Page 1

belshaw-adamatic.com

Belshaw Adamatic

BARO-2E

Double Rack Oven, Electric

Construction features

Heavy-duty stainless steel interior ▪

Oversized low watt-density heater elements ▪

Cooking compartment insulated with 5” thick high-temp ▪

insulation

Fully integrated hood with single point exhaust connection ▪

Automatic, heavy-duty “B” style lift and rotate system ▪

Heavy-duty gear driven rotation system ▪

Cooking chamber illuminated by externally mounted ▪

orescent lamp

Heavy-duty door with 9.75” x 57.5” viewing window ▪

Interior door safety release mechanism ▪

Accommodates two single racks (side load) or one double ▪

rack (end load)

Performance Features

200°-550°F / 93°-288°C temperature range ▪

Low watt-density elements operate at lower temperatures ▪

for extended life

High volume gravity feed, waterfall type steam system ▪

Adjustable air circulation louvers ▪

Self adjusting slip clutch protects operator and prevents ▪

component damage

Automatic rack stop and lower when door is opened ▪

Floor level loading without ramps ▪

Serving the donut and bakery industry for over 85 years

1-800-578-2547 ▪ info@belshaw-adamatic.com ▪ www.belshaw-adamatic.com

BARO-2G Rack Oven

Integrated Hood Features and Performance

Meets the requirements of NFPA 96 & UMC requirements for ▪

Type I & II Hoods

20 Ga stainless steel body ▪

Fully welded construction ▪

Single 8” round collar, Velocity: 2,300 FPM @ 800 CFM ▪

5.9 sq ft of capture area, lter velocity of 120 FPM, 0.03” ▪

wc@800 CFM

Controls Package

Digital controls with large LED readouts for Time and ▪

temperature

Large LCD event screen for programming and oven status ▪

60 Item programmable memory, with 5-events per item ▪

Simple manual program for time, temp., steam and vent ▪

Infrared port for uploading and downloading programs ▪

Flash type programming for revision updates without ▪

replacing PCB

Options

Pass-through option ▪

Prison package ▪

“A” and “C” style lift ▪

Rack Capacity

2 single side-load racks, or 1 double side-load rack

Short Bid Specication

Rack Oven Model BARO-2E shall be a 52kW electrically heated

rotating, double rack capacity unit with: oversized low density

heating elements; gravity feed waterfall type steam generation

system; 5” thick compartment insulation rated at 0” combustible

wall clearance; heavy-duty rack lift and rotate system with gear

driven rotation system; simple solid state controls, with digital

time-temperature readouts, 5 event menu programs for time,

temperature, steam, vent and blower function, 60-item program

memory; an integrated hood meeting NFPA 96 and Type I & II

construction standards, plus all the features listed

Standard Product Warranty

One-Year Parts and Labor, USA and Canada.

(USA includes 50 states + DC unless specied)

Certications

BELSHAW ADAMATIC BAKERY GROUP 206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2009 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

Page 2

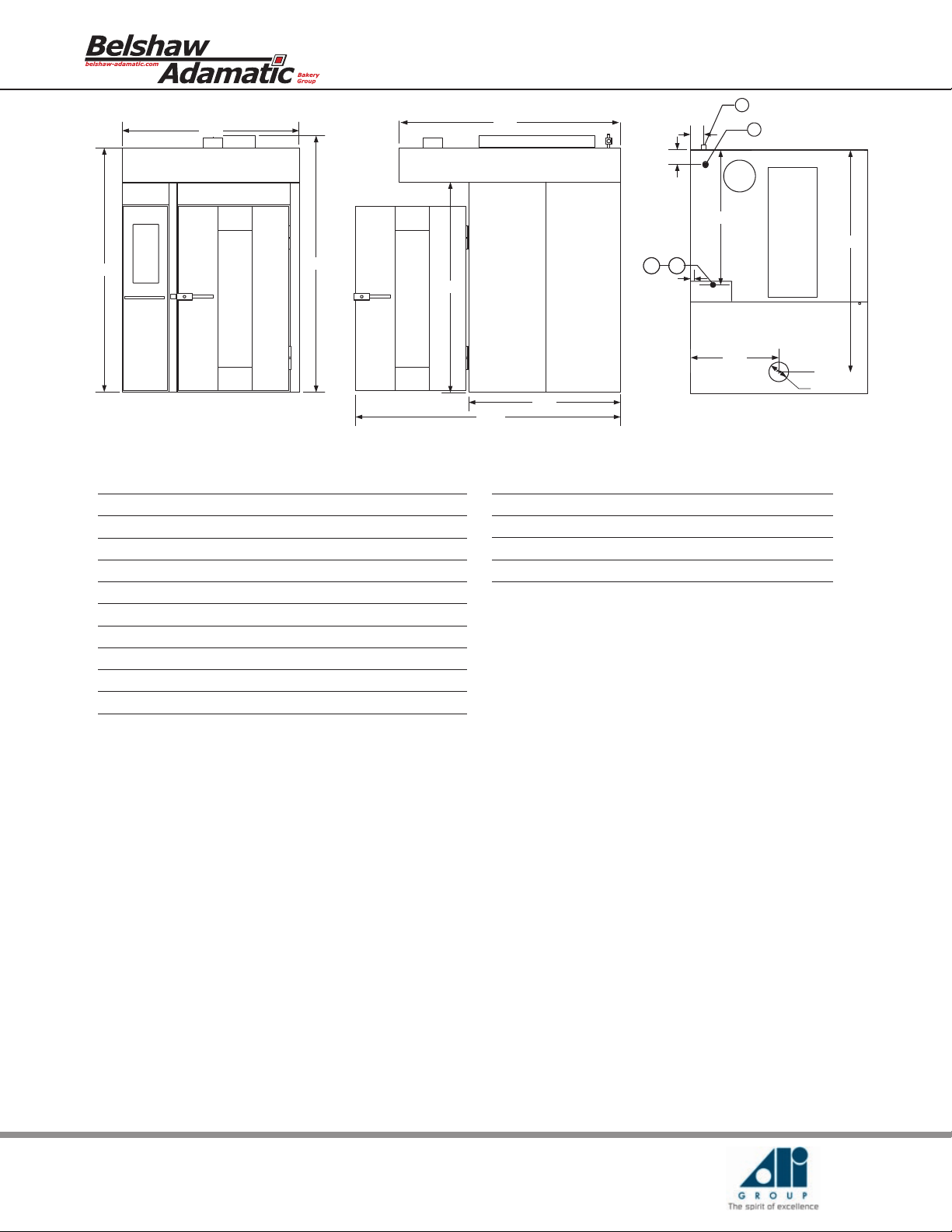

99.75

72.25

104.88

86.00

95.0

BARO-2E: Double Rack Oven, Electric

DRAIN Connection

D

WATER Connection

5.50

5.81

ELECTRICAL

Connections

E1

E2

1.50

W

55.00

86.75

[Front View]

Dimensions

Overall width 72” (1830 mm)

Overall height 104.5” (2655 mm)

Overall depth (inc. hood) 95.0” (2530 mm)

Depth at oor (not inc. hood) 62” (1575 mm)

Clearance required 0” sides and back

Net weight 3380 lbs (1537 kg)

Shipping weight 4380 lbs (1991 kg)

Crate size (each of 2) 113”L x 70”W x 46” H

Crate volume (each of 2) 211 cu. ft.

Freight Class 70

Installation Requirements

Requires on-site installation ▪

KD shipment in two pieces. Will t through 36” opening ▪

Consult factory for shipment fully assembled ▪

112” Floor to ceiling height required for tip-up ▪

Non-combustible oor supported by non-combustible ▪

structure

Zero clearance required from combustible surfaces on side ▪

and back

Ventilation

8” Round vent collar (consult local codes for installation ▪

requirements)

800 CFM Roof vent (not included) ▪

62.00

108.25

[Side View]

Electrical

120V-60-1 E-1 connection 12 A 1.5 kW

208V-60-3 E-2 connection 149 A 54 kW

240V-60-3 E-2 connection 130 A 54 kW

480V-60-3 E-2 connection 64 A 54 kW

Two electrical connections

For Controls/Lift and rotate (E1 on diagram): 1/2” ▪

EMT, 120 VAC 1-Phase

For circulation blower and heaters (E2 on diagram): ▪

1-1/4” EMT, 208-240V or 480V 3-Phase

Water Supply & Drainage

Supply: 1/2” NPT (9 GPM@40 psi) ▪

Drain: 3/4” NPT (210°F, 1 GPM) vented ▪

Line to be dropped from ceiling ▪

Connection will be located 100” above nished oor, 5.5” ▪

from the left side of the oven, 6” from the rear of the oven

Oven comes pre-installed with water pressure regulator, ▪

water pressure gauge, water solenoid and shut-off valve

Your local water conditions may damage your appliance. ▪

Failure to properly treat water may result in damage and

may void your warranty. Ensure that your water supply

meets these minimum water quality specications:

Alkalinity: 22 ppm Aluminum: 17 ppm Calcium: 3.3 ppm Free chlorine residual: 0.6 ppm Magnesium: 0.65 ppm PH range: 8.5 s.u. Sodium: 8.5 ppm Total Hardness: 11.9 ppm -

Consult your local water treatment company for proper ▪

water ltration system.

36.00

[Plan View]

VENT

Connectio

Ø 8.00

n

BELSHAW ADAMATIC BAKERY GROUP 206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2009 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

Loading...

Loading...