Page 1

Aerosoft – Digital Aviation

CRJ-700 CRJ-900

AOM PART 2

Revision Info

VOL

5

5-1-1

26-Jul-2017

Rev #

Date

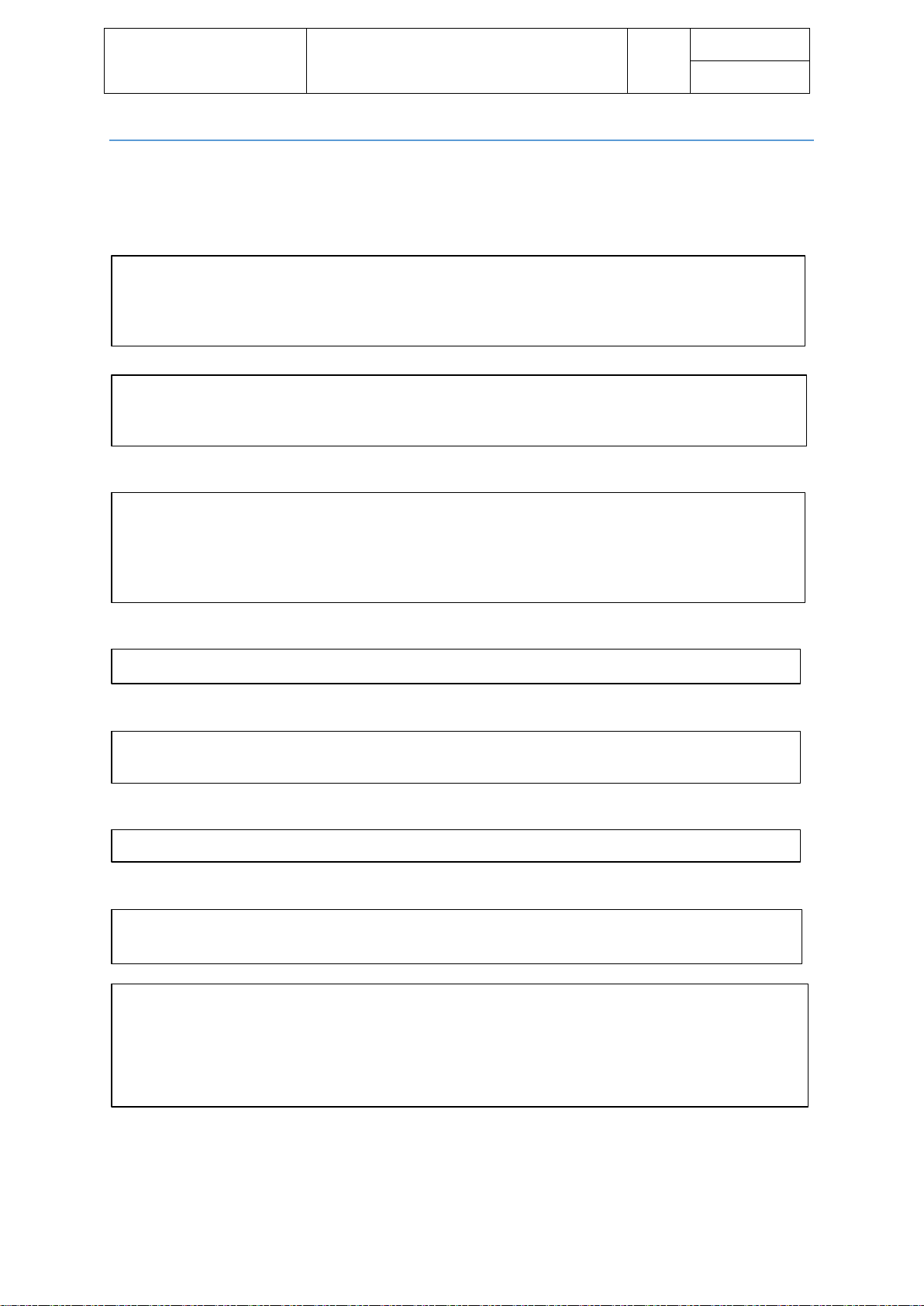

Author

Change

Version

001

11-Oct-15

IV

Start of documentation

0.90

002

31-Dec-16

MK

Updating to new software

0.92

003

20- Apr-17

MK

Finalizing

1.00

004

01-May-17

MK

Updating to latest files

1.00

On behalf of Authority

Page 2

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-2

26-Jul-2017

TABLE OF CON TENTS

AUXILLIARY POWER UNIT ..................................................................................................................... 5

AURAL/VISUAL INDICATING & RECORDING .......................................................................................... 6

EICAS CONTROL PANEL ..................................................................................................................... 7

DISPLAY REVERSION .......................................................................................................................... 8

AURAL WARNINGS / AUDIO SIGNALS ............................................................................................... 9

MASTER WARNING LIGHT ................................................................................................................. 9

MASTER CAUTION LIGHT ................................................................................................................ 10

CREW ALERTING SYSTEM (CAS) .................................................................................................. 10

TAKE-OFF WARNING ....................................................................................................................... 13

LANDING CONFIG WARNING .......................................................................................................... 14

MENU PAGE .................................................................................................................................... 15

FLIGHT DATA RECORDER..................................................................................................................... 15

AUTOMATIC FLIGHT CONTROL SYSTEM .............................................................................................. 15

FLIGHT DIRECTOR............................................................................................................................ 16

FLIGHT MODE ANNUNCIATOR – LATERAL MODES .......................................................................... 17

FLIGHT MODE ANNUNCIATOR – VERTICAL MODES ........................................................................ 18

SYNCHRONIZATION ......................................................................................................................... 20

ALTITUDE ALERT SYSTEM .................................................................................................................... 20

AUTOPILOT ......................................................................................................................................... 21

COMMUNICATIONS ............................................................................................................................ 22

AUDIO CONTROL PANEL ................................................................................................................. 22

INTERPHONE AND INTERCOM CONTROL PANEL ............................................................................. 23

RADIO TUNING UNIT (RTU) ............................................................................................................. 23

COMS MENU ................................................................................................................................... 24

TCAS MENU ..................................................................................................................................... 24

BACKUP TUNING UNIT .................................................................................................................... 25

ELECTRICAL ......................................................................................................................................... 25

ALTERNATING CURRENT, AC SYSTEM ............................................................................................. 26

CONTROLS ON OVERHEAD PANEL .............................................................................................. 28

EICAS SYNOPTIC PAGE – HOW TO OPEN AC & DC ELECTRICAL SYNOPTIC PAGES ....................... 29

EICAS SYNOPTIC PAGE – ELECTRICAL POWER SUPPLIED FROM ENGINES ................................... 29

EICAS SYNOPTIC PAGE – ELECTRICAL POWER SUPPLIED FROM AIR DRIVEN GENERATOR .......... 30

EICAS SYNOPTIC PAGE – ELECTRICAL POWER SUPPLIED FROM EXTERNAL POWER .................... 31

EICAS MESSAGES............................................................................................................................. 31

DIRECT CURRENT, DC SYSTEM ........................................................................................................ 32

EICAS MESSAGES ......................................................................................................................... 33

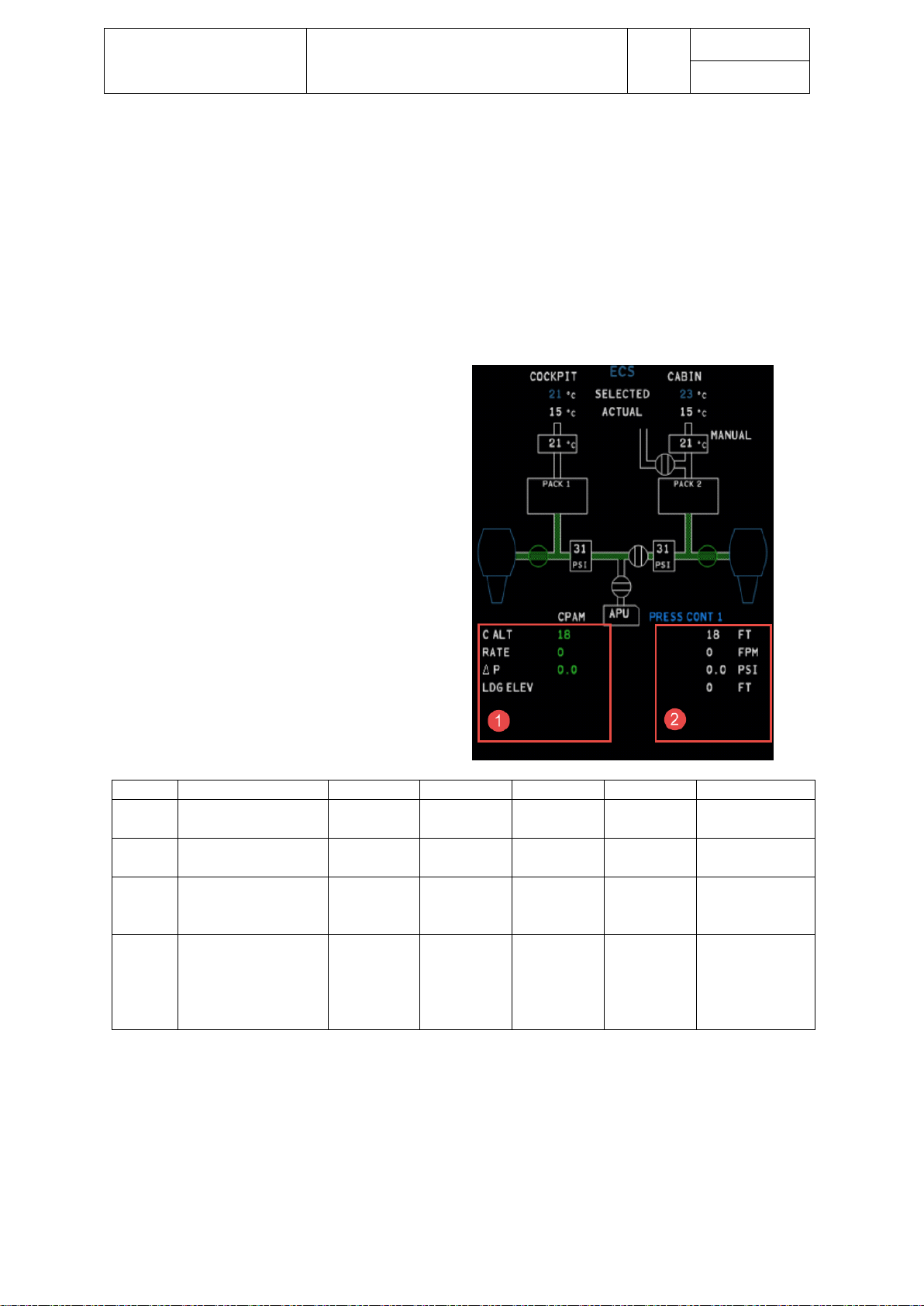

ENVIRONMENTAL CONTROL SYSTEM ................................................................................................. 36

AIR CONDITIONING SYSTEM / PACKS .............................................................................................. 36

ECAM MESSAGES ........................................................................................................................ 37

AVIONICS COOLING SYSTEM ....................................................................................................... 37

ECAM MESSAGES ........................................................................................................................ 38

CABIN PRESSURIZATION SYSTEM .................................................................................................... 38

ECAM MESSAGES ........................................................................................................................ 38

PRESSURIZATION MODES – AUTOMATIC MODES ....................................................................... 40

PRESSURIZATION MODES – MANUAL MODES ............................................................................ 40

SAFETY VALVES ........................................................................................................................... 41

GROUND VALVE .......................................................................................................................... 41

CABIN ALTITUDE LIMIT ................................................................................................................ 41

EMERGENCY DEPRESSURIZATION ............................................................................................... 41

Page 3

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-3

26-Jul-2017

EMERGENCY EQUIPMENT ................................................................................................................... 42

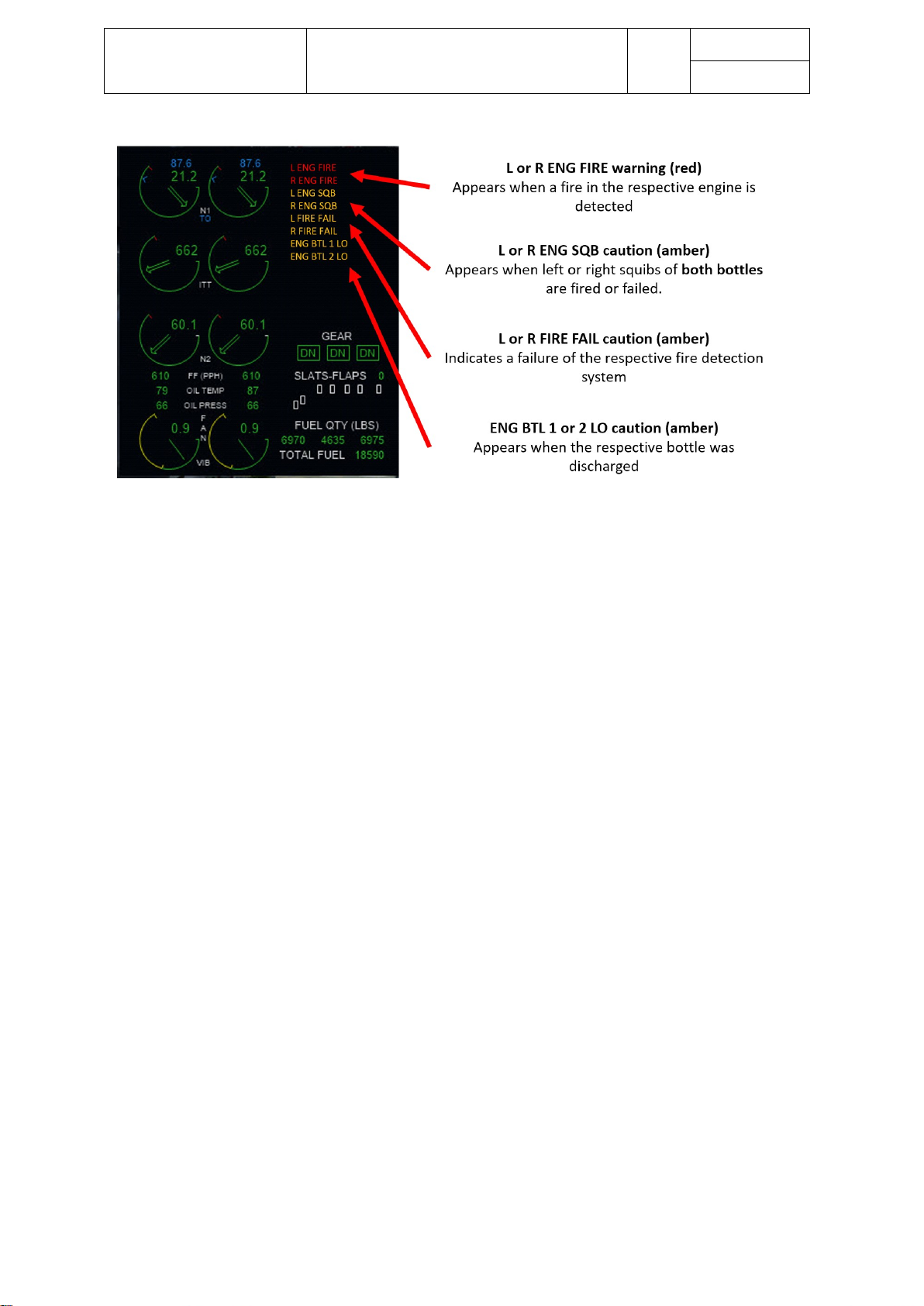

FIRE PROTECTION ............................................................................................................................... 43

ENGINE FIRE CONTROLS & MESSAGES ............................................................................................ 43

ECAM MESSAGE .......................................................................................................................... 43

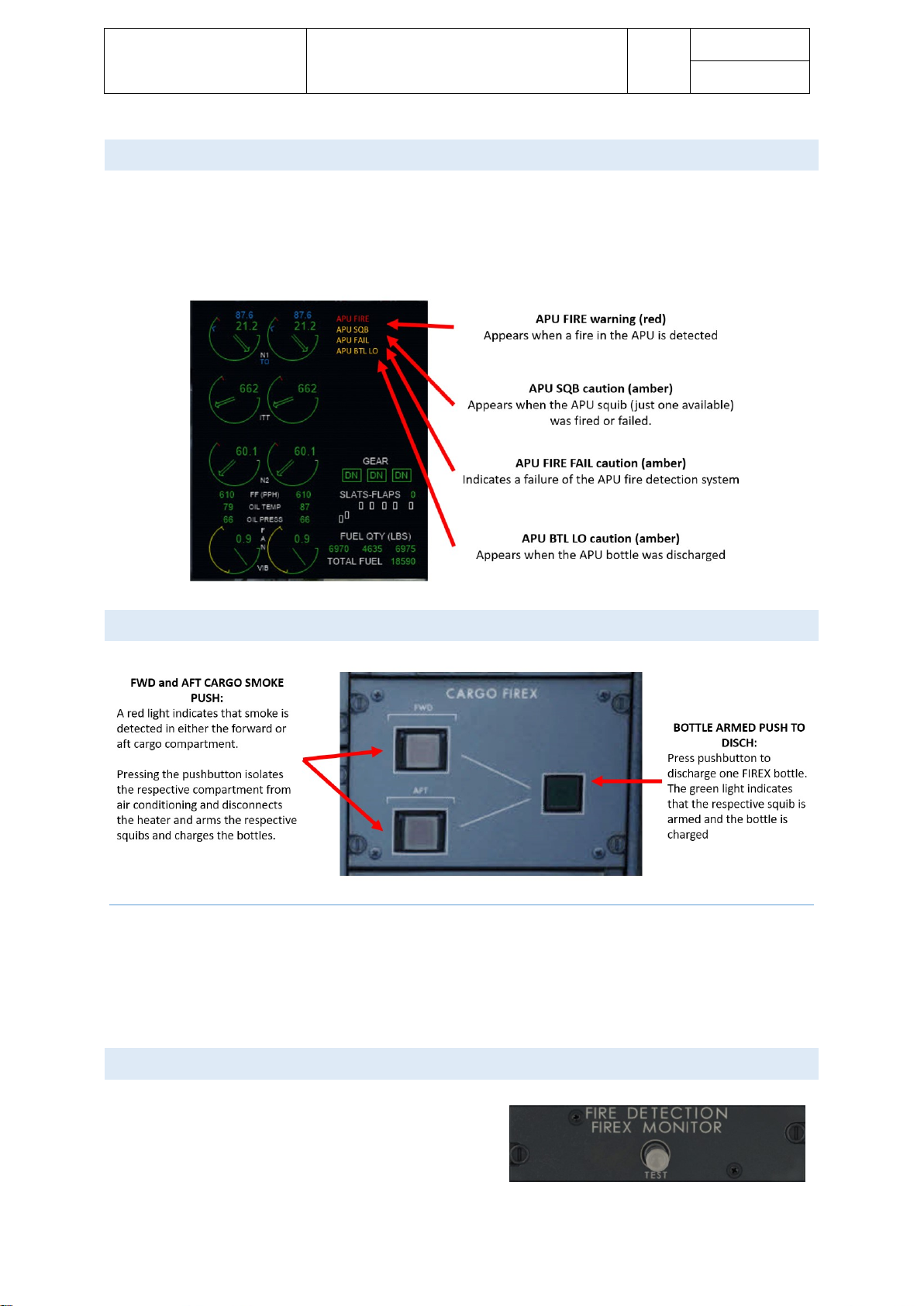

APU FIRE CONTROLS & MESSAGES ................................................................................................. 46

CARGO COMPARTMENT FIRE CONTROLS & MESSAGES.................................................................. 46

ECAM MESSAGES ........................................................................................................................ 46

FIRE SYSTEM TEST ........................................................................................................................... 46

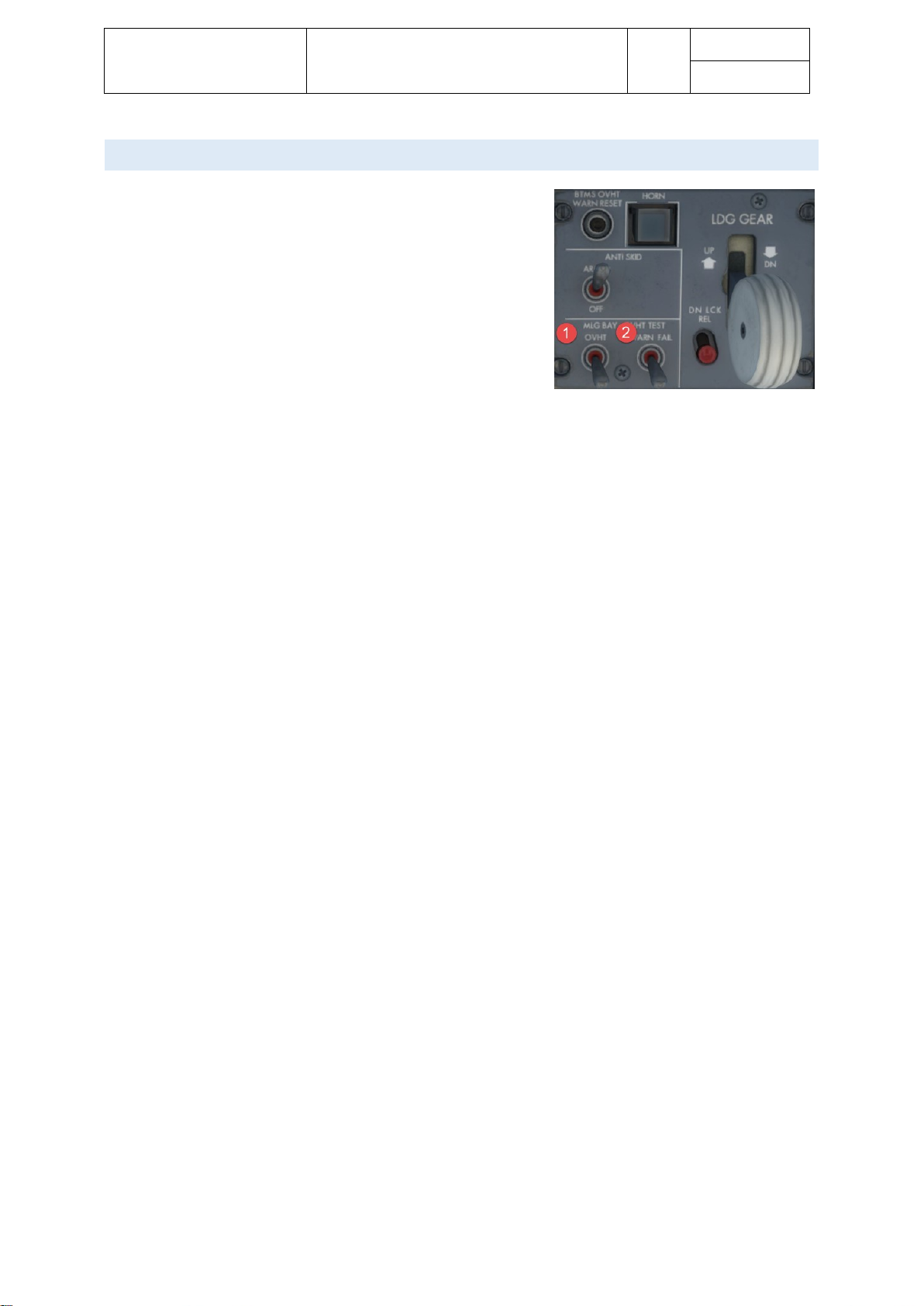

MAIN LANDING GEAR OVERHEAT DETECTION ................................................................................ 47

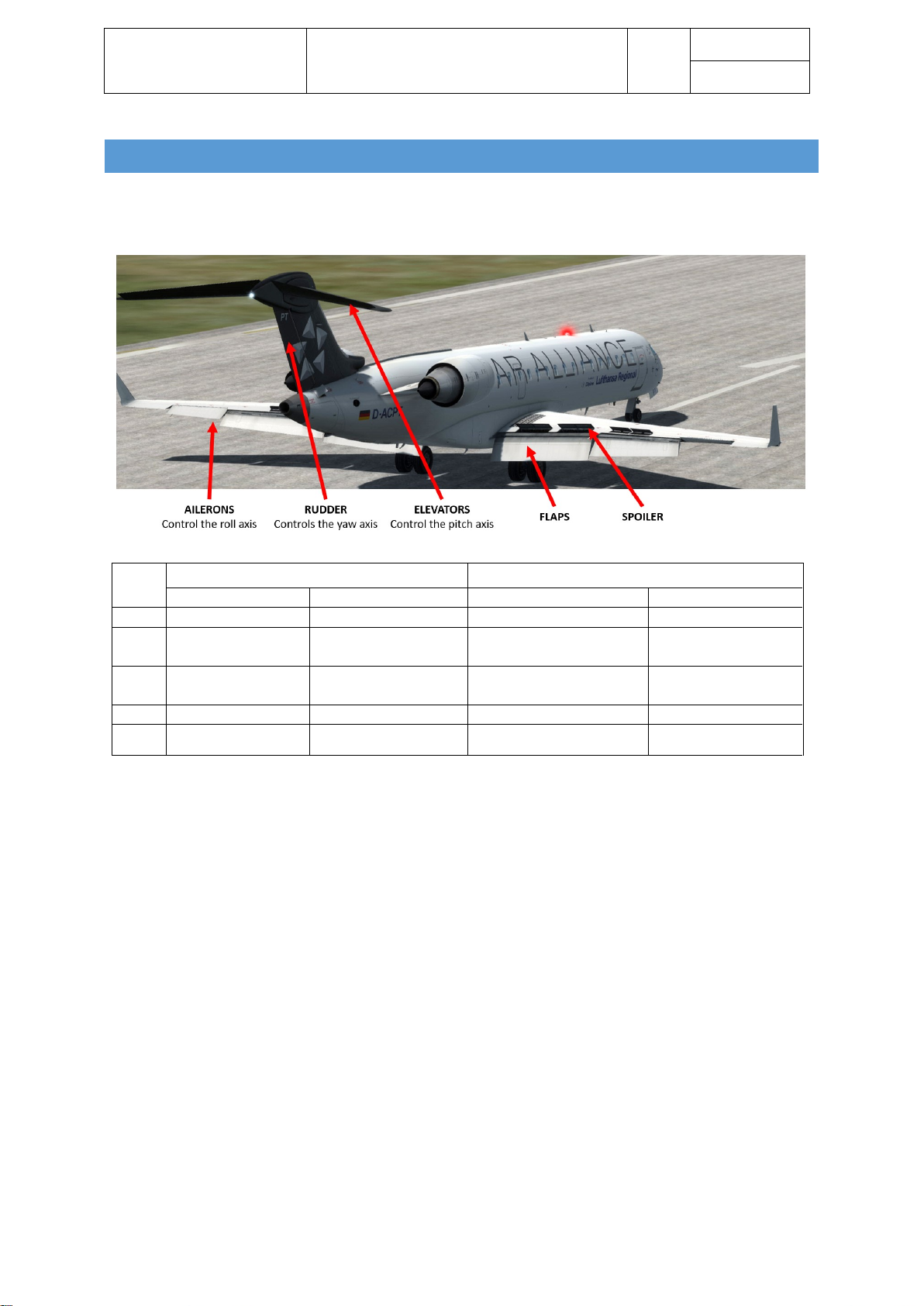

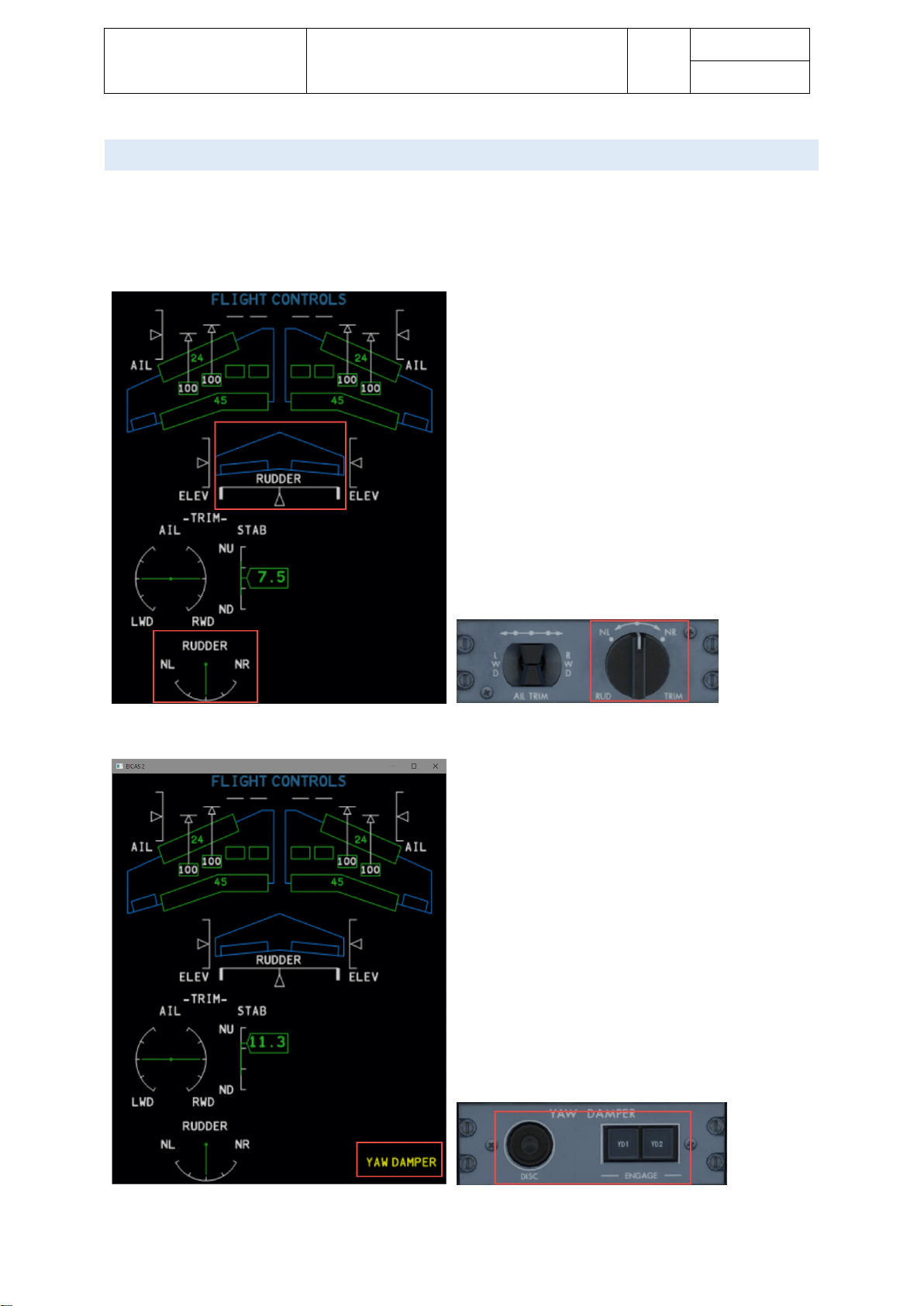

FLIGHT CONTROLS .............................................................................................................................. 48

AILERONS ........................................................................................................................................ 49

RUDDER .......................................................................................................................................... 50

ELEVATOR ....................................................................................................................................... 51

HORIZONTAL STABILIZER TRIM ....................................................................................................... 52

FLAPS AND SLATS ............................................................................................................................ 53

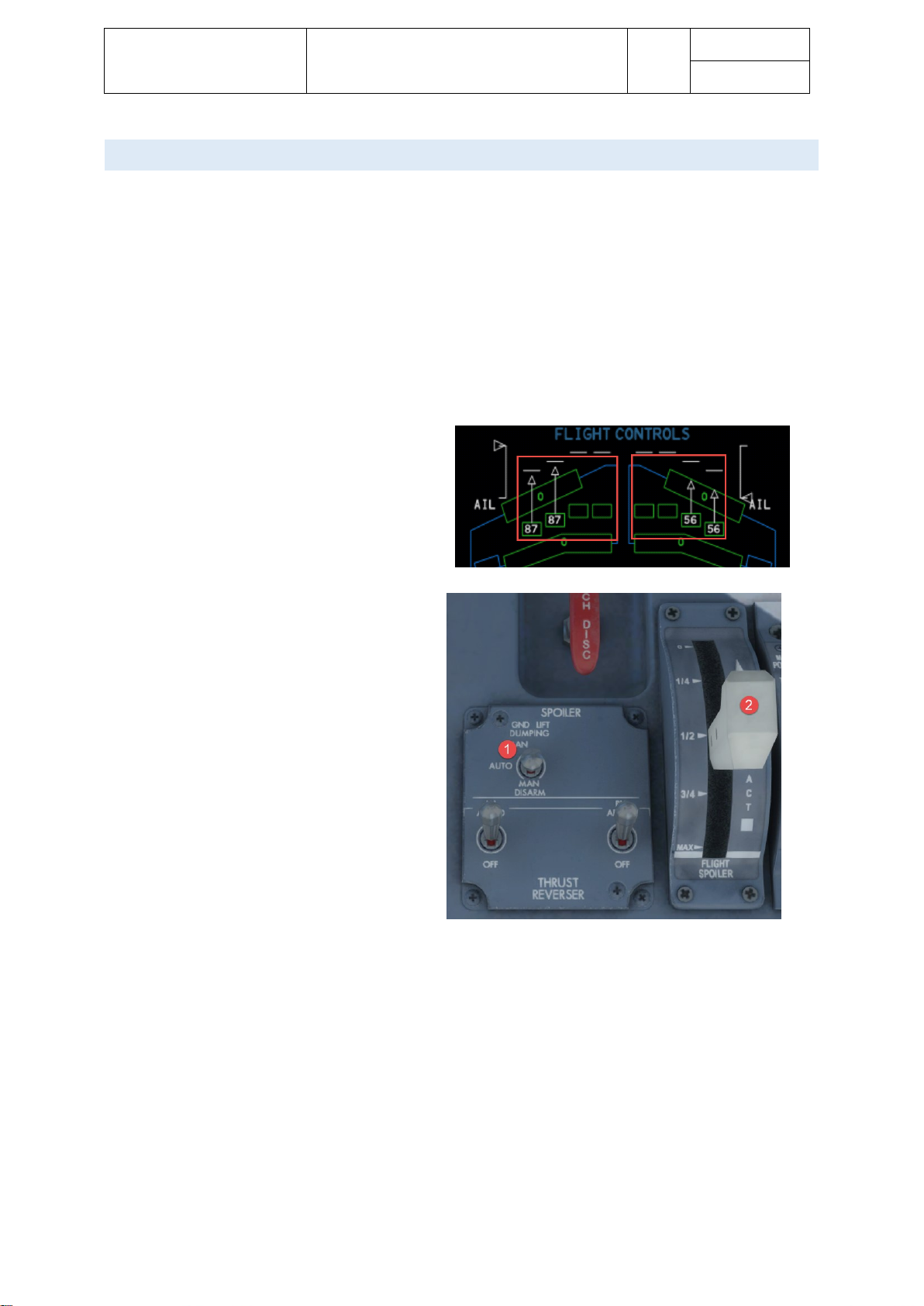

SPOILERS ......................................................................................................................................... 54

STALL PROTECTION SYSTEM ........................................................................................................... 55

FLIGHT INSTRUMENTS ........................................................................................................................ 56

ELECTRONIC FLIGHT INSTRUMENT SYSTEM (EFIS) .......................................................................... 57

DISPLAY REVERSION ........................................................................................................................ 58

DISPLAY CONTROL .......................................................................................................................... 58

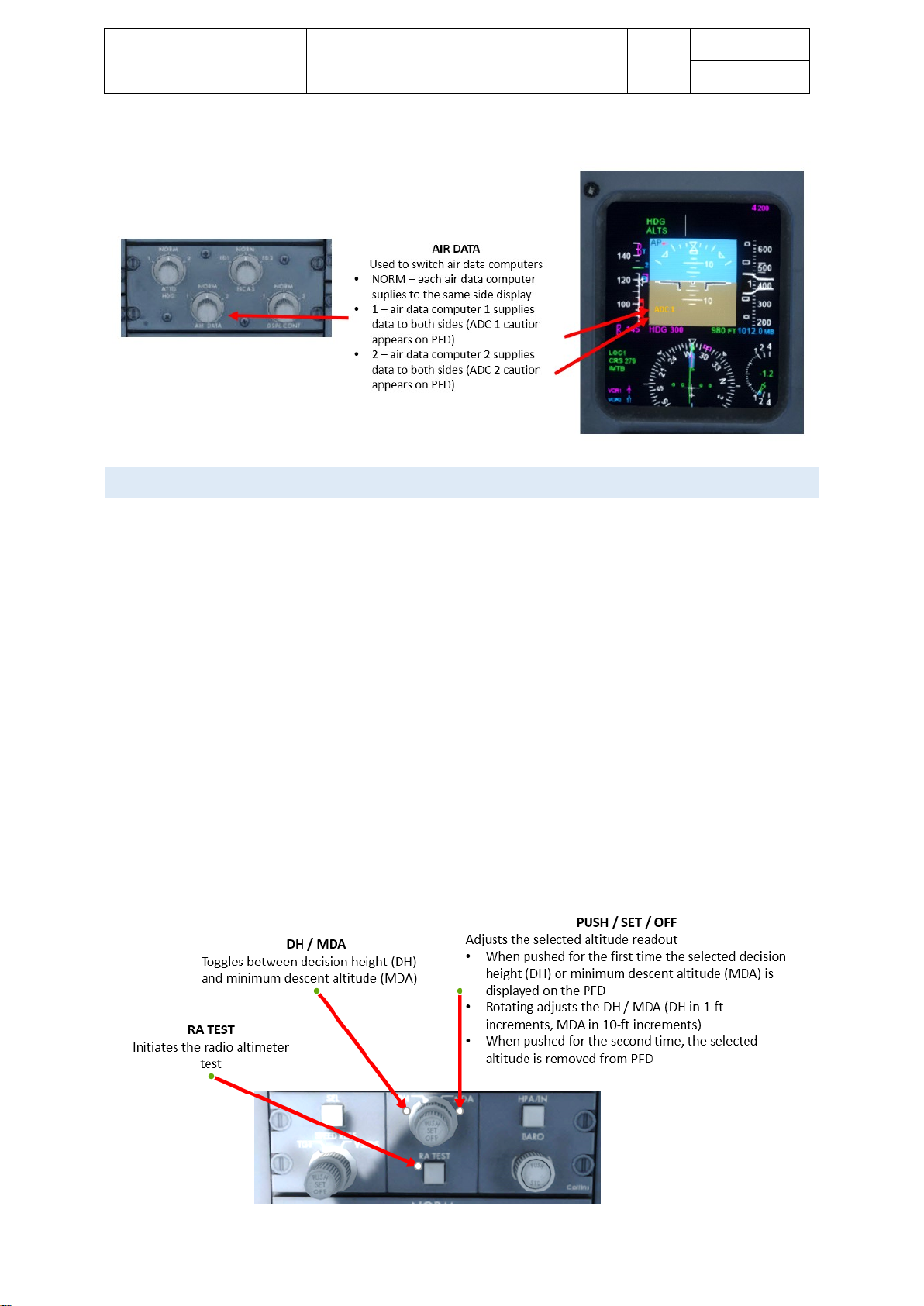

AIR DATA SYSTEM ........................................................................................................................... 59

PITOT STATIC SYSTEM ..................................................................................................................... 59

AIR DATA ......................................................................................................................................... 59

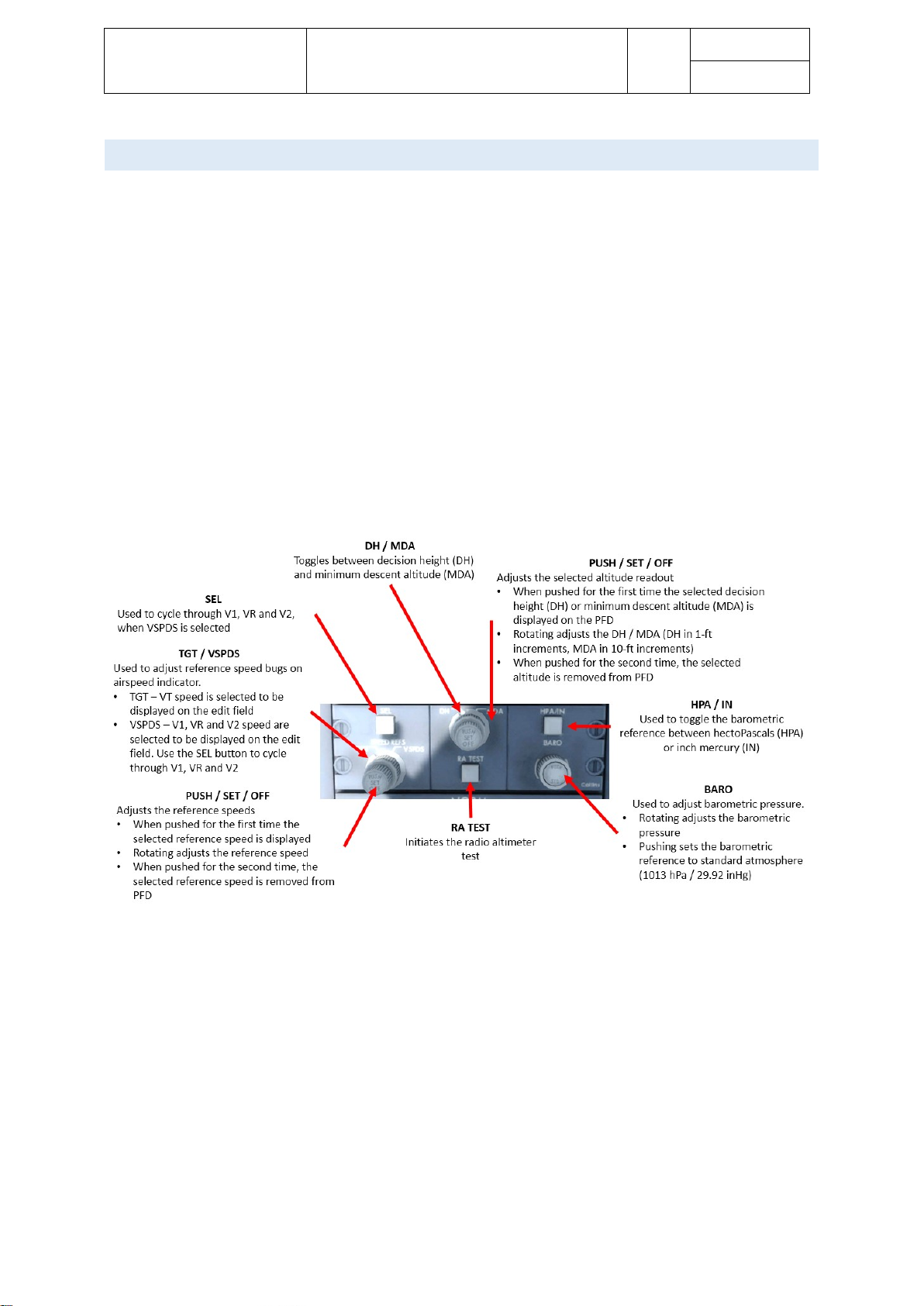

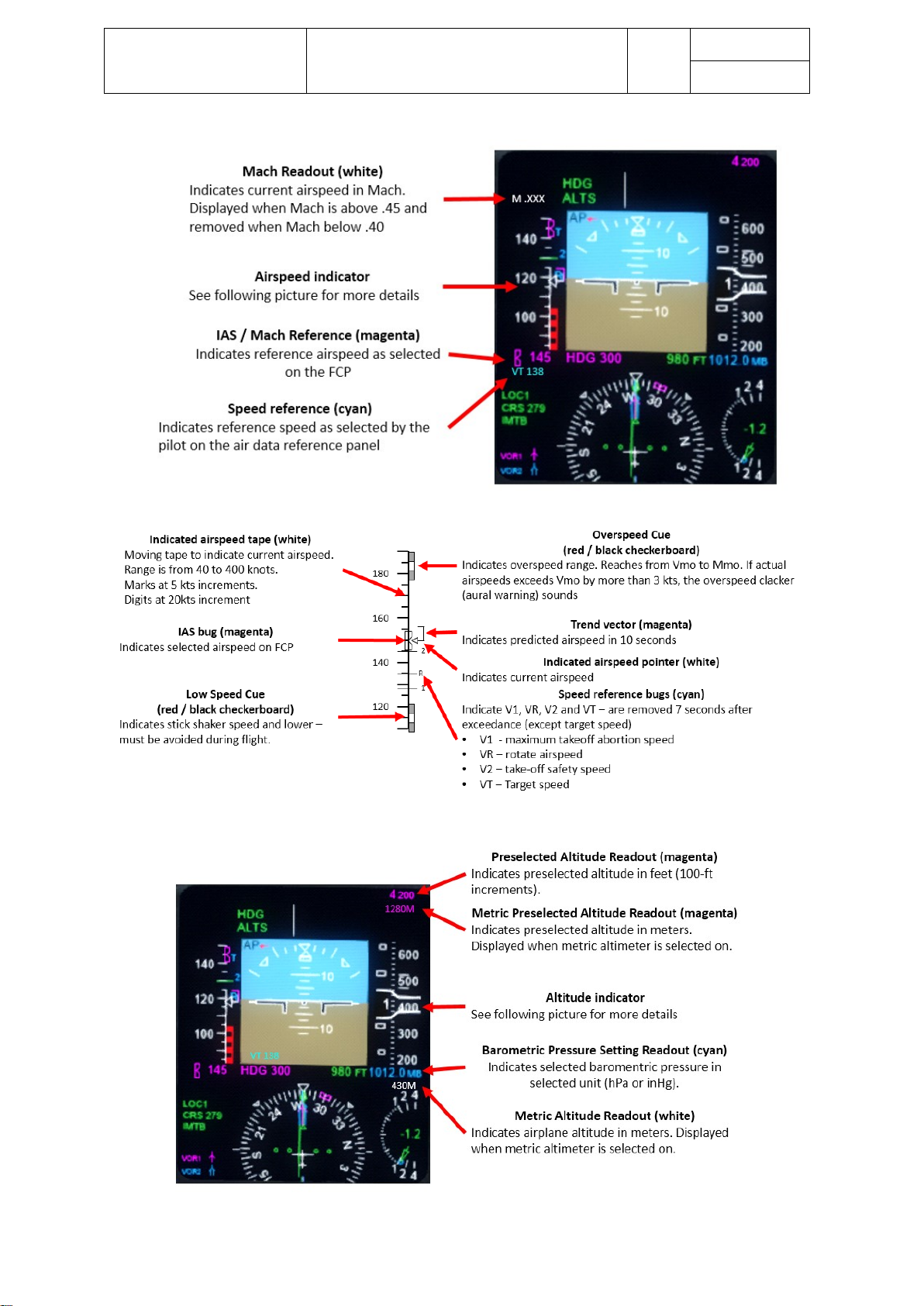

AIR DATA REFERENCE (ARP) PANELS ............................................................................................... 60

ALTITUDE ALERTS ............................................................................................................................ 63

LOW SPEED CUE .............................................................................................................................. 63

AIR DATA REVERSION ...................................................................................................................... 63

RADIO ALTIMETER SYSTEM ............................................................................................................. 64

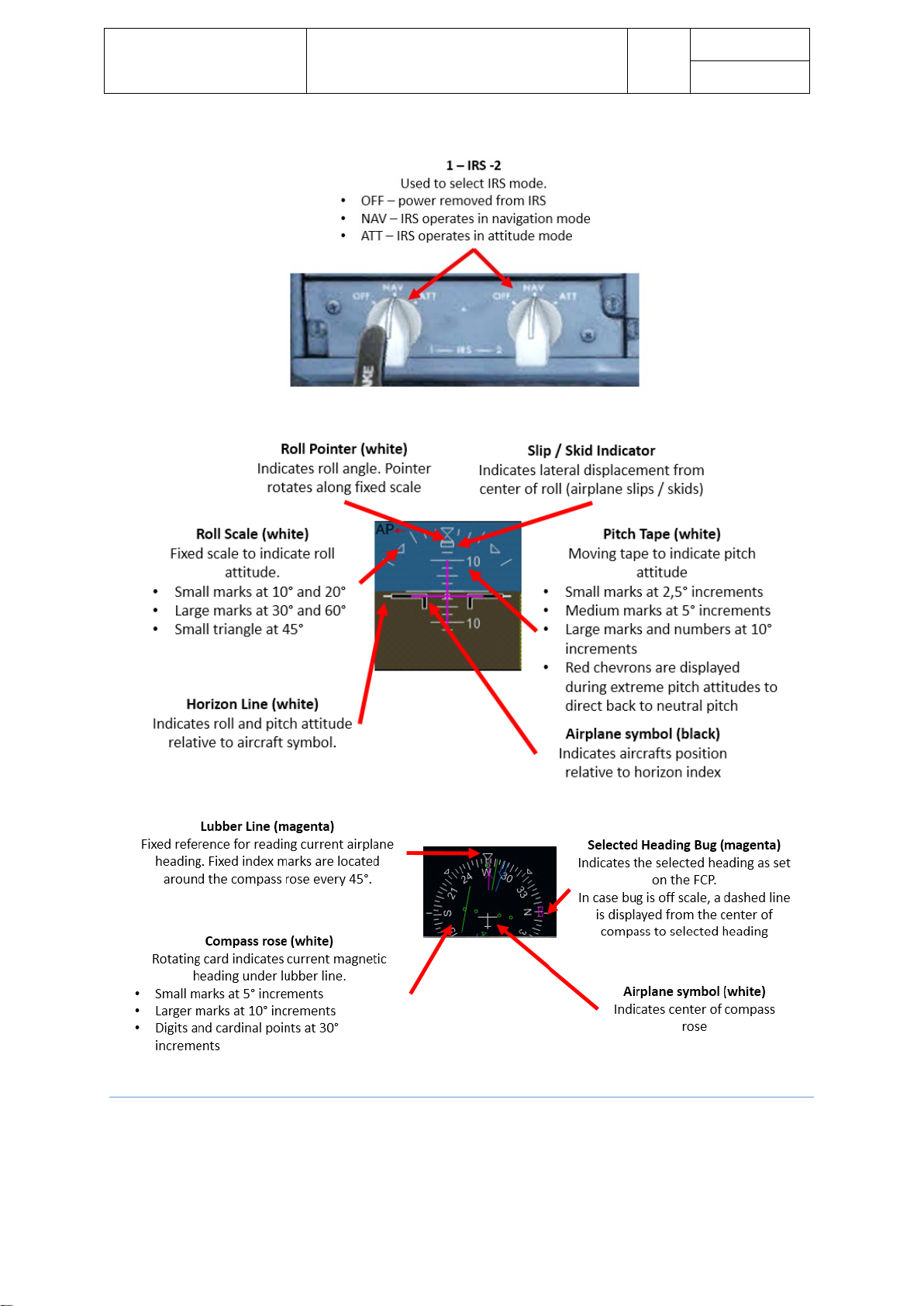

INERTIAL REFERENCE SYSTEM ......................................................................................................... 65

DISPLAY REVERSION .................................................................................................................... 66

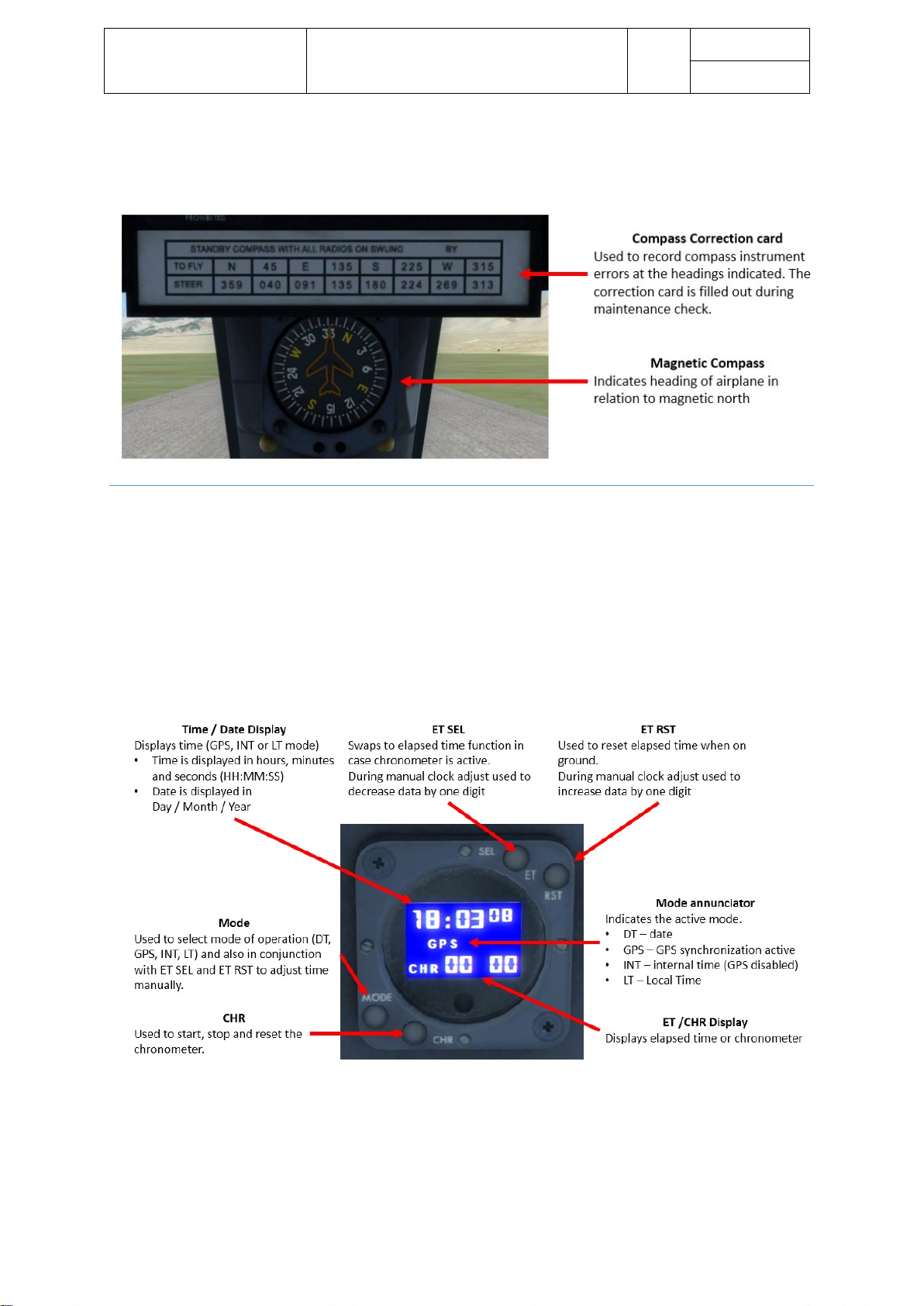

STANDBY INSTRUMENTS AND CLOCKS ........................................................................................... 67

INTEGRATED STANDBY INSTRUMENT ......................................................................................... 67

STANDBY COMPASS .................................................................................................................... 68

CLOCKS ........................................................................................................................................ 69

FUEL SYSTEM ...................................................................................................................................... 70

FUEL TANKS / STORAGE .................................................................................................................. 70

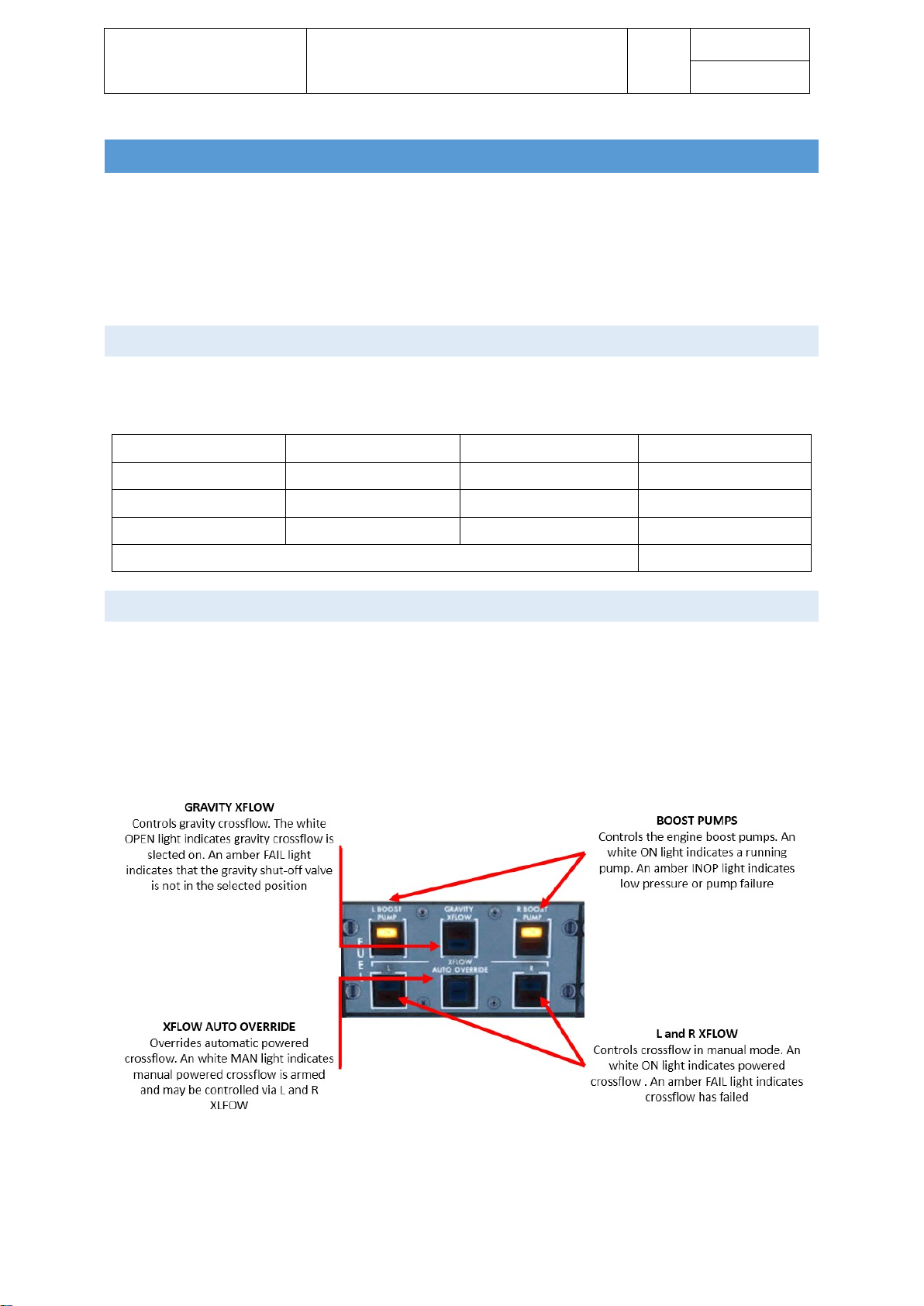

FUEL MANAGEMENT (TRANSFER/CROSSFLOW) & DISTRIBUTION .................................................. 70

FUEL QUANTITY GAUGING .............................................................................................................. 72

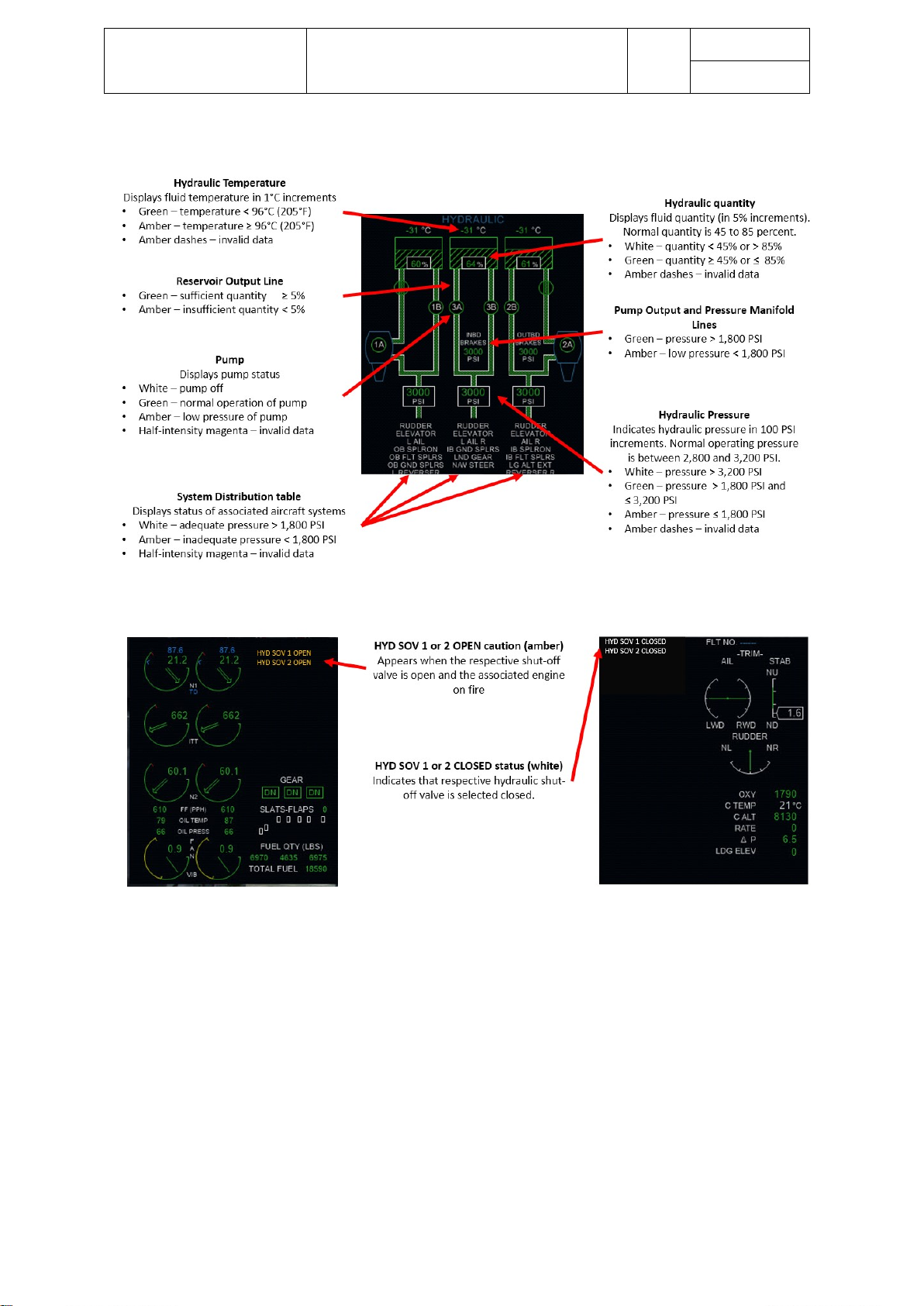

HYDRAULIC POWER ............................................................................................................................ 74

ICE & RAIN PROTECTION ..................................................................................................................... 77

ICE DETECTION SYSTEM .................................................................................................................. 78

WING AND COWL ANTI-ICE SYSTEM ............................................................................................... 79

AIR DATA ANTI-ICE SYSTEM ............................................................................................................ 80

WINDSHIELD AND SIDE WINDOW ANTI-ICE SYSTEM ...................................................................... 81

WINDSHIELD WIPER SYSTEM .......................................................................................................... 81

LANDING GEAR ................................................................................................................................... 82

BRAKE SYSTEM ................................................................................................................................ 83

PARKING BRAKE .......................................................................................................................... 83

BRAKE TEMPERATURE MONITORING SYSTEM ............................................................................ 84

ANTI-SKID .................................................................................................................................... 85

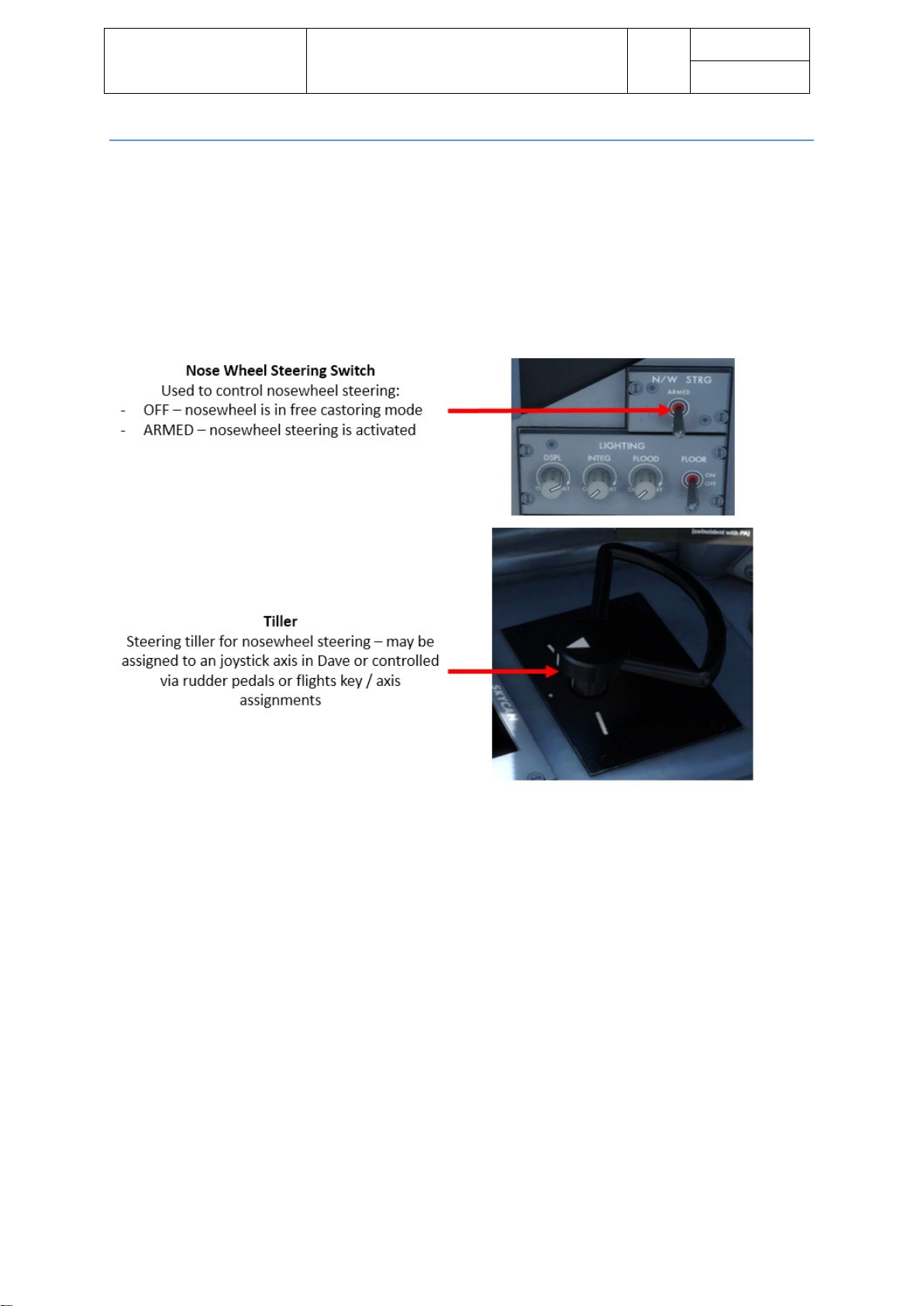

NOSE WHEEL STEERING SYSTEM ................................................................................................. 86

Page 4

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-4

26-Jul-2017

LIGHTING ............................................................................................................................................ 87

COCKPIT LIGHTING .......................................................................................................................... 87

PASSENGER COMPARTMENT LIGHTING .......................................................................................... 88

EXTERNAL LIGHTING ....................................................................................................................... 89

EMERGENCY LIGHTING ................................................................................................................... 91

NAVIGATION SYSTEMS ........................................................................................................................ 91

FLIGHT MANAGEMENT SYSTEM (FMS) ........................................................................................... 92

WHERE TO FIND THE FMS/CDU AND BASIC LAYOUT ...................................................................... 92

PREFLIGHT SETUP AND SEQUENCE OF PAGES ................................................................................ 96

GLOBAL POSITIONING SYSTEM (GPS).............................................................................................. 97

VHF NAVIGATION ............................................................................................................................ 97

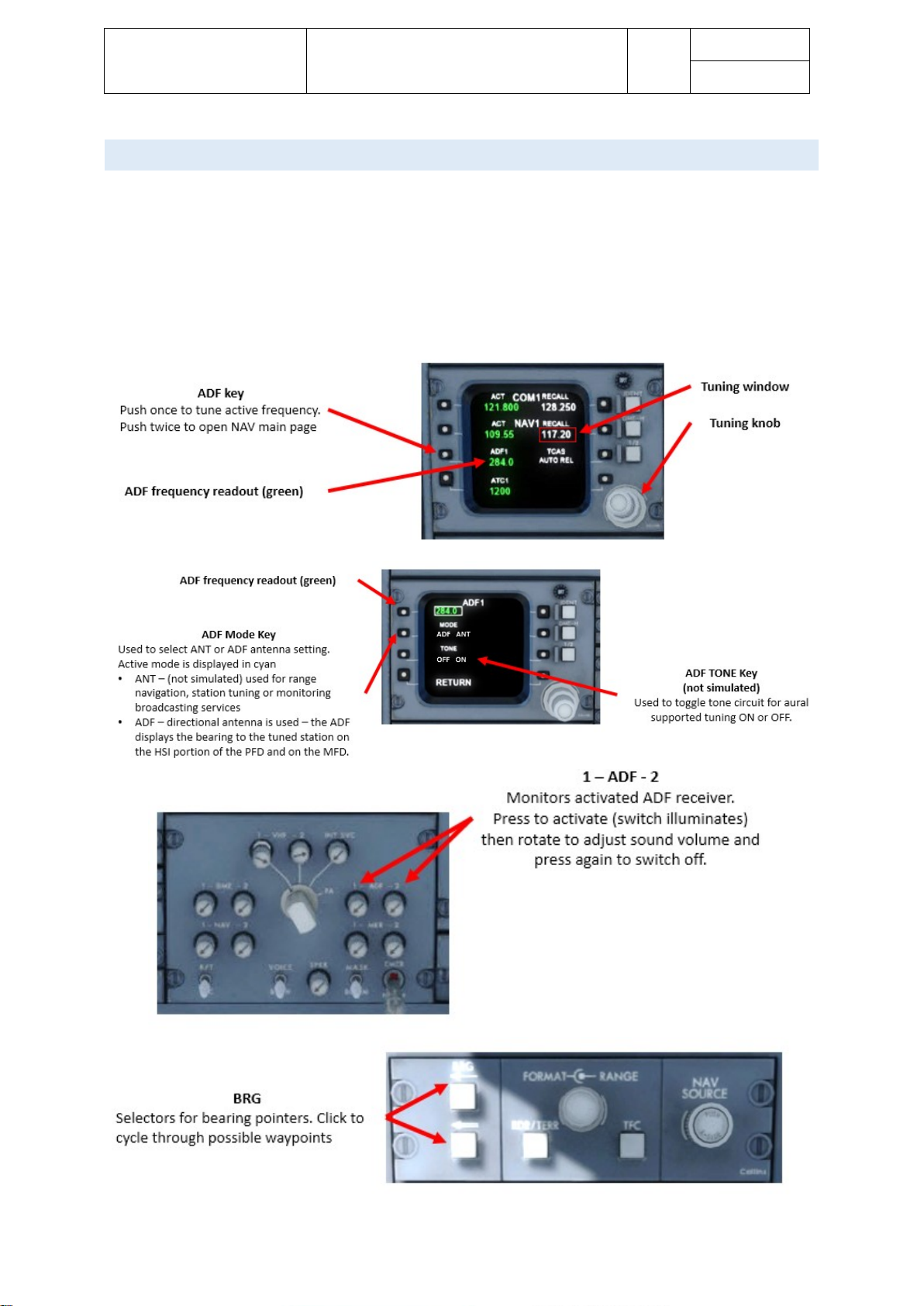

AUTOMATIC DIRECTION FINDER (ADF) ......................................................................................... 100

DISTANCE MEASURING EQUIPMENT (DME) ................................................................................. 101

AIR TRAFFIC CONTROL TRANSPONDER SYSTEM (ACT) .................................................................. 103

TRAFFIC ALERT AND COLLISION AVOIDANCE SYSTEM (TCAS) ....................................................... 104

TRAFFIC ADVISORY (TA) ............................................................................................................ 106

RESOLUTION ADVISORY (RA) .................................................................................................... 106

AURAL WARNING ...................................................................................................................... 107

GROUND PROXIMITY WARNING SYSTEM (GPWS) ........................................................................ 107

MODE 1 – EXCESSIVE DESCENT RATE ........................................................................................ 109

MODE 2 – EXCESSIVE TERRAIN CLOSURE RATE ......................................................................... 109

MODE 3 – ALTITUDE LOSS AFTER TAKE-OFF ............................................................................. 109

MODE 4 – UNSAFE TERRAIN CLEARANCE .................................................................................. 110

MODE 5 – BELOW GLIDESLOPE ALERT ...................................................................................... 110

MODE 6 – CALLOUTS (DESCENT BELOW MINIMUM, ALTITUDE CALLOUTS AND BANK ANGLE

ALERT) ....................................................................................................................................... 110

MODE 7 –WINDSHEAR DETECTION AND ALERTING .................................................................. 110

TERRAIN / OBSTACLE AWARENESS ALERTING AND DISPLAY .................................................... 112

WEATHER RADAR (WXR) ............................................................................................................... 113

POWER PLANT .................................................................................................................................. 114

THRUST CONTROL ......................................................................................................................... 115

FULL AUTHORITY DIGITAL ELECTRONIC CONTROL (FADEC) .......................................................... 117

FLEX POWER ................................................................................................................................. 118

AUTOMATIC POWER RESERVE (APR) ............................................................................................ 118

HIGH POWER SCHEDULE ........................................................................................................... 119

N1 AND N2 SYNCHRONISATION ..................................................................................................... 119

ENGINE OVERSPEED PROTECTION ................................................................................................ 119

ENGINE N2 INDICATIONS WHEN USING WING ANTI-ICE ............................................................... 119

STARTING AND IGNITION SYSTEM ................................................................................................ 119

OIL SYSTEM ................................................................................................................................... 121

FUEL SYSTEM ................................................................................................................................ 122

INTERTURBINE TEMPERATURE (ITT) MONITORING ...................................................................... 123

VIBRATION MONITORING ............................................................................................................. 123

REVERSE THRUST .......................................................................................................................... 124

PNEUMATICS .................................................................................................................................... 125

Page 5

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-5

26-Jul-2017

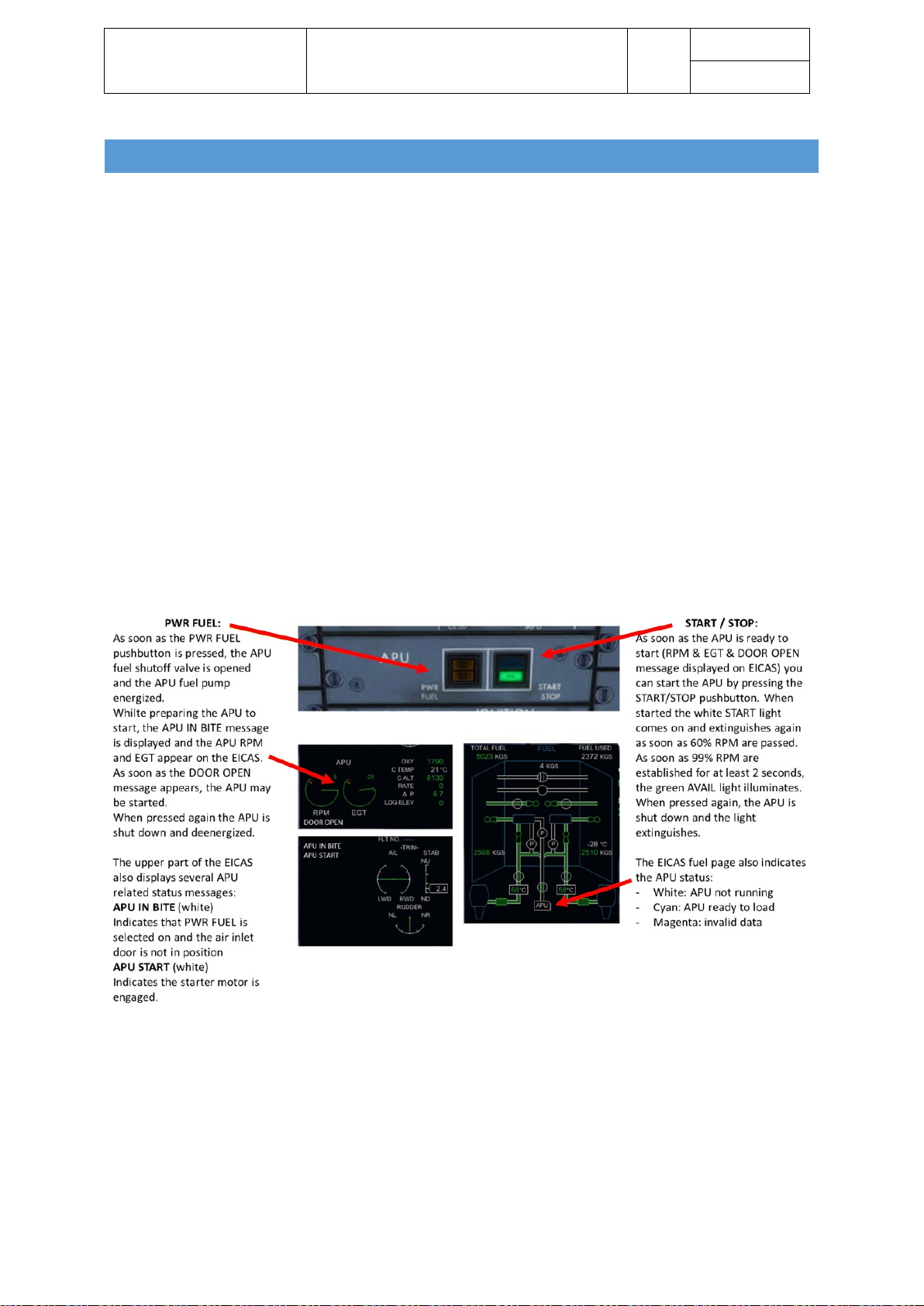

AUXILLIARY POWER UNIT

The CRJ700 and CRJ900 are both equipped with an Allied Signal RE 220 (RJ) auxiliary power unit (APU). The

APU is technically a gas-turbine and it is used to provide electrical power and even more important

compressed air.

The APU is basically comprised of three stages: a compressor followed by a combustion chamber and a

turbine. The APU is started by an electrical motor which rotates the APUs main shaft until it gained enough

speed so that fuel can be injected into the combustion chamber. The fuel burns and hence tries to expand

which accelerates the air even further. The turbine on the other hand drives a generator – so the turbine

converts the accelerated airflow into electrical power. As you can see the basic principle of an APU and an

aircraft engine are technical the same. The major difference is that the APU is not used to produce thrust

therefore APUs are also much smaller than aircraft engines.

Apart from electrical power, bleed air is also drawn from the APU to supply the packs or also the engine

starters (the aircrafts engines are usually started with pneumatic air).

Thus, it is mainly use during aircraft preparation and engine start. Nevertheless, it may also be used as a

backup once an engine failed / was switched off.

The air-inlet-flap of the APU is used to control airflow into the APU. The flaps position is controlled

automatically by the built-in electronics.

Page 6

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-6

26-Jul-2017

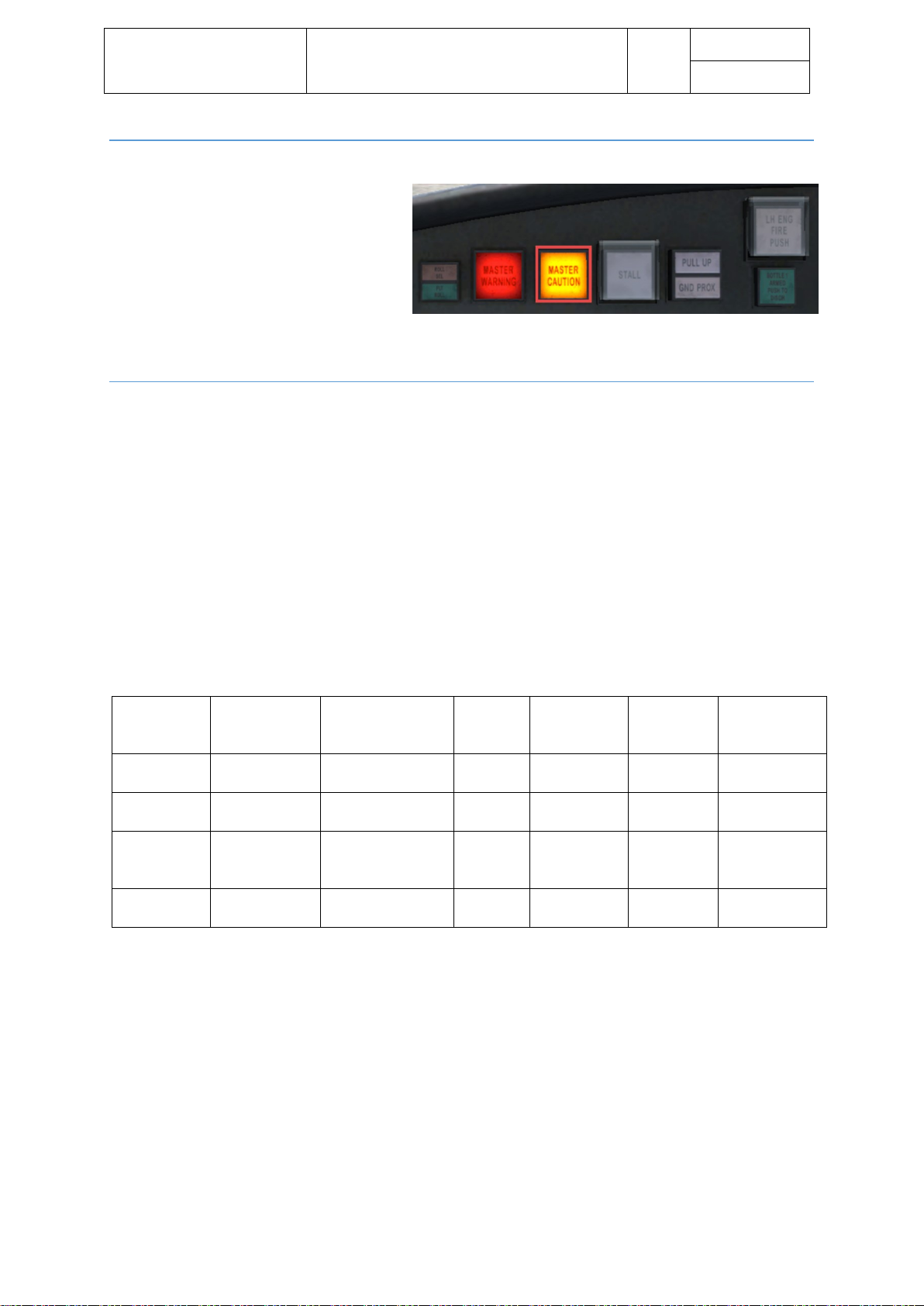

AURAL/VISUAL INDICATING & RECORDING

All aircraft systems do have sensors to detect

abnormal settings or behaviour. All systems –

including the engines – report this information to

two central processing units: the data

concentrator units (1 & 2). The interface to the

pilots is the engine indication and crew alerting

system (EICAS). Certain messages do also trigger

audio signals or trigger the master warning or

master caution light.

The EICAS is comprised of two units – called

EICAS Display 1 & 2 (ED1 and ED2) – basically the

left and the right EICAS display: The left EICAS is called ED1 and the right EICAS ED2.

Normally ED1 displays the primary page and ED2 displays the status page. The EICAS control panel on the

lower pedestal enables the pilots to select if the primary, the secondary or a synoptic page is displayed on

either ED. Please us the display reversion control panels to change whether the primary or secondary is

displayed on ED1 or ED2 respectively. The EICAS source selector panel allows the pilot to select where all EICAS

information is displayed. You may choose between ED1 or ED2 or both (default).

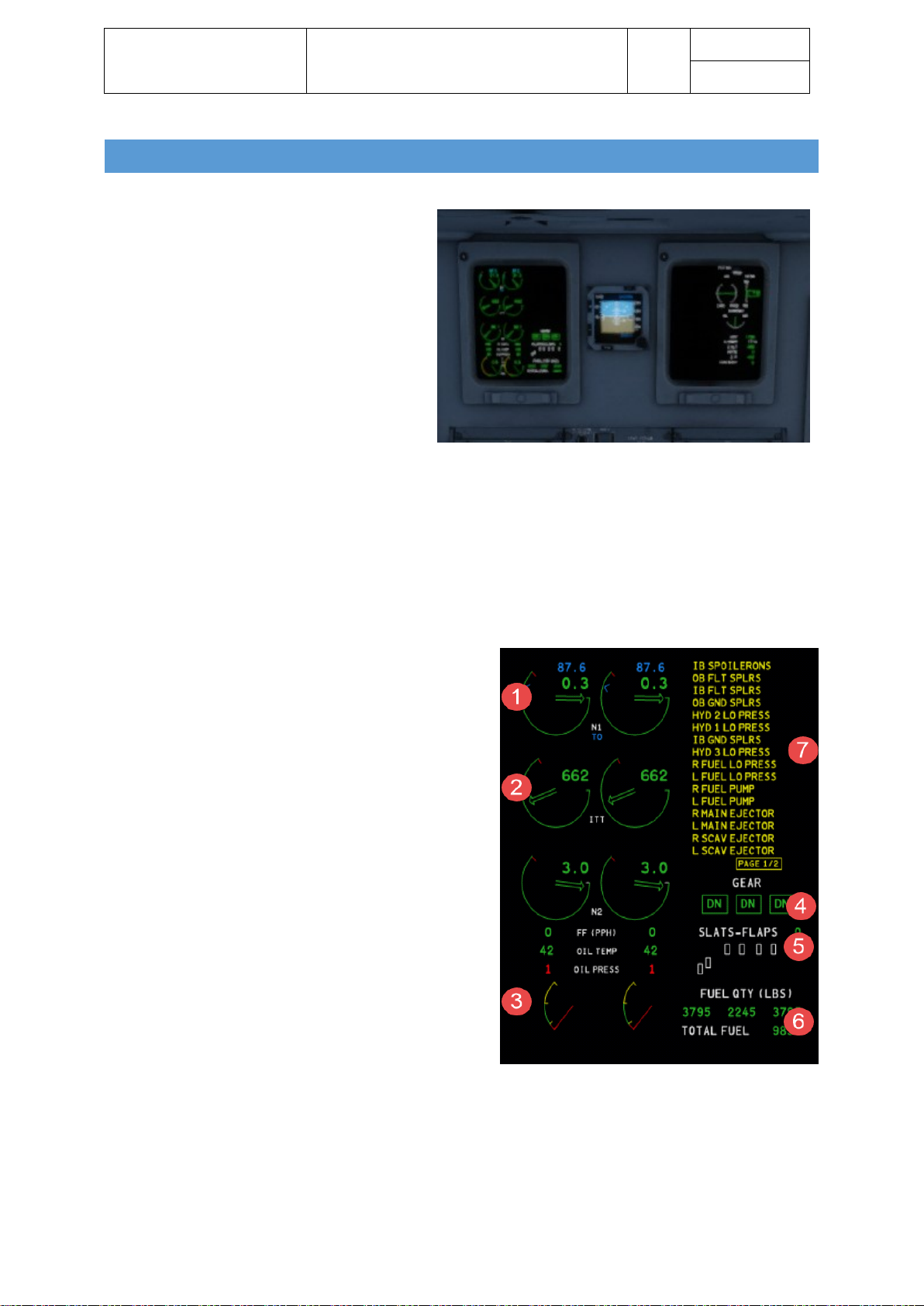

The EICAS primary page displays the following information:

1. Engine compressor and turbine speeds (N1 and N2

rpm)

2. Engine temperature (ITT)

3. Fuel flow (FF)

Oil pressure and temperature

Engine vibration data

4. Landing gear position

5. Slat/flap position

6. Fuel tank quantities and total fuel

7. Crew alerting system (CAS) messages in the form

of red warning and amber caution messages

Page 7

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-7

26-Jul-2017

The EICAS status page displays the following information:

1. Flight control trim indications

2. Auxiliary power unit (APU) indications such as APU

RPM, exhaust gas temperature (EGT) and APU inlet

door status

3. Pressurization data such as cabin altitude, cabin rate

of change, cabin pressure differential, and landing

field elevation

4. Oxygen system pressure

5. Brake system temperature readouts

6. Crew alerting system (CAS) messages in the form of

green advisory and white status messages

• Aircraft systems synoptic pages (via the EICAS

control panel)

See next section for more details

• MENU page (via the EICAS control panel) allows

reset of the fuel used indicator and displays the

engine oil quantity

See respective section of this chapter.

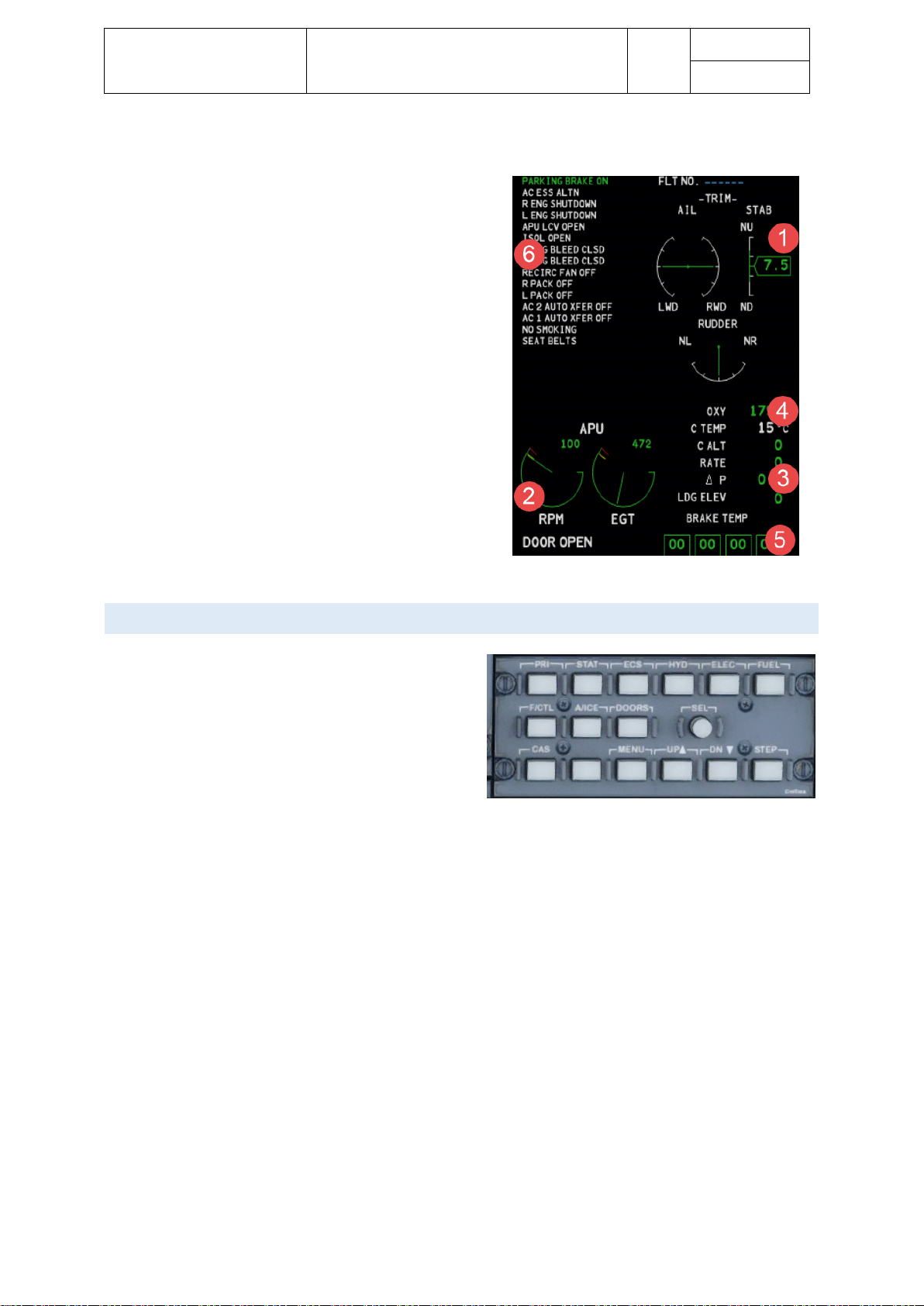

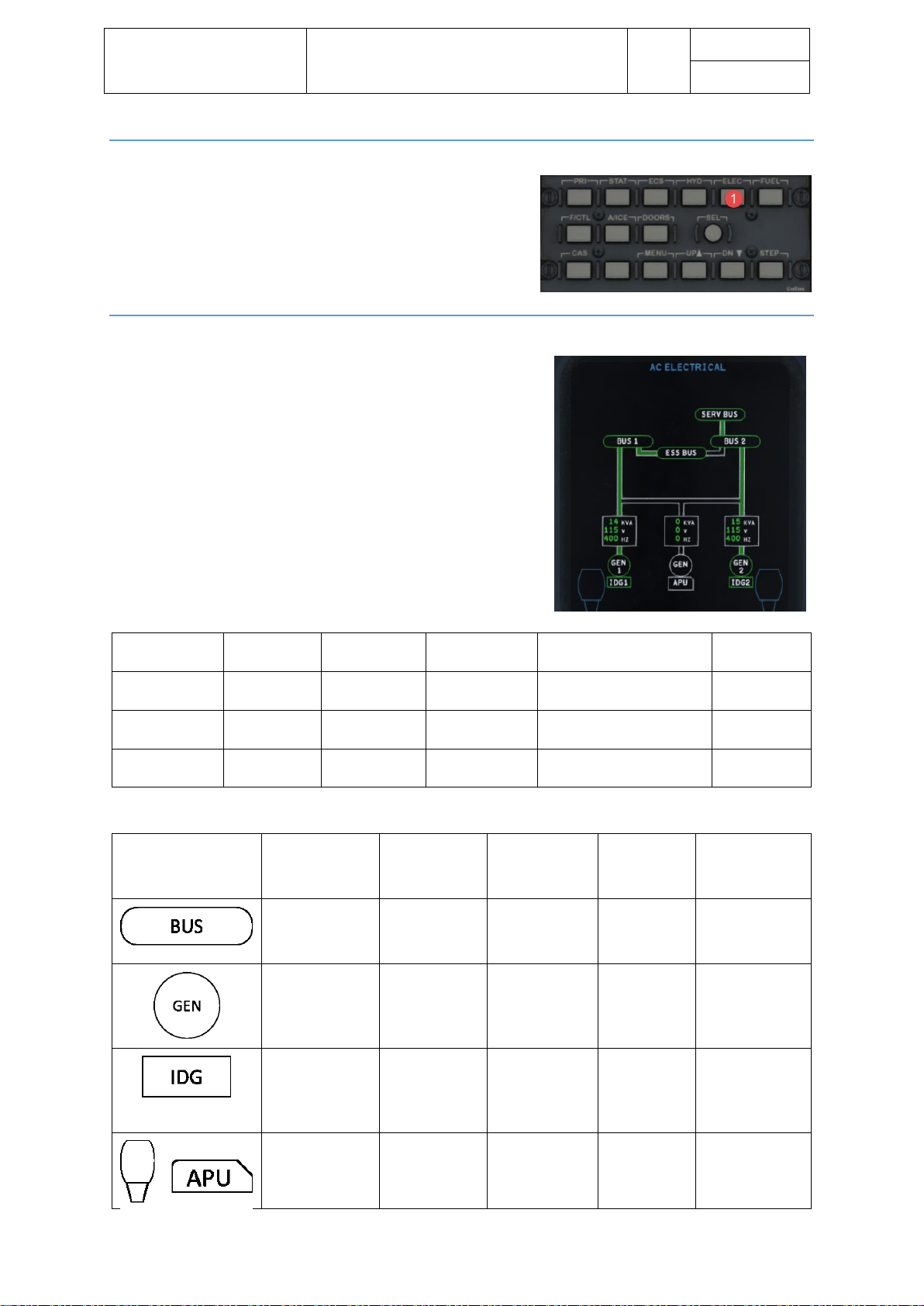

EICAS CONTROL PANEL

The EICAS Control Panel enables you to open the

different aircraft system synoptic pages.

The panel itself is found on the upper pedestal. The

following pushbuttons, respective system pages are

available:

• PRI: Opens Primary Page (normally displayed on ED1) on secondary display (ED2)

• STAT: Displays Status Page. A second push removes all status messages / open further status

messages if several pages of status messages exist.

• Synoptic Pages

o ECS: Opens Environmental Control System page

o HYD: Opens Hydraulic system page

o ELEC: Opens Electrical system page

o FUEL: Opens Fuel system page

o F/CTL: Open Flight Controls system page

o A/ICE: Opens Anti-Ice system page

o DOORS: Opens Door system page

o MENU: Opens the menu page

• SEL: Selector – used to activate a selected item. A change in colour will indicate selection

• CAS: Removes caution messages from primary display. Previously invisible messages get displayed

• UP: Controls cursor

• DN: Controls cursor

• STEP: Steps through pages of secondary page if available

Page 8

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-8

26-Jul-2017

DISP L A Y REVERSION

In case EICAS display ED1 fails, ED2 will automatically switch to primary page. In case EICAS display ED2 fails,

there is no automatic switch. With either display failed, the EICAS control panel is rendered inoperative. Please

switch the EICAS selector on the SOURCE SELECTOR PANEL to the operative display (ED1 or ED2). This reenables you to select and display the EICAS information on the selected display.

Furthermore, a revisionary panel is installed on either pilot’s side panel. They offer three positions:

• PFD 1, respective PFD 2

Switches the respective primary flight display (PFD1 = pilot, PFD 2 = co-pilot) to the adjacent MFD.

• NORM

PFD and MFD in normal operation

• EICAS

Shows the EICAS ED1 display on the MFD.

Page 9

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-9

26-Jul-2017

AURA L WARNING S / AUDIO SIGNALS

The following table shows the available aural warnings / audio signals.

Sound

Indication

Warbler

Stall

Windshear

Windshear

Whoop – Whoop

GPWS (excessive descent or closure rate)

Fire bell

Fire warnings

Clacker

Excessive stabilizer trim Movement

VMO/MMO exceedance

Airspeed too high for current flap setting

Cavalry Charge

Autopilot disconnect

Horn

Gear warning (not down)

Triple chime

Warning tone (indicates an aircraft system voice advisory)

C-chord

Altitude alert

Single chime

Caution tone (indicates an aircraft system voice advisory)

Faulty aural warnings may result from a defective DCU. There are

two guarded pushbuttons on the co-pilots side panel – called the

audio warning panel – to switch off the affected DCU. Open the

guard and press the pushbutton to deactivate the DCU. Switching

a DCU off triggers respective EICAS messages and the pushbutton

will illuminate white.

MASTE R WARNI N G LIGHT

There is a master warning light on either side – the pilot’s and the co-pilot’s side. In case a warning is triggered,

both lights come on and stay flashing if the warning exists or the warning light is pushed by the pilot or copilot. The aural warning and flashing light stay off until the next warning is triggered.

In the following cases the aural warning may

not be muted:

• Stall warbler

• Stabilizer trim clacker

• GPWS/TCAS (voices and aural)

• AP Disconnect cavalry charge

• Overspeed clacker

• Configuration warnings

• Flap clacker

• Gear Horn

Page 10

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-10

26-Jul-2017

MASTE R CAUTIO N LIGHT

Positioned right next to the master warning

light is the master caution light. It works the

same way the master warning light does.

In the following two cases the master caution

may not be muted:

• GPWS and TCAS voice alerts

• Altitude alert (C-chord) aural

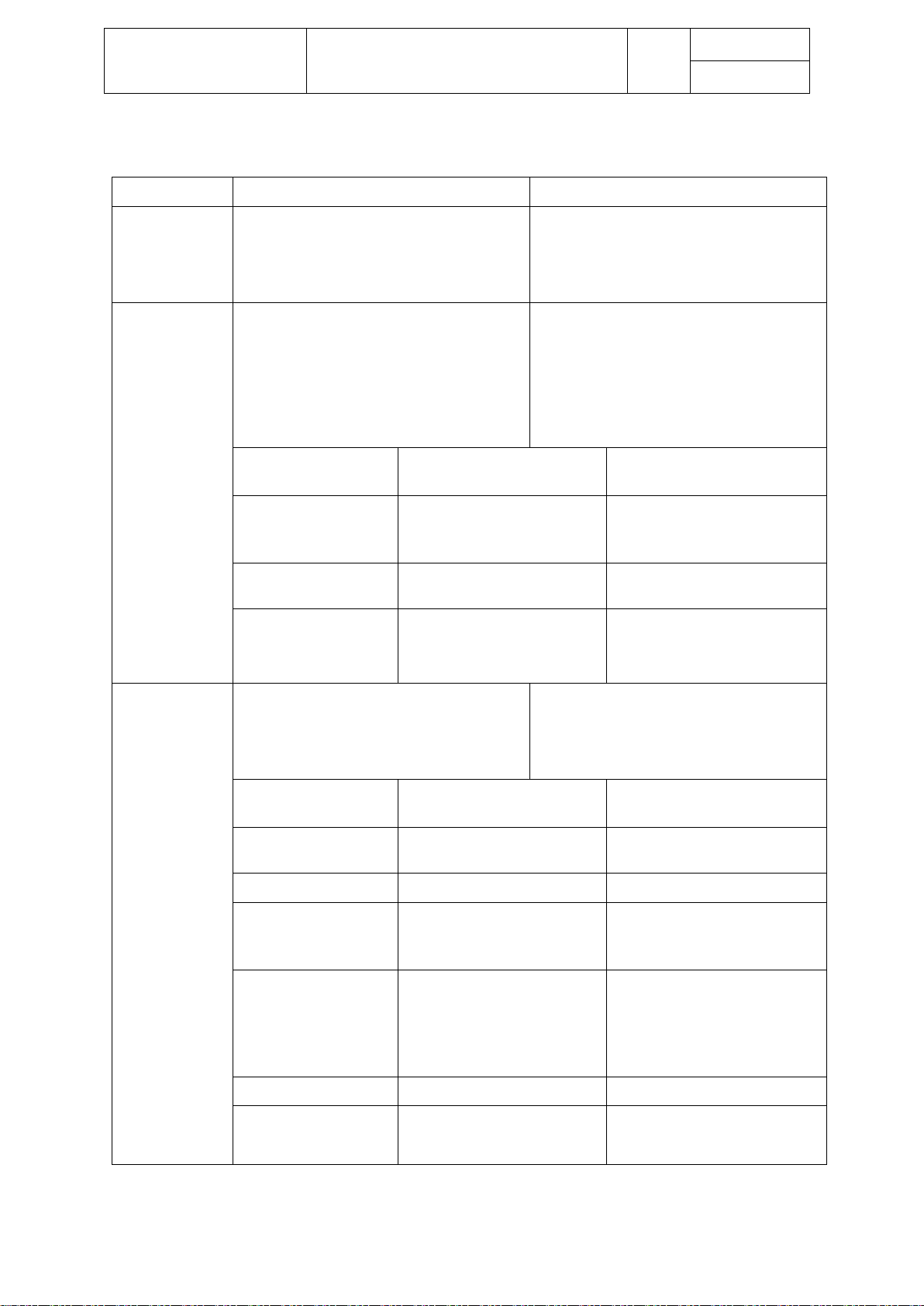

CREW ALERTING SYSTEM ( C AS)

All warning / caution messages are sorted by priority / urgency and order of occurrence. The CAS works with

four categories of messages, with different colour codes and behaviour, indicated in the following table.

In case the triggering condition / fault is removed the message will disappear from the EICAS again. New

messages are added on top according their priority / category.

If the number of message exceeds the available lines in the EICAS, the message “PAGE 1/2” appears in red. All

further messages are available on the following page(s). Press the CAS button to access the messages on the

second side.

When messages are excluded from view by pressing the CAS button a “MSGS” message appears in the EICAS

reminding the crew of the excluded messages. Same goes for advisories and status messages on the STAT

page.

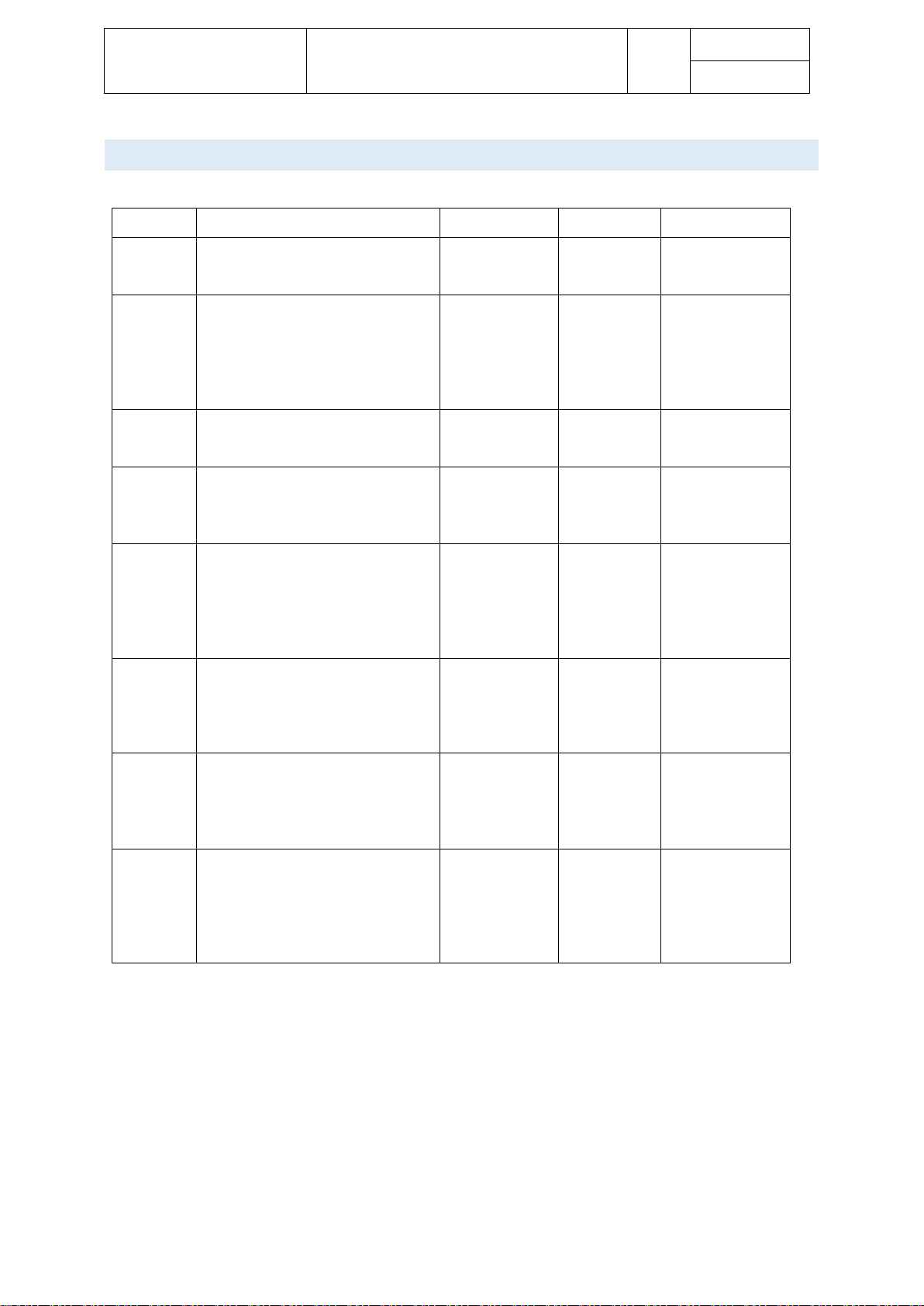

Category

Aural

Warning

Master warning /

master caution

Color

code

Sort order

Displayed

on ED1 /

ED2

Removeable

from EICAS?

Warning

Triple chime

Or voice

Master warning

Red

top

ED1

No

Caution

Single chime

Master caution

amber

Below

warnings

ED1

Yes – CAS

button

Advisory

No

No

Green

Top of ED2

ED2

No – unless

condition is

removed

Status

No

No

White

Below

advisory

ED2

Yes – STAT

button

Page 11

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-11

26-Jul-2017

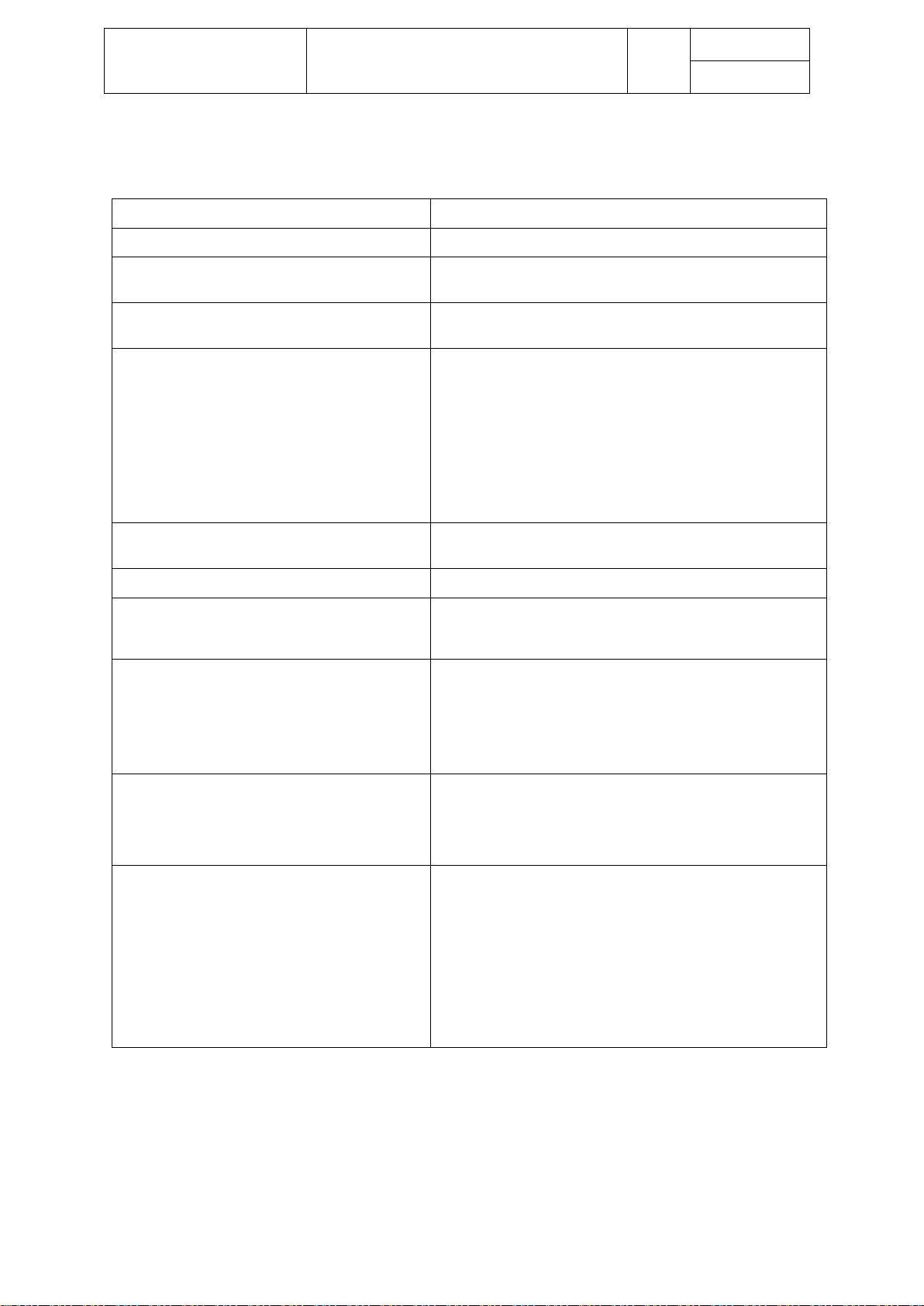

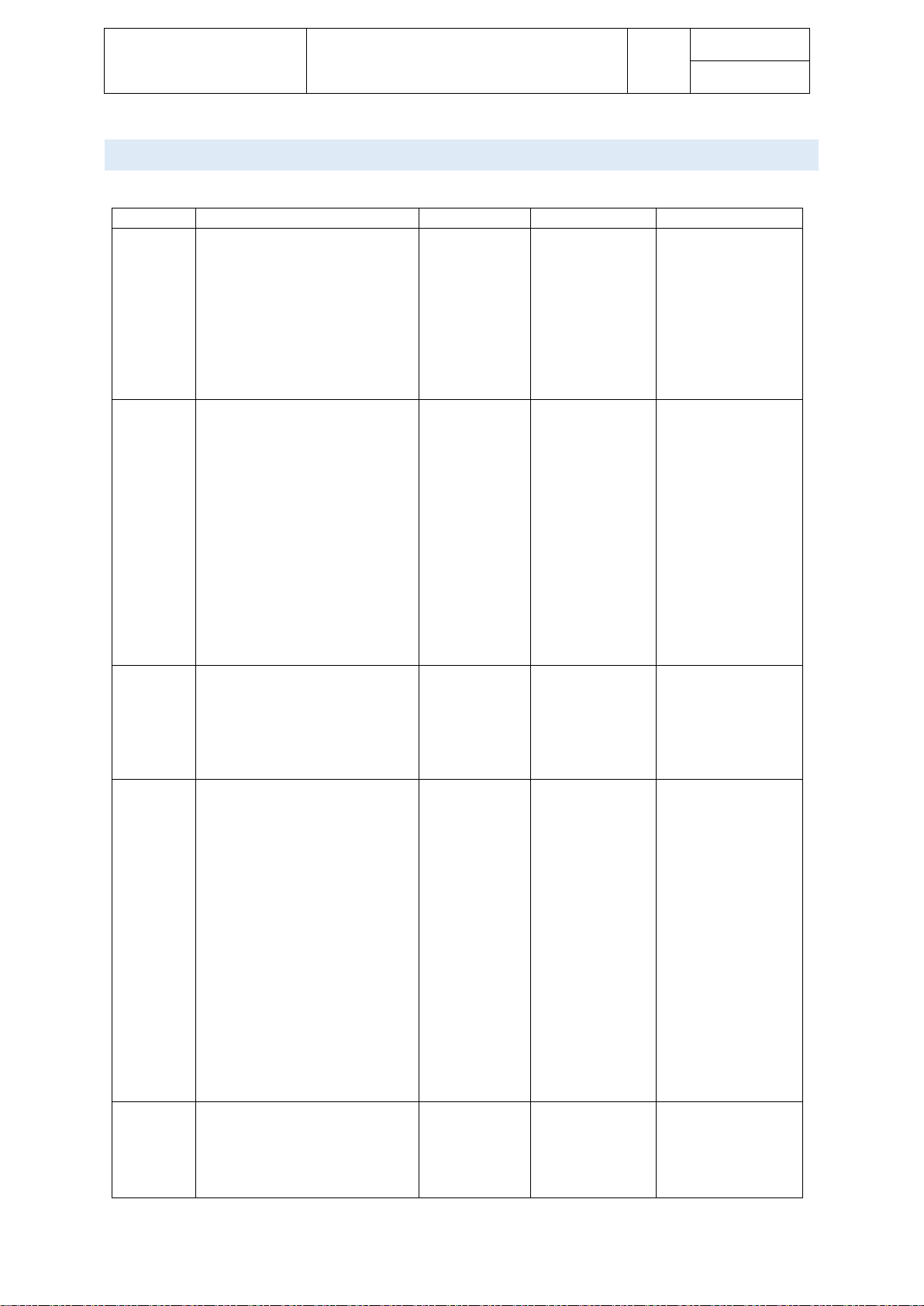

To reduce information during flight phases with high stress level, the DCUs filter information:

Inhibit

Inhibit is enabled when:

Inhibit is removed when:

Initial take-off

• Left and right engine N1 is greater than

79%,

• weight-on-wheels, and airspeed is less

than 100 knots.

• Left and right engine N1 is less than

67.6%, or

• Airplane is in the final take-off phase

Final take-off

• Left and right engine N1 is greater

than 79%, and

• airspeed transitions to greater than

100 knots.

• Left and right engine N1 is less than

67.6%, or

• Radio altitude is greater than 400 ft

AGL, or

• 30 seconds after ground to air

transition.

Aircraft System

Warning Message

(Inhibited during take-off)

Aural

(Inhibited during take-off)

Environmental Control

System

CABIN ALT Cabin Pressure

Flight Controls

Overspeed Clacker

Landing Gear

• GEAR DISAGREE

• NOSE DOOR OPEN

• Gear Disagree

• Nose Door

Landing

• Radio altitude transitions to less than

400 ft AGL, and

• landing gear down and locked.

• 30 seconds after air to ground

transition or

• Radio altitude transitions from less

than 400 ft to greater than 400 ft.

Aircraft System

Warning Message

(Inhibited during take-off)

Aural

(Inhibited during take-off)

Auxiliary Power Unit

APU OVERTEMP

APU

Doors

PASSENGER DOOR

Door

Environmental Control

System

• CABIN ALT

• DIFF PRESS

• Cabin Pressure

• Cabin Pressure

Ice and Rain Protection

• ANTI-ICE DUCT

• L COWL A/I DUCT

• R COWL A/I DUCT

• WING OVHT

• Anti-Ice Duct

• Anti-Ice Duct

• Anti-Ice Duct

• Wing Overheat

Landing Gear

NOSE DOOR OPEN

Node Door

Power Plant

• L ENG OIL PRESS

• R ENG OIL PRESS

• Engine Oil

• Engine Oil

Page 12

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-12

26-Jul-2017

In a similar fashion the cautions are inhibited as well. There are several caution messages which are not

inhibited though:

Airplane system

Caution message (not inhibited)

Automatic Flight Control System

YAW DAMPER

Auxiliary Power Unit

APU LCV CLSD

Fire Protection

FIRE SYS FAULT

Flight Controls

• GLD NOT ARMED

• GLD UNSAFE

• GND SPLR DEPLOY

• IB (OB) FLT SPLRS

• IB (OB) GND SPLRS

• IB (OB) SPOILERONS

• PITCH FEEL

• RUD LIMITER

• SLATS FAIL

• SPOILERONS ROLL

• STAB TRIM

• STAB TRIM LIMIT

• STALL FAIL

Flight Instruments

EFIS COMP MON

Hydraulic Power

HYD 1 (2) (3) LO PRESS

• ICE

• ICE DET FAIL

• L (R) COWL A/I OPEN

• L (R) WING A/I

Landing Gear

• A/SKID INBD (OUTBD)

• IB (OB) BRAKE PRESS

• PROX SYSTEM

• WOW INPUT (OUTPUT)

Pneumatic

• ANTI-ICE DUCT

• L (R) BLEED DUCT

• L (R) COWL LOOP

Power Plant

• L (R) ENG FLAMEOUT

• L (R) ENG SRG CLSD

• L (R) FADEC

• L (R) FADEC OVHT

• L (R) REV INOP

• L (R) REV UNLOCKED

• L (R) REV UNSAFE

Page 13

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-13

26-Jul-2017

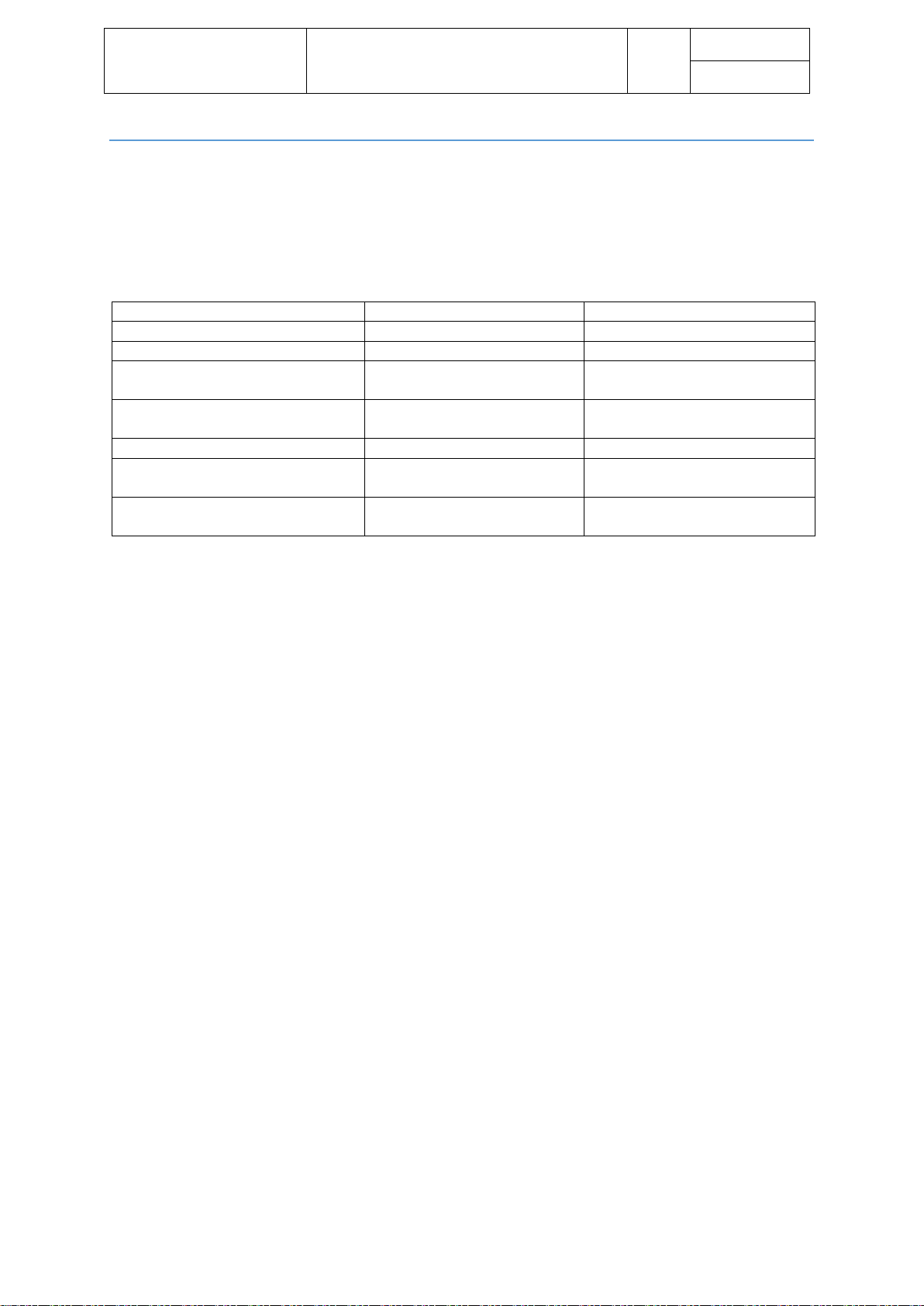

TAKE -OFF WARNI NG

A lot of aircraft do have take-off configuration warning. The actuals aircraft is checked according a

pre-defined logic and in case a deviation is recognized, the crew is informed. The CRJ does this

automatically as soon as the engines are accelerated beyond 70% N1.

The following systems / conditions are checked:

Condition

Voice Message

EICAS Message

Autopilot engaged

Config autopilot

CONFIG AP

Flaps not in take-off position

Config flaps

CONFIG FLAPS

All spoilers not in take-off position

(down)

Config spoilers

CONFIG SPLRS

Horizontal stabilizer outside take-off

range (green band)

Config trim

CONFIG STAB

Parking brake set

Config Brakes

PARKING BRAKE SET

Rudder trim outside of take-off

range (trim > ±1 degree)

Config trim

CONFIG RUDDER

Aileron trim outside of take-off range

(trim > ±1 degree)

Config trim

CONFIG AILERON

If the aircraft detects a deviation it is considered unsafe for take-off. Aural and warning messages

will indicate if such a condition is detected. Furthermore, both MASTER WARNING lights come on.

As soon as the triggering system is corrected, the warning is silenced.

Page 14

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-14

26-Jul-2017

LANDI NG CONFIG WARNING

Like the take-off configuration the landing configuration is automatically checked, too. A deviation will be

indicated by the landing gear horn. Two minutes after lift-off (ground to air transition) the mechanism is armed

and will sound if one of the following conditions exists:

OR

AND

AND

OR

AND

OR

• Radio altitude < 500 ft

• Both throttles at less than maximum landing setting

OR

• Flaps > 30°

• Both throttles at less than maximum landing setting

OR

• Any one throttle is at IDLE with the landing gear warning horn muted

• Airspeed < 170 kts

• Flaps > 30°

OR

• Airspeed < 190 kts

• Flats / slats = 0

• Radio altimeter OR throttle is not valid

• Radio altitude is less than 1000 ft AGL

• vertical speed less than -400 ft/min

• No windshear warning or a windshear warning with a windshear monitor failure

• Radio altitude is less than 1000 ft AGL

• vertical speed OR GPWS not valid

The “Too low gear” aural warning is heard if:

• any landing gear is not down and locked

• radio altitude less than 500 ft AGL

• indicated airspeed at less than 190 knots.

Page 15

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-15

26-Jul-2017

MENU PAGE

The MENU page is divided into three sections: menu section, confirmation section and parameter readout. A

cursor on the left side of the screen is controlled by the UP/DN buttons on the EICAS control panel (ECP). The

SELECT button on the ECP is used to select a line item.

The menu list contains a single FUEL USED RESET line. When the line is selected, the ACCEPT/CANCEL

selections in the confirmation section are used to accept or cancel the request to reset to zero the “Fuel Used”

indication, on the FUEL synoptic page.

The parameter readouts section contains the engine OIL LEVEL indications.

FLIG HT DATA RECORDER

Real aircraft are equipped with flight data and voice recorders. The CRJ’s flight data recorder saves different

information for 25hrs of flight. The FDR automatically starts recording as soon as the BEACON light, STROBE

light is switched ON or a take-off-like condition is detected via the wheels. In case the pilots want to mark a

certain event, they can push the FDR event button for 2 seconds and a timestamp is saved.

The voice recorder saves the last 120 minutes of cockpit communication and passenger announcements as

soon as the aircraft is powered up.

AUTOMATIC FLIGHT CONTROL SYSTEM

The automatic flight control system consists of several systems:

• Flight Director

• Autopilot

• Flight control computers

• Two yaw dampers

• Automatic elevator trim

• Servos / actuators

The flight director computes a flight path which needs to be followed to archive certain pre-set constraints (i.e.

climb at a pre-defined speed to a pre-set altitude). The autopilot computes the required flight control’s

Page 16

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-16

26-Jul-2017

deflections / trim adjustment to archive the commanded flight path. The flight control computers, FCCs,

calculation are based on data from the inertial reference system and air data computers.

Further input sources are selections made on the flight control panel, flight management computer outputs

and radio system outputs.

FLIG H T DIRECTOR

At this point we like to emphasize the difference between the flight director and the autopilot again. The flight

director indicates the needed attitude to archive a pre-set flight path based on selected mode by means of two

cross-hair bars or a v-shaped indication on the PFD’s attitude direction indicator. The flight director does not

control any actuator, flight controls, engine parameters or such to follow the flight path. It is solely for

indication.

The autopilot on the other hand controls the flight control’s servos and actuators to make the aircraft fly along

the pre-set flight path in accordance with the programmed modes. Basically, the autopilot will do everything

needed to follow the flight director.

Bear in mind that the CRJ has no auto throttle – during take-off, climb and go-around you get help from the

FADEC and fixed throttle detents (see later chapters) but especially during descent and levelling off after

descent you must monitor speed closely and adjust thrust as necessary.

The programmed / selected modes are split up in lateral and vertical modes and are presented on the PFD on

top of the attitude direction indicator. The following section introduces and explains the available modes.

Click the FD pushbutton to activate and deactivate the flight director.

Dave allows you to select different types of flight directors as this

differs between companies.

Page 17

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-17

26-Jul-2017

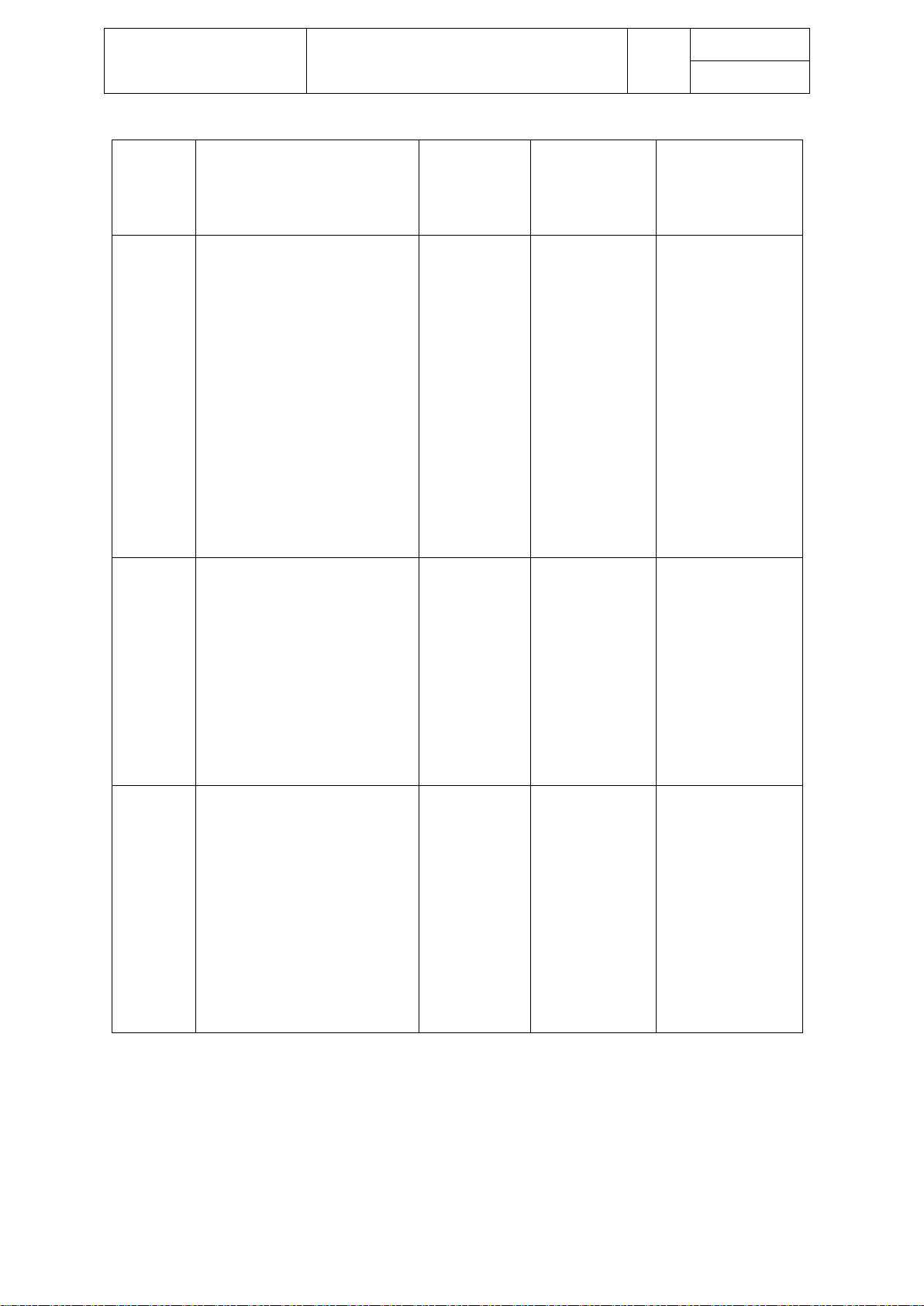

FLIG H T MODE AN NUNCIATO R – LATERAL MODES

Mode

Commanded attitude

Annunciation

Select

Cancel

Take-off

mode

On ground: wings level

After lift-off: heading hold

Bank angle ≤ 5°

TOGA button

on thrust

lever

Synchronize FDs

Select different

lateral mode

Navigation

mode

Capture and follow a track to a

navigation source

Nav source

„VOR1/2,

LOC1/2 or

FMS1/2“

illuminates in

green

NAV button

Heading

select

mode

Capture and hold selected heading

Green HDG

message

Push HDG

knob

Select different

lateral mode

Back

course

mode

Capture and hold selected back

course

Green B/C ½

message

Push B/C

switch

Push B/C switch

again or selecting

another lateral

mode

Roll mode

Holds the existing heading. Given

the roll angle upon initiation was

not over 5°

Green ROLL

message

Roll mode is

selected

automatically

if no other

lateral mode

is active

Selecting any

other lateral

mode

Half bank

mode

Reduces maximum bank angle by

50%

White ½ BNK

message

Push ½ BANK

switch or

climbing

through

31,600ft

Pushing ½ BANK

again

Lateral goaround

mode

Heading Hold command, 5° bank

limit, clears all other modes, turns

on both flight directors and turns

off the autopilot

Green GA

message

Press of

TOGA button

on thrust

lever

Selecting

Synchronization

or selecting

another lateral

mode

Approach

mode

Commands to capture and track

the selected navigation source. In

case no valid navigation source is

received, the mode arms but

tracking won’t work. Automatically

selects glideslope mode

Green message

of the used

navigation

source: VOR ½,

LOC ½, FMS ½.

Press APPR

switch.

Press APPR

switch again,

selecting another

lateral mode,

changing nav

source

Page 18

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-18

26-Jul-2017

FLIG H T MODE AN NUNCIATO R – VERTICAL MODES

Mode

Commanded attitude

Annunciation

Select

Cancel

Vertical

Take-off

mode

Generates a fixed pitch-up

command (pitch angle depends

on take-off speed and difference

between V2 and VR – loss of an

engine reduces commanded

pitch)

clears all other modes, turns on

both flight directors and turns

off the autopilot

Green TO

message

Press of TOGA

button on thrust

lever

Press TOGA switch

again

Engage autopilot

Select

synchronization

Select another

active mode

Pitch

mode

Command to maintain pitch

angle at activation.

Reference value may be altered

using the VS pitch wheel (1/2degree change per click).

When preselecting an altitude –

altitude preselect mode must be

activated before activating pitch

mode

Green PTCH

message

Pitch mode is

automatically

selected when

the flight

director is

activated.

Rotating the VS

pitch wheel also

activates the

pitch mode

(unless in

glideslope

capture or VS

mode)

Selecting a vertical

hold mode

Selecting a vertical

mode capture

Altitude

Hold

mode

Generates commands to

capture and hold selected

altitude.

When the mode is selected, it

sets the current altitude as

reference.

Green ALT

message

Press ALT switch

Press ALT switch

again

Selecting a vertical

hold mode

Vertical mode

capture

Altitude

preselect

mode

Generates commands to

capture and maintain a

preselected altitude. The

preselected value is displayed

on the PFD.

The capture point depends on

the closure rate.

In case the altitude is reselected

during altitude capture (within

200ft of the preselected

altitude), the flight director will

ignore the new setting and

capture the preselected

altitude.

As soon as altitude is captured,

the flight director switches to

altitude hold mode.

Annunciated

by white ALTS

message.

Alt capture is

indicated by

green ALT CAP

message.

It is

automatically

selected as soon

as any vertical

mode (except

glideslope

capture) is

activated.

Cleared by

glideslope capture

or altitude capture

and switching to

altitude hold mode.

Speed

mode

(CLB, DES,

IAS)

Commands pitch in order to

capture and maintain and

preselected airspeed.

Speed is selected by turning the

speed knob.

IAS CLB or IAS

DES

Push the SPEED

knob

Selecting another

vertical capture

mode

Deactivate autopilot

and flight director.

Page 19

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-19

26-Jul-2017

As soon as the autopilot is

activated or synchronization is

activated the current airspeed is

selected as the reference speed.

Capture of

preselected altitude

automatically

deactivates speed

mode.

Vertical

speed

mode

Generates commands to

maintain and preselected

vertical speed.

The selected vertical speed is

displayed on the PFD and may

be selected in a range of ±

12,000 ft/min using the pitch

wheel.

As soon as the autopilot is

engaged or synchronization

selected, the reference vertical

speed is set to the current

vertical speed.

In case a new altitude is

preselected, the altitude must

be preset before activating VS

mode.

Green

VS #.# or

VS #.#

The #.# shows

the current

vertical speed

in thousands

of feet/minute

Push the VS

switch

Push VS switch

again.

Selecting a different

vertical mode

Capture of

preselected altitude

automatically

deactivates vertical

speed mode.

Glideslope

mode

Generates commands to

capture and follow a glideslope

signal. Capture may be

performed from above and

below the glideslope.

Green GS

message

Glideslope mode

is activated

automatically,

when APR mode

is active, the

aircraft is flying

towards

(inbound) a

navigation

source with a

valid glideslope

signal.

Turning outbound

or dialling in a

different navigation

source, deactivating

APP mode clears

glideslope mode.

Vertical

go-around

mode

Fixed pitch-up command. The

commanded pitch angle

depends on if both engines are

running or one engine is

inoperative.

Activation automatically turns

on both flight directors

disengages both autopilots and

clears all other modes.

The resulting autopilot

disengagement warning sound

may be cancelled by pressing

the TOGA switch again.

Green GA

message

Press TOGA

switch on thrust

lever

Engaging the

autopilot.

Selecting

synchronization.

Selection /

capturing or

another active

mode.

Page 20

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-20

26-Jul-2017

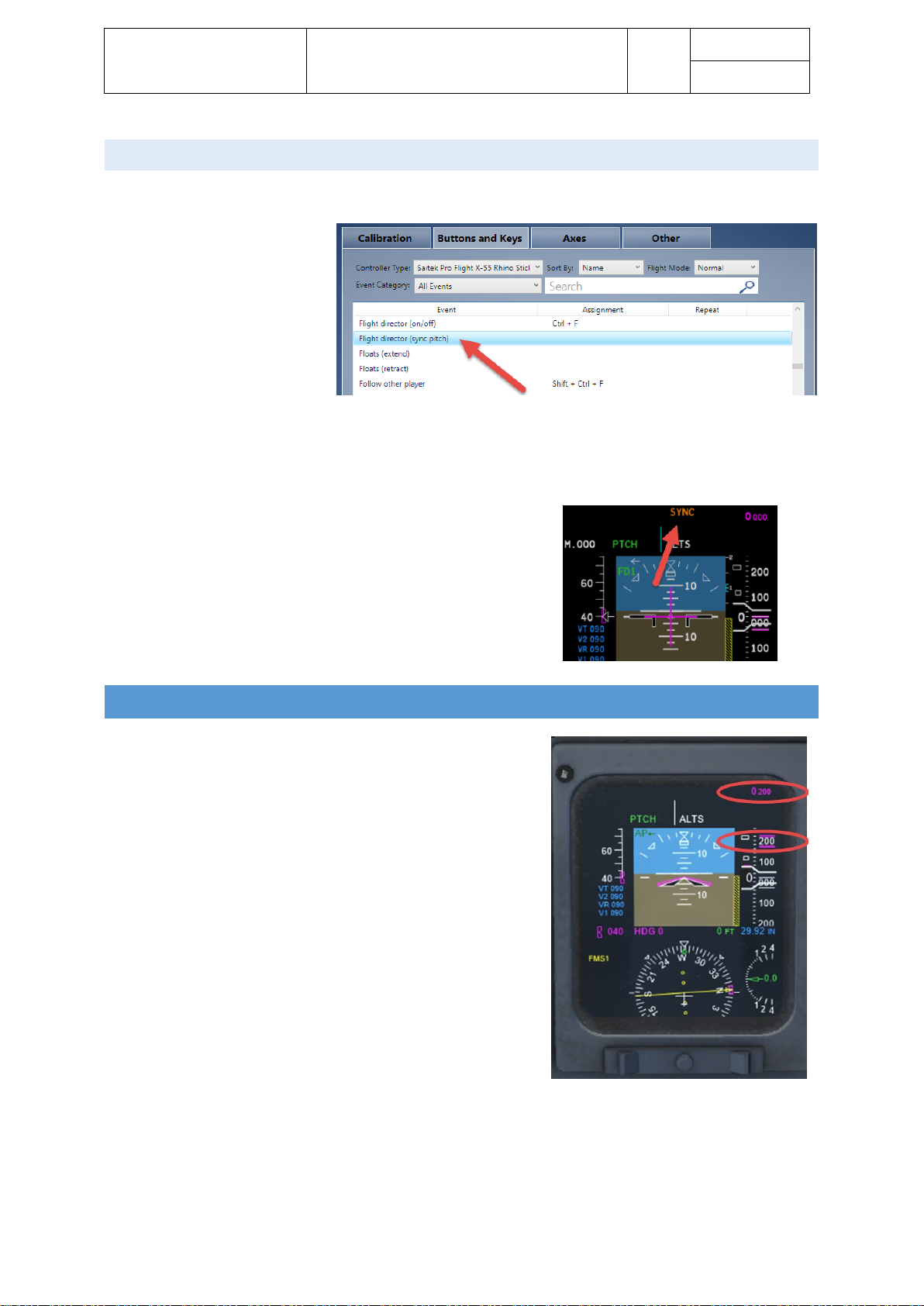

SYNC H RONIZATION

Synchronization enables you to synchronize the flight director bars with the current flight attitude.

The Sync switch on the yoke is

not simulated (because it is

hidden on the backside of the

yoke), so you must use the

standard key assignment “flight

director synchronization”. Please

note this standard key is NOT

assigned in FS/P3D so you must

assign a key to it before it can be used. We used [control]-[shift]-[s].

It has no effect in case the autopilot is engaged and only certain lateral and vertical modes allow

synchronization:

• Lateral

• Bank mode

• Vertical

• IAS mode

• MACH mode

• VS mode

Synchronization is annunciated by an amber SYNC indication on the

PFD. The message disappears after 3 seconds.

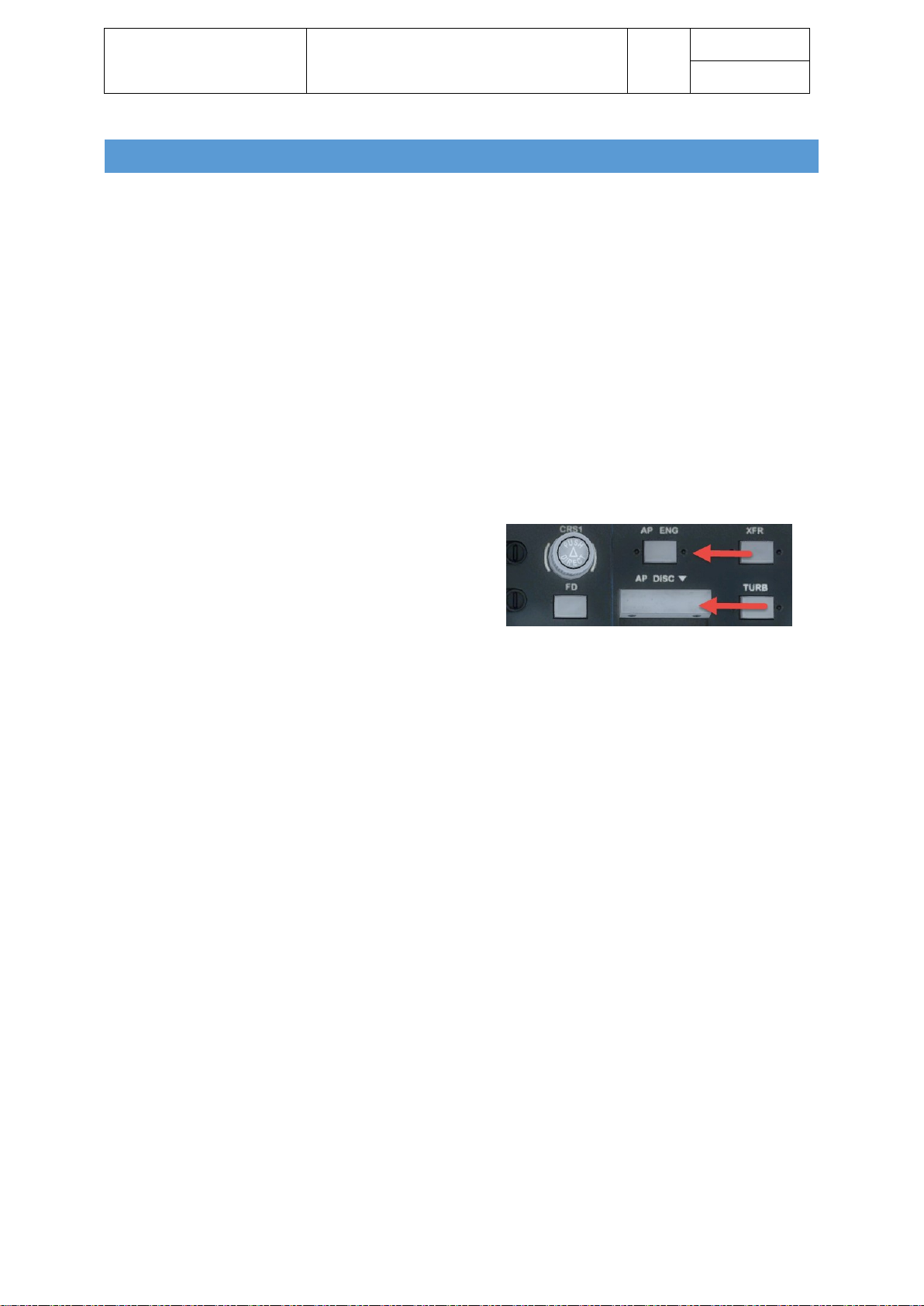

ALTITUDE ALERT SYSTEM

The pilots are notified on the PFD in case they are reaching /

leaving a preselected or selected altitude. The respective advisories

are all displayed on the PFD but in two different places:

• The readouts and bugs change colours and state according

the following rules:

• Approx. 1,000ft before reaching a preselected altitude an

aural warning for approx. 1 second is sounded, and the

readout and bugs flash in magenta for approx. 4 seconds

• Within 200ft of the (pre-)selected altitude the readout and

bugs come steady to indicate altitude capture

• In case the aircraft deviates for more than 200ft from the

selected altitude after capture, a 1 second tone will sound

and the readout and altitude bugs will start to flash amber

(and continue if the deviation occurs or the warning is

cancelled by pressing the ALT switch or selecting a

different altitude)

• In case the aircraft is 200ft below the selected altitude the flashing magenta bugs and readout will

cancel

• If the aircraft deviates further (± 1,000ft) from the selected altitude a 1 second tone sounds

• As soon as the aircraft is again within 200ft of the selected altitude the readout and bugs will cease to

flash

Page 21

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-21

26-Jul-2017

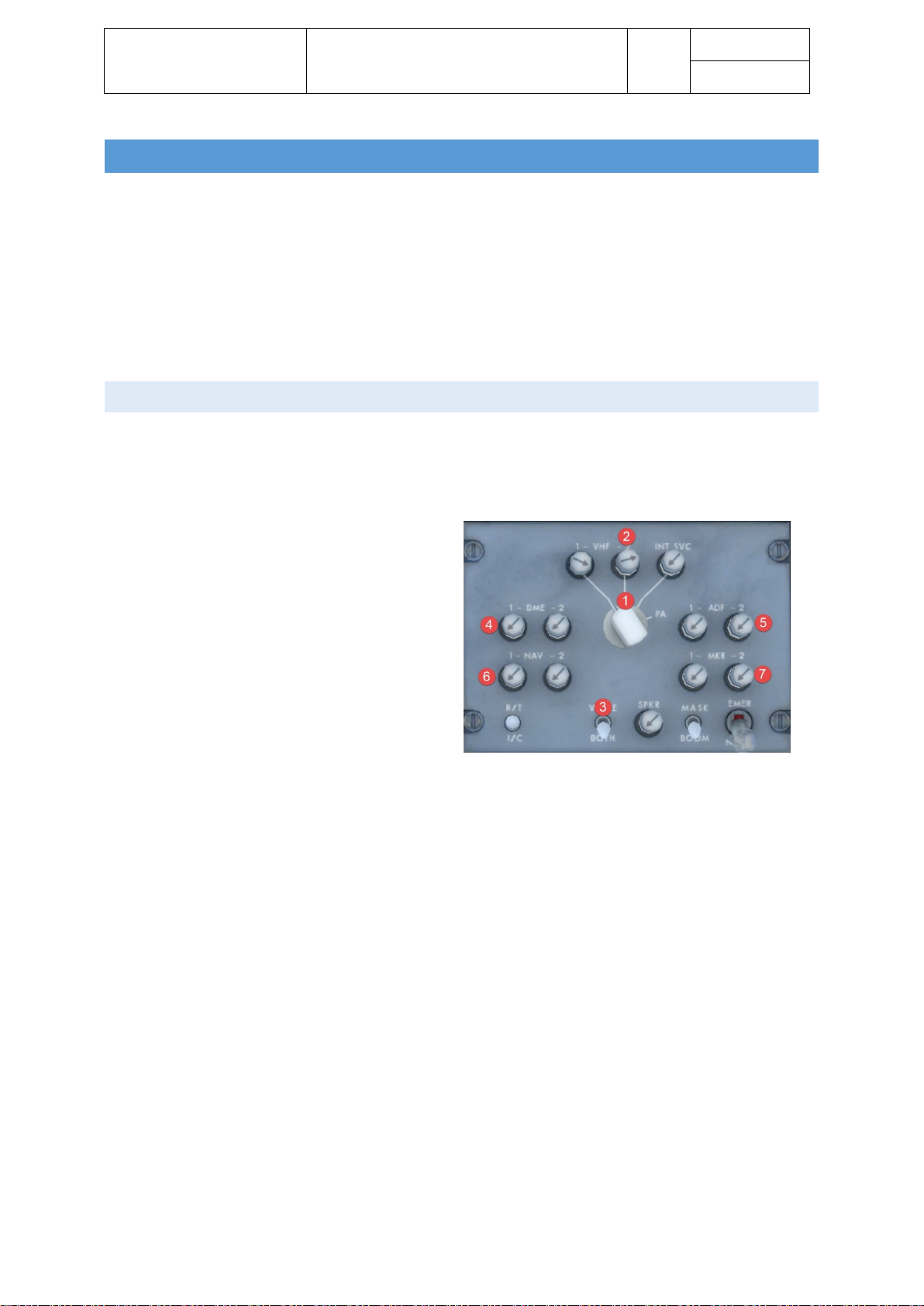

AUTOPILOT

The installed autopilot is a two-axes, digital, fail-passive autopilot. It commands input to the ailerons, elevators

and rudder via the flight control computers, FCCs.

To activate the autopilot the following requirements need to be fulfilled:

• All flight control computers (FCC) are operative

• At least one channel of horizontal trim is available

• At least one yaw damper is engaged

• At least one IRS system is available

• At least one air data computer (ADC) is available

• No significant instability of the aircraft

When flying through turbulent weather autopilot’s corrective signals might reduce passenger comfort. By

selecting the turbulence mode, the intensity of signals is reduced to smooth aircraft motion. Turbulence mode

is automatically cleared as soon as a localizer is captured. The autopilot is activated with the AP ENG

pushbutton and can be deselected by the AP DISC push bar.

The autopilot can also be disengaged by any of the following

controls.

1. Push AP/SP DISC switch on control when – this

equals the autopilot disengage button / key

assignment within FS.

2. Push the AP ENG switch on the flight control panel

3. Lower the AP DISC switch-bar on the right flight control panel

4. Operating the stabilizer trim

5. Pressing the TOGA switch on the thrust levers

6. Disengaging yaw damper by pressing the DISC pushbutton on the yaw damper panel

Disengagement of the autopilot is indicated by an aural warning (cavalry charge) and the AP indications on the

PFDs turns red. After two repetitions of the cavalry charge the warning is cancelled automatically.

Automatic disengagement of the autopilot occurs:

• In case both yaw dampers are disengaged or fail

• In case a failure in the FCC monitoring circuit is detected (not simulated)

• In case a stall warning is triggered

• During a windshear and the subsequent clearance procedure.

It automatically disconnects approx. 2 seconds after the windshear warning

In case the autopilot is disengaged automatically, the following warnings (aural and flashing red AP indication

on the PFD) may be cancelled by pressing the AP/SP DISC switch or either TOGA switch.

Page 22

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-22

26-Jul-2017

COMMUNICATIONS

Some parts of the communication systems cannot be modelled and are not integrated in this package like the

crew / passenger addressing system, boarding music system, external communication panels, attendant

headsets or similar. So, the communication system basically consists of the

• Audio control panel

• Interphone panel on the centre pedestal

• Intercom control panel

• The radio tuning units

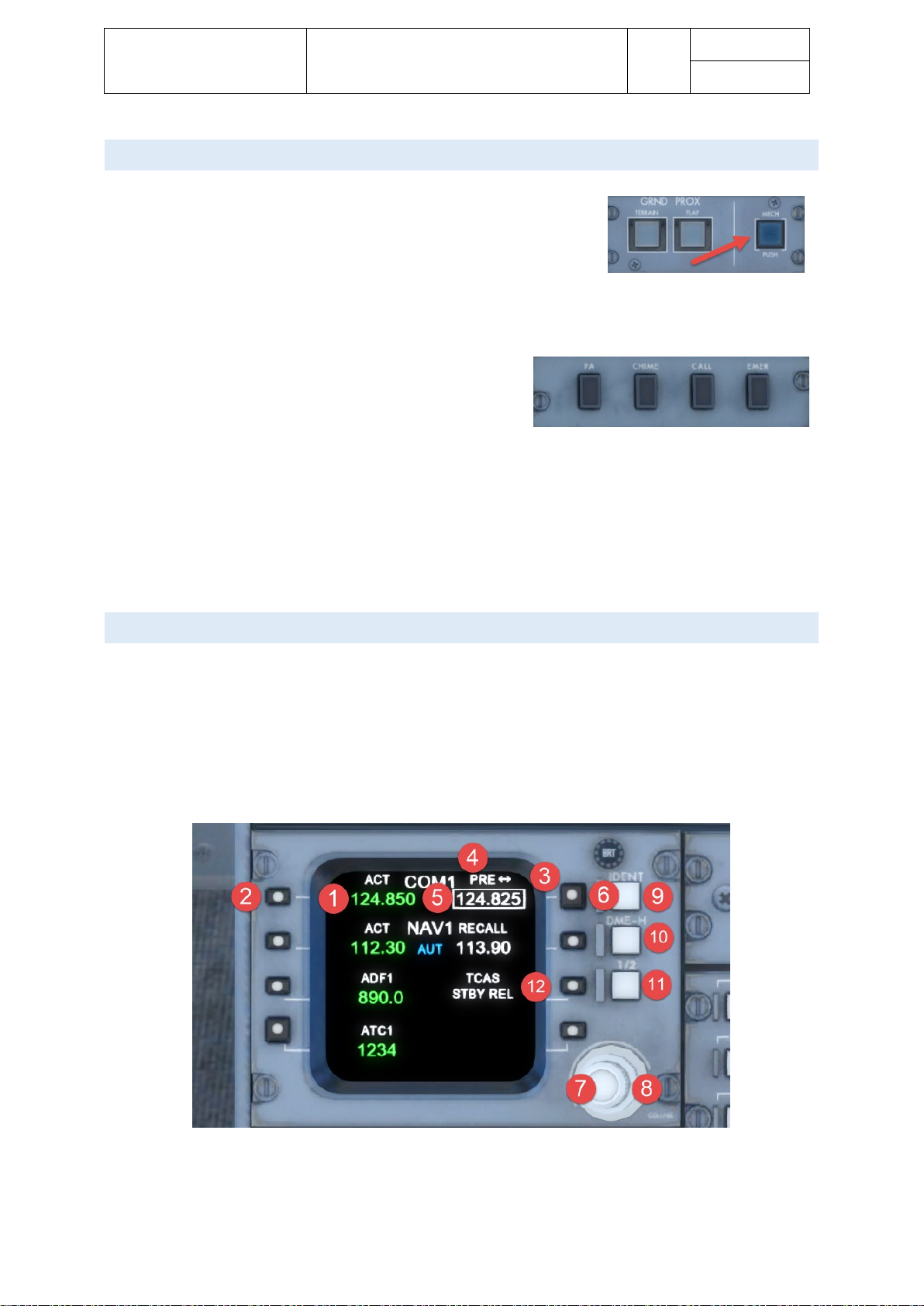

AUDI O CONTROL PANEL

The audio control panel is part of the audio integrating system. The audio integrating system provides display

and control for all incoming and outgoing audio signals of the aircraft’s navigation and communication system.

Three audio control panels are the interface between the crew and the audio integrating system.

1. Transmit Selector: Selects the

communication system, only one can be

active.

2. Receive pushbuttons: Click to select and

deselect.

3. Voice/Both: At voice only the voice

transmissions are audible, at both voice and

station indentification are audible.

4. DME Ident selector: Press to select

5. ADF Ident selector: Press to select

6. NAV Ident selector: Press to select

7. MKR Ident selector: Press to select

The other functions are not simulated.

Page 23

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-23

26-Jul-2017

INTE RPHONE AND INTERC O M CONTROL PANEL

The interphone panel on the centre pedestal is part of the ground crew

interphone. The ground crew interphone is used to establish

communication between crew in- and outside of the aircraft (like during

pushback, engine start, aircraft maintenance). Hence there are several

panels in and outside the aircraft to establish communication. The interphone panel on the pedestal is the only

one modelled and as the counterparts are missing as outside crew there is no function associated with the

ground crew call button which is normally used to establish communication to an outside crew.

The intercom control panel is used for in-airplanecommunication and it faces similar limitations like the

interphone panel. It is not simulated, on the real plane, it offers

four modes of communication:

• PA: Used to address passengers – turns green when activated / pushed

• CHIME: Sounds a chime in the cabin

• CALL: Sounds a chime in the cabin and enables intercom to the flight attendants – turns green when

activated / pushed

• EMER: Used for emergency calls from the flight deck to the flight attendants – flashed in amber when

activated / pushed

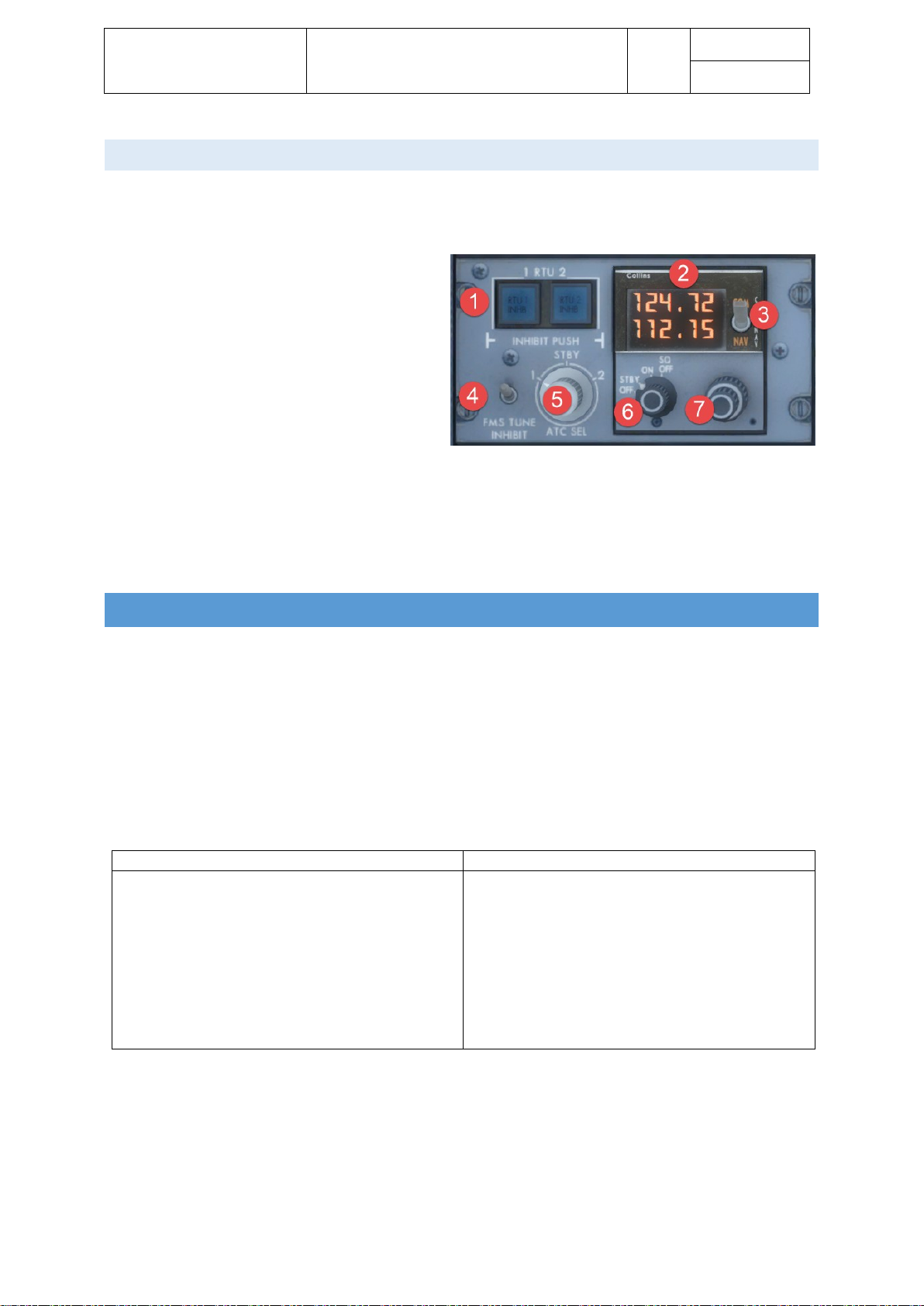

RADI O TUNING UNIT (RTU)

Two VHF (very high frequency) communication systems provide AM (amplitude modulation) voice

communication with ground stations and other aircraft. They operate in a range from 118.000 to 136.975 MHz

They are tuned by via the radio tuning units in normal operation and in case both RTUs fail a backup tuning

unit provides tuning for communication system 1.

The radio tuning units, RTU, are associated with the side they are installed on. Hence the left RTU controls

COM 1 and NAV 1 and the right RTU controls COM 2 and NAV 2.

1. FREQUENCY READOUT: The current active frequency is shown in green

2. SELECT KEY: Push once to directly tune the active frequency, push twice to open COM main page

3. TUNING WINDOW: The while box indicates the frequency that can be adjusted

Page 24

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-24

26-Jul-2017

4. PRE /RECALL: PRE-indicates the frequency was changed, RECALL indicates the frequency was

swapped with the active frequency

5. PRE-SET FREQUENCY: The Preset frequency (shown in white) can be swapped with the active

frequency

6. FREQUENCY SWAP: Push to swap active with Preset

7. ADJUST FREQUENCY: in 25 kHz steps (COM) or 50 kHz steps (NAV)

8. ADJUST FREQUENCY: in 1 MHz steps

9. IDENT: Sends ATC Ident

10. DME-H: Locks frequency for DME measuring.

11. 1/2: Swaps COM1/NAV1/ADF1 with COM2/NAV2/ADF2

12. TCAS: Push to open TCAS menu

COMS MENU

The COMS menu can be accessed by double clicking the

COM select button (see #2 in previous image). It allows the

toggling of Squelch.

TCAS MENU

The TCAS menu can be opened with the TCAS select

button (see #12).

1. MODE: switch between Auto, Standby and Traffic

Advisory Only

2. ALT: Toggles between relative (difference in

altitude between aircraft and target) or absolute

altitude display

3. TEST: Runs a test program

4. RETURN: back to main RTU menu

5. TRAFFIC: toggles display of traffic symbols on

MDF

6. ABOVE: Shows traffic above altitude (can be selected with BELOW)

7. NORM: Standard display

8. BELOW: Shows traffic below altitude (can be selected with ABOVE)

Page 25

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-25

26-Jul-2017

BACKUP TUNING UNIT

The backup tuning unit provides a spare / backup in case both RTUs fail. Normally the backup tuning unit stays

in standby mode the entire flight. As soon as it is switched on it takes control of COM1 and NAV 1.

1. RTU INHIBIT: Disables either RTU

2. FREQUENCY DISPLAY: Shows COM1

(upper) and NAV1) lower, TX is displayed

to indicate transmission

3. TUNING SELECTOR: Toggles between

tuning COM1 and NAV1

4. FMS TUNE INHIBIT: Stops FMS Autotune

function

5. ATC SEL: To select the active transponder

6. MODE SELECTOR:

a. OFF: Display off

b. STB: Displays the frequency shown in RTU1

c. ON: Frequency is controlled by the tuning knob

d. SQ OFF: Squelch selected off

7. TUNING KNOB: To set frequency

ELECTRICAL

The CRJ’s electrical system can be split into an alternating current, AC, subsystem and a direct current, DC,

subsystem. The alternating current, AC system is supplied with power from the engine generators (integrated

drive generators, IDGs), the auxiliary power unit’s generator or the air driven generator, ADG (which is a

backup in case both IDGs fail). The direct current, DC, system is supplied with power from two transformer

rectifier units, TRUs, the main battery, or the APU battery. The TRUs convert alternating current to direct

current. To reload both batteries, battery chargers are installed as well.

Both subsystems use computers to ensure the proper power distribution to the respective systems. The

following table shows the available AC and DC busses.

AC busses

DC busses

• AC BUS 1

• AC BUS 2

• AC ESSENTIAL BUS

• AC SERVICE BUS

• ADG BUS

• DC BUS 1

• DC BUS 2

• DC ESSENTIAL BUS

• DC SERVICE BUS

• DC BATTERY BUS

• DC EMERGENCY BUS

• DC UTILITY BUS

• MAIN BATTERY DIRECT BUS

• APU BATTERY DIRECT BUS

Furthermore – when on ground – an external power receptacle is available which allows the CRJ to be supplied

with ground power. The electrical power panel on the overhead panel is used to control the electrical systems.

Error messages, warning or advisories are indicated on the EICAS.

Page 26

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-26

26-Jul-2017

ALTE RNATING CURRENT, A C SYSTEM

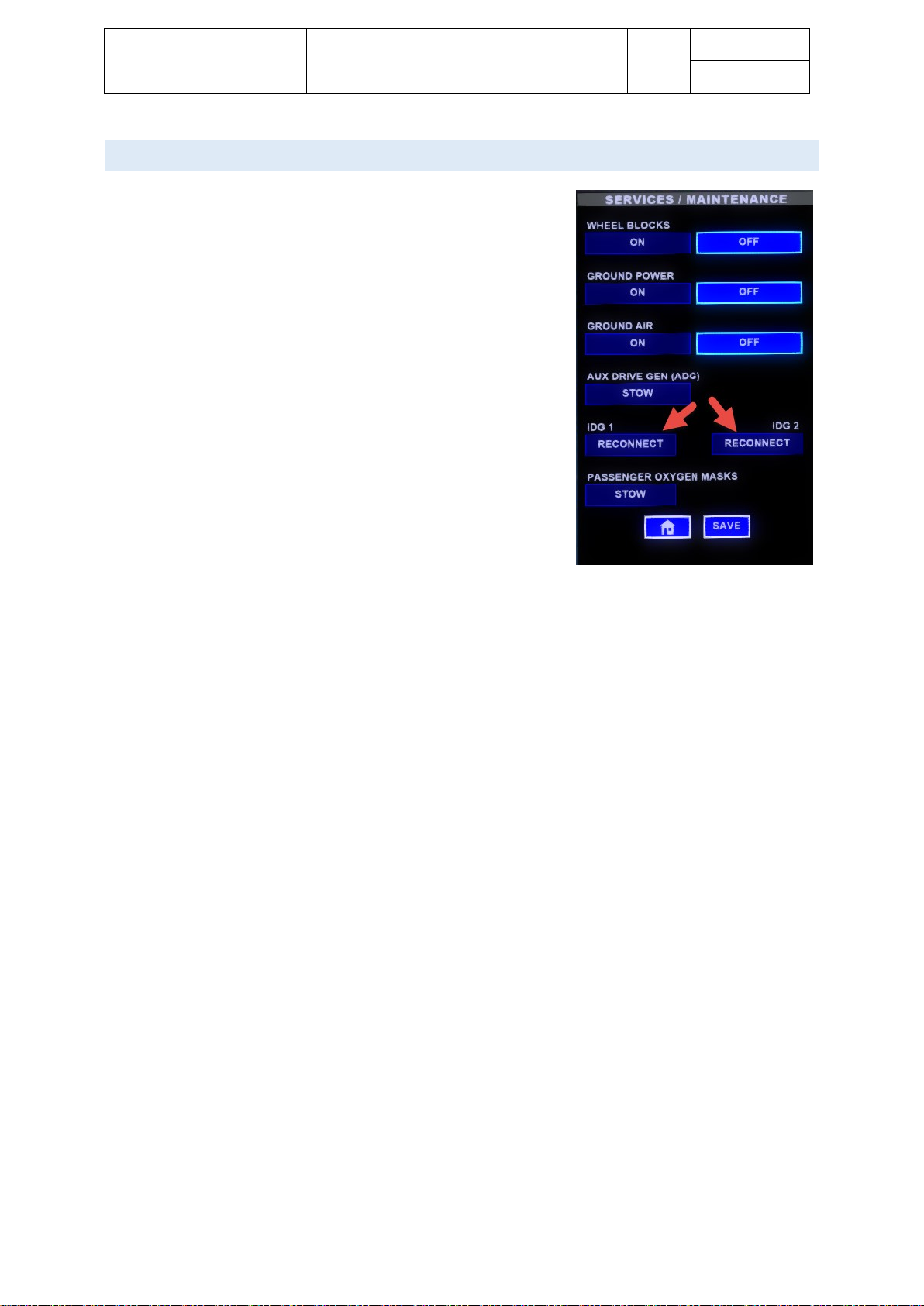

During normal operation, the IDGs supply alternating current. The APU

may be used as a backup in case both IDGs fail. In case even the APU

fails, the CRJ is equipped with an Air Driven Generator, ADG, which is

basically a propeller which is extended into the airstream. The ADG can

provide enough power for the most important aircraft systems to be

still able to fly the aircraft.

The IDGs are monitored regarding temperatures, oil pressure and

supplied power. In case of exceedances the affected IDG can be

disconnected automatically. Nevertheless, there is also a possibility by

means of a switch light on the electrical power panel, to disconnect the

IDG manually.

Please bear in mind that a disconnected IDG (no matter if disconnected

automatically or manually) can only be reconnected on ground. Please

open Dave, go to the “Services / Maintenance” page to reconnect the

IDG. Disconnected IDGs are displayed in blue. Press on “Reconnect”

and “Save” to reconnect.

Before disconnecting you may try to reset the IDG by switching the generator switch on the electrical control

panel to OFF/RESET and then back to ON.

Page 27

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-27

26-Jul-2017

The following table shows the power distribution in the AC system for normal operation:

AC BUS 1

AC BUS 2

AC ESSENTIAL

• Flight Recorder Power

• TRU 1

• Main Battery Charger

• Recirculating Fan 1

• Display Cooling Fan 2

• Lavatory Exhaust Fan

• Baggage Compartment

• Heater

• Slats and Flaps

Channel 1

• Pitch Trim Channel 1

• Hydraulic Pumps 3B

and 2B

• Hydraulic System Fan

• Left Windshield Heater

• TAT Probe Heater

• Right AOA Heater

• Right Pitot Heater

• Enhanced Ground

Proximity

• Warning System

(EGPWS)

• Engine Vibration

Monitor

• Avionics Cooling Fan 2

• ADG Heater

• TRU 2

• Essential TRU 2

• Recirculating Fan 2

• Galley Exhaust Fan

• Galley Heater

• Slats and Flaps

Channel 2

• Pitch Trim Channel 2

• Hydraulic Pumps 3A

and 1B

• Right Windshield

Heaters

• Right Window Heater

• Ice Detector 2

• Co-pilot Panel Integral

Lights

• Inertial Reference Unit

Fan

• Essential TRU 1

• Display Cooling Fan 1

• Avionics Cooling Fan 1

• Crossflow Pump

• Left Pitot Heater

• Standby Pitot Heater

• Left AOA Heater

• Ice Detector 1

• Left Window Heater

• Cabin Ceiling Lighting

• CB Panel Integral Lights

• Pilot Panel Integral Lights

• Overhead Panel Integral

• Lights

• Centre Panel Integral Lights

• Traffic Alert and Collision

• Avoidance System (TCAS)

• Engine Ignition A

AC SERVICE BUS

ADG BUS

• APU Charger

• Logo Lights

• Cabin Sidewall Lighting

• Cabin Ceiling Lighting

• Toilet

• Water System

• Hydraulic Pump 3B

• Pitch Trim 2

• Slats and Flaps #1

• Slats and Flaps #2

Page 28

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-28

26-Jul-2017

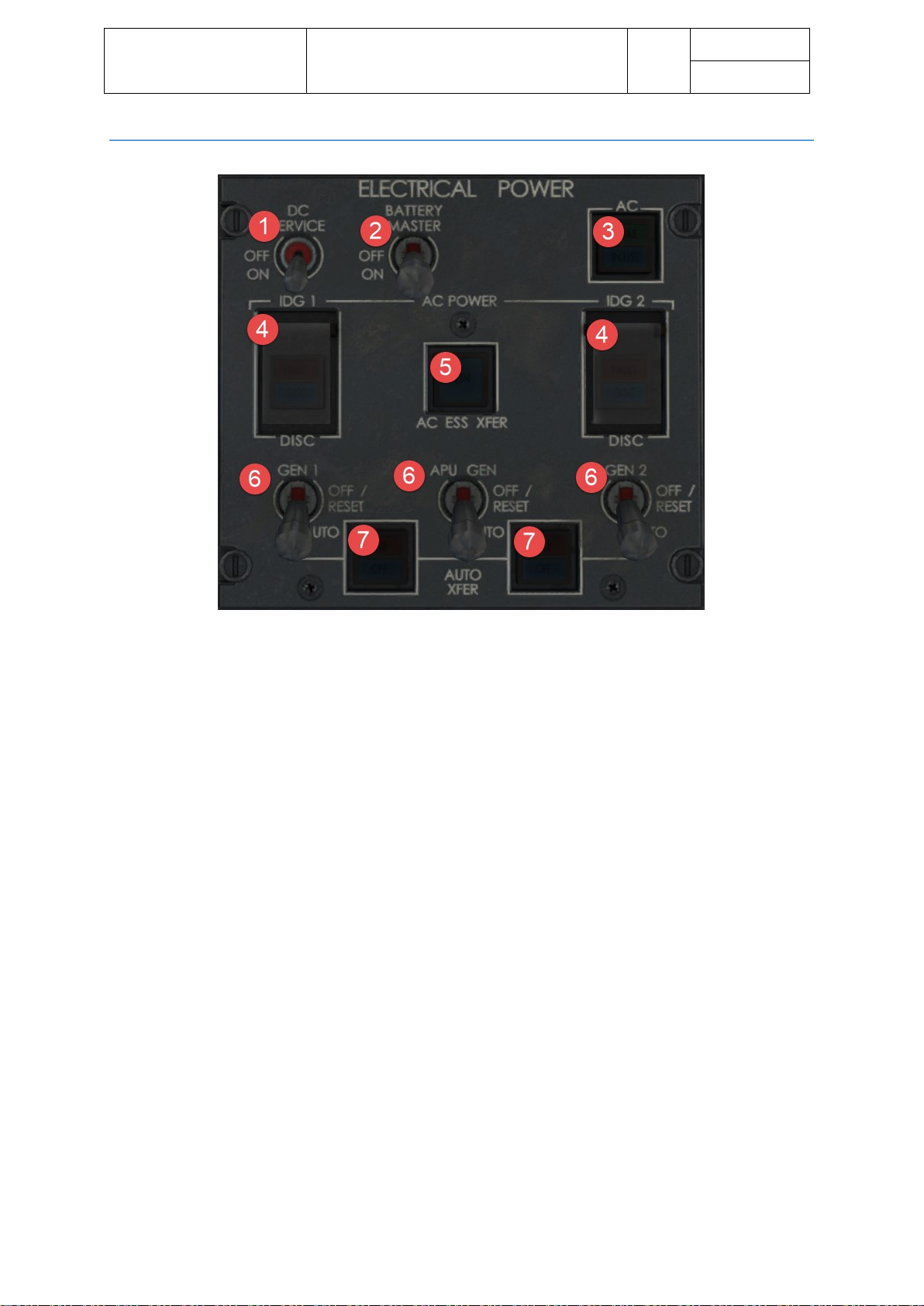

CONTR OLS ON O VERHEAD PANEL

1. DC SERVICE: Connects the DC service bus to the APU battery direct bus

2. BATTER MASTER: Used to supply the battery bus with power from the APU or main direct busses.

Always ON in flight!

3. AC: External Power toggle

- AVAIL indicates connected source

- IN USE indicates AC busses are connected to external power unit

4. IDG1/2 DISCONNECT: Open guard and press push button to disconnect IDG1 (reconnect on ground

only!)

- DISC (white) indicates IDG is disconnected

- FAULT (amber) indicates low oil pressure or high temperature

5. AC ESS XFER: Switches essential bus feed from AC bus 1 to AC bus 2, switches automatic in case of

IDG1 failure

- ALTN (white) indicates essential bus is fed from AC bus 2

6. GEN 1: Used to switch generators between AUTO and OFF

7. AUTO XFER: Disables automatic transfer of respective IDG

- OFF indicates autotransfer is deactivated

- FAIL indicates a fault is preventing autotransfer

Page 29

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-29

26-Jul-2017

EICAS SYNOPTI C PAGE – HOW TO OPEN AC & DC E LECTRIC A L SYNOPTI C PAGES

The AC and DC electrical synoptic page is opened via the EICAS

control panel by pressing the ELEC key (1) once to open the AC

electrical synoptic page and twice to open the DC electrical

synoptic page.

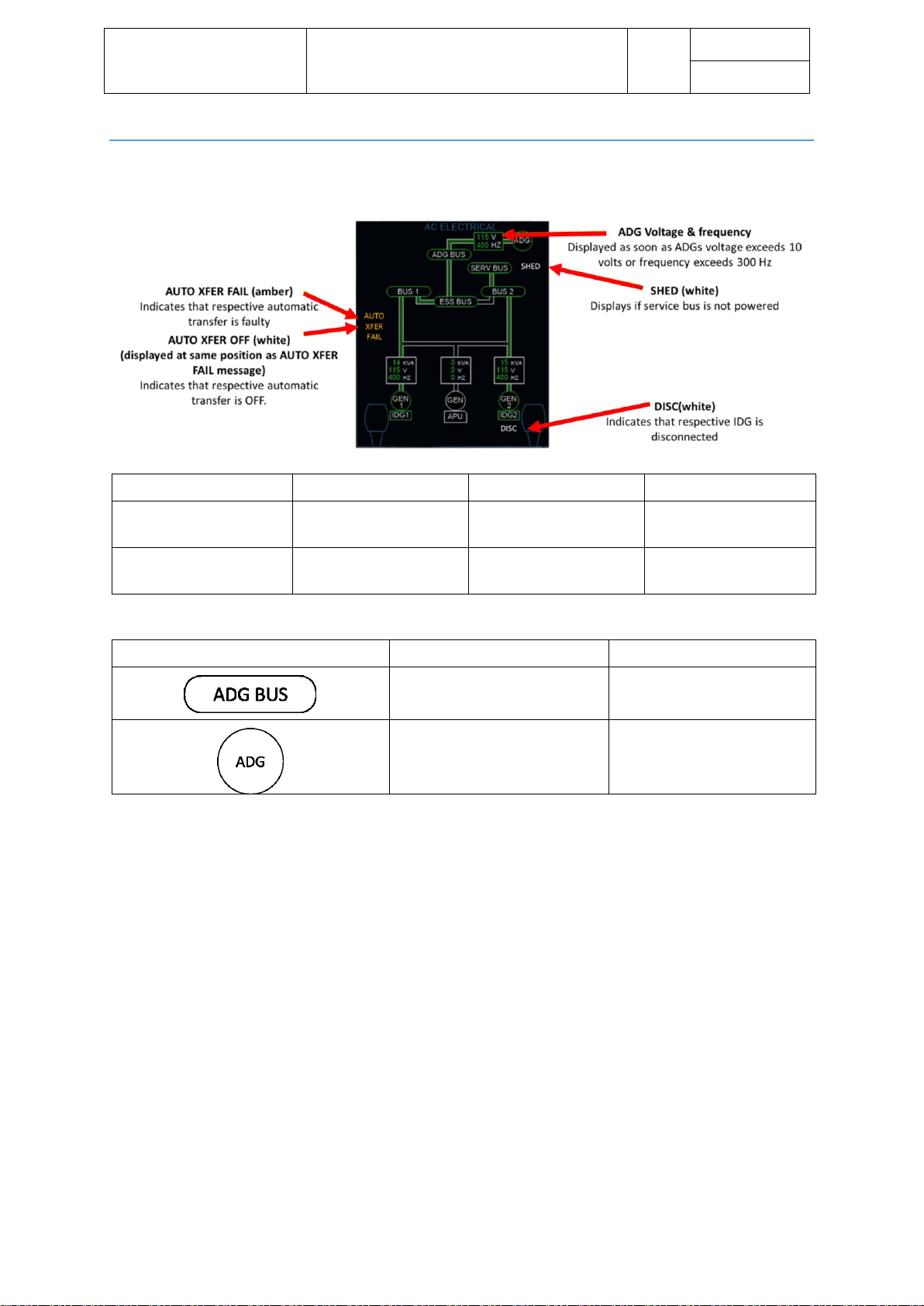

EICAS SYNOPTI C PAGE – ELE C TRICAL POWER SUPPLIED FROM ENGINES

On the EICAS Electrical displays the green flow lines show energized

busses, white lines show not energized busses.

EICAS DIGITAL

READOUT

GREEN

AMBER

WHITE

HALF INTENSITY AMBER

AMBER

DASHES

XXX kVA

Generator

loaded

Generator

overload

Generator not

loaded

Insufficient data

Invalid data

XXX V

Voltage in

range

-

Voltage not in

range

Insufficient data

Invalid data

XXX HZ

Frequency

in range

-

Frequency not

in range

Insufficient data

Invalid data

EICAS OUTLINE

GREEN

AMBER

WHITE

HALF

INTENSITY

AMBER

HALF

INTENSITY

CYAN

Bus powered

Bus not

powered or

voltage low

-

Invalid data

-

Generator on

Generator off

with engine /

APU running

Both

generator and

engine / APU

are off

Invalid data

-

Constant speed

drive on

Low oil

pressure or

high oil

temperature

Engine is off or

IDG is

disconnected

Invalid data

-

-

-

Engine / APU

off

Invalid data

Engine / APU

running and

ready to load

Page 30

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-30

26-Jul-2017

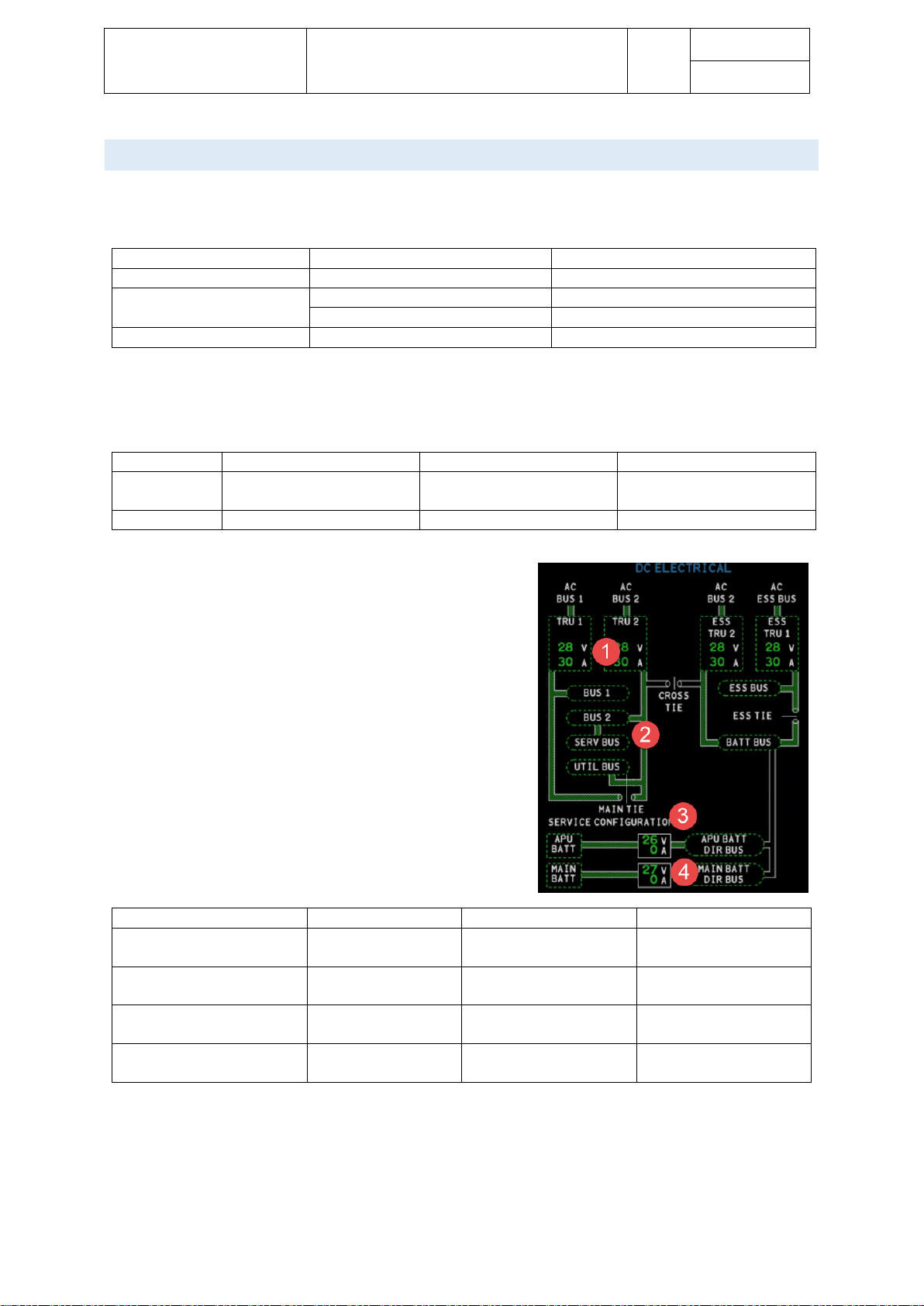

EICAS SYNOPTI C PAGE – ELE C TRICAL POWER SUPPLIED FROM AIR DRI VEN GENER A TOR

EICAS DIGITAL READOUT

GREEN

WHITE

AMBER DASHES

XXX V

Between 108 and 130

volts

Less than 108 or more

than 130 volts

Invalid data

XXX HZ

Between 360 and 440 Hz

Less than 360 or more

than 440 Hz

Invalid data

EICAS OUTLINE

GREEN

WHITE

ADG outline green

ADG outline white

Voltage and frequency digital

readouts green

Voltage or frequency digital

readouts white

Page 31

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-31

26-Jul-2017

EICAS SYNOPTI C PAGE – ELE C TRICAL POWER SUPPLIED FROM EXTERNA L POWER

Before you can connect an external power supply to your aircraft you need to set the parking brake and/or

chocks and then activate the power cart via Dave. So please open Dave and proceed to the “Services /

Maintenance” menu, then activate the chocks and ground power. Then press SAVE.

The green AVAIL light of the AC pushbutton on the overhead panel

will illuminate as soon as the power supply is connected to the

aircraft. Press pushbutton to accept power supply. Please note that

engines and APU generators need to be off.

1. When External Power is available SERVICE

CONFIGURATION will be displayed

2. When External Power is connected to the busses the

Generator load, Voltage and Frequency will be displayed

EICAS MESSAG ES

For certain occurrences, messages are triggered on the EICAS ED1 and ED2 display.

• IDG 1/2 CAUTION (amber): Low oil pressure or high temperature

• GEN 1/2 CAUTION (amber): Generator(s) off

• GEN 1/2 CAUTION (amber): Generator load over 40 kVA

• APU GEN OFF CAUTION (amber): APU generator ready but off

• APU GEN OVLD CAUTION (amber): APU generator load over 40 kVA

• IDG 1/2 DISC (white): IDG(s) disconnected

• EMER PWR ONLY WARNING (red): ADG deployed

• AC BUS 1/2 CAUTION (amber) : Bus not powered

• AC ESS BUS CAUTION (amber) : AC essential bus voltage under 90 Volts

• AC 1/2 AUTOXFER CAUTION (amber) : Automatic bustransfer failed

• AC 1/2 AUTOXFER OFF (white): Automatic bustransfer deactivated

• AC ESS ALTN (white): Essential bus fed from AC bus 2

• ADG FAIL (white): Generator control unit failed

• ADG AUTO FAIL (white): ADG deployment control unit failed

Page 32

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-32

26-Jul-2017

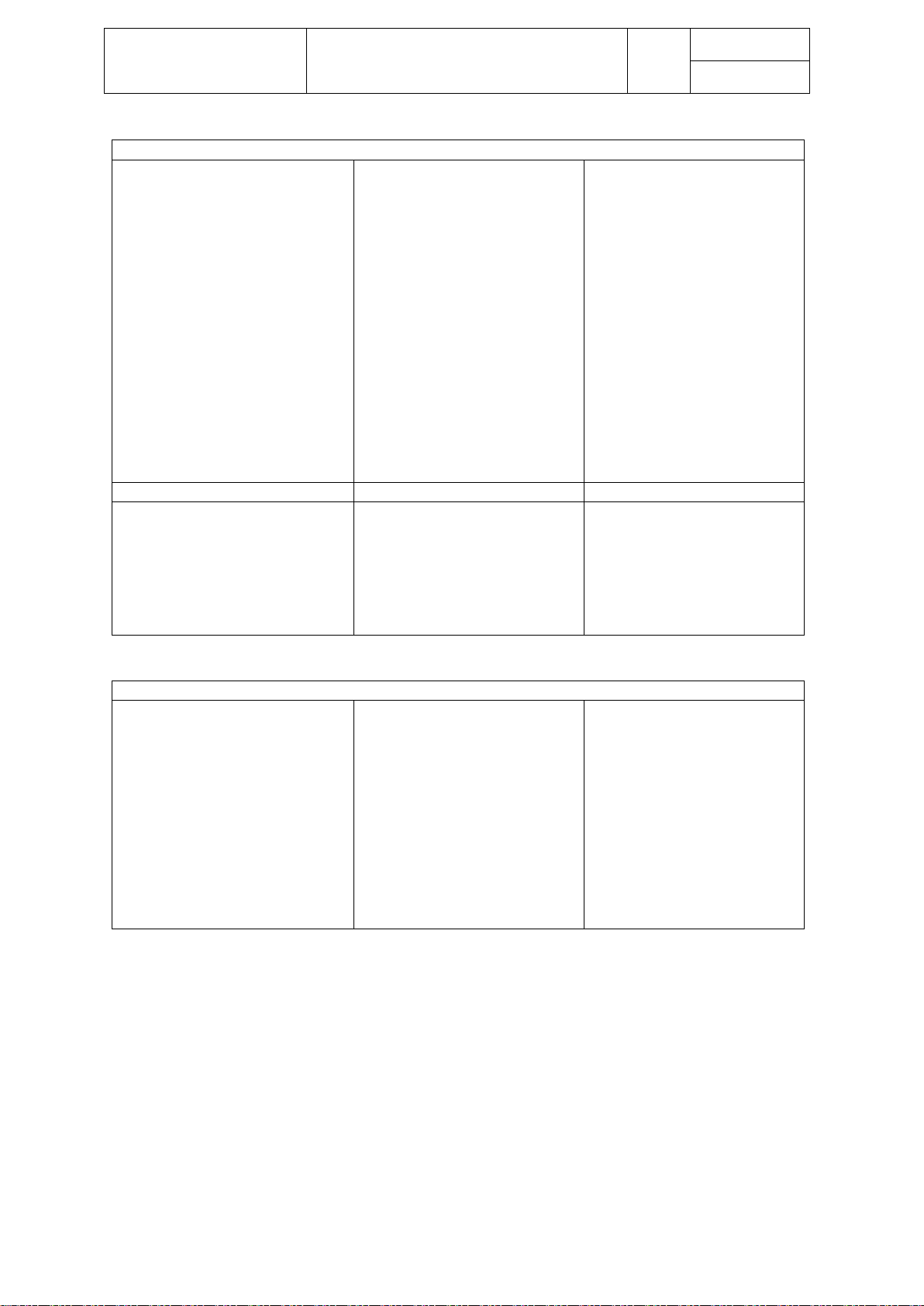

DIREC T CURRENT, DC SYSTEM

Direct power is supplied by four transformer rectifier units, TRUs and two batteries.

The following table shows normal power distribution from the AC to the DC system:

INPUT BUS

TRU

OUTPUT BUS

AC BUS 1

TRU 1

DC BUS 1

AC BUS 2

TRU 2

DC BUS 2 / DC UTILITY BUS

ESSENTIAL TRU 2

DC BATTERY BUS

AC ESSENTIAL BUS

ESSENTIAL TRU 1

DC ESSENTIAL

ESS TRU 2 is normally supplied AC power from AC BUS 2. If AC BUS 2 is not available, ESS TRU 2 will be

automatically supplied from the AC ESS BUS, via the ESS TRU 2 XFR switch.

Battery

location

Output voltage

Capacity

APU

Aft equipment

compartment

24V DC

43 Ah (ampere hours)

MAIN

Nose avionics compartment

24V DC

17 Ah (ampere hours)

1. TRU VOLTAGE / TRU LOAD

2. FLOW LINES: Green indicates bus energized, white

indicates bus not energized

3. SERVICE CONFIGURATION: Indicates DC service is

selected ON

4. BATTERY VOLTAGE / BATTERY LOAD

EICAS DIGITAL READOUT

GREEN

WHITE

AMBER DASHES

XX V (TRU)

Between 22 and 29

volts

Less than 22 volts or

more than 29 volts

Invalid data

XX V (BAT)

Between 18 and 32

volts

Less than 18 volts or

more than 32 volts

Invalid data

XX A (TRU)

Between 3.7 and

120.7 amps

Less than 3.7 amps or

more than 120.7 amps

Invalid data

XX A (BAT)

Between 1.7 or not

less than 12 volts

Less than 1.7 amps and

less than 12 volts

Invalid data

Page 33

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-33

26-Jul-2017

EICAS OUTLINE

GREEN

AMBER

WHITE

AMBER DASHES

ll

Bus powered

Bus not powered

-

Invalid data

Not less than 18

volts

Less than 18

volts

-

Invalid data

Not less than 3.7

amps and not less

than 18 volts

-

Less than 3.7 amps

and less than 18

volts

Invalid data

Not less than 18

volts

Less than 18

volts

-

Invalid data

EICAS MESSAG E S

For certain occurrences, messages are triggered on the EICAS ED1 and ED2 display.

• APU / MAIN BATT OFF CAUTION (amber): APU or main battery is not available

• DC BUS 1/2 CAUTION (amber): DC bus not powered and AC bus 1 or 2 online

• DC EMER BUS CAUTION (amber): Emergency bus not powered

• DC ESS BUS CAUTION (amber): Essential bus not powered in flight / Essential bus not powered and AC

or APU generator on line on ground

• DC SERV BUS CAUTION (amber): Service bus not powered AND either DC bus 2 OR DC SERVICE is

selected AND APU voltage > 18 volts

• BATTERY BUS CAUTION (amber): Battery bus not powered

• DC CROSS / DC MAIN / DC ESS TIE CLSD (white): Respective bus tie closed

• ESS TRU 2 XFR (white): Displayed when essential TRU 2 is powered by AC essential bus

• APU BAT / MAIN BAT CHGR (white): Battery not charging or overheating

• TRU 1/2 FAIL (white): TRU 1/2 voltage < 18 volt with AC BUS 1/2 online

OR main is closed with TRU 1/2 load < 3.7 amps

• ESS TRU 1/2 FAIL (white): Essential TRU 1/2 voltage < 18 volt with AC BUS 1/2 online

OR main is closed with essential TRU 1/2 load < 3.7 amps

DC BUS 1

Flight Recorder Control

EICAS Primary Display

EICAS Secondary Display

Left Lamp Driver Unit

EICAS Dimming

Data Loader

Left IAPS

Boarding Music

Passenger Door Actuator

ACPC Control 1

Baggage Compartment Control

Fan Monitor

Cabin Pressure Control 1

Cockpit Temperature Sensors

Aft Cabin Temperature Sensors

ACS Control 2 Channel A

Lavatory Smoke Detector

SSCU 1 Channel A

Pitch Feel 1

Radio Altimeter 1

Hydraulic Pump 2 and 3B

Control

Hydraulic System Fan Control

Hydraulic System 2 Indication

Anti-Ice Control Channel A

Left T2 Heater

Pilot Windshield Wiper

Left Windshield Heater Control

ADS Heater Control 2

Right Static Heaters

Brake Pressure Application

PSEU Channel A

Nose Wheel Steering

Anti-Skid

Left Cabin Reading Lights

Cockpit Dome Light

Taxi Lights

Nose Landing Lights

Cockpit Floor Lights

Rear Anti-Collision Lights

Wing Inspection Lights

Maintenance Lights

GPS 1

DME 1

Weather Radar

Page 34

Aerosoft – Digital Aviation

CRJ-70 & CRJ-900

AOM PART 2

Systems Description

VOL

5

5-1-34

26-Jul-2017

DC BUS 2

Right IAPS

Right AFCS

Right IAPS Fan

Observer Audio

VHF Communication 2

RTU 2

Service Bus Feed

ACPC Control 2

Left ACS Pressure Sensors

Cabin Pressure Control 2

Galley Heater Control

Fwd Cabin Temperature Sensors

ACS Control 1 Channel B

Right ACS Manual

SSCU 1 Channel B

Aileron and Rudder Trim

Clock 2

Radio Altimeter 2

Air Data Computer 2

Primary Flight Director 2

Multifunctional Display 2

EFIS Control Panel 2

Attitude Heading 2

Right Fuel Pump and Control

Hydraulic System 1 Indication

Hydraulic Pump 1 and 3A

Control

Right T2 Heater

Copilot Windshield Wiper

Right Windshield Heater Control

Right EFIS CRT Dimming

Right Window Heater Control

PSEU Channel B

Nose Wheel Steering

Brake Pressure Indication

Anti-Skid

Chart Holder Lights

Copilot Map Light