AEC WD 350 through WD3000 Dehumidifying Dryers User Manual

OPERATION AND INSTALLATION MANUAL

WD/SDA/CDA SERIES

350 - 2100 CFM

LARGE DEHUMIDIFYING DRYERS

IMPORTANT: PLEASE READ CAREFULLY BEFORE ATTEMPTING TO INSTALL

OR OPERATE EQUIPMENT

Bulletin No: DH1-655 Part No: 882.00225.00 Effective: 11-01-05

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Write Down Your Serial Numbers Here For Future Reference:

_________________________ _________________________

_________________________ _________________________

_________________________ _________________________

We are committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual are subject to change without notice.

DCN No. ____________

© Copyright 2005

All rights reserved.

Bulletin Number ii

Shipping Info

Unpacking and Inspection

You should inspect your dryer for possible shipping damage.

Thoroughly check the equipment for any damage that might have occurred in transit, such as

broken or loose wiring and components, loose hardware and mounting screws, etc.

In the Event of Shipping Damage

According to the contract terms and conditions of the Carrier, the responsibility of the

Shipper ends at the time and place of shipment.

Notify the transportation company’s local agent if you discover damage.

Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods before the transportation company’s inspection and authorization.

File a claim with the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise customer service regarding your wish for assistance and to obtain an RMA (return

material authorization) number.

If the Shipment is Not Complete

Check the packing list as back-ordered items are noted on it. You should have:

; Dehumidifying Dryer

; Bill of lading

; Packing list

; Operating and Installation packet

; Electrical schematic and panel layout drawings

; Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking.

If the Shipment is Not Correct

If the shipment is not what you ordered, contact the shipping department immediately. For

shipments in the United States and Canada, call 1 (800) 233-4819; for all other countries, call

our international desk at (630) 475-7491. Have the order number and item number available.

Hold the items until you receive shipping instructions.

Returns

Do not return any damaged or incorrect items until you receive shipping instructions from the

shipping department.

Bulletin Number iii

Table of Contents

CHAPTER 1: SAFETY................................................................ 6

1-1 How to Use This Manual ............................................................................................. 6

Safety Symbols Used in this Manual.....................................................................6

1-2 Safety Tag Information ................................................................................................ 7

Dryer Safety Tags .................................................................................................7

1-3 Warnings and Precautions .......................................................................................... 8

1-4 Responsibility .............................................................................................................. 9

General Responsibility ..........................................................................................9

Operator Responsibility .........................................................................................9

Maintenance Responsibility................................................................................. 10

Reporting a Safety Defect ................................................................................... 11

1-5 Responsibility ............................................................................................................ 11

CHAPTER 2: FUNCTIONAL DESCRIPTION........................... 12

2-1 Models Covered in This Manual................................................................................12

2-2 General Description................................................................................................... 12

2-3 Typical Features and Components ...........................................................................12

2-4 Optional Features......................................................................................................12

2-5 The Closed Loop Drying System............................................................................... 13

2-6 What is Desiccant?.................................................................................................... 13

2-7 The Process/Regeneration Cycle.............................................................................. 13

2-8 Specifying a Drying System ......................................................................................14

CHAPTER 3: INSTALLATION.................................................. 17

3-1 Work Rules................................................................................................................17

3-2 Electrical Connections............................................................................................... 17

3-3 Check For Proper Blower Rotation............................................................................ 17

3-4 Dryer/Drying Hopper Process Air Hose Connection .................................................17

3-5 Aftercooler Cooling Water Connection ...................................................................... 18

3-6 Drying Hopper Air Trap .............................................................................................18

CHAPTER 4: CONTROL PANEL ............................................. 20

4-1 Control Panel Indicator Lights ................................................................................... 20

4-2 Switches and Meters ................................................................................................. 22

4-3 PLC Control...............................................................................................................23

4-4 Process Air Temperature Controller..........................................................................23

4-5 Temperature Controller LED Indicators..................................................................... 25

4-6 Temperature Controller Keys – (See Figure 5 in Section 3-6) .................................. 26

4-7 Optional Communications Protocols ......................................................................... 26

CHAPTER 5: STARTUP, SHUTDOWN & OPERATION.......... 27

5-1 Pre-Startup Checks ................................................................................................... 27

5-2 Startup.......................................................................................................................27

5-3 Shutdown ..................................................................................................................28

5-4 Setting the Process Air Temperature ........................................................................ 28

Bulletin Number iv

5-5

Setting the High and Low Temperature Alarms ........................................................28

5-6 Temperature Controller Autotune Procedure ............................................................ 29

5-7 Temperature Controller Internal Switches.................................................................29

5-8 Temperature Controller Anti-Tamper Lockout Switch ............................................... 29

5-9 Changing the Display from Fahrenheit to Centigrade ............................................... 30

5-10 Setting the Dewpoint Extend Shift Point.................................................................... 30

5-11 Regeneration Monitoring System Signal Processor.................................................. 31

5-12 Auxiliary Process Safety System (Optional)..............................................................32

5-13 Seven Day Timer (Optional)...................................................................................... 32

CHAPTER 6: MAINTENANCE ................................................. 35

6-1 Servicing the Process Air Filters (Models 350-700) .................................................. 35

6-2 Filter Cleaning/Replacement ..................................................................................... 35

6-3 Servicing the Process Air Filters (Models 850 through 2100) ................................... 36

6-4 Servicing the Regeneration Filter .............................................................................. 37

6-5 Dirty Filter Alarm Calibration .....................................................................................37

6-6 Dewpoint Control System Service............................................................................. 38

6-7 Symptoms of Worn Out Desiccant ............................................................................ 38

6-8 Desiccant Replacement Procedure...........................................................................39

6-9 Process Heater Replacement Procedure.................................................................. 40

6-10 Regeneration Heater Replacement Procedure ......................................................... 41

6-11 Restoring a Temperature Controller to the Factory Setup ........................................42

6-12 Regeneration Monitor Advanced Programming ........................................................ 48

CHAPTER 7: TROUBLESHOOTING ....................................... 52

CHAPTER 8: APPENDIX.......................................................... 55

8-1 Customer Satisfaction Warranty Program................................................................. 55

8-2 Technical Assistance................................................................................................. 58

Parts Department ................................................................................................ 58

Service Department............................................................................................. 58

Sales Department................................................................................................ 58

Contract Department ...........................................................................................58

Bulletin Number v

Chapter 1: Safety

1-1 How to Use This Manual

Use this manual as a guide and reference for installing, operating, and maintaining your

dehumidifying dryer. The purpose is to assist you in applying efficient, proven techniques

that enhance equipment productivity.

This manual covers only light corrective maintenance. No other maintenance should be

undertaken without first contacting a service engineer.

The Functional Description section outlines models covered, standard features, and safety

features. Additional sections within the manual provide instructions for installation, preoperational procedures, operation, preventive maintenance, and corrective maintenance.

The Installation chapter includes required data for receiving, unpacking, inspecting, and setup

of the dehumidifying dryer. We can also provide the assistance of a factory-trained technician

to help train your operator(s) for a nominal charge. This section includes instructions, checks,

and adjustments that should be followed before commencing with operation of the

dehumidifying dryer. These instructions are intended to supplement standard shop

procedures performed at shift, daily, and weekly intervals.

The Operation chapter includes a description of electrical and mechanical controls, in

addition to information for operating the dryer safely and efficiently.

The Maintenance chapter is intended to serve as a source of detailed assembly and

disassembly instructions for those areas of the equipment requiring service. Preventive

maintenance sections are included to ensure that your dehumidifying dryer provides

excellent, long service.

The Troubleshooting chapter serves as a guide for identification of most common problems.

Potential problems are listed, along with possible causes and related solutions.

The Appendix contains technical specifications, drawings, schematics, parts lists, and

available options. A spare parts list with part numbers specific to your machine is provided

with your shipping paperwork package. Refer to this section for a listing of spare parts for

purchase. Have your serial number and model number ready when ordering.

Safety Symbols Used in this Manual

The following safety alert symbols are used to alert you to potential personal injury hazards.

Obey all safety messages that follow these symbols to avoid possible injury or death.

DANGER! DANGER indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

WARNING! WARNING indicates a potentially hazardous situation or practice that, if

not avoided, could result in death or serious injury.

Caution! CAUTION indicates a potentially hazardous situation or practice that, if

not avoided, may result in minor or moderate injury or in property damage.

350-2100 cfm Dryers Chapter 1: Safety 6 of 58

1-2 Safety Tag Information

Dryer Safety Tags

Hot! Read Operation

and Installation

Manual

High Voltage Earth Ground

Inside Enclosure

PE Protected Earth

Lifting Point Ground

350-2100 cfm Dryers Chapter 1: Safety 7 of 58

1-3 Warnings and Precautions

Our equipment is designed to provide safe and reliable operation when installed and operated

within design specifications, following national and local safety codes. This may include, but

is not limited to OSHA, NEC, CSA, SPI, and any other local, national and international

regulations.

To avoid possible personal injury or equipment damage when installing, operating, or

maintaining this equipment, use good judgment and follow these safe practices:

; Read and follow these operation and installation instructions when installing,

operating, and maintaining this equipment. If these instructions become

damaged or unreadable, additional copies are available from the manufacturer.

; Follow all SAFETY CODES.

; Wear SAFETY GLASSES and WORK GLOVES.

; Work only with approved tools and devices.

; Disconnect and/or lock out power before servicing or maintaining the equipment.

; Use care when LOADING, UNLOADING, RIGGING, or MOVING this

equipment.

; Operate this equipment within design specifications.

; OPEN, TAG, and LOCK ALL DISCONNECTS before working on equipment.

You should remove the fuses and carry them with you.

; Make sure the equipment and components are properly GROUNDED before you

switch on power.

; Use EXTREME CAUTION when working with dryer. HIGH HEAT can be

dangerous. Keep body parts, tools, clothing, and debris away from dryer.

; When welding or brazing in or around this equipment, make sure VENTILATION is

ADEQUATE. PROTECT adjacent materials from flame or sparks by shielding with

sheet metal. An approved FIRE EXTINGUISHER should be close at hand and

ready for use if needed.

; Do not restore power until you remove all tools, test equipment, etc., and the

equipment and related components are fully reassembled.

; Only PROPERLY TRAINED personnel familiar with the information in this

manual should work on this equipment.

We have long recognized the importance of safety and have designed and manufactured our

equipment with operator safety as a prime consideration. We expect you, as a user, to abide

by the foregoing recommendations in order to make operator safety a reality.

350-2100 cfm Dryers Chapter 1: Safety 8 of 58

1-4 Responsibility

These machines are constructed for maximum operator safety when used under standard

operating conditions and when recommended instructions are followed in the maintenance

and operation of the machine.

All personnel engaged in the use of the machine should become familiar with its operation as

described in this manual.

Proper operation of the machine promotes safety for the operator and all workers in its

vicinity.

Each individual must take responsibility for observing the prescribed safety rules as outlined.

All warning and danger signs must be observed and obeyed. All actual or potential danger

areas must be reported to your immediate supervisor.

General Responsibility

No matter who you are, safety is important. Owners, operators and maintenance personnel

must realize that every day, safety is a vital part of their jobs.

If your main concern is loss of productivity, remember that production is always affected in a

negative way following an accident. The following are some of the ways that accidents can

affect your production:

• Loss of a skilled operator (temporarily or permanently)

• Breakdown of shop morale

• Costly damage to equipment

• Downtime

An effective safety program is responsible and economically sound.

Organize a safety committee or group, and hold regular meetings. Promote this group from

the management level. Through this group, the safety program can be continually reviewed,

maintained, and improved. Keep minutes or a record of the meetings.

Hold daily equipment inspections in addition to regular maintenance checks. You will keep

your equipment safe for production and exhibit your commitment to safety.

Please read and use this manual as a guide to equipment safety. This manual contains safety

warnings throughout, specific to each function and point of operation.

Operator Responsibility

The operator’s responsibility does not end with efficient production. The operator usually has

the most daily contact with the equipment and intimately knows its capabilities and

limitations.

Plant and personnel safety is sometimes forgotten in the desire to meet incentive rates, or

through a casual attitude toward machinery formed over a period of months or years. Your

employer probably has established a set of safety rules in your workplace. Those rules, this

manual, or any other safety information will not keep you from being injured while operating

your equipment.

350-2100 cfm Dryers Chapter 1: Safety 9 of 58

Learn and always use safe operation. Cooperate with co-workers to promote safe practices.

Immediately report any potentially dangerous situation to your supervisor or appropriate

person.

REMEMBER:

• NEVER place your hands or any part of your body in any dangerous location.

• NEVER operate, service, or adjust the dryer without appropriate training and first

reading and understanding this manual.

• NEVER try to pull material out of the dryer with your hands while it is running!

• Before you start the dryer check the following:

• Remove all tools from the dryer;

• Be sure no objects (tools, nuts, bolts, clamps, bars) are laying in the

hopper area;

• If your dryer has been inoperative or unattended, check all settings before starting the

unit.

• At the beginning of your shift and after breaks, verify that the controls and other

auxiliary equipment are functioning properly.

• Keep all safety guards in place and in good repair. NEVER attempt to bypass, modify,

or remove safety guards. Such alteration is not only unsafe, but will void the warranty

on your equipment.

• When changing control settings to perform a different mode of operation, be sure

selector switches are correctly positioned. Locking selector switches should only be

adjusted by authorized personnel and the keys removed after setting.

• Report the following occurrences IMMEDIATELY:

• unsafe operation or condition

• unusual dryer action

• leakage

• improper maintenance

• NEVER stand or sit where you could slip or stumble into the dryer

while working on it.

• DO NOT wear loose clothing or jewelry, which can be caught while working on a

dryer. In addition, cover or tie back long hair.

• Clean the dryer and surrounding area DAILY, and inspect the machine for loose,

missing or broken parts.

• Shut off power to the dryer when it is not in use. Turn the switch to the OFF position,

or unplug it from the power source.

Maintenance Responsibility

Proper maintenance is essential to safety. If you are a maintenance worker, you must make

safety a priority to effectively repair and maintain equipment.

350-2100 cfm Dryers Chapter 1: Safety 10 of 58

Before removing, adjusting, or replacing parts on a machine, remember to turn off all electric

supplies and all accessory equipment at the machine, and disconnect and lockout electrical

power. Attach warning tags to the disconnect switch.

When you need to perform maintenance or repair work on a dryer above floor level, use a

solid platform or a hydraulic elevator. If there is a permanently installed catwalk on your

dryer, use it. The work platform should have secure footing and a place for tools and parts.

DO NOT climb on dryers, machines, or work from ladders.

If you need to repair a large component, use appropriate handling equipment. Before you use

handling equipment (portable “A” frames, electric boom trucks, fork trucks, overhead cranes)

be sure the load does not exceed the capacity of the handling equipment or cause it to become

unstable.

Carefully test the condition of lifting cables, chains, ropes, slings, and hooks before using

them to lift a load.

Be sure that all non-current carrying parts are correctly connected to earth ground with an

electrical conductor that complies with current codes. Install in accordance with national and

local codes.

When you have completed the repair or maintenance procedure, check your work and remove

your tools, rigging, and handling equipment.

Do not restore power to the dryer until all persons are clear of the area. DO NOT start and

run the dryer until you are sure all parts are functioning correctly.

BEFORE you turn the dryer over to the operator for production, verify all dryer enclosure

panels, guards and safety devices are in place and functioning properly.

Reporting a Safety Defect

If you believe that your equipment has a defect that could cause injury, you should

immediately discontinue its use and inform the manufacturer.

The principle factors that can result in injury are failure to follow proper operating procedures

(i.e. lockout/tagout), or failure to maintain a clean and safe working environment.

1-5 Responsibility

These machines are constructed for maximum operator safety when used under standard

operating conditions and when recommended instructions are followed in the maintenance

and operation of the machine.

All personnel engaged in the use of the machine should become familiar with its operation as

described in this manual.

Proper operation of the machine promotes safety for the operator and all workers in its

vicinity.

Becoming familiar with materials, inspection, speed limitations, screens, and guard

maintenance and total user responsibility will assist you in learning potential areas in need of

observation for danger.

Each individual must take responsibility for observing the prescribed safety rules as outlined.

All caution, warning and danger signs must be observed and obeyed. All actual or potential

danger areas must be reported to your immediate supervisor.

350-2100 cfm Dryers Chapter 1: Safety 11 of 58

Chapter 2: Functional Description

2-1 Models Covered in This Manual

This manual provides operation, installation, and maintenance instructions for

WD/SDA/CDA 350, 425, 500, 600, 700, 850, 1000, 1250, 1500, 1800, and 2100 cfm large

dehumidifying dryers in both standard 300˚ F and 400˚ F high temperature “-RT” models.

Model numbers are listed on the serial tag. Make sure you know the model and serial number

of your equipment before contacting the manufacturer for parts or service.

2-2 General Description

Dehumidifying Dryers are designed to generate heated, dehumidified air at carefully

controlled temperatures for use in closed-loop plastic drying systems. Drying systems are

sized to meet the specific requirements stated by the purchaser at the time of purchase.

Moisture removal from hygroscopic (moisture attracting) plastic pellets is an essential step in

the manufacture of high-quality plastic products.

ACS dryers are used by the plastics industry to generate very low dewpoint air that is heated

to a controlled temperature for drying plastic pellets and regrind.

2-3 Typical Features and Components

1. Branch Fusing provides additional protection to the operator and the components on

the dryer's sub-panel.

2. Dewpoint Monitor indicates dryer efficiency

2-4 Optional Features

Options can tailor an ACS dryer to meet the exact requirements of the drying task being

performed.

• Dirty filter indicator to advise the operator when it's time to clean the filters.

• Water-cooled aftercooler for closed loop regeneration air cooling

• SMART PLC to combine PLC features and a "Plain English" interface. This option is

fully described in its own manual.

• Heater Burnout Indicator to monitor the heater(s) amp draw.

• Compressed air filter cleaning to lower maintenance on regrind/dusty material drying

processes.

• Auxiliary high temperature safety system to cut high voltage to the blowers and

heaters in the event of run-away process heaters.

• Seven day timer to allow programmable dryer start up.

• Communications to meet customer needs.

• Drying Hoppers come in many sizes and mounting configurations.

• Conveying Equipment to transport material to and from the drying system.

• Insulated Process Air Hose to minimize heat loss between the dryer and the drying

hopper.

350-2100 cfm Dryers Chapter 2: Functional Description 12 of 58

2-5 The Closed Loop Drying System

ACS dryers force hot, dry air through the resin in the drying hopper, where the air picks up

moisture from the material and is drawn back to the dryer.

In the dryer, moisture is stripped from the air by a desiccant bed. The dried process air is then

re-heated and delivered back into the drying hopper to dry material again.

This system is a "closed loop", because ambient (outside) air is never introduced into the

process air. The closed loop system is used by ACS because the process air is typically much

drier than ambient air, even after carrying moisture out of the plastic resin. Recycling process

air maintains drying efficiency at a consistently high level.

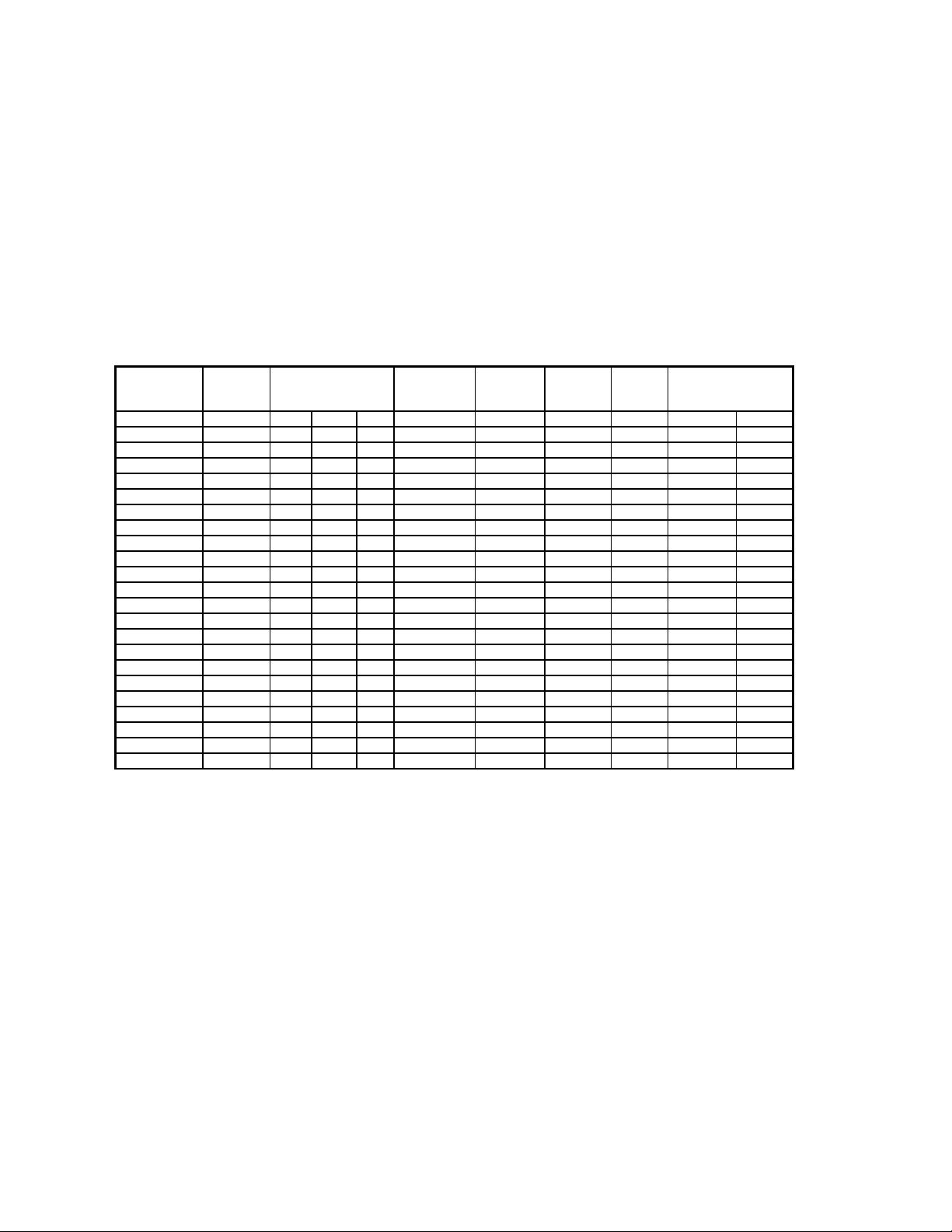

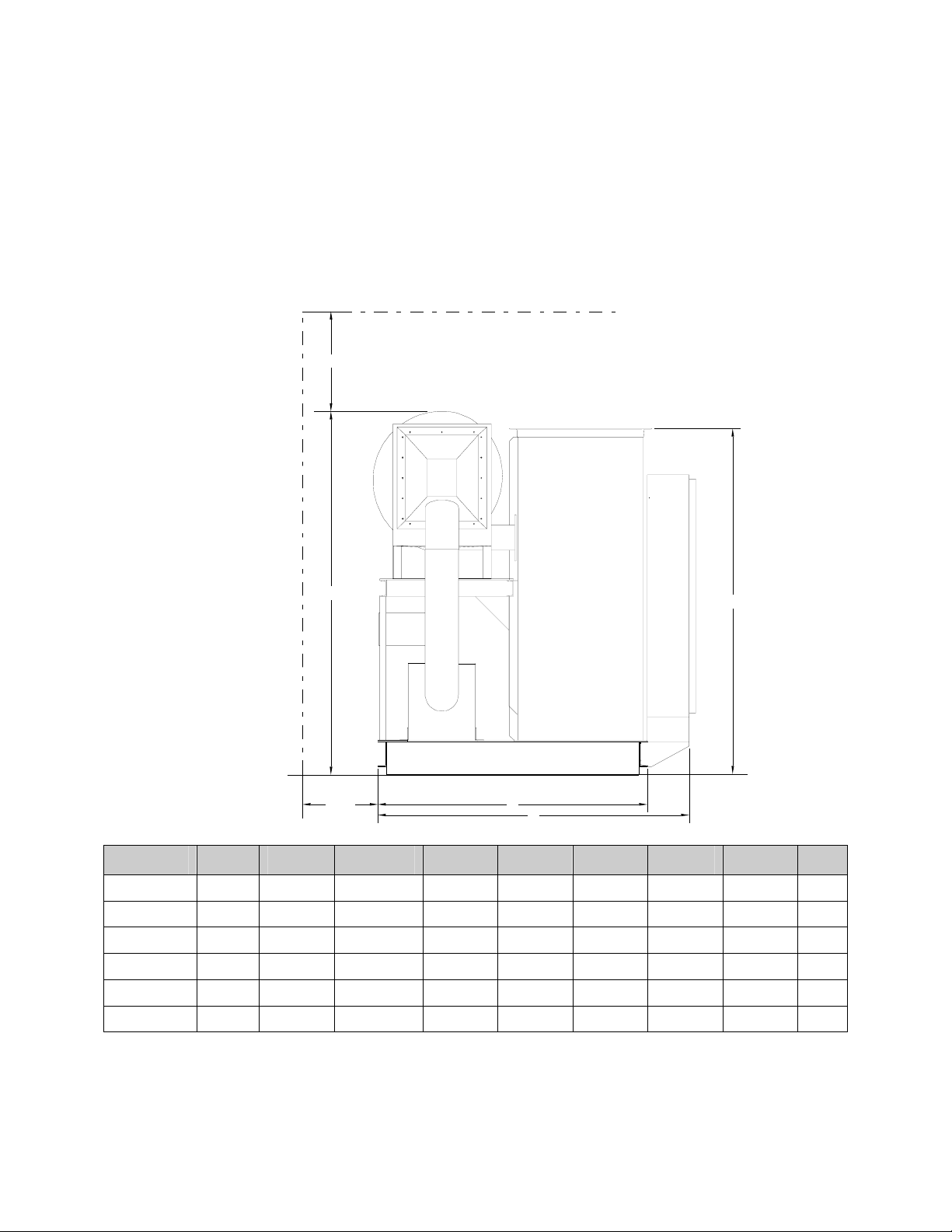

Figure 1: WD/SDA/CDA 350-2100 Dryer Specifications

Model

Number

460-3-60 L W H I.D. Lbs. Hp. Hp. Large Small

350 56 56 73 4 1000 5 ½ 30 76

350-RT 56 56 73 4 1000 5 ½ 30 76

425 61 52 82 5 1100 7½ ½ 30 90

425-RT 61 52 82 5 1100 7½ ½ 30 90

500 63 66 94 5 1200 7½ ¾ 40 100

500-RT 63 66 94 5 1200 7½ ¾ 40 100

600 58 56 88 6 1450 10 ¾ 40 120

600-RT 58 56 88 6 1450 10 ¾ 40 120

700 59 66 93 6 1600 10 ¾ 40 135

700-RT 59 66 93 6 1600 10 ¾ 40 135

850 103 88 84 90 8 3 ¾ 120 120

850-RT 141 88 84 90 8 3 ¾ 120 120

1000 113 88 84 90 8 7½ ¾ 120 130

1000-RT 146 88 84 90 8 7½ ¾ 120 130

1250 138 88 84 90 8 7½ ¾ 120 180

1250-RT 194 88 84 90 8 7½ ¾ 120 180

1500 156 94 100 90 8 7½ ¾ 120 240

1500-RT 213 94 100 90 8 7½ ¾ 120 240

1800 179 94 100 90 8 10 ¾ 120 310

1800-RT 235 94 100 90 8 10 ¾ 120 310

2100 203 94 100 98 10 15 ¾ 120 360

2100-RT 278 94 100 98 10 15 ¾ 120 360

Amp

Draw

Dimensions

(Inches)

Hose

Connection

(Inches)

Shipping

Weight

Process

Blower

Regen

Blower

Desiccant

Lbs./Bed

2-6 What is Desiccant?

Desiccant is a material which attracts and holds (absorbs) water from the air. The desiccant

ACS dryers use is a synthetic crystalline metal aluminosilicate that is blended with a clay

binder and formed into beads.

Absorbed water is driven from saturated desiccant by heating it to a high temperature

(reducing the desiccant's capacity to hold water) and forcing air through it. This moisture

removal process is called "regeneration".

2-7 The Process/Regeneration Cycle

ACS dryers have two desiccant beds. While one bed is on-line in the process air loop, the

other is off-line being regenerated.

350-2100 cfm Dryers Chapter 2: Functional Description 13 of 58

When a desiccant bed is online, it absorbs moisture

from the process air. In

Process Return Air

From Drying Hopper

Bleed

Upper

Control

Valve

time, the bed becomes

saturated with moisture and

needs to be regenerated.

The dryer automatically

Desiccant

Bed

Process

Filter

Assembly

Regeneration

Blower

Desiccant

Bed

Process

Delivery

Air

redirects the process

airflow to the second bed,

and starts the regeneration

cycle on the first bed.

During regeneration, air is

heated to approximately

550°F and forced through

Process

Blower

Lower

Control

Valve

Figure Two:

Airflow Diagram

Regeneration

Heater

Process

Heaters

the desiccant bed. The moisture driven off the bed is bled to the atmosphere.

If the temperature of the air bled to atmosphere (bleed temperature) is measured, a rise can be

observed after a period of time. This condition, called "bed breakthrough" indicates that the

bed is dry. At bed breakthrough, the bleed air temperature peaks between 350°F and 400°F.

Dryer models 350 through 2100 dryers are equipped with the Dewpoint Extend feature. The

regeneration heaters turn off automatically on bed breakthrough for additional energy

savings. A 550°F regeneration temperature will dry the desiccant beds sufficiently to produce

process air dewpoint of -40°F. In a properly sized system, this ultra-low humidity level will

be more than adequate to dry plastics to as little as .003% moisture.

2-8 Specifying a Drying System

There were many variables considered in the selection of your drying system, including: type

of materials, residence time, throughput of the extruder or injection molding machine,

ambient air moisture and temperature, and the altitude at the processing site. Should your

operating environment change, the manufacturer can advise you on necessary equipment and

process time and temperature modifications.

350-2100 cfm Dryers Chapter 2: Functional Description 14 of 58

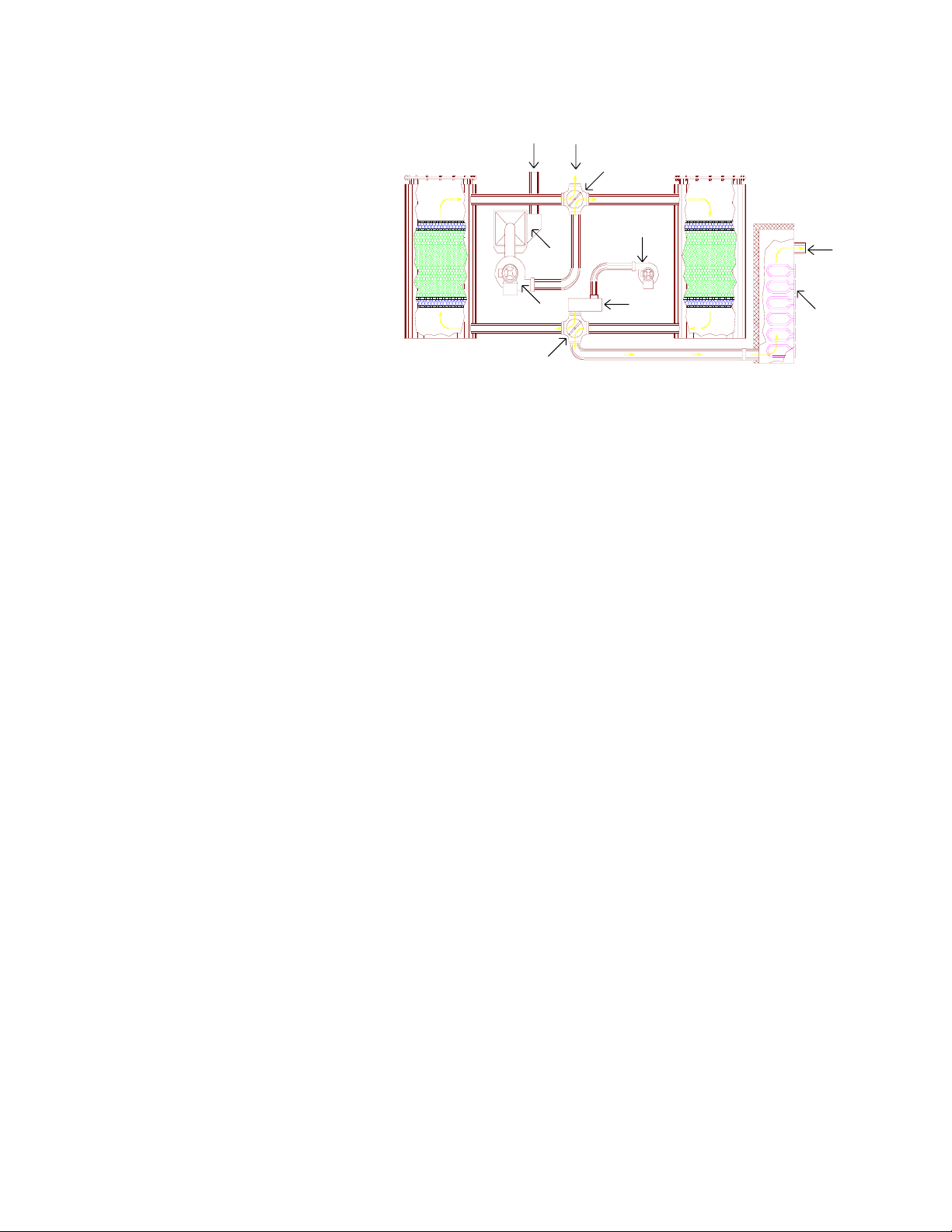

Figure 3: ????????

34" RADIUS

DOOR CLEARANCE

ELECTRICAL ENCLOSURE

AIR OUTLET

B

PROCESS

TOP VIEW

PROCESS BLOWER

DESICCANT TOWER

(LEFT SIDE)

OPTIONAL

AFTERCOOLER

A

REGEN BLOWER AND FILTER

1

2

34

1.5" MPT

INLET

E

1.5" MPT

OUTLET

C

PROCESS HEATER

1) PROCESS BLOWER PRES SWITCH

2) REGEN. DIRTY FILTER PRES. SWITCH

3) REGEN BLOWER PRES. SWITCH

4) DIRTY PROCESS FILTER PRES. SWITCH

?

PROCESS AIR

RETURN, FILTER

INLET

REAR VIEW

PROCESS RETURN

FILTER

D

350-2100 cfm Dryers Chapter 2: Functional Description 15 of 58

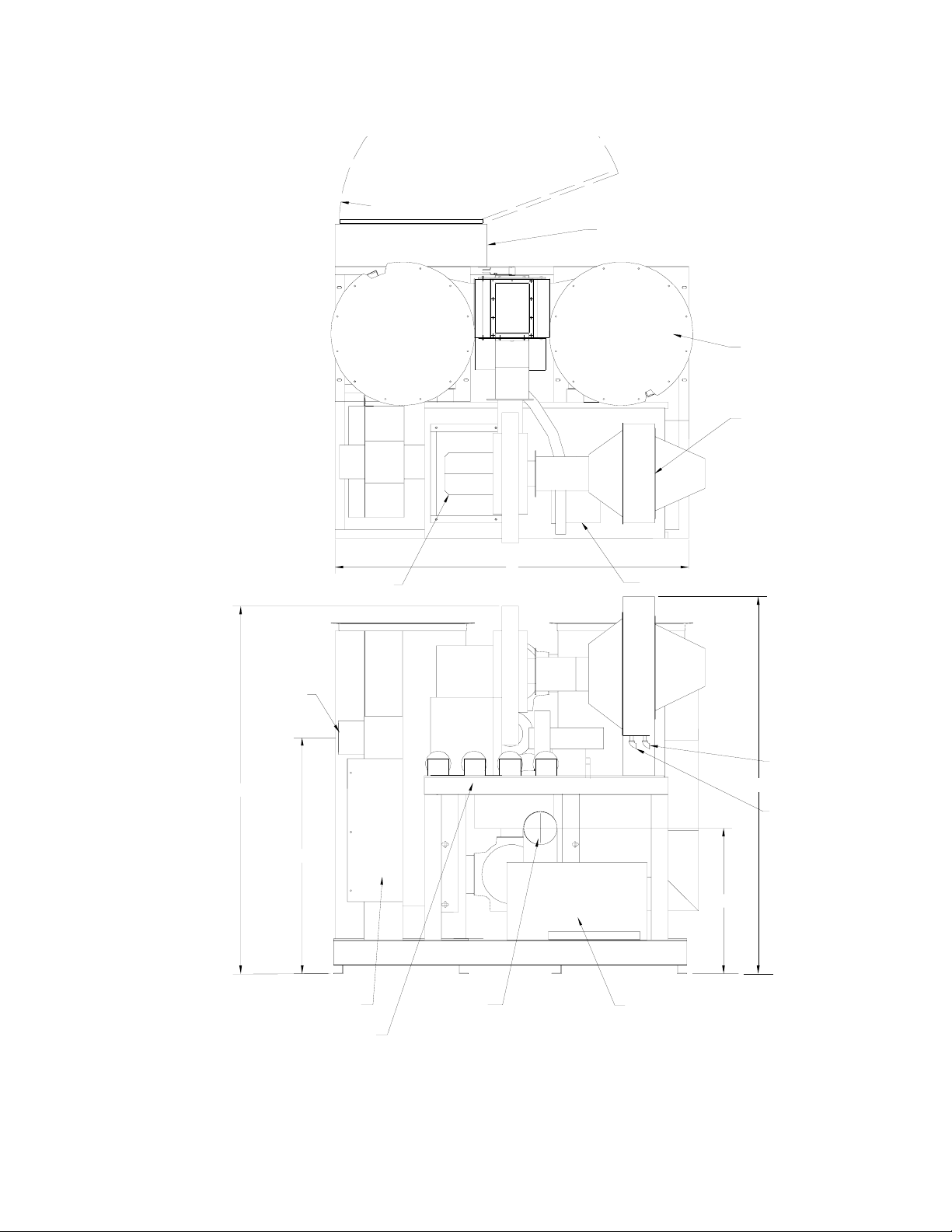

SUGGESTED

24"

CLEARANCE

Figure 4: Dryer Dimensions

WD Dryer Dimensions

WD-2100

WD-1800

WD-1500

WD-1250

WD-1000

WD-850

MINIMUM

VERTICAL

100 90½ 82½ 44½ 90.5 88 70½ 91½ 83

100 90½ 82½ 44½ 90.5 88 70½ 91½ 83

100 90½ 82½ 44½ 90.5 88 70½ 91½ 83

84 88 56 34½ 90 87½ 84½ 74 83

All Dimensions are in Inches

Specifications May Change Without Notice

837484½87½9034½568884

837484½87½9034½568884

IHGFEDCBA

LEFT

F

SIDE

I

VIEW

18"

MINIMUM

MAINTENANCE

CLEARANCE

Model A B C D E F G H I

850

1000

1250

1500

1800

2100

84 88 56 34 ½ 90 87 ½ 84 ½ 74 83

84 88 56 34 ½ 90 87 ½ 84 ½ 74 83

84 88 56 34 ½ 90 87 ½ 84 ½ 74 83

100 90 ½ 82 ½ 44 ½ 90 ½ 88 70 ½ 91 ½ 83

100 90 ½ 82 ½ 44 ½ 90 ½ 88 70 ½ 91 ½ 83

100 90 ½ 82 1/2 44 ½ 90 ½ 88 70 ½ 91 ½ 83

G

H

350-2100 cfm Dryers Chapter 2: Functional Description 16 of 58

Chapter 3: Installation

3-1 Work Rules

The installation, operation, and maintenance of this equipment must be conducted in

accordance with all applicable work and safety codes for the installation location. This may

include, but not limited to, OSHA, NEC, CSA, and any other local, national and international

regulations.

1. Read and follow these operating instructions when installing, operating and

maintaining this equipment. If the instructions become damaged or unreadable,

additional copies are available from the manufacturer.

2. Only qualified personnel familiar with this equipment should work on or with this

dryer.

3. Work with approved tools and devices.

4. Disconnect the electricity before maintenance or service. If the dryer is installed with

a power cord that can be unplugged, unplug it. If the dryer is permanently wired to a

power main, a fused power disconnect must be installed to allow the disconnect to be

locked in the "OFF" position. Open and lock out the disconnect installed in the

control enclosure.

3-2 Electrical Connections

The voltage, phase and amp draw information is listed on the serial tag.

; Line voltage must be within ±10% of the voltage listed on the serial tag, or damage

may occur. Phase imbalance must be less than 5%.

; Fulfill all national, state and local safety and electrical code requirements.

; Connection should be made by a qualified electrician.

; Connect main power to the dryer at the disconnect or terminals in the upper right

corner of the control enclosure.

; Install a fused disconnect with a lockout feature in the power main leading to the

dryer.

; The power drop must include a ground wire.

3-3 Check For Proper Blower Rotation

The blowers are rotating properly when air flows from the delivery outlet.

• Incorrect phasing of power leads will cause backward rotation of blower motors and

contamination of the desiccant.

If both blowers are rotating improperly, reverse any two wires at the fused disconnect outside

the dryer or at the disconnect/terminal in the control enclosure. This assures that both blowers

will be rotating in the proper direction.

• Reverse the wires at the motor starters only if one blower is rotating incorrectly.

3-4 Dryer/Drying Hopper Process Air Hose Connection

; Use high-temperature flexible dryer hose or rigid tubing to connect the dryer to the

drying hopper.

350-2100 cfm Dryers Chapter 3: Installation 17 of 58

Loading...

Loading...