Page 1

ふ

Multi Function Weighing Indicator

WM : PD4000243

Page 2

This is a hazard alert mark.

This mark informs you about the operation of the product.

Note This manual is subject to change without notice at any time to improve the product. No part

of this manual may be photocopied, reproduced, or translated into another language

without the prior written consent of the A&D Company.

Product specifications are subject to change without any obligation on the part of the

manufacture.

Page 3

Contents

1. Compliance........................................................................................ 4

1.1.1. Compliance with FCC rules.......................................................4

1.1.2. Compliance with European Directive.........................................4

2. Outline and Features.........................................................................5

2.1. Precaution.....................................................................................6

2.2. Front Panel....................................................................................7

2.2.1. Keys..........................................................................................7

2.2.2. Symbols ....................................................................................8

2.3. Rear Panel...................................................................................10

3. Installation........................................................................................11

3.1. Mounting Indicator.......................................................................11

3.2. Connecting Loadcell Cable..........................................................12

3.2.1. Verifying Loadcell Output and Input Sensitivity.......................13

3.3. Wiring Power Cord ......................................................................14

3.4. Installing Options.........................................................................15

4. Basic Operation...............................................................................16

4.1. Key Operation Examples............................................................. 16

4.1.1. Standby Mode.........................................................................16

4.1.2. Cursor Operation.....................................................................16

4.1.3. Inputting Characters................................................................16

4.1.4. The Way of Calling a Code .....................................................17

4.1.5. The Way of Entering a Correction Mode.................................17

4.1.6. The Way of Entering Menu......................................................18

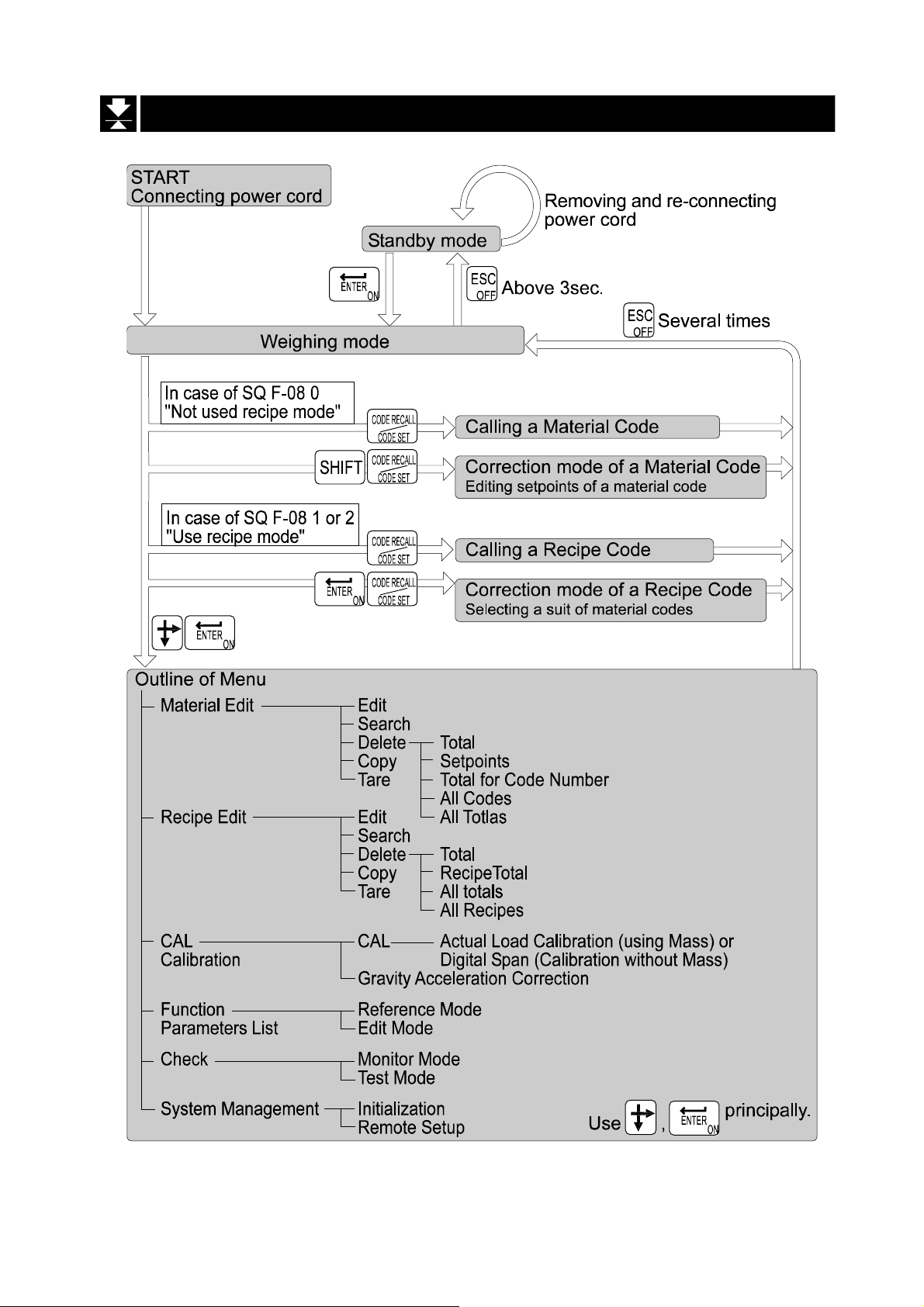

4.2. Status Chart (Mode map) ............................................................19

5. Calibration........................................................................................20

5.1. Actual Load Calibration (using Mass)..........................................21

5.2. Digital Span (Calibration without Mass)....................................... 22

5.3. Gravity Acceleration Correction...................................................23

5.3.1. Gravity Acceleration Reference...............................................23

5.4. Calibration Error ..........................................................................24

6. Applications .....................................................................................25

6.1. Hopper Scale with Material Code................................................25

6.1.1. Definition of Material Code......................................................25

6.1.2. Recalling Material Code..........................................................25

6.1.3. Editing Principle Parameters of Material Code........................26

6.1.4. Referring next Material Code...................................................26

6.1.5. Editing Full Parameters of Material Code................................27

6.2. Simple Hopper Scale with Recipe Code......................................30

6.2.1. Definition of Recipe Code (Formal Function)...........................30

6.2.2. Using a Recipe Code ..............................................................31

6.2.3. Construction of Recipe Code...................................................31

6.2.4. Recalling a Recipe Code.........................................................31

6.2.5. Arranging Material Code in Recipe Code................................32

6.2.6. Editing Full Parameters of Recipe Code .................................32

©A&D Co. ltd., AD-4402 Instruction Manual

International Version 1875-1A-IE 200105

Page 4

6.3. System Design of Hopper Scale..................................................34

6.3.1. Operation and I/O Design........................................................34

6.3.2. Design Example......................................................................34

7. Weighing Mode................................................................................ 35

7.1.1. Contents of Batch Weighing Mode..........................................35

7.2. Batch Weighing Mode .................................................................36

7.2.1. Selection of Batch Weighing....................................................37

7.3. Sequential Weighing Mode..........................................................38

7.3.1. Normal Batching of Sequential Weighing................................38

7.3.2. Loss-in Weight of Sequential Mode.........................................41

7.3.3. Compensation Sequence........................................................43

7.3.4. Entrance Sequence.................................................................45

7.3.5. Discharge Sequence...............................................................47

7.3.6. Plain Recipe Sequence...........................................................49

7.3.7. Automatic Selection of Supplying Mat.....................................51

7.3.8. Nozzle Control Sequence (vacuum cleaner)........................... 52

7.3.9. Mixture Sequence...................................................................53

7.3.10. Safety Check Function............................................................55

7.3.11. Pause and Emergency Stop....................................................55

7.3.12. Restart Sequences from Pause...............................................56

7.3.13. Automatic Free Fall Compensation.........................................57

7.3.14. Real Time Free Fall Compensation.........................................58

7.4. Customer Programmed Control

(Comparison Output)

...............................59

7.4.1. Normal Batching of Comparison Function...............................60

7.4.2. Loss-in Weight of Comparison Function..................................62

7.5. Other Functions...........................................................................64

7.5.1. Re-Zero Operation..................................................................64

7.5.2. Zero Tracking Function ...........................................................64

7.5.3. Tare.........................................................................................65

7.5.4. Preset Tare (Fixed Tare Function) ..........................................65

7.5.5. Customizing Function Key (Key Design).................................65

7.5.6. Customizing Sub Display ........................................................66

7.5.7. Graphic Display.......................................................................67

7.5.8. Accumulation Operation..........................................................68

7.5.9. Undoing Accumulation Operation............................................ 68

7.5.10. Clearing (Deleting) Accumulation Data ...................................68

7.5.11. Error Message and Alarm .......................................................69

7.5.12. Graphic Status Indicator..........................................................71

7.5.13. Memory Backup......................................................................71

8. Interface...........................................................................................72

8.1. Control I/O Function ....................................................................72

8.1.1. Interface circuit........................................................................72

8.1.2. Timing Chart............................................................................73

8.2. Built-in RS-485 Interface .............................................................74

8.2.1. Connection..............................................................................74

8.2.2. Settings of Parameters............................................................75

8.2.3. Timing Chart............................................................................76

8.2.4. General Data Format...............................................................77

8.2.5. A&D Data Format.................................................................... 78

8.2.6. Address...................................................................................78

8.2.7. Command List.........................................................................79

Page 2 AD-4402

Page 5

8.3. Built-in Current Loop Output........................................................ 82

8.3.1. Connection..............................................................................82

8.3.2. Communication Modes............................................................82

8.3.3. Data Format............................................................................83

8.4. BCD Output of Option, OP-01.....................................................83

8.5. Relay Output of Option, OP-02....................................................87

8.6. RS-422/485 Interface of Option, OP-03.......................................88

8.7. RS-232C Interface of Option, OP-04...........................................91

8.8. Parallel I/O of Option, OP-05.......................................................92

8.9. Analog Output of Option, OP-07.................................................. 93

9. Maintenance....................................................................................94

9.1.1. Basic Operation.......................................................................94

9.2. Monitor Mode...............................................................................94

9.2.1. Monitoring Control I/O Function...............................................94

9.2.2. Monitoring Built-in RS-485 Interface........................................94

9.2.3. Monitoring Built-in Current Loop Output..................................95

9.2.4. Monitoring A/D Converter........................................................ 95

9.2.5. Monitoring BCD Output of OP-01............................................95

9.2.6. Monitoring Relay Output of OP-02 ..........................................95

9.2.7. Monitoring RS-422/485 Interface of OP-03.............................96

9.2.8. Monitoring RS-232C Interface o f OP-04..................................96

9.2.9. Monitoring Parallel I/O of OP-05..............................................96

9.2.10. Monitoring Analog Output of OP-07 ........................................96

9.3. Test Mode....................................................................................97

9.3.1. Testing Control I/O Function ...................................................97

9.3.2. Testing Built-in RS-485 Interface.............................................97

9.3.3. Testing Built-in Current Loop Output....................................... 97

9.3.4. Testing A/D Converter............................................................. 98

9.3.5. Testing BCD Output of OP-01.................................................98

9.3.6. Testing Relay Output of OP-02 ...............................................98

9.3.7. Testing RS-422/485 Interface of OP-03..................................98

9.3.8. Testing RS-232C Interface of OP-04.......................................99

9.3.9. Testing Parallel I/O of OP-05...................................................99

9.3.10. Testing Analog Output of OP-07 .............................................99

9.4. Initializing Parameters...............................................................100

9.5. Remote Operation.....................................................................102

10. Function List ..................................................................................103

10.1.1. Operation Keys......................................................................103

10.1.2. Outline of the Function List....................................................104

10.2. Referring Parameters................................................................105

10.3. Parameter Settings....................................................................105

10.4. Parameter List...........................................................................106

11. Specifications.................................................................................132

11.1. Dimensions................................................................................135

11.2. Accessories...............................................................................135

12. References....................................................................................136

12.1. Abbreviation...............................................................................136

12.2. ASCII Code for AD-4402...........................................................137

12.3. Index..........................................................................................138

AD-4402 Page 3

Page 6

1.

1. Compliance

1.1.

1.1.1.

1.1.1. Compliance with FCC rules

1.1.1.1.1.1.

1.1.2.

1.1.2. Compliance with

1.1.2.1.1.2.

Note: The displayed value may be adversely affected under extreme electromagnetic

Compliance with FCC rules

Compliance with FCC rulesCompliance with FCC rules

Please note that this equipment generates, uses and can radiate radio frequency

energy. This eq uipment has be en tested and h as been fou nd to comply with the limits

of a Class a computing device pursuant to Subpart J of Part 15 of FCC rules. These

rules are designed to provide reasonable protection against interference when this

equipment is operated in a commercial environment. If this unit is operated in a

residential area it may cause some interference and under these circumstances the

user would be required to take, at his own expense, whatever measures are

necessary to eliminate the interference.

(FCC = Federal Communications Commission in the U.S.A.)

This appliance complies with the statutory EMC (Electromagnetic Compatibility)

directive 89/336/EEC and t he Low Voltag e Directive 73 /23/EEC for safety of electrical

equipment designed for cer tai n vol tag es.

influences.

Compliance

ComplianceCompliance

Compliance with European Directive

Compliance with Compliance with

European Directive

European DirectiveEuropean Directive

Page 4 AD-4402

Page 7

2.

2. Outline and Feature

2.2.

The AD-4402 is the multi-function weighing indicator for batch weighing and filling

weighing. This indicator has control I/O for weighing sequence and options.

Large display

This indicator has blue vacuum fluorescent display (VFD).

The character height of the main display is 18 mm.

Current weighing data, material names, comparison references and accumulation

data are displayed in the same time.

Material names and recipe

Operation guidance

Message that assists current operation are di splayed in the fron t panel, any one could

operate the indicator without instruction manuals.

Full weighing sequences

The AD-4402 can combine plural mater i al s and the pl ain mi xture function is equipped.

Filling nozzle and agitation sequence is equipped.

Using the forecast control function, the flow control can be performed that is

equivalent to A/D conversion of 1000 times per second.

Outline and Featuressss

Outline and FeatureOutline and Feature

RS-485 interface

32 indicators can be co nnected to a pr ogramma ble controll er or a per sonal compu ter.

These protocols are according to public formats.

Options

There are built-in options of AC 250 V direct drive relay, serial interface, parallel

interface, analog output and etc.

There are built-in options of CC-Link, DeviceNet, PROFIBUS.

There are three expansion slots to install options.

Check mode during operation

The monitor mode can confirm system situation during operation.

The test mode can test Input / Output interface.

Even if there is not monitor instrument, interface can be confirmed.

Recipes and raw material data stored in the indicator

The recipe is described a combination of material codes and weights.

The material code is described th e weighi ng sequence param eters for a r aw material .

Water-resistant panel

The classification code of the front panel is equivalent to IP-65 of IEC 529 using

accessory rubber packing. The "IP-65" code is explained as follows:

IP: International Protection.

6: Against ingress of solid foreign objects.

Dust-tight. No ingress of dust.

5: Against ingress of water with harmful effects.

Protected against water jets (no powerful jets). Water projected in jets against

the enclosure from any direction shall have no harmful effects.

AD-4402 Page 5

Page 8

2.1.

2.1. Precaution

2.1.2.1.

Befor any use, confirm the following articles for the safty operation.

Grounding the indicator

Ground the indicator certainly. The earth terminal is the rear panel.

Separate this earth l ine from other g round line like a motor, inverter or a power source.

Unless the indicator is grounded, it may cause to receive an electric shock, be

happen operation error or catch fire

Use adaptable power cord

Confirm the AC voltage and current of the power cord. If the voltage range of cord is

lower than power line voltage, it may cause of a leak or catching fire. Use

compression terminals to connect the power cord to the terminal of the rear panel.

Fuse

The fuse is installed to prevent the indicator from catching fire.

The indicator is equipped many safety circuits. Therefore, the fuse is not broken in

normal operation. If the fuse i s broken , do no t repl ace the fuse and co ntac t your local

or A&D dealer. This trouble may cause of an electric discharge of thunder.

Precaution

PrecautionPrecaution

Splashing water

The indicator is not water-resistant. When the indicator is mou nted to panel with

accessory rubber, the front panel is equivalent to IP-65.

Flammability gas

Do not install the indicator in any flammable gas.

Radiation of the indicator

Space out instruments to radiate heat sufficiently.

Removing the cover

Remove the power cord terminals i n the side o f the power source before r emoving the

cover to avoid receiving an electric shock.

Do not touch the internal circuit within 10 seconds after turning off the indicator

because of receiving an electric shock.

Page 6 AD-4402

Page 9

2.2.

r

r

r

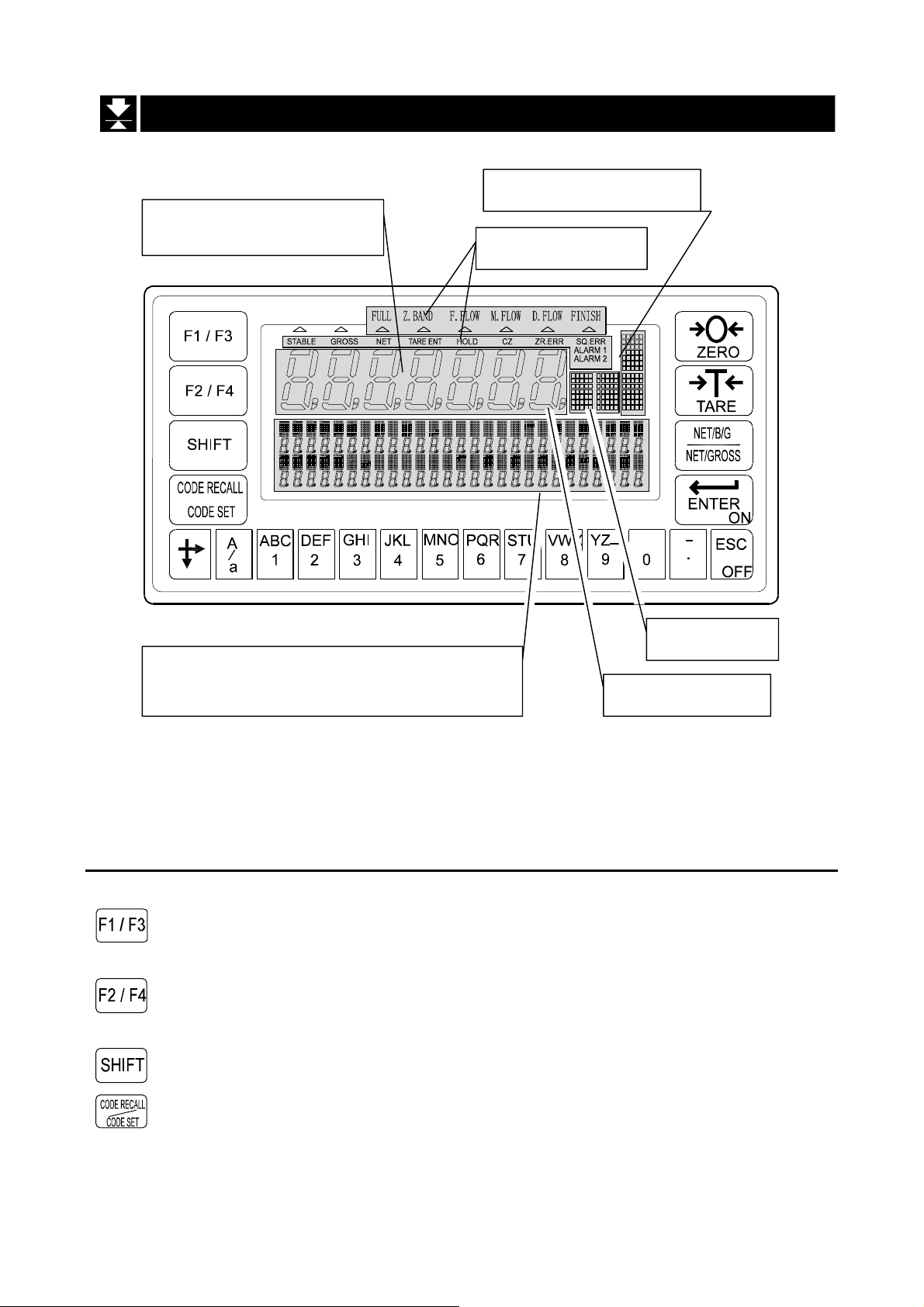

2.2. Front Panel

2.2.2.2.

Main display

Weighing data is displayed.

Front Panel

Front PanelFront Panel

Graphic status indicato

Status indicator

Sub-display

Materials, Accumulation data, parameters

and operation guidance are displayed.

2.2.1.

2.2.1. Keys

2.2.1.2.2.1.

Keys

KeysKeys

Unit indicato

Standby indicato

Pressing this key, the key works as the F1 key.

Pressing the SHIFT key and this key, the key works as t he F3 key.

Pressing this key, the key works as the F2 key.

Pressing the SHIFT key and this key, the key works as t he F4 key.

The key to select a function of the key.

The key to open the material code or recipe code.

Pressing the SHIFT key and this key, the key works as the m ater ial

code edit key.

Pressing the ENTER key and this key, the key works as the recipe

code edit key.

AD-4402 Page 7

Page 10

The key to move the cursor or scroll the function number.

Press and hold the SHIFT key and press the key is used to

decrease the code number.

The key to select alphabetical keys, upper keys, lower keys or

numerical keys.

Alphanumeric keys.

The escape key. Pressing and holdi ng the key ab ove three seconds

in normal weighing mode, the display is turned off (standby mode).

The ESC key is used to undo the last key and to return to the last

mode.

The ENTER key for parameter settings.

The key to be turned on the display.

Pressing the

The key to select net or gross

The tare key. The key is displayed the net value that subtracts tare

weight from a current weighing.

The zero key to zero current weighing display.

key and this key, the key works as the menu key.

2.2.2.

2.2.2. Symbols

2.2.2.2.2.2.

Main display Gross or net is displayed.

Sub display Code numbers, operation guidance, graph, comparison parameter

Unit indicator The indicator is displayed that the weighing unit is selected in the

Status indicator The current weighing status is displayed.

Graphic status

indicator

STABLE Lighting the sign, the current weighing display is stable.

Symbols

SymbolsSymbols

and other are displayed selectiv el y.

calibration mode. Refer to section "5. Calibra tion".

The classification number is displayed, when occurred an error or

informed an alarm.

The current weighing situation is displayed with symbols.

GROSS Displaying the gross data in the main display, the sign is lighted.

Page 8 AD-4402

Page 11

NET Displaying the net data in the main display, the sign is lighted.

TARE ENT Tare entered.

Storing the net value, the sign is lighted.

HOLD Fixing the main display, the sign is lighted.

CZ Center of zero.

When the gross weigh t is in t h e ce nt er of t he zero p oin t, th e s ign is

lighted.

ZR.ERR Zero error.

Error message for zero ing the gross data of the main display.

SQ.ERR The sequence error sign.

A message for weighing sequence error.

ALARM 1 An error sign for over load or emergency stop mode.

ALARM 2 A fatal error sign. Example: The wire form loadcell is broken.

Standby indicator In the standby mod e, al l inter faces ar e turn ed off an d int ernal circ uit

works only.

FULL

Z. BAND

When the gross data exceeds the full limit, the sign is lighted.

The zero band sign.

When the gross data is within the ran ge of the ze ro band (arou nd

the zero point), the sign is lighted.

F.FLOW

M.FLOW

D.FLOW

FINISH

The full flow g a t e sign.

The medium flow gate sign.

The dribble flow gate sign.

The finish sign.

AD-4402 Page 9

Page 12

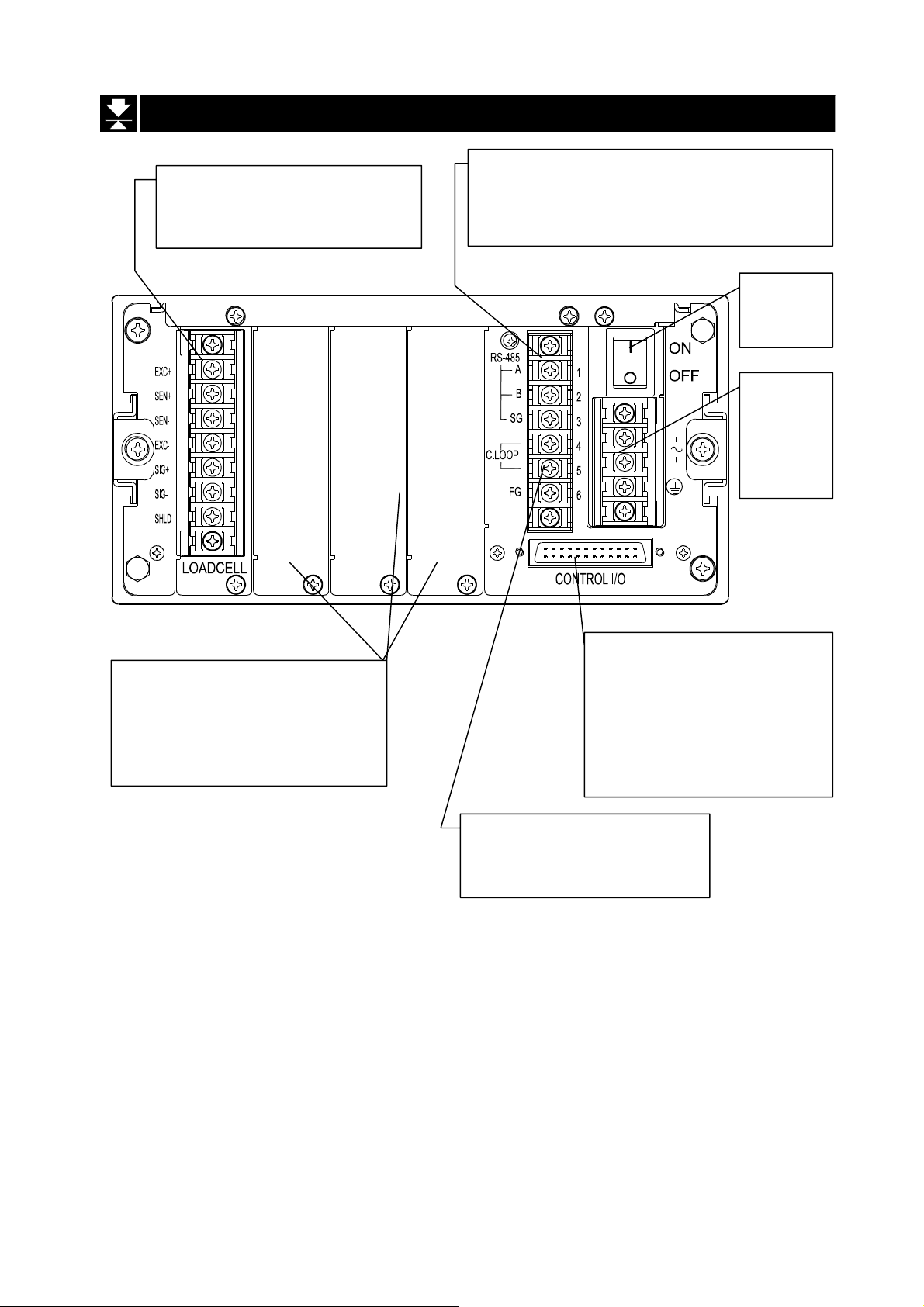

2.3.

,

A

A

A

2.3. Rear Panel

2.3.2.3.

Loadcell terminal.

Eight pieces of 350Ω loadcell

can connect in parallel.

Rear Panel

Rear PanelRear Panel

Built-in RS-485 terminal.

The possibility: to read weighing data,

write parameters, connect 32 units of the

indicator with the multi-drop connection

Main

power

switch

Power

cord

terminal

C85V

~ 250V

Option slot to connect

maximum three options.

Example: BCD output, Relay

output, Analog output and field

bus.

Control I/O to connect to

external control units.

11 input terminals,

11 output terminals,

n input comm on terminal

n output common term inal

Built-in current loop output

Use to connect A&D

external monitor

Page 10 AD-4402

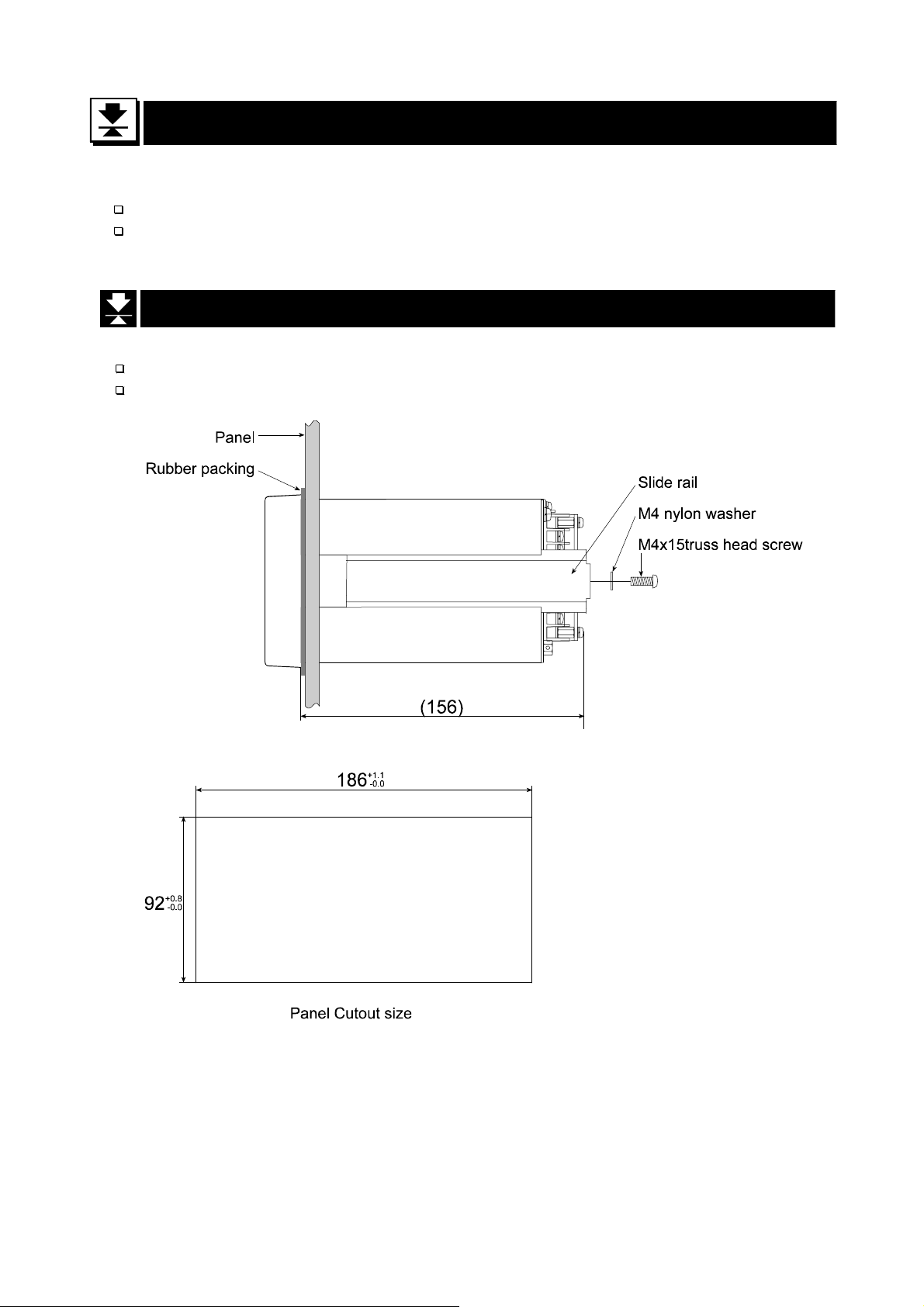

Page 13

Caution

Remove the power cord before installing the indicator and other.

Build in the option before installing the indicator.

The indicator can mount on the panel using the slide rail.

If the accessory packing rubber is used, the front panel is equivalent to IP-65 of IEC 529.

3.

3. Installation

3.3.

3.1.

3.1. Mounting Indicator

3.1.3.1.

Installation

InstallationInstallation

Mounting Indicator

Mounting IndicatorMounting Indicator

AD-4402 Page 11

Page 14

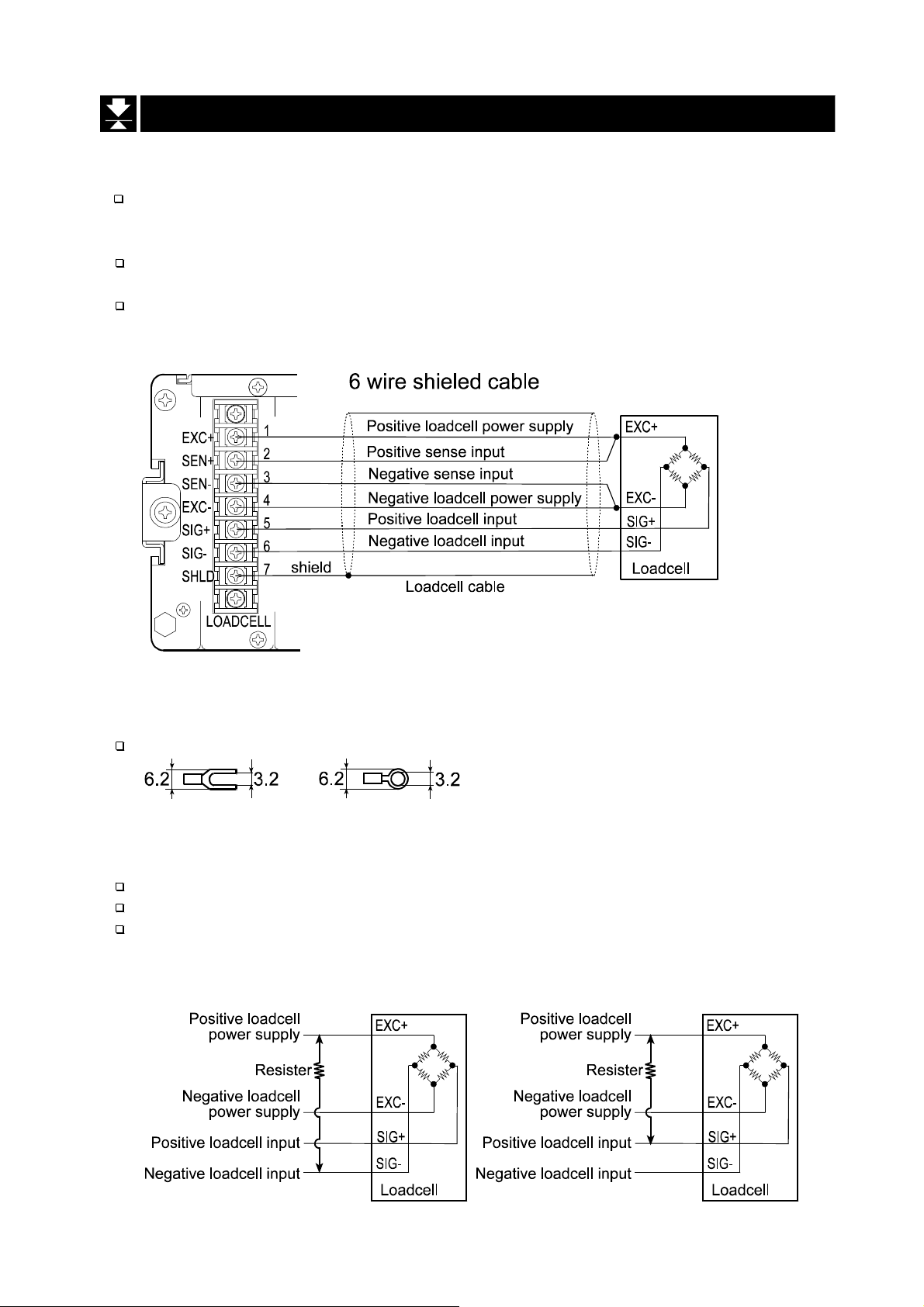

Caution

Share the loadcell cable from noise-generating device and these power lines

beacuse loadcell signal is sensitive.

We recommend you to use the 6 wire shielded cable to prevent loss of weighing

precision.

The loadcell cable l eng th i s shor ter than 5 m, y ou may be use a 4 w ir e shi elded c abl e

with terminals 1 & 2 shorted (EXC+ & SEN+ shorted) and terminals 3 & 4 shorted

(EXC- & SEN- shorted ).

3.2.

3.2. Connecting Loadcell Cable

3.2.3.2.

Connecting Loadcell Cable

Connecting Loadcell CableConnecting Loadcell Cable

Adaptable Compression Terminal Parts

Use the adaptable compression terminal parts to the cables

Loadcell Output Adjustment for Zero Calibration (Zero Point)

When a message "CERR2" is displayed, zero point of zero ca libration is too large.

When a message "CERR3" is displayed, zero point of zero calibration is too small.

Use the resist er more than 50 kΩ with low (good) temperature coefficient, when

adding a resister to adjust the loadcell output to indicator terminals.

In Case of Too Lage Output In Case of Too Small Output

Page 12 AD-4402

Page 15

3.2.1.

3.2.1. Verifying

3.2.1.3.2.1.

Verifying Loadcell Output and Input Sensitivity

VerifyingVerifying

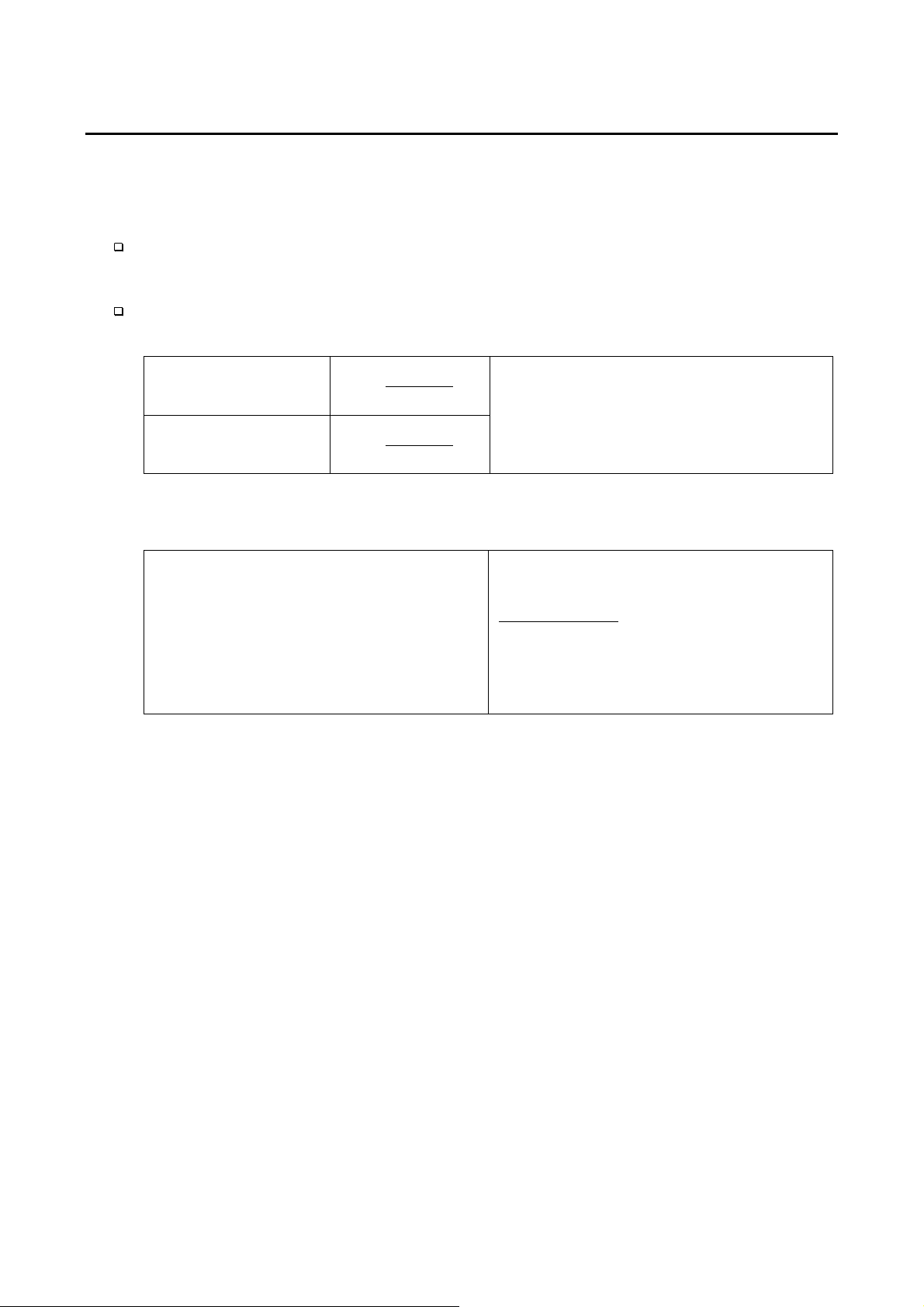

The input sensitivity of the indicator is 0.3µV/division or more. Adapt to the following

inequality, w hen you desig n a weighing instrume nt using the indicator a nd loadc ell(s).

Caution

A change in input voltage sensitivity is equiva lent to a one division change of

the display. Select as large an input voltage sensitivity voltage as possible so

that the weighing interval becomes stable.

Consider the leverage if a lever is used.

Loadcell Output and Input Sensitivity

Loadcell Output and Input Sensitivity Loadcell Output and Input Sensitivity

Weighing instrument

using one loadcell.

Weighing instrument

using multi-loadcell

Verification Example

Verification Example

Verification ExampleVerification Example

Design:

Loadcell N=1

Rated capacity A=750 [kg]

Rated output B=3 [mV/V]

Excitation voltage E=5000 [mV]

Weighing interval D=0.05 [kg]

Weighing capacity 300 [kg]

3.0∗∗≤

3.0

DBE

A

∗∗

≤

DBE

∗

NA

A:Rated capacity of loadcell [kg]

B:Rated output [mV/V]

D:Weighing interval [kg]

E:Excitation voltage [mV]

N:Number of loadcells

05.035000≥=∗∗

750

regard the in strument as a good design.

3.01

. Therefore,

AD-4402 Page 13

Page 16

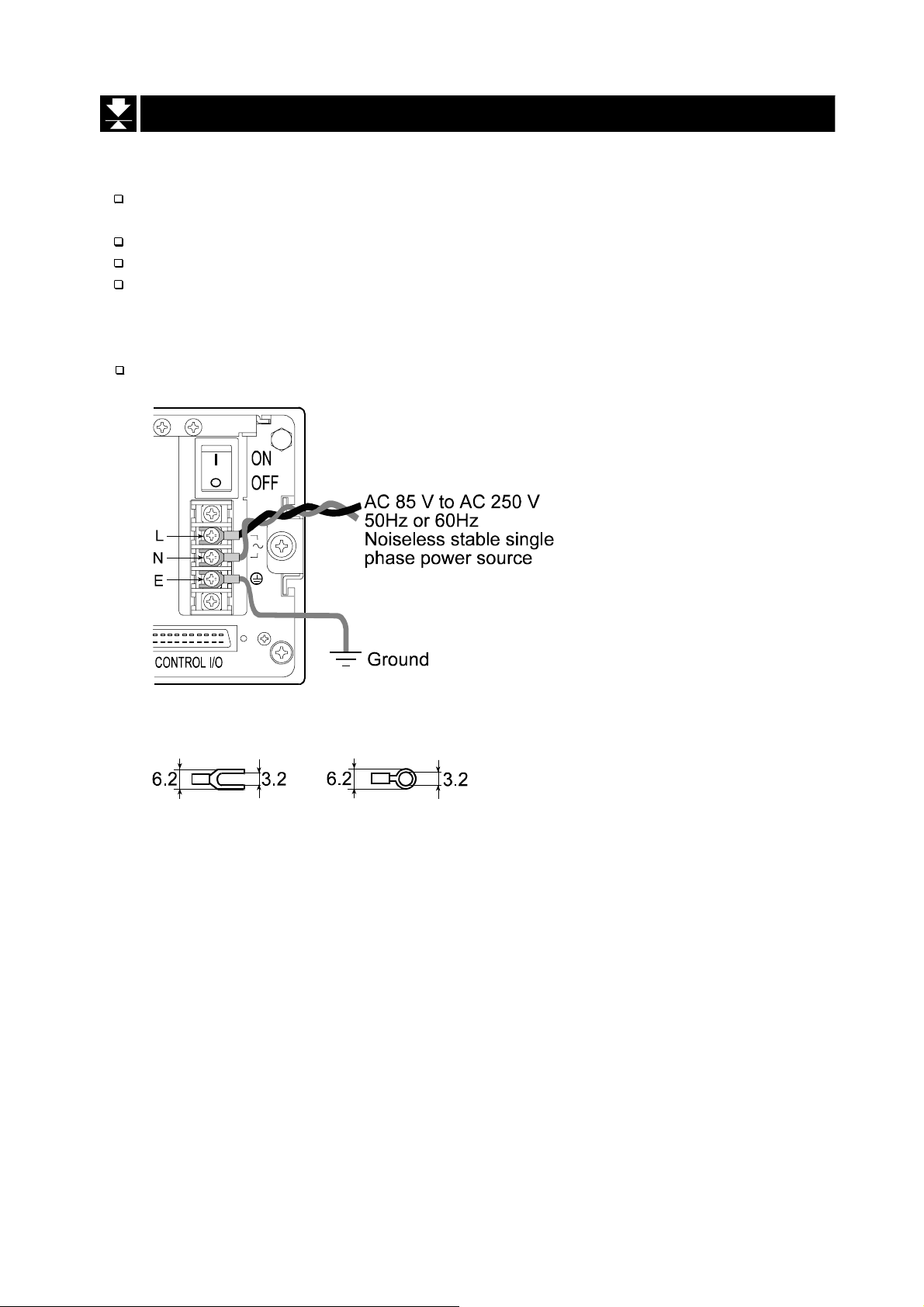

Caution

Gorund the indicator with terminal E to avoid receiving an electric shock and

an error due to discharge a static electricity.

Share the ground wire from electrical device that generats noise .

Do not use unstable power source.

Share the power cord form the moter system (as noise-generating device) to

avoid operation error.

The power source can use AC 85V to AC 250V with 50 Hz or 60 Hz.

3.3.

3.3. Wiring Power Cord

3.3.3.3.

Wiring Power Cord

Wiring Power CordWiring Power Cord

Adaptable Compression Terminal Parts

Page 14 AD-4402

Page 17

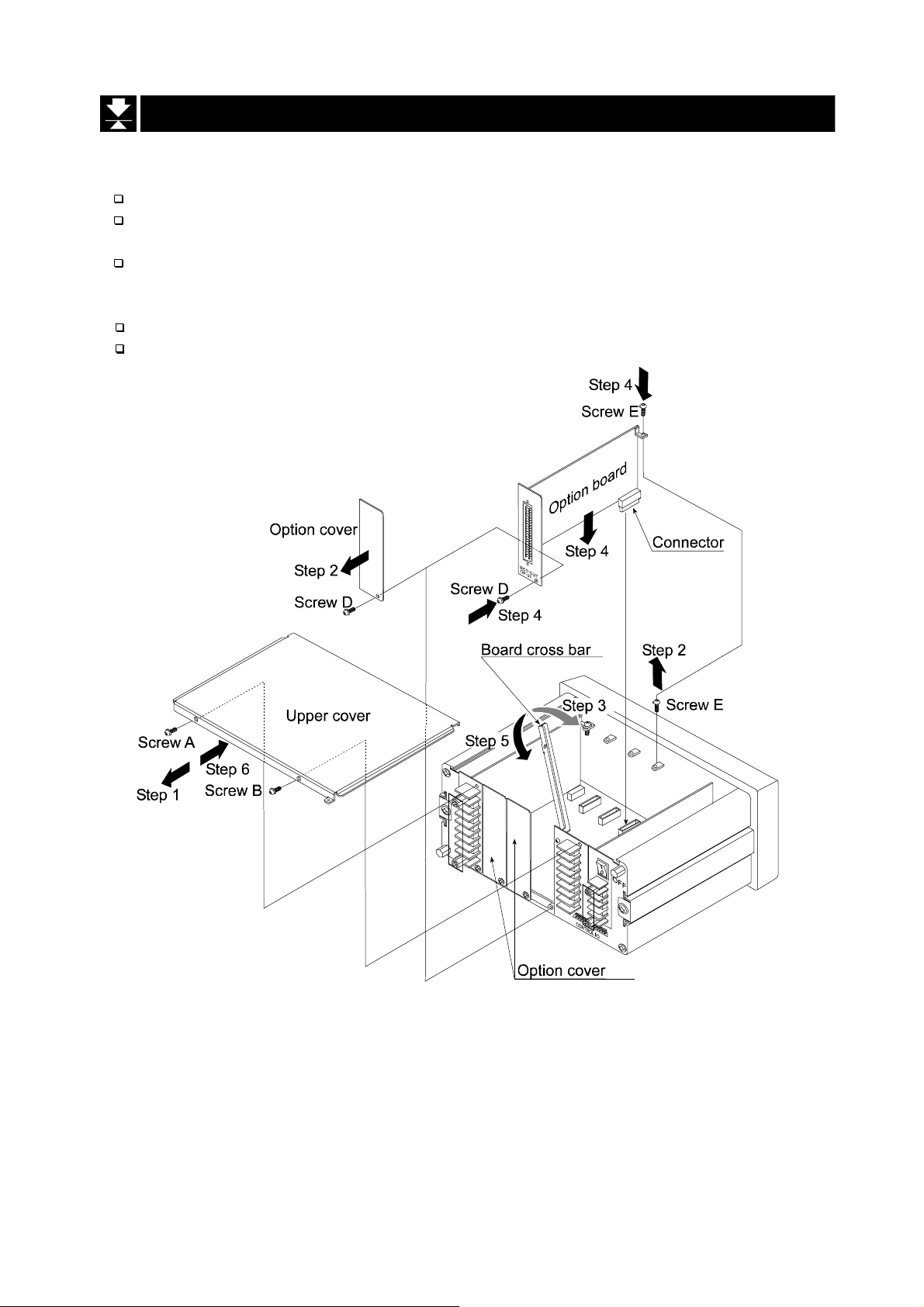

Caution

Remove the power cord before operation to install the option.

Do not touch an inside parts within ten seconds after removing the power cord

because you may receive an electric shock.

Do not forget to tighten the screw. If the screw is not tightened, it may cause

short circuit or an error due to noise.

Three option boards can install in the slots.

Initialize the RAM data in accordance with section 9.4. Initializing Parameters.

3.4.

3.4. Installing Options

3.4.3.4.

Installing Options

Installing OptionsInstalling Options

AD-4402 Page 15

Page 18

4.

4. Basic Operation

4.4.

4.1.

4.1. Key Operation Examples

4.1.4.1.

This section is described the way of key operation.

4.1.1.

4.1.1. Standby Mode

4.1.1.4.1.1.

OFF Press and hold the OFF key above three seconds in the

ON The ON key is used to turn on the indicator.

4.1.2.

4.1.2. Cursor

4.1.2.4.1.2.

Basic Operation

Basic OperationBasic Operation

Key Operation Examples

Key Operation ExamplesKey Operation Examples

Standby Mode

Standby ModeStandby Mode

weighing mode. Then the indicator enters the standby mode

and displays standby indicator.

In the standby mode, All interface is turned off and internal

circuit works only.

Cursor Operation

CursorCursor

Operation

Operation Operation

There is the cursor on a segment (an item) that is turned on and off.

The key is used to move the cursor forward.

SHIFT + Press and hold the SHIFT key and press the key is used to

move the cursor backward.

ENTER The ENTER key is used to enter the selected item.

ESC The ESC k ey is used to re turn to t he las t mode and t o und o the

last key operation.

4.1.3.

4.1.3. Inputting

4.1.3.4.1.3.

The character can be input in a current segment (an item) in adaptable mode.

A/a The A/a key is used to change numerical key, upper keys, lower

Alphanumerical The alphanumerical keys and the ENTER key is used to enter

ENTER The ENTER key is used to specify the alphanumerical data.

ESC The ESC key is used to undo the last key operation and to

Inputting Characters

InputtingInputting

Characters

Characters Characters

keys and alphabetical key.

the parameters and to select a code number directly.

return to the last mode.

Page 16 AD-4402

Page 19

4.1.4.

4.1.4. The Way of Calling a Code

4.1.4.4.1.4.

The Way of Calling a Code

The Way of Calling a CodeThe Way of Calling a Code

In Case of a Material Code:

Step 1 Suppose that is set the function parameter [5qf- 8] to [0] .

Step 2 Press the CODE RECALL key in weighing mode.

Step 3 Set the number of a material code with the following keys:

The key is used to increase the code number.

SHIFT + Press and hold the SHIFT key and press the key is used to

decrease the code number.

Numerical The numerical keys and the ENTER key is used to select a

code number directly and to enter the parameters.

ENTER The ENTER key is used to specify the number.

ESC The ESC key is used to undo the last key and to return to the

last mode.

In Case of a Recipe Code:

Step 1 Suppose that is set the function parameter [5qf- 8] to [1] or [2].

Step 2 Press the CODE RECALL key in weighing mode.

Step 3 Set the number of a recipe code with the following keys:

, SHIFT + , Numerical, ENTER, ESC keys

4.1.5.

4.1.5. The Way of Entering a Correction Mode

4.1.5.4.1.5.

The Way of Entering a Correction Mode

The Way of Entering a Correction ModeThe Way of Entering a Correction Mode

In Case of a Material Code:

Step 1 Press and hold the SHIFT key and press the CODE RECALL key in weighing mode.

Step 2 Select a number of a material code using the following keys:

, SHIFT + , Numerical, ENTER, ESC keys

Step 3 Edit some items of a material code using numerical keys and the ENTER key.

Step 4 Press the ESC key to return to weighing mode.

In Case of a Recipe Code:

Step 1 Press and hold the ENTER key and press the CODE RECALL key in weighing mode.

Step 2 Select a number of a recipe code using the following keys:

, SHIFT + , Alphanumerical, A/a, ENTER, ESC keys

Step 3 Edit some items of a recipe code using alphanumeric keys and the ENTER key.

Step 4 Press the ESC key to return to weighing mode.

AD-4402 Page 17

Page 20

4.1.6.

4.1.6. The Way of Entering Menu

4.1.6.4.1.6.

Step 1 Press and hold the ENTER key and press the key in weighing mode.

Then the first layer of menu is display.

Step 2 Use the following keys in the menu :

Step 3 Press the ESC key to return to weighing mode several times.

The Way of Entering Menu

The Way of Entering MenuThe Way of Entering Menu

, SHIFT, Alphanumerical, A/a , ENTER, ESC keys

Page 18 AD-4402

Page 21

4.2.

4.2. Status Chart (Mode map

4.2.4.2.

Status Chart (Mode map))))

Status Chart (Mode mapStatus Chart (Mode map

AD-4402 Page 19

Page 22

5.

5. Calibration

5.5.

The indicator, which is connected loadcell unit, can weigh the "weight" value on the

loadcell pan and display its "mass" value. The calibration function is used to adjust

the weighing value (displaying value) so that the weighing system can weigh

correctly.

There are two way of the calibration. The "actual load calibration" uses a rated

mass and zero output from the loadcell. The "digital span" inputs arbitrary values

(calculated by hand). T hese methods are selected in the calibration procedure.

There is a compensation function of the "gravity acceleration correction".

This function is used, when a calibrated weighing system is moved to other place.

These calibration para meters are stored in the indicator without any power supply.

Calibration

CalibrationCalibration

Common Calibration Items

Unit The "g", "kg" and "t" or "lb" can be selected.

Decimal point The decimal point can be selected form "not used" to "four

decimal places".

Minimum division The minimum division of the weighing display.

Weighing capacity The maximum display of the weighing display.

Items for the "Actual Load Calibration"

Common items Unit, decimal point, minimum di vi sion and w eighing capacity

Zero point adjustment A zero point output is used from the loadcell unit.

Span adjustment Rated mass is place on the weighing pan and is weighed.

The sensitivity is adjusted. This sensitivity is the same as "

sensitivity " of digital span.

Items for "Digital Span"

Common items Unit, decimal point, minimum di vi sion and w eighing capacity

Zero point output The numerical data is input as zero point output of loadcell

unit.

Rated capacity The rated capacity of the loadcell is input.

The sensitivity of the loadcell is input.

Caution

When the CAL switch on the A/D board is "DISABLE", any calibration can not

perform.

Do not perform any calibration during a weighing sequnce operation.

Entering calibration mode during a weighing sequnce operation, the weighing

sequnce operation is terminated. Calibrate the weighing system, when a

weighing sequnce operation does not work

The accuracy of the "Digital Span (Calibration without Mass)" is 1/1000.

Do not use a "loadcell summing box", the "digital span" is performed.

It is necessary that the loadcell sensitivity is exactly known, if the "digital

span" is used.

Page 20 AD-4402

Page 23

5.1.

5.1. Actual Load Calibration (using Mass)

5.1.5.1.

ESC key If you want to return to the weighing mode during the

ENTER key When the key is pressed, the procedure stores a current

Step 1 Press and hold the ENTER key and press the key to display the

menu in a weighing mode.

Step 2 Press the key twice to select the menu CAL.

Press the ENTER key to enter the calibration mode.

Step 3 Press the ENTER key to enter the menu CAL.

Step 4 Select a unit using the num erical keys and press the ENTER key

to store it.

Step 5 Select a decimal point using the numerical keys and press the

ENTER key to store it.

Actual Load Calibration (using Mass)

Actual Load Calibration (using Mass)Actual Load Calibration (using Mass)

calibration mode, press the ESC key anytime. And it has

effect until the last displayed parameter.

Example: zero adjustment only, etc.

parameter and proceeds to next step.

Step 6 Select a minimum division using the numer ical keys and press the

ENTER key to store it.

Step 7 Select a weighing capcity usi ng the n um eri cal key s and press the

ENTER key to store it.

Step 8 Perform the zero point adjustment.

Place nothing on the weighing pan and press the ENTER key to

store it after the STABLE indicator is displayed.

Whether the STABLE indicator is displayed or not, if you want to

store it, wait for ten seconds and press the ENTER key.

Step 9 Specify a total mass value to place on the weig hing pan using the

numerical keys and press the ENTER key to store it.

Step10 Place the specifyed mass on the weighing pan and press the

ENTER key to store it after the STABLE indicator is displayed.

Whether the STABLE indicator is displayed or not, if you want to

store it, wait for ten seconds and press the ENTER key.

Step11 Press the ESC key to return the weighing mode.

AD-4402 Page 21

Page 24

5.2.

5.2. Digital Span (Calibration without Mass)

5.2.5.2.

ESC key If you want to return to the weighing mode during the

ENTER key When the key is pressed, the procedure stores a current

Step 1 Press and hold the ENTER key and press the key to display the

menu in a weighing mode.

Step 2 Press the key twice to select the menu CAL.

Press the ENTER key to enter the calibration mode.

Step 3 Press the ENTER key to enter the menu CAL.

Step 4 Select a unit using the num erical keys and press the ENTER key

to store it.

Step 5 Select a decimal point using the numerical keys and press the

ENTER key to store it.

Digital Span (Calibration without Mass)

Digital Span (Calibration without Mass)Digital Span (Calibration without Mass)

calibration mode, press the ESC key anytime. And it has

effect until the last displayed parameter.

Example: zero adjustment only, etc.

parameter and proceeds to next step.

Step 6 Select a minimum division using the numer ical keys and press the

ENTER key to store it.

Step 7 Select a weighing capcity usi ng the n um eri cal key s and press the

ENTER key to store it.

Step 8 Press the F1 key to proceed to the digital span procedure.

Step 9 Input the zero point value usi ng the nu mer i cal keys and press the

ENTER key to store it.

Step10 Input the rated capacity of a lo adcell using the nu merical key s and

press the ENTER key to store it.

Step11 Input the sensitivity of the loadcell in the unit of mV/V using the

numerical keys and press the ENTER key to store it.

Step12 Press the ESC key to return the weighing mode.

Advise The digital span can be used for trimming of the actual l oad calibration using mass.

Page 22 AD-4402

Page 25

5.3.

5.3. Gravity Acceleration Correction

5.3.5.3.

Gravity Acceleration Correction

Gravity Acceleration CorrectionGravity Acceleration Correction

The function compensates the weighing error due to the difference of gravity acceleration.

G1 The place where the weighing system is calibrated.

G2 The place where the weighing system is used.

ESC key If you want to return to the weighing mode during the

calibration mode, press the ESC key anytime.

ENTER key When the key is pressed, the procedure stores a current

parameter and proceeds to next step.

Step 1 Press and hold the ENTER key and press the key to display the menu in a

weighing mode.

Step 2 Press the key twice to select the menu CAL. Press the ENTER key to enter the

calibration mode.

Step 3 Select the menu G with the key. Press the ENTER key to enter it.

Step 4 Input the gravity acceleration at G1 using the num erical keys and press the

ENTER key to store it.

Step 4 Input the gravity acceleration at G2 using the num erical keys and press the

ENTER key to store it.

Step 5 Press the ESC key to return the weighing mode.

5.3.1.

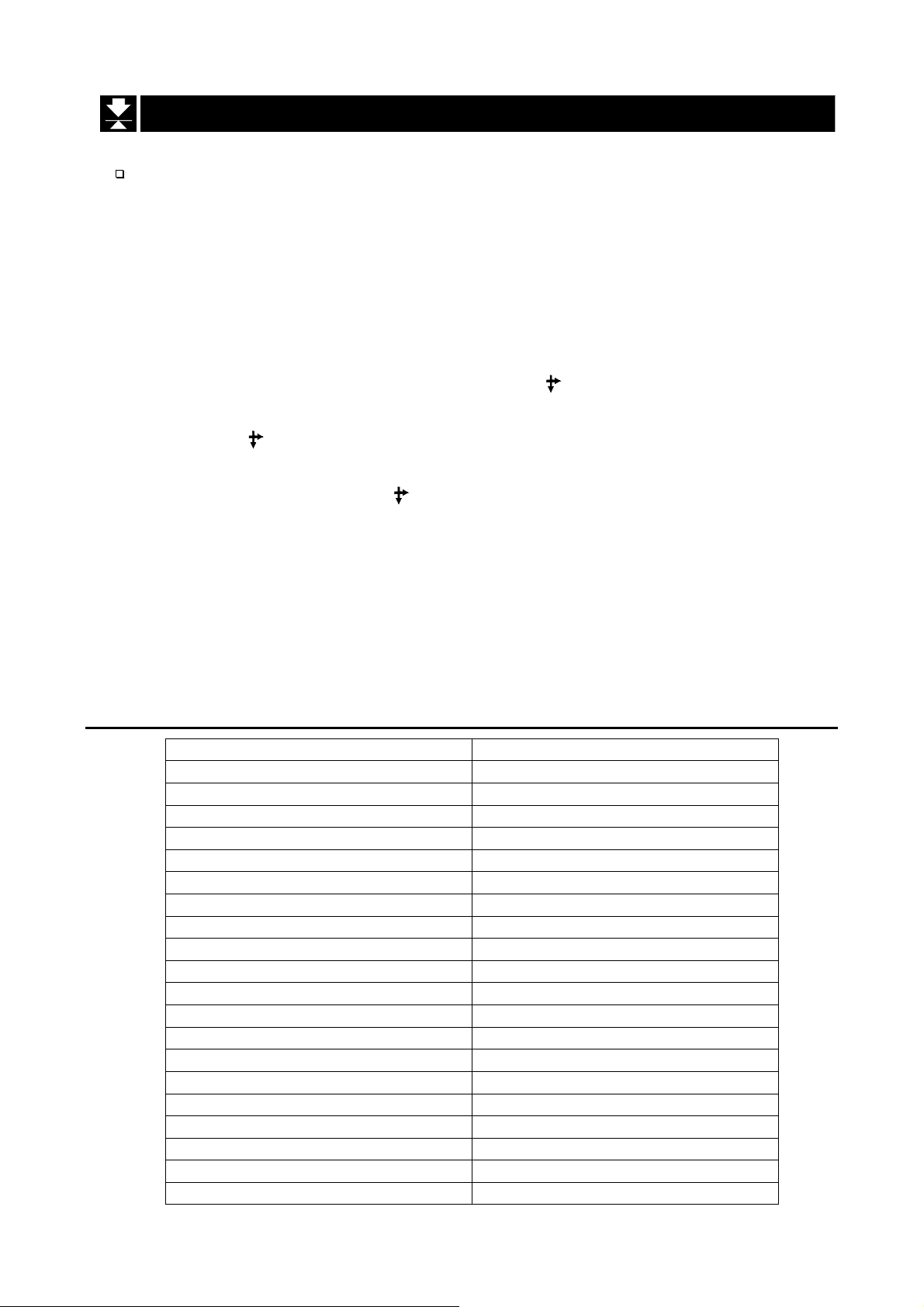

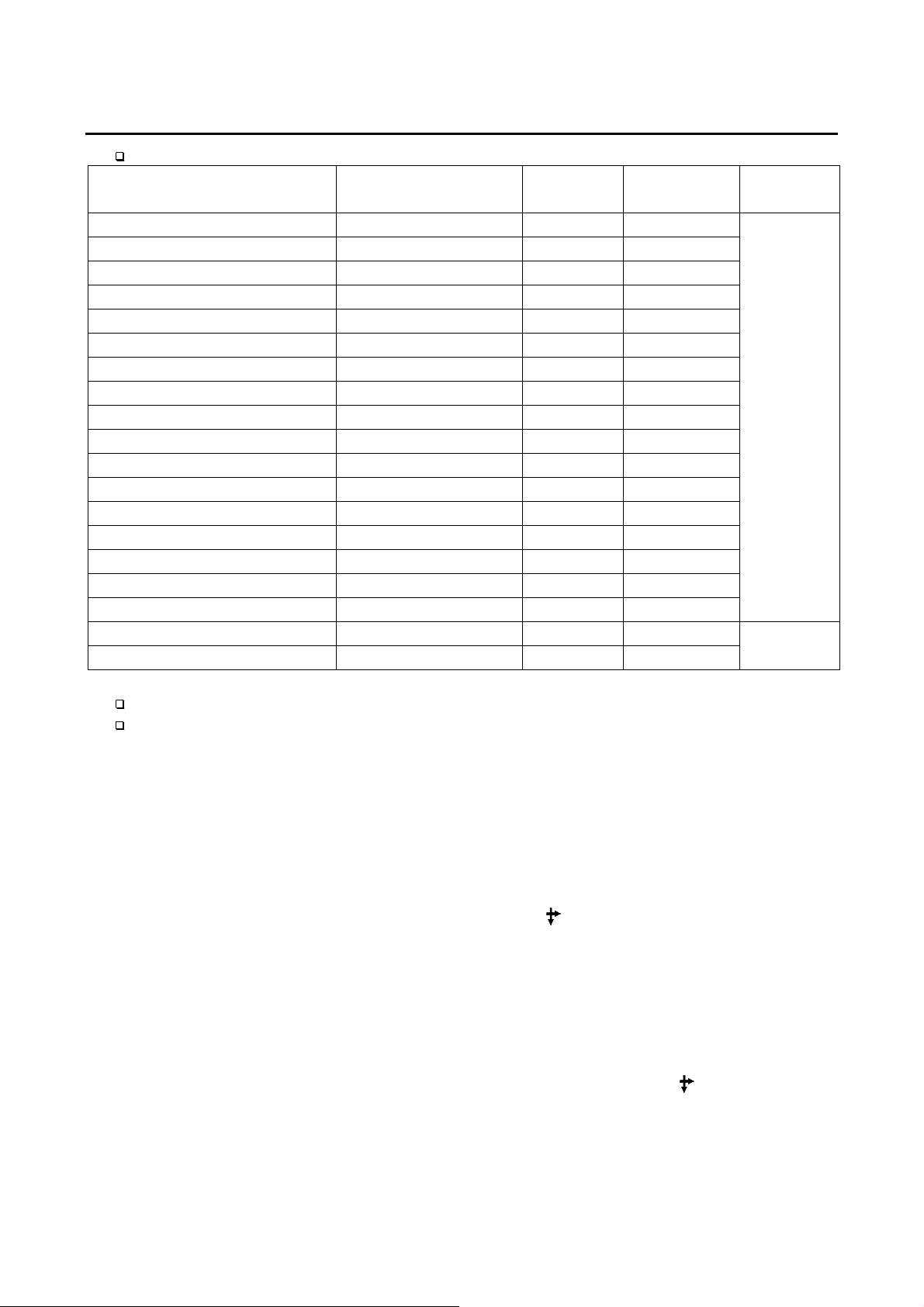

5.3.1. Gravity Acceleration Reference

5.3.1.5.3.1.

Amsterdam 9.813 m/s2Manila 9.784 m/s

Athens 9.800 m/s2Melbourne 9.800 m/s

Auckland NZ 9.799 m/s2Mexico City 9.779 m/s

Bangkok 9.783 m/s2Milan 9.806 m/s

Birmingham 9.813 m/s2New York 9.802 m/s

Brussels 9.811 m/s2Oslo 9.819 m/s

Buenos Aires 9.797 m/s2Ottawa 9.806 m/s

Calcutta 9.788 m/s2Paris 9.809 m/s

Chicago 9.803 m/s2Rio de Janeiro 9.788 m/s

Copenhagen 9.815 m/s2Rome 9.803 m/s

Cyprus 9.797 m/s2San Francisco 9.800 m/s

Djakarta 9.781 m/s2Singapore 9.781 m/s

Frankfurt 9.810 m/s2Stockholm 9.818 m/s

Glasgow 9.816 m/s2Sydney 9.797 m/s

Havana 9.788 m/s2Tainan 9.788 m/s

Helsinki 9.819 m/s2Taipei 9.790 m/s

Kuwait 9.793 m/s2Tokyo 9.798 m/s

Lisbon 9.801 m/s2Vancouver, BC 9.809 m/s

London (Greenwich) 9.812 m/s2Washington DC 9.801 m/s

Los Angeles 9.796 m/s2Wellington NZ 9.803 m/s

Madrid 9.800 m/s2Zurich 9.807 m/s

Gravity Acceleration Reference

Gravity Acceleration ReferenceGravity Acceleration Reference

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

AD-4402 Page 23

Page 26

5.4.

5.4. Calibration Error

5.4.5.4.

Error Code Treatment and Situation

CERR1

CERR2

CERR3

CERR4

CERR5

CERR6

CERR7

CERR8

CERR9

CERR10

CERR11

Calibration Error

Calibration ErrorCalibration Error

Resolution (Weighing ca paci ty / minimum division) is exceeds th e l i mita ti on.

Increase minimum division or decrease weighing capacity.

The initial load (no load output) is larger than 2mV/V.

Confirm the loadcell cable.

Negative loadcell output value. Check wiring.

Confirm the loadcell cable.

Mass value exceeds the we ighing capacity.

Use a mass within the weighing capacity. (Decrease mass value)

Mass value is too light for the calibration.

Increase mass value.

The loadcell output to be equivalent to minimum division is too small.

Use more rough minimum division.

The polarity of loadcell output is inversed.

Confirm the loadcell cable.

The mass value of the weighing capacity exceeds 3.2 mV/V.

Confirm the mass and weighing capacity.

Gravity acceleration is out of range.

Correct the value within the range of 9.770 ~ 9.835 m/s

Zero output of loadcell unit is out of range.

Trim the zero output within 0.0 ~ 2.0 mV/V.

The loadcell output to be equivalent to minimum division is out of range.

Trim the output within 0.0 ~ 3.2 mV/V.

2

.

Page 24 AD-4402

Page 27

6.

6. Applications

6.6.

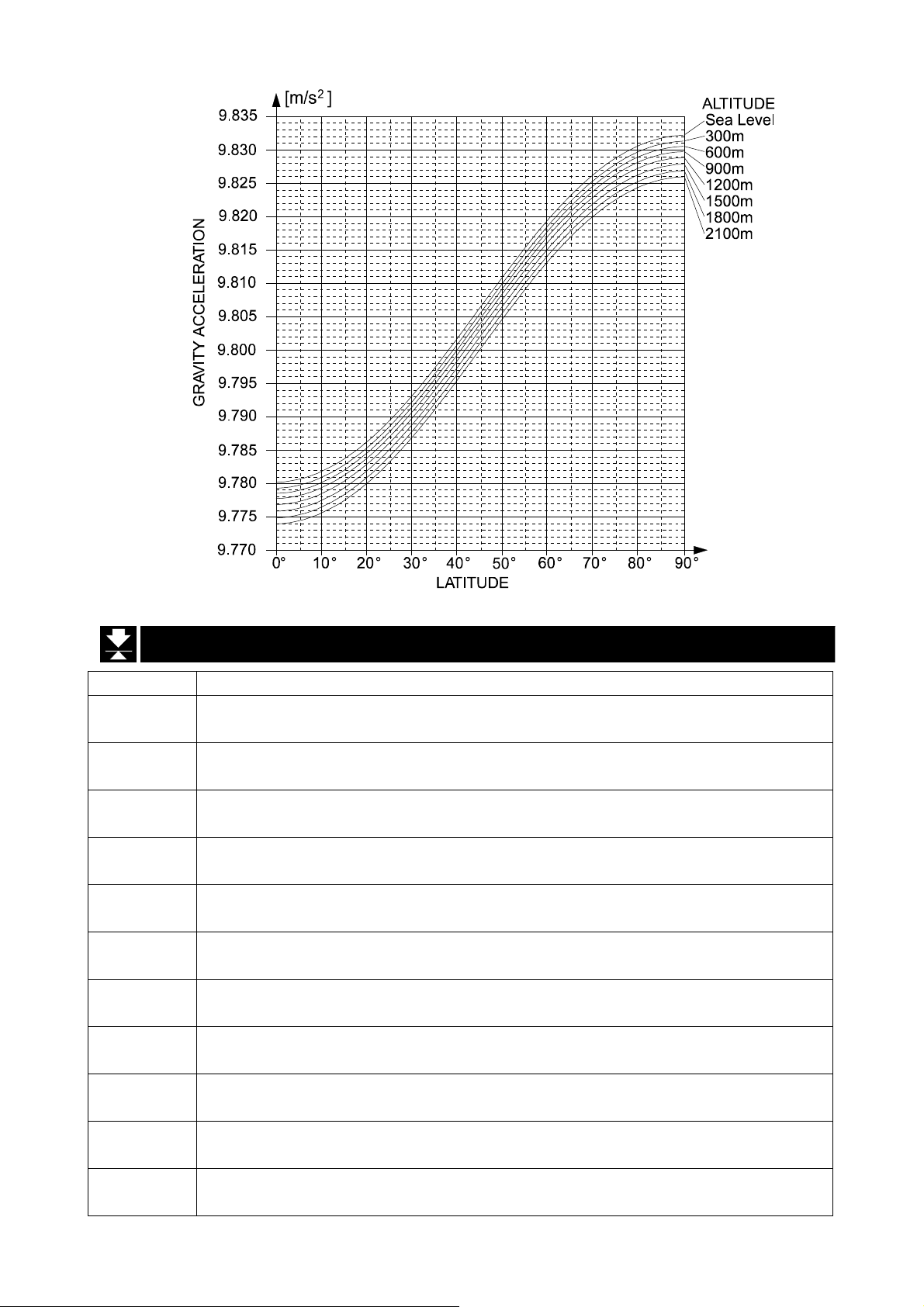

6.1.

6.1. Hopper Scale with Material Code

6.1.6.1.

In the section, ap plicatio ns

are explained according to

the right hopper scale that

performs batch weighing

using a material code.

An application is explained

mixture of materials using

a recipe code.

The foundation of hopper

scale design is explained.

6.1.1.

6.1.1. Definition of Material Code

6.1.1.6.1.1.

Applications

ApplicationsApplications

Hopper Scale with Material Code

Hopper Scale with Material CodeHopper Scale with Material Code

Definition of Material Code

Definition of Material CodeDefinition of Material Code

The material code is necessary to store the details before use.

And the code is called with code number in a weighing.

The material code is used in the procedure that performs batch weighing or loss-in

weigh. As the result of t he procedure , a constant w eig ht of the materi al, is cal led "full "

or "full filling", can be got.

The material code consists of some index number (name) and some comparison

values to get a constant weight of the material.

The AD-4402 can store a hundred kinds of material codes.

6.1.2.

6.1.2. Recalling

6.1.2.6.1.2.

The following steps are the explanation to recall the material code stored in the

indicator. Suppose that the recipe code is not used. (The menu

setting] - [Sequence] - [Basic] - [Recipe mode]

Caution

The material code can be recalled during the last weighing. But the code

effects after the batch finish (after finishing the last weighing).

Step 1 Press the CODE RECALL key.

Recalling MMMMaterial

RecallingRecalling

aterial CCCCode

aterial aterial

ode

odeode

is set to [5q f- 8] [0] )

[Function] - [Function

Then the material code blinks.

Step 2 Enter the material code using numerical keys

The details of the material code are displayed in the sub-display.

Step 3 Press the ENTER key to decide the code.

AD-4402 Page 25

Page 28

6.1.3.

6.1.3. Editing Principle Parameters of Material Code

6.1.3.6.1.3.

You can edit the parameters of target weight, free fall and etc. displayed on the subdisplay during a weighing. And items of sub-display can be selected at the menu

[Function] - [Function setting] - [General] - [Sub-display].

Editing Principle Parameters of Material Code

Editing Principle Parameters of Material CodeEditing Principle Parameters of Material Code

Caution

If the flash memory is selected for memory backup (0tHf-11

sequential weighing is stopped.

Step 1 Press and hold the SHIFT key and press the CODE RECALL key.

Then the material code blinks.

Step 2 Enter the material code using numerical keys

The details of the material code are displayed in the sub-display.

Step 3 Press the ENTER key to decide the code.

Step 4 Select a parameter using the key on the sub-display.

Step 5 Enter the parameter using numerical keys and press the ENTER key to store it.

Step 6 If you continue the change, proceed step 4 and 5.

Step 7 If you want to finish the ch ange, press the ESC key to return to weighing mode

0tHf-11), a current

0tHf-110tHf-11

several times.

6.1.4.

6.1.4. Referr

6.1.4.6.1.4.

You can refer to next material code in the sequential mode that uses plural material

codes. Suppose that the recipe code is not used. (The menu

setting] - [Sequence] - [Basic] - [Recipe mode]

Step 1 Press the CODE RECALL key.

Then principle parameters of the next material code are displayed in the sub-

display.

Step 2 Press the ESC key to return to current mode.

Referring

ReferrReferr

ing next Material Code

inging

next Material Code

next Material Code next Material Code

is set to [5q f- 8] [0])

[Function] - [Function

Page 26 AD-4402

Page 29

6.1.5.

6.1.5. Editing Full Parameters of Material Code

6.1.5.6.1.5.

Editing Full Parameters of Material Code

Editing Full Parameters of Material CodeEditing Full Parameters of Material Code

A material code consists of the following parameters.

Name

Material Code

Material name

Material Hopper No.

Final

Free Fall

Preliminary

Optional Preliminary

Over

Under

Zero Band

Full

Tare

Supplementary Flow Open Timer

Supplementary Flow Close Timer

Automatic Free Fall Range

Initial Dribble Flow

Initial Medium Flow

Total Weight

Total Counts

Display Name Display

Symbol

Code

Mat Name grain

Mat Hopper Hopper 1

Final Final 10.00 kg

Free Fall FFall 0.01 kg

Preliminary Plm 1.00 kg

OP.Preliminary OPPlm 2.00 kg

Over Over 0.10 kg

Undr Undr 0.10 kg

Zero Band 0Band 0.02 kg

Full Full 0.05 kg

Tare Tare 5.00 kg

SF open timer SFOT 0.00 s

SF close SFCT 0.00 s

AFFC range AFFC 0.00 kg

Initial DF IDF 0.00 kg

Initial MF IMF 0.00 kg

Tot Tot 10.00 kg

Tot# Tot# 1

Code

Display

Example

11

Memory

Backed up

RAM

( factory

setting)

or

flash

memory

Backed up

RAM

These parameters are stored in backup memory without power supply.

Refer to the backup method [0tHf-11] of the function list.

Caution

If the flash memory is selected for memory backup [0tHf-11

sequential weighing is stopped.

0tHf-11], a current

0tHf-110tHf-11

Edit Material Code

Step 1 Press and hold the ENTER key and press the key.

Then menu MatEdit blinks.

Step 2 Press the ENTER key to enter the material code edit. Then menu Edit blinks.

Step 3 Press the ENTER key to enter menu edit.

Step 4 Select the material code using numerical keys and press the ENTER.

Step 5 Enter the material name using alpanumerical keys and press the ENTER key.

Step 5 Edit other parameters using numerical keys, ENTER key and key.

Step 6 If you want to finish the ch ange, press the ESC key to return to weighing mode

several times.

AD-4402 Page 27

Page 30

Search Material Code

Use this menu to search blank material code.

Step 1 Press and hold the ENTER key and press the key.

Then menu MatEdit blinks.

Step 2 Press the key to select menu Search. And press the ENTER key.

Step 3 Then the message is displayed.

Step 4 Press the ENTER key to prceed next step.

Then the result is displayed.

Step 5 Press the ESC key to return to weighing mode several times.

Delete Material Code

The parameter of the material code can be reset in the following menu.

Total value

Setpoints

Total of a material code

All material code

All total

Example of Deleting Total Value

Step 1 Press and hold the ENTER key and press the key.

Then menu MatEdit blinks.

Step 2 Press the key to select menu Delete. And press the ENTER key.

Step 3 Select menu Total using the key. And press the ENTER key.

Step 4 Enter the material code using numerical keys and press the ENTER key.

Step 5 Press the ESC key to return to weighing mode several times.

Copy Material Code

The parameters of material code are copied. This copy includes a total weight value

and times of accumulation.

Step 1 Press and hold the ENTER key and press the

Then menu

Step 2 Press the key to select menu Copy. And press the ENTER key.

Step 4 Specify a original code number using numerical keys and press the ENTER key.

Step 5 Specify a duplicated code num ber using numerical keys and press the ENTER key.

MatEdit blinks.

key.

Step 6 Press the ESC key to return to weighing mode several times.

Page 28 AD-4402

Page 31

Tare of Material Code

Use to copy current tare to the preset tare.

Set a preset tare function [gebf-12 ] of the function list.

[gebf-12] [0] If the preset tare of the code is zero, the last tare value effects.

(factory settings)

[gebf-12] [1] If the preset tare of the code is zero, tare value is reset.

Step 1 Press and hold the ENTER key and press the key.

Then menu MatEdit blinks.

Step 2 Press the key to select menu Tare. And press the ENTER key.

Step 4 Specify a code number using numerical keys and press the ENTER key.

Then current tare value is copied to preset tare.

Step 5 Press the ESC key to return to weighing mode several times.

AD-4402 Page 29

Page 32

6.2.

6.2. Simple Hopper Scale with Recipe Code

6.2.6.2.

The section explains for recipe code (another name: formal function). The recipe

code is used on a simple hopper scale to mix several materials that are preset target

value. "The simple hopper scale" means that does not control the ratio and a weight

of ingredient, but simply accumulates the preset target weight of the material code.

Therefore, the recipe code is a code to accumulate the preset target weight of the

material code.

Simple Hopper Scale with Recipe Code

Simple Hopper Scale with Recipe CodeSimple Hopper Scale with Recipe Code

6.2.1.

6.2.1. Definition of Recipe Code (

6.2.1.6.2.1.

A recipe code consists of plural preset material codes.

Maximum ten material codes can be stored in a recipe code.

A recipe code is described in order to accumulate target weight of the material code.

The indicator AD-4402 can store a hundred recipe codes.

The recipe code is necessary to store the details before use.

And the code is called with code number in a weighing.

The recipe code is a co de to accumulate th e preset target w eight of the mat erial code.

If a recipe code is used in the batch w eighing (or loss-in weight), y ou can get a weight

that is accumulated the preset target weight of the material code.

The recipe sequence that is used recipe code ca lls formula sequence, too.

Definition of Recipe Code (Formal

Definition of Recipe Code (Definition of Recipe Code (

Page 30 AD-4402

Formal Function)

FormalFormal

Function)

Function) Function)

Page 33

6.2.2.

6.2.2. Using a Recipe Code

6.2.2.6.2.2.

Using a Recipe Code

Using a Recipe CodeUsing a Recipe Code

Set the menu

sequential mode ( [5q f- 8] to [1] or [2] ), when the recipe code is used .

[5q f- 8] [1] Semi-automatic mixture sequence

[5q f- 8] [2] Automatic mixture sequence

6.2.3.

6.2.3. Construction of Recipe Code

6.2.3.6.2.3.

The indicator AD-4402 can store a hundred recipe codes.

A recipe code can store maximum ten material codes in order of accumulating them.

These parameters are stored in backup memory without power supply.

Refer to the backup method [0tHf-11] of the function list.

Construction of Recipe Code

Construction of Recipe CodeConstruction of Recipe Code

[Function] - [Function setting] - [Sequence] - [Basic] - [Recipe mode]

Caution

If the flash memory is selected for memory backup [0tHf-11

sequential weighing is stopped.

Name

Recipe code

Recipe name

Material codes of maximum ten codes.

It is stored in order to accumlate them.

Accumulated Weight for recipe code

Accumulation Counts for recipe code

Display Symbol & Example Memory

rCode

Blend coffee

Code 1

Total Weight

10.00 kg

Total Counts

10.00 kg

0tHf-11], a current

0tHf-110tHf-11

Backed up RAM

( factory setting)

flash memory

Backed up RAM

to

or

6.2.4.

6.2.4. Recalling

6.2.4.6.2.4.

The following steps are the explanation to recall the recipe code stored in the

indicator. Suppose that the r ecipe code is us ed (The men u

- [Sequence] - [Basic] - [Reci pe mode]

Recalling a Recipe Code

RecallingRecalling

a Recipe Code

a Recipe Codea Recipe Code

is set to [5q f- 8] [1] or [2]). .

Caution

The code can be recalled during the last weighing. But the code effects after

the butch finish (after finishing the last weighing).

Step 1 Press the CODE RECALL key.

Then the recipe code blin ks.

Step 2 Enter the material code using numerical keys

The details of the recipe code are displayed in the sub-display.

Step 3 Press the ENTER key to decide the code.

AD-4402 Page 31

[Function] - [Function se tting]

Page 34

6.2.5.

6.2.5. Arranging Material Code in Recipe Code

6.2.5.6.2.5.

The way of arranging material code described in a recipe code.

Step 1 Press and hold the ENTER key and press the CODE RECALL key.

Step 2 Select a recipe code number using numerical keys and press the ENTER key.

Then first material code blinks.

Step 3 Select a material code using the following keys.

key, numerical keys and SHIFT key

Step 4 Press the ENTER key to store it. T hen the next code blinks.

Step 5 Continue step 3 and 4 until the last material code is stored.

Step 6 Press the ESC key to return to weighing mode several times.

6.2.6.

6.2.6. Editing Full Parameters of Recipe Code

6.2.6.6.2.6.

All parameters of the recipe code can be edited in this menu.

Arranging Material Code in Recipe Code

Arranging Material Code in Recipe CodeArranging Material Code in Recipe Code

Editing Full Parameters of Recipe Code

Editing Full Parameters of Recipe CodeEditing Full Parameters of Recipe Code

Edit Name of Recipe Code

Step 1 Press and hold the ENTER key and press the key.

Press the key. Then menu RecipeEDIT blinks.

Step 2 Press the ENTER key to enter the recipe code edit. Then menu edit blinks.

Step 3 Press the ENTER key to enter menu edit.

Step 4 Select a recipe code using numerical keys and press the ENTER.

Step 5 Name a recipe code using alpanumerical keys and press the ENTER key.

Step 6 If you want to finish the ch ange, press the ESC key to return to weighing mode

several times.

Search of Recipe Code

Use this menu to search blank material code.

Step 1 Press and hold the ENTER key and press the key.

Press the key. Then menu RecipeEDIT blinks.

Step 2 Press the key to select menu Search. And press the ENTER key.

Step 3 Then the message is displayed.

Step 4 Press the ENTER key to prceed next step.

Then the result is displayed.

Step 5 Press the ESC key to return to weighing mode several times.

Delete of Recipe Code

The parameter of the recipe code can be reset in the following menu.

Page 32 AD-4402

Page 35

Total value

Recipe total value

All total value

All Recipes

Example of Deleting Total Value

Step 1 Press and hold the ENTER key and press the key.

Then menu RecipeEDIT blinks.

Step 2 Press the key to select menu Delete. And press the ENTER key.

Step 3 Select menu Total using the key.

And press the ENTER key.

Step 4 Enter the recipe code using numerical keys and press the ENTER key.

Step 5 Press the ESC key to return to weighing mode several times.

Copy of Recipe Code

The parameters of recipe code are copied. This copy includes a total weight value

and times of accumulation.

Set a preset tare function [ genf-12 ] of the function list.

[genf-12] [0] If the preset tare of the code is zero, the last tare value effects.

(factory settings)

[genf-12] [1] If the preset tare of the code is zero, tare value is reset.

Step 1 Press and hold the ENTER key and press the key.

Then menu RecipeEDIT blinks.

Step 2 Press the key to select menu Copy. And press the ENTER key.

Step 4 Specify a original code number using numerical keys and press the ENTER key.

Step 5 Specify a duplicated code num ber using numerical keys and press the ENTER key.

Step 6 Press the ESC key to return to weighing mode several times.

AD-4402 Page 33

Page 36

6.3.

6.3. System Design of Hopper Scale

6.3.6.3.

6.3.1.

6.3.1. Operation and I/O Design

6.3.1.6.3.1.

In General, looking an old type hopper scale design, the simplest indicator only displayed

weighing value, other system devices communicated the control signal with each I/O

interface. And the key operation and monitoring the system separately were controlled.

The indicator AD-4402 has the I/O interface to control the system, sub-display to

monitor system infor mation, mai n display to display w eighing data and keys to c ontrol

the system in a unit.

The indicator is designed so as to be able to select arbitrary keys and terminals to

control the system form front pan el keys and th e I/O interface w ith the men u function.

And the function of keys and terminals can be designed in the same way.

The system information of sub-display can select at the function list.

6.3.2.

6.3.2. Design

6.3.2.6.3.2.

Suppose that the I/O, keys and sub-display are as follows:

Supply start: F1 key, [0thf- 2] [6]

Emergency stop key: F2 key, [0thf- 3] [13]

Dribble signal (low power): terminal B1, [0utf- 1] [6]

Batch finish signal (low power): terminal B2, [0utf- 2] [14]

Not used recipe code at "

Use default setting about sub-display [5ub f 1] [0]

System Design of Hopper Scale

System Design of Hopper ScaleSystem Design of Hopper Scale

Operation and I/O Design

Operation and I/O DesignOperation and I/O Design

Design Example

DesignDesign

Example

Example Example

Not used recipe sequence

"[5q f- 8] [0]

Setup

Step 1 Enter the function list.

Step 2 Select the menu F1 key.

Step 3 Select [6] of Batch start at F1 key and store it.

Step 4 Select [13] of Forced batch finish at F2 key and store it.

Step 6 Select the menu terminal B1.

([Function] - [Function setting] - [Control I/O Function] - [Output] - [OUT (B1)])

Step 8 Select [6] of Dribble flow at terminal B1 and store it.

Step 9 Select [14] of Batch finish at terminal B2 and store it.

Step10 Set [6] of "Not used recipe code" at Recipe sequence.

([Function] - [Function setting] - [Sequence] - [Basic] - [Recipe mode])

Step11 Select [0] of the default menu in the and store it.

([Function] - [Function setting] - [ G eneral] - [Sub-display] - [Weighing display])

Step12 Press the ESC key several times to return to the weinghing mode.

([Function] - [Function setting] - [General] - [Other] - [F1 key])

Operation and Response

When the F1 key is pressed, a batch weighing is started and terminal B1 wo rks.

When the F2 key is pressed, batch weighing is stopped.

When the ta rget weight is got, terminal B2 is turned on.

Page 34 AD-4402

Page 37

7.

7. Weighing Mode

7.7.

7.1.1.

7.1.1. Contents of

7.1.1.7.1.1.

Batch Weighing

Normal Batching Section 7.2

Normal Batching using Sequential Weighing Mode Section 7.3.1

Normal Batching using Customer Programmed Control Section 7.4.1

Loss-in weight Section 7.2

Loss-in weight using Sequ ential Weighing Mode Section 7.4.1

Loss-in weight using Customer Programmed Control Section 7.4.2

Selection of Batch Weighing Section 7.2.1

Controlled Output Signals

The type of the signal output to control gates (valves) in the batch weighing.

Sequential Weighing Mode

Customer Programmed Control

Weighing Mode

Weighing ModeWeighing Mode

Contents of Batch

Contents of Contents of

(built-in automatic program mod e)

Batch Weighing Mode

BatchBatch

(Comparison Output)

Weighing Mode

Weighing Mode Weighing Mode

Section 7.3

Section 7.4

Partial Sequence of Sequential Weighing Mode

Compensation Sequence Section 7.3.3

Approach Sequence Section 7.3.4

Discharge Sequence Section 7.3.5

Plain Recipe Sequence Section 7.3.6

Automatic Selection of Supplying Mat Section 7.3.7

Nozzle Operation (vacuum cleaner) Section 7.3.8

Mixture Sequence Section 7.3.9

Safety Check Function Section 7.3.10

Pause and Emergency Stop Section 7.3.11

Restart Sequence Section 7.3.12

Automatic Free Fall Compensation Section 7.3.13

Real Time Free Fall Compensation Section 7.3.14

AD-4402 Page 35

Page 38

7.2.

7.2. Batch

7.2.7.2.

The mode is used to get a (constant) target weight from a supplying Mat for the

hopper scale and filling machine . And the mode can be classified to normal batch

weighing and loss-in weight.

There are two control methods of the custom er programmed control and sequential

control (built-in automatic program mode).

Batch Weighing Mode

BatchBatch

Weighing Mode

Weighing Mode Weighing Mode

Normal Batching

Normal batch weighing weighs the material charged into the hopper.

The control gates (valves) can be used. (The full flow, medium flow and dribble flow)

Loss-in-weight

Loss-in weight weighs the material discharged form the hopper.

The control gates (valves) can be used. (The full flow, medium flow and dribble flow)

Caution

Use the PLC (programmable logic controller unit) to supply material into the

weighing hopper and monitor the bulk of material of the hopper.

Page 36 AD-4402

Page 39

7.2.1.

7.2.1. Selection of Batch Weighing

7.2.1.7.2.1.

Selection of Batch Weighing

Selection of Batch WeighingSelection of Batch Weighing

Selection of Normal Batching or Loss-in-weight

The mode can be selected at Loss-in weight at the Function list.

([Function] - [Function setting] - [Sequence] - [Basic] - [Current weighing])

[5q f- 3] [0] Normal batch weighing

[5q f- 3] [1] Loss-in weight

[5q f- 3] [2] External selection (Normal batch weighing or Loss-in we ight)

External Selection (Normal batch weighing or Loss-in weight)

Normal batch weighing and Loss-in weight can be selected by a signal of the input

terminal that is set to [9] of External switch control.

(The menu [Function] - [Function setting] - [Control I/O Function] - [Input] )

Example of use: The material of 100 kg is supplied to the hopper in first step. It is

subdivided into material of 10kg.

Advise

If the mode is switched concer ning a speci fied mater ial onl y, set the h opper no . in the

material code, short the hopper no. output line and the supply/discharge switch input

line. Set the delay timer [5q f-32] to "above 0.1sec.".

AD-4402 Page 37

Page 40

7.3.

7.3. Sequential

7.3.7.3.

The sequential weighing mode (built-in automatic program mode) directly outputs

control signals (example: medium flow valve, batch finish) without the PLC.

The sequential weighing mode can include several partial sequences like an

approach sequence, mixture sequence and etc. into basic sequential weighing.

The power of the control I/O signal output is too small to drive a large valve directly.

Use option relay output ( OP-02 ) to drive them.

If the number of the control I/O terminals is not enough, use option parallel I/O ( OP-05 ).

Sequential Weighing Mode

SequentialSequential

Forecast Control Function

The function forecasts a timing to close the dribble flow (valve) and realizes more

precision weighing. T he forecast method calculates the weighing value at some

points between sampli ng da ta and compares it with the dribble setpoint. Th e e ffect is

equivalent to use a high speed A/D converter. The sampling rate of this indicator is

100 [times/second]. But the ratio is equivalent to 1000 [times/second], when the

function is used.

Caution

If prual supplying mat is used (the recipe code is used), the mode ca n not use.

Relation section is " 7.3.7. Automatic Selection of Supplying Mat".

Use the high speed high precision valve like a direct voltage solenoid valve.

Design the mechanical valve so as to minimize the delay time.

Weighing Mode

Weighing Mode Weighing Mode

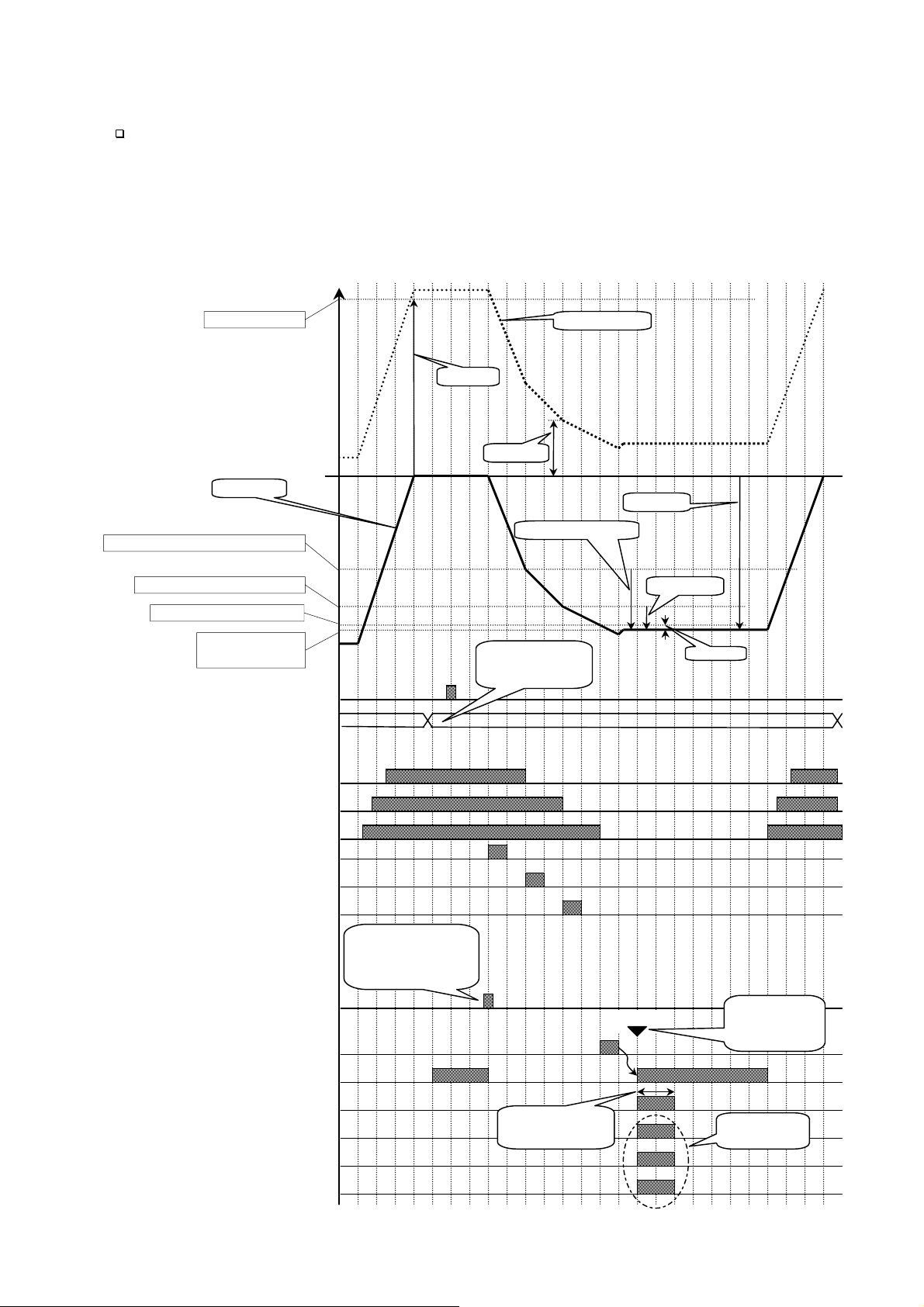

7.3.1.

7.3.1. N

7.3.1.7.3.1.

Normal batch weighing weighs the material charged into the hopper.

The control gates (valves) can be used. (The full flow, medium flow and dribble flow)

Normal

ormal BBBBatching of Sequential

NN

ormal ormal

atching of Sequential Weighing

atching of Sequentialatching of Sequential

Concerning Parameters of the Function

Selecting normal batching of sequential weighing.

[5q f- 1] [2] Sequential weighing

[Function] - [Function setting] - [Sequence] - [Basic] - [Weighing mode]

[5q f- 3] [0] Normal batch weighing

[Function] - [Function setting] - [Sequence] - [Basic] - [Loss-in weight]

Making zero display automatically when starting the sequence.

[5q f-11]

Preventing vibration due to gate operation.

[5q f-33]

[5q f-34]

[5q f-35]

[Function] - [Func tion setting] - [Sequence] - [Control] - [Ba tch s tar t settings]

[Function] - [Function setting] - [Sequence] - [Timer] - [Full flow comparison

interrupt timer]

[Function] - [Function setting] - [Sequence] - [Timer] - [Medium flow

comparison interrupt timer]

[Function] - [Function setting] - [Sequence] - [Timer] - [Dribble flow

comparison interrupt timer]

Weighing

Weighing Weighing

Page 38 AD-4402

Page 41

Making alarm when the sequence is time over.

[5q f-31] Maximum weighing time between start and batch finish can be set.

Error code [SQ.ERR 4] is displa yed, when an error occurs.

[Function] - [Function setting] - [Sequence] - [Timer] - [Batch monitoring

timer]

Removing "stable" from comparison condition.

[5q f-13]

[Function] - [Function setting] - [Sequence] - [Control] - [Eval condition]

Changing the timing of comparison.

[5q f-37]

[Function] - [Function setting] - [Sequence] - [Timer] - [Eval delay timer]

Changing accuracy of comparison.

[5q f-48] The time to average weighing value at batch finish can be set. The

timing of batch finish delays for the time.

[Function] - [Function setting] - [Sequence] - [Timer] - [Average Eval time]

Changing the pulse width of weighing finish output.

[5q f-43] If zero is set to this, the output leaves until next start signal.

[Function] - [Function setting] - [Sequence] - [Timer] - [Batch finish output

on]

Mixing it at weighing finish.

[5q f-14]

[Function] - [Functi on setting] - [Sequence] - [Control] - [Batch finish action]

Discharging it at weighing finish.

[5q f-15]

[Function] - [Function setting] - [Sequence] - [Control] - [Discharge finish

action]

Using customer programmed control for hi signal, go signal and low signal.

[5q f- 5]

[Function] - [Function setting] - [Sequence] - [Basic] - [Comparison]

AD-4402 Page 39

Page 42

Weighing value

5qf-3

5qf-35

A

Final value (Target weight)

Final value - Free fall

Final value - Preliminary

Final value - Optional preliminary

Optional preliminary

Material code, Input

Preliminary

Tare

0

The active code is only read at

each start. And keep it.

1

0

Gross weight

Net weight

Free fall

Zero band

Start command, Input

5qf-32

Batch start delay timer

1

Batch monitoring timer

Full flow, Output

Medium flow, Output

Dribble flow, Output

5qf-33

Full flow comparison interrupt timer

5qf-34

Medium flow comparison interrupt timer

Dribble flow comparison interrupt timer

5qf-37

Discharge start delay timer

Discharge monitoring timer

Eval delay timer

Stable, Output

Batch finish, Output

Over weight, Output

OK, Output

Under weight, Output

Discharge start, Input

Time until supplying it

5qf-43

Batch finish output

on

If discharge sequence,

set the function.

Comparison

The whole time to

supply it

ccording to 5qf-37 and stable.

5qf-13 can be set.

Select a mode

at 5qf-05

Discharge, Output

Nearly zero, Output

Discharge gate close timer

Discharge finish, Output

Drawing: Normal Batching of Sequential Weighing

Page 40 AD-4402

Page 43

7.3.2.

7.3.2. L

7.3.2.7.3.2.

Loss-in weight weighs the material discharged form the hopper.

The control gates (valves) can be used. (The full flow, medium flow and dribble flow)

Concerning Parameters of the Function

Selecting normal batching of sequential weighing.

[5q f- 1] [1] Sequential weighing

[5q f- 3] [0] Normal batch weighing

Making zero display automatically when starting the sequence.

[5q f-11]

Switching normal batching and loss-in we ight from the I/O interface.

[5q f- 3] [2] External exchange

Loss-in

oss-in W

LL

oss-inoss-in

[Function] - [Function setting] - [Sequence] - [Basic] - [Weighing mode]

[Function] - [Function setting] - [Sequence] - [Basic] - [Loss-in weight]

[Function] - [Func tion setting] - [Sequence] - [Control] - [Ba tch s tar t settings]

Set an input terminal to switch the mode at the I/O interface. Material

can be supplied to the hopper with three gates (valves).

[Function] - [Function setting] - [Sequence] - [Basic] - [Loss-in weight]

Weight of Sequential

eight of Sequential Mode

W W

eight of Sequentialeight of Sequential

Mode

Mode Mode

Checking whether is there the remainder weight for one batch weighting.

[5q f-55] [1] When the remainder weight decreases under target weight + nearly

zero, the signal "nearly zero" is output.

[Function] - [Functi on setting] - [Sequence] - [Setpoint (Compared value)] [Add final value and zero band]

[5q f-56] [1] If this is set, when the hopp er is filled fully, the sig nal "Full" is o utput.

[Function] - [Functi on setting] - [Sequence] - [Setpoint (Compared value)] [Add final value and full value]

AD-4402 Page 41

Page 44

Weighing value

r

r

r

r

r

r

5qf-3

5qf-33

Full filling value

- Final value + Optional preliminary

- Final value + Preliminary

- Final value + Free fall

- Final value

or -Target weight

Enable to use automatic tare

Tare command, Input

Material code, Input

Start command, Input

5qf-32

Start delay time

1

Batch monitoring time

Gross weight

Full filling

Zero band

0

Net weight

Final value

Preliminary

Optional preliminary

Free fall

The active code is only read at

each start. And keep it.

Time until supplying it

Monitor to supply it

Full flow, Output

Medium flow, Output

Dribble flow, Output

Full flow comparison interrupt time

5qf-34

Medium flow comparison interrupt time

5qf-35

Dribble flow comparison interrupt time

5qf-37

Eval delay time

Stable, Output

Batch finish, Output

Over weight, Output

Acceptable, Output

Under weight, Output

5qf-43

batch finish output

on

Drawing: Loss-in Weight of Sequential Weighing

Comparison

Select a mode

at 5qf-05

Page 42 AD-4402

Page 45

7.3.3.

7.3.3. C

7.3.3.7.3.3.

The compensation sequence is used to make up (add) the material automatically,

when the result of current batch weighing is under weight.

Compensation

ompensation SSSSequence

CC

ompensation ompensation

equence

equenceequence

Concerning Parameters of the Function

Storing a ma ximum repeat counts of compensation sequ ence.

[5q f-18] If number is zero , this sequence is canceled. When the result is

under weight after the sequence, An error SQ.ERR 2 is displayed.

[Function] - [Function setting] - [Sequence] - [Control] - [Maximum number

of compensation]

Setting the time to open the dribble gate.

Set the time at each material code.

[Function] - [Function setting] - [MatEDIT] - [Edit] - [Compensat ion flow open