Page 1

Acer Service Manual

Service Manual

LCD Monitor Acer

AL2017

0

Page 2

1

Service Manual Versions and Revision

No. Version Release Date Revision

1 1.0 2007/01/18 Initial Release

Copyright

Copyright 2007 InnoLux Tech. Corp. Ltd

All Rights Reserved

This manual may not, in whole or in part, be copied, Photocopied, reproduced, translated, or converted to any

electronic or machine readable form without prior written permission of InnoLux Tech. Corp. Ltd.

Acer AL2017 Service Manual

1

Page 3

Acer Service Manual

Table of Contents

CHAPTER 1- PRECAUTIONS & SAFETY NOTICES ..................................................................................................................... 3

1. SAFETY PRECAUTIONS ................................................................................................................................................. 3

2. PRODUCT SAFETY NOTICE........................................................................................................................................... 3

3. SERVICE NOTES............................................................................................................................................................... 3

CHAPTER 2- SERVICE TOOLS & EQUIPMENT REQUIRED ..................................................................................................... 4

CHAPTER 3- CIRCUIT THEORY ...................................................................................................................................................... 5

1. BLOCK DIAGRAM .............................................................................................................................. 錯誤! 尚未定義書籤。

2. INTERFACE BOARD DIAGRAM ........................................................................................................................................... 5

3. ELECTRONIC CIRCUIT THEORY ............................................................................................................................................... 6

4. INVERTER CIRCUIT.............................................................................................................................錯誤! 尚未定義書籤。

CHAPTER 4- DISASSEMBLY & ASSEMBLY ................................................................................................................................... 9

1. EXPLODED DIAGRAM ............................................................................................................................................................. 9

2. DISASSEMBLY BLOCK ........................................................................................................................................................... 10

3. ASSEMBLY BLOCK ................................................................................................................................................................ 11

CHAPTER 5- TEST AND ADJUSTMENT........................................................................................................................................ 12

1. GENERAL POINTS............................................................................................................................................................. 12

2. INPUT SIGNAL.................................................................................................................................................................. 13

3. FUNCTION CHECK........................................................................................................................................................... 14

4. DISPLAY CHECK............................................................................................................................................................... 15

5. PICTURE CHECK............................................................................................................................................................... 16

CHAPTER 6- TROUBLE SHOOTING.............................................................................................................................................. 19

1. NO POWER & LED OFF .............................................................................................................. 19 錯誤! 尚未定義書籤。

UNSTABLE POWER ................................................................................................................................................................ 20

2.

3. NO RASTER ........................................................................................................................................................................... 21

4. BLACK SCREEN ..................................................................................................................................................................... 22

5. BAD SCREEN......................................................................................................................................................................... 23

6. WHITE SCREEN ..................................................................................................................................................................... 24

ATTACHMENT 1- BILL OF MATERIAL......................................................................................................................................... 25

ATTACHMENT 2- SCHEMATIC....................................................................................................................................................... 34

ATTACHMENT 3- PCB LAYOUT ..................................................................................................................................................... 44

2

Page 4

Acer Service Manual

Chapter 1- PRECAUTIONS & SAFETY NOTICES

1. SAFETY PRECAUTIONS

This monitor is manufactured and tested on a ground principle that a user’s safety comes first.

However, improper used or installation may cause damage to the monitor as well as to the user.

WARNINGS:

This monitor should be operated only at the correct power sources indicated on the label on the rear

of the monitor. If you’re unsure of the power supply in you residence, consult your local dealer or

Power Company.

Do not try to repair the monitor by yourself, as it contains no user-serviceable parts. This monitor

should only be repaired by a qualified technician.

Do not remove the monitor cabinet. There are high-voltage parts inside that may cause electric

shock to human bodies.

Stop using the monitor if the cabinet is damaged. Have it checked by a service technician.

Put your monitor only in a lean, cool, dry environment. If it gets wet, unplug the power cable

immediately and consult your closed dealer.

Always unplug the monitor before cleaning it. Clean the cabinet with a clean, dry cloth. Apply

non-ammonia based cleaner onto the cloth, not directly onto the class screen.

Do not place heavy objects on the monitor or power cord.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety visual inspections and the

protection afforded by them cannot necessarily be obtained by using replacement components rated

for higher voltage, wattage, etc. Before replacing any of these components read the parts list in this

manual carefully. The use of substitute replacement parts, which do not have the same safety

characteristics as specified in the parts list, may create shock, fire, or other hazards.

3. SERVICE NOTES

When replacing parts or circuit boards, clamp the lead wires around terminals before soldering.

Keep wires away from high voltage, high temperature components and sharp edges.

Keep wires in their original position so as to reduce interference.

Adjustment of this product please refers to the user’ manual.

3

Page 5

Acer Service Manual

Chapter 2- SERVICE TOOLS & EQUIPMENT REQUIRED

1. SIGNAL GENERATOR

2. MULTIMETER

3. SCREW DRIVER

4. OSCILLOSCOPE

5. Soldering IRON

6. SOLDER

7. VGA Cable (15pins point to point)

8. Color Analyzer

9. Myson412 ISP Board

10. EDID Board

11. EDID program file

4

Page 6

Acer Service Manual

Chapter 3- CIRCUIT THEORY

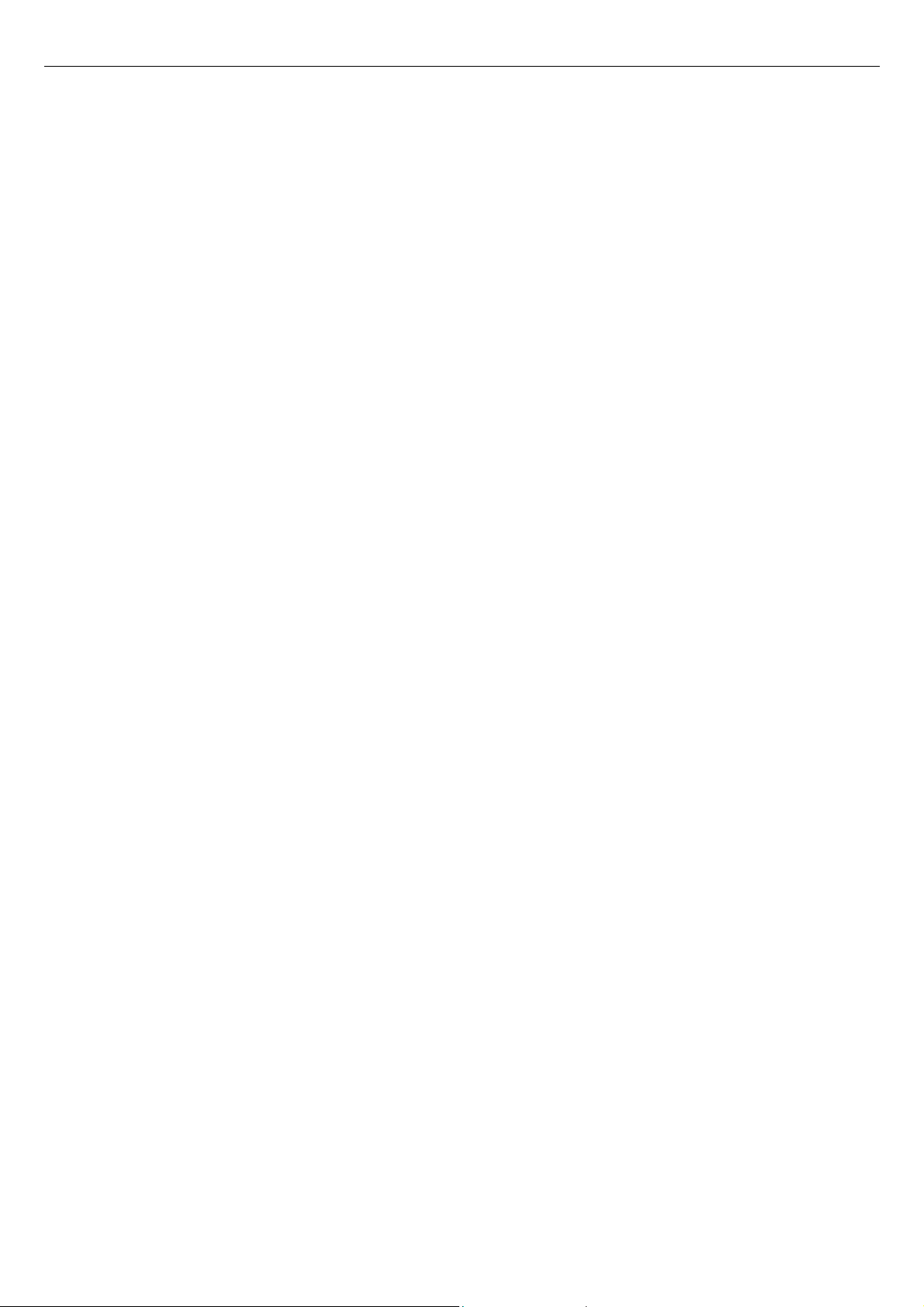

1. Monitor Block Diagram

The LCD Monitor contains an interface board, and inverter/power/Audio board, keypad board and flat

panel. In Inverter/power/Audio board, power section supplies +14V & +5V for Inverter/Audio and

Interface board used. The inverter section drives the backlight of panel and the DC-DC conversion.

2. Interface BOARD DIAGRAM

DVI

(Option)

VGA

Red

Green

Blue

Vsync

Hsync

SCL

SDA

3. Electronic Circuit Theory

1.1 Switching Mode Power Supply

1.1.1 AC Current Input Circuit

P801 is a connector for connecting AC Power. F801 is a fuse to protect all the circuit. AC

input voltage is from 90v to 264V. R801 and R802 joined between two inputting main circuit to

prevent man from shock. L801 is used to clear up low frequency wave. C801 and C802 are used to

discharge the waves that L801 produced. High frequency waves are damped by C801 and C802.

D801 is a rectifier which composed of 4 build-in diodes, it inverts AC to DC.

1.1.2 High Voltage to Low Voltage Control Circuit

DVI

DDC

VGA

DDC

Scaler&MCU

Key-pad

Flash

A/D&

OSD

(EEprom)

To LCD

module

C804 is used to smooth the wave from rectifier. IC802 is a highly integrated PWM controller.

When rectified DC high voltage is applied to the HV pin during start-up, the MOSFET Q804 is

5

Page 7

Acer Service Manual

initially off, and the Vcc pin capacitor is charged. When the Vcc pin voltage reaches approximately

14V, the control circuitry is activated and the soft-start begins. The soft-start circuit gradually

increases the duty cycle of the MOSFET from zero to the maximum value over approximately 4ms.

If no external feedback/supply current is fed into the FB pin by the end of the soft-start, the current

Setpoint will be above the fault level, FAULT flag is raised, if the FAULT duration exceeds 80ms,

the output controller disable resistor R808, R809, R810, R811 are for line over voltage

shutdown(OVP)

When PWM is turned off, the main current flow will be consumed through R804 and D802,

This will prevent MOSFET Q804 from being damaged under large current impulse and voltage

spike.

D803 and C807 to provide internal Auxiliary voltage to Vcc pin during normal operation.

Otherwise, error amplifier and feedback current input the FB pin for duty cycle control.

1.1.3 DC_5V and DC_16V Output Circuit

For DC 5V, D805 is used to rectify the inducted current. R828 and C814 are used to store

energy when current is reversed. The parts including C818, C822, C820,L803 are used to smooth

the current waves.

For DC 16V, D803 is used to rectify the inducted current. R827 and C813 are used to store

energy when current is reversed. The parts including C815, C817 and L802 are used to smooth the

current waves.

1.1.4 Feedback and OVP Protect Circuit

Pin R of IC803 is supplied 2.5-v stable voltage. It connects to 5V and 16V output through

R822, R823 and R824. R822, R823 and R824 are output sampling resistor. When the sampling

voltage more than 2.5V or less than 2.5V, current of FB IC802 will change, this can change the

voltage from T801.

OVP Protect Circuit: When output is overvoltage, the auxiliary winding voltage will be

increased, when it reaches about 14V. Q803 is triggered . It makes the IC802 Pin 1 exceed 5V, then

the IC802 output will be disabled.

Q801, R816, R817 and ZD803 make up of dummy loading circuit. For start-up sequence,

during 5V output take place high loading first, this dummy loading circuit operated to insure 16V

not be increased.

1.2 Interface Board Circuit

1.2.1 RGB CAPTURE

- Signal RED,GREEN,BLUE input through CN103 #1,#2,#3, via R105,FB101, R101,R106,

FB102 ,R102, R107,FB103,R103, Stop DC via C101, C102 and C103, and then enter into U104

(TSUM56AWHK) analog input terminal #59,#56,#54, and then TSUM56AWHK deals with signal

internally. D101, D102, D103 are ESD protector to prevent U104 from ESD.

- Signal DDC_SCL (series clock) inputs via CN103#15, and then passes through ZD104 Zener for

ESD protection, via R121, goes into EDID EEPROM IC U102 #6.

- Signal DDC_SDA (series data) inputs via CN102 #12, and then passes through ZD105 Zener for

ESD protection, via R122, goes into EDID EEPROM IC U102 #5.

- Signal TTL vertical sync. (Vsync) inputs via CN103 #14, and then clamped by D103 Zener, passes

through R116, and then goes into IC U104 #64.

- Signal TTL horizontal sync. (Hsync) inputs via CN103 #13, and then clamped by D102 Zener, passes

through FB104,R115, and then goes into IC U104 #63.

- CN103#5 is defined as cable detect pin, this detector realize passes through R113 ,go into U104#26,

and ZD109 is ESD protector.

- U102 +5V is supplied by PC via CN103#9 with ZD101 for ESD protection, or supplied by Monitor

self via D104.

- U102 is an EEPROM IC which is memory and EDID data saved in it.

6

Page 8

Acer Service Manual

1.2.2 DVI CAPTURE

- Differential Signal input RX0+,RX0-,RX1+,RX1-,RX2+,RX2-,RXC+,RXC- through CN102

#18,#17,#10,#9,#2,#1,#23,#24 via R130, R131, R132, R133, R134, R135, R137, R138 enter into

U104 Digital input terminal #45,#46,#42,#43,#39,#40,#48,#49, and then TSUM56AWHK deals with

signal internally.

- Signal DDC_SCL (series clock) inputs via CN102#6, and then passes through ZD106 Zener for ESD

protection, via R126, goes into EDID EEPROM IC U101 #6.

- Signal DDC_SDA (series data) inputs via CN102 #7, and then passes through ZD107 Zener for

ESD protection, via R127, goes into EDID EEPROM IC U101 #5.

- CN102 #16 is defined as cable detect pin, this detector realize passes through R125 ,go into U104#27,

and D106 is ESD protector.

- U101 +5V is supplied by PC via CN102#14 with ZD108 for ESD protection, or supplied by Monitor

self via D107.

- U102 is an EEPROM IC which is memory and EDID data saved in it.

1.2.3 Buttons Control

- Button “Power” on front of bezel connects to scaler TSUMU58WHJ pin #4 through R159, via

CN102#8.

- Button “MENU” on front of bezel connects to scaler TSUMU58WHJ pin #119 through R153,via

CN102#1; Button “>” (Rihgt) on front bezel connects to scaler TSUMU58WHJ pin #120 through

R154,via CN102#2; Button “<” (Left) on front bezel connects to scaler TSUMU58WHJ pin #121

through R155,via CN102#3;Button “AUTO” on front bezel connects to scaler TSUMU58WHJ pin

#122 through R156,via CN102#4;

- U107 is an EEPROM IC which memory OSD setting and save the value adjusted by user.

- LED Indicator

When monitor normally working, scaler TSUMU58WHJ pin #124 sends out a low potential, via

R107, switch on Q105, then flows to CN102 #7, LED Green ON.

When in “Suspend” mode, scaler TSUMU58WHJ pin #123 sends out a low potential, via R102,

switch on Q102, then flows to CN102 #5, LED Amber ON.

1.2.4 Scaling IC (U104 tsum56AWHK)

- U104 #105~#114 output 8 bit even LVDS digital data to panel control circuit through CN106.

- U104 #118~#127 output 8 bit odd LVDS digital data to panel control circuit through CN106.

- U104 #75 output ”H” potential to make Q106 conducted, and then make Q103 conducted, +5V flow

to CN106#1~#3 as Panel Vdd .

- U104 #20 output,”L” ”H” potential to control Inverter on/off.

- U104 #21 outputs Brightness “PWM” signals to control CCFL brightness.

- TCLK by Crystal 14.318MHz input to U104 #32.

Please refer to tsum56AWHK Pin Assignments table in page

1.2.5 Regulator Circuit

- +5V is from powerboard CN103 #1 and CN102

- +3.3V generates from +5V through D116 and C168 filtering and U103 which is output +3.3V LDO

- +1.8V generates from +3.3V through C143 filtering and U108 which is output +1.8V LDO, for U104

used.

1.3 Inverter circuit

Power supply 5V then pass through R517 to IC501. The extra PWM pulse signal

(BRIGHTNESS signal) input to control IC through R512, R514, C510, The LCT pin is set to a DC

voltage of 0.7V by using a resistor divider(R507, R516), change the duty of PWM pulse, will

regulate the lamp current. The ON/OFF voltage connect to pin10 of IC501 through D501, R501,

7

Page 9

Acer Service Manual

A voltage of 2V to pin10 of IC501 enables the IC and activates the striking timer. The SSTCMP

pin of IC501 performs the soft function, the C511 set the time of SST. The operation frequency

determined by external capacitor C512, C521 and resistor R508 connected at CT pin of IC501.

C515 connect the TIMER pin of IC501, the capacitor to set striking time and shunt down delay

time. DRV!, DRV2 output for power MOSFET U501, U502.

OZ9938 provides two drive signals for U501, U502, and they work in push pull topology

driving, two transformers are connected in parallel with each transformer driving two lamps in

series. Turning each N-Channel MOSFET “on/off” complementarily, produces an alternating

current through the transformer primary and secondary. The “on” duration of the switches

determines the amount of energy delivered to the CCFLs. R504, C504, R505, C505, R532, C529,

R530, C522 are snubber networks, they suppress Voltage transient spike in drain of power

MOSFET.

R506, R510, C509, C513, C514, R525, R531, C528, C525, and C527 are connected between

high voltage output connector and ground, the divided AC voltage is inverted DC voltage through

D502, D503, D508, and D509. The sense voltage feed back to VSEN (pin 6 of IC501) for an over

voltage/over current condition during normal operation. R528, R533,R523,R536 are current sense

resistor, current sense signal feed back to Isense (pin 5 of IC501) for lamp “ON” detection.

8

Page 10

Acer Service Manual

Chapter 4- Disassembly & Assembly

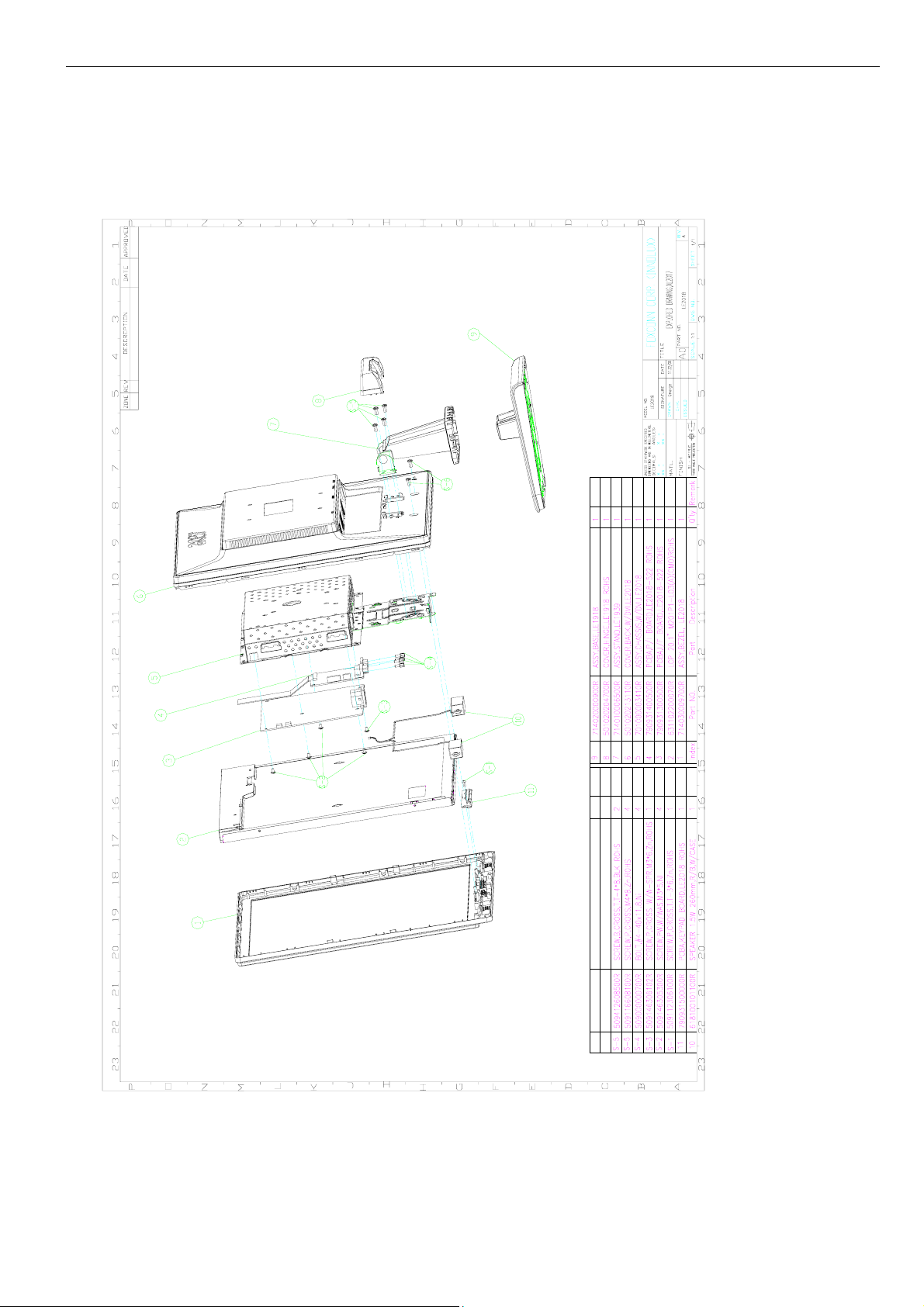

1. Exploded Diagram

Exploded drawing(With DVI)

9

Page 11

Acer Service Manual

Exploded drawing(W/O DVI)

(We will update later)

10

Page 12

Acer Service Manual

,

,

,Zn,

2. Disassembly Block

4. LE2018 BOM Structure

PCBA INV.&DC-DC *1

PCBA I/F BOARD *1

CABLE 30 PIN FFC

BOLT,#4-40x11.8,Ni ROHS *4

TAPE ACE *3

Zn ROHS *1

M3*5

KEY PAD*1

CABLE *1

Zn ROHS *1

T3*6

SPEAKER*1

M3*5,Zn ROHS *4

M3*6,W/W-SPR Zn ROHS *1

ASSY PANEL*1

ASSY BEZEL*1

PANEL CMO M201P1-L01

CHASSIS *1

Gasket,W8*H3*L50*1

Foil,AL,L60*W35*1

BEZEL*1

BUTTON,POWER KEY*1

BUTTON,FUNCTION*1

LENS*1

STAND*1

HINGE*1

BRACKET FINGER*1

SCREW,B,CROSS,W/W-SPR,M4*

20,Zn ROHS *3

BASE*1

RUBBER*4

GASKET*1

PLATE,BASE*1

T4*6

ROHS *2

BACK COVER*1

ASSY STAND*1

SCREW,P,CROSS,M4*8,BLA

CK,NL(NYLOK)

SCREW,B,CROSS,T.T-4*8,BL

K ROHS*2

ASSY BASE*1

HINGE COVER*1

LE 2018

LCD Monitor

11

Page 13

Acer Service Manual

5. LE2018 DIS-assembly Block

LE 2018

LCD Monitor

ASSY, BASE

BASE*1

RUBBER FOOT *4

GASKET*1

PLATE,BASE*1

T4*6,Zn, ROHS *2

HINGE COVER*1

BRACKET FINGER *1

HINGE *1

STAND

SCREW,B,CROSS,W/W-SPR,M4*20,Zn ROHS *3

ASSY STAND

M4*8,Black Zn,NL ROHS *4

SCREW,B,CROSS,T.T-4*8,BLK

ROHS*2

BACK COVER

FRONT BEZEL *1

FUNCTION KEY *1

ASSY FRONT BEZEL

POWER BUTTON *1

LED LENS

SPEAKER*1

CHASSIS *1

PCBA I/F BOARD *1

PCBA INV.&DC-DC *1

CABLE KEYPAD*1

CABLE 30P FFC

BOLT,#4-40x11.8,Ni ROHS *4

M3*5,Ni ROHS *5

TAPE ACE *3

M3*6,W/W-SPR Zn ROHS*1

Gasket,W8*H3*L50*1

Foil,AL,L60*W35*1

Note:

The DIS assembly direction please following direction of arrowhead

ASSY PANEL UNIT

PANEL CMO M201P1-L01

12

Page 14

Acer Service Manual

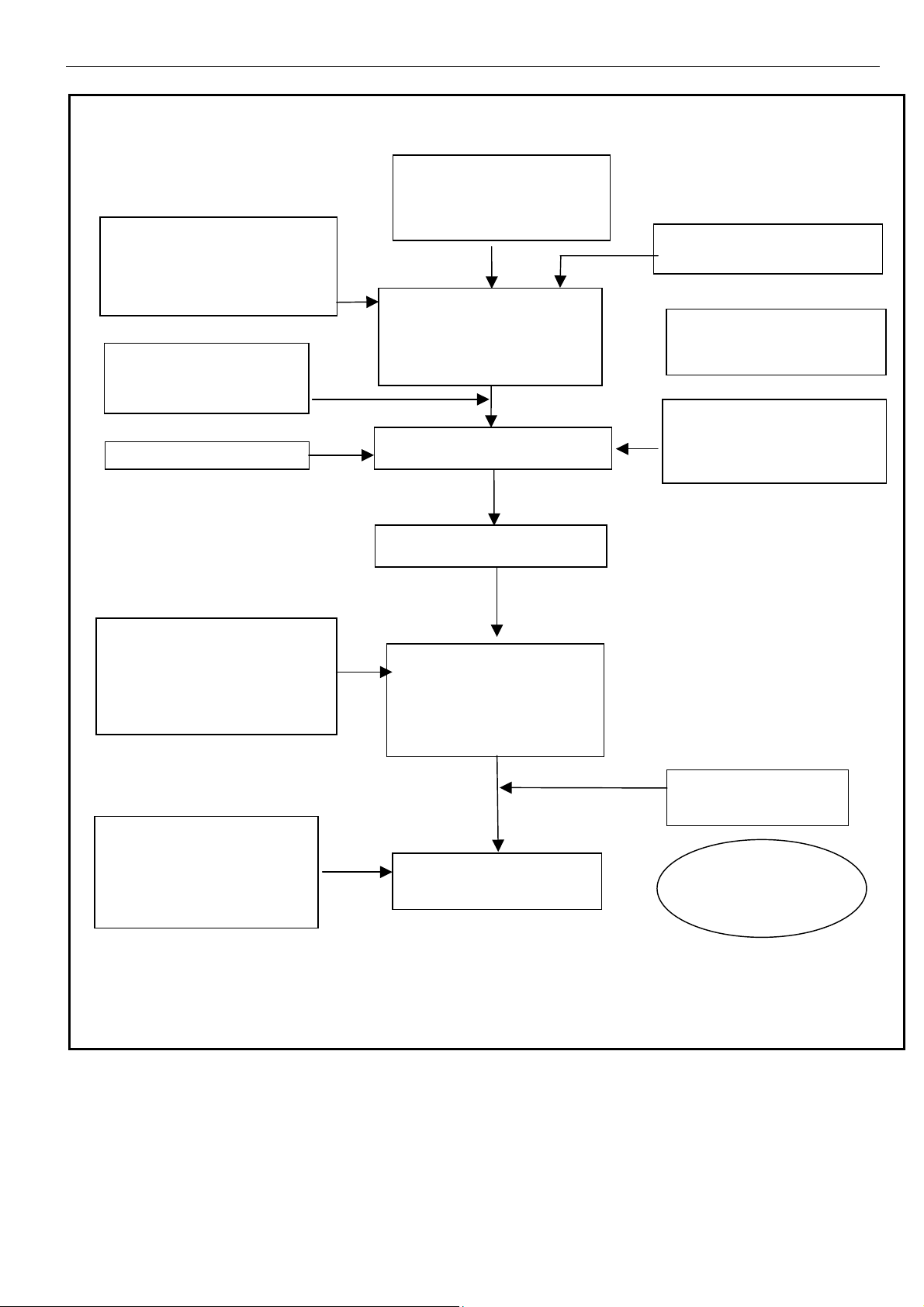

Process To Access Factory Mode

Power Off

Press “AUTO"& "MENU"button at

the same time

Power On

Release the “AUTO"& "MENU"

button

Press “MENU" Button

Press “<" Button

Press “Menu" Button

Enter the factory Mode

13

Page 15

Acer Service Manual

R

Chapter 5- TEST AND ADJUSTMENT

1. GENERAL POINTS

1.1 Test Equipment or Tool

1.1.1 Test pattern generator: PC or video pattern generator (Chroma-2326/2160/2130)

1.1.2 Color analyzer: Chroma-7120

1.1.3 Power meter: AC Source Chroma-6408

1.1.4 Electrical safety tester: Chroma (Zentech) 9032A

1.1.5 Stereo source: Music or signal generator input

1.1.6 Auto shock fixture

1.1.7 Temperature and humidity sensor

1.1.8 DDC interface card and EDID file

1.2 Preset Test Pattern

1.2.1 Crosshatch (General-1)

1.2.2 Gray Bar (16 & 32 levels)

1.2.3 Full White

1.2.4 Aging (Burn-in) Pattern: Full Red, Green, Blue, White, and Black

1.3 AC input

All measurements mentioned hereafter are carried out at a normal mains voltage (90 - 264 VAC for the

model with full range power supply, unless otherwise stated)

1.4 Observation Distance

1.4.1 Observation distance from eyes to panel is defined as 50cm

1.4.2 Visual distance from instrument to panel is defined as 20cm

1.5 Key Function Description

1.5.1 Control buttons on the front bezel

CONTROL

KEY

[AUTO]

[MENU]

[►], [◄]

[POWER] Power on or power off the monitor

A. When OSD un-displays, press [AUTO] to perform auto-adjustment

B. When OSD displays, press [AUTO] to return to previous level menu

A. When OSD isn’t shown on screen, press [MENU] to enter OSD interface

B. When OSD displays, press [MENU] to perform function of menu icon that is

highlight or enter next level menu

A. When “MENU OSD” displays, press these keys to change the contents of an

adjustment item, or change an adjustment value

B. When “MENU OSD” un-displays, press [►],adjust volume high;

press [◄]adjust volume low

KEYS FUNCTION

1.5.2 Hot Key Operation

HOT KEY OPERATION

FUNCTION

AUTO ◄ ► MENU POWE

Press [AUTO] & [MENU] at the same

FACTORY

MODE

● ● ON

14

time, and then press [POWER] for DC

power on. OSD menu will be shown

with “F” on the left top. Select “F” for

entering factory mode.

DESCRIPTION

Page 16

Acer Service Manual

1.6 Burn-in (Aging) Pattern

1.6.1 Burn-in patterns are: full Red, Green, Blue, White and Blac

1.6.2 Stop burn-in pattern by providing with video signal from D-sub connector

1.6.3 Enter or exit burn-in mode by setting “burn-in” to be “on” or “off” in the factory mode

1.7 Warm Up

All test units have to be done warm up after at least 2 hours in a room with temperature of 40±5°C.

(Except particular requirement)

2. INPUT SIGNAL

2.1 Video Signal Input

2.1.1 VESA Analog

The video input consists of red, green, and blue signals. The video signals are analog levels, where

0V corresponds to black and 700mV is the maximum signal amplitude. Input impedance of video

pins is 75 ohm ±1%.

Sync signal input

The capability of sync signal inputs shall include separate sync. Input impedance: 2k2 ohms the

signals are defined as follow:

Separate sync TTL level, Positive/Negative

2.1.2 Input signal mode

PRESET TEST MODE TIMING

Resolution

640 x 480

800 x 600

1024 x 768

1152 x 864 67.5 75.0 108.000

1280 x 960 60.0 60.0 108.000

1280 x 1024

1400 x 1050

640 x 480 35.0 66.7 30.200

832 x 624 49.7 74.6 57.300

1152 x 870 68.7 75.0 100.000

H-Freq.

(kHz)

31.5 60.0 25.175

37.9 72.0 31.500

37.5 75.0 31.500

35.1 56.0 36.000

37.9 60.0 40.000

48.1 72.0 50.000

46.9 75.0 49.500

48.4 60.0 65.000

56.5 70.0 75.000

60.0 75.0 78.750

64.0 60.0 108.000

80.0 75.0 135.000

65.371 59.978 121.75

82.28 74.87 156.0

V-Freq.

(Hz)

Dot Clock

(MHz)

Mode

VESA Standard

Power Macintosh

series

2.1.3 VGA signal cable

15 pin D-sub VGA connector of signal cable.

2.1.4 Interface

Analog signal: The input signals are applied to display through D-sub cable.

15

Page 17

Acer Service Manual

Length: 1.8 m +/- 50 mm (fixed)

Connector type: D-sub male.

With DDC_2B pin assignments.

Blue connector thumb-operated jack screws

Pin Assignment:

PIN No. SIGNAL PIN No. SIGNAL

1 Red video input 9 VGA +5V

GND 2 Green video input 10

3 Blue video input 11 GND

4 GND 12 Serial data line (SDA)

5 Cable detect 13 H. Sync / H+V

6 Red video GND 14 V. Sync

7 Green video GND 15 Data clock line (SCL)

8 Blue video GND

3. FUNCTION CHECK

3.1 OSD Function Test

3.1.1 Test mode: 1400x1050@ 60 Hz

3.1.2 Test pattern: pattern #1 of crosshatch (GENERAL-1)

3.1.3 Check single key function and hot key function about key “Power”, “Menu”,” ►”, “◄ “,

“Exit/Auto”, it should operate normally

3.2 Screen Picture Check

3.2.1 Test mode: 1400x1050 @ 60 Hz

3.2.2 Test pattern: pattern #1 of crosshatch (GENERAL-1)

3.2.3 Select OSD menu to execute ‘Auto’ function, screen picture shouldn’t appear abnormal

phenomenon and picture on screen should fit in with active display screen.

3.3 Auto Color Balance

3.3.1 Test mode: 1400x1050 @ 60 Hz

3.3.2 Test pattern: pattern #42 of 5-MOSAIC

3.3.3 Enter "Factory Mode" pressing "Auto color" key, and execute "AUTO".

3.4 Timing Check

3.4.1 Test mode: Refer to preset timing table and power saving mode

3.4.2 Test pattern: pattern #1 of crosshatch (GENERAL-1)

3.4.3 After change above timing and execute “Auto” function automatically, picture should fit in with

active display screen.

3.4.4 Under power saving mode, LED lamp on the key board should be orange

3.5 Power Consumption Function Test

3.5.1 Test mode: 1400x1050 @ 60 Hz

3.5.2 Test pattern: pattern #41 of “WHITE”

3.5.3 Adjusting both brightness value to maximum,

3.5.4 Measure power consumption as the following

16

Page 18

Acer Service Manual

Status Power Consumption LED Display

Normal < 42W(with audio) Green

Standby (No H/V

sync)

Power off < 1W No display

3.6 VGA Cable Detect Test

If VGA cable of LCD monitor isn’t connected to video pattern generator or PC, “NO SIGNAL” should

be shown on screen.

3.7 Hi-Pot test

Test condition:

a. high voltage

b. leakage current

c. rising time 1 sec.

d. test time 3 sec.

3.8 Grounding Test

Test condition:

a. test current

b. impedance < 0.1Ω

2.3KV(DC)

10mA

30A / 2 sec

< 1W Orange

3.9 Bumping Test

3.9.1 Test mode: 1400x1050 @ 60 Hz;

3.9.2 Test pattern: pattern #1 of crosshatch (GENERAL-1)

3.9.3 To shock LCD monitor lightly at the center of rear cover and edges with 1~2kg/cm2 force for

three times, no abnormal phenomenon is found on panel screen.

4. DISPLAY CHECK

4.1 Panel Flicker Check

Connect LCD monitor to PC, set LCD monitor to be timing of 14400x1050@60 Hz, adjust brightness to

be default value (brightness at maximum), execute “Auto” function, and then check picture of shut

down under windows 98 operating system, or flicker-pattern of pixel on-off. It should be that no flicker

be found on panel screen.

4.2 Panel Defect Inspection

4.2.1 Test mode: 1400 x 1050@60Hz

4.2.2 Test pattern: Crosshatch/Full white/Red/Green/Blue/Black/16 color bar/64 gray bars

4.2.3 Display quality must be (according to DIN 13406-2 pixel fault class II)

Defect Type Specification Major Minor

Bright dot defect

Dark dot defect

THD

THD

․

․

Total bright and dark dots

Bright Dots – 2 Adjacent B

Bright Dots – 3 or more Adjacent

Black Dots – 2 Adjacent B

Black Dots – 3 or more Adjacent

Distance between defect dots

Distance between Dark dots

Note 1: Dot defect is defined as the defective area is not larger than 50% of the dot area. Bright Dot is

THD

THD

THD

THD

THD

THD

THD

17

․

․

․

․

․

․

․

Page 19

Acer Service Manual

defined 5% transmission ND filter.

Note 2: Light Leakage: There shall not be visible light around the customer’s bezel after assembly in

normal View angle.

Defect Type Specification Size Count (N)

Dot Shape(Particle、Scratch

and Bubbles in Display area

or on The Polarizer)

Line Shape

(Particles、Scratch、Fiber and

Bubbles in display area or on

The Polarizer)

Display non-uniformity

Scratch ●

Dirt ●

Bezel

Wrap No harm ●

Sunken No harm ●

No label ●

Invert label ●

Broken ●

Dirt Word can be read. ●

Label

Not clear ●

Word out of

Mistake No ●

Black spots which appear

when B/L operating

0.15mm ≤ D ≤ 0. 5 mm N ≤ 3

L ≤ 0.5mm and W ≤ 0.05 mm Ignored

0.5mm < L ≤ 5mm and

0.05mm < W ≤ 0.1mm

L > 5mm or W > 0.1mm N = 0

There should be non-uniformity through

5% transparency of filter or judge by limit

sample if necessary.

No harm

No

Majo

N ≤4

●

●

Minor

●

●

Position Be attached on right position ●

Screw

Connecto Connection

FPC/FFC Broken No ●

Not enough No ●

Limp No ●

No bend on pins and damage ●

5. PICTURE CHECK

5.1 Check brightness uniformity

5.1.1 Test mode: 1400x1050 @ 60 Hz

5.1.2 Test pattern: pattern #41 of “WHITE”

5.1.3 Test tool: Color Analyzer Chroma7120

18

Page 20

Acer Service Manual

5.1.4 Set brightness and contrast to be maximum, apply pattern as Fig.3, it should be the following

requirement:

L/2 L/4

1

23

4

5

7

Fig. 3

5.2 Color Temperature Check

5.2.1 Test mode: 1400x1050 @ 60 Hz

5.2.2 Test pattern: pattern #41 of “WHITE”

5.2.3 Test tool: Color Analyzer Chroma7120

5.2.4 Set brightness to be maximum and contrast to be 50%, measure color coordinate and luminance by

color analyzer as the following:

)(backlight points nine of luminance Min.

)(backlight points nine of luminance Max.

W/4

6

8

9

W/2

%≥ 75

Mode

Chromaticity Coordinate

x y

9300K 0.283 ± 0.030 0.298 ± 0.030

USER / /

6500K 0.313 ± 0.030 0.329 ± 0.030

5.3 Brightness Out (Video signal input 700mV ± 2%)

5.3.1 Test mode: 1400x1050 @ 60 Hz

5.3.2 Test pattern: pattern #41 of “WHITE”

5.3.3 Test tool: Color Analyzer Chroma7120

Set brightness and contrast to be maximum with white pattern, to measure the screen center, the

light output shall be >= BL cd/m

2

Mode BL (cd/cm2) Remark

CMO M201P1-L03 220

5.4 DDC Data Check

5.4.1 EDID program

5.4.2 Execute main program for EDID writing (refer to model type), using scanner for barcode

19

Page 21

Acer Service Manual

download.

5.4.3 If writing EEPROM is successful, and then shows text "PASS" on screen; if writing EEPROM is

failure, then shows text "FAIL".

20

Page 22

Acer Service Manual

Chapter 6- TROUBLE SHOOTING

1. No Power & LED Off

Check primary

rectifier voltage

Check

circuit if

Check F801, P801,

RT,801,D801

Check IC802,

C804, T801,

Check pin6 of

IC802 voltage

about 12V

Check pin2 of IC802

voltage about 3V

Check pin1 of IC802

voltage is below 1V

CheckC810,D803,C80

7,

Check primary OVP,

OLP and secondary

feedback, OVP circuit

Check R811, R810,

R809, R808,R814

END

21

Page 23

Acer Service Manual

2. No raster

No backlight

Yes

LED lamp is OK

Yes

Is there 16V voltage on

pin3,4 of T501,T502

Yes

Is there PWM signal on

pin4 of IC5 01

Yes

Is there High level voltage

on pin10 of IC501

Yes

Vsense voltage is 2.9V

No

No

No

No Check I/F BD

No Check I/F BD

Yes

No power supply to

inverter

U501, U502 fail No

Lamp connector

opened

Check the cable that from

Yes

I/F BD to P/I BD i s ok

Check power

supply

Replace U501,U502Yes

Are there PWM signal on pin1,

pin15 of IC501

Yes

Pin 5 of IC501 voltage is

Low level

NO

Pin 3 of IC501 voltage is high

level voltage

END

No IC501 failure

Yes Yes

Yes IC501 protected Yes

Feedback circuit

fail ure

Yes

Check C524,R528, R533,

D507

Check D505, D511,

D512, D513, R520, C520

22

Page 24

Acer Service Manual

3.Black screen

Black screen

Check power

supply:pin 1,2 of

CN101

YES

Check power supply

for U105

YES

Check reset (pin84) of

U105

YES

Check crystal (pin 96,97)

waveform of U105

NG

Power fail

NG

Check FB102,FB103,

FB105,FB106

NG

Check C144,R172

NG

Check

X101,C153,C154

YES

Check CCFL-

Enable(pin 85)

of U105

NG

U105 FAIL

Check pin4 of

CN101

NG

YESYES

Inverter Fail

Check R167,Q106,

R108,R110

23

Page 25

Acer Service Manual

4.Bad Screen

24

Page 26

Acer Service Manual

5. White screen

White screen

OK

LVDS Cable

Reinsert

NG

OK

Change

LVDSCable

NG

Workmanship

LVDS cable NG

Check VLCD

is 5V

NG

Check Panel-Enable of

U105(pin48)

OK

Check

Q101,Q103,Q110,

C108,

C109

OK OK

Check LVDS

signal

NG

U105 Fail

NG

Panel Fail

END

25

Page 27

Acer Service Manual

6.No Sound

No Sound

Re-insert or Change the

Line-in Cable

OK

Check Vs of IC 701?

OK

Check the Input of IC 701

OK

Check the output of IC 701

OK

OK

NG

Power Fail

NG

NG

Check the Mute and Volume pins of IC

701 shorted or not?

NG

Change IC 701

End

26

Page 28

Acer Service Manual

7. Unstable Power

Unstable power

Check sampling

Circuit

Check the R pin

voltage of IC803

about 2.5V

Check pin2

of IC802

voltage is 3V

Check R822,

R823, R824

Check the C

pin voltage of

IC803 if 3V

Check R819, R820

Check R818, D804,

C807 if short

Change R822,

R823, R824

Change

IC803

Check pin1 of

IC802 voltage

below 1V

Change

R818,

Change R808, R

809, R810, R 811,

END

27

Page 29

Acer Service Manual

Attachment 1- Bill of Material

PCBA IF

ITEM P/N Description Location

790771300000R PCBA,I/F BOARD,W/SPK,LE1753-012 ROHS

10 629030009100R PROGRAM,W/SPK,LE1753-012 ROHS

20 790771340600R PCBA,I/F BOARD,SMD,LE1753-612

30 790771320600R PCBA,I/F BOARD,OTHERS,LE1753-612

40 511130001200R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5/Ni0.06/Ge0

790771320600R PCBA,I/F BOARD,OTHERS,LE1753-612

10 440819015030R CON,D-SUB,FEM.15P RA W/O SCREW DZ11AA1-H CN101,

20 443842024060R CON,DVI-D RA 24+1P FEM.W/O SCR EW,QH1112 CN102,

30 430631080070R WFR 2.0mm 8P 180°4500-08 RoHS CN103,

40 430631080130R WAFER 2x4P 2.0mm,200PHD-2*4ST RoHS CN104,

50 420271010460R CAP SE 100uF 16V M,105 ST,6.3*11 ROHS℃ C130,

60 420274790560R CAP SE 4.7uF 50V M,105 ST,5X11 ROHS℃ C132,

70 420432200460R CAP EC 22uF 16V M,105 ST, 5x11,RoHS℃ C144,

80 432008010270R XTAL 14.31818MHz HC-49US DIP 16pF 30PPM X101,

90 420431010460R CAP EC 100uF 16V M,105 ST 5x11,RoHS℃ C135, C152, C138,

790771340600R PCBA,I/F BOARD,SMD,LE1753-612

10 444099030030R CON, SMD 1.0mm 30PIN RoHS AL2309-A0G1Z CN106,

20 419301010560R C SMD(0603) NPO 100PF/50V J RoHS C163,C164,C165,C166,C167,

C139,C140,C141,C142,C145,C1

30 419351044010R C SMD(0402) X5R 0.1uF/16V K,RoHS

40 419311040060R C SMD(0603) X7R 0.1uF/50V K RoHS

50 419341054670R C SMD(0805) Y5V 1uF/16V Z RoHS REV:A C160,C137,

60 419301000560R C SMD(0603) NPO 10PF/50V J RoHS C158,C159,

70 419302210560R C SMD(0603) NPO 220PF/50V J RoHS C116,

80 419303300560R C SMD(0603) NPO 33PF/50V J RoHS C115,

90 419314734010R C SMD(0402) X7R 0.047uF/16V K,RoHS

110 414918010050R RES SMD (0402) 10Ω J,RT,RoHS

120 414918560910R RES SMD (0402) 56Ω F,RT,RoHS R101,R102,R103,

130 414916010150R RES SMD (0603) 100Ω J,RT RoHS REV:A R185,R186,

140 414916010250R RES SMD (0603) 1KΩ J,RT RoHS REV:A

150 414916010350R RES SMD (0603) 10KΩ J,RT RoHS

160 414916010450R RES SMD (0603) 100KΩ J,RT REV:A RoHS R147,

190 414916047350R RES SMD (0603) 47KΩ J,RT RoHS R150,

200 414916022250R RES SMD (0603) 2.2KΩ J,RT RoHS R118,R117,

210 414918390010R RES SMD (0402) 390Ω F,RT,RoHS R154,

220 414916047050R RES SMD (0603) 47Ω J,RT RoHS R121,R122,R126,R127,

230 414916047250R RES SMD (0603) 4.7KΩ J,RT RoHS R139,R142,R149,R176,

240 414916022050R RES SMD (0603) 22Ω J,RT RoHS R146,

250 414916750910R RES SMD (0603) 75Ω F,RT RoHS REV:A R105,R106,R107,

46,C147,C148,C149,C153,C154,

C155,C156,C157,

C117,C120,C121,C131,C133,C1

34,C136,C143,C151,C161,C162,

C168,

C101,C102,C103,C106,C108,C1

10,

R130,R131,R132,R133,R134,R1

35,R137,R138,

R113,R115,R116,R125,R143,R1

55,R156,R167,R168,R175,R177,

R111,R123,R124,R136,R141,R1

52,R153,R157,R158,R160,R161,

R162,R163,R164,R172,R173,R1

74,R178,R179,R180,R181,R182,

R183,R184,R119,R120,R128,

R129,

28

Page 30

Acer Service Manual

260 411020026210R DIO BAV99 350mW 70V SOT-23(PHI RoHS D101,D102,D103,

260 411020026390R DIO BAV99,SOT-23(INFINEON)RoHS

260 411020026020R DIO BAV99-LF 350mW 70V SOT-23 (FEC)RoHS

260 411020026090R DIO BAV99 350mW 75V SOT-23(PEC RoHS

270 411020047210R DIO BAV70 85V SOT23 (PHILIPS) RoHS D104,D107,

270 411020047020R DIO BAV70-LF, 70V SOT-23(FEC) ROHS

280 411090005011R SCHTKY SK24A 40V/2A SMA(TSC) DO-214AC Ro D116,

280 411090005311R SCHTKY B240A 40V/2A SMA(DIODES RoHS

310 432002312144R BEAD CORE SMD(0603)120Ω 300mA SBK160808 FB104,

320 432002360012R BEAD CORE SMD(0805)60Ω 800mA GBK201209T FB105,FB106,FB107,

330 410500045210R XSTR PMBT3904 NPN 200MA,40V SOT23(PHILIP Q102,Q106,

330 410500045140R XSTR MMBT3904LT1G NPN 200MA 40V SOT23(ON

330 410500045130R XSTR MMBT3904 NPN SOT-23(INFIN EON)RoHS

330 410500045090R XSTR MMBT3904 NPN SOT-23(PANJIT)RoHS

340 410500068290R XSTR AP2305GN P-CH SOT23(APEC) RoHS Q103,

340 410500075270R XSTR AO3415 P-CH,SOT23(AOS) RoHS

340 410500044270R XSTR AO3401L P-CH(ALPHA-OMEGA) SOT23 RoH

360 410500050210R XSTR 2N7002,N-CH FET SOT-23 (PHILIPS)RoH Q105,

360 410500050130R XSTR SN7002N N-CH SOT-23(INFINEON),RoHS

360 410500050090R XSTR 2N7002 N-CH SOT-23(PANJIT)RoHS

370 410500046210R XSTR PMBT3906 PNP 200MA,40V SOT23(PHILIP Q109,Q108,Q101,

370 410500046130R XSTR MMBT3906 PNP SOT-23(INFIN EON)RoHS

370 410500046180R XSTR MMBT3906LT1G PNP 200mA 40V SOT23(ON

370 410500046090R XSTR MMBT3906 PNP SOT-23(PANJIT)RoHS

380 412000435480R IC AT24C02BN-10SU-1.8 SOIC8 2K (ATMEL)Ro U101,U102,

380 412000480280R IC M24C02-RMN6TP SO8(ST)RoHS

380 412000480990R IC CAT24C02WI-TE13 SOIC-8(CATALYST)RoHS

390 412000372020R IC LD1117AL-3.3V-A SOT-223(UTC RoHS U103,

390 412000372830R IC AS1117L-3.3TR-LF,SOT223(A1S EMI)RoHS

390 412000372070R IC AZ1117H-3.3 SOT-223(AAC)RoHS

400 412000553060R IC TSUM56AWHK-LF-1 PQFP128(MSTAR)RoHS U104,

410 412000486310R IC PM25LV010A-100SCE SOIC8(PMC)RoHS U105,

410 412000373190R IC SST25VF010A-33-4C-SAE,SOIC- 8(SST)RoH

410 412000486190R IC PS25LV010A-100SCE SOIC8(MSTAR)RoHS

420 412000279480R IC AT24C04N-10SU-2.7 SOP8 4K(A TMEL)RoHS U107,

420 412000279280R IC M24C04-WMN6TP4K SOP8 (ST) RoHS

420 412000479990R IC CAT24C04WI-TE13 SOIC-8(CATALYST)RoHS

430 411131562950R ZENER 6.2V BZT52C6V2-7-F SOD-123(DIODES)

430 411121462950R ZENER 6.2V BZT52-C6V2 SOD-123(WILLAS)ROH

430 411130962950R ZENER 6.2V MMSZ5234B SOD-123(PANJIT)RoH

440 506140005700R LABEL,BARCODE,BLANK,33x7mm, ROHS,FOR PCB

460 432002330040R BEAD CORE SMD(0603) 30Ω 500mA HB-1H1608 FB101,FB102,FB103,

470 412000330020R IC LD1117AL-1.8V-A SOT223(UTC) RoHS U108,

470 412000330070R IC AZ1117H-1.8 SOT223(AAC)RoHS

470 412000330830R IC AS1117L-1.8/TR-LF,SOT223(A1 SEMI)RoHS

480 414916033150R RES SMD (0603) 330Ω J,RT RoHS R187,R188,

490 414916010050R RES SMD (0603) 10Ω J,RT RoHS R159,R165,

500 490481300600R PCB,I/F BOARD,LE1753-X12

510 412000531061R IC CAT24C08WI-H-RECV SOIC-8(Mstar)RoHS U106,

510 412000531060R IC CAT24WC08W-H-RECV for HDCP(Mstar) R

ZD101,ZD102,ZD103,ZD104,ZD1

05,ZD106,ZD107,ZD108,ZD109,

29

Page 31

Acer Service Manual

520 414918010150R RES SMD (0402) 100Ω J,RT,RoHS R108,R109,R110,

530 419341054660R C SMD(0603) Y5V 1uF/16V Z,RoHS C150,

540 414916020350R RES SMD (0603) 20KΩ J,RT RoHS REV:A R151,

550 511130002200R SOLDER PASTE,Sn96.5-Ag3.0-Cu0.5 ROHS

550 511130002201R SOLDER PASTE,Sn96.5%Ag3.0%Cu0.5%

550 511130002202R SOLDER PASTE,Sn95.5%Ag3.9%Cu0.6%

PCBA PI

ITEM P/N Description Location

790931400500R PCBA,P/I BOARD,LE2018-522 ROHS

10 430300800660R HRN ASS'Y 8P 80mm UL1007#24,RoHS CN801,

20 430637020030R

30 430631040080R WFR. 4P 2.0mm R/A HF5604E RoHS CN701,

40 426000090800R XFMR SW DIP 142uH EEL19 SPW-080,ROHS T501,T502,

50 416202223610R CAP MEY 2200pF 250V M Y2 Y5V P=7.5mm RoH C801,C802,

60 416194743011R CAP MEX 0.47uF 275V K X2,F15 RoHS C803,

70 420431514280R

80 416202224610R CAP MEY 2200pF 400V M Y,F10mm RoHS C805,

100 418247233020R CAP CD X7R 4700pF 1KV K,W/O FO RMING,RoH C806,

110 418110058560R CAP CD SL 10pF 3KV J,ST,RoHS CC45SL3FD10 C506,C523,

120 418103051910R CAP CD NPO 3pF 3KV D,F7.5, RoHS C528,C509,

130 420421020211R

140 420424710260R

150 420421020102R

160 430613420290R FUSE SLOW 2,250,Axial Lead,3.6 x10mm RoH F801,

170 412140001390R IC EL817M-B(EVERLIGHT)RoHS IC801,

170 412140002380R IC LTV817M-PR VDE (LITE-ON) P=10mm RoHS

180 425000010670R COIL CHK 20mH UU16 CHK-067,RoH S,UF2324S L801,

190 425000010530R COIL CHK 5uH 7.8X10 CHK-053 0 181085R0L L802,L803,

200 440149000220R SKT AC 10A/250V U/C/V,G/Y=45mm TU-301-SP P801,

210 442299001130R CON PHONE JACK GREEN R/A 1P PB J303-2-A P701,

220 432009400701R

230 415350208550R

240 426000090790R XFMR SW DIP 550uH SPW-079,ROHS T801,

250 411050005020R DIO BRDG BL4-06-BF52-LF 600V/4A(FRONTIER D801,

250 411050005090R DIO BRDG FL406 600V/4A(PEC)RoH S

250 411050007010R DIO BRDG KBL405G 600V/4A(TSC) RoHS

260 502040604500R SHIELD EMI LE1915 ROHS H501,

270 735100008600R ASSY,H/S,TDA8496L-J-15-B-T,LE1753

280 790911440500R PCBA,P/I BOARD SMD,LE2041-510 ROHS

290 735100008800R ASSY,H/S,SRF10100/SRF1050,LE2041 ROHS

300 735100007900R ASSY,H/S,AP2761I-A,LE1936

310 410050062330R XSTR AF4971NN N-CH PDIP8(ANACH IP)RoHS U501,U502,

310 410500071290R XSTR AP9971GD,N-CH,PDIP-8(APEC RoHS

320 511130001200R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5/Ni0.06/Ge0

330 511110000101R HOT-MELT ADHESIVES (#526)

340 511110000501R SILICONE RTV RUBBER,UB-511(EURO)

350 416204724610R CAP MEY 4700pF 400V M Y,F10mm RoHS C823-1,

360 418210133030R CAP CD X7R 100pF 1KV K VT RoHS C808,

735100007900R ASSY,H/S,AP2761I-A,LE1936

10 410500059290R XSTR AP2761I-A N-CH TO-220CFM ADVANCED P Q804,

10 410050060130R XSTR SPA06N80C3 N-CH PG-TO220- 3-31(INFI

10 410050059240R XSTR FQPF7N80C N-CH TO220F(FAI RCHILD)Ro

20 507200003700R HEATSINK,46x20xt10mm LE1704/05

30 509112306100R SCREW,P,CROSS,T.T-3*6,ZnROHS

735100008600R ASSY,H/S,TDA8496L-J-15-B-T,LE1753

10 412000526020R IC TDA8496L-J-15-B-T HZIP-15B(UTC)RoHS U701,

20 507200004900R HEATSINK,35x20xt10mm, LE1753

30 509142308101R SCREW,P,CROSS,W/WAS(8mm),T.T-3*8,Zn ROHS

735100008800R ASSY,H/S,SRF10100/SRF1050,LE2041 ROHS

10 411090023040R SCHTKY SRF10150C 150V/10A ITO2 20(MOSPEC D804,

10 411090023020R SCHTKY SRF10-15CT-LF 150V/10A( FEC)RoHS

WFR. 2P P=3.5mm 90°W/LOCK,RoHS

CAP SEK 150uF/420V M,105℃ CF 18x40,RoHS

CAP SD 1000uF 25V M,105℃ F 13x20 RoHS

CAP SD 470uF/25V M 105℃ ST 10x16,RoHS

CAP EC 1000uF/10V M,105℃ N-F 10x16(L-ES

NTC 5Ω 4A 10ψ P=5mm, F RoHS

RES MOF 2W 0.2Ω J,MINI,HK15 RoHS

CN501,CN502,CN503,CN504,

C804,

C815,

C501,C817,C702,

C818,

RT801,

R805,

30

Page 32

Acer Service Manual

10 411090023090R SCHTKY SB10150FCT 150V/10A ITO 220AB(PAN

20 411090024480R SCHTKY SP1040C 40V/10A ITO220(WILLAS)RoH D805,

20 411090040010R SCHTKY SRF1050 50V/10A ITO220AB(TSC)RoHS

30 507200005300R HEATSINK,75x25xt15mm, LP2610

40 509112306100R SCREW,P,CROSS,T.T-3*6,ZnROHS

790911440500R PCBA,P/I BOARD SMD,LE2041-510 ROHS

10 412000495840R IC NCP1337DR2G SOIC-7(ON)RoHS IC802,

20 414904010050R

30 414916010150R

40 414916010250R

50 414908010250R

60 414916100210R

70 414908010350R

80 414916100310R

90 414916010550R

100 414916110310R

110 414908120210R RES SMD (0805) 12K F RT RoHS REV:A R815,

120 414916015050R

130 414916020150R

140 414908020150R

150 414916020250R

160 414908033050R

170 414908300110R

180 414916030350R

190 414916750110R

200 414916330410R RES SMD (0603) 3.3M F RT RoHS R507,

210 414916470010R

230 414916047250R

240 414908510110R

250 414916470210R

260 414908470210R

270 414916470310R

280 414916510110R

290 414916430210R

300 414908047450R

310 414916056250R

320 414916604310R

340 414908750010R

350 419311040060R C SMD(0603) X7R 0.1uF/50V K RoHS

360 419311020060R C SMD(0603) X7R 1000PF/50V K RoHS C510,C516,

370 419311020070R C SMD(0805) X7R 1000PF/50V K RoHS C504,C505,C522,C529,

380 419302210360R C SMD(0603) NPO 220PF/50V G RoHS C812,

390 419312220060R C SMD(0603) X7R 2200PF/50V K RoHS C517,C524,C530,

400 419312220070R C SMD(0805) X7R 2200PF/50V K RoHS C525,C513,

410 419312233060R C SMD(0603) X7R 0.022uF/25V K RoHS C511,

420 419342254670R C SMD(0805) Y5V 2.2uF/16V Z RoHS C507,C515,

420 419352254070R C SMD(0805) X5R 2.2uF/16V K, RoHS

430 419342253670R C SMD(0805) Y5V 2.2uF/25V Z RoHS C502,

440 419312720070R C SMD (0805) X7R 2700pF 50V K ROHS C514,C527,

450 419303310560R C SMD(0603) NPO 330PF/50V J RoHS C512,

460 419314720060R C SMD(0603) X7R 4700PF/50V K RoHS C710,C711,

470 419314744060R C SMD(0603) X7R 0.47uF/16V K,RoHS C704,C706,

480 419301510560R C SMD(0603) NPO 150PF/50V J RoHS C521,

490 411100912020R ZENER 12V MMSZ5242A SOD123(PEC RoHS ZD803,

490 411131512052R ZENER 12V 0.5W DDZ12C-F,SOD123 (DIODES)R

490 411131412020R ZENER 12V MMSZ5242A SOD-123(WILLAS)ROHS

500 412000455630R IC OZ9938GN SOIC16(O2 MICRO)RoHS IC501,

510 411023004021R DIO SN4148-LF 75V/0.15A SMD 1206 (FEC)Ro D501,D505,D511,D512,

510 411020046090R DIO 1N4148W 75V/0.15A(PEC)RoHS SOD-123

510 411020046310R DIO 1N4148W-F 75V/0.15A(DIODES RoHS,SOD-

520 411020026210R DIO BAV99 350mW 70V SOT-23(PHI RoHS D502,D503,D504,D507,D508,D509,

520 411020026390R DIO BAV99,SOT-23(INFINEON)RoHS

RES SMD (1206) 10Ω J,RT RoHS

RES SMD (0603) 100Ω J,RT RoHS REV:A

RES SMD (0603) 1KΩ J,RT RoHS REV:A

RES SMD (0805) 1KΩ J,RT RoHS REV:A

RES SMD (0603) 10KΩ F,RT RoHS

RES SMD (0805) 10KΩ J,RT RoHS REV:A

RES SMD (0603) 100KΩ F,RT RoHS

RES SMD (0603) 1MΩ J,RT RoHS REV:A

RES SMD (0603) 110KΩ F,RT RoHS REV:A

RES SMD (0603) 15Ω J,RT RoHS REV:A

RES SMD (0603) 200Ω J,RT RoHS

RES SMD (0805) 200Ω J,RT RoHS

RES SMD (0603) 2KΩ J,RT RoHS

RES SMD (0805) 33Ω J,RT RoHS

RES SMD (0805) 3KΩ F,RT RoHS REV

RES SMT(0603)30KΩ J,RT RoHS

RES SMD (0603) 7.5KΩ F,RT RoHS

RES SMD (0603) 470Ω F,RT RoHS

RES SMD (0603) 4.7KΩ J,RT RoHS

RES SMD (0805) 5.1KΩ F,RT RoHS

RES SMD (0603) 47KΩ F,RT RoHS

RES SMD (0805)47KΩ F,RT,RoHS

RES SMD (0603) 470KΩ F,RT ROHS

RES SMD (0603) 5.1KΩ F,RT RoHS

RES SMD (0603) 43KΩ F,RT,RoHS

RES SMD (0805) 470KΩ J,RT RoHS

RES SMD (0603) 5.6KΩ J,RT ROHS REV:A

RES SMD (0603) 604KΩ F,RT RoHS

RES SMD (0805)750Ω F,RT,RoHS

31

R827,R828,

R713,

R706,R707,

R813,R819,R820,R821,

R513,R537,R538,R702,R701,R703,

R812,R829,R830,

R501,R520,

R526,R519,

R512,

R534,R535,

R527,R524,

R817,

R710,R709,

R504,R505,R530,R532,

R824,

R714,R705,

R533,R536,

R528,R523,R521,R529,

R708,

R822,

R514,R704,

R823,

R518,

R539,

R508,

R808,R809,R810,R811,

R712,R711,

R516,

R807,R831,R832,

C503,C518,C519,C520,C825,C709,

C703,

Page 33

Acer Service Manual

520 411020026020R DIO BAV99-LF 350mW 70V SOT-23 (FEC)RoHS

520 411020026090R DIO BAV99 350mW 75V SOT-23(PEC RoHS

530 411020068020R DIO BAW56 70V SOT-23(FRONTIER)RoHS D506,

530 411020068090R DIO BAW56 75V SOT-23(PANJIT)RoHS

530 411020068210R DIO BAW56 85V SOT-23(PHILIPS)RoHS

540 410500045210R XSTR PMBT3904 NPN 200MA,40V SOT23(PHILIP Q701,Q702,Q703,

540 410500045140R XSTR MMBT3904LT1G NPN 200MA 40V SOT23(ON

540 410500045130R XSTR MMBT3904 NPN SOT-23(INFIN EON)RoHS

540 410500045090R XSTR MMBT3904 NPN SOT-23(PANJIT)RoHS

560 790911410500R PCBA,P/I BOARD AI,LE2041-510 ROHS

570 414908160110R

790911410500R PCBA,P/I BOARD AI,LE2041-510 ROHS

10 790911450500R PCBA,P/I BOARD AI/A,LE2041-510 ROHS

20 790911460500R PCBA,P/I BOARD AI/R,LE2041-510 ROHS

790911450500R PCBA,P/I BOARD AI/A,LE2041-510 ROHS

10 411020053090R DIO PS1010R 1000V/1A DO-41(PAN JIT)RoHS D802,

10 411032006020R DIO FR10-10-LF 1000V/1A AT(FRO NTIER)RoH

10 411020055330R DIO MUR1100ERL AXIAL LEAD(ON) RoHS

20 411022010010R DIO 1N4003 200V/1A DO-41(TSC) D803,

20 411020052020R DIO A02-LF 200V/1A R1(FEC)RoHS

30 411022003020R DIO 1N4148-LF 75V/0.15A AT (FEC)RoHS D806,

30 411022003210R DIO 1N4148 75V/0.2A AT (PHIL) RoHS

40 415030105540R

50 415130183540R

60 414880155540R

70 415020330540R

80 415320100540R

90 415340101540R

100 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 7.5MM

100 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 7.5MM

110 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 10MM J503,J509,J809,J804,J805,J806,

110 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 10MM

120 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 12.5MM J505,J516,J801,J802,R804,

120 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 12.5MM

130 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 15MM J504,J502,J513,

130 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 15MM

140 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 17.5MM J507,J508,J512,J808,J704,J705,

140 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 17.5MM

150 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 20MM J510,J501,J811,

150 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 20MM

160 411020050090R DIO P6KE150A,DO-15,AT(PANJIT)RoHS ZD802,

160 411020050020R DIO P6KE150A-LF AT(FRONTIER) RoHS

160 411020050010R DIO P6KE150A,DO-15AT,(TSC)RoHS

170 430613040100R FUSE SLOW PICO II 4A/125V U/C,AT,RoHS F802,

180 490901400100R PCB,P/I BOARD,LE2239-X32 ROHS

190 506140005700R LABEL,BARCODE,BLANK,33x7mm, ROHS,FOR PCB

790911460500R PCBA,P/I BOARD AI/R,LE2041-510 ROHS

10 420264700230R

20 418147038530R CAP CD NPO 47pF 1KV J,VT RoHS C809,

40 419111040030R CAP MTL X7R 0.1uF 50V K,VT, RoHS C810,C811,C822,

50 418210227030R CAP CD X7R 1000pF 500V K VT RoHS C813,C814,

60 416231041530R CAP MEB 0.1uF 100V J,(RSB),VT RSBEC3100D C821,

60 416141041531R CAP MKT 0.1uF 100V J,VT(ARCO) RoHS,R82EC

70 418112031530R CAP CD NPO 12pF 1KV J,VT,RoHS C826,

80 412022002240R IC KA431AZ 1%,VT (FAIRCHILD) RoHS IC803,

80 412022002300R IC AP431VL TO-92 1% VT (ATC) RoHS

80 412022002840R IC TL431ACLPG TO-92 1%,VT(ON)RoHS

80 412022002830R IC AS431 TO-92 VT(A1SEMI)RoHS

90 410072013370R XSTR 2SC1815-GR (T2SPF.T) VT (TOSHIBA)Ro Q801,

90 410072013150R XSTR UTC2SC1815L-GR NPN TO92 (UTC)RoHS

90 410072013210R XSTR 2PC1815GR*I VT (PHILIPS) RoHS REV:

100 420271000230R

110 420424710260R

120 420434710431R

RES SMD (0805) 1.6KΩ F,RT,RoHS

RES CF 1/2W 1MΩ J,AT MINI RoHS

RES CF 1/2W 18KΩ J,AT,RoHS

RES MG HV 1Ws 1.5MΩ 2KV J,AT RoHS

RES CF 1/4W 33Ω J,AT MINI RoHS

RES MOF 1/4W 10Ω J,AT MINI RoHS

RES MOF 1W 100Ω J,AT MINI RoHS

CAP SH 47uF 25V M,125℃,VT, 6.3x11,RoHS

CAP SE 10uF 25V M,105℃ VT,5X11 ROHS

CAP SD 470uF/25V M 105℃ ST 10x16,RoHS

CAP EC 470uF 16V M,105℃ VT 8x12,RoHS

R531,R510,

R801,R802,

R803,

R525,R506,

R517,

R806,

R816,

J506,J511,J514,J515,J701,J706,J8

03,J807,J702,J703,J810,J715,J716,

C807,C820,C827,

C701,

C712,

C707,C705,

32

Page 34

Acer Service Manual

130 420262210460R

140 432002200200R FERR BEAD 3.5x6x0.65,VT,RoHS FB801,

CAP SH 220uF 16V M,125℃,ST,10x13,RoHS

C708,

PCBA KEY PAD

ITEM P/N Description Location

790931500000R PCBA,KEYPAD BOARD,LE2018 ROHS

10 430638080020R WFR. 8P 1.5mm R/A S8B-ZR RoHS JST CN107,

20 411070054990R

20 411070053990R

30 430602980120R SW TACT 160gf 1P,H=4.3mm,DIP SFKHHAL2420 SW101,SW102,SW103,SW104,SW105,

40 415020222540R RES CF 1/4W 2.2KΩ J,AT MINI REV:A RoHS R901,R902,

50 490931500000R PCB,KEYPAD BOARD,LE2018 ROHS

60 511130001200R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5/Ni0.06/Ge0

LED G/Y∮3x5mm L-115VCGKSYKW-L 5.33-SZ(K

LED G/Y∮3x5mm 1259-7SYGUYW/S5 30-A3/F14

LED101,

33

Page 35

Acer Service Manual

Attachment 2- Schematic

34

Page 36

Acer Service Manual

35

Page 37

Acer Service Manual

36

Page 38

Acer Service Manual

37

Page 39

Acer Service Manual

38

Page 40

Acer Service Manual

39

Loading...

Loading...