Page 1

User Manual

ADAM-6000 Series

Ethernet-based Data Acquisition

and Control Modules

Page 2

Copyright

Part No. 2003600003 Edition 9

Printed in Taiwan August 2018

The documentation and the software included with this product are copyrighted 2018

by Advantech Co., Ltd. All rights are reserved. Advantech Co., Ltd. reserves the right

to make improvements in the products described in this manual at any time without

notice. No part of this manual may be reproduced, copied, translated or transmitted

in any form or by any means without the prior written permission of Advantech Co.,

Ltd. Information provided in this manual is intended to be accurate and reliable. However, Advantech Co., Ltd. assumes no responsibility for its use, nor for any infringements of the rights of third parties, which may result from its use.

Acknowledgements

Intel and Pentium are trademarks of Intel Corporation.

Microsoft Windows and MS-DOS are registered trademarks of Microsoft Corp.

All other product names or trademarks are properties of their respective owners.

Product Warranty

Advantech warrants to you, the original purchaser, that each of its products will be

free from defects in materials and workmanship for two years from the date of purchase.

This warranty does not apply to any products which have been repaired or altered by

persons other than repair personnel authorized by Advantech, or which have been

subject to misuse, abuse, accident or improper installation. Advantech assumes no

liability under the terms of this warranty as a consequence of such events.

Because of Advantech’s high quality-control standards and rigorous testing, most of

our customers never need to use our repair service. If an Advantech product is defective, it will be repaired or replaced at no charge during the warranty period. For outof-warranty repairs, you will be billed according to the cost of replacement materials,

service time and freight. Please consult your dealer for more details.

If you think you have a defective product, follow these steps:

1. Collect all the information about the problem encountered. (For example, CPU

speed, Advantech products used, other hardware and software used, etc.) Note

anything abnormal and list any onscreen messages you get when the problem

occurs.

2. Call your dealer and describe the problem. Please have your manual, product,

and any helpful information readily available.

3. If your product is diagnosed as defective, obtain an RMA (return merchandize

authorization) number from your dealer. This allows us to process your return

more quickly.

4. Carefully pack the defective product, a fully-completed Repair and Replacement

Order Card and a photocopy proof of purchase date (such as your sales receipt)

in a shippable container. A product returned without proof of the purchase date

is not eligible for warranty service.

5. Write the RMA number visibly on the outside of the package and ship it prepaid

to your dealer.

ADAM-6000 User Manual ii

Page 3

Declaration of Conformity

CE

This product has passed the CE test for environmental specifications when shielded

cables are used for external wiring. We recommend the use of shielded cables. This

kind of cable is available from Advantech. Please contact your local supplier for

ordering information.

FCC Class A

Note: This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Technical Support and Assistance

1. Visit the Advantech web site at www.advantech.com/support where you can find

the latest information about the product.

2. Contact your distributor, sales representative, or Advantech's customer service

center for technical support if you need additional assistance. Please have the

following information ready before you call:

– Product name and serial number

– Description of your peripheral attachments

– Description of your software (operating system, version, application software,

etc.)

– A complete description of the problem

– The exact wording of any error messages

iii ADAM-6000 User Manual

Page 4

Safety Instructions

1. Read these safety instructions carefully.

2. Keep this User Manual for later reference.

3. Disconnect this equipment from any AC outlet before cleaning. Use a damp

cloth. Do not use liquid or spray detergents for cleaning.

4. For plug-in equipment, the power outlet socket must be located near the equip-

ment and must be easily accessible.

5. Keep this equipment away from humidity.

6. Put this equipment on a reliable surface during installation. Dropping it or letting

it fall may cause damage.

7. The openings on the enclosure are for air convection. Protect the equipment

from overheating. DO NOT COVER THE OPENINGS.

8. Make sure the voltage of the power source is correct before connecting the

equipment to the power outlet.

9. Position the power cord so that people cannot step on it. Do not place anything

over the power cord.

10. All cautions and warnings on the equipment should be noted.

11. If the equipment is not used for a long time, disconnect it from the power source

to avoid damage by transient overvoltage.

12. Never pour any liquid into an opening. This may cause fire or electrical shock.

13. Never open the equipment. For safety reasons, the equipment should be

opened only by qualified service personnel.

14. If one of the following situations arises, get the equipment checked by service

personnel:

The power cord or plug is damaged.

Liquid has penetrated into the equipment.

The equipment has been exposed to moisture.

The equipment does not work well, or you cannot get it to work according to the

user's manual.

The equipment has been dropped and damaged.

The equipment has obvious signs of breakage.

15. DO NOT LEAVE THIS EQUIPMENT IN AN ENVIRONMENT WHERE THE

STORAGE TEMPERATURE MAY GO BELOW -20° C (-4° F) OR ABOVE 60° C

(140° F). THIS COULD DAMAGE THE EQUIPMENT. THE EQUIPMENT

SHOULD BE IN A CONTROLLED ENVIRONMENT.

16. CAUTION: DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY

REPLACED. REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE

RECOMMENDED BY THE MANUFACTURER, DISCARD USED BATTERIES

ACCORDING TO THE MANUFACTURER'S INSTRUCTIONS.

17. The sound pressure level at the operator's position according to IEC 704-1:1982

is no more than 70 dB (A).

DISCLAIMER: This set of instructions is given according to IEC 704-1. Advantech

disclaims all responsibility for the accuracy of any statements contained herein.

ADAM-6000 User Manual iv

Page 5

Contents

Chapter 1 Understanding Your System ..............1

1.1 Introduction ............................................................................................... 2

Figure 1.1 ADAM-6000 Module System Architecture .................. 2

1.2 Major Features .......................................................................................... 2

1.3 Specifications ............................................................................................ 4

1.4 Dimensions ............................................................................................... 4

Figure 1.2 ADAM-6000 Module Dimensions ............................... 4

1.5 LED Status ................................................................................................ 5

Chapter 2 Hardware Selection Guidelines..........7

2.1 Selecting an I/O Module............................................................................ 8

Table 2.1: I/O Selection Guidelines............................................. 8

2.2 Selecting a Link Terminal and Cable ........................................................ 8

Figure 2.1 Connecting ADAM-6000 Modules to an Ethernet Ter-

minal via Cable ........................................................... 9

Table 2.2: Ethernet RJ-45 Port Pin Assignment Chart................ 9

2.3 Selecting an Operator Interface ................................................................ 9

Chapter 3 Hardware Installation Guide .............11

3.1 Interface Introduction .............................................................................. 12

3.2 Mounting Options .................................................................................... 13

3.2.1 Panel Mounting ........................................................................... 13

Figure 3.1 Panel Mounting Bracket Dimensions........................ 13

Figure 3.2 How to Fix a Module on the Mounting Bracket......... 13

3.2.2 DIN Rail Mounting....................................................................... 14

Figure 3.3 How to Fix a Module on the DIN Rail Adapter.......... 14

Figure 3.4 How to Secure a Module to a DIN Rail..................... 14

3.3 Wiring and Connections .......................................................................... 15

3.3.1 Power Supply Wiring................................................................... 15

Figure 3.5 How to Connect the Module Power Wires................ 15

3.3.2 I/O Module Wiring ....................................................................... 15

Chapter 4 Introduction to Analog ADAM-6000 I/O

Modules17

4.1 Analog Input Modules ............................................................................. 18

4.2 ADAM-6015 7-ch Isolated RTD Input Module ......................................... 18

4.2.1 Specifications.............................................................................. 18

4.2.2 Application Wiring ....................................................................... 20

Figure 4.1 ADAM-6015 RTD Input Wiring ................................. 20

4.2.3 Address Assignment ................................................................... 20

4.3 ADAM-6017 8-ch Analog Input/2-ch Digital Output Module.................... 20

4.3.1 Specifications.............................................................................. 20

Figure 4.2 ADAM-6017 Jumper Switches.................................. 22

4.3.2 Application Wiring ....................................................................... 23

Figure 4.3 ADAM-6017 Analog Input Wiring............................. 23

Figure 4.4 ADAM-6017 Analog Input Type Setting.................... 23

Figure 4.5 ADAM-6017 Digital Output Wiring ............................ 23

4.3.3 Address Assignment ................................................................... 24

v ADAM-6000 User Manual

Page 6

4.4 ADAM-6018 Isolated Thermocouple Input/8-ch Digital Output Module .. 24

Figure 4.6 ADAM-6018 8-ch Thermocouple Input..................... 24

4.4.1 Specifications.............................................................................. 24

4.4.2 Application Wiring ....................................................................... 26

Figure 4.7 ADAM-6018 Thermocouple Input Wiring.................. 26

Figure 4.8 ADAM-6018 Digital Output Wiring............................ 26

4.4.3 Address Assignment................................................................... 26

4.5 ADAM-6024 12-ch Isolated Universal I/O Module .................................. 26

4.5.1 Specifications.............................................................................. 27

Figure 4.9 ADAM-6024 Jumper Settings................................... 28

4.5.2 Application Wiring ....................................................................... 29

Figure 4.10ADAM-6024 Analog I/O Wiring................................. 29

Figure 4.11ADAM-6024 Digital Input Wiring............................... 29

Figure 4.12ADAM-6024 Digital Output Wiring ............................ 30

4.5.3 Address Assignment................................................................... 30

Chapter 5 Introduction to Digital ADAM-6000 I/O

Modules31

5.1 Digital I/O and Relay Modules ................................................................ 32

5.2 ADAM-6050 18-ch Isolated Digital I/O Module ....................................... 32

5.2.1 Specifications.............................................................................. 32

5.2.2 Application Wiring ....................................................................... 33

Figure 5.1 ADAM-6050 Digital Input Wiring............................... 33

Figure 5.2 ADAM-6050 Digital Output Wiring............................ 33

5.2.3 Address Assignment................................................................... 34

5.3 ADAM-6051 14-ch Isolated Digital I/O Module w/2-ch Counter .............. 34

5.3.1 Specifications.............................................................................. 34

5.3.2 Application Wiring ....................................................................... 35

Figure 5.3 ADAM-6051 Digital Input Wiring............................... 35

Figure 5.4 ADAM-6051 Counter (Frequency) Input................... 35

Figure 5.5 ADAM-6051 Digital Output Wiring............................ 36

5.3.3 Address Assignment................................................................... 36

5.4 ADAM-6052 16-ch Source-Type Isolated Digital I/O Module.................. 36

5.4.1 Specifications.............................................................................. 36

Figure 5.6 ADAM-6052 Jumper Settings................................... 37

5.4.2 Application Wiring ....................................................................... 38

Figure 5.7 ADAM-6052 Digital Input Wiring............................... 38

Figure 5.8 ADAM-6052 Digital Output Wiring............................ 39

5.4.3 Address Assignment................................................................... 39

5.5 ADAM-6060 6-ch Digital Input/6-ch Relay Module ................................. 39

5.5.1 Specifications.............................................................................. 39

5.5.2 Application Wiring ....................................................................... 41

Figure 5.9 ADAM-6060 Digital Input Wiring............................... 41

Figure 5.10ADAM-6060 Relay Output Wiring............................. 41

5.5.3 Address Assignment................................................................... 41

5.6 ADAM-6066 6-ch Digital Input/6-ch Power Relay Module ...................... 42

5.6.1 Specifications:............................................................................. 42

5.6.2 Application Wiring ....................................................................... 43

Figure 5.11ADAM-6066 Digital Input Wiring............................... 43

Figure 5.12ADAM-6066 Relay Output Wiring............................. 43

5.7 Digital Output Diagnostic Function.......................................................... 44

5.7.1 How to Obtain the Digital Output Diagnostic Status ................... 45

Figure 5.13Abnormal DO Diagnostic Status............................... 45

Figure 5.14Normal DO Diagnostic Status .................................. 46

Chapter 6 System Configuration Guide ........... 49

ADAM-6000 User Manual vi

Page 7

6.1 System Requirements............................................................................. 50

6.2 Installing Adam/Apax .NET Utility ........................................................... 50

6.3 Adam/Apax .NET Utility Overview........................................................... 50

Figure 6.1 Adam/Apax .NET Utility Operation Window ............. 51

6.3.1 Menu Bar .................................................................................... 51

6.3.2 Toolbar........................................................................................ 52

Figure 6.2 Adam/Apax .NET Utility Toolbar............................... 52

6.3.3 Module Tree Display Area .......................................................... 53

Figure 6.3 Adam/Apax .NET Utility Module Display Area.......... 53

6.3.4 Status Display Area .................................................................... 53

6.3.5 Configuration of ADAM-6000 Modules ....................................... 53

Figure 6.4 Adam/Apax .NET Utility - Searching for Devices...... 54

6.3.6 Group Configuration.................................................................... 62

6.3.7 I/O Configuration......................................................................... 64

Figure 6.5 All-Channel, Individual Channel, and GCL Configura-

tion Controls ............................................................. 64

6.4 Analog Input Modules (ADAM-6015, ADAM-6017, and ADAM-6018) .... 65

6.4.1 All-Channel Configuration ........................................................... 65

Figure 6.6 Channels Range Configuration Area........................ 65

Figure 6.7 Analog Input Trend Log ........................................... 68

6.4.2 Individual Channel Configuration ................................................ 70

Figure 6.8 Analog Input Alarm Mode Configuration................... 70

6.5 Universal I/O Modules (ADAM-6024)...................................................... 71

6.5.1 All-Channel Configuration ........................................................... 71

Figure 6.9 ADAM-6015 Channel Configuration ......................... 72

Figure 6.10ADAM-6024 Output Tab........................................... 72

6.6 Universal Digital I/O Modules (ADAM-6050, ADAM-6051- ADAM-6052,

ADAM-6060, ADAM-6066)...................................................................... 73

6.6.1 All-Channel Configuration ........................................................... 73

6.6.2 Individual Channel Configuration ................................................ 74

Figure 6.11Digital Input Modes ................................................... 75

Figure 6.12Digital Output Modes ................................................ 78

Figure 6.13Graph Explaining Low to High Delay Output Mode .. 80

Figure 6.14Graph Explaining Low to High Delay Output Mode .. 81

6.7 Introduction to P2P Functions ................................................................. 81

6.7.1 P2P Communication Modes ....................................................... 82

Figure 6.15Basic Mode for P2P.................................................. 82

Figure 6.16Advanced mode for P2P........................................... 83

6.7.2 P2P Communication Methods .................................................... 83

6.7.3 P2P Event Triggers..................................................................... 83

6.8 How to Configure P2P Functions ............................................................ 84

Figure 6.17Peer to Peer/Event Tab ............................................ 84

6.8.1 Basic Mode Configuration........................................................... 85

Figure 6.18P2P Basic Mode Configuration................................. 85

6.8.2 Advanced Mode Configuration.................................................... 86

Figure 6.19P2P Advanced Mode Configuration ......................... 86

Figure 6.20Copy One Setting to Other Channels....................... 87

6.9 ADAM-6000 Web Server......................................................................... 87

6.9.1 HTML 5 ....................................................................................... 88

6.9.2 Java Applet Customization ......................................................... 90

Figure 6.21Structure of the ADAM6060.jar file........................... 93

Figure 6.22Firmware Upgrade .................................................... 93

Chapter 7 Planning Your Application Program....

101

7.1 Introduction ........................................................................................... 102

7.2 ADAM .NET Class Library..................................................................... 102

Figure 7.1 Modifying ADAM-6050 .NET .................................. 103

vii ADAM-6000 User Manual

Page 8

Figure 7.2 Execute the sample code and configure your ADAM

module.................................................................... 103

7.3 Modbus Protocol for ADAM-6000 Modules........................................... 104

7.3.1 Modbus Protocol Structure ....................................................... 104

7.3.2 Modbus Function Code Introductions ....................................... 104

7.4 ASCII Commands for ADAM-6000 Modules......................................... 109

7.4.1 ASCII Syntax ............................................................................ 109

7.4.2 System Command Set.............................................................. 109

7.4.3 Analog Input Command Set...................................................... 113

7.4.4 Analog Input Alarm Command Set ........................................... 124

7.4.5 Universal I/O Command Set ..................................................... 129

7.4.6 Digital I/O Command Set.......................................................... 135

7.5 SNMP for ADAM-6000 Modules ........................................................... 138

7.5.1 ADAM MIB file .......................................................................... 138

7.5.2 SNMP Trap Configuration......................................................... 138

Figure 7.3 Trap Configuration Using Adam/Apax .NET Utility. 139

7.5.3 SNMP OID Value...................................................................... 140

7.6 MQTT for ADAM-6000 modules ........................................................... 141

7.6.1 Introduction of MQTT................................................................ 141

7.6.2 MQTT Format for ADAM module.............................................. 141

7.6.3 MQTT Configuration ................................................................. 144

7.6.4 How to Start MQTT with ADAM-6000 Modules ........................ 147

7.6.5 Real-Time Clock ....................................................................... 149

7.6.6 SNTP Configuration Using Adam/Apax .NET Utility ................. 149

7.6.7 SNTP Configuration Using ASCII Commands.......................... 150

Chapter 8 Graphic Condition Logic (GCL) ..... 151

8.1 Overview ............................................................................................... 152

8.2 GCL Configuration Environment ........................................................... 152

Figure 8.1 GCL Configuration Environment ............................ 153

Figure 8.2 Four Stages for One Logic Rule............................. 154

8.3 Configuring the Four Stages of a Logic Rule ........................................ 155

8.3.1 Input Condition Stage ............................................................... 155

Figure 8.3 Input Condition Stage Configuration ...................... 156

Figure 8.4 Scaling Function of Analog Input Mode.................. 156

Figure 8.5 Engineer Unit and Current Value ........................... 157

8.3.2 Logic Stage............................................................................... 159

Figure 8.6 Logic Stage Configuration ...................................... 159

8.3.3 Execution Stage........................................................................ 160

Figure 8.7 Execution Stage Configuration............................... 161

Figure 8.8 Send to Next Rule Function ................................... 162

Figure 8.9 The Next Logic Rule............................................... 162

8.3.4 Output Stage............................................................................. 163

Figure 8.10Output Stage Configuration .................................... 163

Figure 8.11Remote Message Output ....................................... 166

8.4 Internal Flag for Logic Cascade and Feedback .................................... 168

8.4.1 Logic Cascade .......................................................................... 168

Figure 8.12Local Logic Cascade Architecture .......................... 168

Figure 8.13Configuration of Logic Rule 1 ................................. 168

Figure 8.14Configuration of Logic Rule 2 ................................. 169

Figure 8.15Configuration of Logic Rule 3 ................................. 169

Figure 8.16Distributed Logic Cascade ..................................... 170

Figure 8.17Configuration of Logic Rule 1 ................................. 170

Figure 8.18Configuration of Logic Rule 2 ................................. 170

Figure 8.19Configuration of Logic Rule 3 ................................. 170

8.4.2 Feedback.................................................................................. 171

Figure 8.20Building Logic Feedback ........................................ 171

8.5 Logic Download and Online Monitoring ................................................ 171

ADAM-6000 User Manual viii

Page 9

Figure 8.21Online Monitoring Function..................................... 172

Figure 8.22GCL Execution Sequence ...................................... 173

8.6 Typical Applications with GCL............................................................... 173

Figure 8.23Ladder Diagram for On/Off Control ........................ 174

Figure 8.24GCL Logic for On/Off Control ................................. 174

Figure 8.25Time Chart for Sequence Control ........................... 175

Figure 8.26GCL Logic for Sequence Control (Turns On in Se-

quence and Remains On)....................................... 175

Figure 8.27Time Chart for 12 Digital Inputs to 1 Digital Output 176

Figure 8.28GCL Logic for 12 Digital Inputs to 1 Digital Output. 176

Figure 8.29Time Chart for Flicker Applications......................... 177

Figure 8.30GCL Logic for Flicker .............................................. 177

Figure 8.31Time Chart for Rising Edge .................................... 177

Figure 8.32Ladder Diagram for Rising Edge ............................ 178

Figure 8.33GCL Logic for Rising Edge ..................................... 178

Figure 8.34Time Chart for Falling Edge.................................... 179

Figure 8.35Ladder Diagram for Falling Edge............................ 179

Figure 8.36GCL Logic for Falling Edge .................................... 179

Figure 8.37Time Chart for Sequence Control (Continuously Turn

On and Off in Sequence)........................................ 180

Figure 8.38GCL Logic for Sequence Control (Continuously Turn

On and Off in Sequence)........................................ 180

Figure 8.39GCL Logic for Event Trigger (Only Occurs Once) .. 181

Figure 8.40Event Trigger Configuration (Only Occurs Once)... 181

Appendix A Design Worksheets .........................183

Appendix B Data Formats and I/O Ranges ........187

B.1 ADAM-6000 Command Data Formats .................................................. 188

Figure B.1 Request Comment Structure .................................. 188

Figure B.2 Response Comment Structure ............................... 188

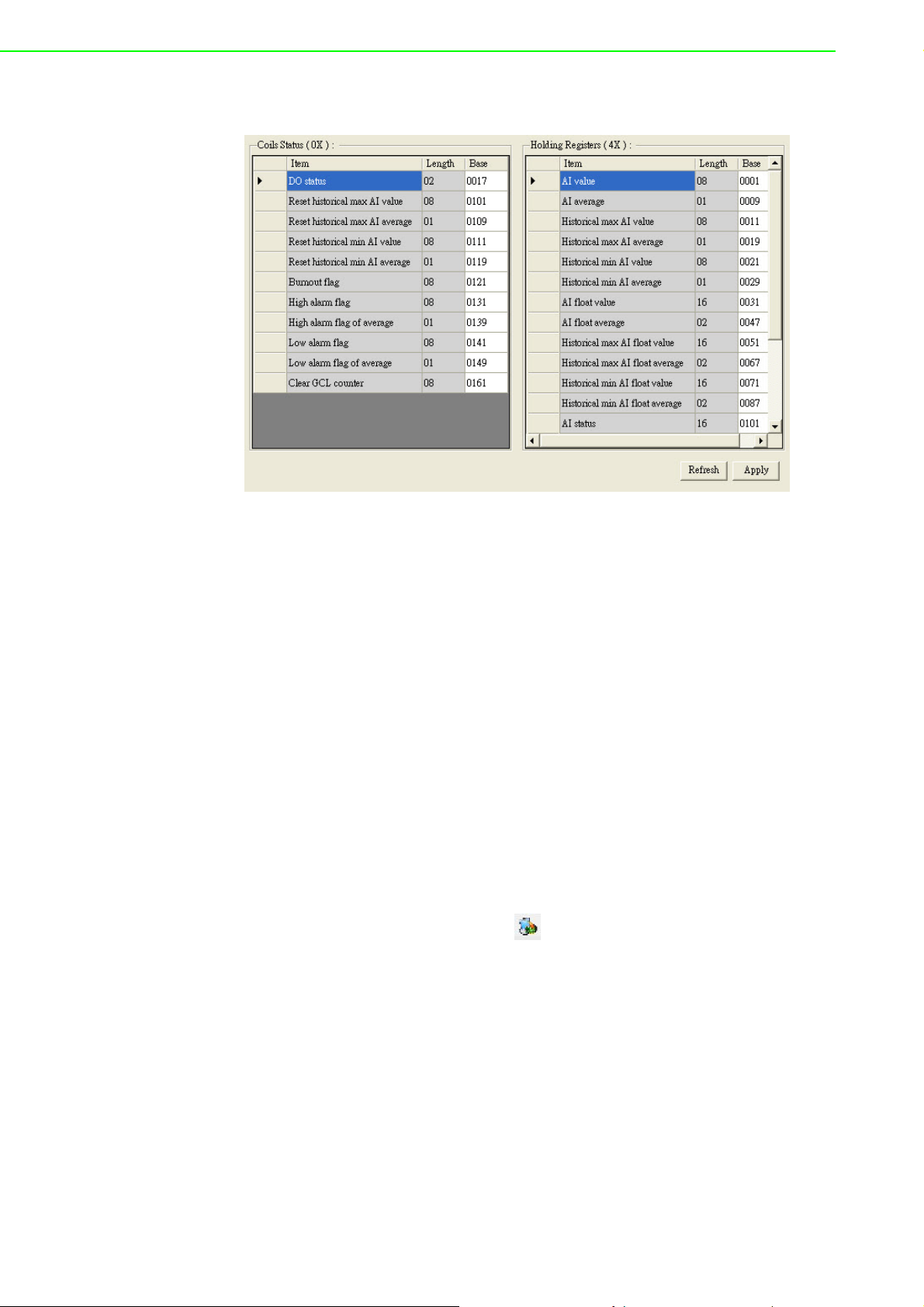

B.2 ADAM-6000 I/O Modbus Mapping Tables ............................................ 193

Appendix C Grounding Reference......................223

C.1 Field Grounding and Shielding Application ........................................... 224

C.1.1 Overview ................................................................................... 224

C.2 Grounding ............................................................................................. 224

C.2.1 The Earth as a Reference......................................................... 224

Figure C.1 Thinking of the Earth as a Ground.......................... 224

C.2.2 Frame Grounds and Grounding Bars........................................ 225

Figure C.2 Grounding Bar ........................................................ 225

Figure C.3 Figure C.3: Normal and Common Mode................. 225

C.2.3 Normal Mode and Common Mode............................................ 225

Figure C.4 Normal and Common Mode ................................... 226

C.2.4 Wire impedance ........................................................................ 226

Figure C.5 High Voltage Transmission.................................... 226

Figure C.6 Wire Impedance ..................................................... 227

C.2.5 Single-Point Grounding............................................................. 227

Figure C.7 Single-Point Grounding .......................................... 227

Figure C.8 Single point grounding ............................................ 227

C.3 Shielding ............................................................................................... 228

C.3.1 Cable Shield.............................................................................. 228

Figure C.9 Single Isolation Cable ............................................. 228

Figure C.10Double Isolation Cable ........................................... 228

C.3.2 System Shielding ...................................................................... 229

ix ADAM-6000 User Manual

Page 10

Figure C.11System Shielding ................................................... 229

Figure C.12The Characteristics of the Cable............................ 229

Figure C.13System Shielding (1).............................................. 230

Figure C.14System Shielding (2).............................................. 230

C.4 Noise Reduction Techniques ................................................................ 230

Figure C.15Noise Reduction Techniques ................................. 231

C.5 Checklist ............................................................................................... 231

Appendix D REST for ADAM-6000...................... 233

D.1 REST Introduction................................................................................. 234

D.2 REST Resources for ADAM.................................................................. 234

D.2.1 Analoginput............................................................................... 234

D.2.2 Analogoutput............................................................................. 235

D.2.3 Digitalinput ................................................................................ 236

D.2.4 Digitaloutput.............................................................................. 237

D.2.5 Counter ..................................................................................... 238

ADAM-6000 User Manual x

Page 11

xi ADAM-6000 User Manual

Page 12

ADAM-6000 User Manual xii

Page 13

Chapter 1

1 Understanding Your

System

Page 14

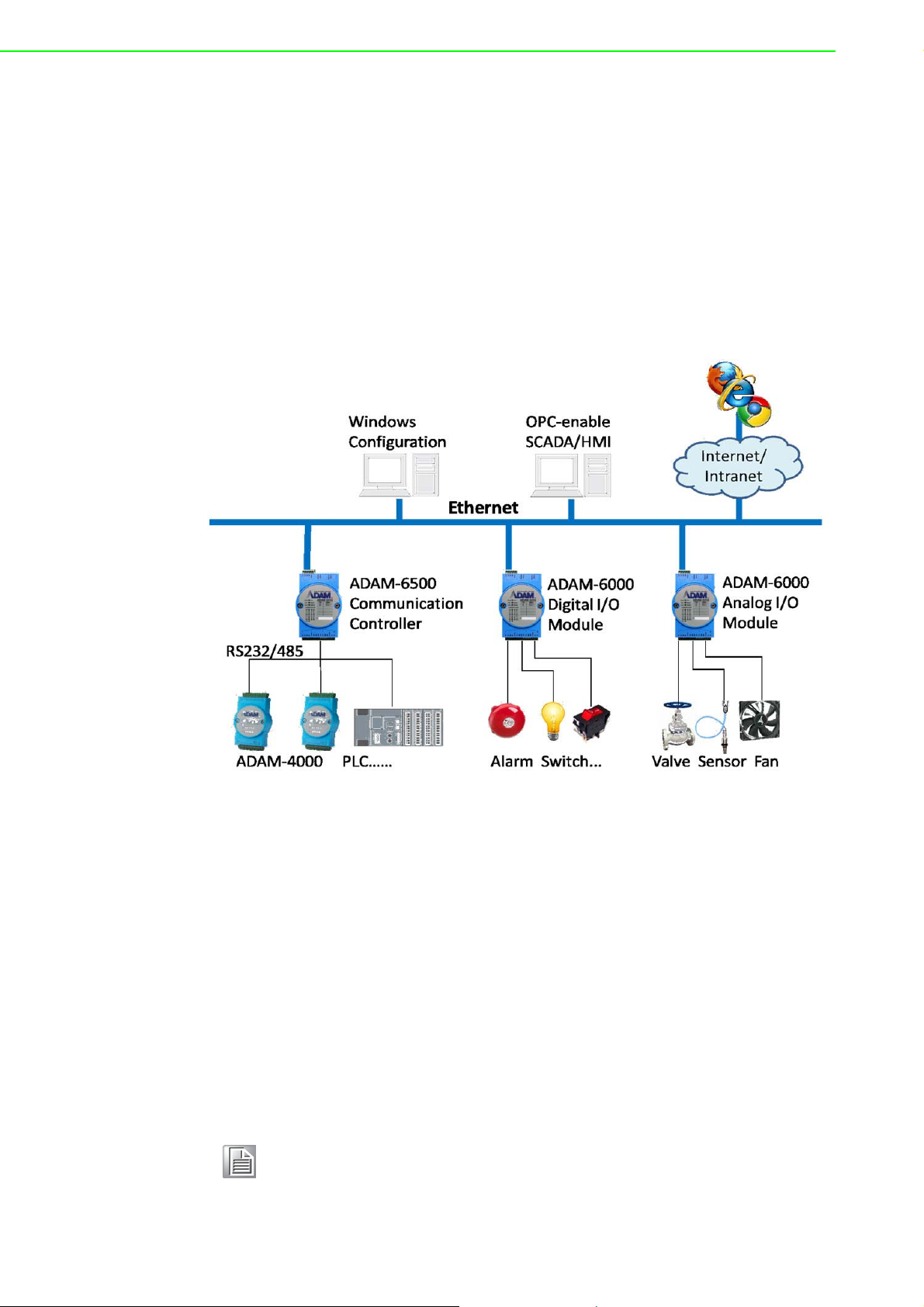

1.1 Introduction

ADAM-6000 series Ethernet-based data acquisition and control (DA&C) modules

provide I/O, data acquisition, and networking capabilities in one module, allowing you

to build a cost-effective distributed monitoring and control solution for a wide variety

of applications. Through a standard Ethernet network, ADAM-6000 modules can

retrieve I/O values from sensors and can publish them as real-time I/O values to networking nodes via LAN, intranet, or the Internet. With Ethernet-enabled technology,

ADAM-6000 modules allow you to build up a cost-effective DA&C system for building

automation, environmental monitoring, facility management, and e-manufacturing

applications. Figure 1-1 gives a brief overview of a system architecture that can be

adopted for ADAM-6000 modules.

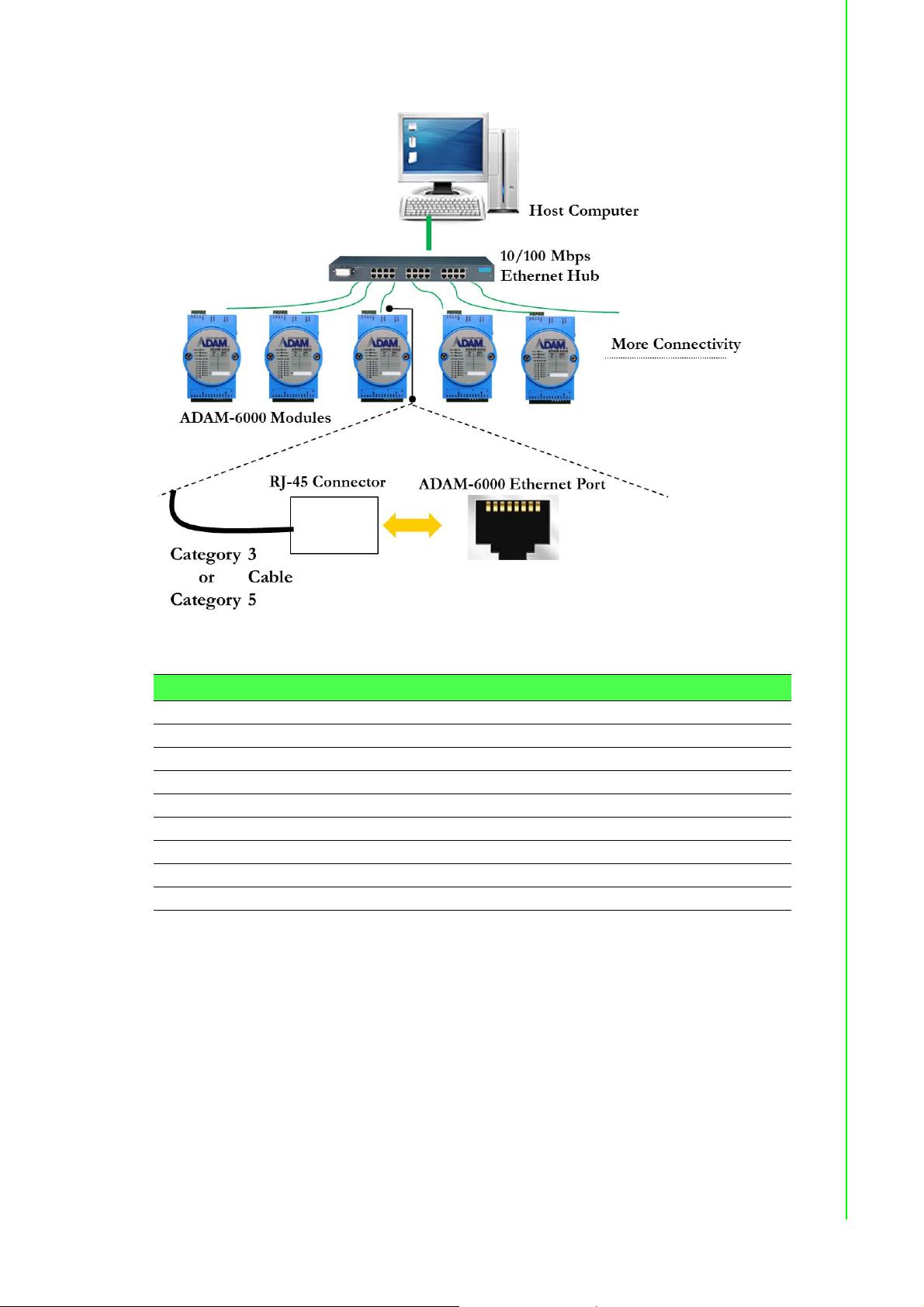

Figure 1.1 ADAM-6000 Module System Architecture

1.2 Major Features

Ethernet-Enabled DA&C I/O Modules

ADAM-6000 modules are based on the widely utilized Ethernet networking standard,

which is employed in most business environments. You can easily add ADAM-6000

series I/O modules to existing Ethernet networks or use them in new Ethernetenabled e-manufacturing networks. This series of modules supports 10/100 Mbps

Ethernet and Modbus/TCP over TCP/IP for data connectivity, and UDP over Ethernet. With UDP/IP, ADAM-6000 series I/O modules can actively transmit data streams

to up to eight Ethernet nodes. Through Ethernet networking, HMI/SCADA systems,

and controllers, you can access and acquire real-time data from ADAM-6000 Ethernet-enabled DA&C modules. The data can then be integrated with business systems

to derive valuable business information.

Note! Some intelligent functions are only provided with the ADAM-6000-CE

version. See Appendix F for further details.

ADAM-6000 User Manual 2

Page 15

Intelligent I/O Modules

Upgraded from traditional I/O modules, all ADAM-6000 series modules have pre-built

intelligent functions that can enhance system capabilities. For example, the digital

input modules provide counter and totalizer functions; the digital output modules provide pulse output and delay output functions; the analog input modules provide

descriptive statistical data calculations (e.g., min., max., and mean); and the analog

output modules provide a PID loop control function.

Mixed I/O for All Applications

The ADAM-6000 series' mixed I/O design provides a cost-effective I/O option for

application systems. The most commonly used I/O types for single-function units are

available in a single module. This design concept not only saves I/O usage as well as

costs, but it also speeds up I/O operations. For small DA&C system or standalone

control units in medium-large systems, the ADAM-6000 series' mixed I/O design can

easily fit your application needs with only one or two modules. With additional

embedded control modules, these modules can be used to easily create a localized,

less complex, and more distributed I/O architecture.

Remote Monitoring and Diagnosis

Previous differences in communication modes and data formats made it difficult to

implement automation control and monitoring in IT-based infrastructure. In particular,

users had to convert data to transform I/O datastreams from SCADA systems before

transfer to a database or IT management system.

ADAM-6000 modules integrate the latest web language (HTML 5) and web-based

architectural style (REST) with basic authentication for users to remotely acquire I/O

data in any smart device web service without routing from the SCADA system. As an

example, a smartphone web browser can now be used to remotely access an I/O

module via HTTP.

Each ADAM-6000 module features a pre-built I/O module web page for displaying

real-time I/O data, alarms, and module status via LAN or the Internet. Using any popular Internet browser, you can perform monitoring from both local and remote sites.

Furthermore, web-enabled monitoring can be completed immediately without requiring any programming.

Chapter 1 Understanding Your System

Modbus/TCP Protocol

ADAM-6000 modules support the widely used industry standard Modbus/TCP protocol, enabling you to connect with any Ethernet controllers or HMI/SCADA software

that supports Modbus/TCP. Advantech also provides an OPC server for Modbus/TCP

so that ADAM-6000 I/O module datastreams can be integrated with OPC clientenabled software, thus freeing you from having to develop new drivers.

Customized Web Page

Since ADAM-6000 modules have a default built-in web page, you can monitor and

control the I/O status from any location by using Internet Explorer. Moreover, customized web pages can be uploaded to ADAM-6000 modules for individual applications.

Advantech provides sample code in JavaScript* as a reference for you to design your

own operator interface and then upload it to the specific ADAM-6000 modules via

Adam/Apax .NET Utility.

Modbus/TCP Software Support

The firmware for ADAM-6000 modules has a built-in Modbus/TCP server. Advantech

provides the ADAM .NET Class Library and Adam/Apax .NET Utility for module con-

3 ADAM-6000 User Manual

Page 16

figuration and customization. You can configure ADAM modules using this utility, and

it can be integrated with any human-machine (HMI) software that supports Modbus/

TCP. You can also purchase Advantech OPC Server to configure the Modbus/TCP

settings.

1.3 Specifications

Ethernet 10/100BASE-T

Wiring UTP (Cat 5 or later)

Bus Connection RJ45 modular jack

Comm. Protocol Modbus/TCP on TCP/IP and UDP

Data Transfer Rate

Status Indicator

Case PC with captive mounting hardware

Screw Terminal Block Accepts wire size #14-28 AWG, stripped length: 6.5 mm

Note! Although the equipment is designed to operate below 30% humidity,

static electricity problems are more common at lower humidity levels.

Ensure you take adequate precautions when handling the equipment.

We recommend using grounding straps, anti-static floor coverings, and

other protection measures if you use the equipment in low-humidity

environments.

Up to 100 Mbps

Unregulated 10 to 30

Power, CPU, Communication

(Link, Collide, 10/100 Mbps, Tx, Rx)

V

DC

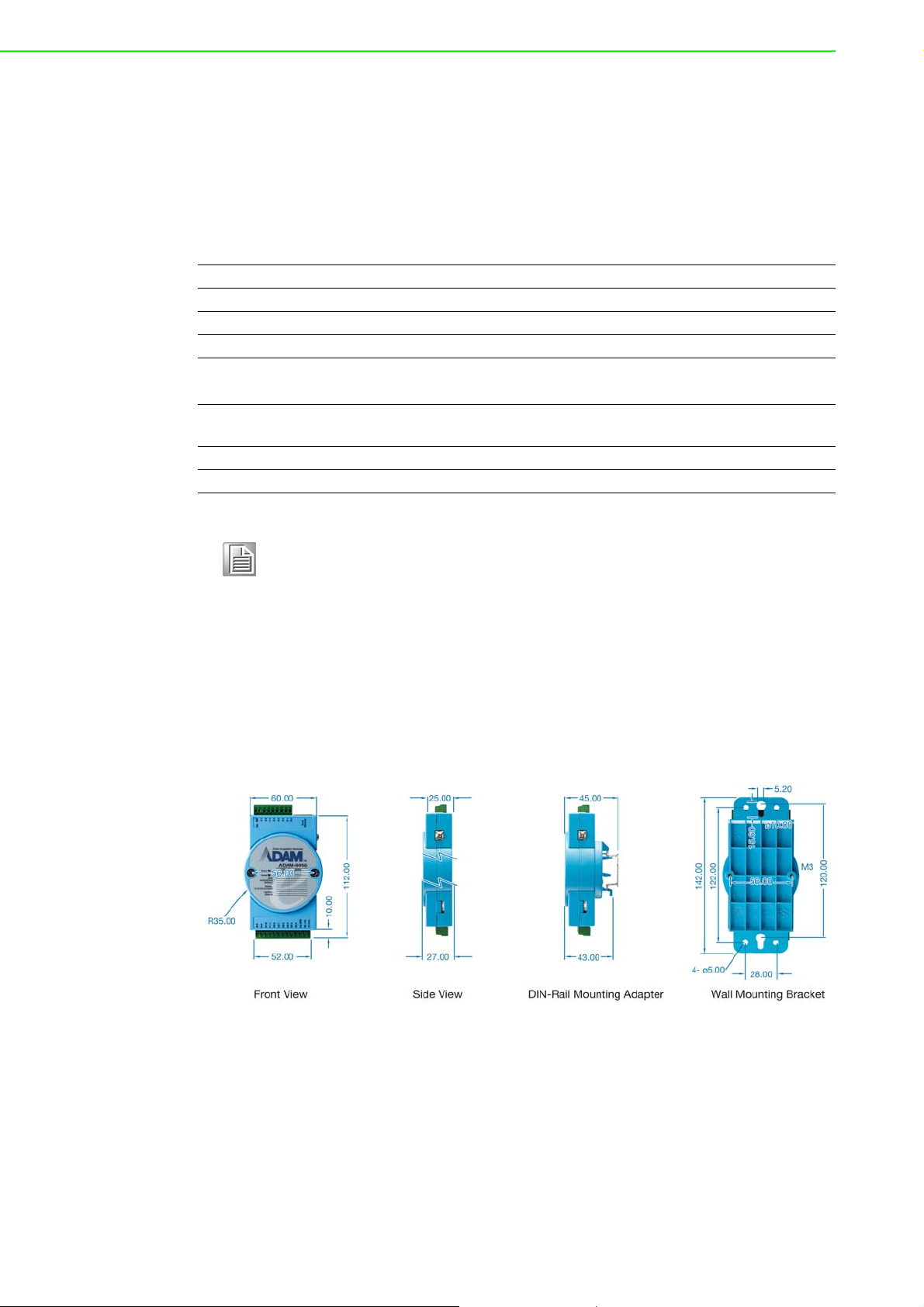

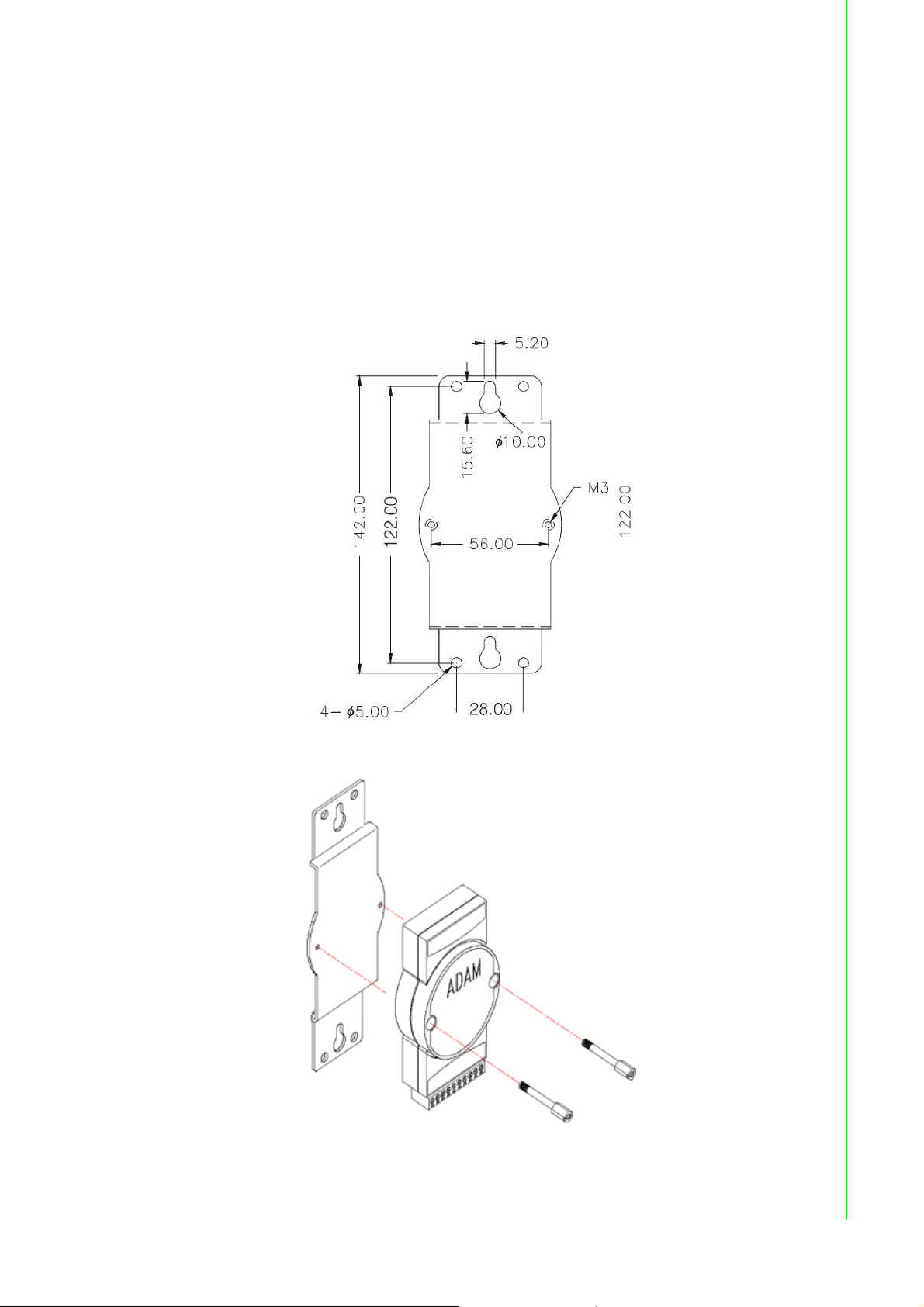

1.4 Dimensions

The following dimensions are given in millimeters. These dimensions are common for

all ADAM-6000 modules.

Figure 1.2 ADAM-6000 Module Dimensions

ADAM-6000 User Manual 4

Page 17

1.5 LED Status

There are two LEDs on the front panel of ADAM-6000 modules. Each LED has two

indicators to represent system status:

Chapter 1 Understanding Your System

LED Color Indication Behavior

Blink Module is normally running

Status

Link Green ON Ethernet is connected

Speed

COM Green Blink

Orange (when Status and

Link are on at the same time)

Orange (when speed and

COM are on at the same

time)

Red

Red ON Ethernet speed is 100 Mbps

ON for 30s

When user enable LOCATE

function

Module is transmitting or

receiving data

5 ADAM-6000 User Manual

Page 18

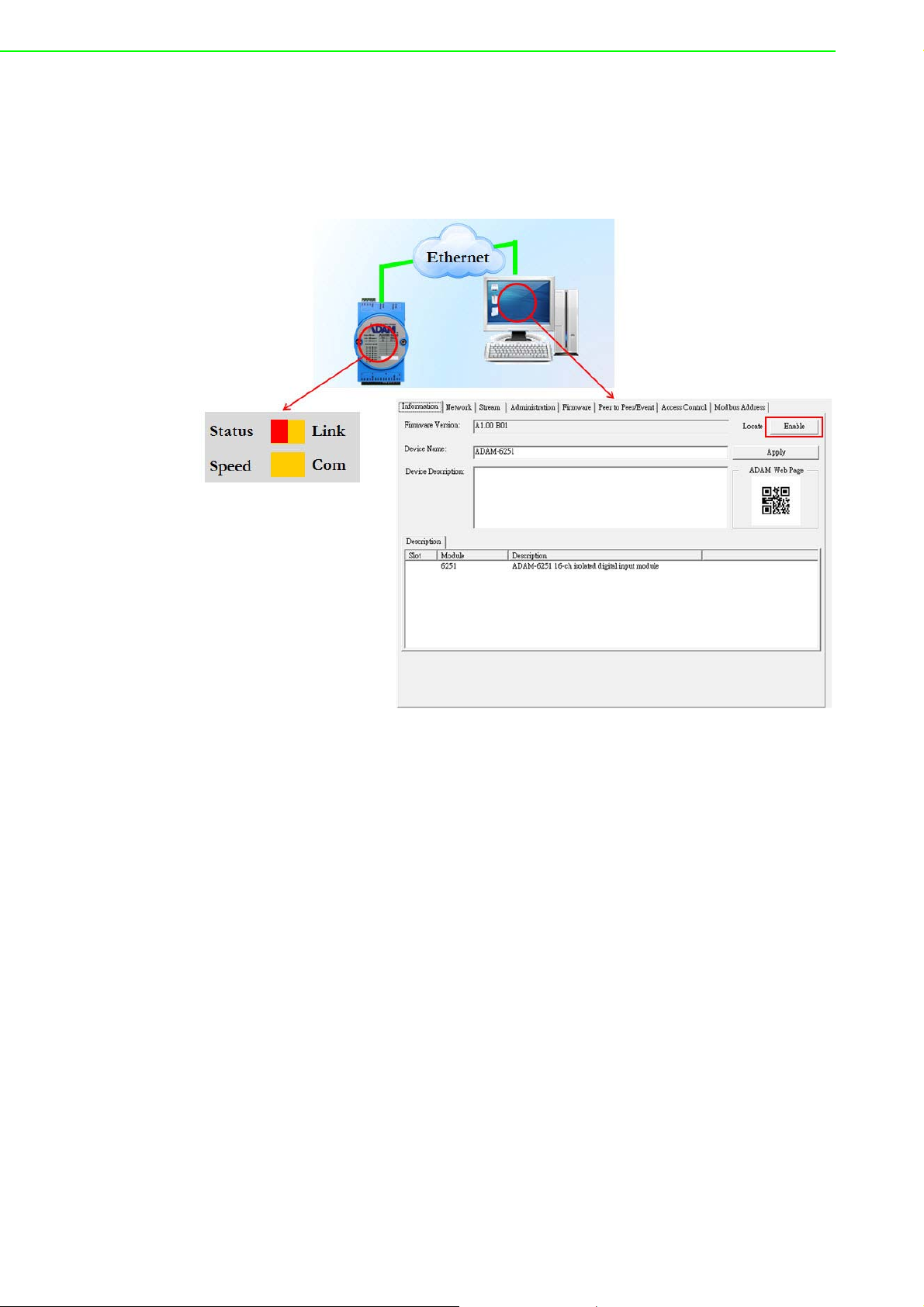

How to Locate Your Module

ADAM-6000 modules also have a locate function to help you physically identify a

specific module that you may be looking for. When this function is enabled, the Status

LED will remain red for 30 s. In Adam/Apax .NET Utility, you can enable the locate

function by clicking Enable in the Information tab.

ADAM-6000 User Manual 6

Page 19

Chapter 2

2 Hardware Selection

Guidelines

Page 20

2.1 Selecting an I/O Module

To organize an ADAM-6000 remote DA&C system, you will need to select I/O modules to act as an interface between the host PC and field devices or sensors. The following should be considered when deciding which I/O modules to select.

What types of I/O signals does your system use?

How many inputs and outputs does your system require?

How many modules are required for distributed I/O point arrangement?

How will you arrange the modules to handle I/O points in individual areas of the

installation site?

How many hubs will you require to connect all of the modules?

What is the required voltage range for each I/O module?

What isolation environment is required for each I/O module?

What are the noise and distance limitations for each I/O module?

Examples of I/O module selection considerations are detailed in Table 2.1.

Table 2.1: I/O Selection Guidelines

Type of I/O

Module

Discrete input

module and

block I/O

module

Discrete output

module and

block I/O

module

Analog input

module

Analog output

module

Example Operations Explanation

Selector switches, push buttons, photoelectric eyes, limit switches, circuit breakers,

proximity switches, level switches, motor

starter contacts, relay contacts, and thumbwheel switches

Alarms, control relays, fans, lights, horns,

valves, motor starters, and solenoids

Thermocouple signals, RTD signals, temperature transducers, pressure transducers,

load cell transducers, humidity transducers,

flow transducers, potentiometers.

Analog valves, actuators, chart recorders,

electric motor drives, analog meters

Input modules sense ON/OFF

or OPENED/CLOSED signals

Output module signals interface with ON/OFF or

OPENED/CLOSED devices

Convert continuous analog

signals into input values for a

host device

Set a host device’s output to

analog signals (generally

through transducers) for field

devices

2.2 Selecting a Link Terminal and Cable

Use an RJ-45 connector to connect the Ethernet port of ADAM-6000 modules to a

hub. The cable employed for the connection should be a Cat 3 (10 Mbps) or Cat 5

(100 Mbps) UTP/STP cable, both of which comply with EIA/TIA 586 specifications.

The maximum length between a hub and any ADAM-6000 module is 100 m (approx.

330 ft).

ADAM-6000 User Manual 8

Page 21

Chapter 2 Hardware Selection Guidelines

Figure 2.1 Connecting ADAM-6000 Modules to an Ethernet Terminal via Cable

Table 2.2: Ethernet RJ-45 Port Pin Assignment Chart

PIN Number Signal Function

1 RD+ Receive (+)

2 RD- Receive (-)

3 TD+ Transmit (+)

4 (Not used) 5 (Not used) 6 TD- Transmit (-)

7 (Not used) 8 (Not used) -

2.3 Selecting an Operator Interface

To complete your DA&C system, it is necessary to select an operator interface. Supporting the Modbus/TCP protocol, ADAM-6000 modules can easily be integrated into

different systems for various applications.

The real-time status of ADAM-6000 modules can be read from a web page using the

following browsers:

Microsoft Internet Explorer (version 9 or later)

Google Chrome (version 30 or later)

Safari (version 6 or later)

Mozilla Firefox (version 25 or later)

9 ADAM-6000 User Manual

Page 22

If you want to integrate ADAM-6000 modules with HMI software in a SCADA system,

HMI software packages that support Modbus/TCP can be used. Examples are as follows:

Advantech PM Designer

Wonderware InTouch

Any software that supports the Modbus/TCP protocol

You can also purchase Advantech OPC Server, a highly user-friendly data exchange

tool. Any HMI software designed with OPC Client can be employed to access ADAM6000 modules.

To develop your own applications, the Adam .NET Class Library is ideal for building

up user interfaces.

With these ready-to-go software packages, tasks such as remote data acquisition,

process control, historical trending, and data analysis require only a few keystrokes

to utilize.

ADAM-6000 User Manual 10

Page 23

Chapter 3

3 Hardware Installation

Guide

Page 24

3.1 Interface Introduction

Package Contents and System Requirements

Prior to installing ADAM-6000 modules, please check the following.

The package should contain the following contents:

ADAM-6000 module with one bracket and DIN-rail adapter

ADAM-6000 module user manual

The minimum specifications for the host computer are listed as follows:

Microsoft Windows XP/7

32 MB RAM

20 MB of hard disk space

VGA color monitor

CD-ROM drive

Mouse or other pointing device

10/100 Mbps Ethernet card

The following equipment will also be required to complete the installation:

Ethernet hub (at least 2 ports)

Two Ethernet cables with an RJ-45 connector

Power supply for the ADAM-6000 module (+10 to 30 V, unregulated)

ADAM-6000 User Manual 12

Page 25

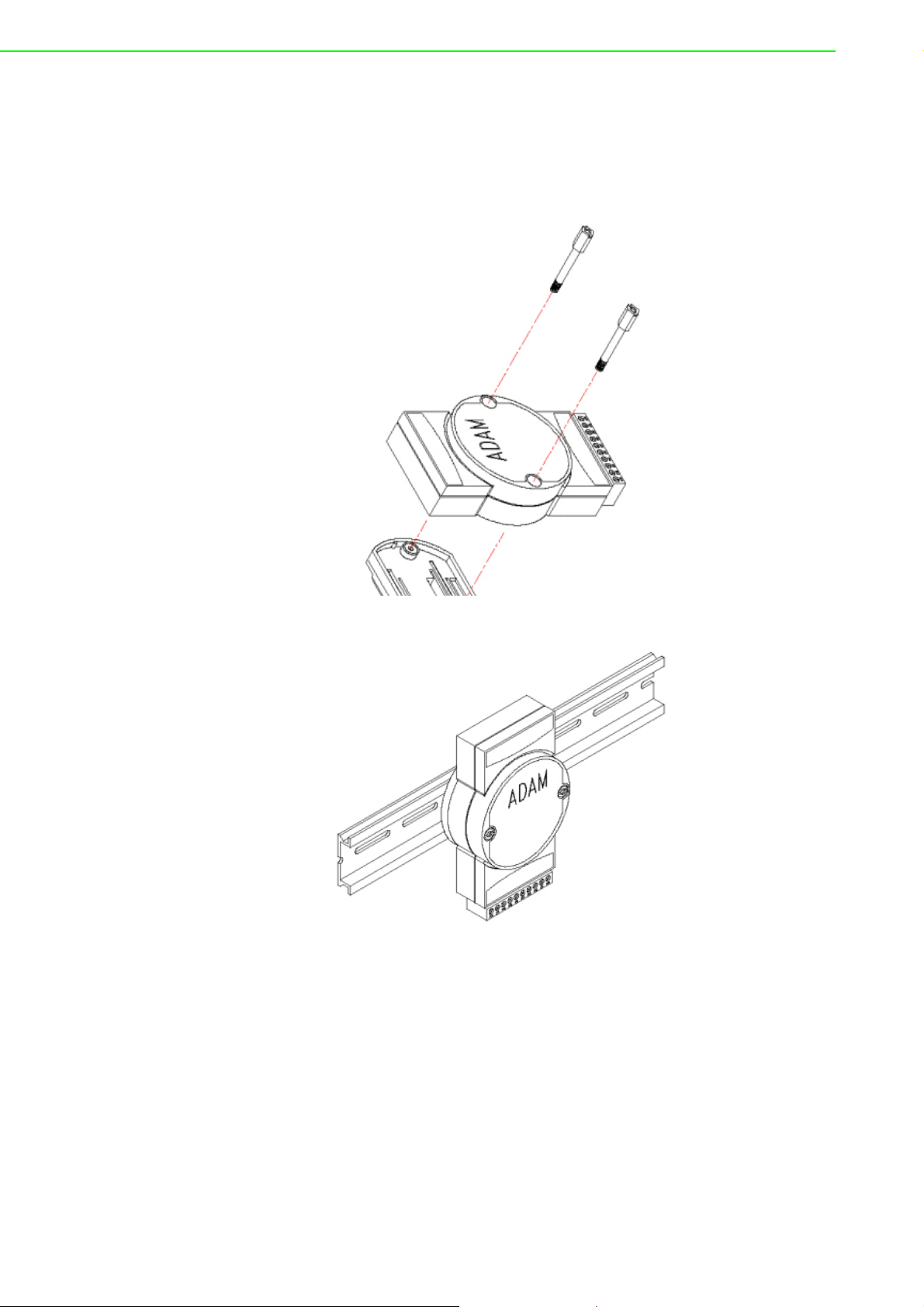

3.2 Mounting Options

ADAM-6000 modules are compact units that can be installed with a panel mounting

bracket or a DIN rail mounting bracket.

3.2.1 Panel Mounting

Before installing the ADAM-6000 module, you should determine the optimal placement in a panel or cabinet by referring the bracket dimensions shown in Figure 3.1.

First, fix the bracket and then fix the ADAM-6000 module on the bracket, as shown in

Figure 3.2.

Chapter 3 Hardware Installation Guide

Figure 3.1 Panel Mounting Bracket Dimensions

Figure 3.2 How to Fix a Module on the Mounting Bracket

13 ADAM-6000 User Manual

Page 26

3.2.2 DIN Rail Mounting

The ADAM-6000 module can also be secured to a cabinet by using DIN rails. First,

fix the ADAM-6000 module to the DIN rail adapter (Figure 3-3) and then secure it on

the DIN rail (Figure 3-4). When mounting the module on the rail, you should consider

using end brackets at each end of the rail in order to prevent the module from sliding.

Figure 3.3 How to Fix a Module on the DIN Rail Adapter

Figure 3.4 How to Secure a Module to a DIN Rail

ADAM-6000 User Manual 14

Page 27

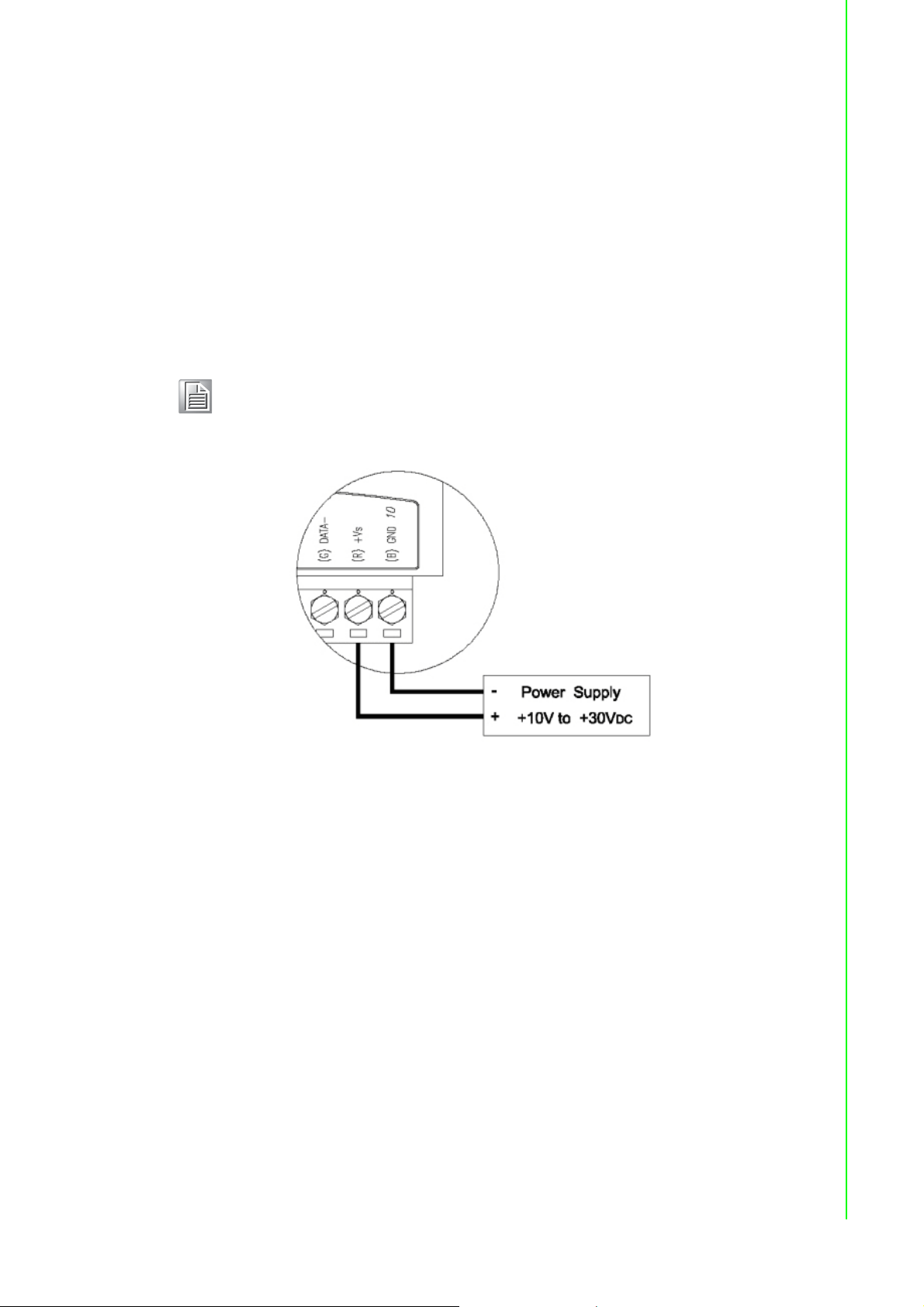

3.3 Wiring and Connections

This section provides basic information on wiring the power supply, I/O units, and network connection.

3.3.1 Power Supply Wiring

Although ADAM-6000/TCP systems are designed for a standard industrial unregulated 24 V

within the range of +10 to 30 V

peak-to-peak, and the immediate ripple voltage should be maintained between +10

and 30 V

Note! The wires should be at least 2 mm in diameter.

power supply, they accept any power unit that supplies input power

DC

. Power supply ripple must be limited to 200 mV

DC

. Screw terminals +Vs and GND are for wiring the power supply.

DC

Chapter 3 Hardware Installation Guide

Figure 3.5 How to Connect the Module Power Wires

We advise using the following standard colors (which are also indicated on the modules) for the power lines:

+Vs (R) Red

GND (B)Black

3.3.2 I/O Module Wiring

A plug-in screw terminal block is used for the interface between I/O modules and field

devices. The following information must be considered when connecting electrical

devices to I/O modules.

The terminal block accepts Wire Size #14~28 AWG (stripped length: 6.5 mm)

Always use a continuous length of wire; do not combine wires

Use the shortest possible wire length

Use wire trays for routing where possible

Avoid running wires near high-energy wiring

Avoid running input wiring proximal to output wiring

Avoid creating sharp bends in the wires

15 ADAM-6000 User Manual

Page 28

ADAM-6000 User Manual 16

Page 29

Chapter 4

4 Introduction to Analog

ADAM-6000 I/O

Modules

Page 30

4.1 Analog Input Modules

Analog input modules use an A/D converter to convert sensor voltage, current, thermocouple, and RTD signals into data, which are then translated into engineering

units. When prompted by the host computer, the data are sent via standard 10/

100BASE-T Ethernet or IEEE 802.11b WLAN. The current status can then be read

using a pre-built webpage or any HMI software that supports Modbus/TCP. Analog

input modules protect your equipment from ground loops and power surges by providing opto-isolation of the A/D input as well as transformer-based isolation.

4.2 ADAM-6015 7-ch Isolated RTD Input Module

The ADAM-6015 is a 16-bit, 7-ch RTD input module with programmable input ranges

on all channels. It accepts various RTD inputs (PT100, PT1000, Balco 500, and Ni),

and data are transmitted to the host computer in engineering units (°C). Each analog

channel can be configured to an independent range, thus allowing individual channels to be used simultaneously in different applications.

4.2.1 Specifications

Communication: 10/100BASE-T Ethernet

Supported protocols: Modbus/TCP,TCP/IP, UDP, HTTP, ICMP, DHCP, and ARP

Supports P2P and GCL (see Section 6.7 and Chapter 8)

High-Speed Mode (DE Version Only)

In high-speed mode, the maximum total sample rate is 1 kHz (i.e., if 7 channels are

used, then the sampling rate will be 1000/7, which is approximately 142 Hz per channel). This will be influenced by the number of connected Modbus clients and the

Ethernet quality. To maximize performance in high-speed mode, any channels that

are not in use should be disabled; otherwise, the accuracy may be affected.

Note! When using a calibrator to simulate resistors in high-speed mode, no

more than one channel should be enabled.

ADAM-6000 User Manual 18

Page 31

/

Analog Input

Channels: 7 (differential)

Input impedance: >10 M

Input connections: 2- or 3-wire

Input types: Pt 100/1000, Balco 500, and Ni 518 RTD

RTD types and temperature range:

– Pt 100: -50~150°C

0~100°C

0~200°C

0~400°C

-200~200°C

IEC RTD 100 ( = 0.0385)

JIS RTD 100 ( = 0.0392)

– Pt 1000: -40~160°C

– Balco 500: -30~120°C

– Ni 518: -80~100°C

0~100°C

Accuracy:

– ±0.1% or better

– ±0.5% or better (high-speed mode)

(measured by 3-wire RTD)

Span drift: ±25 ppm/°C

Zero drift: ±6 mV/°C

Resolution: 16-bit

Sample rate (total):

– 10 Hz

– 1 kHz (high-speed mode; DE version only)

CMR @ 50/60 Hz: 90 dB (not supported in high-speed mode)

NMR @ 50/60 Hz: 60 dB (not supported in high-speed mode)

Wire burnout detection

Overvoltage protection: ±35 V

Built-in TVS/ESD protection

DC

Chapter 4 Introduction to Analog ADAM-6000 I

General

Built-in watchdog timer

Isolation protection: 2000 V

Power input: Unregulated 10~30 V

Power consumption: 2.5 W @ 24 V

Power reversal protection

Operating humidity: 20~95% RH (non-condensing)

Storage humidity: 0~95% RH (non-condensing)

Operating temperature: -10~70°C

Storage temperature: -20~80°C

DC

DC

DC

19 ADAM-6000 User Manual

O Modules

Page 32

4.2.2 Application Wiring

Figure 4.1 ADAM-6015 RTD Input Wiring

4.2.3 Address Assignment

Based on the Modbus/TCP standard, the addresses of ADAM-6000 module I/O

channels in the system are defined by a simple rule. See Appendix B.2.1 for information on mapping the I/O addresses.

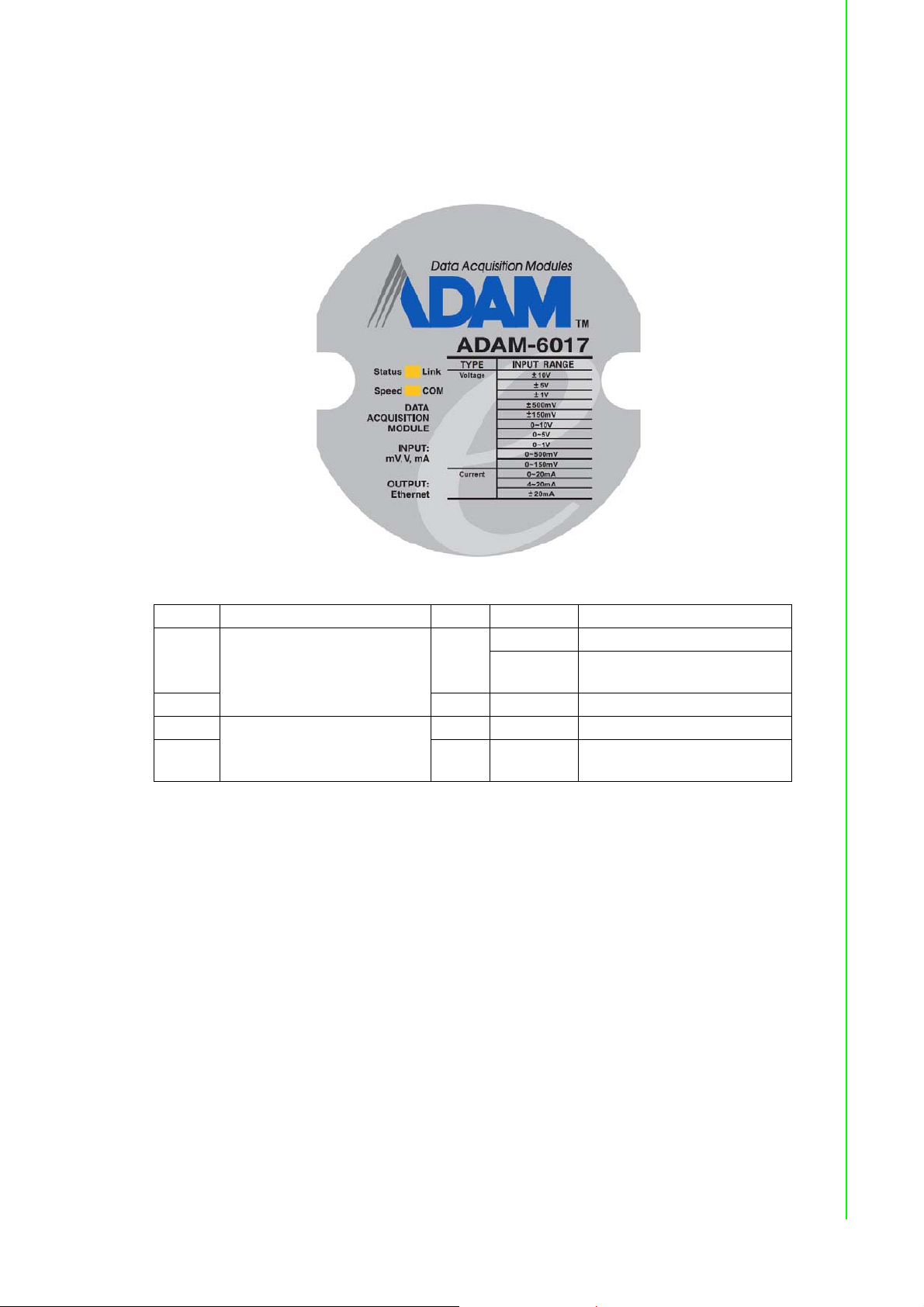

4.3 ADAM-6017 8-ch Analog Input/2-ch Digital

Output Module

The ADAM-6017 is a 16-bit, 8-ch analog differential input module with programmable

input ranges on all channels. The module has been designed with eight analog inputs

and two digital outputs. The accepted input types are millivolt (±150, ±500, 0~150,

0~500 mV), voltage (±1, ±5, ±10, 0~1, 0~5, 0~10 V), and current (0~20, 4~20, ±20

mA) signals, and data are transmitted to the host computer in engineering units (mV,

V, or mA). Each analog channel can be configured to an independent range, thus

allowing individual channels to be used simultaneously in different applications.

4.3.1 Specifications

Communication: 10/100BASE-T Ethernet

Protocols: MQTT, SNMP, Modbus/TCP, TCP/IP, UDP, HTTP, ICMP, DHCP, ARP

Supports P2P and GCL (see Section 6.7 and Chapter 8)

ADAM-6000 User Manual 20

Page 33

/

Analog Input

Channels: 8 (differential)

Input impedance: >10 M (voltage), 120 (current)

Input type: mV, V, mA

Input range: ±150 mV, ±500 mV, ±1 V, ±5 V, ±10 V, 0~150 mV, 0~500 mV, 0~1 V,

0~5 V, 0~10 V, 0~20 mA, 4~20 mA, ±20 mA

Accuracy:

– ±0.1% of FSR (voltage) @ 25°C

– ±0.2% of FSR (current) @ 25°C

Span drift: ±25 ppm/°C

Zero drift: ±6 mV/°C

Resolution: 16-bit

Sample rate (total):

– 10 Hz

– 100 Hz (CE version only)

CMR @ 50/60 Hz: 90 dB

NMR @ 50/60 Hz: 67 dB

Calibration: Auto calibration

Burnout detection (4~20 mA only)

Common-mode voltage: 350 V

DC

Chapter 4 Introduction to Analog ADAM-6000 I

Digital Output

Channels: 2

Sink type: Open collector to 30 V, 100 mA (max. load)

Power dissipation: 300 mW for each module

Output-delay on: 100 µs

Output-delay off: 150 µs

Overvoltage protection (max.): 42 V

Overcurrent protection (max.): 2 A

Leakage current: 200 µA (max.) for D version

General

Isolation protection: 2000 V

Power input: 10~30 V

Power consumption: 2.7 W @ 24 V

Power reversal protection

Operating humidity: 20~95% RH (non-condensing)

Storage humidity: 0~95% RH (non-condensing)

Operating temp (exclusive of RTC function): -20~70°C (-40~70°C for D version)

Storage temp (exclusive of RTC function): -30~80°C (-40~85°C for D version)

Watchdog timer (system): 1.6 s

RTC (D version only): ISO8601 format

DC

DC

DC

DC

O Modules

Note! The operation/storage temperature for the RTC function is -30~70°C.

21 ADAM-6000 User Manual

Page 34

Jumper Settings

ADAM-6017-CE ADAM-6017-AE&BE

Channel Number Select Jumper Channel Number Select Jumper

CH0 CN3 CH0 JP6

CH1 CN4 CH1 JP7

CH2 CN5 CH2 JP8

CH3 CN6 CH3 JP1

CH4 CN7 CH4 JP2

CH5 CN8 CH5 JP3

CH6 CN9 CH6 JP4

CH7 CN10 CH7 JP5

To simplify the jumper settings, for the ADAM-6017 (D version), you can set the analog input type to voltage or current by adjusting the switch without opening the case.

Figure 4.2 ADAM-6017 Jumper Switches

Switch SW1 SW2

Analog input channel CH0 CH1 CH2 CH3 CH4 CH5 CH6 CH7

Switch ON Current input mode

Switch OFF (default) Voltage input mode

Note! Using tools wider than 0.65 mm to adjust the switch will result in damage

to the switch.

ADAM-6000 User Manual 22

Page 35

/

4.3.2 Application Wiring

Figure 4.3 ADAM-6017 Analog Input Wiring

The ADAM-6017 has a 120- resistor built in to each channel; thus, no additional

resistors need to be added for current input measurements. Simply adjust the jumper

setting according to the input type you require. Figure 4.3 shows the jumpers for setting the inputs to voltage mode or current mode.

Chapter 4 Introduction to Analog ADAM-6000 I

O Modules

Figure 4.4 ADAM-6017 Analog Input Type Setting

Figure 4.5 ADAM-6017 Digital Output Wiring

23 ADAM-6000 User Manual

Page 36

4.3.3 Address Assignment

Based on the Modbus/TCP standard, the addresses of ADAM-6000 I/O channels you

place in the system are defined by a simple rule. See Appendix B.2.2 for information

on mapping the I/O addresses.

4.4 ADAM-6018 Isolated Thermocouple Input/8-ch

Digital Output Module

The ADAM-6018 is a 16-bit, 8-ch thermocouple input module with programmable

input ranges on all channels. The module has eight thermocouple inputs (Types J, K,

T, E, R, S, and B) and eight digital outputs. Each input can be configured to an independent range, thus allowing individual channels to be used simultaneously in different applications.

Figure 4.6 ADAM-6018 8-ch Thermocouple Input

4.4.1 Specifications

Communication: 10/100BASE-T Ethernet

Supported protocols: Modbus/TCP, TCP/IP, UDP, HTTP, ICMP, DHCP, and ARP

Supports P2P and GCL (see Section 6.7 and Chapter 8)

ADAM-6000 User Manual 24

Page 37

/

Analog Input

Channels: 8 (differential)

Input impedance: >10 M

Input type: Thermocouple

Thermocouple type and range:

– Type J: 0~760°C

– Type K: 0~1370°C

– Type T: -100~400°C

– Type E: 0~1000°C

– Type R: 500~1750°C

– Type S: 500~1750°C

– Type B: 500~1800°C

Accuracy: ±0.1% or better

Span drift: ±25 ppm/°C

Zero drift: ±6 mV/°C

Resolution: 16-bit

Sample rate: 10 Hz

CMR @ 50/60 Hz: 90 dB

NMR @ 50/60 Hz: 60 dB

Overvoltage protection ±35 V

Built-in TVS/ESD protection

Wire burnout detection

Chapter 4 Introduction to Analog ADAM-6000 I

DC

Digital Output

Channels: 8

Sink type: Open collector to 30 V, 100 mA (max. load)

Power dissipation: 300 mW for each module

General

Built-in watchdog timer

Isolation protection: 2000 V

Power input: Unregulated 10~30 V

Power consumption: 2 W @ 24 V

Power reversal protection

Operating humidity: 20~95% RH (non-condensing)

Storage humidity: 0~95% RH (non-condensing)

Operating temperature: -10~70°C

Storage temperature: -20~80°C

DC

DC

DC

O Modules

25 ADAM-6000 User Manual

Page 38

4.4.2 Application Wiring

Figure 4.7 ADAM-6018 Thermocouple Input Wiring

Figure 4.8 ADAM-6018 Digital Output Wiring

4.4.3 Address Assignment

Based on the Modbus/TCP standard, the addresses of ADAM-6000 I/O channels you

place in the system are defined by a simple rule. See Appendix B.2.3 for information

on mapping the I/O addresses.

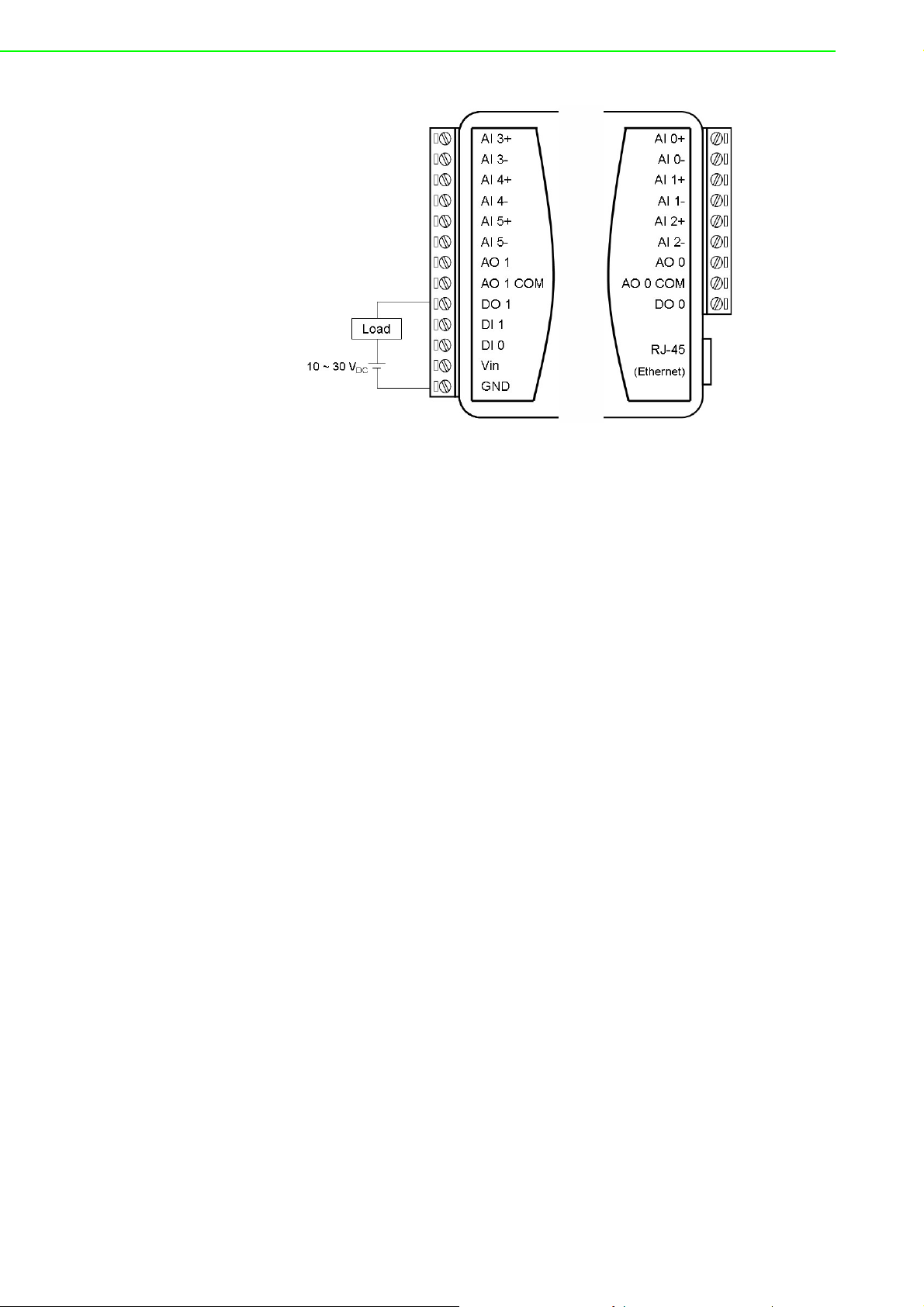

4.5 ADAM-6024 12-ch Isolated Universal I/O Module

The ADAM-6024 is a 12-ch universal I/O module with programmable input ranges on

all channels. The module has six analog inputs, two analog outputs, two digital

inputs, and two digital outputs. The analog input channels are 16-bit universal signal

ADAM-6000 User Manual 26

Page 39

/

inputs, accepting voltage (±10 V) and current (0~20, 4~20 mA) signals. The analog

output channels are 12-bit outputs for volts (0~10 V) and current (0~20 mA, 4~20

mA). Each analog channel can be configured to an independent range, thus allowing

individual channels to be used simultaneously in different applications.

4.5.1 Specifications

Communication: 10/100BASE-T Ethernet

Supported protocols: Modbus/TCP,TCP/IP, UDP, HTTP, ICMP, DHCP and ARP

Receives data from other modules that support P2P and GCL functionality, and

generates analog output signals (see Section 6.7 and Chapter 8 for more detail

about P2P and GCL)

Analog Input

Channels: 6 (differential)

Range: ±10 V

Input impedance: >10 M

Accuracy: ±0.1% of FSR

Resolution: 16-bit

CMR @ 50/60 Hz: 90 dB

NMR @ 50/60 Hz: 60 dB

Span drift: ±25 ppm/°C

Zero drift: ±6 mV/°C

Isolation protection: 2000 V

, 0~20 mA, 4~20 mA

DC

DC

Chapter 4 Introduction to Analog ADAM-6000 I

Analog Output

Channels: 2

Range: 0~10 V

Accuracy: ±0.1% of FSR

Resolution: 12-bit

Current load resistor: 500 (max.)

Voltage load resistor: 1 k (min.)

Isolation protection: 2000 V

Drift: ±50 ppm/°C

Digital Input

Channels: 2

Dry contact:

– Logic level 0: close to GND

– Logic level 1: open

Wet contact:

– Logic level 0: 0~3 V

– Logic level 1: 10~30 V

, 0~20 mA, 4~20 mA

DC

DC

DC

DC

O Modules

Digital Output

Channels: 2

Sink type: Open collector to 30 V, 100 mA (max.)

Power dissipation: 300 mW for each module

27 ADAM-6000 User Manual

Page 40

General

Built-in watchdog timer

Isolation protection: 2000 V

Power input: Unregulated 10~30 V

Power consumption: 4 W @ 24 V

DC

DC

DC

Power reversal protection

Operating humidity: 20~95% RH (non-condensing)

Storage humidity: 0~95% RH (non-condensing)

Operating temperature: -10~50°C

Storage temperature: -20~80°C

Jumper Settings

Channel Jumper Current Voltage

AI0 J1 I V

AI1 J2 I V

AI2 J3 I V

AI3 J4 I V

AI4 J5 I V

AI5 J6 I V

AO0 J7 I V

J8 I V

AO1 J9 I V

J10 I V

Figure 4.9 ADAM-6024 Jumper Settings

ADAM-6000 User Manual 28

Page 41

/

4.5.2 Application Wiring

Figure 4.10 ADAM-6024 Analog I/O Wiring

Chapter 4 Introduction to Analog ADAM-6000 I

Figure 4.11 ADAM-6024 Digital Input Wiring

29 ADAM-6000 User Manual

O Modules

Page 42

Figure 4.12 ADAM-6024 Digital Output Wiring

4.5.3 Address Assignment

Based on the Modbus/TCP standard, the addresses of ADAM-6000 I/O channels you

place in the system are defined by a simple rule. See Appendix B.2.4 for information

on mapping the I/O addresses.

ADAM-6000 User Manual 30

Page 43

Chapter 5

5 Introduction to Digital

ADAM-6000 I/O

Modules

Page 44

5.1 Digital I/O and Relay Modules

Digital I/O modules can be connected to digital sensors and actuators. These modules support both dry and wet contact for different applications. Relays, on the other

hand, are electrically operated switches. Relay modules are typically employed to

control a circuit by using a low-power signal. When prompted by the host computer,

data are sent through a standard 10/100BASE-T Ethernet or IEEE 802.11b WLAN.

You can read/set the digital I/O status via a pre-built web page or HMI software that

supports the Modbus/TCP protocol.

5.2 ADAM-6050 18-ch Isolated Digital I/O Module

The ADAM-6050 is a high-density I/O module with a built-in 10/100BASE-T interface

for seamless Ethernet connectivity. The module has 12 digital inputs and 6 digital outputs with 2000 V

important signal handling, and they can be used as 3-kHz counter and frequency

input channels. The outputs support pulse output.

5.2.1 Specifications

Communication: 10/100BASE-T Ethernet

Supported protocols: MQTT, SNMP, Modbus/TCP, TCP/IP, UDP, HTTP, ICMP,

DHCP, and ARP

Supports P2P and GCL (see Section 6.7 and Chapter 8)

isolation protection. All inputs have a latch function for handling

DC

Digital Input

Channels: 12

Dry contact:

– Logic level 0: Close to GND

– Logic level 1: Open

Wet contact:

– Logic level 0: 0~3 V

– Logic level 1: 10~30 V

Supports 3-kHz counter input (32-bit with overflow flag)

Frequency input range: 0.2~3 kHz

Supports inverted digital input status

Digital Output

Channels: 6

Sink type: Open collector to 30 V, 100 mA (max. load)

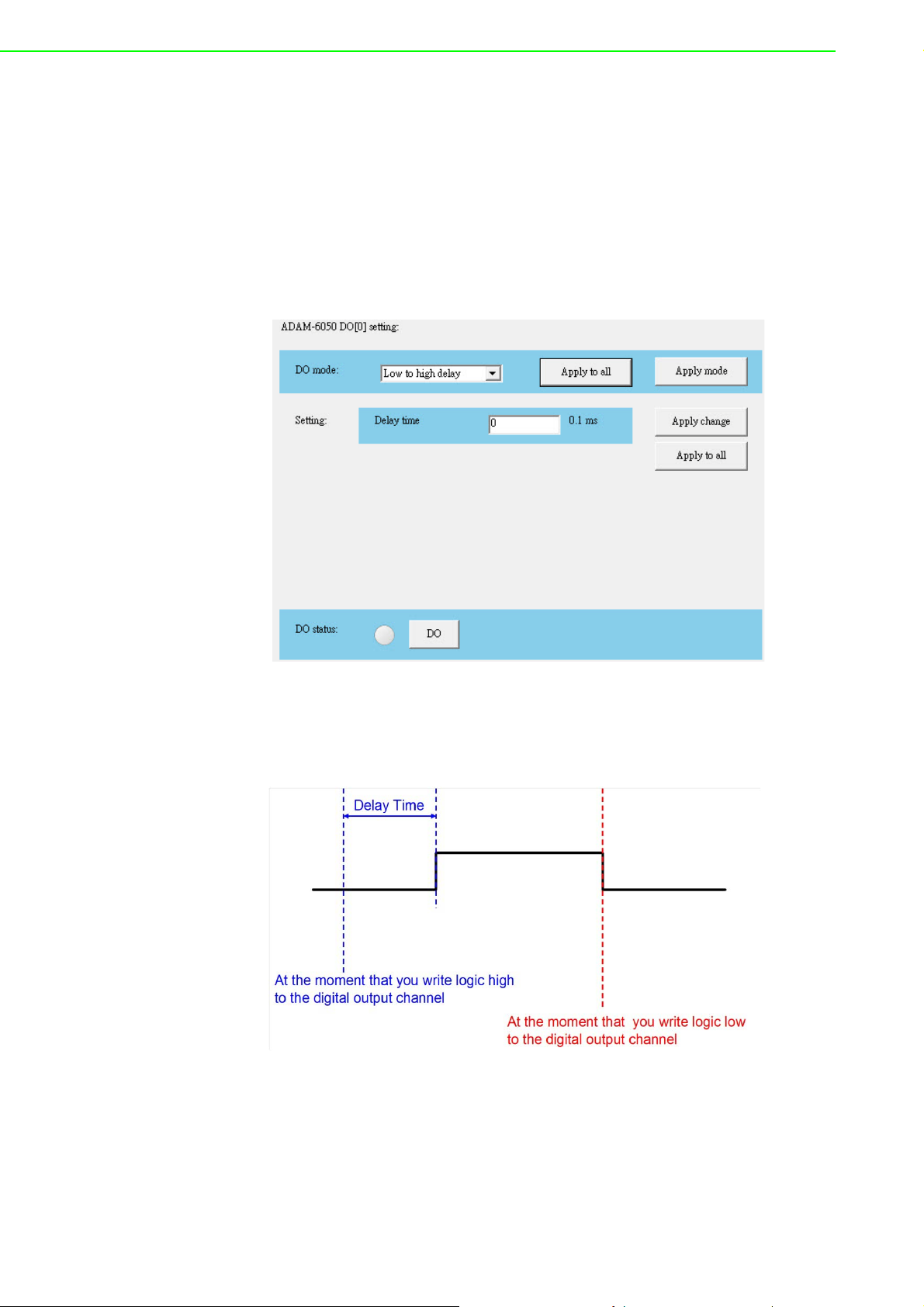

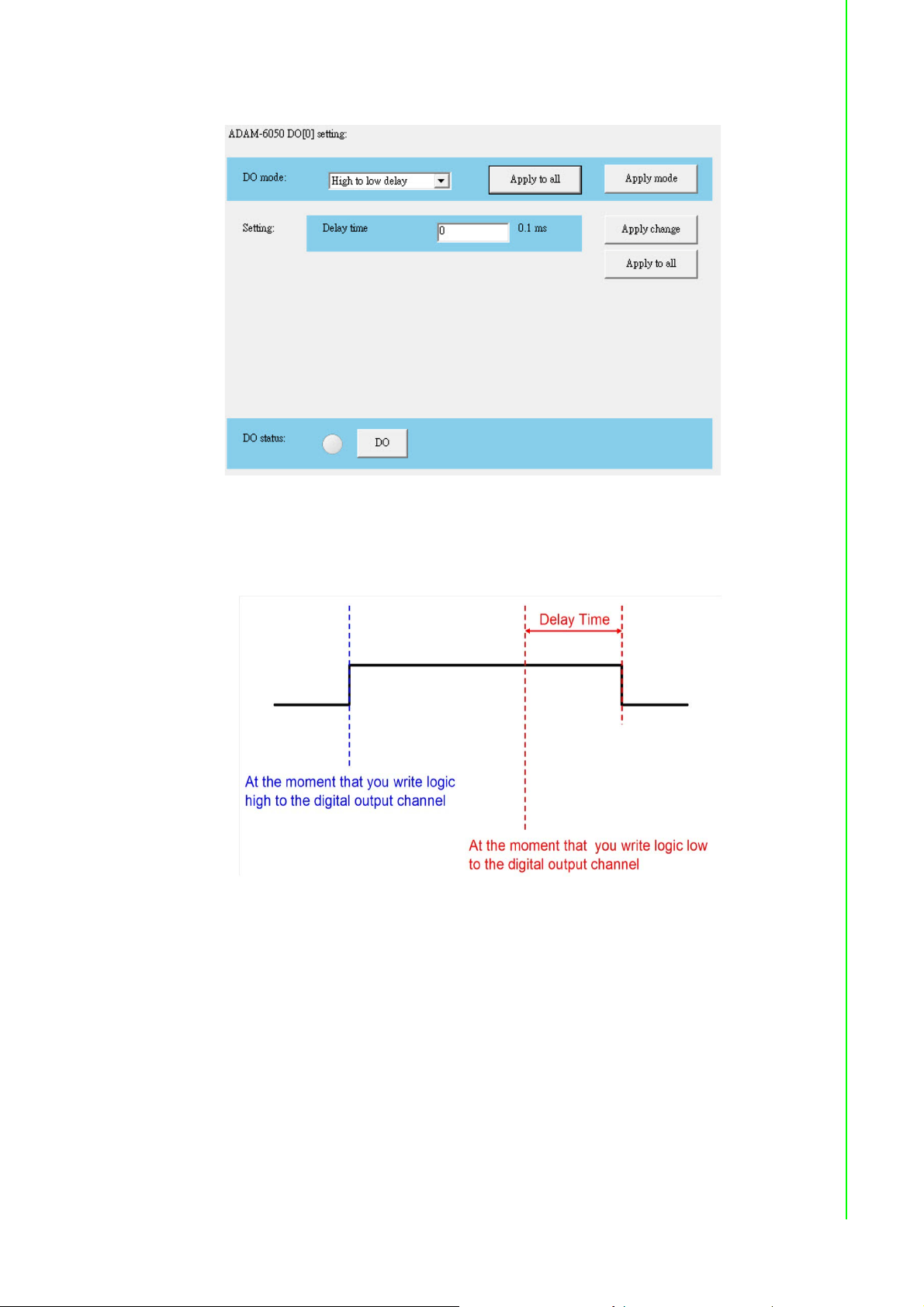

Supports 5-kHz pulse output

Supports high-to-low and low-to-high delay output

Leakage current: 200 A (max.) (D version)

DC

DC

ADAM-6000 User Manual 32

Page 45

/

General

Built-in watchdog timer

Isolation protection: 2000 V

Power input: Unregulated 10~30 V

Power consumption: 2 W (max.) @ 24 V

Power reversal protection

Operating humidity: 20~95% RH (non-condensing)

Storage humidity: 0~95% RH (non-condensing)

Operating temperature: -20~70°C (D version: -40~70°C)

Storage temperature: -30~80°C (D version: -40~85°C)

5.2.2 Application Wiring

Chapter 5 Introduction to Digital ADAM-6000 I

DC

DC

DC

Figure 5.1 ADAM-6050 Digital Input Wiring

O Modules

Figure 5.2 ADAM-6050 Digital Output Wiring

33 ADAM-6000 User Manual

Page 46

5.2.3 Address Assignment

Based on the Modbus/TCP standard, the addresses of ADAM-6000 I/O channels you

place in the system are defined by a simple rule. See Appendix B.2.5 for information

on mapping the I/O addresses. All inputs in the ADAM-6050 can be configured to be

used as 32-bit counters (each counter has two addresses: a low word and a high

word) by using Windows Utility (see Section 6.3).

5.3 ADAM-6051 14-ch Isolated Digital I/O Module w/

2-ch Counter

The ADAM-6051 is a high-density digital I/O module with a built-in 10/100BASE-T

interface for seamless Ethernet connectivity. The module has 12 digital inputs, 2

counter channels, and 2 digital outputs with 2000 V

inputs have a latch function for important signal handling and can be used as 3-kHz

counter and frequency input channels. The digital outputs support pulse output.

5.3.1 Specifications

Communication: 10/100BASE-T Ethernet

Supported protocols: MQTT, SNMP, Modbus/TCP, TCP/IP, UDP, HTTP, ICMP,

DHCP, and ARP

Supports P2P and GCL (see Section 6.7 and Chapter 8)

isolation protection. All digital

DC

Digital Input

Channels: 12

Dry contact:

– Logic level 0: Close to GND

– Logic level 1: Open

Wet contact:

– Logic level 0: 0~3 V

– Logic level 1: 10~30 V

Supports 3-kHz counter input (32-bit with overflow flag)

Supports 3-kHz frequency input

Supports inverted digital input status

Counter Input

Channels: 2 (32-bit with overflow flag)

Maximum count: 4,294,967,295

Frequency range:

– 0.2~4500 Hz (frequency mode)

– 0~4500 Hz (counter mode)

DC

DC

Digital Output

Channels: 2

Sink type: Open Collector to 30 V, 100 mA (maximum load)

Supports 5-kHz pulse output

Supports high-to-low and low-to-high delay output

Leakage current: 200 A (D version)

ADAM-6000 User Manual 34

Page 47

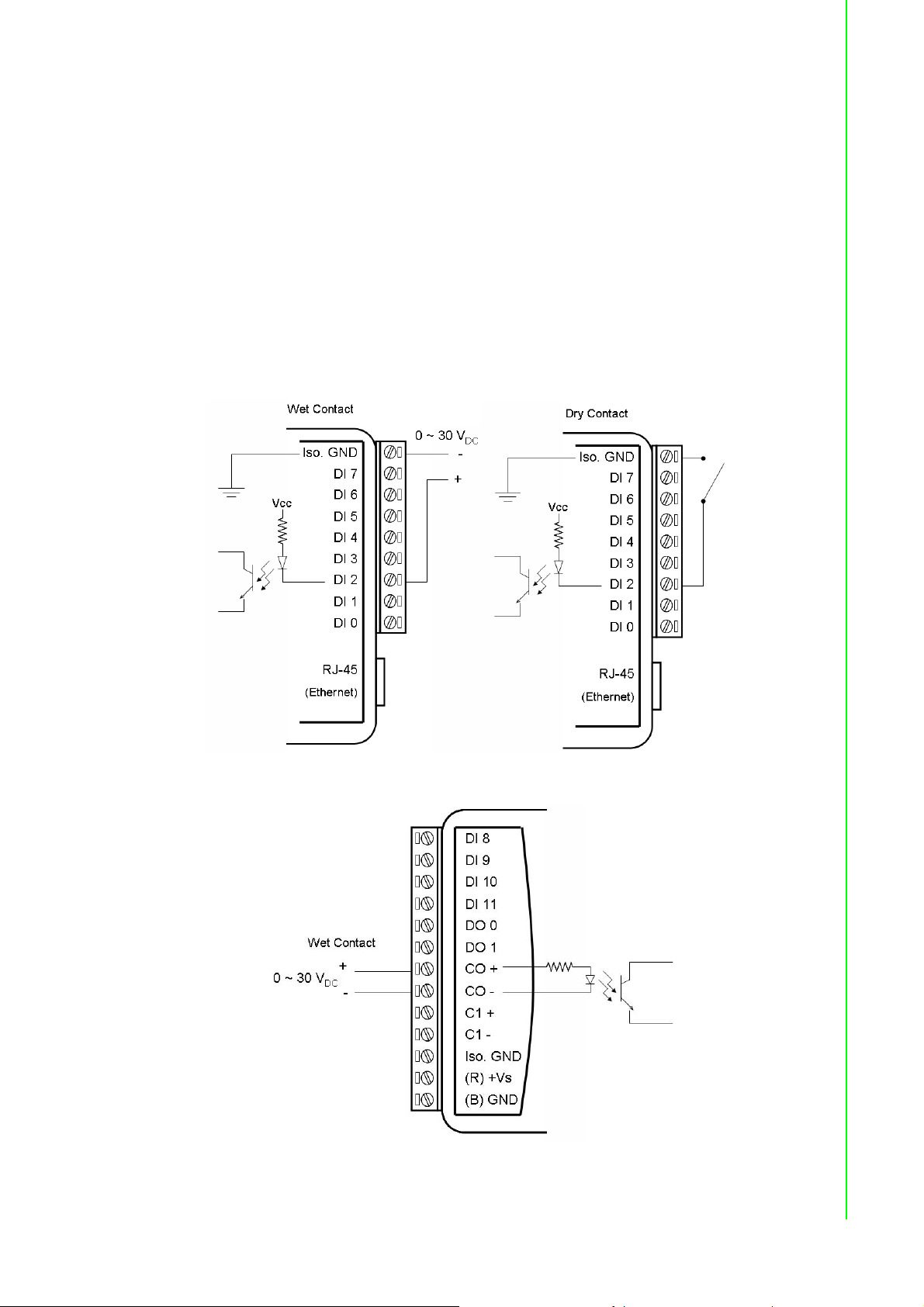

/

General

Built-in watchdog timer

Isolation protection: 2000 V

Power input: Unregulated 10~30 V

Power consumption: 3 W @ 24 V

Power reversal protection

Operating humidity: 20~95% RH (non-condensing)

Storage humidity: 0~95% RH (non-condensing)

Operating temperature: -20~70°C (D version: -40~70°C)

Storage temperature: -30~80°C (D version: -40~85°C)

5.3.2 Application Wiring

Chapter 5 Introduction to Digital ADAM-6000 I

DC

DC

DC

Figure 5.3 ADAM-6051 Digital Input Wiring

O Modules

Figure 5.4 ADAM-6051 Counter (Frequency) Input

35 ADAM-6000 User Manual

Page 48

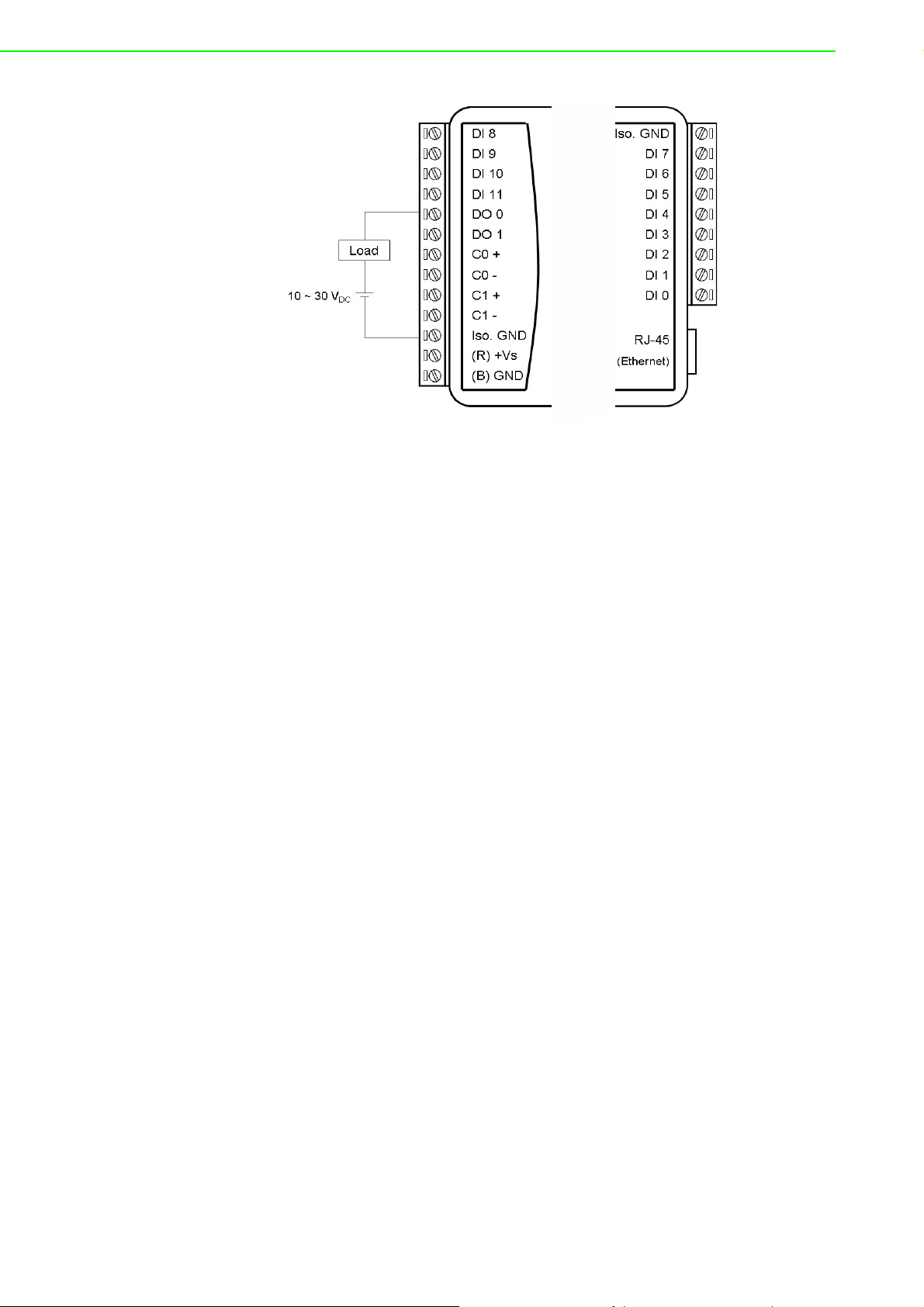

Figure 5.5 ADAM-6051 Digital Output Wiring

5.3.3 Address Assignment

Based on the Modbus/TCP standard, the addresses of ADAM-6000 module I/O

channels you place in the system are defined by a simple rule. Please refer to

Appendix B.2.6 for information on mapping the I/O addresses. All digital inputs in the

ADAM-6051 can be configured to be used as 32-bit counters (each counter has two

addresses: a low word and a high word) by using Windows Utility (see Section 6.3).

5.4 ADAM-6052 16-ch Source-Type Isolated Digital

I/O Module

The ADAM-6052 is a high-density digital I/O module with a built-in 10/100BASE-T

interface for seamless Ethernet connectivity. The module has 8 digital inputs and 8

digital outputs. All inputs have a latch function and can be used as 3-kHz counter and

frequency input channels. The outputs support source-type and pulse output.

5.4.1 Specifications

Communication: 10/100BASE-T Ethernet

Supported protocols: MQTT, SNMP, Modbus/TCP, TCP/IP, UDP, HTTP, ICMP,

DHCP, and ARP

Supports P2P and GCL (see Section 6.7 and Chapter 8)

Digital Input

Channels: 8

Dry contact:

– Logic level 0: Open

– Logic level 1: Close to Ground

Wet contact:

– Logic level 0: 0~3 V

– Logic level 1: 10~30 V

Supports 3-kHz counter input (32-bit with overflow flag)

Supports 3-kHz frequency input

Supports inverted digital input status

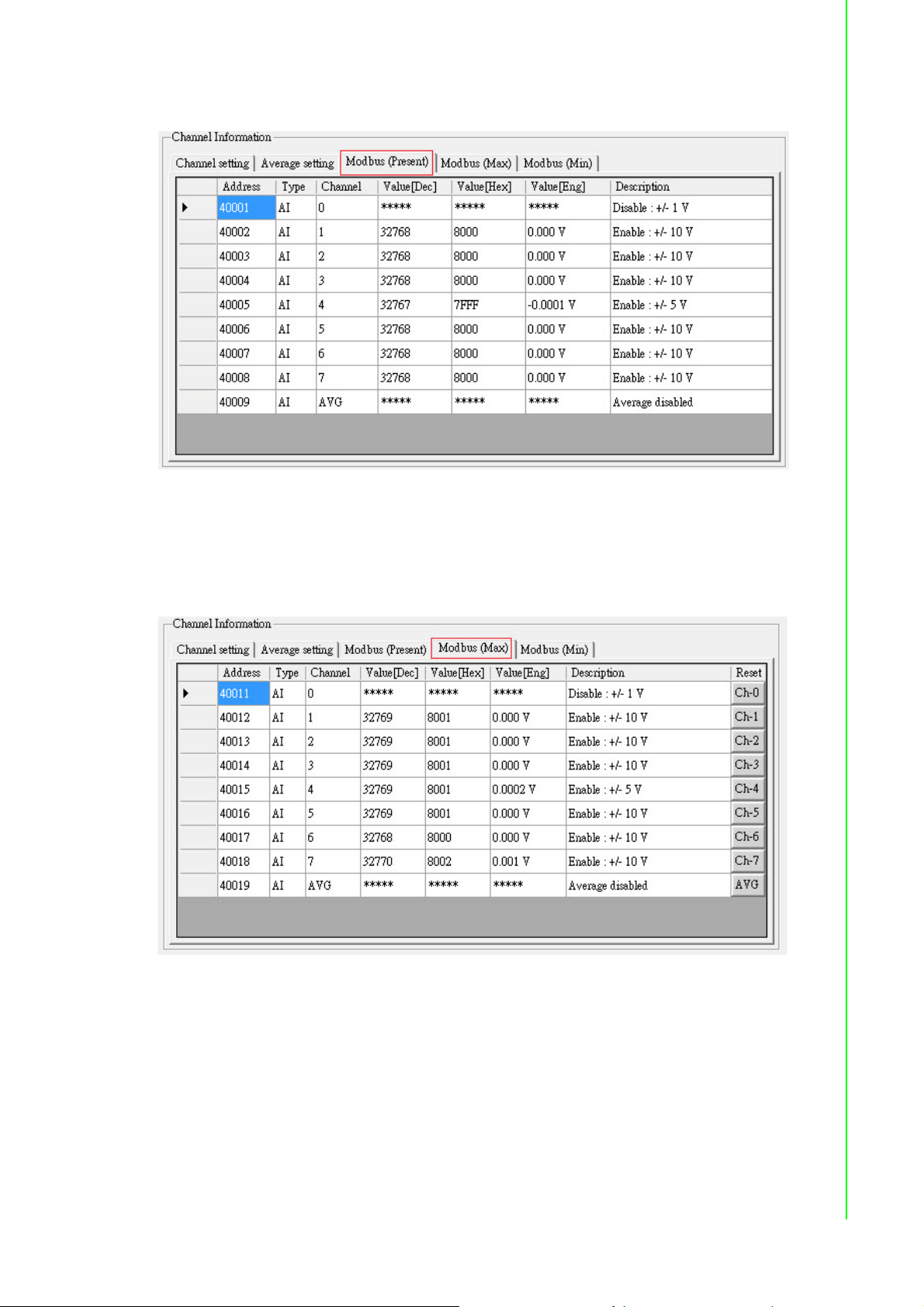

DC

DC

ADAM-6000 User Manual 36

Page 49

/

Digital Output

Channels: 8

Source type: 10~35 V

Note: When operating at 70°C, the maximum total current for DO0~DO3 and

DO4~DO7 is recommended to be less than 3 A

Supports 5-kHz pulse output

Supports high-to-low and low-to-high delay output

General

Built-in watchdog timer

Isolation protection: 2000 V

Power input: Unregulated 10~30 V

Power consumption: 2 W @ 24 V

Power reversal protection

Operating humidity: 20~95% RH (non-condensing)

Storage humidity: 0~95% RH (non-condensing)

Operating temperature: -20~70°C (D version: -40~70°C)

Storage temperature: -30~80°C (D version: -40~85°C)

, 1 A (per channel)

DC

DC

DC

DC

Chapter 5 Introduction to Digital ADAM-6000 I

Jumper Settings

O Modules

Figure 5.6 ADAM-6052 Jumper Settings

37 ADAM-6000 User Manual

Page 50

5.4.2 Application Wiring

The ADAM-6052 supports both dry and wet contact for the inputs. You can change

between dry and wet contact mode by adjusting the jumper.

Figure 5.7 ADAM-6052 Digital Input Wiring

ADAM-6000 User Manual 38

Page 51

/

Figure 5.8 ADAM-6052 Digital Output Wiring

5.4.3 Address Assignment

Based on the Modbus/TCP standard, the addresses of ADAM-6000 module I/O

channels are defined by a simple rule. Please refer to Appendix B.2.7 for information

on mapping the I/O addresses. ADAM-6052 inputs can be configured as 32-bit counters (each counter has two addresses: a low word and high word) by using Adam/

Apax .NET Utility (see Section 6.3).

Chapter 5 Introduction to Digital ADAM-6000 I

5.5 ADAM-6060 6-ch Digital Input/6-ch Relay Module

The ADAM-6060 is a high-density I/O module with a 10/100BASE-T interface. Bonding with an Ethernet port and web page, the module provides 6 digital inputs and 6

relay outputs (Form A) and has a contact rating of 120 V

A. All inputs have a latch for important signal handling and can be used as 3-kHz

counter and frequency input channels. The outputs support pulse output.

5.5.1 Specifications

Communication: 10/100BASE-T Ethernet

Supported protocols: MQTT, SNMP, Modbus/TCP, TCP/IP, UDP, HTTP, ICMP,

DHCP, and ARP

Supports P2P and GCL (see Section 6.7 and Chapter 8)

Digital Input

Channels: 6

Dry contact:

– Logic level 0: Close to GND

– Logic level 1: Open

Wet contact:

– Logic level 0: 0~3 V

– Logic level 1: 10~30 V

Supports 3-kHz counter input (32-bit with overflow flag)

Frequency input range: 0.2 Hz~3 kHz

Support inverted digital input status

Keep/discard counter value when powered off

DC

DC

@ 0.5 A and 30 VDC @ 1

AC

O Modules

39 ADAM-6000 User Manual

Page 52

Relay Output

Channels: 6 (Form A)

Contact rating (Resistive):

– 120 V

– 30 V

Breakdown voltage: 500 V

AC

@ 1 A

DC

@ 0.5 A

(50/60 Hz)

AC

Relay-on time: 7 ms

Relay-off time: 3 ms

Total switching time: 10 ms

Insulation resistance: 1 G (min.) @ 500 V

DC

Maximum switching rate: 20 operations/min (at rated load)

Electrical endurance

– At 12 V/10 mA: 5 x 107 operations (typical)

– At 6 V/100 mA: 1 x 107 operations (typical)

– At 60 V/500 mA: 5 x 105 operations (typical)

– At 30 V/1000 mA: 1 x 106 operations (typical)

– At 30 V/2000 mA: 2 x 105 operations (typical)

Mechanical endurance

– 108 operations (typical)

Supports pulse output (max. 3 Hz)

General

Built-in watchdog timer

Isolation protection: 2000 V

Power input: Unregulated 10~30 V

Power consumption: 3 W (max.) @ 24 V

DC

DC

DC

Power reversal protection

Operating humidity: 20~95% RH (non-condensing)

Storage humidity: 0~95% RH (non-condensing)

Operating temperature: -20~70°C (D version: -40~70°C)

Storage temperature: -30~80° C (D version: -40~85°C)

ADAM-6000 User Manual 40

Page 53

/

5.5.2 Application Wiring

Figure 5.9 ADAM-6060 Digital Input Wiring

Chapter 5 Introduction to Digital ADAM-6000 I

Figure 5.10 ADAM-6060 Relay Output Wiring

5.5.3 Address Assignment

Based on the Modbus/TCP standard, the addresses of ADAM-6000 module I/O

channels you place in the system are defined by a simple rule. Refer to Appendix

B.2.8 for information on mapping the I/O addresses. All inputs in the ADAM-6060 can

be configured to be used as 32-bit counters (each counter consists of two addresses:

a low word and a high word) by using Windows Utility (see Section 6.3).

O Modules

41 ADAM-6000 User Manual

Page 54

5.6 ADAM-6066 6-ch Digital Input/6-ch Power Relay

Module

The ADAM-6066 is a high-density I/O module with a 10/100BASE-T interface for

seamless Ethernet connectivity. It has 6 digital inputs and 6 high-voltage relay outputs (Form A). The module has a contact rating of 250 V

All inputs have a latch function for important signal handling and can be used as 3kHz counter and frequency input channels. The outputs support pulse output.

5.6.1 Specifications:

Communication: 10/100BASE-T Ethernet

Supported protocols: MQTT,SNMP,Modbus/TCP, TCP/IP, UDP, HTTP, ICMP,

DHCP, and ARP Modbus/TCP,SNMP,TCP/IP, UDP, HTTP, ICMP, DHCP and

ARP

Supports P2P and GCL (see Section 6.7 and Chapter 8)

Digital Input

Channels: 6

Dry contact:

– Logic level 0: Close to GND

– Logic level 1: Open

Wet contact:

– Logic level 0: 0~3 V

– Logic level 1: 10~30 V

Supports 3-kHz counter input (32-bit with overflow flag)

Supports 3-kHz frequency input

Supports inverted digital input status

DC

DC

@5A and 30 VDC @ 3 A.

AC

Relay Output

Channels: 6 (Form A)

Contact rating (Resistive):

– 250 V

– 30 V

Breakdown voltage: 500 V

Relay on time: 7 ms

Relay off time: 3 ms

Total switching time: 10 ms

Insulation resistance: 1 G (min.) at 500 V

Maximum switching rate: 20 operations/min (at rated load)

Electrical endurance: 1 x 105 operations

Mechanical endurance

– 2 x 107 operations (typical)

– (Under no load at an operating frequency of 180 operations/min)

Supports pulse output (max. 3 Hz)

AC

@ 3 A

DC

@ 5 A

(50/60 Hz)

AC

DC

ADAM-6000 User Manual 42

Page 55

/

General

Built-in watchdog timer

Isolation protection: 2000 V

Power input: Unregulated 10~30 V

Power consumption: 2.5 W @ 24 V

Power reversal protection

Operating humidity: 20~95% RH (non-condensing)

Storage humidity: 0~95% RH (non-condensing)

Operating temperature: -20~70°C (D version: -40~70°C)

Storage temperature: -30~80°C (D version:-40~85°C)

5.6.2 Application Wiring

Chapter 5 Introduction to Digital ADAM-6000 I

DC

DC

DC

Figure 5.11 ADAM-6066 Digital Input Wiring

O Modules

Figure 5.12 ADAM-6066 Relay Output Wiring

43 ADAM-6000 User Manual

Page 56

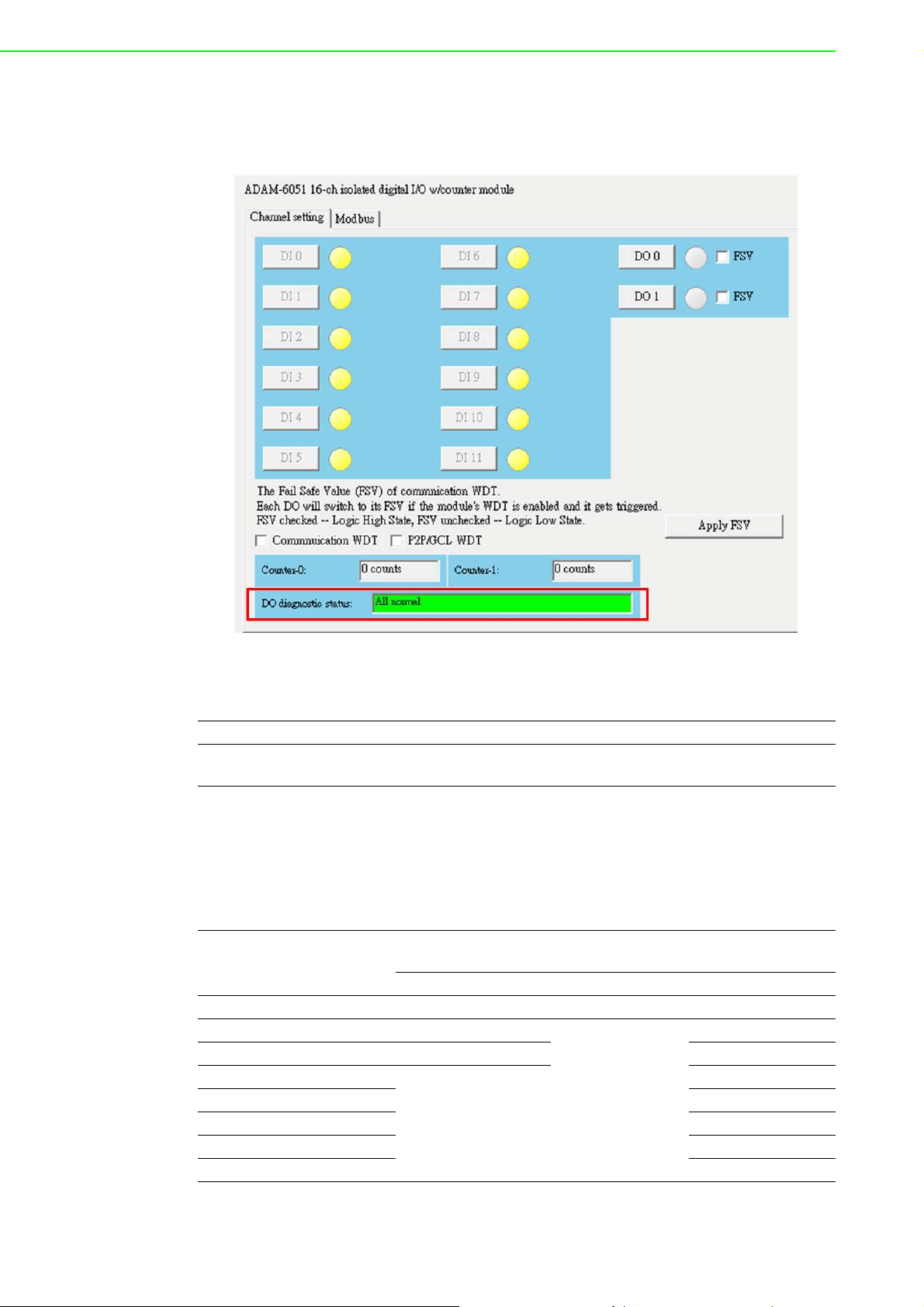

5.7 Digital Output Diagnostic Function

When a digital output is active, a circuit wire break or short to ground will cause the

output to fail. To help clarify such a situation quickly, ADAM-6000 modules (all D versions) have a digital output diagnostic function that can detect abnormalities in the

digital output and issue a notification. The diagnostic status is given according to the

following groups:

Module Diagnostic Group Output Channel

ADAM-6017 Group 0 DO0, DO1

Group 0 DO0, DO1

ADAM-6050

ADAM-6051 Group 0 DO0, DO1

ADAM-6052

Group 1 DO2, DO3

Group 2 DO4, DO5

Group 0 DO0

Group 1 DO1

Group 2 DO2

Group 3 DO3

Group 4 DO4

Group 5 DO5

Group 6 DO6

Group 7 DO7

Note that for the ADAM-6050 and ADAM-6051, each group corresponds to a pair of

digital outputs, whereas for the ADAM-6052, each group corresponds to an individual

channel. When an error occurs with one or both channels in a group, the diagnostic

status for that group will change. Possible reasons for an abnormality are given as

follows.

For the ADAM-6017, ADAM-6050, and ADAM-6051

When the digital output is not active:

The digital output circuit wire break has occurred (open load)

The digital output connection is short to ground

When the digital output is active:

The output has been exposed to an overcurrent (>1 A)