Page 1

11210

INSTRUCTION MANUAL

Page 2

Important Safety Instructions

When using an electrical appliance, basic safety precautions should always be followed, including the

following: Read all instructions before using your household sewing mac hine.

DANGER-To reduce the risk of electric shock :

Your household sewing machine should never be left unattended when plugged in. Always unplug your

machine from the electric outlet immediately after using and before cleaning.

Always unplug before changing lamp. Use a bulb 15 W max.

WARNING-to reduce: the risk of burns, fire, el e c tri c shoc k or injury to persons

- Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or

near children.

- Use this machine only for its intended use as described in thi s manual.

- Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it

has been dropped or damaged or dropped into water. Return the sewing machine to the nearest

authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

- If the supply cord that fixed with foot controller is damaged, it must be replaced by the manufacturer or

its service agent or a similar qualified person in order to avoid a hazard.

- Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the

sewing ma ch ine and foot controll e r free from the accum u l ation of lint, dust and cloth.

- Never drop or insert any object into the opening.

- Do not use outdoors.

- Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

- Do not put anything on the foot controller because the ma chine may accidentally start and the motor

or the foot controller may overheat.

- To disconnect turn all controls to the off position, then remove plug from outlet.

- Do not unplug by pulling on cord. To unplug, hold the plug, not the cord.

- Keep fingers away from all moving parts. Special care is required around the sewing needle.

- Always use the proper needle plate. The wrong plate can caus e the needle to break.

- Do not use bent needles.

- Do not pull or push fabric while stitching. It may deflect the needle.

- Switch the machine off when making any adjustments in the needle area, such as threading needle,

changing needle or changing presser foot and the like.

- Always unplug the sewing machine from the electric outlet when making any user servicing mentioned

in the instruction manual.

- Use only identical replacement parts.

- This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

- Children should be supervised to ensure that they do not play with the appliance.

SAVE THESE INSTRUCTIONS

Warning

When wor ki n g close to the needle b e ve r y careful n ot to prick your finger s. When you u se the machi ne

for the first time, put a piece of cloth under the presser foot und run the machine without thread for some

minutes. Dry any oil spots which may appear.

Please use for your sewing machine the ZHEJIA NG FOUNDE R press er foot, type KD-2902.

Power rating: 220 - 240V ~ , 50Hz

Current rating: 1.0A

Protection Class : II

The sound pressure level under normal operating conditions is 78dB (A).

- 1 -

Page 3

CONTENTS

Name of parts...........................................................................................3-4

Accessories................................................................................................. 5

Before sewing (Power supply and sewing lamp).......................................... 6

Removing extension table ........................................................................... 7

Free-arm sewing..........................................................................................7

Winding the bobbin......................................................................................8

Removing bobbin case and bobbin..............................................................9

Inserting bobbin into bobbin case ................................................................9

Inserting bobbin c ase into shuttle race.......................................................10

Threading upper thread & Twin needle threading...................................... 11

Drawing up the bobbin thread....................................................................12

Changing sewing directions.......................................................................12

Levelling the machine................................................................................13

Adjusting thread tension ............................................................................14

Changing needle .......................................................................................15

Insert “darning pla te “..................................................................................15

Fabric-Thread-Needle-table.......................................................................16

Sewing (pattern selector) and operation t able............................................17

To start sewing..........................................................................................18

How to finish stitches.................................................................................19

Straight stitch.............................................................................................20

Zigzag sewing............................................................................................20

Automatic embroidery................................................................................20

Overcasting...............................................................................................21

Straight and zigzag s tretch stitches ...........................................................21

Blind stitch............................................................................................22-23

Button sewing............................................................................................24

Binding ......................................................................................................24

Zipper sewing ............................................................................................25

Buttonhole sewing.....................................................................................26

Hemming...................................................................................................27

Twin needle...............................................................................................28

Embroidery................................................................................................28

Quilter........................................................................................................29

Seam guide...............................................................................................29

Maintenance (Cleaning and oiling) ............................................................30

Checking performance problems-Tr oubleshooting ....................................31

- 2 -

Page 4

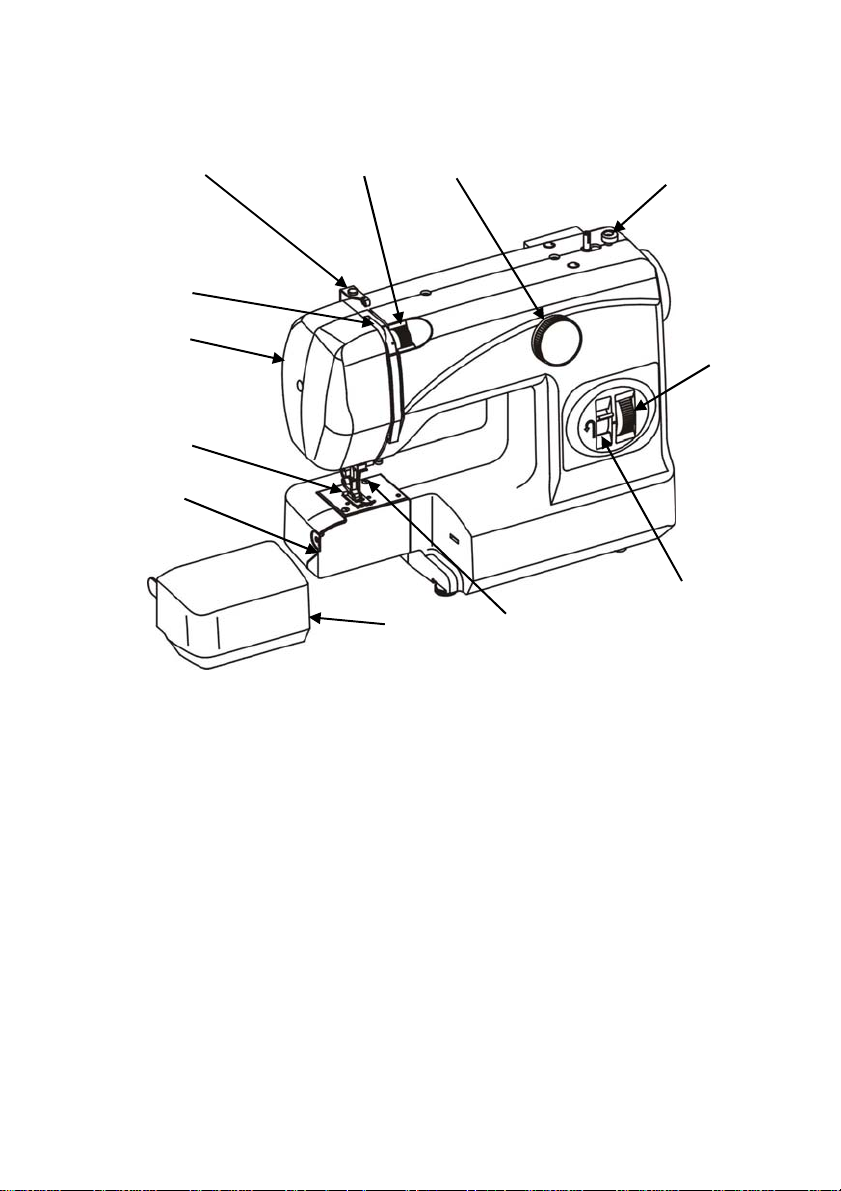

NAME OF PARTS (FRONT VIEW)

12

1

2

3

11

10

4

9

8

7

6

5

1. Thread tension dial

2. Pattern selector dial

3. Bobbin winder stopper

4. Stitch length dial

5. Reverse button

6. Thread guide and needle clamp

7. Extension table

8. Shuttle cover

9. Presser foot

10. Face cover

11. Take up lever

12. Upper thread guide

- 3 -

Page 5

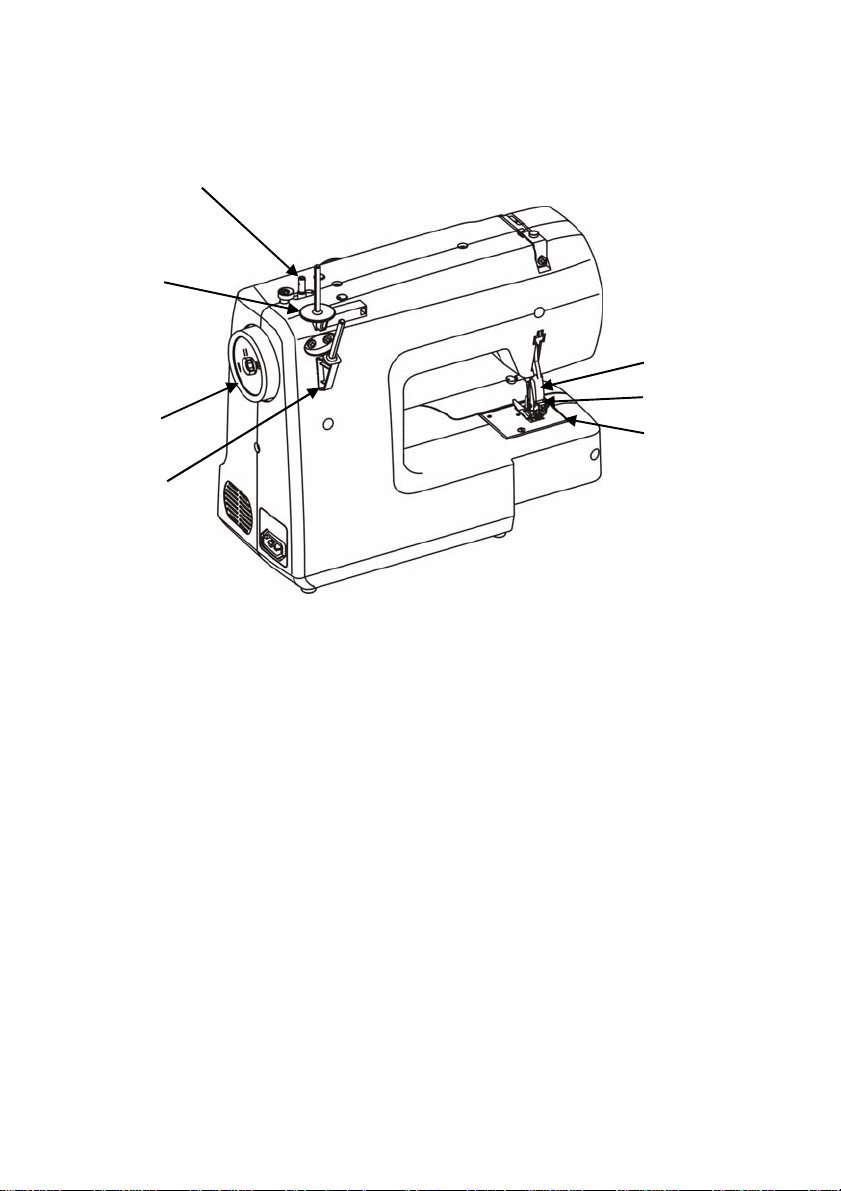

REAR VIEW

7

6

5

1

2

3

4

1. Presser foot lever

2. Thumb screw

3. Needle plate

4. Spool pin (B)

5. Hand wheel

6. Spool pin (A)

7. Bobbin winder spindle

- 4 -

Page 6

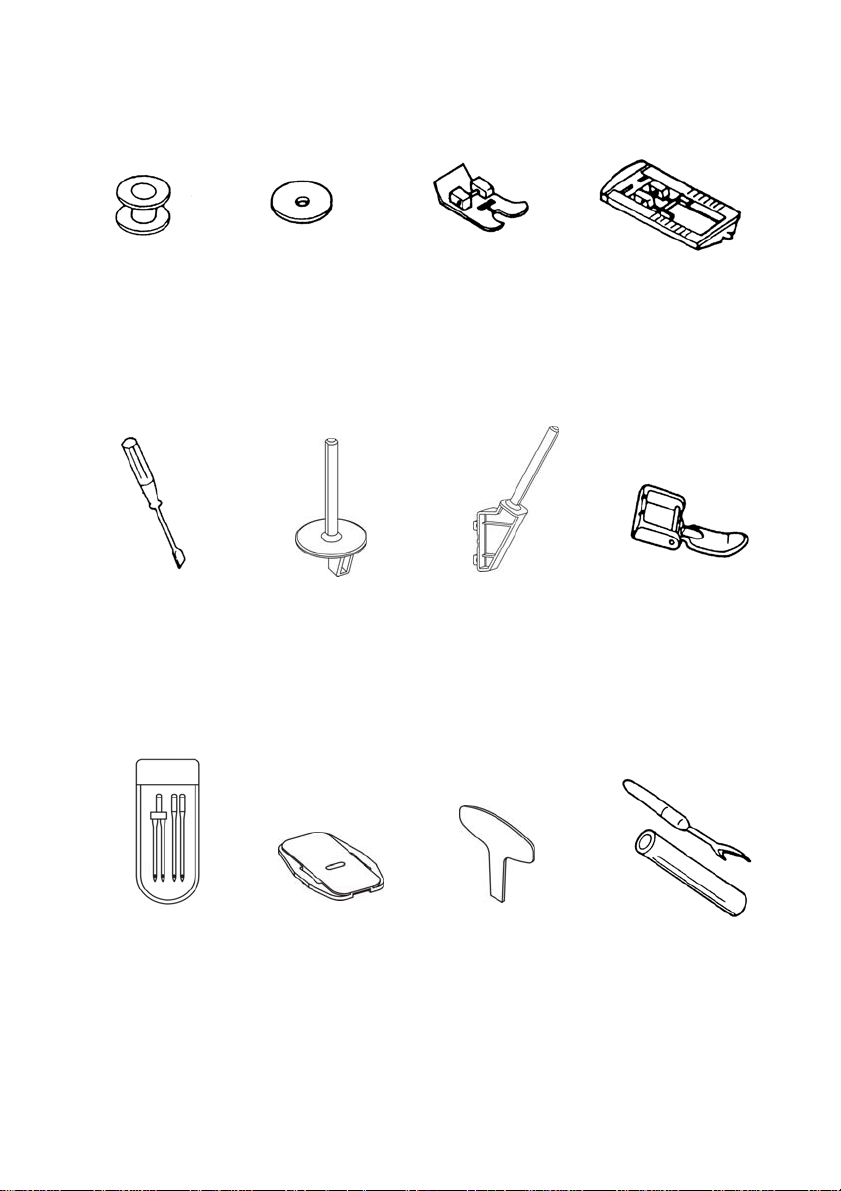

ACCESSORIES

Bobbin

(Use only original

plastic bobbins. )

Felt

Zigzag foot

(on machine)

Buttonhole foot

Screw driver

Needle

Spool pin (A)

Darning plate

Spool pin (B)

Needle plate

screw driver

Zipper foot

Buttonhole cutt er

- 5 -

Page 7

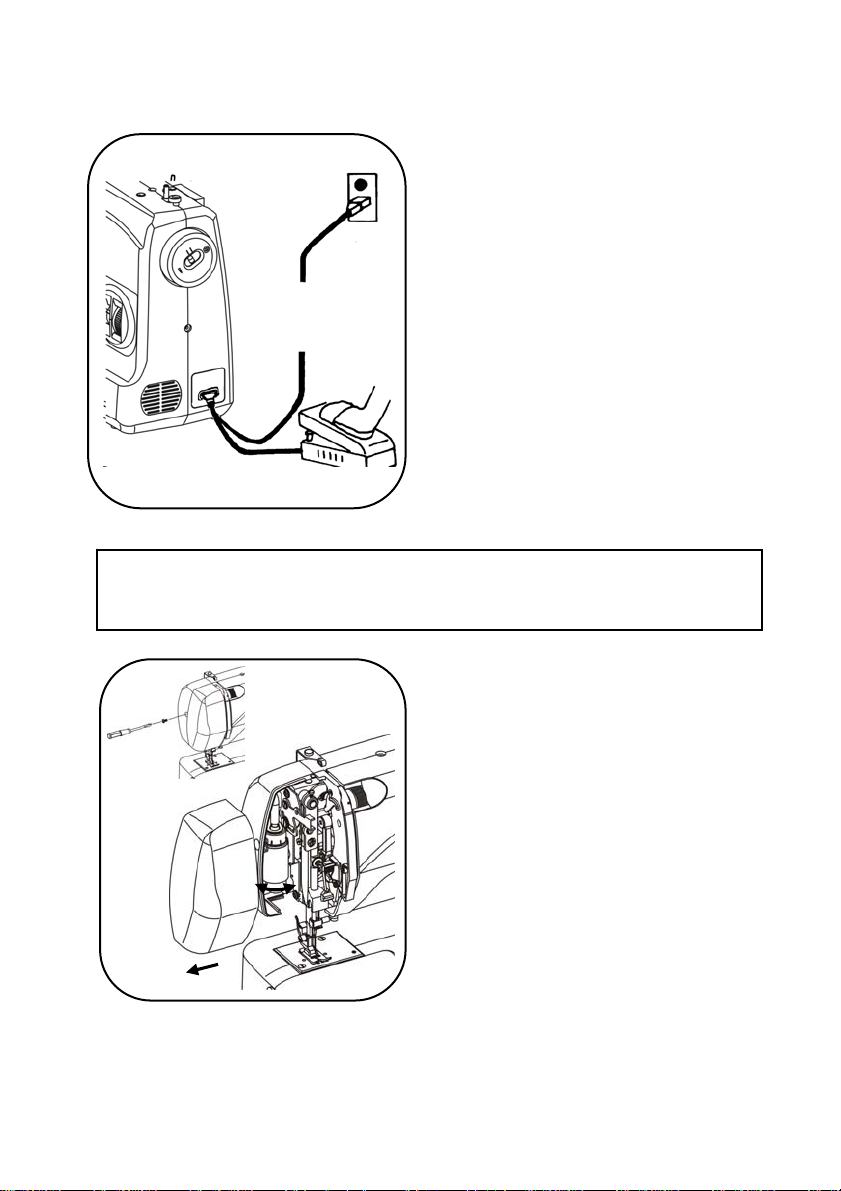

BEFORE SEWING

Power supply / Power suppl y plug

Power supply

Plug receptacle

machine plug

1. Fit plug into the machine.

2. Insert plug into the main socket.

3. Sewing speed can be varied by the foot

control.

Use only ZHEJIANG FOUNDER model

KD-2902 foot contr oller with sewing

machine.

Speed Controller

.CAUTION: Please always unplug the power plug before you change the bulb or

perform maintenance work to the machine so t hat you prevent deadly

peril and electr ic shock.

Sew lamp

Bulb replacement:

1. Open face cover in direction of arrow.

2. Remove bulb by unscrewing it

counter-clockwise.

3. Install a new bulb b y screwing it in

clockwise.

4. Use a 15 watt bulb. (m ax)

- 6 -

Page 8

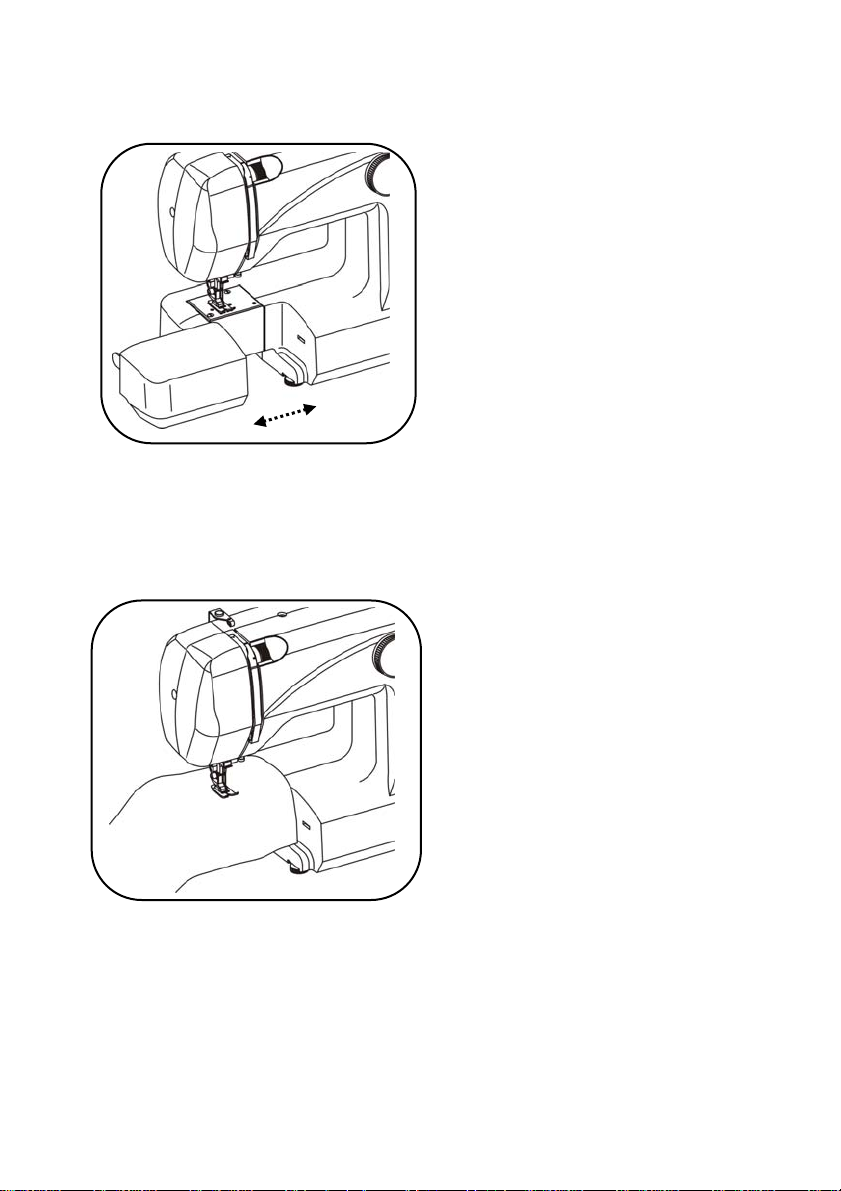

REMOVING EXTENSION TABLE

FREE-ARM SEWING

Hold the left end of the table and pull it

out in direction of the arrow.

1. This sewing machi ne can be used as

a flat bed machine but eas ily converts

to a free arm machine by removing

the extension tabl e.

2. Especially us eful for sewing sleeves,

pant legs, tubular fabrics etc. more

easily.

3. To sew tubular items just slip the

sleeve or leg of pants on the free arm

as shown on the illustration.

- 7 -

Page 9

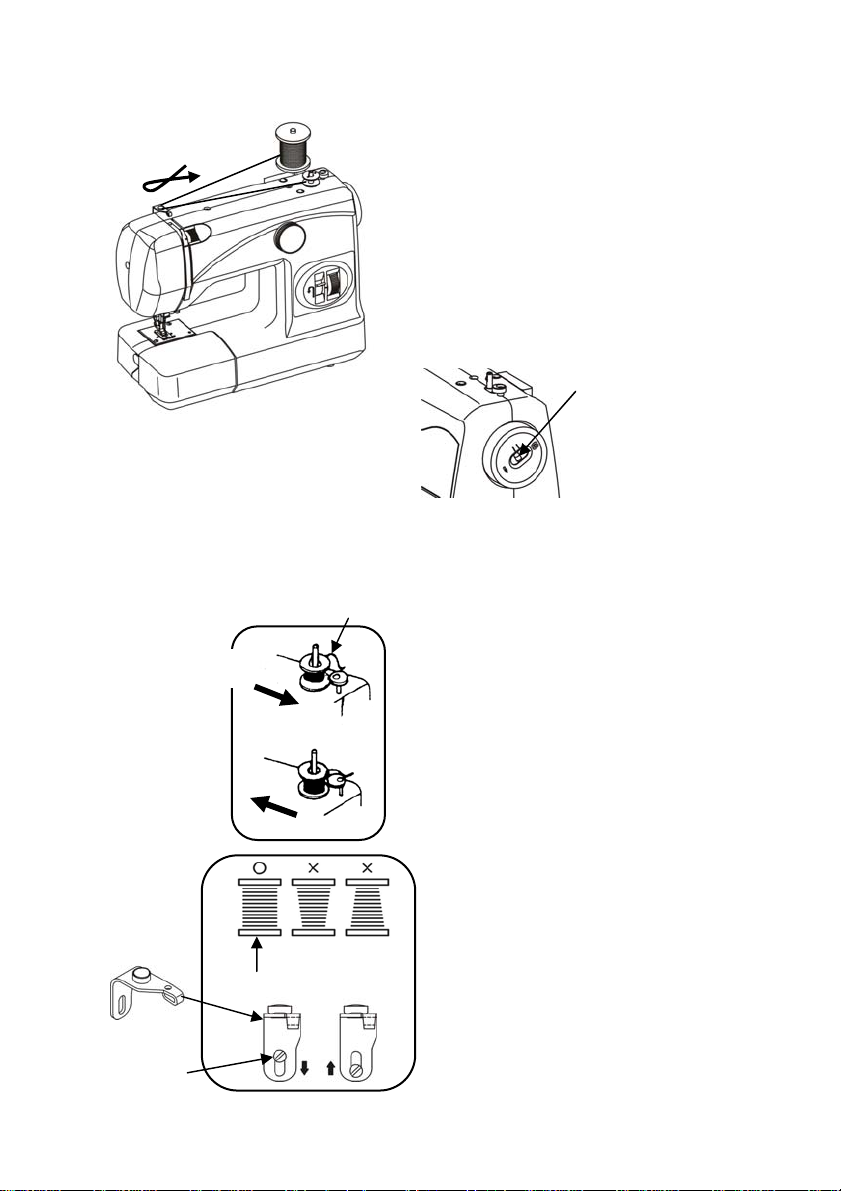

WINDING THE BOBBIN

Winder spindle

5 cm thread

Correct

1. Release by p ushing clutch button to

2. Push bobbin winder from left to right,

3. Push bobbin winder from right to left and

bobbin and lock by pushing it to needle.

then it starts winding.

move clutch button t o needle sign, then it

starts sewing.

Clutch button

Push bobbin winder spi ndle in directi on of

the arrow. When bobbin winding is

completed, return spindle to its original

position.

When bobbin winding is incorrect, r elease

the screw of the upper t hread guide and

adjust up or down unti l bobbin the

winding is balanced.

Screw

- 8 -

Page 10

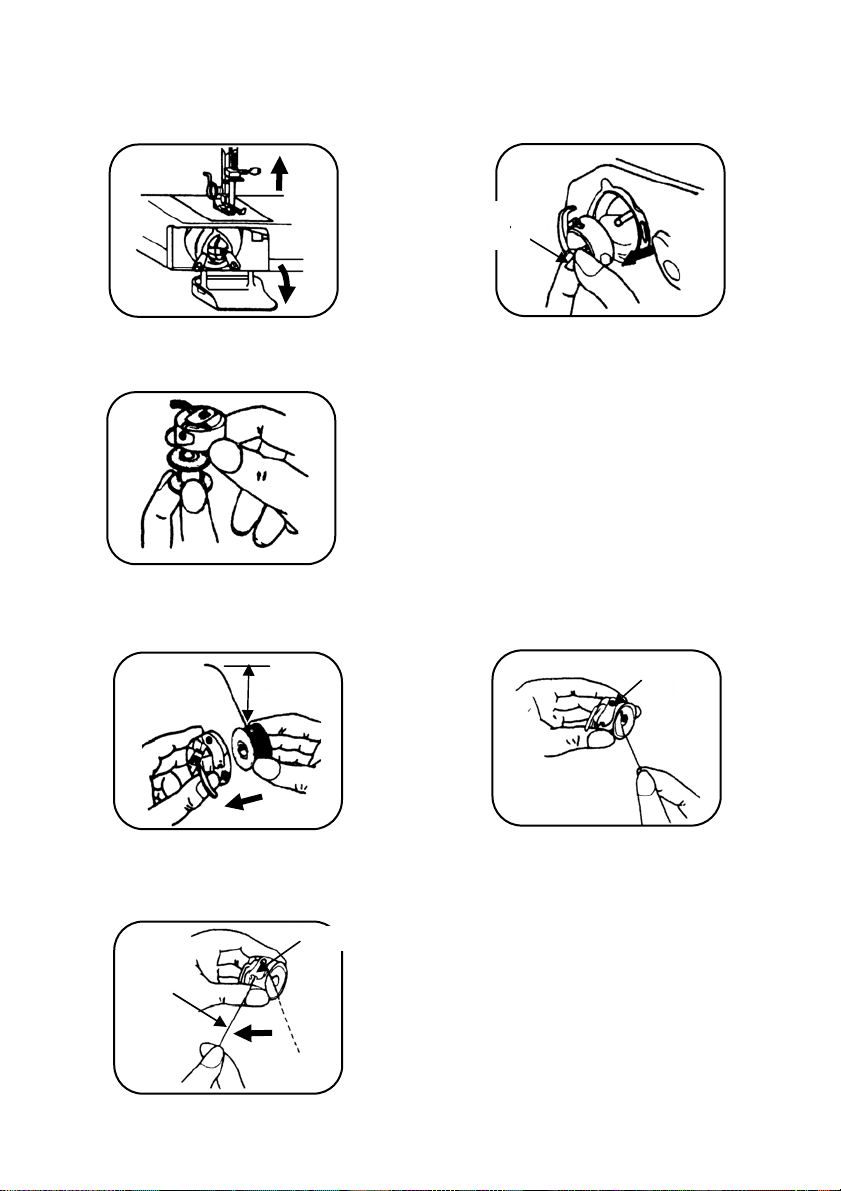

REMOVING BOBBIN CASE AND BOBBIN

Hinged latch

1. Raise the needle t o its highest

position and open shuttle race cover.

3. Release the latch and the bobbin will fall out

easily.

INSERTING BOBBIN INTO BOBBIN CASE

5 cm

2. Open the hinged lat ch of the bobbin

case and pull the bobbin case out of

the machine.

Slot

1. Pull 5 cm of thread from bobbi n and

insert it into bobbin case as shown.

2. Guide the end of thread into the slot.

10 cm

Tension spring

3. Pull the thread through the slot and under t he

tension spring and dr aw out about 10 cm of

thread.

- 9 -

Page 11

INSERTING BOBBIN CASE INTO SHUTTLE RACE

Finger

Hinged latch

1. Raise the needle to its highest position. Pull the thread to t he front, open the latch of

the bobbin case and hold it.

Insert

2. Holding the latch open, place bobbin case onto the center pin in the shuttle and

release latch.

- 10 -

Page 12

THREADING UPPER THREAD

Pass the thread fr om A to H as shown.

H

E

B

G

F

E

C

D

B

A

D

Twin needle threadi ng.

C

F

H

G

- 11 -

Page 13

DRAWING UP THE BOBBIN THREAD

1. Hold the upper thread with left hand, turn the

hand wheel slowly t owards you until the needle

goes down and comes up. Th en stop the hand

wheel when the take up lev er is at its highest

position.

Lightly draw up the upp er thread, by which the

lower thread will be brought up in a loop.

2. Pull out both threads and place them together

under presser foot to the rear of the machine.

3. Place fabric under presser foot from t he front,

lower presser foot.

4. Start to sew.

CHANGING SEWING DIRECTIONS

1. Lower needle down int o fabric and

raise presser foot, pivot the fabr ic

around the needle to change direction

as desired.

- 12 -

2. Lower the presser foot and start to sew.

Page 14

LEVELLING THE MACHINE

Down

Up

- 13 -

Page 15

ADJUSTING THREAD TENSION

Normal upper thread tension: 4 – 6

Upper thread tension may be adjusted

by turning the threa d tension dial.

Fabric

Incorrect

Correct

Upper thread

Bobbin thread

Inside of fabri c

Upper thread

Lower thread tension can be

increased by turni ng the screw of the

bobbin case slightly to the right

(clockwise). Turning it to the left

(counter -clockwise) decreases

tension.

- 14 -

Page 16

CHANGING NEEDLE

Needle clamp screw

Tighten

Loosen

Face flat side away from you

1. Raise the needle bar to its highest posi tion.

2. Loosen needle clamp screw and remove the old needle.

3. With the flat side of the needle facing away from you, insert t he needle as far up as it

will go.

4. Tighten the needl e clamp screw securely.

INSERT “DARNING PLATE“

Sometimes you will want to control the feeding of fabric yourself. Turn the needle bar to its

highest positi on and raise the presser foot over the needle plate, aligning two pins of the

darning plate with holes of needle plate. You may then determine the movement of the fabric

by yourself. See page 24 for button sewing application.

- 15 -

Page 17

FABRIC-THREAD-NEEDLE-TABLE

Please pay attenti on to the following list as a guide for sewing different types of f abric.

Fabric Thread Needle Length of Stitc hes

Straight

stitch

Stitch Length Dial

ZZ

Indication of

Upper

Tension

Light

Medium

Heavy

Nylon

Tricot

Silk

Woo l silk

Gingham 60-80

Thin Jersey 60 S Fiber

Gabardine 50 Silk

Denim

Jersey

Tweed

80 Cotton

60 S Fiber

silk

50 Silk

50 S Fiber

silk

Cotton

50 Cotton

50 S Fiber

50 Silk

70 (10)

80 (12)

80-90

(12-14)

80 (12)

90-100

(14-16)

80-90

(12-14)

80-90

(12-14)

1 - 3 1 - 4

0.5 - 3 0.5 - 4

0.5 - 3 0.5 - 4

- 16 -

Page 18

SEWING (PATTERN SELECTOR) AND OPERATION TABLE

Straight stitch

A

Zigzag

B-E

Blind stitch

F

Blind hem

G

Three step zigzag stitch

H

Slant over edge

I

Single overlock stitch

J

Honeycomb stitc h

K

Zigzag stitch

L

Stitch patterns

Stitch length Presser foot

Straight stretch stitch

M

N

O

Automatic embroidery

P

Q

Buttonhole

R-T

Free-hand embroidery

- 17 -

Without

Darning

plate

Page 19

TO START SEWING

Important hints:

1. Raise the take- up lever to its highest pos ition before starting and after stopping

sewing.

2. Hold both threads about 10 cms to the rear of the machine for the f irst two or three

stitches.

3. Sufficient fabric should be placed under needle before lowering the presser foot.

4. Depress foot/speed control and start to sew.

5. Test the machine stitches on a scrap of fabric you plan to use, adjusting the machine

for the length of the stitch and tension suitable to your fabric.

6. Separate the machin e from the power system i f you leave it unsupervis ed.

Attention

1. When turning the balance wheel manually, always turn it towar d you.

2. Guide the cloth gently with your hand.

3. To prevent breaking needles, always r aise the needle out of t he fabric when you stop

:

sewing.

- 18 -

Page 20

HOW TO FINISH STITCHES

1. Sew to the edge of seam.

2. Push the reverse button and sew in revers e for about 3-4 cms.

3. Raise needle to its highest position.

4. Lift the press er foot and pull the fabric out of the back of the machine.

Cutting thread slot

5. Cut threads as shown on the thread cutter.

- 19 -

Page 21

Q

STRAIGHT STITCH

1. This type of sti tching is used most frequently.

2. The zigzag presser foot can be used for bot h straight and zigzag sewing.

3. For sewing light fabric, use a smaller stitch size. (Ref er to page 16 for dial setting).

ZIGZAG SEWING

Pattern selector position

Satin stitching can be used for sewing

initials, patterns, appliqué, etc.

The zigzag stitch is a universal stitch. The

satin stitch pattern has short tense stitches

which can be used for sewing.

AUTOMATIC EMBROIDERY

N

O P

These stitches have a wi de range of

decorative and utility applications and are

particularl y suitable for woven fabrics.

The Scallop stit ch (N) is ideal for edging

collars, cuffs, tablecloths, serviettes etc. For

all the stitches, the stitch lengt h can be

reduced to achieve a close “satin st itch” if

required.

With satin stitch a paper backing, will

improve the result.

- 20 -

Page 22

OVERCASTING

Use these stitc hes for oversewing rough

edges.

STRAIGHT AND ZIGZAG STRETCH STITCHES

Use this stitch with knitted, tricot or other

stretchy fabr ics.

The stitch enables your seam to stretch

without breaking the thread.

- 21 -

Page 23

BLIND STITCH (Optional)

1. Fold fabric as shown.

2. Finish the seam as shown.

- 22 -

Page 24

Adjust the width to obtain the correct seam.

Wrong: Needle is not piercing edge

to fold at all.

(A)

Needle pierces the edge of fold too

much.

(B)

Correct seam.

(C)

- 23 -

Page 25

BUTTON SEWING (Optional)

Utilize the button presser foot.

Match

(Use Darning plate see page 15)

1. Place the darning plate properly.

2. Place button presser foot in position and attach it fir m ly.

3. Place the button between presser foot and fabric and lower the presser foot.

4. Manually turn hand wh eel towards you, ensuring that the needl e enters into both holes

of button without obstruction. (I ncrease or decrease width setting).

5. Sew about 7 stitches.

6. Pull both threads to the underside and ti e them together.

BINDING

To sew fabrics edge sel ect the multi-zigzag

stitch.

- 24 -

Page 26

ZIPPER SEWING

Utilize the zipper foot.

Select straight stitch.

1. Zipper foot is designed to sew cl ose to a raised edge,

thus preventing sewi ng on zipper.

2. Place zipper foot in position and attac h firmly.

3. Fold the fabric about 2 cm and place the fabric

under foot.

1. To sew the left side of the zipper, set the zipper on

the right side of the needle.

2. To sew the right s ide of the zipper, set it on the left

side of the needle.

Sew as illustrated.

- 25 -

Page 27

BUTTONHOLE SEWING

Use the buttonhole f oot.

Set the stitch length dial.

Pattern select or dial

Steps

1. Set dial t o “1“ position

2. Sew left side

3. Raise the needle

4. Set dial to “2“ position

5. Sew 5-6 stitches

6. Raise t he needle

7. Set dial to “3“ position

8. Sew right side

9. Raise the needle

10. Set dial to “4“ position

11. Sew 5-6 stitches

12. Raise the needle

Setting

Before sewing, fit buttonhole foot as

shown.

Cut buttonhole along centre with cutt er

as shown.

- 26 -

Page 28

HEMMING

(Optional)

3 mm

1 mm

20 mm

1. Raise the foot and the needle to its highest position. Replace t he foot with the picot foot.

2. Fold over the fabric edge by about 3 mm and place it under the foot. Sec ure the folded

edge with a few stit ches. Slide the hem of your project into the pi cot foot by pulling the

threads.

3. Lower the foot and sew the hem.

4. While sewing fo ld the fabric to the left a little and guide it into the hemmer foot.

5. Make sure that t he fabric does not move under the right half of the foot. The fabric must

be fed into the scroll of the hemmer sufficiently so that the project edge runs freely

through the groove under the foot.

Only suitable materials can be used and some practice may be necessary to achieve

the best results .

- 27 -

Page 29

TWIN NEEDLE

Please place second spoon pin ( B) into the position for twin needle sewing as page 4, no.

4 pic.

Put in the twin needle with the flat side backwards.

Thread the machine for normal sewing, leading b oth threads to needle and passing

their ends separately through its eye.

Sewing width should not exceed the third widest stitch width, as this will break the

needles.

EMBROIDERY

(Use Darning plate see page 15)

Remove the presser foot and attach the darning plate.

Lower feed dog and move the hooped fabric slowly in the desired dir ection until the

fabric has been embroi dered.

- 28 -

Page 30

QUILTER (Optional)

1. Slide the arm through the hole on top of the pres ser foot holder.

2. Move the quilter to the required sti tch distance.

SEAM GUIDE (Optional)

1. Use the seam guide to s ew long seams of an equal distance from the edge of the fabric.

2. Screw the guide on the r ight side of the needl e plate and adjust the desired distance.

3. While sewing, the edge of the fabric must touch the guide.

- 29 -

Page 31

MAINTENANCE

.CAUTION: When cleaning the machine or changi ng its lamp, disconnect it from

the mains. You avoid accidents through el ectric shock.

A

B

C

A

1. Raise needle to its highest position.

2. Take out the bobbin case.

3. Turn the latch k nob A as illustrated.

4. Take off shuttle race cover.

5. Take out shuttl e hook.

6. Clean and oil shut tle race and hook,

thereafter repl ace all parts in

reverse order.

Cleaning shuttle race

(A) Latch knob

(B) Shuttle race cover

(C) Shuttle hook

Open face cover and oil the parts indic ated.

Cleaning feed dog.

- 30 -

Page 32

CHECKING PERFORMANCE PROBLEMS – TROUBLESHOOTING

Problem Probable cause What to do

Fabric does not

move

Breaking needle

Breaking upper

thread

Breaking bobbin

thread

Machine

jamming

Puckering

- Feed teeth down

- Stitch length dial “0“ position

- Light presser foot pressure

- Incorrect insertion of needle

- Bent needle

- Fabric is being pul led

- Needle, thread and f abric do

not match

- Faulty adjustment of zigzag

width

- Improper threading

- Tight upper thread tension

- Bent needle

- Scratches or nicks on bobbin

case

- Tight bobbin thread tension

- Incorrect insertion of needle

- Improper threading

- Lint or thread in bobbin case

- Excessive tensi on

- Presser foot pr essure too

strong

- Needle, thread and f abric do

not match

- No oil

- Tension too tight

- Sewing foot press ure too

strong

- Incorrect fabric, needle,

and thread

- Raise feed teeth

- Set dial between 1 and 4

- Increase pressure

- Re-insert needle

- Replace needle

- Do not pull fabric

- Use correct needle an d thread

- Re-adjust zigzag wi dth

- Re-thread machine

- Reduce upper thread tension

- Replace needle

- Polish or replac e bobbin case

- Reduce bobbin thread tension

- Re-insert needle

- Rethread machine

- Clean bobbin case

- Re-adjust tension

- Change pressure accordingly

- Reduce proper needle and

thread according to type of

fabric

- Oil moving parts

- Reset

- Reduce sewing foot pr essure

- Use correct fabric, needle

and thread

- 31 -

Page 33

Guarantee 24 Months

The receipt of purchase with date of purchase is the certificate for the guarantee.

Please always keep carefully. In case of guarantee please contact our service

hotline number. The guaranteeing is only for material defect and production errors,

not for high mortality parts or damage on breakable parts; e.g. spool pin. The

sewing machine is only for private and not for commercial or industrial use.

Guarantee expires when there is improper or inappropriate use, use of force or

engagement from non – authorized services. Your legal rights are not restricted

through this guarantee. This guarantee is applied for the first buyer and is not

transferable.

SDC Vertriebs GmbH ; Mittelwegring 12

Servicehotline: + 49 (0)7271 / 9337-99

76751 Jockgrim

Use separate collection facilities to dispose electrical appliances. Contact

your local community for information.

Product Specifications:

Measures of machine: (L) 380 x (H) 320 x (W) 170 mm

Weight: 7,5 kg

75W (Motor 60W/Lamp 15W) 230V

TÜV/GS and CE certified

- 32 -

Loading...

Loading...