Page 1

INSTRUCTIONS

FOR USE

A-dec SC

AIR COMPRESSOR

Page 2

A-dec SC Air Compressor Instructions for Use

Copyright

© 2021 A-dec, Inc. All rights reserved.

A-dec, Inc. makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability

and tness for a particular purpose. A-dec, Inc. shall not be held liable

for any errors contained herein or any consequential or other damages

concerning the furnishing, performance or use of this material. The

information in this document is subject to change without notice. If you

nd any problems in the documentation, please report them to us in

writing. A-dec, Inc. does not warrant that this document is error-free.

No part of this document may be copied, reproduced, altered, or

transmitted in any form or by any means, electronic or mechanical,

including photocopying, recording, or by any information storage and

retrieval system, without prior written permission from A-dec, Inc.

Trademarks and Additional Intellectual Property Rights

A-dec, the A-dec logo, A-dec Inspire, Cascade, Century Plus, Continental,

Decade, ICX, ICV, Performer, Preference, Preference Collection,

Preference ICC, Radius, and reliablecreativesolutions are trademarks of

A-dec, Inc. and are registered in the United States and other countries.

A-dec 500, A-dec 400, A-dec 300, A-dec 200, and EasyFlex are also

trademarks of A-dec, Inc. None of the trademarks or trade names in this

document may be reproduced, copied, or manipulated in any manner

without the express, written approval of the trademark owner.

Certain touchpad symbols and icons are proprietary to A-dec, Inc. Any

use of these symbols or icons, in whole or in part, without the express

written consent of A-dec, Inc., is strictly prohibited.

Regulatory Information and Warranty

For additional required regulatory information and the A-dec warranty,

see the Regulatory Information, Specications, and Warranty document

p/n

86.0221.00) available in the Resource Center at www.a-dec.com.

(

Intended Use

A dental air compressor is intended to provide air pressure to dental

devices for use during diagnostic and therapeutic treatment by licensed

health care professionals.

Expected Service Life

The Expected Service Life of A-dec compressors is 10 years when

following the recommended maintenance schedule.*

Product Service

Product service is available through your local authorized A-dec dealer.

To locate an authorized dealer, or for additional service information,

visit www.a-dec.com or contact A-dec at 1.800.547.1883 in the USA and

Canada or 1.503.538.7478 worldwide.

Product Models and Versions Covered in This Document

Model Version Description

SC3/SC5

SC7/SC10

SC12

n/a Air Compressor

86.0887.00 Rev A

* Service Life information is provided for general planning purposes only and should not be

relied upon for any reason. Service Life does not include normal service “wear and tear”

components and is separate from the warranty period. There are no implied or explicit

extensions of the warranty period. For complete warranty details, see the Regulatory

Information, Specications, and Warranty document referenced above.

Page 3

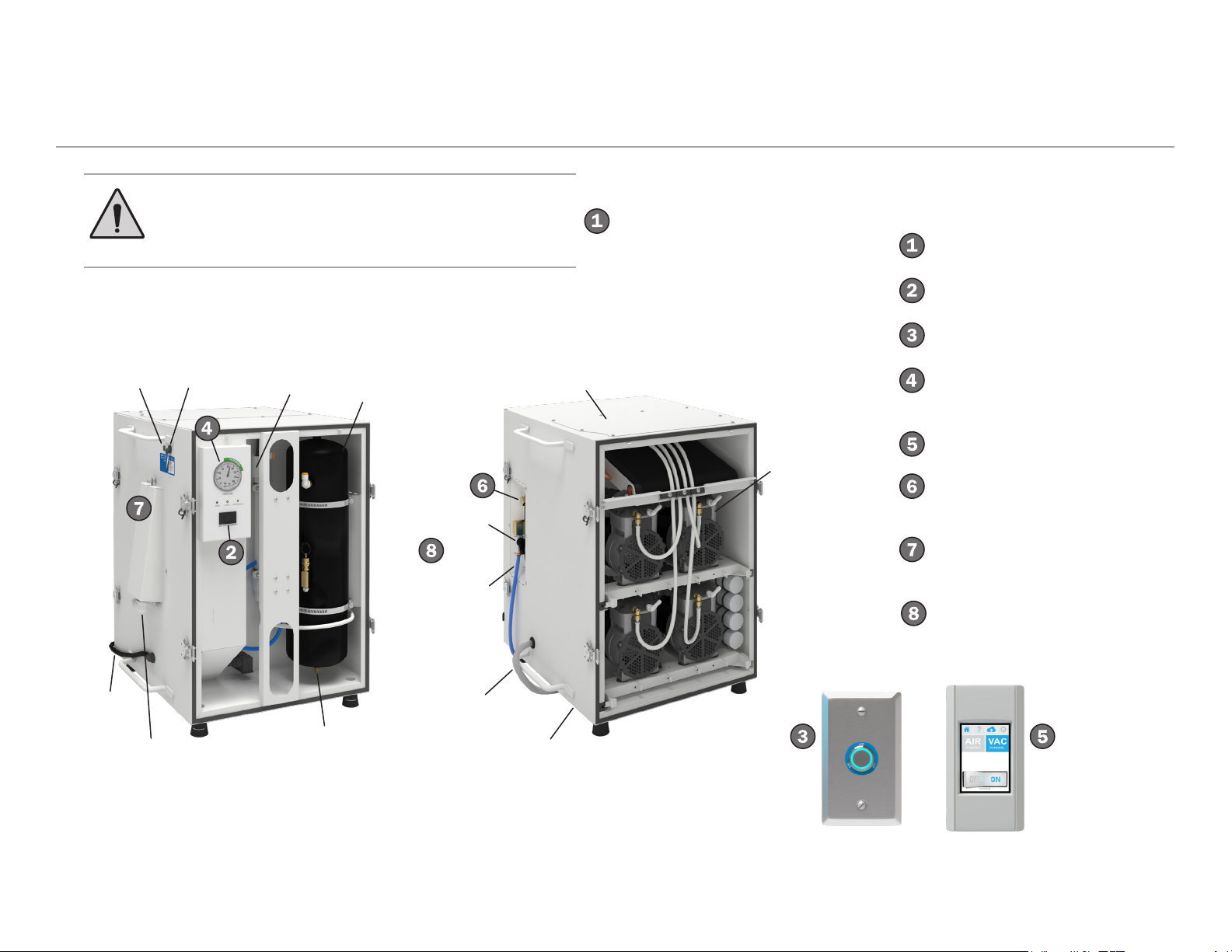

A-dec SC Air Compressor Instructions for Use Content Map

Content Map

Ethernet

Connection

WARNING Do not open or remove the compressor

service panels. These are intended for qualified

service technician access only and are removed from

the systems below for informational purposes only.

Remote

Switch

Connection

Air

Dryer

Air

Tank

Top Plate

Air Shutoff

Valve

Air

Discharge

Hose

Compressor

Pump with

Motor

Features/Topics

Safety Precautions ........................ 2

Master Power Switch ....................4

LED Push-Button Controls ............ 4

Control Panel/Pressure Gauge/

Status Indicators ............................ 5

Smart Shield Touchscreen ........4, 6

Maintenance/

Moisture Indicator .......................... 9

Fresh Air Housing/

Filter Replacement ......................10

Troubleshooting Tasks ................ 11

Power

Cord

Fresh Air

Intake

Connection

86.0887.00 Rev A 1

Tank Drain

Bleed Valve

Condensate

Hose

Condensate Tray

(not shown)

Page 4

A-dec SC Air Compressor Instructions for Use Safety Precautions and Other Regulatory Information

80 kPa

110 kPa

110 kPa

Safety Precautions and Other Regulatory Information

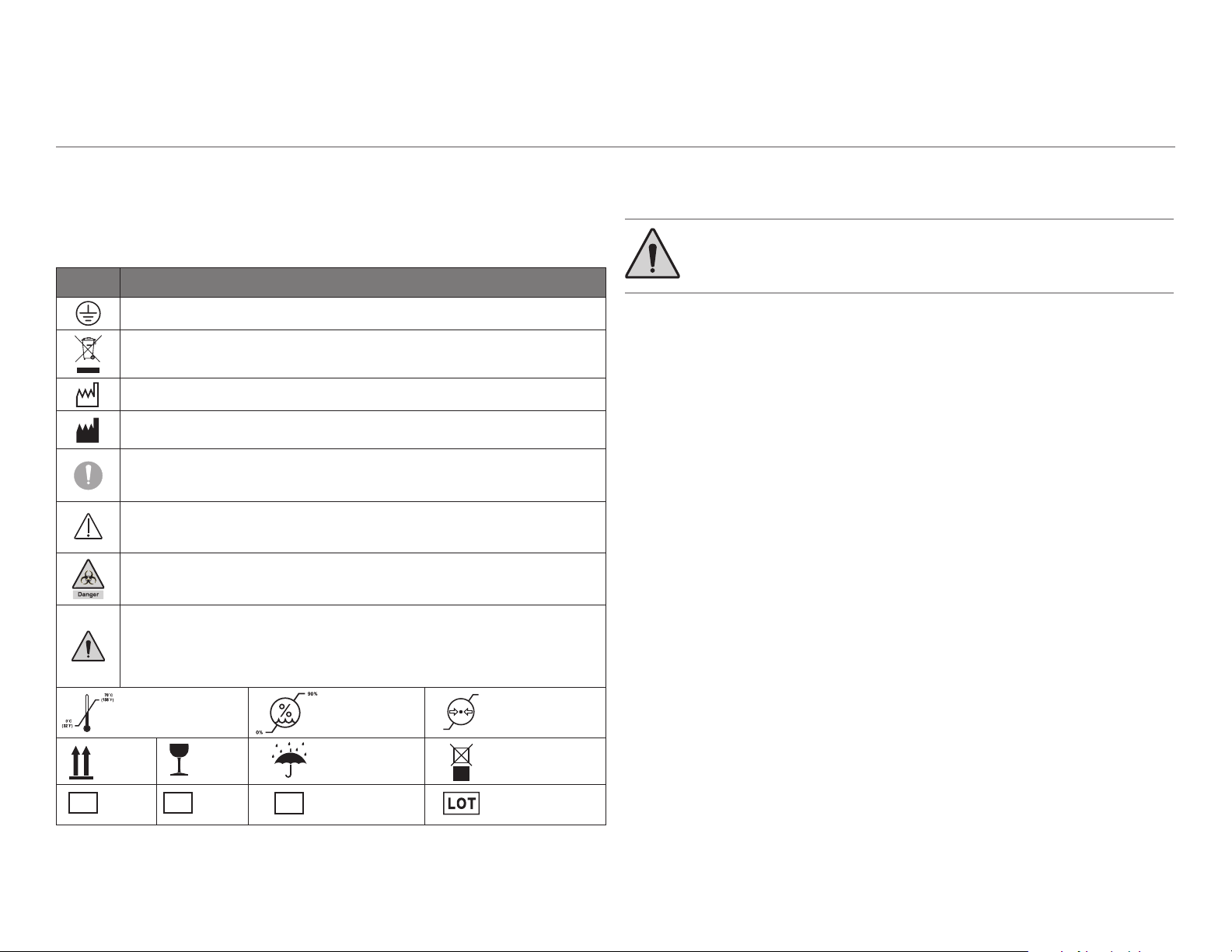

Identification of Symbols

These symbols appear on the actual product or are used in documentation to alert

the user about cautions, warnings, hazards, or tips.

Symbol Description

Protective earth (ground).

Electrical and electronic waste. Do not dispose of with domestic waste.

Date of manufacture.

Manufacturer of equipment.

General mandatory action sign. Not a caution. Take note of additional important

instructions.

e.g., NOTE: Assemble parts as shown.

Caution. Failure to follow instructions may result in product damage or minor injury.

e.g., CAUTION: Do not overtighten the adjustment screw. Overtightening could break

the screw.

Warning. Biological hazard.

e.g., WARNING: Infectious waste may be present. Follow asepsis protocol to prevent

cross contamination.

Warning. Failure to follow instructions may result in product damage or serious injury or

death.

e.g., WARNING: Turn off the power before removing the pump cover. Failure to turn off the

power before you begin this procedure can lead to product damage and result in serious

injury or death.

REF

Temperature shipping

and storage limits.

This way

up.

Model

Number

SN

Relative humidity

PN

shipping and

storage limits.

Part Number. Lot Code.

Fragile. Keep dry.

Serial

number.

80 kPa

Atmospheric

pressure shipping

and storage limits.

Do not stack.

Safety Precautions

WARNING Failure to follow these safety and operation

precautions can result in injuries or equipment damage.

The following safety precautions listed below must be observed:

1. Read all instructions completely before operating the air compressor.

2. For installation, follow all local electrical and safety codes, as well as the

National Electrical Code (NEC) and the Occupational Safety and Health Act

(OSHA).

3. Protect the power cable from coming into contact with sharp objects. Do not

kink the power cable and never allow it to come in contact with oil, grease, hot

surfaces, or chemicals.

4. Make certain that the power source conforms to the requirements of your

equipment.

5. Pull the main electrical disconnect switch and disconnect any separate control

lines, if used, before attempting to work or perform maintenance on the air

compressor or unit. “Tag Out” or “Lock Out” all power sources.

6. Do not attempt to remove any compressor parts without rst relieving the

entire system of pressure.

7. Do not attempt to service any part while the compressor is in an operational

mode.

8. Do not operate the compressor at pressures in excess of its rating.

9. Periodically check all safety devices for proper operation. Do not change the

pressure setting or restrict operation.

10. Be sure that no tools, rags, or loose parts are left on the compressor or

drive parts.

11. Do not use ammable solvents for cleaning any parts.

86.0887.00 Rev A 2

Page 5

A-dec SC Air Compressor Instructions for Use Safety Precautions and Other Regulatory Information

Safety Precautions (continued)

12. Exercise cleanliness during maintenance and when making repairs. Use a clean

piece of paper or cloth to cover and keep dirt away from parts and openings.

13. Do not operate the compressor without the service panels in place.

14. Do not operate the compressor in an environment that exceeds 104°F (40°C).

15. Do not operate compressor in areas where it might intake ammable or toxic

fumes.

16. Inspect the unit daily to observe and correct any unsafe operating condition.

17. Compressed air is a hazard and can result in air embolisms if it enters the

blood stream. Take care when using compressed air and only use air powered

medical products consistent with their intended use and user instructions.

18. Compressed air from this machine must not, under any circumstances, be used

for food processing or breathing air without adequate downstream lters,

puriers, and controls.

19. Always use an air pressure regulating device at the point of use. Do not use air

pressure greater than the marked maximum pressure of attachment.

20. Check hoses for weak or worn condition before each use, and make certain that

all connections are secure.

Decommissioning and Disposal of A-dec Equipment

A-dec dental equipment removed from service should be decommissioned in

accordance with local regulatory requirements. Circuit boards and electrical

cabling should be recycled as electrical salvage. Aluminum, brass, iron, and steel

components should be recycled as metal salvage. Molded plastic components

include mold marks indicating the type of plastic and should be recycled

accordingly. Any material unsuitable for recycling should be disposed of

appropriately. For information regarding material type of A-dec equipment, please

contact A-dec Customer Service.

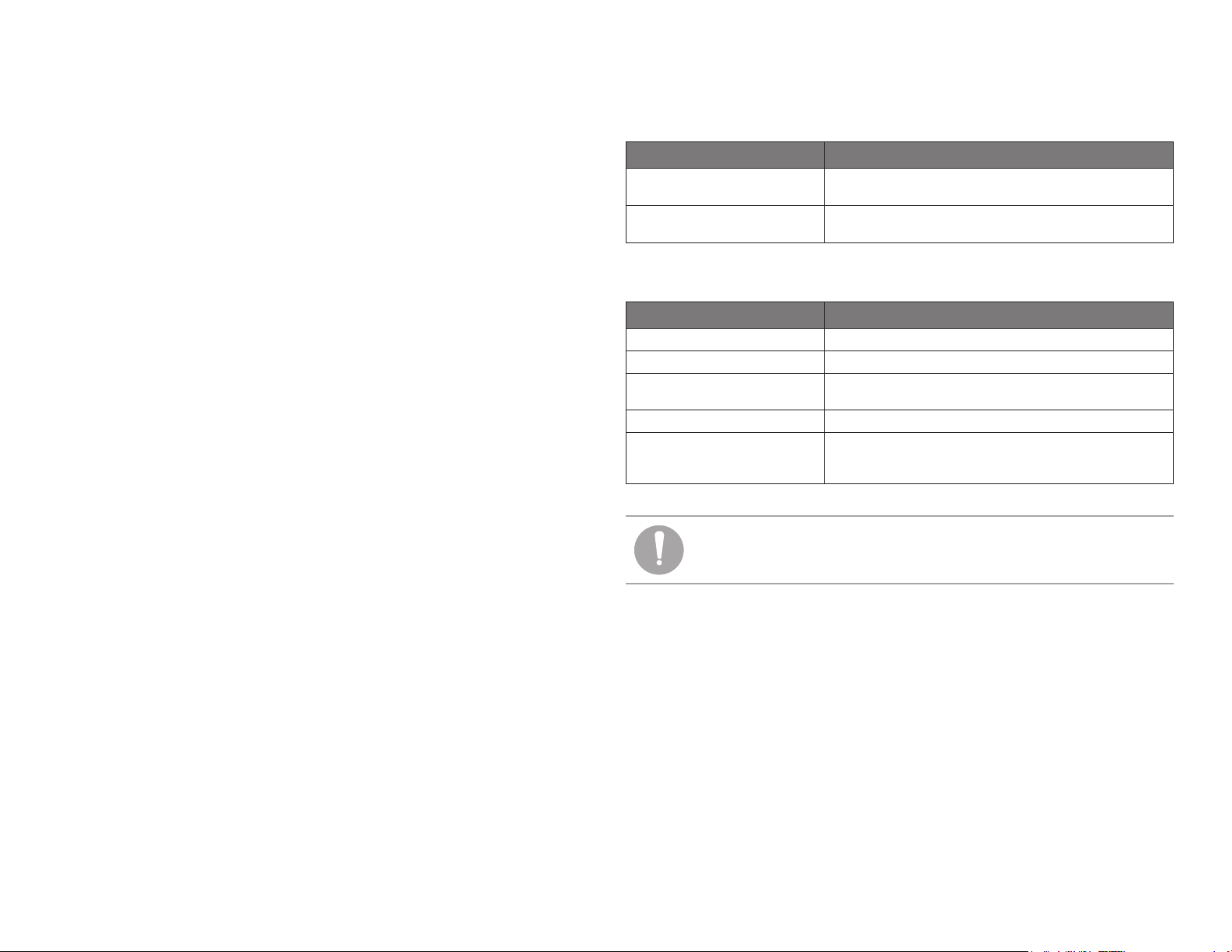

Environmental Specifications

Temperature/Humidity Specication

Storage/Transportation

Temperature

Operating Temperature

(Room Ambient Temperature)

32°F to 158°F (0°C to 70°C); relative humidity to 90%, no

condensation.

40°F to 104°F (4°C to 40°C); relative humidity to 80%, no

condensation.

Classification of Equipment (IEC-60601-1)

Type/Mode Classication

Types of Shock Protection CLASS I EQUIPMENT: All A-dec products with mains voltage.

Degree of Shock Protection Not Classied—no applied parts.

Degree of Protection Against

Water Ingress

Mode of Operation Continuous with 50% full load duty cycle.

Flammable Gasses Not suitable for use in the presence of a ammable anesthetic

Not Classied—IPX0.

mixture with air, oxygen, or nitrous oxide, where such gasses may

accumulate in concentration (closed space).

NOTE Allowable mains voltage fluctuations ± 10% of rated

voltage.

Electromagnetic Interference

A-dec mechanical room systems are designed and built to minimize electromagnetic

interference with other devices. However, if interference is noticed between another

device and your vacuum system:

• Remove interfering device from room.

• Plug interfering device into an isolated circuit.

• Increase separation between unit and interfering device.

• Contact your authorized A-dec dealer if interference persists.

86.0887.00 Rev A 3

Page 6

A-dec SC Air Compressor Instructions for Use Operate

Operate

Turn On/Turn Off Power

NOTE For longer periods of non-use, such as an extended

shutdown of the ofce, disconnect power to the compressor

to save energy and reduce the chance of air leaks in your

piping system and treatment rooms.

Master Power Switch

Master Power Switch

The master power switch turns the vacuum unit on or off. It also

overrides the other remote power functions. If your compressor is

connected to remote LED push-button controls or a Smart Shield

touchscreen, this switch should be in the REMOTE position.

LED Push-Button Control

(single-button)

LED Push-Button Control

(four-button)

Optional LED Push-Button Controls

If you have LED push-button controls, press the button once to turn the

compressor on or off. Blue LED lighting indicates that the compressor

is on. If the LED does not illuminate, check and verify that the master

power switch on the compressor is in the REMOTE position.

Optional Smart Shield Touchscreen Controls

For congurations with the Smart Shield

touchscreen, use the power switch icon

at the bottom of the screen or tap the AIR

icon to turn the compressor on or off. If the

Smart Shield does not operate, check and

verify that the master power switch on the

compressor is in the REMOTE position.

For more information on the touchscreen,

see “Smart Shield Touchscreen Controls”

on page 6.

86.0887.00 Rev A 4

OFFOFF

Page 7

A-dec SC Air Compressor Instructions for Use Operate

Control Panel Gauge and Operational Status

Pressure Gauge

After initial startup, when the system is fully pressurized, the pressure

gauge indicator should stay within the normal range. Contact your

authorized A-dec dealer if the pressure remains outside this range

during normal operation.

Status Indicators

Status

Indicators

The control panel includes three status indicators. These illuminate

differently, according to various conditions:

Indicator/

Color

RUN/

Green

INFO/Yellow

ATTENTION/

Yellow

Illumination

State Condition

Solid illumination. A motor is running.

Flashes continuously. The system is in standby (full pressure

reached, no motors running).

Flashes once every

10 seconds.

Flashes in intervals. The number of ashes per interval

Flashes in intervals. Fault code. For more information, see

The unit is connected to power.

indicates the number of motors

running.

“Troubleshooting Tasks” on page 12.

NOTE In addition to hearing the motors and pumps operate,

you may also hear other noises from the compressor. These

are normal and come from the cooling fans, air dryer, and

other components during various operational cycles.

86.0887.00 Rev A 5

Page 8

A-dec SC Air Compressor Instructions for Use Operate

Smart Shield Touchscreen Controls

The optional Smart Shield touchscreen provides power control and

system status of your mechanical room equipment.

Service

Contact

Information

Home

System

Status

Icons

(Tap to turn

equipment

on or off

individually.)

Remote Monitoring

Status

Software Version

and Reset

Power Switch

(Tap to turn all

attached equipment

on or off at the

same time.)

Tap the power switch icon at the bottom of the screen to turn all

connected equipment on or off at the same time. Tap the blue system

status icons to turn individual equipment on or off. These status icons

also dynamically change according to the operational state of the

equipment (see “Compressor System Status Icons” table on page 7).

Compressor Startup

When you rst start the compressor, Smart Shield displays the AIR

RUNNING icon, which includes the number of motors currently

running to increase air pressure (in the upper right corner of the icon).

When the system has reached the normal operating pressure range, the

AIR STANDBY icon appears.

AIR Running

(Pressurizing)

4

AIR Standby

(Pressurized)

NOTE If the Smart Shield does not operate, check and

verify that the master power switch on the compressor

is in the REMOTE position. For more information, see

“Troubleshooting Tasks” on page 11.

86.0887.00 Rev A 6

Page 9

A-dec SC Air Compressor Instructions for Use Operate

MANUAL

Smart Shield Touchscreen Controls (continued)

Compressor System Status Icons

Service

Contact

Information

Home

System

Status

Icons

(Tap to turn

equipment

on or off

individually.)

Remote Monitoring

Status

Software Version

and Reset

Power Switch

(Tap to turn all

attached equipment

on or off at the

same time.)

Icon State/Status

Displays during initial startup while the compressor motors

are pressurizing. The number in the upper right corner

indicates how many motors are currently running, which

varies per model (SC3: 2, SC5: 3, SC7: 4, SC10: 5, SC12: 6).

Displays intermittently while the compressor motors are

pressurizing the system, typically during initial system

startup.

Displays when the compressor motors have nished

pressurizing the system.

“MANUAL” appears on status icons when the master power

switch on the compressor is in the ON or OFF position. To

control power through the Smart Shield touchscreen, ensure

that the master power switch on the compressor is in the

REMOTE position.

Displays when the compressor is turned off from the Smart

Shield touchscreen controls.

OFF

Displays when the annual maintenance interval is reached.

This caution/reminder is reset whenever power to the

NOTE If additional warning icons appear on

system is disconnected.

your screen and are not shown here, contact your

authorized A-dec dealer for more information.

86.0887.00 Rev A 7

Displays when there is a fault in the system. Contact your

authorized A-dec dealer for service.

Page 10

A-dec SC Air Compressor Instructions for Use Operate

Smart Shield Touchscreen Controls (continued)

Additional Smart Shield Functions

Service

Contact

Information

Home

System

Status

Icons

(Tap to turn

equipment

on or off

individually.)

Remote Monitoring

Status

Software Version

and Reset

Power Switch

(Tap to turn all

attached equipment

on or off at the

same time.)

Icon State/Status

Q uestions?

1-800-547-1883

PRESS HERE TO

REQUEST SERVICE

Software V ersion

20180309

Displays contact information that will

route you to A-dec, Inc.

Displays your status as enabled if you

are registered with the remote

monitoring service. For questions,

contact your authorized A-dec dealer,

or call A-dec Customer Service.

Displays software version. The reset

button turns off the screen, reboots the

software, and reloads the equipment

status. You can use RESET during

specic faults with the equipment. For

more information, see “Troubleshooting

Tasks” on page 11.

RESET

86.0887.00 Rev A 8

Page 11

A-dec SC Air Compressor Instructions for Use Maintain/Troubleshoot

Maintain/Troubleshoot

Regular Maintenance Tasks

WARNING Do not attempt to open or remove the

compressor service panels. These are intended for

qualified service technician access only.

Control Panel

Status Indicators

Moisture

Service Panel

Indicator

(blue = normal

operation)

WARNING Before performing any maintenance function,

disconnect main power to the compressor and ensure that all

air pressure is relieved. Failure to do so may result in injury

or equipment damage.

To keep your compressor running smoothly, be sure to schedule a

service checkup with your authorized A-dec dealer every year. And

although the SC compressor requires very little maintenance, see the

table below for important recommended maintenance tasks.

Frequency Item Task/Procedure

Weekly Control panel and

moisture indicator.

Visually inspect the control panel.

If the air pressure does not remain

in the normal operation zone after

initial startup, contact your authorized

A-dec dealer for service. Ensure that

the RUN and INFO status indicators

are illuminating properly (see “Status

Indicators” on page 5 for more

information).

Visually inspect the moisture indicator.

Blue indicates normal operation. If

the indicator is pink, there’s moisture

in your compressed air. Contact your

authorized A-dec dealer for service.

Monthly Exterior case and

tubing connections.

86.0887.00 Rev A 9

Use a dry, lint-free cloth to dust off

and clean the exterior. Listen for any

noticeable air leaks.

Page 12

A-dec SC Air Compressor Instructions for Use Maintain/Troubleshoot

Regular Maintenance Tasks (continued)

WARNING Before performing any maintenance function,

disconnect main power to the compressor and ensure that all

air pressure is relieved. Failure to do so may result in injury

or equipment damage.

Contact your authorized A-dec dealer if you are unable to

access the air filters. Do not attempt to open or remove the

compressor service panels. These are intended for qualified

service technician access only.

Filter Housing

Thumbscrew

1

Fresh Air

Filter Housing

2

Foam Filter

Mesh Filter

Front Service Panel

Ambient Air

Screen Filter

3

Frequency Item Task/Procedure

Yearly Air lters:

• Fresh air foam

• Fresh air mesh

• Ambient air screen

Every

5 years

Internal dryer

cartridge lter.

Replace the fresh air and ambient air

lters once a year. Turn off power to the

compressor before following these steps:

1. Loosen and remove the fresh air

lter housing

remove the housing to access the

fresh air lters.

2. Pull out and replace the foam and

mesh lters. Reinstall the housing.

3. Slide the ambient air lter out from

the front service panel and replace.

*Forairlterreplacement,orderthefollowing

maintenance kits:

• p/n A0050, for model SC3/SC5/SC7

• p/n A0150, for model SC10/SC12

This task requires a service technician.

Contact your local authorized A-dec

dealer for the internal cartridge lter

replacement.

thumbscrew, then

86.0887.00 Rev A 10

Page 13

A-dec SC Air Compressor Instructions for Use Maintain/Troubleshoot

Troubleshooting Tasks

WARNING Do not attempt to open or remove the

compressor service panels. These are intended for

qualified service technician access only.

your compressor that may or may not require attention. For problems

that require access to internal compressor components, always contact

your local authorized A-dec dealer for service.

Condition Potential Cause Procedure/Remedy

The following table is intended to help you identify common issues with

LED push-button or

Smart Shield controls

do not function.

Air pressure outside

the normal range.

Master power switch on the compressor is not in

the REMOTE position.

Communication disruption/fault between system

and Smart Shield touchscreen.

Incomplete initial startup and pressurization. Check the INFO status indicator on the compressor control panel. If the indicator

A leak in the compressor, piping, or dental

equipment.

Ensure that the master power switch on the compressor is in the REMOTE

position. If it is, and you have push-button controls, contact your authorized

A-dec dealer for service. If the master power switch is in the REMOTE position

and you have the Smart Shield touchscreen, see the remedy below.

Tap on

resolve the condition, unplug the Smart Hub router power cord, wait 10 seconds,

then plug it back in. If this does not resolve the condition, contact your

authorized A-dec dealer for service.

is ashing in intervals, the compressor motors are still working to reach full

pressurization. Recheck after the compressor has completed the initial startup

sequence. If the pressure remains outside the normal range, contact your

authorized A-dec dealer for service.

Turn the air shutoff valve to the OFF (or “closed”) position to help identify if the

air leak is within the compressor or external to the compressor.

at the top of the touchscreen, then tap RESET. If this does not

OFF or

“Closed”

ON or

“Open”

With the valve closed (which shuts off

the air supply to the treatment rooms),

watch the pressure gauge to see if the

compressor has an internal leak. If

you detect any leaks, contact your

authorized A-dec dealer for service.

Be sure to return the air shutoff valve to

the ON (or “open”) position for normal

operation.

86.0887.00 Rev A 11

Page 14

A-dec SC Air Compressor Instructions for Use Maintain/Troubleshoot

Troubleshooting Tasks (continued)

WARNING Do not attempt to open or remove the

compressor service panels. These are intended for

qualified service technician access only.

Condition Potential Cause Procedure/Remedy

ATTENTION status

indicator is ashing.

1 time per interval

Excessive demand on the compressor (greater

than 100 percent capacity).

Contact your authorized A-dec dealer for service.

2-3 times per interval

4 times per interval

5 times per interval

High ambient temperature warning/shutdown. Contact your authorized A-dec dealer for service.

Annual maintenance timeout. Schedule an annual service checkup with your authorized A-dec dealer.

5-year maintenance timeout. Schedule service with your authorized A-dec dealer to remove and replace the

internal dryer cartridge lter.

6-12 times per interval

Moisture indicator

Mechanical fault with motor or fan. Contact your authorized A-dec dealer for service.

Dryer not cycling properly. Contact your authorized A-dec dealer for service.

is pink.

Dryer cartridge past working life (5 years). Contact your authorized A-dec dealer to remove and replace the internal dryer

cartridge lter.

Excessive Vibration. Worn vibration/tray isolators. Contact your authorized A-dec dealer for service.

86.0887.00 Rev A 12

Page 15

Page 16

A-dec Headquarters

2601 Crestview Drive

Newberg, Oregon 97132

United States

Tel: 1.800.547.1883 within USA/CAN

Tel: +1.503.538.7478 outside USA/CAN

www.a-dec.com

A-dec St. Louis

1601 Manufacturers Drive

Fenton, Missouri 63026

United States

A-dec Australia

Unit 8

5-9 Ricketty Street

Mascot, NSW 2020

Australia

Tel: 1.800.225.010 within AUS

Tel: +61.(0).2.8332.4000 outside AUS

A-dec China

A-dec (Hangzhou) Dental Equipment Co., Ltd.

Building 5, No. 528 Shunfeng Road

Tangqi Town, Yuhang District,

Hangzhou, Zhejiang, China 311100

Tel: 400.600.5434 within China

Tel: +86.571.89026088 outside China

A-dec United Kingdom

Austin House

11 Liberty Way

Nuneaton, Warwickshire CV11 6RZ

England

Tel: 0800.ADEC.UK (2332.85) within UK

Tel: +44.(0).24.7635.0901 outside UK

ÍvÈ.Ç(wÈ.00CÎ

86.0887.00 Rev A

Date of Issue 2021-01-19

Copyright 2021 A-dec, Inc.

All rights reserved.

IFUnewcov1

Loading...

Loading...