Page 1

Data sheet DS/C1300–EN Rev. I

C1300

Advanced Circular Chart Recorder

C1300 – dependable recording

in a rugged, functional

instrument

High-definition backlit display

— latest LCD panel display technology ensures instrument

operation and configuration is as easy as possible

Simple-to-configure totalizers

— automatic calculation of the relationship between units of

measure and volume flow units

Designed to survive

— environmental protection options up to NEMA 4X for the

entire recorder, providing reliable operation for wall-, paneland pipe-mount versions

Data logging

— logging of totalizer and instantaneous readings to a

Compact Flash card

Fully field-upgradeable

— additional options easy to add

Configuration backup

— ability to backup and restore configurations from a PC

Page 2

C1300

Standard Hardware per Pen

Universal Input

Thermocouple

RTD

mA

V, mV

2-wire transmitter PSU

1 Relay Output

1 Analog Output

2 Digital Inputs

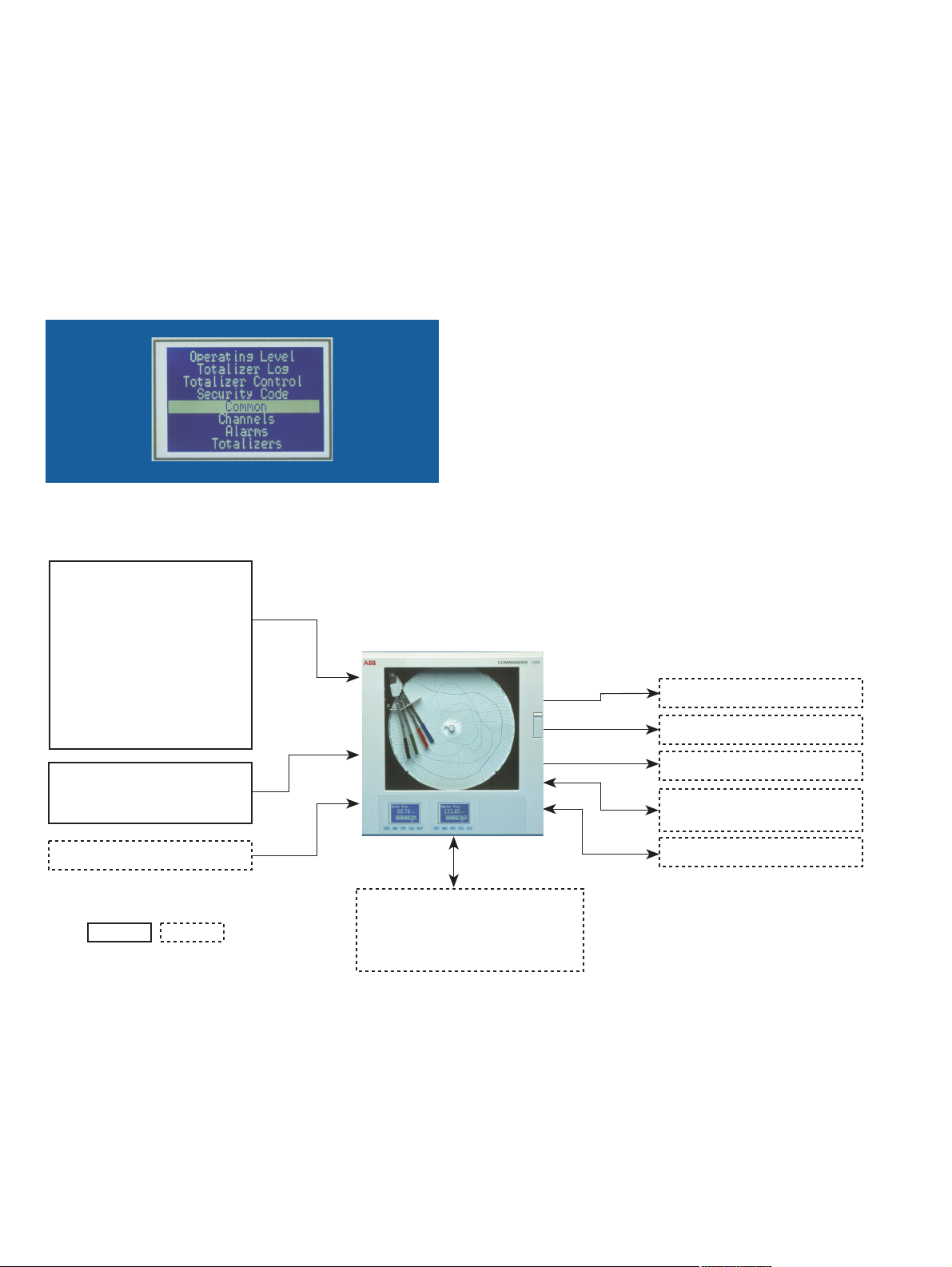

Optional Software Functions

Up to 4 Totalizers

2 Real-time Alarms (Timers)

4 Math Blocks

KEY:

Software Functions

Up to 16 Process Alarms

8 Logic Equations

Serial Communications

RS485 Modbus RTU

Up to 8 Additional Relays

Up to 16 Additional Digital Inputs

Up to 16 Additional Digital Outputs

True-time Event Pen

Standard

Option

Data Logging

Advanced Circular Chart Recorder

C1300

The C1300 is an advanced, programmable circular chart

recorder for up to four process signals. It combines traditional

circular chart values with data logging technology from ABB's

award-winning SM Series videographic recorders to create a

labour-saving recording solution. The C1300's straightforward

operator controls and robust construction make it suitable for a

variety of industrial environments. With many features supplied

as standard and a powerful range of options, the C1300 is a

truly flexible unit that can adapt to match your process

requirements.

Clear, Intuitive Display Menus

Comprehensive Process Information

The C1300 incorporates up to two graphical display panels to

keep the operator informed of process status. Each panel is

capable of displaying up to eight lines of descriptive text to

simplify both configuration and operation of the recorder. The

display technology used increases visibility in high ambient light

conditions.

Simple Operation

The clearly-labelled tactile keypad gives direct access for

operator adjustments and configuration, without the need to

open the recorder's door. Clear text prompts on the digital

displays guide the user through the various menus. A

password-protected security system prevents unauthorized

access to configuration adjustment menus.

2 DS/C1300–EN Rev. I

Page 3

C1300

AND

Channel 1

Alarm

Relay

Annunciator

Logic Equation

Timer 1

12

6

3

9

11

10

1

2

5

7

4

8

Advanced Circular Chart Recorder

Advanced Totalizer Technology

The C1300 features some of the most advanced totalizing

features of any recording instrument, giving it the ability to

autoconfigure totalizers to specific requirements. For example, it

is possible to measure flow in one volumetric unit and totalize in

another; the C1300 automatically calculates the relationship

between the two volume units and configures this information.

No longer is it necessary to deal with unit conversion tables and

timebases.

Totalizer control is enhanced further by reset functionality that is

set in real-time. If the totalizer is required to reset at midnight

every Sunday simply set it to do so. Totalizer logs also eliminate

the requirement for the operator to go to the recorder at the

same time each day to take readings. The totalizer log contains

historical information of the date, time and individual totalizer

values; enabling comparison of process volumes directly from

the front panel of the recorder.

Timers and Clock

The C1300 provides two event timers driven by the recorder's

real-time clock. The timers can be configured to operate relays,

start/stop the chart or trigger other actions within the recorder;

such as allowing alarm annunciation only during night hours.

Alarm Annunciation Enabled During Night Hours Only

Comprehensive Flow Totalizer Displays

PC Configuration Backup

Fitted as standard to every C1300 is a PC Configuration Backup

port. Using this port, an instrument's configuration can be both

uploaded and downloaded to a PC, enabling a backup of a

recorder's configuration to be saved for future use.

Configuration time of multiple units with similar configurations is

also greatly reduced via use of this feature.

Connecting Your PC to the Recorder

DS/C1300–EN Rev. I

3

Page 4

C1300

Flow A

Flow B

Flow C

A + B + C

Math Equation

Totalizer

C1300

Advanced Circular Chart Recorder

Math and Logic

Optional math functions, mass flow calculations and RH tables

are available, enabling the solving of real process problems,

quickly and simply. Math functions include addition, subtraction,

multiplication and division.

Logic capability is provided as standard, for interlocking and

integration of discrete and continuous functions to address a

wide range of process criteria.

Boolean logic functions enable the grouping of alarms to a

single 'common-trouble' relay, saving time and money or

allowing interlocking to create almost infinite combinations of

'If…Then' scenarios.

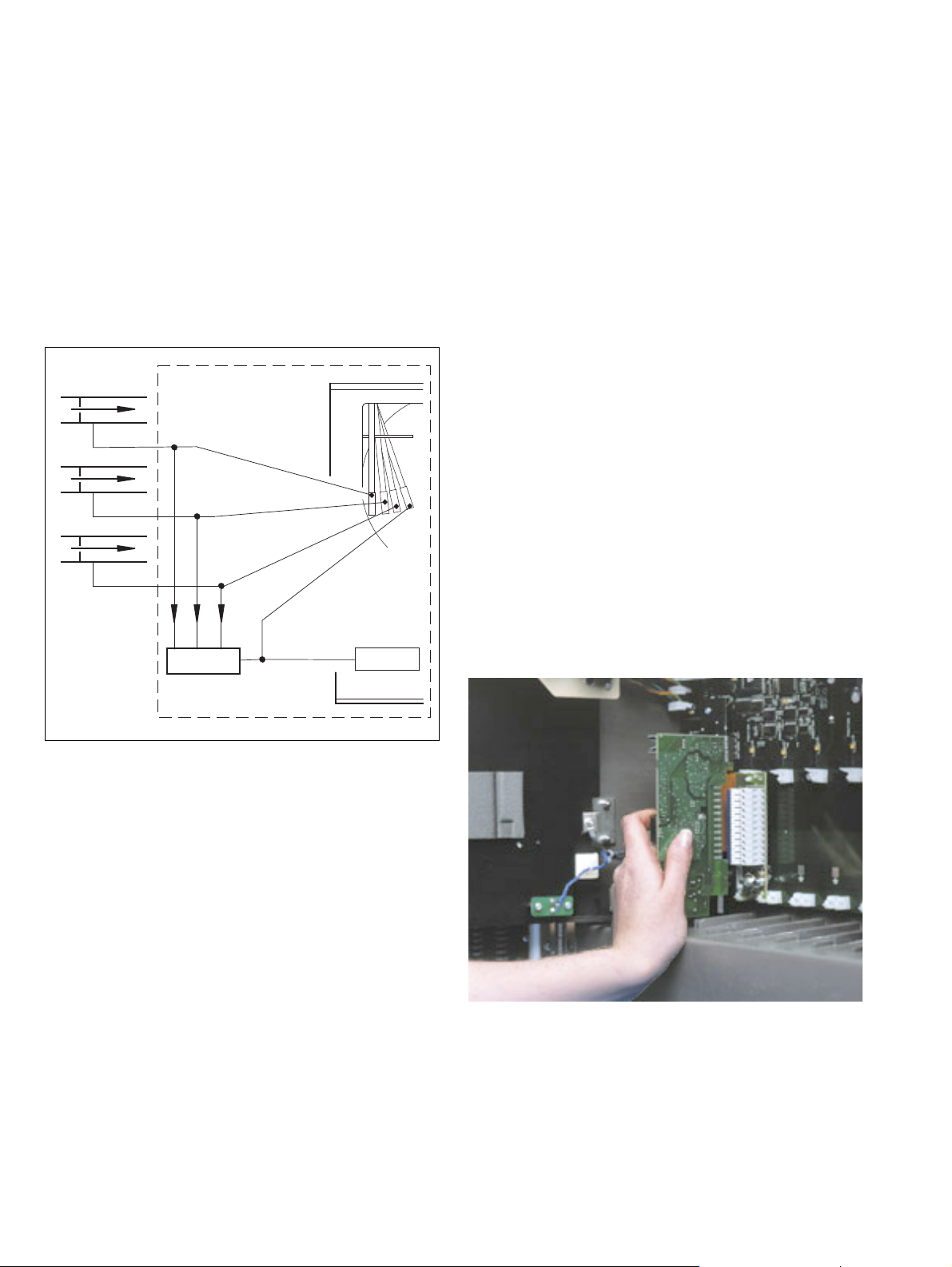

Built to Meet Your Needs

The C1300's modular architecture enables a high level of

hardware choice.

The standard input/output module supplied with every pen

comes complete with a fully isolated universal analog input, a

relay output, transmitter power supply, an isolated analog output

and two digital inputs.

Further input and output capability is provided by a range of

plug-in modules:

Four relays – channel alarm outputs

Eight digital inputs – linked using logic equations

Eight digital outputs – TTL level alarm outputs

True-time event pen (Violet) – event pen is additional to

standard pens

Modbus RS485 communications – interfaces with PCs

Data logging – to Compact Flash card

Expandable for the Future

The C1300 can be upgraded quickly to meet your changing

process requirements.

Additional recording channels, math capability or input and

output functions can be retrofitted on-site using plug-in modules

and easily-fitted pen arms. Input calibration data is stored on

each card, enabling quick changes of input modules without the

need for recalibration.

Changes to input sensors or recording requirements are

accommodated by reconfiguration using the keypad.

Summation of Three Flows

4 DS/C1300–EN Rev. I

Modular Design Enables Unit to be Upgraded Quickly

Modbus RS485 Communications

Communications with PCs or PLCs are achieved via the RS485

serial communications link, enabling the C1300 to serve as the

front end of plant-wide data acquisition systems. Using Modbus

RTU protocol all process inputs and other variables can be read

continuously by a host PC running any of a wide range of

standard SCADA packages.

Page 5

C1300

Pipe-mounting

Wall-mounting

Panel-mounting

Advanced Circular Chart Recorder

4-Pen Recording

Available with up to four trending pens, the C1300 enables pen

ranges to be configured independently from each other and their

corresponding inputs. This enables the pens to be scaled to the

best effect and potentially minimizes the requirement for costly

multiple-scaled consumables. The C1300 also offers a true-time

event-pen facility that ensures that process actions are logged

on the same timeline as Pen 1.

4-pen Recorder with Two Graphical Display Panels

Designed to Survive

Optional NEMA 4X protection ensures the C1300 can survive in

the harshest environments and makes the recorder ideal for use

in panels that are hosed down regularly. The tough,

acid-resistant case provides NEMA 4X rating for all mounting

options.

Easy to Install

A choice of mounting options enables simple installation of the

recorder in a panel, on a wall or on a pipe. Detachable terminal

blocks provide trouble-free connection of input and output

wiring. Mains isolation can be provided by an optional power

switch within the instrument.

Data Logging

The C1300 can be fitted with a data logging option that

automatically stores the totalizer log entries and instantaneous

channel data to a Compact Flash card. Once logged to a card,

ABB's DataManager software can be used to analyze the

totalizer log and create graphs of the instantaneous data.

Simple operation is ensured due to the automatic initiation of

logging upon the insertion of a Compact Flash card and

extremely simple card removal procedure.

As a result of the large capacity of Compact Flash cards,

exceptionally long recording durations can be achieved which

minimizes the requirement for operator intervention to retrieve

data.

The Compact Flash card is located behind the door of the

recorder and can be protected by the optional door lock.

Choice of Mounting Options

Summary

1, 2, 3 or 4 pens

10 in. or 105mm chart size

Standard I/O with each pen includes:

analog input, analog output, transmitter power supply,

relay output and 2 digital inputs

Removing Compact Flash Card

DS/C1300–EN Rev. I

5

Page 6

C1300

Advanced Circular Chart Recorder

Specification

Construction

Size 15.23 in. (h) x 15.04 in. (w) x 5.57 in. (d)

(386.8 x 382.0 x 135mm)

Weight 18lb (8.2kg)

Case material Glassfiber-filled reinforced polyester

Window material Polycarbonate or glass

Door latch High-compression with optional lock

Environmental

Operational temperature range 0° to 55°C (32° to 130°F)

Operational humidity range 5 to 95%RH (non-condensing)

5 to 80%RH (chart only)

Case sealing NEMA 3 (IP54)

NEMA 4X (IP66) (optional)

Installation

Mounting options Panel, wall or pipe

Ter m i n a l typ e Sc r e w

Wire size (max) 14 AWG (I/O), 12 AWG (power)

Operation and Configuration

Programming method Via front panel keys

Security Password-protected menus

Safety

Power Supply

Voltage 100 to 240V AC ±10%

(90V min. to 264V AC max.), 50/60Hz

Consumption <30 VA (typical for full spec. unit)

Line interruption Up to 60ms

Process Inputs and Outputs

General

Noise Rejection Common mode

>120dB at 50/60Hz

Normal (series) mode

>60dB at 50/60Hz

CJC rejection ratio <0.05°C/°C (0.1°F/°F)

Sensor break protection Upscale or downscale drive

Out of range detection 0 to 100% of engineering span

Temperature stability <0.02% of reading/°C

(0.04% of reading/°F) or 1µV/°C

Long-term drift <0.01% of reading or 10µV annually

Input impedance >10MW (mV and V inputs)

39W (mA input)

Analog Inputs

Signal types mV, V, mA, W

Thermocouple types B, E, J, K, N, R, S, T

Resistance thermometer Pt 100

1/2

3/2

Other linearizations x

Sample interval 250ms per channel

Dielectric 500V DC channel/channel

Digital Filter 0 to 60s (programmable)

, x

, x

5/2

, linear

General safety EN61010

Installation category II

Pollution degree 2

Dielectric 500V DC (channel/channel)

2kV DC (channel/ground)

Memory protection Nonvolatile FRAM

Approvals CE

CSA General Safety (option)

UL General Safety (option)

Ty pe Range Low Range High Minimum Span Accuracy

mV 0 150 5 ±0.1% reading or 10µV

V 0 5 0.1 ±0.1% reading or 20mV

mA 0 50 1 ±0.2% reading or 0.2µA

Ohms (low) 0 750 20 ±0.2% reading or 0.1W

Ohms (high) 0 10k 400 ±0.5% reading or 10

Analog Input Performance

6 DS/C1300–EN Rev. I

Page 7

C1300

Advanced Circular Chart Recorder

Ty pe

B –18 1800 0 3270 ±2.0°C (above 200°C) (3.6°F [above 434°F])

E –100 900 –140 1650 ±0.5°C (0.9°F)

J –100 900 –140 1650 ±0.5°C (0.9°F)

K –100 1300 –140 2350 ±0.5°C (0.9°F)

N –200 1300 –325 2350 ±0.5°C (0.9°F)

R –18 1700 0 3000 ±1.0°C (above 300°) (1.8°F [above 572°F])

S –18 1700 0 3000 ±1.0°C (above 200°C) (1.8°F [above 434°F])

T –250 300 –400 550 ±0.5°C (0.9°F)

PT100 –200 600 –325 1100 ±0.5°C (0.9°F)

Range Low Range High Range Low Range High

°C °F

Accuracy (excluding CJC)

Thermocouple Performance

2-Wire Transmitter Power Supplies

Number 1 per channel

Voltage 24V DC nominal

Drive Up to 25mA

Isolation 500V DC channel-to-channel

Analog Outputs

Typ e 4 t o 2 0 m A

Accuracy ±0.1%

Maximum load 750W

Dielectric 500V DC

Relay Outputs

Type SPDT

Rating (with non-inductive load) 5A at 115/230V AC

Digital Outputs

Type 5V TTL

Rating 5mA per output

Dielectric 500V DC between modules,

no isolation within module

Serial Communications

Connections RS485, 4-wire

Protocol Modbus RTU

Data Logging

Memory card type Compact Flash Type 1

Card size Max. 1Gb

Recording Duration See table below

Digital Inputs

Type TTL or volt-free

Minimum pulse 250ms

Dielectric 500V DC between modules,

no isolation within module

(4 Channels) 128Mb 256Mb 512Mb 1Gb

1 s 1.1 months 2.3 months 4.5 months 8.8 months

5 s 5.6 months 11.3 months 1.9 years 3.6 years

10 s 11.3 months 1.9 years 3.7 years 7.2 years

30 s 2.8 years 5.6 years 11.1 years 21.7 years

60 s 5.6 years 11.1 years 22.2 years 43.4 years

5 min. 27.8 years 55.5 years 111.0 years 216.8 years

10 min. 55.5 years 111.0 years 222.1 years 433.7 years

30 min. 166.5 years 333.1 years 666.2 years 1301.1 years

1 hour 333.1 years 666.2 years 1332.3 years 2602.2 years

6 hour 1998.5 years 3996.9 years 7993.9 years 15613.1 years

Recording Duration

DS/C1300–EN Rev. I

7

Page 8

C1300

Advanced Circular Chart Recorder

Recording System

Pens

Number 1, 2, 3, or 4 (red, green, blue, black)

Response 7 seconds (full scale)

Resolution 0.1% steps

Pen lift Motor-driven, with optional autodrop

Event Pens

Standard 3-position event recording on any channel

Real time 3-position event recording on the same time

line as Pen 1

Chart

Chart size 10 in. or 105mm

Chart speed 1 to 167 hours or 7 to 32 days per revolution

Rotation accuracy <0.5% of rotation time

Graphical Display Panels

Displays

Number 1 (1 or 2 pens) or 2 (3 or 4 pens)

Type High contrast 128 x 64 STN dot matrix LCD

(graphics) module

Status indicators Indicate channel number on display

Alarm indicators Indicate channel with active alarms

Logic Equations

Number 4

Function OR, AND

Inputs Alarm states, digital inputs, totalizers, logic

Outputs Relays, digital outputs, chart stop,

alarm acknowledge

Advanced Software Functions

Totalizers

Number Up to 4

Size 999,999,999 max.

Output External counter driver, 'wrap' pulse signal

Totalizer log Max. 21 entries per totalizer

Math

Number of equations 4

Type +, –, x, ÷, low & high select, maximum,

minimum, average, mass flow, RH

Timers

Number 2

Type Real-time clock driven event,

adjustable duration

Output Relay, digital output, logic equation

Panel keys

Function Programming access, increment/decrement,

pen lift and menu key

Alarms and Logic

Alarms

Number 4 per channel

Type High/low process, fast/slow rate of change,

time delay

Adjustments Hysteresis, time delay

Alarm indicators Indicate channel with active alarms

I/O Per Module

Module Type

Analog I/P Analog O/P Tr a n s . P SU Relays Digital I/P Digital O/P Comms.

Standard I/O 1 1 1 1 2 4

4 relays 4 2

8 digital I/P 83

8 digital O/P 83

RS485 comms. 11

EMC

Emissions and Immunity

Meets requirements of:

EN50081-2

EN50082-2

EN61326 for an industrial environment

CE Mark

Max. No. Per

Instrument

Option Module Types

8 DS/C1300–EN Rev. I

Page 9

C1300

3

6

+

e Thermocouple

1

2

7

8

9

10

11

12

Analog Output

+

Relay

Output

Normally Open

Common

Normally Closed

Logic Inputs

Common

Logic 1

Logic 2

Analog Input see b to h

3

4

5

6

Summary of Connections

4

6

+

+

Tx

d 2-wire Transmitter

3

6

+

g Low Voltage (mV)

3

4

+

c Current

(non 2-wire Transmitters)

3

6

+

b Voltage

Standard Input/Output Modules

1

2

7

8

9

10

11

12

3

4

5

6

Normally Closed

Normally Open

Relay 1

Common

Normally Closed

Normally Open

Relay 2

Common

Normally Closed

Normally Open

Relay 3

Common

Normally Closed

Normally Open

Relay 4

Common

Four-Relay Output Module

1

2

7

8

9

10

11

12

3

4

5

6

Common

Input 1

Common

Input 7

Input 8

Input

Connections

Input 5

Input 6

Input 3

Input 4

Input 2

Common

Output 1

Common

Output 7

Output 8

Output

Connections

Output 5

Output 6

Output 3

Output 4

Output 2

or

Digital Input/Output Module

4

5

6

Red

White

Red

f 3-wire RTD

5

6

White

Red

Link

4

h 2-wire RTD and

Resistance

Power Switch (Optional)

Fuse (Optional)

X

Line

Neutral

Earth (Ground) Stud

2 3 4 5 6

Advanced Circular Chart Recorder

Electrical Connections

Power Supply Connections

DS/C1300–EN Rev. I

9

Page 10

C1300

8.3 (0.32)

320.8 (12.63)

320.8

(12.63)

56.8

(2.23)

30.1 (1.18)30.1 (1.18)

66 (2.60)

35.1 (1.38)

22.4 (0.94)

183.4

(7.22)

36.6 (1.44) Typical Space Between

Adjacent Knockout Centers

33 (1.30)

386.8

(15.23)

382 (15.04)

323

(12.72)

323

(12.72)

Panel Cut-out Size

360.4

(14.19 )

285.75

(11.25)

355.6

(14.00)

16.25 (0.64)

43.2

(1.70)

Wall-mount Dimensions

4 holes 7.14 (0.281) dia.

or tap for

1

/4 in. thread

Dimensions in mm (in.)

Advanced Circular Chart Recorder

Overall Dimensions

10 DS/C1300–EN Rev. I

Page 11

C1300

Advanced Circular Chart Recorder

Ordering Information

C1300 Advanced Circular Chart Recorder 131 X XXXXXXXXXXXXXXXX

Pens

One Pen (Red)

Two Pens (Red, Green)

Three Pens (Red, Green, Blue)

Four Pens (Red, Green, Blue, Black)

Chart Type

Standard (ER/C)

KPC 105 PX and PXR type charts

Chessell Brand charts

Electrical Code

Standard

CSA approved

UL approved

Software Options

None

1 Totalizer, Math & Timers

2 Totalizers, Math & Timers

3 Totalizers, Math & Timers

4 Totalizers, Math & Timers

Environmental Protection

IP54 & NEMA3

IP66 & NEMA4X

Door Color

ABB standard

Grey

Window Material

Glass

Polycarbonate

Door Lock

No lock

Lock fitted

Power Supply

100 to 240V AC ±10% (90V min. to 264V) max.

100 to 240V AC ±10% (90V min. to 264V) max. with on/off switch

I/O Modules Module Type (see key on back page)

Module Position 2/Channel 2 Input* 01

Module Position 3/Channel 3 Input* 0 1

Module Position 4/Channel 4 Input* 013456

Module Position 5 0 3 4 5 8

Module Position 6 0458L

Special Settings

Company standard

Customer setting

Special

* On 2, 3 or 4 pen instruments, a standard I/O module is always fitted in the corresponding module position

(enter '0' in the corresponding order code field)

1

2

3

4

J

K

C

A

C

U

0

1

2

3

4

0

N

0

G

G

P

0

L

1

2

STD

CUS

SXX

DS/C1300–EN Rev. I

11

Page 12

C1300

Advanced Circular Chart Recorder

Standard Accessories

(supplied with each recorder)

Set of pens

Pack of 10 charts (0 to 100, 24 hour)

Wall-mount kit

Optional Accessories

Part No. Description

C100/0051 PC configuration backup cable

C1900/1713 Pipe-mount kit

SW/DATMGR DataManager Software

B12028 Card Reader

B11867 Compact Flash Card

12 DS/C1300–EN Rev. I

Page 13

C1300

65432

2 3 4 5 61

Advanced Circular Chart Recorder

…Ordering Information

Module Positions

0 No module fitted/pen input channel

1 Standard input/output

3Four relays

4 Eight digital inputs

5 Eight digital outputs

6 True-time event pen –Violet (additional to standard pens)

8 Modbus RS485 communications

L Data logging

Key to Module Types

DS/C1300–EN Rev. I

13

Page 14

C1300

Advanced Circular Chart Recorder

Notes

14 DS/C1300–EN Rev. I

Page 15

C1300

Advanced Circular Chart Recorder

DS/C1300–EN Rev. I

15

Page 16

Contact us

ABB Limited

Process Automation

Howard Road

St. Neots

Cambridgeshire PE19 8EU

UK

Tel: +44 (0)1480 475321

Fax: +44 (0)1480 217948

ABB Inc.

Process Automation

125 E. County Line Road

Warminster

PA 18974

USA

Tel: +1 215 674 6000

Fax: +1 215 674 7183

www.abb.com

Note

We reserve the right to make technical changes or

modify the contents of this document without prior

notice. With regard to purchase orders, the agreed

particulars shall prevail. ABB does not accept any

responsibility whatsoever for potential errors or

possible lack of information in this document.

We reserve all rights in this document and in the

subject matter and illustrations contained therein.

Any reproduction, disclosure to third parties or

utilization of its contents in whole or in parts – is

forbidden without prior written consent of ABB.

Copyright© 2011 ABB

All rights reserved

3KXR200102R1001

Modbus™ is a trademark of Modicon, Inc.

DS/C1300–EN Rev. I 07.2011

Loading...

Loading...