Page 1

ÖKO_LAVAMAT 1370

TURBO sensortronic

The ecological washer-dryer

AEG

User Instruction Book

AUS

ERFAHRUNG

GUT

Page 2

Allow me to introduce myself

Page 3

Contents

Warnings

Before installing

Warnings (washing)

Warnings (drying)

The AEG Öko-System / Ecological hints

Installation instructions

Removing the transit devices

Positioning

Connection

Electrical connection

Connection to the mains water supply

Water drainage

Brief instructions

Preliminary operations for washing

Sorting and selecting garments

Pre-treatment

Precautions

Load sizes

Selecting the programme

Programme selector/switching on

Programme phase indicator

Option buttons and functions

Detergents

Choice of detergent

Amount of detergent

Preliminary water softening

Using the detergent

Programme chart (washing)

End of programme

Special rinse

Preliminary operations for tumble drying

Protect the environment

Preparation for tumble drying

Items not suitable for tumble drying

Drying code symbols

Selecting the drying programme

Drying only

Automatic washing and drying

Drying time chart

Maintenance and cleaning

Detergent dispenser drawer

Cleaning the filter/Emergency emptying

Other

How to deal with problems...

Customer service

Technical specifications

4

4

4

5

7

9

9

10

12

12

13

14

15

16

16

16

17

17

18

18

19

20

23

23

24

24

25

26

28

28

29

29

29

30

30

31

31

33

34

36

36

37

38

39

42

43

Page 4

Warnings

Before

installing...

- Follow the instructions for installation and electrical connection.

- Do not connect the appliance if it is damaged (for example dur

ing transport).

- Any water found in the detergent dispenser drawer is there as a

result of factory testing.

- To remove any manufacturing residues from the drum and

detergent dispenser drawer, carry out a wash cycle without any

laundry, with the machine set on the 60°C coloureds pro

gramme and with 1/2 a measure of detergent.

Warnings AEG household electrical appliances comply with general techni-

(washing) cal safety manufacturing standards and with ail safety regulations

on the use of electrical appliances. However, the manufacturer is

obliged to bring the following safety points to the attention of the

user:

- Before using the appliance, make sure that the voltage and type

of current indicated on its rating plate correspond to the mains

voltage and type of current in the place where it is to be

installed. The rating plate also gives details of the electrical pro

tection required.

- If the appliance is installed in a location which is not insulated

against frost, the emergency emptying procedure (see “Emer

gency emptying”) should be used whenever there is any risk of

the temperature dropping below zero.

- Always disconnect the appliance before cleaning it or carrying

out any maintenance. To be absolutely safe, check that the plug

is removed from the socket or that the mains switch or safety

circuit breaker are in the OFF position (see instructions for

installation and electrical connection).

- Avoid spraying the appliance with water.

- Never remove the plug from the socket by pulling the cable;

always take hold of the plug itself!

- Never start the appliance if:

■ the power supply cable is damaged

■ there are obvious signs of damage in the control panel area,

to the top or along the base.

- Repairs must only be carried out by qualified persons.

Inexperienced repairs can seriously endanger the user.

Always contact the Service Centre or an authorized dealer. Only

genuine AEG spares comply with all standards!

Page 5

- If the appliance is to be installed under a worktop in a fitted

kitchen or laundry room, the appliance cover must first be

removed and a protective plate must then be fitted, as

described in the installation instructions.

- Do not allow children to play with the appliance and keep pets

well away from it.

- For safety, when disposing of the appliance make sure that the

door catch is inoperative and cut off the power supply cable.

- The Manufacturer accepts no liability for damage caused by

incorrect or improper use of the appliance for purposes for

which it was not originally designed.

- Never put your hands in the drum whilst it is still rotating.

- Never touch the glass in the porthole door when the appliance

is being used on a high-temperature programme; the glass gets

very hot and can cause burns.

- There is a danger of scalding if the porthole door or filter cover

are opened during operation.

- The water drain hose must be properly fixed to avoid any risk of

scalding or flooding.

- In the event of a fault, close the mains water taps and discon

nect the appliance from the power supply by pulling out the

plug or switching the safety circuit breaker (or breakers) to the

OFF position.

- Keep packaging materials away from children, especially cello

phane which is particularly dangerous.

- If washing garments which have previously been dry cleaned,

first make sure that any remaining inflammable solvents have

completely evaporated.

- If the appliance is to be connected to a rainwater or other simi

lar source of water instead of the mains water supply, follow the

Water Board regulations.

The appliance must only be used to tumble dry normal house

hold laundry.

Dry only laundry which has previously been washed in water.

It is quite normal for the sides of the appliance to get hot during

drying. Avoid touching them!

Warnings

(drying)

Page 6

Never tumble dry quilted garments containing foam rubber or

similar materials; they could catch fire.

Never tumble dry fabrics stained with hair lacquer, nail varnish

remover or other similar substances whiqh would give off toxic

fumes.

Laundry dried in a tumble dryer comes out soft to the touch.

This means you can help protect the environment by using less

fabric softener in the wash.

If so-called “ecological” or “perfume-free” detergents are used,

tumble-dried laundry may not have the typical “smell of fresh

ness”. This is not due to a fault in your appliance, but simply to

the natural smell of the fabric which is not neutralised during

washing because the detergent contains no deodorants.

The Manufacturer accepts no responsibility for accidents

resulting from failure to observe the above safety recom

mendations.

Page 7

The AEG OKO-System / Ecological hints

This new machine is part of AEG’s OKO-System range, which

meets all requirements for modern handling of laundry with

reduced consumption of water, energy and detergent.

This is a rinsing and spinning process developed by AEG which

ensures the best washing results with reduced water consump

tion.

The automatic metering device automatically regulates the

amount of water used according to the size of load and type of

fabric.

The drum is fitted with special paddles which keep the water

moving upwards. In this way, the laundry is soaked more evenly

and faster.

Preliminary softening of the water, achieved by means of a twostage device for dispensing the softener and detergent, ensures

ecological operation even in very hard water areas.

All the materials used for packaging are non-polluting! They may

be disposed of quite safely.

Plastic materials can be recycled and are marked with the follow

ing symbols:

>PE< polyethylene

>PS< polystyrene

>PP< polypropylene

Sensortronic

Automatic

metering

Drum paddies

Preiiminary

water softening

Packaging

information

You are advised to dispose of all cardboard packaging in special

paper collection containers so that it can be recycled.

Page 8

Ecological

suggestions for

economical

washing

For medium soiling, use programmes without prewash. This

will save detergent and water.

Make full use of all the advantages offered by two-part deter

gents.

Always wash full loads for maximum savings.

Use the “ENERGY SAVING” (Economy) programme for nor

mally or lightly soiled cottons and coloureds.

For best results, even at low temperatures, remove individual

stains from laundry before washing.

Use minimum amounts of detergent. Follow the instructions

on the pack.

Page 9

Installation instructions

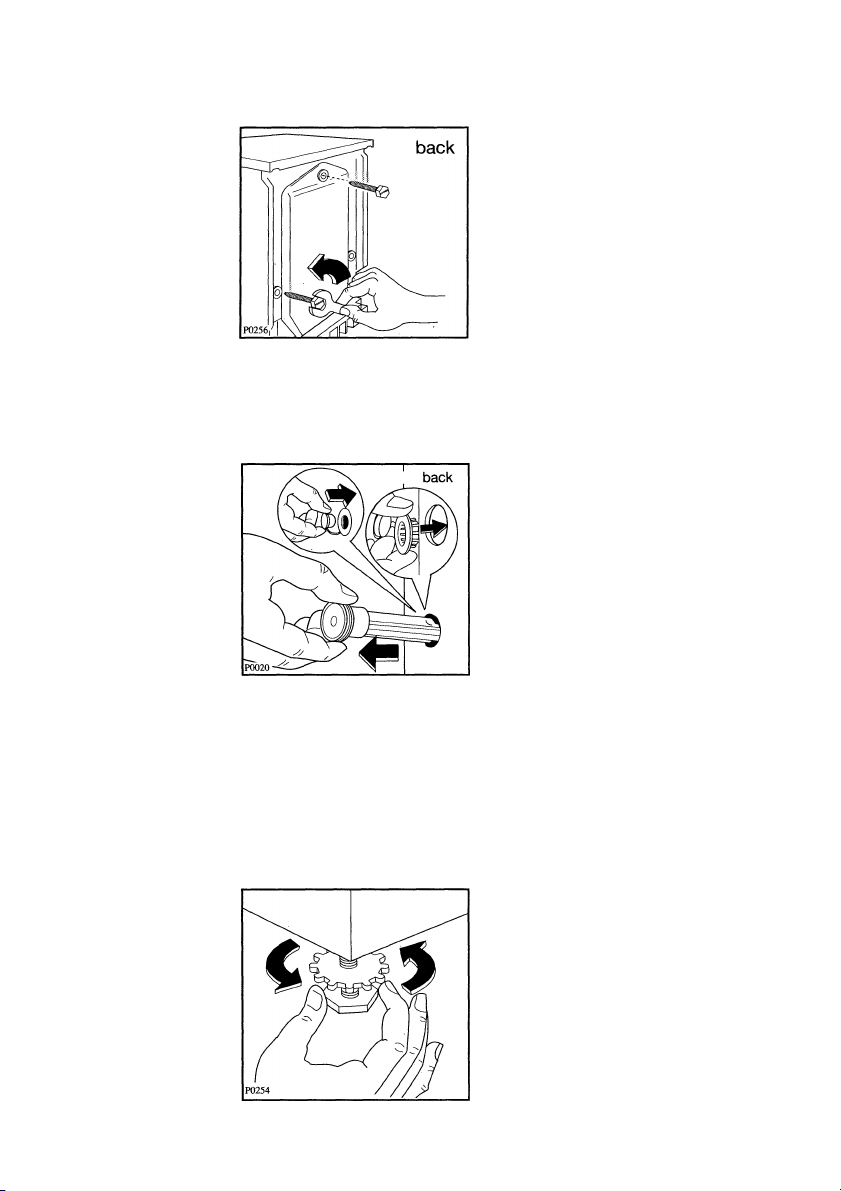

All transit devices must be removed before installing and connecting the appliance.

Proceed as follows:

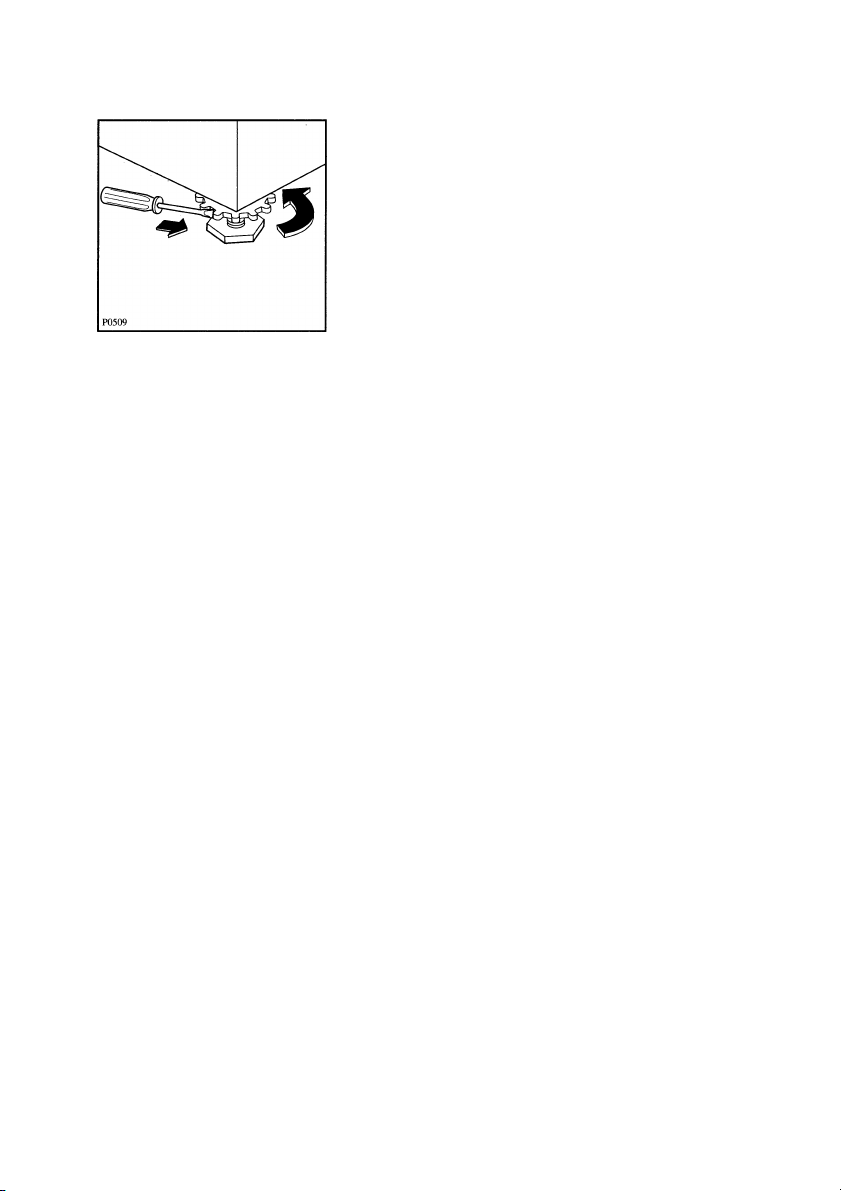

Using a spanner, remove the bolt on the right at the back of the

machine.

Gently lay the machine on its back, taking care not to squash the

hoses.

This can be done more easily by placing one of the corner pack

ing pieces between the machine and the floor.

Remove the polystyrene packing piece.

Removing the

transit devices

Peel off the adhesive strip and carefully remove the right-hand

polythene bag (1), then the left-hand bag (2) by pulling both

towards the centre of the machine.

Page 10

Set the machine upright and unscrew, the remaining two bolts on

the back.

Remove the three plastic pins from the holes in which the bolts

were fitted.

Blank off the holes with the plastic plugs supplied, which you will

find in the bag with the instruction book.

Hint:

Keep all transit devices for re-use in case you move house.

Positioning The machine stands on four adjustable rubber feet which can be

used to compensate any unevenness in the floor or to adjust the

machine to the correct height.

10

Page 11

Lock the feet in position by fully tightening up the locknuts.

The appliance must be level and resting on all four feet. It must

not tilt when pressure is exerted on one side only. If necessary,

use a spirit level to check that it is perfectly level.

The floor must be clean, dry and free of any wax residue or other

polish to prevent any risk of sliding. Never use viscous substances

to move the appliance by sliding it across the floor!

It is inadvisable to stand the appliance on long pile carpet or ,rugs

or on layers of foam rubber, as this could make it unstable. Place

a rubber mat beneath the appliance if the floor is made of very

small tiles.

If the appliance is to be placed on non-solid flooring, especially

made of wooden joists and flexible boards, a waterproof wood

panel, 15 mm thick, must be secured with screws to at least two

of the floor joists. If possible, the machine should be placed in a

corner of the room, as this is where the joists are most firmly fixed

and have less tendency to flex.

Never use wedges of wood, cardboard or other similar materials

to compensate for unevenness in the floor.

If space is tight and you cannot avoid placing the machine next to

a gas oven or coal burning stove, a sheet of insulating material

(85 X 57 cm), covered with aluminium foil on the side facing the

oven or stove, must be fitted between the two appliances.

Before building the machine in under a fitted kitchen worktop,

remove the cover and install a special protective plate, which is

available from your local Service Centre, part number 645 426 133.

11

Page 12

Connection

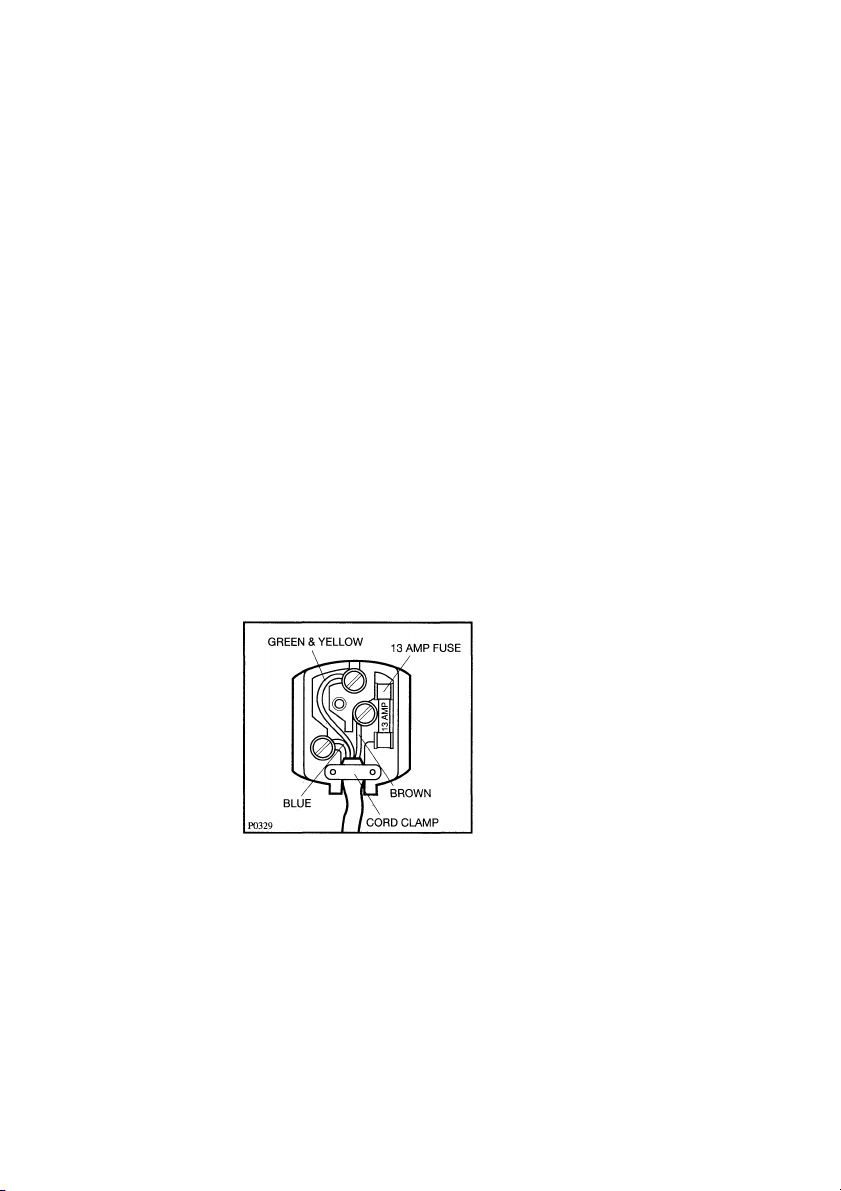

Electrical Details of the mains voltage, type of current and protection

connection required are given on the appliance rating plate which can be

found on the frame, after opening the porthole door.

WARNING: THIS APPLIANCE MUST BE EARTHED.

The manufacturer declines any liability should this safety

measure not be observed.

If the plug that is fitted to your appliance is not suitable for your

socket outlet, it must be cut off and the appropriate plug fitted.

Remove the fuse from the cut off plug.

The cut off plug should then be disposed of to prevent the hazard

of shocks in case it should be plugged into a 1 Samp socket in

another part of your home.

IMPORTANT

The wires in the mains lead are coloured in accordance with the

following code:

Green and Yellow - Earth

Blue - Neutral

Brown - Live

If you fit your own plug, the colours of the wires in the mains lead

of your appliance may not correspond with the markings identify

ing the terminals in your plug, proceed as follows:

Connect the Green and Yellow (earth) wire to the terminal in the

plug which is marked with the letter «E» or the earth symbol © ,

or coloured green and yellow.

Connect the blue (neutral) wire to the terminal in the plug which is

marked with the letter «N» or coloured black.

Connect the brown (live) wire to the terminal in the plug which is

marked with the letter «L» or coloured red.

The plug moulded onto the lead incorporates a fuse. For replace

ment, use a 13amp BS1362 fuse. Only ASTA or BSI approved

fuses should be used.

The plug must not be used if the fuse cover/carrier is lost. The cover/

carrier is indicated by the coloured insert at the base of the plug.

12

Page 13

A replacement cover/carrier must be obtained from your local

AEG Service Centre.

This appliance complies with the E.E.C. Directive No. 87/308 of

2.6.87 relative to radio interference suppression.

If the appliance is to be permanently connected to the power

supply you must install a circuit breaker with a gap of at least

3 mm between the contacts, which enables the appliance to be

completely isolated from the mains supply.

The mains supply cable must not be extended. If it is not long

enough, replace it with a new, longer cable or move the appliance

closer to the power socket.

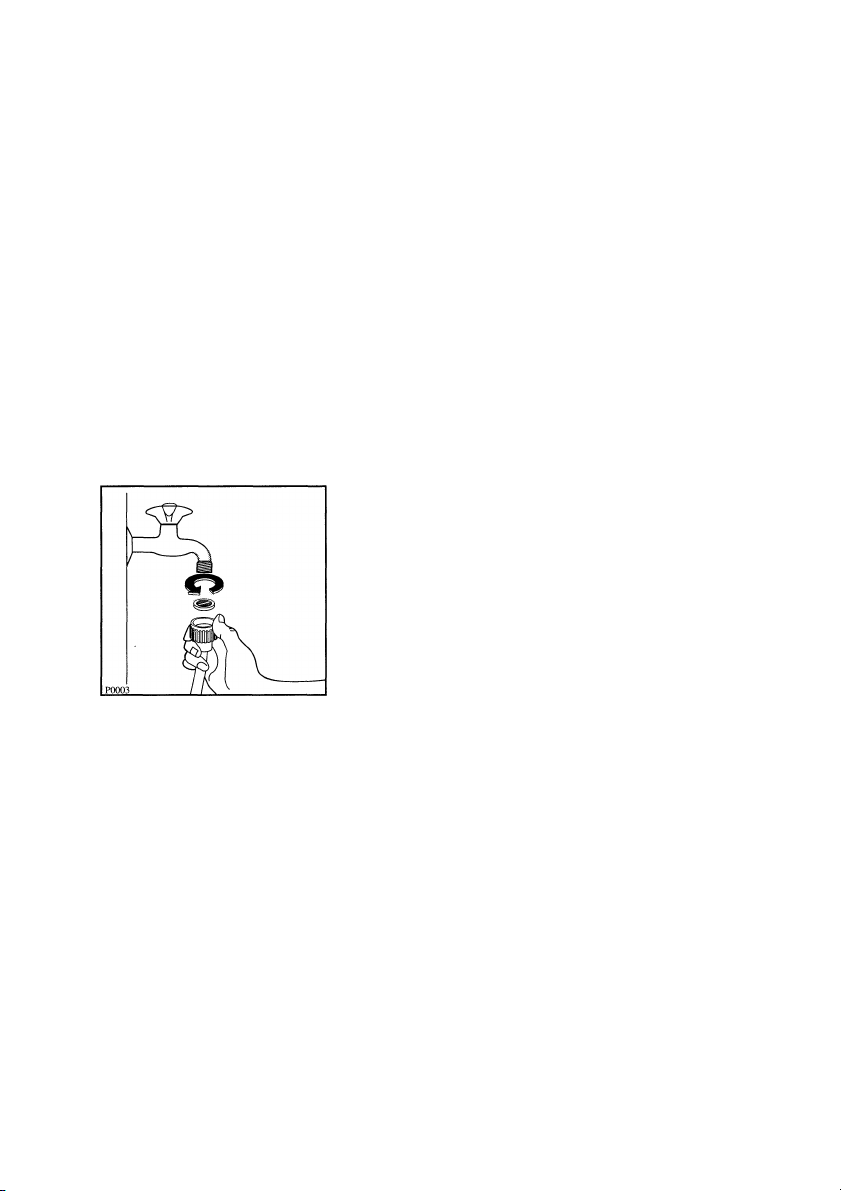

The appliance has two inlet valves, hot and cold, with female 3/4"

BSP thread connectors. The water inlets on the back of the

machine are colour coded, blue for cold and red for hot. Before

connecting the hoses.be sure to fit the mesh filters supplied.

If only a cold water supply is available, connect the two hoses to a

cold water outlet by means of a «Y» connection piece.

Installation should comply with local water authority and building

regulations’ requirements.

The appliance must be given a separate cold water supply and

not be connected to a mixer tap, a single outlet water heater or a

booster pump. A minimum water pressure of 7psi is required for

safe operation of the appliance.

If you cannot make the cold water connection direct from the ris

ing mains, you may be able to operate the appliance from your

cold water storage system.

There should be a minimum distance of 5.02m (16 V2 ft) between

the appliance’s inlet and the bottom of the tank.

There will be sufficient pressure for the hot water supply from the

hot water cylinder if the height between the appliance’s inlet and

the bottom of the cold water storage cistern (not between the

appliance and hot water cylinder) is at least 2.74m (9ft).

Connection to

the mains

water supply

13

Page 14

The end of the hose connected to the back of the machine can

be turned in any direction. Simply slacken the connector fitting,

position the hose as required and fully tighten the connector to

avoid leakage of water.

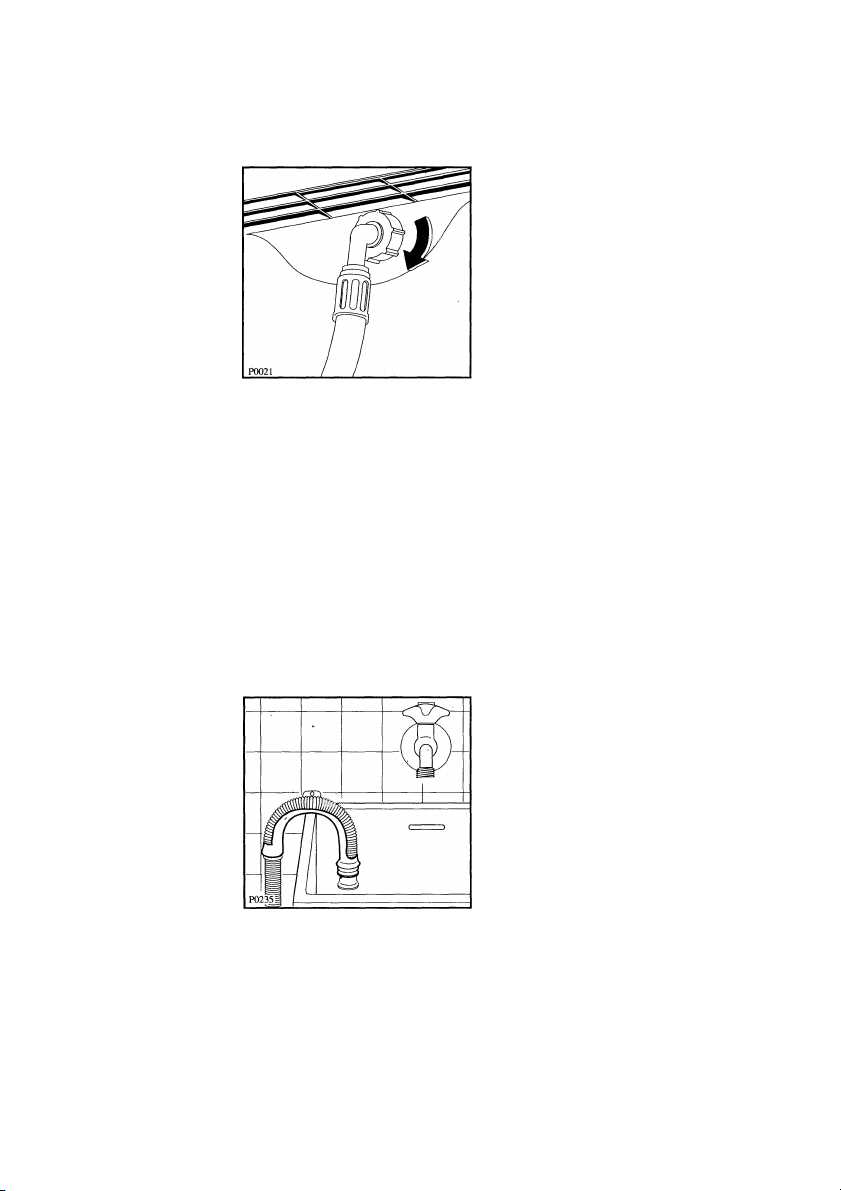

Water drainage

Every appliance is fitted with a pump for discharging the wash

and rinse water. This pump is controlled by the programme selec

tor mechanism and is capable of pumping water through the

drain hose to a height of up to 1 m above the surface on which

the machine is standing.

The curved end of the drain hose can be positioned in two ways:

Hooked over the edge of the sink. In view of the speed with

which the water comes out during the discharge phase, it is

important to ensure that the curved end of the hose cannot slip

off the edge of the sink. It should therefore be tied to the,tap with

a piece of string or secured to the wall with a hook, by inserting

the hook into the hole provided in the curved part of the hose.

Joined into a branch of the sink waste pipe. The branch

must be above the sink trap and at least 60 cm above the floor.

The drain hose may be extended up to a maximum length of

180 cm. Use an extension with an internal diameter the same as

that of the original hose. Use a suitable connector.

The hose extension must rest on the floor and only the part near

the drainage point must be raised.

14

Page 15

Brief instructions

■ Prepare the laundry

Sort and select garments, carry out any pre-treatment.

■ Switch the machine on

, Press the ON/OFF button

■ Select the programme

Turn the selector dial to the required programme

Press any option buttons required

■ Open the porthole door

■ Load the laundry into the machine

■ Close the porthole door

■ Measure out the detergent

■ Press the START/PAUSE button

■ At the end of the programme

Open the porthole door and remove the laundry.

■ Release the ON/OFF button

15

Page 16

Preliminary operations for washing

Sorting and

selecting

garments

Check that garments are machine-washable by looking at the

international wash code symbols on the label.

Whites

Coloureds

Synthetics

Delicate fabrics

Wool

Sort clothing according to type of fabric, degree of soiling and

wash temperature.

Wool garments marked with only the ^ symbol should not

be washed in your machine, but those on which the symbol is

accompanied by the words “non felting” or “machine-washa

ble” may be machine-washed.

Never machine-wash garments labelled with the following

symbols:

Hand wash only

Do not wash in water

ÌL

mi \4o_

\6o/ \mi

Pre-treatment

16

Dry clean only

Do not dry clean

May be bleached

Do not use bleach

Always follow the instruction “Wash separately”.

New coloured items often contain excess dye which could run

and stain other, lighter items in the wash. It is advisable to

wash these items separately the first time.

If possible, treat stains when they are still new. Use water, soap or

suitable detergents (stain remover spray, stick, paste, etc.).

® ©

:ùsi

0

Page 17

Empty all pockets

Be particularly careful to remove metal objects (paper clips,

safety pins, loose change, etc..).

Do up buttons and hooks, close zips and press studs.

Tie up loose b6lts or long apron strings.

Turn woollen garments, coloured embroidered garments and

those with sewn-on designs inside out.

Very small or delicate items (e.g. baby socks, tights) can

be protected by placing them inside a pillowcase with zip fas

tener, or inside long socks.

Treat net curtains with special care.

The fabric may be damaged by opening the window or when

removing the curtains for washing (pulled threads). Remove

metal or plastic hooks or enclose in a net or doth bag.

The manufacturer accepts no responsibility for any damage.

Net curtains should be spin dried only if the manufacturer’s

label states that this may be done.

Precautions

Whites/coloureds (cotton and linen)

Soak

Easy care fabrics

Delicate fabrics

Curtains

Woollens

Quick wash programme for

cottons/coloureds

Quick wash programme for

easy care/delicate fabrics

Whenever possible, load the machine to maximum capacity; full

loads are more economical.

Do not however exceed the maximum load as this could lead to

poor washing results.

Reduce the load when washing fabrics which are particularly sub

ject to creasing.

5.0 kg'

5.0 kg

2.0 kg

2.0 kg

15-20 m^ depending

on type of material

1.0 kg

2.5 kg

2.0 kg

Load sizes

(Maximum ioad

of dry iaundry)

17

Page 18

Selecting the programme

Programme selector/Switching on

The programme selector knob may be turned clockwise or anti

clockwise.

When the ON/OFF button is pressed the machine switches on

(power ON) or off.

ECONOMY

SOAKING

18

You may select normal washing and drying programmes, or the

following special programmes;

For normally or lightly soiled cotton and linen whites the

ECONOMY (E) programme may be used instead of the 95°C pro

gramme. The duration of the programme will be prolonged, but

the washing temperature is reduced to about, 67°C, so saving

energy. ’

For heavily soiled fabrics (except wool) the SOAK programme may

be selected.

The cycle is pertormed at 40°C and ends with water in the drum.

To drain the water depress the START/PAUSE button. After 18

hours soaking the water is drained automatically.

Page 19

This programme allows you to rinse and spin separately, items

which have been washed by hand.

GENTLE RINSE

This programme is for garments which have just been washed

and need starching. Dissolve powdered starch or dilute liquid

starch, then pour it into the dispenser compartment marked with

the ® symbol.

Water may be pumped out at the end of a programme, without

spinning.

Spin for cottons and coloureds.

Spin for easy care/delicate fabrics and for woolens.

Cancels the previously selected functions

Programme phase indicator

PREWASH

MAIN W ASH

RINSE HOLD

PUMP OUT

When a programme is selected, the lights corresponding to the

phases making up the programme come on,

When the programme starts, the light corresponding to the pro

gramme phase in progress comes on.

The end of the programme is indicated by the END light.

RINSE

SPIN

DRYING

END

O

o

o

o

o

o

O

o

STARCHING

PUMP OUT

SPIN

GENTLE SPIN

CANCEL

19

Page 20

Option buttons and functions

When these buttons are pressed, the corresponding pilot lights

come on. When they are pressed again, the lights go out.

If a button whose function is not compatible with the programme

selected is pressed, all the lights will start to flash. After about 1

second, they will go out.

ON

OFF

О

ON/OFF ■ ON/OFF button

When this button is pressed, the machine switches on.

The pilot light on the left comes on.

The pilot light corresponding to the Start/Pause button flashes

and the programme phase indicator shows the different phases

that make up the cycle.

When the button is pressed again, the machine switches off.

SPIN

■ Spin

700 - 900 - 1300

This button allows you to select a slower spin speed than normal.

If this button is not pressed spinning will automatically be per

formed at the maximum speed for the programme selected.

This is important when wishing to dry laundry in the

machine because you will save time and energy and you

will obtain better results with electronic drying.

If you select 900 or 700 rpm for cottons/coloureds the machine

will carry out an extra rinse.

By selecting 700 rpm for cottons/coloureds it is not possible to

dry automatically after washing.

Easy cares and wool are spun at a maxinrium of 900 rpm. The

spin speed may be reduced from 900 to 700 rpm.

For delicate fabrics, the maximum spin speed is 700 rpm.

If you select 700 rpm for easy cares, the machine will rinse with

more water.

20

DRYING

TIME

О

QUICK VARIO- PRE- START

WASH MATIC WASH INTENSIVE PAUSE

700 900 1300

ООО

SPIN

О

О О О О о

оооо о

Page 21

■ Quick wash

The quick wash option may be selected with all programmes,

except .the following: Economy, wool, délicates, intensive and all

programmes with prewash. It is particularly suitable for lightly

soiled loads. The washing time is reduced.

QUICK WASH

■ Variomatic

A specially gentle spin may be selected with all programmes, giv

ing the following effects:

- for cottons and coloureds, starching and spin programme

a VARIOMATIC spin programme is performed before the normal

final spin. The spin takes place in stages, so allowing the laun

dry to untangle itself during and at the end of the spin pro

gramme. The cycle time is increased.

- for easy cares/delicate fabrics

The “Rinse Hold” phase is eliminated and a single gentle spin is

performed at a maximum of 900 rev/min for easy cares, and

700 rev/min for delicate fabrics.

- for wool

The “Rinse Hold” phase is eliminated and a single gentle spin is

performed at a maximum of 900 rev/min.

■ Prewash

A programme with prewash may be selected for heavily soiled

items.

Result:

A prewash cycle at a maximum temperature of 40°C is performed

before washing.

VARIOMATIC

PREWASH

The prewash function cannot be used with the wool programme

or when the QUICK WASH button is-depressed.

■ Intensive

The intensive option may be selected with all programmes except

ECONOMY, WOOL, DELICATES and when the QUICK WASH

button is depressed. It allows thorough washing of heavily soiled

laundry. The wash cycle time is extended by 10 minutes.

INTENSIVE

21

Page 22

START/PAUSE

■ Start/Pause

After the machine has been switched on, the pilot light over this

button starts to flash.

When the button is pressed, the programme starts and the pilot

light goes out.

To interrupt the programme or to open the porthole door in the

middle of a programme, press this button again. The pilot light will

start to flash.

The door can only be opened after about 2 minutes.

When the button Impressed again, the programme resumes and

the light goes out.

Important: The door can only be opened if the water level is

lower than the bottom of the porthole. Otherwise, the water must

first be pumped out.

The START/PAUSE button can also be used to pump out the

water after the SOAK programme and after a RINSE HOLD pro

gramme: the soaking water is only pumped out, whilst in the other

programmes the machine will perform a short spin.

22

Page 23

Detergents

Any of the modern, commercially available detergents made for

use in domestic washing machines may be used.

The type of detergent used depends on the type of fabric and

soiling.

The various types of soiling are:

■ Dirt, e.g. dust, soot, sweat, organic stains, etc.

■ Stains which respond to bleach, e.g. red wine, fruit, vege

tables, etc.

■ Protein stains, e.g. blood, milk etc.

Detergents are available in the following forms:

■ Powder detergent, with bleaching agent

■ Liquid detergent, without bleaching agent

■ Colour-safe detergents for delicate fabrics and col

oureds, without bleaching agent and often also without whit-

eners

■ Detergents for wool, without bleach or enzymes, which will

not damage wool fibres.

■ Detergents for net curtains, with optical whiteners and

substances which prevent the curtains from yellowing in sun

light.

■ Building-block-system detergents which allow separate

dosing of the basic detergent, water softener and bleaching

agent.

Choice of

detergent

■ Water softening agents to reduce the hardness of tap

water.

■ Bleaching agents or stain removing salts, for concen

trated use on stains or as an additive with bleach-free deter

gents.

■ Pre-treatment agents, for removing stains prior to washing.

■ Fabric softeners, to eliminate static charge for easy cares

and to make fabrics feel soft.

■ Starches and dressing agents, to nnake garments hold

their shape and make them easier to iron.

■ Dyes and colour removers may be used in the washing

machine only if indicated on the product pack.

23

Page 24

Amount of

detergent

The amount of detergent used depends on the size of load, water

hardness and degree of soiling.

Refer to the instructions on the products.

Information on the hardness of water in residential areas can be

obtained from the Local Water Authorities.

Water hardness

Preliminary

water softening

Level

of hardness

• soft

II - medium

hard

IV - very hard

If the detergent manufacturer gives no indication of how much

detergent to use for a part load, we recommend that you reduce

the detergent measure by 1/3rd for a half load and that you use a

half measure of detergent for a minimum load.

The washer-dryer is fitted with a special device for preliminary sof

tening of the water by dispensing the softener and the detergent

in two stages. In programmes without prewash it enables the

softener and detergent to be dispensed separately for increased

saving on detergent, and therefore less water pollution.

Separate dispensing of the two substances means that initially,

only the softener is added to the water. When the detergent is

then added, because the water is already soft, it starts to act

immediately on dirt in the fabrics. This process ensures optimum

washing results, even with minimum measures of detergent.

Normal water softening agents should be measured out accord

ing to the hardness of the water, following the instructions on the

pack but, because of the preliminary softening device, you may

reduce the quantity by 20%. In this case, always use the amount

of detergent recommended on the detergent pack for level I

Clarke

degrees

less than 8

8-14

15-21

more than 21

°T.H. (French degrees)

less than 13

13-24

25-36

more than 36

hardness of water (soft).

Even when a prewash programme is selected, it is still possible

to protect the environment. Pour the detergent and water soften

ing agent together into the prewash and main wash dispenser

compartments.

You may obviously continue to use normal detergents without sof

tening agent, using an amount based on the pack recommenda

tions and the degree of water hardness.

24

Page 25

Softening agent or

prewash detergent

Main wash detergent

Liquid additives

.Programme chart

Using the

detergent

Warning:

■ For programmes with Prewash in which the softening agent

and detergent are poured into the same dispenser compart

ment, always pour in first the detergent and then the sof

tening agent.

If you prefer liquid detergents, use the dispenser supplied

with the product.

The measure of liquid additive used must not exceed the

‘MAX’ level mark on the dispenser drawer.

If thick fabric softeners or concentrated starches are

used, it is advisable to dilute them by pouring water into the

dispenser compartment, up to the ‘MAX’ level mark.

On the programme chart you will find the main washing and

drying programmes.

Powder

detergents

Liquid

detergents

Liquid additives

Programme

chart

25

Page 26

Programme chart (Washing)

Washing symbols

used on fabric

labels

XMi

Cottons/coloureds

Cottons (Whites)

Xgj Xgi

Easy cares (synthetics,

mixed fabrics)

\4^ \:^

Synthetics/net curtains/

Dresses and jackets

Wool/Wool mixtures/

Silk

Cottons/

easy cares

Programme selector

Whites 95

Coloureds 60 50 40 30

Energy saving programme

(Economy) E

Easy cares 60 50 40 30

Délicates 40 30

Wool 40 30 COLD

Soaking

Max. load

5 kg

2 kg

2 kg

1 kg

5 kg

2 kg

Easy cares/Delicates/

Wool

Cottons/Coloureds

All fabrics

Cottons/Coloureds

Easy cares/Delicates/

Wool

26

Gentle rinse

Starching

Pump out

Spin

Gentle spin

Cancel

2 kg

1 kg

5 kg

5 kg

5 kg

2 kg

1 kg

Page 27

Suitable option buttons

PRE-WASH QUICK WASH INTENSIVE VARIOMATIC

PRE-WASH VARIOMATIC

PRE-WASH QUICK WASH INTENSIVE VARIOMATIC

PRE-WASH VARIOMATIC

VARIOMATIC

VARIOMATIC

VARIOMATIC

27

Page 28

End of programme

Opening the

porthole door -

Switching off

At the end of the programme, open the porthole door when the

END light comes on.

Check that the drum has been completely emptied to avoid any

items accidentally left there being damaged in a subsequent wash

(e.g. shrinking), or their colour running into the next laundry load.

Clean the filter, especially after a drying programme.

Special rinse

The machine always operates with minimum water consumption.

Selecting

an additional

rinse cycle

Additional rinse

adjustment

device

28

An additional rinse may be selected with programmes for cottons

and easy cares.

This increases both the amount of water used and the pro

gramme time.

Pull out the detergent dispenser drawer until the rinse water

adjuster is accessible on the left-hand side.

Use a coin to turn the adjuster to the (••) symbol.

Page 29

Preliminary operations for tumbie drying

All washer-dryers consume power to dry laundry. The machine will

operate most economically if the advice below is followed:

Remove as much water as possible from the laundry!

The machine will use less energy if the laundry is thor

oughly spun before drying. A good spin reduces power con

sumption, shortens the drying time and enables the machine

to operate more economically.

Use optimum loads!

Keep to the loads recommended in the programme

chart to ensure economical drying. The following list may be

used as a guide to estimate the weight of common laundry

items:

Weight

Approximate dry weights of cotton items:

Bathrobe

Work shirt

Quilt cover

Sheet

Blouse

Towelling towel

Tea-cloth

Man’s shirt

Pillowcase

Nightdress/pyjamas

Tablecloth

Underwear

1200g

300-600 g

700 g

500 g

100 g

200 g

100 g

200 g

200 g

200-250 g

200-300 g

250 g

Protect the

environment...

As a dryer, the machine operates on the condensation principle.

However, even during the drying cycle, the water tap must

be left open and the water drain hose must discharge into a

sink or into a drain connection.

Load

Cottons/coloureds

Easy cares

max. 2.5 kg

max. 1.75 kg

Warning:

Washing loads which exceed these weights must be split

for drying, otherwise good results will not be achieved.

Preparation for

tumble drying

29

Page 30

Items not

suitable for

tumble drying

Particularly delicate fabrics such as synthetic net curtains, gar

ments made of wool or silk or with metal inserts, nylon stockings,

bulky items such as anoraks, bed covers, quilts, sleeping bags

should not be tumble dried.

Drying code

symbois

Always check whether garments are suitable for tumble drying.

This information is given on the label.

The following symbols are for drying:

May be tumble dried

□

Normal drying"(normal temperature)

□

Delicate drying (reduced temperature)

LLd

Do not tumble dry

Garments marked with the ^ symbol must never be tumble

dried.

30

Page 31

Selecting the drying programme

ON

OFF

O

If you wish to carry out a drying cycle on its own, turn the pro

gramme selector knob to DRYING. This is possible only in the

sector for cottons and easy care fabrics. Digit 10 will appear in the

display.

DRYING TIME selector button

With this button, the drying time can be adjusted in 5 minute

increments, up to a maximum of 130 minutes for cottons and col

oureds, or up to a maximum of 100 minutes for easy care fabrics.

The time selected appears on the display next to the button.

When selecting the drying time, take into account the type of fab

ric to be dried (cottons, coloureds, easy cares) and the degree of

drying required (extra dry, cupboard dry, iron dry).

Refer to the chart.

When selecting the drying time, you should also remember that it

includes a 10 minute cooling phase.

DRYING

TIME

O

700 900 1300 SPIN

# •

o

Drying only

For example, if you select a drying time of 60 minutes, the

machine will dry for 50 minutes and will then cool for the remain

ing 10 minutes.

As soon as the drying programme is started, the display shows

the remaining time, counting down in minutes'.

If you wish to delay the programme start, select the desired time

by depressing the relevant button and then depress the START/

PAUSE button.

Cooling phase

10 minutes before the end of the cycle, an automatic cooling

phase is carried out to cool the laundry.

This phase cannot be shortened, stopped or avoided, as this

could cause skin burns or damage to the laundry.

31

Page 32

Duration of drying cycle

The duration can vary according to:

- the speed of the final spin;

- the required degree of drying (extra dry, cupboard dry or iron dry)

- the type of laundry

- the size of load.

The chart on pages 34-35 shows normal drying times. With a little

experience, you will soon come to know the most suitable drying

times for your own laundry requirements.

Porthole door lock

After having started the required drying programme, the door

stays locked throughout the whole cycle.

Fibre residues

After drying fabrics which, lose bits of fibre, for example new

towels, it is advisable to carry out a delicate drying cycle to ensure

that any residue left in the drum is completely eliminated and does

not stick to laundry in the next load.

You should check the filter after each drying cycle and clean it if

necessary.

Additional drying

If, at the end of the programme, the laundry is still too damp, an

additional drying cycle may be selected.

Warning: Do not over-dry, so as to avoid creasing or shrink

ing of garments.

32

Page 33

NON-STOP operation can be used for

cottons •

easy cares

starching

spin

It cannot be used for delicate fabrics and wool.

Warning: When using NON-STOP operation for washing plus

drying, it is essential to keep to the following maximum loads:

Automatic

washing

and drying

(NON-STOP

operation)

Cottons

Easy cares

The drying time must be selected at the same time as the wash

programme and is displayed throughout the wash cycle.

Drying for cotton fabrics is carried out at full heating power, for

easy cares at reduced heating power.

If you wish to change the selected drying time during washing,

depress the Drying Time button until no digits appear in the dis

play and then select the new time.

max. 2.5 kg

max. 1.75 kg

Important: For cottons/coloureds it is not possible to reduce the

spin speed to 700 rpm when selecting the NON-STOP operation.

33

Page 34

Drying time chart

Indicative values for dry clothing

Degree of drying

Type of fabric

Examples of laundry/

clothing

Extra dry

Cupboard dry

Iron dry

Heavy cottons and linens

Cottons to be completely

dried

Easy care, synthetic and

mixed fabrics which do

not need ironing

Cottons and linens which

need ironing

Flannel sheets, linen

towelling bathrobes

Towels, T-shirts, fully

dried sheets, tea-cloths,

bathrobes

Synthetic mix Jumpers,

blouses, household

linen, baby clothes,

socks, underwear

Sheets, tablecloths, teacloths

Easy care, synthetic

and mixed fabrics which

need ironing

0 Reduced load to avoid creasing of these fabrics.

For loads not shown in the chart, select longer or shorter drying times as

required.

Synthetic fabric shirts,

household linen

34

Page 35

Load

kg

Spin speed

rpm

Cycle duration

min

2.50

1.00

2.50

1.00

1.75

1.000

2.50

700

900

1300

700

900

1300

700

900

1300

700

900

1300

700

900

700

900

700

900

1300

95-105

85- 95

80- 90

65-75

55-65

50-60

85-95

75-85

70-80

55-65

45-55

40-50

90-100

85-95

60-70

55-65

65-75

55-65

50-60

1.00

1.75 . .

1 .ООП

700

900

1300

700

900

700

900

45-55

35-45

30-40

75-85

70-80

45-55

40-50

35

Page 36

Maintenance and cleaning

Detergent From time to time, clean off any detergent residue remaining in the

dispenser bottom of the drawer compartments.

drawer - To do this, pull out and remove the drawer by pressing down

the catch.

The upper part of the liquid additive compartment can also be

removed for easy cleaning.

Drawer recess

Detergent residue can also accumulate inside the drawer recess,

which should be cleaned occasionally with an old toothbrush.

After cleaning, refit the drawer and push it fully in.

After each wash programme, partially pull out the detergent

drawer to let it dry.

36

Page 37

The filter collects fluff and any small objects which may acciden- Cleaning

tally have been left in the laundry. the filter /

If this filter gets clogged, the programmes will not function prop- Emergency

erly. emptying

The filter should therefore be cleaned from time to time. Hot water

remaining in the filter can scald! Allow it to cool before cleaning.

Open the filter cover.

Place a basin under the filter and unscrew it in order to remove it.

Remove the filter.

37

Page 38

Clean it under a running tap

The drum

Porthole door

Descaling

Control panel

The drum is made of stainless steel. Any rusty items left in the

laundry {see “Preliminary operations for washing”) could leave rust

stains on the surface of the drum. These stains can be removed

with a suitable stainless steel cleaner, available from the Service

Centre.

Remove any deposits or foreign objects from the rubber seal on

the porthole door.

Never close the porthole door immediately after washing; leave it

open to allow the drum to dry and ensure that the machine is

properly aired.

if the correct amount of detergent is used, descaling should not

be necessary. If, however, it does become necessary, use only

branded, non-corrosive descalers suitable for washing machines.

These are available from the Service-Centre.

If necessary, clean the control panel with warm water only.

38

Page 39

How to deal with problems...

. the machine does not start:

Check that the appliance is plugged in.

Check that a progrannnne has been selected.

Check that the START/PAUSE button has been pressed.

Check that the porthole door is firmly shut.

Check that the fuse has not blown.

. the door will not open:

Check whether a programme is in progress.

Check whether a programme without final spin has been

selected.

Check whether the water level is higher than the bottom of the door.

. the machine does not fill:

I

Check that the taps are on.

1

Check whether the filters in the inlet hoses are blocked.

If the machine takes longer than usual to fill with water, check

whether the filters in the inlet hoses are blocked.

To do this, shut the water taps. Unscrew the hoses from the

taps and remove the filters. Clean them with an old toothbrush

then refit them.

Tighten up the inlet hoses.

Problems you

can solve

yourself

. spinning starts slowly:

The electronic unbalance detection device has tripped

because the laundry is not evenly distributed in the drum.

When rotation of the drum is reversed the laundry re-distrib

utes itself. This may happep several times before the unbal

ance disappears and the spin resumes normally.

. the machine vibrates or is noisy:

I

With very small loads (for example just one bathrobe) the ma

chine may start to vibrate. This does not however affect per

formance.

I

Check that the support feet are correctly adjusted. Refer to

the installation instructions.

1 Check that all the transit bolts and packing have been re

moved. Refer to the installation instructions.

39

Page 40

... the machine does not empty or does not spin:

■ Check whether the drain hose is kinked.

■ Check whether the filter is blocked.

... spinning is uneven:

■ If an, excessive amount of foam has been formed, the machine

starts spinning and then stops until the foam has gone. Spin

ning then resumes normally.

When selecting the next programme, check the amount of

detergent used.

... the machine makes strange noises:

■ The machine is fitted with a modern starting system which

makes an unusual whistling or hissing noise, compared with

other machines.

This new system allows spinning to be started more gently

and provides better control of gradual increase in spin speed.

This improves machine performance and reduces water con

sumption.

... too much foam forms during washing:

■ Too much detergent is being used or the detergent is of the

wrong type. Check the amounts required.

... water is leaking from the bottom of the machine:

■ Check whether the inlet hose is leaking.

■ Check whether the drain hose clip has worked loose.

■ Check whether the drain hose is damaged.

■ ' Check that the filter is fully screwed in and properly fitted.

... washing results are poor:

■ Too little detergent has been used or detergent is of the wrong

type.

If insufficient detergent is used, the laundry will look grey and

lime deposits will be left in the machine. Use the correct

amount of detergent.

■ Check whether stains were adequately treated prior to wash

ing.

■ Check whether the programme and temperature selected

were correct.

... stains remain even though they have been treated before

washing:

■ Probably the stains are indelible. Check with an expert.

... there are grey marks on the laundry:

■ Laundry stained with grease, creams or oil has been washed

with insufficient detergent. The detergent was not strong

enough to shift these stains.

■ Check whether the temperature selected was too low.

40

Page 41

... the fabric softener has left marks on the laundry:

■ In this case the fabric softener, especially if of the concen

trated type, has come into direct contact with the laundry.

Wash out these marks immediately.

... detergent residue is left after the wash cycle:

■ This is most probably due to non soluble components con

tained in modern detergents, it is not a sign of inadequate

rinsing.

Brush or shake the garments and, if necessary, wash them

again.

... the fabric softener has not been introduced in the tub or

there is water left in the compartment marked with the [^J

symbol:

■ The drawer was pulled out whilst the machine was filling, or

the drawer was not fully inserted.

... foam remains after the last rinse:

■. Modern detergents can produce foam even after rinsing, but

this will not affect the quality of the wash.

... no water is visible in the drum:

■ Machines based on modern technology operate very eco

nomically using very little water. Their performance however is

excellent.

... the laundry is not sufficiently spun and there is still water in the drum:

■' Check whether the drain hose is kinked.

■ Check whether the filter is blocked.

... the machine does not dry:

■ Check that the drying time has been selected.

■ Check that the tap is open.

■ Check that the filter is not blocked.

■ Check that the drum has not been over-filled.

■ Check that the correct drying time has been selected. .

If the Service Centre is called out for one of the faults listed

above, or as a result of incorrect usage of the machine,

repairs will not be carried out free of charge, even if the

guarantee has not yet expired.

41

Page 42

Customer service

If you are unable to identify or resolve the problem by reading the

instruction book, contact our Service Department. Always start

by quoting the product code (E-Nr.) and the batch number (F-Nr)

shown on the rating plate.

L___ " -J

pD

For convenience, you are advised to note these details below.

E-Nr..............................................................

F-Nr.

.............................................................

AEG

Mod.

E-Nr.

F-Nr.

42

Page 43

Technical specifications

Dimensions:

With worktop:

Height 85.0 cm

Width 60.0 cm

Depth 60.0 cm

Without worktop:

Height 82.0 cm

Width 59.5 cm

Depth 57.0 cm

Connection

Details concerning electrical connection are given on the rating

plate.

When connecting the appliance, make sure that the mains supply

voltage' and type of current shown on the rating plate are the

same as those in the location where it is being installed.

Drum speed

Washing max. 55 rev/min

Spinning max. 1300 rev/min

selectable: 900/700 rev/min

Water pressure:

minimum (hot)

minimum (cold)

maximum

5psi

7psi

110psi

Net weight:

approx. 87 kg

43

Page 44

AEG

AEG Hausgeräte AG

Postfach 1036

D 90429 Nürnberg

© Copyright by AEG

H 243 219 640

124 983 030

124983030

ТАЛ//5

5 6 7 8 9 10 11 12 / 1994

GFP7516

Loading...

Loading...