Page 1

O

O

W

W

A

A

NEE

N

R

R

R’’SS

R

O--

O

2

2

& II

&

M

M

G//

G

NSSTT

A

N

A

N

N

U

P

P

U

R

O--

R

O

ALLLL

A

ALL

A

2

G

2

G

ATTII

A

O

O

N

N

Page 2

This manual must be kept in a safe place for future reference.

Be sure to read, understand and follow the instructions and

warnings contained in this manual.

¾ WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury or

death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this

equipment.

¾ FOR YOUR SAFETY: Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of this or any other

appliance.

WARNINGS

¾ WHAT TO DO IF YOU SMELL GAS:

1. Do not try to light the appliance

2. Do not touch any electrical switches or use any phones

within the building

3. Immediately call your gas supplier from a neighbor’s phone

and follow the gas suppliers instructions

4. If you cannot reach your gas supplier, call the Fire

Department

NOTE: Obtain information to be prominently posted near the

oven from you gas supplier.

¾ In the event of a power failure, do not attempt to operate this

equipment.

ARO-2G Double Rack Oven - 2 - Rev. 1.0, Dec. 2006

Page 3

Page

1. Table of Contents………………………………………………….. 3

2. General Information…………………………………..………….... 4

3. Basic Operation………………………………………..……………7

4. Control Overview………………………………………..…………10

5. Entering Programmed Bake Cycles……………………………..14

6. Maintenance & Cleaning………………………………………….16

7. Assembly & Installation……………………………………………17

8. Electrical schematics………………………………………………50

CONTENTS

ARO-2G Double Rack Oven - 3 - Rev. 1.0, Dec. 2006

Page 4

GENERAL INFORMATION

Shipping support angle

ARO-2G Double Rack Oven - 6 - Rev. 1.0, Dec. 2006

Page 5

PREHEAT OVEN

1. Close oven door.

2. Press the “BAKE” key. The Bake indicator light and all the displays will

illuminate.

3. Enter a SET TEMPERATURE to preheat the oven by pressing the “UP”

or “DOWN” set temperature arrow keys to adjust the set temperature

displayed.

¾ NOTE: Racks will not start rotating until “TIMER START” key is

4. Allow oven to preheat at least 20 minutes longer from when the OVEN

TEMPERATURE reaches the SET TEMPERATURE.

MANUALLY SET CONTROL

1. Enter a SET TEMPERATURE, if different from preheat temperature, by

pressing the “UP” or “DOWN” set temperature arrow keys to adjust the

set temperature displayed.

pressed.

OPERATION

2. Enter a BAKE TIME (in minutes) by pressing the “UP” or “DOWN” bake

time arrow keys to adjust the bake time (in minutes) displayed.

3. Enter a STEAM TIME (in seconds) by pressing the “UP” or “DOWN”

steam time arrow keys to adjust the steam time (in seconds) displayed.

USING A PROGRAM TO SET CONTROL

1. Enter a PROGRAM # by pressing the “NEXT PROG.” key to change the

program number displayed.

¾ NOTE: The set temperature, bake time and steam time displayed will

be for Step 1 of the entered program # and the oven will preheat to the

set temperature display.

LOADING PROCEDURES

1. Slowly open the oven door.

¾ CAUTION: Steam and hot air will escape from oven door when

opened. To avoid burns keep hands and face away from door

opening. Oven interior surfaces are very hot, use oven mitt while

touching.

2. Align the channels on the oven rack(s) with the rack carrier and push to

the rear stop.

3. Close the oven door.

ARO-2G Double Rack Oven - 7 - Rev. 1.0, Dec. 2006

Page 6

¾ NOTE: Racks will not start rotating until “TIMER START” key is

pressed.

4. Press the “TIMER START” key to initiate the bake cycle. The indicator

light in the corner of the bake time display will begin blinking and the clock

will start counting down.

¾ NOTE: Oven damper can be opened during bake cycle to evacuate

steam by pressing the “DAMPER” key.

¾ NOTE: If using a programmed bake cycle with multiple steps the timer

counts down the duration of each step separately the buzzer won’t

sound until the time elapses on the last programmed step.

5. A buzzer will sound and all the displays will flash when the bake timer

display counts down to 00:00.

¾ NOTE: Rack will continue rotating until the “TIMER STOP” key is

pressed.

UNLOADING PROCEDURES

1. Press the “TIMER STOP” key to silence the buzzer and stop the rack

rotation.

OPERATION

2. Slowly open the oven door, swing door completely open.

¾ CAUTION: Steam and hot air will escape from oven door when

opened. To avoid burns keep hands and face away from door

opening. Oven racks and interior surfaces are very hot, use oven mitt

while touching.

3. Using oven mitts, open rack locks on rack carrier.

4. Using oven mitts, remove rack(s) from rack carrier.

¾ NOTE: The door could be closed and the “JOG” key pressed to rotate

the rack carrier 180

o

and improve access for removing the second

rack.

5. Close oven door.

SHUT DOWN PROCEDURES

1. Press the “OFF” key. The displays go blank and the oven will turn off.

¾ NOTE: The exhaust hood fan will continue to run for 20 minutes after

the oven is turned off.

¾ NOTE: To cool oven off quicker, press the “FAN” key and open the

oven door. The fan indicator light will illuminate and the fan will run

continuously without a call for heat.

ARO-2G Double Rack Oven - 8 - Rev. 1.0, Dec. 2006

Page 7

¾ WARNING: For service or extended periods of shutdown,

turn the power off at both the 120 V control ci rcuit and 208

– 480 V main power circuit breakers.

ARO-2G Double Rack Oven - 9 - Rev. 1.0, Dec. 2006

Page 8

Adjustment of Air Distribution Panel on New ARO/PRO Oven

*The louver settings are in millimeters.

*A set of metric Allen wrenches will facilitate the job.

*The measurements must be taken at the top and the

bottom of each adjusable louver,

Not at the top and bottom ends of the slots.

BACK MIDDLE FRONT

078

078

068

068

268

367

457

4 4.5 6

4 4.5 6

4.5 4.5 6

5 4.5 6

5 4.5 7

Prepared: 05/15/07

Page 9

6

5

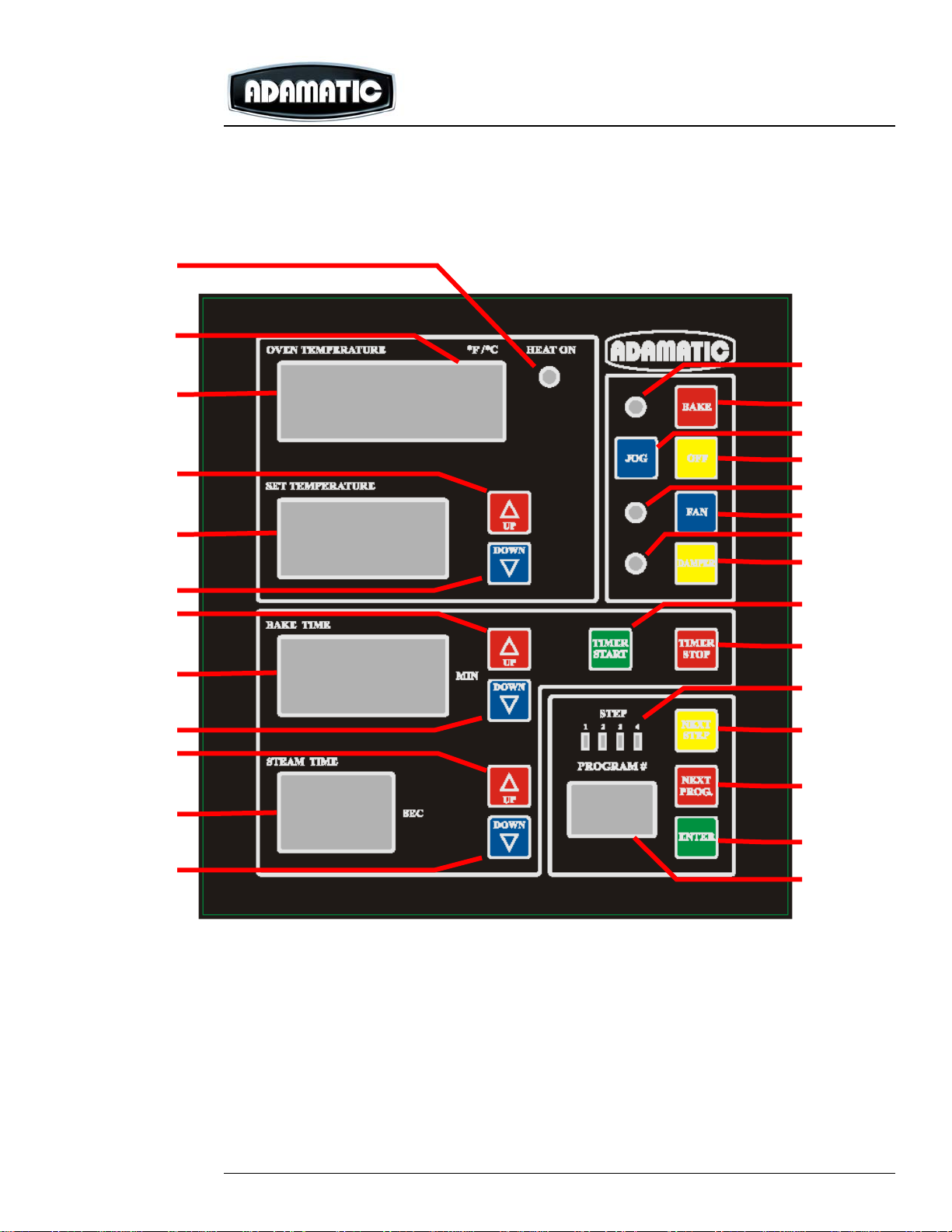

CONTROLS

16

1

3

2

4

8

7

9

11

10

15

19

22

21

13

14

24

23

25

27

12

26

ARO-2G Double Rack Oven - 10 - Rev. 1.0, Dec. 2006

Page 10

TEMPERATURE FUNCTIONS

1. “OVEN TEMPERATURE” DISPLAY – indicates the actual temperature

inside the oven

CONTROLS

¾ NOTE: The displayed temperature will be the same the set

temperature when the oven is within 10

o

F of the set temperature.

2. “SET TEMPERATURE” DISPLAY – indicates the temperature the oven is

set at

3. SET TEMPERATURE “UP” ARROW KEY – pressed to raise the

temperature the oven is set at

4. SET TEMPERATURE “DOWN” ARROW KEY – pressed to lower the

temperature the oven is set at

oF/o

5. OVEN TEMPERATURE “

C” DISPLAY – indicates the units

temperature is measured in (i.e. “F” for degrees Fahrenheit or “C” for

degrees Celsius)

6. “HEAT ON” INDICATOR LIGHT – illuminates when the control is

requesting heat

¾ NOTE: This light will go out when the oven has reached set

temperature.

TIMER FUNCTIONS

7. “BAKE TIME” DISPLAY – indicates the number of minutes the bake cycle

is set for or has remaining

¾ NOTE: An indicator light will blink in the lower right corner of the

display when the Bake Timer is actively counting down.

¾ NOTE: When less then 3 minutes is remaining in the bake cycle the

time will be displayed in min:sec instead of just minutes.

8. BAKE TIME “UP” ARROW KEY – pressed to raise the numb er of minutes

the bake timer is set for

¾ NOTE: Time can be added to the bake timer at any time during the

bake cycle.

9. BAKE TIME “DOWN” ARROW KEY – pressed to lower the number of

minutes the bake timer is set for

¾ NOTE: Time can be removed from the bake timer at any time during

the bake cycle.

10. “STEAM TIME” DISPLAY – indicates the time the steam cycle is set for or

has remaining

¾ NOTE: An indicator light will blink in the lower right corner of the

display when the Steam Timer is actively counting down.

ARO-2G Double Rack Oven - 11 - Rev. 1.0, Dec. 2006

Page 11

11. STEAM TIME “UP” ARROW KEY – pressed to raise the number of

seconds the steam timer is set for

12. STEAM TIME “DOWN” ARROW KEY – pressed to lower the number of

seconds the steam timer is set for

13. “TIMER START” KEY – pressed to start the bake timer counting down

¾ NOTE: The bake timer will stop counting down if the oven door is

opened.

14. “TIMER STOP” KEY – pressed to silence the bake timer buzzer at the

end of a bake cycle or to pause the bake timer in the middle of a bake

cycle

¾ NOTE: If bake timer has less then 1 minute left in the bake cycle,

pressing the “TIMER STOP” key will clear the remaining time and start

the bake timer buzzer, pressing it a second time will silence the bake

timer buzzer.

OVEN FUNCTIONS

15. “BAKE” KEY – pressed to turn on the oven and controls

CONTROLS

¾ NOTE: The control displays and bake indicator light will illuminate

when the oven is turned on.

16. BAKE INDICATOR LIGHT – illuminates when the oven is on

17. “OFF” KEY – pressed to turn off the oven and controls

¾ NOTE: The exhaust hood fan will continue to run for 20 minutes after

the oven is turned off.

o

18. “JOG” KEY – pressed to rotate the rack carrier 180

for easy removal

when two single racks are used

¾ NOTE: This key will only be active when the oven door is closed.

19. “FAN” KEY – pressed to switch to cool down mode

¾ NOTE: The fan indicator light will illuminate and the fan will run

continuously, without a call for heat, the oven door can also be opened

to help cool down the oven quicker.

20. FAN INDICATOR LIGHT – illuminates when the oven is in cool down

mode

21. “DAMPER” KEY – pressed to open the motorized cavity damper (if

provided).

¾ NOTE: The damper indicator light will illuminate when the damper is

open.

22. DAMPER INDICATOR LIGHT – illuminated whenever the damper is open

with either the “DAMPER” key, “FAN” key or during a programmed bake

cycle. .

ARO-2G Double Rack Oven - 12 - Rev. 1.0, Dec. 2006

Page 12

PROGRAMMING FUNCTIONS

23. “NEXT STEP” KEY – pressed to cycle through steps in a bake cycle

program

¾ NOTE: The step indicator lights will illuminate to show the active step.

24. “STEP” INDICATOR LIGHTS – Indicates the active step when

programming or running a bake cycle program.

25. “NEXT PROG.” KEY – pressed to cycle through available bake cycle

programs

26. “PROGRAM #” DISPLAY – Indicates the bake cycle program selected to

run or to be programmed.

27. “ENTER” KEY – pressed to select a program number or to save a bake

cycle program while in programming mode.

CONTROLS

ARO-2G Double Rack Oven - 13 - Rev. 1.0, Dec. 2006

Page 13

ENTER PROGRAMMING MODE

1. With the oven and control off, press and hold the “NEXT PROG”, “NEXT

STEP” and “BAKE” keys at the same time for 3 seconds.

2. When the control beeps once, release the buttons and all the displays will

illuminate but the PROGRAM # display will be flashing a number.

SELECT PROGRAM NUMBER

1. Press the “NEXT PROG” key until the program number to be entered is

indicated in the PROGRAM # display.

¾ NOTE: Each time the “NEXT PROG.” Key is pushed the program

number will increment one digit, if you press and hold the “NEXT

PROG.” key the program number will be scrolled through.

¾ NOTE: The Step 1 indicator will be illuminated in the STEP indicator

lights.

ENTER STEP 1 PARAMETERS

PROGRAMMING

1. Enter a Step 1 SET TEMPERATURE by pressing the “UP” or “DOWN”

set temperature arrow keys to adjust the set temperature displayed.

2. Enter a Step 1 BAKE TIME (in minutes) by pressing the “UP” or “DOWN”

bake time arrow keys to adjust the bake time (in minutes) displayed.

2. Enter a Step 1 STEAM TIME (in seconds) by pressing the “UP” or

“DOWN” steam time arrow keys to adjust the steam time (in seconds)

displayed.

3. Enter a Step 1 DAMPER TIME (in minutes) by pressing and holding the

damper button while pressing the “UP” or “DOWN” bake time arrow keys

to adjust the damper open time displayed in the bake time display.

¾ NOTE: The damper will be held open for the entered period of time at

the end of a step. (For example - if the damper is programmed for 1

minute in a step with a 5 minute bake time, the damper won’t open

until the first 4 minutes of the step have expired.)

¾ NOTE: The damper time can not exceed the total bake time for the

step.

ENTER NEXT STEPS

1. Press the “NEXT STEP” key to proceed to the next step as indicated by

the steps indicator lights.

2. Repeat Steps 1 – 4 under ENTER STEP 1 PARAMETERS.

3. Press the “NEXT STEP” key to proceed to the next step as indicated by

the steps indicator lights as required.

ARO-2G Double Rack Oven - 14 - Rev. 1.0, Dec. 2006

Page 14

¾ NOTE: The next step can not be accessed until a Bake Time greater

then 00:00 is entered for the current step.

SAVING PROGRAMS

1. Press the “ENTER” key to save the program currently being worked on a s

indicated by the steps indicator lights.

2. Press the “NEXT PROG” key until the program number to be entered is

indicated in the PROGRAM # display.

EXITING PROGRAMMING MODE

1. Press the “OFF” key to turn the oven off and exit programming mode.

¾ NOTE: Press the “ENTER” key prior to the “OFF” key to save any

changes made to the active program.

PROGRAMMING

ARO-2G Double Rack Oven - 15 - Rev. 1.0, Dec. 2006

Page 15

DAILY CLEANING

1. Allow oven to cool until it reaches room temperature.

¾ NOTE: To cool oven off quicker, press the “FAN” key and open the

oven door. The fan indicator light will illuminate and the fan will run

continuously without a call for heat.

2. Sweep out interior of the oven.

WEEKLY CLEANING

1. Perform Daily Cleaning.

2. Clean both sides of door window and interior surface of the light window

using a mild soap/water solution or commercial glass cleaner and a clean

soft towel.

¾ NOTE: Heavy build-up on the interior surface of the glass may be

cleaned using a straight blade window scraper.

3. Clean interior stainless steel surfaces of the oven using a mild soap/water

solution and wipe dry with clean soft towel.

CLEANING

¾ CAUTION: Never use chlorinated cleaners, abrasive pads or metallic

scrapers on stainless steel surfaces.

¾ Note: When cleaning stainless steel wipe the surfaces by following the

grain.

4. Clean exterior stainless steel surfaces of the oven using a mild

soap/water solution and wipe dry with clean soft towel. A stainless steel

polish may be used after initial cleaning

¾ CAUTION: Never use chlorinated cleaners, abrasive pads or metallic

scrapers on stainless steel surfaces.

¾ Note: When cleaning stainless steel or applying polish wipe the

surfaces by following the grain.

5. Clean the control panel using a mild soap/water solution and a clean soft

towel.

¾ CAUTION: Never use chlorinated cleaners, abrasive pads or metallic

scrapers on control panel.

ARO-2G Double Rack Oven - 16 - Rev. 1.0, Dec. 2006

Page 16

¾ WARNING: Installation must be performed by a factory

authorized installation company. Improper installation can

cause personnel injury and/or damage the equipment. Oven

warranty will be void if installation is not performed by a

factory authorized installation company.

¾ WARNING: Installation and utility connections must be

performed by a licensed contractor to all applicable local

codes, or in the absence of local codes, with th e Nati onal Fuel

Gas Code, ANSI Z223.1.

¾ WARNING: Oven must be electrically grounded in accord ance

with the local codes, or in the absence of local codes, with

the National Electrical Code, ANSI/NFPA 70-1996.

¾ CAUTION: Oven must be installed heat resistant floor to reduce risk of

fire.

ASSEMBLY

PREPARING SITE

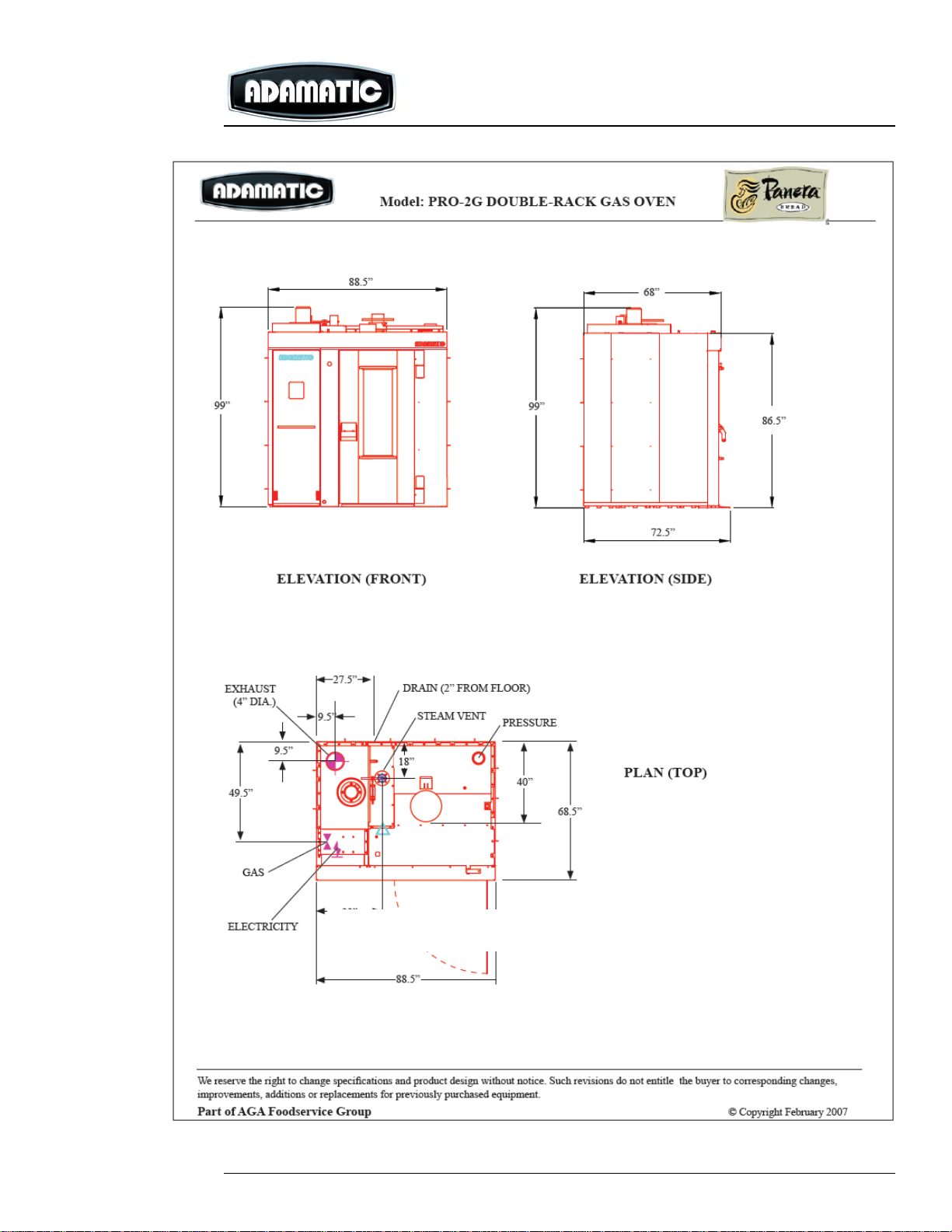

1. Verify there is adequate egress to bring the oven sections to where they

are being installed

¾ Heat Exchanger Section: 26” W x 69-1/2 D x 99” H

¾ Front Section with Door: 63” W x 36-1/4” D x 88” H

¾ Rear Section: 63” W x 33-3/4” D x 90” H

2. Verify there is sufficient space for the oven to be installed.

¾ Width: 88”

¾ Depth: 67-1/4” (plus 37” for door swing)

¾ Height: 106” minimum (120” recommended for service)

NOTE: It is recommended to have 2 feet clearance on all sides of the

oven to ease the assembly process.

3. Verify the floor under and 37” in front of oven is level to within ¼”.

4. Verify flooring is of a heat resistant construction both under and in front of

the oven where hot racks will be removed.

5. Verify the following utilities have been provided:

¾ Electrical: 120/60/1 @ 7.4 amp control circuit

208 – 240/60/3 @ 8.4 amp main power supply

(440 – 480/60/3 @ 4.2 amp optional power supply)

NOTE: National Electrical Code requires a disconnecting means

within sight of oven or be capable of being locked open.

ARO-2G Double Rack Oven - 17 - Rev. 1.0, Dec. 2006

Page 17

¾ Gas: 1” NPT @ 375,000 BTU’s Natural Gas with 7” – 14” WC static

pressure

(Optional LP requires 9” – 14” WC static pressure)

¾ Water: ½” NPT with 20 – 75 psi dynamic pressure

¾ Drain: 1” NPT

¾ Combustion Vent: 8” diameter

NOTE: Oven is supplied with barometric damper and 175 cfm draft

inducer.

¾ Hood Vent: 8” diameter

NOTE: 6” steam damper and 6” over pressure outlets to be ducted 8”

hood vent.

RECEIVING AND UNCRATING

1. On receipt of oven, check for both visual and concealed shipping

damage. Visible damage should be noted on the freight bill at time of

delivery and signed by the carrier. Claims for concealed damaged should

be made with the carrier’s agent within 15 days of delivery.

NOTE: If a claim is made, save all packing material for inspection by the

carrier.

2. Move oven crates to area the oven is to be installed. Remove the crating

material and plastic wrap from each section, but to not remove the straps

holding them to the skid.

3. Remove the following loose parts that are packaged with the rear section:

F

E

C

D

A Draft Inducer 1

B Barometric Damper 1

C Pressure Switch w/ Tube & Bracket 1

ARO-2G Double Rack Oven - 18 - Rev. 1.0, Dec. 2006

Page 18

K

D Carrier and Shaft Assembly 1

E Pivot Bracket Assembly 1

F Turnbuckle Assembly 1

G

G Cam Lift 1

H Steam Trays 99

I Steam Damper 1

J Hardware Kit 1

K Rack Limit Switch Bracket 1

ARO-2G Double Rack Oven - 19 - Rev. 1.0, Dec. 2006

Page 19

O

L Ramp 1

M Heat Exchanger Splash Shield 1

N

N Front Interior Side Panel 1

ARO-2G Double Rack Oven - 20 - Rev. 1.0, Dec. 2006

Page 20

O Rear Interior Side Panel 1

P Exterior Side Panels 2

ARO-2G Double Rack Oven - 21 - Rev. 1.0, Dec. 2006

Page 21

R

Q Front Steam Injection Pipe 1

R Rear Steam Injection Pipe 1

S Steam Drain Pan 1

T Steam Tray Mullion 1

ARO-2G Double Rack Oven - 22 - Rev. 1.0, Dec. 2006

Page 22

U Top Cover Panel (heat exchanger to

chamber section)

V Top Cover Panel (front chamber to rear

chamber)

W Rack Support Beam 1

1

1

X Interior Top Trim 1

4. Open the hardware box and check for the following contents:

ARO-2G Double Rack Oven - 23 - Rev. 1.0, Dec. 2006

Page 23

m

h

g

o

p

q

l

u

t

aa

a Steam Nozzle Cover

b Damper Clevis 1

c “U” Bolt with Nuts 1

d Steam Cable Bracket 1

e Cam Lift Shim Plates

f Teflon Tape 1 Roll

g Steam Injection Pipe Bracket 2

h Steam Injection Pipe Hold Down 2

i ? mounting Plate 1

j ½” Brass Union (Male to Female) 1

k ½” Brass Cap 1

l ½” Brass Nut 1

m 8 mm Wash er 1

n 10 mm Washer 1

o 10 mm x 80 mm Black Bolt (long) 1

p 8 mm x 20 mmBlack Bolt (short) 1

q 8 mm x 20 mm Stainless Steel Bolt 2

r 8 mm x 20 mm Stainless Steel Allen Bolt 1

s Pipe Gasket 1

t Lock Nut 1

u High Temp Silicone 1

v Insulation Hanger 1

w 8 mm x 25 mm Brass Bolt 1

x 5 mm x 16 mm Stainless Steel Screw 1

y 8 mm Brass Nut 1

z 8 mm Stainless Steel Nut

aa 8 mm Steel Nut

y

ARO-2G Double Rack Oven - 24 - Rev. 1.0, Dec. 2006

Page 24

5. If any of these parts are missing, please contact Adamatic to acquire a

replacement.

ASSEMBLE BAKE CHAMBER

1. Tilt the three bake chamber section to the vertical position.

¾ Raise each section using a forklift (if a forklift is not available use a

pallet jack, but do not try to lift these sections by hand). Place the

forks under the skid at the top of each section and tilt up 60

o

.

ARO-2G Double Rack Oven - 25 - Rev. 1.0, Dec. 2006

Page 25

¾ Raise each section to the vertical position by hand and carefully lower

them to the floor as to do not damage them.

¾ WARNING: Keep body parts from beneath the oven during the

raising process.

¾

¾ Assemble Front Bake Chamber Section to Rear bake Chamber

Section

1. Place the rear baking section first as close to the final position as possible

leaving 2 feet clearance between wall and oven section

2. .Place the front baking section in front of the rear baking section allowing

6 to 8 inches between the sections to apply a silicone bead

NOTE: Apply silicone only between the baking sections not the heating

section.

¾ .

ARO-2G Double Rack Oven - 26 - Rev. 1.0, Dec. 2006

Page 26

Silicone Bead

.

3. Apply a 3/8” bead of silicone on the mating flange making sure you go

around bolt holes. Apply a heavier bead in the corners. Silicone the floor

seam.

4. After the bead has been applied move the front section to join up with the

rear section making sure the section line up. Make sure the 4 alignment

pins for the line up

5. Use non-stainless steel bolts with s/s nuts and washes to fasten sections

together. Use a washer on both the bolt and nut side. Do not tighten

until all bolts are in place

6. Tighten all bolts.

> NOTE: Remove shipping bar from bake chamber.

Assemble Bake Chamber to Heat Exchanger section

1. Move the heating section into place leaving 8 to 12 inches between

baking section and heating section

3. Apply a 3/8” bead of silicone on the mating flange making sure to go

around bolt holes. Apply a heavier bead in the corners.

Silicone the floor seam.

4. Move heating section and bake chamber together and lining up bolt

holes. Make sure studs on heating section pass through holes in Bake

chamber first.

5. Install all bolts across the top, back and inside the baking chamber. Use

s/s bolts on inside and non-stainless on the outside and top

6. After all bolts are in place ,tighten all bolts

ARO-2G Double Rack Oven - 27 - Rev. 1.0, Dec. 2006

Page 27

INSTALL STEAM DRAIN PAN

1. Install steam drain pan.

¾ Screw one 1” diameter lock nut on rear drain pipe.

¾ Place one 1” diameter pipe gasket on rear drain pipe.

¾ Insert rear drain pipe into hole in rear of heat exchanger section.

¾ Apply a bead of silicone around flange on front drain manifold.

¾ Align hole in front of steam drain pan with front drain manifold and

secure with four 8mm x ????? stainless steel bolts, 8 mm stainless

steel washer and 8 mm stainless steel nuts.

ARO-2G Double Rack Oven - 28 - Rev. 1.0, Dec. 2006

Page 28

¾ Tighten the locknut on the rear drain pipe against the interior wall of

the heat exchanger section.

¾ Place the second 1” diameter pipe gasket on the rear drain pipe from

the exterior of the heat exchanger section.

¾ Screw the second 1” diameter lock nut on the rear drain pipe from the

exterior of the heat exchanger section and tighten

Installing Insulation and Exterior Wall Panels

> Insure all bolts and nuts are tight

> Fill all exterior oven section seam with sheets of mineral wool, 2

layers thick.

> Use insulation holders to keep insulation in place

> Install wall panels (P) on the side and back

> If oven is draining from the back remove knockout in bottom of cover.

NOTE : This would be a good time to move the oven to its final resting

place before you add more weight to the oven.

2. Install the heat exchanger splash shield over the opening in front of the

heat exchanger.

ARO-2G Double Rack Oven - 29 - Rev. 1.0, Dec. 2006

Page 29

¾ Bend the eight (8) tabs on the heat exchanger splash shield 90

¾ Place the splash shield over the opening by inserting the tabs into the

slots on the heat exchanger section.

3. Install the steam tray mullion using XXXXXX bolts .

¾

o

.

4. Install the single row steam trays toward the front of the oven.

¾ Apply Teflon tape and screw the brass nut and female end of the

unions to the front steam pipes in the roof in front of the heat

exchanger.

¾ Apply Teflon tape and screw the brass cap to the long end of the front

steam injection pipe.

ARO-2G Double Rack Oven - 30 - Rev. 1.0, Dec. 2006

Page 30

¾ Apply Teflon tape and screw the male half of the brass union to the

short end of the front steam injection pipe.

¾ Secure the rear and front steam injection tubes to the brass unions in

the ceiling with the injection branches oriented away from the heat

exchanger.

NOTE: Steam injection tubes are only being used to determine

position of steam nozzles covers and will be re-installed under steam

nozzle covers after steam trays have been installed.

¾ Bend the tabs on only one sides of eight (8) steam nozzle covers as

shown below.

ARO-2G Double Rack Oven - 31 - Rev. 1.0, Dec. 2006

Page 31

¾ Install the first steam tray in the two slots in the front mullion such that

the open end rests against the edge of the steam drain pan.

¾ Install the next steam tray in the two slots in the middle mullion such

that the open end rests against the first steam tray.

¾ Continue installing steam trays, alternating sides until your reach the

height of the first branch on the steam injection pipe.

ARO-2G Double Rack Oven - 32 - Rev. 1.0, Dec. 2006

Page 32

¾ Place a steam nozzle cover in the tray such that the bent tab is toward

the inside of the oven and the long end of the cover extends to the rear

of the oven.

¾ Continue installing steam trays and steam nozzle covers until all the

slots in the mullions have been filled.

¾ Unscrew the steam injection pipe from the union in the roof, rotate it

such that the branches extend under the steam nozzle covers and

attach it back to the union in the roof

ARO-2G Double Rack Oven - 33 - Rev. 1.0, Dec. 2006

Page 33

5. Install the single row steam trays toward the front of the oven.

¾ Apply Teflon tape and screw the brass nut and female end of the

unions to the rear steam pipe in the roof in front of the heat exchanger.

ARO-2G Double Rack Oven - 34 - Rev. 1.0, Dec. 2006

Page 34

¾ Apply Teflon tape and screw the brass cap to the short end of the rear

steam injection pipes.

¾ Apply Teflon tape and screw the male half of the brass union to the

long end of the rear steam injection pipe.

ARO-2G Double Rack Oven - 35 - Rev. 1.0, Dec. 2006

Page 35

¾

¾ Secure the rear and front steam injection tubes to the brass unions in

the ceiling with the injection branches oriented away from the heat

exchanger.

NOTE: Steam injection tubes are only being used to determine

position of steam nozzles covers and will be re-installed under steam

nozzle covers after steam trays have been installed.

¾ Bend the tabs on both sides of eight (8) steam nozzle covers for use in

the first row steam trays.

ARO-2G Double Rack Oven - 36 - Rev. 1.0, Dec. 2006

Page 36

¾ Bend the tabs on only one sides of eight (8) steam nozzle covers as

shown below.

ARO-2G Double Rack Oven - 37 - Rev. 1.0, Dec. 2006

Page 37

Install steam center support. Slip tab on top of support into receiver on

inside ceiling of oven, angle support so bottom of support is in drain

pan, bring support vertical. It should line up with support in heating

section

Mount inside roof cover strip using s/s 4 mm bolts

¾ Install the first steam tray in both rows in the two slots in the middle

mullion such that the open end rests in the steam drain pan toward the

rear of the oven.

¾ Install the next steam tray in the two slots in the middle mullion such

that the open end rests against the first steam tray.

¾ Continue installing steam trays, alternating sides until your reach the

height of the first branch on the steam injection pipe.

¾ Continue installing steam trays, alternating sides until your reach the

height of the first branch on the steam injection pipe.

¾ Place the steam nozzle cover with both tabs bent in the first steam tray

with the long end toward the front of the oven and the steam nozzle

ARO-2G Double Rack Oven - 38 - Rev. 1.0, Dec. 2006

Page 38

cover with one bent tab in the second row of steam trays also with the

long end toward the front of the oven.

¾ Continue installing steam trays and steam nozzle covers until all the

slots in the mullions have been filled.

¾ Unscrew the steam injection pipe from the union in the roof, rotate it

such that the branches extend under the steam nozzle covers and

attach it back to the union in the roof.

ARO-2G Double Rack Oven - 39 - Rev. 1.0, Dec. 2006

Page 39

6. Install water tube bottom clamp. ( G,H)

7. Mount front steam unit cover (O) using brass 8mm bolts with s/s washers.

8. Mount rear steam unit cover (N) using brass 8mm bolts with s/s washers

ARO-2G Double Rack Oven - 40 - Rev. 1.0, Dec. 2006

Page 40

NOTE: Where front and rear panels overlap use 8mm round head bolts

AIR DISTRIBUTION PANEL

Install the air distribution panels on the interior right side of baking chamber.

> Mount the rear panel which has 2 rows of slots using 8mm brass bolts

and s/s washers

> Mount the front panel which has 1 row of slot using 8mm brass bolts

with s/s washers

ARO-2G Double Rack Oven - 41 - Rev. 1.0, Dec. 2006

Page 41

> Leave all bolts loose. Where panels meet apply a bead of silicone (red)

and move panels together. Tighten all bolts and remove excess

silicone

RACK LIFT ASSEMBLY

> Bolt the rack lift support beam (W) in place. This beam mounts across

the width of the bake Chamber on top of oven. It fastens with 2 10mm

bolts on each end’

> NOTE: After the beam is mounted it is a good time to fill in the seams

on top of the oven with mineral wool insulation and to bolt on the top

covers which cover insulation using Non-stainless steel 8mm bolts and

washers.

ARO-2G Double Rack Oven - 42 - Rev. 1.0, Dec. 2006

Page 42

Adjustment of Air Distribution Panel on New ARO/PRO Oven

*The louver settings are in millimeters.

*A set of metric Allen wrenches will facilitate the job.

*The measurements must be taken at the top and the

bottom of each adjusable louver,

Not at the top and bottom ends of the slots.

BACK MIDDLE FRONT

078

078

068

068

268

367

457

4 4.5 6

4 4.5 6

4.5 4.5 6

5 4.5 6

5 4.5 7

Prepared: 05/15/07

Page 43

> Bolt the lifting cam (G) to the rack support beam. ( there are shims

provided for height adjustment for different style rack lifts. The ‘C’ style

rack lift requires no shims) Make sure the orientation is correct.

> Insert the rack lift (D) from inside the oven up through the roof

> Install the retaining ring to hold the shaft in place

> Install the turning cam (E) with the recessed cup up and the rod end

pointing towards the hinge of the baking chamber door.

> Install the thrust bearing with the large inside diameter on the bottom. The

bottom race should fit loosely over the shaft and the top race should fit

snug. It’s a good idea to lubricate this bearing at this time with high temp

grease

> Install the upper bearing cup with recess down to cover bearing

Install the 2 large washers

> Install the pulley making sure key is in keyway

> Install 1” washer and nut and tighten

> Tighten set screws in pulley

> Install turn buckle rod assembly (F) with the forked end of the turn buckle

attached to the rod end of the turning cam.

ARO-2G Double Rack Oven - 43 - Rev. 1.0, Dec. 2006

Page 44

> Secure the rod end of this assembly to the flat plate of the bake chamber

hinge assembly.

Install the rack drive belt

Install the rack stop switch bracket and switch

ARO-2G Double Rack Oven - 44 - Rev. 1.0, Dec. 2006

Page 45

WATER SOLENIOD

> Install the water solenoid assembly to the rear ½” pipe that extends

through the roof of the oven. Make sure the compression fitting faces the

front pipe

> Connect the coupling and 90 degree elbow to the from ½” pipe that

extends through the roof of the oven. Make sure the compression fitting

faces the rear pipe.

> Connect the 2 together with the copper tube provided

ARO-2G Double Rack Oven - 45 - Rev. 1.0, Dec. 2006

Page 46

DOOR SWITCH

> The door switch is mounted through the light fixture compartment on a

bracket located near the bottom of the compartment. Remove 1 mounting

nut and pass shaft of the switch through mounting hole and secure with

the nut you just removed on the other side.

> Adjust the switch so that the plunger moves freely with the door open or

closed.

LIGHTS

> The light fixture is installed between the brackets provided and is allowed

to pivot freely for placement of the tubes and removal of the tubes when

they go out. There is 1 bolt at the top of the fixture and 1 at the bottom.

DO NOT TIGHTEN THESE BOLTS

> The color coded wires connect to the ‘J’ box mounted in the burner

compartment Use the included wire nuts.

ARO-2G Double Rack Oven - 46 - Rev. 1.0, Dec. 2006

Page 47

MOUNT EVACUATION DAMPER ASSEMBLY

¾ Mount Damper assembly (I) using 4 brass bolts with s/s washers

¾ Fold and slide damper clevis (B) over damper shaft

¾ Use damper ‘U’ bolt (C) to secure to shaft

ARO-2G Double Rack Oven - 47 - Rev. 1.0, Dec. 2006

Page 48

ARO-2G Double Rack Oven - 48 - Rev. 1.0, Dec. 2006

Page 49

¾ Mount cable mount bracket (D) to roof panel

¾ Attach cable to bracket and to damper clevis

¾ Adjust cable so with damper knob pulled out damper is fully open

ARO-2G Double Rack Oven - 49 - Rev. 1.0, Dec. 2006

Page 50

ARO-2G Double Rack Oven - 50 - Rev. 1.0, Dec. 2006

ARO-2G Double Rack Oven - 50 - Rev. 1.0, Dec. 2006

Page 51

ARO-2G Double Rack Oven - 51 - Rev. 1.0, Dec. 2006

Page 52

ARO-2G Double Rack Oven - 52 - Rev. 1.0, Dec. 2006

ARO-2G Double Rack Oven - 52 - Rev. 1.0, Dec. 2006

Loading...

Loading...