Page 1

SOFTSTARTER

HANDBOOK

Page 2

FOREWORD

This book is written with the thought of being a general guide for people working with

softstarter applications but also for those just interested in learning more about this type

of starting method. It doesn’t matter if you are an expert or novice, hopefully you will find

some interesting and useful information either by reading from cover to cover or just the

chapters of interest.

The index at the end of the book can be used to simplify your search.

The content of this book is very much based on the 20 years of experience we have within

ABB of developing, manufacturing and selling low voltage softstarters.

The book is not a complete technical guide or manual for all type of ABB Softstarters that

may exist on the market. It is a complement to the technical catalogues and brochures we

have for our products and will give a general picture of what to think about when working

with softstarters.

More information about softstarters as well as other ABB products is available on www.abb.com

All advice given in this book is only general and every single application must be handled

as a specific case.

ABB Automation Technology Products AB, Control

February 2003

Magnus Kjellberg Sören Kling

Page 3

ABB will not take any responsibility for any type of faults or damage due to the use of this

handbook.

Page 4

Contents

Standards ...1

European Directives ...1

CE Marking ...1

Specification in USA and Canada ...1

Used standards ...1

General about motors ...2

Squirrel cage motors ...3

Voltage ...4

Power factor ...5

Speed ...6

Torque ...7

Slip-ring motors ...7

Different starting methods ...8

Direct-on-line start (D.O.L) ...9

Star-delta start ...10

Frequency converter ...12

Softstarter ...13

Common problem when starting and stopping motors ...14

Different applications ...15

Centrifugal fan ...16

Direct-on-line start (D.O.L) ...16

Star-delta start ...17

Softstarter ...17

Selection of a suitable Softstarter ...18

Contents

I

Centrifugal pump ...19

Direct-on-line start (D.O.L) ...19

Star-delta start ...20

Softstarter ...21

Selection of a suitable Softstarter ...22

Page 5

Compressor ...23

Direct-on-line start (D.O.L) ...23

Star-delta start ...24

Softstarter ...25

Contents

Selection of a suitable Softstarter ...26

Conveyor belt ...27

Direct-on-line start (D.O.L) ...27

Star-delta start ...28

Softstarter ...29

Selection of a suitable Softstarter ...30

How to select a softstarter ...31

Description of the softstarters ...33

Description of different components ...34

Common settings ...36

II

Start ramp ...36

Stop ramp ...36

Initial voltage ...36

Current limit ...37

Step down voltage ...38

Adjustable rated motor current ...38

Different indications ...39

Different voltage names ...40

Ambient temperature ...41

High altitudes ...42

Start of several motors ...43

Parallel start of motors ...43

Sequential start of motors ...44

Page 6

Different ways of connecting the softstarter ...45

In-Line connection ...46

Inside Delta connection ...46

Location of the main contactor ...47

Basic settings ...49

Table for settings without current limit function ...50

Table for settings with current limit function ...51

Starting capacity and overload protection ...52

Starting capacity for softstarters ...52

Starting capacity when using by-pass contactor ...53

Starting capacity when using overload protection ...53

Number of starts/hour ...54

Intermittance factor ...54

Contents

Harmonics ...55

Harmonic content ...55

Explosive atmospheres (EEx) ...56

Hazardous areas and zones ...57

Location and selection of softstarter ...57

Co-ordination ...58

Types of co-ordination ...59

Utilization Categories ...60

Types of fuses ...61

Where to find the co-ordination tables ...62

How to read the co-ordination tables ...63

ESD aspects ...65

Two type of faults and different circuits ...65

Electro static voltage levels ...66

Protection against ESD damages ...66

III

Page 7

Frequently Asked Questions (FAQ) ...67

Environmental information ...69

LCA ...69

Contents

EPD ...70

Industrial IT ...71

Different levels ...72

Softstarter level ...72

Formulas and conversion factors ...73

Formulas ...73

Quantities and units ...75

Conversion factors ...76

Glossary ...78

IV

Index ...84

Page 8

Standards

All ABB low voltage softstarters are developed and manufactured according to the rules

set out in the IEC (International Electrotechnical Commission) which is a part of the

International Standard Organisation, ISO.

ISO issue IEC publications that act as a basis for the world market.

Softstarters built according to these standards are in most countries not subject to

any other tests besides the manufacturer responsibility. In some countries, law requires

certificates.

For softstarters used on board ships, maritime insurance companies sometimes require

certificates of approval from BV (Bureau Veritas), GL (Germanisher Lloyd) and LRS

(Lloyd’s Register of Shipping) or other independent certification organisation.

European Directives

There are three essential European directives:

Low Voltage Directive 73/23/EEC

Concerns electrical equipment from 50 to

1000 V AC and from 75 to 1500 V DC.

Machines Directive 89/392/EEC

Concerns safety specifications of machines

and equipment on complete machines.

Electromagnetic Compatibility Directive

89/336/EEC

Concerns all devices able to create electro-

magnetic disturbance including the level of

emission and immunity.

CE Marking

When a product is verified according to its

applicable IEC standard (IEC 947-4-2 for

softstarters) the product will then fulfil both the

”Lown Voltage Directive” and ”Electromagnetic

Compability Directive” and it is allowed to use

the CE marking on the product. In this case

the CE marking does not cover the ”Machines

Directive” concerning the connection of the

softstarter for a safe run of the motor.

The CE marking is not a quality label; it is proof

of conformity with the European Directives

concerning the product.

Specifications in USA and

Canada

The specifications for the American and

Canadian markets are quite equal but differ a

lot from the IEC standards and other European

specifications.

USA UL Underwriters Laboratories

File ref. 072301-E161428

110800-E161428

Canada CSA Canadian Standards

File ref. 1031179

Used standards

Following standards are used or partly used for

the softstarters.

IEC 60947-1

IEC 60947-1/A11

IEC 60947-4-2, Amd 1

EN 50082-2

UL 508

CSA C22.2 No. 14 - M91

LRS 00/00154

Standards

1

Page 9

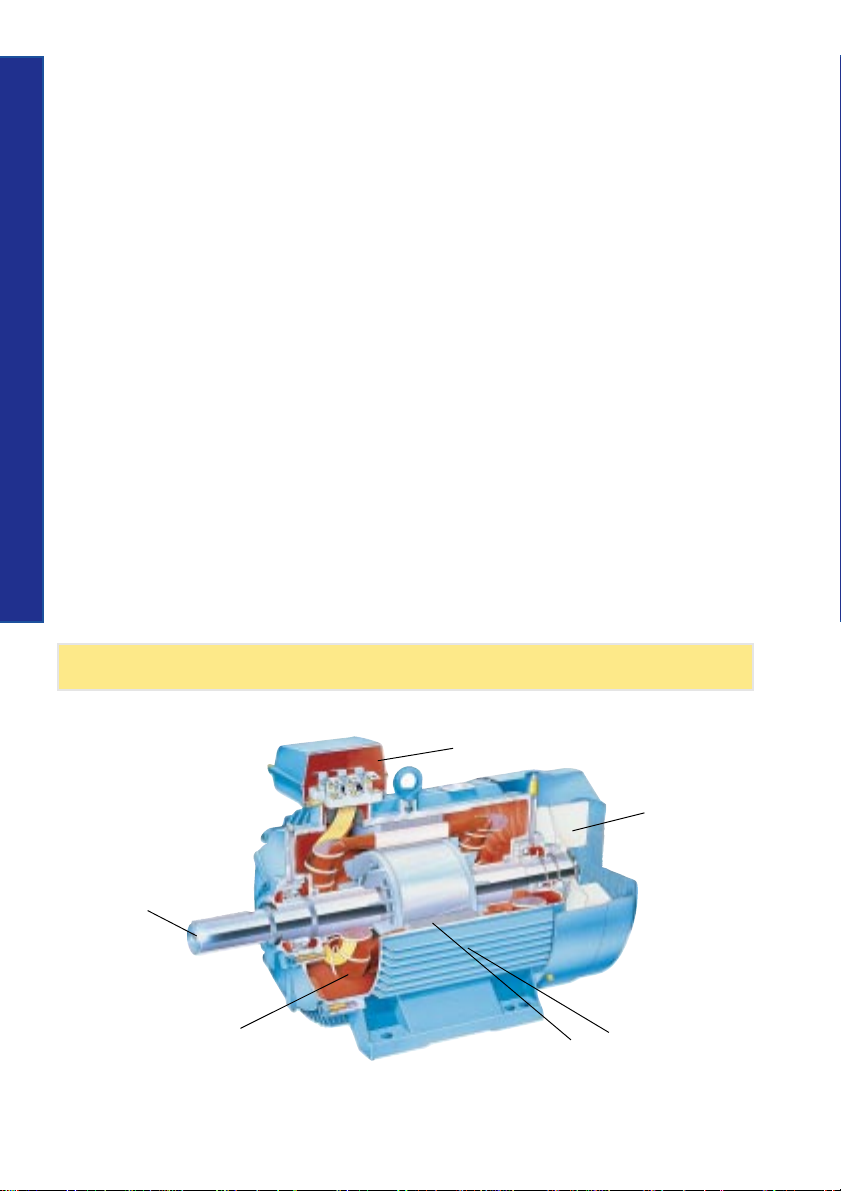

About Motors

Modern electrical motors are available in many different forms, such as single phase

motors, three-phase motors, brake motors, synchronous motors, asynchronous motors,

special customised motors, two speed motors, three speed motors, and so on, all with

their own performance and characteristics.

For each type of motor there are many different mounting arrangements, for example

foot mounting, flange mounting or combined foot and flange mounting. The cooling

method can also differ very much, from the simplest motor with free self-circulation of

About Motors

air to a more complex motor with totally enclosed air-water cooling with an interchangeable

cassette type of cooler.

To ensure a long lifetime for the motor it is important to keep it with the correct

degree of protection when under heavy-duty conditions in a servere environment.

The two letters IP (International Protection) state the degree of protection followed

by two digits, the first of which indicates the degree of protection against contact

and penetration of solid objects, whereas the second states the motor’s degree of

protection against water.

The end of the motor is defined in the IEC-standard as follows:

• The D-end is normally the drive end of the motor.

2

• The N-end is normally the non-drive end of the motor.

Note that in this handbook we will focus on asynchronous motors only.

Drive shaft

Stator windings

Terminal box

Cooling fan

N-endD-end

Stator

Rotor

Page 10

Squirrel cage motors

In this book the focus has been placed on the

squirrel cage motor, the most common type of

motor on the market. It is relatively cheap and

the maintenance cost is normally low. There are

many different manufacturers represented on the

market, selling at various prices. Not all motors

have the same performance and quality as for

example motors from ABB. High efficiency

enables significant savings in energy costs during

the motor’s normal endurance. The low level of

noise is something else that is of interest today,

as is the ability to withstand severe environments.

There are also other parameters that differ.

The design of the rotor affects the starting current

and torque and the variation can be really large

between different manufacturers for the same

power rating. When using a softstarter it is

good if the motor has a high starting torque at

Direct-on-line (D.O.L) start. When these motors

are used together with a softstarter it is possible to

reduce the starting current further when compared

to motors with low starting torque. The number

of poles also affects the technical data. A motor

with two poles often has a lower starting torque

than motors with four or more poles.

About Motors

3

I

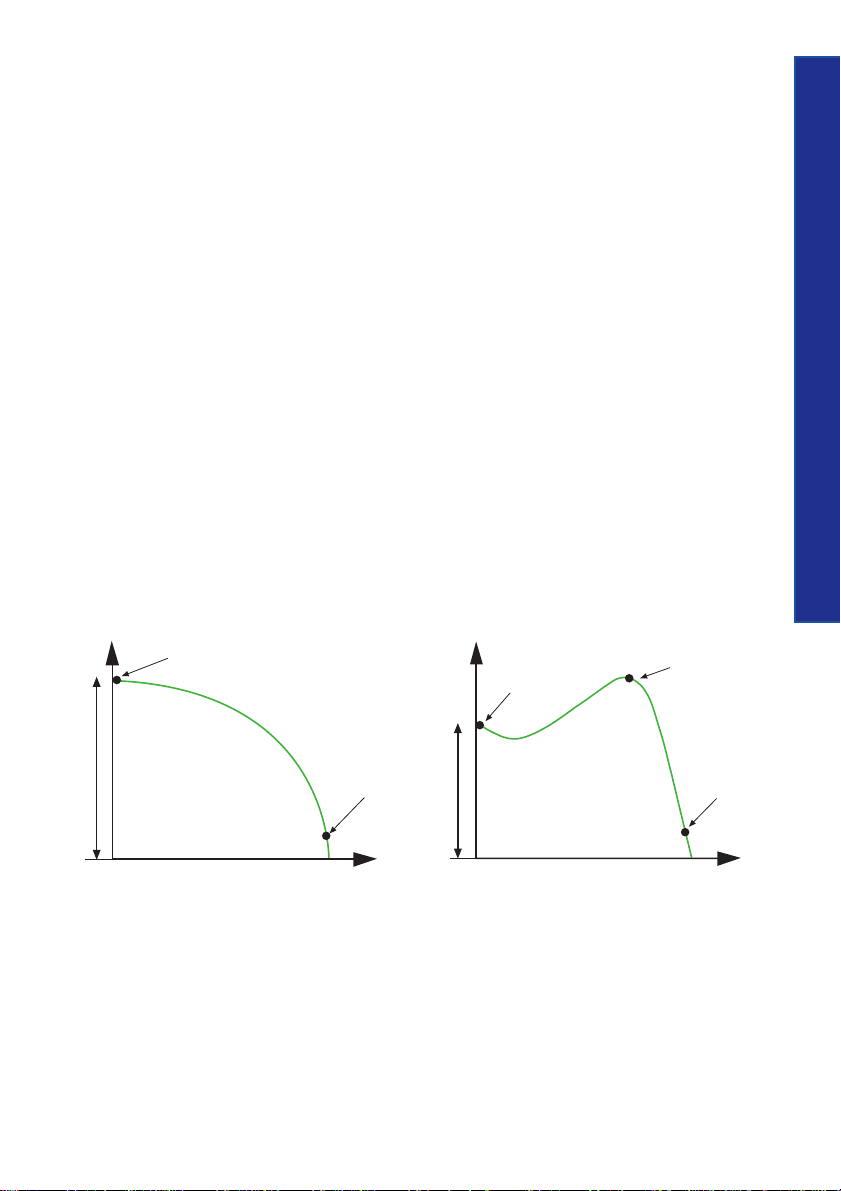

Current diagram for typical sqirrel cage motor

Max. starting current

Rated current

rpm

T

Starting torque

Torque diagram for a typical squirrel cage motor

Max. torque

Rated torque

rpm

Page 11

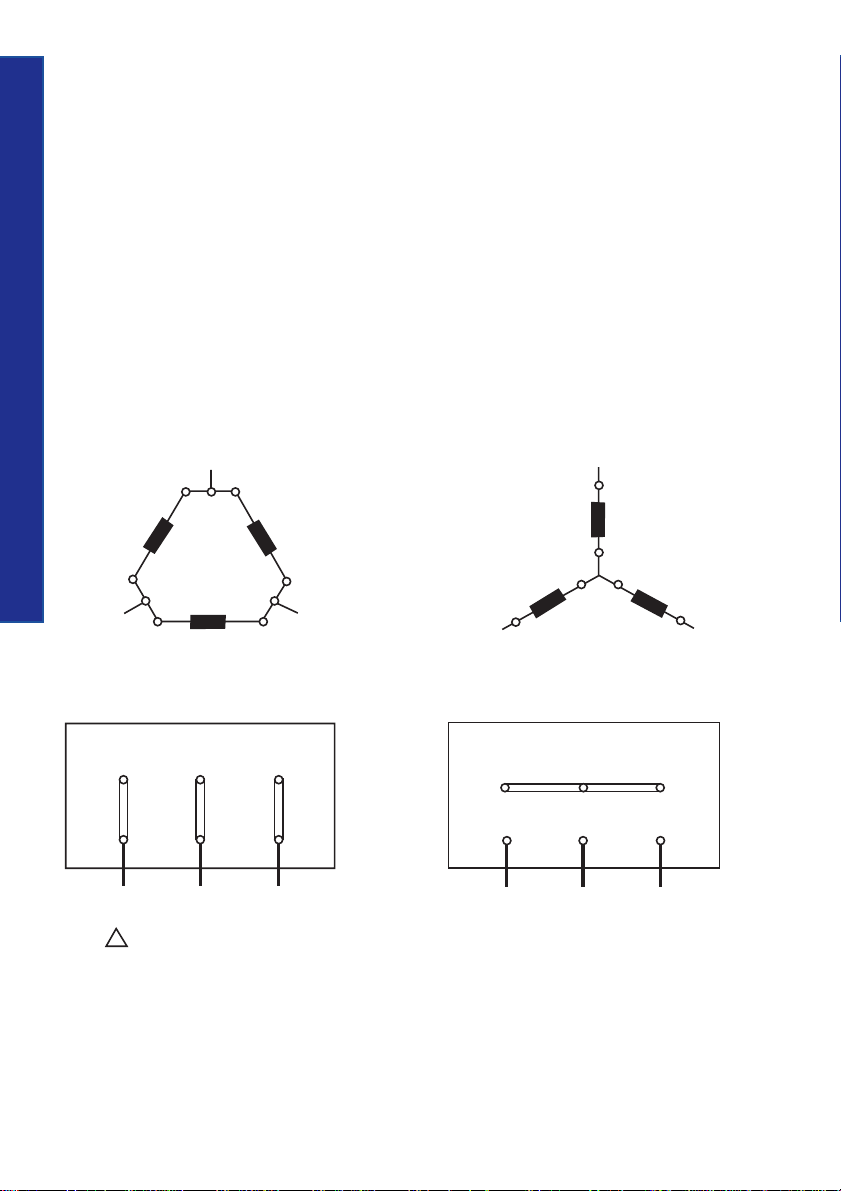

Voltage

Three-phase single speed motors can normally

be connected for two different voltage levels.

The three stator windings are connected in star

(Y) or delta (D).

The windings can also be connected in series or

About Motors

parallel, Y or YY for instance. If the rating plate

on a squirrel cage motor indicates voltages for

both the star and delta connection, it is possible

to use the motor for both 230 V, and 400 V as an

example.

The winding is delta connected at 230 V and if

the main voltage is 400 V, the Y-connection is

used.

When changing the main voltage it is important

to remember that for the same power rating the

rated motor current will change depending on the

voltage level.

The method for connecting the motor to the

terminal blocks for star or delta connection is

shown in the picture below.

W2

4

W1

L3

V2 V1

– Connection

230 V

(400 V)

Wiring diagram for Y- and Delta connection

L1

W1U1 V1

U1

L1

U1

U2

W2

V2

V1

L2

V2W2 U2

U2

L2

L3

W1

V2W2 U2

W1U1 V1

L3L1 L2

L3L1 L2

Y – Connection

400 V

(690 V)

Page 12

Power factor

A motor always consumes active power, which it

converts into mechanical action. Reactive power

is also required for the magnetisation of the motor

but it doesn’t perform any action. In the diagram

below the active and reactive power is represented

by P and Q, which together give the power S.

The ratio between the active power (kW) and the

reactive power (kVA) is known as the power

factor, and is often designated as the cos ϕ. A

normal value is between 0.7 and 0.9, when

running where the lower value is for small motors

and the higher for large ones.

About Motors

P

ϕ

Q

Diagram indicating P, Q, S and Cos ϕ

S

5

Page 13

Speed

The speed of an AC motor depends on two things:

the number of poles of the stator winding and

the main frequency. At 50 Hz, a motor will run

at a speed related to a constant of 6000 divided

by the number of poles and for a 60 Hz motor

the constant is 7200 rpm.

About Motors

To calculate the speed of a motor, the following

formula can be used:

2 x f x 60

n =

p

n = speed

f = net frequency

p = number of poles

Example:

4-pole motor running at 50 Hz

2 x 50 x 60

n =

6

This speed is the synchronous speed and a

squirrel-cage or a slip-ring motor can never

reach it. At unloaded condition the speed will

be very close to synchronous speed and will

then drop when the motor is loaded.

4

= 1500 rpm

The difference between the synchronous and

asynchronous speed also named rated speed is

”the slip” and it is possible to calculate this by

using the following formula:

n1 - n

s =

n

1

s = slip (a normal value is between 1 and 3 %)

n1 = synchronous speed

n = asynchronous speed (rated speed)

Table for synchronous speed at different

number of poles and frequency:

No. of poles 50 Hz 60 Hz

2 3000 3600

4 1500 1800

6 1000 1200

8 750 900

10 600 720

12 500 600

16 375 450

20 300 360

T

Diagram showing syncronous speed vs.rated speed

Rated speed

Syncronous

speed

}

rpm

Slip

Page 14

Torque

The starting torque for a motor differs significantly

depending on the size of the motor. A small

motor, e.g. ≤ 30 kW, normally has a value of

between 2.5 and 3 times the rated torque, and

for a medium size motor, say up to 250 kW, a

typical value is between 2 to 2.5 times the rated

torque. Really big motors have a tendency to have

a very low starting torque, sometimes even lower

than the rated torque. It is not possible to start

such a motor fully loaded not even at D.O.L

start.

The rated torque of a motor can be calculated

using the following formula:

9550 x P

=

M

r

Mr = Rated torque (Nm)

Pr = Rated motor power (kW)

nr = Rated motor speed (rpm)

r

n

r

Slip-ring motors

In some cases when a D.O.L start is not permitted

due to the high starting current, or when starting

with a star-delta starter will give too low starting

torque, a slip-ring motor is used. The motor is

started by changing the rotor resistance and when

speeding up the resistance is gradually removed

until the rated speed is achieved and the motor

is working at the equivalent rate of a standard

squirrel-cage motor.

The advantage of a slip-ring motor is that the

starting current will be lower and it is possible to

adjust the starting torque up to the maximum

torque.

In general, if a softstarter is going to be used for

this application you also need to replace the motor.

T

About Motors

7

T

Tst/Tn1.5...2.5

Torque diagram for a typical squirrel cage motor

rpm

rpm

Torque diagram for a slip-ring motor

I

T

n

rpm

Current diagram for a slip-ring motor

Page 15

Different starting methods

The following is a short description of the most common starting methods for

squirrel cage motors.

An overview of common problems when starting and stopping a motor with different

starting methods, see page 14

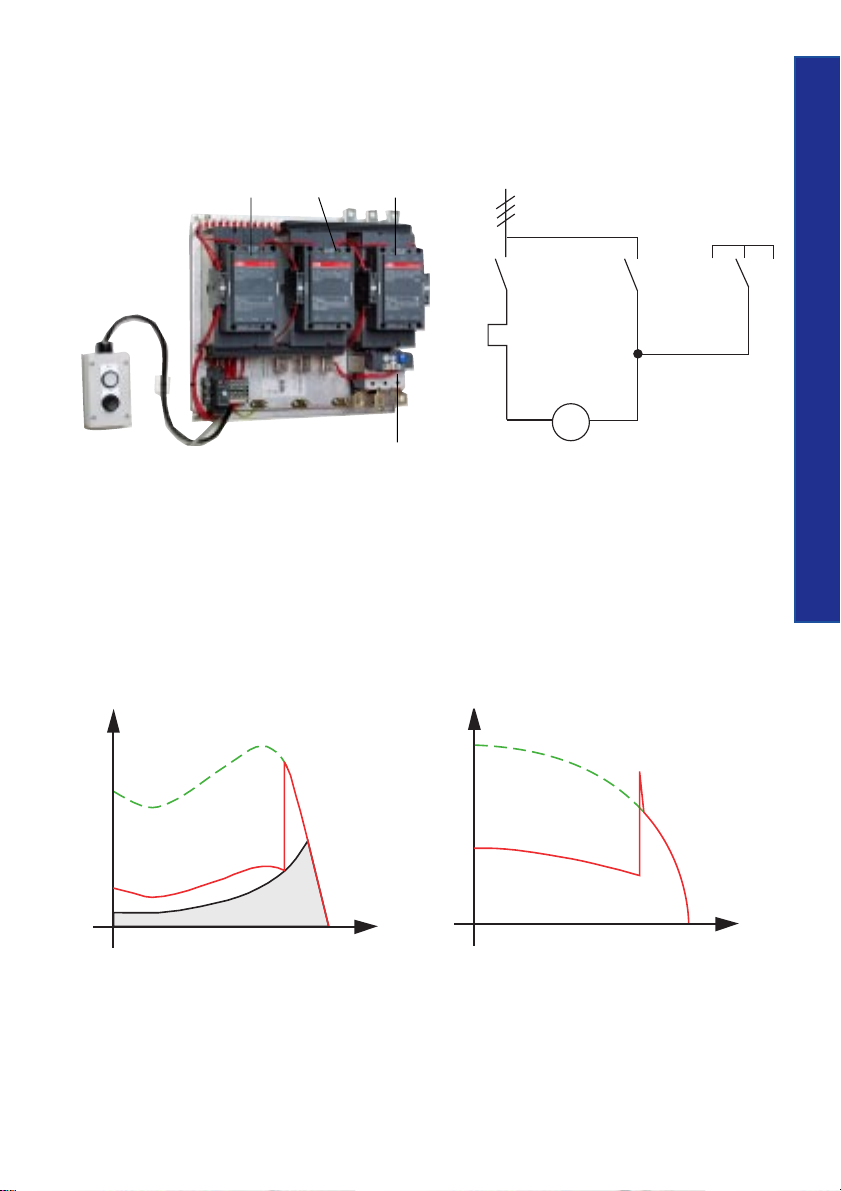

Direct-on-line start (D.O.L)

Different starting methods

8

Start-delta start

Frequency converter

Softstarter

Page 16

Direct-on-line start (D.O.L)

This is by far the most common starting method

available on the market. The starting equipment

consists of only a main contactor and thermal or

electronic overload relay. The disadvantage with

this method is that it gives the highest possible

starting current. A normal value is between 6 to 7

times the rated motor current but values of up to

9 or 10 times the rated current exist. Besides the

starting current there also exists a current peak

that can rise up to 14 times the rated current

since the motor is not energised from the the first

moment when starting.

The values are dependent on the design and size

of the motor, but in general, a smaller motor

gives higher values than a larger one.

During a direct-on-line start, the starting torque

is also very high, and is higher than necessary for

most applications. The torque is the same as the

force, and an unnecessary high force gives

unnecessary high stresses on couplings and the

driven application. Naturally, there are cases

where this starting method works perfectly and

in some cases also the only starting method that

works.

Different starting methods

D.O.L. starter with contactor

and O/L relay

KM 1 Main contactor

FR 1 Overload relay

KM 1

FR 1

M

Single line diagram

for a D.O.L.

T

Starting torque

Torque/speed curve att D.O.L start

I

Current curve at D.O.L start

Max. starting current

Max. torque

9

Rated torque

rpm

Rated current

rpm

Page 17

Star-delta start

This is a starting method that reduces the starting

current and starting torque. The device normally

consists of three contactors, an overload relay and

a timer for setting the time in the star-position

(starting position). The motor must be delta

connected during a normal run, in order to be

able to use this starting method.

The received starting current is about 30 % of

the starting current during direct on line start and

the starting torque is reduced to about 25 % of

the torque available at a D.O.L start. This starting

method only works when the application is light

Different starting methods

loaded during the start. If the motor is too heavily

loaded, there will not be enough torque to

10

accelerate the motor up to speed before switching

over to the delta position.

When starting up pumps and fans for example,

the load torque is low at the beginning of the

start and increases with the square of the speed.

When reaching approx. 80-85 % of the motor

rated speed the load torque is equal to the motor

torque and the acceleration ceases. To reach the

rated speed, a switch over to delta position is

necessary, and this will very often result in high

transmission and current peaks. In some cases the

current peak can reach a value that is even bigger

than for a D.O.L start. Applications with a load

torque higher than 50 % of the motor rated torque

will not be able to start using the start-delta starter.

Page 18

KM 2

KM 3 KM 1

400 V

Different starting methods

230 V

KM 1 Main contactor

KM 2 Delta contactor

KM 3 Star contactor

FR 1 Overload relay

T

FR 1

FR 1

I

KM 1

KM 3KM 2

M

Single line diagram for a Star-delta starterStar-delta starter with contactors and O/L relay

11

rpm

Torque/speed curve at Star-Delta start Current curve at Star-Delta start

rpm

Page 19

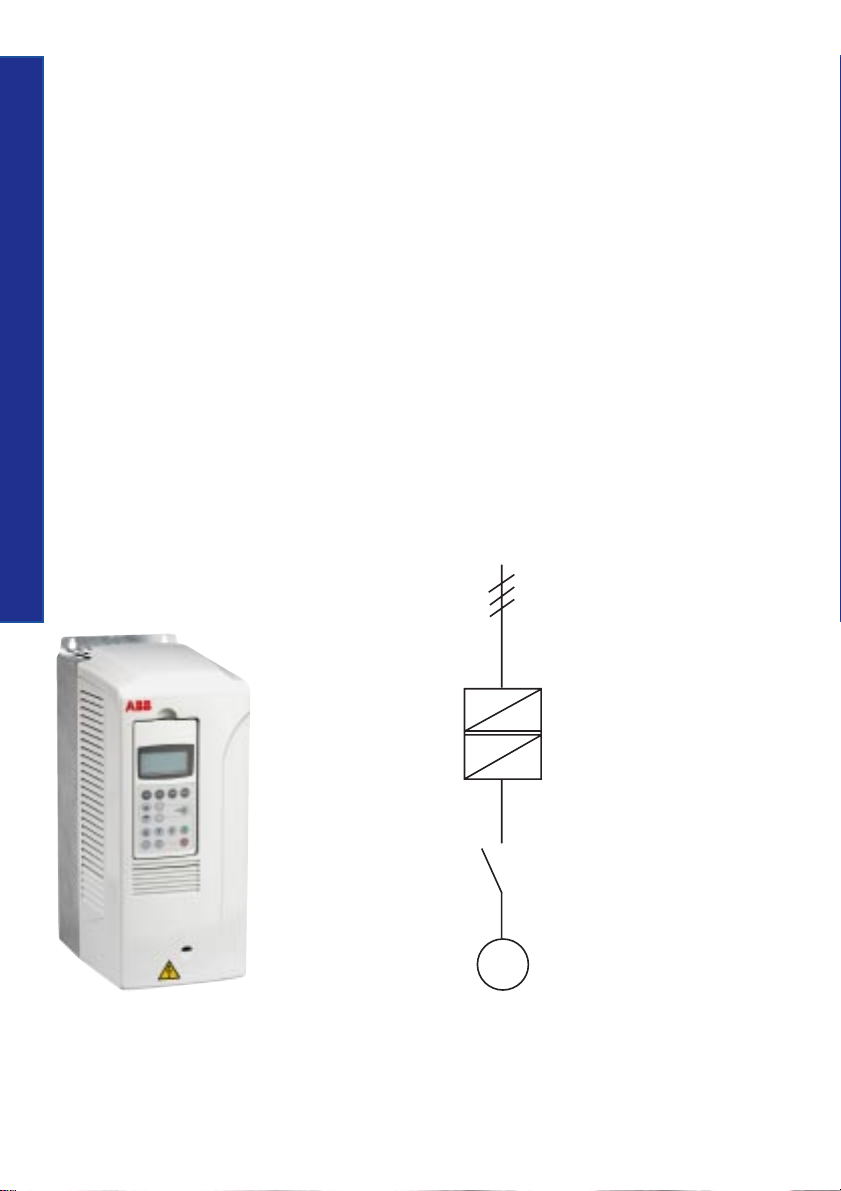

Frequency converter

The frequency converter is sometimes also

called VSD (Variable Speed Drive), VFD

(Variable Frequency Drive) or simply Drives,

which is probably the most common name.

The drive consists primarily of two parts, one

which converts AC (50 or 60 Hz) to DC and the

second part which converts the DC back to AC,

but now with a variable frequency of 0-250 Hz.

As the speed of the motor depends on the

frequency this makes it possible to control the speed

of the motor by changing the output frequency

from the drive and this is a big advantage if there

Different starting methods

is a need for speed regulation during a continuous

run.

In many applications a drive is still only used

for starting and stopping the motor, despite the

12

fact that there is no need for speed regulation

during a normal run. Of course this will create a

need for much more expensive starting equipment

than necessary.

By controlling the frequency, the rated motor

torque is available at a low speed and the starting

current is low, between 1 and 1.5 times the rated

motor current. Another available feature is softstop,

which is very useful, for example when stopping

pumps where the problem is water hammering

in the pipe systems at direct stop. The softstop

function is also useful when stopping conveyor

belts from transporting fragile material that can

be damaged when the belts stop too quickly.

It is very common to install a filter together with

the drive in order to reduce the levels of emission

and harmonics generated.

KM 1 Main contactor

Q 1 Frequency converter

AC

DC

Q 1

DC

AC

Frequency converter

KM 1

M

Single line diagram for a frequency converter

Page 20

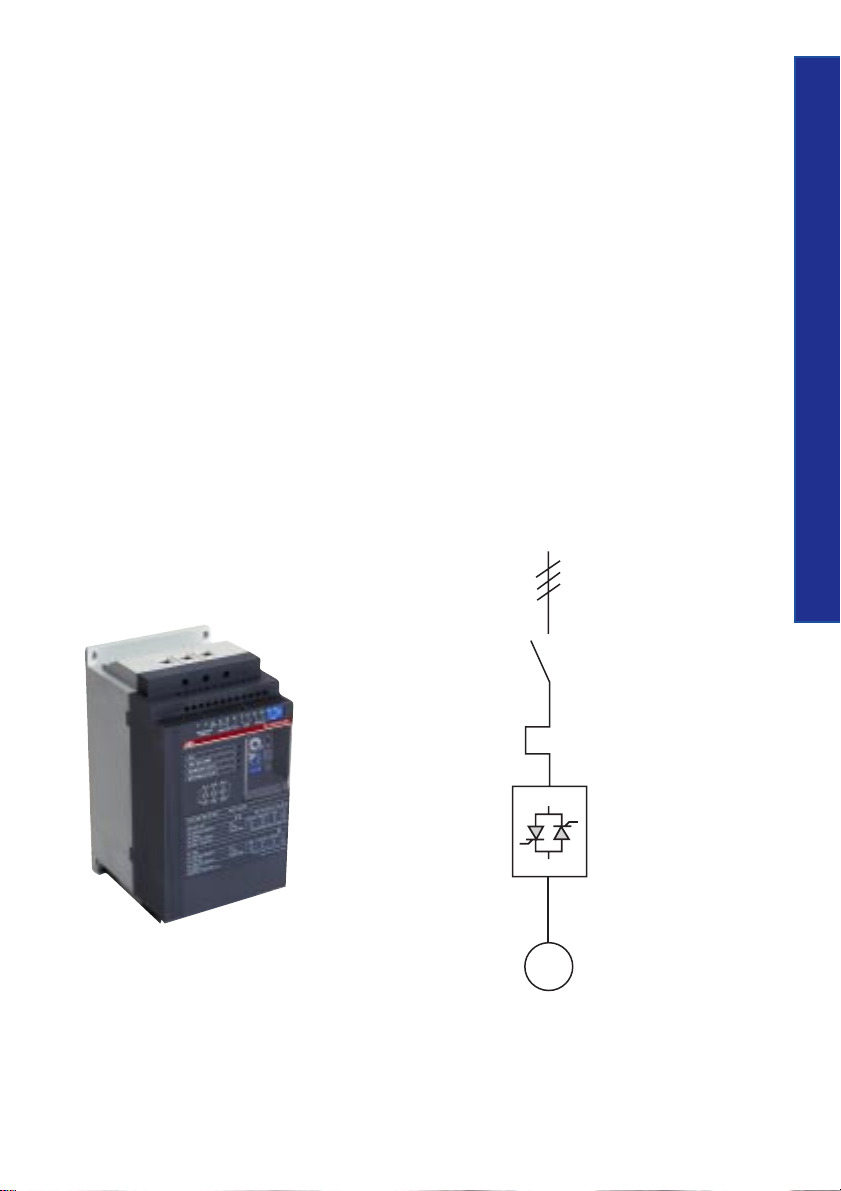

Softstarter

A softstarter has different characteristics to the

other starting methods. It has thyristors in the

main circuit, and the motor voltage is regulated

with a printed circuit board. The softstarter makes

use of the fact that when the motor voltage is low

during start, the starting current and starting

torque is also low.

During the first part of the start the voltage to

the motor is so low that it is only able to adjust

the play between the gear wheels or stretching

driving belts or chains etc. In other words,

eliminating unnecessary jerks during the start.

Gradually, the voltage and the torque increase

so that the machinery starts to accelerate.

One of the benefits with this starting method is

the possibility to adjust the torque to the exact

need, whether the application is loaded or not. In

principle the full starting torque is available, but

with the big difference that the starting procedure

is much more forgiving to the driven machinery,

with lower maintenance costs as a result.

Another feature of the softstarter is the softstop

function, which is very useful when stopping

pumps where the problem is water hammering

in the pipe system at direct stop as for star-delta

starter and direct-on-line starter.

The softstop function can also be used when

stopping conveyor belts to prevent material

from damage when the belts stop too quickly.

Different starting methods

13

Softstarter

KM 1

FR 1

Q 1

KM 1 Main contactor

FR 1 Overload relay

Q 1 Softstarter

M

Single line diagram for a softstarter

Page 21

Common problems when starting and stopping motors with

different starting methods

Type of problem Type of starting method

Direct-on-line Star-delta start Drives Softstarter

Slipping belts and Yes Medium No No

heavy wear on bearings

High inrush current Yes No No No

Heavy wear and tear Yes Yes No No

Different starting methods

on gear boxes (loaded start)

Damaged goods / Yes Yes No No

products during stop

14

Water hammering in pipe Yes Yes Best Reduced

system when stopping solution

Transmission peaks Yes Yes No No

Auto transformer start and start of a part winding motor have similar problems to the star-delta start.

Page 22

Different applications

All motors are used for starting and running different applications. This chapter

covers the most common ones. The different applications will also result in different

load conditions for the motor. There are two factors to consider:

1. Braking load torque, a direct braking force on the motor shaft. To be able to

accelerate, the motor has to be stronger than the load. The accelerating torque

is the difference between the available motor torque and the load toque.

Accelerating torque = Available motor torque – load torque

2. Involved moment of inertia or flywheel mass will also affect the start.

The bigger inertia the longer starting time for the same motor.

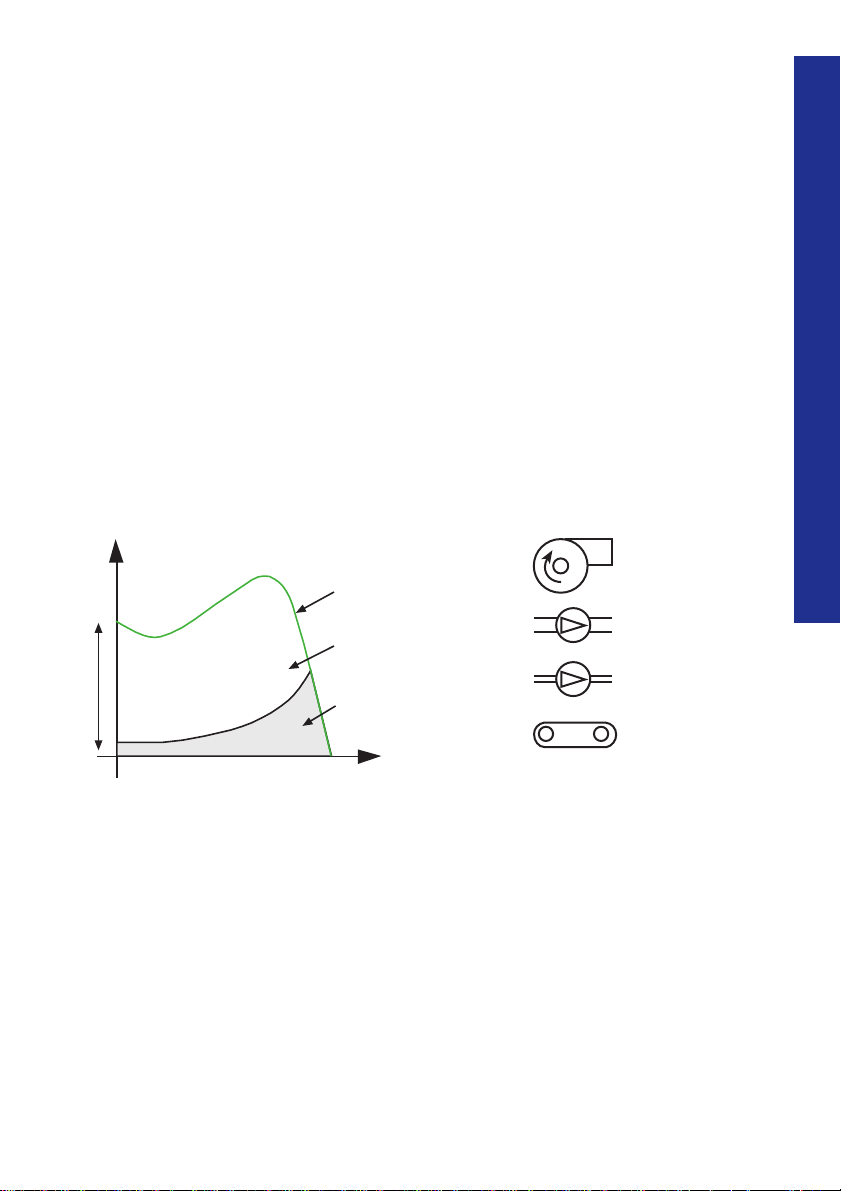

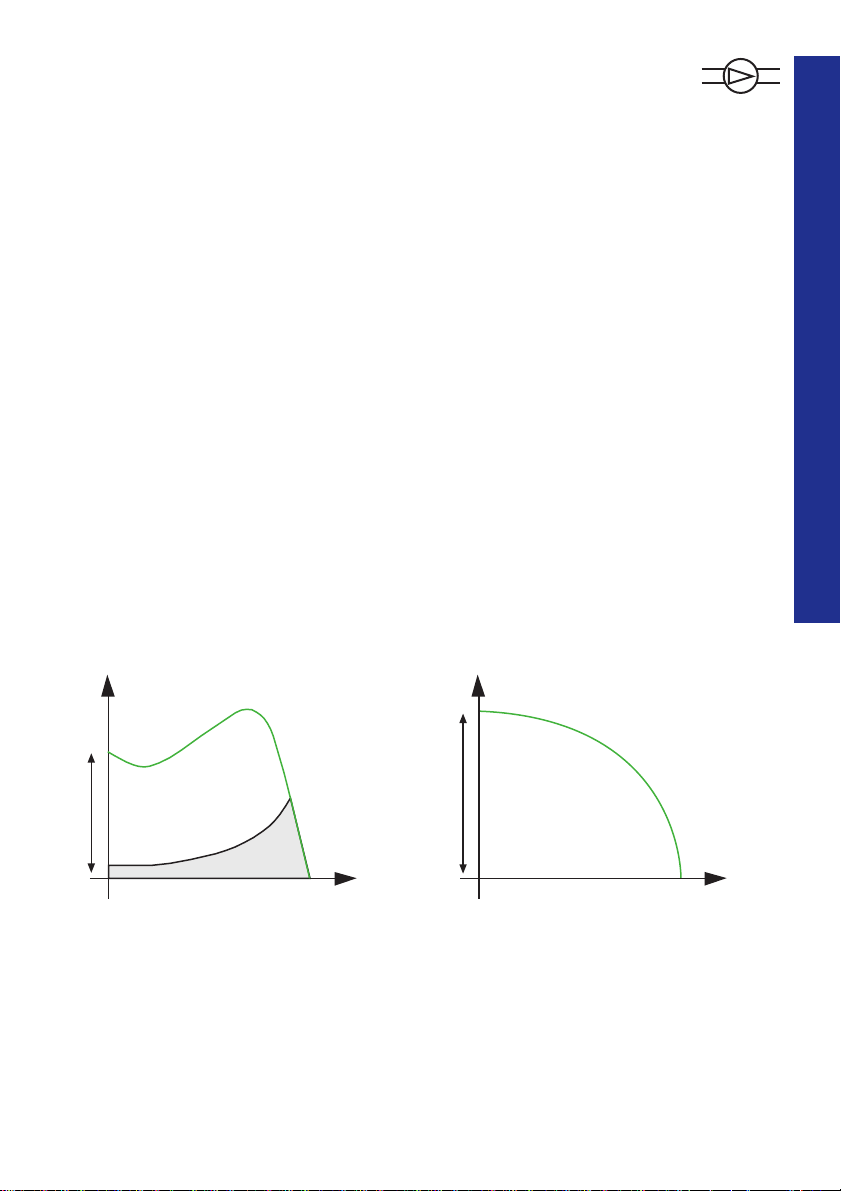

T

Available

motor torque

Accelerating

torque

Braking load

(load torque)

rpm

Centrifugal fan

Centrifugal pump

Compressor

Conveyor belt

Different applications

15

Page 23

Centrifugal fan

For some applications the motor is started with reduced load torque, i.e. unloaded

start. Big centrifugal fans are often started with a closed damper and this will make

the start easier (shorter) but since the moment of inertia is still present the starting

time might be quite long anyway.

Direct-on-line start

Centrifugal fans are very often driven by one or

more drive belts. During a D.O.L start these belts

have a tendency to slip. The reason is that these

Different applications

types of fans always have a more or less high

moment of inertia (big flywheel). So even if the

fan is started unloaded, the flywheel is still there.

1616

T

rpm

Torque/speed curve at D.O.L start Current curve at D.O.L start

The belts slip depending on whether the starting

torque from the motor is too high during the

start sequence and the belts are not able to

transfer these forces. This typical problem gives

high maintenance costs but also production

losses when you need to stop production to

change belts and bearings.

I

rpm

Page 24

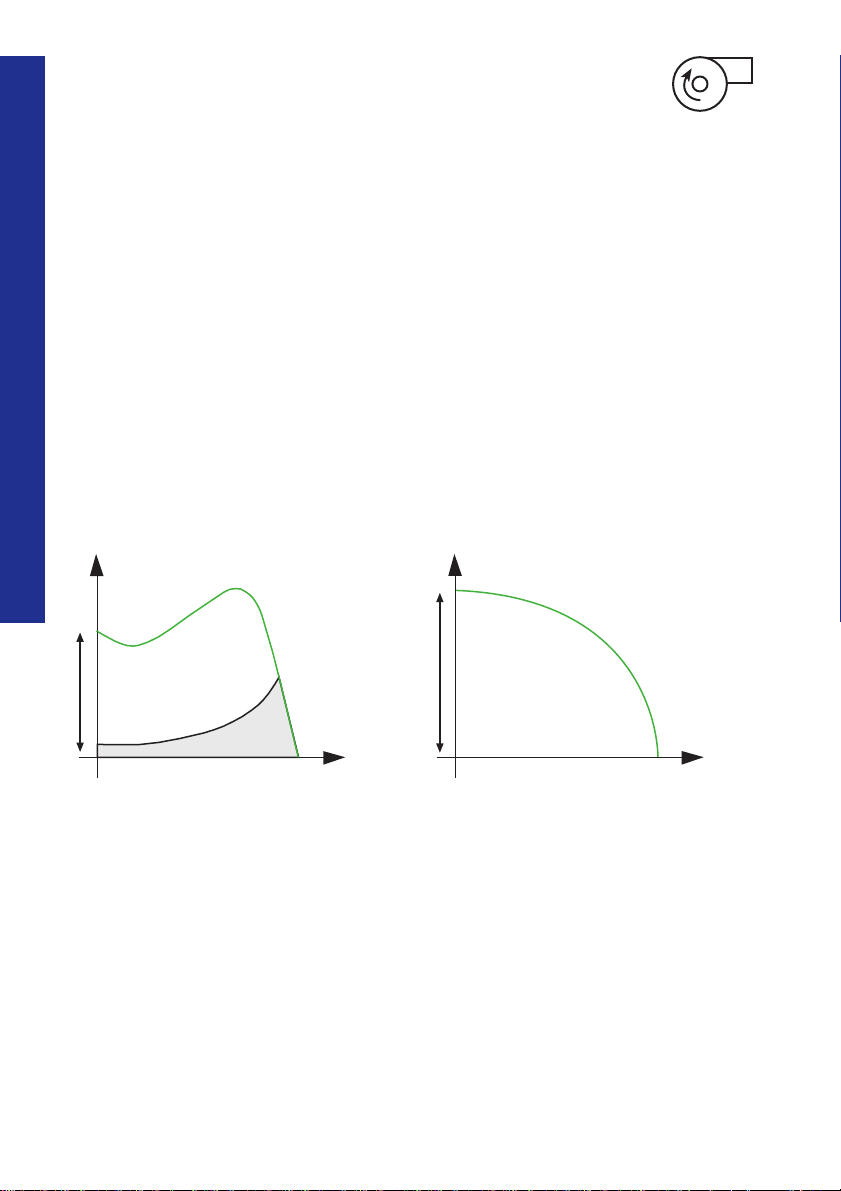

Star-delta starter (Y-D)

The star-delta starter gives lower starting torque

but depending on the fact that the load torque

increases with the square of the speed, the motor

torque will not be high enough in the star position

to accelerate the fan to the rated speed.

When switching over to delta position it will

be both a high transmission and current peak,

often equal to values when making a D.O.L start

or even higher, with a slipping belt as a result.

It is possible to reduce the slip by stretching the

belts very hard. This gives high mechanical

stresses on bearings both in the motor and the

fan with high maintenance costs as result.

Softstarter

Different applications

The key to solve these problems is to reduce the

starting torque from the motor during start.

By using an ABB softstarter the voltage is

decreased to a low value at the beginning of the

start, low enough to avoid slip but high enough

to start up the fan. The softstarter provides the

ability to adjust to fit any starting condition, both

unloaded and fully loaded starts.

T

Torque/speed curve at Star-Delta start

I

Current curve at Star-Delta start

rpm

rpm

T

17

rpm

Torque/speed curve when using a softstarter

I

rpm

Current curve when using a softstarter

Page 25

Selection of a suitable

softstarter

Normal start

For fans with small or medium large flywheels,

select a softstarter according to the rated motor

power.

The above is valid if the time for D.O.L start

is less than 5 seconds.

Heavy duty start

For fans with large flywheels, select a softstarter

Different applications

designed for heavy duty start according to the

rated motor power. It is also possible to select a

softstarter for normal start, select a unit with one

size bigger power rating than the motor and use

an overload relay class 30.

The above is valid if the time for D.O.L start

is more than 5 seconds.

1818

Recommended basic settings:

Start ramp: 10 sec.

Stop ramp: 0 sec.

Initial voltage: 30 %

Current limit is recommended for use.

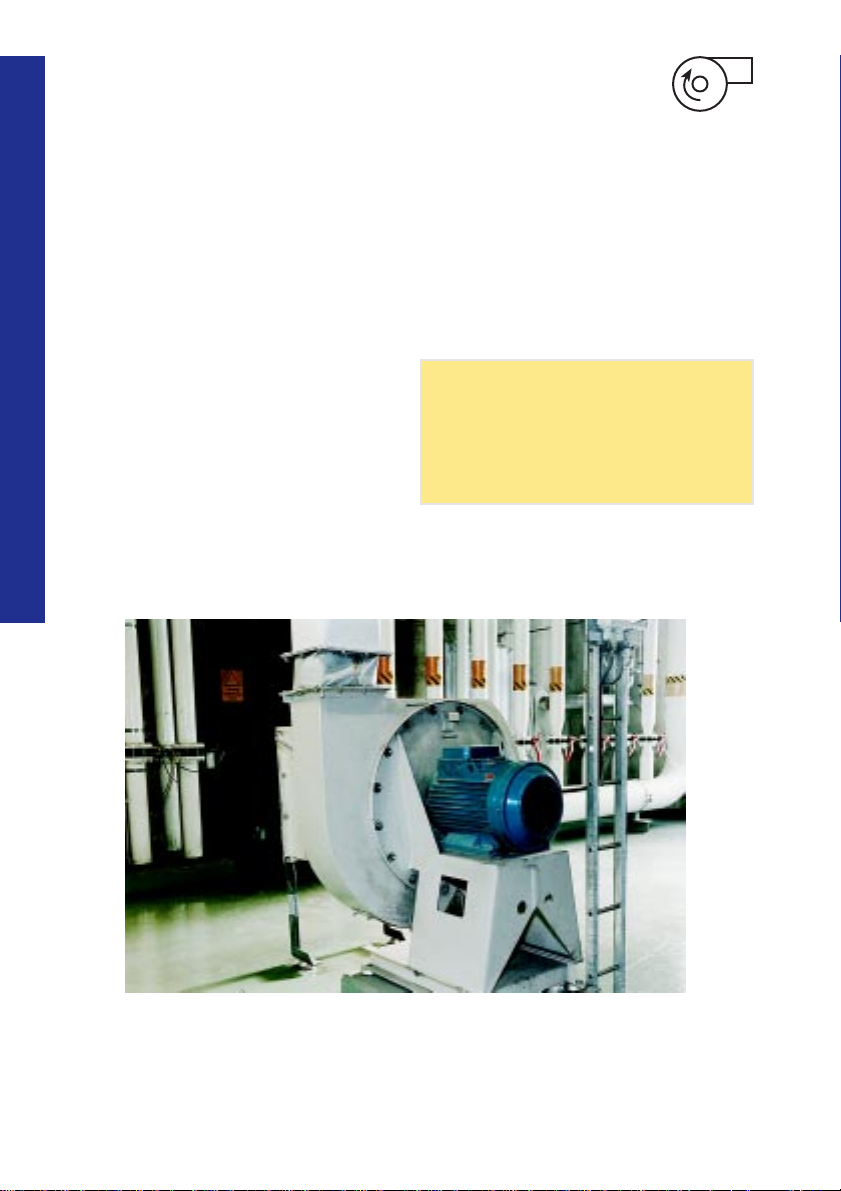

Application with a centrifugal fan

Page 26

Centrifugal pump

There are a lot of different types of pumps; like piston pumps, centrifugal pumps,

screw pumps etc. But the most common version is the centrifugal pump and we

have selected this one to describe.

Direct-on-line start

Starting up a pump is normally not a problem

for a squirrel cage motor. The problem is the

wear and tear depending on pressure waves in

the pipe system created when the motor starts

and stops too quickly. During a D.O.L start the

motor gives much too high starting torque

with the result that the motor accelerates and

reaches nominal speed too quickly. The reason

is that the braking load torque is low for a pump

during start. This starting method also gives

maximum possible starting current.

T

I

Different applications

19

Torque/speed curve at D.O.L start

rpm

rpm

Current curve at D.O.L start

Page 27

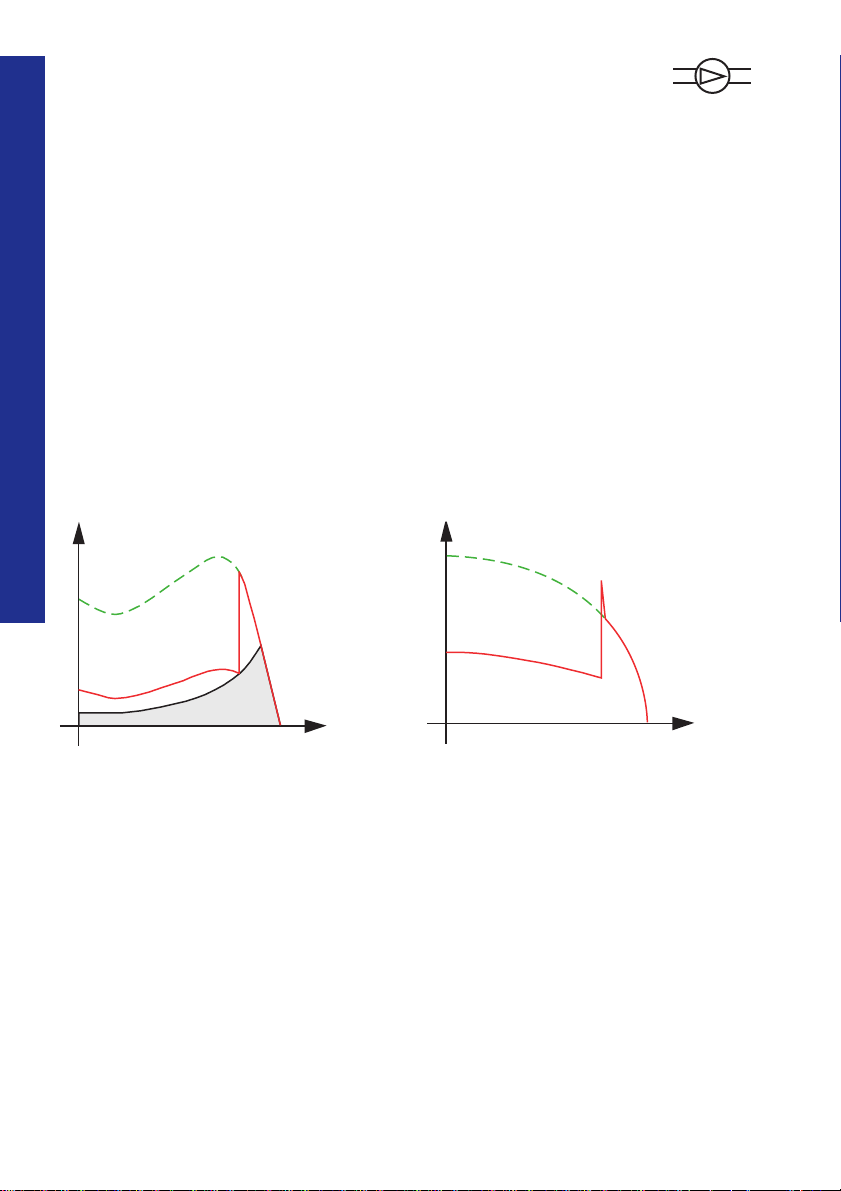

Star-delta starter (Y-D)

When stopping a pump

By using a star-delta starter it is possible to

reduce the starting torque. The motor torque

in the star position is too weak to be able to

complete the start and reach the rated speed.

The quadratic load torque will become too high

for the motor when reaching approx. 80-85 % of

the rated speed and the switch over to the delta

position will give both high transmission and

current peaks with pressure waves as a result.

Different applications

The current peaks can be equally high as at a

D.O.L start or even higher.

T

During stop it is also normal to have problems.

When making a direct stop by disconnecting

the main supply the motor stops too quickly.

Depending on high mass flow in the pipe system

the water will continue with the same speed for

a short period and then come back again,

backwards in the pipe system. This creates high

pressure shocks on valves and gives high

mechanical stresses on the pipe system.

I

2020

rpm

Torque/speed curve at Star-Delta start Current curve at Star-Delta start

rpm

Page 28

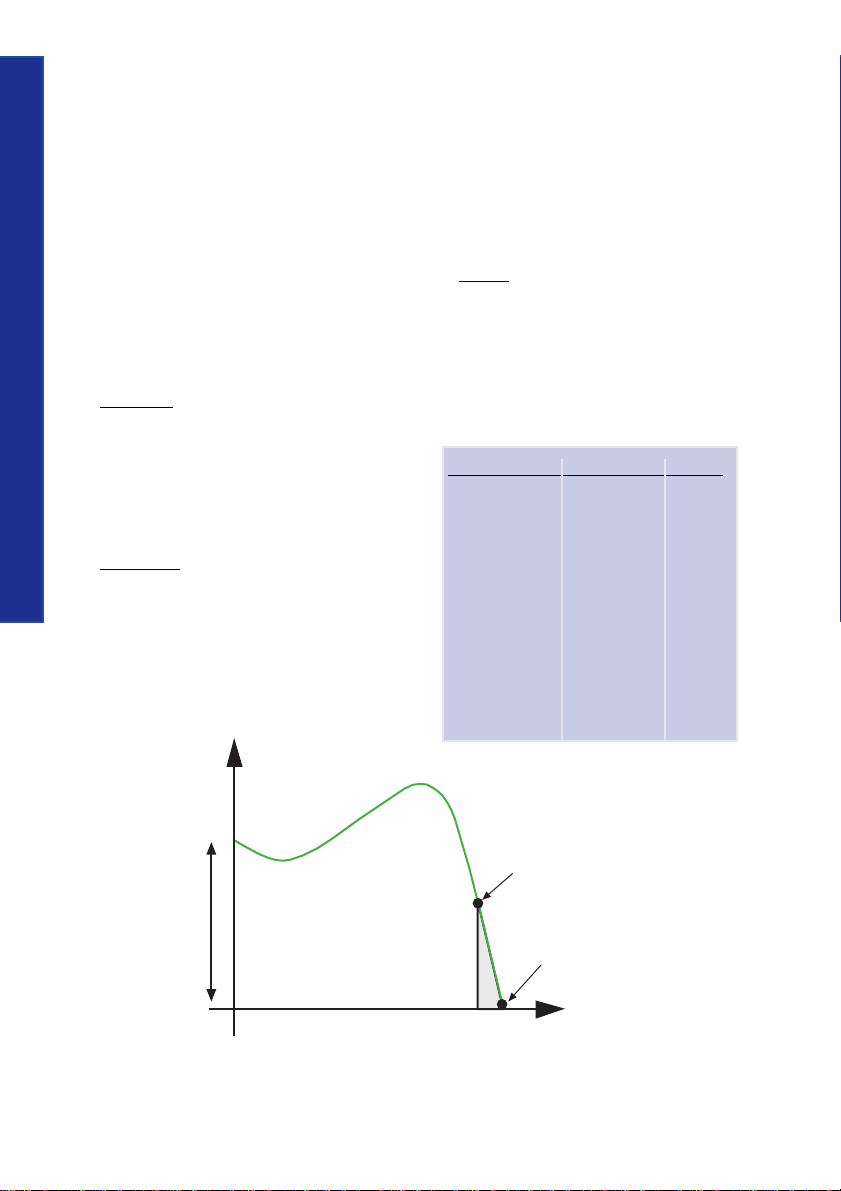

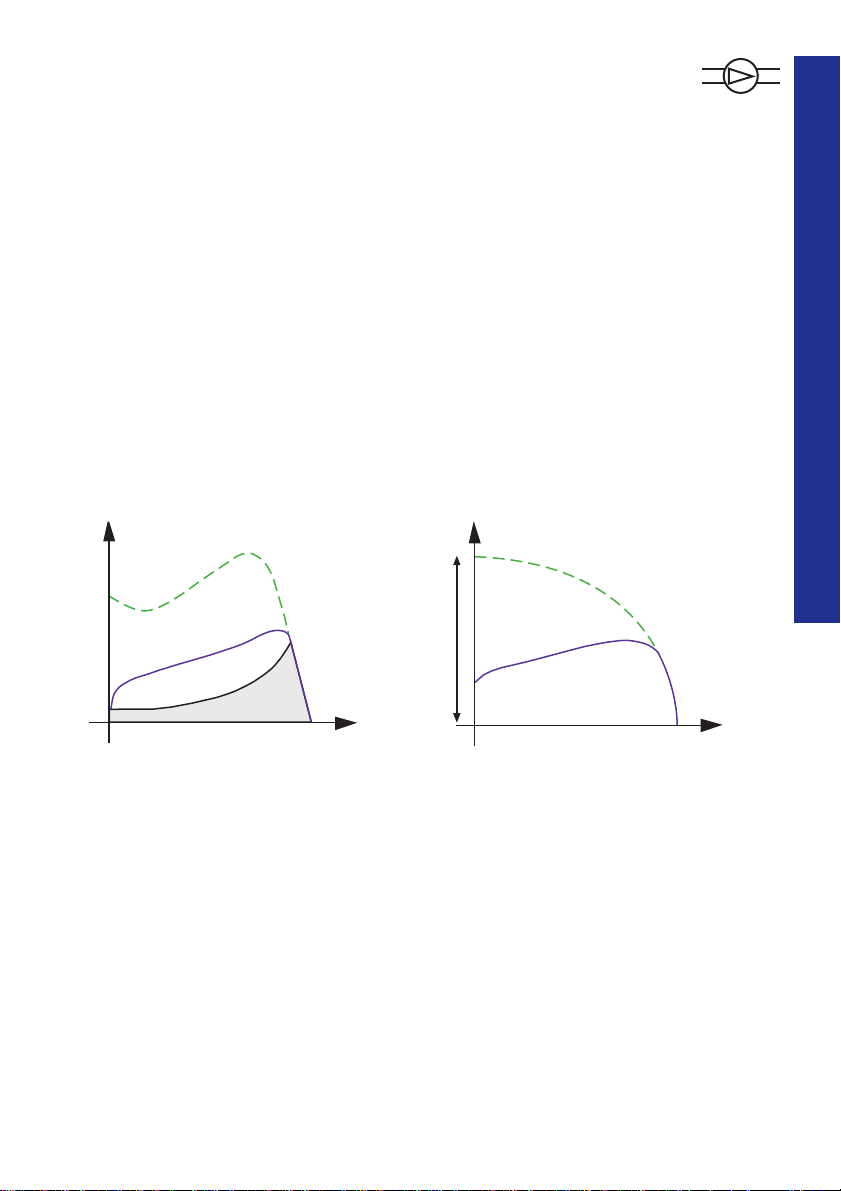

Softstarter

By using an ABB softstarter the voltage is reduced

during the start sequence with the result that the

motor torque is reduced. During the start

sequence the softstarter increases the voltage so

that the motor will be strong enough to accelerate

the pump to the nominal speed without any

torque or current peaks. A normal starting

current with a softstarter when starting a fully

loaded centrifugal pump is approx. 4 times rated

motor current.

Also during the stop sequence the softstarter is

the solution. The softstarter reduces the voltage

during stop via a voltage ramp and the motor

becomes weaker and weaker. Because of this the

water speed slows down very smoothly without

creating any pressure waves.

A special function on the softstarter is sometimes

available, called "step-down voltage",which ensures

an optimum setting to the actual need for any

pipe system.

Different applications

T

rpm

Torque/speed curve when using a softstarter Current curve when using a softstarter

I

21

rpm

Page 29

Selection of a suitable

softstarter

Normal start

Starting a pump is a typical normal start

condition.

Select a softstarter according to the rated

motor power.

Heavy duty start

Not applicable for this application.

Different applications

2222

Recommended basic settings:

Start ramp: 10 sec.

Stop ramp: 20 sec.

Initial voltage: 30 %

Application with a pump.

Page 30

Compressor

Smaller compressors are often of piston type and the load torque increases linearly

with the speed. Screw compressors are often used when there is a bigger need for air

flow and this type has a load torque increasing with the square of the speed.

Drive belts are often used between motor and compressor but direct connections via

some type of toothed couplings are also common. Some compressors are started with

reduced load.

Direct-on-line start (D.O.L)

Compressors started direct-on-line are exposed

to high mechanical stresses on the compressor

itself, but also on drive belts and couplings. The

result is shortened endurance. In cases where the

T

drive belts are used the belts very often slip

during start. The high starting torque received

during starting with this method is the source

of the problems. The starting current is always

high at D.O.L start. A normal value can be

approx. 7 times rated motor current.

I

Different applications

23

Torque/speed curve at D.O.L start

rpm

rpm

Current curve at D.O.L start

Page 31

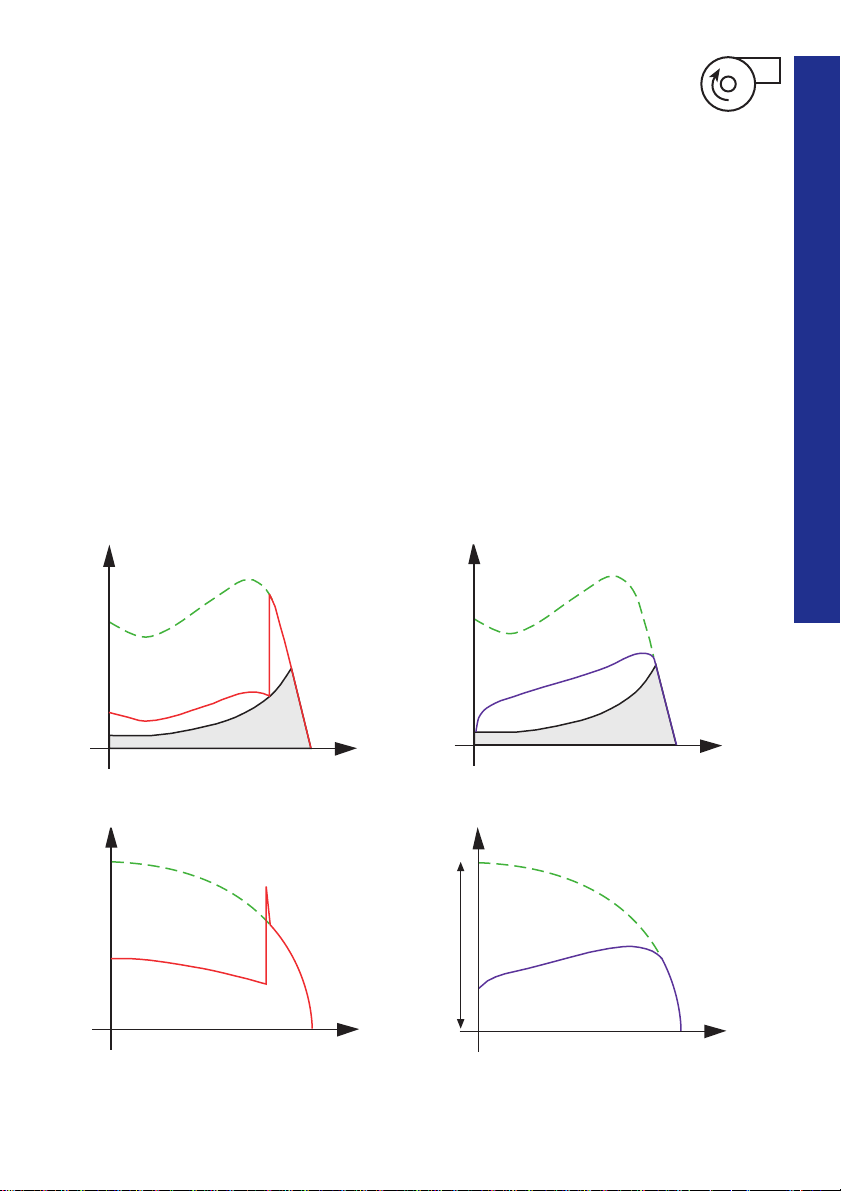

Star-delta starter (Y-D)

Star-delta start gives a lower starting torque and

starting current but the motor is too weak during

the start up to be able to accelerate the motor

up to nominal speed. When switching to the

delta position both current and torque peaks

Different applications

will occur with high mechanical stresses as a

result. Compressors are very often running at

no load condition for longer periods when the

pressure in the system is high. A motor running

under these circumstances always has a poor

power factor and low efficiency. Some times the

value is so low that it must be compensated.

T

I

2424

rpm

Torque/speed curve at Star-delta start Current curve at Star-delta start

rpm

Page 32

Softstarter

By using an ABB softstarter it is possible to

limit the starting torque to a level suitable for

all different applications. The result is less stress

on couplings, bearings and no slipping belts

during start. The maintenance cost will be

reduced to a minimum. When using a softstarter

the starting current received is approx. 3 to 4

times the rated motor current.

Different applications

T

rpm

Torque/speed curve when using a softstarter Current curve when using a softstarter

I

25

rpm

Page 33

Selection of a suitable

softstarter

Normal start

For compressors with D.O.L starting time less

than 5 seconds, select a softstarter according to

the rated motor power.

Heavy duty start

For compressors with D.O.L starting time more

than 5 seconds, select a softstarter designed for

heavy duty start according to the rated motor

Different applications

power.

It is also possible to select a softstarter for

normal start, select a unit with one size bigger

power rating than the motor and use an overload

relay class 30.

2626

Recommended basic settings:

Start ramp: 10 sec.

Stop ramp: 0 sec.

Initial voltage: 30 % (piston compressor)

40 % (screw compressor)

Application with a compressor

Page 34

Conveyor belt

Conveyor belts can have a lot of different looks and directions of use. It is a typical

constant torque load with low to high braking torque depending on how heavy it is loaded.

Direct-on-line start (D.O.L)

Conveyor belts often need a starting torque very

near or just above the rated torque of the motor.

A direct-on-line start with a normal squirrel cage

motor gives approx. 1.5 to 2.5 times rated torque

of the motor depending on motor size, type etc.

When making a direct-on-line start there is a

very high risk of slipping between the belt and

Low braking torque

T

the driving role depending on this high starting

torque.

Gearboxes and couplings are also exposed to high

mechanical stresses. This result is considerable

wear and tear and often high maintenance costs.

Sometimes fluid couplings are used to reduce the

transferred torque. This method is expensive and

requires a lot of maintenance.

High braking torque

T

Different applications

27

Torque/speed curve at D.O.L start

I

Current curve at D.O.L start

rpm

rpm

Torque/speed curve at D.O.L start

rpm

I

rpm

Current curve at D.O.L start

Page 35

Star-delta start

It is not possible to use this starting method

when the load torque is close to the rated motor

torque during start (see figure below, High

braking torque).

Different applications

Low braking torque High braking torque

T

T

2828

rpm

Torque/speed curve at Star-delta start Torque/speed curve at Star-delta start

I

rpm

I

Current curve at Star-delta startCurrent curve at Star-delta start

rpm

rpm

Page 36

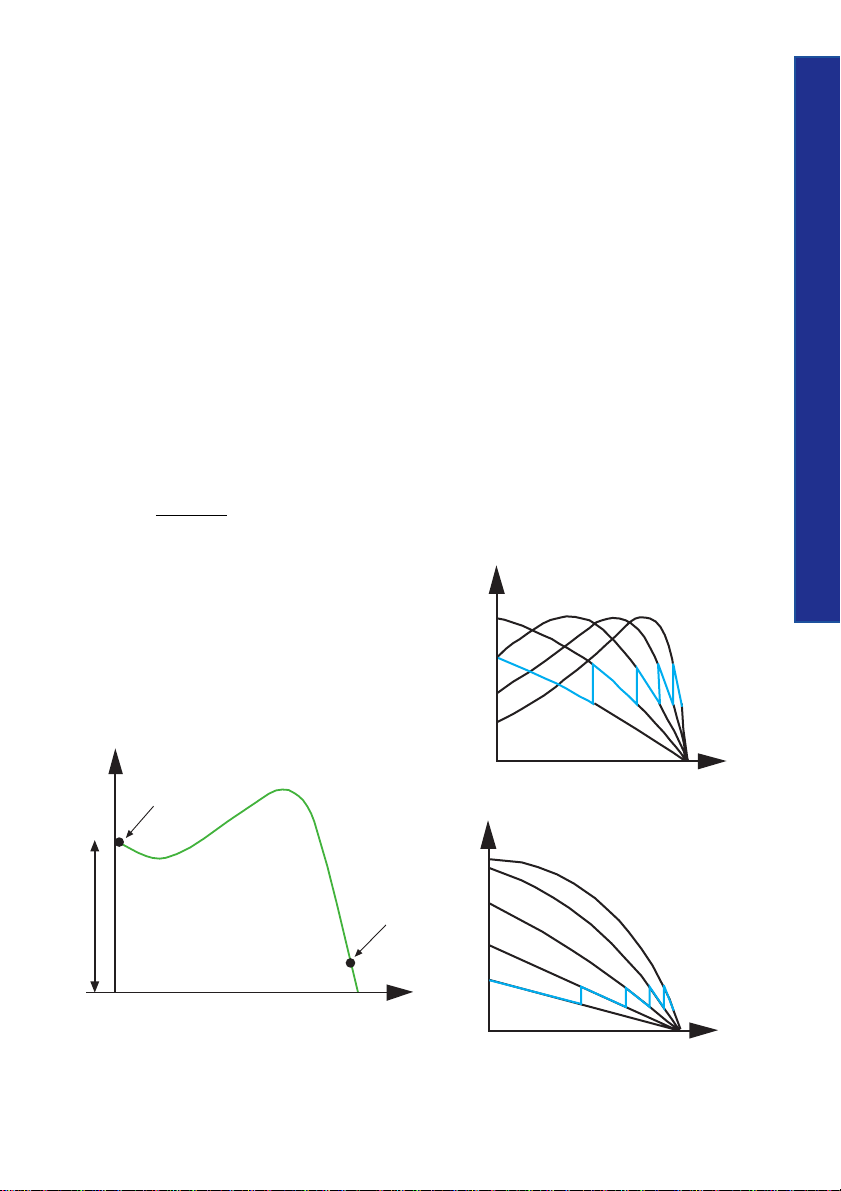

Softstarter

Different applications

By using an ABB softstarter the starting torque

can be reduced to a minimum value still able to

start up the conveyor belt. The setting possibility

of the softstarter makes it possible to adjust the

torque to exactly the level that is necessary for

the start. The result is the least possible stress on

T

rpm

Torque/speed curve when using a softstarter

gearboxes and couplings and no slipping belts

during start. This will reduce the maintenance

cost to a minimum. When using a softstarter

you will receive approx. 3 to 4 times rated motor

current during start.

High braking torqueLow braking torque

T

29

rpm

Torque/speed curve when using a softstarter

I

Current curve when using a softstarter

rpm

I

rpm

Current curve when using a softstarter

Page 37

Selection of a suitable

softstarter

Normal start

A start of short and light loaded conveyor belt is a

typical normal start.

For conveyors with D.O.L starting time less

than 5 seconds, select a softstarter according to

the rated motor power.

Heavy duty start

Conveyor belts can in some cases be very long and

Different applications

if the belt is fully loaded during start the starting

time can be very long. For such applications select

a softstarter designed for heavy duty start. It is also

possible to select a softstarter for normal start if

the softstarter is chosen one size larger than the

rated motor power and use an overload relay

class 30.

3030

Recommended basic settings:

Start ramp: 10 sec.

Stop ramp: 0 sec.

(If fragile material use 10 seconds)

Initial voltage: 40 %

Application with a conveyor belt

Page 38

How to select a softstarter for

different applications

It is normally possible to select a softstarter according to the rated motor power. In

some cases it is neccessary to select a larger softstarter than the rated motor power

depending on the starting conditions (heavy duty start, many starts/h etc.) The

starting capacity of a softstarter is very much depending on the thyristor capacity and

the heat sink.

The table below can be used as a guide to select a softstarter if you need a quick

answer and you want to be sure that the size is large enough to suit the application.

This selection will not give the most optimized solution.

If an opimised solution is required, the software selection program ”ProSoft”

for selection of softstarters can be used, available on www.abb.com/lowvoltage.

Quick guide

How to select a softstarter

Normal start

Typical applications

Bow thruster »Centrifugal pump

»

»Compressor »Conveyor belt (short)

»Elevator »Escalator

Selection

Select the softstarter according to the

rated motor power.

For units with built-in overload, select

trip class 10.

Select one size larger than the selection above.

If more than 6 starts /h

Heavy duty start

Typical applications

Centrifugal fan »Conveyor belt (long)

»

»Crusher »Mill

»Mixer »Stirrer

Selection

For softstarters designed for nomal start,

select one size larger than the rated motor

power.

For softstarters designed for heavy duty

start, select according to the rated motor

power.

For units with built-in overload, select trip

class 30.

31

Page 39

32

Page 40

Description of the softstarters

- Design, settings and signals

A softstarter in general is built up with a few main components such as a printed

circuit board (PCB), heat sink, thyristors, fans and housing (plastic or metal).

The controlling circuits can be of digital type, analogue type or a combination of

these. The output signal relays can be of a type with fixed function or as a free

programmable type where the user can decide upon the output function.

The softstarter is sometimes equipped with a built-in electronic overload relay

(EOL) replacing the conventional bi-metal relay which is normally used.

A built in EOL has much better accuracy than a conventional relay, since the values

are calculated electronically and this is especially useful when on intermittent duty.

The need for communication between different devices in a plant and from the

devices to a control board is increasing all the time. Many of today’s softstarters are

equipped with a port for such communication, which normally consists of a few

fibre optic cables instead of former solutions, which often reqired hundreds of

thousands of wires. Many different communication protocols exist today and some

of them are more common than others, for example Modbus, Profibus, DeviceNet,

Interbus-S, LON Works and so on.

Description of the softstarter

33

Page 41

Description of different components:

Housing

Printed circuit board

Description of components

34

Thyristor

Housing

Main terminals

Heat sink

Fan

Page 42

Printed circuit board is used to

control the firing of the thyristors based on the

current and voltage references, and also for the

calculation of different values, for example the

power factor, active power, etc. It can also be

used for storing historical data, the event log,

indicating trends and much more.

Heat sink is used to get rid of the heat in

the softstarter generated by the current during

the start and the continuous run. The capacity

of the heat sink very much reflects the starting

capacity and the operational current of the

softstarter.

Fans are used to increase the cooling

capacity of the heat sink. One, two or several

fans can be used depending on size and design.

Some smaller softstarters don’t have fans at all

and the number of starts may be limited.

Zero crosses

Housing can be made of plastic material,

Description of components

metal or a combination of these, and its function

is to protect the inside components from

mechanical and electrical damage. It is also used

to protect the components from dust and dirt.

For total outside protection from dust and dirt

a separate enclosure is often required since the

degree of protection (IP class) of the unit itself

is too low.

Thyristors are semi-conducting

components connected in an anti-parallel fasion

and placed in two or three phases of the main

circuit. They regulate (by increasing or decreasing) the level of voltage during start and the

stop ramp, as described in the picture below.

During a continuous run the thyristors are

conducting fully.

35

Firing angle

Start: The thyristors let part of the voltage through at the beginning and

then increase it, according to the set ramp time for the start.

Stop: The thyristors are fully conducting and when soft stopping, they

decrease the voltage according to the set ramp time for stop.

Off : Thyristor is non-conducting

On : Thyristor is conducting

Page 43

Common settings

This section includes a short description of some common setting parameters

available on most of the softstarters. Other settings may be available depending

on the type of softstarter and manufacturer. The setting can be done either by

adjusting potentiometers, changing dip switches, using a key pad, a computer or

similar.

Start ramp is the time from were the

Common settings

softstarter start its ramp (initial voltage) until

full voltage is reached. The ramp time should

not be too long, as this will only result in

unnecessary heating of the motor and a risk

of the overload relay to trip. If the motor is

unloaded the start time for the motor will

probably become shorter than the set ramp

time, and if the motor is heavily loaded, the

start time will probably become longer.

Stop ramp is used when a soft stopping

36

of the motor is required, for example a pump

or a conveyor belt. The stop ramp is the time

from full voltage until stop voltage (initial

voltage) is reached. If the ramp time is set to

zero the stop will be like a direct stop.

U

e

Initial voltage

(U

)

ini

Initial voltage. Sometimes named

pedestrian voltage or torque, this is the point

from where the softstarter starts or stops its ramps.

The torque of the motor will drop with the

square of the voltage and if the voltage is set

too low, for example 20 %, the starting torque

will become 0.22 = 0.04 = 4 % only, and the

motor will not start from the very beginning.

Therefore it is very important to find a level

that is just high enough to make the motor take

off directly to avoid unnecessary heating.

Start ramp Stop ramp

Diagram showing start ramp, stop ramp and initial voltage

Time

Page 44

Current limit can be used in applications

where a limited starting current is required, or

at a heavy-duty start when it is difficult to

achieve a perfect start with the setting of the

initial voltage and the start ramp only. When

the current limit is reached, the softstarter will

temporarily stop increasing the voltage until the

current drops below the set limit, and then

continues ramping up to full voltage.

Note that this feature is not available on

all softstarters.

U

100 %

fixed voltage

30 %

Common settings

reached set level

of current limit

37

1

t

t1 + t2 = set ramp time

I

5

2

Current limit function in softstarter use

2

t

set level of

current limit

Time

Time

Page 45

Step down voltage gives a special

type of stop ramp. It is possible to adjust the

voltage to drop to a level where the speed of

the motor starts to reduce immediately at the

stop command. For low loaded motors the

speed will not reduce until a very low voltage

is reached, but using the step down voltage

function can eliminate this phenomenon and

is especially useful for stopping pumps.

Common settings

Adjustable rated motor

current makes it possible to set the motor

rated current on the softstarter for the used motor.

This setting may affect other values as well, such

as the trip level of the electronic overload relay,

the level of the current limit function and so on.

38

Step down voltage = U

U

100 %

Example 50 %

30 %

Curve showing the step down voltage function

SD

Initial voltage 30 %

(= end voltage 30 %)

Stop Time

Page 46

Different indications

The indications on a softstarter differ very much from one type to another and also between

manufacturers. Some of the most common indications are described below.

Different indications

On normally indicates that the power supply

is connected to the softstarter and that the unit

is ready to start the motor.

Top of Ramp indicates that the start

ramp is completed and full voltage is reached.

If a by-pass contactor is used it will be activated

at this point.

Fault indication can be of many different

types. One is if there is an internal fault on the

softstarter itself, a fault on the feeding side (phase

loss, blown fuse or similar) or on the motor side

(motor not connected, phase missing etc.)

Overload indicates that the overload

protection has tripped. The reason for a tripping

overload can be too high motor current, too long

starting time, too many starts after each other,

wrong set overload, wrong trip class of overload

or a combination of these.

Overtemperature indicates that the

softstarter unit is over-heated, due to the number

of starts exceeded, too high-rated current, too

long starting time or similar.

39

Page 47

Different voltages

Different named voltages are used for the softstarters. The name and use of these

different voltages is stated in the IEC-standard as below.

Main Voltage (Ue),

which is the voltage feeding the motor and

also the voltage exposed to the main circuit

(thyristors) in the softstarter. 200 - 690 V

Different voltages

are normal values.

Supply voltage (Us),

which is the voltage feeding the electronic

components inside the softstarter, for example

the printed circuit board.

Common values are 110 - 120 V or 220 - 240 V.

40

Internal

supply

Main Voltage (Ue)

L1

L3

L2

Start

Stop

T1

T2

Power

supply

T3

M

Main voltage and supply voltage to a softstarter

Supply

Voltage (Us)

Control Voltage (Uc),

which is the voltage for controlling the start

and stop command of the softstarter.

Values between 24 - 480 V exist.

Main Voltage (Ue)

L1

L3

L2

Control

Voltage (Uc)

Start

Stop

T1

T2

Power

supply

T3

(Internal

power

supply)

M

Main voltage and control voltage to a softstarter

Page 48

Ambient temperature

The ambient temperature is the average

surrounding temperature of the softstarter over a

period of 24 hours. For most types of softstarter

the temperature may not exceed 40 oC without

derating the operational current for the unit.

The maximum ambient temperature during

operation differs from one type of softstarter

to another and must be checked individually

according to the manufacturer’s specification.

When using an ABB softstarter with an

ambient temperature of above 40 oC, the

following formula can be used to calculate

the operational current:

Ie derated = I

Ie derated = maximum operational current

I

e

- (∆ T x I

e

after derating

= rated current of the softstarter

x 0.008)

e

∆ T = temperature difference

0.008 = derating factor

Example 1

Rated current: 105 A

Ambient temperature: 48 oC

Derating with 0.8 % per oC above 40 oC

(PS S 18...300)

∆ T = 48-40

New current = I

105 - (8 x 105 x 0.008) = 98,2 A

Example 2

Rated current: 300 A

Ambient temperature: 46 oC

Derating with 0.8 % per oC above 40 oC

(PS S 18...300)

∆ T = 46-40

New current = I

300 - (6 x 300 x 0.008) = 285.6 A

o

C = 8 oC

- (∆ T x I

e

o

C = 6 oC

- (∆ T x I

e

x 0.008) =

e

x 0.008) =

e

Ambient temperature

41

Page 49

Derating when used at high

altitudes

When a softstarter is used at high altitudes the

rated current for the unit has to be derated, due

High altitudes

to less cooling. For most manufacturers the

catalogue values are valid up to 1000 m above

sea level before derating is necessary.

In some cases a larger softstarter is required to

be able to cope with the motor current when

used at high altitudes.

For ABB softstarters the following formula

can be used for calculating the derating:

x - 1000

% of I

100 %

90 %

150

e

42

% of Ie = 100 -

x = actual altitude for the softstarter

Example:

Softstarter with rated current 300 A used at

2500 meter above sea level.

1500

2500 - 1000

150

= 90

=

% of Ie = 100 -

= 100 -

150

Ie = 300 x 0.9 = 270 A

The diagram below can also be used for

defining the derating of the softstarter.

80 %

1000

Derating of motor current at high altitudes

2000

meter above sea level

3000

4000 m

Page 50

Start of several motors

M

M

In some applications, more than one motor will be started with one softstarter,

in parallel with each other or in a sequence. This is often possible to do but some

data has to be taken into consideration.

Parallel start of motors

If a softstarter is going to be used for starting

several motors at the same time (parallel start),

there are two important parameters to check:

1. The softstarter must be able to cope with

the rated current for all motors together.

2. The softstarter must be able to cope with

the starting current for all motors together

until rated speed is achieved.

Note! If a by-pass contactor is used for

the softstarter, only point 2 above has

to be taken into consideration.

Example:

Start of two motors with I

relative starting current 4 x Ie.

Starting time is 10 seconds.

Total starting current is 100 x 4 x 2 = 800 A

over 10 seconds.

Check the softstarter starting capacity graph to

verify the selected size.

= 100 A and

e

KM 1

FR 1

Q 1

Parallel start of motors using a softstarter

KM 1 Main contactor

FR 1 Overload relay

Q 1 Softstarter

Start of several motors

43

Page 51

Sequential start of motors

If a softstarter is going to be used for starting

several motors one by one (sequential start), it

is important to check that the softstarter is able

to cope with the starting current for each motor

during the whole starting sequence.

Example:

Start of three motors with Ie=100 A and

relative starting current 4 x Ie.

Starting time for the motors is:

Start of several motors

Motor 1 = 5 seconds

Motor 2 = 10 seconds

Motor 3 = 8 seconds

44

The starting current for the motors is 100 x 4 =

400 A and the total starting time is 5 + 10 + 8 =

23 seconds.

Check the softstarter starting capacity graph

to verify the selected size.

Note! It is not possible to add the starting

time for each motor if the rated current

is different from one motor to another. A

separate calculation has to be made for

those applications.

KM 1 Main contactor

K 25, 27, 29 Starting contactor

K 26, 26, 30 Run contactor

FR 1, 2, 3 Overload relay

Q 1 Softstarter

KM 1

Q 1

K 25 K 27 K 29

K 26

FR 1 FR 2 FR 3

MM

Sequential start of motors using a softstarter

K 28 K 30

M

Page 52

Different ways of connecting the

softstarter

There are two different ways of connecting the softstarter - In line, which is the

most common method, and Inside Delta. Note that only a few types of softstarters

can actually be connected Inside Delta for example the ABB softstarter range

PS S 18/30...300/515.

Different ways of connecting

45

In line Inside Delta

Page 53

In-line connection

This is easily the most common way to connect

the softstarter.

All three phases are connected in a series with

the overload relay, the main contactor and other

devices used just like the diagram below.

The selected devices for Inline connection must

be chosen to cope with the rated motor current.

Example: 100 A motor requires a 100 A

softstarter, 100 A main contactor etc.

Different ways of connecting

46

100 A

100 A

100 A

Inside Delta connection

The Inside Delta connection makes it possible

to place the softstarter in the delta circuit and

in that way it can easily replace an existing

Y/D-starter.

When the softstarter is Inside Delta it will

only be exposed to 58 % (1/√3) of the In-line

current. Therefore it is possible to downsize the

devices in order to achieve a more cost-effective

solution.

Example: A 100 A motor requires a 58 A

softstarter, a 58 A main contactor if placed in

the delta circuit, etc.

A motor used for an Inside Delta connection

must be able to delta-connect during a continuous

run. In the USA and some other countries a

special six-wire motor has to be ordered for this

type of connection.

100 A

100 A

M

100 A

Softstarter connected In-line with the motor

58 A

58 A

58 A

M

100 A

Softstarter connected Inside Delta

Page 54

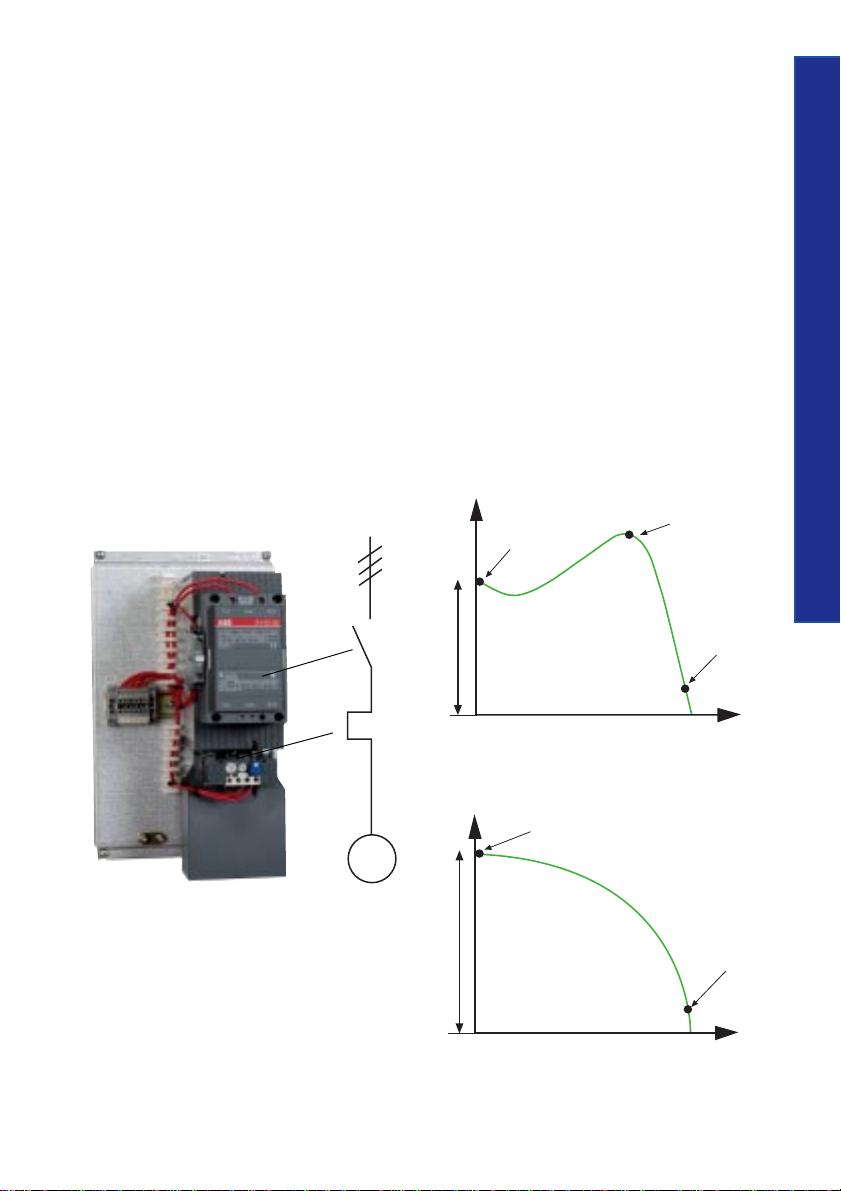

Location of the main contactor

B

M

x

When using the softstarter Inside Delta there

are two options for the main contactor: in the

delta circuit or outside. Both locations will stop

the motor but in alternative A, the motor is still

considered to be under tension.

In alternative B the main contactor must be

chosen according to the rated current of the

motor, while the contactor in alternative A can

be chosen according to 58 % (1/√3) of the

rated current.

x

Different ways of connecting

47

Alternative A

Main contactor located in the delta circuit

M

A

Alternative B

Main contactor located outside the delta circuit

Page 55

48

Page 56

Basic settings

for

different

applications

The required settings for the softstarter will differ from one application to another

depending on the type of load, motor characteristics, how much the motor is

loaded, etc.

For a more in depth description of each setting, please see chapter ”Description

of the softstarters”.

Note ! All settings on next page are only proposals and may change from one application

to another and therefore need to be checked individually.

Basic settings

49

Page 57

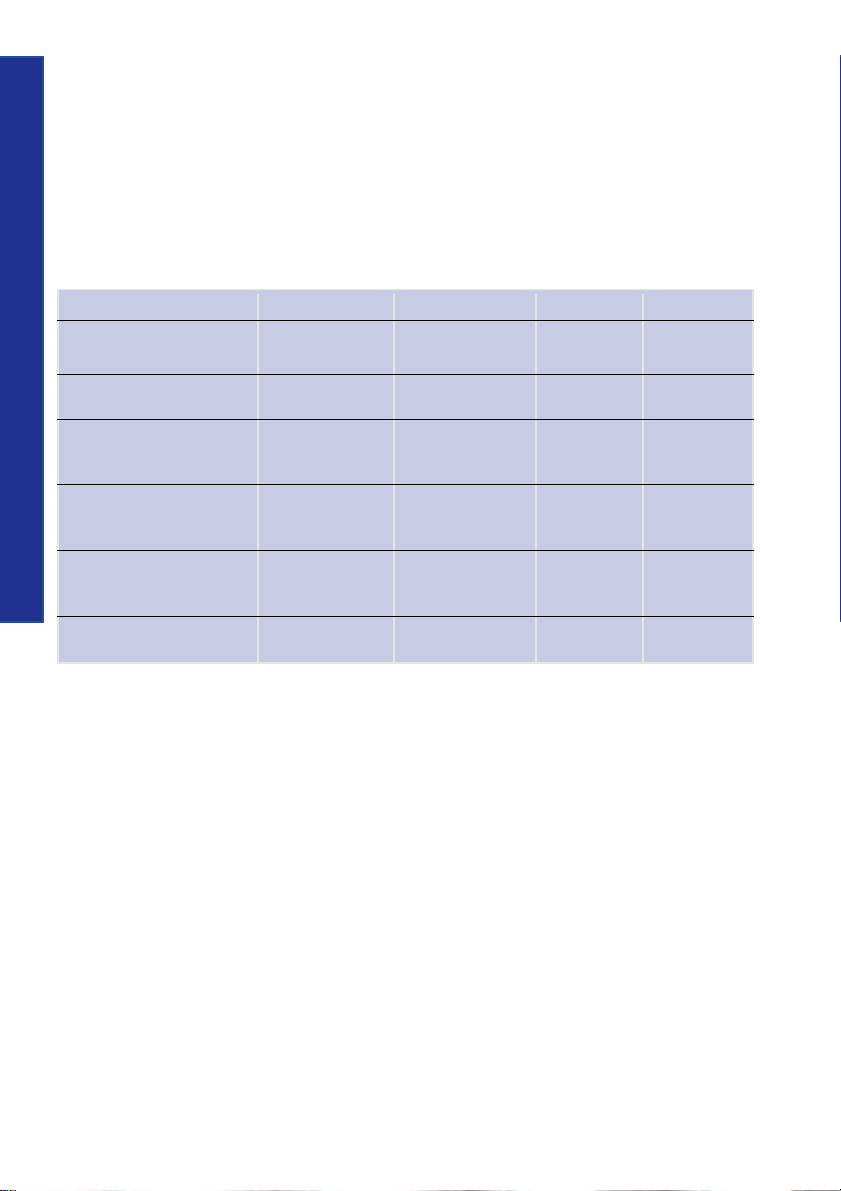

Settings when using a softstarter without current limit function

Type of load Ramp time for Ramp time Initial voltage

Basic settings

Bow thruster 10 0 30 %

Centrifugal fan 10 0 30 %

Centrifugal pump 10 20 30 %

Centrifuge 10 0 40 %

Conveyor belt 10 0

Crusher 10 0 60 %

Escalator 10 0 30 %

50

Heat pump 10 20 30 %

Hydraulic pump 10 0 30 %

Lifting equipment 10 10 60 %

Mill 10 0 60 %

Piston compressor 10 0 30 %

Rotary converter 10 0 30 %

Scraper 10 10 40 %

Screw compressor 10 0 40 %

Screw conveyor 10 10 40 %

Stirrer, Mixer 10 0 60 %

Unloaded motor 10 0 30 %

start (sec.) for stop (sec.) U

1)

ini

40 %

1) If fragile material, use 10 seconds.

Page 58

Settings when using a softstarter with current limit function

Type of load Ramp time for Ramp time Initial voltage Current limit

start (sec.) for stop (sec.) Uini ( x Ie)

Bow thruster 10 0 30 % 3

Centrifugal fan 10 0 30 % 4

Centrifugal pump 10 20 30 % 3.5

Centrifuge 10 0 40 % 4.5

Conveyor belt 10 0

Crusher 10 0 60 % 5

Escalator 10 0 30 % 3.5

Heat pump 10 20 30 % 3.5

Hydraulic pump 10 0 30 % 3.5

Lifting equipment 10 10 60 % 4

Mill 10 0 60 % 5

Piston compressor 10 0 30 % 4

Rotary converter 10 0 30 % 3

Scraper 10 10 40 % 4.5

Screw compressor 10 0 40 % 4

Screw conveyor 10 10 40 % 4

Stirrer, Mixer 10 0 60 % 5

Unloaded motor 10 0 30 % 2.5

1)

40 % 4

Basic settings

51

1) If fragile material, use 10 seconds.

Page 59

Starting capacity and overload

protection

Starting capacity for softstarters

When starting a squirrel cage motor there will

Starting capacity

always be a starting current (Ist) which is

higher than the rated motor current.

The starting current depends on what type of

starting method is used and in some cases also

the size of the motor, particular at D.O.L-start.

For a softstarter a normal value is 3-4 times the

rated motor current.

52

Time

Sec.

1000

100

Heavy duty applications normally require

a starting current between 4 and 5 times the

rated motor current.

The maximum permitted starting current for

a softstarter depends on the starting time. The

ratio between the current and time is displayed

in the graph below.

A higher starting current will give a shorter

possible starting time, for example a crusher

application. A lower current will allow a longer

starting time, for example a pump application.

10

1

100

Typical starting capacty graph for a softstarter

200

300 400

A

Starting

current

Page 60

Starting capacity when using

by-pass contactor

Starting capacity when using

Starting capacity

overload protection

When using a softstarter with a by-pass contactor

it is sometimes possible to select a softstarter with

a lower rated power than the motor rated power

since the softstarter will be working during start

and stop only, not continuously.

The softstarter can not withstand the rated

motor current and therefore a check of the starting capacity must be carried out for the selected

size.

Time

b

a

The overload protection for the motor (thermal

or electronic) will very often set the limit of the

starting capacity. A class 10 relay is used for

normal starts in general while a class 30 relay is

used for heavy-duty starts where a longer starting time must be used.

In some applications where the overload

protection is by-passed (other protection active)

during a start to achieve a longer available

starting time, it is particularly important to

check the softstarter starting capacity since this

will be the limitation.

53

Starting

a) Tripping curve for overload protection

b) Max starting capacity for a softstarter (This will limit the starting time / current if the overload is

by-passed during start)

current

Page 61

Number of starts/hour

The maximum number of starts/hour for a softstarter depends on several different

factors such as the starting current, ambient temperature, starting time and the

intermittens factor.

Intermittens factor

The intermittens factor is a figure indicating

how long the softstarter has been running

for (starting time and running time) compared

with the total cycle time.

It is important to define the intermittens

Number of starts/hour

factor when talking about the number of starts/

hour since the OFF time is the cooling time for

the softstarter.

A high starting current and a long starting time

require a longer OFF time than a low starting

current and short time to maintain the same

number of starts/hour.

54

I

ntermittens factor =

Duty cycle

On

Examples:

If a softstarter has been running for 5 minutes

of a total duty cycle of 10 minutes then the

intermittens factor is 50 % ON time and 50 %

OFF time.

If a softstarter has been running for 45

minutes of a duty cycle of 60 minutes then

the intermittens factor is 75 % ON time and

25 % OFF time.

Off

on

on + off

x 100 %

Time

Page 62

Harmonics

Harmonics are unwanted voltages and currents existing in almost every electrical

system today and are always a multiple of the rated frequency.

Typical harmonics are 3rd, 5th, 7th, 9th etc. The harmonics contribute to the

unnecessary heating of motors, cables and other equipment and may shorten the

lifetime of these devices if exposed for a long period of time.

It can sometimes also disturb functions on electronics and systems. The harmonic

contents and the level naturally depends on the source but also on several other

parameters such as the impedance in the feeding network, the motor, capacitors and

other devices used in the system altogether - in other words a quite complex

phenomenon.

Harmonic content and

softstarters

The question of harmonic content for softstarter

applications is actually in general not relevant

at all. These reflections usually come from

drive applications where harmonics are generated

continuously and a filter is always required in

public networks and very often used also in

industrial networks. With our softstarters we

fulfil the EMC directive concerning emission

and immunity and there is no need for any

particular actions regarding this matter at all.

Harmonics

55

55

Page 63

Explosive atmospheres (Ex)

For plants in environments where the hazard of explosion is due to an explosive

mixture of gases, explosive matter or combustible dust other than explosive dust,

special provisions are applicable regarding the use of electrical material. For electrical

motors there are two main principles for explosion protection. One is to design

the motor so that no sparks or dangerous heat occurs. The other method is to isolate

sparks and dangerous heat inside the motor to prevent ignition of any explosive

mixture of gases outside the motor.

The different classes of explosive protection (Ex) are described by the following parts of

IEC 60079:

Explosive atmospheres

IEC 600079-1: flameproof enclosures ”d”

IEC 600079-2: pressurised enclosures ”p”

IEC 600079-5: powder filling ”q”

IEC 600079-6: oil immersion ”o”

IEC 600079-7: increased safety ”e”

56

IEC 600079-11: intrinsic safety ”i”

IEC 600079-18: encapsulation ”m”

IEC 600079-22: caplights for mines susceptible to firedamp (under consideration)

Example: Electrical apparatus for explosive atmospheres - oil immersion ”o” shall be recognised as Exo.

Page 64

Hazardous areas and zones

The hazardous areas are categorised in

zones as follows:

Zone 0

An area in which an explosive gas atmosphere is

present continuously or for long periods. Only

intrinsically-safe circuits of category Exi may be

used in this zone. Motors are thus excluded.

Zone 1

An area in which an explosive gas atmosphere is

likely to occur in normal operation. Motors of

category Exd, Exe and Exp may be used in this

zone.

Zone 2

An area in which an explosive gas atmosphere is

not likely to occur during normal operation and

if it does occur it will exist for a short period

only. Equipment permitted in zones 0 and 1

may of course be used. Under certain conditions

the equipment, motors for instance, need not to

be of explosion-protected design.

3 m

r4.5 m

Location and selection

of softstarter for Ex

environments

If a softstarter is going to be used for an Ex

application it is normally located in a separate

enclosure outside any of the hazardous zones.

The overload relay used shall be of a special

version designed for EEx motors, for example

TA 25 DU...V 1000 to T 900 DU/SU...V 1000.

This type of relay has a more accurate tripping

curve compared with the standard relay. Special

attention has to be paid to this.

The softstarter type and size and other devices

used in the circuit shall suitably be selected

according to type 2 co-ordination.

Note !

If any electrical equipment is going to be

used in any of the hazardous zones a special

enclosure must be used. This type of

enclosure (steel box or similar) must be

able to withstand an inside explosion

caused by any of the components without

letting anything out to the surroundings.

This solution is in general very unusual.

Explosive atmospheres

57

57

3 m

Low point

Zone 0

Example of classification and extent of the hazardous area in a tank

Zone 1

Zone 2

To wall

Surface of liquid

Height

of wall

Page 65

Co-ordination

By co-ordination we mean a selected combination of electrical apparatus which is

safe for the surroundings and personnel, even if an overload or a fault should occur

in the system.

The co-ordinated group must ensure the following four essential functions:

• Protection against overloads. A protection, which guards all components, cables

Co-ordination

58

and the motor from overheating, active for all currents up to, locked rotor current.

This device will send a trip signal to a disconnection mean, which is normally a

contactor used for the motor control.

• Motor control. This function is commonly carried out by a contactor.

• Protection against short-circuits, which takes care of all currents above the locked

rotor current - i.e. all fault currents.

• Isolation. Ensure an isolating air-gap when opened for personnel safety.

The co-ordinations for the ABB softstarters are done according to IEC 60947-4-2

”AC semiconductor motor controllers and starters” and EN 60947-4-2.

The provisions of IEC 60947-1, General Rules, are applicable to IEC 60947-4-2

where specifically called for.

Page 66

Types of co-ordination

The standard IEC 60947-4-2 defines two types

of co-ordination according to the expected level

of service continuity. The standard IEC 60947-1,

General Rule are applicable to this standard,

where specifically called for.

Type 1:

Co-ordination requires that, under short-circuit

conditions, the device shall cause no danger to

persons or installation and may not be suitable

for further service without repair and replacement

of parts.

Type 2:

Co-ordination requires that, under short-circuit

conditions, the device shall cause no danger to

persons or installation and shall be suitable for

further use. For hybrid controllers and starters,

the risk of contact welding is recognized, in

which case the manufacturer shall indicate the

measures to be taken as regards the maintenance

of the equipment.

Note !

When using a softstarter in a type 2

co-ordination, replacing the fuses and

restart has to be accepted after a shortcircuit. Only semi-conductor fuses can

be used to achieve a type 2 co-ordination

for a softstarter.

Co-ordination

59

59

Page 67

Utilization Categories

Some utilization categories are stated in the standard IEC 60947-4-2, ”AC semiconductor

motor controllers and starters”. The one used for ABB Low Voltage softstarters is AC-53.

Co-ordination

Utilization Typical application

Category

AC-52a Control of slip-ring motor stators: 8 h duty with on-load currents for

start, acceleration, run

AC-52b Control of slip-ring motor stators: intermittent duty

AC-53a Control of squirrel cage motors: 8 h duty with on-load currents for

60

AC-53b Control of squirrel cage motors: intermittent duty

AC-58a Control of hermetic refrigerant compressor motors with automatic resetting of

AC-58b Control of hermetic refrigerant compressor motors with automatic resetting of

start, acceleration, run

overload releases: 8 h duty with on-load currents for start, acceleration, run

overload releases: intermittent duty

Remarks

AC-53 is the utilization category used for softstarters in general since this is about

controlling squirrel cage motors. This is the category stated in the header of the

co-ordination tables for softstarters.

AC-53a is about softstarter designed for use without by-pass contactor.

AC-53b is about softstarter designed for use with by-pass contactor.

Page 68

Types of fuses

There are basically three types of fuses used on the market (see below) with different

functions and characteristics. One type of fuse cannot in general replace another

type without checking the other protection devices in the circuit since the protection

characteristic of the fuse is different between the types. If replacing a 100 A fuse with

another 100 A fuse (same rating) without checking the type there is a risk of losing

protection since the first type may be of type with both short-circuit protection and

thermal protection while the replacement fuse is only short-circuit protection.

gL/gG fuses have a combination of short circuit

protection and thermal overload protection

(5s > 3,5 x In) for cables.

If using these types of fuses together with a

softstarter, type 1 co-ordination can be achieved.

For type 2 co-ordination semi-conductor fuses

must be used.

aM fuses have only a short-circuit protection

(5s > 9 x In), and for thermal overload

protection a separate protection device is

required.

If using these types of fuses together with a

softstarter, type 1 co-ordination can be achieved.

For type 2 co-ordination semi-conductor fuses

must be used.

Semi-conductor fuses (High speed fuses) are

the only type of fuses that are fast enough to

achieve a fully type 2 co-ordination when

using a softstarter. A separate overload relay

for the motor protection is always required

in combination with this type of fuse. If

replacing the semi-conductor fuses with an

MCCB, MMS or similar, type 1 co-ordination

will be achieved instead.

Time

a

c

b

d

a: Characteristic of the overload relay

b: Characteristic of a gL/gG fuse

c: Characteristic of a semi-conductor fuse

d: Area where the gL/gG fuse is not fast enough

to achieve a type 2 co-ordination

Current

Co-ordination

61

61

Page 69

Where to find the co-ordination tables

The co-ordination tables for softstarters can be found on internet page www.abb.com

under Low Voltage Products - Product Coordination.

When selecting the wanted product type, for example softstarters the table below

will show up.

Co-ordination

Ue Main voltage for the application

Iq Short-circuit current rating

Coor. Type Type of co-ordination

Starting type Type of start, normal or heavy duty