Page 1

ADAMATIC / BELSHAW

Rack Ovens, Gas

Model: BARO-1G

Single Rack Oven

Gas

Model: BARO-2G

Double Rack Oven

Gas

OPERATOR MANUAL

ADAMATIC, Inc.

607 Industrial Way

Eatontown, NJ 07724

BELSHAW BROTHERS, Inc.

814, 44th Avenue NW

Auburn, WA 98001

Phone: 800.526.2807

www.adamatic.com

Phone: 800.578.2547

www.belshaw..com

Page 2

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

READ FIRST

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

POST IN A PROMINENT LOCATION:

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THAT USER SMELLS

GAS. THIS INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR

LOCAL GAS SUPPLIER. AS A MINIMUM, TURN OFF THE GAS AND CALL

YOUR GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT.

EVACUATE ALL PERSONNEL FROM THE AREA.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

Model #: Purchased From:

Serial #:

Date Purchased:

Purchase Order #:

ETL File 3028821 2 REV.B2006

Location:

Date Installed:

For Service, Call:

Page 3

TABLE OF CONTENTS

CHAPTER PAGE

1. TABLE OF CONTENTS ............................................................................... 3

2. WARNING..................................................................................................... 4

3. EQUIPMENT DESCRIPTION ...................................................................... 7

4. INSTALLATION INSTRUCTIONS ............................................................. 10

5. EMERGENCY OPERATION........................................................................ 17

6. GENERAL OPERATION.............................................................................. 18

7. GENERAL MAINTENANCE ....................................................................... 20

8. RESISTANCE CHARTS ............................................................................... 22

9. SAFETY CONSIDERATIONS ..................................................................... 23

10. ILLUSTRATED PARTS BREAKDOWN..................................................... 24

11. WIRING DIAGRAM (STANDING PILOT MODELS)................................ 34

12. CONTROL PANEL LAYOUT...................................................................... 35

13. WIRING DIAGRAM (GAS CONTROL CIRCUITS)................................... 36

14. WIRING DIAGRAM (HOT SURFACE IGNITION MODELS) .................. 37

15. TROUBLESHOOTING MANUAL............................................................... 38

16. CLEANING RECOMMENDATIONS.……

17. GUIDE TO USING THE BARO OVEN CONTROLS ….............…..……...46

………………………………...44

ETL File 3028821 3 REV.B2006

Page 4

WARNINGS

WARNING THE WATER FROM THE STEAM DRAIN OUTLET IS EXTREMELY

HOT AND MAY CAUSE SERIOUS BURNS.

NOTICE

Left rear drain point is provided. Route to a floor drain. A 1”

gap must be provided between oven drain and floor drain.

WARNING WIRES ENTERING THE DISCONNECT MAY STILL BE LIVE EVEN

WHEN THE SWITCH IS TURNED OFF. SWITCH THE MAIN BREAKER

AT THE WALL TO “OFF” WHEN SERVICING THE OVEN

CAUTION

TO REDUCE THE RISK OF FIRE, THE APPLIANCE IS TO BE

MOUNTED ON FLOORS OF NON-COMBUSTIBLE CONSTRUCTION

WITH NONCOMBUSTABLE FLOORING AND SURFACE FINISH AND

WITH NO COMBUSTIBLE MATERIAL AGAINST THE UNDERSIDE

THEREOF, OR ON NONCOMBUSTABLE SLABS OR ARCHES

HAVING NO COMBUSTIBLE MATERIAL AGAINST THE UNDERSIDE.

SUCH CONSTRUCTION SHALL EXTEND A MINIMUM OF 12-INCHES

BEYOND THE EQUIPMENT ON ALL SIDES. See fig. 1

PG. 7

PG. 7

PG. 8

PG. 10

Fig. 1

Floor

Construction

ETL File 3028821 4 REV.B2006

Page 5

WARNINGS CONT’D

WARNING

WARNING

CAUTION

CAUTION

CAUTION

WARNING

DO NOT UNLOAD THE RACK FROM THE OVEN WHILE THE

CARRIER IS IN THE LIFT POSITION. LOADED RACKS CAN BE

EXTREMELY HEAVY.

DO NOT REMOVE A FLAMING PRODUCT FROM THE OVEN.

SEVERE BURNS AND PROPERTY DAMAGE CAN RESULT.

INSTALLATION MUST CONFORM WITH LOCAL CODES OR IN THE

ABSENCE OF LOCAL CODES THE NATIONAL FUEL GAS CODE,

ANSIZ223.11996.

THIS APPLIANCE, WHEN INSTALLED, MUST BE ELECTRICALLY

GROUNDED IN ACCORDANCE WITH LOCAL CODES, OR IN THE

ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL

CODE, ANSI/NFPA 70-1996.

FOR INSTALLATION IN CANADA THE INSTALLATION MUST BE IN

ACCORDANCE WITH CAN/CGA-B149.1&2 OF THE INSTALLATION

CODE, AND LOCAL CODES WHERE APPLICABLE. ALL ELECTRIC

WIRING MUST BE IN ACCORDANCE WITH THE CURRENT

CANADIAN ELECTRICAL CODE, C22.1 PART 1. GROUNDING THIS

APPLIANCE MUST CONFORM TO CANADIAN ELECTRICAL CODE,

CSA C22.2.

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING

IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL

AND /OR DAMAGE TO EQUIPMENT. UNIT MUST BE INSTALLED IN

ACCORDANCE WITH ALL APPLICABLE CODES.

PG. 17

PG. 17

PG. 10

PG. 11

PG. 11

PG. 11

WARNING

NOTICE

NOTICE

NOTICE

WARNING

NOTICE

DO NOT ALLOW ANY PART OF YOUR BODY TO BE UNDER THE

OVEN DURING THE LIFTING PROCESS. KEEP EVERYONE CLEAR

FORM THE OVEN IF IT SHOULD FALL.

It is imperative that a mechanical exhauster is installed, and a

pressure sensitive switch is installed at the collar of the hood. If a

negative draw of 0.6 is not achieved, the burner will not come on.

No other exhaust systems may be connected to this system. Do not

try to vent or exhaust another appliance into this hood.

Do not allow more than 14 inches pressure to be applied to the gas

valve at any time.

WHEN REMOVING THE RACK OR PRODUCT FROM THE RACK

WHERE OVEN MITTS TO AVOID SERIOUS BURNS.

Always ensure the grease filters supplied with the oven are used.

Replacement filters may be ordered from a Adamatic/Belshaw

service representative.

PG. 11

PG. 14

PG. 14

PG. 14

PG. 17

PG. 14

ETL File 3028821 5 REV.B2006

Page 6

WARNINGS CONT’D

WARNING

THIS ADAMATIC/BELSHAW OVEN PRODUCES HUMIDITY THAT CAN CAUSE

THE INTERIOR FLOORING AND ADJACENT EXTERIOR FLOORING

TO BECOME SLIPPERY. USE EXTREME CAUTION WHEN WALKING

ON A WET OR DAMP FLOOR.

PG. 18

NOTICE

NOTICE

WARNING

NOTICE

NOTICE

NOTICE

The ambient temperature outside the oven should not exceed 104° F

(40° C). This includes the temperature of the air above and around

the oven.

During the first few hours of operation you may notice a small

amount of smoke coming off of the oven, and a faint odor from the

smoke. This is normal for a new oven and will disappear after the

first few hours of use.

WHEN THE LOADING DOOR IS OPENED, HOT AIR AND STEAM ARE

RELEASED FROM THE OVEN INTERIOR. TO AVOID BURNS OPEN

DOOR SLOWLY AND KEEP YOUR FACE AND HANDS CLEAR OF

THE OPENING. ALL INTERIOR SURFACES ARE VERY HOT. DO NOT

TOUCH ANYTHING WITHOUT OVEN MITTS.

The steam, vent and fan functions cannot be used together in the

same step.

Service on this ADAMATIC/BELSHAW bakery appliance must be

performed by qualified personnel only. Consult your distributor

or dealer or call the factory at 1-800-578-2547, or go to

ADAMATIC.COM or BELSHAW.COM for authorized service.

To maintain optimum safety and performance for Adamatic/Belshaw

oven models BARO-1G & BARO-2G, a program

of scheduled periodic maintenance be implemented. It is the sole

responsibility of the user to establish, schedule and enforce such a

program. Although the actual service interval will vary depending on

the environment in which the equipment is operating, it is

recommended the following be done by an ADAMATIC/BELSHAW

authorized service agency at least every 6 months.

PG. 18

PG. 18

PG. 18

PG. 20

PG. 24

PG. 24

NOTICE

WARNING

NOTICE

For periodic maintenance and repairs, electrical diagrams are

included in this manual and with the oven (on the back of the control

door).

SINCE RESETS FOR THE CIRCULATION BLOWER MOTOR AND THE

LIFTER MOTOR / ROTATOR MOTOR ARE AUTOMATIC, ALL POWER

TO THE OVEN MUST BE TURNED OFF BEFORE SERVICING.

If shutter settings are to be adjusted differently than the

recommended factory settings, the best results will be obtained if

you. (A) Start with the factory settings. (B) Close shutters to lighten

a product in a given area- do not open shutters to darken a product.

(C) Do not move a shutter more than 1/32” or 1mm (see step gauge

and shutter setting illustration) at any one time. (D) Be sure all

settings for left hand shutters match those for right hand shutters.

(E) Do not adjust more than two shutters per side per time (four

shutters total).

PG. 24

PG. 25

PG. 25

ETL File 3028821 6 REV.B2006

Page 7

EQUIPMENT DESCRIPTION

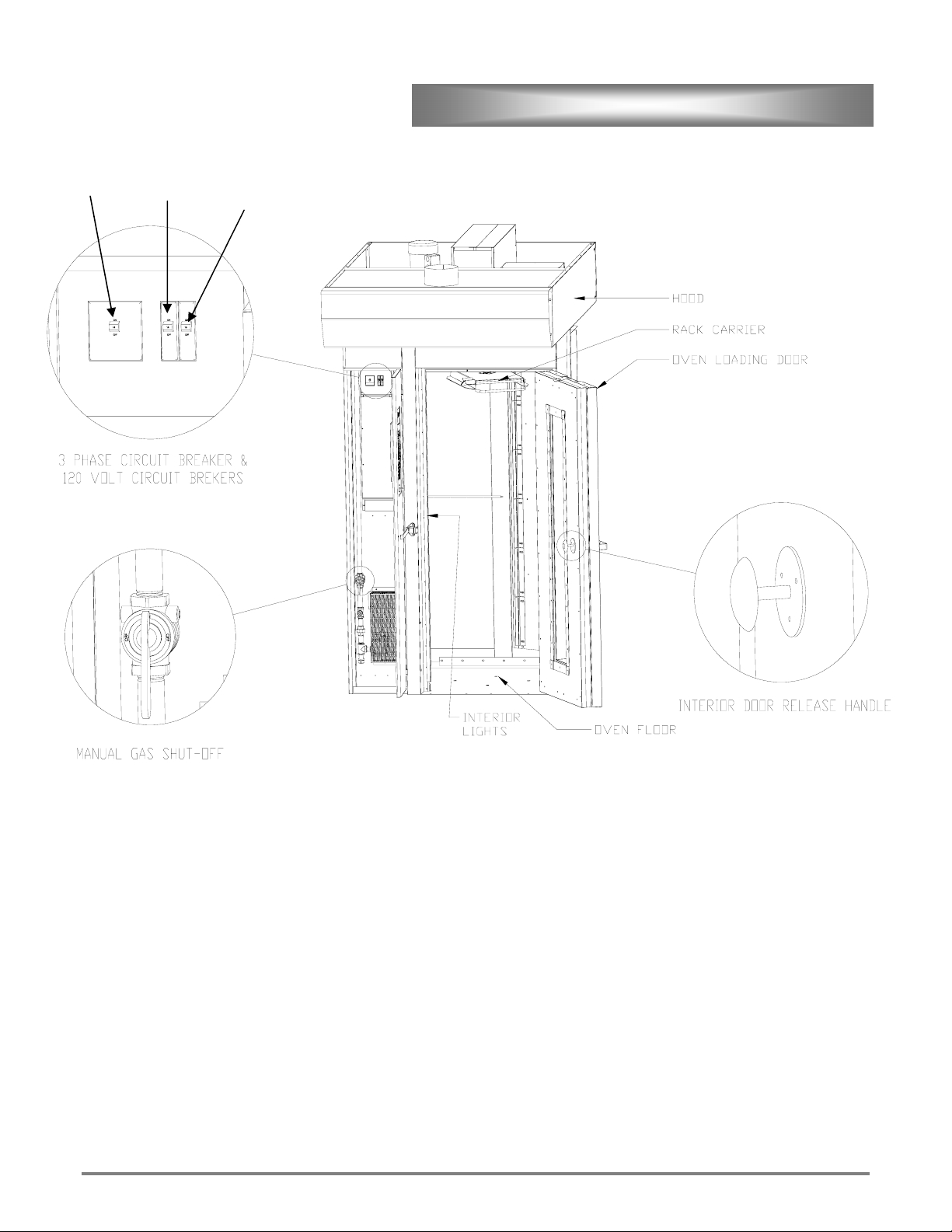

Data Plate

On this plate you will find the oven model, serial number, electrical ratings, (BTU’s, and gas type for gas

ovens), and clearance specification. Data plate is located behind controller door on component cover.

Exterior Construction

BARO-2G oven exterior dimensions are 72” (1829 mm) wide x 105” (2667 mm) high x 62” (1575 mm)

The

Deep. The Top, front, Back and Sides are constructed of stainless steel with 5 inches of insulation.

The BARODeep. The Top, front, back and sides are constructed of stainless steel with 5 inches of insulation.

The oven is designed for floor level loading.

Type I or Type II compliant hood with single 8” point exhaust connection complying with Uniform

Mechanical Code and NFPA 96: State, County and local codes may vary; always check with local code

officials.

The oven door is constructed of stainless steel with a full height single pane window and an interior

releasing mechanism.

Interior Construction

An externally mounted florescent light provides excellent product visibility.

The BARO-2G oven cavity dimensions are 52” (1320 mm) wide x 75” (1905 mm) high x 52” (1320 mm)

deep. The interior is constructed of stainless steel.

The BARO-1G oven cavity dimensions are 36.5” (927 mm) wide x 75” (1905 mm) high x 39” (9906 mm)

deep. The interior is constructed of stainless steel.

The Rack Carrier facilitates smooth and simple rack loading and unloading.

The Rack Lift provides gentle rack lift and rotation protecting delicate products.

The built in steam generator generates steam quickly.

Oven air circulation is fully adjustable, providing even baking or cooking.

Controls

1G oven exterior dimensions are 55” (1397 mm) wide x 105” (2667 mm) high x 51” (1295 mm)

The large digital display is easy to understand and operate.

Pre-Programmable product selections simplify operation.

Step functions allow for special menus

Automated control functions include temperature, time, steam, vent, and fan delay

Technical

The oven requires a 120-volt single-phase power supply and a 208/240-volt three-phase power supply.

The oven requires a 1” NPT connection for gas supply.

The oven requires a ½” NPT connection for water supply.

The oven requires no clearance from combustible wall construction.

The oven will be heated by natural gas or propane at a heating rate of 175,000 BTU for the BARO-1G and

290,000 BTU for BARO-2G. NG (LP must be specified when ordering).

WARNING THE WATER FROM THE STEAM DRAIN OUTLET IS EXTREMELY

Steam Drain Outlet

Water exits the steam generating system through this outlet It is located at left rear corner of the oven.

NOTICE

HOT AND MAY CAUSE SERIOUS BURNS.

Left rear drain point is provided. Route to a floor drain. A

1” gap must be provided between oven drain and floor

drain.

ETL File 3028821 7 REV.B2006

Page 8

EQUIPMENT DESCRIPTION CONT’D

Floor Drain

This drain (customer supplied) receives the excess water from the steam generating system.

Rack Carrier

The Rack Carrier attaches to the top of the oven rack.

When the loading door is closed, the rack carrier lifts and rotates the oven rack.

Rack Stop

The two rack stops are located on the carrier and secure the oven rack in place during baking. The leading

edge of the forward stop must be manually flipped down to unload the oven rack. The stop will

automatically return to the up (loading) position when the rack is removed.

Hood

Steam and burner exhaust is discharged into the hood. Grease, if present, is channeled to and collected in

a grease cup for later removal.

Hood Exhaust

Cooking fumes and burner exhaust pass through a duct to the hood exhaust outlet. A customer-supplied

exhaust blower is required. The hood can be wired to the external device terminals in the service box.

This insures the hood is on whenever the oven is on. The “POWER” switch on the oven control panel

activates the blower. The blower must be running before the oven will operate. A factory installed airflow

switch disables heat until airflow exists.

Interior Door Release

This door release allows the door to be opened from inside the oven.

120V Circuit Breakers

Power to run the control panel and hood blower can be disconnected at these points. Switch to “OFF”

when servicing oven or blower.

WARNING WIRES ENTERING THE DISCONNECT MAY STILL BE LIVE EVEN

Manual Gas Shutoff

Gas is supplied to the oven through this valve. This valve is typically left open, but needs to be closed

when servicing the oven. To close the valve, turn its handle to a horizontal position.

3-Phase Circuit Breaker

This disconnect provides short circuit protection for the circulation blower motor. Switch to OFF when

servicing the oven.

WHEN THE SWITCH IS TURNED OFF. SWITCH THE MAIN

BREAKER AT THE WALL TO “OFF” WHEN SERVICING THE

OVEN

ETL File 3028821 8 REV.B2006

Page 9

EQUIPMENT DESCRIPTION CONT’D

Circulation

Blower

Vent Blower Controls

ETL File 3028821 9 REV.B2006

Page 10

INSTALLATION INSTRUCTIONS

CAUTION

Receiving the Oven

TO REDUCE THE RISK OF FIRE, THE APPLIANCE IS TO BE

MOUNTED ON FLOORS OF NON-COMBUSTIBLE

CONSTRUCTION WITH NONCOMBUSTABLE FLOORING AND

SURFACE FINISH AND WITH NO COMBUSTIBLE MATERIAL

AGAINST THE UNDERSIDE THEREOF, OR ON

NONCOMBUSTABLE SLABS OR ARCHESHAVING NO

COMBUSTIBLE MATERIAL AGAINST THE UNDERSIDE. SUCH

CONSTRUCTION SHALL EXTEND A MINIMUM OF 12-INCHES

BEYOND THE EQUIPMENT ON ALL SIDES. See fig. 1 Page 4.

Upon receipt, check for freight damage

on the freight bill at the time of delivery and signed by the carrier's agent. Concealed loss or damage

means loss or damage which does not become apparent until the merchandise has been unpacked. If

concealed loss or damage is discovered upon unpacking, make a written request for inspection by the

carrier's agent within 15 days of delivery. All packing material must be kept for inspection. Do not

return damaged merchandise to Adamatic or Belshaw. File your claim with the carrier.

Pre-Installation

Check the area where the oven is to be installed for the following:

• No electrical conduit or wires are to be under the floor of the oven.

• The oven must be mounted on a non-combustible surface. This includes the structure beneath the

floor. The floor must me level within 3/4”. See Fig. 1 Page 4, and above CAUTION!

• Ceiling height above the oven should be sufficient to allow servicing the lifter, vent, and blower

motor assemblies. The maximum height needed for tilting the oven up is 105 inches.

• Clear access is needed to the roof or exterior of the facility for hood exhaust. Check local codes for

correct venting.

• Caution should be taken when enclosing hood to ceiling and oven is under a fire sprinkler; hood

exhaust stack will emit heat.

• Access is needed for an air-gap drain in the rear left corner of the oven.

• Adequate space is needed in front of the oven to load and unload racks. Racks are hot and need

space to cool.

• The oven needs make-up air to operate. The hood exhaust will need at least 600 CFM for Model

BARO-1G and 800 CFM for model BARO-2G.

• Local and national codes will require an electrical shut-off within a reasonable distance to the oven.

• Local and National codes will require access to a manual Gas Shut-off.

• The door swing (46.0”) will need to be clear to allow adequate loading and unloading of the oven.

Check the space next to the oven and be sure it does not interfere with the door.

Un-Crating

, both visible and concealed. Visible damage should be noted

The oven is shipped in either one or two main pieces not including hood. If oven is shipped in two pieces

read and review the assembly instructions. If it comes in one main piece the assembly instructions will

not be necessary.

Move the large oven crates into the room, near where it is to be installed. Allow clear access for a forklift

or lifting apparatus at the top end of the oven. The bottom end of the oven crate is beveled at the skids.

Remove crating materials and plastic wrap from the oven. Remove the heat exchanger vent duct from the

skid.

CAUTION

INSTALLATION MUST CONFORM WITH LOCAL CODES, OR IN

THE ABSENCE OF LOCAL CODES TO THE NATIONAL FUEL

GAS CODE, ANSIZ223.11996.

ETL File 3028821 10 REV.B2006

Page 11

INSTALLATION CONT’D

CAUTION THIS APPLIANCE, WHEN INSTALLED, MUST BE ELECTRICALLY

GROUNDED IN ACCORDANCE WITH LOCAL CODES, OR IN THE

ABSENCE OF LOCAL CODES, WITH THE NATIONAL

ELECTRICAL CODE, ANSI/NFPA 70-1996.

CAUTION FOR INSTALLATION IN CANADA THE INSTALLATION MUST BE

IN ACCORDANCE WITH CAN/CGA-B149.1&2 OF THE

INSTALLATION CODE, AND LOCAL CODES WHERE

APPLICABLE. ALL ELECTRIC WIRING MUST BE IN

ACCORDANCE WITH THE CURRENT CANADIAN ELECTRICAL

CODE, C22.1 PART 1. GROUNDING THIS APPLIANCE MUST

CONFORM TO CANADIAN ELECTRICAL CODE, CSA C22.2.

WARNING INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING

IMPROPER INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND /OR DAMAGE TO EQUIPMENT. UNIT MUST

BE INSTALLED N ACCORDANCE WITH ALL APPLICABLE

CODES.

WARNING DO NOT ALLOW ANY PART OF YOUR BODY TO BE UNDER THE

OVEN DURING THE LIFTING PROCESS. KEEP EVERYONE

CLEAR FROM THE OVEN IF IT SHOULD FALL.

Raising

Note: Single ovens come pre-assembled and will not require assembly.

Assembly

Note: Nudge the halves with pry bars to move them. Do not force parts to fit.

Raise the oven to its vertical, upright position with the use of a forklift or other lifting device. Lower the

oven to the floor without dropping.

• Raise one end of each oven skid with a forklift until the oven is at 60° from horizontal. (If a forklift

is not available, use a pallet jack and successive stacks of pallets to raise the oven. DO NOT LIFT

THE OVEN BY HAND). Tilt the oven to the vertical position by hand from the raised position.

• Ease the oven to the floor and do not allow it to fall over. OVEN HALVES ARE UNSTABLE.

• Move the erected oven halves to where the mating faces are 2-3 feet apart.

• Place the oven floor on the ground against the right wall of the oven and 6 inches forward of the rear

wall.

• Carefully raise the front edge of the right wall with a pry bar and slide the floor back until it touches

the back wall.

• Slide the right half of the oven toward the left half until the two mate together.

• Bolt the inner skin together at the rear, top and front header using 5/16-18 gimlet point screws

provided.

• Install ½-13x1 hex head bolts, nuts, and lock washers at the joint in the rear base, rear top frame and

header. Snug all bolts tight.

• Install the insulation provided at the center joint so that there are three layers and no voids.

• Slide the rear joint panel into the upper frame at the back of the oven and drop it into the lower

frame to close the back of the oven.

• Place the top insulation cover in place and secure it to the outer ceiling panel with the drill tip screws

provided.

ETL File 3028821 11 REV.B2006

Page 12

INSTALLATION CONT’D

Assembly Cont’d

• Raise the front header cover into position between the front jambs and slip it over the header frame until it

is flush with the front. Install two drill-tip screws through the top flange of the header cover. Install

#10x¾ stainless steel sheet metal screws through the bottom flange of the header cover. Use care to keep

the gasket in place.

• Install ¼-20x½” truss head stainless steel screws through the inner ceiling joint, inside the oven.

• Place the floor clamp strips around the inside walls of the oven. Install, using ¼-20x½” truss head screws,

washers and lock-washers; longer screws are provided for the overlapping joints at the corners. Do not

tighten these screws until the oven has been placed at its final location and leveled.

Note: Lifter installation is not required on some ovens

• Place the lifter assembly on top to the oven without the rotator assembly. Center the lifter over the rotator

shaft housing with the lift motor to the rear of the oven.

• Install the rotator assembly through the lifter, using care to locate the spring-steel clip between the

elevation micro-switches.

• Move the lifter assembly around until the rotator assembly is clear of the lifter frame and all moving parts

are free (this should be where the lifter is centered on the rotator shaft). Anchor the lifter assembly in place

with the fasteners provided.

• Remove the snap ring, square washer and shipping spacer from the rotator shaft.

• Remove the rack carrier from the bottom of the hood crate. Install the carrier on the rotator shaft inside the

oven using the snap ring provided. Install the four set-screws in the carrier-shaft collar. Do not tighten yet,

as this will allow the carrier to be aligned later.

• Install the end of the flex conduit from the blower motor into the lift frame.

• Uncoil the hi-limit switch from the hi-limit protector bracket and install in the side of the lifter frame with

the screws provided.

• Install the door micro-switch, (shipped wired to the lifter frame) at the door switch actuator bracket above

the loading door. Adjust the switch for 1/8” over travel. Adjust the switch actuator for maximum travel.

• Connect the wires (34, 35 and 36) from the blower motor to the same wires in the lifter frame.

• Connect the wires (48 and 49) to the terminal at the high-limit switch.

• Connect the white plastic connector from the main harness to the white plastic connector on the lifter

harness.

• Check the location of all of the wires to ensure that they are free of sharp edges or moving parts.

• Install the transport wheel on the left jamb by raising the oven with the left front jackscrew, located behind

the control door. Use the pan head machine screws provided.

• Extend the transport wheel by adjusting the leveling jack-screws in the rear.

ETL File 3028821 12 REV.B2006

Page 13

INSTALLATION CONT’D

Setting

Remove the vinyl protective coating from all of the exterior surfaces.

Roll the oven into its final installed position. (You may wish to install the hood before locating the oven.)

Adjust the left front leveling screw until the weight is removed from the wheel assembly. Remove the

wheel assembly.

For right hand doors: adjust the rear leveling screws and the left front leveling screws until the left jamb

is level from left to right and front to back. Lock the left front adjusting screw in place.

Install the loading door.

• Remove the loading door from its crate.

• Stand the door upright and move it into place with a hand truck.

• Align and screw the hinge plate to the door jamb.

• Use care to avoid damaging the door seal.

Adjust the right front leveling screw until the gap at the top of the door opening is even all across. Check

the gap along the left side of the door. Recheck the level of the oven.

For left hand doors: adjust the rear leveling screws and the right front leveling screws until the right

jamb is level from left to right and front to back. Lock the right front adjusting screw in place.

Install the loading door.

• Remove the loading door from its crate.

• Stand the door up right and move it into place with a hand truck.

• Raise the door hinges over the jamb hinges with the hand truck and lower into place.

• Use care to avoid damaging the door seal.

Adjust the left front leveling screw until the gap at the top of the door opening is even all across. Check

the gap along the right side of the door. Recheck the level of the oven.

Loosen the floor clamp screws around the perimeter of the oven floor.

Walk around the stainless floor until it is in full contact with the concrete floor. Retighten the floor clamp

screws.

Drill the floor with a 3/8” diameter drill to accept the concrete floor anchors.

• Mark the drill bit at 1-1/2” from the end with tape. Drill until the mark is at the top of the

stainless steel floor. Do not drill too deep.

• Clean the holes of concrete dust.

• If the oven is mounted on stone or ceramic tile, extend the holes and the anchors into the

concrete substrate.

Install the anchors in the holes and set in place with the anchor-setting tool. (Note: One good solid blow

is better than many little taps.)

Install the flat head screws in the anchors. Use the anchor washers in the holes at the middle of the floor

these are larger anchor holes.

Adjust the Loading door latch to ensure a good seal around the door. Do not over tighten the door.

Adjust the floor seal at the bottom of the door with door closed to insure a good seal to the floor

when the door is closed. This is important for as even of bake as possible.

ETL File 3028821 13 REV.B2006

Page 14

INSTALLATION CONT’D

Check the level of the rack carrier shaft. Place an accurate level on the top of the carrier and rotate the carrier

to the four points of the compass. The level bubble should be in the same position relative to the carrier

when rotated. If not, remove the carrier and level the shaft.

• Loosen the four corner screws on the rotator shaft level adjusting plate on the under side of the

inner ceiling. Remove the two remaining screws.

• Move the shaft manually until the shaft is level in all four directions.

• Retighten the four corner screws.

Drill two new screw holes in the adjusting plate with a #7 drill bit and tap #¼-20. Install the two remaining

screws to lock the shaft level in place.

NOTICE It is imperative that a mechanical exhauster is installed, and the

pressure sensitive switch provided is connected at the collar of

the hood. If a negative draw of 0.6” W.C. is not achieved, the

burner will not come on.

NOTICE No other exhaust systems may be connected to this system. Do

not try to vent or exhaust another appliance into this hood.

Installing the Hood

• Remove the hood from the hood crate. Place the body of the hood on the floor with the open side down.

Use cardboard or other protective material to avoid scratches.

• Remove all protective vinyl coatings and place the hood side support trim on each side of the hood and

screw to the front of the hood with (4) #1/4-20 stainless steel truss head machine screws and spacer

bushings. Install (4) #10-32 truss head stainless steel machine screws through the side support trim and

into the top of the hood.

• Attach the rear trim to the opposite end of the hood side support trim using (4) ¼-20 truss head stainless

steel machine screws.

• Place the combustion exhaust duct (shipped strapped to the oven skid) on the top of the heat exchanger

exhaust opening.

• Lift the hood and trim assembly and place it over the top of the oven so that the side and rear trim rest on

the top of the oven.

• Push the hood assembly toward the rear of the oven and align the vent exhaust opening and the exhaust

duct opening with the associated ducts on the oven.

• Attach the hood side support trim and the rear trim to the top of the oven with ¼-20 stainless steel truss

head machine screws.

• Attach the hood to the exhaust and vent ducts using #10 stainless steel sheet metal screws.

• Install the hood airflow sensor tube at the hood collar opening and at the airflow switch in the lifter

assembly located at the top of the oven. Double-check this connection for leaks or crimps in the tube or

hose.

• Install the hood deflector using #10-32 stainless steel round head machine screws at the back of the

deflector and #10-32 stainless steel truss head machine screws at three holes at the front edge of the

deflector.

• Place the three hood filters and the filler channel in the hood filter holder and onto the front lip of the

hood.

• Place the hood grease cup on the rear lip of the hood at the drain opening.

• Install the hood valance on the front of the hood.

ETL File 3028821 14 REV.B2006

Page 15

INSTALLATION CONT’D

Connecting Utilities

NOTICE

• Connect gas to the oven at the gas connection pipe located at the upper left corner of the oven, above the

control cabinet. Be sure that there will be ample gas supply to operate the oven with 5” to 14” W/C at all

times with never more than ½” W/C pressure drop. All gas equipment on supply line on and running.

RO-1G 175,000 BTU each, BARO-2G 290,000 BTU each.

BA

•

• Connect the

voltage ratings. 208, 240 or 480 three phase and 120V single phase required. Wire in compliance with

local requirements and the National Electric Code.

• Connect water supply to the oven at the water solenoid valve at the top left corner of the oven. Water

supply must be between 20 and 80 PSI at all times with a water flow of 9 gallons per minute max only

while steaming. Steam is only used 10 seconds every ½ hour so water consumption will be very low.

Provide a water shut-off valve near the oven for servicing.

• Connect the drain to the oven. Water drained from the oven will reach temperatures near boiling. The

drain line must be provided with an air gap to prevent back siphoning.

Start-up

• Remove all protective coatings from the oven surface, inside and out.

• Turn on the gas and water supplies to the oven. Check for leaks. Repair any leaks before proceeding.

• Confirm that all electrical connections are proper and all covers are in place. Confirm that the oven is

• Turn on electrical power to the oven. Turn on all circuit breakers located in the electrical compartment.

• Press and hold the power button until the display turns on. The oven interior light should turn on and the

• Close the loading door. The lifter and rack carrier should raise and begin to rotate. Open the door and

• Place a “B” type oven rack in the oven. Measure the spacing between the oven rack top channels and the

• Close the loading door and check the direction of rotation of the blower motor. The motor should rotate

• Heat the oven to 300°F. (Refer to the programming section of this manual for control operating

• Check the oven for gas leaks, excessive smoke, vibration and general operation.

properly grounded.

control display should light up.

allow the carrier to stop rotating. Check the position of the alignment of the carrier to the door with no

load on rack carrier. If the carrier needs adjustment, remove the chrome caps from the center channel on

the rack carrier. Loosen the four set-screws that lock the carrier to the shaft. Rotate the carrier until it

aligns with the door and retighten the set-screws. Replace the chrome caps.

rack carrier. The space between the carrier lip and the top flange of the rack channel should be

approximately ¾”. Adjust the lifter micro-switch mount on the lifter body to compensate.

counterclockwise when viewed from the top. If motor runs counterclockwise when viewed from the top

reverse L1 and L2 at the power supply side of the motor circuit breaker. This is very important for an

even bake.

instructions.)

Do not allow more than 14 inches pressure to be applied to the

gas valve at any time.

electrical service connection to the oven. Consult the data plate for specific current and

ETL File 3028821 15 REV.B2006

Page 16

INSTALLATION CONT’D

CAUTION

ETL File 3028821 16 REV.B2006

IF BLOWER ROTATION IS INCORRECT, IT WILL CAUSE SEVERE

DAMAGE TO HEAT EXCHANGER

Page 17

EMERGENCY OPERATION

WARNING

Power Failure

Do not attempt to operate oven.

Turn the Circuit Breakers off until power is restored.

Remove the product from the rack.

WARNING

Burner Failure

1. Reset the burner:

a. Turn the controller off.

b. Turn burner gas shut off valve’s to “OFF”.

NOTICE

c. Turn burner gas shut-off valves to “ON”.

WHEN REMOVING THE RACK OR PRODUCT FROM THE RACK,

WHERE HOT MITTS TO AVOID SERIOUS BURNS.

DO NOT UNLOAD THE RACK FROM THE OVEN WHILE THE

CARRIER IS IN THE LIFT POSITION. LOADED RACKS CAN BE

EXTREMELY HEAVY.

Wait a minimum of five minutes before proceeding to the next

step.

d. Turn the controller back on.

e. If necessary re-adjust the Temp to the desired temperature.

2. Burner should now restart.

Product fire in the baking chamber

1. Turn circuit breakers off.

2. Wait until the fire has gone out and oven chamber cools before opening the door.

WARNING

WARNING

NOTICE

NOTICE

WARNING

DO NOT REMOVE A FLAMING PRODUCT FROM THE OVEN.

SEVERE BURNS AND PROPERTY DAMAGE CAN RESULT.

THIS ADAMATIC/BELSHAW OVEN PRODUCES HUMIDITY THAT

CAN CAUSE INTERIOR FLOORING AND ADJACENT EXTERIOR

FLOORING TO BECOME SLIPPERY. USE EXTREME CAUTION

WHEN WALKING ON A WET OR DAMP FLOOR.

The ambient temperature outside the oven should not exceed

104° F (40° C). This includes the temperature of the air above

and around the oven.

During the first few hours of operation you may notice a small

amount of smoke coming off of the oven, and a faint odor from

the smoke. This is normal for a new oven and will disappear

after the first few hours of use.

WHEN THE LOADING DOOR IS OPENED, HOT AIR AND STEAM

ARE RELEASED FROM THE OVEN INTERIOR. TO AVOID BURNS

OPEN DOOR SLOWLY AND KEEP YOUR FACE AND HANDS

CLEAR OF THE OPENING. ALL INTERIOR SURFACES ARE

VERY HOT. DO NOT TOUCH ANYTHING WITHOUT OVEN MITTS.

ETL3028821 17 REV.B2006

Page 18

GENERAL OPERATION

Loading Procedures

Set the controls.

Open the door (slowly). Wait for the rack carrier to stop and lower.

Confirm that the rack stop is in the loading (LEADING FLAP UP) position.

Align the top channels of the oven rack with the rack carrier and push the rack past the rack stop.

Close the loading door. The rack carrier will automatically lift the rack and begin to rotate.

Begin baking by pressing START. A buzzer will sound when baking is completed.

Unloading Procedure

Press the Silence button or open the loading door to turn off the buzzer.

You can view your product through the window. If it appears ready, SLOWLY open the loading door

about 6 inches. Let steam and hot air escape from the opening (to be removed through the hood.)

Open the door completely. The rack carrier will come to a stop and the rack will lower.

USING OVEN MITTS flip the rack stop to the unloading (LEADING FLAP DOWN) position.

Remove the rack from the rack carrier.

Close the loading door.

Shut Down Procedure

1. Press the power button. Display, Lights, and Vent Blower should shut off.

2. For lengthy shutdown periods or maintenance, turn power off at the120-volt and 208/240-volt control

power circuit breakers.

3. Turn off the gas supply by setting the Manual Gas Supply Shutoff valves to “OFF”.

4. For suggested cleaning schedule

see the final pages of this manual.

ETL3028821 18 REV.B2006

Page 19

GENERAL OPERATION CONT’D

NOTICE

Service on this ADAMATIC/BELSHAW appliance must be

performed by qualified personnel only. Consult your dealer

or distributor, or call the factory at 1-800-578-2547 for

authorized service.

NOTICE

To maintain optimum safety and performance for this Adamatic/

Belshaw Rack Oven, it is recommended that a program of

scheduled periodic maintenance be implemented. It is the sole

responsibility of the user to establish, schedule and enforce

such a program. Although the actual service interval will vary

depending on the environment in which the equipment is

operating, it is recommended the following be done by an

authorized service agency at least every 6 months.

For a suggested cleaning schedule, see the final pages of this manual.

ETL3028821 19 REV.B2006

Page 20

BARO-1G

ETL3028821 20 REV.B2006

Page 21

ETL3028821 21 REV.B2006

Page 22

RESISTANCE CHARTS

Measure the probe resistance against actual temperature in the Pressure Panel, not Control

Panel Display temperature. Place thermocouple in Pressure Panel just behind louvers about waist

high, not in center of oven

when reading air temperature.

70403-03 Water Valve 3.5

70403-04 120V Vent Solenoid 80

30701-05 Relay 24V 35

80505-14 Gas Valve MV Pins 1-2 62

80505-14 Gas Valve Brown Wire to Brown Wire 19

30700-14 Motor Contactor 5.5

ETL3028821 22 REV.B2006

. Make sure tip of thermocouple does not come in contact with metal

Page 23

SAFETY CONSIDERATIONS

ADAMATIC/BELSHAW bakery oven is ETL listed a

Your

A)

The responsibility of the manufacturer

recommendations for the operation and maintenance of the subject units.

B) Trained, qualified personnel must perform all operation, maintenance and repair of the subject units. It is the

responsibility of the owner/operator

C) A regular periodic program of cleaning, inspection and maintenance must be established and comprehensive

maintenance records maintained. It is the sole responsibility of the user

frequency and scope of these programs in keeping with recommended practice and with due consideration given to

For a suggested cleaning schedule, see the final pages of this manual.

D)

actual operating conditions.

The units must be operated within limits, which will not exceed the working limits of any component.

is to supply suitable, comprehensive instructions and

to insure this happens.

s a unit, and meets safety standards.

to establish, schedule and enforce the

ETL3028821 23 REV.B2006

Page 24

ETL File 3028821 24 REV.A2002

ITMEM # QTY. PART # DESCRIPTION

1A BARO-1G gets 20 BARO-2G get 28 80400-14 GAS ORIFICE SPUD, #53 DRILL, NG

1B BARO-1G gets 20 BARO-2G get 28 80400-31 GAS ORIFICE SPUD, #58 DRILL, LP

1C BARO-1G gets 20 BARO-2G get 28 80400-34 GAS ORIFICE SPUD, #578 DRILL, LP (FOR INSTALLATIONS BETWEEN 3000’ & 6000’)

2 BARO-1G gets 20 BARO-2G get 8000 BURNER

3 1 80201-29 PILOT BURNER WITH SPARK ELECTRODE (STANDING PILOT MODELS ONLY)

Not Shown 1 80302-12 HOT SURFACE IGNITER ( HOT SURFACE IGNITION MODELS ONLY)

Not Shown 1 41100-36-1 SENSOR ( HOT SURFACE IGNITION MODELS ONLY)

PARTS LIST

Page 25

ETL File 3028821 25 REV.B2006

ITMEM # QTY. PART # DESCRIPTION

OLT SPARK MODULE (STANDING

1 1 80300-03

2 1 150-621

3 1 80506-01

4

Not Shown

1

80300-18

120-V

PILOT MODELS ONLY)

LAME SENSOR MOUNT (STANDING PILOT

F

MODELS ONLY

ILOT FLAME SWITCH (STANDING PILOT

P

MODELS ONLY

GNITION CONTROL (HOT SURFACE IGNITION

I

MODELS)

)

)

PARTS LIST CON’T

Page 26

PARTS LIST CONT’D

ITEM# QTY PART # DESCRIPTION

1 1 70404-03 GAUGE 0-100 PSI

2 1 70404-05 REGULATOR, WATER 10 PSI

3 1 70302-39 BRASS PIPE NIPPLE, ½ NPT

4 1 70101-102 BRASS TEE, ½ NPT

5 1 70302-39 BRASS PIPE NIPPLE, ½ NPT

6 1 70403-03 SOLENOID VALVE, WATER

7 1 70307-08 PIPE REDUCER, ½ X 3/8

8 1 41100-33 TEMPERATURE SENSING PROBE

9 1 70101-100 COMPRESSION FITTING FOR PROBE

10 1 30301-02 MICRO SWITCH DOOR

11 1 70701-92 BRASS FITTING-PACKING FOR STAT

12 1 70307-04 PIPE REDUCER, ½ X 1/4

ETL File 3028821 26 REV.B2006

Page 27

PARTS LIST CONT’D

ITMEM # QTY. PART # DESCRIPTION

1 1 50800-103 MAIN HANDLE ASSEMBLY

2 1 72609-18 SWEEPER BARO-1

2 1 72609-181 SWEEPER BARO-2

3 1 150-786 FEMALE HINGE ASSEMBLY, LOWER

4 1 150-786-1 FEMALE HINGE ASSEMBLY, UPPER

5 1 150-703 ESCAPE HANDLE ASSEMBLY

6 1 71301-19 WINDOW ASSEMBLY

ETL File 3028821 27 REV.B2006

Page 28

PARTS LIST CONT’D

Item # Part # Description QTY

2 30701-05 24V Coil Relay 2 Pole 3

3 30402-38 Stat Adj 450° 72" C/T SP173 1

4 30303-06 Swt Tog On-On 2 Pole 1

Swt Tog On-On Mom W/

5 30303-16

6 20102-06 6-32x 3/8" Bolt 2

8 70701-17 Knob "B" Assy 1

9 60301-158-99 Label Back Up Control 1

Spring

1

ETL File 3028821 28 REV.B2006

Page 29

PARTS LIST CONT’D

NOTE: If Overload is not marked

LR2 D13 a 30707-06 base must

be ordered with the 30707-06

Item No. Qty. Part No. Description

1 4 30500-16 TERMINAL BLOCK

2 1 31800-12 3 PHASE, 15 AMP CIRCUIT BREAKER

3 2 150-657 DINRAIL, 6”

4 1 30700-15 CONTACTOR, CIRCULATION BLOWER

5 1 30707-03 OVERLOAD, CIRCULATION BLOWER

6 1 31600-12 LIGHT BALLAST

7 5 30701-05 RELAY, 24-VOLT

8 1 31400-32 TRANSFORMER, 120/24 VOLT

9 1 31400-31 OBSOLETE TRANSFORMER

O

10 1 30707-06

10 A 1 30707-07 BASE PLATE FOR 30707-06

11 1 31200-08 GROUND LUG

12 2 31800-13 SINGLE POLE CIRCUIT BREAKERS 120V 15A

13 1 60301-142 PANEL LABEL

13 A 1 40102-54 CIRCUIT BOARD, COMPLETE

13 B 1 40102-54-1 CIRCUIT BOARD, LED

13 C 1 40102-54-3 CIRCUIT BOARD, CPU / LCD

13 D 1 40102-54-4 CIRCUIT BOARD, RELAY OUTPUT BOARD

13 E 1 40102-54-5 CIRCUIT BOARD, KEY PAD

VERLOAD, LIFT ROTATE ASSEMBLY

USES WITH BASE 30707-07 SEE ABOVE NOTE.

ETL File 3028821 29 REV.B2006

Page 30

PARTS LIST CONT’D

NOTE: Serial

numbers beginning

with S- use Linear

Actuator part #

30200-64

All Pass-through’s

use 30200-57

ETL File 3028821 30 REV.B2006

Page 31

PARTS LIST CONT’D

ITMEM # QTY. PART # DESCRIPTION

1 2 50803-003 DRIVE BUSHING

2 1 70200-11 BUSHING

3 1 70200-12 WASHER

4 1 73000-06 DRIVE SPROCKET

4 1 73000-06a DRIVE GEAR

5 1 73000-05 MOTOR SPROCKET

5 1 73000-05a MOTOR GEAR

6 1 40704-06 MOTOR CAPACITOR

7 1 71500-12 ROTATION MOTOR FAN

8 1 30200-56 DRIVE MOTOR

9 1 30301-15 ROTATOR MICRO SWITCH

10 1 50803-002 DRIVE COLLAR

11 1 70200-14 WASHER FRICTION THRUST

12 1 70200-13 BUSHING, CHAIN GEAR

Not Shown 2 20601-04 1.438” SNAP RING

Not Shown 19.5 73100-06 CHAIN ROLLER

ETL File 3028821 31 REV.B2006

Page 32

PARTS LIST CONT’D

ITEM# QTY. PART# DESCRIPTION

1 1 30200-59 MAIN BLOWER MOTOR

1 1 30200-61 SINGLE PHASE ONLY MOTOR

2 1 71500-14 MAIN BLOWER HEAT SINK

3 1 20601-07 RETAINING SNAP RING

4 1 150-368 BUSHING

5 1 71500-13 MAIN BLOWER WHEEL BARO1

5 1 71500-15 MAIN BLOWER WHEEL BARO2

ETL File 3028821 32 REV.B2006

Page 33

PARTS LIST CONT’D

ITEM # QTY. PART # DESCRIPTION

1 1 150-135 LIGHT HOUSING BACK

2 2 31602-07 LIGHT SOCKET

3 1 31600-13 4 FOOT FLUORESCENT BULB

4 2 20201-09 5/16” WASHER

5 1 50803-009 DAMPER ROD

6 1 150-790 DAMPER FORK

7 1 150-353 DAMPER ARM

8 1 150-349 DAMPER MOUNT

9 1 70403-04 120-VOLT DAMPER SOLENOID

10 1 80505-14 GAS VALVE, NG OR LP

ETL File 3028821 33 REV.B2006

Page 34

WIRING DIAGRAM

Standing Pilot Models

120 VAC

CB1 CB2

LINE

LINE

3

TB1

To Vent Motor

5

TB2

NGND

7

2 2

4

6

TR2

3

2

44

TR1-1

1

J 1

13

2

J6

2

2

RTD

45

208/240 VAC

44

44

44

44

44

44

44

87

J4

65

J4

50

43

J4

4

3

J5

21

J4

MR5

59

46

MR1

P1-5

HL1

48

OL1

P1-6

52

MR6

53

6

12 13 14

OL2

51

MR4

17

45

AS1

57

45

P2-4

P2-5

49

MR2

SV1

SA1

60

57

P2-1 P2-2

MS2

CA1

MS3

15

UP

16

DN

18

MS4

Heat

Circuit

45

45

28

61

12

J5

MR3

58

4547

45

1 - 21 120 Volt

31 - 36 208/240 Volt

41 - 61 24 Volt

Shielded 5 Volt DC

Cable

56

MS1

45

45

45

J1 - J6 Computer

P1 [1 - 9] Plug, Control

P2 [1 - 9] Plug, Lift -

RED

19

M2

M

BLK

BLK

M

RED

M3

P2-3

2

2

CB3

L1 L2 L3

31 32 33

34 35 36

M

M1

L1 - T1,T7

L2 - T2,T8

L3 - T3,T9

(T4,T5,T6)

Inputs and

Outputs

Component

Mount

Rotate

Assembly

IL1

20 21

6

BA1

2

ETL File 3028821 34 REV.B2006

Page 35

CONTROL PANEL LAYOUT

Item # Description

TB2 Terminal Block 2, Roof ventilator connection

TB1 Terminal Block 1, Roof ventilator connection

CB1 Circuit Breaker 3-phase power supply, 30 Amp

OL1 Over Load Circuit Protection, Circulation Blower

Ballast 120 V Lamp Ballast

CB4 Circuit Breaker 1-phase 120V Line supply, 15 Amp

CB5 Circuit Breaker 1-phase 120V Line (Jump from CB4), 15 Amp

TB3 Terminal Block, 120V Neutral Supply

OL2 Lift and Rotation Motor Overload Protection

TR1 Transformer (120V – 10V) Control Circuit (no installed on hot

surface models)

TR2 Transformer (120V – 24V) All Controls

MR1 Main 120V supply (Note: On Hot Surface models this is MR2)

MR2 4 Pole Circulation Blower contactor, Heat call safety

(Note: On Hot Surface models this is MR1)

MR3 24 V 1 set of contacts for CPU door switch, 1 set of points

for MR4

MR4 Coil controlled by MR3 and rotation switch. Points control Lift

actuator in N/C and rotation motor in N/O.

MR5 OL2 controls coil contacts control linear actuator and rotation.

MR6 Vent control

MR7,8 & 9 Back-up controls relay

Note: On Hot

Surface Ignition

Models This is

MR1

Note: On

Hot Surface

Ignition

Models This is

MR2

ETL File 3028821 35 REV.B2006

Page 36

GAS CIRCUITS

For Models Using Hot Surface

Ignition

1 brown wire from valve

goes to pin 1.

1 brown wire from valve

goes to pin 2.

For Models Using Pilot Ignition

Systems

1 brown wire from valve

goes to pin 1.

1 brown wire from valve

goes to pin 4.

ETL File 3028821 36 REV.B2006

Page 37

WIRING DIAGRAM

ETL File 3028821 37 REV.B2006

Page 38

Service and Troubleshooting

Model BARO Rack Oven

1.

Door Open in display

2. Preheat in display

3. No power to heat circuit wires 54 and 45

No or Low Heat

• If display reads Door Open while door is shut and rack carrier lifts and rotates

check MR3 for normal operation. Test heat circuit by jumping J5 on relay

board; at this point display should read Preheat and burner should fire. If J5 is

jumped and display still reads door open replace relay board.

• If display reads Door Open and rack does not lift or rotate check door switch

and MR3 for normal operation. Test heat circuit by jumping J5 on relay board;

at this point display should read Preheat, burner should fire and rack carrier

should lift and rotate. If J5 is jumped and display still reads door open replace

relay board.

• LD3 on relay board will illuminate when board is calling for heat; 24VAC from

wire 47 to wire 45 should then be present.

• If blower delay is set oven will not call for heat until set time elapses.

• Check to assure circulation blower contactor is closed and 24VAC is present

between wires 49 and 45 (ground on ovens built after Jan. 2005). If voltage is

present 24VAC should also be present at heat circuit.

• Check for 24VAC on relay board when LD3 is illuminated between wires 47

and 45. Check air switch for 24VAC to ground. Jump out air switch or test for

continuity. Check for water in air line; bend upward loop in airline to prevent

water from entering air switch. Check for required airflow: Singles (BARO-1)

1520 FPM @ 530 CFM. Doubles 2300 FPM @ 800 CFM. A negative draw of

0.6” Water Column is necessary to close air switch. This can be an intermittent

issue; if the vent motor is tripping on thermal overload or pulling a borderline

volume of air it can appear to be an oven issue. Keep checking water column if

air switch is intermittently opening. 120VAC is supplied to roof vent blower

through CB5 and MR2. 120VAC should be present on TB1 and TB2.

• If air switch is closed test high limit; at this point 24VAC should be present at

circulation blower contactor wire 49 to 45 (ground on ovens built after Jan.

2005) and then to wire 54 to heat circuit.

ETL File 3028821 38 REV.B2006

Page 39

BARO Rack Oven

Model

4. Power to heat circuit, low heat, slow heat

• Check for 24VAC at wires 54 and 45 on hot surface igniter and ignition control

simultaneously. Ignition control should blink once and hot surface igniter

should glow red hot. If igniter glows intermittently replace igniter.

• Ignition control proves hot surface igniter amps. After approximately 7 seconds

24VAC from ignition control should be present to wires 45 and 45A on pins 1

and 2 of main valve, and at 2 brown wires also plugged into pins 1 and 2 on

main valve. Valve should then open igniting burners.

• Main valve coil (pins 1 and 2) with 2 brown wires unplugged should read 62.

Redundant pilot valve (2 brown wires) should read 19 unplugged.

• Once burners are lit 4 micro amps should be present from flame sensor to pin S2

on ignition control. If micro amps are weak check gas supply pressure, NG 5”14” and LP 10”-14” with never more than a ½” W/C pressure drop—this could

indicate low gas volume. Manifold pressure on BARO-1G 3” NG and 8” LP.

Manifold pressure on BARO-2G 2.5”-2.8” NG (see tag on valve) and 6” LP. If

gas supply is sufficient and micro amp reading is low replace flame sensor.

• If burner does not stay lit long enough to develop a micro amp reading on flame

sensor check for continuity between wire 45 on valve and chassis ground.

• Check oven calibration and probe reading.

Temperature Erratic

1. Temperature in display jumping

• Make sure a program is correct (0 blower delay) and countdown timer is

running. Display temperature will jump around dramatically when Automatic

Energy Management System turns on; this is a normal energy saving feature. If

temperature stays at one temperature or drops before preheat temperature is

achieved or to turn AEMS off, (on software versions 3.07 and newer) contact

factory @ 1-888-722-5686.

• Temperature will drop when steam is run. More than 15 seconds of steam is not

recommended; at this point no more steam is generated and oven is drastically

cooled.

• After temperature begins to climb in preheat the temperature should increase in

increments of 2-3 degrees every 4-7 seconds. If temperature is sticking on one

temperature in preheat and taking more than 7 seconds to change contact factory

@ 1-888-722-5686.

ETL File 3028821 39 REV.B2006

Page 40

Model BARO Rack Oven

No Steam

1. Oven not generating steam

• Preheat oven to at least 300º for at least 20 minutes before steam cycle. Wait at

least 20 minutes between cycles.

• Check for 30 plus PSI to oven.

• Check water supply valves and filters. Is other equipment on same water supply

line working?

• Check steam tubes in oven for security.

• LD5 on relay board will illuminate when steam relay is closed; 24V from wire

52 to wire 45 (ground on ovens built after Jan. 2005) should then be present. At

this point you should have 24V to solenoid and solenoid should open. Check

solenoid coil for 80.

No Rack Lift/Rotate and, or Light

1. Display on, no rack lift/rotate or light

• With display turned on LD4 illuminates; at this point 24VAC should be present

from wire 46 to wire 45 (ground on ovens built after Jan. 2005). At this point

you should have 24VAC to MR2 coil.

• Check MR2 for normal operation; at this point 120VAC should be present

between wire 6 and wire 2 and the roof vent blower and light should turn on.

• If light does not turn on check bulb and ballast.

• If rack carrier does not lift and rotate check door switch and

MR3 for normal operation; at this point you should have Preheat in display and

24VAC to MR4 coil.

• If 120VAC is not present from wire 13 to ground on MR4 check MR5 and OL2

for normal operation. If 120VAC is present from wire 13 to ground on MR4 and

through MR4 on wire 14 to upper limit switch check upper limit switch for

120VAC to ground.

• In normally closed condition the upper limit switch should send 120VAC to lift

motor on wire 16 until upper limit switch clicks to normally open, then

120VAC through wire 15 should be present at rotate motor. Check wire 15 and

16 to ground for 120VAC.

• If 120VAC is present at wire 16 to wire 2 and lift actuator will not lift check

capacitor before changing lift motor.

• If 120VAC is present at wire 15 to wire 2 and rotate motor will not turn check

capacitor before changing motor.

• If rotation motor is turning and rack carrier is not turning check motor sprocket

(or motor gear on models built after July 06), chain (on models built before July

06 only), friction washer, drive sprocket (or drive gear on models built after July

06) and drive collar for security and proper operation. At this point rack carrier

should turn.

ETL File 3028821 40 REV.B2006

Page 41

Model BARO Rack Oven

1. Display on, no rack lift/rotate or light continued

• Check for proper rack (height and slide dimensions) and upper limit switch for

proper adjustment. Make sure both rack clips on carrier lock.

• Check floor anchors for security. If floor is not secure it will buckle up and

keep racks from turning.

• Check oven level and shaft plumb.

Rack Continues to Rotate or Does not Lower

1. Rack continues to rotate or does not lower when door is open

• Check door switch for normal operation.

• Check MR3 for normal operation.

• Display at this point should read door open.

• Check pointer switch for normal operation. When pointer switch is open and

MR3 points are open MR4 should be in normally closed condition.

• Check MR4 and lower limit switch for normal operation.

• If 120VAC is present between wires 18 and 2 on lift actuator and actuator will

not lower check capacitor before changing actuator.

Burner Screeching or Banging on Ignition

1. Gas pressure

• Check gas supply pressure, NG 5”-14” and LP 10”-14” with never more than a

½” W/C pressure drop—this could indicate low gas volume. Manifold pressure

on BARO-1G 3” NG and 8” LP. Manifold pressure on BARO-2G 2.5”-2.8” NG

(see tag on valve) and 6” LP.

2. Exhaust plugged

• Check exhaust for obstructions.

3. Cracked heat exchanger

• Inspect heat exchanger for cracks.

4. Inshot burners obstructed or damaged

• Visually check flames to make sure they are burning straight up burner tubes

and not rolling into manifold.

• Pull manifold and correct burner alignment.

• Remove foreign objects and clean flour or dust buildup from burners.

5. Valve leaking

• If valve does not seat closed gas can leak into heat exchanger when not

calling for heat.

ETL File 3028821 41 REV.B2006

Page 42

Model BARO Rack Oven

1. Circulation blower running backwards

• Circulation blower motor should spin counterclockwise when viewed from top.

If blower is spinning backward it will cause longer baking times and uneven

bake.

2. Timer not counting down

• Allow oven to preheat then select program and press start. Cooking in energy

saving mode or with too much blower delay will cause longer baking times and

uneven bake.

3. Baking / product temperature

• Lower temperatures will result in a more consistent, even bake. Baking

temperatures should be about 50° lower and times should be about 10% lower

then standard (non convection) bake oven recipes.

• Product core temperature uneven.

• Product different size or density.

• Calibration accurate. Temps taken inside pressure panel, not center of oven. See

operation instructions or contact factory @ 1-888-722-5686 to enter calibration

mode.

• After temperature begins to climb in preheat the temperature should increase in

increments of 2-3 degrees every 4-7 seconds. If temperature is sticking on one

temperature in preheat and taking more than 7 seconds to change contact factory

@ 1-888-722-5686.

4. Airflow

• Check air shutter settings. See service manual or contact factory

@ 1-888-722-5686.

• Foreign object blocking air flow into heat exchanger.

• Pans too close together. Leave at least 2-3 inches between top of finished

product and bottom of next pan.

1. No LED (red) Display

• No countdown timer. Make sure time is set correctly and press start.

• No countdown timer or red display. Shut off 120V circuit breakers CB4 and

CB5 located behind control panel and turn back on. If display comes back on

contact factory.

Uneven Bake, Burning

No Display

ETL File 3028821 42 REV.B2006

Page 43

Model BARO Rack Oven

2. No LCD (green) Display

• Press power button; at this point display should turn on.

• Check CB4 and CB5 for 120VAC on load side to TB3; at this point you should

have 120VAC to transformer on wires 2 and 3.

• Check transformer for normal operation. Check primary (120V) side of

transformer for 4.5. Too many amps on secondary side of transformer will

pop primary side of transformer. Check transformer secondary side for 12VAC

on center tap. Center tap should read .3. Check transformer secondary for

24VAC on outside 2 pins and for .5.

• Check J1 for 12VAC; at this point LD8 should illuminate. Check grey

communication cable between relay board and CPU display board; at this point

LD1 and LD2 on CPU should illuminate. When power button is pressed the

button board sends information to the CPU and both CPU and LCD display

should illuminate.

3. LCD (green) display hard to read

• A small, grey, square trim pot for adjusting display contrast is located on the top

right corner viewed from rear of CPU/LCD.

• If display overheats lines may develop in display making it hard to read. As

display cools this should go away; however if display is exposed to continuous

high heat this condition may be permanent. If condition reoccurs a cooling fan

may be necessary.

ETL File 3028821 43 REV.B2006

Page 44

CLEANING FOR RACK OVENS & PROOFERS

Read First

Contrary to popular belief stainless steel is susceptible to rusting. Stainless steel is a

passive metal because it has an invisible passive film that covers the surface acting as a

shield against corrosion. If this passive film is broken down corrosion can set in and

begin to spread.

The three primary enemies of stainless steel are:

1. Mechanical abrasion: Anything that will scratch the steel’s surface. Steel pads,

wire brushes, and metallic scrapers are the most common culprits.

2. Water: Hard water leaves deposits that will break down the passive layer and

begin corroding your stainless steel. A water test with a reputable water company

is always a good idea to assure your water quality is up to par.

3. Chlorides and Chloride Cleaners: Chlorides are in water, food, and table salt.

The worst chloride invasion, however, comes from household and industrial

cleaners not made for stainless steel.

Daily Cleaning

Use proper cleaners and tools. Use alkaline, alkaline chlorinated or non-chloride

containing cleaners with soft cloths, soft bristled brushes, plastic scrapers, and plastic

scouring pads.

1. Let unit cool.

2. Sweep floor with heat resistant (straw) broom.

3. Clean both sides of oven window with mild soap and water.

4. Clean control panel with mild soap and water.

5. Clean handle with mild soap and water.

Page 45

Weekly Cleaning

Use proper cleaners and tools. Use alkaline, alkaline chlorinated or non-chloride

containing cleaners with soft cloths, soft bristled brushes, plastic scrapers, and plastic

scouring pads.

1. Perform daily cleaning.

2. Clean interior stainless steel surfaces with a stainless safe cleaner. Dish soap,

ammonia, detergent, and Medallion are all good choices. Rinse with clean water

and dry immediately. The quicker you wipe off standing water that contains

cleaning agents, the better.

Monthly Cleaning

Use proper cleaners and tools. Use alkaline, alkaline chlorinated or non-chloride

containing cleaners with soft cloths, soft bristled brushes, plastic scrapers, and plastic

scouring pads.

1. Perform daily cleaning.

2. Perform weekly cleaning

3. Remove hood filters from oven and clean interior of hood and filters. Make sure

all filters and spacers are reinserted. If not reinserted the lack of vent suction may

keep the oven from heating; also the hood may no longer meet code.

4. Turn off all three circuit breakers on ovens located behind the control panel door.

5. Clean exterior stainless steel surfaces. Dish soap, ammonia, detergent, and

Medallion are all good choices. Rinse with clean water and dry immediately. The

quicker you wipe off standing water that contains cleaning agents, the better.

6. Turn on all three oven circuit breakers.

Quarterly

If water filters are installed contact your water treatment vendor for filter replacement.

Page 46

Page 47

Page 48

Loading...

Loading...