Page 1

PRODUCT

SUPPORT

MANUAL

Y1-03-0146

Rev. D

MS-2000 (M)

Product No. 3990

Distress Marker Light

ACR Electronics, Inc.

5757 Ravenswood Road

Fort Lauderdale, Fl 33312

+1(954) 981-3333 • Fax +1 (954) 983-5087

www.acrelectronics.com

Email: Info@acrelectronics.com

A Chelton Group

Company

Page 2

TABLE OF CONTENTS

1. GENERAL............................................................................................................................. 3

2. PURPOSE.............................................................................................................................. 3

3. GENERAL CHARACTERISTICS..................................................................................... 3

4. OPERATING INSTRUCTIONS......................................................................................... 3

5. PERFORMANCE TESTING..............................................................................................4

6. TEST EQUIPMENT AND TOOLS....................................................................................6

7. THEORY OF OPERATION ............................................................................................... 6

8. MAINTENANCE REQUIREMENT ..................................................................................6

9. PREVENTIVE MAINTENANCE CHECKS..................................................................... 6

10. ALIGNMENT ....................................................................................................................... 7

11. PERIODIC INSPECTION REQUIREMENTS................................................................. 7

12. REPLACEMENT PARTS LIST .........................................................................................7

13. PARTS REPLACEMENT PROCEDURE......................................................................... 7

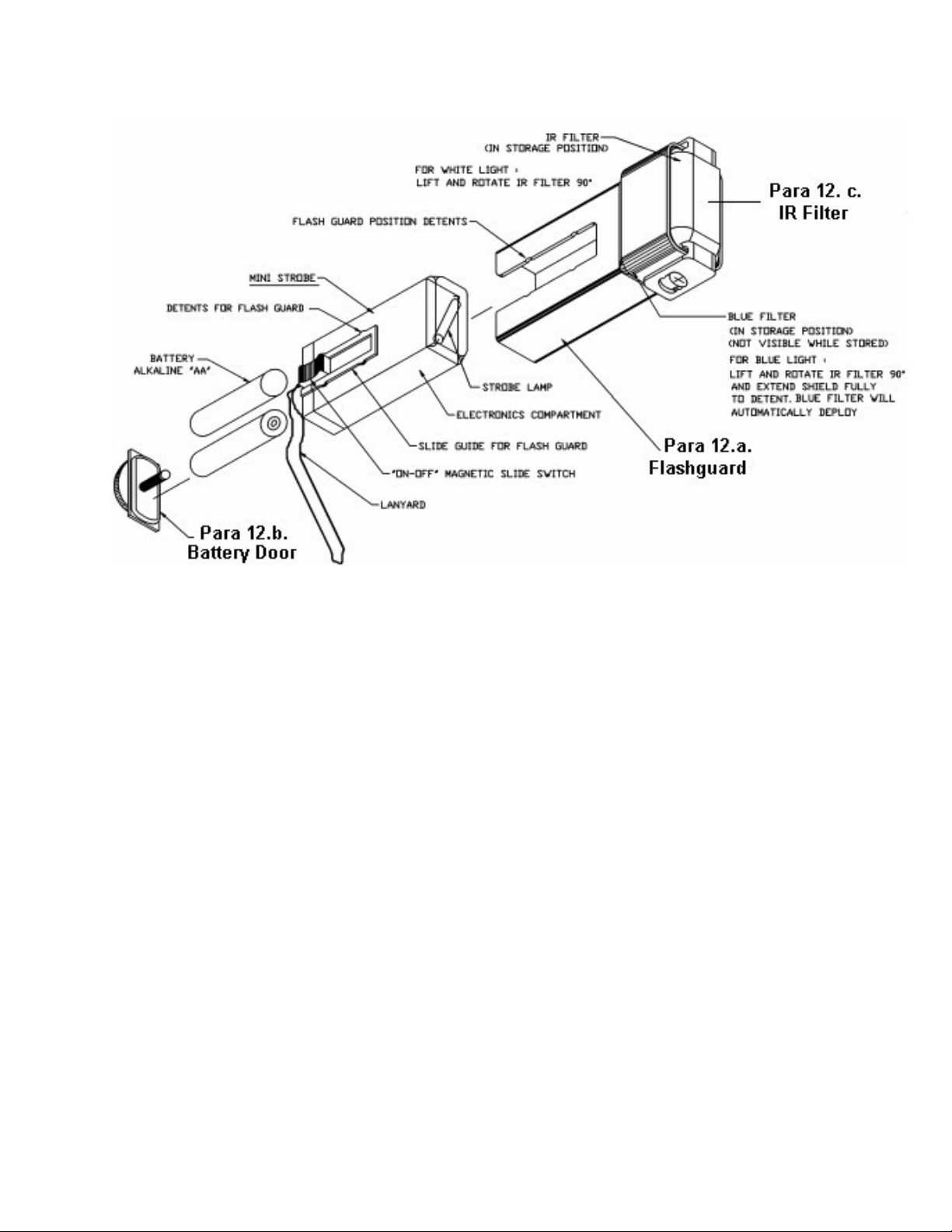

FIGURE 1.......................................................................................................................................7

FIGURE 2.......................................................................................................................................8

FIGURE 3.......................................................................................................................................9

FIGURE 4.....................................................................................................................................10

2

Y1-03-0146 Rev. D

Page 3

1. General

This publication provides maintenance and operating instructions for the MS-2000(M)

Distress Marker Light.

2. Purpose

The light is designed and intended to provide aircrew and other personnel with a highintensity visual distress marker signal for use in the event of unscheduled abandonment

of aircraft in isolated regions and other emergency and/or special operational mission

situations.

3. General Characteristics

a. The MS-2000(M) Distress Marker Light is a lightweight, compact, battery

operated, portable unit that is designed to be used as a multi-functional light

during emergency and/or clandestine special mission situations. The light is

designed to attract attention; to assist in location; and to facilitate personnel

rescue operations in both overt and covert operations.

b. The light system consists of a main body case containing the electronics, lamp,

batteries and the flashguard (FG) shield containing one Infra Red (IR) and one

blue filter. The flashguard also has raised battery polarity indicators to assist in

non-visual battery replacement. The case is fabricated of high impact, cut

resistant thermoplastic material and designed to insure watertight integrity of the

main body case. The light utilizes a xenon strobe lamp, is powered by two AA

batteries and is actuated by a magnetic reed switch. The light is designed for onehanded operation and may be operated by either hand or attached to any object.

c. The flashguard shield contains both an IR and Blue filter which are used as

safeguards in hostile territories so as to prevent possible signaling confusion (i.e.,

small arms ground fire) between the signaler and observer. The IR filter provides

omni-directional transmission of IR wavelengths. The Blue filter is used for lineof-sight (directional) light transmissions. The IR filter is designed for use during

clandestine operations.

d. Electrical power for the MS-2000(M) is provided by two 1.5V, AA, alkaline

batteries located in the base of the main body case. A retained battery door is

provided with an "O" ring seal to insure its watertight integrity. Additionally,

electrical power is controlled by a magnetic reed switch located on the side of the

main body case. This switch also insures waterproof integrity of the main body

case.

4. Operating Instructions

a. Turn "ON". Slide switch up until it stops. The strobe should begin flashing

within a few seconds.

3

Y1-03-0146 Rev. D

Page 4

b. Turn "OFF". Slide switch down until it stops. The unit will stop operating.

c. White Light. With the flashguard shield in the retracted (stored) position, slightly

raise the IR filter and rotate it either left/right 90°, push filter in to lock into place.

(Figure 2)

d. IR Light. With the flashguard shield in the retracted (stored) position, insure that

the IR filter is resting on the top (vertical) end of the light over the clear lens, then

push filter down to lock into place. (Figure 3)

e. Blue Light. With the flashguard shield in the retracted (stored) position, slightly

raise the IR filter and rotate it either left/right 90°. Then snap it in toward the side

of the light to lock it into position. While 'Holding the main body case with either

hand, grasp the flashguard shield with the other hand and pull it up until it stops

or a slight locking sound is detected, then release. This is an indication that the

Blue filter has been released and fully engaged to its proper operating position.

(Figure 4)

5. Performance Testing

a. Light Leakage Test

With the IR filter in its operation position (Figure 3), turn the switch ON and

observe that no light is transmitted through the sides of the case or the flashguard

shield. Turn switch OFF. No light leakage is allowed in the IR mode. If

necessary, replace the flashguard shield assembly and repeat the test. If a new

flashguard shield fails to remedy the problem, the light is to be condemned and

discarded in accordance with local procedures.

b. Flash Rate Test.

(1) Initial. A ten minute MANUAL flash rate test is a one-time requirement for

all new MS-2000(M) lights received from supply stock. This test is required for

initial acceptance of the light and is conducted to insure that the light is capable of

sustained operations. Select the White Light function (Figure 2), turn the switch

to ON and observe that the strobe lamp flashes. Allow the light to flash for nine

(9) minutes, and then manually count the flash rate of the strobe during the final

one minute of the test. This rate should be 50 ± 10 flashes. It is not necessary to

directly observe the light flashes during this evaluation. This inspection should

be performed in a dark room or enclosure. If any light fails to meet the 50 ± 10

flash rate requirements, check the batteries and, if necessary, replace both

batteries and repeat the test. Additionally, the battery contacts in the battery well

should be checked and, if necessary, cleaned with a small brush. Hold vertical

while using brush so that any debris falls out of the light. Repeat the test again.

If battery replacements or cleaning contacts fail to correct the problem, discard

the light in accordance with local procedures.

(2) Periodic. Normally this test is accomplished in conjunction with other life

support survival kit / vest test requirements and/or as required by specific

MAJCOM directives. This test may be accomplished MANUALLY or

4

Y1-03-0146 Rev. D

Page 5

AUTOMATICALLY by using the TS-23/A Strobe Light Tester. If the test is to

be conducted MANUALLY, follow the test procedures as outlined in paragraph

(1) above, except limit the test duration to two (2) minutes. Again, a flash rate of

50 ± 10 flashes per minute is the acceptable test rate. If using the TS23/A Strobe

Light Tester for this inspection, the light can be tested in the TS-23/A with the IR

filter in place, by placing the lens/filter over the inspection window on the TS-23

face label and then pressing the trap door down to turn the TS-23 "ON", or by

removing the flashguard shield and inserting it into the tester. This is

accomplished by separating the main body of the light from its flashguard shield.

This separation is performed by holding the main body of the light with one hand

while grasping the flashguard shield with the other and pulling in opposite

directions. After separation, insert the top of the light into the trap door on the top

of the TS-23/A, insuring that the xenon lamp is fully inserted into the tester. Turn

the light switch ON and note the numerical reading recorded on the digital

readout of the tester. An acceptable reading between 100-150 is required and

equates to a flash rate of 50 ± 10 flashes per minute. If a reading of less than 100

is noted, replace both batteries and, if necessary, clean the battery contacts in the

light, then repeat the test. Should any light continue to fail this test, discard the

light in accordance with local procedures. Upon completion of this test, the light

is to be reassembled by inserting the top of the light (lamp) into the bottom of the

flashguard and pushing upward until it stops.

Note: Standard ambient temperature for performing flash rate test is 70°

Fahrenheit. Lower temperature may perhaps result in somewhat lower flash

rates.

c. BA-3058/U battery ("AA" Alkaline) or equivalent. Currently only a commercial

test fixture exists to test the BA-3058 Radio Shack part number 910-2135 Type

22-096 or equivalent. Therefore, batteries surpassing their

lifecycle/manufacturing duration's or batteries that are found to be defective will

be discarded in accordance with local disposition instructions/guidelines.

5

Y1-03-0146 Rev. D

Page 6

6. Test Equipment and Tools

No special test equipment other than the TS-23/A Strobe Light Tester is required to test

the MS-2000(M) strobe light. If this tester is not available or functionally inoperative,

flash rate testing can be accomplished MANUALLY in accordance with procedures

outlined in paragraph 5.b.(1) except limit the test to two (2) minutes, counting the rate in

the last minute. Test equipment for the BA-3058/U battery is commercially available.

7. Theory of Operation

All electrical circuitry comprising the MS-2000(M) strobe light is enclosed within its

main body case assembly. Briefly, these circuits operate to step up the battery voltage to

a level sufficient to fire the xenon flash tube. This stepped-up voltage is so timed that the

flash tube will fire between 40-60 flashes per minute.

8. Maintenance Requirement

Since all electronic circuitry of the MS-2000(M) strobe is enclosed within its main body

case assembly and cannot be disassembled without destroying its integrity, preventive

maintenance requirements are limited to initial and periodic flash rate testing and visual

inspections. Battery preventive maintenance visual checks will be performed during

initial and periodic inspections of the light.

9. Preventive Maintenance Checks

DO NOT PERFORM PREVENTIVE MAINTENANCE IN FLAMMABLE ATMOSPHERE

OR NEAR OPEN FLAME.

a. MS-2000(M)/ Distress Marker Light

(1) Check that the xenon flash tube lens is not cracked or discolored.

(2) Check both the main body and flashguard shield cases for cracks or

excessive abrasions.

(3) Check for full and free operations of both the IR and Blue light filters.

(4) Check that the IR and Blue filters are not cracked and discolored.

(5) Check that the light switch moves up and down freely.

(6) Check that the battery wells are free of dust and are clean.

b. BA-3058/U Battery (or equivalent) 1.5V, AA, Alkaline.

(1) Check the battery case for cracks, swelling or leakage. Replace as

necessary.

(2) Do not mix different battery brands.

(3) Do not mix old and new batteries.

6

Y1-03-0146 Rev. D

Page 7

(4) Replace batteries if device is used on a mission or annually.

10. Alignment

No alignment procedures or special inspection requirements must be performed on the

MS-2000(M).

11. Periodic Inspection Requirements

Normally the MS-2000(M) and associated batteries will be inspected concurrently with

other equipment installed in aircraft/ejection seat survival kits, aircrew survival vest or

other special requirements. Such inspection intervals will be as specified by respective

MAJCOM/agency life support directives. Periodic inspections will include both flash

rate and preventative maintenance checks.

See paragraphs 5 and 9 for details. Record inspection dates per MAJCOM/agency

procedures and directives.

12. Replacement Parts List

a. Flashguard shield assembly A3-06-1920

b. Battery door assembly A3-06-1921-3

c. IR Filter A1-18-1322

Item a. comes complete with blue filter, IR filter and labels.

Item b. comes complete with retention cable, battery cover screw, door and o-ring.

13. Parts Replacement Procedure

To replace flashguard, remove the old flashguard by grasping the flashguard with one

hand and the light body and lanyard in the other. Pull them sharply away from each

other. Then slide the new flashguard in place until it clicks into the locked position.

To replace the battery door, just unscrew the wire cable from the insert in the battery

compartment. To install new battery door, screw the cable end through the insert in the

battery compartment. The cable is held in place after the threaded cable-end goes all the

way through the insert.

To replace the IR filter, remove the old filter by locking it in the IR position, then slide a

7 level screwdriver between the flashguard case and the IR filter attachment leg twist the

screwdriver or pry upward and the leg will pop off of the retainer. Put the replacement

filter into place then press with thumb to seat legs over retainers.

7

Y1-03-0146 Rev. D

Page 8

FIGURE 1

8

Y1-03-0146 Rev. D

Page 9

FIGURE 2

9

Y1-03-0146 Rev. D

Page 10

FIGURE 3

10

Y1-03-0146 Rev. D

Page 11

FIGURE 4

11

Y1-03-0146 Rev. D

Loading...

Loading...