Page 1

The First Name In Bakery

Adamatic

ARO-2G

Double Rack Oven, Gas

STANDARD FEATURES:

Stainless steel interior/exterior •

Heavy duty self contained steam system•

Digital control panel with 99 menus •

High volume/low velocity airow•

Fits two single racks or one double rack •

up to 75” tall with “C” style lift

Maintenance free mechanical lift rack system•

Heavy duty dual lock door handle and hinges•

Automatic overpressure steam duct•

Shipped in three pieces for easy assembly•

Reinforced oor (requires no anchoring)•

Heavy duty heat exchanger •

High density insulation 6.25 lbs/cu. ft.•

One year parts/labor warranty•

Three year heat exchanger warranty (parts •

only)

Division of Bakery Group

OPTIONS

“A” or “B” style lifts•

Liquid Propane •

High altitude draft inducer•

Aluminum or stainless steel races•

480V motor circuit•

#3062800

ANSI Z83.11a-2004

Model shown: ARO-2G Rack Oven

ADAMATIC • Division of

Phone: 732-544-8400 | 800-526-2807 Fax: 732-544-0735 • info@adamatic.com • www.adamatic.com

©1/2008 Product specications may be changed without notice. Always obtain current spec sheet at time of purchase.

Belshaw-Adamatic Bakery Group,

814 44th St NW, Suite 103, Auburn WA 98001

Page 2

The First Name In Bakery

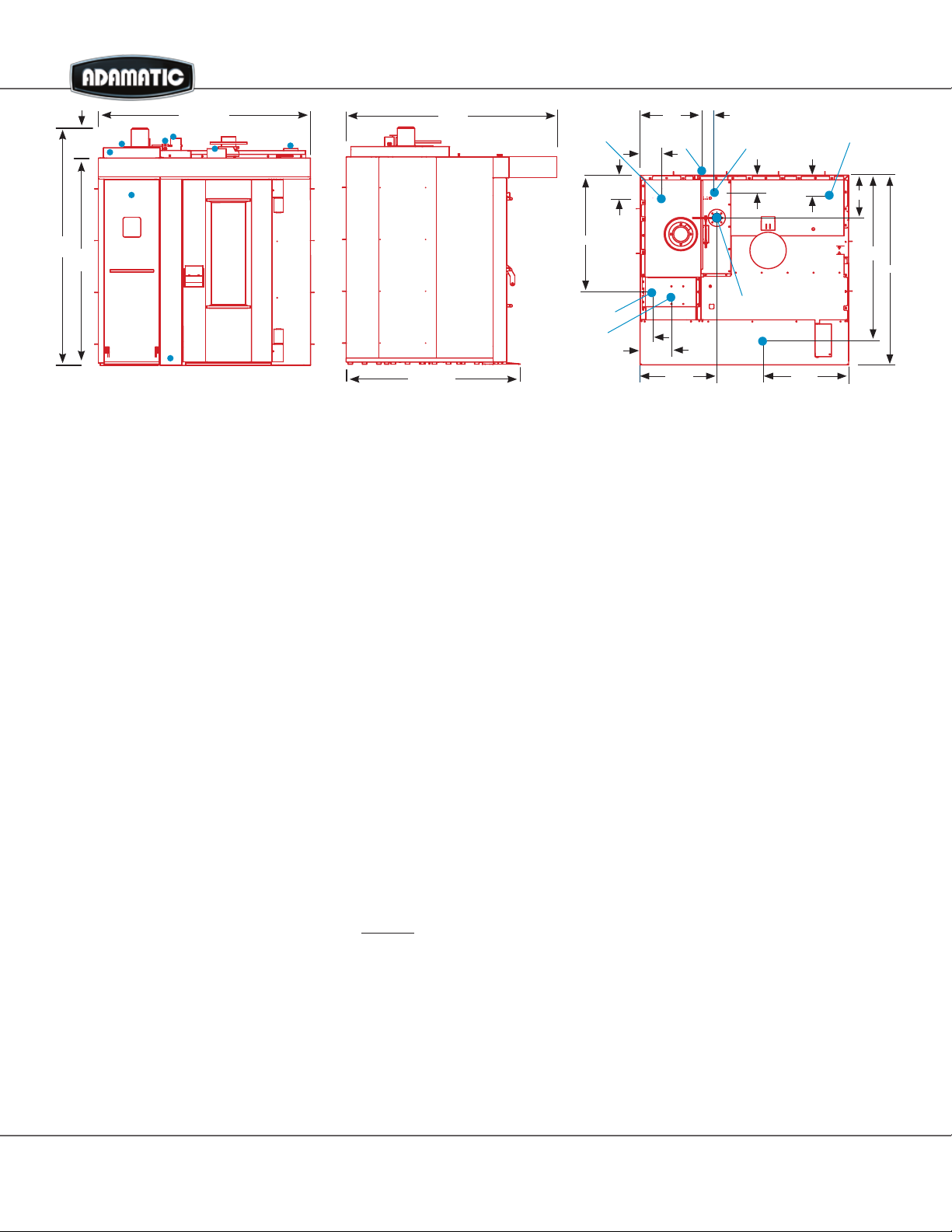

ARO-2G Double-Rack Gas Oven

88.5”

S

99”

12.5”

86.5”

W

C

G

E

H

D

O

FRONT

ELECTRICAL SUPPLY

Two electrical connections (E) required. These are located in the •

control housing located on the left side of the oven. P

Power leads should be dropped from above the oven; actual •

connection is located 12” from the left side, 53” from rear and 73”

from oor.

Control Circuit 120VAC-60-1 @7.4 Amps (minimum 15 Amp •

dedicated breaker)

Standard Motor Circuit 208-240VAC-60-3 @8.4 Amps (minimum •

breaker size 15 amps)

Optional Motor Circuit 480VAC-60-3 @3.6 Amps•

WATER SUPPLY

Hot or cold water 40-75 psi •

Line to be dropped from ceiling (see (W) for connection location)•

Connection will be located 95” above nished oor, 31” from the •

left side of the oven, 5” from the rear of the oven

NOTE: For proper operation of the steam system it is •

recommended that the water supply follow these specications:

Total Dissolved Solids: 10 ppm minimum –

Hardness: 6 grains/gal. max –

Calcium: 4 ppm max –

Magnesium: 4 ppm max –

PH range: 7.0 – 8.5 –

Chloride: 50 ppm max –

Alkalinity: 20 ppm max –

Consult your local water treatment company for proper water

ltration system.

DRAIN REQUIREMENTS

1” NPT connection from front or rear of the oven•

Oven comes with front and rear drainage. Use of rear drain •

is recommended, if front drain must be used it CAN NOT be

terminated directly in front of the oven or inside the control

housing.

Rear drain location is 2” above the nished oor, 28” from the –

rear left side of the oven

Front drain has a knockout located 2” above nished oor, 21” –

from front left hand corner of the oven

NOTE: Drain line to be pitched to a oor sink. •

GAS REQUIREMENTS

3/4” NPT connection•

350,000 BTU/hr Natural Gas supply @ 7” - 14” static pressure•

Optional Liquid Propane @ 9”-14” static pressure•

9.5”

28”

DRAIN (D)

2”fr. oor

9”

3”

12”

33”

3”

WATER

CONNECTION

(W)

5”

STEAM VENT (S)

STEAM EXHAUST (H)

HOOD

72.5”

85”

SMOKE

EXHAUST (C)

50”

GAS (G)

ELECTRICITY

(E)

SIDE TOP

1” connection (G) located 3” from left side, 49.5” from rear •

and 89” from oor

If gas supply exceeds 14” static pressure, a pressure regulator •

must be installed in addition to the pressure regulator

supplied with the oven

COMBUSTION VENTING REQUIREMENTS

Combustion vent has an 8” diameter collar (C), located 9” •

from the left side, 9.5” from the rear and 96” from the oor

NOTE: Oven is supplied with a barometric damper and draft •

inducer with integral air ow proving switch. Barometric

damper should be installed in a tee 12” above the oven and

draft inducer installed in a single wall duct 40” above the oven.

NOTE: Flue should be run as straight as possible. Draft inducer •

can compensate for a 20’ horizontal offset, but only 45˚ elbows

should be used

NOTE: Flue must be terminated with a wind proof cap and •

discharge a minimum of 4’ above the roof line or 2’ above any

parapet walls.

STEAM, OVER PRESSURE AND HOOD VENTING

REQUIREMENTS

Steam vent has a 4” diameter collar (S), located 33” from left •

side, 18” from rear and 98” from oor.

Over pressure vent has a 6” diameter collar (O), located 83” •

from left side, 7” from rear and 90.5” from oor.

Hood has an 8” diameter collar (H), located 49” from the left •

side, 73.5” from rear and 90.5” from the oor.

NOTE: Steam vent and overpressure vent can be ducted to and •

exhausted through a common ue with the hood.

NOTE: All ues must be terminated with a wind proof cap and •

discharge a minimum of 4’ above the roof line or 3’ above any

parapet walls.

OTHER INSTALLATION REQUIREMENTS

Oven must be installed on a smooth level (within 1/8” per foot) •

and heat resistant oor.

Oven is listed for zero clearance to combustible surfaces. •

Oven requires a minimum ceiling height of 10’ to allow access For •

installation and service

Oven installation must be supervised by a factory authorized •

installation technician and startup performed by an authorized

service technician to validate warranty.

Utility and Venting connections must be made in accordance •

with National Electrical Code, National Fuel Gas Code and other

federal, state and local codes. Consult the Local Authority having

Jurisdiction for approval prior to installing oven.

7”

39.5”

OVER

PRESSURE (O)

18”

73.5”

85”

ADAMATIC • Division of

Belshaw-Adamatic Bakery Group,

814 44th St NW, Suite 103, Auburn WA 98001

Phone: 732-544-8400 | 800-526-2807 Fax: 732-544-0735 • info@adamatic.com • www.adamatic.com

©1/2008 Product specications may be changed without notice. Always obtain current spec sheet at time of purchase.

Loading...

Loading...