Installation and

Maintenance manual

Softstarters

PST / PSTB

Installation and maintenance manual

PST30...PSTB1050

PST30... PST1050

Installation and maintenance manual

Introduction ....................................................................1.1 - 1.3

Quickstart ...............................................................2.1 - 2.3

Description ...................................................................3.1 - 3.10

Mounting ........................................................................4.1 - 4.3

Connection .....................................................................5.1 - 5.9

Human Machine Interface (HMI) ....................................6.1 - 6.7

Settings and confi guration ...........................................7.1 - 7.23

1

2

3

4

5

6

7

Fieldbus communication (option) ...................................8.1 - 8.2

Maintenance ...................................................................9.1 - 9.2

Functions ..................................................................10.1 - 10.19

Troubleshooting ..........................................................11.1 - 11.6

Diagrams ....................................................................12.1 - 12.5

Low Voltage Products & Systems I

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

8

9

10

11

12

General information about this manual

1 General

This is the Installation and maintenance manual for Softstarters PST30...

PSTB1050

Document number: 1SXU 132 021 M0201

Edition: 01

Revision: 01

Issue Date: April 11, 2005

1

Date subject to change without notice.

We reserve all rights to this document, even in the event that a patent is

issued and a different commercial proprietary right is registered. Improper

use, in particular reproduction and dissemination to third parties, is not

permitted.

This document has been carefully checked. If the user nevertheless

detects any errors, please notify us as soon as possible.

The data contained in this manual is intended solely for the product description and is not to be deemed to be a statement of guaranteed properties. In the interests of our customers, we constantly seek to ensure that

our products are developed to the latest technological standards.

As a result, it is possible that there may be some differences between the

softstarter and the information in this manual.

Author’s address:

Low Voltage Products and Systems

ABB Inc.

1206 Hatton Road

Wichita Falls, TX 76302

Tel: 888.385.1221

940.397.7000

Fax: 940.397.7085

Web: www.abb-control.com

3 Safety signs

3:1 Use of Caution, Warning and Information

Caution icon indicates the presence of a hazard which could result

in personal injury.

!

Warning icon indicates the presence of a hazard which could result

in corruption of software or damage to equipment/property.

Alerts the reader to pertinent facts and conditions.

Caution!

Warning!

Information!

2 Safety

This section describes warning and information signs used in this manual.

The user should pay close attention to these signs.

The softstarter should be installed by authorized personnel only.

This manual is a part of the softstarter and should always be accessible to

personnel working with this product.

The manual should always be read before performing any installation or

commissioning tasks.

II Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Installation and maintenance manual

PST30...PSTB1050

About the documentation for the softstarter .........................................................1.2

About the installation and commissioning manual ...............................................1.2

Intended audience ........................................................................................ 1.2

General ...................................................................................................... 1.2

Requirements ............................................................................................. 1.2

Chapters included ................................................................................................. 1.2

Revision notes .......................................................................................................1.3

Acronyms and abbreviations ................................................................................. 1.3

Chapter 1

Introduction

1

Low Voltage Products & Systems 1.1

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 1

Introduction

1:1 About the documentation for the softstarter

For the softstarter, the following documents are available:

PST30/PSTB1050 Softstarters

Installation and Maintenance manual

Document ID: 1SXU 132 021 M0201 - English

1SFC132003M0101 (German)

1SFC132003M0101 (German)

1

1SFC132003M3401 (Swedish)

1SFC132003M0301 (French)

1SFC132003M0901 (Italian)

1SFC132003M0701 (Spanish)

1SFC132003M3101 (Dutch)

1SFC132003M1601 (Portuguese)

1SFC132003M1801 (Finnish)

1SFC132003M1101 (Russian)

1SFC132003M2001 (Chinese

1SFC132003M1901 (Turkish)

Soft Starter Catalog

Document ID: 1SXU 132 019 C0201

For other documents related to the PST Softstarters, see www.abb-control.com/products/softstarters.htm#type_pst

1:2 About the installation and commissioning manual

This manual contains instructions on how to install and commission the softstarter. The manual covers procedures for mechanical and electrical installation and installation of communication devices. It also covers how to energize, set, confi gure and verify settings.

For the quickest possible start, read Chapter 2 “ Quickstart” .

1:2.1 Intended audience

1:2.1.1 General

The installation and commissioning manual is intended for personnel responsible for installing, commissioning and maintaining the softstarter.

1:2.1.2 Requirements

All personnel who interact with the softstarter must have a basic knowledge in handling electric equipment. The commissioning and maintenance personnel must be well experienced in using this kind of equipment.

1:2.2 Chapters included

• Introduction introduces the reader to this manual.

• Quickstart contains information on how to install the softstarter and put it into oper ation in the quickest and safest way. This chapter is intended for

the experienced user.

• Description describes the softstarter in general, its functions and specifi cations.

• Mounting contains information on receiving, unpack ing and mounting the softstarter.

• Connection contains instructions on how to make the electrical connections as well as connections for com munication devices.

• Human-Machine Interface describes the local Human-Machine Interface, how it works and what it contains.

• Settings and confi guration describes all possible set tings and how to navigate in the menu system.

• Fieldbus communication describes how to install and set up the fi eldbus communication.

• Maintenance describes what maintenance is required.

• Functions describes all functions included in the soft starter. This chapter also describes parameter ranges and default values.

• Trouble shooting contains instructions on how to quickly fi nd and correct the most common faults.

• Diagrams contains a number of electrical diagrams for the softstarter itself. It also contains some typical application diagrams.

1.2 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Chapter 1

Introduction

1:2.3 Revision notes

Please check www.abb-control.com/products/softstarters.htm#type_pst for latest information on revisions.

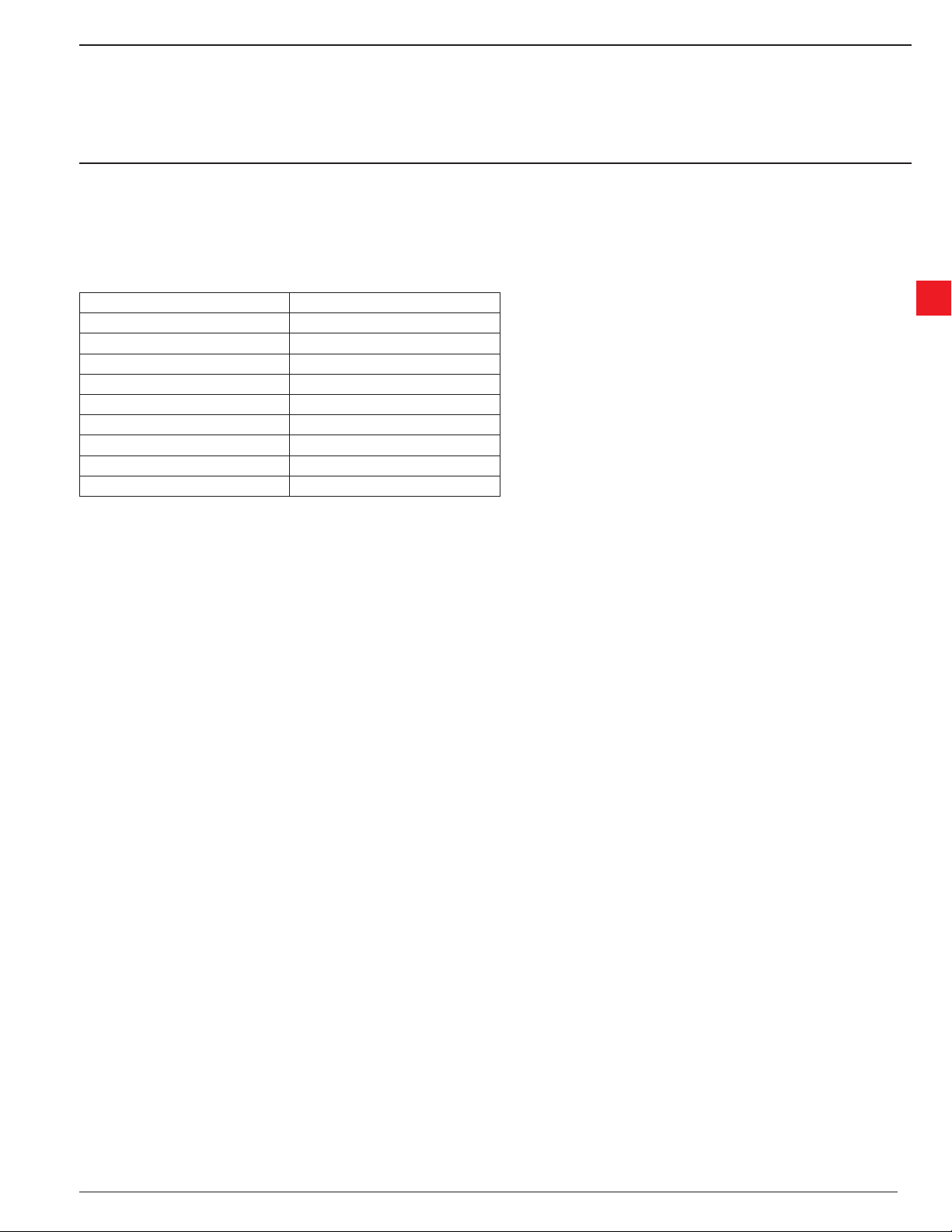

1.2.4 Acronyms and abbreviations

The following acronyms and abbreviations are used in this manual.

Acronym/abbreviation Description

LED Light Emitting Diode

LCD Liquid Crystal Display

SCR Silicon Controlled Rectifi er

IT Information T echnology

HMI Human-Machine Interface

FBP Fieldbusplug

PLC Programmable Logic Controller

PCB Printed Circuit Board

TOR Top of Ramp (full voltage)

1

Low Voltage Products & Systems 1.3

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Notes

1

1.4 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Installation and maintenance manual

PST30...PSTB1050

Connection .............................................................................................................2.2

Confi guration ..........................................................................................................2.3

Start of the motor ....................................................................................................2.3

Chapter 2

Quickstart

2

Low Voltage Products & Systems 2.1

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 2

Quickstart

1

Power on ProtectionFault

2

4

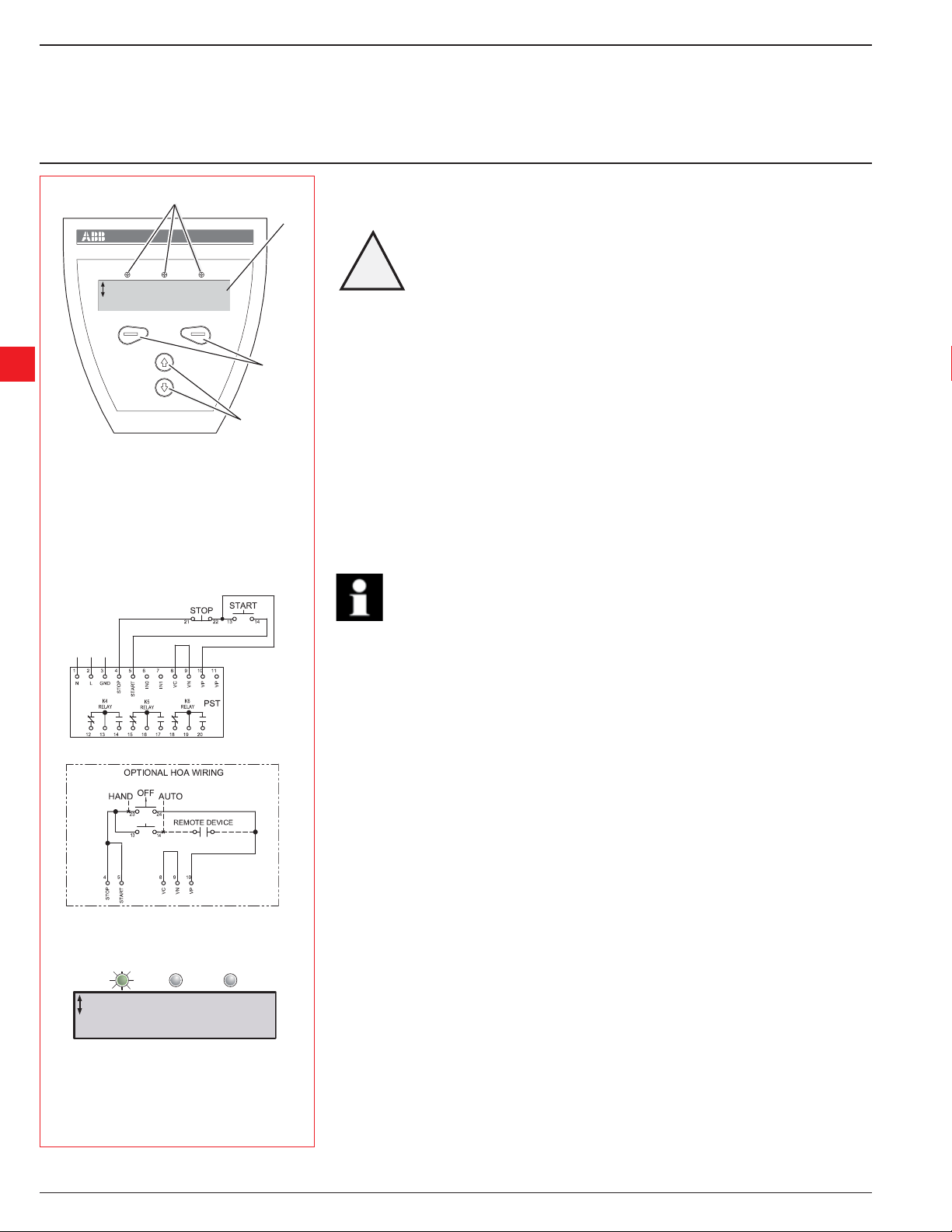

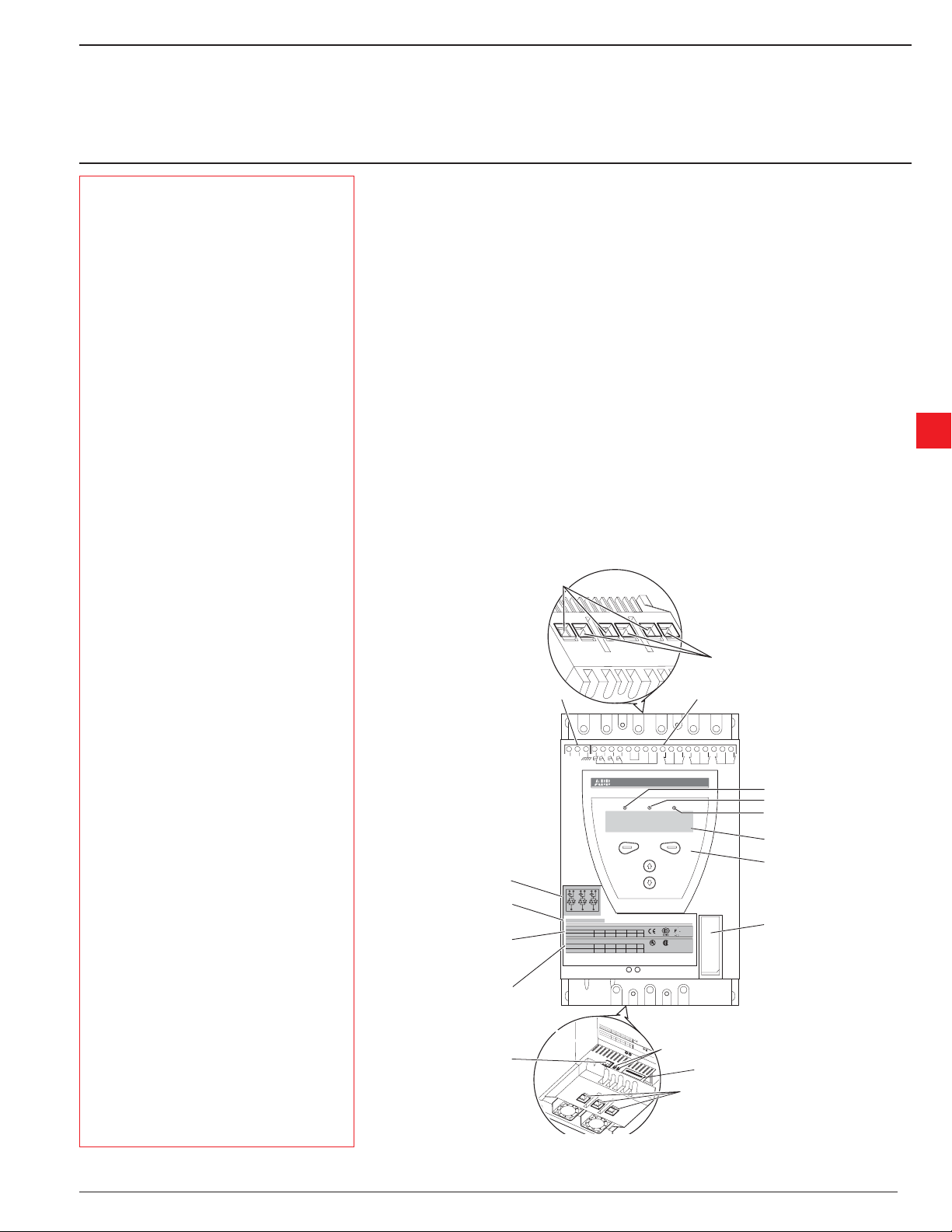

Figure 1:

1 Status indication LEDs

2 LCD display

3 Selection keys for selecting, changing and storing parameters

4 Navigation keys for navigating in the menus

* Arrows shown in the display indicate that the value/menu is

possible to change or scroll

This chapter is a short guide on how to connect, confi gure and start the softstarter in the quickest

and safest way.

2

!

Warning!

Mounting and installing the softstarter shall be done in accordance with local laws and

regulations and must be performed by authorized personnel only.

Do not change any parameters in the Service Settings menu.

3

2:1 Connection

1. Mount the softstarter according to Chapter 4 “ Mounting” .

2. Be aware of the ambient temperature. Derating is required above 40 °C (104 °F). See Chapter

3 for more information.

3. Connect the main circuit: terminals 1L1 - 3L2 - 5L3 to the line side and terminals

2T1 - 4T2 - 6T3 to the motor side.

4. Connect the control voltage: terminals 1 and 2 (100-250V 50/60Hz).

5. Connect the functional ground: terminal 3.

Figure 2: Standard connection PST

Power on ProtectionFault

Figure 3: Top level

Information!

The wire shall be as short as possible, and be connected to the mounting plate.The

mounting plate should also be grounded.

6. Connect the start/stop circuits: terminal 4, 5, 8, 9 and 10 according to Figure 2. 24 VDC only!

7. Verify that the main and control voltage corresponds to the softstarter ratings.

8. Switch on the control voltage.

9. The green “Power on” LED should be lit and the LCD should appear as shown in Figure 3.

2.2 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Chapter 2

Quickstart

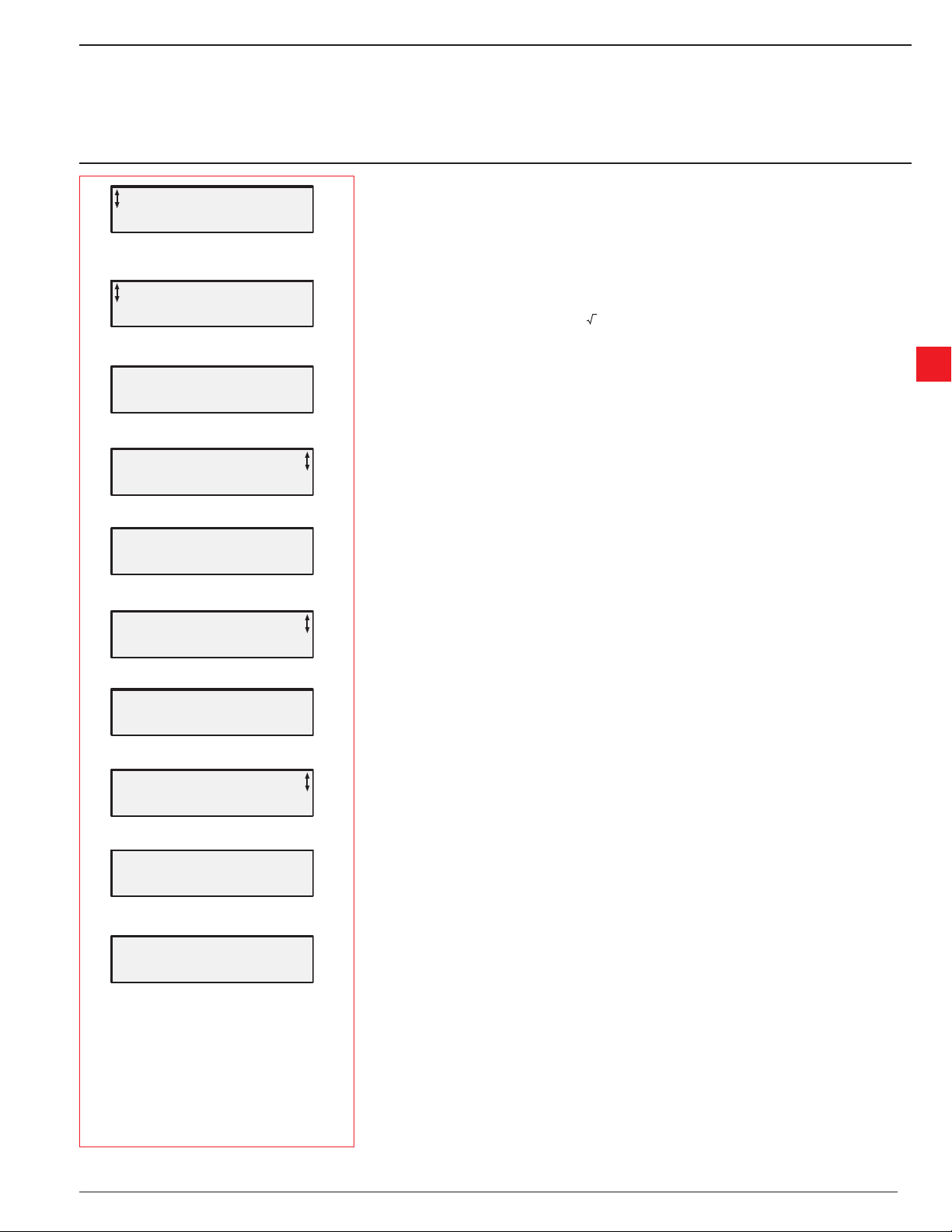

Application Setting

Select Back

Figure 4: Application setting menu

Centrifugal Pump

Store Set Back

Figure 5: Centrifugal pump

Centrifugal Pump

Next Back

Figure 6: Centrifugal pump stored

Setting Ie 99.0A

Store

Figure 7: Setting Ie

Setting Ie 99.0A

Next Back

Figure 8: Setting Ie stored

OL Class 10

Store

Figure 9: OL Class

2:2 Confi guration

1. Enter the Application Setting by pressing the left selection key twice. Press Select using the

left selection key. See Figure 4.

2. Select the appropriate type of load by using the navigation keys. See Figure 5.

3. Press Store Set and Next to continue or Back to previ ous parameter using the selection

keys. See Figure 6.

4. Set Ie (motor FLA) using the navigation keys.

In Line connected = rated motor current

Inside Delta connected = 58% (1/( 3)) of the rated motor current. For example, if the soft

starter is connected in line with a 100A motor, Ie = 100A. If the softstarter is connected inside

the delta of a 100A motor, Ie = 58A. See Figure 7.

5. Press Store and Next to continue or press Back to access the previous parameter. See Fig-

ure 8.

6. Set the required overload class using the navigation keys. See Figure 9.

7. Press Store and Next to continue or press Back to access the previous parameter. See Fig-

ure 10.

8. If an external by-pass contactor is used set Ext ByPass to Yes using the navigation keys.

(PST30...300 only). See Figure 11.

9. Press Store and Next to continue or Back to previous parameter using the selection keys.

See Figure 12.

10. Select Yes if ready or Tune Set if ramp times, initial voltage, current limit etc. need to be

adjusted. See Figure 13.

11. To change language, see Section 7:2.5.

2:3 Start of the motor

1. Switch on the main voltage.

2. Give a start command to the softstarter.

(To start the softstarter from the keypad, enter the LOCAL CONTROL menu, select Start/

Stop and press Start. The motor must be stopped before leaving this menu.)

2

OL Class 10

Next Back

Figure 10: OL Class stored

Ext ByPass No

Store

Figure 11: External Bypass

Ext ByPass No

Next Back

Figure 12: External Bypass stored

Ready?

Yes Tune Set

Figure 13: Ready / Tune Set

Low Voltage Products & Systems 2.3

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Notes

2

2.4 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Installation and maintenance manual

PST30...PSTB1050

Overview.................................................................................................................3.2

Functions ................................................................................................................3.2

Markings and connections ......................................................................................3.3

Type designation ....................................................................................................3.4

Industrial IT .............................................................................................................3.4

Environmental infl uence .........................................................................................3.4

Specifi cations .........................................................................................................3.4

Technical data ........................................................................................................3.5

General .............................................................................................................3.5

Semi-conductor fuses .......................................................................................3.5

Softstarter types ................................................................................................3.6

Weights .............................................................................................................3.7

PSTB AC3 (Across the line) Contactor Ratings ................................................3.7

UL Information ...................................................................................................3.7

Dimensions ............................................................................................3.8 - 3.10

Chapter 3

Description

3

Low Voltage Products & Systems 3.1

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 3 - Description

This chapter describes the softstarter in general, specifi cations and available accessories and

spare parts.

3:1 Overview

The PST softstarter is a microprocessor-based softstarter designed with the latest technology for

the soft start and soft stop of squirrel cage motors. The softstarter has several advanced motor

protection features as standard.

The softstarter is designed to be used with or without a by-pass contactor except for the larger

sizes, PSTB370...1050 where the bypass contactor is integrated. In an emergency, it is possible

to start the motor across the line with the integrated bypass contactor. See Section 3:8.4 for AC3

ratings.

The keypad on the front is designed to be as user-friendly as possible, with a clear text display. It

is possible to choose between twelve different languages (default is English).

The softstarter can be controlled in four ways:

3

• Hardware inputs

• Keypad control (local)

• Fieldbus communication interface

• Remote keypad (option)

The integrated fans for cooling are operated only during ramping (start/stop) and when the tem-

perature of the heat sink is too high. The temperature is monitored by a thermistor.

Only one type of control method can be enabled simultaneously.

Default selection is hardware inputs.

Information!

Keypad control has the highest priority and overrides all other control methods.

3:2 Functions

The PST softstarter has several integrated protection and warning functions. Almost any type of

fault can be detected and displayed.

All available protections, warnings and fault indications are listed below.

Start/Stop functions

• Start ramp

• Stop ramp (also called soft stop or decel)

• Initial voltage

• Step down voltage

• Current limit

• Kick Start

• Extended start range

• Extended stop range

• Sequence start

Protection functions

• Motor overload protection

• Locked rotor protection

• Motor underload protection

• High current protection

• Phase imbalance protection

• Phase reversal protection

• SCR overload protection

• PTC input for motor protection

• Shorted SCR

3.2 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Chapter 3 - Description

Warning functions

• Warning high current

• Warning low current

• Warning motor overload

• Warning SCR overload

Fault Supervision functions

• Internal softstarter faults

• Shorted SCR

• Non conducting SCR

• Open circuit motor side

• Over-temperature heat sink

• Phase loss

• Frequency out of range

• Fieldbus communication

• Non-closing by-pass contactor

• Non-opening by-pass contactor

Other functions

• Jog

• Real time clock

• Event log

• Keypad password

3

3:3 Markings and connections

Line side

connection

e

1234567891011121314151617181920

L

N

100-250V

Stop

50/60 Hz

1L1

B1 B2 B3

3L2 5L3

2T1 4T2 6T3

1SFA 894 007 R1002

IEC 947-4-2

Us: 100-250V AC/DC

Ie: 37-72A

Overload Capacity 115% of Continuous

UL 508

Uc: 100-250V AC/DC

FLA: 37-68A

Fuse 250A TYPOWER ZILOX

CAUTION

Max short circuit current 65kA at 480V

Terminal marking

of main circuit

Order code

Technical data

according to

IEC 947-4-2

Technical data

according to

UL 508

Control voltage U

Start

In1 Vc Vn Vp Vp

In0

Made in Sweden

72: AC-53a: 8-1.6: 80-6

Ue: 220-230 380-400 500 V

In line 18,5 37 45 kW

Ue 208 220-240 440-480 V

In line 20 20 50 Hp

PTCKeypad Fieldbus

IND. CONT. EQ

LISTED

7F39

K4

Wire 1-8 Al Cu 75C only, 35lb-in

Bypass connection

(PST30...300 only)

Terminal marking

of control circuits

K5 K6

Green

Red

Yellow

Display

Keypad

Fieldbus connection

Us: 100

-250V AC/DC

Ie: 37-7

2A

UL

Ue:

Uc: 100

In line

220-23

-250V AC/DC

Overload Capacity

FLA: 37-6

0

18,5

380-400

8A

CAUTI

Ue

37

1

15% of Contin

500

ON

Fuse 250

In lin

V

45

Max short circui

208

e

uous

A

T

kW

YPOW

22

20

0-240

ER ZILOX

t current 65kA

44

20

0-480

L

IS

50

V

at

T

ED

Keypad

IND. C

7

F3

Hp

ON

9

T

.

EQ

.

PTC connection

External keypad

connection

PTC

Wire 1-8

Al Cu 75C

only, 35lb-in

Fieldb

us

213

11

456789101

123

103020123

1S160100

Serial number

Motor side connection

Figure 1: Markings and connections

Low Voltage Products & Systems 3.3

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

3:4 Type designation

Chapter 3 - Description

]

PST B 370-600 -70

]

3

3:4 Industrial

]

]

]

Control Voltage

70 = 100 - 250V 50/60 Hz

Main Voltage

600 = 208 - 600V 50/60 Hz

690 = 400 - 690V 50/60 Hz

Current Rating

600 = 208 - 600V 50/60 Hz

690 = 400 - 690V 50/60 Hz

Bypass contactor

600 = 208 - 600V 50/60 Hz

690 = 400 - 690V 50/60 Hz

Softstarter type

IT

Thanks to ABB’s broad program of product standardisation, today’s Industrial IT components are - whether they are products or systems, hardware or

software - the building blocks of larger solutions, incorporating functionalities that will allow seamless interactions in real-time automation and information systems.

At the product level, ABB’s Industrial IT enabled symbol ensures that all the products can fully interact. All product information pertaining to these

products is available in electronic format, based on Aspect Object

equipped with the tools necessary to install, operate and maintain it effi ciently throughout the product’s life cycle.

The PST softstarters is an Industrial IT enabled product. Documentation such as brochures, catalogues, certifi cates and drawings can be found at :

www.abb-control.com/products/softstarters.htm#type_pst.

TM

technology. The Industrial IT commitment from ABB ensures that every product is

3:6 Environmental infl uence

The product is designed to minimize the environmental affects during manufacturing and use of the product. Most of the materials used are recyclable.

3:7 Specifi cations

Item Specifi cation

Degree of protection (main circuit) IP 10 for PST30...72; IP 00 for PST85...1050

Operating position Vertical at ± 10°

Ambient temperature Storage: -25°C to +70°C (-13°C to 158°F)

Operation

Without derating

With derating

Altitude 1000 m (3281 ft.) above sea level without derating

Pollution degree 3

Relative humidity 5 - 95% (non-condensing)

Standards UL508

PTC input IEC 60947-8 Mark A detectors, DIN 44081 and DIN 44082

Marine approvals Contact your ABB sales offi ce

3.4 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

0°C to +40°C (32°F to 104°F)

+40° C to +50°C (104°F to 122°F) of 0.8% / °C (1.8%/°F)

1000 - 4000 m (3281 - 13,123 ft.) by derating 1% for each 333 ft above 3300 ft.

IEC 60947-1

IEC 60947-4-2

EN 60947--1

Chapter 3 - Description

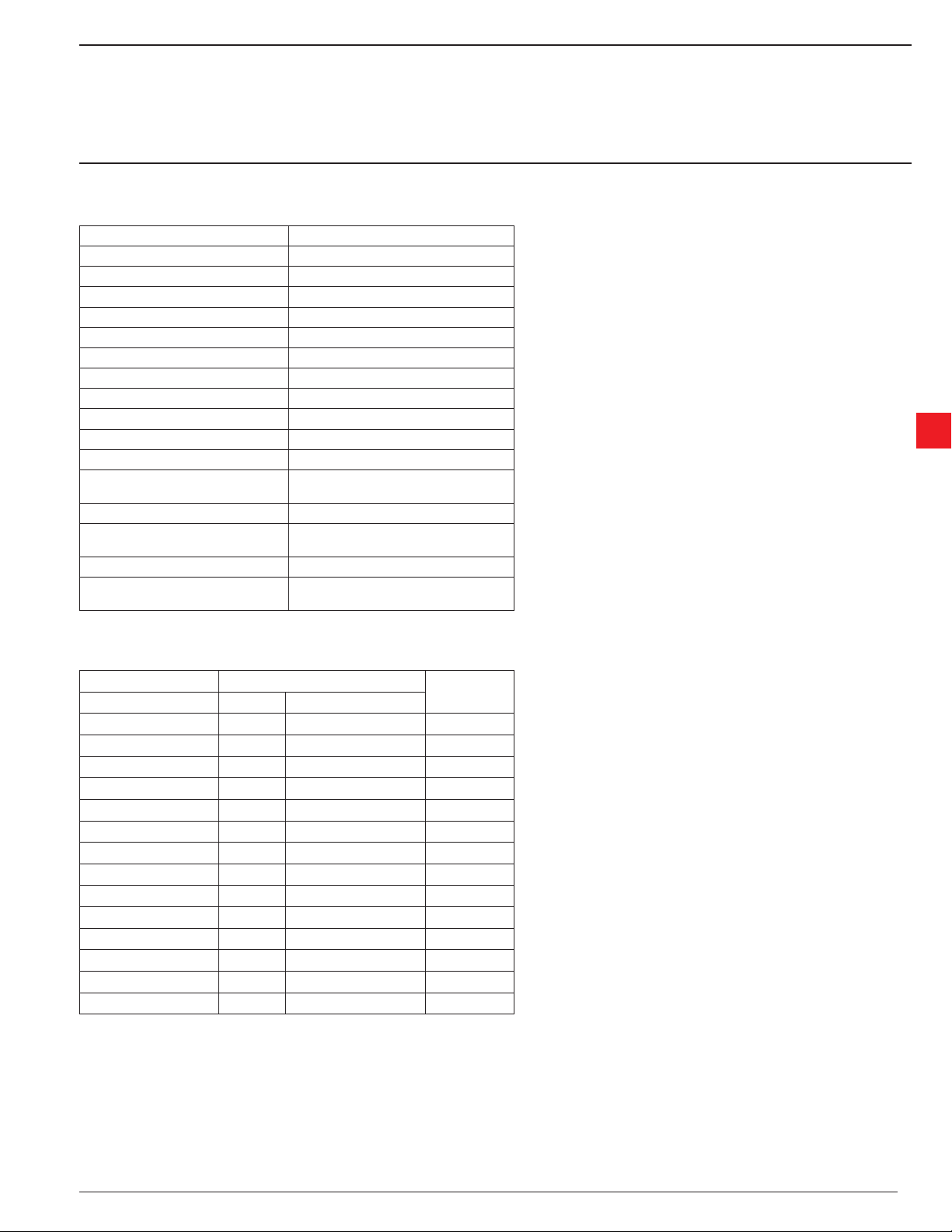

3:8 Technical data

3:8.1 General

Item Technical data

Rated insulation voltage, Ui 690V

Rated operational voltage, Ue 208-690 V (in two modes)

Rated control voltage, Us 100 - 250 V 50/60 Hz

Rated frequency 50 / 60 Hz

Voltage tolerances +10% to -15%

Frequency tolerances ±5%

Rated impulse withstand voltage 2 kV

Number of controlled phases 3

Programmable inputs 24 VDC, 10 mA

Output relays 250 VAC, Ith = 5A, le = 1.5A (AC-15)

Battery back-up D20mm Lithium 3V CR2032

PTC input 2825 ohm ±20% switch off resistance

1200 ohm ±20% switch on resistance

Cooling system Fan

Recommended fuse for control circuit 6A Delayed

MCB use C characteristics

Service factor 115% (100% for PSTB1050)

Communication protocols AS-Interface DeviceNet / Profi bus DP /

Modbus

3

3:8.2 Semi-conductor fuses

Softstarter type Bussmann fuses Holders

A Type

PST30 80 170M1366 170H1007

PST37 125 170M1368 170H1007

PST44 160 170M1369 170H1007

PST50 160 170M1369 170H1007

PST60 200 170M1370 170H1007

PST72 250 170M1371 170H1007

PST85 315 170M1372 170H1007

PST105 400 170M3019 170H3004

PST142 450 170M3020 170H3004

PST175 500 170M3021 170H3004

PST210 630 170M5012 170H3004

PST250 700 170M5013 170H3004

PST300 900 170M5015 170H3004

PSTB370 700 170M5013 170H3004

Low Voltage Products & Systems 3.5

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 3 - Description

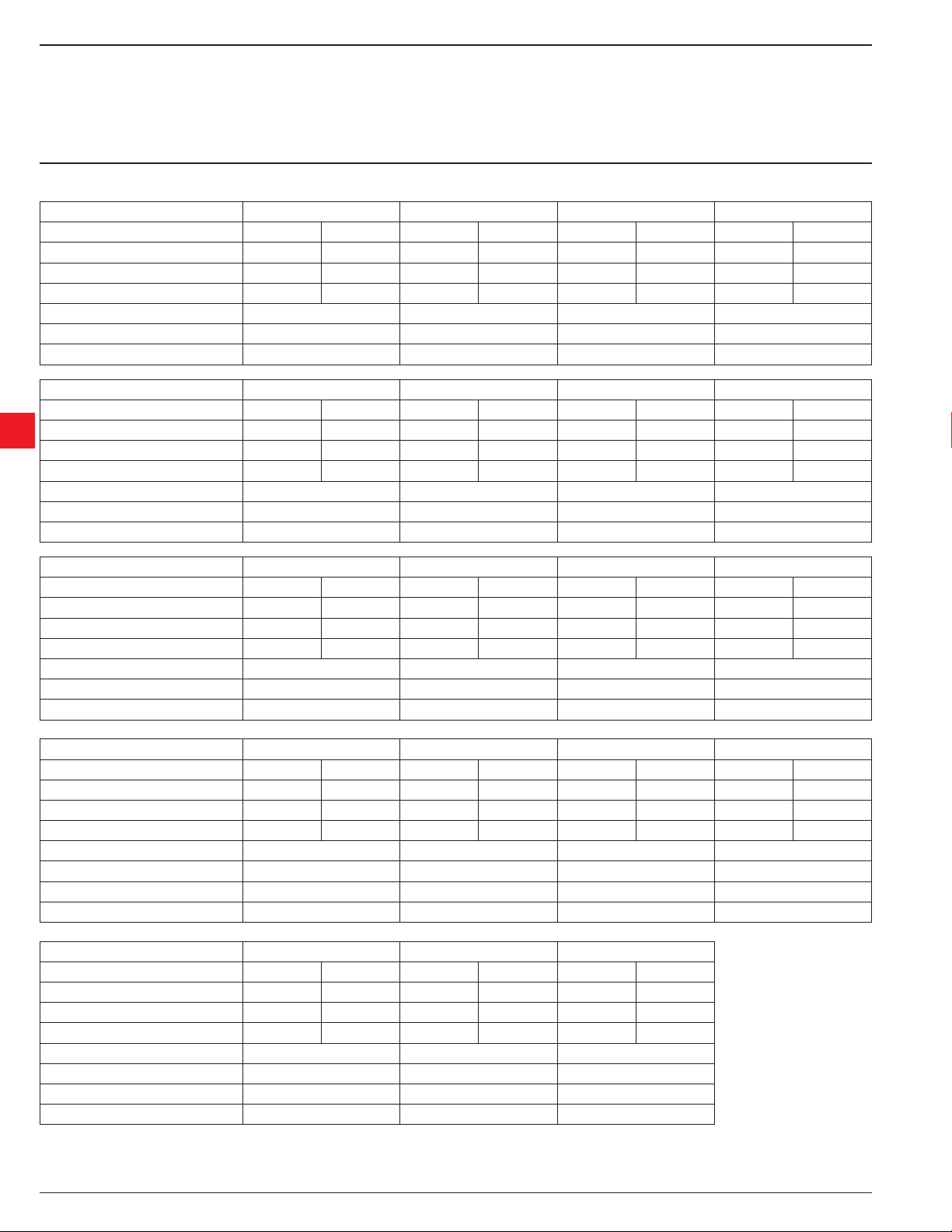

3:8.3 Softstarter types

Type PST30 PST37 PST44 PST50

Connection method Inline Delta Inline Delta Inline Delta Inline Delta

Rated Current Ie (A) 30 52 37 64 44 76 50 85

Motor rating at 480V (HP) 20 30 25 40 30 50 40 60

Motor rating 380-415V (KW) 15 25 18.5 30 22 37 25 45

AC-3 Rating with integrated Bypass (A) ––––

Power loss at rated current (W) 100 120 140 160

Control power requirements (VA) 5555

Type PST60 PST72 PST85 PST105

Connection method Inline Delta Inline Delta Inline Delta Inline Delta

Rated Current Ie (A) 60 105 72 124 85 147 105 181

3

Motor rating at 480V (HP) 40 75 50 75 60 100 75 150

Motor rating 380-415V (KW) 30 55 37 59 45 75 55 90

AC-3 Rating with integrated Bypass (A) ––––

Power loss at rated current (W) 190 230 270 325

Control power requirements (VA) 5 5 10 10

Type PST142 PST175 PST210 PST250

Connection method Inline Delta Inline Delta Inline Delta Inline Delta

Rated Current Ie (A) 142 245 175 300 210 360 250 430

Motor rating at 480V (HP) 100 150 125 200 150 250 200 350

Motor rating 380-415V (KW) 75 132 90 160 110 184 132 220

AC-3 Rating with integrated Bypass (A) ––––

Power loss at rated current (W) 435 540 645 765

Control power requirements (VA) 10 15 15 15

Type PST300 PSTB370 PSTB470 PSTB570

Connection method Inline Delta Inline Delta Inline Delta Inline Delta

Rated Current Ie (A) 300 515 370 640 470 814 570 987

Motor rating at 480V (HP) 250 400 300 500 400 600 500 700

Motor rating 380-415V (KW) 160 257 200 355 250 450 315 475

Contactor type – AF302 AF302 AF480

AC-3 Rating with integrated Bypass (A) – 302 302 480

Power loss at rated current (W) 920 90 110 110

Control power requirements (VA) 15 20/480 20/480 25/900

Type PSTB720 PSTB840 PSTB1050

Connection method Inline Delta Inline Delta Inline Delta

Rated Current Ie (A) 720 1247 840 1455 1050 1810

Motor rating at 480V (HP) 600 1000 700 1200 900 1500

Motor rating 380-415V (KW) 400 670 450 780 560 875

Contactor type AF580 AF750 AF750

AC-3 Rating with integrated Bypass (A) 590 720 720

Power loss at rated current (W) 110 170 170

Control power requirements (VA) 25/860 25/860 25/860

3.6 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Chapter 3 - Description

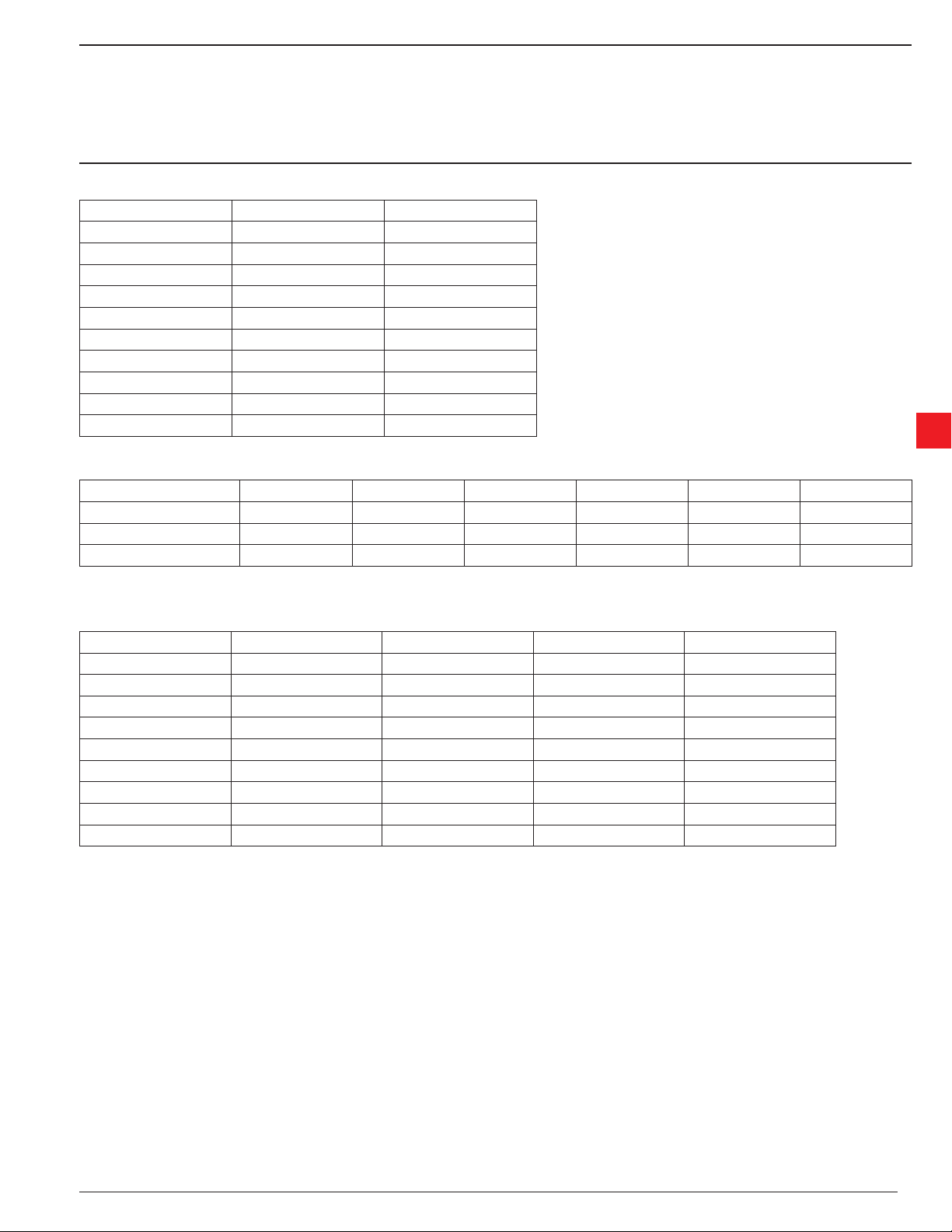

3:8.4 Weights

Type Weight in kg Weight in lbs

PST30...50 4.8 10.6

PST60...72 5.0 11.0

PST85 11.2 24.7

PST105...142 13.0 28.7

PST175...210 21.5 47.4

PST250...300 23.0 50.7

PST370...470 31.0 68.3

PSTB570 52.0 114.6

PSTB720 55.0 121.3

PSTB840...1050 60.0 132.3

3:8.5 PSTB AC3 Integrated contactor ratings

PST type PSTB370 PSTB470 PSTB570 PSTB720 PSTB840 PSTB1050

Contactor type AF300 AF300 AF460 AF580 AF750 AF750

AC3 Rating @ 480V HP 250 250 400 500 600 600

AC3 Rating A 302 302 480 590 720 720

3

3:8.6 UL information

Equipment suitable for use in a circuit with maximum available fault current as shown when protected by devices indicated.

Model Rating (kA) Max V Fuse (A) MCCB (A)

PST30...142 10 600 Any UL Listed Any UL Listed

PST175...300 18 600 Any UL Listed Any UL Listed

PSTB370...470 30 600 Any UL Listed Any UL Listed

PSTB570 30 600 Any UL Listed Any UL Listed

PSTB720 42 600 1200/L 1200

PSTB840 42 600 1200/L 1200

PSTB1050 85 480 - 800

PSTB1050 85 600 1200/L PSTB1050 42 600 - 1200

Low Voltage Products & Systems 3.7

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 3 - Description

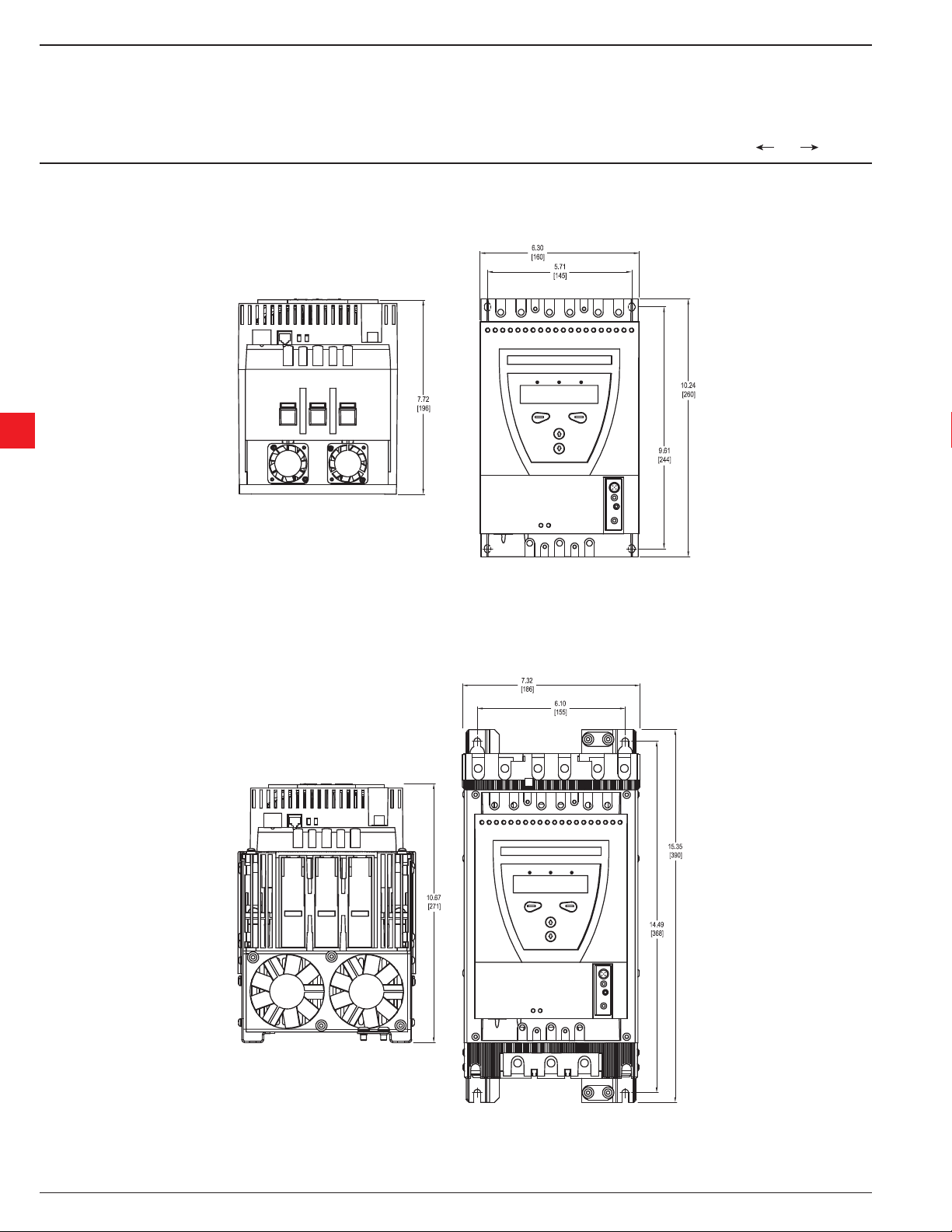

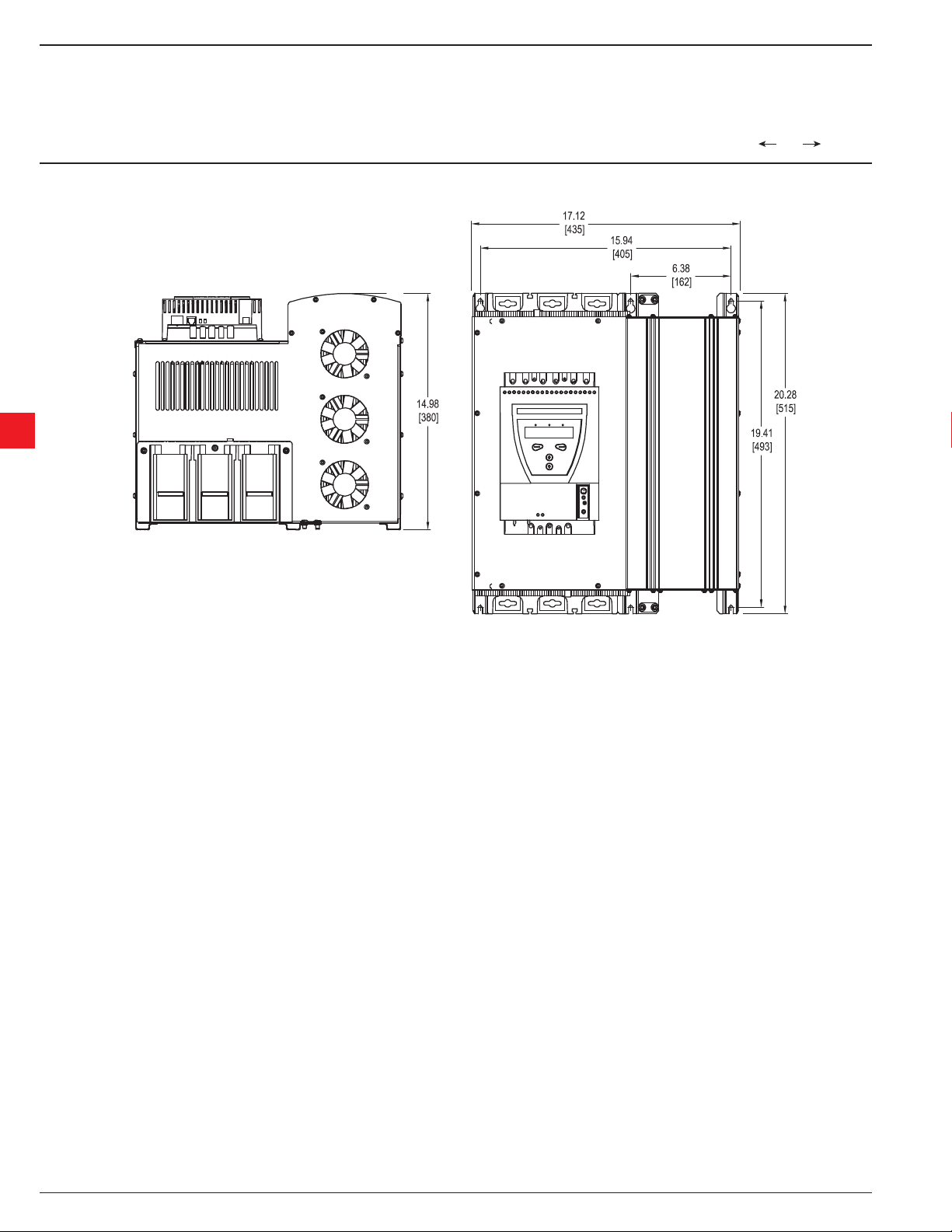

3:8.7 Dimensions

PST30...72

3

Figure 1: Dimensions PST30...72

[

Inches

[

Millimeters

PST85...142

Figure 2: Dimensions PST85...142

3.8 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Chapter 3 - Description

[

Inches

[

Millimeters

PSTB175...300

3

Figure 3: Dimensions PST175...300

PSTB370...470

Figure 4: Dimensions PSTB370...470

Low Voltage Products & Systems 3.9

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

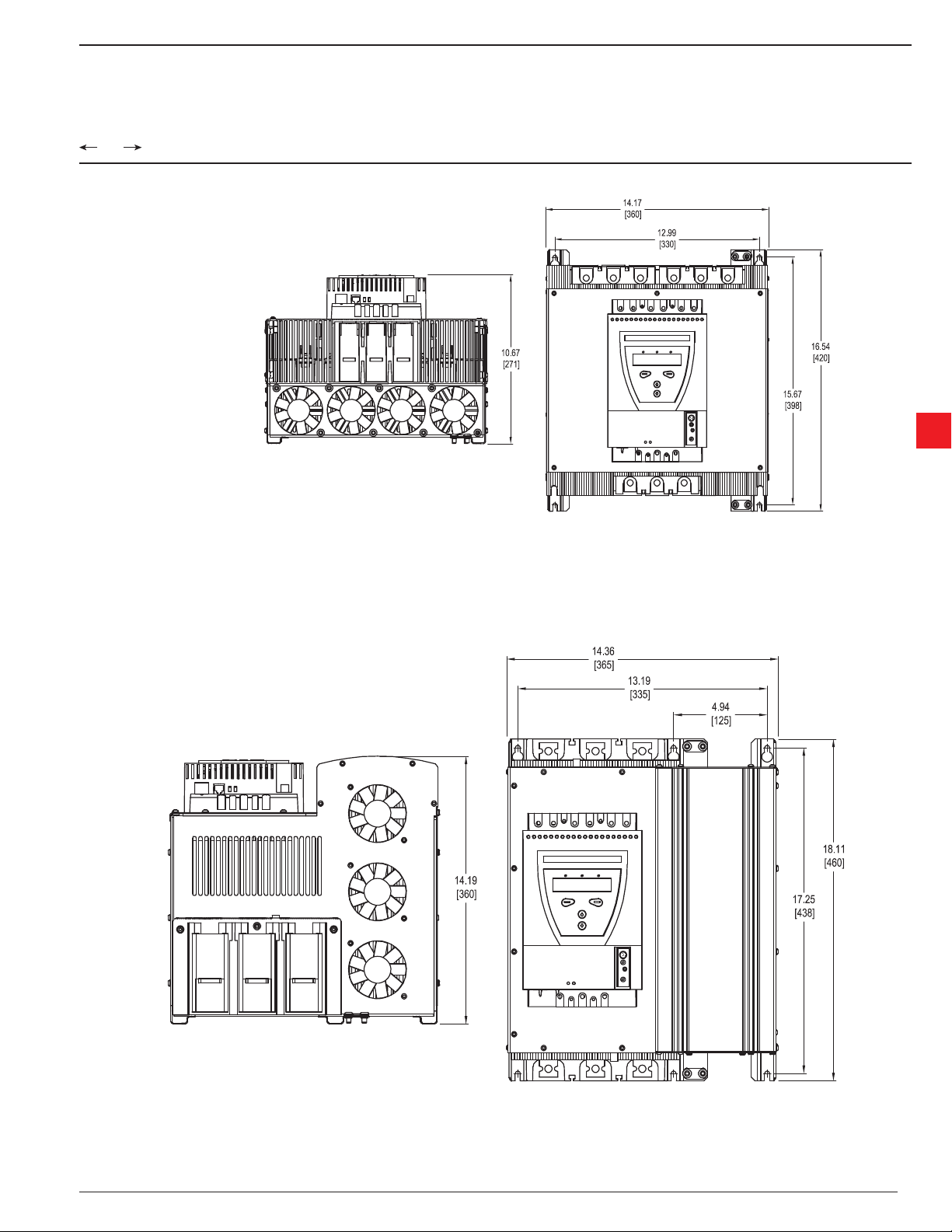

Chapter 3 - Description

PSTB570...1050

3

[

Inches

[

Millimeters

Figure 5: Dimensions PSTB570...1050

3.10 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Installation and maintenance manual

PST30...PSTB1050

Receiving, unpacking and checking .......................................................................4.2

Intermediate storage .........................................................................................4.2

Mounting .................................................................................................................4.2

Handling when mounting ..................................................................................4.2

Requirements ....................................................................................................4.2

Minimum distance to wall/front ..........................................................................4.2

Minimum enclosure sizes ..................................................................................4.3

Chapter 4

Mounting

4

Low Voltage Products & Systems 4.1

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 4

Mounting

This chapter describes instructions on how to receive the softstarter and how to mount it in the proper

way.

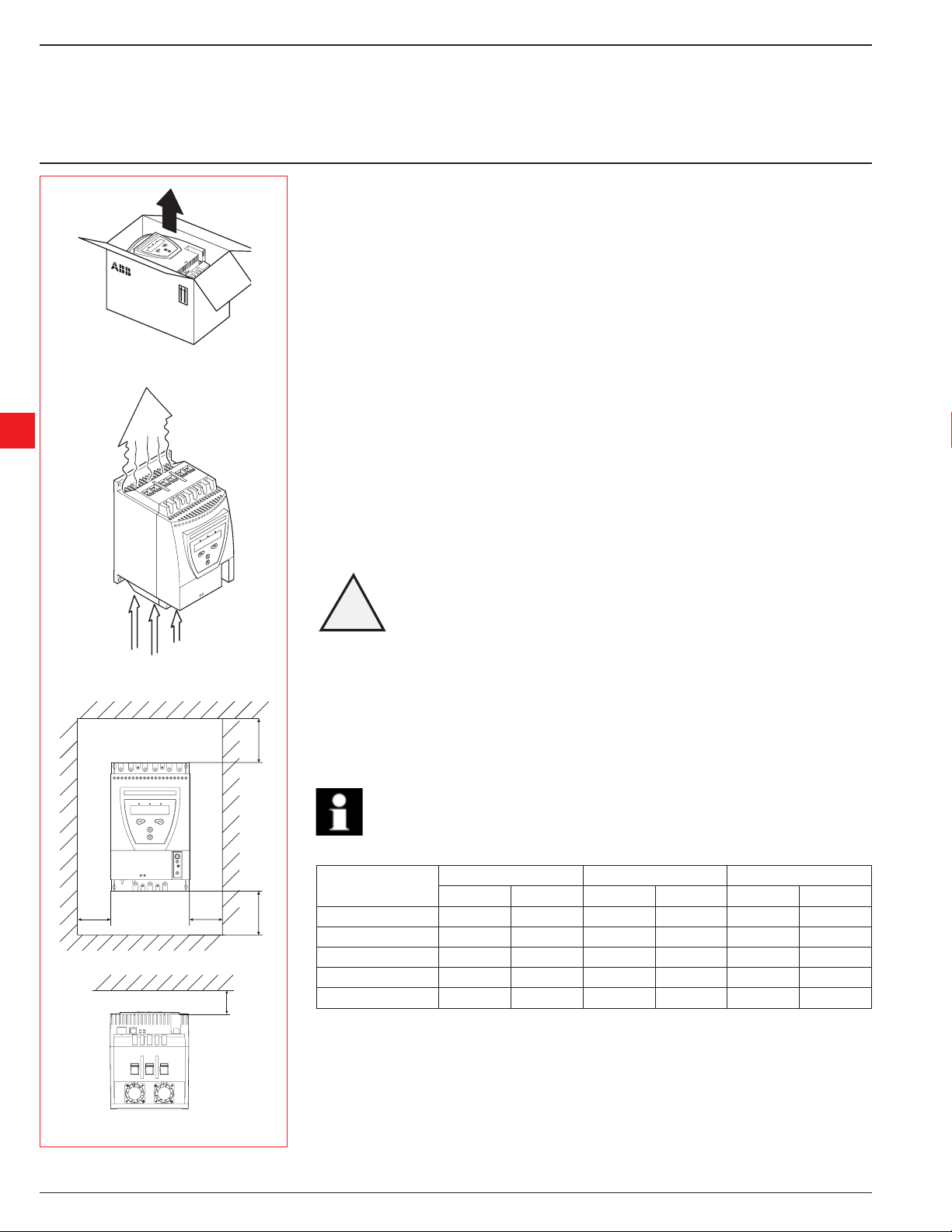

4:1 Receiving, unpacking and checking

• Check that the package is turned with the correct side up, Figure 1.

• Check for transport damages

• Remove transport casing.

• Visually inspect the softstarter

• Check that the serial number corresponds with the delivery documents

Figure 1: Package

4

• Check the softstarter as well as the package. If you fi nd any damages, please contact the transport

company or supplier immediately.

4:1.1 Intermediate storage

Until the softstarter is mounted, it should be stored in its package.

4:2 Mounting

4:2.1 Handling when mounting

The softstarter is available in fi ve physical sizes. Models PST30 to PST300 can be taken out of the

packages and mounted without lifting equipment.

For all other models, lifting equipment is recommended due to the weight.

See Chapter 3 “Description”, for weights.

Figure 2: Airways

B B

Do not lift the softstarter by the connection bars. Lifting by the connection bars may cause

4:2.2 Requirements

See Chapter 3 “Description” for environmental requirements.

A

4:2.3 Minimum distance to wall/front

To ensure a suitable cooling, the softstarter must be mounted vertically and in such a way that the

Use the table below and Figure 3 for minimum distances between wall/front of the PST softstarter.

The values are minimum distances.

A

C

!

Warning!

damage to the product.

airways are not blocked, see Figure 2.

Information!

Softstarter type

PST30...72 100 3.94 10 0.39 20 0.79

PST85...300 100 3.94 10 0.39 20 0.79

PST175...300 100 3.94 10 0.39 20 0.79

PSTB370...470 150 5.91 15 0.59 20 0.79

PSTB570...1050 150 5.91 15 0.59 20 0.79

ABC

mm in mm in mm in

Figure 3: Minimum distances, wall/front

4.2 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Chapter 4 - Mounting

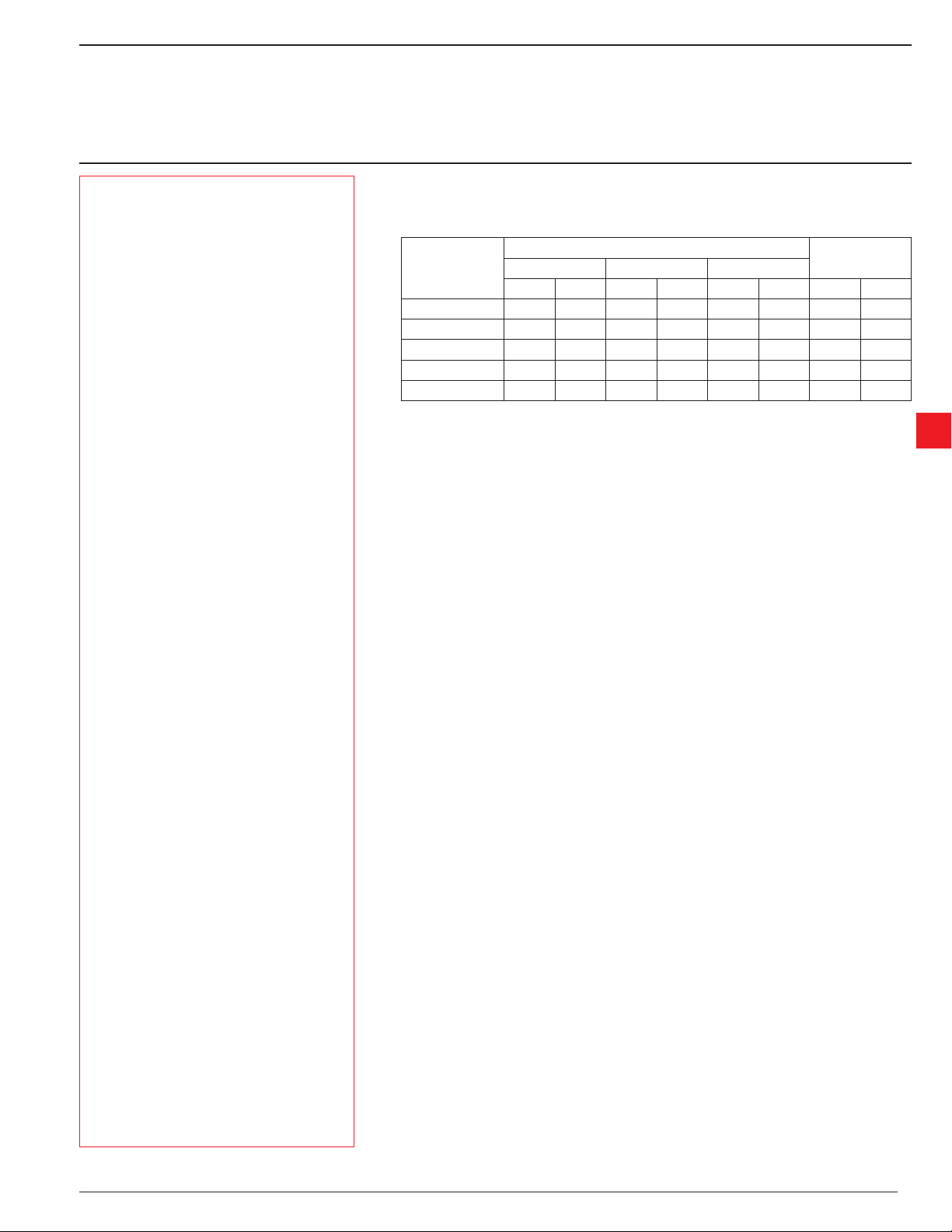

4:2.4 Minimum enclosure sizes

In applications where the softstarter is installed in an enclosure, the following minimum

enclosure sizes and fan capacities are recommended.

Minimum enclosure dimensions

Softstarter type

PST30...72 300 12 400 16 250 10 42 25

PST85...300 400 16 500 20 300 12 95 60

PST175...300 500 20 600 24 300 12 210 125

PSTB370...470 600 24 600 24 400 16 210 125

PSTB570...1050 750 30 900 36 400 16 210 125.00

WHD

mm in mm in mm in m3/h ft3/min

Fan capacity

Dimensions and drilling plan: See Chapter 3, “Description”

4

Low Voltage Products & Systems 4.3

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Notes

4

4.4 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Installation and maintenance manual

PST30...PSTB1050

General .................................................................................................................5.2

Electrical connection .............................................................................................5.2

Main circuit .......................................................................................................5.2

External Bypass contactor ...............................................................................5.3

Protective earthing ...........................................................................................5.3

Control voltage and control circuit ....................................................................5.4

Control voltage, terminals 1 and 2 ...........................................................5.4

Grounding, terminal 3 ..............................................................................5.4

Start and Stop, terminals 4, 5, 8, 9, 10, 11 ...............................................5.4

Programmable inputs, terminals 6 and 7 .................................................5.5

Programmable output relay K4, terminals 12, 13 and 14 ........................5.6

Programmable output relay K5, terminals 15, 16 and 17 ........................5.7

Programmable output relay K6 terminals 18, 19 and 20 .........................5.7

PTC input .................................................................................................5.7

Connection of communication devices (optional) ..................................................5.8

Fieldbus communication ..................................................................................5.8

External keypad ...............................................................................................5.8

Transferring parameters ...................................................................................5.8

Uploading parameters .............................................................................5.8

Technical data ..........................................................................................5.9

Chapter 5

Connection

5

Low Voltage Products & Systems 5.1

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 5

Connection

This chapter describes the electrical connections as well as connections for communication

devices (optional) that must be made before the softstarter can be operated.

5:1 General

PST30...

PSTB1050

Caution!

All wiring and connection must be carried out by a qualifi ed electrician, and in

accordance with installation standards and safety regulations.

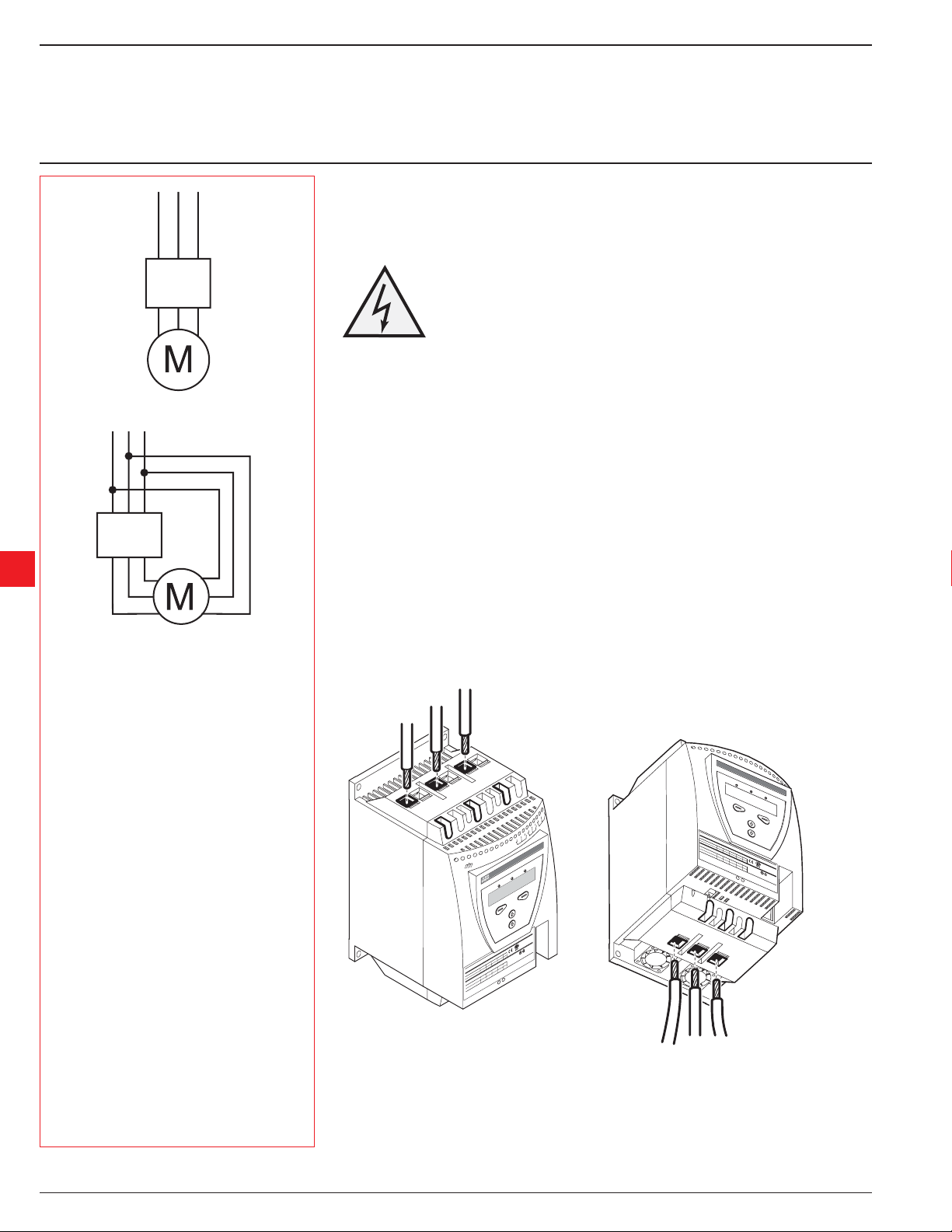

Figure 1: In Line Connection

PST30...

PSTB1050

5

Figure 2: Inside Delta connection

See Chapter 2 “ Quickstart”.

5:2 Electrical connection

5:2.1 Main circuit

Softstarters PST30...PSTB1050 can be connected both “ In Line”, see Figure 1, and “ In-

side Delta”, see Figure 2.

Connect the line side to terminals 1L1, 3L2, 5L3.

Connect the motor to terminals 2T1, 4T2, 6T3 on the motor side.

The terminal marking is printed on the front label.

For torque requirements and cable sizes, see Figure 5.

1L1

3L2

5L3

Line side

20

19

18

K6

17

16

15

K5

14

13

12

11

K4

10

Vp

9

Vp

8

Vn

7

Vc

6

In1

5

In0

4

3

Start

p

2

Sto

1

0V

0-25

10

Hz

/60

50

en

Swed

Made in

.

n

7F39

i

V

-

6:

lb

.

ED

kW

35

500

ly,

8-1

n

CONT. EQ

LIST

.

USS

45

C o

a:

B

D

75

IND

0-400

FEL

Cu

0 38

Al

AC-53

37

V

us

re 1-8

220-23

o

72:

u

Wi

5

,

n

80

i

4 007

18

Cont

f

89

440-4

Ue:

o

%

40

ne

5

li

11

In

20-2

y

1SFA

t

7-4-2

2

paci

94

208

Ca

d

oa

l

IEC

er

Ov

Us: 100-250V AC/DC

Ue

PTC

OX

t

37-72A

L

ZI

Ie:

A a

R

DC

65k

WE

rrent

u

TYPO

t c

UL

ui

rc

i

100-250V AC/

Pad

-

ort c

Uc:

use 250A

h

-68A

F

Key

s

ax

: 37

M

FLA

ON

I

T

CAU

Figure 3: Connection of line side and motor side

2T1

4T2

1SF

A 8

IEC

Us: 100

947-4-2

-250V AC/DC

Ie: 37-72A

UL

Uc: 100

-250V AC/DC

FLA: 37

-68A

CAU

TI

ON

94 007

Ue:

In

Ov

er

l

oa

d

Capac

Ue

F

u

In

se 250A

li

M

ne

a

x

s

h

TYPO

ort ci

rc

ui

6T3

72:

Made in Sweden

AC-53a:

22

li

ne

0-230

18

380-400

8-1

,5

.

6:

i

t

y

37

11

5

500

%

of

Cont

45

V

208

i

n

u

ou

kW

220-24

s

20

W

E

0 440-480

t c

R

u

Z

rrent

ILOX

20

65k

A at

50

Ke

y

-

P

a

d

PT

C

Motor side

LISTED

V

IND. CONT

7F39

Hp

. EQ

.

Wi

re 1-8 Al C

u 75C on

ly,

35

lb-in

FIELD

B

US

5.2 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Chapter 5

Connection

B3

B2

B1

17

16

15

K5

14

13

12

11

K4

10

Vp

9

Vp

8

Vn

7

Vc

6

In1

5

In0

4

3

Start

2

Stop

1

100-250V

50/60 Hz

Figure 4: External bypass contactor

connection

5:2.1.1 External Bypass contactor

An external by-pass contactor can be used for softstarter sizes PST30...300 (built in for

PSTB370...1050).

Connect the contactor to terminals B1, B2 and B3 on the line side and terminals 2T1, 4T2

and 6T3 on the motor side.

The terminal markings are printed on the front label.

20

19

18

K6

Information!

Do not use terminals B1, B2 or B3 for the “Inside Delta” connection. The current

measurement will be wrong.

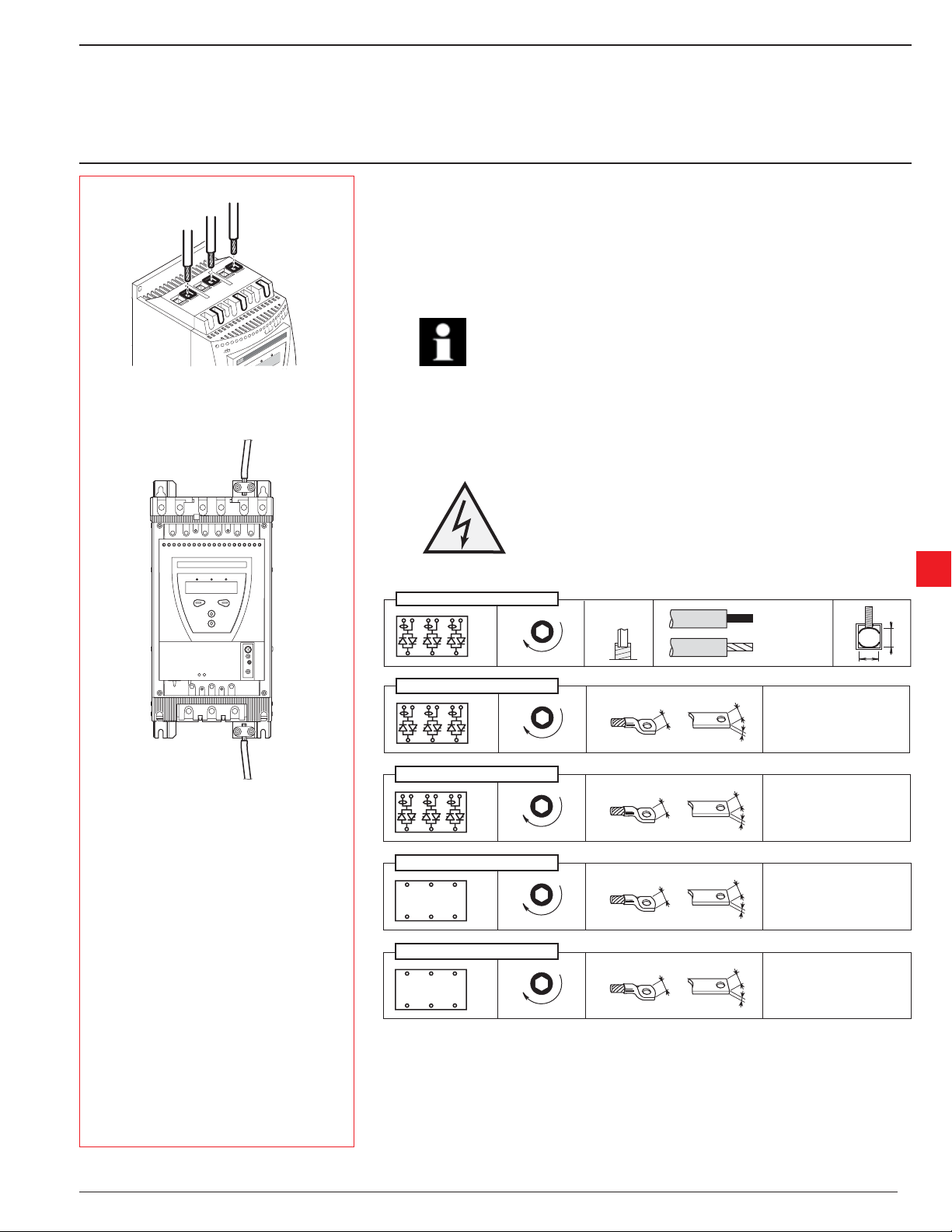

5:2.1.2 Protective earthing

Softstarters type PST85...PSTB1050 should be earthed using the terminals as shown in

Figure 5 (one connection is suffi cient).

Warning!

Do not operate machine with the grounding wire disconnected

PST 30...72

B1 B2 B3

3L2 5L3

1L1

2T1 4T2 6T3

4 mm

M8

6 Nm - 53 lb.in

1 x 6 ...... 70 mm

2 x 6 ...... 35 mm

!WG 1...8

1 x 6 ...... 70 mm

2 x 6 ...... 35 mm

2

2

2

2

14

5

14

Figure 5: Protective earthing.

PST 85...142

B1 B2 B3

3L2 5L3

1L1

2T1 4T2 6T3

PST 175...300

1L1

B1 B2 B3

3L2 5L3

2T1 4T2 6T3

PSTB 370...470

3L2

1L1

2T1 4T2 6T3

5L3

PSTB 570...1050

3L2

1L1

2T1 4T2 6T3

5L3

M8

9 Nm - 80 lb.in

M8

18 Nm - 160 lb.in

M10

40 Nm - 354 lb.in

M12

45 Nm - 443 lb.in

Figure 6: Tightening torques and cable sizes

Low Voltage Products & Systems 5.3

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

V

Chapter 5

Connection

5:2.2 Control voltage and control circuit

N

5:2.2.1 Control voltage, terminals 1 and 2

L

Connect the hot and neutral and phase to terminals 1 and 2.

Information!

Check that you have the correct control voltage Us.

7

6

In1

5

In0

4

rt

3

Sta

2

Stop

1

100-250V

Hz

0

/6

50

Figure 7: Control voltage

5:2.2.2 Grounding, terminal 3

Connect the cable to a grounding point close to the softstarter. The cable should be as short as possible. A

suitable grounding point would be next to the softstarter on the mounting plate, see Figure 8. The mounting

plate should also be grounded.

Information!

This is not a protective ground, it is a functional ground. The grounding cable should be

as short as possible. Maximum length: 1.5 ft.

5

7

6

In1

5

In0

4

t

3

Star

1

0-250V

10

Hz

/60

50

Figure 8: Functional ground

2

Stop

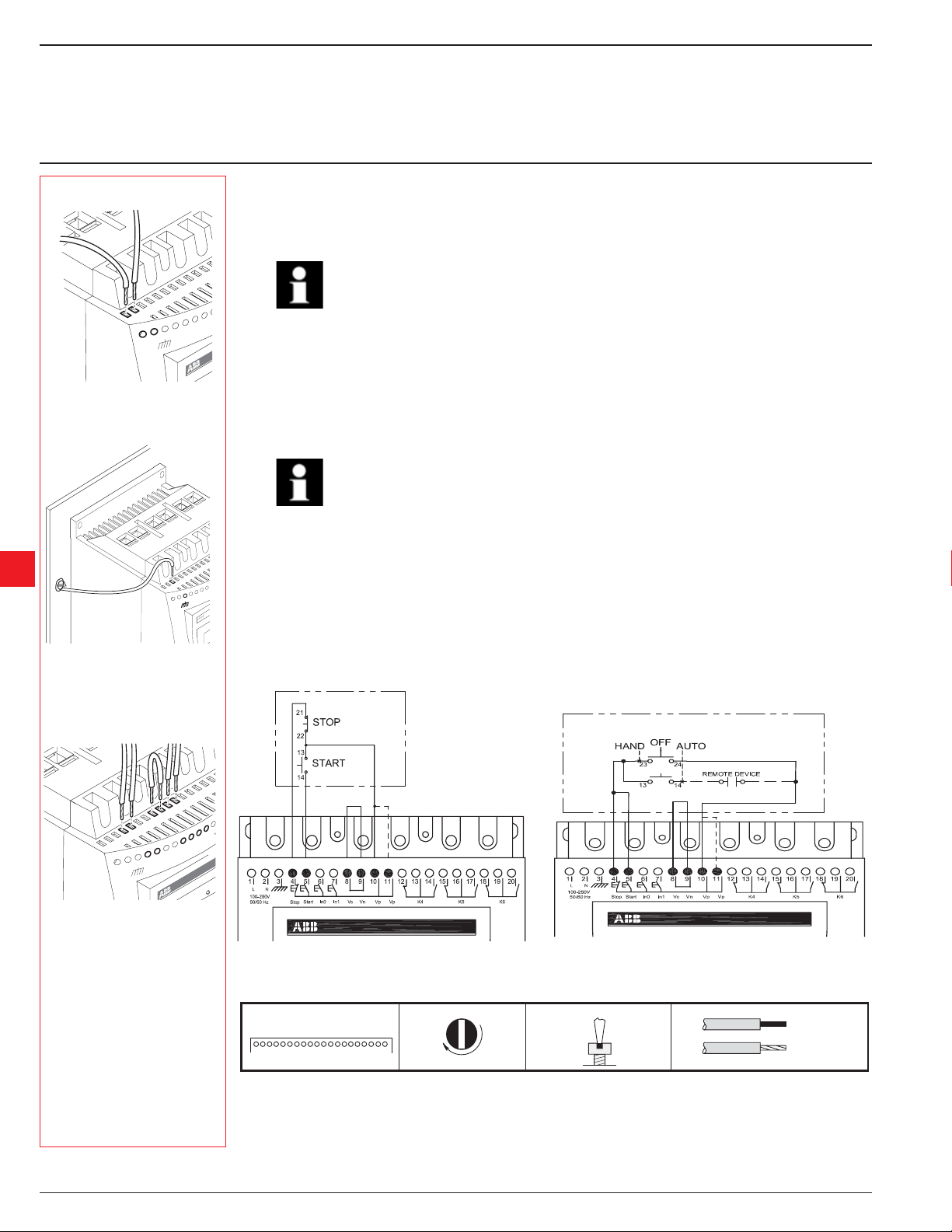

5:2.2.3 Start and Stop, terminals 4, 5, 8, 9, 10, 11

Internal control voltage

The softstarter has a built-in holding circuit which does not require any external power source for start and

stop, See Figure 10.

A conventional circuit with a HOA switch is also possible, see Figure 11.

12

11

10

p

V

9

p

V

8

n

V

7

Vc

6

1

In

5

In0

4

3

Start

p

2

Sto

1

0-250V

10

Hz

0

/6

50

Figure 9: Terminals 4, 5, 8, 9, 10, 11

Figure 10: Holding circuit (momentary start signal required)

M3

1. . . . . . . . . . . . . . . . . . . . . . . . 20

?

0,5 Nm - 4,3 lb.in

Figure 11: Conventional circuit (maintained start signal required)

3,5x0,6

0,14 ... 2,5 mm

AWG 12 ... 22

0,14 ... 2,5 mm

Figure 12: Tightening torques and cable sizes

5.4 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

2

2

Chapter 5

Connection

External control voltage

The softstarter can, if required, also be used with an external 24 V DC source from a PLC or similar.

Connect the cables according to Figure 13 or Figure 14 depending on which type of control method is

used.

6

5

In0

4

3

Start

2

Stop

1

0-250V

10

Hz

/60

50

Figure 15: Terminals 6, 7

Figure 14: Conventional circuit with external control voltage (maintained start signal is required)Figure 13: Holding circuit with external control voltage (momentary start signal required)

5

5:2.2.4 Programmable inputs, terminals 6 and 7

The softstarter has two programmable inputs.

In0: default, reset event

In1: default, reset event

See Chapter 7 “ Settings and confi guration” for programming.

Connect the cables according to Figure 16 or Figure 17 depending on whether the internal or external

12

11

10

Vp

9

Vp

8

n

V

7

c

V

In1

source is being used.

Information!

See next page for multiple motor (sequence) starting

Figure 16: Internal control voltage

M3

1. . . . . . . . . . . . . . . . . . . . . . . . 20

Low Voltage Products & Systems 5.5

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

?

0,5 Nm - 4,3 lb.in

Figure 18: Tightening torques and cable sizes

3,5x0,6

Figure 17: External control voltage

0,14 ... 2,5 mm

AWG 12 ... 22

0,14 ... 2,5 mm

2

2

Chapter 5

Connection

Programmable Inputs (Sequence start)

When sequence start is going to be used, the wiring should be according to Figure 18 or Figure 19.

The start command (Terminal 5, 6 and 7) must be maintained during th complete starting sequence;

otherwise, a direct stop will be performed.

Soft stop can only be performed for the motor currently fed by the softstarter and will be achieved by

opening the Stop command (Terminal 4).

Start seq.

st

nd

Stop

1

Start seq.

Start seq.

rd

2

3

Start seq.

st

Stop

1

Start seq.

Start seq.

nd

rd

2

3

DC

+

-

5

1234567891011121314151617181920

L

N

100-250V

50/60 Hz

Start

Stop

In1 Vc Vn Vp Vp

In0

K4

K5 K6

Figure 18: Internal control voltage Figure 19: External control voltage

5:2.2.5 Programmable output relay K4, terminals 12, 13 and 14

The output relay gives a signal depending on the selected function.

Default: Run

See Chapter 7 “ Settings and confi guration” for programming.

Connect the cables to terminal 12, 13 and 14.

M3

1. . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 21: Tightening torques and cable dimensions (1 mm=0,0394 in)

20

19

18

6

K

17

16

15

K5

14

13

12

11

K4

10

Vp

9

Vp

8

Vn

7

Vc

6

In1

In0

?

0,5 Nm - 4,3 lb.in

1234567891011121314151617181920

L

N

100-250V

50/60 Hz

Start

Stop

In1 Vc Vn Vp Vp

In0

K4

K5 K6

3,5x0,6

0,14 ... 2,5 mm

AWG 12 ... 22

0,14 ... 2,5 mm

2

2

Figure 20: Terminals 12, 13, 14

5.6 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

0

17

0

16

15

K5

14

13

12

11

K4

10

Vp

9

Vp

8

Vn

7

Vc

In1

Figure 22: Terminals 15, 16, 17

17

16

15

K5

14

13

12

11

K4

10

Vp

9

Vp

8

Vn

7

Vc

In1

Chapter 5

Connection

5:2.2.6 Programmable output relay K5, terminals 15, 16 and 17

The output relay gives a signal depending on the selected function.

Default: Top of ramp

See Chapter 7 “ Settings and confi guration” for programming.

Connect the cables to terminal 15, 16 and 17.

20

19

18

K6

5:2.2.7 Programmable output relay K6, terminals 18, 19 and 20

The output relay gives a signal depending on the selected function.

Default: Event

See Chapter 7 “ Settings and confi guration” for programming.

Connect the cables to terminal 18, 19 and 20.

20

19

18

K6

5

Figure 23: Terminals 18, 19, 20

5:2.2.8 PTC input

If the motor is protected by PTC elements, the cables must be connected to terminals PTC, see Figure 24.

1SF

A 8

94 007 R1

IEC

Us: 100

94

7-4-2

-250V AC/DC

Ie: 37

002

-72A

UL 508

72:

Ue:

Made in

Uc: 100

AC-53

I

n

lin

22

-250V AC/DC

Sw

Ov

e

FLA: 37

0-230

e

a

rload

eden

: 8-

18

380-400

-68A

C

,5

apa

1

CAU

.

6:

c

ity

Ue

1

TI

37

15

ON

500

%

of

Fu

I

C

n

se 250A

V

45

ontinuou

lin

Max

208

e

s

TYPOW

hort

kW

220-24

s

20

c

irc

uit

ER

0 44

c

urr

Z

20

IL

0-480

ent

OX

65

LISTE

k

A

50

V

at

K

IND. CONT. EQ

D 7F39

e

y

-

Pad

Hp

.

PTC

Wire 1-8 A

l

C

u

75C

only

, 35

lb

-in

FELD

B

USS

Figure 24: PTC connection

Low Voltage Products & Systems 5.7

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

See Chapter 7 “ Settings and confi guration” for programming.

M3

1. . . . . . . . . . . . . . . . . . . . . . . . 20

?

0,5 Nm - 4,3 lb.in

Figure 25: Tightening torques and cable sizes

3,5x0,6

0,14 ... 2,5 mm

AWG 12 ... 22

0,14 ... 2,5 mm

2

2

20

19

18

K6

17

16

15

K5

14

13

12

11

K4

10

9

Vp

8

Vp

7

6

Vn

5

Vc

4

In1

3

2

In0

1

N

Start

L

Stop

100-250V

AC/DC, 50/60 Hz

B3

L3

5

B2

3L2

eden

B1

1L1

39

Made in Sw

.

V

n

i

-

6:

lb

. EQ

.

ED 7F

kW

6T3

500

ly, 35

IST

L

: 8-1

45

-400

75C on

IND. CONT

4T2

u

FELDBUSS

C

l

37

AC-53a

T1

s

V

u

2

re 1-8 A

o

72:

220-230 380

u

Wi

n

80

i

18,5

Cont

440-4

f

Ue:

o

0

%

ne

5

li

In

-4-2

y 11

1SFA 894 007

t

i

220-24

208

Capac

d

oa

l

IEC 947

er

A

Ov

Us: 100-250V AC/DC

C

X

Ue

PT

O

IL

Z

Ie: 37-72

A at

k

R

E

rrent 65

u

TYPOW

t c

UL

rcui

d

i

a

A

se 250A

ort c

Uc: 100-250V AC/DC

u

h

F

Key-P

x s

a

M

FLA: 37-68

ON

I

CAUT

Figure 26: Fieldbus plug

Chapter 5

Connection

5:3 Connection of communication devices (optional)

5:3.1 Fieldbus communication

The fi eldbus communication plug must be connected to the communication interface on the front of the PST,

see Figure 26. Make sure that the plug is in correct position and tighten the screw with 0.8 Nm (7.1 lb in) and

additional 1/4 turn.

For programming and other information, see Chapter 7 “ Settings and confi guration” and Chapter 8 “ Field-

bus communication (option)”.

Made in Sweden

PTCKey-Pad Fieldbus

5

Figure 27: Principle of a fi eldbus network with PST softstarters connected

Made in Sweden

PTCKey-Pad Fieldbus

5:3.2 External keypad

An external keypad for door mounting can be connected to the softstarter. A 3-meter cable including both the

serial communication and the power supply to the keypad makes the connection.

The external keypad can also be used for transferring parameters from one softstarter to another during

commissioning (temporarily handheld). Note that NEMA 4/4X cannot be achieved when the keypad is not

mounted.

When thee external keypad is used, both keypads will work in parallel but the softstarter keypad always has

the highest priority if the keys on both units are pressed simultaneously.

Figure 28: External keypad

5:3.3 Transferring parameters

20

19

18

K6

17

16

15

K5

14

13

12

11

K4

10

9

Vp

8

Vp

7

6

Vn

5

Vc

4

In1

3

2

In0

1

N

Start

L

op

St

0V

100-25

AC/DC, 50/60 Hz

B3

L3

5

B2

3L2

B1

Sweden

1L1

9

3

Made in

.

V

in

lb

. EQ

ED 7F

kW

6T3

T

, 35

500

ly

IS

L

45

75C on

IND. CONT

4T2

u

FELDBUSS

C

l

37

s

V

u

2T1

o

72: AC-53a: 8-1.6:

u

Wire 1-8 A

220-230 380-400

n

i

18,5

Cont

f

894 007

Ue:

440-480

o

%

ne

5

li

11

In

y

1SFA

t

220-240

i

Capac

d

208

oa

l

IEC 947-4-2

er

Ov

Us: 100-250V AC/DC

C

Ue

PT

OX

t

IL

Z

Ie: 37-72A

A a

k

R

E

rrent 65

u

TYPOW

t c

UL

ui

rc

d

a

P

-

se 250A

ort ci

Uc: 100-250V AC/DC

y

u

h

F

Ke

s

x

a

M

FLA: 37-68A

ON

I

T

CAU

Figure 29: Upload

To transfer (copy) parameters from one softstarter to another, connect the keypad to the chosen softstarter and follow the

sequence below.

5:3.3.1 Uploading parameters

Enter the menu Transfer par. Select To Keypad and confi rm by pressing Select. A text Load to Keypad will be displayed..

Continue by pressing Execute and then Yes when the text Are You Sure is displayed. Transfer OK will now be displayed

if the transmission was successful. Otherwise, Transfer Not OK will be displayed.

5.8 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Figure 30: Download

Chapter 5

Connection

5:3.3.2 Downloading parameters

To download the parameters, connect the keypad to the chosen softstarter and select To Starter. A text

20

19

18

K6

17

16

15

K5

14

13

12

11

K4

10

9

Vp

8

Vp

7

6

Vn

5

c

V

4

1

n

I

3

2

0

In

1

t

tar

N

S

L

p

o

St

V

Hz

0

6

0/

5

100-250

,

DC

AC/

B3

L3

5

B2

n

3L2

e

ed

1

B

w

S

1

L

in

1

9

ade

3

M

.

V

F

7

n

i

-

3

EQ

b

6:

D

l

.

.

0

T

E

0

kW

6T

N

T

, 35

5

S

ly

O

S

I

8-1

C

S

L

5

.

4

BU

2

5C on

D

3a:

7

IND

L

4T

u

5

80-400

E

F

3

C

l

7

0

3

3

2

1

1-8 A

V

s

e

u

2T

r

i

220-

o

007

72: AC-

u

W

5

,

n

80

i

4

nt

18

o

0-

C

e:

f

44

894

U

o

%

ne

5

li

11

In

20-240

y

1SFA

2

t

i

C/DC

ac

A

8

ap

0

C

50V

2

2

d

oa

l

00-

IEC 947-4-2

1

:

ver

s

A

O

U

C

72

e

T

X

U

7-

P

O

t

3

IL

e:

Z

I

A a

k

C

R

5

D

6

E

t

C/

W

n

A

O

rre

P

u

0V

Y

c

5

T

t

i

-2

UL

u

0A

c

00

r

5

d

i

1

2

c

a

t

P

A

c:

r

-

se

8

o

U

y

u

6

h

e

F

s

K

x

37

a

:

A

M

L

F

ON

TI

CAU

Load to Start will be displayed. Continue by pressing Execute and then Yes when the text Are You Sure is

displayed. Transfer OK will now be displayed if the transmission was successful; otherwise, Transfer Not OK

will be displayed. Set the parameter Setting le and confi rm by pressing Next.

Information!

The parameters in the menu Service Settings will not be transferred.

To learn how to operate the keypad, see Chapter 6 “Human-Machine Interface (HMI)”

5:3.3.3 Technical data

Display LCD type

Signal indication LEDs Power on: Green

Protection: Yellow

Fault: Red

Ambient temperature Storage: -25°C to +70°C (-13°F to 158°F)

Operation: 0°C to +50°C (32°F to 122°F)

Degree of protection IP66

UL approval Type 1

Type 4X Indoor

Type 12

Marine approvals Contact your ABB sales offi ce

5

Low Voltage Products & Systems 5.9

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Notes

5

5.10 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Installation and maintenance manual

PST30...PSTB1050

Overview........................................................................................................6.2

Application ............................................................................................... 6.2

Design ...................................................................................................... 6.2

Password .................................................................................................6.3

Setting password ................................................................................6.3

Wrong password ................................................................................6.3

Locking/unlocking the keypad ..................................................................6.3

Menu tree ......................................................................................................6.4

Overview ..................................................................................................6.4

Top level ...................................................................................................6.4

Settings menu ..........................................................................................6.5

Local Control menu ..................................................................................6.5

Start/Stop the motor ...........................................................................6.6

Jog ..................................................................................................... 6.6

DOL start ............................................................................................6.6

Event Log menu .......................................................................................6.7

Status Information menu ..........................................................................6.7

Reset Events menu .................................................................................. 6.7

Chapter 6

Human Machine Interface (HMI)

6

Low Voltage Products & Systems 6.1

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 6

Human-Machine Interface (HMI)

1

Power on ProtectionFault

Figure 1: Human-Machine Interface

1 Status indication LEDs

2 LCD display

3 Selection keys

4 Navigation keys

1

Power on ProtectionFault

Setting Ie 100A

Change Back

Power on ProtectionFault

Setting Ie 100A

Store Cancel

Figure 2: Menu examples

1 Scrolling icons

6

U = 0% I = 0.0A

Menu

Figure 3: Top level

SETTINGS

Select Back

Figure 4: SETTINGS menu

Application Setting

Select Back

Figure 5: Application Setting menu

Functional Settings

Select Back

Figure 6: Functional settings menu

Start/Stop

Select Back

Figure 7: Start/stop menu

Setting Ie 100A

Change Back

Figure 8: Setting Ie menu

Setting Ie 100A

Store Cancel

Figure 9: Setting Ie menu, changing menu

This chapter describes how the human-machine interface (keypad and display) works.

2

6:1 Overview

6:1.1 Application

The Human-Machine Interface is used for several purposes such as programming the softstarter, i.e setup of

inputs and outputs, protection functions, warning levels, fi eldbus communication, etc. The HMI is also used for

3

4

1

monitoring, local control and receiving status information from the softstarter.

6:1.2 Design

The HMI consists of:

• Status indication LED indicators

• LCD display

• Selection and Navigation keys

The LED indicators work as follows:

LED Color Description

Power on Green Control voltage connected

Fault Red Indicates faults

Protection Yellow Indicates protective function has activated

When a Fault or Protection LED is activated, the LCD displays the actual fault or protection.

The keypad is based on the same user concept as today’s mobile phones.

The LCD contains two rows with 20 characters each.

The top row presents various information depending on its state. The bottom row indicates which function is

currently selected.

A scrolling icon indicates what parameter or setting value is possible to change at the position.

The Selection keys normally have more than one function, such as selecting, changing and storing parameters.

See the text on the bottom row of the LCD.

The Navigation keys are used for navigating through the various menus to the desired setting.

When selecting from a list, the scrolling is done in a closed loop fashion.

The functionality of the keypad is illustrated by the following example:

Changing the rated motor current ( Setting I

1. You will fi nd the setting as well as a short explanation and the path to it in Chapter 10 “ Functions”.

Path in menu:

Menu/SETTINGS/Functional Settings/

Start/Stop /Setting Ie

2. The top level of the softstarter start menu looks as in Figure 3. Press the left selection key to enter the menu.

The display now appears as in Figure 4.

3. Press the left selection key to select SETTINGS. The display appears as in Figure 5.

4. Press the lower navigation key until the display appears as in Figure 6.

5. Press the left selection key to select Functional set tings. Press the left selection key to select Start/Stop,

Figure 7.

6. Press the left selection key to Change the Setting Ie, Figure 8.

The display now appears as in Figure 9.

7. Use the navigation keys to set the rated current. If you want to quit, you select Cancel, using the right selec-

tion key. Otherwise, you store the new setting by selecting Store with the left selection key. The display should

now appear as in Figure 10.

8. Press the right selection key four times to return to top level.

).

e

Setting Ie 99.5A

Change Back

Figure 10: Setting Ie menu, changing setting

6.2 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Change Password

Select Back

Figure 11: Change password

New Password 1

Store Back

Figure 12: New password

New Password 1

Next

Figure 13: New password stored

Chapter 6

Human-Machine Interface (HMI)

6:1.3 Password

To lock the keypad from control and change of settings, a password can be set. When the keypad is locked, all

menus are available but no changes or actions can be initiated.

6:1.3.1 Setting password

The default password is always 1.

1 Press the upper navigation key once to enter the parameter Change Password.

2 Select Change Password, Figure 11

3 Set the new password (No or 1...255) using the navigation keys.

Select Store and Next, Figure 12 and Figure 13.

Select Back to return to top level.

Wrong Password

Next

Figure 14: Wrong password

Support Code 1

Next

Figure 15: Support code

Keypad is Active

Lock

Figure 16: Keypad is menu

Keypad is Locked

Unlocked Back

Figure 17: Locked keypad menu

6:1.3.2 Wrong password

If an incorrect password is entered, the text “Wrong Password” will be displayed, Figure 14.

A support code will be given, Figure 15. The code can be ignored and an unlimited number of attempts can be

made.

If you are unable to unlock the keypad, note the support code and contact your local ABB sales offi ce.

6:1.4 Locking/unlocking the keypad

1 Press the upper navigation key twice to enter the parameter Keypad is Figure 16. The keypad is unlocked if

the display indicates Active in the upper right corner.

2 Lock the keypad

Select Lock.

Enter the correct password.

Select Enter. Keypad is now locked.

Select Back to return to top level.

3 Unlock the keypad.

Select Unlock.

Enter the correct password.

Select Enter. The keypad is now active.

Select Back to return to top level.

6

Low Voltage Products & Systems 6.3

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 6

Human-Machine Interface (HMI)

6:2 Menu tree

6:2.1 Overview

The menu tree includes menus for:

• Settings

• Local Control

• Event Log

• Status information

• Reset events

Top level

6

Settings

Local Control

Event Log

Status Information

Reset Events

Application setting

Basic settings

Functional settings

Presentation settings

Service settings

All settings

Changed settings

Reset all settings

Operation mode

Start / Stop

Jog

DOL Start

Figure 18: Menu tree

Start / Stop

Protections

Warnings

Faults

Inputs

Outputs

Fieldbus

Seq. Start

Top level

Settings

Local Control

Event Log

Status Information

Reset Events

Figure 19: Top level

6:2.2 Top Level

Top Level contains general softstarter information, and the menus can be reached from

here.

Use the navigation keys to cycle through the various menus.

Press Select to enter a menu.

Press Back to return to previous state

Menu Description

Settings Set up softstarter parameters

Local control Control the softstarter

Event log

Status Information Present various information

Reset Events Reset of events

Present the Event Log, faults, protections,

warnings

6.4 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Chapter 6

Human-Machine Interface (HMI)

Top level

Top level

Settings

Local Control

Event Log

Status Information

Reset Events

Figure 20: Settings menu

Settings

Local Control

Event Log

Status Information

Reset Events

Figure 21: Local control menu

Application setting

Basic settings

Functional settings

Presentation settings

Service settings

All settings

Changed settings

Reset all settings

Operation mode

Start / Stop

Jog

DOL Start

6:2.3 Settings menu

The settings menu is used to set up the softstarter parameters for various applications.

Use the navigation keys to cycle through the various sub menus.

Function Description

Application setting Predefi ned parameters for typical ap-

Basic settings The basic and most used start/stop

Functional settings Language, date, time, etc.

Service settings Service and repair settings

All settings A list with all possible settings

Changed settings A list of all changed settings

Reset all settings Reset all settings to factory default

Operation mode Test mode for softstarter

plications

settings

settings

Figure 20: Settings menu

6:2.4 Local Control menu

The Local Control menu is used to start or stop the motor from the keypad. When local con-

trol is selected, the softstarter can only be controlled by the keypad.

The previous type of control is activated when exiting local control.

Three different selections are possible (see the table below).

Press navigation keys to view different types of local control.

Information!

The LOCAL CONTROL menu can not be entered if Sequence start is selected.

Once the motor has been started in this menu, it must fi rst be stopped before you leave the

menu. If the motor is already running when the menu is entered, it is possible to leave the

menu without stopping the motor.

Function Description

Start/stop To start and stop the motor with the

Jog To run the motor as long as Jog is

DOL start

(PSTB370...PSTB1050 only)

keypad

pressed

To start and stop the motor with the built-

in by-pass contactor. (See Chapter 3 for

AC3 ratings.)

Figure 21: Local control menu

6

Low Voltage Products & Systems 6.5

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Chapter 6

Human-Machine Interface (HMI)

6

Top level

Top level

Top level

Settings

Local Control

Event Log

Status Information

Reset Events

Figure 22: Start/Stop menu

Settings

Local Control

Event Log

Status Information

Reset Events

Figure 23: Jog menu

Settings

Local Control

Event Log

Status Information

Reset Events

Figure 24: DOL start menu

Start / Stop

Jog

DOL Start

Start / Stop

Jog

DOL Start

Start / Stop

Jog

DOL Start

6:2.4.1 Start/Stop the motor

Start

Enter the Start/Stop menu, Figure 22.

Select Start. The motor will now start and run according to the set parameters.

Stop

Select Stop. The motor will stop according to the set parameters. It is possible to press the stop

command during the start ramp if necessary.

6:2.4.2 Jog

Enter the Jog menu, Figure 23.

Select Jog. The motor will start and accelerate to rated speed according to the set parameters as

long as the Jog command is activated.

The motor stops immediately as soon as the command is released.

6:2.4.3 DOL start

(PSBT370...1050 only)

Start from the softstarter

If necessary, the motor can be started DOL (Direct On Line/across the line) with the integrated by-

pass contactor.

Select the DOL start menu, Figure 24.

Select DOL start to close the integrated by-pass contactor.

Select Stop to open the contactor.

!

Warning!

The rated motor current must never exceed the AC-3 rating of the integrated by-pass contactor.

See Chapter 3 for AC3 ratings.

100-250V

50/60 Hz

8

Figure 25: Connection when the contactor is operated

from the keypad (factory wiring).

Figure 26: Connection when the by-pass contactor is operated

separately (emergency DOL)

8

6.6 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Chapter 6

Human-Machine Interface (HMI)

Top level

Top level

Settings

Local Control

Event Log

Status Information

Reset Events

Figure 25: Event log menu

Settings

Local Control

Event Log

Status Information

Reset Events

Figure 26: Status information menu

6:2.5 Event Log menu

The Event Log menu is used to check the event log in the softstarter. When entering this menu, the

twenty latest events in the log are presented, in chronological order with the latest event as No. 1,

the second latest as No. 2 etc.

The events are presented with “type of event”, date and time.

Use the navigation keys to view all entries in the event log.

6:2.6 Status Information menu

The Status information menu is used to present various information.

Use the navigation keys to cycle through the various sub menus.

If the unit is connected “inside delta”, the displayed phase currents, L1, L2 & L3 are inside delta cur-

rent values.

Display text Function

Frequency Measured frequency

Phase seq Phase sequence indication

Connection Type of connection, In Line/Inside Delta

Phase L1 Phase current L1

Phase L2 Phase current L2

Phase L3 Phase current L3

Run time Total run time of the motor

No. of Starts Run counter

SW Ver. CU Software version CU.

SW Ver. FU Software version FU.

SW Ver KP 1

DB Version Database version

MAC Address Internal addressing

LV Board No Serial No of the LV PCB

Software version External Keypad

6

1 Only if connected.

Top level

Settings

6:2.7 Reset Events menu

The Reset Events menu is entered automatically when a fault has occurred or a protection is acti-

vated. It can also be entered through the main menu.

Local Control

Event Log

Status Information

Reset Events

Figure 27: Reset events menu

Low Voltage Products & Systems 6.7

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 132 021 M0201

Use the navigation keys to view all events. Each event can be reset.

Notes

6

6.8 Low Voltage Products & Systems

1SXU 132 021 M0201 ABB Inc. • 888-385-1221 • www.abb-control.com