Page 1

Job name ___________ Job # ____________

________________________________________________________________________________________________________

Adamatic

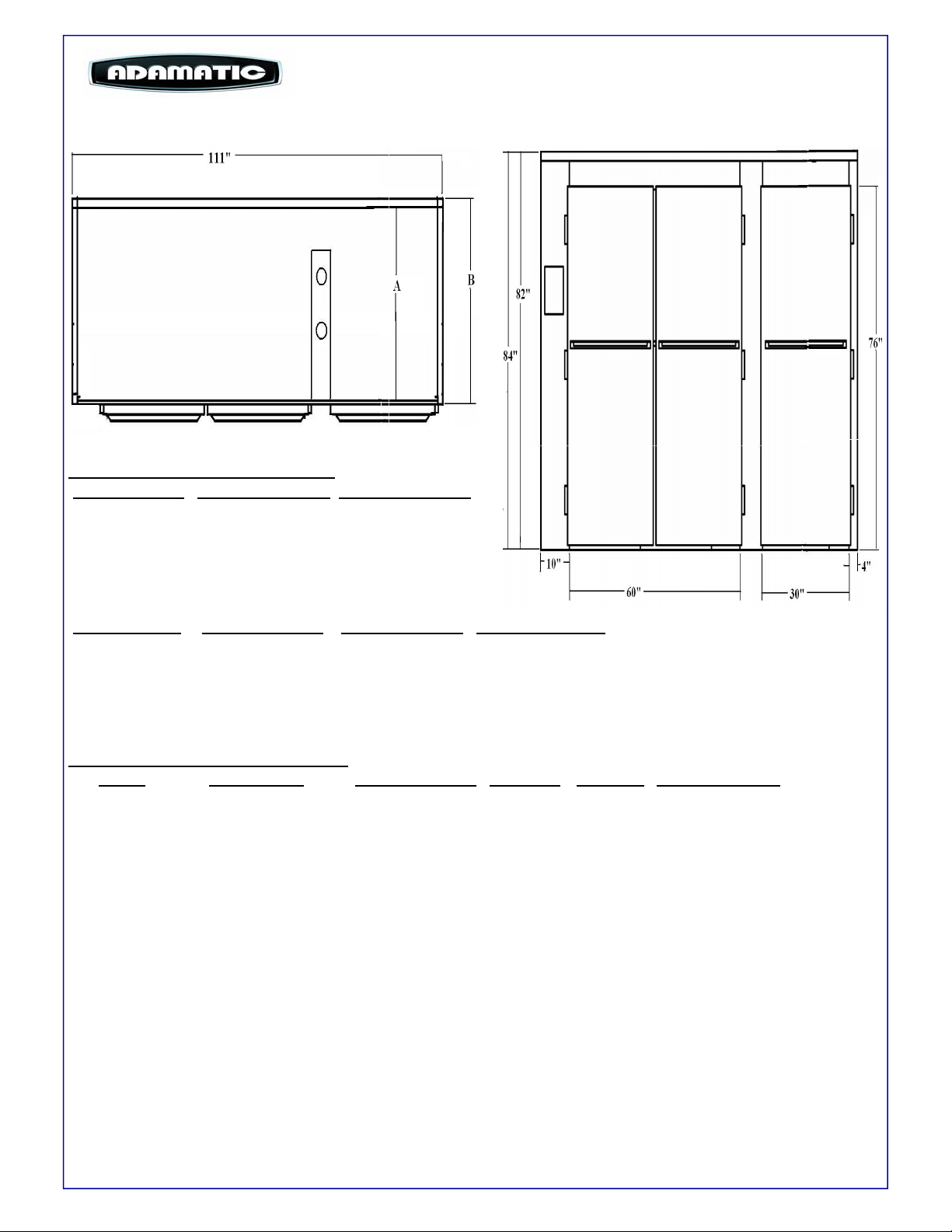

Model AP-3W

Three Wide

Proof Box Series

Standard Features:

•

Full stainless steel construction

300 series s/s interior

400 series s/s exterior

• Internally mounted air-wash

humidification system

• Modular cam lock wall and roof construction

•

Interior and exterior bumper guards

•

Accommodates up to 75” tall racks

•

2” polyurethane insulated wall/roof panels

•

Eye level digital control panel features:

-Temperature control

-Humidity control

-Countdown timers

-Main power switch

•

Three heavy duty cam lift hinges (w/stay Models:

open feature) per door Inside Depth Without floor With floor

•

Heavy duty door closures 28” AP3W-3S AP3W-3SF

•

Multiple depths available 48” AP3W-3D AP3W-3DF

•

One year parts/labor warranty

Options:

• Upper closure panel

• Side closure panel (one or both sides)

• Pass-thru

• Heavy duty stainless steel floor

(adds 2” to overall height of the unit)

• Correctional package ________________

Adamatic

607 Industrial Way West

Eatontown, N.J. 07724

Phone: 732-544-8400

Fax : 732-544-1216

Website: www.adamatic.com

Page 2

Three Wide Proof Box

____________________________________________________

Interior/Exterior Depth Dimensions

Model Number

AP3W-3S 28” 31”

AP3W-3D 48” 51”

Note: for pass-thru models add 3” to exterior depth

dimension. Interior depth dimension remains the same.

If equipped with floor overall height is 86”

Rack Capacity Single End Load Single Side Load Double End Load

AP3W-3S 3 3 1

AP3W-3D 6 6 3

Note: Above capacities are for standard 18x26 sheet pan racks. Consult factory for proof box capacity on

other pan sizes or rack capacities.

A= Interior Depth B=Exterior Depth

Utility Specifications/Shipping Weight

Model

AP3W-3S 240/60/3 @ 19.6 amps 8 3/4” NPT 1” NPT 1496 lbs

AP3W-3D 240/60/3 @ 24.3 amps 10 3/4” NPT 1” NPT 1861 lbs

NOTE: A GROUND WIRE MUST BE SUPPLIED FOR ALL INSTALLATIONS.

Notes:

(1) Single point electrical connection located on the top rear of the box. 37” from left hand corn er, 6” from the rear, 84” fr om

the floor .

Electrical (1) Power Input Kw Water (2) Drain (3) Shipping Weight

(2) Water supply connection. Hot or cold water supply @25-50 psi. Located 72” from t he front left side, 20” from front, 84” from

floor. For proper operation of the steam system it is recommended that the water supply follow these specifications: Hardness

of 2-4 grains per gallon, p h range of 7.0 to 8.0 and chloride concentration of 0-30 ppm. Consult your water treatment company

for proper water filtration system.

(3) Drain factory equipped for rear exit (can be field modified for front exit). Drain exit located 78” from rear left hand corner,

5” from floor. Drain must be installed angled to floor prior to routing to drain source for proper drainage.

A hard smooth level floor is required on which to po sition the proof box and access for maintenance is located on the top or

inside the unit. It is recommended that a minimum of 24” be available on top of the proof box for servicing.

Proof Box installation mu st be performed by factory authorized technicians and all utility connect ions must be performed by

licensed contractors to meet all federal, state and local codes.

We reserve the right to change specifications and product design without notice. Such revisions do not entitle the buyer to corresponding changes, improvements,

additions or replacements for previously purchased equipment.

______________________________________________________________________________________________

Part of AGA Foodservice Group © Copyright June 2005 Printed in U.S.A.

Loading...

Loading...