Page 1

System Board

1.1 Features

The M9A is a dual-processor system board that supports the Intel

P54C and P55C CPUs. The board contains an exc lusiv e slot for the

CPU board that carries the 321-pin zero-insertion force (ZIF) CPU

sockets plus the embedded 512-KB pipeline burst second-level

cache.

This high-perf orm ance 64-bi t system board utilizes both the EISA and

the PCI loc al bus architecture. Two EISA, four PCI bus slots, and one

EISA/PCI shared slot reside on the board to allow installati on of either

master or slave devices.

The system board has four DRAM banks composed of eight 72-pin

SIMM sockets that accommodate both fast-page mode and EDO

(extended dat a output) SIMMs. The sockets support a tot al of 512MB system memory using 64-MB SIMMs.

A 50-pin Fast SCSI-II interface and a 68-pin Wide SCSI interface

come with the system board to connect SCSI devices. Standard

external I/O interfaces include two 9-pin serial ports, one par all el port ,

a video port, and keyboar d and mouse ports.

The system board supports two optional features that allow better

server management, the ASM Pro and the remote diagnostic

management (RDM). The ASM Pro detects system problems, such

as CPU thermal condi tion, 5V/ 3.3V detecti on, and PCI bus utilization

calculat ion. The RDM all ows execution of a diagnosti c program f rom

a remote stat ion to f ix the detected problems or to reboot t he system.

System Board 1-1

Page 2

1.2 Major Components

The system board has the following major components:

•

Four DRAM banks com posed of eight 72-pi n SIMM sockets that

support single- and doubl e- densi ty 60 ns SIMMs

•

CPU board slot

•

Four PCI, two EISA bus slots, and one EISA /PCI shared slot

•

256-KB Flash ROM for system BIOS

•

System clock/calendar plus 8 KB extended CMOS RAM with

battery backup

•

50-pin Fast SCSI-II and 68-pin W ide SCSI i nterfaces

•

Two 24-pin RDM int er faces

•

IDE hard disk and di sket te drive inter faces

•

Onboard VRAM and VRAM sockets for video memory upgrade

•

Power connector f or 350- watt or 420- watt switc hing power supply

•

Super I/O, SCSI, VGA, memory, and Advanced Server

Management (ASM) control ler chipsets

•

External ports:

• Two 9-pin serial por ts

• PS/2-compatibl e k ey boar d por t (optional AT-keyboard por t)

• PS/2-compatibl e mouse port

• Parallel port

• Video port

1-2 User’s Guide

Page 3

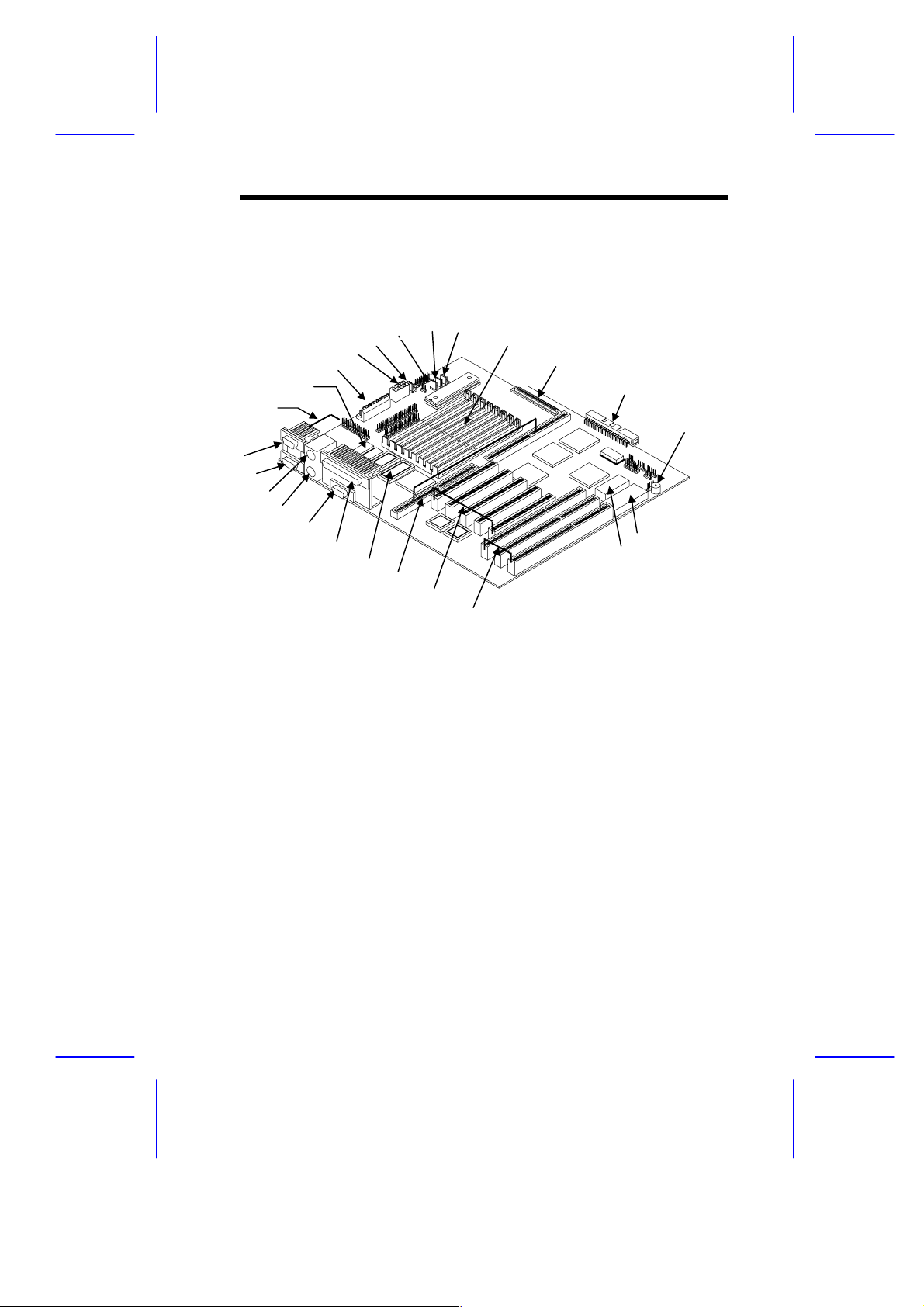

1.3 Layout

6

7

Figure 1-1 shows the system board components.

19

20

21

22

23

24

1

2

3

4

5

1 COM1

2 COM2

3 Mouse port

4 Keyboard port

5 Video port

6 Parallel port

7 Video upgrade sockets

8 CPU board slot

9 PCI slots

10 EISA slots

11 Real-time clock

12 Flash ROM BIOS

18

8

17

16

15

14

13

12

11

9

10

13 Buzzer

14 Narrow SCSI connector

15 W ide SCSI connector

16 SIMM sockets

17 Fan connector 1 ( FA1)

18 Fan connector 2 ( FA2)

19 Fan connector 3 ( FA3)

20 420W 5V standby power connector

21 Power connect or

22 Power connect or

23 Video RAM

24 RDM connectors

Figure 1-1 System Board Layout

System Board 1-3

Page 4

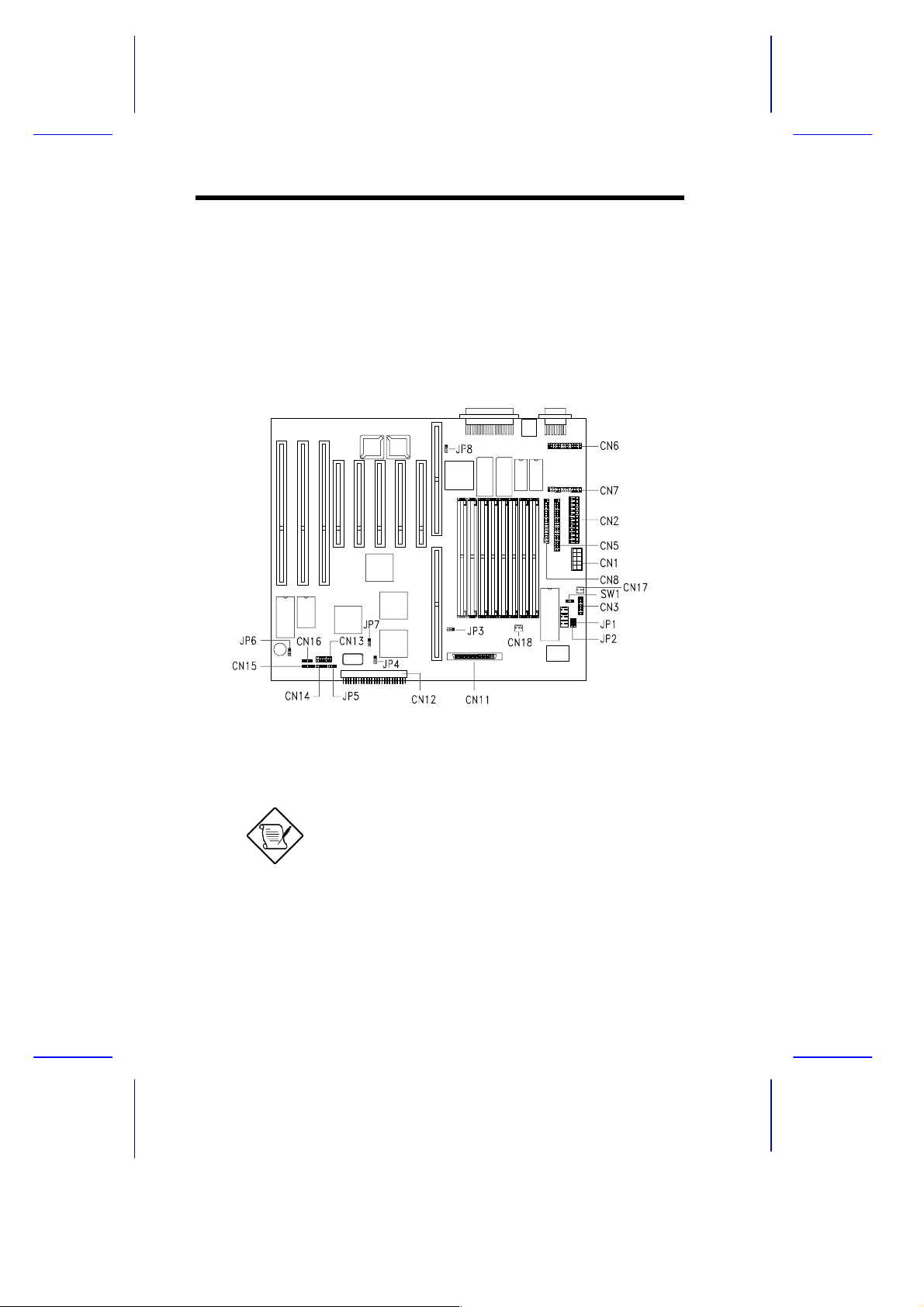

1.4 Jumpers and Connectors

1.4.1 Jumper and Connector Locations

Figure 1-2 shows the jum per and connector l ocations on t he system

board.

Figure 1-2 System Board Jumper and Connector Locations

Jumpers are prefixed “JP”. Connectors are

prefixed “CN” and “SW.

The blackened pin of a jumper r epr es ents

pin 1.

1-4 User’s Guide

Page 5

1.4.2 Jumper Settings

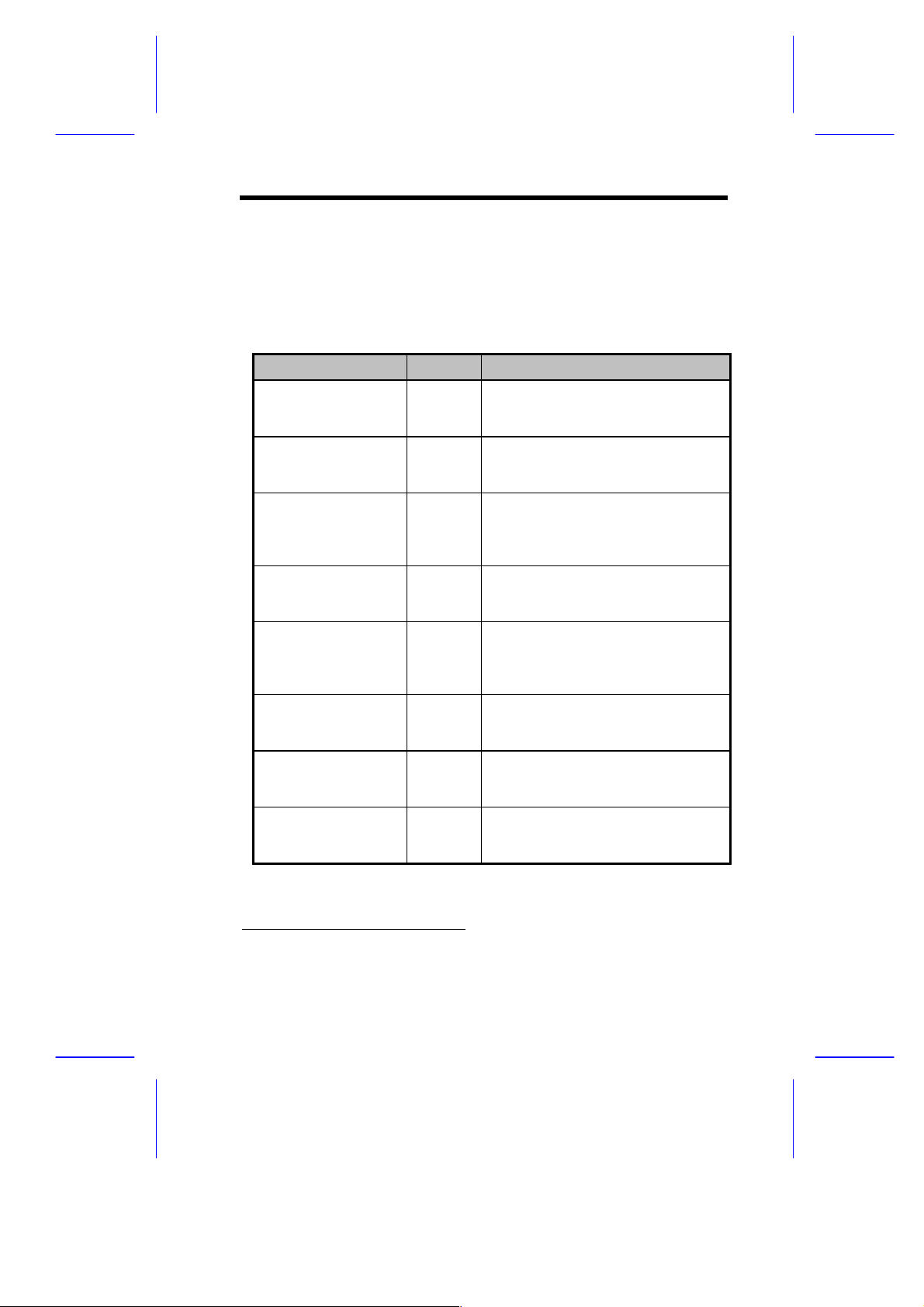

Table 1-1 lists the system board jumpers with their corresponding

settings and func tions.

Table 1-1 System Board Jumper Settings

Jumper Setting Function

Password Security

JP1 1-2

BIOS Type

JP2 1-2*

SCSI Termi n ation

JP3 1-2

SCSI Selection

JP4 1-2*

Hardware Reset

JP5 1-2

Sound Feature

JP6 1-2*

SCSI Feature

JP7 1-2*

VGA Feature

JP8 1-2*

2-3

2-3

2-3*

2-3

2-3*

3-4

2-3

2-3

2-3

*

Check password

Bypass password

Acer

OEM

Terminator al ways set to ON

Use SCSI Setup Utility to set

terminator to ON or OFF

Wide SCSI

Standard

Software shutdown enabled

Hardware reset enabled

Hardware reset button connector

Buzzer

Speaker

Enabled

Disabled

Enabled

Disabled

*

Default setting

System Board 1-5

Page 6

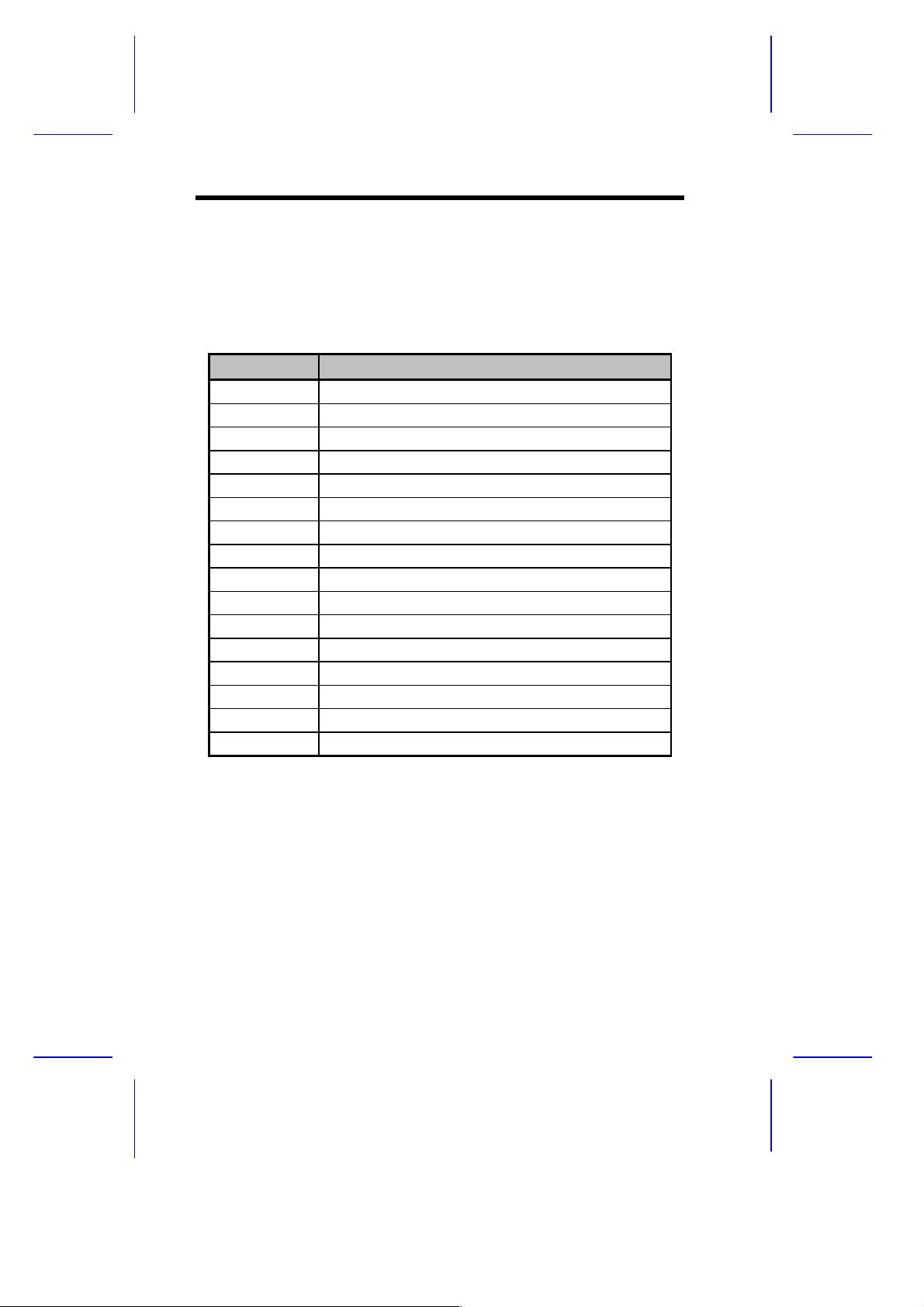

1.4.3 Connector Functions

Table 1-2 l ists the dif f erent c onnectors on the system board and their

respective func tions.

Table 1-2 Connector Func tions

Connector Function

CN1 Power connector

CN2 Power connector

CN3 Backplane board HDD stat us c onnector

CN5 IDE hard disk connector

CN6 RDM connector

CN7 RDM connector

CN8 Diskette drive connector

CN11 68-pin Wide SCSI connector

CN12 50-pin Fast SCSI-II connector

CN13 RDM cable and LED board connector

CN14 Hard disk LED connector

CN15 Power LED connector

CN16 Speaker connector

CN17 420W 5V standby power connector

CN18 200W 5V standby power connector

SW1 NMI switch

1-6 User’s Guide

Page 7

1.5 ESD Precautions

Always observe the following electrostatic discharge (ESD)

precautions before installing a system c omponent:

1. Do not remov e a component from its antistatic packaging until

you are ready to i nstall it.

2. Wear a wrist grounding strap before handling electronic

components. Wrist grounding straps are available at most

electronic component stor es.

Do not attempt t he procedures described in

the following sec tions unless you are a

qualified technician.

1.6 Memory Upgrade

The system board comes with eight 72-pi n SI MM socket s that support

4-MB and 16-MB single-density SIMMs as well as 8-MB and 32-MB

double-density SIMMs for a total system memory of 256-MB. The

sockets support both the fast page mode and EDO 60 ns SI M M s.

See Table 1-3 for a list of some possible mem or y c onfigurations.

1.6.1 Rules for Adding Memory

•

Use only one type of SIMM in a giv en bank. You m ay combi ne

diff erent types of SI MMs for a mem ory confi guration as long as

the SIMMs in eac h bank ar e of the same type.

•

You may use the memory banks (Bank 0 ~ Bank3) in any or der .

•

Always install SIMMs in pairs. For example, for a total memory

of 16 MB, install two 8-MB SIMMs in a bank. You can not use a

16-MB SIMM alone for a 16-MB memory.

System Board 1-7

Page 8

1.6.2 Memory Configurations

Table 1-3 Memory Configur ations

Bank0 Bank1 Bank2 Bank3 Total

S1 S2 S3 S4 S5 S6 S7 S8 Memory

8 MB 8 MB 16 MB

16 MB 16 MB 32 MB

32 MB 32 MB 64 MB

64 MB 64 MB 128 MB

8 MB 8 MB 16 MB 16 MB 48 MB

8 MB 8 MB 32 MB 32 MB 80 MB

16 MB 16 MB 32 MB 32 MB 96 MB

64 MB 64 MB 32 MB 32 MB 192 MB

8 MB 8 MB 16 MB 16 MB 48 MB

8 MB 8 MB 16 MB 16 MB 16 MB 16 MB 80 MB

8 MB 8 MB 16 MB 16 MB 32 MB 32 MB 112 MB

8 MB 8 MB 16 MB 16 MB 32 MB 32 MB 64 MB 64 MB 240 MB

8 MB 8 MB 8 MB 8 MB 16 MB 16 MB 16 MB 16 MB 96 MB

8 MB 8 MB 8 MB 8 MB 32 MB 32 MB 32 MB 32 MB 160 MB

16 MB 16 MB 16 MB 16 MB 32 MB 32 MB 32 MB 32 MB 192 MB

32 MB 32 MB 32 MB 32 MB 64 MB 64 MB 64 MB 64 MB 384 MB

8 MB 8 MB 8 MB 8 MB 8 MB 8 MB 8 MB 8 MB 64 MB

16 MB 16 MB 16 MB 16 MB 16 MB 16 MB 16 MB 16 MB 128 MB

32 MB 32 MB 32 MB 32 MB 32 MB 32 MB 32 MB 32 MB 256 MB

64 MB 64 MB 64 MB 64 MB 64 MB 64 MB 64 MB 64 MB 512 MB

The above configurat ions ar e only s om e of

the available memory com binations. You

can use other combinat ions as long as y ou

follow the rules for upgrading memory in

section 1.6.1.

1-8 User’s Guide

Page 9

1.6.3 Installing a SIMM

Follow these steps to install a SIM M :

1. Careful ly slip a SIMM at a 45° angle into a socket m aking sure

that the curv ed edge indicati ng the pin 1 of the SIMM matches

pin 1 of the socket.

A SIMM fits only in one dir ec tion. If you slip

in a SIMM but would not c om pletely fit, y ou

may have inserted it the wrong w ay .

Reverse the orientation of the SIMM.

2. Gently push the S IMM to a v er tic al posi tion until t he pegs of t he

socket slip into t he hol es on the SIM M, and t he hol ding c li ps loc k

the SIMM into position. The SIMM should be at a 90° angle

when installed.

1

Pin 1 Indicator

(curved edge)

Figure 1-3 Installing a SIMM

System Board 1-9

2

Peg

Hole

Page 10

1.6.4 Removing a SIMM

Follow these steps to remove a S IMM:

1. Press the holding clips on both sides of the SIMM outward to

release it.

2. Move the SIMM to a 45° angle.

3. Pull t he S IMM out of the socket.

Holding Clip

1

3

2

Figure 1-4 Removing a SIMM

1-10 User’s Guide

Page 11

1.6.5 Reconfiguring the System

You must enter Setup after installing or removing SIMMs to

reconfigure the system.

Follow these steps to reconfigure t he system:

1. Turn the system on. A memory error message appears,

indicat ing t hat t he tot al m em ory does not m atc h t he v al ue stored

in CMOS.

2. Press

appears indicating an incorrec t mem or y c onfiguration.

3. Press

The system boots with t he new m emory configuration.

+ + to enter Setup. A warning message

twice to ex it and reboot t he system.

If you run Windows NT, NetWar e, or

UnixWare in the system, make sure to run

ECU every time you c hange the memory

size. See Chapter 4 for inform ation on ECU.

System Board 1-11

Page 12

1.7 Video Memory Upgrade

Larger video memory allows you to display higher resolutions and

more colors. The system board comes with a 1-MB video memory

onboard upgradable to 2 MB .

Follow these steps to upgrade the vi deo memory :

1. Locate the v ideo DRAM upgrade sockets labeled U18 and U21

on the system board. S ee Figure 1-1.

2. Gently insert a video chip into each of the upgrade sockets.

Make sure that the pin 1 indicator on the c hip

matches the not c hed c or ner of the socket .

Pin 1 Indicator

Notched

Corner

Figure 1-5 Installing a Video Memor y Chip

1-12 User’s Guide

Page 13

1.8 PCI Slot Configuration

1.8.1 PCI-to-PCI Bridge Feature

The system board carr ies a PCI-to-PCI bri dge controll er chipset that

expands the capability of the PCI system by allowing all the five PCI

slots in the system to be bus m asters. The br idge has t wo i nterfaces.

The primary interface connects directly to the PCI bus close to the

host CPU. The secondary interfac e creates a new PCI bus that can

operate independently fr om the pri mary PCI bus.

1.8.2 Installing PCI Devices

The devi ces you install in PCI sl ots 1 and 2 operate on the primary

PCI bus while those in PCI slot s 3, 4, and 5 oper ate on t he secondary

PCI bus.

Since the primary PCI bus operates faster than the secondary PCI

bus, install PCI add-on boards in PCI slots 1 and 2 f irst then on PCI

slots 3, 4, and 5 to achiev e better system performanc e. See Figure

1-1 for t he locations of the PCI slots.

System Board 1-13

Page 14

1.9 ASM Pro

The ASM Pro is a server management tool based on the Simple

Network Management Protocol (SNMP). It detects server problems

related to t he CPU thermal c ondition, 5V/3.3V detec tion, or PCI bus

utilization calculation.

This feature is designed primarily for server supervisors and

management i nf orm at ion system (MIS ) personnel t o hel p t hem detect

errors or potential trouble spots in their network servers through a

single management station.

The ASM Pro consists of two major parts:

•

ASM-Station - a Windows-based monitoring station that

communicates with the ASM-Agents.

•

ASM-Agent(s) - the individual servers managed by the

ASM-Station.

Refer to the ASM Pro user’s manual for more i nformation.

1-14 User’s Guide

Page 15

1.10 Remote Diagnostic Management

The Remote Diagnostic Management (RDM) is a network

management tool t hat utilizes modems and telephone li nes to cont rol

a host of serv ers f rom a r em ote stat ion. It m oni t ors and anal yzes t he

server condi tion, updates the BIO S settings if necessary, or reboots

the server in the event of failure and quickly return it to normal

operation. This capability to execute the RDM program from a

remote sit e bridges the di stance barri er in f ix ing serv er pr oblem s and

reduces wasted time due to system failure.

1.10.1 Installing the RDM Module

The system board comes with connectors CN6 and CN7 to

accommodate the RDM module, and CN13 to connect the RDM

cable.

Follow these steps to install the RDM module and connect the cable:

1. See Figure 1-1 for the location of the RDM connectors.

2. Gently i nsert the RDM m odule into CN6 and CN7. The m odule

fits only in one di r ec tion. Do not force i t into to the connectors.

CN6

CN7

Figure 1-6 Installing the RDM M odule

System Board 1-15

Page 16

3. Insert the cable end with the RDM button into the slot on the

housing front panel.

4. Attach the ot her end of t he RDM cabl e t o CN13 (pi ns 5-6, 11-12)

on the system board. Note that the covered pin of the cable

connector does not connect to any pin.

RDM Cable

CN13

12

1

7

Figure 1-7 Connecting the RDM Cable

Refer to the RDM User’s Guide f or detailed instr uctions on the RDM

installation.

1-16 User’s Guide

Page 17

1.11 Error Messages

Do not continue usi ng the computer if you receiv e an error m essage

of any type. Note the message and take corrective action. This

section explains the different types of error messages and

corresponding corrective measures.

There are two general t y pes of error m essages:

•

Software

•

System

1.11.1 Software Error Messages

Software error messages are returned by your operating system or

application. These messages typically occur after you boot the

operating system or when you run your appli cations. If you receive

this type of message, consult your application or operating system

manual for help.

1.11.2 System Error Messages

A system error message indicates a problem with the c omputer itself .

A message of this type normally appears during the power-on selftest, bef or e the operating system prompt appear s.

Table 1-4 l ists the system error messages.

System Board 1-17

Page 18

Table 1-4 System Error Messages

Message Action

CMOS Battery Error Replace the RTC chip or

contact your dealer.

CMOS Checksum Error Check the RTC chip and the

necessary jumper. If the

battery is still good, run

Setup.

Display Card Mismat ch Run Setup.

Diskette Dr ive Controller

Error or Not Installed

Diskette Drive Error Diskette may be defective. If

Diskette Drive A Type

Mismatch

Diskette Drive B Type

Mismatch

Equipment Configuration

Error

Hard disk Controller Error Run Setup.

Hard disk 0 Error Check all cable connections.

Hard disk 1 Error Check all cable connections.

Keyboard Error or No

Keyboard Connected

Keyboard Interface Error Replace the keyboar d or

Check and connect the

control cable to the diskette

controller.

not, replace the diskette drive.

Run Setup and select the

proper drive type.

Run Setup and select the

proper drive type.

Modify the m emory

configurati on t o agr ee with

one of the options in Table

1-3.

Replace hard disk.

Replace hard disk.

Check and connect the

keyboard to the system unit.

contact your dealer.

1-18 User’s Guide

Page 19

Table 1-4 System Error Messages (continued)

Message Action

Memory Error at:

MMMM:SSSS:OOO

(W :XXXX, R:YYYY)

where:

M: MB, S: Segment,

O: Offset, X/Y: write/read

pattern

Memor y Size Mismatch

CPU Clock Mismatch

Onboard Serial Port 1

Conflict

Onboard Serial Port 2

Conflict

Onboard Parallel Port

Conflict

Pointing Device Error Check and connect pointing

Pointing Device Interface

Error

Press F1 key to continue or

Ctrl-Alt-Esc for Setup

Real Time Clock Error Check the RTC chip. If it is

Check SIMMs on the system

board. Contact your dealer.

Run Setup. Check if the

values shown in the memory

parameters are correct. If

correct, exit Setup and reboot

the system. If the error

message reappears, seek

technical assistance.

Run Setup and disable the

port.

Run Setup and disable the

port.

Run Setup and disable the

port.

device.

Replace the pointing device or

contact your dealer.

Press

Setup.

still good, run Setup. If not,

replace the RTC chip.

or

+ + to enter

System Board 1-19

Page 20

1.11.3 Correcting Error Conditions

As a general rule, if an error m essage says "Press F1 t o conti nue," it

is caused by a confi guration probl em, which can be easily corrected.

An equipment malfunction is more likely to cause a fatal error, i.e., an

error that causes com plete system fail ur e.

Here are some corrective measures for er r or c onditions:

1. Run Setup. You m ust know the correct configur ation v alues for

your system before you enter Setup, which is why you should

write them down when the system is correctly configured. An

incorrect configuration is a major cause of power-on error

messages, especially for a new system.

2. Remov e the system unit c over. Check t hat the jum pers on the

system board and any ex pansi on boar ds are set cor r ec tly.

3. If you cannot access a new disk, it m ay be because your disk is

not properly formatted. Format the disk first using the FDISK

and FORMAT c ommands.

4. Check that al l connectors and boards are securely plugged in.

If you go t hrough t he correc ti ve steps above and still receive an error

message, the cause may be an equipment malfunction.

If you are sure that your configuration values are correct and your

battery is in good condition, the problem may lie in a damaged or

defectiv e c hip.

In either c ase, c ontact an authorized service center for assistance.

1-20 User’s Guide

Loading...

Loading...