Page 1

RESTRICTIONS ON USE OF MATERIALS

:

Projector Service Manual

Model : X1130P, X1130PA, X1230PK,X1230P,

X1230PA, X1237

Version: Rev3

First Edition (Jul. 2009)

1

Page 2

Index

REVISION LIST .................................................................................................................... 3

CHAPTER 1 SYSTEM SPECIFICATION ......................................................................... 4

Product Specification.................................................................................................................... 4

Electrical Specification............................................................................................. 11

Power Supply Specification..................................................................................... 15

System Block Diagram ............................................................................................................... 16

Product Overview........................................................................................................................ 17

CHAPTER 2 SYSTEM UTILITIES.................................................................................. 21

Firmware Upgrade SOP............................................................................................................. 21

Method to enter factory menu ................................................................................................... 29

EDID Upgrade SOP.................................................................................................................... 30

Serial Number Upgrade SOP.................................................................................................... 33

How to Change Model name..................................................................................................... 35

CHAPTER 3 SYSTEM DISASSEMBLING AND REPLACEMENT................................36

Main Unit Disassembling............................................................................................................ 36

Module Assembly Key Point - Optical Engine ........................................................................ 41

Module Assembly Key Point – Mechanical ............................................................................. 54

CHAPTER 4 TROUBLESHOOTING.............................................................................. 71

System Analysis .......................................................................................................................... 71

Optical Problems Checking Items ............................................................................................ 72

Power Supply Problems Checking Flow ................................................................................. 74

LED Messages Definition........................................................................................................... 75

Error Count Messages Definition.............................................................................................. 76

RS232 Connection...................................................................................................................... 77

Adjustment / Alignment Procedure........................................................................................... 79

CHAPTER 5 FRU LIST .................................................................................................. 84

Exploded Diagram....................................................................................................................... 84

Module 1 – Total Exploded View............................................................................................... 84

Module 2 – ASSY UPPER CASE ............................................................................................. 86

Module 3 – ASSY LOWER CASE ............................................................................................ 87

Module 4 – ASSY FRONT CASE ............................................................................................. 88

FRU List........................................................................................................................................ 89

APPENDIX A - CODE LIST: IR / RS232 / DDC DATA........................................................ 94

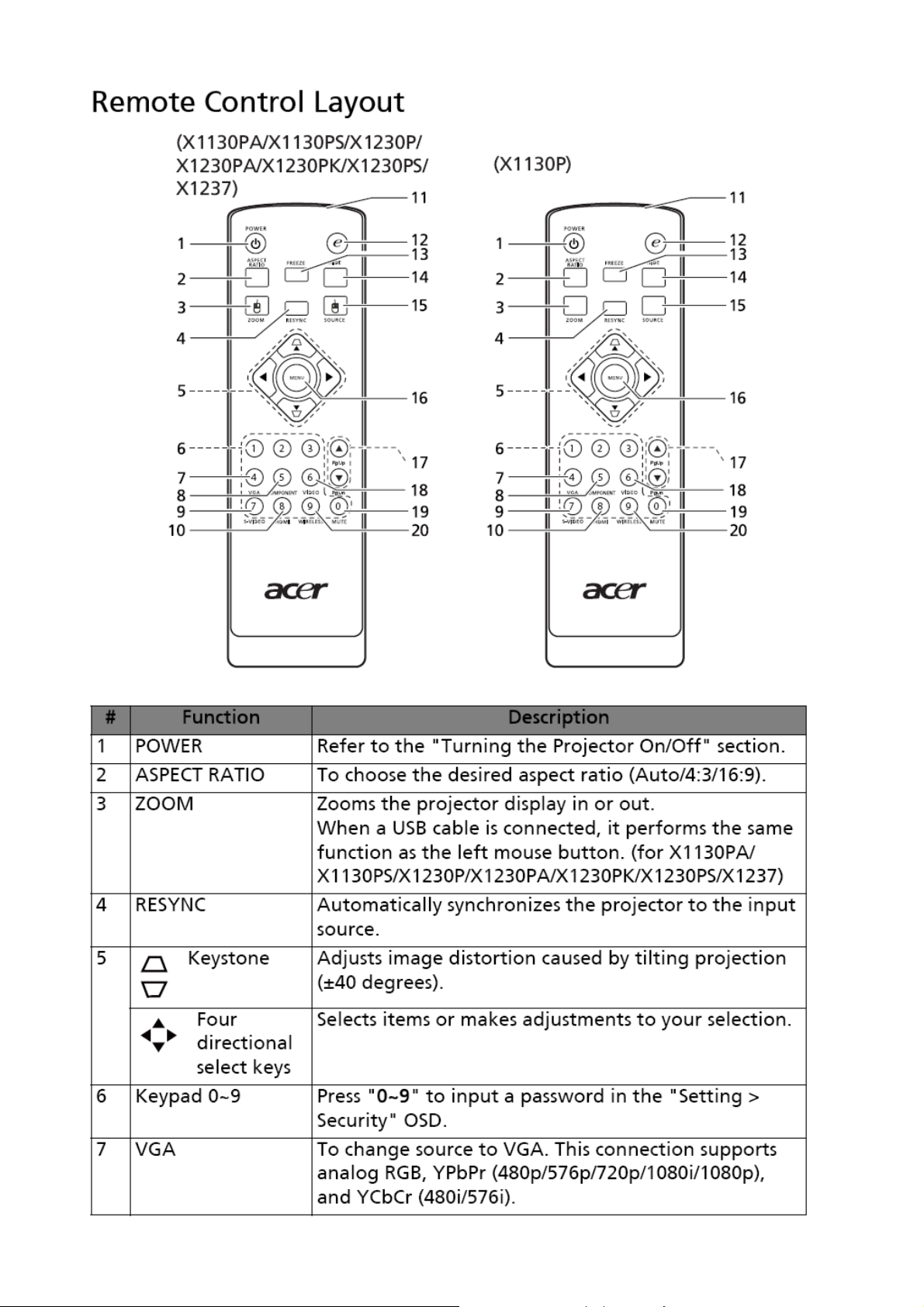

1. Remote Control Code: ........................................................................................................... 94

2. RS-232 Command Code ....................................................................................................... 96

3. DDC Data................................................................................................................................. 98

2

Page 3

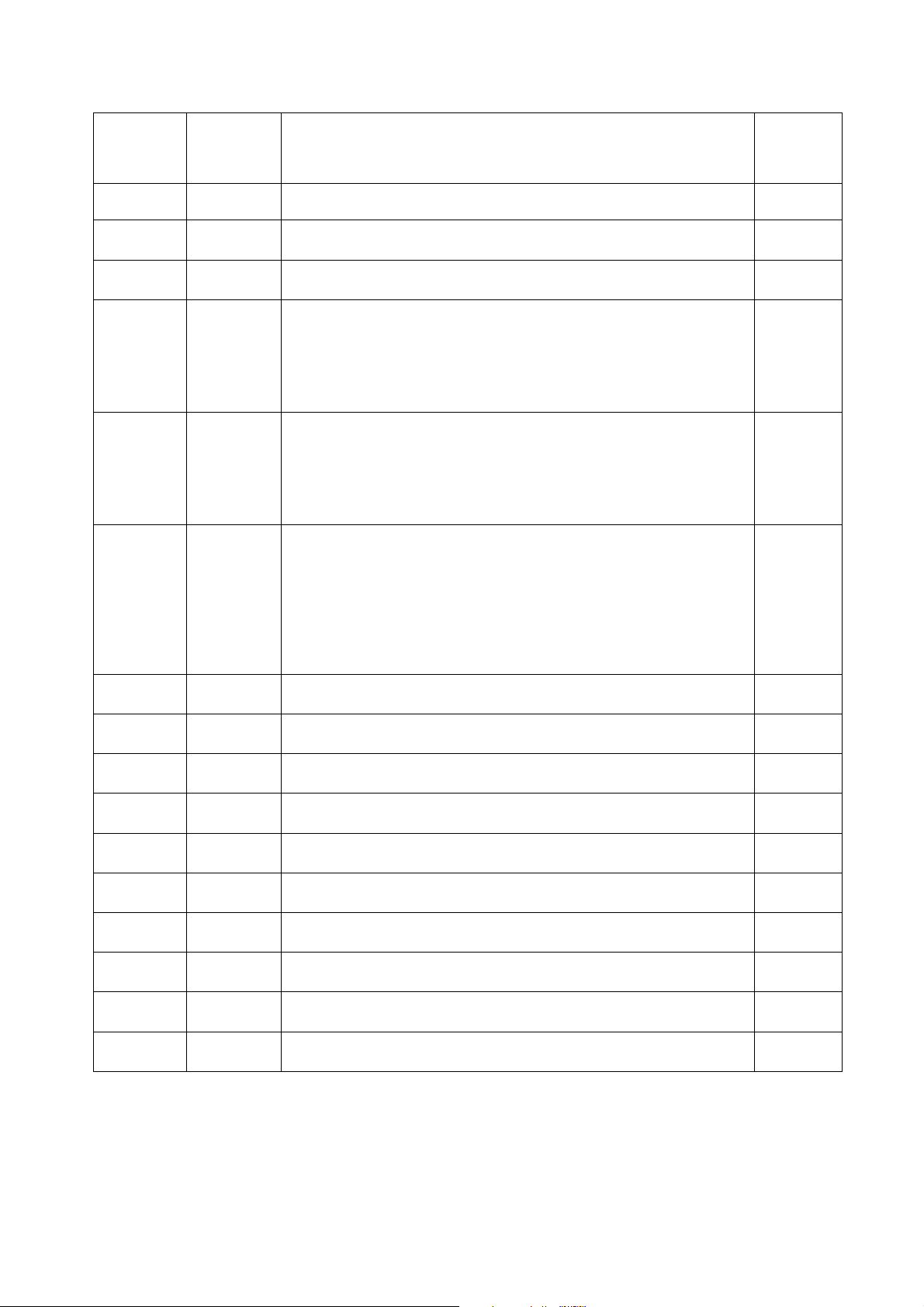

Revision List

Version

Rev0 2009.07.16 First Release

Rev0 2009.07.20 Modify FRU List—service lamp P/N

Rev0 2009.07.27

Rev1 2009.07.29

Rev2 2009.09.11

Rev3 2009.09.23 Add X1230P, X1230PA, X1237 different part

Release

Date

Revision History

(P.5) Modify SPEC : Projection Offset = 120% ±5%

Add X1230PK different part :

(1) Ch1- SPEC,

(2) Ch3- Disassembly process, Module Assembly Key Point

(3) Ch4- alignment procedure

(4) Ch5-FRU List

(5) Appd. A- DDC table

Add X1130PA different part :

(1) Ch1- SPEC,

(2) Ch3- Disassembly process, Module Assembly Key Point

(3) Ch4- alignment procedure

(4) Ch5-FRU List

(5) Appd. A- DDC table

(1) Ch1-SPEC

(2) Ch2-“How Change Model Name” for X1230P/X1230PA/X1237

(3) Ch3- Disassembly process

(4) Ch4-Adjustment / Alignment Procedure

(5) Ch5-FRU List

(6) Appendix A-Remote Control Code

(7) Appd. A- DDC table

Vendor

Model

Name

3

Page 4

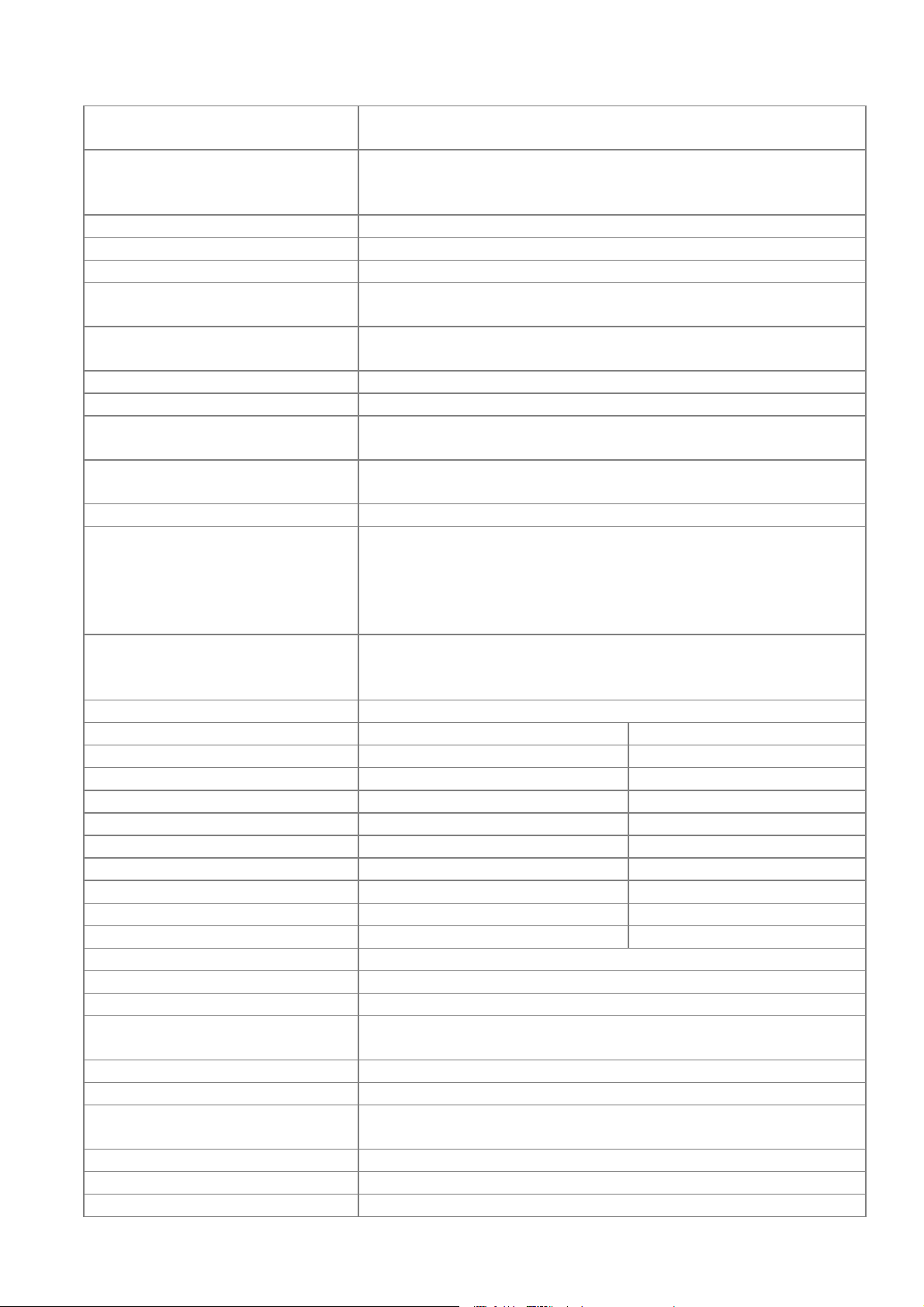

Chapter 1 System Specification

Product Specification

1.0 Optical Performance

2.0 Image Quality

3.0 Mechanical Specification

4.0 Packaging

5.0 Thermal Specification

6.0 Environmental

7.0 Regulatory

8.0 Reliability

9.0 Power Requirements

10.0 Panel Specification

11.0 Compatibility

12.0 Image Interface

13.0 Control Interface

14.0 User Interface

4

Page 5

1.0 Optical Performance

1.1 ANSI Brightness

1.2 Brightness Uniformity

1.2.1 ANSI Uniformity Minimum 55%

1.2.2 JBMA Uniformity Minimum 75%

1.2.3 Upper-Down

unbalance

1.2.4 Left-Right

unbalance

1.3 Contrast Ratio

1.3.1 ANSI Contrast Minimum 150:1

1.3.2 FOFO Contrast

without APM

1.3.3 FOFO Contrast with

APM

1.4 Light Leakage

1.4.1 Light Leakage in

Active Area

1.4.2 Light Leakage out of

Active Area

(Except DMD Defect)

1.5 Color

X Y

1.5.1 White 0.314±0.04 0.377±0.04

1.5.2 Red 0.647±0.04 0.341±0.04

1.5.3 Green 0.344±0.04 0.587±0.04

1.5.4 Blue 0.139±0.03 0.090±0.03

1.6 Color Uniformity X Y

1.6.1 White 0.040 0.040

1.6.2 Red 0.040 0.040

1.6.3 Green 0.040 0.040

1.6.4 Blue 0.040 0.040

1.7 Color Gamut Typ 60% compare NTSC

2.0 Image Quality

2.1 Throw Ratio 52.5”±3% Diagonal at 2m, Wide

2.2 Zoom Ratio (tolerance

applied)

2.3 Distortion

2.3.1 Keystone Distortion <1.0%

2.3.2 Vertical TV

Distortion

2.4 Projection Offset 120% ±5%

2.5 Focus Range

2.5.1 Visible Range 1~8 m

Tested under 60” (diagonal) image size with Wide

projection lens position unless other specified.

X1130P/X1130PA/X1230P : Minimum 2000 Lumens

X1230PK/X1230PA : Minimum 1840 Lumens

X1237 Minimum 2400 Lumens

0.5~2

0.6~1.67

X1130P/X1130PA/ X1230P/ X1237: Minimum 1600:1

X1230PK/X1230PA : Minimum 1100:1

X1130P/X1130PA/ X1230P/ X1237: Minimum 2100:1

X1230PK/X1230PA : Minimum 1200:1

<0.5 lux compared to center point within 60” (Diagonal at

2.3m, Wide) image size. Note: This light leakage in Active

area is only described as the spot light with obvious shape.

It is not included the uniformity difference of the projector for

black pattern.

<0.5 lux with 60”~80“(Diagonal at 2.3m, Wide) image size

1.1±2%

<1.0%

5

Page 6

2.5.2 Clearly Focus

Range

1.5~6 m(Spec. defined as item 2.6)

2.6 Focus

(1) If pattern can be uniformly focused (not worse than Limit

2.6.1 区 Pattern

Sample), then pass!

(2) If it’s difficult to judge, then check 2.6.2

X1130P :

Defocus: R<=3.0; G<=3.0; B<=3.0 pixel

Flare: R<=3.5; G<=3.5; B<=3.5 pixel

2.6.2 Defocus and Flare

Slight flare is not counted as flare.

X1130PA/X1230PK/X1230P/X1237/X1230PA:

Defocus: R<=3.5; G<=3.0; B<=3.0 pixel

Flare: R<=4.0; G<=4.0; B<=4.0 pixel

Slight flare is not counted as flare.

2.6.3 Focus unbalance

2.7 Lateral Color

Adjust focus from near to far until one corner clear,

difference less than 50 cm

Center of

49”diagonal area

All other area

R-G <2/3 <1

G-B <2/3 <1

R-B <1 <1

2.8 Image Quality

2.8.1 DMD Image Quality

2.8.2 Image Imperfection

2.9 Lamp Type Philips UHP 185W-160W 0.9 E20.9 with VIDI

3.0 Mechanical Specification

3.1 Dimensions 264 x 225 x 95 mm (L x W x H)

3.2 Weight <2350g

3.3 Security Slot Kensington compatible slot 150N break away force

3.5 Lens Cover Lens Cover

3.6 Feet

Fast adjustable foot in front, Adjustable foot and Fixed foot

in rear. foot Tilt:0-6∘,right/left: +2.2 /∘ -0.5∘

4.0 Packaging Detail refer to following Packing section

4.1 Outside Dimensions 360 x 180 x 297mm (L x W x H)

4.2 Weight <4100g

4.3 Transportation

40 feet container 2688 sets, 20 feet container 1344 sets

By air 48 sets

5.0 Thermal Specification Mechanical component temperature at ambience 0~35℃

5.1 Surface held or

touched for short periods

5.2 Surface which may be

touched

5.3 Exhaust Air

Metal < 65°C; Plastic<85°C

Metal Plastic

<65°C <85°C

<95°C

6.0 Environmental

6.1 Temperature

Operating

0~35°C, without condensation

Storage -30~65°C, without condensation

6.2 Humidity

Operating 10~90%RH, without condensation

Storage 10~90%RH, without condensation

6

Page 7

X1130P/X1130PA /X1230P/X1237:

Normal mode: 34dBA @ 23±2°C, CW x2 speed

Eco mode: 29dBA @ 23±2°C, CW x2 speed

Normal mode: 36dBA @ 23±2°C, CW x3 speed

Eco mode: 31dBA @ 23±2°C, CW x3 speed

Typical

6.3 Audible Noise Level

Maximum

X1230PK/X1230PA :

Normal mode: 36dBA @ 23±2°C, CW x2 speed

Eco mode: 31dBA @ 23±2°C, CW x2 speed

Normal mode: 38dBA @ 23±2°C, CW x3 speed

Eco mode: 33dBA @ 23±2°C, CW x3 speed

X1130P/X1130PA/X1230P/X1237 :

Normal mode: 36dBA @ 23±2°C, CW x2 speed

Eco mode: 31dBA @ 23±2°C, CW x2 speed

Normal mode: 38dBA @ 23±2°C, CW x3 speed

Eco mode: 33dBA @ 23±2°C, CW x3 speed

X1230PK/X1230PA :

Normal mode: 38dBA @ 23±2°C, CW x2 speed

Eco mode: 33dBA @ 23±2°C, CW x2 speed

Normal mode: 40dBA @ 23±2°C, CW x3 speed

Eco mode: 35dBA @ 23±2°C, CW x3 speed

Operating:

1. 12,000 feet @ 25°C (3.5 hours)

6.4 Altitude

2. Altitude Ramp rate: <= 3500 feet per minute (1 hour)

Non-operating:

40,000 feet @ -30 °C (1 hour)

7.0 Regulatory

Safety

EMC CE, FCC, VCCI

CB, GS, cTUVus, PSE, CCC

ESD

8.0 Reliability

8.1 MTBF 25000 hours except Lamp

Normal : 3000 hours

8.2 Lamp Lifetime

Eco: 4000 hours

(50% of Projector will have 50% initial minimum brightness)

9.0 Power Requirements Adhere to “Power Supply Specification” section

9.1 Power Supply (Normal) VAC 100 – 240 (50/60Hz),

9.2 Power consumption

Typical 280W Max.

Standby 1W Max.

9.3 Power Connector IEC-06

10.0 Panel Specification

10.1 Type

X1130P/

X1230PK/X1230PA : 0.55” XGA 2xLVDS Series 450 Super

value DMD

X1130PA

: 0.55” SVGA 2xLVDS Series 450 DMD

X1230P/X1237:0.55” XGA 2xLVDS Series 450 DMD

10.2 Pixels

X1130P/X1130PA : H: 800 X V: 600

X1230PK/ X1230P / X1230PA / X1237: H: 1024 X V: 768

10.3 Color Depth 30 Bits (1.07 Billion Colors)

11.0 Compatibility Adhere to “Electrical Specification” section

11.1 PC

PC Compatible 640X480 1024X768, compressed

1600X1200; Composite-Sync; Sync-on-Green

7

Page 8

11.2 Video

11.3 YpbPr

NTSC/ NTSC4.43/ PAL (Including PAL-M, PAL-N)/ SECAM/

PAL60/

NTSC (480i)/ 480p/ PAL (576i)/ 576p,

HDTV (720p/1080i/1080p)

11.4 DDC EDID 1.3

12.0 Image Interface Adhere to “Electrical Specification” section

X1130P/X1230PK:

15 pin D-Sub (Female) x 1 (Reserved 2nd VGA IN)

G(Y): Video amplitude 0.7/1.0 Vp-p : Impedance 75Ω

RB(CbCr): Video amplitude 0.7 Vp-p : Impedance 75Ω

HD/VD/CS: TTL Level

12.1 Analog RGB Input

X1130PA/ X1230P/ X1237 /X1230PA:

15 pin D-Sub (Female) x 2

G(Y): Video amplitude 0.7/1.0 Vp-p : Impedance 75Ω

RB(CbCr): Video amplitude 0.7 Vp-p : Impedance 75Ω

HD/VD/CS: TTL Level

12.2 Video Input

RCA jack (Yellow)

Video amplitude 1.0 V

: Impedance 75Ω

p-p

4 pin Mini-Din (Female)

12.3 S-Video Input

Y: Luminance amplitude 1.0 V

C: Chroma amplitude 0.286 V

: Impedance 75Ω

p-p

: Impedance 75Ω

p-p

12.4 YPbPr Input 15 pin D-Sub (Female) x 1

Y: Luminance amplitude 1.0 V

PbPr/CbCr: Chroma amplitude 0.7 V

: Impedance 75Ω

p-p

: Impedance 75Ω

p-p

12.5 Analog RGB Output X1130P : None

X1130PA/X1230PK/X1230P/ X1237/ X1230PA :

15 pin D-Sub (Female) x 1 (Only support D-sub 1)

G(Y): Video amplitude 0.7/1.0 Vp-p : Impedance 75Ω

RB(CbCr): Video amplitude 0.7 Vp-p : Impedance 75Ω

HD/VD/CS: TTL Level

13.0 Control Interface

13.1 IR Receiver

13.2 Serial Connector

13.3 USB Connector

IR Receiver x 2 (Front/Top)

Angle: ±0° Distance 0~10m ; ±40° Distance 0~8m

RS232 Mini DIN 3pin,

command table adhere to “Electrical Specification” section

X1130P : None

X1130PA/ X1230PK/ X1230P/ X1237/ X1230PA: Mini USB

TYPE B Terminal for page up/down

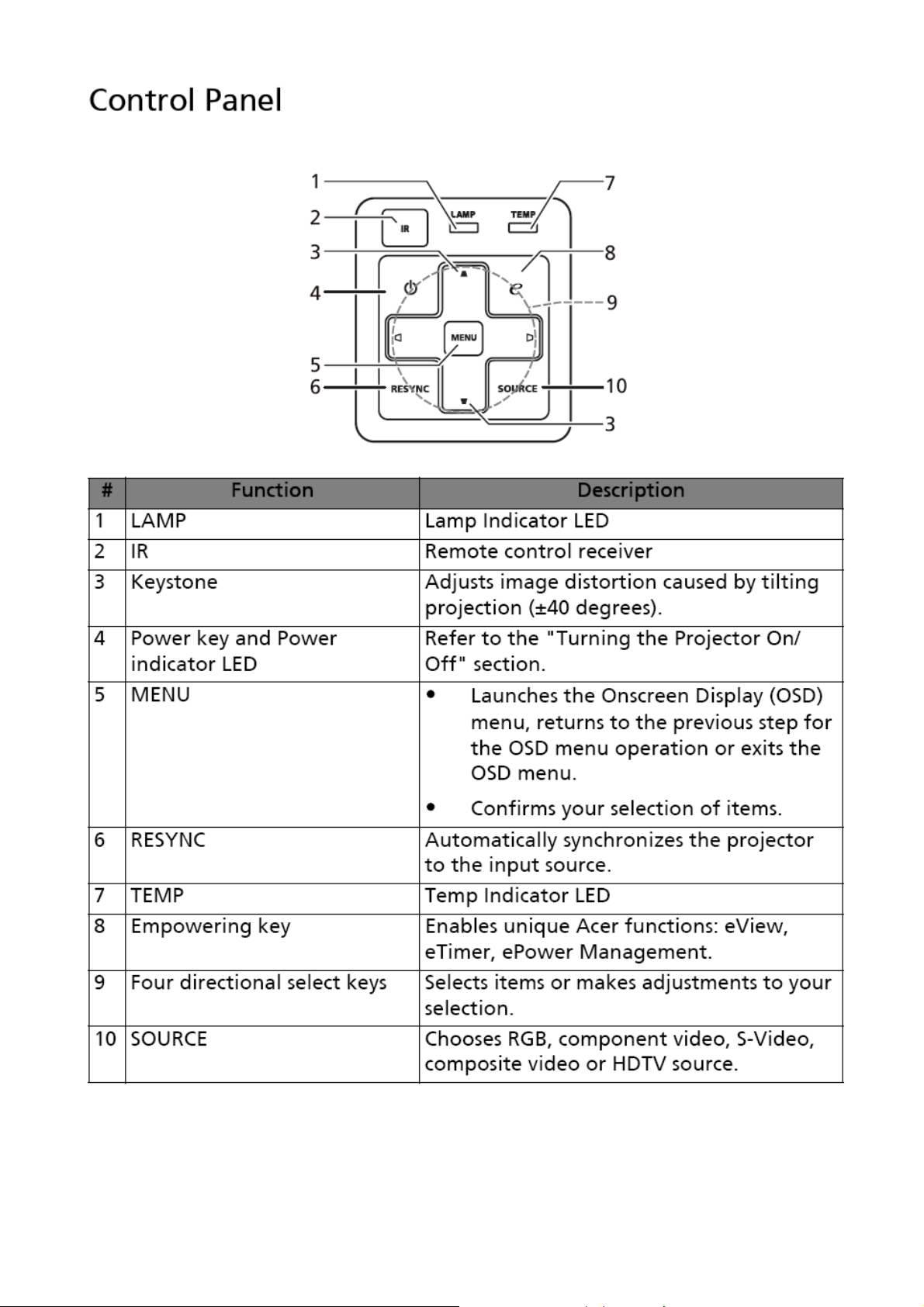

14.0 User Interface Adhere to “Electrical Specification” section

9 Keys:

14.1 Operator Keypad

Power ; Source ; Resync ; e ; Menu ; Left ; Right ;

Up(Keystone-) ; Down(Keystone+)

14.2 Indicators

14.3 Electric Keystone

14.4 Auto Ceiling mount

detection

3 LEDs:

Power On/Off Status; Lamp Status; Temperature Status

Manual vertical keystone and adjustable range ±40°

X1130P/X1130PA : None

X1230PK/

X1230P/X1237/ X1230PA: Projector will

auto-detect and project by aligned screen like

auto-keystone effect no matter which projection method

8

Page 9

(Front, Rear).

15.0 Audio X1130P: None

X1130PA / X1230PK/ X1230P/ X1237/ X1230PA: see below

SPEC

15.1 PC Audio Input X1130PA / X1230PK/ X1230P/ X1237/ X1230PA :

Φ3.5mm stereo mini jack

500mVrms 10 KΩ or more

15.2 Speaker

16.0 Lamp hour

X1130PA /X1230PK / X1230P/ X1237/ X1230PA:

Speaker 8Ω 2W X 1, Amplifier 1W X1

Lamp hour = [Hour used in Normal Mode] + 3/4 *[Hour used

in Eco. Mode]

17.0 Closed Caption (CC)

17.1 CC version CC1/CC2/CC3/CC4

(Running change to phase-in X1130P/X1130PA /X1230PK /

X1230P/ X1237/ X1230PA MP stage)

18.0 Instant On

After turn off projector, there is 120 seconds called “Instant

On stage”. At this stage, user can turn on the projector. Aftet

this stage, projector will cooling for 20 seconds, and all

keypads are not allowed to operate.

(Running change to phase-in X1130P/X1130PA /X1230PK /

19.0 3D Projection

X1230P/ X1237/ X1230PA MP stage)

See below detail description.

3D Projection :

This function is only for 3D contents and must wear 3D glasses.

TI DDP DDP2430 TI DDP DDP2431

• Does not support FRC (Frame Rate Conversion)

• Can not support HQFS 60Hz 3D source from

DVD which need to go thru FRC

• Can only support 120Hz 3D source from PC

(VGA/DVI/HDMI)

• Support FRC (Frame Rate Conversion)

• Can support HQFS 60Hz 3D source from

DVD which need to go thru FRC

• Can support 120Hz 3D source from PC

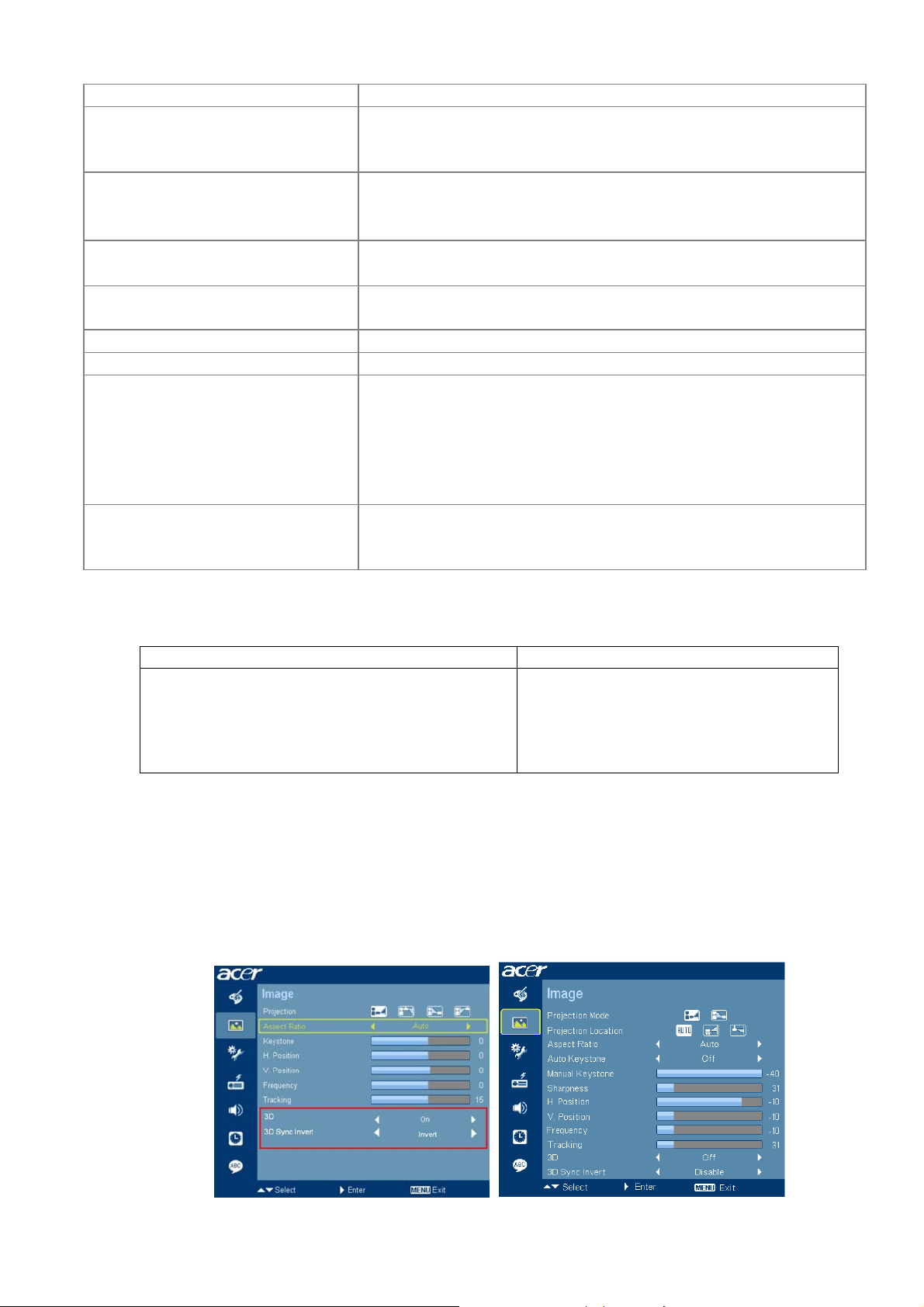

OSD :

− Add “3D”, “3D Sync Invert” in Image Page

− “3D Sync Invert” is adjustable when above "3D" is on. Otherwise 反白

− When 3D is enabled, Display Mode(in Color Page) is not adjustable (反白).

− For DDP2430 models : 3D / 3D Sync Invert , only appear for VGA/DVI/HDMI source.

Disappear if other sources.

− For DDP2230/2431 models : no this limitation.

9

Page 10

Reminder screen :

− Pop-up screen and appear 10 sec in the center of the screen. End-users can press Menu to

exit within 10 sec.

− (1) When 3D enable, this screen will appear after exit OSD menu.

− (2) There has reminder screen if 3D still enable when power on projector.

− Priority : PWD login screen (Security fn is on) Lamp life reminder 3D reminder

Screen Timer and other OSD pup-up fn.

10

Page 11

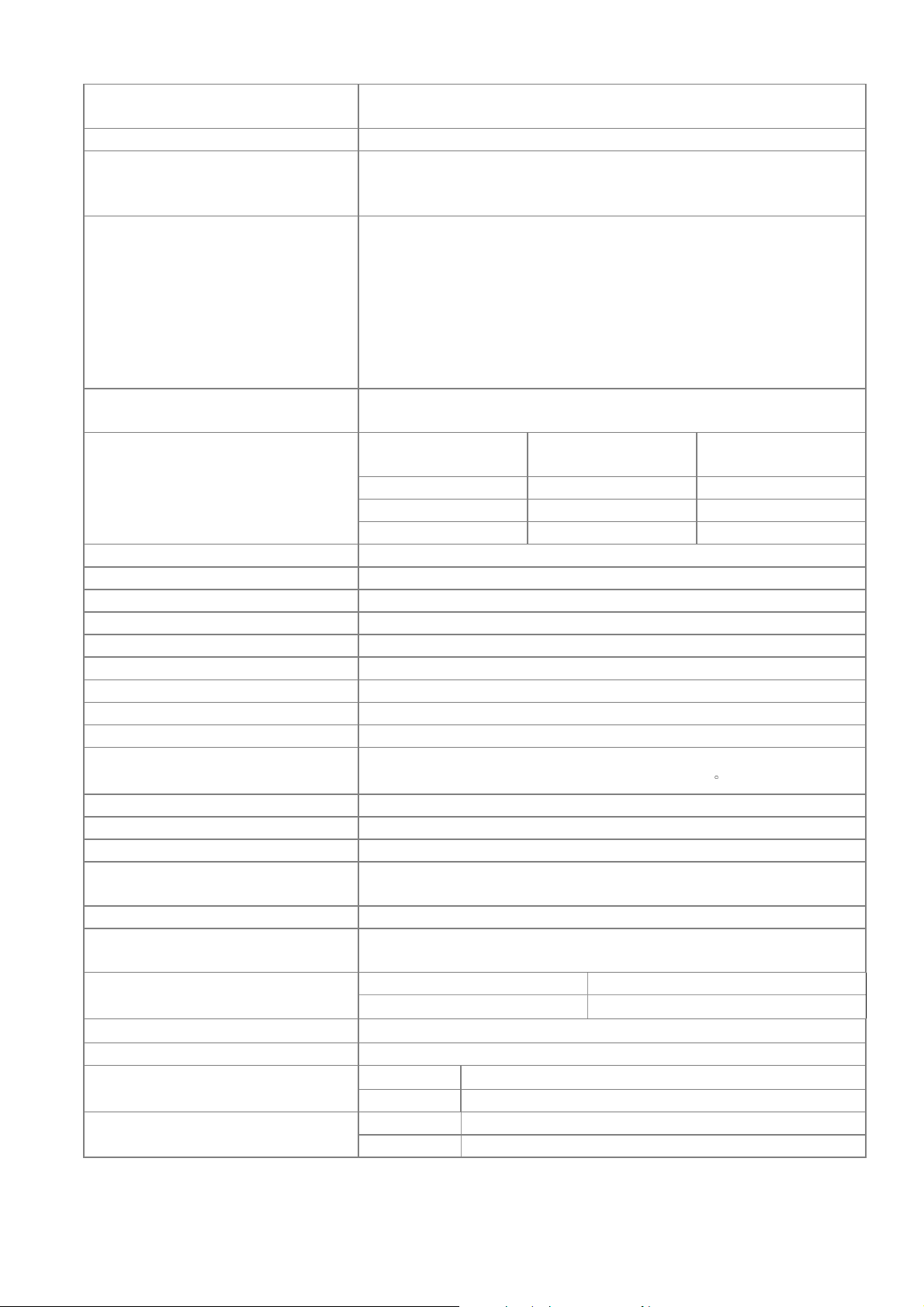

Electrical Specification

1. Timing Table

The PC timing is as following:

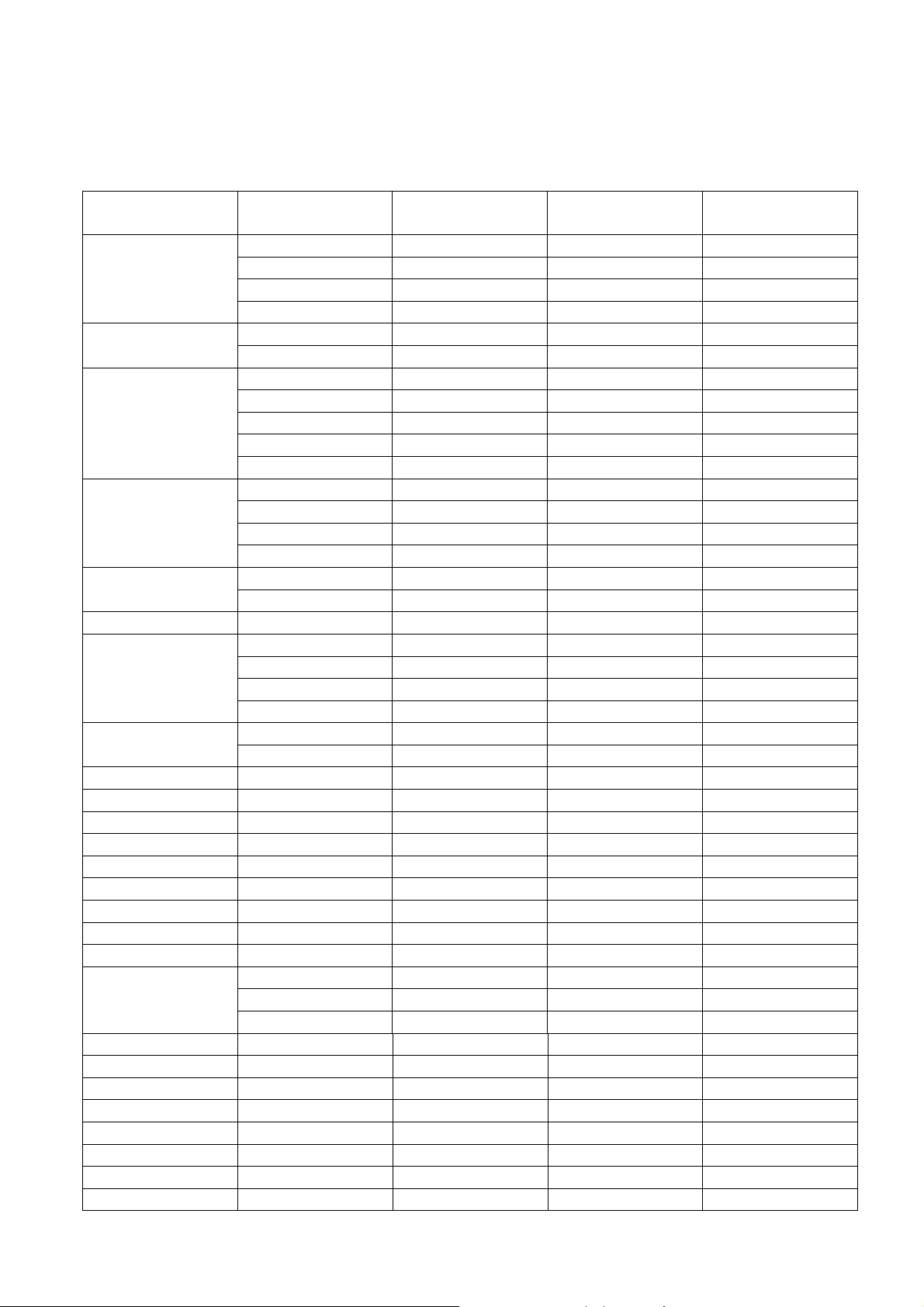

Resolution Mode

Refresh rate

(Hz)

H-frequency

(kHz)

(MHz)

VGA_60 59.940 31.469 25.175

640 x 480

VGA_72 72.809 37.861 31.500

VGA_75 75.000 37.500 31.500

VGA_85 85.008 43.269 36.000

720 x 400

VGA_70 70.087 31.469 28.3221

VGA_85 85.039 37.927 35.500

SVGA_56 56.250 35.156 36.000

SVGA_60 60.317 37.879 40.000

800 x 600

SVGA_72 72.188 48.077 50.000

SVGA_75 75.000 46.875 49.500

SVGA_85 85.061 53.674 56.250

XGA_60 60.004 48.363 65.000

1024 x 768

XGA_70 70.069 56.476 75.000

XGA_75 75.029 60.023 78.750

XGA_85 84.997 68.677 94.500

1152 x 864

SXGA_70 70.012 63.851 94.500

SXGA_75 75.000 67.500 108.000

1152 x 864 SXGA_85 84.990 77.094 121.500

SXGA_60 60.020 63.981 108.000

1280 x 1024

SXGA_72 72.000 76.970 134.600

SXGA_75 75.025 79.976 135.000

SXGA_85 85.024 91.146 157.500

1280 x 960

QuadVGA_60 60.000 60.000 108.000

QuadVGA_75 75.000 75.000 126.000

1400 x 1050 SXGA+_60 59.978 65.317 121.750

1600 x 1200 UXGA_60 60.000 75.000 162.000

640x480@60Hz

640x480@67Hz

800x600@60Hz

832x624@75Hz

1024x768@60Hz

1024x768@75Hz

1152x870@75Hz

Mac G4 59.940 31.469 25.170

MAC13 66.667 35.000 30.240

Mac G4 60.317 37.879 40.000

MAC16 74.546 49.722 57.280

Mac G4 60.004 48.363 65.000

MAC19 75.020 60.241 80.000

MAC21 75.061 68.681 100.00

WXGA_60 59.870 47.776 79.500

1280 x 768

WXGA_75 74.893 60.289 102.250

WXGA_85 84.837 68.633 117.500

1280 x 720 WXGA_60 60.000 45.000 74.250

1280 x 800 WXGA_60 59.810 49.702 83.500

1440 x 900 WXGA+_60 59.887 55.935 106.500

1680 x 1050 1680x1050_60 59.954 65.290 146.250

1920 x1080 1920x1080_60 60.000 67.500 148.500

1366 x 768 acer_16:9 59.790 47.712 85.500

1024 x 600 acer_timing 60.000 37.500 50.400

640 x 480 VGA_120 119.518 61.910 52.500

Clock

11

Page 12

800 x 600 SVGA_120 119.854 77.425 83.000

1024 x 768 XGA_120 119.804 98.958 137.750

Note:3D timing will phase in after MP when 3D function ready

YPbPr support timing is as following:

Signal format fh(kHz) fv(Hz)

480i(525i)@60Hz 15.73 59.94

480p(525p)@60Hz 31.47 59.94

576i(625i)@50Hz 15.63 50.00

576p(625p)@50Hz 31.25 50.00

720p(750p)@60Hz 45.00 60.00

720p(750p)@50Hz 37.50 50.00

1080i(1125i)@60Hz

1080i(1125i)@50Hz

1080P@60HZ 67.5 60.00

1080P@50Hz 56.26 50.00

Video, S-Video support timing is as following:

Video mode fh(kHz) fv(Hz) fsc(MHz)

NTSC 15.73 60 3.58

PAL 15.63 50 4.43

SECAM 15.63 50 4.25 or 4.41

PAL-M 15.73 60 3.58

PAL-N 15.63 50 3.58

PAL-60 15.73 60 4.43

NTSC4.43 15.73 60 4.43

2. Characteristics of inputs/outputs

Signal Parameter Min Type Max

RDATA

GDATA

BDATA

GDATA_SO

G

HDATA

VDATA

Impedance 75 Ohm

Amplitude 0.7 Volts peak-to-peak

Black pedestal 0 Volts

Pixel Clock 165 M Hz

Impedance 75 Ohm

Amplitude 1 Volts peak-to-peak

Video amplitude 0.7 Volts peak-to-peak

Sync amplitude 0.3 Volts peak-to-peak

Black pedestal 0 Volts

Pixel Clock 165 M Hz

Impedance 1 K ohm

Amplitude, low level 0 0.8 volt

Amplitude, high level 2.5 5 Volt

Frequency 31 93 K Hz

Impedance 1 K ohm

Amplitude, low level 0 0.8 volt

Amplitude, high level 2.5 5 Volt

Frequency 48 120 Hz

Amplitude, low level 0 0.8 volt SDADATA

Amplitude, high level 2.5 5 Volt

33.75 60.00

28.13 50.00

12

Page 13

Amplitude, low level 0 0.8 volt SCLDATA

Amplitude, high level 2.5 5 Volt

RXD Amplitude -25 25 Volt

TXD Amplitude -13.2 13.2 Volt

CVBS

Luminance

Amplitude, total (video+

sync)

1 Volts peak to peak

Amplitude, video 0.7 Volts peak to peak

Amplitude, sync 0.3 Volts peak to peak

Impedance 75 ohm

Amplitude 300 m Volts peak to peak CVBS

Chroma

Audio

(for

X1130PA /

X1230PK/

X1230P/

X1237/

X1230PA)

Impedance 75 ohm

Impedance (audio in) 10 Kohm

Amplitude (audio in) 0 0.50 Volts rms

Bandwidth 300H

16kHz

z

S/N Ratio 40 %

Total Harmonic

10 %

Distortion

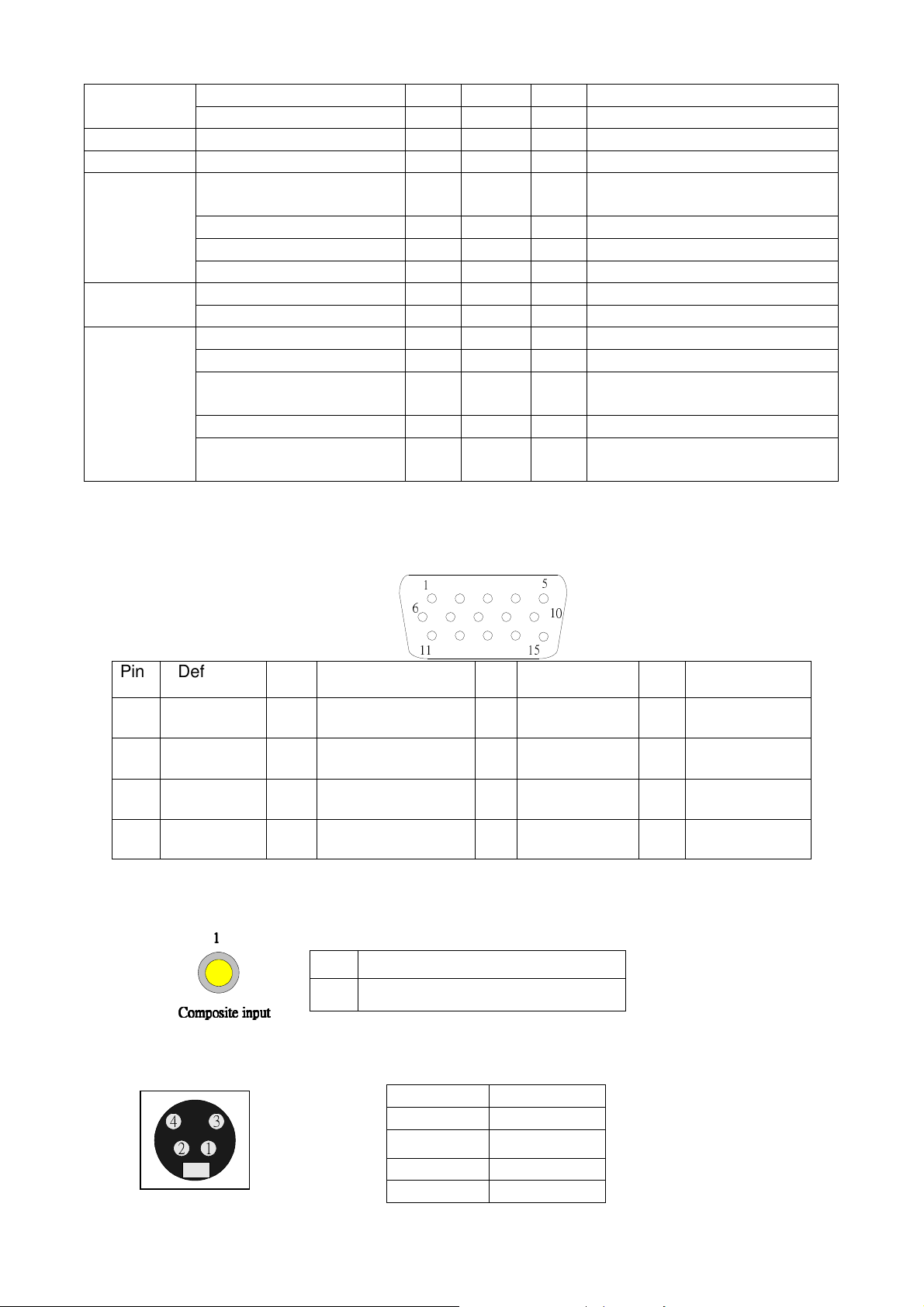

3. Electrical Interface Character

Interface Definition

15 pin definition of the mini D-sub male for DDC2B protocol

1

6

11

Pin Definition Pin

1 Red video

(Pr)

5 NC 6 Red Video Return 7 Green Video

9 DDCP 5V 10 GND 11

13 Horizontal

Sync

2 Green Video

14 Vertical Sync 15

Definition Pin Definition Pin

3 Blue Video

(Y)

5

10

15

(Pb)

Return

GND 12 Bi-directional

Data clock

(SCL)

Video Input

1111

Pin

Definition

1 Composite video input

Composite input

Composite input

Composite inputComposite input

Definition

4 NC

8 Blue Video

Return

data (SDA)

S-Video input

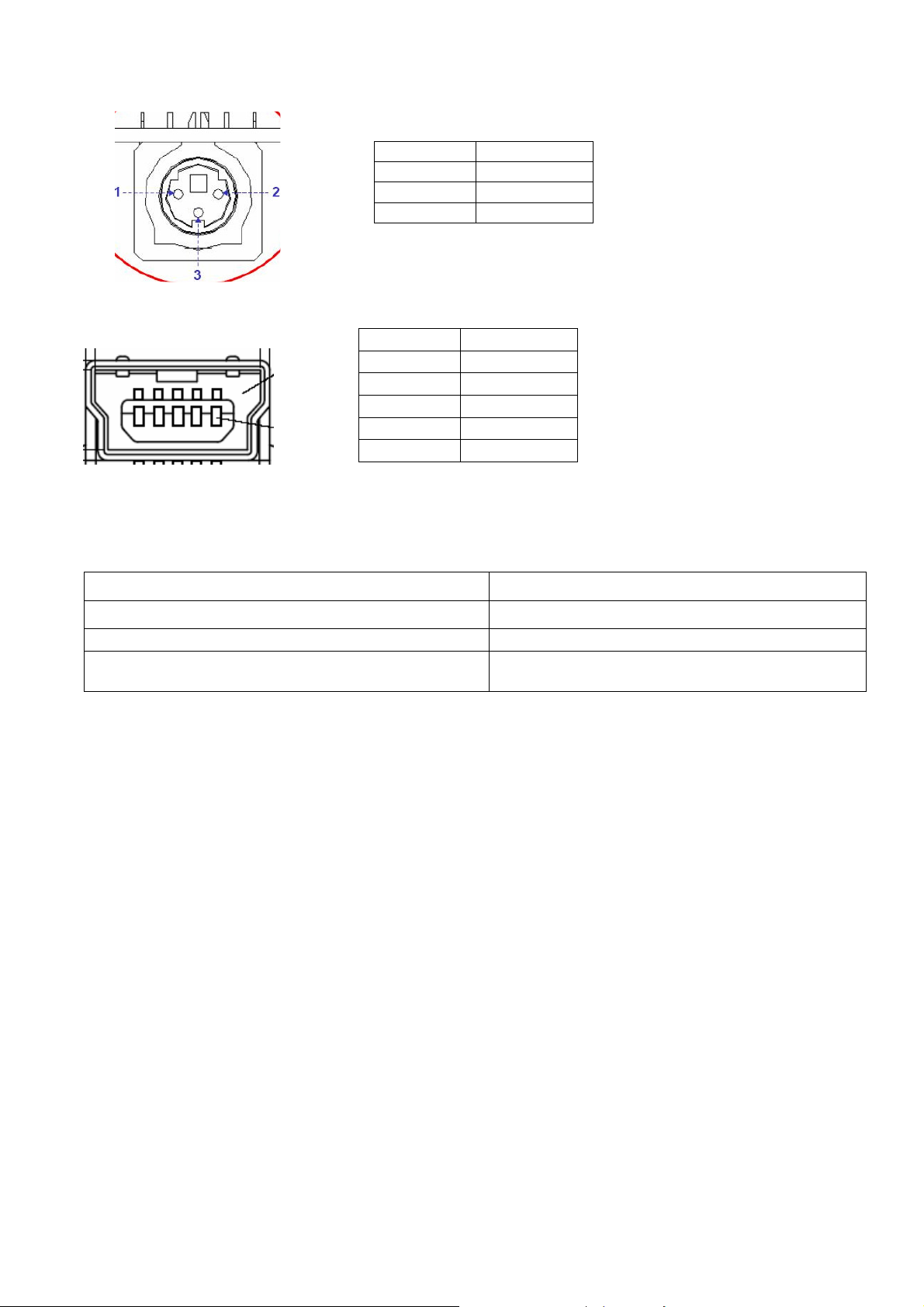

Pin Description

3

241

1 GND

2

GND

3 Luminance

4 Chroma

13

Page 14

Control Port

Pin Description

1 TX

2 RX

3 GND

Mini USB TYPE B (for X1130PA /X1230PK/ X1230P/ X1237/ X1230PA)

Pin Description

1 Vbus

2 D3 D+

4 ID

5 GND

4. Functionality

External Message indicator

Message Occasion

D-sub /Composite Video /S-Video Searching The system does not detect the signal

Input Not Supported The signal is over the specification

Lamp is approaching the end of its useful life in full

power operation. Replacement suggested!

Lamp Hour is at 2970 hours

14

Page 15

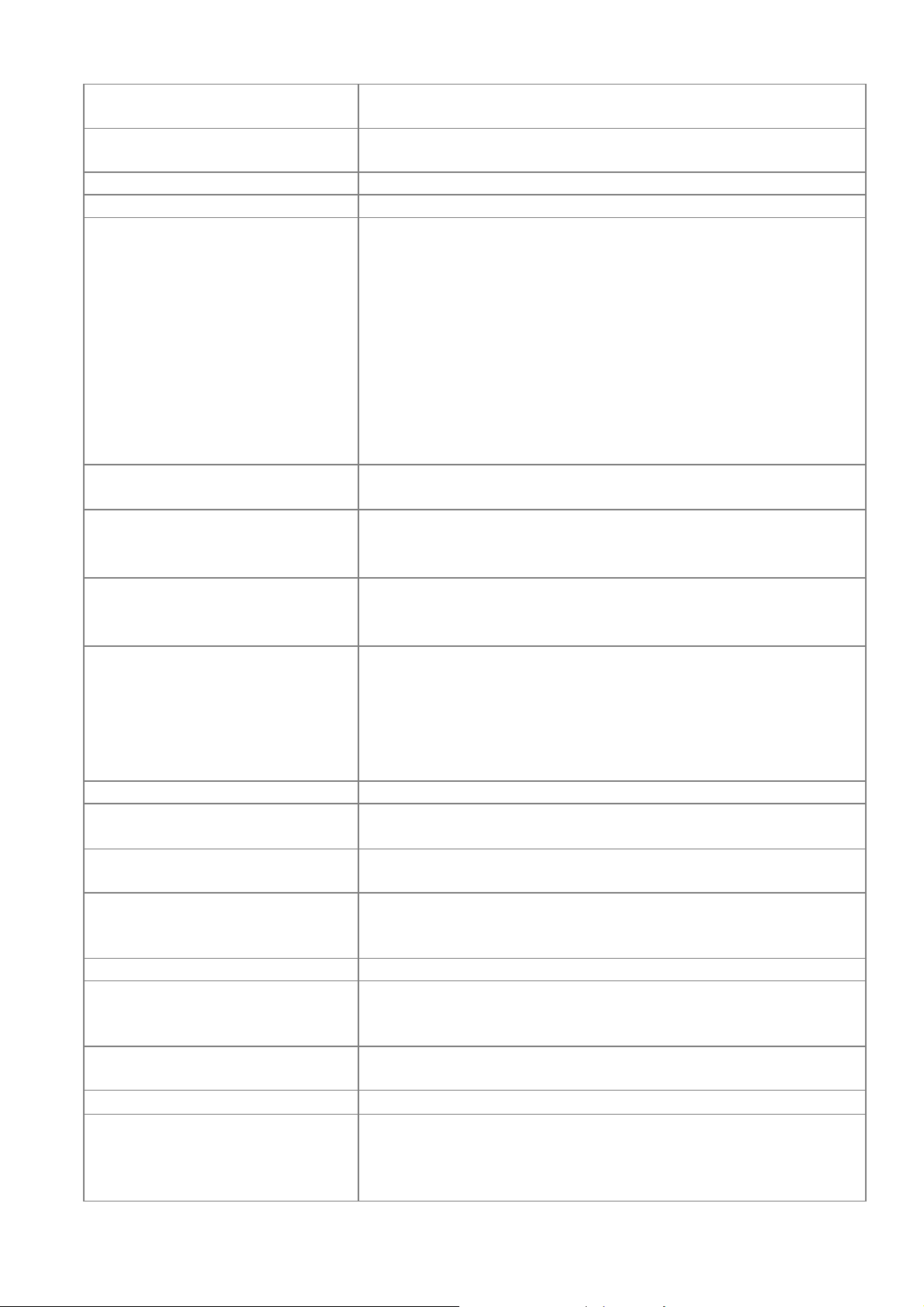

Power Supply Specification

1. Input Power Specification

Specification Description

Input Voltage Range The unit shall meet all the operating requirements with the

range 90 ~ 264 VAC

Frequency Range The unit shall meet all the operating requirements with an input

frequency range 47 Hz ~ 63 Hz

Power Consumption Normal operation: 280W (Max)

standby mode: < 1W (loop through is disabled), at

100~240VAC

Regulation Efficiency 85 % (typical) measuring at 115Vac and full load

2. Output Power Requirement

The power supply can provide DC 12V output as below:

NO. Voltage

1

2

The power supply can provide DC 380V output as below:

NO. Voltage

1

3. Lamp Power specifications

Specification Description

Applicable Lamp Philips Normal 189W, ECO 163W AC operation

Starting pulse from Ignitor 2.5KV

4. Power Protection

Item Criteria

Short protection No damage

OVP 16Vdc Max@12V

OPP DC-DC 130~250%

5. Surge test: Meet EN61000-4-5

L N 1KV, L, N PE 2KV, Criteria B

Electrical Fast Transients (EFT):Meet EN61000-4-4

1 KV, Criteria B

7. Voltage Dips: Meet EN61000-4-11

>95% reduction for 0.5 periods, Criteria B

Harmonic current test: Meet EN61000-3-2

+12 V

+5 V

380 V

Regulation Load Current Range Ripple & Noise

±5 %

±5 %

Range Load Current

370~400V 0.5 A TYP.

6.5Vdc Max@5V

PFC 130~160%

0.15 A ~ 2.5 A 120mV/240 mV

0.04 A ~ 0.5 A 50mV/100 mV

15

Page 16

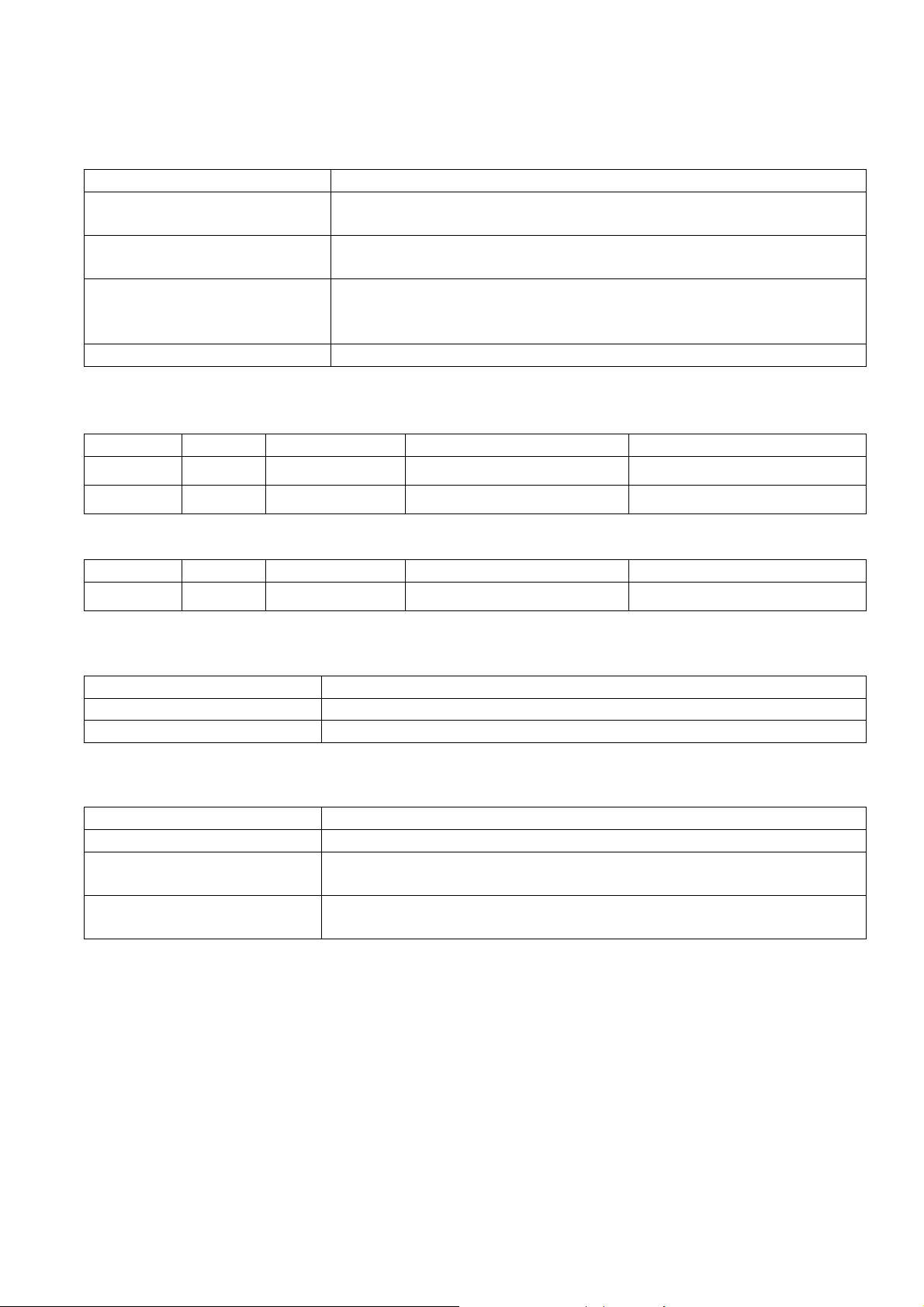

System Block Diagram

16

Page 17

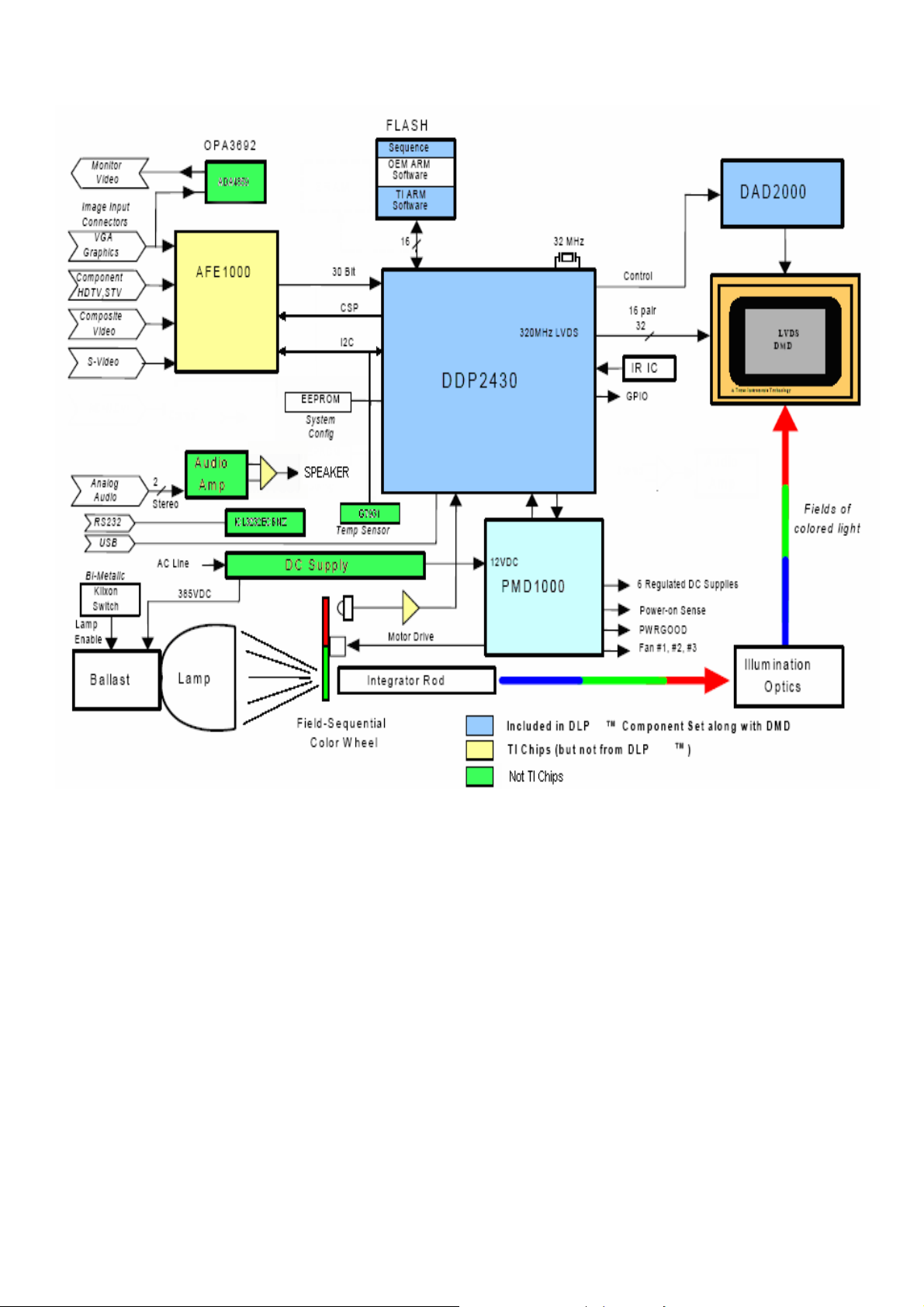

Product Overview

17

Page 18

18

Page 19

19 20 21

Page 20

Page 21

Chapter 2 System Utilities

Firmware Upgrade SOP

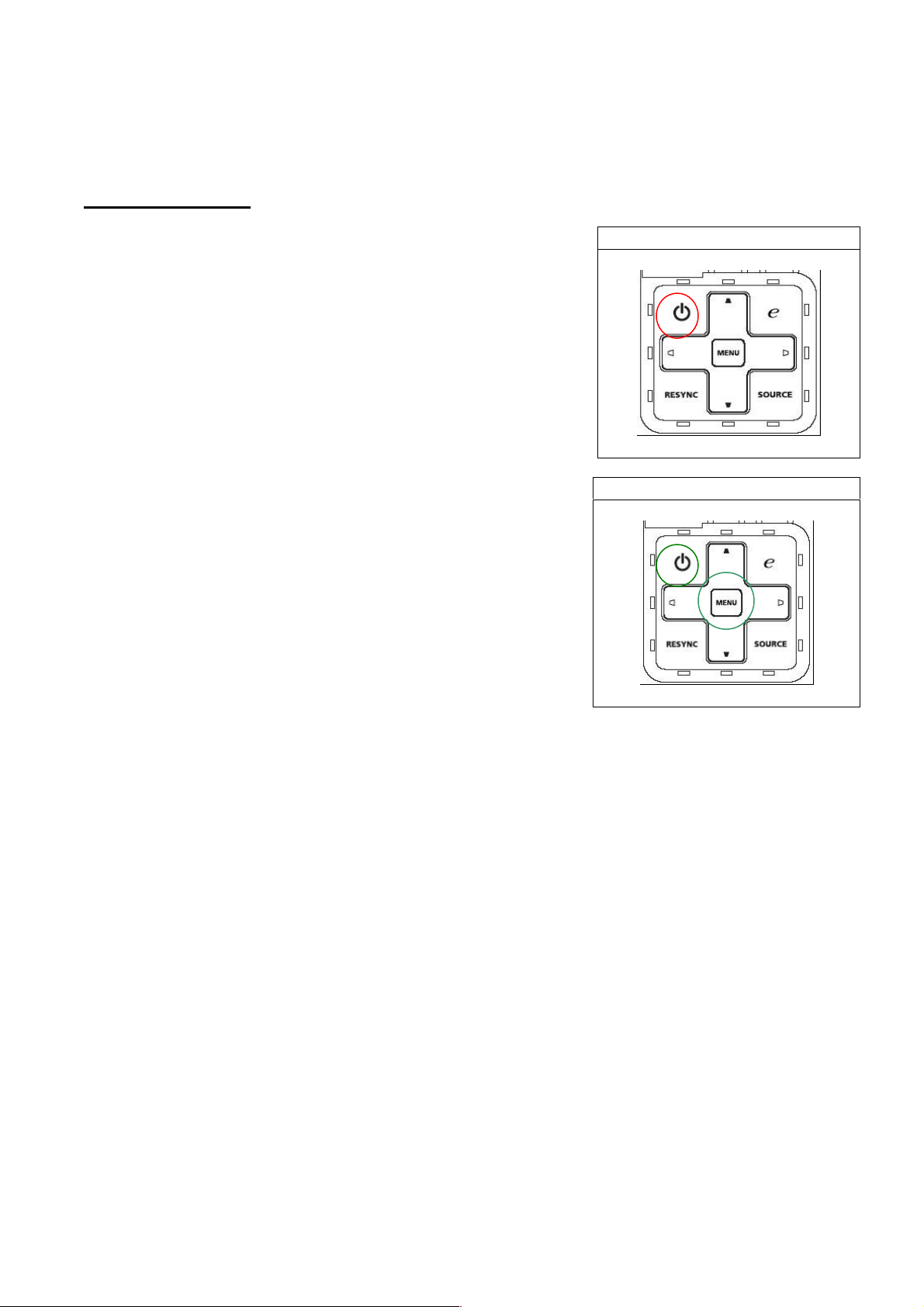

Basic Operating

Standby Mode::::

When standby mode, system power consumption will

be less than 1 Watt.

If user wants to enter this mode, user can just plug in

power cord. Power, Lamp, Temp LED will show Red for

1 sec then power LED show red continuously as the

figure shown. When the power LED shows Red, it means

system is ready for standby.

Besides, user can press power key to turn on projector

after plugging in power cord when power led is red.

Download Mode::::

This mode is applied for Download firmware.

If operator wants to enter this mode, he should press

and hold keypad Power and Menu together, then plug

in power cord. Release the two keypads. Power,

Lamp, Temp LED will show red light continuously. In

download mode, you can use DLP composer to download

new firmware and power LED will show purple while

downloading.

Standby Mode

Download Mode

Download WT6702 MCU Code::::(in Low-Power 1 Watt Standby)

System needs a few sec to download WT6702 MCU automatically.

When Downloading:Temp LED will show red.

When Download Success:System will go back Low-Power standby mode and Power LED

will show red.

When Download Fail: Lamp LED will show red.

<Notice:Do NOT interrupt power when downloading MCU Code.>

Page 22

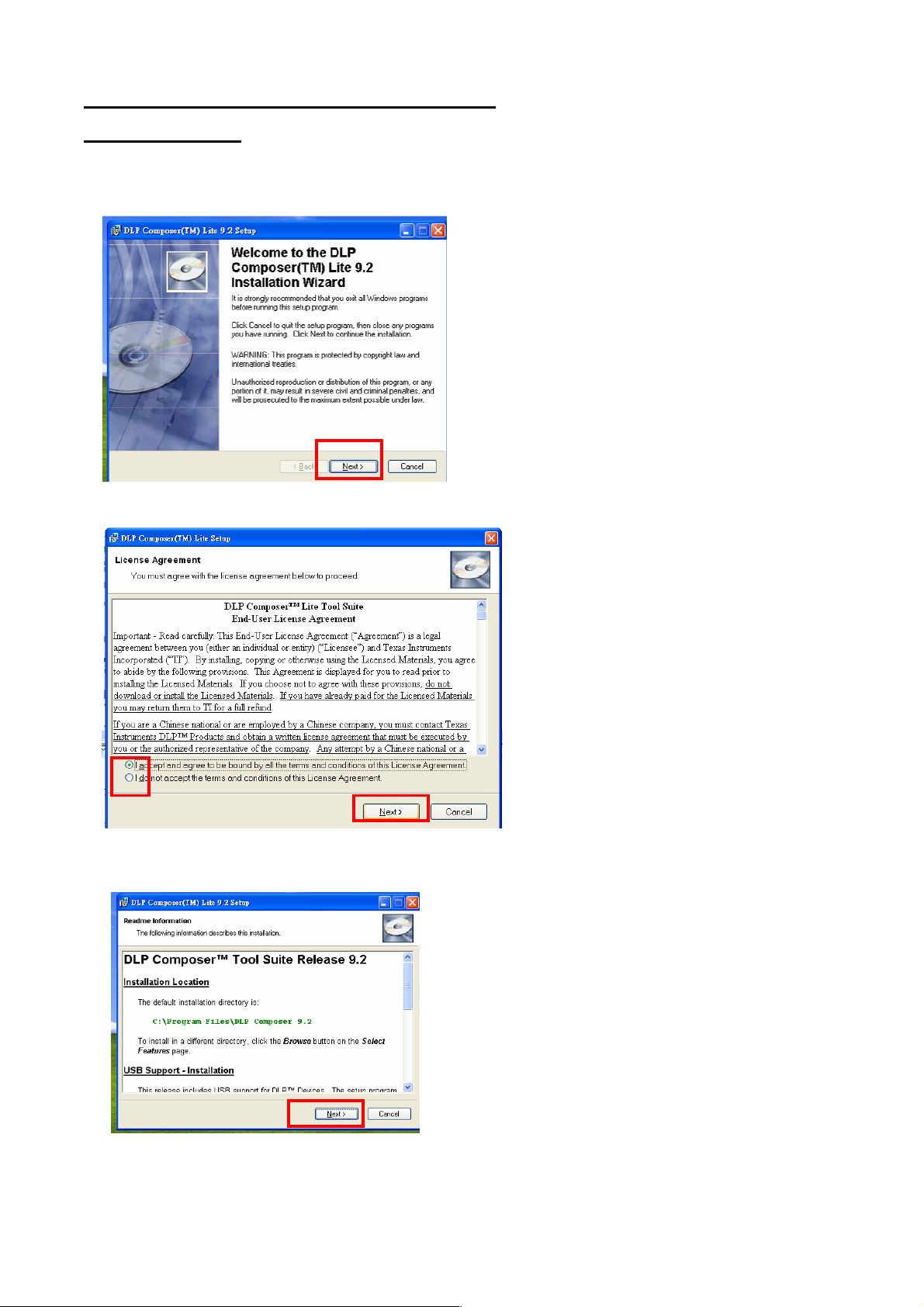

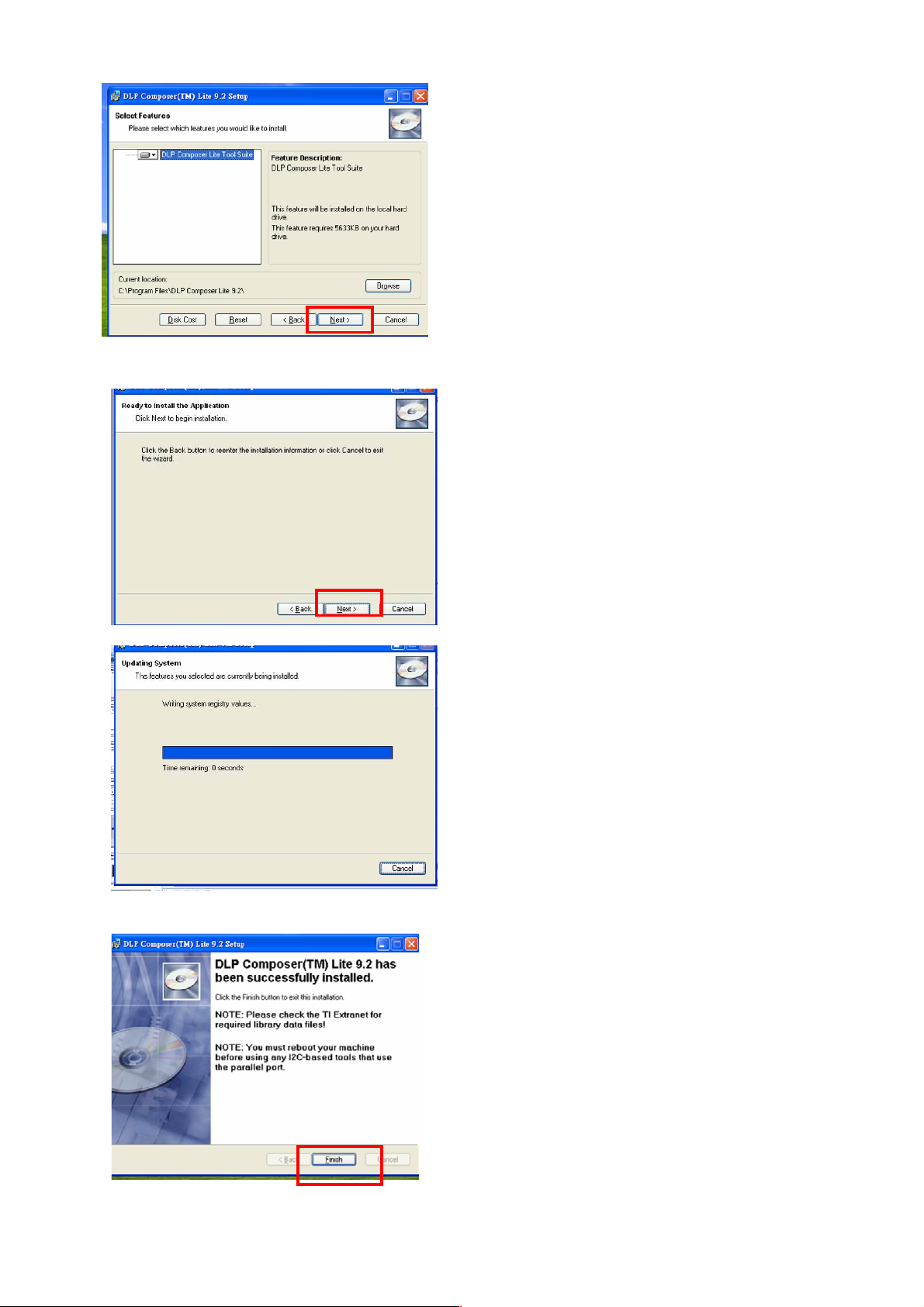

DLP Composer LIte Installation Process

(1) Installation

1. Double click the Setup file for DLP Composer Lite(to unzip “TI Download Tool V1.1 (for

DDP243x).rar” to start to install program.

2. When the Installation Wizard appears, click “Next”.

3. Select to accept the License Agreement, than click “Next”

4. Click “Next” in the following steps to continue installation process.

22

Page 23

Note:

The default installation directory is:

C:\Program Files\DLP Composer Lite9.2

If you want to install to a different directory (perhaps

alongside a prior release of DLP Composer™ Lite),

click the "Browse" button on the "Select Features"

page.

5. When finishing installation, click “Finish”, and then restart your computer to complete the

installation process.

23

Page 24

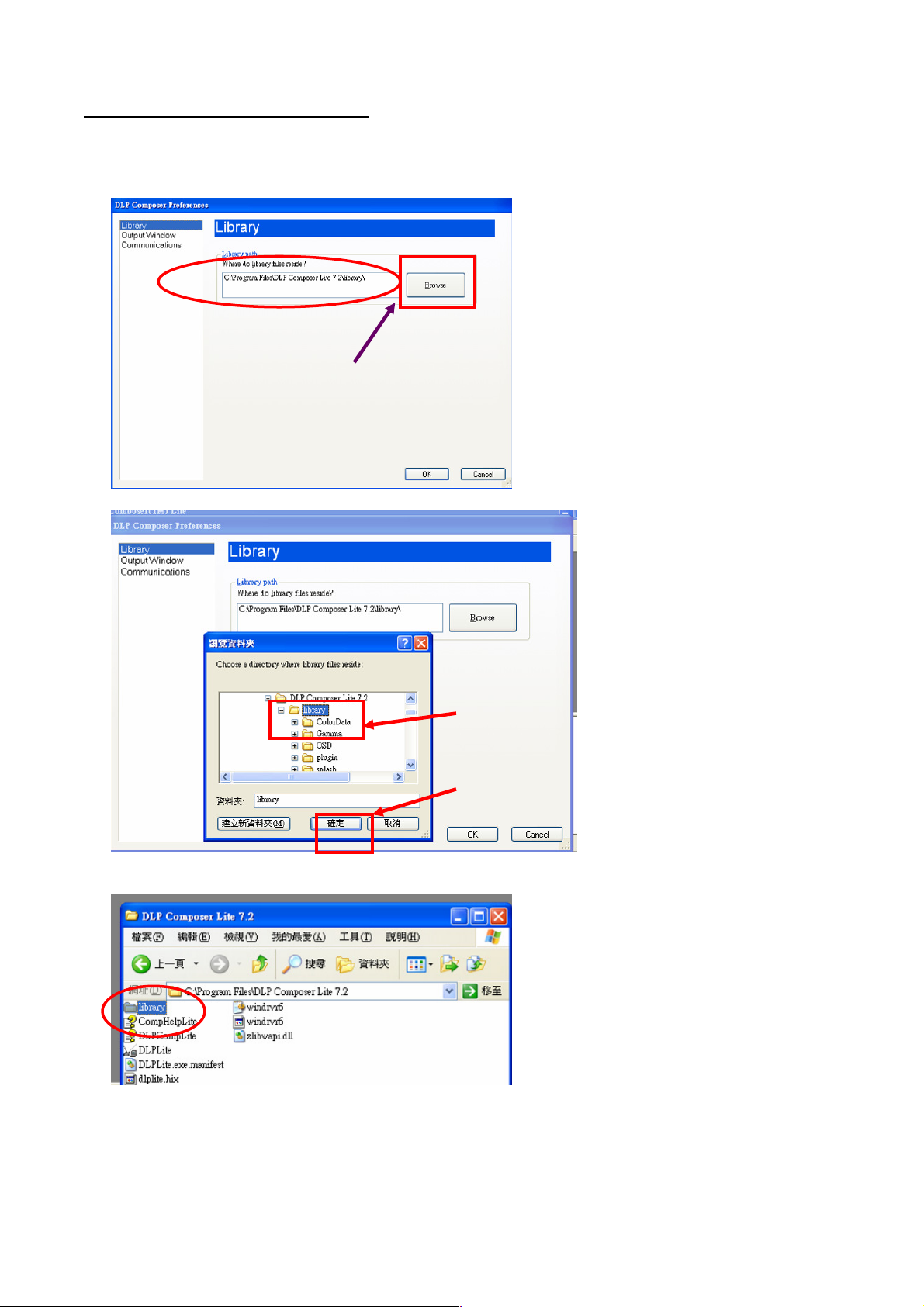

(2) Setting for your first use

Click

Click Click

Click

““““

Browse

BrowseBrowse

Browse

””””

to

to to

to

select

select select

select

Click the

Click the Click the

Click the

library

librarylibrary

library

Select Library:

1. When start to use this program to download at first time, you need to check if the library

folder is existed under the path of Library.

path for library files

path for library files

path for library filespath for library files

folder to assign

folder to assign

folder to assign folder to assign

the path.

the path.

the path.the path.

Then Click

Then Click ““““OK

Then Click Then Click

2. Check if there are library files in the assigned path. If not, unzip the library file into the path.

OK””””....

OKOK

24

Page 25

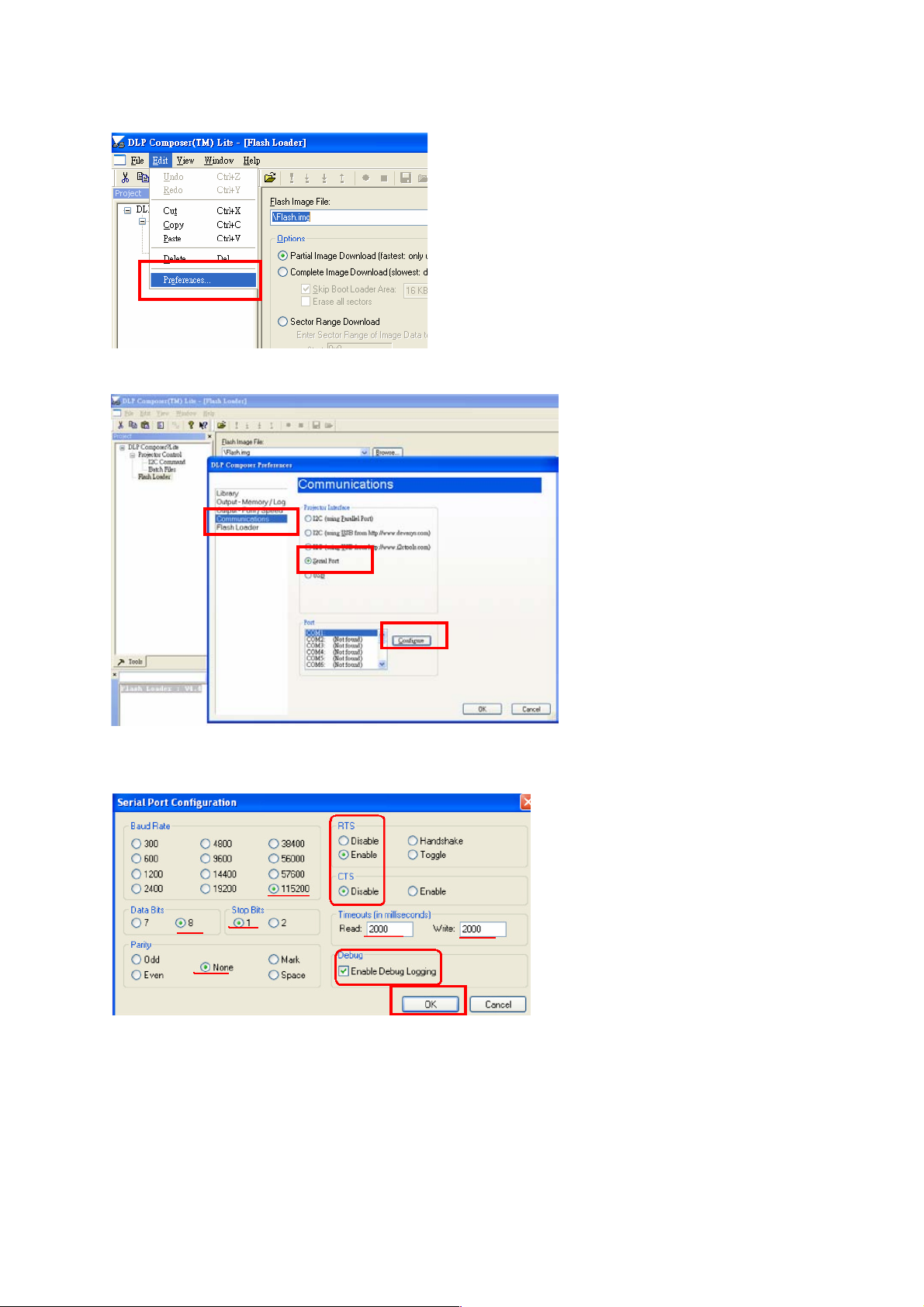

Set communication (for download by RS232):

1. Select “Edit”->”Preference”.

2.

Select “Communications”-> “Serial Port” -> ”Config”.

3. Make sure the settings are the same as below figure-> Click ”OK”.

4. Click ”OK”.

25

Page 26

(1) Download Procedure

Notice: for X1130P, since the Main board P/Ns are different in with-3D and without-3D

function SKUs, need to download correct FW into corresponding Main board.

How to download

Hardware required

1. Standard RS232 Download cable

2. Personal computer or laptop computer

Software required

1. DLP Composer Lite program

2. New version FW

Download procedure

1. Connect RS-232 cable to PC and projector

2. Let projector be in Download Mode :

-> Press and hold keypad Power and Menu together, then plug in power cord.

-> Release the two keypads.

-> Power, Lamp, Temp LED will show red light continuously.

3. Execute DLP Composer Lite 9.2 program

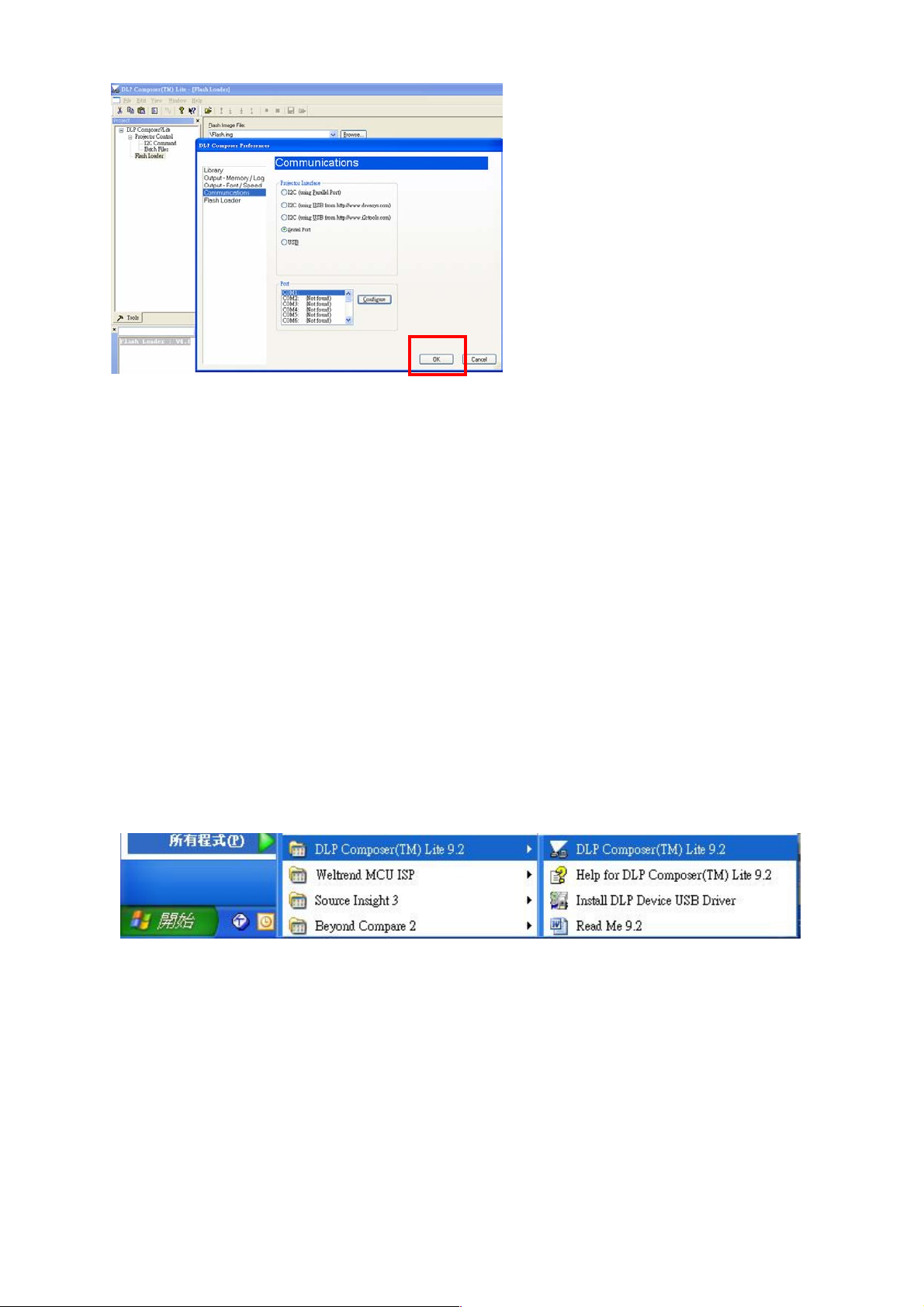

4. To select the RS-232 communications interface, choose "Preferences" from the

"Edit" menu, click the "Communications" page and choose "Serial Port".

26

Page 27

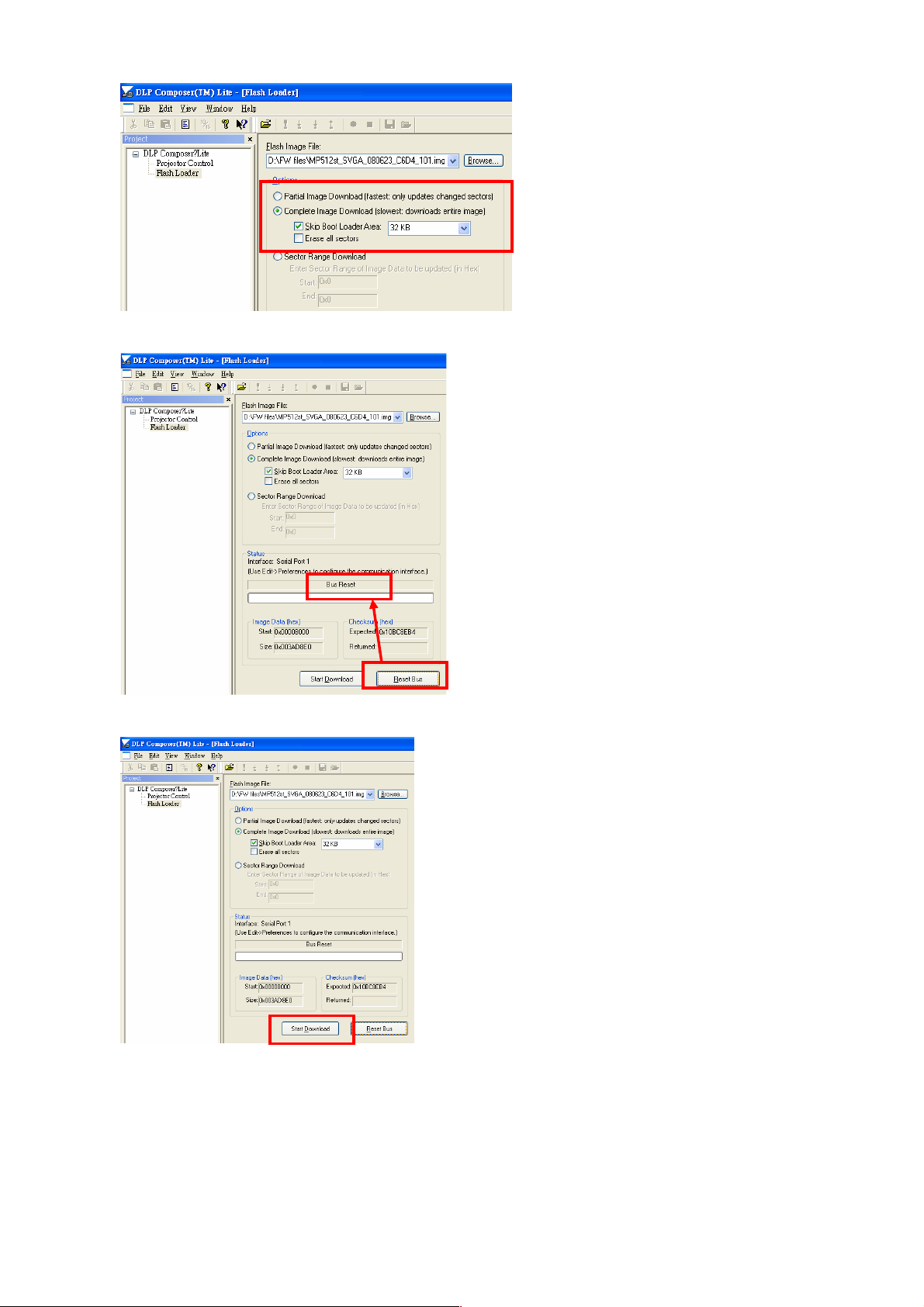

5. Click on “Flash Loader” and browse the image file (new version firmware)

6. Select Complete Image Download, and make sure to check “Skip Boot loader area

(32KB)”

27

Page 28

7. Press “Reset Bus” and check the status which should show “Bus Reset”

8. Press “Start Download” to begin update new firmware.

9. Press “Yes” to continue. (when download new firmware and power LED will show

purple.)

28

Page 29

10. Wait till composer lite notice download complete.

When download complete, LED signal on projector will show standby status.

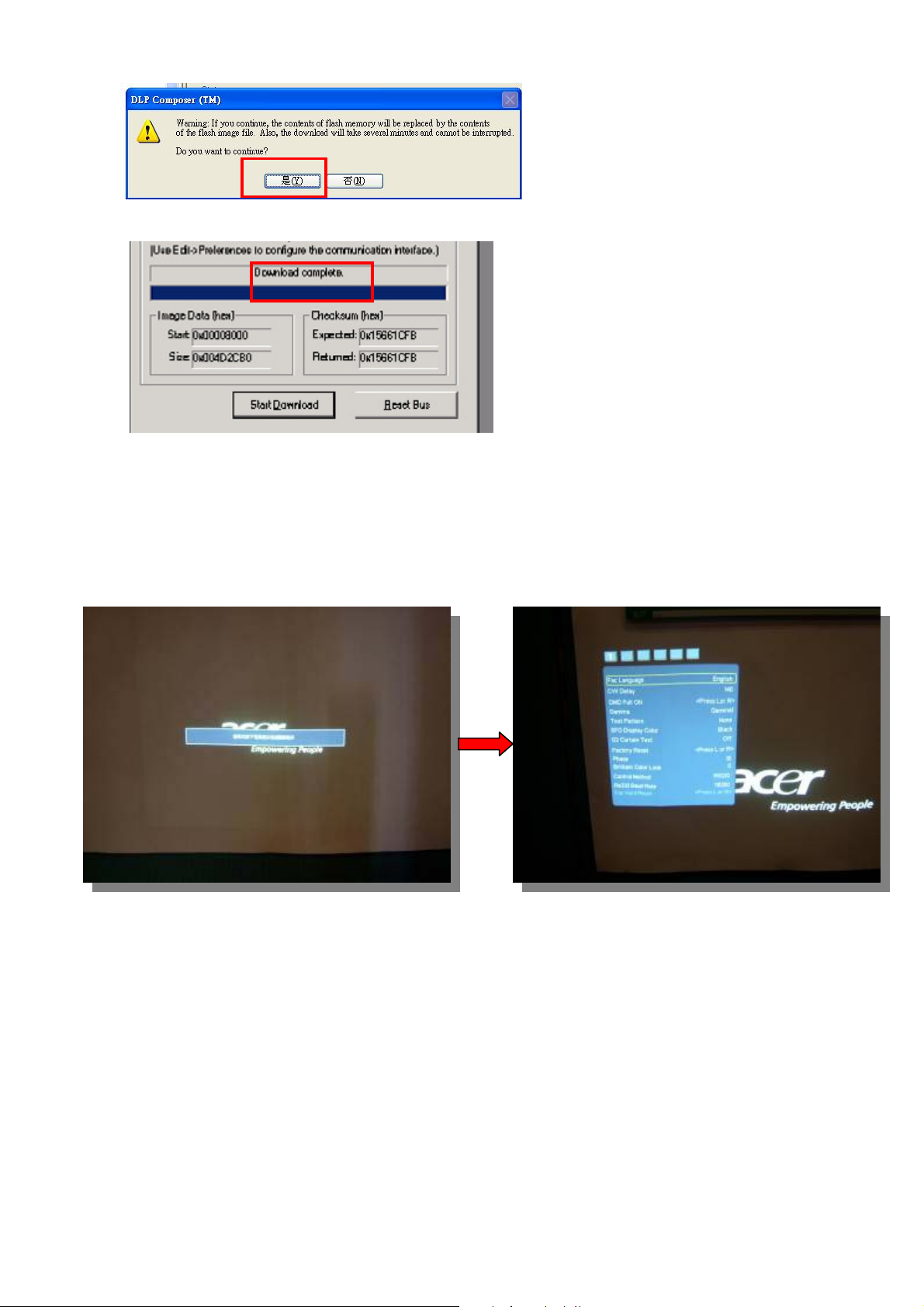

Method to enter factory menu

1. Press keypad Power and image will show Power Down OSD function

2. Press keypad Left twice then press Menu, then enter the Factory mode.

Step 1

Step 2

29

Page 30

EDID Upgrade SOP

Link to Main

Link to Projector :

Link to Projector :

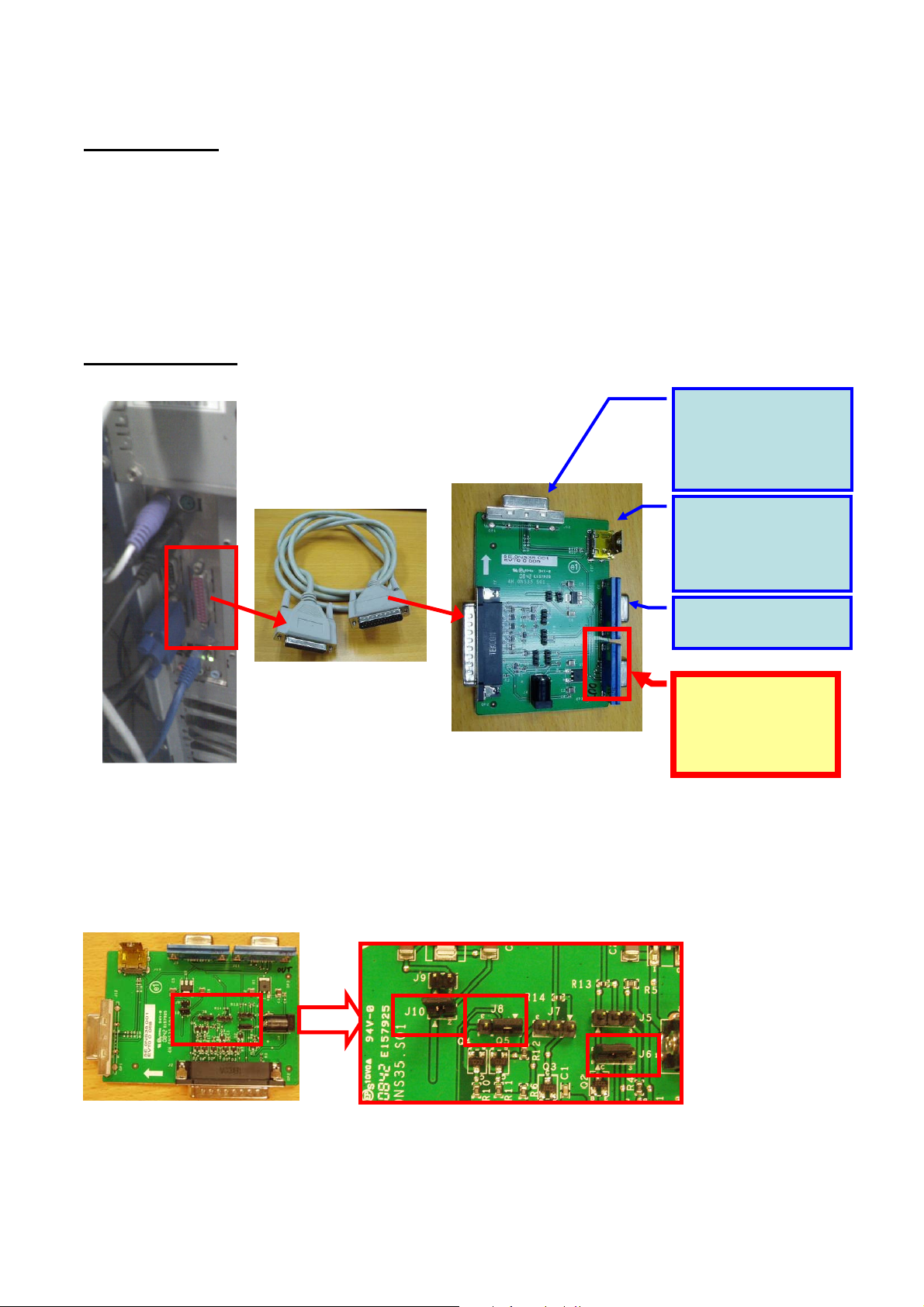

Equipment List

1. PC : with parallel (printer) port

2. EDID Board

3. Printer cable : 25pin male-female (connect PC to EDID board)

4. D-sub cable* : with full 15pin (connect EDID board to Projector)

5. HDMI cable*(connect EDID board to Projector)

6. DVI cable* (connect EDID board to Projector)

(*Note: Not every model’s EDID input (D-sub, DVI, HDMI) is the same. Need to check what

kind of file you need before download.)

Setup Equipment

1. Connect between PC, EDID board and the Projector:

DVI-D DDC download

(no need in X1130/ X1230/

X1230S/ X1235/ X1230K

series)

For HDMI DDC

download

X1130/ X1230/ X1230S/

X1235/ X1230K series)

(no need in

For

“25pin male-female

cable” (normal

printer cable)

PC with parallel

(printer) port

2. Need to set Jumper before using EDID board :

<Jumper setting :>

J6 : 1,2 short

J8 : 1,2 short

J10 : short

EDID board

Please ignore this

connector

board :

For D-sub DDC

download

3. How to use Download Tool :

30

Page 31

Software Installation, Un-installation :

Unzip the “Q-EDID” program files in the same directory.

Install Q-EDID tool : Execute “Install Q-EDID.BAT” to install & register EDID Board into

the computer.

Un-install Q-EDID tool : If you want to uninstall this tool, execute “Uninstall

Q-EDID.BAT”, then it will remove EDID Board from the computer.

How to use Download Tool :

(1) Execute EDID Tools V0.16:

1. Run “Q-EDID-V016.exe”.

2. Program will appear as below picture.

(2) Write EDID:

• When write D-SUB/DVI EDID:

1. EDID Type Selection : Choose ‘‘EDID 128 Bytes’’.

2. Open Files : Click “Open File” to select file “*.DDC”

(Note : If your DDC file name is not like “*.DDC” (e.g. “*.2dc”), please rename it to “*.DDC”)

3. Write EDID : Click “Write EDID”, and it will execute writing process.

4. While complete, it will show message as ’’Write EDID OK…’’.

(Note : Check cable connection before write. It will show Write EDID OK even the connection is

not stable.)

31

Page 32

Step1

Step2

Step3

Step4

(3) Read EDID:

• Read D-SUB/DVI EDID:

1. EDID Type Selection : Choose ‘‘EDID 128 Bytes’’

2. Read EDID : Click “Read EDID”.

3. While complete, it will show message’’ Read EDID OK… ‘’, and the read-out DDC will

show in the table in program.

Important Note :

Be reminded to connect Only One port every time, because the software will not be able to

identify the command signal from which port.

After connecting all equipment, always read DDC before writing DDC to ensure the

connection status is OK for writing DDC.

32

Page 33

Serial Number Upgrade SOP

Hardware required

1. Standard RS232 Download cable

2. Personal computer or laptop computer

Software required

1. Acer_Service_Tool(Data)_3.1.exe

When need to use this Serial Number Upgrade program:

When it’s time to replace Main board for repair, it’s necessary to rewrite original S/N and

some adjustment values into new Main board by the following process.

Upgrade procedure

1. Prepare the download equipment: RS232 cable connect to PC and projector

2. Plug power cord into projector, and the projector will be in stand by mode.

3. Execute “Acer_Service_Tool(Data)_3.1.exe”, and it will appear as below picture.

4. Change to connected COM port and Click “Port Open” icon.

4-1. Change to

connected COM Port

number

4-2. Click “Port

Open”

5. Read data from original Main board:

Click “Read system Data”, and it will read the Adjustment data (except Auto keystone

data) & Serial Number from projector and show the “Read complete” message in

information block.

5-1. Click this icon to

read all data

5-2. Show “Read

Complete!”

33

Page 34

6. Click “Save” to save data into the assigned file name.

6-2. This window will

pop out, and it shows

the file saving folder.

6-3. Enter file name here.

Suggest to use Serial

Num as the file name.

6-4. Click “Save” to save

data.

6-1. Click “Save” icon.

7. Change new Main board:

(1) Unplug power cable and RS232 cable from projector, and change new Main board

into Projector.

(2) After changing Main board, reconnect power cable and RS232 cable into Projector.

8. Write S/N & data into new Main board:

Press “Retrieve System” and write Data & SN to projector.

9. “Load from data” & “Retrieve System” :

(1) Click “Load from data” and select load file.

(2) Click “Retrieve System” to write the values into main board.

9-1. Click “Load From

Data” to load data.

9-2. Select the file

source

10. Click “Retrieve System”

to write data.

9-3. Click “Load” to

finish file load.

34

Page 35

How to Change Model name

(Only for X1230P/X1230PA/X1237)

Since X1230P/X1230PA/X1237 use the same Main board, after replacing new Main board, it’s

necessary to change model name:

1. Enter Factory menu.

2. Go to Page2 (as below figure).

3. Default Model name is “X1230P”. When change Main board on X1230PA or X1237,

please press right/left key to choose correct model name.

35

Page 36

Chapter 3 System Disassembling and Replacement

4

2

Main Unit Disassembling

Tool : Screw Driver --Hex (#4-40) and Cross(Mechanical : M3,M4, Opt.Engine :M2)

Process :

Step Discription Photo Tool

5

1

3

Disassemble the

1

screw*5(M3*7L)

Take off the the IR

sensor wire from

mainboard, then take

off upper case

module,

2

Notice : When taking

off upper case

module, don't break

the IR sensor wire.

Take off the case left

3

module and the front

case module

screw

driver

2

keypad Rubber

keypad braket

FRONT

IR BD

(1) Take off screws:

For X1130P :

Disassemble the

screw*2(STAND OFF

XH4#-40*6L).

For X1230PK :

Disassemble the

screw*4(STAND OFF

4

XH4#-40*6L).

For X1130PA/

X1230P/X1230PA/X12

37: Disassemble the

screw*6(STAND OFF

XH4#-40*6L)

(2) Take off the rear

case.

For X1130P:

For X1230PK:

4

1

rear case

1

For X1130PA/X1230P/X1230PA/X1237:

screw

driver

2

3

3 4 5

1 2

6

36

Page 37

Disassemble the

2

3

wire

screw*5(M3*5L), and

5

take off the M/B

shielding.

screw

1

4

CLAMP

5

driver

(1)Take off the long

wire (one of twin fan

wire), then

6

disassemble the twin

fan.

(2)Take off the twin

fan wire from M/B.

(1)Take off the C/W

FPC wire, blower fan

wire, C/W sensor wire,

Ballast 5-Pin wireform

M/B.

7

(2)Take off right cass

module.(X1130PA/X1

230PK/X1230P/X1237

/X1230PA have

Speaker)

twin fan

take off this long wire first

C/W FPC wire

C/W sensor wire

blower fan wireballast 5pin wire

For X1130PA/X1230PKX1230P/X1237/X1230PA:

sponge*3

8 Take off the M/B

speaker

Main BD

Circuit boards > 10cm2 has been highlighted with the yellow

Note:

rectangle as above image shows. Please detach the Circuit boards and

follow local regulations for disposal.

37

Page 38

(1)Disassemble the

screw*2(M3*6L), and

take off the lamp door.

9

(2)Disassemble the

screw*1(M3*4L) and

lamp wire, and take off

the lamp module.

(1)Disassemble the

screw*3(M3*8L).

(2)Disassemble the

10

grounding

screw*1(M4*6L), and

take off the Power B/D

SHD.

1

2

screw*1

Screw*3

screw

driver

screw

driver

grounding screw *1

Disassemble the

wire*2 and screw*1

11

(M3*7L), and take off

the power BD and

ballast Mylar.

(1)Disassemble the

screw*2(M3*7L), and

take off the lamp box.

12

(2)Disassembly the

screw*2(M3*8L), and

take off the blower fan

screw*1

screw*1

blower fan's

thermal wire

Ballast Mylar

ballast wire

Note: Circuit boards > 10cm2 has been highlighted with the yellow

rectangle as above image shows. Please detach the Circuit boards and

follow local regulations for disposal.

screw*1

screw*1

screw*1

screw

driver

screw

driver

38

Page 39

1

2

Disassemble the

13

screw*3(M3*7L), and

take off the OPT eng .

Disassemble the

screw*2, the ballast

14

BD, and

wire*3(M3*5L).

Take off the push

15

button .

screw

driver

anchor

定位

3

point

3pin wire

screw

1

2

push button

5pin wire 2pin wire

shielding

driver

screw

driver

(1)Take off the

gasket*2.

16

(2)Disassemble the

focus ring.

Take off th LENS

screw*3(M3*4L) and

17

Ring Zoom and Ring

Focus

screw*2(M2*3.5L)

ring

focus

1

gasket*2

2

3

screw

driver

1

2

screw

driver

39

Page 40

Disassemble the

screw*4(M3*7.5L),

18

and take off the

HSINK and DMD chip

with Chip BD.

2

4

screw

3

1

driver

(1)Disassemble the

baffle DMD.

(2)Disassemble the

19

screw*3(M3*4L) and

take off the CW

module.

Rotate to open the

switch on socket, and

20

take off the DMD

chip.

(1)Disassemble ILL

module screw*2

(M2.5*5L).

(2)Take off

21

screw*1(M2*8L), FM

holder, fold mirror, FM

clip*2, clip CM front,

clip CM side and

sponge.

baffle DMD

Note:

1

2

Circuit boards > 10cm2 has been highlighted with the yellow

CW module

3

rectangle as above image shows. Please detach the Circuit boards and

follow local regulations for disposal.

1

2

screw*1

sponge

screw

driver

screw

driver

screw

driver

(1)Disassembly the

screw*1(M2*3L).

22

(2)Take off the LP

module and LP

screw*2(M2*8L).

screw*1

40

screw

driver

1

2

L/P

Page 41

Module Assembly Key Point - Optical Engine

Adjustment S

crew

1. Light Pipe Module assembly and overfill alignment

1.1 Assembly LP Module to HSG DMD

(1) Assembly two Overfill adjustment screws to HSG DMD (Fig. 1-1).

** Adjustment criteria refer to below item

(2) Assembly “Clip LP” and lock with screw well (Fig. 1-2).

(3) Press CLIP of RE_BKT_LP first, and then push it into the hole (Fig. 1-3).

(4) Placed LP Module on LP datum of “DMD HSG” and adjustment screw well (Fig.1-4).

(5) Assembly “Baffle LP” first (Fig. 1-5-1) & push “Baffle LP” to hook DMD HSG, and then

lock with screw well (Fig. 1-5-2).

1.2 Overfill Adjustment @ LP Module

Overfill Adjustment Criteria:

(1) Pre-assembly 2 adjusting screws. Criteria shown as Fig.1-6.

(2) Alignment Sequence:

a. To adjust “Horizontal Adjustment Screw” firstly, and then “Vertical Adjustment

Screw”.

b. Refer to Fig. 1-6.

(3) For Overfill Re-adjustment:

a. Those 2 Adjustment Screws must be released closely to the “Pre-assembly”

positions first.

b. Follow adjustment steps shown in Item 1.2.

Overfill Vertical

Adjustment Screw

Clip LP

Overfill Horizontal

Fig. 1-1 Fig. 1-2

41

Page 42

2. Insert

the LP

Module

1. Press down

the Clip

Fig. 1-3

Fig. 1-4

LP Datum of DMD HSG

Overfill adjustment screws

42

Page 43

1. Place Clips on

BKT surface

Fig. 1-5-1 Fig. 1-5-2

3. Lock screw

2. Push Baffle LP

to hook DMD HSG

Pre assemble this screw not

over the bottom surface.

Fig. 1-6

Pre assemble this screw

not over the side surface.

43

Page 44

2. Assembly FM Module:

Place FM on “HLD FM” surface(Fig. 2-1) and use “Clip FM” to fix FM(Fig. 2-2).

Touch the

side surface

Fig. 2-1 Fig. 2-2

3. Assembly HSG ILL Module:

3.1 CM Assembly

Clip FM hook

the punch

points

I. Insert “Clip CM Side” first, and then place “Clip Front CM” to fixed-shaft of ILL SUB

before locking screw (Fig. 3-1, Fig. 3-2).

II. Assemble CM to HSG ILL and to make CM contact three datum on the HSG ILL

Well (Fig. 3-3).

III. Assemble “CLIP TOP CM” (with forceps) to the “HSG IL” (Fig. 3-4,).

IV. To check and make sure “CLIP of CM” hooks the HSG ILL very Well (Fig. 3-5).

V. Paste “Sponge tube AL” on cannelure of” HSG ILL” (Fig. 3-6).

6.2 FM Module Assembly

1. FM Module must be placed to fixed shaft and on the datum surface of “ILL SUB”

and then lock with screw well (Fig. 3-7).

Clip CM Side

Fixed shafts

of ILL SUB

Fig. 3-1 Fig. 3-2

44

Screw

Page 45

Datum3

Datum1

Datum2

Fig. 3-3

Clip UP CM

Fig. 3-4 Fig. 3-5

Fig. 3-6

Sponge

45

Page 46

screw

Fig. 3-7

4. AL, HSG ILL and HSG DMD Assembly:

4.1 Placed “AL” on the “HSG DMD”. The “raised surface” of “AL” shall toward “DMD

direction” (Fig. 4-1).

4.2 To assemble ”HSG ILL SUB Module” with “HSG DMD” and cover over on “AL” and the

then lock with screws (Fig. 4-2).

AL

screw

Fixed shafts& holes

DMD Direction

Fig. 4-1 Fig. 4-2

46

Page 47

5. DMD and Chip B/D Module:

Damper

5.1. Judge Chip B/D and DMD alignment keying first (Fig. 5-1, 5-2).

5.2. Alight keying and Assemble DMD to Chip B/D (Fig. 5-3).

5.3. Push DMD slightly and use screwdriver rotate clockwise button to lock (close notation)

DMD on Chip B/D (Fig. 5-4).

Fig. 5-1 Fig. 5-2

Alignment keying

Open notation

Button

Fig. 5-3 Fig. 5-4

5.4 Place Damper on the surface of Chip-BD Fig. 5-5.

Fig. 5-5

Close notation

.

47

Page 48

6. Assembly Optical Engine:

6.1 Assemble “BKT Link Lamp & CW shield” on “DMD HSG” and then lock with screws well

(Fig. 6-1).

Shield CW

Screw

BKT Link

Lamp

Fig. 6-1

7. Assembly OP ENG

7.1 Assemble “Baffle DMD” to “HSG DMD” (Fig.7-1).

7.2 Assemble “Sponge DMD” to “HSG DMD” (Fig.7-1).

7.3 Assemble Chip B/D Module to “HSG DMD” (Fig. 7-2).

Alignment keying

Baffle DMD

Sponge DMD

Fig.7-1

48

Page 49

Fixed shafts of

DMD HSG

Fig.7-2-1

Fixed holes of DMD

Fig.7-2

7.4 Assemble Thermal Pad & Gasket Hest-sink then place contact DMD (Fig. 7-3).

i. Pre-fastening Sequence: [ 1 ] - [ 2 ] - [ 3 ] - [ 4 ].

ii. Fastening Sequence: [ 2 ] - [ 1 ] - [ 4 ] - [ 3 ].

iii. Screw Torque must be confirmed to be 6 kg-cm.

49

Page 50

○

○

4

1

Gasket

Screw

○

3

○

2

Fig. 7-3

7.5 Assemble “CW Module” to “DMD HSG” and lock with screws well (Fig.7-4).

Screw

Fixed shafts

of DMD HSG

Fig.7-4

50

Page 51

7.6 Assemble “Mylar Antidust” well (Fig. 7-5).

Mylar Antidust

Fig.7-5

Fixed shafts of DMD HSG

7.7 Assemble PL LENS” and lock with screws well (Follow MP522 assembly) (Fig. 7-6).

Screw

Fig. 7-6

51

Page 52

7.8 Assemble “Ring Zoom” and lock with screws well (Fig. 7-7).

Screws* 2PCS

7.9 Assemble “Ring Focus” (Fig. 7-8).

Fig. 7-7

Insert and push Ring Focus until fix on the pin of LENS

Fig. 7-8

52

Page 53

7.10 Assemble Lamp Module to “BKT Link Lamp” and then lock with screw well (Fig. 7-10,

Fig. 7-11).

Screw

Fixed shafts

Fig. 7-10

Fig. 7-11

53

Page 54

Module Assembly Key Point – Mechanical

1. Assemble Lower case

This module includes LC*1pcs,Sponge*1pcs,

SHD LC*1pcs,Screw*3pcs

Sponge pasted as lower case, must closed

to hook.

Screw*3pcs

54

Page 55

2. Lower case and Adjust foot

Spring no bend

3. Blower module assemble with LC

This step includes blower module*1pcs and screw2pcs

Screw*2pcs

4. Ballast wire Alignment dressed

It needs screw*2pcs

55

Page 56

The EMI cord will behind

the mylar-ballast

screws*2

The wire needn’t around

this rib.

Ballast to Lamp wire should

align in to this groove

56

Page 57

5. Mylar-ballast and blower module assembly

First: assy Blower module

Second: assy Mylar Ballast

6. Lamp box assemble with lower case Rib

This step needs screw*2pcs to fix assembly lamp-box with LC!

Ballast to Lamp wire

also should align in to

Mylar Ballast groove

57

Page 58

58 59

Page 59

7. PWR BD board must check the height of soldering tin

This step needs check connector and boss height.

A piece of screw*1pcs needs dress.

Screw*1pc

This cord direction should like this

8. The assembly of OPE and LC

This step needs screw/8F.VA564.7R0*3pcs to tighten.

And the sequence needs obey according to picture.

For EMI, the rubber power is necessary.

Page 60

Screw*3pcs

Rubber Power

9. Fix PWR between SHD-PWR and LC

Assemble SHD-Power

This assembly includes SHD/3K.0R501.031*1pcs, saddle/4B.0R501.001*1pcs and a

piece of mylar/4K.0R501.001*1pcs.

This step needs screw*4pcs to tighten parts.

60

Page 61

Screw

Screw

Confirm the position of EMI cord right.

61

Page 62

10. Main BD assembly and connector position

Need check the connectors OK completely

This step adds sponge*1pcs

62

Page 63

11. Assemble Main BD SHD

CW sensor board wire and CW FPC alignment

Please align the CW FPC, then put the sensor wire into the saddle together.

Second, screw*4pcs will be done firstly.

The add screw*1pcs and clip*1pcs

Finally, assemble fan and fix the wire by clip.

First Screw*4pcs

Screw*1

63

Page 64

12. Front IR wire to MB alignment

Front IR wire should align

in to these grooves

64

Page 65

13. Stick the leakage Mylar

Align IR-holder side (A and B) paste mylar

A

B

14. Dress the Inlet-case, outlet-case and rear-case

It is necessary to confirm the position of SHD when assembling the rear-case!

65

Page 66

Please attention a piece of Mylar on Rear-case

Refer to its assembly as follows:

Shield K-LUCK light leakage

Action: add new Mylar at rear case

Align this side

Align this side

No adhesive

area

66

Page 67

15. Assembly side case

Assy case-inlet:

Assy case-outlet: (For X1130PA / X1230PK/ X1230P/ X1237/ X1230PA)

It includes Case-outlet*1pcs, sponge*3pcs, speaker*1pcs and screw*2pcs.

67

Page 68

For this module, pay attention to the first position of sponge and the orientation of SPK.

16. Assembling the case-upper

Align this side pasted sponge

Push bkt-key and key closed

Add washer and screw to hold key-bkt

68

Page 69

Add a piece of sponge for light leakage

17. Ballast to lamp wire alignment

Lamp box should close up the opening of lower case

Lamp connector assemble with rib

69

Page 70

18. Lamp Door screw assemble sequence

19. Protect firm at upper case must have no bubble

Must use a scraper to removed the bubbles.

20. Add a piece of Mylar for light leakage

70

Page 71

Chapter 4 Troubleshooting

System Analysis

Keypad LED OK?

YES

Lamp On?

YES

No Signal?

NO

Power Auto Turn Off?

NO

NO

NO

YES

YES

Step

:

1. Check Lamp Door

2. Check Connection between Power BD and Main BD

3. Check Power Board and Interlock

4. Check Main Board

Step

:

1. Check Lampen wire , Lamp wire and Ballast wire

2. Check C/W and wire connection

3. Check Main board

4. Check Lamp

5. Check Ballast

Step

:

1. Check Input Cable

2. Check OSD Source set up

3. Check Main board

Step

:

1. Check OSD Lamp Hours

2. Check Lamp Door

3. Check Lamp still light or not?

4. Check Fan still spin or not?

5. Check Thermal status

IR Remote Control NG?

NO

Pixel Fail?

YES

YES

Step

:

1. Check Remote module battery

2. Check Remote module

3. Check IR wire between Main board and IR board

4. Check IR Reciver on IR board

Step

:

1. Check the connection between

Main BD and Chip BD

2. Check the connection between

OP engine and DMD Chip

3. Check Chip board

4. Check Main board

71

Page 72

Optical Problems Checking Items

No. Item Trouble Shooting Guide

1 Brightness

2 Uniformity

3 FOFO Contrast

4 ANSI Contrast

1. Change lamp

1. Change lamp

1. Check ADC calibration

2. Check user’s menu brightness & contrast are default

3. Clean DMD

4. Clean PL

5. Check ILL stop assy

1. Clean PL

2. Clean DMD

3. Change PL

5 Color

6 Color Uniformity

7 Blue Edge

8 Blue/Purple Border

9 Focus

10 Dust

11

Horizontal/Vertical

Strips

1. Check color wheel delay

2. Check CW 50% point. Replace CW if necessary

1. Change lamp

1. Refer to next page

2. Change CM

3. Change SUB HSG

1. Refer to next page

2. Change CM

3. Change SUB HSG

1. Change Projection Lens

2. Check PL datum and DMD parallel

Clean DMD

1. Check connector between chip BD and Main BD

2. Re-install DMD with chip BD

3. Check if any pin of C-Spring is missing, damaged or dirty

4. Change new Chip BD/C-Spring

5. Change new DMD

12 Pixel Fail Change new DMD

72

Page 73

“Blue Edge” Trouble Shooting:

I. Re-adjust “Overfill” first.

For Overfill Re-adjustment:

i. Those 2 Adjustment Screws must be released for around 2 mm first.

ii. Alignment Sequence:

a. To adjust “Horizontal Adjustment Screw” firstly, then “Vertical Adjustment

Screw”.

b. Refer to below Figure.

(2) Overfill Vertical

Adjustment Screw

(1) Overfill Horizontal

Adjustment Screw

II. Re-assemble LP module—include LP, LP Baffle, LP clip.

73

Page 74

Power Supply Problems Checking Flow

74

Page 75

LED Messages Definition

0.5 second H(On), 0.5

Will automatically turn

0.5 second H(On), 0.5

External Status indicator

LED Name Detailed Description

Power LED Display the power on/off sequence status

Lamp Status LED Display the Lamp status (Lamp fail, Lamp spoil etc.)

Temperature Status LED Display the Thermal status (Fan Fail, Over Temperature, etc.)

Lamp_LED Temp_LED Power_LED Power_LED

Red Red Red Blue

Power Plug Flash ON to OFF Flash ON to OFF Flash ON to OFF -Standby -- -- ON --

Power button ON -- -- -- ON

Lamp retry -- -- --

0.5 second H(ON),

Cooling state -- --

Power button OFF:

Cooling completed;

Standby Mode

Firmware Download ON ON

Thermal sensor error

(T2 8≧5℃) (Lamp

Over Temperature)

OSD shows

“Projector

Overheated”

Thermal sensor error

(T1 40

≧ ℃

shows “Projector

Overheated”

Fan lock error OSD

shows red “Fan Fail,

off soon”

Lamp error (Lamp,

ballast)

Color Wheel fail

) OSD

0.5 second H(ON),

0.5 second L(OFF)

-- -- ON --

-- ON -- ON

-- ON -- ON

--

ON -- -- ON

flashing

second L(Off) flashing

-- -- ON

0.5 second L(OFF)

flashing

-- ON

second L(Off) flashing

--

75

Page 76

Error Count Messages Definition

Error Count Definition Specification

LAMP Fail error LAMP OFF DETECT LAMPLIT

FAN 1 Speed Error LAMP FAN SPEED ERROR SPEED OVER ± 20%

FAN 2 Speed Error BALLAST FAN SPEED ERROR SPEED OVER ± 20%

FAN 3 Speed Error BLOWER FAN SPEED ERROR SPEED OVER ± 20%

Sensor 1 Open Error Main Board SENSOR ERROR DETECT Sensor 1

Sensor 2 Open Error Power board SENSOR ERROR DETECT Sensor 2

Sensor 1 Short Error Main Board SENSOR ERROR DETECT Sensor 1

Sensor 2 Short Error Power board SENSOR ERROR DETECT Sensor 2

Temperature 1 Error over limited temperature N/A

Temperature 2 Error over limited temperature N/A

FAN IC I2C ERROR I2C communication error N/A

Fan 3 :

Blower Fan

Fan 1 :

Lamp Fan

Thermal

sensor 1

Fan 2 :

Power Fan

LED

message

Thermal sensor 2

76

Page 77

RS232 Connection

1. Connection:

Below shows the illustration of connection between PC and Projector.

<CAUTION>

Make sure that your computer and projector are turned off before connection.

Power on the computer first, and then plug the power cord of the projector. (It may

cause Com port incorrect function, if you do not follow this instruction)

Adapters may be necessary depending on the PC connected to this projector. Please

contact with your dealer for further details.

2. Hardware connection

<download cable 1>

<pin assignment for this two end>

77

Page 78

Interface Settings

RS-232 protocol

Baud Rate 115200 bps

Data Length 8 bit

Parity Check None

Stop Bit 1 bit

Flow Control None

Command Category

Refer to Appendix A

78

Page 79

Adjustment / Alignment Procedure

Content :

1. Color Wheel Delay Alignment

2. Overfill adjustment

3. PC Alignment Procedure

4. Keystone Calibration

79

Page 80

1. Color Wheel Delay Alignment

Procedure:

1. Enter Factory Mode

2. Enter Block 1

3. Change CW Delay by adjusting the following gray pattern to smooth

32 Gray pattern

80

Page 81

2. Overfill adjustment (Blue Edge adjustment)

1. “Full White Pattern” is suggested for this alignment.

2. Adjust 2 LP-alignment Screws (upper side / lower front side of Optical Engine) behind

Color Wheel.

3. Alignment Criteria is to adjust these 2 screws until “No Dark Edges” and “ No

Shadows” can be observed in image.

81

Page 82

3. PC Alignment Procedure

OSD Default value:

Item Value

Cal R Offset 512

Cal G Offset 512

Cal B Offset 512

Cal R Gain 1024

Cal G Gain 1024

Cal B Gain 1024

YPbPr R Offset 512

YPbPr B Offset 512

Procedure:

Gray Level:

1. Connect power cord, D-sub cable, and pattern generator into projector

2. Light on projector

3. Change Timing and pattern of pattern generator

4. Timing:

For X1130P/X1130PA : 800*600 @60Hz (SVGA)

For X1230PK/ X1230P/ X1230PA/ X1237: 1024*768@60Hz (XGA)

5. Pattern: pattern 1

6. Press keypad “Resync” to confirm image frame is correct

7. Enter factory mode and select 3rd page in factory mode

8. Set Factory values to default

9. Change Timing and pattern of pattern generator

10. Timing:

For X1130P/X1130PA : 800*600 @60Hz (SVGA)

For X1230PK/ X1230P/ X1230PA/ X1237: 1024*768@60Hz (XGA)

11. Pattern: As Figure above {A near white color (240,240,240) and a near black color

(16,16,16)}

12. Press “Calibration RGB” to let the black level to just distinguish, and the light output

of white level to just max

13. Check the 32 levels of gray. All steps must appear

14. Done.

White-black pattern

82

Page 83

4. Keystone Calibration

Condition:Horizontal plane(0∘)

1. Make projector be horizontal

2. Enter factory menu

3. Enter into Block 3 in factory menu

4. Select item “AutoKeystoneCal”

5. Press key Left or Right to do auto calibration

6. Finish 0 calibration and bellow items will show data∘ :

AutoKeystoneXCal: 5≦

AutoKeystoneXOffset: 20≦

83

Page 84

Chapter 5 FRU List

Exploded Diagram

Module 1 – Total Exploded View

84

Page 85

85

Page 86

Module 2 – ASSY UPPER CASE

86

Page 87

Module 3 – ASSY LOWER CASE

87

Page 88

Module 4 – ASSY FRONT CASE

88

Page 89

FRU List

MAIN BOARD (W/

Model CATEGORY PARTNAME ACER PART NO.

Projector Remote

Control Qisda RC

X1130P ACCESSORY

X1130PA/X1230

PK/X1230PA/X1

230P/X1237

X1130P BOARD

ACCESSORY

Q5 layout (25

keys w/o Laser,

w/o Mouse, with

PgUp/PgDn)

Projector Remote

Control Qisda RC

Q3 layout (25

keys w/o Laser,

Mouse,

PgUp/PgDn)

MAIN BOARD(W/

KEYPAD

BOARD)

VZ.K0300.002

VZ.K0300.001

55.K060Q.001

Photo

X1130PA BOARD

X1230PK BOARD

X1230PA/X1230

P/X1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

BOARD

BOARD

BOARD POWER BOARD 55.K060Q.003

KEYPAD

BOARD)

MAIN BOARD(W/

KEYPAD

BOARD)

MAIN BOARD(W/

KEYPAD

BOARD)

BALLAST (LAMP

DRIVER)

55.K090Q.001

55.K030Q.001

55.K100Q.001

55.K060Q.002

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

BOARD DMD CHIP BAOD 55.K060Q.004

BOARD

IR SENSOR

BOARD

55.J900Q.005

89

Page 90

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

CABLE

CABLE

CABLE

CABLE

CABLE

CABLE

CABLE

CABLE

CABLE

CABLE

POWER CORD

UK

POWER CORD

EUR

POWER CORD

SWIS

POWER CORD

ARF

POWER CORD

US

POWER CORD

AUS

POWER CORD

CHINA

POWER CORD

THAILAND

POWER CORD

INDIA

POWER CORD

JP

27.LDW0Q.001 -

27.LBJ0Q.001 -

50.LE20Q.004 -

27.LCE0Q.002 -

27.LBJ0Q.002 -

27.LBJ0Q.004 -

50.LE10Q.004 -

27.J900Q.001 -

27.LCE0Q.001 -

27.LE20Q.001 -

X1130PA/X1230

P/X1237

CABLE

POWER CORD

KOR

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

CABLE D-SUB CABLE 50.J900Q.001 -

1237

X1230PK/X1230

P/X1237

CABLE RCA CABLE 50.J900Q.002

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

CABLE

CABLE M/B TO

IR BOARD

27.K090Q.001

50.J900Q.003

90

Page 91

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

CABLE

CABLE BALLAST

TO LAMP

50.K060Q.001

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P

X1230PK

X1130PA/X1230

PA/X1230P/X12

37

CABLE

CABLE

CASE/COVER/B

RACKET

ASSEMBLY

CASE/COVER/B

RACKET

ASSEMBLY

CASE/COVER/B

RACKET

ASSEMBLY

CABLE POWER

BOARD TO

50.K060Q.002

BALLAST

CABLE M/B TO

BALLAST

50.K060Q.003

REAR CASE 60.K060Q.001

REAR CASE 60.K030Q.001

REAR CASE 60.K090Q.001

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

CASE/COVER/B

RACKET

ASSEMBLY

CASE/COVER/B

RACKET

ASSEMBLY

CASE/COVER/B

RACKET

ASSEMBLY

CASE/COVER/B

RACKET

ASSEMBLY

CASE/COVER/B

RACKET

ASSEMBLY

INTEL CASE 60.K060Q.002

OUTLET CASE 60.J900Q.003

UPPER CASE

(W/ KEYPAD

RUBBER&

60.K060Q.003

BRACKET)

LOWER CASE

(W/ ADJUST

60.J900Q.005

FOOT)

FRONT CASE

(W/O IR BOARD)

60.J900Q.006

91

Page 92

X1130P/X1130P

X1130P/X1230PK

A/X1230PK/X12

30PA/X1230P/X

1237

CASE/COVER/B

RACKET

ASSEMBLY

LAMP DOOR 60.J900Q.007

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P

X1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

1237

CASE/COVER/B

RACKET

ASSEMBLY

CASE/COVER/B

RACKET

ASSEMBLY

DIGITAL LIGHT

DEVICE

DIGITAL LIGHT

DEVICE

DIGITAL LIGHT

DEVICE

ZOOM RING 60.J900Q.008

FOCUS RING 60.J900Q.009

Phillips

Lamp Module

EC.K0600.001

189W, DIT85,

DDP2430

Lamp Module for

X1237 (Phillips

UHP 185-163W

EC.K1200.001

/E20.6-B)

COLOR WHEEL

MODULE(W/

SENSOR BD &

57.K060Q.001

CABLE)

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

DIGITAL LIGHT

DEVICE

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

DIGITAL LIGHT

DEVICE

1237

X1130P/X1130PA DIGITAL LIGHT

DEVICE

X1230PK/X1230

PA

X1230P/X1237

DIGITAL LIGHT

DEVICE

DIGITAL LIGHT

DEVICE

LIGHT PIPE 57.J900Q.002

LENS 57.K060Q.002

DMD CHIP 57.K060Q.003

DMD CHIP 57.K030Q.001

DMD CHIP

TBC

92

Page 93

X1130P/X1130PA DIGITAL LIGHT

DEVICE

X1230PK/X1230

PA

X1230P/X1237

DIGITAL LIGHT

DEVICE

DIGITAL LIGHT

DEVICE

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

FAN FAN (X2) 23.K060Q.001

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

FAN

1237

ENGINE

MODULE

ENGINE

MODULE

ENGINE

MODULE

FAN BLOWER

MODULE

57.K060Q.004

57.K030Q.002

TBC

23.K060Q.002

X1130PA/X1230

PK/X1230PA/X1

SPEAKER SPEAKER 23.K030Q.001

230P/X1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

MISCELLANEO

US

FOOT ADJFOOT 47.J900Q.001

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

MISCELLANEO

US

RUBBER

ADJFOOT PAD

1237

X1130P/X1130P

A/X1230PK/X12

30PA/X1230P/X

JIG BOARD

TOOL KIT FOR

EDID UPLOAD

1237

(Note) The updated P/N refers to latest Spare Part List

47.J900Q.002

6K.J900Q.001

93

Page 94

Appendix A - Code List: IR / RS232 / DDC Data

1. Remote Control Code:

IR setting value

Frequency: 38kHz

Protocal: NEC format

b. IR command code

X1130P:

Customer code::::0813

94

Page 95

X1130PA/ X1230PK/ X1230P/ X1230PA/ X1237:

Customer code::::0813

95

Page 96

2. RS-232 Command Code

General command type (Projector ‘receives’ commands)

No

Code (character)

1 OKOKOKOKOK Power On support

2 * 0 IR 001 Power On support

3 * 0 IR 002 Power Off support

4 * 0 IR 004 Keystone support

5 * 0 IR 006 Mute support

6 * 0 IR 007 Freeze support

7 * 0 IR 008 Menu support

8 * 0 IR 009 Up support

9 * 0 IR 010 Down support

10 * 0 IR 011 Right support

11 * 0 IR 012 Left support

12 * 0 IR 013 Enter

13 * 0 IR 014 Re-Sync support

14 * 0 IR 015 Source Analog RGB for D-sub support

15 * 0 IR 016 Source Digital RGB

16 * 0 IR 017 Source PbPr for D-sub

17 * 0 IR 018 Source S-Video support

Function feature Note

Unsupport

Unsupport

Unsupport

18 * 0 IR 019 Source Composite Video support

19 * 0 IR 020 Source Component Video support

20 * 0 IR 021 Aspect ratio 16:9 support

21 * 0 IR 022 Aspect ratio 4:3 support

22 * 0 IR 023 Volume + support

23 * 0 IR 024 Volume – support

24 * 0 IR 025 Brightness support

25 * 0 IR 026 Contrast support

26 * 0 IR 027 Color Temperature support

27 * 0 IR 028 Source Analog RGB for DVI Port

28 * 0 IR 029 Source Analog YPbPr for DVI Port

29 * 0 IR 030 Hide support

30 * 0 IR 031 Source support

31 * 0 IR 032 Video: Color saturation adjustment

32 * 0 IR 033 Video: Hue adjustment support

33 * 0 IR 034 Video: Sharpness adjustment support

34 * 0 IR 035 Query Model name support

35 * 0 IR 036 Query Native display resolution support

Unsupport

Unsupport

support

36 * 0 IR 037 Query company name support

37 * 0 IR 040 Aspect ratioL.Box

38 * 0 IR 041 Aspect ratio 1:1

39 * 0 IR 042 Keystone Up support

40 * 0 IR 043 Keystone Down support

Unsupport

Unsupport

96

Page 97

41 * 0 IR 044 Keystone Left

Return the Native display

42 * 0 IR 045 Keystone Right

43 * 0 IR 046 Zoom support

44 * 0 IR 047 e-Key support

45 * 0 IR 048 Color RGB support

46 * 0 IR 049 Language support

47 * 0 IR 050 Source HDMI

Unsupport

Unsupport

Unsupport

General command type (Projector ‘transmits’ commands)

NO

Code (character)

1 Model XXXXXXXX Return the Model name support

2 Res XXXXX

3 Name XXXXXXXX Return the company name support

resolution

Function feature Note

support

Lamp command type (Projector ‘receives’ commands)

NO

Code (character)

1 * 0 Lamp ? Query the lamp ON/OFF support

2 * 0 Lamp Query the lamp hours support

Function feature Note

Lamp command type (Projector ‘transmits’ commands)

NO

Code (character)

Function feature Note

1 Lamp 0 Return Lamp OFF status support

2 Lamp 1 Return Lamp ON status support

3 XXXX Return Lamp hours support

Source command type (Projector ‘receives’ commands)

NO

Code (character)

1 * 0 Src ? Query source input type support

Function feature Note

97

Page 98

3. DDC Data

X1130P EDID

EDID Block 0, Bytes 0-127 [00H-7FH]

Block Type: EDID 1.3

0 1 2 3 4 5 6 7 8 9 A B C D E F

________________________________________________________________

0 | 00 FF FF FF FF FF FF 00 04 72 05 06 01 00 00 00

10 | 01 13 01 03 0E 00 00 78 0A D1 8A A5 57 58 96 23

20 | 17 50 60 3F CF 80 31 7C 45 7C 61 7C 81 80 81 C0

30 | 81 00 95 00 B3 00 A0 0F 20 00 31 58 1C 20 28 80

40 | 14 00 00 00 00 00 00 1E 00 00 00 FD 00 30 78 1F

50 | 5D 11 00 0A 20 20 20 20 20 20 00 00 00 FC 00 58

60 | 31 31 33 30 50 0A 20 20 20 20 20 20 00 00 00 FF

70 | 00 4B 30 36 30 35 30 30 31 38 34 30 31 0A 00 AF

______________________________________________________________________

(08H-09H) ID Manufacturer Name _________________________ = ACR

(0AH-0BH) Product ID Code ______________________________ = 0605

(0CH-0FH) Last 5 Digits of Serial Number _______________ = 00001

(10H) Week of Manufacture __________________________ = 01

(11H) Year of Manufacture __________________________ = 2009

(12H) EDID Version Number __________________________ = 1

(13H) EDID Revision Number _________________________ = 3

(14H) VIDEO INPUT DEFINITION:

Analog Signal

0.700, 0.300 (1.000 Vp-p)

Sync on Green, Composite Sync, Separate Syncs

(15H) Maximum Horizontal Image Size ________________ = mm

(16H) Maximum Vertical Image Size __________________ = mm

(17H) Display Gamma ________________________________ = 2.20

(18H) DPMS and Supported Feature(s):

Preferred Timing Mode

Display Type = R/G/B Color

(19H-22H) CHROMA INFO:

Red x - 0.647 Green x - 0.344 Blue x - 0.139 White x - 0.314

Red y - 0.341 Green y - 0.587 Blue y - 0.090 White y - 0.377

(23H) ESTABLISHED TIMING I:

640 x 480 @ 60Hz (IBM,VGA)

640 x 480 @ 67Hz (Apple,Mac II)

640 x 480 @ 72Hz (VESA)

640 x 480 @ 75Hz (VESA)

800 x 600 @ 56Hz (VESA)

800 x 600 @ 60Hz (VESA)

(24H) ESTABLISHED TIMING II:

800 x 600 @ 72Hz (VESA)

800 x 600 @ 75Hz (VESA)

1024 x 768 @ 60Hz (VESA)

1024 x 768 @ 70Hz (VESA)

1024 x 768 @ 75Hz (VESA)

1280 x 1024 @ 75Hz (VESA)

(25H) Manufacturer's Reserved Timing:

1152 x 870 @ 75Hz (Apple,Mac II)

(38-53) Standard Timing Identification:

Standard Timing ID 1: 640 x 480 @120Hz

::::

98

Page 99

Standard Timing ID 2: 800 x 600 @120Hz

Standard Timing ID 3: 1024 x 768 @120Hz

Standard Timing ID 4: 1280 x 1024 @60Hz

Standard Timing ID 5: 1280 x 720 @60Hz

Standard Timing ID 6: 1280 x 800 @60Hz

Standard Timing ID 7: 1440 x 900 @60Hz

Standard Timing ID 8: 1680 x 1050 @60Hz

______________________________________________________________________

(36H-47H) Detailed Timing / Descriptor Block 1:

800x600 Pixel Clock: 40.00 MHz

______________________________________________________________________

Horizontal Image Size: 0 mm Vertical Image Size: 0 mm

Refreshed Mode: Non-Interlaced Normal Display - No Stereo

Horizontal:

Active Count: 800 pixels Blanking Count: 256 pixels

Sync Offset: 40 pixels Sync Pulse Width: 128 pixels

Border: 0 pixels Frequency: 37.88 kHz

Vertical:

Active Count: 600 lines Blanking Count: 28 lines

Sync Offset: 1 lines Sync Pulse Width: 4 lines

Border: 0 lines Frequency: 60.32 Hz

Digital Separate, Horizontal Polarity (+) Vertical Polarity (+)

______________________________________________________________________

(48H-59H) Detailed Timing / Descriptor Block 2:

Monitor Range Limits:

Min Vertical Freq - 48 Hz

Max Vertical Freq - 120 Hz

Min Horiz. Freq - 31 kHz

Max Horiz. Freq - 93 kHz

Pixel Clock - 170 MHz

GTF - Not Used

______________________________________________________________________

(5AH-6BH) Detailed Timing / Descriptor Block 3:

Monitor Name:

X1130P

______________________________________________________________________

(6CH-7DH) Detailed Timing / Descriptor Block 4:

Monitor Serial Number:

K06050018401

(7EH) Block No: No Extension EDID Block(s)

(7FH) CheckSum OK

99

Page 100

X1130PA EDID

EDID Block 0, Bytes 0-127 [00H-7FH]

Block Type: EDID 1.3

0 1 2 3 4 5 6 7 8 9 A B C D E F

________________________________________________________________

0 | 00 FF FF FF FF FF FF 00 04 72 05 09 01 00 00 00

10 | 01 13 01 03 0E 00 00 78 0A D1 8A A5 57 58 96 23

20 | 17 50 60 3F CF 80 31 7C 45 7C 61 7C 81 80 81 C0

30 | 81 00 95 00 B3 00 A0 0F 20 00 31 58 1C 20 28 80

40 | 14 00 00 00 00 00 00 1E 00 00 00 FD 00 30 78 1F

50 | 5D 11 00 0A 20 20 20 20 20 20 00 00 00 FC 00 58

60 | 31 31 33 30 50 41 0A 20 20 20 20 20 00 00 00 FF

70 | 00 4B 30 39 30 35 30 30 31 38 34 30 31 0A 00 88

______________________________________________________________________

(08H-09H) ID Manufacturer Name _________________________ = ACR

(0AH-0BH) Product ID Code ______________________________ = 0905

(0CH-0FH) Last 5 Digits of Serial Number _______________ = 00001

(10H) Week of Manufacture __________________________ = 01

(11H) Year of Manufacture __________________________ = 2009

(12H) EDID Version Number __________________________ = 1

(13H) EDID Revision Number _________________________ = 3

(14H) VIDEO INPUT DEFINITION:

Analog Signal

0.700, 0.300 (1.000 Vp-p)

Sync on Green, Composite Sync, Separate Syncs

(15H) Maximum Horizontal Image Size ________________ = mm

(16H) Maximum Vertical Image Size __________________ = mm

(17H) Display Gamma ________________________________ = 2.20