Page 1

115 D

Extractor Hood

Installation and Operating Instructions

Page 2

Contents

Introduction 3

Extractor version 3

Recirculating mode 4

Electrical connections 5

Safety warnings for electrician 5

Specifications 8

Installation 9

Safety warnings for kitchen unit installer 9

Wall unit mounting 10

Wall mounting 11

Hood operation 12

Safety warnings for user 12

Maintenance and care 13

Opening the grille 13

Grease filter 13

carbon filter 13

Changing the light bulb 14

Cleaning 15

Special Accessories 15

Technical Assistance Service 16

OKO SYSTEMOKO SYSTEM

MADE IN GERMANY

Printed on recycled paper.

AEG – putting words into action.

2

Page 3

Introduction

The hood is supplied as an extractor unit and can also be used

with a filtering function by fitting activated carbon filters (special

accessory).

Extractor

version

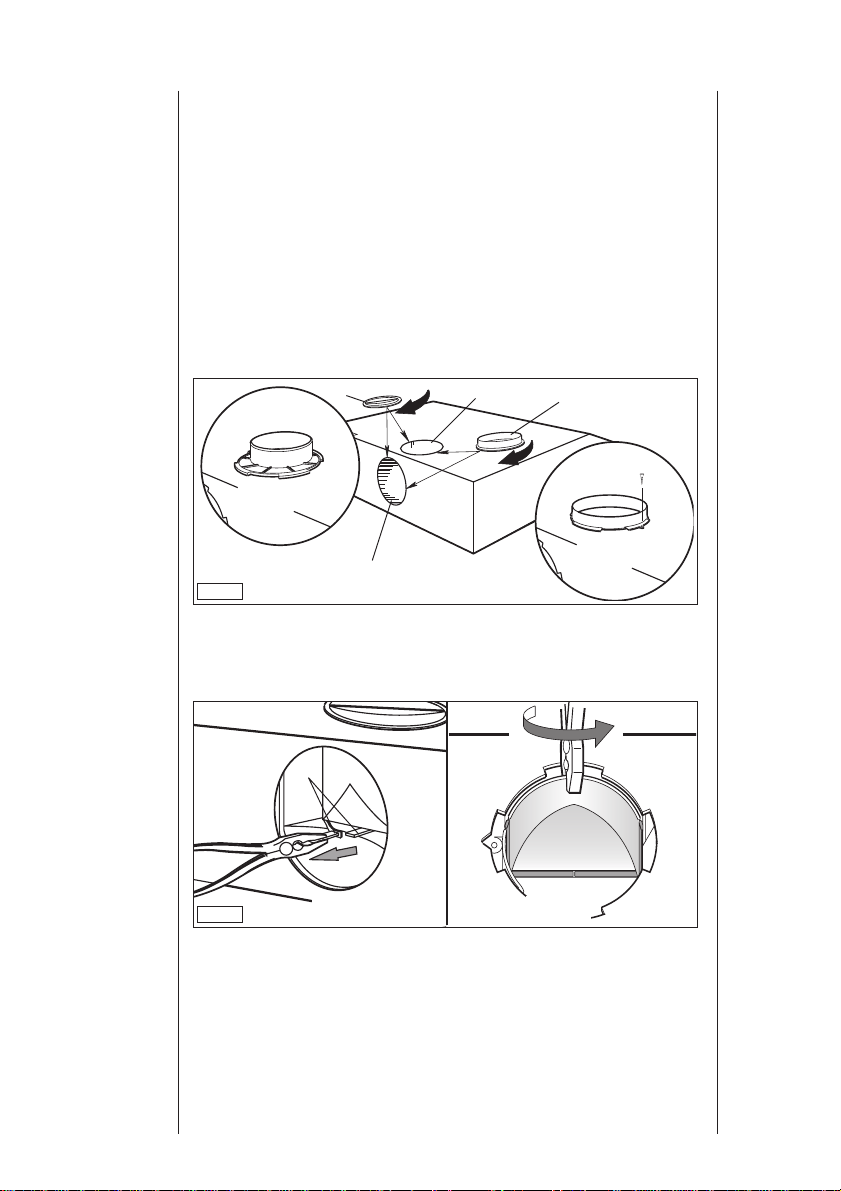

The unit features two outlet holes, one of which A is located on the

top of the unit while the other B is located on the rear.

To connect up the hose, you should first fit the bayonet-mounting

flange C (100 or 120 mm) on the outlet required (if using the top

outlet, fix the flange in place using the screw supplied as shown

in Fig. 1).

Close off the unused hole using the bayonet-fitting caps D.

D

A

C

¯ 100 mm

B

1

If using the rear hole, open the air passage by removing the

partition (E — Fig. 2)

E

¯ 120 mm

Rear

Top

2

outlet hole

outlet hole

Move the lever F to position A — Fig. 3.

When connecting up the hood using a telescopic wall pipe,

you should use a non-flammable outlet hose No. E 647 000

012 or 647 000 010 (120 mm Ø or 100 mm Ø) from our

range of special accessories.

3

Page 4

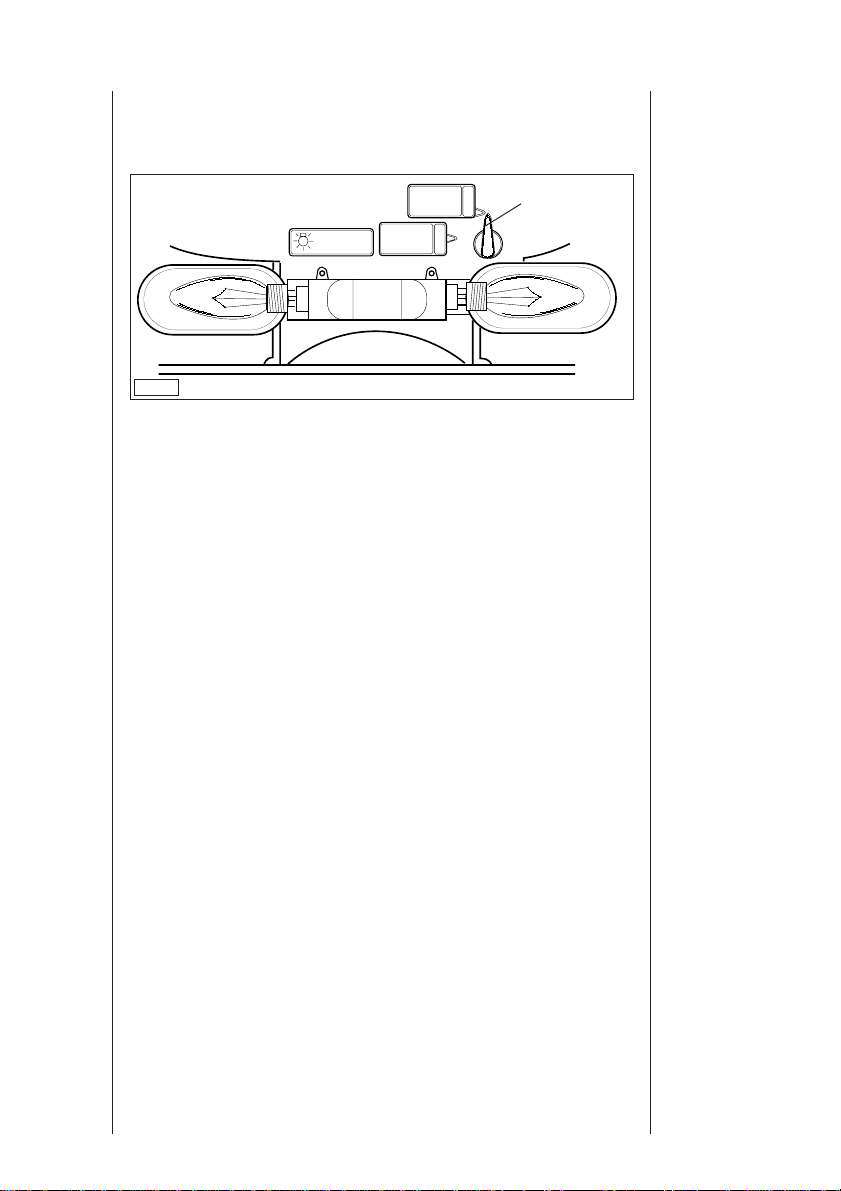

The air is filtered and recirculated through the front grille.

Move the handle F to position F — Fig. 3.

Recirculating

mode

MAX 40W

EXHAUSTING

ABLUFT

EVACUATION

ASPIRANTE

RECIRCULATION

UMLUFT

RECICLAGE

FILTRANTE

A

F

F

3

You will need an original AEG KLF60/80 activated carbon filter for

the recirculating mode. (See special accessories).

Summer/winter operation changeover

To avoid unnecessary outdoor transport of thermal energy

during exhaust air operation in winter, we reccommend you to

convert the fume extractor hood to winter operation (return air).

The covering foil over the return air slots is to be removed.

You also need an active carbon filter (special accessory).

When outdoor temperatures become warmer (spring), the

active carbon filter is removed again and the fume extractor

hood reset to exhaust air operation as per installation sequence. The return air slots on the upper side of the appliance

are to be sealed e.g. with self-adhesive aluminium foil. See

also for exhaust air operation installation.

4

Page 5

Electrical connections

Voltage and

current

Important

Please ensure that the voltage and current indicated on the rating

plate agree with the voltage of your electricity supply.

If your appliance has been equipped with a mains lead with a

moulded-on type plug, you must comply with the following

regulations:

The plug moulded on to the lead incorporates a fuse. For

replacement, use a 5 amp BS1362 fuse. Only ASTA approved or

certified fuses should be used. If the fuse cover/carrier is lost, a

replacement cover/carried must be obtained from an electrical

goods retailer. If the socket outlets in your home are not suitable

for the plug fitted to the appliance, then the plug must be cut off

and destroyed for safety reasons, and an appropriate plug fitted.

When wiring the plug ensure that all strands of wire are securely

retained in each terminal. Do not forget to tighten the mains lead

clamp on the plug.

This unit is screened against radio interference in compliance

with European Community directives 87/308 EEC, EN 55014/

DIN VDE 0875 Part 1.

Electrical connections

230 V - using fixed power supply line with plug.

240 V - using fixed power supply line (Great Britain).

Fuse rating 13 amps

(The unit should only be connected up by an authorized electrician).

See rating plate for further information.

It is recommended that the socket for the plug is sited above the

cooker hood or above the overhead cabinet.

This has 2 advantages:

1) The socket is not visible.

2) The appliance can easily be unplugged when necessary.

If a fixed connection is required the cooker hood should be

connected by an electrical installer registered with a competent

electricity company. An isolating device is to be provided on the

fixed wiring side. Switches with a contact opening of more than

3mm apply as isolating devices.

These include-automatic cut-out switches, fuses and contactors

(VDE 0730, s. 7, Part1).

5

Page 6

Your appliance must be connected to fixed wiring via the use of

a double pole swiched fused spur outlet with or without pilot

lamp.

We strongly recommend the appliance is connected by a qualified electrician who is a member of the NICEIC who will comply

with the IEE and any local regulations.

NOTE:

The terminology “DOUBLE POLE” means that both the live

and neutral supplies are swiched and disconnected at the

same time.

The terminations labelled SUPPLY are for the connection for

the internal house wiring and the ter minations labelled LOAD

are for the appliance.

IMPORTANT

The wires of the mains lead supplied with this appliance

are coloured in accordance with the following code:

Blue-Neutral

Brown-Live

As the colours of the flexible cord of this appliance ma y not

correspond with the coloured markings identifying the terminals in your plug, pr oceed as follo ws: The whire which is

coloured brown must be connected to the terminal which is

marked with the letter L or coloured red.

The wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured black.

Appliances

with 2 wires

FUSE

BLUE

(NEUTRAL)

SUPPLY

N

ON

N

LOAD

SUPPLY

DP 13A, 250V

BROWN

(LIVE)

L

LOAD

L

6

Page 7

Appliances

with 3 wires

Your appliance must be connected to fixed wiring via the use of

a double pole swiched fused spur outlet with or without pilot

lamp.

We strongly recommend the appliance is connected by a qualified electrician who is a member of the NICEIC who will comply

with the IEE and any local regulations.

NOTE: The terminology “DOUBLE POLE” means that both

the live and neutral supplies are swiched and disconnected

at the same time.

The terminations labelled SUPPLY are for the connection for

the internal house wiring and the ter minations labelled LOAD

are for the appliance.

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT

The wires in this mains lead are coloured in accordance with the

following code:

Green/Yello w - Earth

Blue - Neutral

Brown - Live

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings identifying the

terminate in your spur box, pr oceed as f ollo ws:

The wire which is coloured green and yellow must be connected

to the terminal which is marked with the letter “E” or by the earth

symbol or coloured green or green and yellow. The wire which

is coloured blue must be connected to the terminal which is

marked with the letter “N” or coloured black.

The wire which is coloured brown must be connected to the

terminal which is marked with the letter “L” or coloured red.

FUSE

BLUE

(NEUTRAL)

SUPPLY

N

ON

LOAD

DP 13A, 250V

SUPPLY

N

GREEN & YELLOW

(EARTH)

BROWN

(LIVE)

L

LOAD

L

7

Page 8

Specifications

Dimensions:

Height Width Depth (in mm)

152 599 505

Weight:

Net: 8.7 Kg

Gross: 9.6 Kg

Length of the cable: 140 cm

Maximum absorbed power: 230 W

Motor absorption: 1 x 150 W

Lighting: 2 x 40 W

Fan powers (levels), levels in compliance with DIN 44971

Level: Min. Max. Intensive

Extractor: 116 m3/h 175 m3/h 265 m3/h

Filter: 60 m3/h 14 5 m3/h 175 m3/h

Extractor system: 100 and 120 mm Ø

8

Page 9

Installation

Safety

warnings for

kitchen unit

installer

When used as an extractor unit, the hood must be fitted with a 100

or 120 mm diameter hose.

If the outlet hose is installed in a horizontal position, it must be

slanted at an angle of 10° so that the air can flow outside without

impediment.

When installing the hood, make sure you respect the following minimum distance from the top edge of the cooking hob/

ring surfaces:

electric cookers 650 mm

gas cookers 650 mm

coal and oil cookers 700 mm min.

The air outlet must not be connected to chimney flues or

combustion gas ducts. The air outlet must under no circumstances be connected to ventilation ducts for rooms in which

fuel-burning appliances are installed.

It is advisable to apply for authorization from the relevant

controlling authority when connecting the outlet to an unused chimney flue or combustion gas duct.

The air outlet installation must comply with the regulations

laid down by the relevant authorities.

When the unit is used in its extractor version, a sufficiently

large ventilation hole must be provided, with dimensions

that are approximately the same as the outlet hole.

National and regional building regulations impose a number

of restrictions on using hoods and fuel-burning appliances

connected to a chimney, such as coal or oil room-heaters

and gas fires, in the same room.

Hoods can only be used safely with appliances connected to

a chimney if the room and/or flat (air/environment combination) is ventilated from outside using a suitable ventilation

hole approximately 500-600 cm

2

large to avoid the possibility

of a depression being created during operation of the hood.

If you have any doubts, contact the relevant controlling

authority or building inspector’s office.

Where flexible ducting is fitted the length should be no more

than:

— 3 metres with one 90° bend

— 2 metres with two 90° bends.

Bends of more than 90° will reduce the efficiency of the hood

and reduce the air flow.

9

Page 10

Since the rule for rooms with fuel burning appliances is

“outlet hole of the same size as the ventilation hole”, a hole

of 500-600 cm2, which is to say a larger hole, could reduce the

performance of the extractor hood.

If the hood is used in its recirculating mode, it will operate

simply and safely in the above conditions without the need

for any of the aforementioned measures.

When the hood is used in its extractor function, the following

rules must be followed to obtain optimal operation:

— short and straight outlet hose

— keep bends in outlet hose to a minimum

— never install the hoses with an acute angle, they must

always follow a gentle curve only

— keep the hose as large as possible (100 or 120 mm Ø

min.).

Failure to observe these basic rules will drastically reduce

the performance and increase the noise levels of the extractor hood.

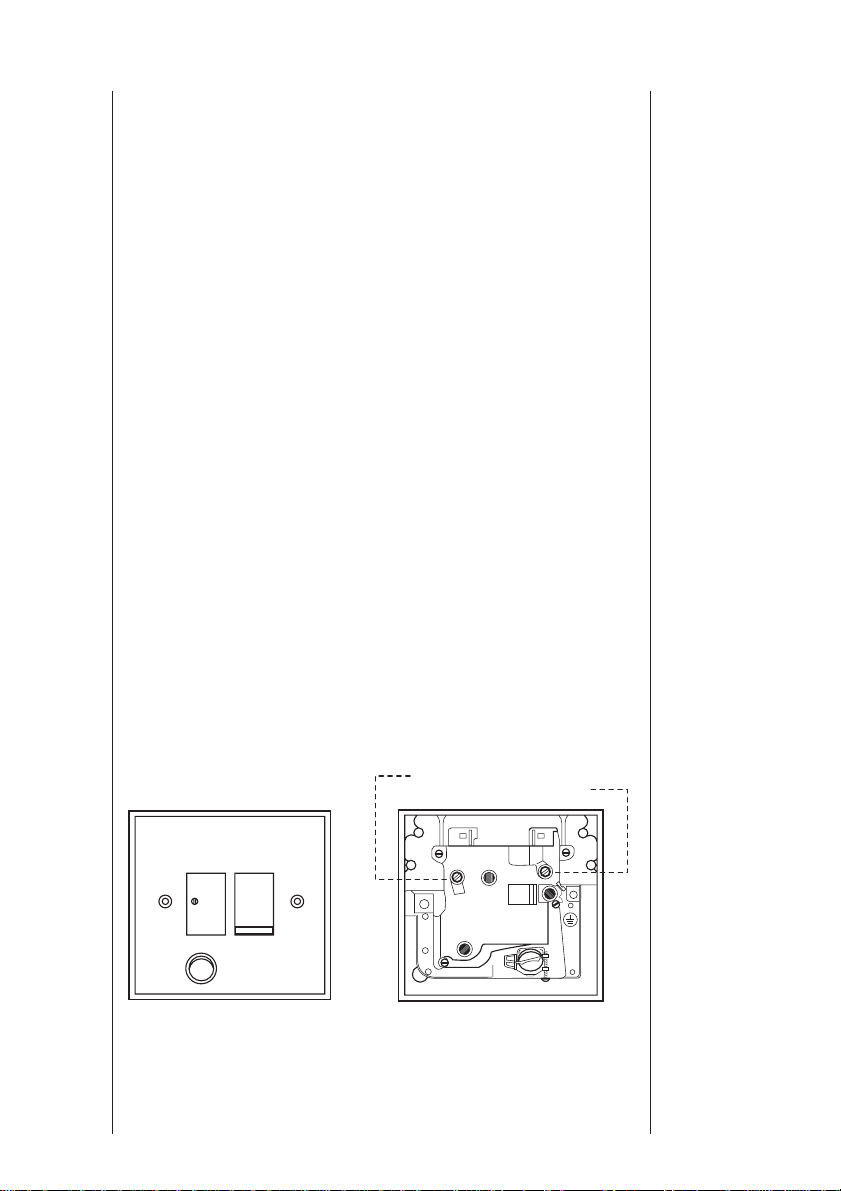

— Drill four 6 mm Ø holes in the base of the wall unit using the

template supplied.

— Mount the hood unit on the base of the wall unit using four

4.2 x 35 mm screws. — Fig.4

200

64

65

4

5

If using an interchangeable model, fit the plastic caps supplied in

any unused mounting holes. — Fig. 5

10

Wall unit

mounting

Page 11

Wall

mounting

— Position the template on the wall.

— Drill four 8 mm Ø holes in the wall, 2 in points H and 2 in points

I.

— Fit the four 8 mm screw anchor plugs in the wall.

— Screw two 5 x 45 mm screws in points H but do not tighten

them fully home.

— Adjust the unit so that it is positioned at a right angle to the wall

by turning the two support screws G.

— Now hang the hood on the wall (holes H). Tighten the first two

screws and, for safety’s sake, screw the other two 5 x 45 mm

screws into the holes in the hood. — Fig. 6

H

G

6

I

36,5

G

13

46

11

Page 12

Hood Operation

The hood is fitted with a variable speed motor. The most effective

use of the hood is obtained by switching it on a few minutes before

you start cooking and leaving it on a for approximately 15 minutes

after you have finished, thus ensuring all cooking odours are

eliminated. The control switches are located on the unit’s front

panel: the light switch switches the hood lamp on and off;

the motor switch switches the cooking smoke and vapour

extractor motor on and off, enabling you to select one of the four

different speeds.

Light switch

On/Off

6

Never leave a cooking hob or ring on without a pot or pan on top

of it, to avoid the possibility of excess heat damaging the unit.

Gas, oil or coal cooker flames in particular should never be left

uncovered.

Special care should be taken when using deep fat fryers since the

oil in them can overheat and burst into flames.

The risk of a fat fire increases when using dirty oil.

It is extremely important to note that overheating can cause a fire.

Never carry out any flambé cooking under the hood.

Always disconnect the unit from the power supply before

carrying out any work on the hood, including replacing the

light bulb (take the cartridge fuse out of the fuse holder or switch

off the automatic circuit breaker).

It is very important to clean the hood and replace the filter at

the recommended intervals. Failure to do so could cause

grease deposits to build up, causing a fire hazard.

Motor

continuous sliding

switch

Safety

warnings

for user

12

Page 13

Maintenance and care

The hood must always be disconnected from the mains power

supply before beginning any maintenance work.

Opening

the grille

Grease filter

— Open the latch L and swing the grille downwards. — Fig. 7.

— To remove the grille, pull it forwards from the right and release it.

L

CLOSED

OPEN

7

M

The metal grease filter has been designed to absorb the grease

particles that are formed during cooking and is always used,

irrespective of whether the hood is set up for extractor or filter

operation.

The metal grease filter is positioned on the inside of its related

support grille.

Leave the metal grease filter panel to soak for approximately 1

hour in very hot water with grease-dissolving detergent and then

rinse it with very hot water. Repeat the operation if necessary.

Load the grease filter panel in a dishwasher, selecting the most

intensive washing programme and maximum temperature, at

least 65½C. Repeat the operation if necessary.

Carbon filter

The grille should be cleaned with luke warm water and nonabrasive detergent when you change the filter.

The grease filter can be ordered from AEG service.

Open the grille and push on the stops M to take out the filter.

See Fig. 7.

The activated carbon filter should only be used if you want to use

the hood in its recirculating mode.

To do this you will need an original AEG activated carbon filter

(see special accessories).

This filter cannot be cleaned or reused.

As a general rule, the activated carbon filter should be

13

Page 14

Removing the filter

— Press the stops N and remove the filter by pulling it down-

wards. — Fig. 8

N

8

Always specify the hood model code number and serial number

when ordering replacement filters. This information is shown on

the registration plate located on the inside of the unit.

The activated carbon filter can be ordered from AEG service.

Failure to observe the instructions on cleaning the unit and

changing the filters will cause a fire hazard. You are therefore

strongly recommended to follow these instructions.

— Disconnect the unit from the mains power supply.

— Remove my cover

— Replace the old light bulb with a new light bulb (40 W max.).

— If the light does not come on, make sure the bulb has been

screwed in correctly before contacting the AEG service.

N

Warning

Changing

the light bulb

14

Page 15

Cleaning

Warning: always disconnect the hood from the mains power

supply before cleaning it.

Never insert pointed objects in the motor’s protective grille.

Wash the outside surfaces using a delicate detergent solution.

Never use caustic detergents or abrasive brushes or powders.

Only ever clean the switch panel and filter grille using a damp

cloth and delicate detergents.

It is extremely important to clean the unit and change the filters at

the recommended intervals. Failure to do so will cause grease

deposits to build up that could constitute a fire hazard.

Special accessories

Wall box (Ø 120mm) E-Nr.647 000 016

Wall box (Ø 100mm) 647 000 020

120 mm outlet hose 647 000 012

100 mm outlet hose 647 000 010

Synthetic grease filter 660 951 157

KLF60/80 activated carbon filter 610 899 421

15

Page 16

Technical assistance service

In case of any enquiries and faults, please call AEG After-Sales Service:

AEG Domestic Appliances Limited

Head Office:

217 Bath Road

Slough, Berks SL1 4AW

Tel: 01753 872506

Telefax: 01753 512271

AEG Northern Service Centre:

Unit 20, Haigh Park

Haigh Avenue

Stockport

GL Manchester SK4 1QR

Tel: 0161 487 2205

Telefax: 0161 474 1191

Service Appointments

Bristol: 01179 252880

Norfolk: 01603 765515

When calling please state the following

1. The model number

2. The E-No.

3. The F-No.

The manufacturer reserves the right to make alterations in design

and colour in the interests of technical development without prior

notice.

AEG Scottish Service Centre:

Block 11, Unit 1

Dundyvan Industrial Estate

Coatbridge

Lanarkshire ML5 4AQ

Tel: 01236 440387

Telefax: 01236 440256

16

Page 17

If your appliance has a fault, please contact our service engineer

and state the following numbers:

E-Nr. 610

F-Nr.

AEG Hausgeräte AG

Postfach 1036

D-90327 Nürnberg

© Copyright by AEG

H 260 287 140

L 489B Ed. 05/95

159/95

Page 18

documentation manual, user maintenance, brochure, user reference, pdf manual

This file has been downloaded from:

User Manual and User Guide for many equipments like mobile phones, photo cameras, monther board, monitors, software, tv, dvd, and othes..

Manual users, user manuals, user guide manual, owners manual, instruction manual, manual owner, manual owner's, manual guide,

manual operation, operating manual, user's manual, operating instructions, manual operators, manual operator, manual product,

Loading...

Loading...