Page 1

BETRIEBSANLEITUNG/OPERATING INSTRUCTIONS

Thyro-P

Thyristor-Leistungssteller

kommunikationsfähig

1

Thyristor Power Controller

Communication Capable

DE EN

Page 2

2

SAFETY INSTRUCTIONS

THE SAFETY INSTRUCTIONS AND OPERATING MANUAL ARE TO BE CAREFULLY READ PRIOR

TO INSTALLATION AND COMMISSIONING.

OBLIGATION TO GIVE INSTRUCTIONS

The following safety and operating instructions must be carefully read before assembly, installation

and commissioning of Thyro-P by those persons working with or on Thyro-P.

These operating instructions are part of the Power Controller Thyro-P.

The operator of this device is obliged to provide these operating instructions to all persons

transporting, commissioning, maintaining or performing other work on the Thyro-P without any

restrictions.

In accordance with the Product Liability Act, the manufacturer of a product has an obligation to

provide explanations and warnings as regards:

• the use of the product other than for the intended use,

• the residual product risk and

• operating error and its consequences.

The information given below must be understood in this respect. It is to warn the product

user and protect him and his systems.

PROPER USE

• The Thyristor Power Controller is a component which may only be used for control and regulation

of electrical energy in industrial alternating current or 3-phase networks.

• The Thyristor Power Controller may at maximum be operated using the maximum admissible

connected load according to information on the type plate.

• The Thyristor Power Controller may only be operated in connection with a suitable and series

connected power supply disconnecting device.

• As a component the Thyristor Power Controller is unable to operate alone and must be projected

for its intended use to minimize residual risks.

• The Thyristor Power Controller may only be operated in the sense of its intended use; otherwise,

personal hazards (for instance electrical shock, burns) and hazards for systems (for instance overload) may be caused.

RESIDUAL HAZARDS OF THE PRODUCT

• Even in case of proper use, in case of fault, it is possible that control of currents, voltages and

power is no longer performed in the load circuit by the Thyristor Power Controller.

In case of destruction of the power components (for instance breakdown or high resistance), the

following situations are possible: power interruption, half-wave operation, continuous power fl ow.

If such a situation occurs, then load voltages and currents are produced from the physical dimensions of the overall power circuit. It must be ensured by system design that no uncontrolled large

currents, voltages or power results. It is not possible to totally exclude that during operation of

Thyristor power controllers other loads show abnormal behaviour. The physically determined

network reactions, depending on the operating mode, must be considered.

DANGER OF ELECTRIC SHOCKS

Even if the Thyristor Power Controller is not triggered, the load circuit is not disconnected from the

mains.

It is possible to safely disconnect the Thyristor Power Controller as under IEC 60950

Page 3

MALOPERATION AND THE RESULTS

With maloperation, it is possible that power, voltage or current levels which are higher than planned

reach the Thyristor Power Controller or load. On principle, this can lead to the Power Controller or

load being damaged. It is important that preset parameters are not adjusted in any way that may

cause the Power Controller to overload.

TRANSPORT

Thyristor Power Controllers are only to be transported in their original packaging (protection

against damage, e.g. due to impact, being knocked, soiling).

INSTALLATION

• If the Thyristor Power Controller is brought into the operations room from a cold environment,

moisture can occur. Prior to it being commissioned, the Thyristor Power Controller must be

absolutely dry. For this reason, wait for a minimum period of two hours before commissioning.

• Install the device upright.

CONNECTION

• Prior to connection, it must be ensured that the voltage information on the type plate corresponds with the mains voltage.

• The electrical connection is carried out at the designated points with the required cross section

and the appropriate screw cross sections.

3

OPERATION

• The Thyristor Power Controller may only be connected to the mains voltage if it has been ensured

that any hazard to people and system, especially in the load section, has been eliminated.

• Protect the device from dust and moisture.

• Do not block vents.

MAINTENANCE, SERVICE, MALFUNCTIONS

The icons used below are explained in the chapter safety regulations.

CAUTION

Should smoke, smell or fi re occur the Power Controller must be disconnected from the mains

immediately.

CAUTION

For maintenance and repair work, the Power Controller must be disconnected from all external voltage sources and protected against restarting. Make sure to wait minimum 1 minute after switch-off

(discharge time of the attenuation capacitors). The voltage-free state is to be determined by means

of suitable measuring instruments. This work is only to be carried out by a skilled electrician. The

electrical regulations which are locally valid are to be adhered to.

CAUTION

The Thyristor Power Controller contains hazardous voltages. Repairs may generally only be performed by qualifi ed and trained maintenance personnel.

Page 4

4

CAUTION

Hazard of electrical shock. Even after disconnection from the mains voltage, capacitors may still

contain a dangerously high power level.

CAUTION

Hazard of electrical shock. Even when the Thyristor Power Controller is not triggered, the load

circuit is not disconnected from the mains.

ATTENTION

Different components in the power section are screwed in place using exact torques. For safety

reasons, power components repairs must be performed by AEG Power Solutions GmbH.

Page 5

TABLE OF CONTENTS

Safety instructions 2

Schedule of Illustrations and Tables 7

Safety Regulations 8

Remarks on the present operating instructions and Thyro-P 11

1. Introduction 13

1.1 General 13

1.2 Specific characteristics 13

1.3 Type designation 14

2. Functions 15

2.1 Overview of operating modes 15

2.2 Set point control characteristic 16

2.3 Control types 18

2.3.1 Controlled value 18

2.4 Indications 19

2.4.1 LED indications 19

2.4.2 Relay indications K1-K2-K3 19

2.5 Monitoring 20

2.5.1 Load monitoring 21

2.5.2 Ventilator monitoring 24

5

3. Mode of Operation 25

3.1 Local operating and display unit (LBA) 25

3.1.1 LBA keyboard functions 25

3.1.2 LBA main menu 26

3.1.3 LBA submenus 27

3.1.4 Copying function using the LBA 32

3.1.5 Operation display 32

3.1.6 Line diagram 33

3.1.7 Last function 33

3.1.8 Status line 33

3.1.9 LBA submenus with password protection 34

3.2 Cabinet installation kit (SEK) 34

3.3 Thyro-Tool Family 34

3.4 Diagnosis / fault indications 36

4. External Connections 38

4.1 Power supply for Thyro-P 38

4.2 Power supply for the control device A70 38

4.3 Power supply for the ventilator 38

4.4 RESET 39

4.4.1 Software-RESET 39

4.5 Controller lock 39

4.6 QUIT 40

4.7 Set point value inputs 40

4.8 ASM input 40

4.9 Analog outputs 40

4.10 Current transformer 41

4.11 Voltage transformer 41

4.12 Other connections and terminal strips 42

4.13 Synchronization 44

4.14 Component mounting diagram control device 45

5. Interfaces 46

5.1 RS 232 interface

47

Page 6

6

5.2 Fibre optic interfaces 48

5.2.1 Fibre optic distribution system 48

5.3 Bus interfaces (option) 51

5.3.1 Profibus 51

5.3.2 Modbus RTU 55

5.3.3 DeviceNet 55

6. Mains Load Optimization 56

6.1 SYT-9 procedure 56

6.2 Software synchronization 56

6.3 ASM procedure (patented) 56

7. Connecting diagrams 58

7.1 1-phase 58

7.2 2-phase 59

7.3 3-phase 60

8. Special Remarks 61

8.1 Installation 61

8.2 Comissioning 61

8.3 Service 62

8.4 Checklist 62

9. Type Overview 64

9.1 Type range 400 volts 64

9.2 Type range 500 volts 65

9.3 Type range 690 volts 66

10. Specifications 67

11. Dimensional Drawings 70

12. Accessories and Options 83

13. Approvals and Conformities 84

Page 7

SCHEDULE OF ILLUSTRATIONS AND TABLES

Fig. 1 Control characteristic for U control 17

Fig. 2 Total set point 17

Fig. 3 Switch-on fault bridging 20

Fig. 4 Absolute value monitoring 21

Fig. 5 Relative monitoring 21

Fig. 6 Local operating and display unit (LBA) 25

Fig. 7 Operation display 32

Fig. 8 Cabinet installation kit 34

Fig. 9 Example for the user interface Thyro-Tool Familiy 35

Fig. 10 File component mounting diagram control device 45

Fig. 11 Interfaces of Thyro-P 46

Fig. 12 Connection of a PC to Thyro-P via RS 232 47

Fig. 13 X10-allocation 48

Fig. 14 Signal converter RS 232/fibre optic 49

Fig. 15 Schematic diagram fibre optic Thyro-P with LLV and PC 50

Fig. 16 Profibus slot card 52

Fig. 17 Special function Motorpoti 53

Fig. 18 Special inputs 54

Fig. 19 Modbus slot card 55

Fig. 20 ASM wiring 57

7

Tab. 1 Behaviour in case of load change 19

Tab. 2 Partial load breakdown with heating elements switched in parallel, undercurrent 22

Tab. 3 Partial short-circuit with heating elements switched in series, overcurrent 23

Tab. 4 Overview monitoring 23

Tab. 5 Functions of the LBA-keys 26

Tab. 6 LBA main menu 27

Tab. 7 Copying function using the LBA 32

Tab. 8 Line diagram time base 33

Tab. 9 Elements of the status line 33

Tab. 10 Allocation of the message register 37

Tab. 11 Terminal strip X1 38

Tab. 12 RESET 39

Tab. 13 Controller lock 39

Tab. 14 QUIT 40

Tab. 15 Current transformer 41

Tab. 16 Voltage transformer 41

Tab. 17 Voltage measurement jumper 42

Tab. 18 Terminal strip X2 for K1, K2, K3 42

Tab. 19 Terminal strip X5 43

Tab. 20 Terminal strip X6 43

Tab. 21 Terminal strip X7 44

Tab. 22 Synchronization jumper 44

Tab. 23 Fibre optic distances 49

Tab. 24 Profibus baud rates 51

Tab. 25 Pin assignment X21 53

Page 8

8

SAFETY REGULATIONS

IMPORTANT INSTRUCTIONS AND EXPLANATIONS

Operation and maintenance according to regulation as well as observance of the listed safety

regulations is required for protection of the staff and to preserve readiness to operate. Personnel

installing/uninstalling the devices, commissioning them, operating them, maintaining them must

know and observe these safety regulations. All work may only be performed by specialist personnel

trained for this purpose using the tools, devices, test instruments and consumables provided for

this purpose and in good shape.

In the present operating instructions, important instructions are marked using the terms

„CAUTION“, „ATTENTION“ and „REMARK“ as well as using the icons explained below.

CAUTION

This instruction shows work and operating procedures to be observed exactly to exclude hazards

for persons.

ATTENTION

This instruction refers to work and operating procedures to be observed exactly to avoid damage

or destruction of Thyro-P or parts thereof.

REMARK

This is where remarks about technical requirements and additional information is given, which the

user has to observe.

ACCIDENT PREVENTION RULES

The accident prevention rules of the application country and the generally applicable safety

regulations must be observed in any case.

CAUTION

Before starting any work on Thyro-P, the following safety regulations must be observed:

• switch voltage-free,

• secure against switching on,

• determine if it is voltage-free,

• ground and short-circuit it,

• cover or block neighboring parts under voltage.

QUALIFIED PERSONNEL

Thyro-P may only be transported, installed, connected, commissioned, maintained and operated

by specialists in command of the respective applicable safety and installation regulations. All work

must be monitored by the responsible specialist personnel. The specialist personnel must be

authorized for the work required by the person responsible for the safety of the system.

Specialists are persons who

- have received training and have experience in the respective fi eld of work,

- know the respective applicable standards, regulations, terms and accident prevention rules,

- have been familiarized with the function and operating conditions of Thyro-P,

- are able to detect and avoid hazards.

Page 9

WORK OBSERVING SAFETY REGULATIONS

Before removing safety installations for performance of maintenance and repair work or other work,

measures due to operation must be initiated.

Work observing safety regulations also means to point out faulty behaviour to colleagues and to

notify the offi ce or person responsible about defects detected.

INTENDED USE

CAUTION

The Thyristor Power Controller may only be employed in the sense of its purpose of use (see the

section of the chapter safety instructions under the same name), otherwise hazards for persons (for

instance electrical shock, burns) and systems (for instance overload) may occur.

Any unauthorized reconstruction and modifi cation of Thyro-P, use of spare and exchange parts not

approved by AEG Power Solutions as well as any other use of Thyro-P is not allowed. The person

responsible for the system must ensure that

- hints on safety and operating instructions are available and observed,

- operation conditions and specifi cations are observed,

- protective installations are used,

- required maintenance work is performed,

- maintenance personnel are immediately notifi ed or Thyro-P is immediately put out of commission

if abnormal voltages or noises, higher temperatures, vibrations or similar occur to determine the

causes.

These operating instructions contain all information required by specialists for use of Thyro-P.

Additional information and hints for unqualifi ed persons and for use of Thyro-P outside of industrial

installations are not contained in these operating instructions.

9

The warranty obligation of the manufacturer applies only if these operating instructions are observed.

Page 10

10

LIABILITY

In case of use of Thyro-P for applications not provided for by the manufacturer, no liability is

assumed. The responsiblity for required measures to avoid hazards to persons and property is

borne by the operator respectively the user. In case of complaints, please immediately notify us

stating:

- type name,

- production number,

- objection,

- duration of use,

- ambient conditions,

- operating mode.

GUIDELINES

The devices of the type range Thyro-P conform to the currently applicable EN 50178 and

EN 60146-1-1.

The CE mark on the device confi rms observation of the general EG guidelines for 2006/95/EG –

low voltage and for 2004/108/EG – electromagnet compatibility, if the instructions on installation

and commissioning described in the operating instructions are observed.

Regulations and defi nitions for qualifi ed personnel are contained in DIN 57105/VDE 0105 Part 1.

Safe isolation to VDE 0160 (EN 50178 Chapter 3)

Page 11

REMARKS ON THE PRESENT OPERATING INSTRUCTIONS AND THYRO-P

VALIDITY

These operating instructions refer to latest technical specifi cation of Thyro-P at the time of publication and are for information purposes only. Every effort has been taken to ensure the accuracy of

this specifi cation, however, in order to maintain our technological lead and for product enhancement, we are continually improving our products which could, without notice, result in amendments

or omissions to this specifi cation. AEG PS cannot accept responsibility for damage, injury, loss or

expenses resulting therefrom.

HANDLING

These operating instructions for Thyro-P are organized so that all work required for commissioning,

maintenance and repair may be performed by corresponding specialist personnel.

If hazards to personnel and property cannot be excluded for certain work, then this work is marked

using certain icons. The meaning of these icons may be found in the prior chapter safety regulations.

ABBREVIATIONS

In this description, the following specifi c abbreviations are used:

11

AEG PS = AEG Power Solutions GmbH

ASM = automatic synchronization in multiple Power Controller application

(dynamic network load optimization)

DaLo = data logger (fault storage)

LBA = lokal operating and display unit

SEK = cabinet installation kit

LL = fi bre optic

LLS = fi bre optic transmitter

LLE = fi bre optic receiver

LLV.V = fi bre optic distribution supply

LLV.4 = fi bre optic distribution, 4-fold

SYT = synchronized clock

TAKT = Pulse full cycle

WARRANTY

Customer shall provide written particulars, enclosing the delivery note, within 8 working days to

AEG PS on becoming aware of any defects in the goods during the Warranty period and shall use

its best endeavours to provide AEG PS with all necessary access, facilities and information to

enable AEG PS to ascertain or verify the nature and cause of the defect and carry out its warranty

obligations.

If goods are found not to be defective or if any defect is attributable to Customer’s design or material in operation of the goods, AEG PS will levy a testing charge and where relevant will return the

goods to Customer at Customer’s expense, and shall be entitled to payment in advance of the

whole testing and transport charge before such return.

AEG PS accepts no liability for defects caused by the Customer’s design or installation of the

goods; or if the goods have been modifi ed or repaired otherwise than as authorised in writing by

AEG PS; or if the defect arises because of the fi tting of the goods to unsuitable equipment.

AEG PS will cancel all possible obligations incurred by AEG PS and its dealers, such as warranty

commitments, service agreements, etc., without prior notice if other than original AEG spare parts

or spare parts purchased from AEG PS are used for maintenance or repair.

Page 12

12

SERVICE HOTLINE

Our service is available to you through the following hotline:

AEG Power Solutions GmbH

Emil-Siepmann-Straße 32

D-59581 Warstein

Phone +49 (0) 2902 763-100

http://www.aegps.com

powercontroller@aegps.com

INTERNET

Further information on our company or our products can be found on the internet under

http://www.aegps.com.

COPYRIGHT

Passing on, duplication and/or takeover of these operating instructions using electronic or mechanical means, even in excerpts, is subject to express prior written approval of AEG PS.

© Copyright AEG Power Solutions 2012. All rights reserved.

Copyright notice

Thyro-P is an internationally registered trademark of AEG Power Solutions GmbH.

Windows and Windows NT are registered trademarks of Microsoft Corporation.

All other company and product names are (registered) trademarks of their respective owners.

Page 13

1. INTRODUCTION

For transport, assembly, installation, commissioning, operation and decommissioning, the safety

instructions contained in these operating instructions must be applied in any case and made

available to all persons handling this product.

CAUTION

It is important that preset parameters are not adjusted in any way that may cause the Power Controller to overload. In case of uncertainties or missing information, please contact your supplier.

1.1 GENERAL

Thyro-P is a Thyristor Power Controller able to communicate. Below, it is also referred to simply

as Power Controller. It may be employed in any place where voltage, current or power has to be

controlled or regulated in processing technology. Several modes of operation and control, good

coupling ability to process and automation technology, high control precision by application of a

32 bit RISC processor and simple handling ensure that Thyro-P is suitable for new applications as

well.

Thyro-P is suitable for

• direct supply of ohmic loads

• for loads with large R

• as primary Power Controller for a transformer with subsequent load

Due to use of state-of-the-art thyristors, the Thyristor Power Controller Thyro-P has a type range

up to 2900A, the nominal design loads reach up to about 2860kW.

hot/Rcold

ratio

13

1.2 SPECIFIC CHARACTERISTICS

Thyro-P is characterized by a multitude of specifi c characteristics, for instance:

• easy handling

• menu-driven user interface

• type range 230-690 Volts, 37-2900A, single, double, triple phase

• broadband power supply AC 200-500V, 45-65Hz

• ohmic load and transformer load

• as well as load with large R

• soft start function for transformer load

• load circuit monitoring

• automatical rotating fi eld recognition for 2P and 3P

• U, U2, I, I2, P control as well as without control

• operating modes TAKT, VAR, Soft-Start-Soft-Down, MOSI, ASM

(optional sub-operating mode of TAKT)

• control of analog set points or via interfaces

• fi bre optic and RS 232 interfaces as standard

• electrical separation according to EN 50178 chap. 3

• Measured values are given at analog outputs

• 4 set point channels incl. Motorpoti, which parameters can be set

The specifi c characteristics especially include the following options:

• Bus connection via bus adaptor cards to plug into the Thyro-P Power Controller, coupling to

different bus systems, for instance Profi bus, other bus systems upon enquiry.

• Patented ASM procedure for dynamic mains load optimization. The ASM procedure (automated

synchronization of multiple Power Controller applications) is used for dynamic mains load optimization. It reacts to changes in load and set point, minimizes mains load peaks and associated mains

feedback. Minimizing of mains load peaks means cost savings in operating and investment cost.

hot/Rcold

for 1P and 3P

Page 14

14

• Local operating and display unit (LBA), able for graphics display, menu-driven, pluggable. The

integrated copying function by replugging the LBA enables simple transfer of Power Controller

parameters between power controllers of the type Thyro-P.

• Cabinet installation kit (SEK) for the local operating and display unit. The SEK enables installation

of the local operating and display unit into the switching cabinet door. It consists of cables and

an installation frame.

• The PC-Software Thyro-Tool Familiy for effective commissioning and simple visualization tasks.

Functions are for instance loading, storing, modifi cation, comparing and printing of parameters,

set points and actual value processing, line diagrams of process data (including printing and

storing option), bar diagrams, simultaneous display of process data from different Power Controllers, simultaneous connection of up to 998 Thyro-P Power Controllers.

1.3 TYPE DESIGNATION

The type designation of the Thyristor Power Controllers are derived from the construction of its

power section:

TYPE RANGE DESIGNATION FEATURES

Thyro-P 1P single phase power section,

for single phase operation

2P double phase power section, for three phase operation

in three phase economizing circuits,

not for phase-angle control (VAR)

3P three phase power section,

for three phase operation

.P400 Type voltage 230-400 Volt, 45-65 Hz

.P500 Type voltage 500 Volt, 45-65 Hz

.P690 Type voltage 690 Volt, 45-65 Hz

.P ...-0037 Type current 37A (Typecurrent range 37A-2900 A)

.. ...-.... . H Integrated semi-conductor fuse (all Thyro-P)

.. ...-.... . F Forced air cooling with integrated ventilators

The complete type range can be found in the type overview in chapter 9.

Page 15

2. FUNCTIONS

15

For optimum adjustment to different products and production processes as well as differently

electrical loads, the most favorable operating and control modes may be set according to the

following overview.

2.1 OVERVIEW OF OPERATING MODES

This chapter gives an overview of the various, partly type-specifi c and optional operating modes.

Full wave switch mode (TAKT)

Depending on the prescribed set point, the

mains voltage is periodically switched. In this

operating mode, almost no harmonics are

created. Whole multiples of the mains periods

are switched, avoiding DC components. The full

oscillation clock principle is especially suited for

loads with thermal inertia. For optimization of

the mains load, the optional ASM process may

be applied in this operating mode.

Phase-angle principle (VAR, with 1P and 3P)

Depending on the prescribed set point, the sine

oscillation of the mains voltage is gated using a

larger or smaller control angle a. This operating

mode is characterized by high control dynamics.

In case of phase-angle control, it is possible to

compensate harmonics of the mains voltage by

using circuit variants (for instance vector group

transformer).

Soft-Start-Soft-Down (SSSD)

The operation of large individual loads using the operating mode TAKT may lead to voltage variations on the mains side. The operating mode SSSD greatly reduces the pulse-shaped mains load.

MOSI operation for 1P and 3P

MOSI is a sub-operating mode of the operating modes TAKT and VAR for sensitive heating materials with a high R

starts with phase-angle maximum value and actual value to avoid high current amplitudes during

the heating-up phase and then automatically switches to the set operating mode.

ratio, for instance molybdenum disilicide. The Power Controller always

hot/Rcold

Page 16

16

Mains load optimization (ASM procedure)

For systems in which several Power Controllers are employed in full wave switch mode TAKT, it is

possible that individual Power Controllers are synchronized so that a regular mains load is achieved

by defi ned switching of the individual Power Controller in sequence. This avoids load peaks by

random simultaneous switching of many Power Controllers and load troughs are fi lled up. The

upstream transformer and/or the upstream feed point may be designed for a lower load. Besides

savings in investment and operating cost, lower mains reactions also result.

2.2 SET POINT CONTROL CHARACTERISTIC

The set point control characteristic of Thyro-P may be easily adapted for the control output signal

of the upstream process controller or automation system. All signals customary on the market may

be used. The adaption is made by changing the starting and ending points of the control characteristic. Inverted operation (ending value is smaller than the starting value in voltage or current) is also

possible.

The effective set point is the total set point. It is formed by adding the four set points as shown in

fi g. 2.

In the simplest case all the set point values are added algebraically. The prerequisite for a set point

to infl uence the total set point value is that it must be enabled by the set point Enable Register.

• Set point 1 (X5.2.10 - X5.1.13 ground) 0-20mA default

• Set point 2 (X5.2.11 - X5.1.13 ground) 0-5V default

The inputs set point 1, 2 are two electrically equal analogue inputs for current or voltage signals,

with subsequent A/D converter (resolution 0.025% of the fi nal value), and they may be set to the

following signal ranges:

0(4)-20 mA (Ri about 250⍀) max. 24mA siehe ”ATTENTION“

0-5 V (Ri about 8,8k⍀) max. 12V

0-10 V (Ri about 5k

The following table shall be used for the hardware confi guration of the set point inputs (see also

FILE COMPONENT MOUNTING DIAGRAM CONTROL DEVICE, fi gure 10). If the hardware confi guration is changed, the Thyro-P parameters must be changed accordingly with the LBA or the

Thyro-Tool.

X221 for Set point input 1

Bridge X221 Signal range Set point input 1

closed* 0(4) -20mA (X5.2.10)

open 0-5V / 0-10V (X5.2.10)

X222 for Set point input 2

Bridge X222 Signal range Set point input 2

closded 0(4)-20mA (X5.2.11)

open* 0-5V / 0-10V (X5.2.11)

ATTENTION

If the open-circuit voltage of the connected set point exceeds 12V in the 20mA signal range, the

set point inputs can be destroyed, if the belonging bridge (X221, X222) is open.

Within the stated input ranges, these values with the control characteristic may be adjusted to any

common signal characteristic.

⍀) max. 12V

* default

Page 17

FIG. 1 CONTROL CHARACTERISTIC FOR U CONTROL

For a set point poti (e.g. 5-10 K⍀) 5V supply voltage can be taken from terminal X5.2.5 (Ri = 220⍀,

short-circuit-proof).

17

SET POINT CONTROL CHARACTERISTICS

The set point control characteristic (Fig. 1) of Thyro-P may be easily adapted for the control output

signal of the upstream process controller or automation system. All signals customary on the market

may be used.

The adaption is made by changing the starting and ending points of the control characteristic. Inverted operation (ending value is smaller than the starting value in voltage or current) is also possible.

• Set point 3:

Set point of the superordinate system or PC via fibre optic connection (standard) X30, X31 or via

the optional bus interface.

• Set point 4:

Set point input (motor potentiometer function) via LBA or RS 232 from the superordinate system or

PC. Set point 4 is stored in case of mains failure.

EFFECTIVE TOTAL SET POINT VALUE

The algebraic addition of the results of set point (1,2) to set point 3 and 4 gives the (effective) total

set point value for the set point control characteristic as shown in the following figure.

FIG. 2

TOTAL

SET POINT

Page 18

18

The prerequisite for a set point to infl uence the total set point value is that it must be enabled by

the set point Enable Register. Set point 1 and 2 can be linked using the following functions. The

result of this link is called set point (1,2).

Set point link

ADD Set point (1,2) = Set point 1 + Set point 2

IADD Set point (1,2) = Set point 1 - Set point 2

_Pro Set point (1,2) = Set point 1 *

Set point 2 [%]

100%

_IPro Set point (1,2) = Set point 1 * (1 -

Set point 2 [%]

)

100%

VALUE RANGE OF SET POINT (1,2)

For the link result of set point (1,2) the following value range applies:

울 Set point (1,2) 울 Set point max (U

0

max

, I

, P

).

max

max

SET POINT ENABLE REGISTER

The set point Enable Register (AD_P_SW_ENABLE, adr. 94) enables the 4 set points to be shut off

or enabled independently. Only enabled set point inputs are part of the effective total set point

value.

The shut off or inactive set points are shown by the LBA and can thus, if necessary, be checked

before connecting.

The set point Enable Register can be changed from all service units (Bus, Thyro-Tool Familiy, LBA).

Example:

8 4 2 1 VALUE ABBR. EXPLANATION

1 1 1 1 15 STD Standard (all ON)

1 0 0 0 8 LOC Motor poti-set point 4 (LOCAL)

0 1 0 0 4 REMOTE Bus set point 3

0 0 1 1 3 ANA Analog-set points 1,2

0 0 0 0 0 All set points inactive

2.3 CONTROL TYPES

Thyro-P has fi ve control types effective as underlying controls. Mains voltage variations and load

changes are directly and therefore quickly adjusted by bypassing of the slow temperature control

system.

Before commissioning of the Power Controller and selection of a control type, you should be

familiar with the operating procedure respectively the effect for application.

2.3.1 CONTROLLED VALUE

The controlled value effective on the load is proportionate to the total set point, depending on the

control type:

CONTROL TYPE CONTROL VALUE (PROPORTIONATE TO THE TOTAL SET POINT)

P control output (active) power, P

U control output voltage, U

U2 control output voltage, U

I control output current, I

I2 control output current, I

LIMITING OF SIGNALS

Independent of the control type set, additionally minimum and maximum limiting values may be

set. For this purpose, also refer to Fig. 1 control characteristic.

The maximum limiting values determine the maximum modulation of the load.

rms

2

rms

rms

2

rms

Page 19

The minimum limiting values should ensure minimum modulation via the control angle (for instance

minimum heating of the load).

CONTROLLER RESPONSE

If the load resistance changes, for instance due to temperature effect, ageing or load fault, then the

values effective on the load change as follows:

UNDERLYING LOAD RESISTANCE LOAD RESISTANCE EFFECTIVE*

DECREASES INCREASES LIMITATIONS

CONTROL LIMIT P U

U U

U2 (UxU) U

I I

I2 (IxI) I

P P

larger = larger smaller = smaller I

rms max

larger = larger smaller = smaller I

rms max

smaller smaller = larger larger = U

rms max

smaller smaller = larger larger = U

rms max

= smaller larger = larger smaller U

max

I

LOAD

without control larger = larger smaller = smaller U

P

P U

LOAD

I

LOAD

LOAD

rms max

rms max

rms max

rms max

rms max

rms max

max

P

P

P

P

I

I

* If one of the limits is exceeded, then the signaling relay K2 and the LED „limit“ react

(default values of parameter settings).

General modulation limit Ts=T

␣=␣

s max

max

19

max

max

max

max

rms max

rms max

TAB. 1 BEHAVIOUR IN CASE OF LOAD CHANGE

2.4 INDICATIONS

2.4.1 LED INDICATIONS

The LEDs on the front side signal the following states:

• ON green: operating indication, power supply controller board

red: RESET active

• CONTROL modulation percentage indication, fl ashing*

• LIMIT limitation is active, relay K2 switches*

• PULSE LOCK Controller Lock active, but load control is continued at pulse limits

(default value = 0)*

• FAULT fault present*

• OVERHEAT overheating of power section

(in case of ..HF types, check ventilator)*

* Default setting

Activation of the integrated semiconductor fuse may be signalled using the fault indicating relay K1

rest current, contactor, otherwise separate supply of the control device required). In case of Power

Controllers from model current 495A, additional signalling is performed via an indicator at the

semiconductor fuse.

2.4.2 RELAY INDICATIONS K1-K2-K3

The Thyro-P Power Controller is fi tted with three relays. Each of these relays has a change over

contact in principle be allocated a value in the event register. The following table shows the contactor allocation of the relays at the corresponding terminal strips. Presets of parameters by the works

(default values) may be found in chapter 3.4.

Page 20

20

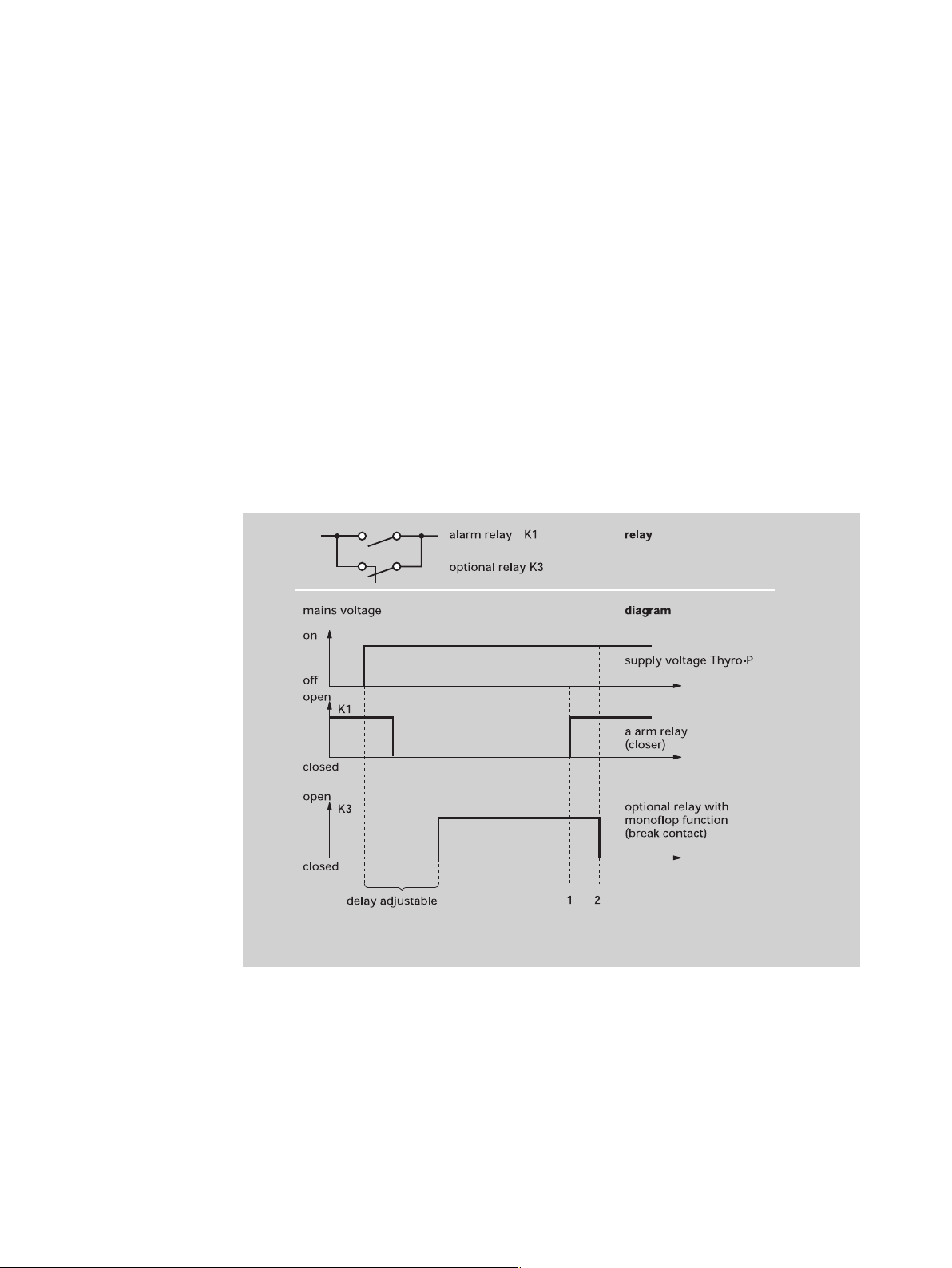

ALARM RELAY K1

The relay K1 is activated if a fault is detected in the system. The effective direction, whether it

should close or open in case of fault, may be set using the parameter K1 closed-circuit OFF, ON by

using LBA or Thyro-Tool Familiy. Which indications lead to switching of the relay may also be set.

Recommendation: keep the default setting.

LIMITING RELAY K2

The relay K2 only closes (in default setting) if at least one of the following values is exceeded:

• 1. max. admissible effective value of the load current

• 2. max. admissible effective value of the load voltage

• 3. max. admissible active power of the load

The relay releases if none of the values is exceeded anymore. It is possible to set which indications

lead to switching of the relay. Recommendation: keep the default setting.

OPTIONAL RELAY K3

If changes are made to the default relay settings due to the application, then preferrably the relay

K3 should be reparameterized.

It is possible to realize functions like for instance a follow-up relay for ventilator control or by pass

the alarm relay at startup of the system. It may also be used as a further alarm relay or limiting relay,

by reparameterization.

The illustration shows the relay K3 for bridging the startup alarm.

FIG. 3 SWITCH-ON FAULT BRIDGING

2.5 MONITORING

Faults occurring in the Power Controller or in the load circuit are signalled. Signalling is performed

via LED (FAULT) and via relay with potential-free change-over contact. The fault buffer may be

read via LBA or the interface after selecting the status line. Simultaneously with the fault signal,

the pulse shutdown may optionally also be set (Imp.-Absch. OFF, ON). Faults having occurred are

shown in the display of LBA by text status indications in the status line. After selecting the status

line, the indication may be called up.

Page 21

21

2.5.1 LOAD MONITORING

MONITORING OF THE LOAD AND MAINS VOLTAGE

Each power section is fi tted with its own transformer for creating the synchronization voltages. This

also allows monitoring of the phase voltages. In the LBA menu monitoring, the limits may be set for

U

and U

Line min

ABSOLUTE OR RELATIVE MONITORING

Relative monitoring for heating elements for R

elements with R

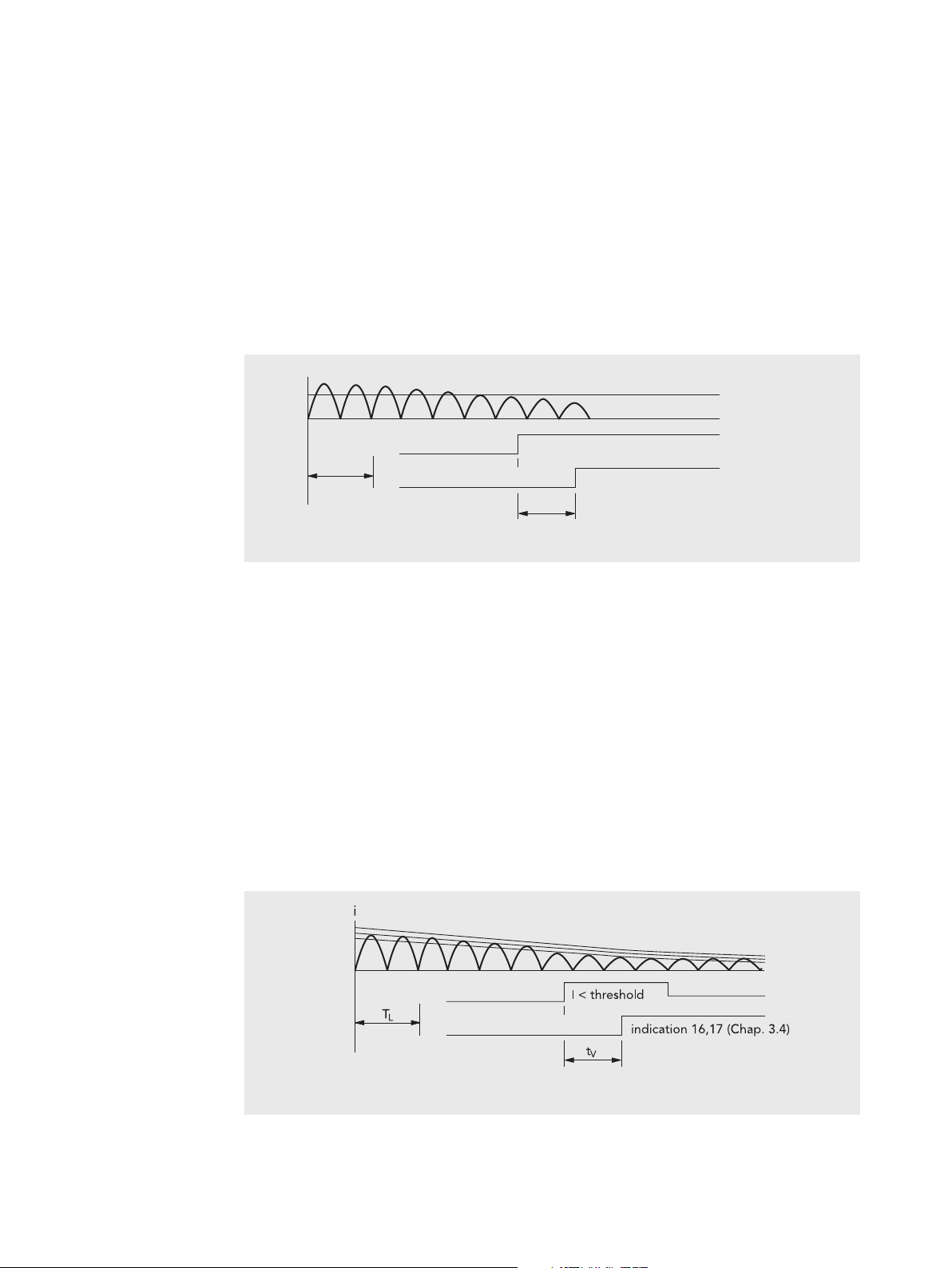

ABSOLUTE VALUE MONITORING CURRENT

This function allows monitoring of a freely selectable absolute current limit. The parameters for

the value may be set in ampere.

i

T

L

. If larger deviations are detected, then a fault indication is generated.

Line max

≈ 1 and absolute monitoring for heating

≠ 1 are possible.

hot/Rcold

hot/Rcold

I < threshold

indication 16,17 (Chap. 3.4)

t

V

FIG. 4 ABSOLUTE VALUE MONITORING

This absolute value monitoring lends itself to one or more load resistances organized in parallel or

in series. Generally, the effective current value measured is continuously compared with a presettable absolute current limit for undercurrent or overcurrent. If these limits are undercut or exceeded

an indication shows. In case of resistor elements organized in parallel, it is therefore possible, using

the lower current limit, to select a partial load interruption. Using the upper current limit, in case of

resistors switched in series, short-circuiting of an element may be detected.

RELATIVE MONITORING

This monitoring is sensible if the resistance value of the load slowly changes. Changes in resistance

may for instance be caused by temperature changes or by ageing. The current (b) of the Power

Controller is regarded as 100% load current (current in fault-free state) after activation of the RESET

or CONTROLLER LOCK. The RESET is automatically activated after each startup, restart or after

mains outage. In case of relatively slow changes of the current, due to characteristics of the above

mentioned heating elements, automatic adjustment of the internal reference value to 100% is

performed (b‘).

FIG. 5 RELATIVE MONITORING

Page 22

22

Quick current changes, which may for instance occur in case of partial.

Quick current changes, which may for instance occur in case of partial short-circuit, may be

detected by overcurrent monitoring (max., a – a‘).

Quick current changes, which may for instance occur in case of load breakdown may be detected

by undercurrent monitoring (min., c – c‘).

NOTE FOR LOAD MONITORING:

Changes of the burden resistor and parameters can be necessary in case of small load currents or

small current fl ow angles (i. e. small phase angles).

If a Thyro-P 3P is used in phase-angle operating mode, the star point of the load and the star point

of the (built-in) voltage transformers should be connected together to ensure an accurate load

monitoring. Please contact us in case of need..

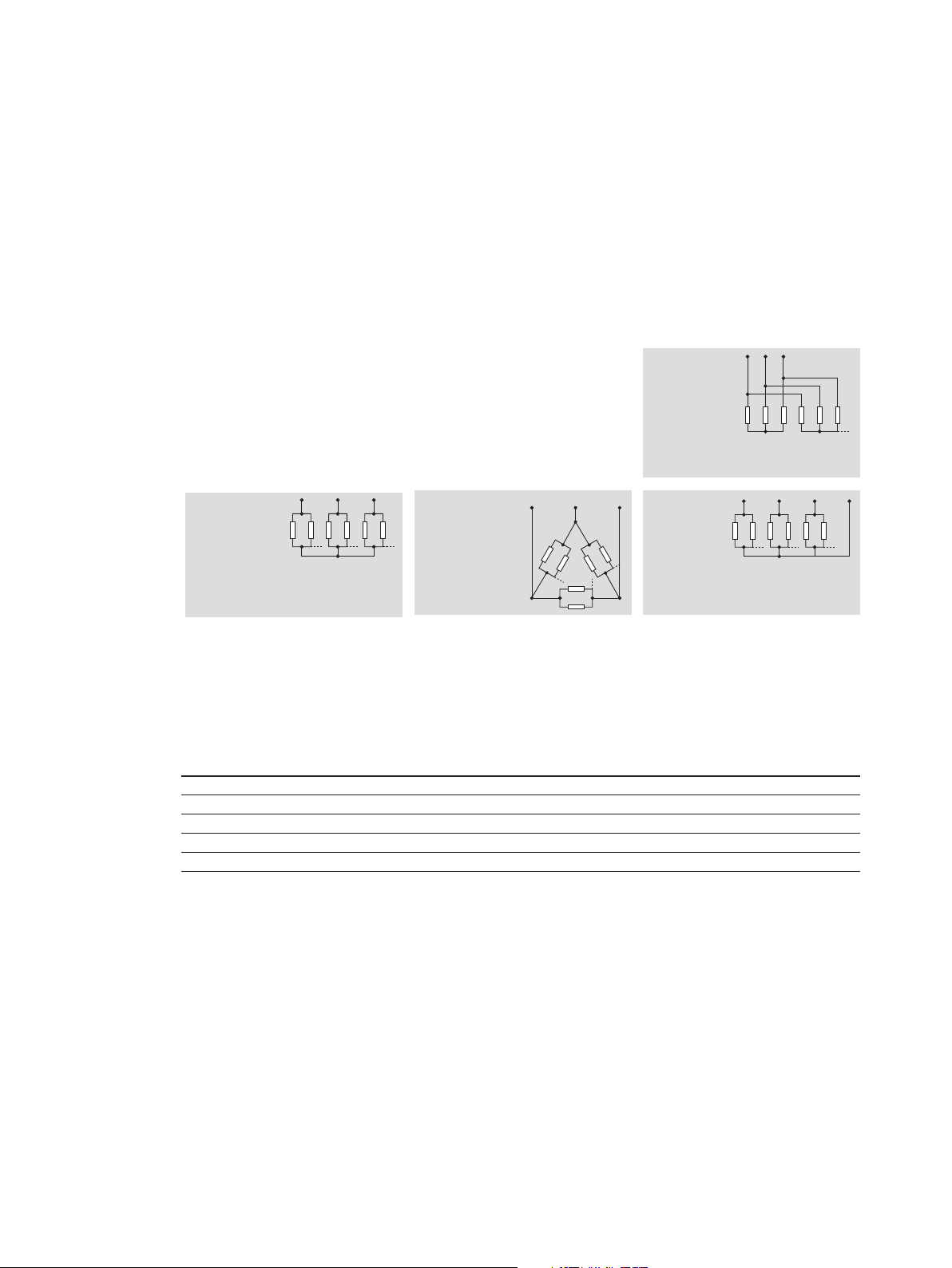

The values in the following table apply to ohmic loads.

Different values apply may be required for specific heating resistors, for instance IR radiators. The adjustable %

values shown in the tables are load current variations on

the present operating values.

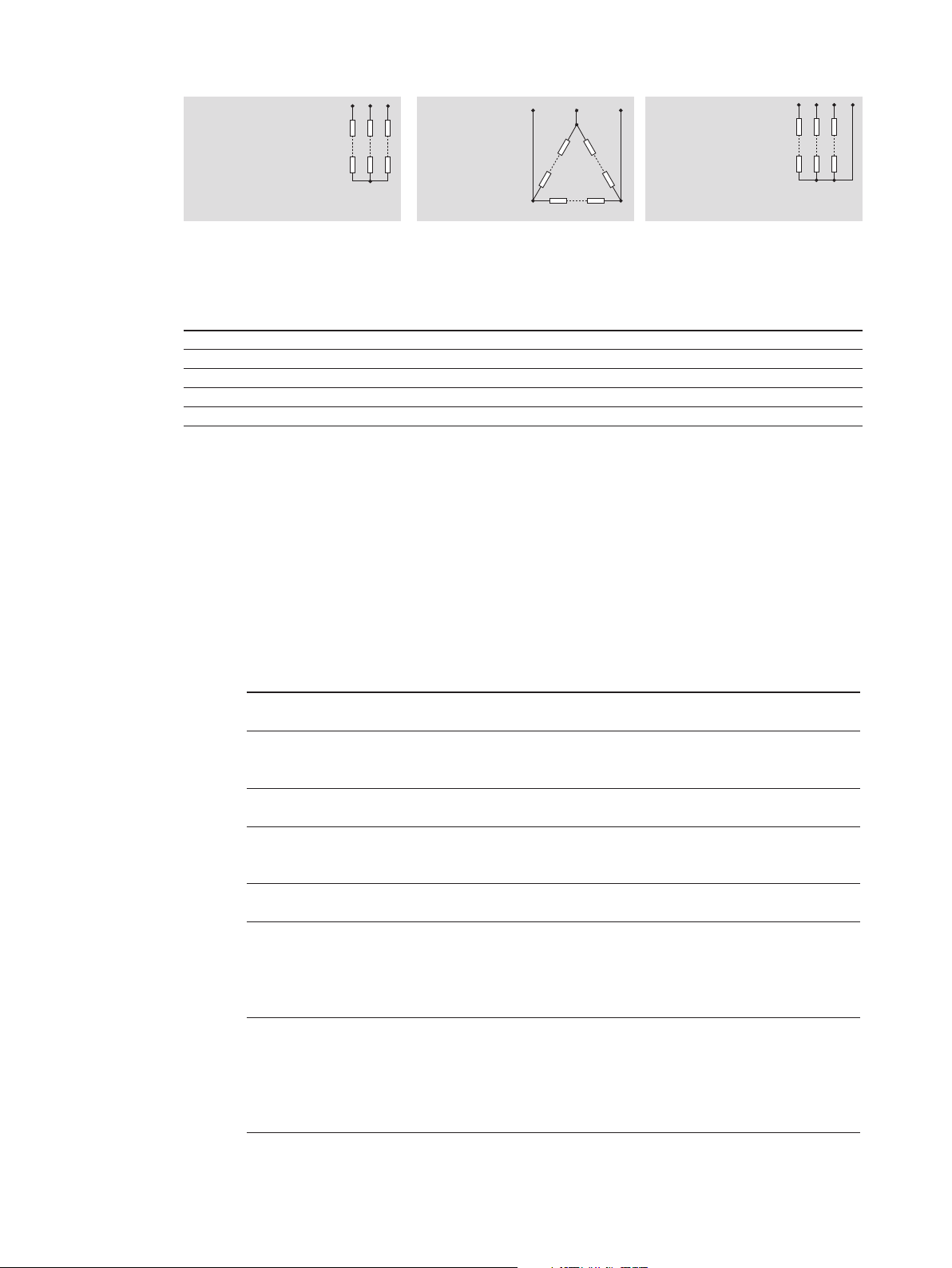

Star connection

with separate star points

Star connection

without neutral conductor

HEATING 1P 2P*/3P 3P

ELEMENTS

IN PARALLEL STAR CONNECTION STAR CONNECTION DELTA STAR CONNECFOR EACH WITH SEPARATE WITHOUT CONNEC- CONNECTION TION WITH

STRAND STARPOINTS TED NEUTRAL CONNECTED

CONDUCTOR NEUTRAL CONDUCTOR

5 10% 10% – – 10%

4 13% 13% 10% – 13%

3 17% 17% 13% 10% 17%

2 25% 25% 20% 12% 25%

1 50% 50% 50% 21% 50%

* for Thyro-P 2P: additional external converters in phase L2 are possible.

TAB. 2 PARTIAL LOAD BREAKDOWN WITH HEATING ELEMENTS SWITCHED IN PARALLEL,

UNDERCURRENT, RELATIVE MONITORING

Delta connection

Star connection

with neutral conductor

Page 23

23

Star connection

without neutral conducter

Delta connection Star connection

with neutral conductor

HEATING 1P 2P 3P

ELEMENTS

IN SERIES FOR STAR CONNECTION DELTA CONNECTION STAR CONNECTION

EACH STRAND WITHOUT CONNECTED WITH CONNECTED

NEUTRAL CONDUCTOR NEUTRAL CONDUCTOR

6 10% – – 10%

5 13% 10% – 13%

4 17% 10% 10% 17%

3 25% 14% 13% 25%

2 50% 25% 26% 50%

TAB. 3 PARTIAL SHORT-CIRCUIT WITH HEATING ELEMENTS SWITCHED IN SERIES, OVERCURRENT, RELATIVE MONITORING

AGEING OF LOAD RESISTORS

Thyro-P determines the load conductance separately for each phase. These values are available

from LBA, Thyro-Tool Familiy and the Bus interface. The current resistance can be determined by

reading out and converting from the conductance.

The following table offers an overview of the possible monitoring functions of the Thyristor Power

Controller Thyro-P.

TYPE OF PARAMETER DEFAULT /

MONITORING SETTINGS REMARKS

U

mains overvoltage input in volts Type voltage + 20%

net max

mains undervoltage input in volts Type voltage - 20%

U

net min

I

overcurrent 0-100% REL_ABS = REL

load max-REL

overcurrent relative Re: measured load current UE_S = ON

after each RESET/control lock

I

load max-ABS

overcurrent input in ampere REL_ABS = ABS

absolute UE_S = ON

I

undercurrent 0 to 99% REL_ABS = REL

load min-REL

relative Re: measured load current UN_S = ON

after each RESET/control lock

I

undercurrent input in ampere REL_ABS = ABS

load min-ABS

absolute UN_S = ON

pulse switch pulse switch off ON: pulse switch off after indication is always

off by software fault indication issued

OFF: in case of fault

in case of synchronization

SYT 9, RESET of all Power

Controllers is required

K1 alarm relay K1 ON: relay K1

open circuit released in case of fault

OFF: relay K1 the alarm relay switches

pulled-in in case of fault upon activation of

RESET

TAB. 4 OVERVIEW MONITORING

Page 24

24

2.5.2 VENTILATOR MONITORING

The separately ventilated Power Controllers (-...HF) are fi tted with thermal monitoring. The temperature is measured on the heat sink. In case of a temperature overrange, a fault inducation is issued

(Profi bus, LED OVERHEAT).

ATTENTION

Activating this monitoring function is obligatory if the Thyro-P is operated under UL conditions.

Page 25

3. MODE OF OPERATION

This chapter shows the operating options of Thyro-P using LBA and Thyro-Tool Familiy.

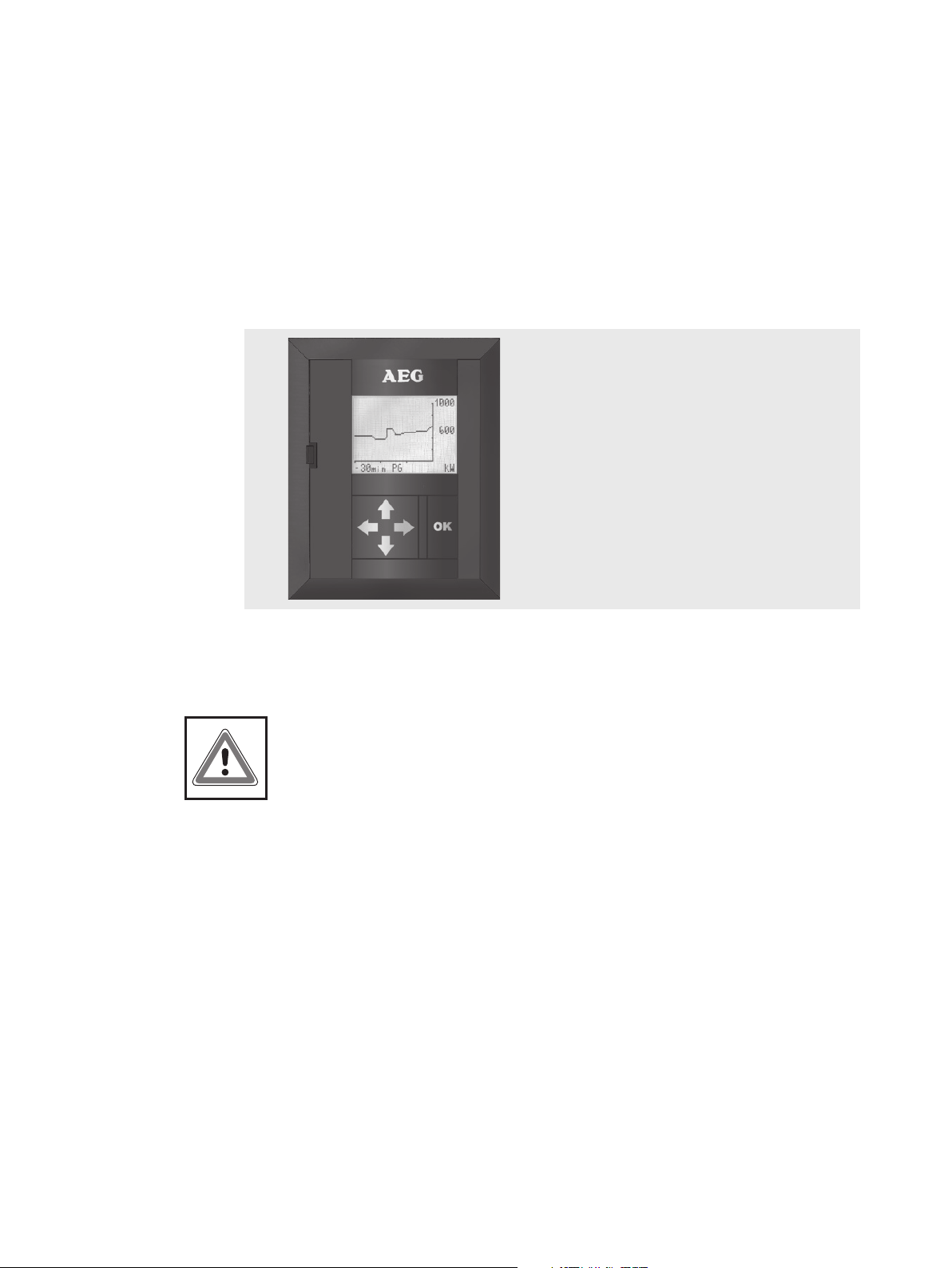

3.1 LOCAL OPERATING AND DISPLAY UNIT (LBA)

The optional LBA (IP30, protection classifi cation 3) has fi ve keys and a backlit graphical LC display

for 7 x 19 characters respectively 64 x 114 pixels. In the standard version, the languages German,

English and French are available.

25

FIG. 6 LOCAL OPERATING AND

DISPLAY UNIT (LBA)

The LBA may be connected or disconnected from the RS 232 interface of the Thyro-P control device

during operation. After plugging into the interface and automatic loading of the parameters, the

LBA displays its main menu.

ATTENTION

Before storing (store in Thyro-P / LBA under Thyro-P) the parameters must always be saved in the

EEPROM of the LBA fi rst (store in LBA).

If no key is pressed for one minute the operation display appears. This does not apply if a line

diagram is running. If no communication is achieved after plugging in the LBA between LBA and

Power Controller in case of fault, then a self-test is performed. Using the LBA, Thyro-P may be

parameterized and monitored under menu control. It is possible to display up to three process

data values (for instance the actual values of current, voltage or power occurring at the load) in

double character height. Further values which may be displayed are the set point value as well as

parameter data and fault indications. Furthermore, display of a value in graphical form as line diagram is possible. The time and value axes may be set by parameters and so adjusted to requirements. Using the LBA, the parameters of one Thyro-P may be copied to another Thyro-P. More

details on this can be found in the chapter LBA menus.

3.1.1 LBA KEYBOARD FUNCTIONS

The LBA has a total of 5 standard keys: with an activatable parameterizing lock (see table 5). Four

arrow keys and one OK key. By moving the cursor mark (>) using the corresponding keys (up arrow,

down arrow), the desired function may then be selected using the OK key. An underlined language/

function is in each case selected. An unnamed 6th key is available behind the opening in the front

of the LBA, the reset key. If this is operated, then the functions RESET of Thyro-P is performed.

Page 26

26

FUNCTIONS OF LBA KEYS:

KEY DISPLAY FUNCTION

Cursor before menu text: selection of the higher level (back)

Cursor on the figure: select prior (higher value) position

Cursor on the figure: select next (lower value) position

Cursor before menu text: move cursor to the prior line, possible scroll

upward (only indented lines may be scrolled)

Cursor on the figure: increase value

Cursor on the parameter: switch on

Cursor before menu text: cursor on subsequent line, possible scroll down-

ward

Cursor on the figure: reduce value until minimal admissible value is

reached

Cursor on the parameter: switch off

OK Cursor before menu text: selection of a figure or of an input field

Cursor on the figure: takeover of the modification into Thyro-P and

deselection of the selected field

Cursor on the parameter: takeover of the modification into Thyro-P and

deselection of the selected field

Operation display: deselection of the operation display

Thyro-P → LBA inactivated

OK OK Line diagram: deselection of the line diagram display

No key pressed operation display is activated; this does

(for 1 minute) not apply in case of selected line diagram

Operation display: Parameterizing lock is self-activating on release

Parameter loading process

Parameterizing process is temporarily

TAB. 5 FUNCTIONS OF THE LBA-KEYS

3.1.2 LBA MAIN MENU

The top line always contains the name of the menu or of the submenu. The lowest line, the status

line, always contains the confi guration of the Power Controller or in case of existing indications,

the word status indication.

The main menu (function selection menu) appears on the LBA display after plugging the LBA into

Thyro-P. It looks like this:

Page 27

MAIN MENU FUNCTION

Language selection operating language

Load/store data load and store data

Set points/characteristics set point processing

Parameter display and modification of parameters

Operation display select operation display

Last function energy and operating hours

TAB. 6 LBA MAIN MENU

3.1.3 LBA SUBMENUS

The first six lines of the above main menu contain the names of the sub-menus. These are shown

below, with explanations, in the sequence they are contained in the menu.

= Main menu (appears after plugging in the LBA)

27

Menu

Submenu

Main menu

Sprache/language

Deutsch x

English

Francais

Sprache/language

Open/save data Loading, storing, copying of parameter sets

Thyro-P -> LBA 1

LBA -> Thyro-P 2 Parameter from LBA-EEPROM to Thyro-P RAM

Store in LBA Parameter from LBA-RAM to LBA-EEPROM

Save Thyro-P Parameter from Thyro-P RAM to Thyro-P EEPROM

1 Open data again

Thyro-P -> LBA Store parameters from Thyro-P in LBA

waiting time

the parameter lock

ASIC-SW Shows production date of controller software

Open/save data

Code LBA Shows version of LBA software

2 Save data again

LBA -> Thyro-P Store parameters from LBA in Thyro-P

waiting time Observe waiting time!

Set points/curve Remark: Display is refreshed after max. 10 sec.

motor pot. 0 Display and modification set point 4

Term. (10) Display set point 1

Term. (11) Display set point 2

Master(bus) Display set point 3 (bus)

Act.pwr.tot:xx,xxmA

Absolute set points

in a submenue depending on control mode

STD,LOC,REMOTE,ANA STD Choice of set point inputs

ADD,IADD, PRO,IPRO ADD

5V,10V,mA term(10) mA Selection signal type for set point 1*

Set points/curve

5V,10V,mA term(11) 5V Selection signal type for set point 2*

Ctrl.start 1 4.00mA 0.3mA Control start set point SW1

Ctrl.end1 20.00mA 20.0mA Control start set point SW1

Ctrl.start2 20.00V 0.07V Control start set point SW2

Ctrl.end 2 10.00 V 5.0V Control end set point SW2

* refer to ”ATTENTION” on page 16

Adress

Bus+LL-compound xxx

in case of Profibus DP 001 - 125

000 and 999 have specific functions

Parameters

Display total set point

100 xxx for fibre optic 001 - 998

Default

next

submenu

During active circuit set point is displayed

Value

User

Value

Observe waiting time! OK key during charging releases

SW1+SW2, SW1-SW2, SW1*SW2%/100%, SW1*(1-SW2%/100%)

Remarks

Page 28

28

= Main menu (appears after plugging in the LBA)

Default

Submenu

Main menu

Menu

next

submenu

Value

User

Value

Act. val. select

Analog outp.(32)

Analog outp.(33) 3

Analog outp.(34)

Display top

Display middle 4

Display bottom

Average xx 25

Graphics 5 Parameterization line diagram

Parameterization for analog output 1, terminal 32

Parameterization for analog output 2, terminal 33

Parameterization for analog output 3, terminal 34

Parameterization for operation display, value top

Parameterization for operation display, value middle

Parameterization for operation display, value bottom

Mean value analog display of xx mains/cycle periods

Analog outp.(32)

3 Analog outp.(33)

Analog outp.(34)

Analog outp.(xx)

Select and OK

Selected analog output 1,2,3 (terminal 32,33,34)

Selection of (if ecisting in the Power Controller):

U1, I1, P1, PG U1(32) U1, I1, P1, PG

U2, I2, P2 I1(33) U2, I2, P2

U3, I3, P3, alpha P1(34) U3, I3, P3, alpha, total set point

U3, I3, P3, set point Display total set point

U

min,Imin,Pmin

U

max,Imax,Pmax

Current output OFF,ON Changeover 10V/20mA

Minimum and maximum values of U, I, P since

last RESET respectively voltage startup.

Full scale xx,xmA Measuring device end scale deflection e.g. 20mA

Offset 0mA

Full scale value xxx y

Y=dimension depending on display V, A, kW

Offset signal for output value, for instance 4mA

Display top

4 Display middle

Display bottom

Display

Select and OK

U1, I1, P1, PG U1, I1, P1, PG

Parameters

U2, I2, P2 U2, I2, P2

Operation display: top, middle, bottom (3 values)

Selection of (if ecisting in the Power Controller):

U3, I3, P3, alpha U3, I3, P3, alpha, total set point

U3, I3, P3, set point Display total set point

U

min,Imin,Pmin

U

max,Imax,Pmax

Minimum and maximum values of U, I, P since

last RESET respectively voltage startup.

5 Line diagram

X - axis - time Scaling of the time axis (resolution pixels)

1,5min;30min;1h;3h

Y - axis - value

1.5min

Selection of (if existing in the Power Controller type):

U1, I1, P1, PG U1 U1, I1, P1, PG (resolution 50 pixels)

U2, I2, P2, alpha U2, I2, P2, alpha,

U3, I3, P3, set point U3, I3, P3, total set point,

Start graphic Start line diagram

bar, average value

Display band (all measured values) or average value

limitations Presets limiting values

U

I

P

op. time

Ft.

Rr.

on. time

U

I

P

Phase swingL xxx 0 Phase swing for L1, L2, L3

xxxxV type Display/default

rms max

xxxxA type Display/default

rms max

xxxxkW type Display/default

max

xxxxms 1000ms

max

xxx°e 180 Only for the operating mode VAR

Imp End

xxx°e 0 Only for VAR

Imp End

xxxxms * 0

min

xxxxV * 0

rms min

xxxxA * 0

rms min

xxxxkW * 0

min

Only for the operating modes TAKT and SSSD (< To)

* password protection

Remarks

(at 3P default setting phase voltage)

Page 29

= Main menu (appears after plugging in the LBA)

29

Submenu

Main menu

Menu

Default

next

submenu

Value

User

Value

Remarks

Operating mode

TAKT/FC TAKT

Operating mode selection full oscillation clock principle

VAR /PA Operating mode selection phase-angle principle

SSSD/FC-PA Operating mode selection Soft-Start-Soft-Down

Res Reserve

No.ctrld.phase 123 1 Number of phases controlled (power paths)

Load R,RL,transf.,C

R: without startup ramps, C: like R, only for TAKT

Service OFF,ON OFF Operation without controls or limitations

ASM OFF, ON, OFF OFF Display for ASM process

Uses analog output 2, terminal 33

MoSi OFF,R,S OFF R: ramp, S: steer

Afterpulse OFF,ON ON Only for 3-phase and VAR

TDS OFF,ON OFF Only for 3-phase and VAR

Neutral OFF,ON OFF Only for 3-phase

Hardware parameters

Curr.conv. xxxxx 100 Transformation ratio ü:1

Volt.conv. xxxx 16 Transformation ratio ü:1

X501-3 1-2,2-3,3-4

Voltage adjustment measurement range 3 see chapter

Voltage transformer

Type current xxxxx type See name plate

Type voltage xxxx type See name plate

Burden load. xxx,xx 1 Ohm current transformer adjustment incl. tolerances

Frequency Only display of the mains frequency

Date yyyymmdd Input and display

Time hhmmss Input and display

Cntr. data log. x Current count of data logger counter 1 to 16

Peak value xxxxx 65000

Peak current value at which instant impulse lock

shall be set (in Ampere)

SW_FA_1-6 *

list_L1-3_FA *

DAC1-3_FA *

Parameters

TI_FA *

KP_FA *

Puls.s.off OFF,ON ON

K1 closed-c OFF,ON * ON

IMAB: shutdown of the Power Controller in case of fault

K1RU: switching open contact/closed contact (only K1)

Monitoring Display/setting of the monitoring values

Relative/Absolute R/A

Undercurrent OFF/ON x

Overcurrent OFF/ON y

Monit. L2 OFF/ON

Monit. L3 OFF/ON

U

U

Temperature 6

xxxV

line max

xxxV

line max

Messages 7

2)

1)

absolute limiting value, see Fig. 4

1)

absolute limiting value, see Fig. 4

1)

change of absolute limiting value is only possible if

the corresponding relative limiting value are zero/255.

change of absolute limiting value is only possible if

the corresponding relative limiting value are zero/5000.

Monitoring Relativ

Undercurrent xx % Cursor is in front of the selected value

XR

Overcurrent xx %

YR

Value unequal

ZERO!

Monitoring absolut

Undercurrent xx A Cursor is in front of the selected value

XA

Overcurrent xxx A

YA

ZERO!

* password protection

Page 30

30

= Main menu (appears after plugging in the LBA)

Default

Submenu

Main menu

Menu

next

submenu

Value

User

Value

6 Temperature

PT1000,PT100,NTC PT1000 Sensor used

Ch.curve no. X type Type-dependent, see chapter type overview

Temperature xxx°C Display actual temperature (relative value)

Lev.wire br. *

Lev. sh-circ. *

Comp.val.DAC *

7 No.,DaLo,K1,K2,K3 Status- / fault name

1 Communication with RS 232 active

2 Communication with fibre optic active

3 Power value negative

4 Communication fault RS 232 or fibre optic

5 Synchr. interfaces failure (e.g. Profibus)

6 External processor on the SSC signals fault

7 K3 after RESET

8 RESET active

9 Data in EEPROM invalid (reload parameters)

10 Internal message

11 x K2 Limiting value is exceed

12 Excess device temperature is present

13 Instant current interruption has responded

14 Internal message

15

Fault exists in load circuit-collective fault 16,17

16 Undercurrent exists in the load circuit

17 Overcurrent exists in the load circuit

18 Internal message

19 x Dalo Circuit OK

20 Undervoltage exists in the power section

21 Overvoltage in the power section

22 Internal message

23 Internal message

Parameters

24 x K1 Synchronization fault

25 Collective fault 4,6,9,10,11,12,14-24

(each fault leads to switching)

26 Internal message

27 Internal message

28 Internal message

29 Internal message

30 Power Controller is in peak current limitation

(only for operating mode MOSI)

31

Temperature sensor, short circuit or sensor break

Controls Parameterization control characteristic

U

U

I

I

Active power P

No control

PID factors 8

^2 UxU UxU Selection control characteristic U

load

U Selection control characteristic U

load rms

^2 IxI Selection control characteristic I

load

I Selection control characteristic I

load rms

Selection control characteristic effective load, P

Selection set operation (phase-angle control angle)

Parameterization controller parameters, password prot.

8 PID factors

Sta.-Regl. OFF,ON ON

With standard control OFF the control parameters

can be stipulated

P - part type Controller parameters, P-part

I - part type Controller parameters, I-part

D - part type Controller parameters, D-part

Remarks

2

load

load

2

load

load

* password protection

Page 31

= Main menu (appears after plugging in the LBA)

Default

Menu

next

Submenu

Main menu

Times

Approach 1. xx°e 60°el

Softdown xx,xs 0.3

Softdown xx,xs 0.3

Cl.puls.dur xxxxxms 1.000 Display/Default of pulse period duration To

On-time xxxxms Display of on-time Ts

Sync.del. xxxms Display of on-time Ts

Min. pause 60ms Transformer dependent, default value

Puls.dur.max 50s Fixed parameter control range, default value,

password protection

Set pointm2 OFF/ON 9 OFF

9 Local/Remote

Local/Remote when parameter set point 2=ON

Motorp SW xx %, kW, A depending on set cascade control

Master SW xx

ParametersOperation display

Total Pwr x %, total power; U1, I1 depending on set cascade

control

Total SW x Total set point value also in %, kW, V, A

submenu

Value

User

Value

60°el. in case of 1P, otherwise 90°el., default value for transformers

0 to (To-20ms), default value 400ms, ramp time up

0 to (To-20ms), default value 400ms, ramp time down

On activating, a jump is made from the operation

display directly into this set point menu. The main

menu can be reached from here with the left key

Set point menu 2 direct from the operation display

Remarks

31

.

Pa-lock OFF,ON OFF

with OK, is reactivated after one minute of operation

display

Password

Password entry Enabling of password functions

----------------- Condition: Consultation/training

****** o.k. Valid until LBA is unplugged from the Power

Controller

-----------------

Code xxxxxxxxxx EEPROM version number

Operation display Current operation indication, exit using OK

U1

I1

P1

Status messages 11 Display of status information: select this line

and confirm using OK

11 State messages Examples for status indications

jjjjmmtt ddmmss

Limit

jjjjmmtt ddmmss

Limit

jjjjmmtt ddmmss

Undervoltage

Last function Return to the parameter last processed

Last

function

456,7V Display top

1567,9A Display middle

1234,8kW Display bottom

With parameter lock ON, the lock, which is enabled

REMARK

Type setting dependent on the type

Some further menues are only accessible after input of a password.

Page 32

32

3.1.4 COPYING FUNCTION USING THE LBA

It is possible to load the complete user-specific data record (parameters) of a Power Controller

(for instance no. 1) into the memory of the LBA (RAM), store it in the LBA (EEPROM) and then

copy it into another Power Controller (for instance no. 2):

PLUG LBA INTO POWER CONTROLLER NO. 1

1. reload data (data is stored in the LBA RAM)

2. storing in the LBA

(data is copied into the LBA-EEPROM)

After the waiting time unplug LBA from Power Controller 1.

Plug LBA into Power Controller no. 2

3. LBA -> Thyro-P

After the waiting time data from LBA are in Power Controller 2.

4. Save Thyro-P

TAB. 7 COPYING FUNCTION USING THE LBA

Data from Power Controller 1 have now been copied to Power Controller 2.

ATTENTION

Only parameters of equal Power Controllers (for instance type voltage, type current, phase

number) may be copied.

3.1.5 OPERATION DISPLAY

On the operation display, one, two or three actual values are optionally displayed in double digit

size. An example for the operation display able to be configured using parameters is shown

below:

U1 456.7V

I1 1567.9A

PG 1234.8kW

Status messages

FIG. 7 OPERATION DISPLAY

The operating data displayed are the values U, I and P (P

also possible to display data of other phases. The lowest line is the status line; this is where the

device configuration is displayed, if no indications are waiting. Otherwise, „status messages“ is

displayed. By selecting the key, the indications are displayed:

Status messages ^v

yyyymmdd hhmmss

limit 1250kW

yyyymmdd hhmmss

for 3-phase system) of phase 1. It is

ges

fault type, load, Power

Controller type, limitations,

etc. are notified with the

corresponding time of day. etc.

undervoltage <360V

Page 33

33

With the 씯 key it is possible to leave the status messages display. The operation display now

appears without the word status message. Only when new information arrives does status message

appear again in the bottom line of the operation display.

Additionally, input error indications or further parameters may be stated, which are self-explaining

in connection with the menu heading.

As shown before, automatic switch to this display is made if more than one minute has passed

since the last key has been pressed. The operation display is exited by simple acknowledgement

(OK key).

3.1.6 LINE DIAGRAM

The line diagram has the same functionality as a page recorder. The „writing pen“ and therefore

the current measurement value are found on the Y axis. The line diagram is scrolled left pixel by

pixel. Measured value collection supplies one measured value each second. Because the time axis

is resolved in 90 pixels, the following values result for the time bases from 1.5min up to 3h:

TIME BASE MEASURED VALUES PER TIME-PIXEL

1.5 min 1 *

30 min 20

1 h 40

3 h 120

*) for this resolution, no band display is possible

TAB. 8 LINE DIAGRAM TIME BASE

There are two display modes: band and average value display. In case of band display, each measured value is displayed unfi ltered. The number of measured values displayed for each time pixel

is shown in the above table.

In case of average value display, the average value is formed from several measured values and

displayed in one pixel.

The „windmill“ icon on the LBA display shows current data transfer between LBA and Power

Controller. In case of still or non-existant icon, the data transfer is faulty.

To exit the line diagram, the OK key must be pressed twice.

3.1.7 LAST FUNCTION

If the OK key is pressed during operation display, then the LBA will display the main menu. If the

lowest menu item last function is selected, then the menu is displayed which has been processed

last before operation display.

3.1.8 STATUS LINE

The status line is the lowest line of each menu. It looks like this:

1P VAR Trafo UxU Example for status line

and may contain the following values:

1P, 2P or 3P for the Power Controller type

VAR, TAKT, SSSD for the operating mode

Trafo, R-Last or RL-La. for the load type

U, UxU, I, IxI or P for the control type

TAB. 9 ELEMENTS OF THE STATUS LINE

Page 34

34

3.1.9 LBA SUBMENUS WITH PASSWORD PROTECTION

REMARK

After password input, further parameters may be modifi ed. These are mainly adjusting parameters

required for achieving power control specifi cations. The modifi cation of these parameters requires

extended specialist knowledge (for instance by training) and is not required under normal circumstances.

3.2 CABINET INSTALLATION KIT (SEK)

Using the cabinet installation kit, the LBA may be installed in switching cabinet doors with a thickness of up to 4 mm. It consists of an adaptor frame 96x72mm (cut-out dimensions 92x68mm) and

a cable. Using the cable, the LBA is connected to the RS 232 interface of Thyro-P.

The LBA locks in the adaptor frame and may only be removed with the cabinet door open. This

enables an instructed specialist to set parameters (for instance adjustment to changing tools) and

manual setting of set points (motor potentiometer) as well as for reading the actual value display

without opening the cabinet door (VBG4). In order to avoid the accidental input of data by touching the LBA, there is a self-activating parameterizing lock to enable (see Table 5).

FIG. 8 CABINET

INSTALLATION KIT

If the LBA is connected to the Power Controller using a longer cable and does not operate, then

this may possibly be remedied by increasing the supply voltage (open the jumper R 155 in the

control device).

ATTENTION

In case of open jumper R 155, the LBA may not be connected to the Power Controller without

cable (hazard of destruction). The position of the jumper on the control device PCB can be found in

the component mounting diagram (Fig. 10, page 45).

3.3 THYRO-TOOL FAMILY

Thyro-Tool Familiy is an optional software for commissioning and visualization under Windows

95/98/NT 4.0/XP and higher. It includes all functions of Thyro-Tool P and it is connected to Thyro-P

via either one of the two standard interfaces (RS 232 respectively fi bre optic).

Page 35

35

Thyro-Tool Familiy may be employed as an alternative to LBA and as already stated above has the

following functions, for which several windows may be opened simultaneously:

• set point and actual value processing with overview display for 22 set point/actual value input

options for Motorpoti and total set points.

• loading, storing, modifi cation and printing of parameters

• comparison of parameters

It is possible to compare two sets of parameters (Power Controller or data fi le). It is thus possible,

to detect deviations from the desired confi guration.

• line diagrams of process data with printing function, as well as storage of faults (diverse measured

values from different Thyristor Power Controllers may be displayed simultaneously).

• bar diagram display

It is possible to simultaneously display several bar diagrams. Each diagram has its own window.

These can be adjusted in size and location. The confi guration of the display may be stored.

• simultaneous display of data and parameters from several Power Controllers

• simultaneous connection of up to 998 Thyro-P Power Controllers using fi bre optic distributors

• settings of the interface (baud rate, com...)

Thyro-Tool Familiy is supplied with a help system and installed on the PC under user guidance

using an installation software.

FIG. 9 EXAMPLE FOR THE USER INTERFACE THYRO-TOOL FAMILY

In the above illustration, you can see windows containing:

- 1 line diagram with several measured values

- 4 bar diagram (several are possible), as well as

- 1 parameter input section

- 1 actual value display

The location of the windows may be adjusted to the requirements by the user.

Page 36

36

3.4 DIAGNOSIS / FAULT INDICATIONS

Faults can occur in the load circuit and in the Power Controller itself. Often, the sequence of fault

indications or events is decisive for a positive diagnosis. Diagnosis of unexpected operating behaviour is performed by LEDs on the front panel of the control device, with parameter comparison

(whereby the modifi ed parameters may be listed), as well as by reading from the Thyro-P fault

memory (data log). In Thyro-P, faults occurring and indications are entered in the fault memory with

the event time and are preserved in case of mains outage as well. Up to 16 entries are possible.

If further entries are made, then the fi rst entry is overwritten. Therefore, the most current 16 events

may be recalled at any time. Should faults or incidents occur, the selected operation display on the

LBA will show status indications.

The indication is of the format

yyyymmdd hhmmss [ fault ] [ value ]

The status line only appears in the operation display (see fi g. 7).

When using Thyro-Tool Familiy and an active line diagram, for any faults occuring their respective

indications are displayed in a window and stored on disk associated with the line diagram.

Using an optional bus interfecace (e.g. Profi bus DP, a corresponding indication is automatically

issued.

The status indications (faults, warnings, messages) generated by Thyro-P may, as already mentioned, be classifi ed as load and as Power Controller faults. Depending on the application, warnings

or status messages may be read.

Data log

yyyymmdd hhmmss

[ fault no. ] [ limiting value ]

All indications may be switched to the data log and the relays deviating from default settings.

Page 37

EVENT NO. PRESET STATUS MESSAGE

LOG RELAY

1 Communication RS 232 interface active

2 Communication fi bre optic interface active

3 Negative power (calculated value)

4 Communication fault RS 232 or fi bre optic interface

5 Synchronous interface fault (for instance Profi bus)

6 External processor on the SSC signals fault

7 K3 after RESET - monofl op function

8 Controller lock is active

9 Data in the EEPROM invalid

(then reload Thyro-P parameter memory using

Thyro-Tool Familiy)

10 Internal message

11 K2 Limiting exceeded

12 Device overtemperature

13 Quick circuit interruption has responded

14 Internal message

15 Failure in load circuit, collective failure

16 Undercurrent in load circuit, when activated

17 Overcurrent in load circuit, when activated

18 Internal message

19 DaLo Indication appears on return of supply

20 Undervoltage in the power section

21 Overvoltage in the power section

22 Internal message

23 Internal message

24 K1 Synchronization fault

25 Collective fault

(each fault leads to switching of the output)

26 Internal message

27 Internal message

28 Internal message

29 Internal message

30 For the operating mode MOSI:

Power Controller has run into peak current limitation

31 Temperature sensor, short circuit or sensor break

37

TAB. 10 ALLOCATION OF THE MESSAGE REGISTER

Page 38

38

4. EXTERNAL CONNECTIONS

This chapter describes external connections of the Thyro-P as well as all available terminal strips

and signals as necessary. Shielded cables grounded on the Thyro-P side must be used for the connection of the control signals (setpoint inputs and analogue outputs). For the connections to RESET,

Controller lock and QUIT, twisted cables must be used.

Bus interfaces can be found in chapter 5 INTERFACES. To operate the Thyro-P at least the following

signals described up to chapter 4.5 QUIT must be connected.

4.1 POWER SUPPLY FOR THYRO-P

In the case of types 400V and 500V, connecting the regulator to the power supply also connects the

control device Thyro-P to the power supply (see also chapter POWER SUPPLY FOR THE CONTROL

DEVICE A70). The control device for 690V types must be supplied separately.

Details on connecting power supply can be taken from the chapters TECHNICAL DATA and connecting diagrams. This particularly applies when using the control device in UL applications.

4.2 POWER SUPPLY FOR THE CONTROL DEVICE A7

The Thyristor Power Controller Thyro-P is fi tted with a wide-band power supply. The mains connection is designed for input voltages from 230V -20% to 500V +10% and nominal frequencies from

45Hz to 65Hz. The power consumption is max. 30W. Depending on the switch mode power supply,

a 100VA control transformer must be used.

For the type ranges 400V (230-400V) and 500V nominal mains voltage, the control device is supplied directly from the power section. It is therefore a unit ready to connect.

STRIP TERMINAL X1

X1 mains supply connected internally

1 phase

2 N or phase

TAB. 11 STRIP TERMINAL X1

REMARK

If required, e.g. when operating with Profi bus, the control device can also be supplied separately.

With supply voltages outside the nominal range the control device must be supplied separately

with an input voltage within the above-mentioned voltage range. The phase position of this control

voltage is optional. In this case the plug (A70/X1) must be pulled.

CAUTION

The pulled plug has mains voltage of the load circuit! The new connecting lines must be fused

according to the applicable regulations (plug see chapter 12).

4.3 POWER SUPPLY FOR THE VENTILATOR

With Thyro-P Thyristor Power Controllers furnished with integrated ventilators (HF types), the ventilator must be supplied with a voltage of 230V 50/60Hz according to the connecting plans and the