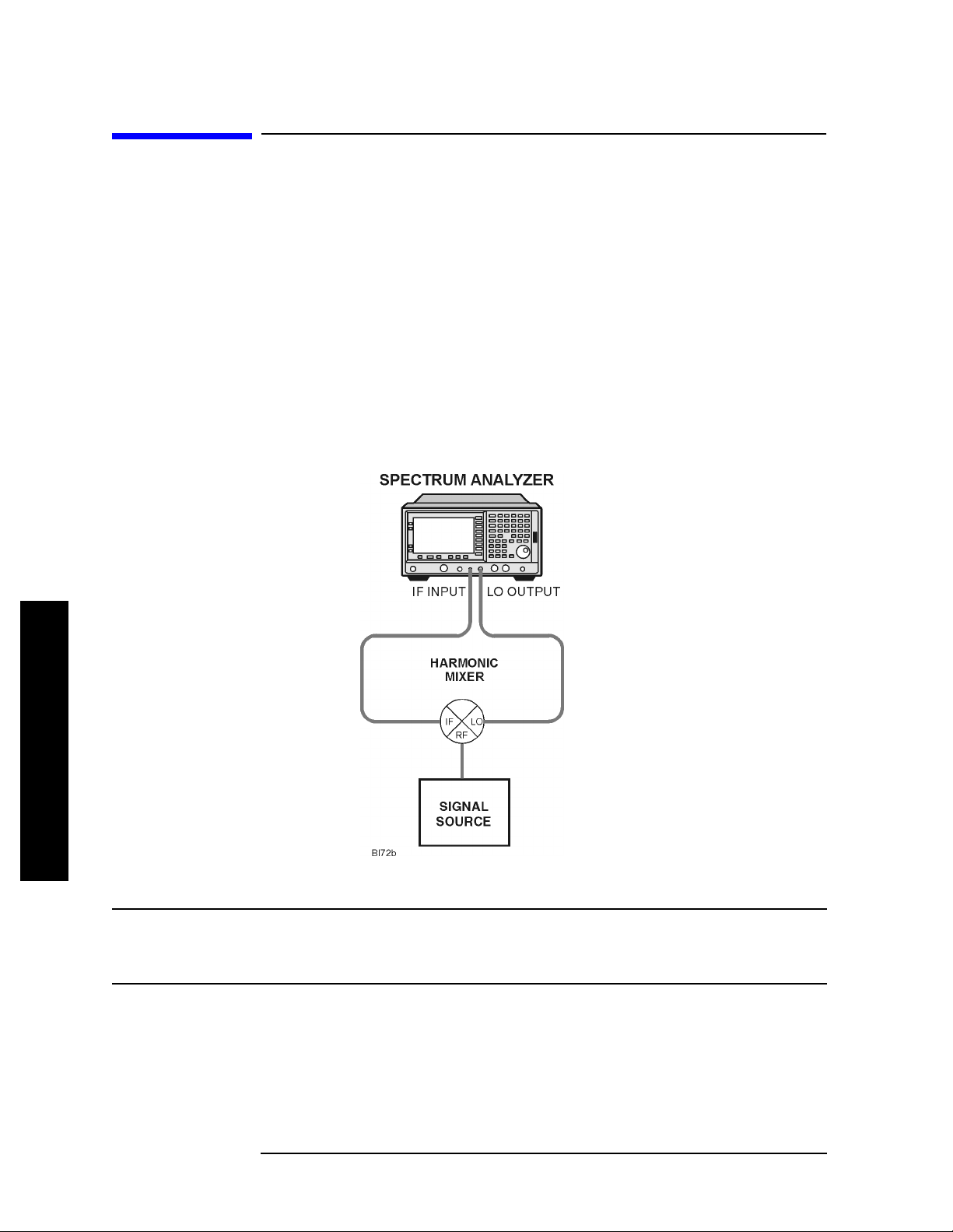

Set up the equipment

1. Connect the signal source and harmonic mixer to the analyzer, as shown in Figure 2-2.

Figure 2-2 Harmonic Mixer Setup

Operation

NOTE Agilent 5061-5458 SMA type cables should be used to connect the mixer IF

and LO ports to th e an a l y z e r. Do not over-tighten the ca b l es. The ma x i m u m

torque should not exceed 112 N-cm (10 in-lb.)

22 Chapter 2

Page 23

Using the Mixers with the E4407B Spectrum Analyzer (Option AYZ)

2. On the analyzer, press Preset, Factory Preset, if present.

Operation

3. Select external mixing by pressing

4. The analyzer frequency band will be set to

Ext Mix Band , then press the desired band frequency range/letter key. For this

press

Input/Output, Input Mixer, Input Mixer (Ext).

26.5 - 40 GHz (A). To choose a different band,

example, we will use band A, which ranges from 36.5 GHz to 40 GHz.

Amplitude Calibration

The conversion loss versus frequency data can be entered on your analyzer from one of

three sources.

• From a Conversion Loss Data Disk, supplied with your mixer . See “Using a

Conversion-Loss Data Disk with the ESA or PSA Series Analyzers” on page 21 .

• Data from the calibration sheet supplied with your mixer.

• From conversion-loss data located on the mixer bo dy label.

Manually Enter i ng Co n v er sio n -L os s D ata

1.The analyzer frequency band will be set to

Ext Mix Band and then press the desired band frequency range/letter key. For this

press

26.5 – 40 GHz (A). To choose a different band,

example, we will use band A, which ranges from 26.5 GHz to 40 GHz.

NOTE To correct for the conversion-loss of the harm onic mixer in use, the analyzer

amplitude correction feature is used .

2. Press

external mixing. The recommended set to use is

AMPLITUDE Y Scale, More , Corrections. Select a correction set for use with

Other although any available set could

be used.

3. Press

Edit to enter the appropriate conversion loss data for the mixer in use. These

values are listed on the mixer, or a calibration sheet that is supplied with the mixer.

NOTE More correction points entered across the band in use will improve frequency

response accuracy. Up to 200 points may be defined for each set.

4. Once the desired correction points are entered, press

correction set

Other. This will also turn corrections on resulting in a calibrated display.

Return, Correction (On) to activate

It is recommended that the correction set entered be saved on the internal memory or

the floppy dr ive for futur e reference. See th e ES A User’s and Programmer’s Reference

guide for information on saving correction values.

Operation

Chapter 2 23

Page 24

Operation

Using the Mixers with the E4407B Spectrum Analyzer (Option AYZ)

Signal Identification

The IF output of a harmonic mixer will contain a signal at the intermediate frequency of the

analyzer whenever the harmonic frequency of the LO and the frequency of the RF differ by the

intermediate frequency.

As a result, within a single harmonic band, a single input signal can produce multiple responses on

the analyzer display, only one of which is valid (see Figure 2-3.). These responses come in pairs,

where members of the valid response pair are separated by 642.8 MHz and either the right-most

(for negative harmonics) or left-most (for positive harmonics) member of the pair is the correct

response.

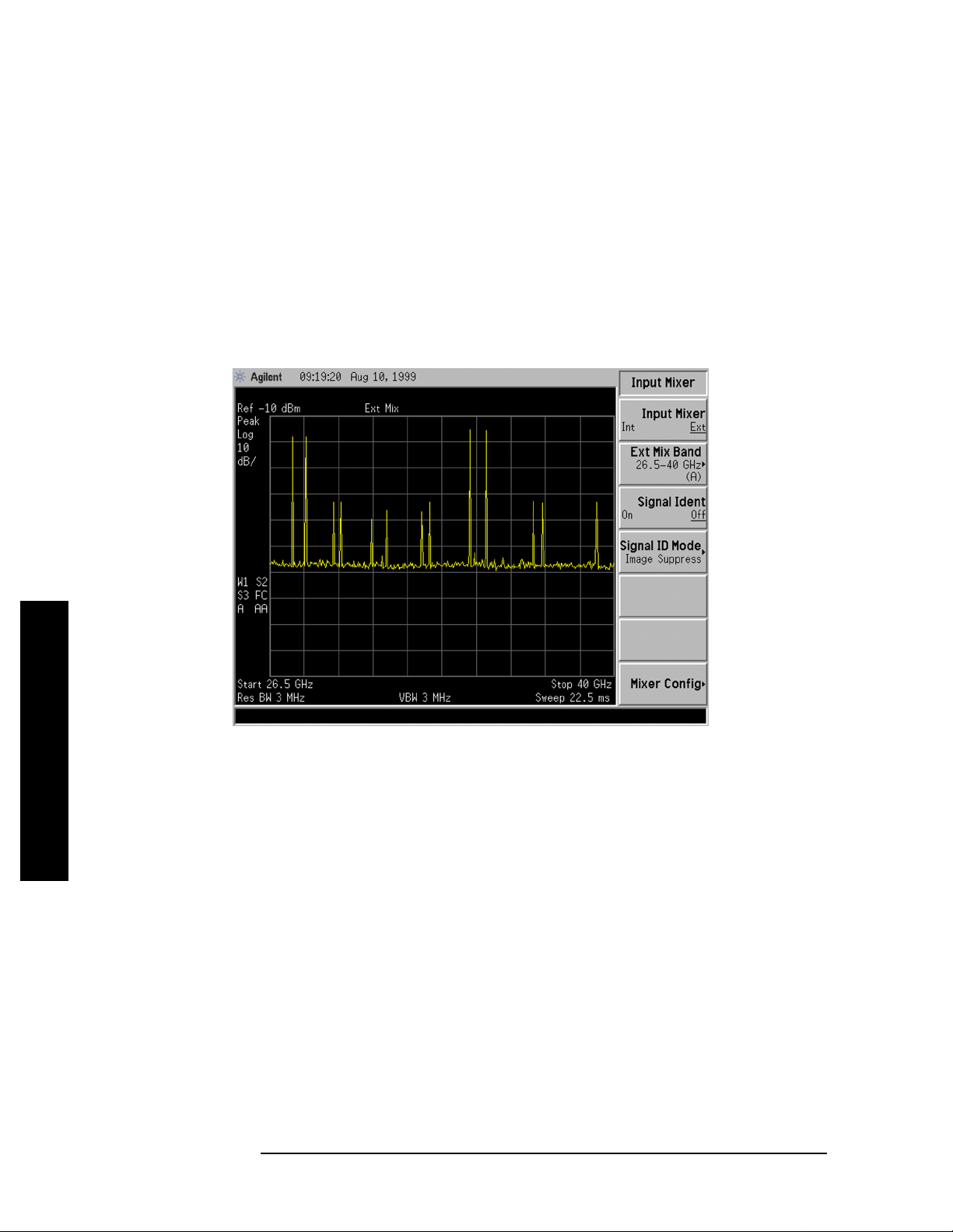

Figure 2-3.

Operation

Identification of valid responses is achieved by simply turning on the signal-identification feature.

(instrument preset selects the Image Suppress signal identification mode.) Press

Mixer

, Signal Ident (On) and note that now only the valid response (35 GHz) remains.

Press

Peak Search to place a marker on the remaining response. The signal-identification routine

Input/Output, Input

can introduce slight amplitude errors which is indicated by the message Signal Ident On,

Amptd Uncal. Refer to Figure 2-4..

After identifying a signal of interest, press

Signal Ident (Off) before making final amplitude

measurements. Note that Image Suppress should only be used to identify the fundamental signal

and not for accurate amplitude measurements.

24 Chapter 2

Page 25

Figure 2-4.

Operation

Using the Mixers with the E4407B Spectrum Analyzer (Option AYZ)

Operation

Chapter 2 25

Page 26

Operation

Using the Mixers with the E4440A, E 4446A, or E 4448A P SA Series Spectrum Anal yzer ( Option AYZ)

Using the Mixers with the E4440A, E4446A, or E4448A

PSA Series Spectrum Analyzer (Option AYZ)

Be sure to refer to “Spectrum Analyzer Retrofit Requirements” on page 9 for instrument

requirements for the PSA Series spectrum analyzers . The Agilent Technologies PSA Ser ies

spectrum analyzers contain an extensive menu of functions that help with millimeter

measurements. The following examples explain how to connect external mixers to the

spectrum analyzer, how to choose the band of interest, how to store and activate

conversion-loss factors, and how to use the signal-identification functions.

Set up the equipment

1. Connect the signal source and harmonic mixer to the analyzer, as shown in Figure 2-2.

Figure 2-5 Harmonic Mixer Setup

Spectrum Analyzer

IF INPUT

1st LO OUTPUT

Operation

SIGNAL

SOURCE

unpremix5

NOTE Agilent 5061-5458 SMA type cables should be used to connect the mixer IF

and LO ports to th e an a l y z e r. Do not over-tighten the ca b l es. The ma x i m u m

torque should not exceed 112 N-cm (10 in-lb.)

SMA Cable

SMA Cable

RF Input

IF

LO

Agilent 11970 SERIES

HARMONIC MIXER

26 Chapter 2

Page 27

Using the Mixers with the E4440A, E4446A, or E4448A PSA Series Spectrum Analyzer (Option

2. On the analyzer, press Preset, Factory Preset, if present.

Operation

AYZ)

3. Select external mixing by pressing

4. The analyzer frequency band will be set to

Ext Mix Band , then press the desired band frequency range/letter key. For this

press

Input/Output, Input Mixer, Input Mixer (Ext).

26.5 - 40 GHz (A). To choose a different band,

example, we will use band A, which ranges from 36.5 GHz to 40 GHz.

Amplitude Calibration

The conversion loss versus frequency data can be entered on your analyzer from one of

three sources.

• From a Conversion Loss Data Disk, supplied with your mixer . See “Using a

Conversion-Loss Data Disk with the ESA or PSA Series Analyzers” on page 21 .

• Data from the calibration sheet supplied with your mixer.

• From conversion-loss data located on the mixer bo dy label.

Manually Enter i ng Co n v er sio n -L os s D ata

1.The analyzer frequency band will be set to

Ext Mix Band and then press the desired band frequency range/letter key. For this

press

26.5 – 40 GHz (A). To choose a diff erent band,

example, we will use band A, which ranges from 26.5 GHz to 40 GHz.

NOTE To correct for the conversion-loss of the harm onic mixer in use, the analyzer

amplitude correction feature is used .

2. Press

external mixing. The recommended set to use is

AMPLITUDE Y Scale, More , Corrections. Select a correction set for use with

Other although any available set could

be used.

3. Press

Edit to enter the appropriate conversion loss data for the mixer in use. These

values are listed on the mixer, or a calibration sheet that is supplied with the mixer.

NOTE More correction points entered across the band in use will improve frequency

response accuracy. Up to 200 points may be defined for each set.

4. Once the desired correction points are entered, press

correction set

Other. This will also turn corrections on resulting in a calibrated display.

Return, Correction (On) to activate

It is recommended that the correction set entered be saved on the internal memory or

the floppy dr ive for futur e reference. See th e ES A User’s and Programmer’s Reference

guide for information on saving correction values.

Operation

Chapter 2 27

Page 28

Operation

Using the Mixers with the E4440A, E 4446A, or E 4448A P SA Series Spectrum Anal yzer ( Option

AYZ)

Signal Identification

The IF output of a harmonic mixer will contain a signal at the intermediate frequency of the

analyzer whenever the harmonic frequency of the LO and the frequency of the RF differ by the

intermediate frequency.

As a result, within a single harmonic band, a single input signal can produce multiple responses on

the analyzer display, only one of which is valid (see Figure 2-6.). These responses come in pairs,

where members of the valid response pair are separated by 642.8 MHz and either the right-most

(for negative harmonics) or left-most (for positive harmonics) member of the pair is the correct

response.

Figure 2-6.

Operation

Identification of valid responses is achieved by simply turning on the signal-identification feature.

(instrument preset selects the Image Suppress signal identification mode.) Press

Mixer

, Signal Ident (On) and note that now only the valid response (35 GHz) remains.

Press

Peak Search to place a marker on the remaining response. Refer to Figure 2-7.

After identifying a signal of interest, press

Signal Ident (Off) before making final amplitude

Input/Output, Input

measurements. Note that Image Suppress should only be used to identify the fundamental signal

and not for accurate amplitude measurements.

28 Chapter 2

Page 29

Figure 2-7.

Operation

Using the Mixers with the E4440A, E4446A, or E4448A PSA Series Spectrum Analyzer (Option

AYZ)

Operation

Chapter 2 29

Page 30

Operation

Using the Mixers with the 856X Series Spectrum Analyzers

Using the Mixers with the 856X Series Spectrum Analyzers

External millimeter mixers can be used to extend the frequency coverage of the 8560

E-Series and EC-Series spectrum analyzers. (The 8560E/ EC Option 002 and Option 327 do

not have external mixing capability.)

The 8560 E-Series and EC-Series spectrum analyzers contain an extens ive me nu of

functions that help with millimeter measurements. This example explains how to connect

external mixers to the spectrum analyzer, how to choose the band of interest, how to store

conversion-loss factors, and how to use the optional automat i c sig nal-identification

functions.

Set up the equipment

1. Figure 2-8 illustrates how to connect an external harmonic mixer to the s pectrum

analyzer.

Figure 2-8 External Mixer Setup

Operation

NOTE Good-quality shielded SMA-type cable s should be used to connect the mixer t o

the spectrum analyzer to ensure that no signa l attenuation occurs. Agilent

5061-5458 SMA-type cables may be used. Do not over-tighten the cables; the

maximum torque should not exceed 112 N-cm (10 in-lb.) .

30 Chapter 2

Page 31

Operation

Using the Mixers with the 856X Series Spectrum Analyzers

Select the Frequency Band

2. Specify unpreselected external mixing by pressing CONFIG, then EXT MXR PRE UNPR

until UNPR is selected.

3. To select a frequency above 18 GHz:

a. Press

AUX CTRL, EXTERNAL MIXER to set the analyzer to external mixer mode.

b. Enter the desired frequency directly using the center-frequency function.

c. Notice i n Table 2-1 that some frequencies overlap and fall into two bands. To be sure

that the desi re d band is select ed , re f e r to Table 2-1 and select the desired frequency

band, then use the full band function to enter this band.

d. In the external mixer menu, press

FULL BAND, then press the step up ⇑ key until the

letter preceding BAND in the active function area corresponds to the desired

frequency band.

Table 2-1 External Mixer Frequency Ranges

Frequency

Band

K 18.0 to 26.5 6

A 26.5 to 40.0 8− 30 dB

Q 33.0 to 50.0 10

U 40.0 to 60.0 10

V 50.0 to 75.0 14− 30 dB

E 60.0 to 90.0 16

Frequency

Range (GHz)

Mixing

Harmonic

− 30 dB

− 30 dB

− 30 dB

− 30 dB

Conversion

Loss

Operation

W 75.0 to 110.0 18

F 90.0 to 140.0 24− 30 dB

D 110.0 to 170.0 30

G 140.0 to 220.0 36

Y 170.0 to 260.0 44− 30 dB

J 220.0 to 325.0 54

Chapter 2 31

− 30 dB

− 30 dB

− 30 dB

− 30 dB

Page 32

Operation

Using the Mixers with the 856X Series Spectrum Analyzers

In this example, we’ll look at U-band, which ranges from 40 GHz to 60 GHz, as shown in

Figure 2-9. The

ensuring that the spectrum analyzer sweeps onl y the chosen band.

automatica l l y se t to O N when

LOCK HARMONIC function “locks” the spectrum analyzer in that band,

LOCK ON OFF is

FULL BAND is pressed.

Figure 2-9 Select the band of interest.

Save the average conversion-loss value

4. Default conversion-loss values that are stored in the analyzer for each fre quency band

are listed in Table 2-1. These values approximate the values for the Agilent 11970 series

Operation

mixers. Other conversion-loss values may be entered into the spectrum analyz er in two

ways. The first method lets you to save the average conversion-los s value for the entire

band using

a. Press

A VERAGE CNV LOSS. To activate this function:

AUX CTRL, EXTERNAL MIXER, AMPTD CORRECT, AVERAGE CNV LOSS.

b. Enter the appropriate average conversion-loss value. On Agilent 11970 Series

harmonic mixers, these values are printed on the mixer. The U-band mixer used for

this example had an average conversion loss of 23.5 dB, as shown in Figure 2-10.

32 Chapter 2

Page 33

Using the Mixers with the 856X Series Spectrum Analyzers

Figure 2-10 Store and correct for conversion loss.

Operation

The second method for storing conversion-loss information lets you save individual

conversion-loss data points at specific intervals across the harmonic band, using

LOSS VS FREQ

.

CNV

To view or enter a conversion-loss data point:

a. Press

CNV LOSS VS FREQ.

b. Enter the conversion-loss data at the frequency shown.

c. Use the step up

⇑ key to step through the band, entering the conve rsion loss at each

step.

Signal Identification

5. The IF output of a harmonic mixer contains many mixer products (frequencies of LO ±

source, 2LO

harmonic band, a single input signal can produce many responses, only one of which is

valid.

These responses come in pairs, where the members of the valid pair are spaced 621.4

MHz apart (see Figure 2-11) and the right-most member for the pair is the correct

response (for this analyzer, the left member of a pair is not valid).

± source, 3LO ± source…nLO ± source). As a result, within a single

Operation

Chapter 2 33

Page 34

Operation

Using the Mixers with the 856X Series Spectrum Analyzers

Figure 2-11 Signal Responses Produced by a 50 GHz Signal in U Band

Identify signals with the frequency-shift method

6. Signal-identification routines that identify the signal and images are available on

instrument s w i th fi r m wa re re v isi ons

method of identifying valid signal s uses the spectrum-analyzer function

When using this function, smaller spans will yield more accurate measurements.

a. Span down to 50 MHz.

Operation

b. Press

c. Press

AUX CTRL, EXTERNAL MIXER, SIGNAL IDENT.

SIG ID ON OFF until ON is selected.

Any signal not produced by the currently se lected harmonic will be shifted horizontally

on alternate sweeps (see Figure 2-12). Therefore, when viewing the display, on alternate

sweeps the signal will app ear, then not appear, at the frequency of interest. The correc t

signal produced by the selected harmonic will be shifted in a vertical direction only, as

shown in Figure 2-13.

≤920528, or with Option 008. The frequency-shift

SIG ID ON OFF.

34 Chapter 2

Page 35

Figure 2-12 Response for Invalid Signals

Operation

Using the Mixers with the 856X Series Spectrum Analyzers

Figure 2-13 Response for Valid Signals

Operation

Chapter 2 35

Page 36

Operation

Using the Mixers with the 856X Series Spectrum Analyzers

Identify signals in wide frequency spans

SIG ID AT MKR identifies signals in wide frequency spans, using harmonic search. SIG ID

7.

AT MKR

automatically determines the proper frequency of a signal and displays its

value on the spectrum analyzer.

• Activating

SIG ID AT MKR on an image of the signal will yield a reading in the active

block, as shown in Figure 2-14. The true signal frequency is given with an identifier

that the marker resides on an image. If the marker is placed on a true signal, and

SIG ID AT MKR is activated, the si g nal frequency will appear without the IMAGE

notation, as shown in Figure 2-15.

8. To activate

SIG ID AT MKR:

a. Place a marker on a signal.

b. Press

9. To exit the external mixer mode, press

Figure 2-14

AUX CTRL, EXTERNAL MIXER, SIGNAL IDENT, SIG ID AT MKR.

AUX CTRL, then INTERNAL MIXER.

SIG ID AT MKR Performed on an Image Signal

Operation

36 Chapter 2

Page 37

Using the Mixers with the 856X Series Spectrum Analyzers

Figure 2-15 SIG ID AT MKR P erformed on a True Signal

Operation

Operation

Chapter 2 37

Page 38

Operation

Using the Mixers with MMS Analyzers

Using the Mixers with MMS Analyzers

Preliminary Operation

NOTE This section provides information for the Agilent 70907A (or B), however the

operation of the Agilent 70909A and Agilent 70910A is similar. Minor

differences may be noted , but the necessary deviations from these exact

instructions will be obvious.

Equipment Connection

Connect the equipment as shown in Figure 2-16 Use the following checklist to verify the

connections:

• Agilent 11970 LO IN to Agilent 70907B LO OUTPUT (SMA cable, 5061-5458)

• Agilent 11970 IF OUT to Agilent 70907B IF INPUT (SMA cable, 5061-5458)

Figure 2-16 Agilent 11970 Connections to the Agilent 71000 Series Spectrum Analyzer

Operation

38 Chapter 2

Page 39

Operation

Using the Mixers with MMS Analyzers

Operation

Band Selection

Use the following key sequence to enter the external mixing mode and to select the desired

band of operation:

MENU

Select Input

State

ext mixer

fulband KAQUVE

- choose external mixer input, for example: “IN 2 EM 70910A”

Press the softkey for the desired band.

NOTE The above band selection key sequence must be used to enter the external

mixing band of operation. Do not enter in the center frequency of the band

directly.

Amplitude Calibration for a Single Frequency

Enter the conversion loss at the desired frequency from either the calibration label on the

end of the Agilent 11970 or the supplied calibration sheet by using the following key

sequence:

State

ext mixer

Operation

CONV LOSS

Enter the conversion loss value of the desired frequency, then terminate the entry with dB.

NOTE The above procedure is a single-point conversion-loss correction. For an

alternative procedure, available by remote programming only, refer to

“Conversion Loss Versus Frequency Correction” on page 43.

Chapter 2 39

Page 40

Operation

Using the Mixers with MMS Analyzers

General Descriptions of Agilent 71000 Series Spectrum Analyzer

External-Mixing Functions

ext mixer Allows access to the following softkey func tions that control the

measurement range when an external mixer extends the

ext mixer softkey can be

fulband KAQUVE

spectrum analyzer frequency range. The

found under the

fulband KAQUVE

fulband WFDGYJ

CONV LOSS

SIGNAL IDENT

State key.

and

fulband WFDGYJ Specify the frequency range for measurements made with

external mixers. Twelve frequency bands are available. Table 2-2

lists the start and stop frequencies of each band and also shows

which local-oscillator harmonic (N) is used for the mixing process .

Once a band is selected, the frequency range is locke d and the

spectrum a n a l y z er tunes with the local-o s c i l la tor harmon i c for

that band only.

Table 2-2 External Mixing Bands and Associated Mixing Harmonics

Band Harmon ic Number (N) Frequency Range (GHz)

K6

A 8+ 26.5 to 40.0

Operation

Q 10+ 33.0 to 50.0

U 10+ 40.0 to 60.0

V 14+ 50.0 to 75.0

E 16+ 60.0 to 90.0

W 18+ 75.0 to 110.0

F 24+ 90.0 to 140.0

D 30+ 110.0 to 170.0

G 36+ 140.0 to 220.0

Y 42+ 170.0 to 260.0

J 50+ 220.0 to 330.0

− 18.0 to 26.5

40 Chapter 2

Page 41

Operation

Using the Mixers with MMS Analyzers

CONV LOSS

(conversion loss) Offsets the reference level to compens ate for amplitude losses at

the active input port. If necessary, use

select input to activate the

desired inp u t po rt before spec i fying its conv e rsion-loss of fset.

To clear the offset, enter a conversion loss of zero.

After the instrument preset, a default value of 30 dB is activated

automatically for the input port of the external-mixer-interface

module.

Preset Input Sets which active input port will be selected when the INSTR

PRESET

pressing

INSTR PRESET R esets to the preset input and to the lowest full frequency range

is pressed. The preset input softkey can be accessed by

State, then MORE.

available. (For an external mixer, this is band A.) This is a front

panel key.

SIGNAL IDENT

(signal i dentify) Press Frequency, More, sig id options.

Executes a routine to identify real, in-band signals using either

the image (default) or shift methods.

Several options are available under

SIG ID ⇒ CF Places the marker on the identified real signal and

-

sig id options:

centers the signal on the display.

SIG ID MAN OFF Selects manual or automatic (default) mode.

-

-

IMAGE/SHIFT Selects the routine to use for identification.

-

SIG ID AMPTD ∆ Specifies the amplitude difference between the

marked signal and signals tested as images or

harmonics (default is 10 dB; applies only to IMAGE

mode.)

IMAGE N START Determines the frequency range for possibl e image or

harmonic responses by sele cting the lowest and

highest local oscillator harmonic used for mixing,

according to the tuning equation below:

= N x FLO ± IF

F

s

Default is 1.

-

IMAGE N STOP See “IMAGE N START” definition above.

Operation

Default is 40.

Chapter 2 41

Page 42

Operation

Using the Mixers with MMS Analyzers

NOTE See the tabl e below for available frequency ranges and related harmonic numbers. Use

the IMAGE N START and IMAGE N STOP softkeys for the image identification only.

Table 2-3 Frequency Ranges and Corresponding Harmonic Numbers

Band/Range Harmonic Number and Sign of

IF (N)

Internal Mixing - Agilent

71210C

Internal Mixing - Agilent

71200C

External Mixing - Agilent

70907A

7090

7B

709

10A

709

09A

2.9 - 6.2

6.0 - 12.7

12.5 - 19.9

19.7 - 22.0/26.5

2.9 - 6.2

6.0 - 12.8

12.6 - 22.0

K 18.0 - 26.5

A 26.5 - 40.0

Q 33.0 - 50.0

U 40.0 - 60.0

V 50.0 - 75.0

E 60.0 - 90.0

W 75.0 - 110.0

F 90.0 - 140.0

D 110.0 - 170.0

G 140.0 - 220.0

Y 170.0 - 260.0

J 220.0 - 330.0

−1

−2

+3

+4

−1

−2

−4

+6

+8

+10

+10

+14

+16

+18

+24

+30

+36

+42

+50

Operation

42 Chapter 2

Page 43

Operation

Using the Mixers with MMS Analyzers

Conversion Loss Versus Frequency Correction

The Agilent 71000 Series Spectrum Analyzers with the Agilent 70907A (or B) External

Mixer Interface Module installed has the am plitude-correction function (AMPCOR)

available by remote programming.

Use AMPCOR to compensate for the Agilent 11970 Series frequency-dependent

conversion-loss variations. Up to 200 pairs of frequency-amplitude correction p oints can be

entered, depending on the amount of available internal memory. The frequency values

entered must be in increasing order, or an error condition results. Whenever AMPCOR is

on, the correction values are added to all measurement results.

The values of the correction points are applied across the active measurement range.

Between points, the correction value are interpolated. When the measuring at frequencies

outside of the first and last correction pairs from memory.

When AMPCOR is executed, the frequency pairs are stored in internal memory. The

remote commands DISPOSE ALL, FORMAT, ERASE, and DISPOSE AMP COR erase the

amplitude-correction pairs from memory.

NOTE DISPOSE ALL, FORMAT, and ERASE erases much more than the

amplitude-correction pairs from memory. Do not use these commands without

referring to the programmer’s manual for the Agilent 70000 and Agilent

70900B to determine their effect on instrument programming.

Because AMPCOR adjusts IF gain and attenuation, AMPCOR should be used with care

when measuring signals near the compression level (also at a frequency that is corr ected

by the AMPCOR command).

To use AMPCOR for the Agilent 11970 conversion los s c orrection, first set the single- point

conversion loss function to zero with the following command:

OUTPUT 718; “CNVLOSS 0DB;”

Then build the AMPCOR table with frequency conversion loss pairs. The following

example program line shows three pairs of frequency conversion loss values for a typical

Agilent 11970V.

OUTPUT 718; “AMPCOR 50GHZ, 49.6DB, 51GHZ, 49.1DB, 52GHZ,48.6DB;”

The conversion loss corrections are activated by the AMPCOR ON command; use

AMPCOR OFF to deactivate the function (be sure to manually enter a single-point

conversion-loss value if AMPCOR has been used).

Operation

Chapter 2 43

Page 44

Operation

Using the Mixers with MMS Analyzers

To pr int out an existing AMPCOR table, use the program listed below:

10 dim A$ (1:20) [30]

20 OUTPUT 718; “CONVLOSS 0DB;”

30 OUTPUT 718; “AMPCOR 50 GHZ, 46.1DB, 52GHZ, 46.7DB, 53GHZ,47.2DB;”

40 !

50 OUTPUT 718; “AMPCOR?;”

60 ENTER 718 USING “%,k”;A$ (*)

70 !

80 FOR I=1 TO 10

90 PRINT “Point “;I,A$ (I)

100 NEXT I

110 END

Line 30: Generates an AMPCOR table.

Line 60: % specifies that an EOI terminates the en tire stat ement. “K” specifie s that

an

terminates the individual string entry.

L

F

Returned values are in the format where the frequen cy in Hz is listed first, fo llowed by the

conversion loss in dB . See the following example:

Point 1 50.00000000E+9,46.1

Point 2 52.00000000E+9,46.7

Point 3 53.00000000E+9,47.2

Point 4

Point 5

Point 6

Point 7

Point 8

Point 9

Point 10

Operation

Point 11

NOTE For further information, consult the Agilent 70900B

Local-Oscillator-Controlled Modules Programming Manual, part number

70900-90284.

44 Chapter 2

Page 45

Operation

Using the Mixers with the 8566B Spectrum Analyzer

Using the Mixers with the 8566B Spectrum Analyzer

Set up the equipment

1. Co n nect the exte r n a l harmonic m i x e r to the spectr u m a n a lyzer, as shown in Figure 2-17.

NOTE Good-quality shielded SMA-type cable s should be used to connect the mixer t o

the spectrum analyzer to ensure that no signa l attenuation occurs. Agilent

5061-5458 SMA-type cables may be used. Do not over-tighten the cables; the

maximum torque should not exceed 112 N-cm (10 in-lb .).

Figure 2-17

External Mixer Connection

Operation

CAUTION Before connecting the Agilent 11975A Amplifier, set the ALC switch to ON.

Failure to do so can damage the mixer.

2. Power up the spectrum analyzer and then the amplifier.

3. Adjust the amplifier power to 16 dBm.

4. To access the spectrum analyzer’s millimeter bands, press

⇑

until the desired band is displaye d on the screen, as shown in Figure 2-18. Note that

SHIFT and then the up arrow

this is important because toggling throu gh the bands , causes the band to autom atically

harmonic lock as evidenced by the on-screen annotatio n of “Harmonic 6” changing to

Chapter 2 45

Page 46

Operation

Using the Mixers with the 8566B Spectrum Analyzer

“Harmonic 6L”, where “L” stands for locked, or you could press Shift+z to manually

harmonic lock.

Figure 2-18

TYPICAL MILLIMETER SIGNAL DISPLAY

A menu of millimeter measurement functions is accessed by pressing SHIFT, 1, MHz. Even

though the spectrum analyzer is in an external mixer band, the 8566B spectrum analyzer

retains full operation capabil ity (except for use of the RF input attenuator and prese lector).

Amplitude Calibration

Procedure

Operation

Each 11970 series harmonic mixer is characterized at the factory and comes with a

calibration chart (See Figure 2-19). The horizontal axis of the chart gives the frequency

range of the mixer and the two vertical axis scales are calibrated in conversion loss and in

reference level offset.

To correct the amplit ude calibrati on of the spectrum analyzer to account for the conv ersi on

loss of the harmonic mixer, press

SHIFT, 5, MHz to access conversion loss entry and key in the appropriat e value on the

press

SHIFT, 1, MHz, which accesses the mil limeter menu . Then

spectrum analyzer as shown on the mixer calibration chart.

For measurements that span the entire band, choose an average value of conversion loss

from the conversion loss chart. For those spectrum analyzers with date codes earlier than

13.8.86, the conversion loss is changed using the ref erence level function. Press

REFERENCE LEVEL, then key in the reference level offset shown on the right side of the

SHIFT, then

mixer calibration chart.

46 Chapter 2

Page 47

Operation

Using the Mixers with the 8566B Spectrum Analyzer

Signal Identification

Figure 2-18 shows a typical full-band display of a single input signal. Direct interpretation

of the display is difficult because of the large number of responses produced by several

local oscillator harmonics generated in the mixer. To solve this problem the 8566B

spectrum analyzer uses two methods of signal identification.

The first is an automatic image search in which the spectrum analyzer looks for a signal

image within a preset range of harmonic numbers. This automatic signal identification

routine is initiated by pressing

appears on the CRT: SIGNAL NOT IDENTIFIED, SIGNAL IDENTIFIED OUT OF BAND (w i t h

the frequency), or CENTER (with the identified signal frequency). The range of harmonic

numbers through which the spectrum analyzer searches can be changed by accessing

“search start HN” and “sea rch st op HN,” which are

respectively.

The second method, manual signal identification, is a fast method of verifying that the

displayed signal is a true signal in the specified band. Press

function. P ositive signal ident ification is ind icated if the signal in question does not change

frequency and is reduced in amplitud e by one to two divisions on alt ernate sweeps . A faile d

signal identification is indicated by the signal disap pear i ng or shifting in frequency.

SHIFT, 3, MHz. Upon completion, one of three messages

SHIFT, 7, MHz and SHIFT, 8, MHz,

SHIFT, 4, MHz to activate this

Operation

Chapter 2 47

Page 48

Operation

Using the Mixers with the 8566B Spectrum Analyzer

Figure 2-19 Sample Mixer Calibration Ta ble

Operation

48 Chapter 2

Page 49

3 Performance Tests

Performance Tests

49

Page 50

Performance Tests

Introduction

Introduction

This section contains instructions for testing the performance of the 11970 Series Mixers.

Performance tests are used to check the mixers at incoming inspection and for periodic

evaluation. The tests verify the specifications listed for the mixers in Table 1-1.

Test equipment required for the performance tests is listed in Table 3-1. for the 11970K,

Table 3-2. for the 11970A, Table 3-3. for the 11970Q, Table 3-4. for the 11970U, Table 3-5. for

the 11970V and Table 3-6. for the 11970W. Test ins truments other than those lis ted may be

used provided their performance equals or exceeds the critical specifications listed in

Tables 3-1 through 3-6.

Test Record

At the end of each test is a test record, which is used for recording the performance test

data. Make copies of these test records and use them as worksheets when doing the tests.

Performance Tests

50 Chapter 3

Page 51

Performance Tests

Performance Test Procedures

Performance Test Procedures

Description

Each performance test procedure is contained in a single paragraph. The first entry in

each paragraph is the specification for the parameter being measured as described in Table

1-1 This is followed by a general description of the test and any special instructions or

problem areas. Appropriate test setup illustrations are included in this section and are

referenced in the proc edures . You MUST do the tests, and the ste ps within eac h tes t, in the

order they are given.

Table 3-1. Recommended Test Equipment for 11907K

Instrument Critical Specifications Recommended Model

Spectrum Analyzer LO and IF ranges compatible with mixer 8566B

Synthesized Sweeper Frequency: 18 to 26.5 GHz

Output Level: >-10 dBm

Amplifier Output Level: >18 dBm leveled

Frequency Range: 3 to 4.5 GHz

Power Meter Compatible with Power Sensor 436A

Power Sensor SWR: <1.3 8485A

Directional Coupler

Isolator Insertion Loss: <1.5 dB

Adapter (2 required) 3.5 mm female to WR-42

Cables (3 required) Connectors: SMA male P/N 5061-5458

Cable Connectors: SMA

1

Coupling: 10 dB

Directivity: >40 dB

Primary Arm SWR: <1.05

Auxiliary Arm SWR: <1.2

Isolation: >20 dB

SWR: <1.2

SWR: <1.1

Loss: <1.0 dB @ 20 GHz

8340A

11975A

K752C

P/N 0960-0081

K281C

P/N 8120-4396

1. Calibration data for the coupling ratio b etween the output arm and the auxiliary

arm is necessary for accurate measurement s.

Performance Tests

Chapter 3 51

Page 52

Performance Tests

Performance Test Procedures

Table 3-2. Recommended Test Equipment for 11970A

Instrument Critical Specifications Recommended

Model

Spectrum Analyzer LO and IF ranges compatible with mixer 8566B

Synthesized Sweeper Frequency: 8 to 13.5 GHz

8340A

Output Level: >0 dBm

Amplifier Output Level: >18 dBm leveled

11975A

Frequency Range: 3 to 5 GHz

Amplifier Frequency Range: 8 to 13.5 GHz

8349A

Output Level >15 dBm

Power Meter Compatible with Power Sensor 436A

Power Sensor SWR: <2.0 R8486A

Power Sensor SWR: <1.3 @ 6 GHz 8485A

Directional Coupler

1

Coupling: 20 dB

R752D

Directivity: >40 dB

Primary Arm SWR: <1.05

Auxiliary Arm SWR: <1.2

Isolator Insertion Loss: <1.5 dB

P/N 0960-0082

Isolation: >20 dB

SWR: <1.2

Frequency Tripler Input Power: >10 dBm minimum

Conversion Loss: <15 dB

Spacekom Microwave

TKa-1

2

Adapter SMA female to SMA female P/N 1250-1158

Adapter SMA female to Type N female P/N 1250-1404

Adapter (2 required) Type N male to SMA female P/N 1250-1250

Cables (3 required) Connectors: SMA male P/N 5061-5458

Cable Connectors: SMA male

P/N 8120-4396

Loss: <1.0 dB @ 20 GHz

Cable Connectors: BNC male 11086A

1. Calibration data for the coupling ration between the output arm and the auxiliary arm is necessary for accurate measurements.

2. Honeywell, Inc. Spacekom Microwave Cente r, Santa Barbara, CA

Performance Tests

52 Chapter 3

Page 53

Performance Tests

Performance Test Procedures

Table 3-3. Recommended Test Equipment for 11970Q

Instrument Critical Specifications Recommended Model

Spectrum Analyzer LO and IF ranges compatible with mixer 8566B

Synthesized Sweeper Frequency: 11.0 to 16.7 GHz

8340A

Output Level: >0 dBm

Amplifier Output Level: >18 dBm leveled

11975A

Frequency Range: 4 to 6 GHz

Amplifier Frequency Range: 11.0 to 16.7 GHz

8349A

Output Level >15 dBm

Power Meter Compatible with Power Sensor 436A

Power Sensor SWR: <2.0 Q8486A

Power Sensor SWR: <1.3 @ 6 GHz 8485A

Directional Coupler

Coupling: 20 dB

Q752D

1

Directivity: >30 dB

Auxiliary Arm SWR: <1.2

Isolator Insertion Loss: <2 dB

Q365A

Isolation: >20 dB

SWR: <1.5

Frequency Tripler Conversion Loss: <20 dB

Spacekom Microwave

TKa-1

Adapter SMA female to Type N female P/N 1250-1404

2

Adapter SMA female to SMA female P/N 1250-1158

Adapter (2 required) Type N male to SMA female P/N 1250-1250

Cables (4 required) Connectors: SMA male P/N 5061-5458

Cable Connectors: SMA male

P/N 8120-4396

Loss: <1.0 dB @ 20 GHz

Cable Connectors: BNC male 11086A

1. Calibration data for the coupling ration between the output arm and the auxiliary arm is necessary for accurate measurements.

2. Honeywell, Inc. Spacekom Microwave Cente r, Santa Barbara, CA

Chapter 3 53

Performance Tests

Page 54

Performance Tests

Performance Test Procedures

Table 3-4. Recommended Test Equipment for 11970U

Instrument Critical Specifications Recommended Model

Spectrum Analyzer LO and IF ranges compatible with mixer 8566B

Synthesized Sweeper Frequency: 13.3 to 20 GHz

8340A

Output Level: > 9 dBm

Amplifier Output Level: > 18 dBm leveled

11975A

Frequency Range: 4 to 6 GHz

Amplifier Frequency Range: 13.3 to 20 GHz

8349A

Output Level >15 dBm

Power Meter Compatible with Power Sensor 432A

Thermistor Mount SWR: <2.0

Hughes

1

45773H-1100

Thermistor Mount SWR: <1.3 @ 6 GHz 478A

Directional Coupler

2

Coupling: 20 dB

U752D

Directivity: >30 dB

Auxiliary Arm SWR: <1.2

Isolator Insertion Loss: <2 dB

U365A

Isolation: >20 dB

SWR: <1.5

Frequency Tripler Conversion Loss: <20 dB

Spacekom Microwave

TKa-1

Adapter SMA female to Type N female P/N 1250-1404

3

Adapter SMA female to SMA female P/N 1250-1158

Adapter (2 required) Type N male to SMA female P/N 1250-1250

Cables (4 required) Connectors: SMA male P/N 5061-5458

Cable Connectors: SMA male

P/N 8120-4396

Loss: <1.0 dB @ 20 GHz

Cable Connectors: BNC male 11086A

1. Hughes Aircraft Co. Electron Dynamics Division, Torrance, CA

2. Calibration data for the coupling ration between the output arm and the auxiliary arm is necessary for accurate measurements.

3. Honeywell, Inc. Spacekom Microwave Cente r, Santa Barbara, CA

Performance Tests

54 Chapter 3

Page 55

Performance Tests

Performance Test Procedures

Table 3-5. Recommended Test Equipment for 11970V

Instrument Critical Specifications Recommended Model

Spectrum Analyzer LO and IF ranges compatible with mixer 8566B

Swept Source Compatible with V-Band Plug-In 8350B

V-Band Source Plug-In Frequency Range: 50 to 75 GHz

Hughes

1

47724H-1510

Output Level: >0 dBm

Amplifier Output Level >18 dBm leveled

11975A

Frequency Range: 4 to 6 GHz

Power Meter Compatible with Power Sensor 432A

Thermistor Mount SWR: <2.0 Hughes 45774H-1100

Thermistor Mount SWR: <1.3 @ 6 GHz 478A

Directional Coupler

2

Coupling: 20 dB

Hughes 45324H-1220

Directivity: >20 dB

Auxiliary Arm SWR: <1.5

Variable Attentuator Range: 0 to 15 dB

TRG

3

510V/385

Adapter SMA female to Type N female P/N 1250-1404

Adapter SMA female to SMA female P/N 1250-1158

Adapter (2 required) Type N male to SMA female P/N 1250-1250

Cables (4 required) Connectors: SMA male P/N 5061-5458

Cable Connectors: SMA male

P/N 8120-4396

Loss: <1.0 dB @ 20 GHz

Cable Connectors: BNC male 11086A

1. Hughes Aircraft Co. Electron Dynamics Division, Torrance, CA

2. Calibration data for the coupling ration between the output arm and the auxil iary

arm is necessary for accurate measurement s.

3. Alpha Industries Inc. TRG Division, Woburn, MA

Chapter 3 55

Performance Tests

Page 56

Performance Tests

Performance Test Procedures

Table 3-6. Recommended Test Equipment for 11970W

Instrument Critical Specifications Recommended

Model

Spectrum Analyzer LO and IF ranges compatible with mixer 8566B

Swept Source Compatible with W-Band Plug-In 8350B

W-Band Source Plug-In Frequency Range: 75 to 110 GHz

Hughes

1

47726H-1510

Output Level: >0 dBm

Amplifier Output Le v el >18 dBm leveled

11975A

Frequency Range: 4 to 6 GHz

Power Meter Compatible with Power Sensor 432A

Thermistor Mount SWR: <2.0 Hughes 45776H-1100

Thermistor Mount SWR: <1.3 @ 6 GHz 478A

Directional Coupler

2

Coupling: 20 dB

Hughes 45326H-1220

Directivity: >20 dB

Auxiliary Arm SWR: <1.5

Variable Attentu ator Range: 0 to 15 dB

TRG

3

W510

Adapter SMA femal e to Ty p e N fe ma l e P/N 1250-140 4

Adapter SMA female to SMA female P/N 1250-1158

Adapter (2 required) Type N male to SMA female P/N 1250-1250

Cables (4 required) Connectors: SMA male P/N 5061-5458

Cable Connectors: SMA male

P/N 8120-4396

Loss: <1.0 dB @ 20 GHz

Cable Connectors: BNC male 11086A

1. Hughes Aircraft Co. Electron Dynamics Division, Torrance, CA

2. Calibration data for the coupling ration between the output arm and the auxiliary arm is necessary for accurate measurements.

3. Alpha Industries Inc. TRG Division, Woburn, MA

Performance Tests

56 Chapter 3

Page 57

Conversion Loss and Frequency Response

Conversion Loss and Frequency Response

Specifications

Conversion Loss:

For a CW RF input power of less than -20 dBm

11970K: 24 dB maximum

11970A: 26 dB maximum

11970Q: 28 dB maximum

11970U: 28 dB maximum

11970V: 40 dB maximum

11970W: 47 dB maximum

Performance Tests

Frequency Response:

For an LO amplitude between 14.5 and 16.0 dBm

11970K: ±1.9 dB

11970A: ±1.9 dB

11970Q: ±1.9 dB

11970U: ±1.9 dB

11970V: ±2.1 dB

11970W: ±3.0 dB

For an LO amplitude between 14.0 and 18.0 dBm

11970K: ±2.8 dB

11970A: ±2.8 dB

11970Q: ±2.8 dB

1197OU: ±2.8 dB

11970V: ±2.8 dB

Performance Tests

11970W: ±4.0 dB

Chapter 3 57

Page 58

Performance Tests

Conversion Loss and Frequency Response

Description

The frequency response and conve rsion loss are checked at four LO power levels. A known

input power is applied to the input of the mixer. The IF output power is measured on the

8566B Spectrum Analyzer. From these measurements, the conversion loss and frequency

response are calculated.

1. Connect an SMA cable from the 1st LO OUTPUT of the spectrum analyzer to the

INPUT of the amplifier. Connect a second SMA cable to the OUTPUT of the amplifier.

2. For 11970K: Zero and c alibrate the power meter. For 11970A, 11970Q, 11970U, 11970V

or 11970W: Connect the 478A Power Sensor to the power meter sensor cables , then zero

the power meter.

3. Set the 8566A/B Spectrum Analyzer controls as follows:

SHIFT, ↑, KSU

FREQUENCY SPAN, 0, Hz

SHIFT

, SWEEP, CONT, KSt

CENTER

, 2, 4, [.] 5, GHz

CAUTION When you are using a 11975A Amplifier with a 11970 Series Mixer, you

MUST set the amplifier rear-panel ALC switch to ON before you connect the

amplifier into the test set up . If the ALC switc h is left in the OFF posit ion, the

amplifier output power is high enough to destroy the mixer diodes.

4. On the 11975A Amplifier, set the rear panel ALC switch to ON, then connect the power

sensor to the free end of the cable installed on the OUTPUT connector of the amplifier.

Set the power meter Cal Factor to the appropriate value for a frequency of 4 GHz.

5. Adjust the amplifier OUTPUT POWER LEVEL for a reading of 14.0 ± 0.1 dBm on the

power meter. Record the LO power in Table 3-7.

6. Set the power meter Cal Factor to 100 percent.

7. Connect the equipment, as shown in Figure 3-1.

CAUTION Make sure the 8349A Amplifier, used in the signal generator system for

11970A, Q and U tests, is set for external leve ling before you turn it on.

Failure to do so may allow the amplifier output to rise about 20 dBm (high

enough to damage the frequency tripler).

8. Set the signal generator for a CW output signal at the frequencies listed below:

11970K: 18.0 GHz

11970A: 26.5 GHz

11970Q: 33.0 GHz

Performance Tests

11970U: 40.0 GHz

58 Chapter 3

Page 59

11970V: 50.0 GHz

11970W: 75.0 GHz

Performance Tests

Conversion Loss and Frequency Response

Chapter 3 59

Performance Tests

Page 60

Performance Tests

Conversion Loss and Frequency Response

9. Adjust the output power of the signa l gene rato r for a r eading of ap pr oximately -10 dBm

on the power meter for the 11970K, V or W and for approximately -3 dBm for the

11970A, Q or U. (Make sure that the unleveled light is not on for the 11970V and