Page 1

Analytical Balance

BM-5

BM-5D

BM-20

BM-22

BM-252

BM-200

BM-300

BM-500

1WMP

D4002195F

Page 2

© 2019 A&D Company , Limited. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, or translated into any lang uage in

any form by any means without the written permission of A&D Company, Limited.

The contents of this manual and the specifications of the ins trument covered by this manual are subject to

change for improvement without notice.

Windows, Word and Excel are regi stered trademarks of Microsoft Corpora tion.

Page 3

Contents

Basic Operation

Adapting to the Environment

Selecting Functions

1. Introduction .............................................................................................................................. 3

1.1. Features ............................................................................................................................... 4

1.2. Compliance .......................................................................................................................... 5

2. Unpacking the Balance ........................................................................................................... 6

3. Installi ng th e Bala nce and Prec auti ons ................................................................................... 9

3.1. Installi ng th e Bala nce ........................................................................................................... 9

3.2. Precautions Before Use ..................................................................................................... 12

3.3. Precautio ns D uri ng Us e ..................................................................................................... 14

3.4. Precautio ns After Use ........................................................................................................ 15

3.5. Precautio ns for P ower Su pply ........................................................................................... 15

4. Display Symbols and Key Oper ati on .................................................................................... 16

5. Weighing U ni ts ...................................................................................................................... 17

5.1. Units ................................................................................................................................... 17

5.2. Storing Active Units ............................................................................................................ 21

5.3. Selecting Uni t s and Weighing Modes ................................................................................ 22

6. Weighing................................................................................................................................ 24

6.1. Basic Operat ion (Gram Mode) .......................................................................................... 24

6.2. Smart Rang e ...................................................................................................................... 26

6.3. Counting Mode (PC) .......................................................................................................... 27

6.4. Percent Mode (%) .............................................................................................................. 29

6.5. Ionizer (Neutraliz ati on D ev ice) ........................................................................................... 30

6.6. Monitoring the Clock and Environment al S ensor s ............................................................ 32

6.7. Repeatability T est ............................................................................................................... 33

7. Response Adj ustment ........................................................................................................... 34

7.1. Automatic Response Adjus tment ...................................................................................... 34

7.2. Manual Response Adjust ment ........................................................................................... 35

8. Calibration ............................................................................................................................. 36

8.1. Calibration Group ............................................................................................................... 36

8.2. Automatic Se lf Cali br ation ................................................................................................. 37

8.3. Calibratio n U sing t he Int ern al M as s ................................................................................... 38

8.4. Calibratio n Test Using the I nter nal Ma ss ........................................................................... 39

8.5. Calibratio n U sing a n Ext ern al Weight ................................................................................ 40

8.6. Calibratio n Test Using an External Weig ht ........................................................................ 41

8.7. Correcting the In tern al Mass Value ................................................................................... 42

9. Function Switch and Initialization .......................................................................................... 43

9.1. Permit or Inhi bit .................................................................................................................. 43

9.2. Initializi ng the B alan ce ....................................................................................................... 44

10. Function T able ....................................................................................................................... 45

10.1. Setting the Function T able ................................................................................................. 45

10.2. Details o f th e F unct io n Table ............................................................................................. 47

10.3. Descriptio n of t he C l ass "Env ir on men t, Dis pl ay " ............................................................... 49

10.4. Description of the Item "Data Output Mode" ..................................................................... 51

BM series 1

Page 4

10.5. Description of the Item "Data Format" ............................................................................... 52

Interface and Communication

Maintenance

10.6. Data Format Examples ...................................................................................................... 55

10.7. Clock and Calendar Function ............................................................................................ 57

11. ID Number and GLP Report.................................................................................................. 58

11.1. Setting the ID Number ....................................................................................................... 58

11.2. GLP Report ........................................................................................................................ 59

12. Data Memory ......................................................................................................................... 65

12.1. Notes on U sing D at a M e mory ........................................................................................... 65

12.2. Data Memory for Weighing Data ....................................................................................... 65

12.3. Data Mem ory for C ali br ati on an d C ali bra tion Test Data .................................................... 69

13. Underhook ............................................................................................................................. 71

14. Density M easur e ment ( Specific gravity ) ............................................................................... 72

15. Password Function ................................................................................................................ 75

15.1. Balance So f tw are Version 1.50 to 1. 64 ............................................................................. 75

15.2. Balance Sof twar e Version 1.660 or later ........................................................................... 76

15.3. Using the Password Function ............................................................................................ 77

15.4. Entering th e Passw ord Be for e We ighi ng .......................................................................... 78

15.5. Logging Out ....................................................................................................................... 80

15.6. Stor i ng or C h angi ng th e P assw or d .................................................................................... 81

15.7. Changing the Passw ord .................................................................................................... 82

15.8. Deleting th e Passw ord (U5ER 0 1~10) ............................................................................ 83

15.9. Forgotten Pas sw ord ........................................................................................................... 83

16. Standard Input and Output Interface ..................................................................................... 84

16.1. RS-232C Interface ............................................................................................................. 84

16.2. Connecting to Peripheral Equipment ................................................................................. 85

16.3. Commands ........................................................................................................................ 89

17. Key Lock Function ................................................................................................................. 94

17.1. Locking All the Keys ........................................................................................................... 94

17.2. Locking t he Specified Key s ................................................................................................ 95

18. Checking th e Bala nce S oftw are Version............................................................................... 95

19. Maintenance .......................................................................................................................... 96

19.1. Cleaning an d Handli ng t he Bal ance .................................................................................. 96

19.2. Error Codes ........................................................................................................................ 96

19.3. Other Dis play ..................................................................................................................... 98

19.4. Checking th e Bala nce P erfor manc e and Env iro nmen t ..................................................... 99

19.5. Asking for Re pai r ............................................................................................................... 99

20. Specifications ...................................................................................................................... 100

20.1. External D ime nsi ons ........................................................................................................ 102

20.2. Options and Peripheral Equipment ................................................................................. 103

21. Terms/Index ......................................................................................................................... 107

21.1. Terms ............................................................................................................................... 107

21.2. Index ................................................................................................................................ 108

2 BM series

Page 5

1.

Introduction

About this manual

Balance software version

18. Checking the Balance Software Version

This manual describes how the BM series balan ces wo rk and how to ge t the mo st out of them in

terms of performance. Read this manual thoroughly before using the balance and keep it at hand

for future r efere nce.

This manual cons ists of the fol low ing fi ve par ts:

Basic operati on

Adapting to the environment

Selecting functi ons

Interface and communication

Maintenance

..............................

...........

..........................

..........

..................................

Describes precautions, the balance's construction and basic

operation.

Describes response (and stability) adjustment to adapt to the

environmen t w her e t her e is v ibr ati on or dr afts , t he w ay to

maintain w eig hing pr ec i sio n i n a v ari a tio n o f a mbi ent

temperatur e, cal ibra tion an d cali brati on tes t.

Describes fu ncti ons o f the bal ance .

Describes the ser i al i nt e rfac e us e d for c o mmuni c ati ng w ith a

computer t hat req u ests w eig hing data and controls the

balance, and for us e with a pr int er

Describes mai nt ena nc e, er r or c ode s, tr oubl es ho oti ng,

specifica tions and opti ons .

Some balance operations vary depending on the balance software version. For details on

checking t he s o ftw are ver si on , r efer t o “

”.

BM series 3

Page 6

1.1.

Features

15. Password Function

BM-5D

BM-22

BM-5, BM-5D, BM-20

BM-22

AD-1688

A built-i n i oni z er can eliminate static electricity from the weighing sample before weighing,

reducing wei ghi ng error s.

Each electrode unit of the ionizer is desi g ned t o be re mov ed, cl ea ned an d r epl ac ed.

Automatic self calibration, using the internal mass, adapting to changes in temperature.

Response adj ust ment a dapti ng to dr afts and/or vibr ation in the e nvir onmen t automatically.

Memory function to store weighing data and calibration data.

When only weighing data is stored, a maximum of 200 data can be stored.

Interval mode to stor e the weig hing data per io dical ly.

Good labor at ory pr acti c e ( GLP) / Good manufacturing practice (GMP) data can be output using

the RS-232C serial inter face .

A built-i n cl oc k and cal end ar t hat c a n add the tim e and dat e to th e outp ut dat a. (Changing the

clock sett ing c an b e l i mite d to t he ad mini st rat or . Re fer to “

The password function can be use d t o r es tri ct bala nc e us er s or c ha nge s t o t he fun cti on s et ti ngs .

”.)

The key lo ck func ti on disables the bal anc e key op erati on an d enabl es the bal anc e to be o perat ed

only by comma nds fr om ext ernal devi ces.

Underhook , for meas uri ng de nsi ty a nd w eig hing m agn eti c mat eri als .

Multiple wei ghi ng unit s w ith most of the co mmo n units used ar oun d the w orld.

Gram, Milligram, Counting mode, Per cent mode, Ounce (Avoir), Troy Ounce, Metric carat, Momme,

Pennyweight, Grain (UK), Tael (pres et at the factory), Tola (India), Messghal and Densi ty mode

The

The micro tube holder is included in the accessories of the

Density mod e for cal cul ating the d ensity of a sol id.

The BM series balances are equip ped wit h an RS-2 32 C s eri al i nt er fac e an d a USB inter face t o

(readability: 1 μg) after zer oing a tare wei ght , if wi thin the w eig hing c apac ity .

communicate with a computer. While outputting data to a printer using the RS-232C interface,

data can be transmitted to a computer at the same time using the US B i nter fac e.

Using the RS-232C interface and the Windows communication tools softw are (WinCT) enables bi-

directional communication between a Windows computer and the balance.

The current v ersi on of the WinCT can be downl oaded from the A&D website.

and

are equi ppe d wit h a smart range function to weigh in the precision range

and

.

Connecting the US B inter face o f the bal anc e by a cabl e to a Window s comp uter allow s

transmissi on of t he weig hing data t o Excel or Word.

When multipl e bala nces have th e BM-08 Ethern et i nter fa ce i nstal l ed i n pl ace of th e U SB i nt er fac e

and connected to a LAN, data can be acquired from each of them using the WinCT-Plus so ftw ar e.

When the accessory data logger (

using a computer.

4 BM series

) is c onnected, weigh ing data can be stored without

Page 7

1.2.

Compliance

1.2.1.

Compliance with FCC Rules

Please note that this equipment gene rates, uses and can radiate radio frequency energy. This

equipment has b een tes t ed and h as been f ound to com p ly with the limit s of a C las s A comp utin g

device pursuant to Subpart J of Part 15 of FCC rules. These rules are designed to provide

reasonable protection against interference when equipment is operated in a commercial

environment. If this unit is operated in a residential area, it may cause some interference and

under these circumstances the user would be required to take, at his own expense, whatever

measures ar e neces sar y to eli mina te the i nter feren ce.

(FCC = Fe der al C om muni ca tio ns Co mmi ssi on in th e U. S. A.)

BM series 5

Page 8

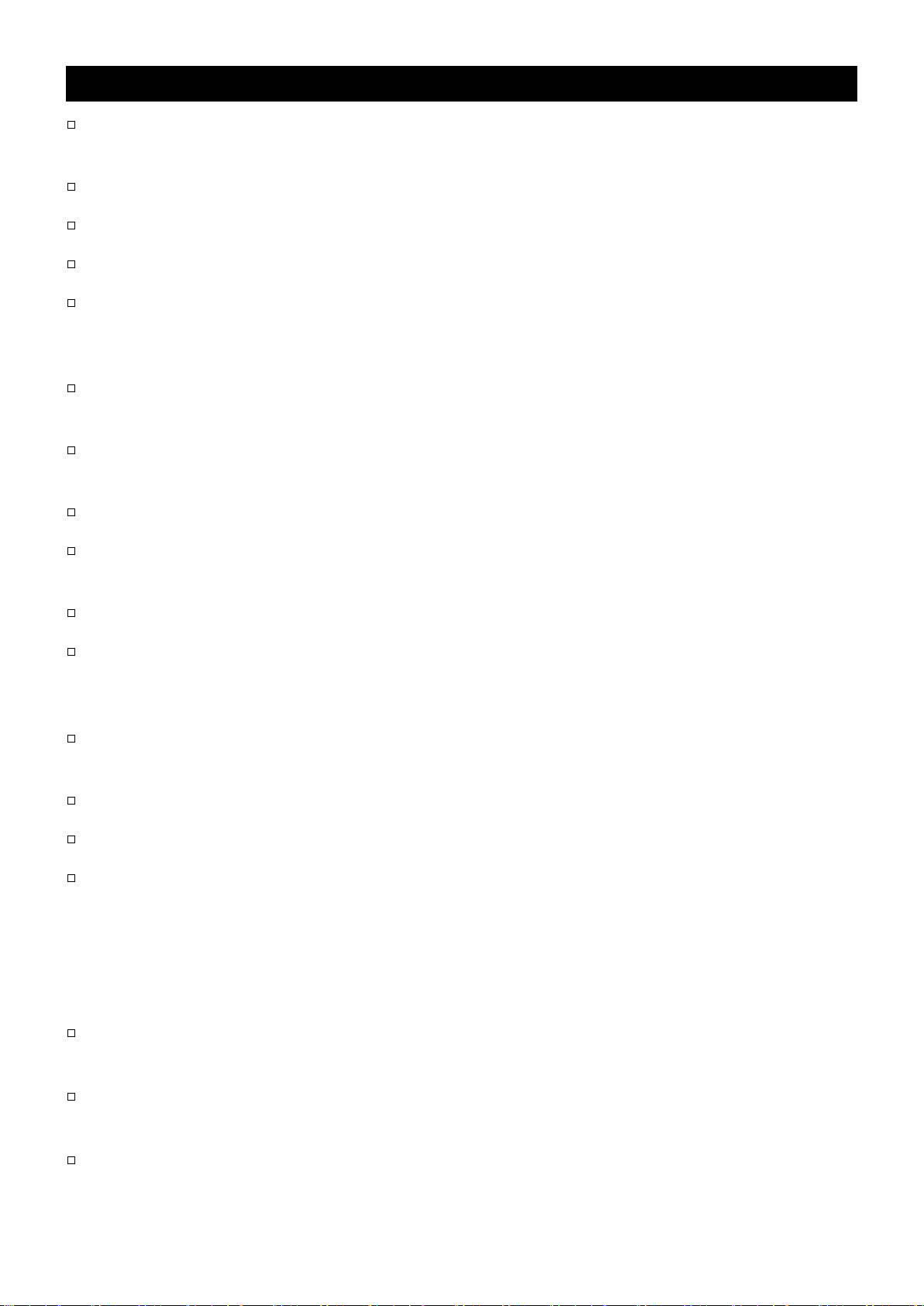

2.

Unpacking the Balance

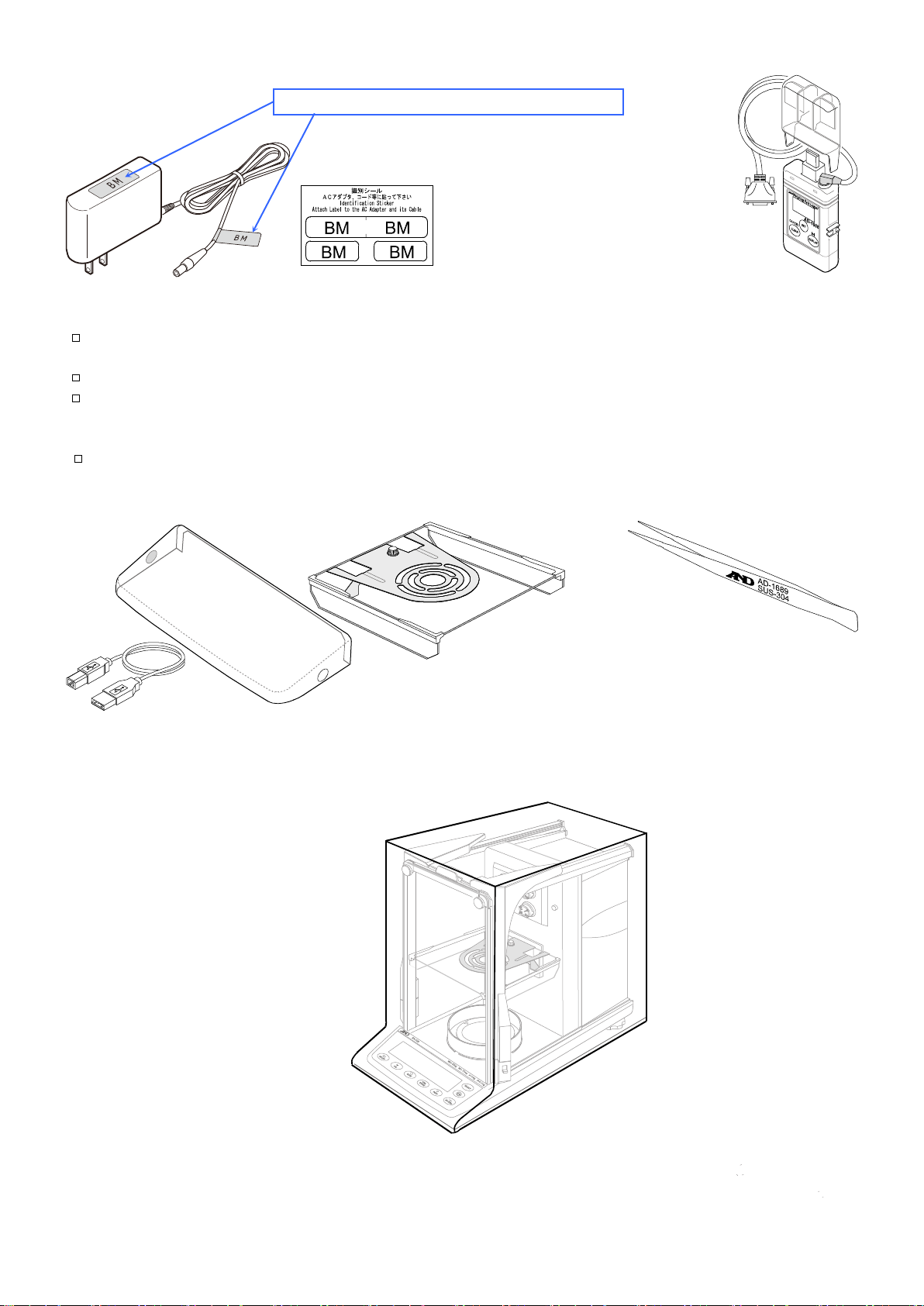

Accessories for each model

BM-5, BM-5D, BM-20, BM-22

BM-252

BM-200, BM-300

BM-500

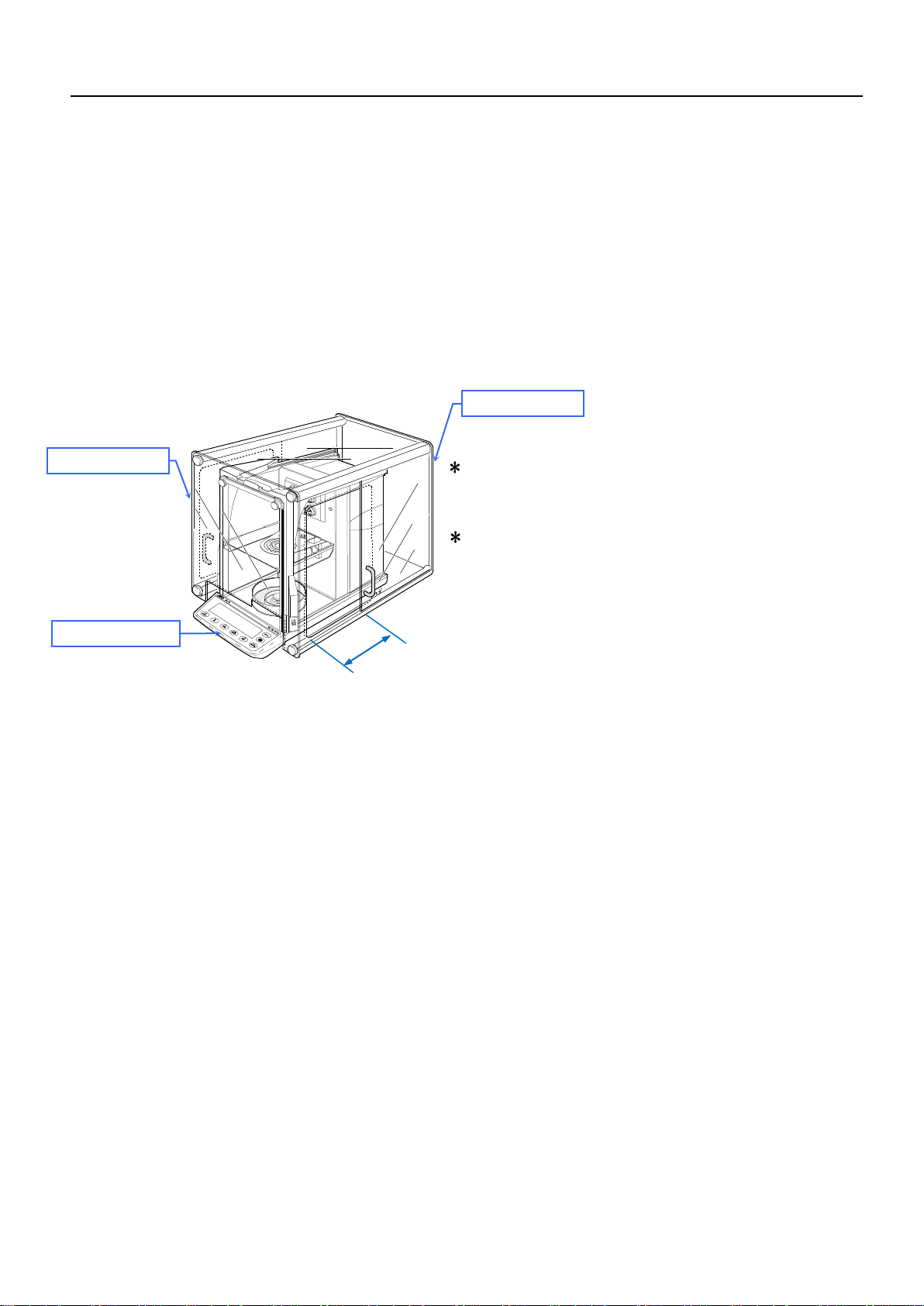

Tabletop Breeze break (M)

Unpack the balan ce carefull y. Keep the pa cking materia l to be used fo r transport ing the balance

in the future. See the illustrations to confirm that everything is included.

Small weighing Large weighing

pan for filter pan for filter

Weighing pan Pan support

Micro tube holder

Small fine range ring

Fine range ring

Dust plate

φ15, 0.8 mL φ12, 0.3 mL φ8, 0. 05 mL

Large Medium Small

Round aluminum analytical pans (

10 pieces each

Weighing pan Pan support

Fine range ring

Breeze break ring

Dust plate

)

Weighing pan

Pan support

Breeze break ring

Dust plate

6 BM series

Page 9

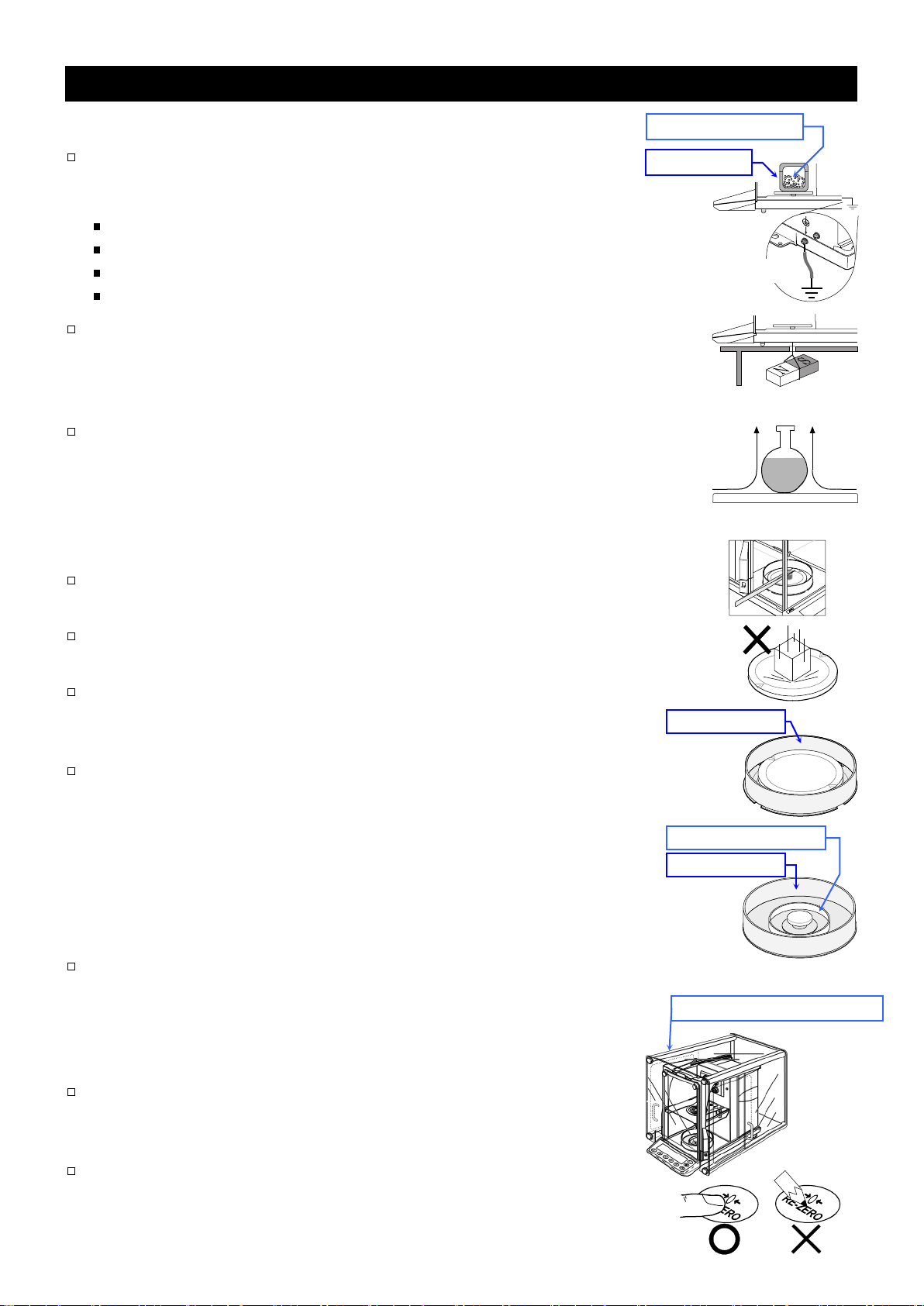

Common accessories

AC adapter AC adapter labels

Data logger

232C interface of

(1.5 m or 1.8 m)

(PET resin)

Tweezers

Use it to avoid temper atur e changes

n the

weighing chamber, thus to perform

D-sub 9 pins

Positions to place the AC adapter labels

Attach t he AC adapter l abel s to the AC adapter

as shown in the illus trati on.

Notes

Please confirm that the AC adapter ty pe is correct for your local

voltage and receptacle type.

Please use the dedicated AC adapter specified for the balance.

Do not use the AC adapter provided with the balance for other

models or equipment with which the AC adapter may not be

compatible.

If you use the wrong AC adapter, the balance and other equipment

may not operate properly.

USB cable

Body cover

BM series 7

Display cover

Cover during storag e to prevent dust and dirt contamination.

The cover can b e used for the b alanc e wit h the AC adapter and other cabl es

connected.

Separation plate

If unnecess ary, r emov e it.

AD-1688

The weighing data can be

stored when connected to

the RSthe balance.

AD-1689

Tweezers for handling a weight.

due to having your hand i

accurate calibratio n.

Page 10

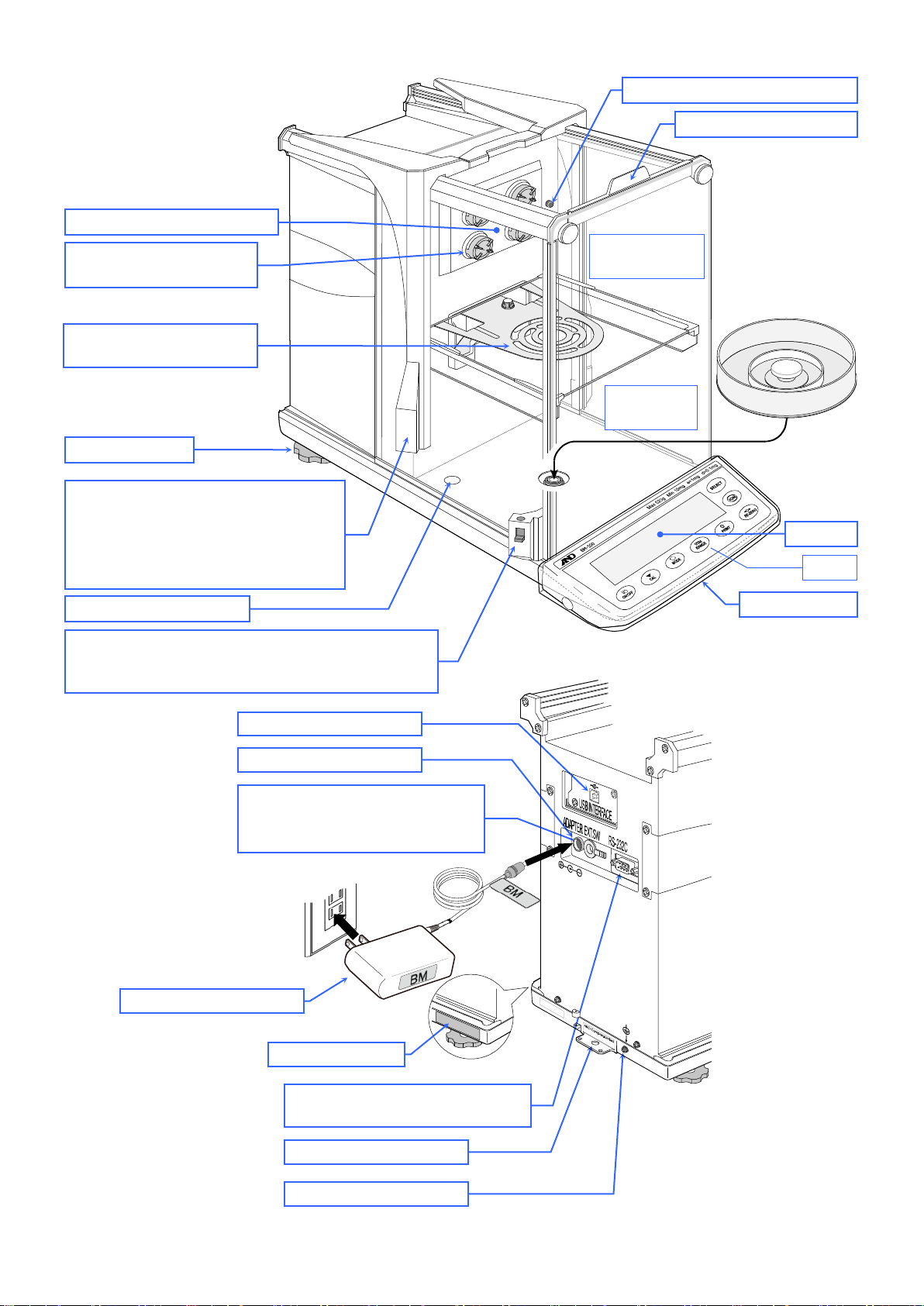

Grounding terminal

Anti-theft device

AC adapter jack

USB interface

External key jack

Cap the termi nal with the acces sory

RS-232C serial interface

D-su b 9 pins

Outlet example

Serial number

Ionizer

Electrode unit of the

ionizer

Separation plate

If unnecessary , remove it.

Joint handle

Bubble spirit level

Leveling foot

Glass door handle

The handle can be jointed to the joint handle

Neutralization

area

Glass door handle

Display cover

LED of the ionizer

Example of BM-20

Weighing

chamber

Display

Keys

When jointed to the right (left) g lass

door handle, the right (left) glass

door c an be opened or closed with

the left (right) joint handle.

The handle for the glass door .

rubber cap whe n it is not used.

8 BM series

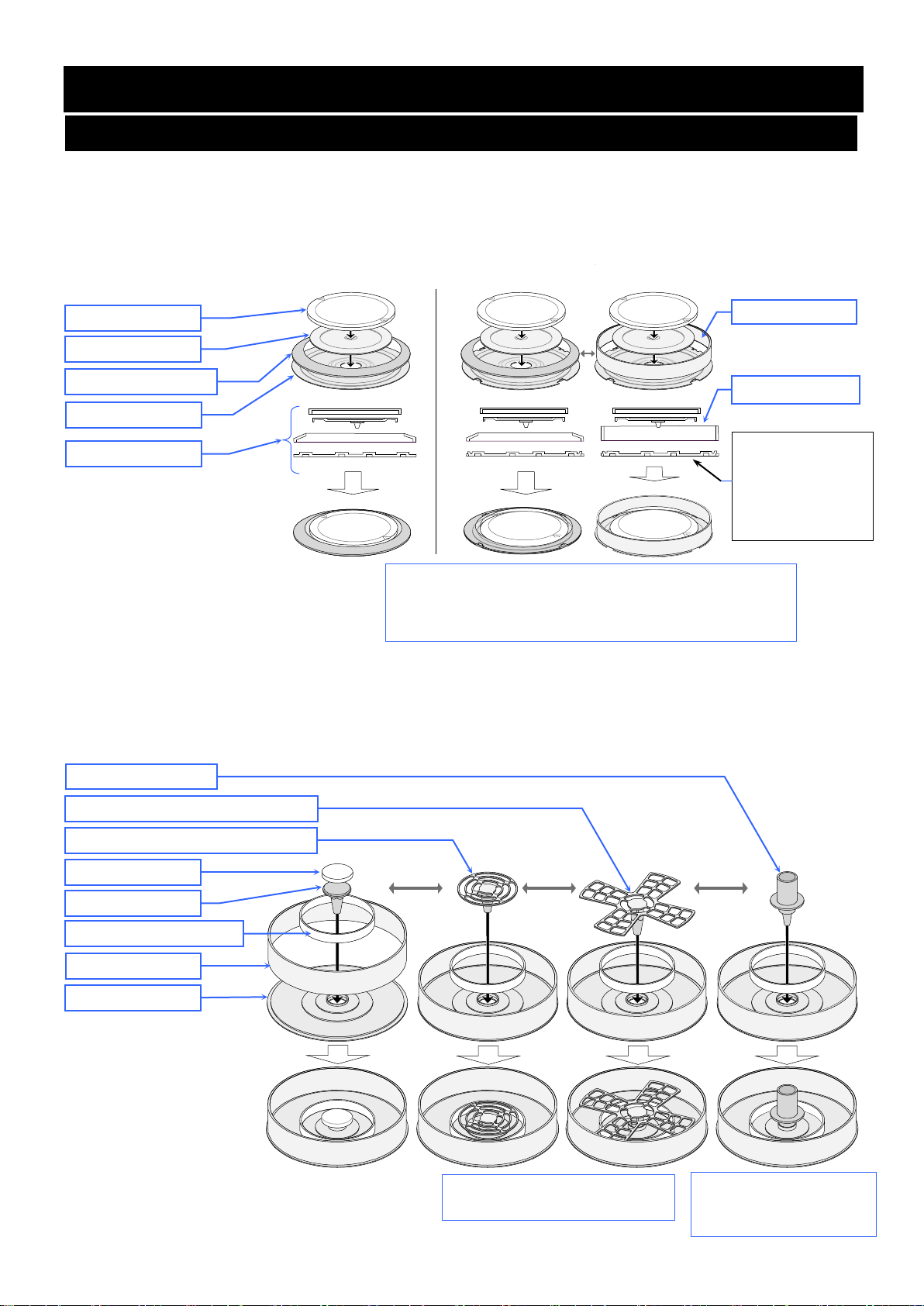

Page 11

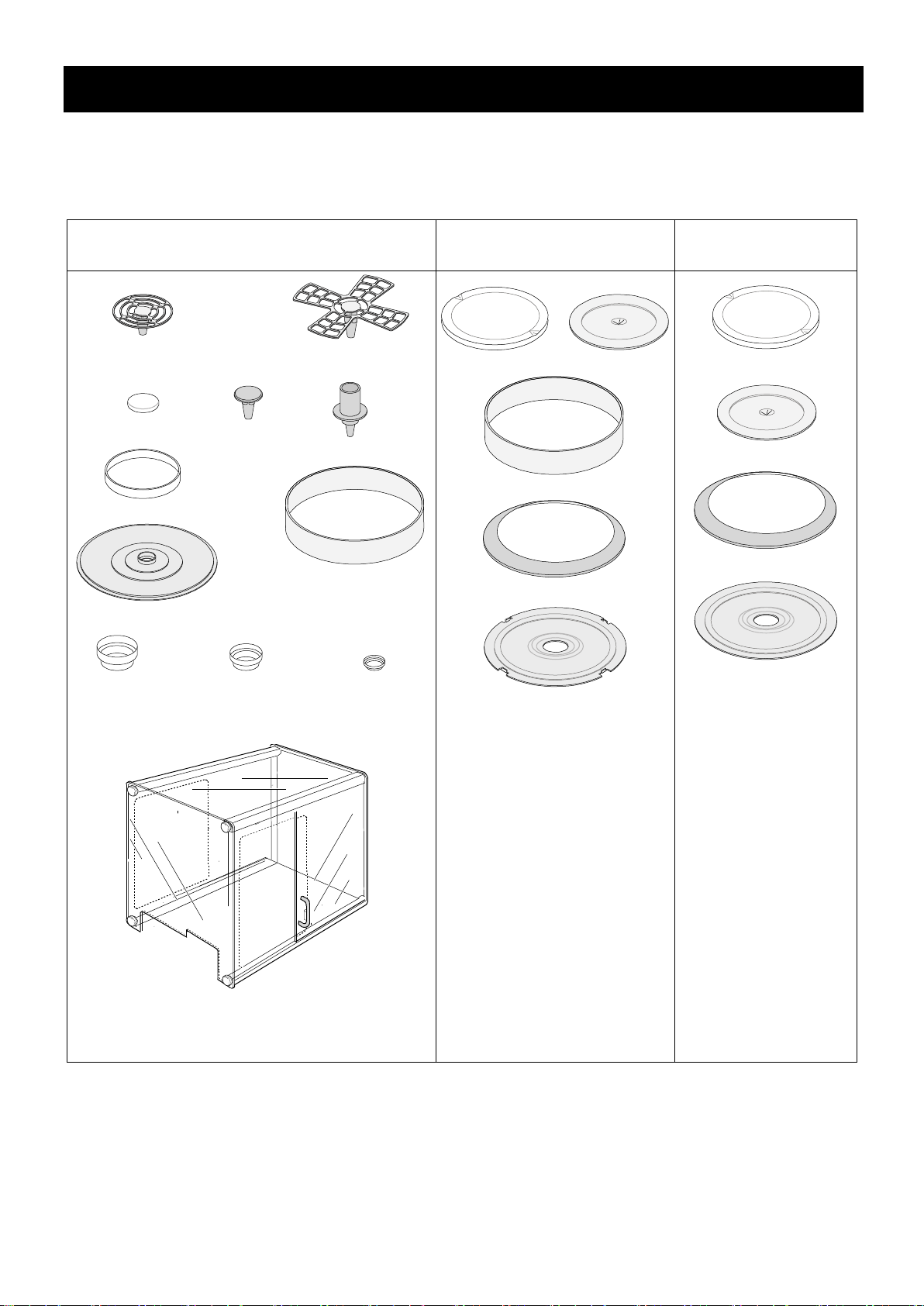

3.

Installing the Balance and Precautions

3.1.

Installing the Balance

3.2. Precautions Before Use

BM-200, BM-300, BM-500 BM-252

BM-5, BM-5D, BM-20, BM-22

Weighing pan

Breeze break ring

Dust plate

Pan support

Use the fine r ange ri ng in pl ace o f the bre eze br eak

ring

with

Fine range ring

Sectional view

Pan support

Weighing pan

Small fine range ring

Dust plate

Fine range ring

Large weighing pan for filter

Small weighing pan for filter

Choose the w eighing pan

appropriate to the filt er s ize.

Micro tube holder

Use the holder for

of φ12 m m or less .

Fine range ring

Note

1 Place the balance on a sol id wei ghi ng tabl e. Refer to "

a place to install the balance.

2 Assemble the weighing pan and other parts in accordance with the model and use as sh own bel ow.

" for det ails on

to avoid err ors ca used by draf t s when weighing

a readability of 0.01 mg.

The mounting

direction (head /

tail) of the dust

plate.

Note When using the micro tube holder for the BM-5 and BM-5D:

The micro tube holder is ap proxima tely 2 g heavier than the sta ndard pan (w eighing pan a nd

pan support). When a micro tube holder is used for the BM-5 and BM-5D, the available weighing

range will be up to approximately 3 g including the tare such as a micro tube and test tube.

BM series 9

micro tube or t est tu be

Page 12

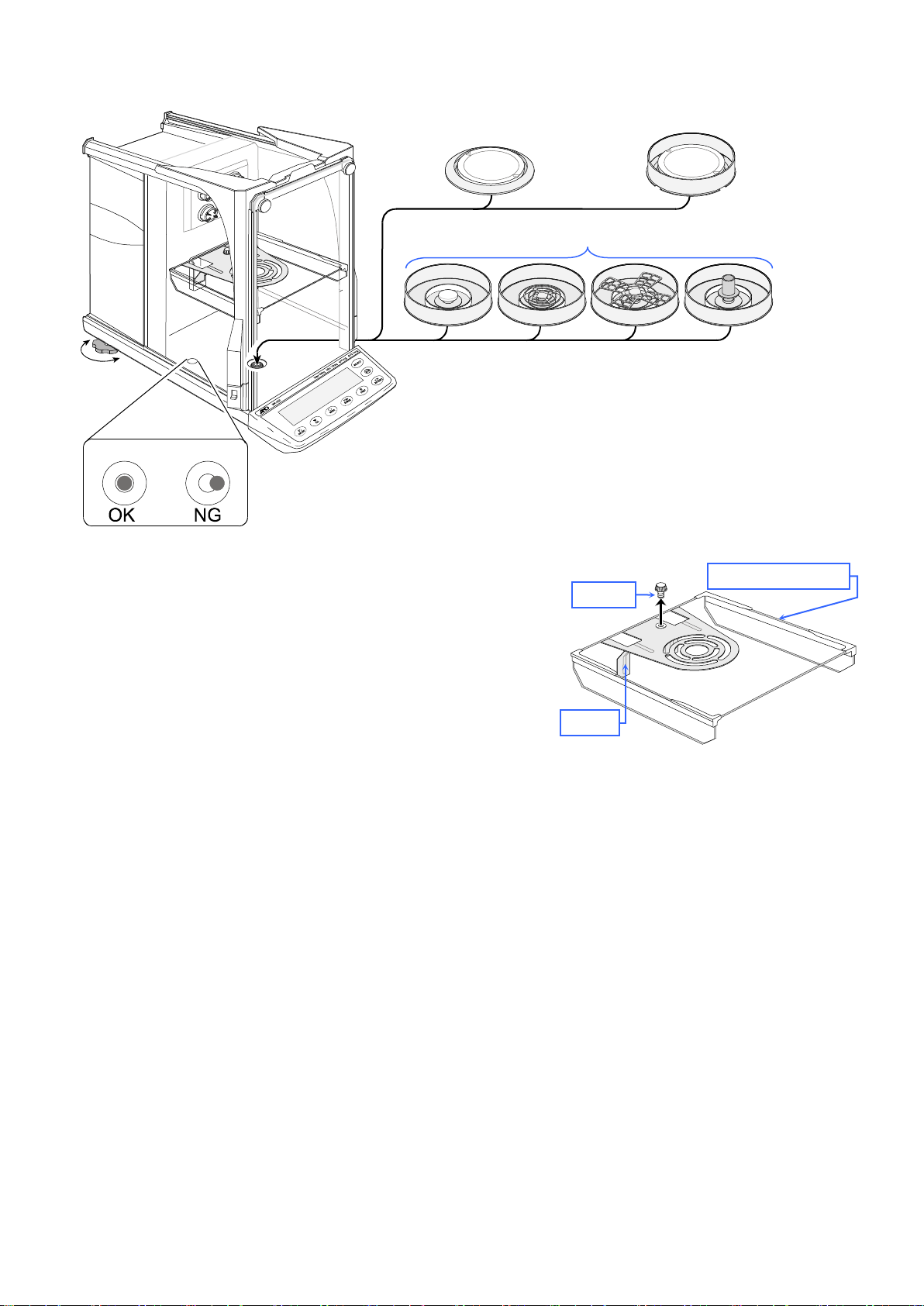

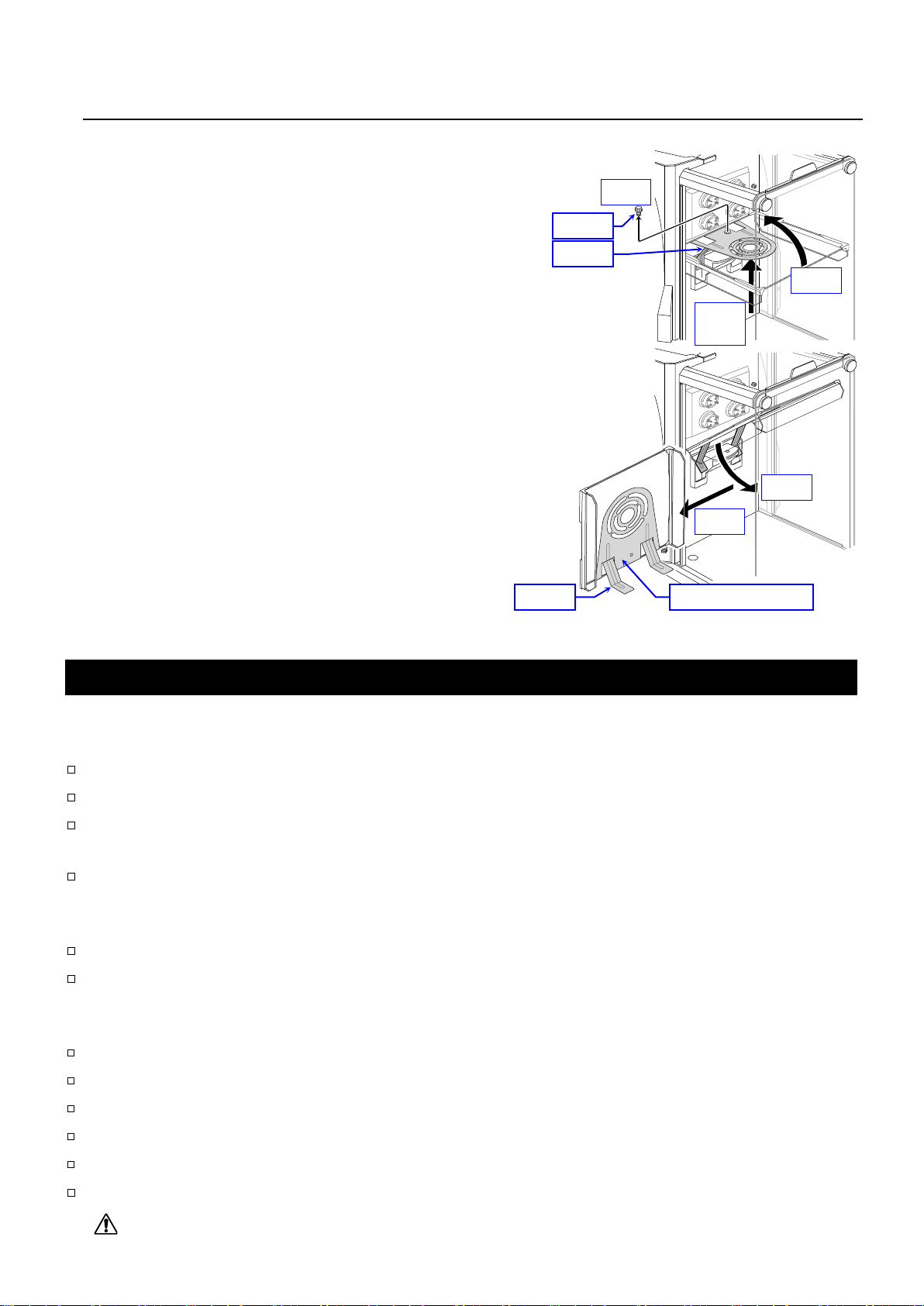

Assembling the parts in the weighing chamber

3.1.2

Removing and attaching the separation plate

Adjusting the Level

Screw

Hook

Separ ation plate

Leveling

f

BM-252, BM-200 BM-252

BM-300, BM-500

Bubble spirit level

BM-5, BM-5D, BM-20, BM-22

oot

3 If the separation plate is not necessary, remove the

screw and take the plate off. Refer to "

.

".

4 Adjust the level of the balance using the leveling feet.

(Refer to "

" on page 14.)

5 Confirm that the AC adapter type is correct for your local

voltage and power receptacle type.

6 Connect the specified AC adapter to the balance. Warm

up the balance for at least one hour wit h nothing on the

weighing pan.

10 BM series

Page 13

3.1.1.

•

•

BM series

Front p anel

Rear panel

A

How to use the Tabletop breeze break (For BM-5, BM5D, BM-20, BM-22)

Features

T his Tabletop breeze break is used to prevent from ambient drafts due to air conditioning and body motion so as

to reduce weighing error.

Be sure to install this breeze break on the balance, as it is affected by even the slightest wind.

This breeze break is designed for the BM series with most suitable use.

The transparent panel assembly consists of antistatic plastic material, which protects the balance from static

electricity.

The rear panel is equipped the hole that i s used to pass the RS-232C and AC adapter cables through.

How to install

We recommend to install the tabletop breez e break (M) in a

position where the display of the balance can be seen

easily and the balance can be operated properly .

Minimize the opening width A of the slide door as narrow

as possible so as to reduce influence of ambient drafts.

Caution

Do not use organic solvents to clean the breeze break because it may damage the transparency and anti-static

properties of the p anels.

Use a sof t l int free clot h dampe ned wi th warm wate r a nd a mil d de tergent whe n cle aning the br eeze br eak.

BM series 11

Page 14

3.1.2.

Removing and attaching the separation plate

Removing the separation plate

Attaching the separation plate

3.2.

Precautions Before Use

BM-5, BM-5D, BM-20

BM-22

AD-

1671

AD-8922A

BM-5, BM-5D, BM-20

BM-22

AD-1672/AD-1672A

AD-1676

Hook

Screw

Step

1

Step

1

Step

2

Step

3

Step

3

Step 4 Hook

Separation plate

Note Take care not to dama ge th e sep ar atio n p lat e when handlin g it.

1 Support the separation plate and

remove the screw from the plate.

2 Lift the plate and unhook the hooks.

3 Rotate the plate on the axis of the front edge.

Rotate the plate on the axis of the back edge.

4 Remove the plate from the chamber.

Use the arrow s in rev erse t o atta ch the pl ate.

5 Insert the plate i nto the chamber.

6 Rotate the plate on the axis of the back edg e.

Rotate the plate on the axis of the front edge.

Level the pla te.

7 Insert the hooks and hook the plate.

8 Support the plate and secure t he scr ew.

To ensure that you g et the m ost from y our bal anc e, please tr y t o follow thes e conditi ons as closel y as

possible, especiall y for the

The best oper a ting t e mper at ure i s ab out 20° C / 6 8°F at a bout 50 % R el ativ e Hu midi ty .

The weighing room should be free of dust.

Clean the weighing chamber and its surroundings to prevent foreign matter from invading,

especially when wei ghi ng a v ery sm all a mou nt of sample.

The weighing table shoul d be soli d and free from vibr ation, drafts ( such as frequen tly openi ng doors

or windows) and as level as possible. W e recommend that you use the anti-vibration table (

) and the remote c ontroller (

Do not install the balance where it will be subject to vibration. Corners of rooms on the first floor are best.

Do not install the balance near a heater, air conditioner, or in a breeze. The influence of breezes

can be reduced by using the tabletop breeze break (L) (

breeze break (M) (

).

) for the

and

that are sensitive.

and

.

) or t he tabletop

Do not instal l the b alanc e in dir ect sun light . Av oid ex cessi ve te mperat ure c hang es.

Do not use the bal anc e near o ther equip ment w hich pr oduc es mag neti c fiel ds.

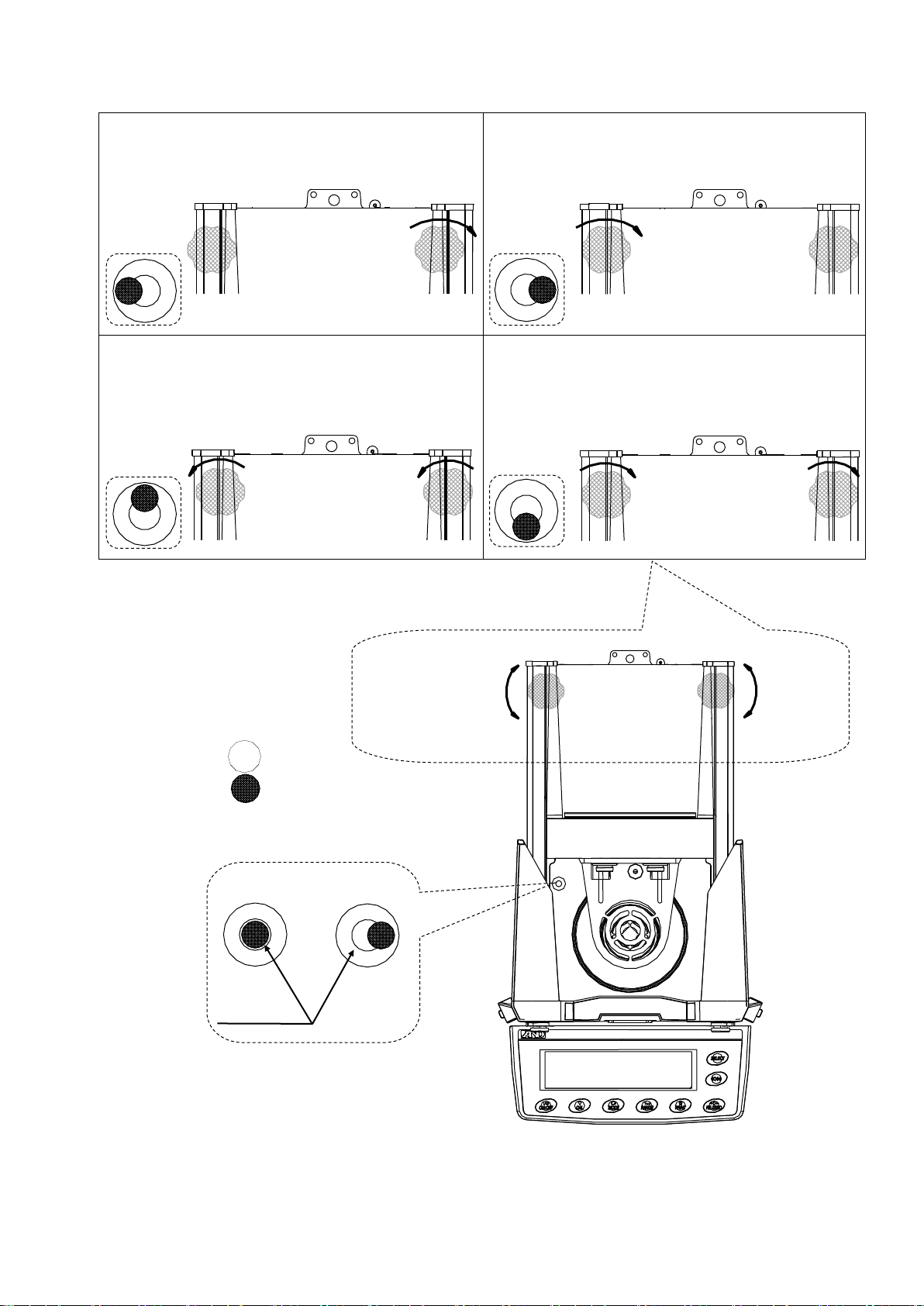

Adjust the lev el of t he bala nce usi ng th e lev elin g feet .

Please warm u p the bal anc e for at least one ho ur. Plug in the AC adap ter as usual .

Calibrate the balance if it is installed for the first time or relocated, or w hen a weig hing pan is repl aced.

Ensure a stabl e pow er s our ce w hen usi ng th e A C a dap ter .

Do not place or use the balance where there is flammable or corrosive gas present.

12 BM series

Page 15

Adjusting the level

When the bubble is off to the left:

on the rear right in the

When the bubble is off to the right:

Turn the leveling foot on the rear left in the

When the bubble is off to the backward

:

leveling feet on the rear in the

When the bubble is off to the forward

:

Turn both leveling feet on the rear in the

Up

Down

Bubble spirit level

Turn the leveling foot

clockwise direction.

Level

clockwise direction.

Level

position

Turn both

counterclockwise direction at the same time.

Level

Red circle

Bubble

OK NO

Red circle

Leveling foot

Down

position

clockwise direction at the same time.

Level

水平器

Leveling foot

Up

BM series 13

Page 16

3.3.

Precautions During Use

13. Underhook

BM-252

BM-5

BM-5D, BM-20

BM-22

BM-5, BM-5D, BM-20

BM-22

Grounding

Metal case

Charged mat erial

Magnetic material

40°C

20°C

Draft Weighing pan

Fine range ring

BM-252

Shock

BM-5

BM-5D

BM-20

BM-22

Fine range ring

Small fine range ring

Tabletop breeze break (M)

BM-5

BM-5D

BM-20

BM-22

Note the foll owi ng i t ems t o ge t ac cur at e w eig hi ng dat a.

Discharge static electricity from the weighing sample. When a

weighing s ampl e (pl as ti cs, ins ul at or, etc .) co ul d hav e a s ta tic

charge, the weight value is influenced. Ground the balance, and

Eliminate the static electricity using the built-in ionizer.

Try to keep the ambient humidity at or above 45% RH in the room.

Use a metal shield case.

Wipe a charged material (plastic sample, etc.) with a damp cloth.

This balance us es a s trong magnet as part o f t he bal a nce assembly,

so please use caution when weighing magnetic materials. If there is

a problem, use the underhook (refer to "

suspend the m aterial away from th e in fluence of t he mag net.

Eliminate temperature differences between the weighing sample and

the environment. When a sample is warmer (cooler) than the ambient

temperature, the sample will appear lighter (heavier) than the true

mass. This error is due t o the r ising (fall ing) draft around t he sa mple. If

you touch the sample, the same type of error will occur. Do not touch

the sample directly with your hand. Use tweez ers or other to ols.

") to

Do not drop things upon the weighing pan, or place a weight

beyond the range of the balance on the weighing pan.

Make each weighing gently and quickly to avoid errors due to

changes in t he e nv iro nm ental c o ndi tio ns.

Use the fine range ring and attach the separation plate (in condition

at shipping from factory) in order to avoid weighing errors caused by

drafts when weighing using the

Use the small fine range ring and fine range ring and attach the

separation plate ( in condition at shipping from factory) in order to avoid

weighing err ors caused by dr afts wh en weighing using the

reduce the influence of breezes, mini mize o perati on o f doors o f the

weighing c ham ber . In addition , i n or der to w eigh m ore acc ura tely

while reduc i ng t he ef fect s o f the s urro undi ng environment, be sur e t o

install the tabletop br e ez e br eak (M) to the weighing cha mber .

The weighing value of the

may change after the stabilization indicator is displayed. We

recommend that you set a certain amou nt of wait time (appro x. 10

seconds) before reading the value after the stabilization indicator is

displayed.

or

(readability: 0.01 mg and 0.001 mg). To

(r eadability: 0.01 mg).

and

,

If contamination may be a problem, perform sampling operations

outside the weighing c hamber in order to prevent the sample from

scattering in the weighing chamber.

Take into consideration the affect of air buoyancy on a sample

when more acc uracy is requi red .

14 BM series

Page 17

Do not use a sharp instr ument (suc h as a pen cil or ball p oint pe n) to

3.4.

Precautions After Use

3.5.

Precautions for Power Supply

BM-5, BM-5D, BM-20

BM-22

press the keys, use your finger only.

Press the RE-ZERO key before e ac h w eig hin g to pr ev ent po ssi ble

errors.

Keep the bala nce i nter i or fr ee o f foreign matter (dust, liquid or metal

fragments).

Avoid mech ani ca l s hock t o y our bal a nce.

Do not disassemble the balance. Contact your local A&D dealer if your balance needs service

or repair .

Do not use solvents to clean the balance. F or best cleaning, wipe wit h a dry lint free cloth or a

lint free c lot h tha t i s moi ste ned w ith w arm wat er a nd a mil d d et erge nt .

Keep the balance interior free of foreign matter (dust, liquid or metal fragments).

Do not remove the AC adapter while the internal mass is in motion, for example, right after the

AC adapter is co nn ecte d, or dur ing c ali bra tio n u si ng the i n ter nal m ass .

If the AC adapter is removed under the co nditions described above, the internal ma ss will be

left unsecur ed, that may caus e mech anical dam age wh en th e b ala nc e is mov ed.

Before removing the AC adapter, press the ON:OFF key and confirm that zero is displayed in

the weighing mode.

After connecting the AC adapter to the balance, warm up the balance for at least one hour

before wei ghi ng.

When the AC adapter is c onn ecte d, the ba lance is in the standb y mo de if the s tandb y ind ica tor

is on. This is a normal state and does not harm the balance. For accurate weighing, we

recommend that the AC adapter be kept connected , especially for the

and

.

BM series 15

Page 18

4.

Display Symbols and Key Operation

Display

12. Data Memory

Key operation

Key

When pressed and released

When pressed and held (approx. 2 seconds)

Turns the display on and off. The stan dby indicator i s displayed whe n the display is tur ned off.

15.4. Entering

the Password Before Weighing

and turn t he dis play off.

Cancels the operation when performing

mass.

Switches the preset w ei ghi ng uni ts stor ed

Refer to "5. Weighing Units".

Displays the function table menu.

10. Function Table

Refer to "6.7. Repeatability Test".

No function at the factor y set ting .

The data m emory menu is di spl ayed .

The key to moni tor the time and dat e, and the environmental sensors (temper ature, humidity, barometric

pressure), for several seconds. Refer to "6.6. Monitoring the Clock and Environmental Sensors".

Response indicator for approx. 30

seconds when weighing st arts.

The amount of stored data w ith data memory function

Humidity (%)

St a nd by i ndi cat or o f

interval memory func tio n

Ionizer oper ati on indi cat or

Units.

Refer to "5. Weighing Units".

Active indicator of

interval memory function

Prior notice indicator of

automatic self calibration

St abilization indicator

The current data number

St a nd by i ndi cat or

of power s uppl y

Blinking indicators

Weighing data or stored data

Active processing indicator

Density mode, Display lock

Right and left glass door indi cator

Barometric pressure (hPa)

Processing indicator

The interval memory function is used to store the weighing data periodically. Refer to "

Press and release the key immediately or "Click the key"

Press and hold the key (for approx. 2 seconds)

When the display is turned on, the weighing mode is enabled. If the passw ord func tion i s

used,

This key is av ailabl e an ytime . Pres sing the key during oper atio n will inte rrup t the oper ati on

function settings.

Enters the calibration mode us ing the internal

in the function table.

In the weighing mode, turns the minimum

weighing v alue on and off.

In the counting or perc ent mode, ent ers

the unit mass stor ing mode or ref erence

mass storing m ode.

is displayed to prompt you to enter a pas sword. Refer to "

pa55

".

..............................................................................

...................................................................

Displays other items of the calibration menu.

Performs automatic response adjustment.

Refer to "

Perform s a r ep eat ab ili ty t est w hen pr ess ed

and held for ano ther 2 s econ ds aft er th e

function t able me nu is di splay ed.

".

".

The key to output the weighing data to a

printer or per son al com puter (or stor e it i n

memory) dep endi ng on the f uncti on tabl e

settings. (Factory sett ing = out put)

The key to se t t he dis pl ay t o z er o.

The key to tur n the io niz er on and off.

16 BM series

By changing the function tabl e:

"Title block" and "End block" for GLP /

GMP report ar e out put.

Page 19

5.

Weighing Units

5.1.

Units

5.2. Storing Active Units

Gram

g

1 g

-

-

Ounce (Av oir)

oz

28.349523125 g

Metric Carat

ct

0.2 g

Tael (HK ge n eral , Sing a por e)

37.7994 g

Tael (Taiw an)

37.5 g

Density mode

DS

Refer to "14. Density Measurement"

14. Density Measurement

The units and weighing modes can be selected and sto red in the function table as described i n

"

The sequence of displaying them can be arranged to fit the frequency of use.

They are stored and are mai ntai ne d i n n on-volatile m emory , eve n if the AC ada pter i s remov ed.

If the law in your area permits, you may use all of the units. You can disable the units that you

don't regul arly use. An d you are able to turn th em bac k on.

If a weighing mode (or unit of mass) has been turned off, that mode or unit will be missing in the

sequence. Ta el has four varie ties, o ne of which c an be sel ect ed and i nstall ed at the fac tory .

Press the MODE key to select a unit or mo de for wei ghi ng.

For details ab out th e unit s and mo des, see the t able b elow :

Name (unit, mode) Abbreviation Display u nit Conversio n fact or

".

Milligram mg

Counting mo de PC

Percent mode %

Troy Ounce ozt 31.1034768 g

Momme mom 3.75 g

Pennyweight dwt 1.55517384 g

Grain (UK) GN 0.06479891 g

Tael (HK jewelry) 37.429 g

tl

Tael (Chin a) 31.25 g

Tola (Indi a) t 11.6638038 g

Messghal m 4.6875 g

0.001 g

Density mode

To use the densit y mod e, it mu st be st ored i n the fu ncti on tabl e as described on page 21.

For details about t his mod e, r efer to "

To s elec t the den sity mode, pres s the MODE key until the pr ocess ing i ndict or blinks with

the unit "g" dis pl ayed.

BM series 17

".

Page 20

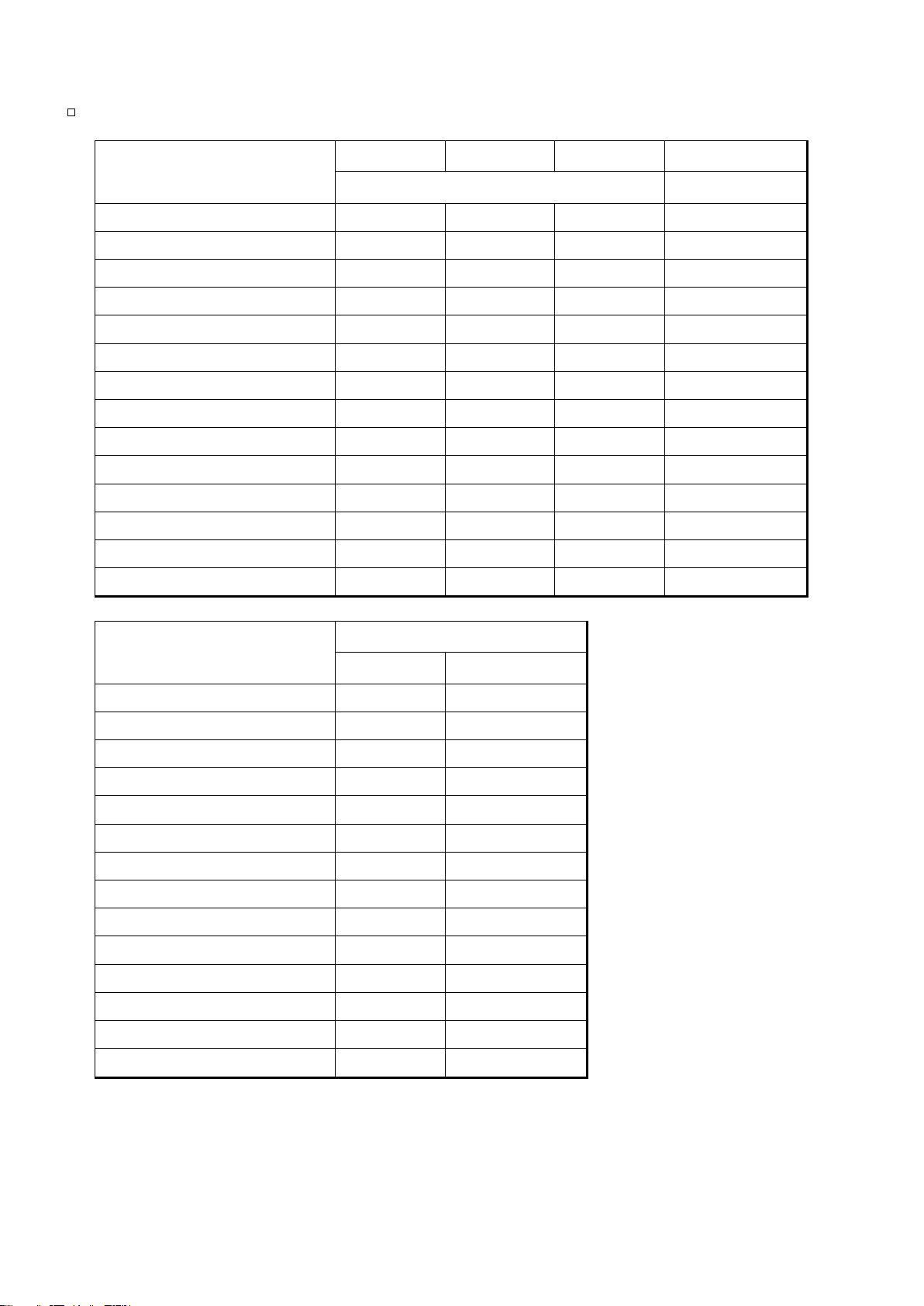

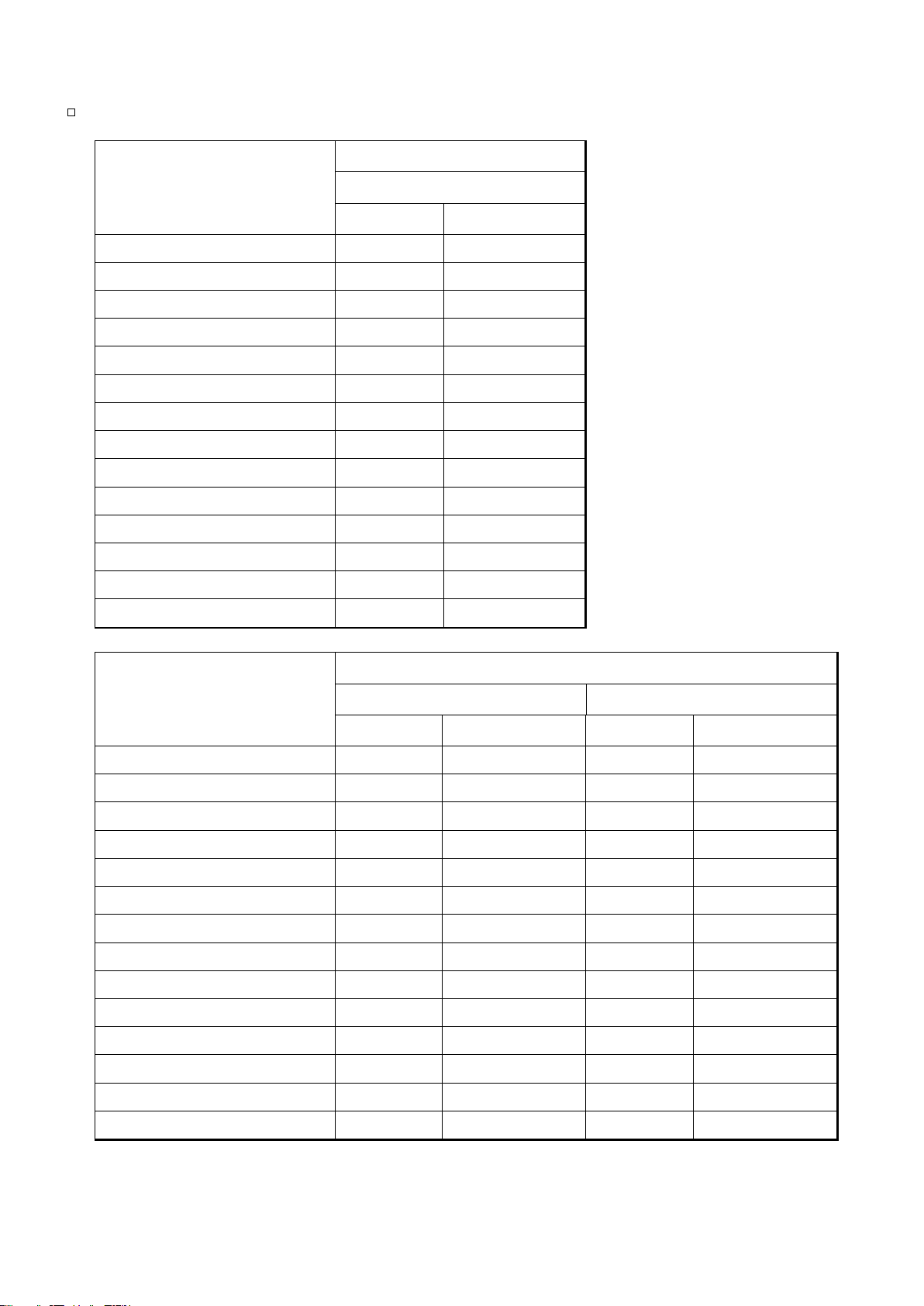

Capacity and readability for the BM-252, BM-200, BM-300, BM-500

BM-200

BM-300

BM-500

Gram

220

320

520

0.0001

Milligram

220000

320000

520000

0.1

Ounce (Avoir)

7.76

11.2

18.3

0.00001

Troy Ounce

7.07

10.2

16.7

0.00001

Metric Carat

1100

1600

2600

0.001

Momme

58.6

85.3

138

0.0001

Pennyweight

141

205

334

0.0001

Grain (UK)

3395

4938

8024

0.002

Tael (HK general, Singapore)

5.82

8.46

13.7

0.00001

Tael (HK jewelry)

5.87

8.54

13.8

0.00001

Tael (Taiwan)

5.86

8.53

13.8

0.00001

Tael (China)

7.04

10.2

16.6

0.00001

Tola (India)

18.8

27.4

44.5

0.00001

Messghal

46.9

68.2

110

0.0001

BM-252

Gram

250

0.00001

Milligram

250000

0.01

Ounce (Avoir)

8.81

0.000001

Troy Ounce

8.03

0.000001

Metric Carat

1250

0.0001

Momme

66.6

0.00001

Pennyweight

160

0.00001

Grain (UK)

3858

0.0002

Tael (HK general, Singapore)

6.61

0.000001

Tael (HK jewelry)

6.67

0.000001

Tael (Taiwan)

6.66

0.000001

Tael (China)

8.00

0.000001

Tola (India)

21.4

0.000001

Messghal

53.3

0.00001

The tables b elow in dica te the w eigh ing ca pacity and t he rea dabil ity for eac h bala nce.

Unit

Capacity

Readability

Unit

Capacity

Readability

18 BM series

Page 21

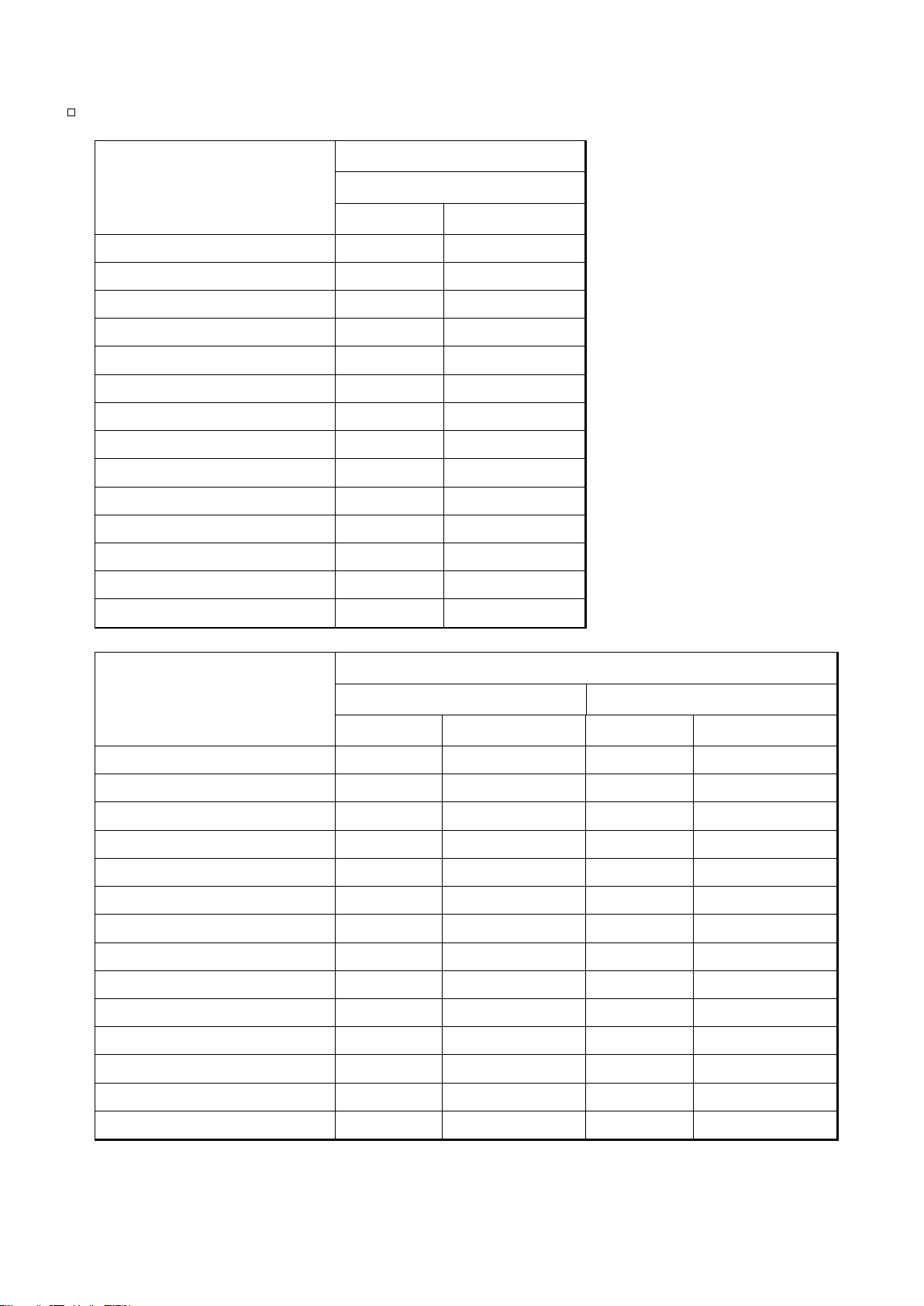

Capacity and readability for the BM-5

BM-5D

BM-5D

BM-5

Gram

5.20

0.000001

Milligram

5200

0.001

Ounce (Avoir)

0.183

0.0000001

Troy Ounce

0.167

0.0000001

Metric Carat

26.0

0.00001

Momme

1.38

0.000001

Pennyweight

3.33

0.000001

Grain (UK)

80.1

0.00002

Tael (HK general, Singapore)

0.137

0.0000001

Tael (HK jewelry)

0.138

0.0000001

Tael (Taiwan)

0.138

0.0000001

Tael (China)

0.166

0.0000001

Tola (India)

0.444

0.0000001

Messghal

1.10

0.000001

BM-5D

Gram

2.10

0.000001

5.20

0.00001

Milligram

2100

0.001

5200

0.01

Ounce (Avoir)

0.0737

0.0000001

0.183

0.000001

Troy Ounce

0.0671

0.0000001

0.167

0.000001

Metric Carat

10.5

0.00001

26.0

0.0001

Momme

0.560

0.000001

1.38

0.00001

Pennyweight

1.34

0.000001

3.33

0.00001

Grain (UK)

32.4

0.00002

80.1

0.0001

Tael (HK general, Singapore)

0.0551

0.0000001

0.137

0.000001

Tael (HK jewelry)

0.0560

0.0000001

0.138

0.000001

Tael (Taiwan)

0.0560

0.0000001

0.138

0.000001

Tael (China)

0.0671

0.0000001

0.166

0.000001

Tola (India)

0.179

0.0000001

0.444

0.000001

Messghal

0.444

0.000001

1.10

0.00001

and

The

is equipped with the precision range and standard range of the smart range function.

Unit

Precision range

Capacity Readability

Unit

Precision range Standard range

Capacity Readability Capacity Readability

BM series 19

Page 22

Capacity and readability for the BM-20

BM-22

BM-22

BM-20

Gram

22.0

0.000001

Milligram

22000

0.001

Ounce (Avoir)

0.776

0.0000001

Troy Ounce

0.707

0.0000001

Metric Carat

110

0.00001

Momme

5.86

0.000001

Pennyweight

14.1

0.000001

Grain (UK)

339

0.00002

Tael (HK general, Singapore)

0.582

0.0000001

Tael (HK jewelry)

0.587

0.0000001

Tael (Taiwan)

0.586

0.0000001

Tael (China)

0.704

0.0000001

Tola (India)

1.88

0.0000001

Messghal

4.69

0.000001

BM-22

Gram

5.10

0.000001

22.0

0.00001

Milligram

5100

0.001

22000

0.01

Ounce (Avoir)

0.179

0.0000001

0.776

0.000001

Troy Ounce

0.163

0.0000001

0.707

0.000001

Metric Carat

25.5

0.00001

110

0.0001

Momme

1.36

0.000001

5.86

0.00001

Pennyweight

3.27

0.000001

14.1

0.00001

Grain (UK)

78.7

0.00002

339

0.0001

Tael (HK general, Singapore)

0.134

0.0000001

0.582

0.000001

Tael (HK jewelry)

0.136

0.0000001

0.587

0.000001

Tael (Taiwan)

0.136

0.0000001

0.586

0.000001

Tael (China)

0.163

0.0000001

0.704

0.000001

Tola (India)

0.437

0.0000001

1.88

0.000001

Messghal

1.08

0.000001

4.69

0.00001

and

The

is equipped with the pr ecisi o n r ang e an d s ta ndar d r ang e o f the s mart r ang e func ti on.

Unit

Precision range

Capacity Readability

Unit

Precision range Standard range

Capacity Readability Capacity Readability

20 BM series

Page 23

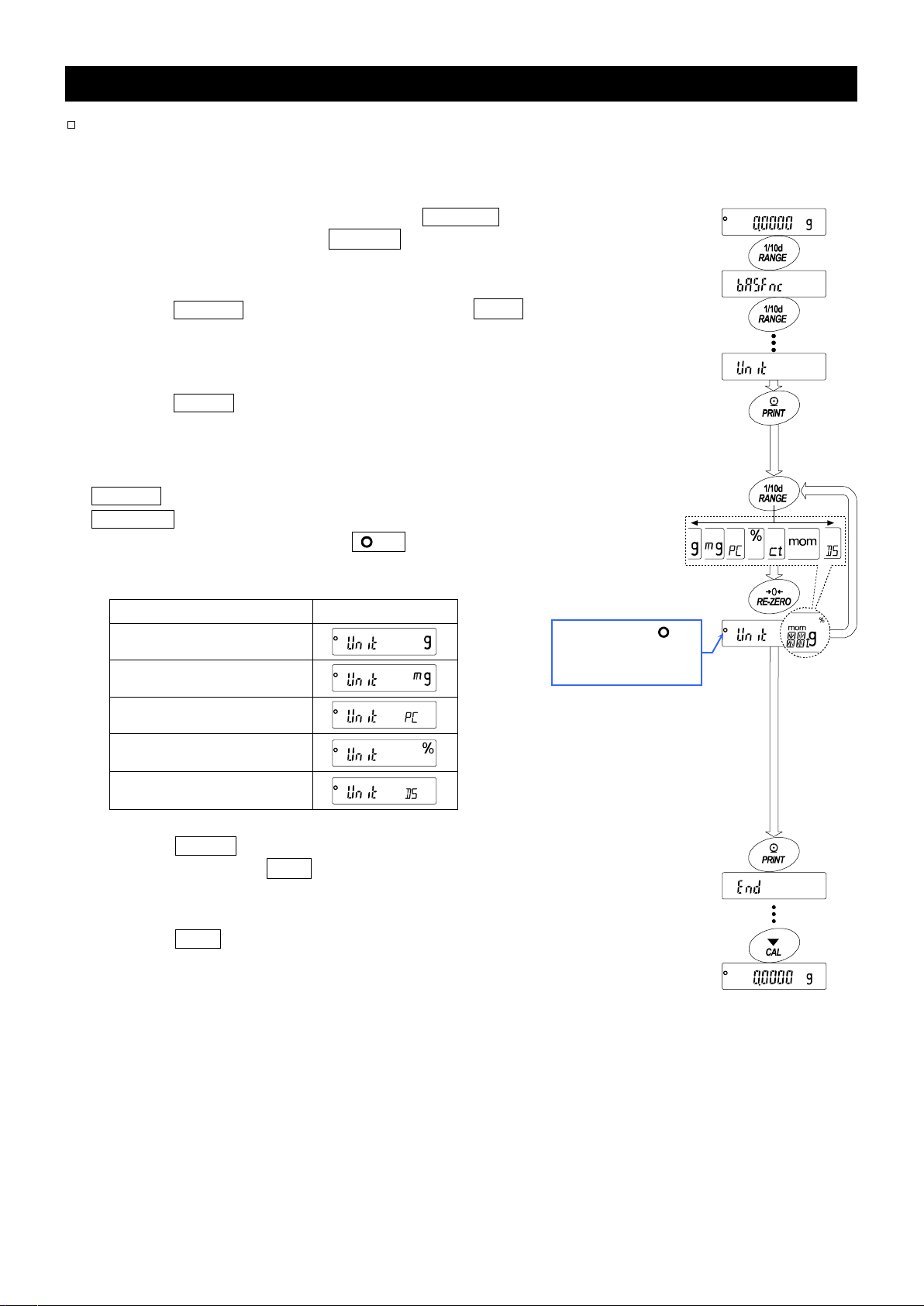

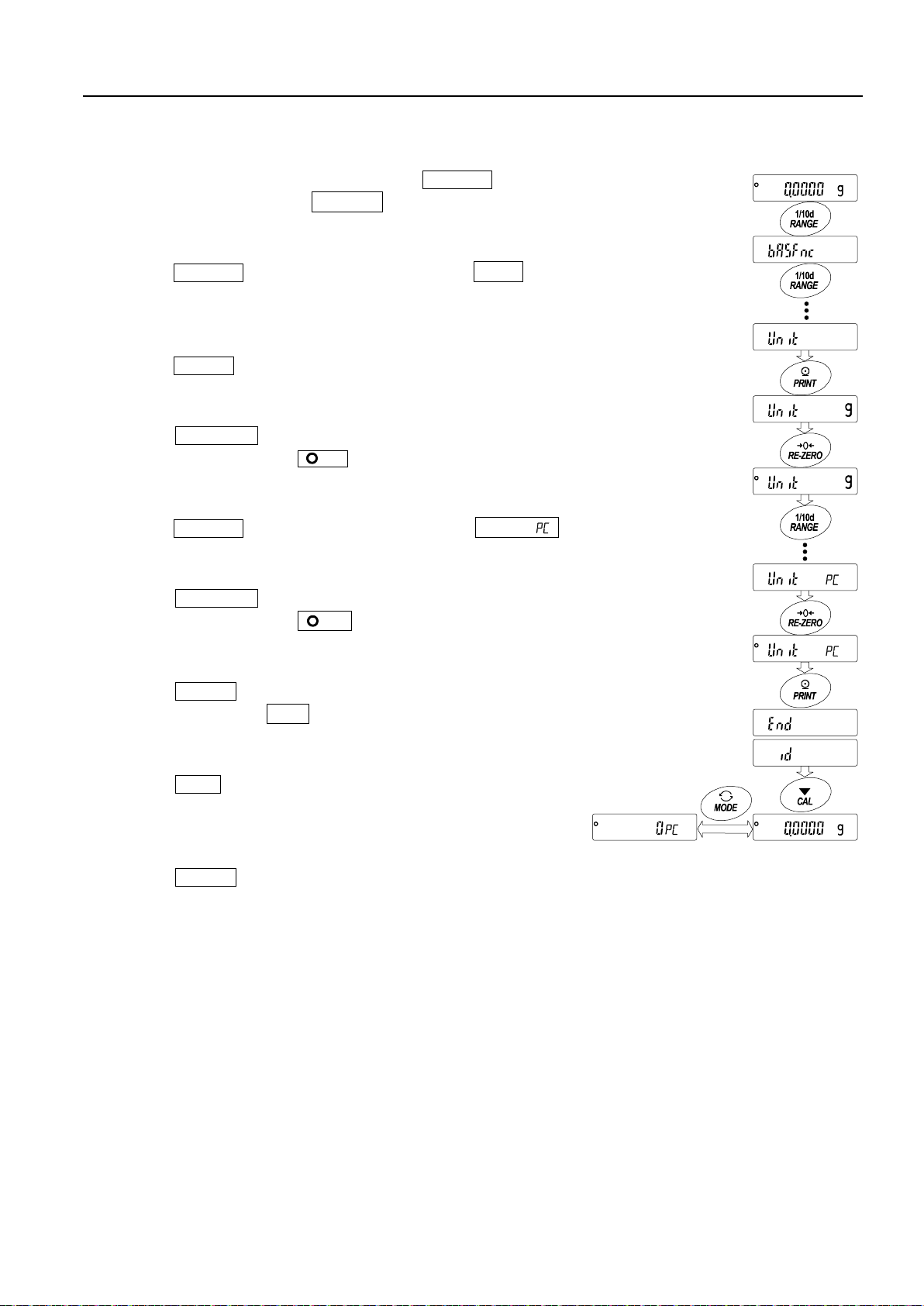

5.2.

Storing Active Units

Unit

Display

Specify the unit

Press and hold

Press several times

The indicator is

units specified.

Store

Selection key

Examples

The units and mod es ca n be sel ecte d and store d in the functi on ta ble.

The sequence of displaying them can be arranged to fit the frequency of use.

The units stor ed ar e m ai ntai ne d i n n on-volatile m emory , eve n if the AC ada pter i s remov ed.

1 In the weighing mode, press and hold the RANGE

key (for approx . 2 seconds) until ba5fnc is displayed,

and then release the key.

2 Press the RANGE key several tim es to dis pl ay Unit .

3 Press the PRINT key to enter the uni t sele cti on mod e.

4 Specify a unit or mode in the or der to be dis play ed

using the foll ow ing k ey s.

RANGE key

RE-ZERO key

Examples

.........

To display t he unit s seq uenti ally.

......

To specify a uni t or m ode.

The indica tor appears when

the display ed unit or mo de is spec ifi ed.

(approx. 2 seconds)

Gram g

Milligram mg

Counting mode PC

Percent mode %

Density mode DS

5 Press the PRINT key to st ore t he uni ts or mod es.

The balance di splay s end and then display s the n ext

menu item of the function table.

6 Press the CAL key to exit the function table.

Then the bala nce r etur ns to the w eig hing mode w i th th e

selected un it.

displayed at the

BM series 21

Page 24

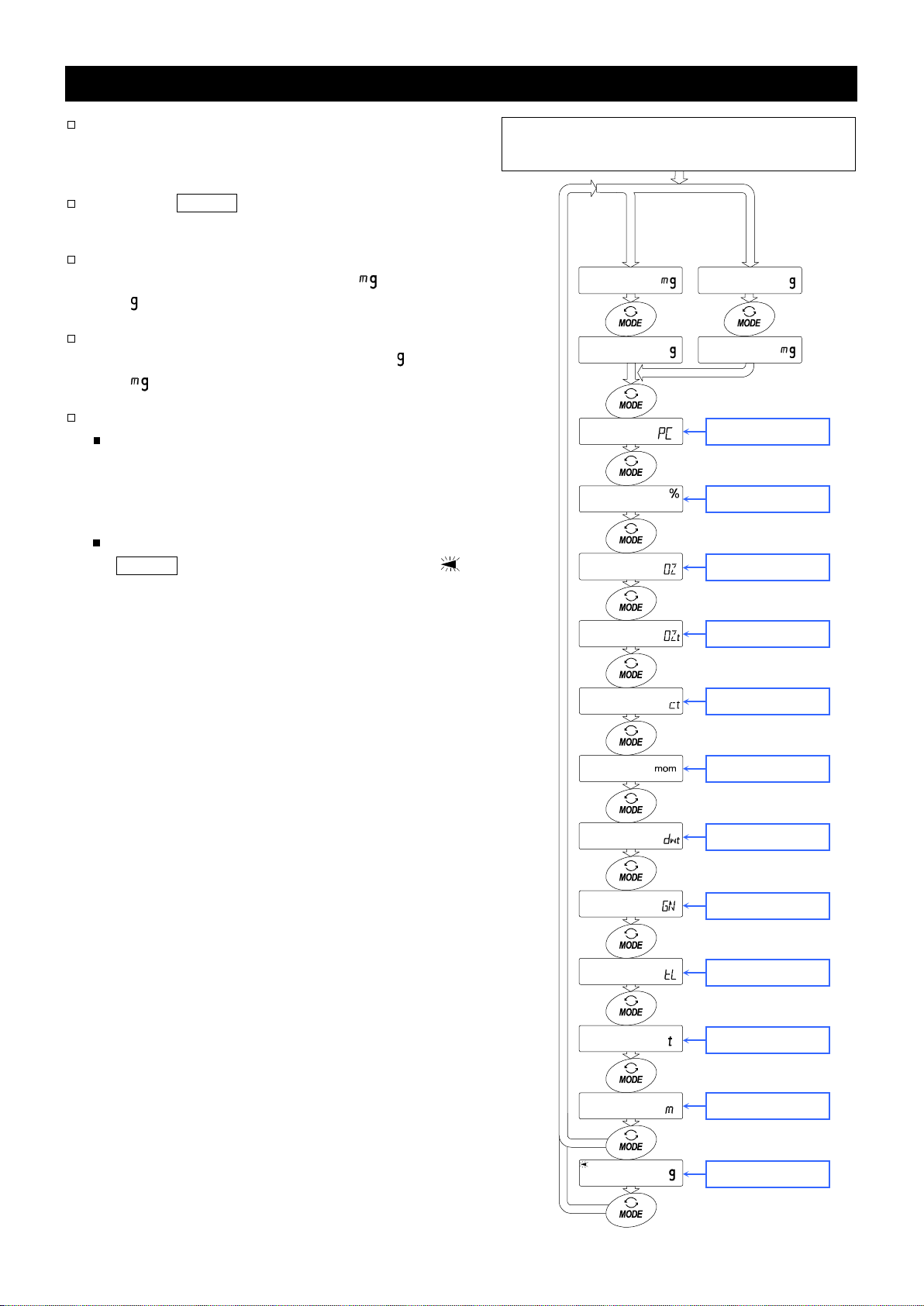

5.3.

Selecting Units and Weighing Modes

5.2. Storing Active Units

BM-5, BM-5D, BM-20

BM-22,

BM-252, BM-200, BM-300

BM-

500

14. Density Measurement

The unit sequence of the factory settings.

Turning the display on.

BM-5 BM-252

BM-5D BM-200

BM-20 BM-300

BM-22 BM-500

Counting mode

Percent mode

Ounce (Avoir)

Troy Ounce

Metric Carat

Momme

Pennyweight

Grain (UK)

Tael

Tola (India)

Messghal

Density mode

Preset the seq uenc e of dis playi ng uni ts and

weighing mod es to fi t th e freq uency of use .

Refer to "

Press th e MODE key in the weighing mode to

display the u nits and weighing modes in order.

For the

the units preset at the factory, (Milligram)

and (Gram), are dis pla yed in this order.

".

and

For the

and (Milligram), are di s play ed in this order.

Density mode

To use the densit y mod e, it mu st be stored in

To selec t the density mode, press the

, the units preset at the factory, (Gram)

the function table as described on page 21.

Refer to "

details about the mode.

MODE key until the pr ocessi ng indi ct or

blinks with t he unit "g" di splay ed.

and

" for

22 BM series

Page 25

5.3.1.

Unit Setting Example

Press several times

Press several times

Specify gram

Specify counting mode

Store

Press and hold

The example below sets the units in the order with g (gram) as the first unit followed by PC

(counting mo de) .

1 In the weighing mode, press and hold the RANGE key

(for approx. 2 seconds) until ba5fnc is displayed, and

then release the key.

2 Press the RANGE key several tim es to dis pl ay Unit .

3 Press the PRINT key to enter the uni t sele cti on mod e.

4 Press the RE-ZERO key to specify the unit of g.

The stabili za tio n i ndi c ator appears when the unit is

specified.

5 Press the RANGE key several tim es to dis pl ay Unit .

6 Press the RE-ZERO key to speci fy the u nit of PC.

The stabili za tio n i ndi c ator appears when the unit is

specified.

7 Press the PRINT key to st ore t he uni ts.

The balance di splay s end and then displays the next

menu item of the function table.

8 Press the CAL key to exit the fu nctio n tabl e. The n the

balance r etur ns to th e w eig hi ng mod e wi th g , th e uni t

selected first.

9 Press the MODE key to switch between g and PC.

(approx. 2 seconds)

BM series 23

Page 26

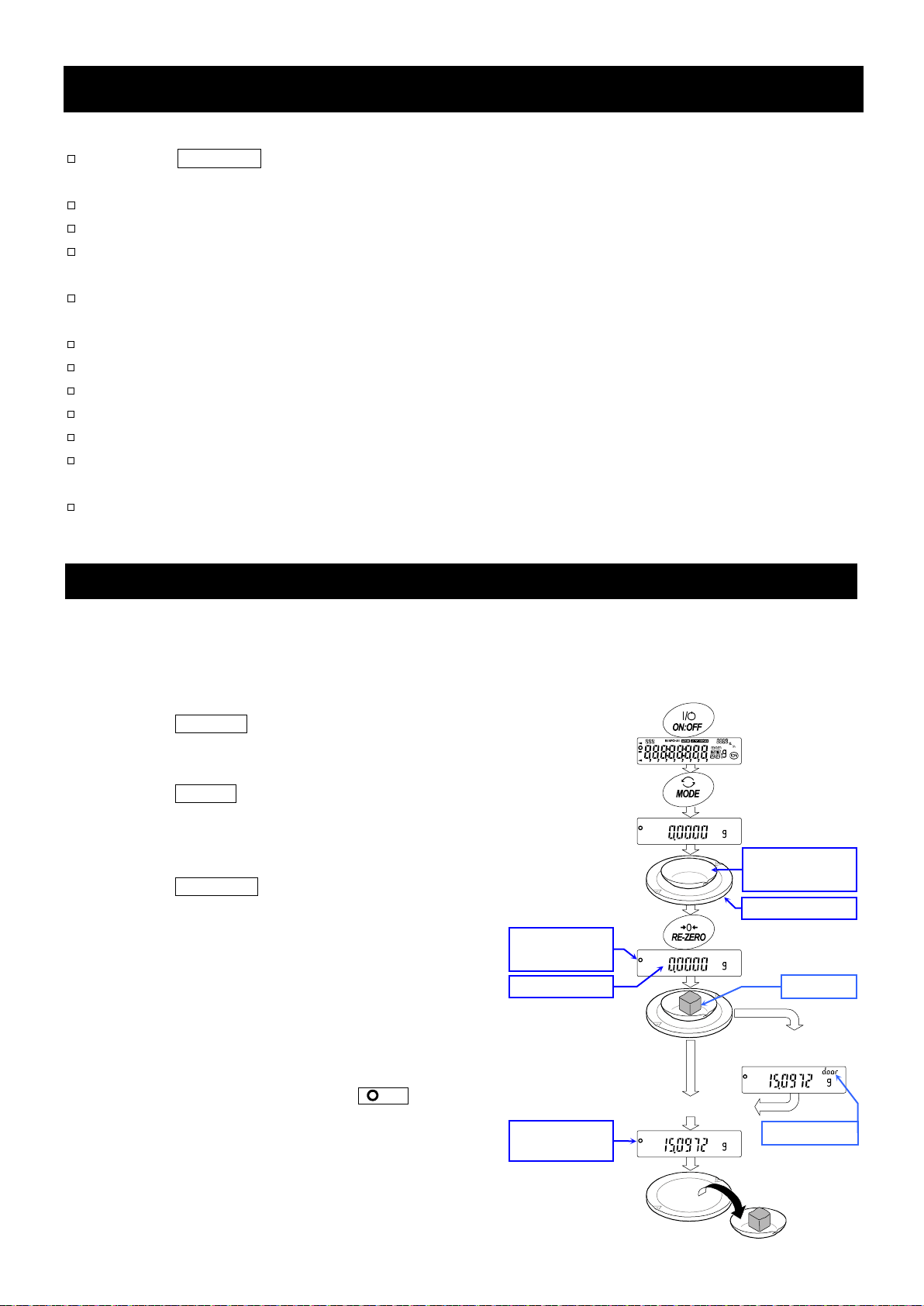

6.

Weighing

Precautions for the weighing operation

8. Calibration

BM-5, BM-5D, BM-20

BM-22

3. Installing the Balance and Precautions

6.1.

Basic Operation

4. Display Symbols and Key Operation

Container

(tare)

Weighing pan

Stabilization

Stabilization

indicator

The glass door

is not closed

Close the door

Remove

Zero display

Press the key

to select a unit,

Warning

Sample

Press the RE-ZERO key each time, before placing a sample on the weighing pan, to prevent

possible er r ors .

Place a sample in the center of the weighing pan gently.

Temperatur e c h ange s d uri ng me as urem ent ma y cau se w ei ghing errors.

Shorten the o perati on ti me as much as possib le. (

Material w ith an el ectr os tati c c har ge or th at is mag neti c may ca us e w eig hing er r ors.

Use a pair of tweezers to avoid a temperature change due to having your hand in the weighing

chamber.

Do not dr op thi ng s on t he pan , or plac e a w eig ht on th e p an t hat is b ey ond th e w eig hing r ang e.

Keep the ar ea clea n and dr y.

Do not pr ess k ey s w ith a sh arp i nstr u men t (s uc h as a pe ncil or b all poi nt pe n).

For precisi on w eighi ng, ke ep the AC adapt er co nnecte d to th e bala nce.

Calibrate periodi cally to mai ntain w eighi ng acc uracy . Refer to "

For the

precision wei ghi ng c an be p er for med .

Consider section "

and

Opening and closing door, placing and removing sample)

, perfo rm p re-weighing of the container (tare) so that

" for the w eighing opera tion .

".

Refer to "

Note When turning the bala nce on with a ta re weight pl aced on the

1 Press the ON:OFF key to turn the displ ay on.

2 Press the MODE key to select a unit, if neces sary .

3 Place a container (tare) on th e w eig hi ng pan, i f ne ces sar y.

Press the RE-ZERO key to c anc el th e tar e w eight .

Then zero is dis pl ayed .

Tare : A vessel placed on the pan, but not

4 Place a sample on the pan or in the container.

Close the door .

5 Wait for th e stab iliz ation indic ator to be

displayed, and th e n rea d the v al ue.

6 Remove the sample and container from the pan.

pan, the b alan c e au to mati c ally d isp lay s t he zer o d isp l ay .

to be included in the weighing data.

Example: Container.

(Gram Mode)

" before operation.

indicator

if necessary.

24 BM series

Page 27

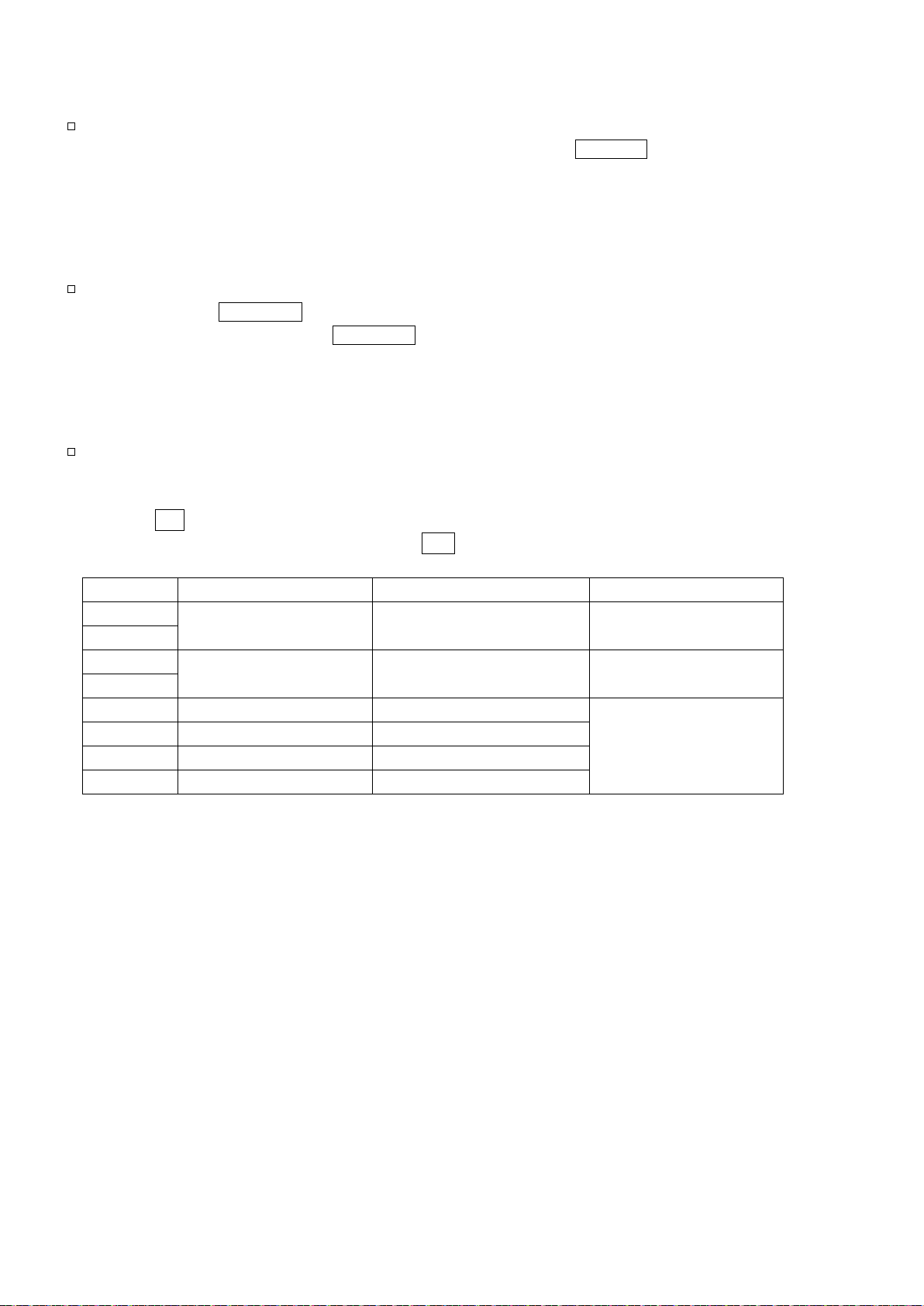

Zero operation, tare operation and weighing range

Model

Power on zero range

Zero range

-E di splay range

BM-5

BM-5D

BM-20

BM-22

BM-252

Approx. ±25 g

Approx. -37 g to +5.0 g

BM-200

Approx. ±22 g

Approx. -37 g to +4.4 g

BM-300

Approx. ±32 g

Approx. -37 g to +6.4 g

BM-500

Approx. ±52 g

Approx. -37 g to +10.4 g

When weighing is started

The balance will determine the reference zero point when the ON:OFF key is press ed to en ter

the weighing mode.

Depending on the load condition at that time, the balance will automatically judge whether to

perform zero or tar e o pe rati on . T he c o ndit ion for deter mi ni ng w hi ch i s us ed i s " p ower on z ero

range", a nd w he n p ow er o n zer o r a nge i s ex ce ede d, t h e t ar e oper ati on i s p erf or med.

Re-zero operation

By pressi ng the RE-ZERO key, t he dis pl ay can be set t o zer o.

The re-zero operation with the RE-ZERO key will autom ati call y j udg e w heth er t o per for m z er o or

tare operation.

The condit ion for det er mi ning w hich is us ed i s "z ero ra nge ", and w hen z ero r ang e i s ex ceed ed , t he

tare operation is performed.

Weighing range

The range th at t he bal anc e c a n wei gh v arie s depe ndi ng on th e m odel .

When the t ot al a moun t ( ne t w eig ht + tar e w ei gh t) dis pl ay ed for eac h mo del ex c ee ds t h e max i mu m

display,

When exceeded in the negative direc tion, -E is displayed.

E is displ aye d t o in dic a te t ha t t he w ei ghi ng r ang e i s ex ceed e d.

Approx. ±0.1 g Approx. -3.0 g to +0.1 g Less than approx. -3 g

Approx. ±2.2 g Approx. -3.0 g to +0.4 g Less than approx. -3 g

Less than approx. -37 g

BM series 25

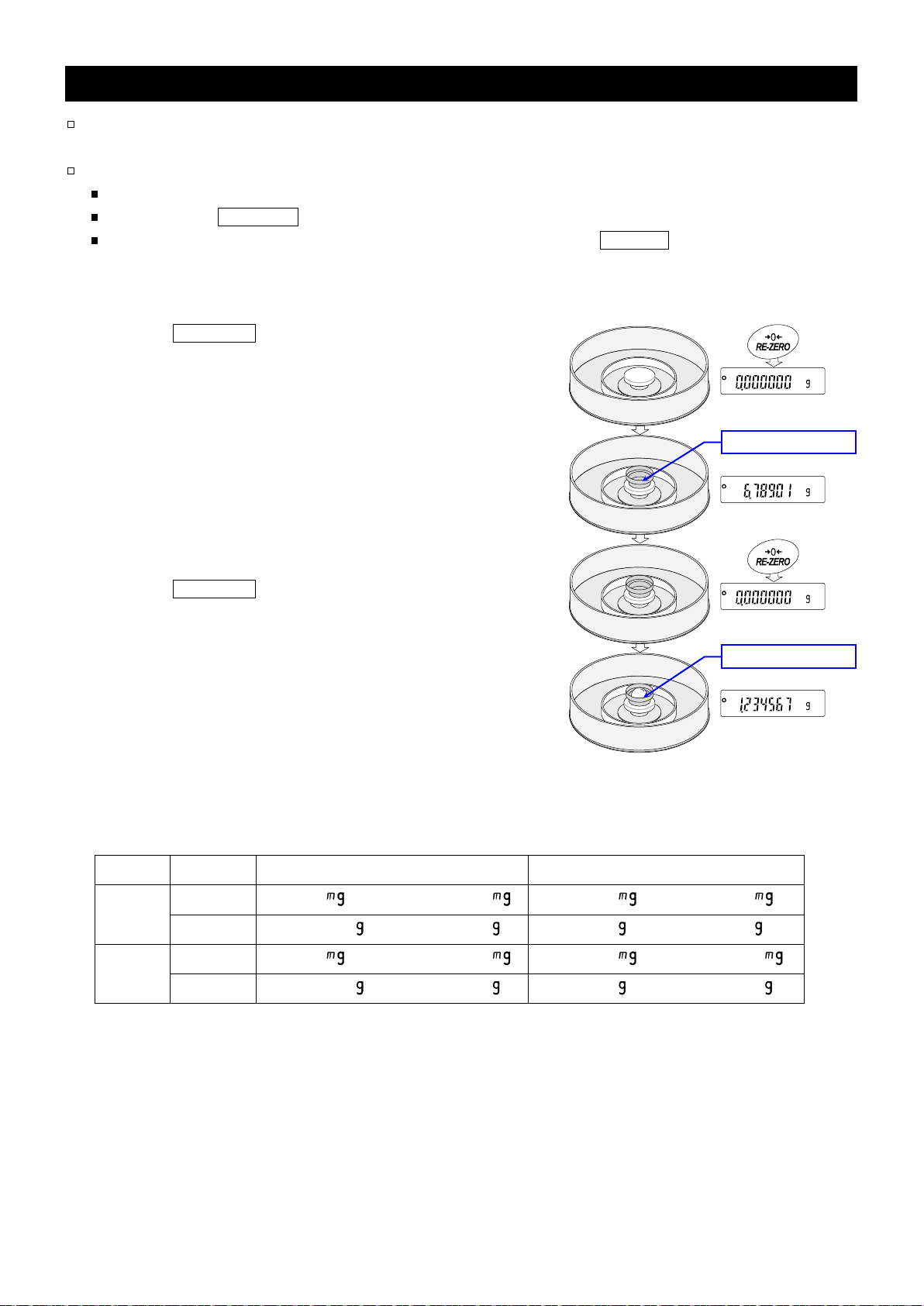

Page 28

6.2.

Smart Range

BM-5D

BM-22

Example

Precision range and standard range

BM-5D

BM-22

Precision range

Container (tare)

Weighing sample

The smart range for the

(high resol uti o n).

Smart rang e fu nctio n

The rang e switc hes a uto matic ally, depending o n the val ue dis playe d.

Pressing t he RE-ZERO key allows weig hing in the precis ion r ange, r egar dless of the tare value .

The rang e c a n be fix e d to t he s t an dar d r ang e b y pres sing t he RANGE key.

1 Press the RE-ZERO key to use t he prec isi on rang e.

The balance di splay s ze ro.

2 Place a container (tare) on the weig hi ng p an .

When the value of the container (tare) exceeds the

precision range, the balance automatically switches

to the standard range.

3 Press the RE-ZERO key to use t he prec isi on rang e.

The balance di splay s ze ro.

4 Place the weighing sample in the container (tare).

When the sample is within the precision range,

the weighing value can be read in high resolution.

and

consists of the standard range and precision range

Standard r ang e

Precision range

Precision range

Model Unit Precision range Standard range

Refer to pag es 20 and 21 for other u nits.

Milligram 0.000 to 2100.009 2100.01 to 5200.08

Gram 0.000000 to 2.100009 2.10001 to 5.20008

Milligram 0.000 to 5100.009 5100.01 to 22000.08

Gram 0.000000 to 5.100009 5.10001 to 22.00008

26 BM series

Page 29

6.3.

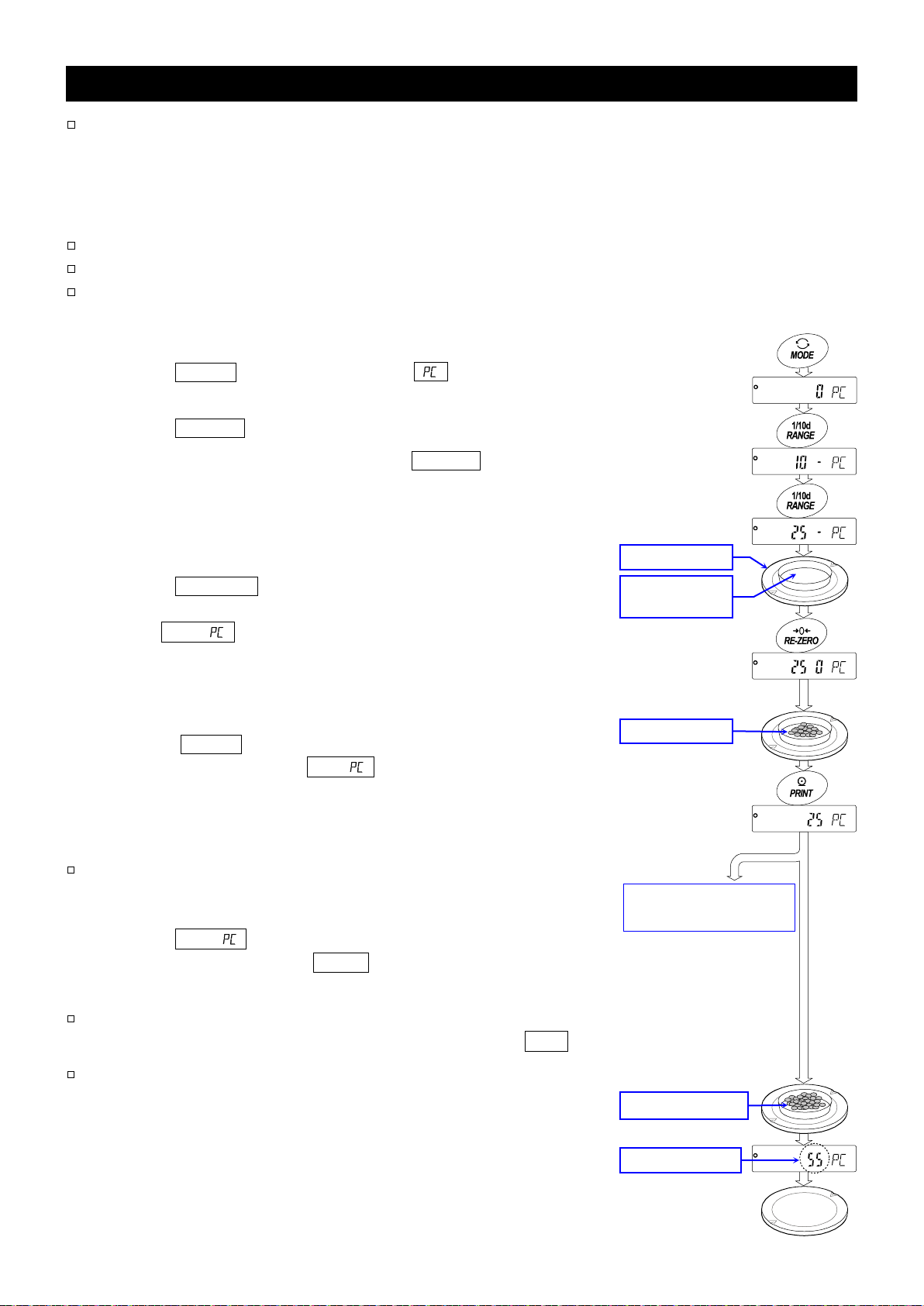

Counting Mode (PC)

Selecting the counting mode

Storing a sample unit mass (Weighing input mode)

50 -

lo

Counting operation

Weighing pan

Container

(tare)

25 samples

Place samples

Counting result

To

Step

8 when using

This is the mode to determi ne the num ber of objects in a sam ple based on the standard sample

unit mass. The un it mass means an average m ass of the samples. The sm aller the variation in

the samples is, the more accurate the count will be. The balance is equ ipped with the Aut omatic

Counting Ac cur ac y I mpr ov e ment (AC AI) func ti on to i mpr ov e t he cou nti n g acc ur acy .

Notes

Use samples with a unit mass of 1 mg or more for count ing.

If the samp le u ni t m as s v ari ab le i s t oo la rge , it m ay caus e a cou n tin g e rro r.

To improve the counting performance, use the ACAI function frequently or divide the

samples into several groups and count each group.

1 Press the MODE key to sel ec t t he u nit (counting mode).

2 Press the RANGE key to enter th e sam ple uni t m as s s tor ing mo de .

3 Select the number of samples using the RANGE key.

It may be set to 10 , 25, 50 or 10 0.

Note A greater number of s amp les wi ll yield more accurate

counting result.

4 Place a container (tare) on th e w eig hi ng pan, i f ne ces sar y.

Press the RE-ZERO key to ca ncel th e w eig ht ( tar e) .

The number specified in Step 3 appears.

Example

5 Place the number of samples specified on the pan.

In this exampl e, 25 pi ec es.

6 Wait for the stabilization indic ator to be di splay ed.

Press the PRINT key to calculate and store the unit mass.

Then the bala nc e dis pl ay s 25 and is set to count samples

with this unit mass. To improve the accuracy of the unit mass,

proceed to Step 8.

Notes

If the balance judges that the mass of the samples is too light

to acquire accurate w eighing, i t displa ys an error requirin g the

addition of more samples to th e specified number.

Example:

25 samples and press the PRINT key. When the unit mass is

stored correctly, the balance proceeds to the counting mode.

: 25 0 is displayed if 25 is s el ect ed i n St ep 3.

appears, requiring 25 more samples. Add

the ACAI function.

If the balance judges that the mass of the samples is too light (

0.0001g

The sample unit mass is stored in non-volatile memory, and

is maintai ned even if the A C ada pt er is remo v ed .

7 Place the samples to be counted on the pan.

Read the result and remove the samples from the pan.

BM series 27

) and cannot be stored as t he unit mass, it display s

under

.

Page 30

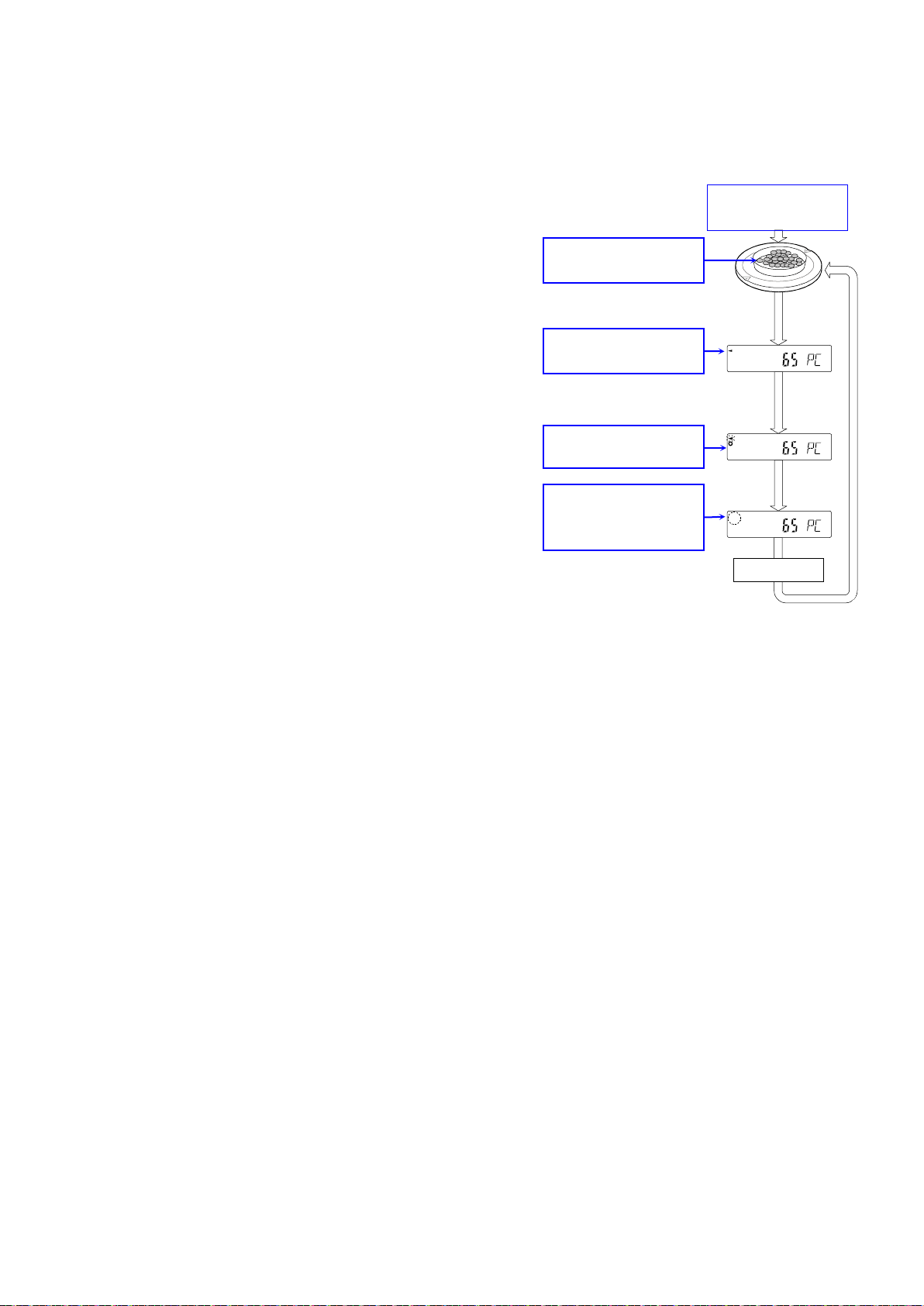

Counting mode using the ACAI function

From S tep 6 on

Add a few more

samples.

The indica tor t urns

on at prop er r a nge.

The indicator blin ks

during calc ul ati o n.

The indica tor t urns

mass is im pr oved.

Repeat

The ACAI is a function that improves the accuracy of the unit mass automatically by increasing

the number of samples as the counting process.

ACAI: Automatic C ount ing A cc uracy Impr ov em ent

Proceed to Step 8 a fter s toring a unit mass on the previ ous p age.

8 If a few more samples are added, the processing

indicator turns on. To prevent an error, add three or

more. The processing indicator does not turn on if

overloaded. Try to add the same number of samples

as displayed .

9 The balance re-calculates the unit mass while the

processing indicator is blinking. Do not touch the

balance or samples on the pan until the processing

indicator t urns o ff.

10 Counting accuracy is improved when the processing

indicator t urns o ff.

Each time the above operation is performed, a more

accurate unit mass will be obtained. There is no

definite upper lim it to the ACAI ran ge for the number

of samples exceeding 100. Try to add the same

number of samples as displayed.

11 Remove all the samples used in ACAI and proce ed

with the counting operation using the improved unit

mass.

off after the unit

the previ ous page

28 BM series

Page 31

6.4.

Percent Mode (%)

Selecting the percent mode

5. Weighing Units

Storing the 100% reference mass

BM-252, BM-200

BM-300, BM-500

BM-5, BM-5D

BM-20, BM-22

100% mass

Readability

100% mass

Readability

0.0100 g to 0.0999 g

1 %

0.00100 g to 0.0099 g

1 %

0.1000 g to 0.9999 g

0.1 %

0.01000 g to 0.0999 g

0.1 %

1.0000 g to

0.01 %

0.10000 g to

0.01 %

lo

Reading the percentage

100% mass

Place sample

Percentage

Weighing pan

Container

(tare)

The percent mode dis play s the weight value in per cent age co mpar ed to a 100 % re ferenc e mass

and is used for tar get w eig hi ng or c hec ki ng t he sa mpl e v ari anc e.

1 Press the MODE key to selec t t he uni t % (Percent mod e).

If the percent mode cannot be selected, refer to "

".

2 Press the RANGE key to enter the 100% reference mass

storing mode.

3 Place a container (tare) on the w ei ghi ng pa n, i f nec ess ary .

Press the RE-ZERO key to ca ncel th e w eig ht ( tar e) .

The balance di splay s 100 0 % .

4 Place the sample to be set as the 100% reference mass on

the pan or i n th e c ont ai ner .

5 Press the PRINT key to st ore t he r e fere nce mas s.

The balance di splay s 100.00 % .

Notes

The read abi lity depends on the 100% mass.

If the b alan c e ju dg es t hat th e mas s o f th e sa mpl e is t oo li ght

(

under 0.01g

The 100% refer ence mass can be stor ed in t he non-volatile

memory and is maintaine d ev en if the A C adapter is remov ed.

6 Remove the sample.

) to be u sed as a r ef er ence , it d isp l ay s

.

7 P lace a sample to be compared to the refe rence mass on

the pan. The disp layed percentage is based on the 100%

reference m ass.

BM series 29

Page 32

6.5.

Ionizer

Operation

BM-5, BM-5D, BM-20, BM-22

BM-252

6.5.1.

Maintenance of the Electrode Units

Replacing the electrode units

Ionizer

LED

Sample

Sep aration plate

Press

In neutralization

Weighing mode

Example: Display of BM-20

Electrode unit

Step

1

Step

2

Cleaning

Electrode needle

The BM series is equipped with four ionizer electrode units to neutralize static electricity from a

charged weighing sample.

Neutral iz ing st a tic el ect ri cit y b ef ore w ei ghi ng w ill im prov e stability, reducing err or s.

Neutralizing ion : The discharge electrodes of the ionizer continuously generate bi polar ions by corona

Static electricity : In general, when the ambient humidity is less than 45% RH, nonconductors

(Neutralization Device)

discharge. Applying these ions to the w eighing sample neutralizes the stat ic charge.

such as powders, paper and plastics easily become charged with static

electricity. The influence of the static electricity may cause a weighing error of

several milligrams. The ionizer effectively neutr al iz es t h e el ectr ic al ch arg e.

1 Place the sample to be weighed on the center

(of the metallic circle) of the separation plate to

neutralize t he static charge.

2 Press the ION key to star t th e neutr aliz atio n.

The mark and the LED blink .

The neutral iz at ion w i ll s t op a f ter t he pre se t ti m e

of "Neutralization time (ion)" in the fu nc ti on

table (th e fact ory set ting is 3 sec onds) .

The readability of the

neutralization.

Pressing the ION key during neutralization stops

the neutralization.

Notes

Keep the weighing sample away from the electrodes

while neutralizing. Placing the sample too close to the

electrodes may cause the s ample to beco me ch arged .

Remove any obstacle between electrodes and the weighing sample.

When using the ionizer for a long time, dust and stains may

stick to the electrodes. Clean them periodically to maintain

performance.

When needles of the electrodes are worn down and

neutralization ability is not restored after cleaning them,

replace all four electrodes with new ones. The standard life of

an electr ode uni t is appr oxi matel y 1000 0 hours .

is switched to 0.1 mg while performing the

and

1 Turn the el ectrode units 45 degrees counter clock wi se and

remove them from th e ioni zer.

2 Replace all four uni ts with new ones .

Note Do not replace, remove an d clean the el ectr ode s while the ionizer is in op eratio n as

there is a d ang er of e lect rica l shoc k.

3 Turn the el ectr ode u nit s 45 degrees clockwise and insert them into the ioniz er .

30 BM series

Page 33

6.5.2.

Controlling the Ionizer Externally

Ionizer function External control i np ut

AX-SW137-PRINT

AX-SW137-REZERO

key

key

key

key

key

key

Pin No.

Description

1

GND

2

RE-ZERO Exter nal con t ac t i np ut

3

PRINT External c on t ac t i npu t

Assign the

key

key on

the AD-8922A.

It is possible to control the BM ioniz er function by connecting the remote c ontroller

(AD-8922A) or the foot switch (AX-SW137-PRINT, AX-SW137-REZERO).

When specifying "on" to “AD-8922A control (8922)” in the

function table (ionfnc 8922 on), the balance assigns the

function of the ION key to the MODE key on the AD8922A.

ION

to the MODE

When specifying “External con tr ol i np ut (e-5)” in “Ionizer func tion (ionfnc)”, the follow ing

functions can be assigned to AX-SW137-PRINT (option) or AX-SW137-REZERO (option)

terminals.

ionfnc e-5 0

ionfnc e-5 1 PRINT

ionfnc e-5 2 ION

PRINT

RE-ZERO

ION

RE-ZERO

Factory settings

By using aφ3.5 stereo plug MP-013LC (Marushin Electric Mfg. Co., Ltd.) or an equivalent product, you

can create your own switch.

(To us e a switch, you need to solder theφ3.5 stereo plug and the switch that y ou obtain yoursel f. )

External contact input terminal Compatible plug: φ3.5 mm 3-pole stereo plug

MP-013LC or t h e equivalent

Example of external contact input terminal

External contact input circuit Pin assignments

When pin 1 and pin 3 or pin 1 and pin 2 are shorted 100 ms or longer, the switch can operate the

balance in the same way as the balance PRINT key or the RE-ZERO key , respectively.

AX-SW137-PRINT or AX-SW137-REZERO (optional foot swi tches sold separately) can be used.

BM series 31

Page 34

6.6.

Monitoring the Clock and Environmental Sensors

Specifications of the environmental sensors

Sensor

Resolution

Measurement range

Applicable range

Temperature

±1.5 °C

5 °C to 40 °C

Humidity

±10 %

0 % to 100 %

Barometric pressure

±10 hPa

300 hPa to 1 100 hPa

20. Specifications

Operation

10.7. Clock and Calendar Function

5-td

10.2. Details of the Function Table

5-tp

10.2. Details of the Function Table

Humidity Barometric pressure

Temperature

Weighing mode

In the weighing mode, the built-in clock and environmental sensors (temperature, humidity,

barometric pressure) can be monitored and temperature data can be output in the function

settings.

Notes

The environmental sensors are built in to the balance casing. There fore, these values are

not in accordance with the environmental c ondition.

Refer to "

Press the SELECT key in the weighing

mode. The current time, date and sensor

values (temperature, humidity, barometric

pressure) are displayed for several seconds

in order. The balance returns to the

weighing mode automatically.

When pressing the SELECT key

while the current data is displayed,

the display proceeds to the next

data.

When pressing the CAL key

while the current data is displayed,

the balance returns to the weighing

mode.

Notes

When adjusting the built-in clock, ref er to "

When adding the ti me and date to t he output data, refer to “Time/Date output (

"

When adding temp erature data to the output data, refer to “Temperature output (

of "

32 BM series

5 °C to 40 °C

" for the balance operating conditions.

Time

5 seconds

Date

5 seconds

Environmental sensors

10 seconds

Weighing mode

".

".

".

)” of

)”

Page 35

6.7.

Repeatability Test

20. Specifications

BM-5, BM-5D

BM-20, BM-22

BM-252, BM-200, BM-300, BM-500

Press and hold

Release

In measurement

Cancel

or

Result

Counter

Example of BM-20

Weighing m ode

Weighing m ode

Repeatability is an index of variation in weighing values when the same mass is repeatedly

loaded and unloaded. St andard deviation is generally used for the indicator of repeatability.

The repeatability test measures t he i nt ern al ma ss 10 times a nd dis play s th e s t and ard devi ati on .

Use the repeatability test function to inspect the perform ance of the balance when changing the

environment or when moving the balance to a new l ocat io n.

Example: "Standard deviation = 0.2 mg" means that the results of repeated measurements of the

same mass fall wit hin th e range o f ±0.2 mg at a frequency of about 68%.

Notes

When the password function is used, the repeatability test function is available only when

logged in as an administrator ( AdmIN).

The repeatability test uses the internal mass. Therefore, the o btained standard de viation

may disagree with that of the repeatability of "

deviation as a reference.

Model Internal mas s

Approx. 5 g

Approx. 20 g

". Regard the standard

Approx. 190 g

1 Press and hold the RANGE key (for approx. 4 seconds)

until rep te5t is displayed , and the n rel ease

the key.

2 When rep te5t is displayed, the me asure ment

is automatically started, "r"e"p blinks and the

measuremen t c oun t ( 0 to 10) is di spl ay ed.

To cancel the current measurement,

press the CAL key.

Note Avoid vibration and breeze s f or

precise measurement during this test.

3 At the end of the measurement,

the stand ard dev iati on of th e

repeata bility is dis play ed.

(approx. 4 seconds)

St andard deviation

4 Press the CAL key or PRINT key

to return to the w eig hi ng mo de.

BM series 33

Page 36

7.

Response Adjustment

Indicator

Parameter

Response Stability

FAST

Fast response, Sensitive value

Slow response, Stable value

MID.

SLOW

7.1.

Automatic Response Adjustment

CH ng

CH e

7.2. Manual Response Adjustment

Press and hold

Result

Response indicator

This function stabilizes the weight value by reducing the influence on weighing that is caused

by drafts and/or vibration at the place where the balance is installed. The adjustment of the

function can be performed by analyzing the environment automatically or hand-operation.

The state of the function has three stages as follows :

Cond 0

Cond 1

Cond 2

This function automatically updates the response adjustment by analyzing the influence of

the environment using the internal mass.

1 Press and hold the MODE key (for approx. 2 seconds)

until RESPONSE is display ed, and then release th e key.

(approx. 2 seconds)

2 The balance automa tic a lly set s t he r es po nse ch ara ct erist ic .

Caution Do not allow vibration or drafts to affect the

balance during adjustment.

3 After automatic adjustment, the balance displays end ,

returns to the weighing mode and displays the updated

response i ndi cat or for a bout t hir ty se cond s.

Notes

If the auto mat ic r espo n se adj u stm ent fa ils , t he b al an ce

displays

as breeze and vibration, also c heck t he wei ghin g pan.

Then, perform adjustment again. Press the CAL key

to return to the weighing mo de.

If there is anything on the weighing pan, the balance

displays

Press t he CAL key to return to the weighing mode.

If the automatic respo nse adjust me nt is not helpful, try

"

. Check the ambi ent condi tions suc h

. Remove the substance fr om the pan.

".

Release

34 BM series

Page 37

7.2.

Manual Response Adjustment

Cond

ba5fnc

Display

Cond(Condition

FAST 0

MID. 1

SLOW

2

Cond

ba5fnc

10. Function Table

Press and hold

press again immediately

Select a parameter

Result

Release and wait

1 Pr ess and hold the MODE key (for approx. 2 seconds)

until RESPONSE is displayed, and then release the key.

Press the MODE key again imm edi atel y.

2 Select a setting for t he r es po nse a djus tmen t using the

MODE key. Either FAST , MID. or SLOW can be

selected.

3 The balance displays 1end1, returns to the weighing

mode and displays the updated response indicator for

about thir ty s ec on ds.

Notes

When the response adjustment is selected, the

"Condition (

Display (

changed accordingly as shown b elow.

)" parameter of "Environment,

)" in the function table will be

(approx. 2 seconds)

Release and

)

The response adjustment s etting can be c hanged

by the "Condition (

"Environment, Display (

table. F o r d etai ls , r ef er t o “

)" parameter of

)" in the function

”.

BM series 35

Page 38

8.

Calibration

8.1.

Calibration Group

Calibration (Sensitivity adjustment)

Calibration test(Sensitivity check)

info

10. Function Table

10.7. Clock and Calendar Function

info

data

12. Data Memory

Note on using an external weight

Model

Usable weight

Adjustabl e ra nge

BM-5

1 g 2 g 5 g*

BM-5D

1 g 2 g 5 g*

BM-20

1 g 2 g 5 g 10 g 20 g*

BM-22

1 g 2 g 5 g 10 g 20 g*

BM-252

10 g 20 g 50 g 100 g 200 g*

-15.00 mg to +15.99 mg

BM-200

50 g 100 g 200 g*

BM-300

50 g 100 g 200 g* 300 g

BM-500

50 g 100 g 200 g* 300 g 500 g

Since the balance's resolution is high, weighing values may change due to gravity and daily

environment al ch anges. It is n ecess ary to p erfor m calibr ation ( sensit ivit y adjus tment) wi th the w eight

in order to k eep the weighi ng v alues from cha nging even i f grav ity or the env iron ment cha nges.

Calibrate the balance if it is installed for the first time or relocated, or when the weighing values

change significantly in daily inspection.

Calibration means to adjust the weighing value of the balance using the reference weight or

internal mass. Calibration test means to weigh with the reference weight and compare how much

the result deviates from the reference value. (Calibration test does not perform adjustment.)

Automatic self calibration ------------------------- Automatically adjusts the balance using the internal mass

depending on the temperature change of the operating

environment.

Calibration using the internal mass ----------- Using the internal mass, adjusts the balance with a single touch.

Calibration using an external weight ---------- Using an external weight, adjusts the balance.

Calibration test using the internal mass ------ Checks the accuracy of weighing using the internal mass and

outputs the result.

*No adjustment is made.

Calibration test using an exter nal weight ---- Checks the accuracy of weighing using an external weight

(target weight) and output s the result.

*No adjustment is made.

Notes

Do not allow vibration or draft s to affect the balan ce during calibrat ion.

When using the data output for GLP / GMP using the RS-232C interface, set "GLP output (

the function table. Ref er to "

If the time and date are incorrect, refer to "

Calibration test is av ailable on ly when "GLP output (

The calibration and calibration test data can be stored in memory. When using memory,

set "Data me mory (

)" of the function table. Ref er to "

". The time and date can be added to the GLP report.

" and adju st them .

)" is set to "1" , "2" or "3".

" for details.

)" of

The accuracy of an ex ter nal weight can in fluenc e the ac cur acy o f weighi ng.

Select a weig ht for cali brat ion an d cali brati o n t est fro m t h e fol l owi ng t a ble.

Bold ty pe*: Factory set ti ng s. Th e w ei ght v al ue can be a djus te d w ithi n the r ange a bov e.

36 BM series

-3.000 mg to +3. 099 mg

-30.0 mg to +30.9 mg

Page 39

About the internal mass

8.7. Correcting the Internal Mass Value

Display

8.2.

Automatic Self Calibration

Automatic self calibration due to changes in temperature