Page 1

& K DSWHU

System Board

1.1 Features

The M9N is a dual-processor system board that supports the Intel

Pentium II CPU. It contains an exclusive connector for the CPU board

that carries two slots for the Pentium II CPU modules.

This high-perform ance 64-bit system board utilizes both the ISA and

the PCI local bus architecture. Two ISA and five PCI bus slots reside

on the board to allow installation of either master or slave devices.

A 50-pin Fast SCSI-II interface and two 68-pin W ide SCSI interfaces

come with the system board to connect SCSI devices. External I/O

interfaces include a parallel port and a video port, RJ-45 and USB

connectors, and keyboard and mouse ports.

The system board supports two optional features, the ASM Pro and

the remote diagnostic management (RDM), that allow better server

management. The ASM Pro detects problems in CPU thermal

condition, CPU working voltage detection (±12V/±5V/3.3V/1.5V), and

PCI bus utilization calculation. It also detects if the CPU fan or the

chassis fan malfunctions. The RDM allows execution of the RDM

diagnostic program from a remote RDM station to fix detected

problems or to reboot the system.

System Board 1-1

Page 2

1.2 Major Components

The system board has the following major components:

CPU board slot

•

Two ISA and five PCI bus slots (one PCI slot may include an

•

optional RAID port)

256-KB Flash ROM for system BIOS

•

System clock/calendar with battery backup

•

50-pin Fast SCSI-II and two 68-pin Wide SCSI interfaces

•

Two 24-pin RDM interfaces

•

IDE hard disk and diskette drive interfaces

•

Onboard VRAM and VRAM sockets for video memory upgrade

•

Power connector for both standard 420-watt SPS and redundant

•

420-watt SPS

Super I/O, SCSI, VGA, memory, and Advanced Server

•

Management (ASM) controller chipsets

External ports:

•

PS/2-compatible keyboard port (optional AT-keyboard port)

•

PS/2-compatible mouse port

•

Parallel port

•

Video port

•

RJ-45 connector

•

Universal Serial Bus (USB) connector

•

1-2 User’s Guide

Page 3

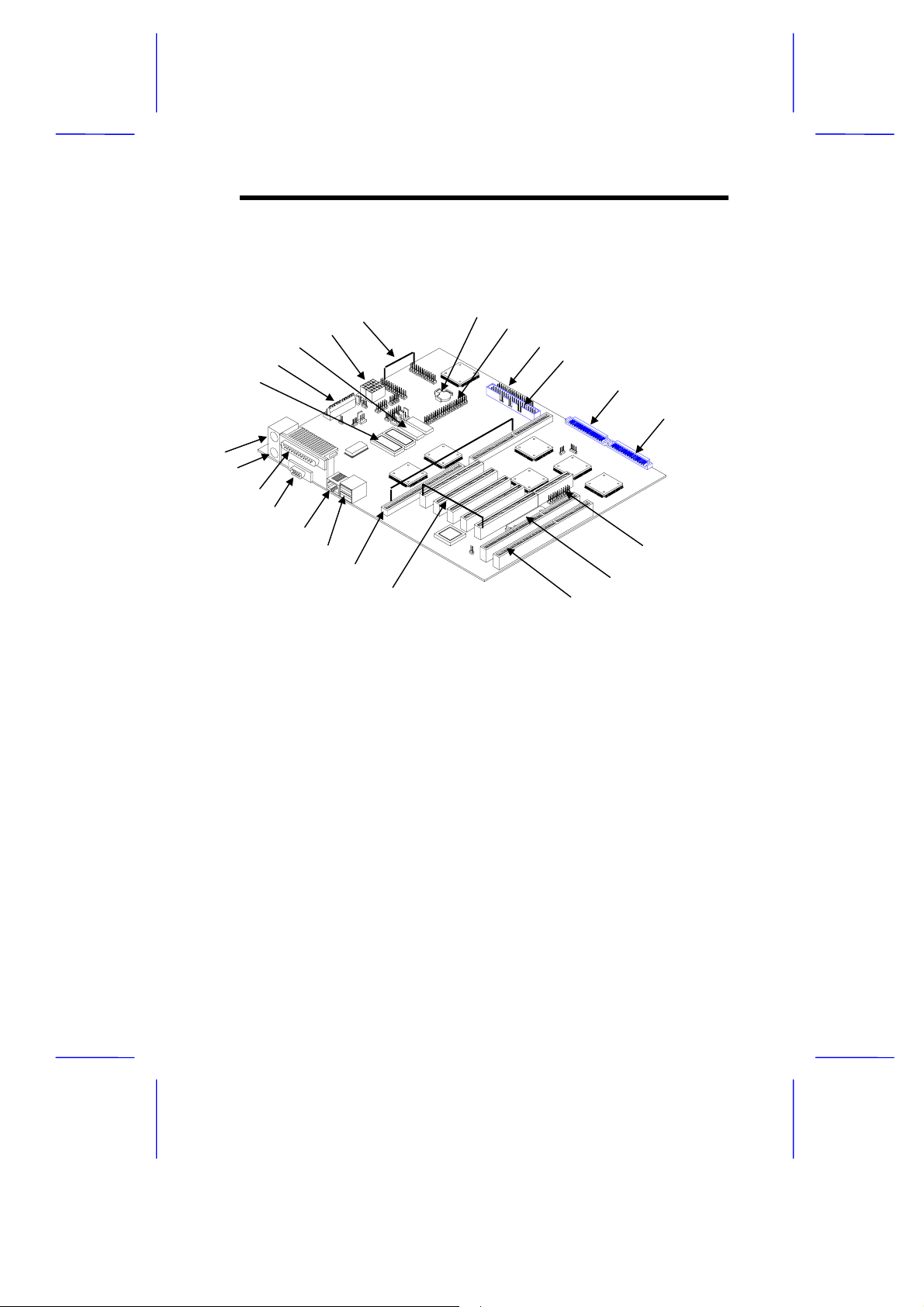

1.3 Layout

3

5

278

9

918

2

4

6

0

Figure 1-1 shows the system board components.

17

1

2

21

2

1

16

15

14

13

12

11

10

1 Keyboard port

2 Mouse port

3 Parallel port

4 Video port

5 RJ-45 connector

6 USB connector

7 CPU board slot

8 PCI slots

9 ISA slots

10 Flash ROM BIOS

11 RAID port (optional)

12 Wide SCSI connector 2

13 Wide SCSI connector 1

14 Narrow SCSI connector

15 Diskette drive connector

16 EIDE connector

17 Battery

18 RDM connectors

19 Power connectors

20 Video RAM

21 Power connector

22 Video RAM upgrade sockets

Figure 1-1 System Board Layout

System Board 1-3

Page 4

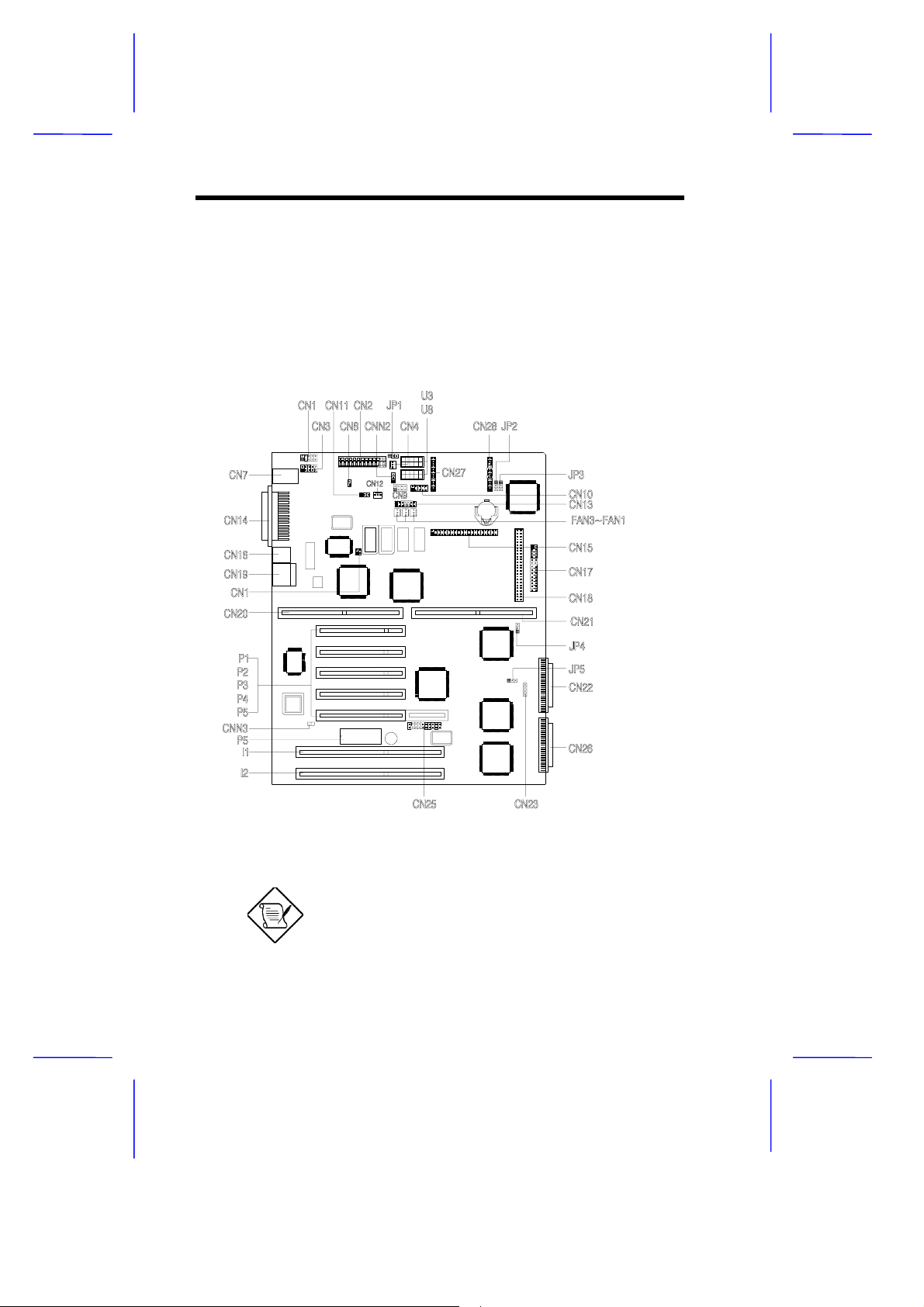

1.4 Jumpers and Connectors

1.4.1 Jumper and Connector Locations

Figure 1-2 shows the jumper and connector locations on the s ystem

board.

Figure 1-2 System Board Jumper and Connector Locations

Jumpers are prefixed “JP”. Connectors are

prefixed “CN”. The blackened pin of a jumper

represents pin 1.

1-4 User’s Guide

Page 5

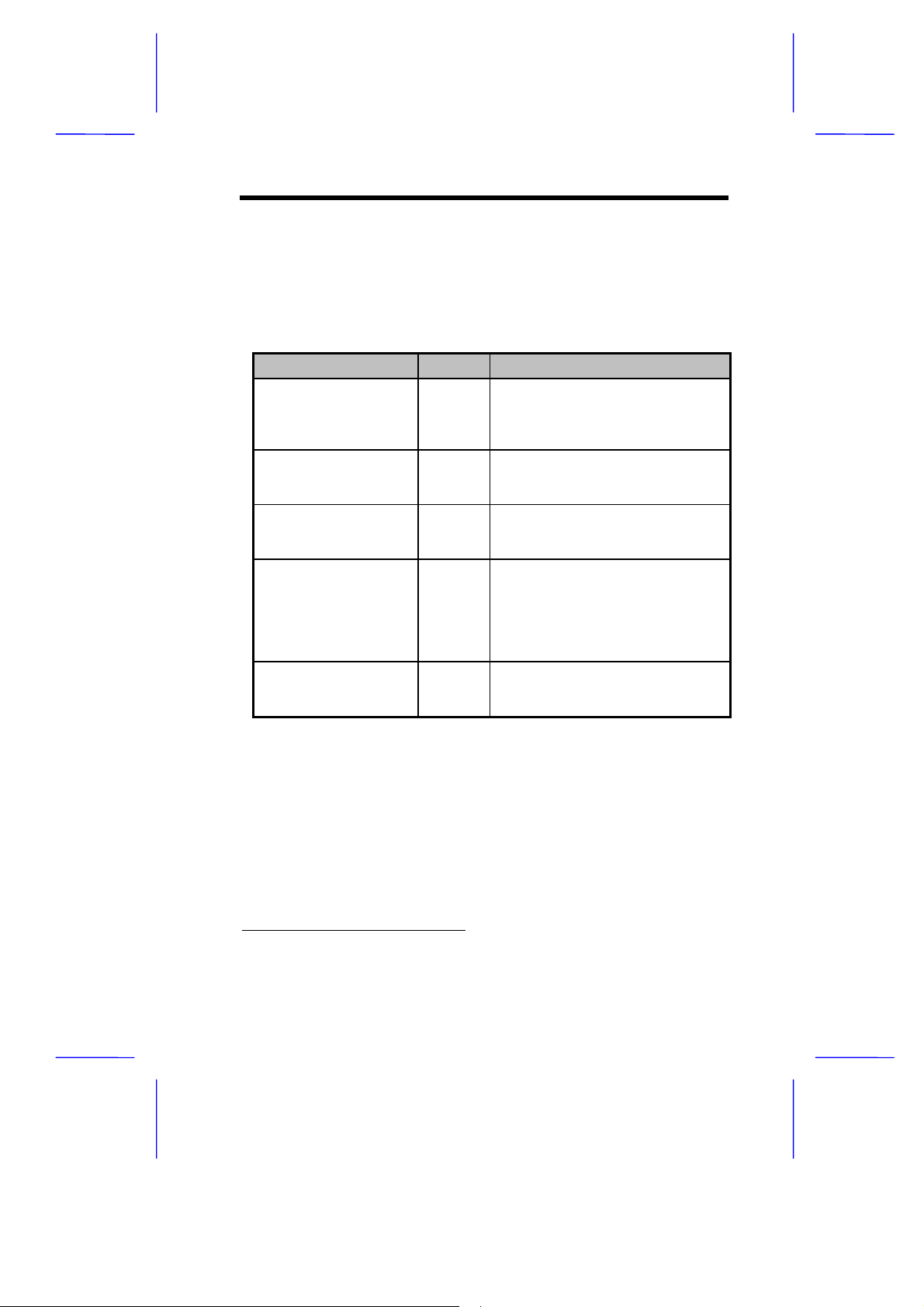

1.4.2 Jumper Settings

Table 1-1 lists the system board jumpers with their corresponding

settings and functions.

Table 1-1 System Board Jumper Settings

Jumper Setting Function

Software Shutdown

Control for CN4

JP1 1-2

BIOS Type

JP2 1-2

Password Security

JP3 1-2

SCSI Channel 1

High-Byte Termination

JP4 1-2*

VGA Feature

JP5 1-2*

*

2-3

2-3*

2-3*

2-3

Open

2-3

Enabled

Disabled

Branded

Generic

Check password

Bypass password

Terminator always set to ON

SCSI terminator set to ON or OFF

by software

Terminator set to OFF

Normal (Auto)

Onboard VGA always disabled

*

Default setting

System Board 1-5

Page 6

1.4.3 Connector Functions

Table 1-2 lists the differ ent connectors on the system board and their

respective functions.

Table 1-2 Connector Functions

Connector Function

CN1 COM 1

CN2, U3, U8 Power connectors

CN3 COM 2

CN4 Software shutdown connector for 420-watt SPS

CN7 PS/2 mouse (above) / keyboard (below) connectors

CN8 Power switch

CN9 Power LED and keylock connector

CN10 Monitor signal connector for redundant power supply

CN12 Software shutdown connector for redundant power

CN13 Backplane board LED connector

CN14 Printer port (above) / video port (below)

CN15 IDE connector

CN16 LAN connector

CN17 Diskette drive connector

CN18 Channel 1 narrow SCSI connector

CN19 Universal serial bus (USB) ports

CN22 Channel 1 wide SCSI connector

CN23 Hard disk LED connector

CN25 SMM connector

CN26 Channel 2 wide SCSI connector

CN27, CN28 RDM connectors

CNN3 Connec tor for chassis intrusion prevention

FA1, FA2, FA3 Fan connectors

supply

1-6 User’s Guide

Page 7

1.5 ESD Precautions

Always observe the following electrostatic discharge (ESD)

precautions before installing a system component:

1. Do not remove a component from its antistatic packaging until

you are ready to install it.

2. Wear a wrist grounding strap before handling electronic

components. Wrist grounding straps are available at most

electronic component stores.

Do not attempt the procedures described in

the following sections unless you are a

qualified technician.

System Board 1-7

Page 8

1.6 Video Memory Upgrade

Larger video memory allows you to display higher resolutions and

more colors. The system board comes with a 1-MB video memory

onboard upgradable to 2 MB.

Follow these steps to upgrade the video memory:

1. Locate the video DRAM upgrade sockets labeled U36 and U37

on the system board. See Figure 1-1.

2. Gently insert a video chip into each of the upgrade sockets.

Make sure that the pin 1 indicator on the chip

matches the notched corner of the socket.

Pin 1 Indicator

Notched Corner

Figure 1-3 Installing a Video Memory Chip

1-8 User’s Guide

Page 9

1.7 ASM Pro

The ASM Pro is a server management tool based on the Simple

Network Management Protocol (SNMP). It detects server problems

related to the CPU thermal condition, 5V/3.3V/1.5V detection, or PCI

bus utilization calculation.

This feature is designed primarily for server supervisors and

management inform ation system (MIS) personnel to help them detect

errors or potential trouble spots in their network servers through a

single management station.

The ASM Pro consists of two major parts:

ASM-Station - a Windows-based monitoring station that

•

communicates with the ASM-Agents.

ASM-Agent(s) - the individual servers managed by the

•

ASM-Station.

Refer to the ASM Pro user’s manual for more information.

System Board 1-9

Page 10

1.8 Remote Diagnostic Management

The Remote Diagnostic Management (RDM) is a network

management tool that utilizes modems and telephone lines to control a

host of servers from a remote station. It monitors and analyzes the

server condition, updates the BIOS settings if necessary, or reboots

the server in the event of failure and quickly return it to normal

operation. This capability to execute the RDM program fr om a rem ote

site bridges the distance barrier in fixing server problem s and reduces

wasted time due to system failure.

1.8.1 Installing the RDM Module

The system board comes with connectors CN27 and CN28 to

accommodate the RDM module.

Follow these steps to install the RDM module and connect the cable:

1. See Figure 1-1 for the location of the RDM connectors.

2. Gently insert the RDM module into CN27 and CN28. The module

fits only in one direction. Do not force it into to the connectors.

CN28

CN27

Figure 1-4 Installing the RDM Module

Refer to the RDM User’s Guide for detailed instructions on RDM

installation.

1-10 User’s Guide

Page 11

1.9 Error Messages

Do not continue using the computer if you receive an error m es sage of

any type. Note the message and take corrective action. This sec tion

explains the different types of error messages and corresponding

corrective measures.

There are two general types of error messages:

Software

•

System

•

1.9.1 Software Error Messages

Software error messages are returned by your operating system or

application. These messages typically occur after you boot the

operating system or when you run your applications. If you receive

this type of message, consult your application or operating system

manual for help.

1.9.2 System Error Messages

A system error message indicates a pr oblem with the computer itself .

A message of this type normally appears during the power-on self-test,

before the operating system prompt appears.

Table 1-3 lists the system error messages.

System Board 1-11

Page 12

Table 1-3 System Error Messages

Message Action

CMOS Battery Error Replace the RTC chip or

contact your dealer.

CMOS Checksum Error Check the RTC chip and the

necessary jumper. If the

battery is still good, run

Setup.

Display Card Mismatch Run Setup.

Diskette Drive Controller

Error or Not Installed

Diskette Drive Error Diskette may be defective. If

Diskette Drive A Type

Mismatch

Diskette Drive B Type

Mismatch

Equipment Configuration

Error

Hard disk Controller Error Run Setup.

Hard disk 0 Error Check all cable connections.

Hard disk 1 Error Check all cable connections.

Keyboard Error or No

Keyboard Connected

Keyboard Interface Error Replace the keyboard or

Check and connect the

control cable to the diskette

controller.

not, replace the diskette drive.

Run Setup and select the

proper drive type.

Run Setup and select the

proper drive type.

Modify the memory

configuration to agree with

one of the options in Table

2-x.

Replace hard disk.

Replace hard disk.

Check and connect the

keyboard to the system unit.

contact your dealer.

1-12 User’s Guide

Page 13

Table 1-3 System Error Messages (continued)

Message Action

Memory Error at:

MMMM:SSSS:OOO

(W:XXXX, R:YYYY)

where:

M: MB, S: Segment,

O: Offset, X/Y: write/read

pattern

Memory Size Mismatch

CPU Clock Mismatch

Onboard Serial Port 1

Conflict

Onboard Serial Port 2

Conflict

Onboard Parallel Port Conflict Run Setup and disable the

Pointing Device Error Check and connect pointing

Pointing Device Interface

Error

Press F1 key to continue or

Ctrl-Alt-Esc for Setup

Real Time Clock Error Check the RTC chip. If it is still

CPU BIOS Code Mismatch Contact your dealer.

Check installed DIMMs.

Contact your dealer.

Run Setup. Check if the values

shown in the memory

parameters are correct. If

correct, exit Setup and reboot

the system. If the error

message reappears, seek

technical assistance.

Run Setup and disable the

port.

Run Setup and disable the

port.

port.

device.

Replace the pointing device or

contact your dealer.

Press

Setup.

good, run Setup. If not, replace

the RTC chip.

or

+ + to enter

System Board 1-13

Page 14

1.9.3 Correcting Error Conditions

As a general rule, if an error message says "Press F1 to continue," it is

caused by a configuration problem, which can be easily corrected. An

equipment malfunction is more likely to cause a fatal error, i.e., an

error that causes complete system failure.

Here are some corrective measures for error conditions:

1. Run Setup. You must know the correct configuration values for

your system before you enter Setup, which is why you should

write them down when the system is correctly configured. An

incorrect configuration is a major cause of power-on error

messages, especially for a new system.

2. Remove the system unit cover. Check that the jumpers on the

system board and any expansion boards are set correctly.

3. If you cannot access a new disk, it m ay be because your disk is

not properly formatted. Format the disk fir st using the FDISK and

FORMAT commands.

4. Check that all connectors and boards are securely plugged in.

If you go through the corrective steps above and still receive an error

message, the cause may be an equipment malfunction.

If you are sure that your configuration values are correct and your

battery is in good condition, the problem may lie in a damaged or

defective chip.

In either case, contact an authorized service center for assistance.

1-14 User’s Guide

Loading...

Loading...