Page 1

ABB industrial drives

Firmware manual

ACS880 IGBT supply control program

Page 2

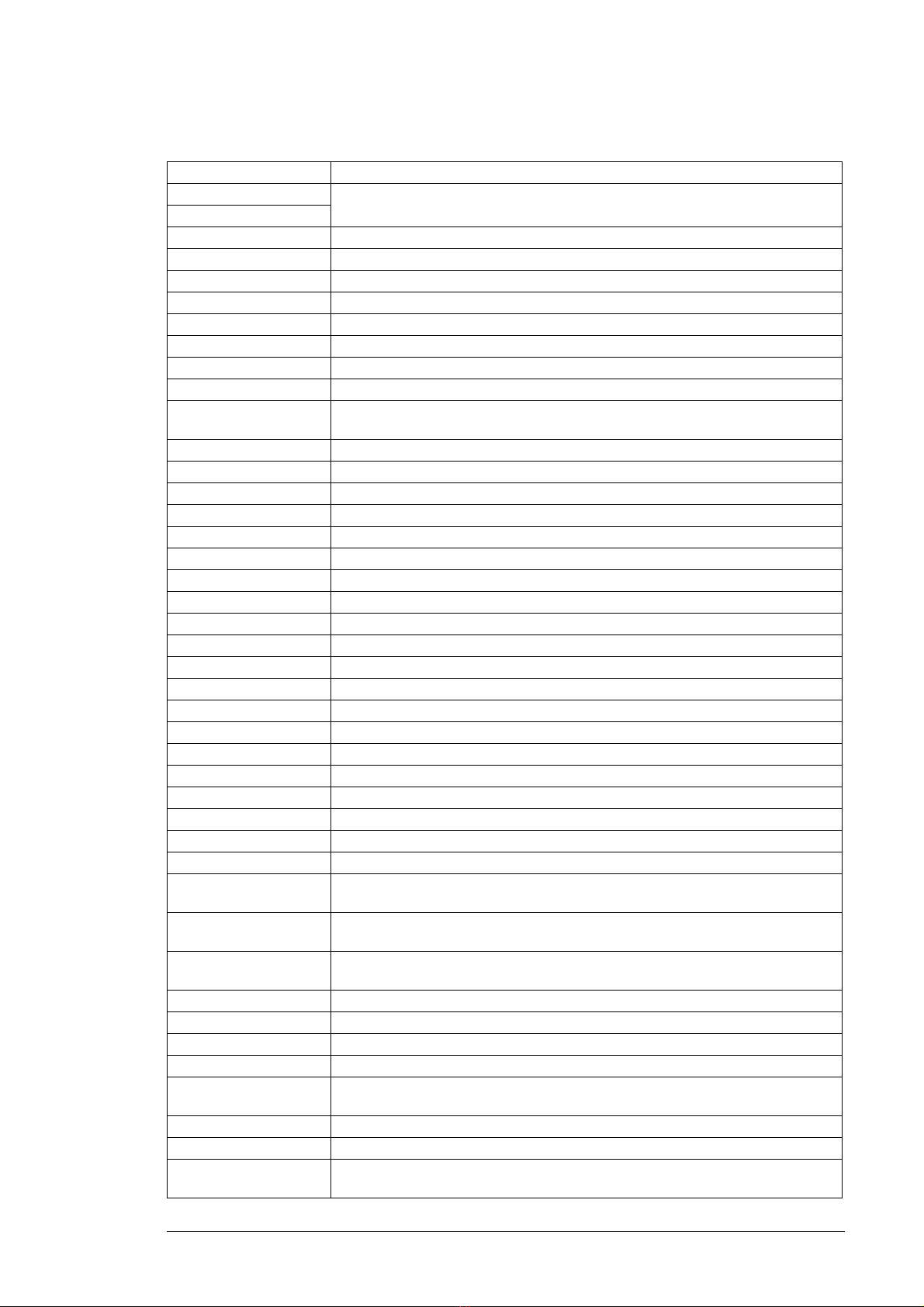

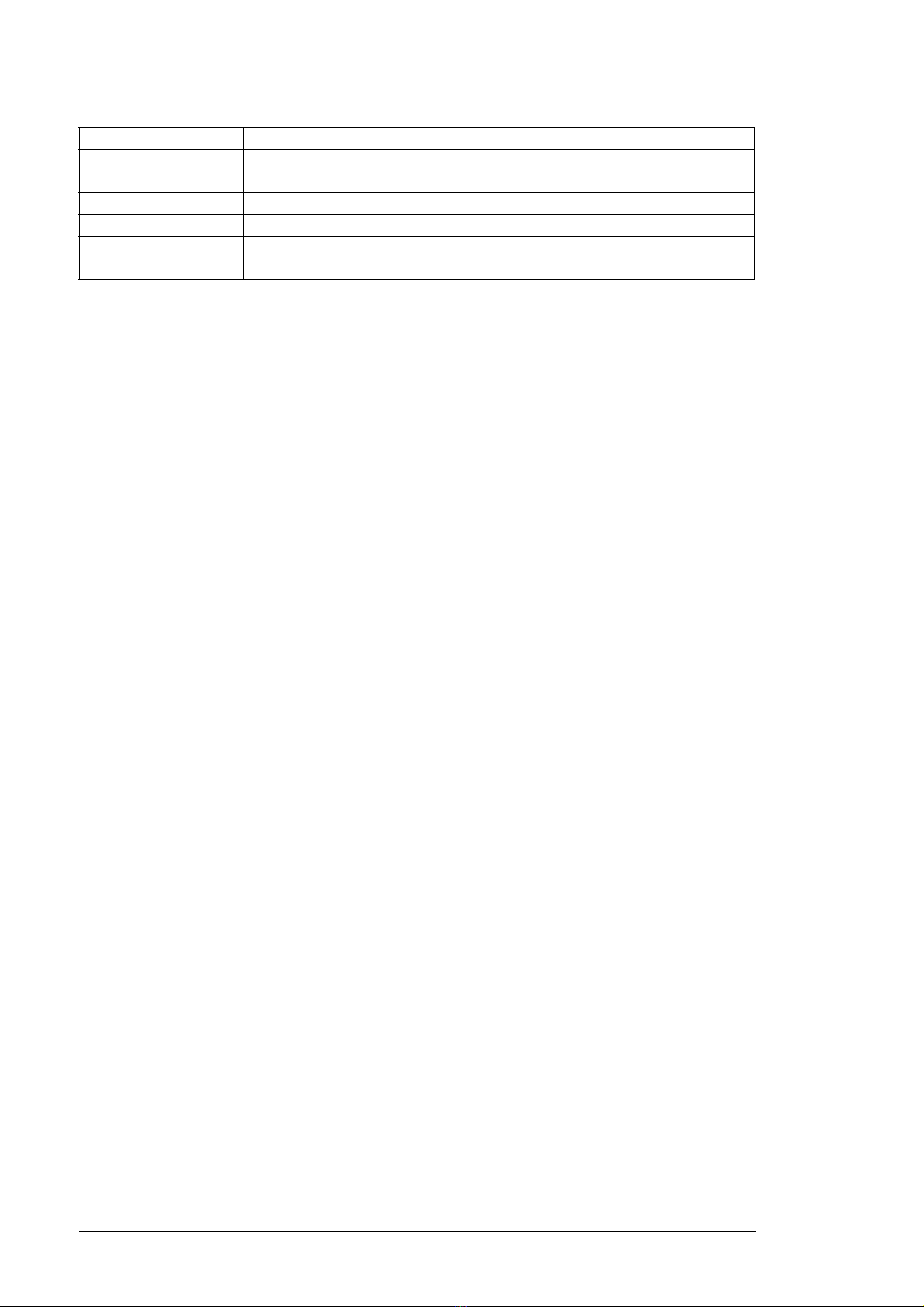

List of related manuals

General manuals Code (English)

Safety instructions for ACS880 multidrive cabinets and modules 3AUA0000102301

Electrical planning instructions for ACS880 multidrive cabinets

and modules

Mechanical installation instructions for ACS880 multidrive

cabinets

Cabinet design and construction instructions for ACS880 air-

cooled and liquid-cooled multidrive modules

Inverter module manuals and guides

ACS880-104 inverter modules hardware manual 3AUA0000104271

ACS880-104LC inverter modules hardware manual 3AXD50000045610

ACS880 primary control program firmware manual 3AUA0000085967

ACS880 primary control program quick start-up guide 3AUA0000098062

Supply module manuals

ACS880-204 IGBT supply modules hardware manual 3AUA0000131525

ACS880 IGBT supply control program firmware manual 3AUA0000131562

ACS880-304 +A003 diode supply modules hardware manual 3AUA0000102452

ACS880-304 +A018 diode supply modules hardware manual 3AXD50000010104

ACS880-304LC+A019 diode supply modules hardware manual 3AXD50000045157

ACS880 diode supply control program firmware manual 3AUA0000103295

ACS880-904 regenerative rectifier modules hardware manual 3AXD50000020457

ACS880 regenerative rectifier control program firmware manual 3AXD50000020827

3AUA0000102324

3AUA0000101764

3AUA0000107668

Brake module and DC/DC converter module manuals

ACS880-604 1-phase brake chopper units as modules hardware

manual

ACS880-604 3-phase brake modules hardware manual 3AXD50000022033

ACS880 brake control program firmware manual 3AXD50000020967

ACS880-1604 DC/DC converter modules hardware manual 3AXD50000023642

ACS880 DC/DC converter control program firmware manual 3AXD50000024671

Cabinet-installed multidrive manuals

ACS880-107 inverter units hardware manual 3AUA0000102519

ACS880-207 IGBT supply units hardware manual 3AUA0000130644

ACS880-307 (+A003) diode supply units hardware manual 3AUA0000102453

ACS880-307 +A018 diode supply units hardware manual 3AXD50000011408

ACS880-607 1-phase brake units hardware manual 3AUA0000102559

ACS880-607 3-phase brake units hardware manual 3AXD50000022034

ACS880-907 regenerative rectifier units hardware manual 3AXD50000020546

ACS880-1607 DC/DC converter units hardware manual 3AXD50000023644

Option manuals and guides

ACX-AP-x assistant control panels user’s manual 3AUA0000085685

Drive composer start-up and maintenance PC tool user’s manual 3AUA0000094606

Manuals and quick guides for I/O extension modules, fieldbus

adapters, safety options, application programs etc.

3AUA0000106244

You can find manuals and other product documents in PDF format on the Internet. See section

Document library on the Internet on the inside of the back cover. For manuals not available in the

Document library, contact your local ABB representative.

Page 3

Firmware manual

ACS880 IGBT supply control program

Table of contents

2. Start-up

2017 ABB Oy. All Rights Reserved.

3AUA0000131562 Rev F

EN

EFFECTIVE: 2017-08-30

Page 4

Page 5

5

Table of contents

1. Introduction to the manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Contents of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cybersecurity disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2. Start-up

3. Using the control panel

4. Control locations and operating modes

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Local control vs. external control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

External control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Local control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5. Program features

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Overview of the control program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Control program configuration and programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Application programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Programming via parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Run enable, Start/stop and Start enable control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Settings and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Programmable analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Programmable analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Programmable digital inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Programmable relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Programmable I/O extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

External controller interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reference chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DC voltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Active power control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Reactive power control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Net lost detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Settings and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Reduced run function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Activation of the reduced run function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 6

6

Settings and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Programmable protection functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

External events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Earth fault detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

External earth leakage fault source selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

External earth leakage action selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Supply phase loss detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Local control loss detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Automatic fault resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Thermal switch monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Power limiting due to heat rise in the supply module . . . . . . . . . . . . . . . . . . . . . . . . 34

Counting the number of charging attempts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DC overvoltage and undervoltage protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Maintenance timers and counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

User parameter sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Settings and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

User lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Data storage parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Settings and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Settings and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DDCS communication with inverter unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Settings and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Default I/O connection diagram (BCU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Default I/O connection diagram (ZCU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Parameters that define the use of relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Parameters that define the use of digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Power share with droop control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Master/follower link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Before start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Master/follower functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Construction of the master/follower link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Example parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Specifications of the fiber optic master/follower link . . . . . . . . . . . . . . . . . . . . . . . . . 53

Settings and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6. Parameters

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Reserved digital inputs and relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Summary of parameter groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Parameter listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

101 Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

103 Input references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

104 Warnings and faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Page 7

7

105 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

106 Control and status words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

107 System info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

110 Standard DI, RO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

111 Standard DIO, FI, FO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

112 Standard AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

113 Standard AO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

114 Extension I/O module 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

115 Extension I/O module 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

116 Extension I/O module 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

119 Operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

120 Start/stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

121 Start/stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

122 Power reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

123 DC voltage reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

124 Reactive power reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

130 Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

131 Fault functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

133 Generic timer & counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

136 Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

146 Monitoring settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

147 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

149 Panel port communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

150 FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

151 FBA A settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

152 FBA A data in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

153 FBA A data out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

154 FBA B settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

155 FBA B data in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

156 FBA B data out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

160 DDCS communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

161 DDCS transmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

162 DDCS receive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

195 HW configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

196 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

7. Additional parameter data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Fieldbus addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Parameter groups 101…107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Parameter groups 110…196 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

8. Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

How to reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Warning/fault history and analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Event logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Other data loggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Parameters that contain warning/fault information . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Fault and warning words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Page 8

8

Warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

9. Fieldbus control through the embedded fieldbus interface (EFB)

10. Fieldbus control through a fieldbus adapter

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Basics of the fieldbus control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Control word and Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Contents of the fieldbus Control word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Contents of the fieldbus Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

The state diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Setting up the IGBT supply unit for fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Setting up communication through inverter unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

11. Drive-to-drive link

12. Control chain diagrams

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

DC voltage reference chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Power reference chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Reactive power reference chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Reactive power control overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Reactive power control detail – Processing of the reference type AC voltage . . . . 251

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Providing feedback on ABB manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Page 9

Introduction to the manual 9

1

Introduction to the manual

What this chapter contains

This chapter describes the contents of the manual. It also contains information on the

compatibility, safety and intended audience.

Applicability

This manual applies to ACS880 IGBT supply control program (AISLX v2.6x or later) and

ACS880 IGBT supply control program 2Q (ALHLX v2.6x or later) used in ACS880 drives.

The manual covers two versions of the control program: IGBT supply control program for

the regenerative drives, and IGBT supply control program for the ultra-low harmonic drives

(non-regenerative). The regenerative drives are ACS880 multidrive with IGBT supply unit,

ACS880-14 and ACS880-17. The ultra-low harmonic drives are ACS880-34 and

ACS880-37.

Safety instructions

Follow all safety instructions delivered with the drive.

• Read the complete safety instructions before you install, commission, or use the

drive. See ACS880 multidrive cabinets and modules safety instructions

(3AUA0000102301 [English]).

• Read the firmware function-specific warnings and notes before changing

parameter values. These warnings and notes are included in the parameter

descriptions presented in chapter Parameters.

Target audience

This manual is intended for people who design, commission, or operate the drive system.

Page 10

10 Introduction to the manual

Contents of the manual

This manual consists of the following chapters:

• Start-up refers to where the start-up procedure of the supply unit is described.

• Using the control panel provides the basic instructions for use of the control panel.

• Control locations and operating modes describes the control locations and operating

modes supported by the control program.

• Program features describes the features and I/O interface of the control program.

• Parameters describes the parameters of the control program.

• Additional parameter data contains further information on the parameters.

• Fault tracing lists the warning and fault messages with possible causes and remedies.

• Fieldbus control through the embedded fieldbus interface (EFB) describes the

communication to and from a fieldbus network using the embedded fieldbus interface.

• Fieldbus control through a fieldbus adapter describes the communication to and from

a fieldbus network using an optional fieldbus adapter module.

• Drive-to-drive link describes the communication between drives connected together

by the drive-to-drive (D2D) link.

• Control chain diagrams presents the control chain diagrams of the control program.

Related documents

A list of related manuals is printed on the inside of the front cover.

Page 11

Introduction to the manual 11

Terms and abbreviations

Term/abbreviation Definition

ACS-AP-I Types of control panel used with ACS880 drives

ACS-AP-W

ADC Analog-to-digital converter

AI Analog input; interface for analog input signals

AO Analog output; interface for analog output signals

BCU Type of control unit used in ACS880 drives.

BU Branching unit

Control board Circuit board in which the control program runs.

Control unit Control board built in a rail-mountable housing

DC link DC circuit between rectifier and inverter

DDCS Distributed drives communication system; a protocol used in optical fiber

communication

DI Digital input; interface for digital input signals

DIO Digital input/output; interface that can be used as a digital input or output

DO Digital output; interface for digital output signals

EFB Embedded fieldbus

FAIO-01 Optional analog I/O extension module

FBA Fieldbus adapter

FIO-01 Optional digital I/O extension module

FIO-11 Optional analog I/O extension module

FCAN-0x Optional CANopen® adapter

FCNA-0x Optional ControlNet™ adapter

FDCO-0x Optional DDCS communication module

FDIO-01 Optional digital I/O extension module

FDNA-0x Optional DeviceNet™ adapter

FEA-03 Optional I/O extension adapter

FECA-01 Optional EtherCAT® adapter

FENA-11 Optional EtherNet/IP™, Modbus TCP® and PROFINET IO® adapter

FENA-21 Optional dual-port EtherNet/IP, Modbus TCP and PROFINET IO adapter

FEPL-0x Optional Ethernet POWERLINK adapter

FPBA-0x Optional PROFIBUS DP® adapter

FSCA-0x Optional Modbus® adapter

IGBT Insulated gate bipolar transistor; a voltage-controlled semiconductor type widely

used in converters due to their easy controllability and high switching frequency

IGBT supply unit (ISU) IGBT supply module(s) under control of one control board, and related

components such as LCL filters, main contactor, fuses etc.

Inverter unit (INU) Inverter module(s) under control of one control board, and related components.

One inverter unit typically controls one motor.

I/O Input/Output

LCL filter Inductor-capacitor-inductor filter for attenuating harmonics

LSB Least significant bit

LSW Least significant word

MCB Main circuit breaker. Electrically-controlled main switching and protecting device.

A withdrawable breaker can also be used as the main disconnector.

MSB Most significant bit

MSW Most significant word

Parameter User-adjustable operation instruction to the drive, or signal measured or

calculated by the drive

Page 12

12 Introduction to the manual

Term/abbreviation Definition

PLC Programmable logic controller

RDCO-0x DDCS communication module

RO Relay output; interface for a digital output signal. Implemented with a relay.

STO Safe torque off

ZCU Type of control unit used in ACS880 drives.

The control unit may be fitted onto the power module, or installed separately.

Cybersecurity disclaimer

This product is designed to be connected to and to communicate information and data via

a network interface. It is Customer's sole responsibility to provide and continuously ensure

a secure connection between the product and Customer network or any other network (as

the case may be). Customer shall establish and maintain any appropriate measures (such

as but not limited to the installation of firewalls, application of authentication measures,

encryption of data, installation of anti-virus programs, etc) to protect the product, the

network, its system and the interface against any kind of security breaches, unauthorized

access, interference, intrusion, leakage and/or theft of data or information. ABB and its

affiliates are not liable for damages and/or losses related to such security breaches, any

unauthorized access, interference, intrusion, leakage and/or theft of data or information.

See also section User lock (page 37).

Page 13

2

Start-up

Start-up 13

See the appropriate hardware manual. See List of related manuals on page 2.

Page 14

14 Start-up

Page 15

3

Using the control panel

Using the control panel 15

See ACX-AP-x assistant control panels user’s manual (3AUA0000085685 [English]).

Page 16

16 Using the control panel

Page 17

Control locations and operating modes 17

4

Control locations and operating modes

What this chapter contains

This chapter describes the control locations and operating modes supported by the control

program.

Page 18

18 Control locations and operating modes

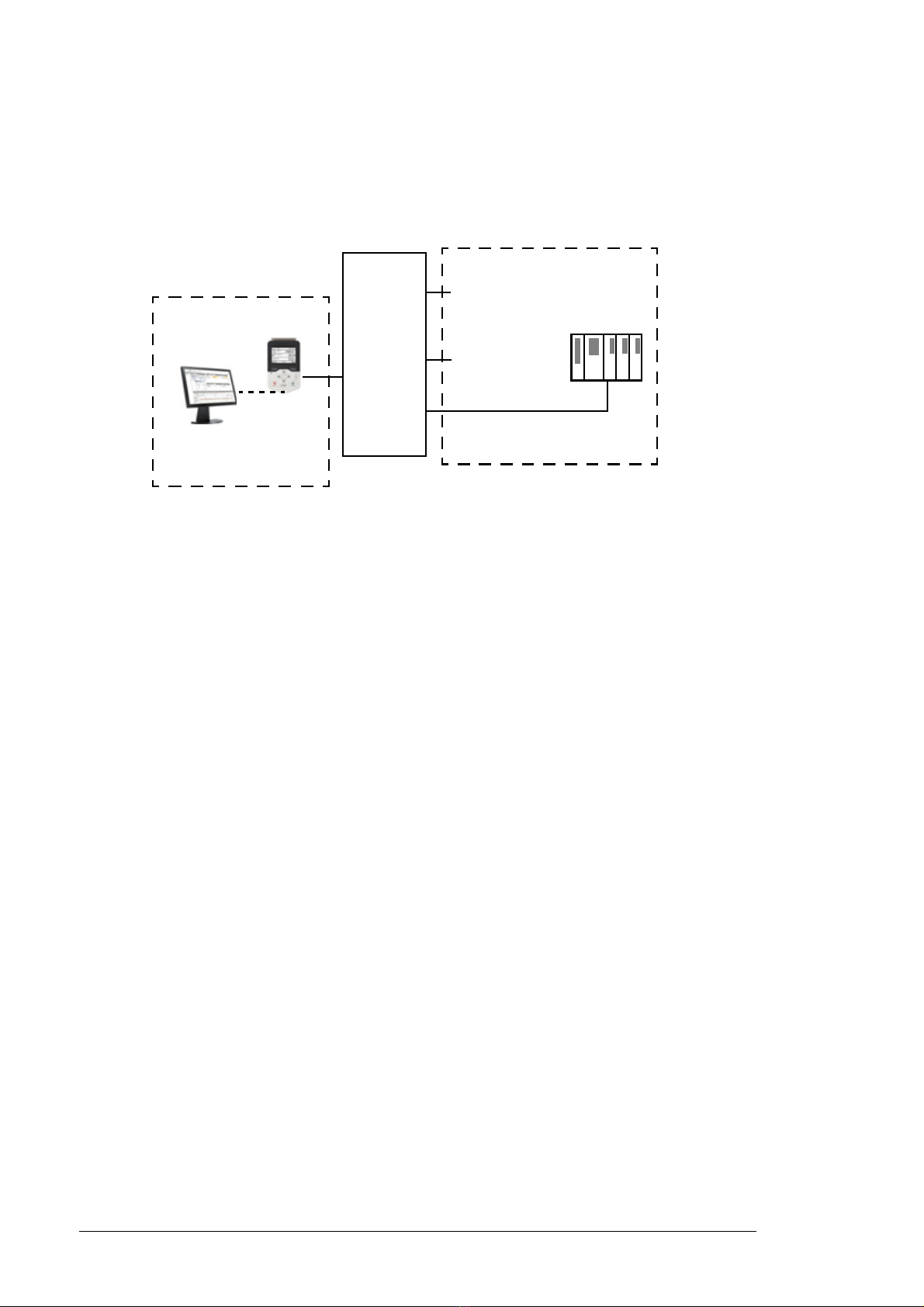

Control panel or Drive composer

PC tool (optional)

Fieldbus adapter (Fxxx) or DDCS

communication module

1) Extra inputs/outputs can be added by installing optional I/O extension modules (FIO-xx)

in the option slots of the control unit.

PLC

(= Programmable

logic controller)

I/O

1)

Drive-to-drive (D2D)

link or Embedded

fieldbus interface

External control

Local control

ACS880

Local control vs. external control

The ACS880 has two main control locations: external and local. The control location is

selected with the Loc/Rem key on the control panel or in the PC tool.

External control

When the supply unit is in external control, control commands are given through

• the I/O terminals (digital and analog inputs), or optional I/O extension modules

• the embedded fieldbus interface or an optional fieldbus adapter module

• the external (DDCS) controller interface, and/or

• the drive-to-drive link.

External references are given through the fieldbus interface, analog inputs or drive-to-drive

link.

Two external control locations, EXT1 and EXT2, are available. The user can select control

signals (e.g. start and stop) and control modes for both external control locations.

Depending on the user selection, either EXT1 or EXT2 is active at a time. Selection

between EXT1/EXT2 is done via any binary source such as a digital input or fieldbus

control word (see parameter 119.11 Ext1/Ext2 sel).

Note: Typically, ABB wires essential external control signals and status monitoring signals

of a supply unit of the cabinet-installed drive to its digital inputs and relay outputs at the

factory. We also set the parameters related to the external control signals accordingly. The

commission engineer must not change these settings or the external control does not

operate as planned. See the delivery-specific circuit diagrams.

Local control

The control commands are given from the control panel keypad or from a PC equipped

with Drive composer when the supply unit is in local control.

Local control is mainly used during commissioning and maintenance. The control panel

always overrides the external control signal sources when used in local control. When

switched to local control, the control panel Start and Stop keys override the external

Start/Stop source defined for the control program. However, to control the supply unit on

Page 19

Control locations and operating modes 19

and off by the panel, you must still have the external Run enable and Start enable signals

switched on at the appropriate digital inputs of the supply unit. See section Run enable,

Start/stop and Start enable control on page 23. Changing the control location to local can

be disabled by parameter 119.17 Local control disable.

The user can select by a parameter (149.05 Communication loss action) how the supply

unit reacts to a control panel loss or PC tool communication break.

Operating modes

The IGBT supply unit can operate in two operating modes with different types of reference:

• DC control

• power control.

In both of these modes, the reactive power reference is possible simultaneously. The

mode is selectable for each control location (Local, EXT1 and EXT2) in parameter group

119 Operation mode. For control chain diagrams for each reference type, see chapter

Control chain diagrams.

Page 20

20 Control locations and operating modes

Page 21

5

Program features

Program features 21

What this chapter contains

This chapter describes the features and I/O interface of the control program.

Overview of the control program

ACS880 IGBT supply control program controls the IGBT supply unit with an IGBT bridge

type supply module. The main functions of the control program are:

• maintain DC or active power reference,

• maintain reactive power reference,

• control external charging circuit (when used),

• control main contactor.

In addition, the control program protects the unit against overtemperature, DC or AC

overvoltage and DC undervoltage. See section Charging on page 39. The control program

also limits the active and reactive power as a function of the external temperature, and the

temperature of the IGBTs. See section Power limiting due to heat rise in the supply module

on page 34.

Page 22

22 Program features

Application program Firmware

Logic

I/O interface

Fieldbus interface

Protections

Feedback

Standard

block library

Function block

program

Control program

Firmware

blocks

(parameter

interface)

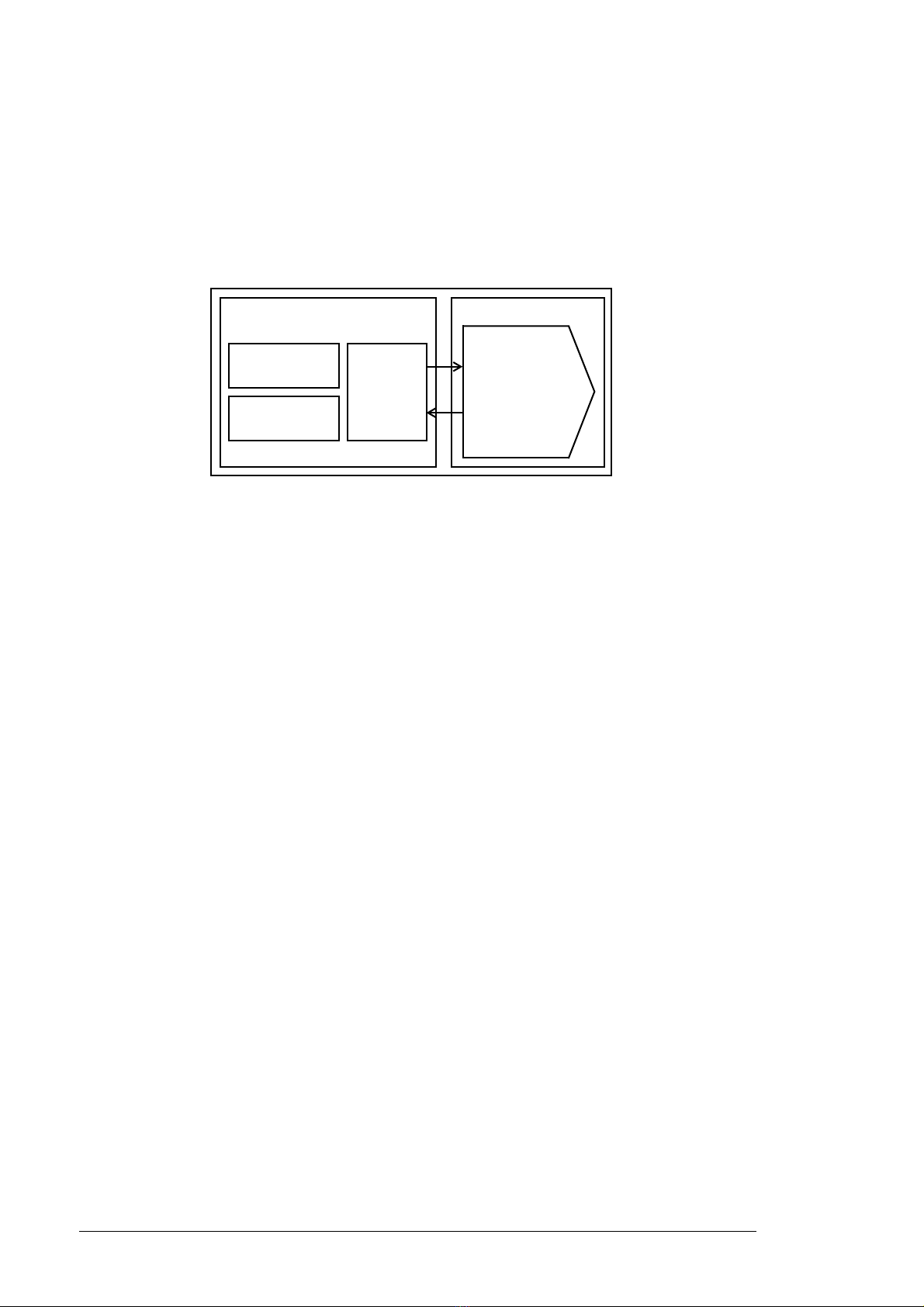

Control program configuration and programming

The control program is divided into two parts:

• firmware program (forms the control program alone as standard)

• application program (addition by the customer, for special cases only).

The firmware program performs the main control functions, including handling of DC

voltage reference, reactive power reference, active power reference, supply unit logic

(start/stop), I/O, feedback, communication and protection functions. Firmware functions

are configured and programmed with parameters.

Application programming

The functions of the firmware program can be extended with application programming. (A

standard delivery does not include an application program.) Application programs can be

built out of function blocks based on the IEC 61131-3 standard using a PC tool available

separately.

For more information, see Programming manual: Drive application programming (IEC

61131-3) (3AUA0000127808 [English]).

Programming via parameters

Parameters can be set via

• the control panel, as described in chapter Using the control panel

• the Drive composer PC tool, or

• the fieldbus interface, as described in chapters Fieldbus control through the

embedded fieldbus interface (EFB) and Fieldbus control through a fieldbus adapter.

All parameter settings are stored automatically to the permanent memory of the supply

unit. However, if an external +24 V DC power supply is used for the control unit, it is highly

recommended to force a save by using parameter 196.07 Parameter save manually

before powering down the control unit after any parameter changes.

If necessary, the default parameter values can be restored by parameter 196.06

Parameter restore.

Page 23

Program features 23

Run enable, Start/stop and Start enable control

The user controls the operation of the IGBT supply unit with the Run enable command,

Start/Stop command and Start enable command. When all commands are on in the

control program, it controls the main contactor of the supply unit on with a relay output

(relay output RO3 by default), and the charging contactor/relay (relay output RO1 by

default). The main contactor connects the supply unit to the power line and the supply unit

starts rectifying. If the Start/stop command or the Run enable command is off, the control

program de-energizes the relay output and the main contactor switches off.

Note: If all supply and inverter modules connected to the common DC link have internal

charging circuits of their own, no common charging circuit in the supply unit is needed, and

the supply unit can start without doing the charging first. For more information, see section

Charging on page 39. If any of the commands is off, the control program de-energizes the

relay output and the main contactor switches off.

There is a parameter in the control program for defining the value or source for each of the

commands. By default, the parameters define the command values or sources as follows:

• Control program reads the Run enable command from digital input DI2.

• Control program reads the Start/Stop command from digital input DI2.

• Start enable is set on constantly.

Typically, DI2 is connected to the operating switch installed on the cabinet door. When the

switch is on, the control program receives both the Run enable and Start/Stop commands

via DI2.

Note: When you switch the control panel to local control, the control program starts

reading the Start/Stop from the panel (Start and Stop keys). The parameter-defined

Start/Stop source is not valid until you switch the panel back to remote control. The

Loc/Rem key of the panel selects between local and remote control.

Note: Despite of the Local/Remote mode selection by the panel, the program reads the

Run enable and Start enable from the interface defined by the appropriate parameters.

Note: Do not change the parameter settings related to Run enable, Start/Stop or Start

enable unless you are absolutely sure what you are doing. The parameters settings and

I/O wirings of the cabinet-installed unit are done at the factory according to the application

requirements.

Settings and diagnostics

Control panel key: Loc/Rem

Parameters: parameter group 119 Operation mode, 120.01 Ext1 commands…120.09 Ext2

in2 source, 120.12 Run enable 1 source, 120.19 Enable start command

Warnings: AE5A Enable start signal missing, AE5B Run enable missing

Faults: 5E06 Main contactor Fault, 3E08 LSU charging

Page 24

24 Program features

Control interfaces

Programmable analog inputs

The control unit has two programmable analog inputs. Each of the inputs can be

independently set as a voltage (0/2…10 V or -10…10 V) or current (0/4…20 mA) input by

a jumper or switch on the control unit. Each input can be filtered, inverted and scaled. The

number of analog inputs can be increased by using FIO-11 or FAIO-01 I/O extensions.

Settings and diagnostics

Parameters: parameter group 112 Standard AI

Warnings: AE27 AI parameterization

Programmable analog outputs

The control unit has two current (0…20 mA) analog outputs. Each output can be filtered,

inverted and scaled. The number of analog outputs can be increased by using FIO-11 or

FAIO-01 I/O extensions.

Settings and diagnostics

Parameters: parameter group 113 Standard AO

Programmable digital inputs and outputs

The control unit has six digital inputs, a digital start interlock input, and two digital

input/outputs.

Digital input/output DIO1 can be used as a frequency input, DIO2 as a frequency output.

The number of digital inputs/outputs can be increased by installing FIO-01, FIO-11 or

FDIO-01 I/O extensions (see Programmable I/O extensions below).

Note: Do not change the settings of the reserved digital inputs (or outputs, if any). See

subsection Reserved digital inputs and relay outputs on page 56.

Settings and diagnostics

Parameters: parameter groups 110 Standard DI, RO and 111 Standard DIO, FI, FO

Programmable relay outputs

The control unit has three relay outputs. The signal to be indicated by the outputs can be

selected by parameters. Relay outputs can be added by installing FIO-01 or FDIO-01 I/O

extensions.

Note: Do not change the settings of the reserved relay outputs. See subsection Reserved

digital inputs and relay outputs on page 56.

Settings and diagnostics

Parameters: parameter group 110 Standard DI, RO

Page 25

Program features 25

Programmable I/O extensions

The number of inputs and outputs can be increased by using I/O extension modules. The

I/O configuration parameters include the maximum number of DI, DIO, AI, AO and RO that

can be in use with different I/O extension module combinations. Slots can be added by

connecting an FEA-03 I/O extension adapter.

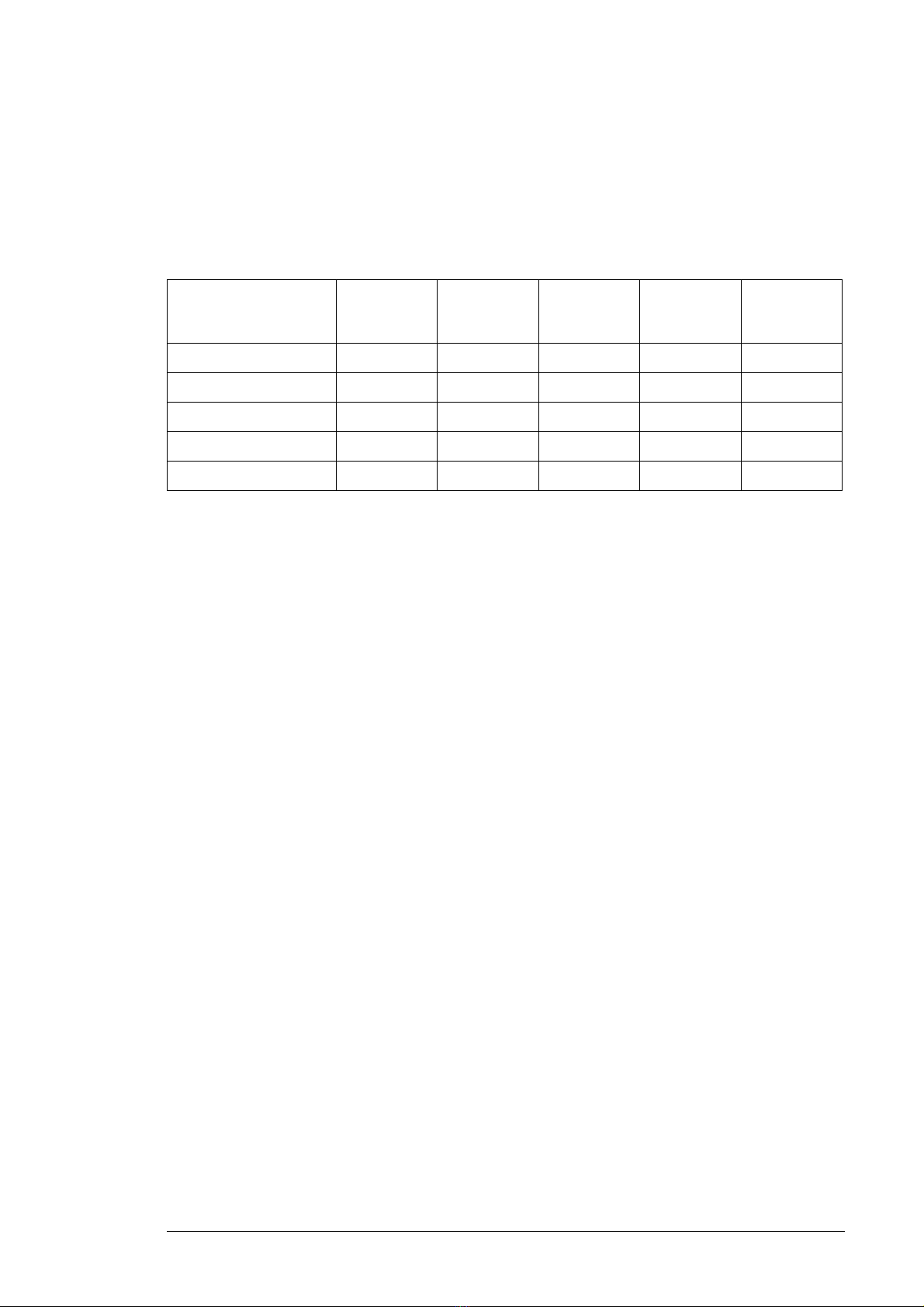

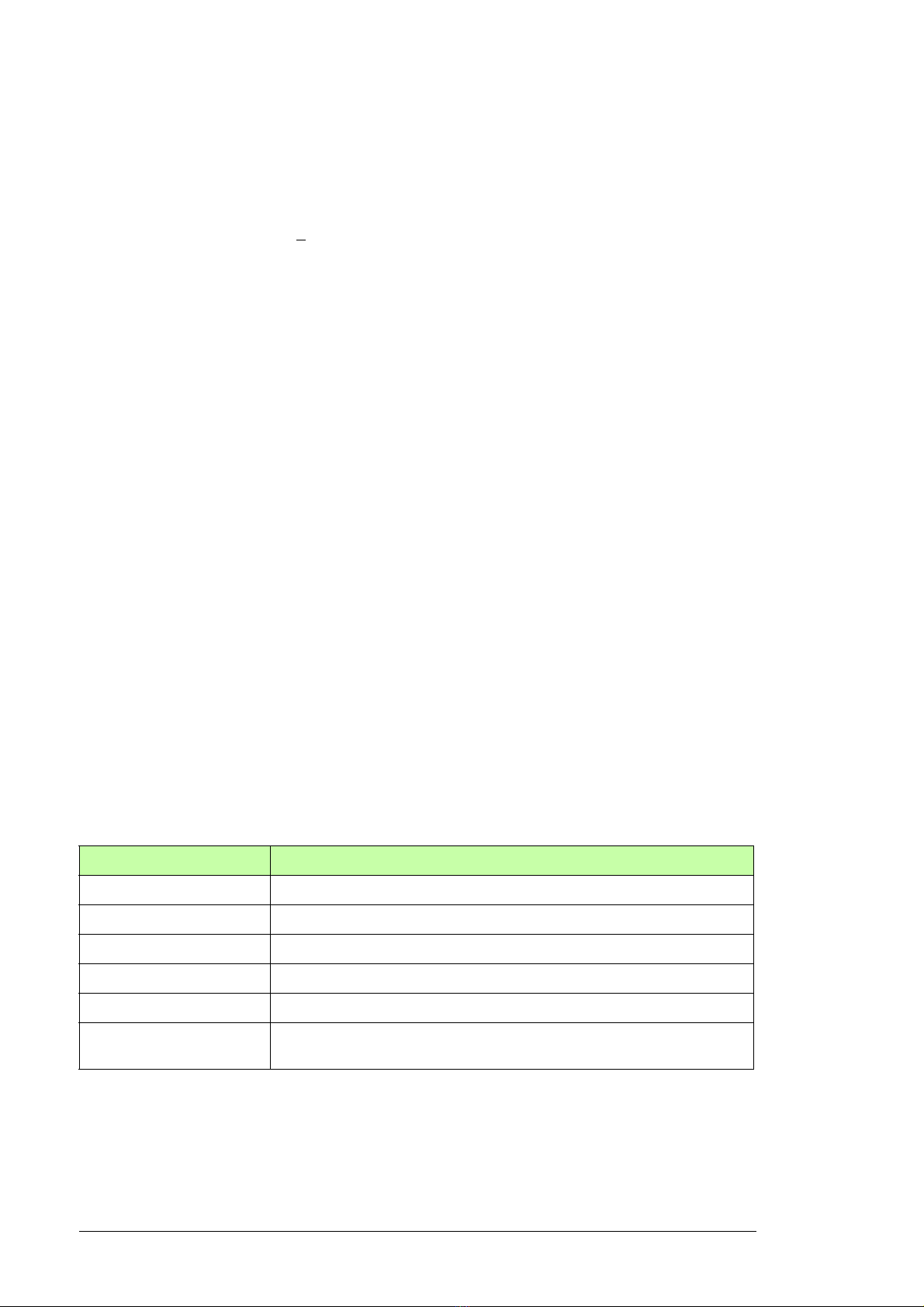

The table below shows the possible I/O combinations:

Digital

Location

Control unit 7 2 2 2 3

FIO-01 - 4 - - 2

FIO-11 - 2 3 1 -

FAIO-01 - - 2 2 -

FDIO-01 3 - - - 2

inputs

(DI)

Digital I/Os

(DIO)

Analog

inputs

(AI)

Analog

outputs

(AO)

Relay

outputs

(RO)

Note: Not all the FIO-xx I/O extensions are supported by the current firmware version.

(FIO-11 is supported.)

Settings and diagnostics

Parameters: parameter groups 110 Standard DI, RO, 111 Standard DIO, FI, FO,

112 Standard AI, 113 Standard AO, 114 Extension I/O module 1,

115 Extension I/O module 2, 116 Extension I/O module 3

Warnings: AE2E Extension AI parameterization, AE2F Extension I/O configuration failure

Faults: 7E00 Option module comm loss

Fieldbus control

The supply unit can be connected to an overriding control system via an optional fieldbus

adapter. See chapter Fieldbus control through a fieldbus adapter (page 235).

Settings and diagnostics

Parameters: parameter groups 150 FBA, 151 FBA A settings, 152 FBA A data in, 153 FBA

A data out, 154 FBA B settings, 155 FBA B data in, 156 FBA B data out

Warnings: AE25 FBA A parameter conflict, AE26 FBA B parameter conflict, AE30 FBA A

communication, AE31 FBA B communication

Faults: 6E01 FBA A mapping file, 6E02 FBA B mapping file, 6E0D FBA A parameter

conflict, 6E0E FBA B parameter conflict, 7E0B FBA A communication, 7E0C FBA B

communication

Page 26

26 Program features

T = Transmitter; R = Receiver

ACS880

(BCU) Control unit

RDCO

CH0

Controller

RT

RT

ACS880

(ZCU) Control unit

FDCO

RT

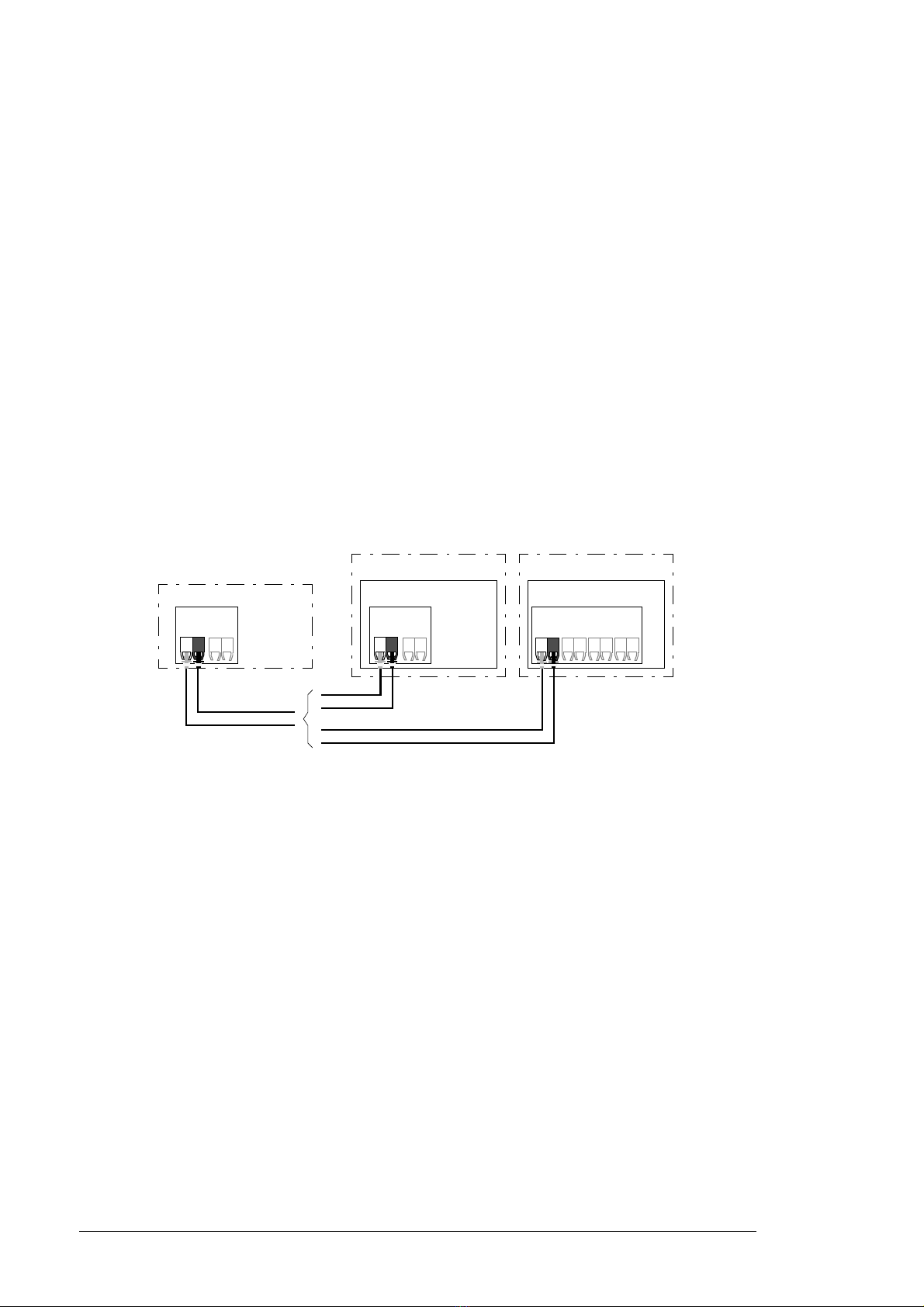

External controller interface

General

The IGBT supply unit can be connected to an external controller (such as the ABB

AC 800M) using either fiber optic or twisted-pair cable. The ACS880 is compatible with

both the ModuleBus and DriveBus connections. Note that some features of DriveBus

(such as BusManager) are not supported.

Topology

An example connection with either a ZCU-based or BCU-based IGBT supply unit using

fiber optic cables is shown below.

IGBT supply units with a ZCU control unit require an additional FDCO DDCS

communication module; IGBT supply units with a BCU control unit require an RDCO or

FDCO module. The BCU has a dedicated slot for the RDCO – an FDCO module can also

be used with a BCU control unit but it will reserve one of the three universal option module

slots. Ring and star configurations are also possible much in the same way as with the

master/follower link; the notable difference is that the external controller connects to

channel CH0 on the RDCO module instead of CH2. The channel on the FDCO

communication module can be freely selected.

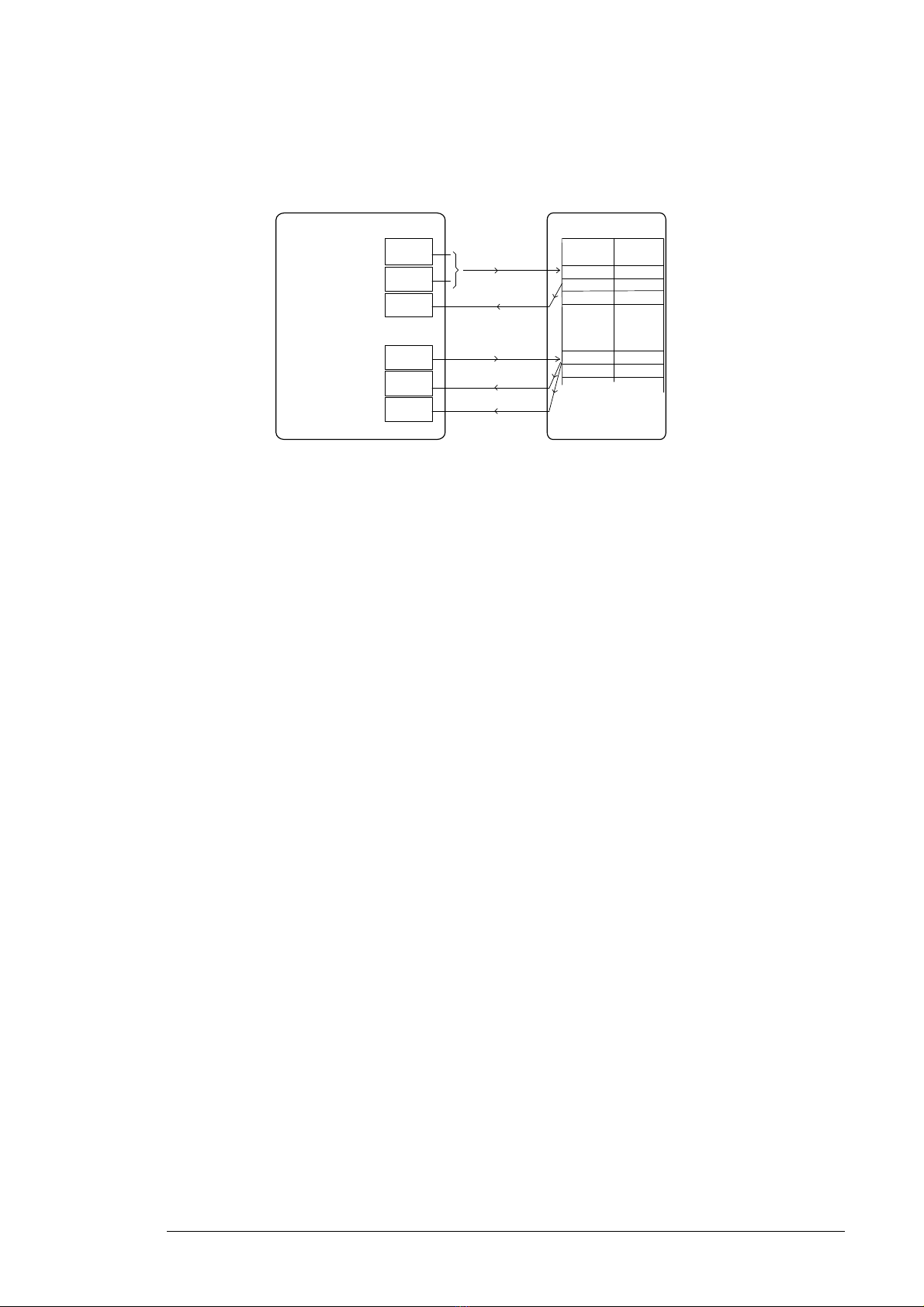

Communication

The communication between the controller and the IGBT supply unit consists of data sets

of three 16-bit words each. The controller sends a data set to the IGBT supply unit, which

returns the next data set to the controller.

The communication uses data sets 10…33. The contents of the data sets are freely

configurable, but data set 10 typically contains the control word, while data set 11 returns

the status word and selected actual values.

The word that is defined as the control word is internally connected to the logic; the coding

of the bits is as presented in section Contents of the fieldbus Control word (page 239).

Likewise, the coding of the status word is as shown in section Contents of the fieldbus

Status word (page 240).

Page 27

Program features 27

3 3 . 1

3 2 . 1

3 2 . 2

3 3 . 3

3 2 . 3

3 3 . 2

1 9 . 0 1

1 2 3 4

1

2 4 . 0 3 4 3 0 0

.

.

.

.

.

.

.

.

.

.

.

.

Data set

Data set

Data set

Data set

Data set

Data set

Par.

Value

Parameter write to ISU

Parameter read from ISU

Transmit address

Value = 37653*

Transmit data

Value = 1234

Transmit address

feedback

Value = 37653*

Inquire address

Value = 37654**

Inquired data

Value = 4300

Inquire address

feedback

Value = 37654**

Controller ACS880

*147.21 -> 93h.15h -> 9315h -> 37653

**147.22 -> 93h.16h -> 9316h -> 37654

147.21

147.22

By default, data sets 32 and 33 are dedicated for the mailbox service, which enables the

setting or inquiry of parameter values as follows:

By parameter 160.64 Mailbox dataset selection, data sets 24 and 25 can be selected

instead of data sets 32 and 33.

The update intervals of the data sets are as follows:

• Data sets 10…11: 2 ms

• Data sets 12…13: 4 ms

• Data sets 14…17: 10 ms

• Data sets 18…25, 32, 33: 100 ms.

Settings

Parameter groups 160 DDCS communication (page 151), 161 DDCS transmit (page 158)

and 162 DDCS receive (page 162).

Page 28

28 Program features

Reference chains

Reference chains of the control program are

• DC voltage reference chain,

• active power reference chain, and

• reactive power reference chain.

Tasks of the reference chains are reference source and type selection, limitation and

ramping. The active power, DC voltage and reactive power reference chains are controlled

by reference chain control. All of the reference chains are controlled by the bits of limit

word (130.01).

DC voltage control

DC voltage is controlled by the DC voltage reference chain. DC voltage control is the

default control mode of the supply unit. It is also the alternative control mode for the active

power control. DC voltage control includes DC voltage reference selection, limitation and

ramping. Incoming DC reference is limited between maximum and minimum of the DC

limits. If the incoming reference exceeds the defined limits, the limit word is updated. DC

reference is ramped according to DC ramp up and DC ramp down times.

Control chain diagram

See page 248.

Internal DC voltage reference

Lowest possible DC voltage level in IGBT supply unit is defined by AC voltage level. If DC

voltage reference is lower than what the IGBT supply unit can achieve with control,

reference is limited internally to the lowest possible value. Minimum DC voltage reference

is filtered with 10 second time constant to prevent immediate drop in DC voltage reference

while AC voltage level drops. See also the table on page 47.

Settings and diagnostics

Parameters: parameter groups 123 DC voltage reference and 130 Limits

Active power control

Active power is controlled by the power reference chain. Active power control is an

alternative main control mode for the IGBT supply unit with the DC voltage control (which

is the default control mode of the supply unit). Power reference chain includes reference

selection, limitation and ramping.

The power reference modifies the input reference to active current reference for the ramp

function. Possible input reference types are:

• Active current reference in Amperes

• Active current reference in percent of the nominal current

• Power reference in kW

• Power reference in percent of the nominal power.

Main tasks of active current ramping are:

• Active current reference limitation

• Active current reference ramping.

The control program contains a limitation feature for limiting the active power based on

ambient temperature or the temperature of the IGBTs. The user can tune the limitation

parameters.

Page 29

Program features 29

Control chain diagram

See page 249.

Settings and diagnostics

Parameters: parameter groups 122 Power reference and 130 Limits

Reactive power control

Reactive power is controlled by the reactive power reference chain. Reactive power (or

current) control is the secondary control mode for the IGBT supply unit, and it is executed

in parallel with either of the main control options (DC voltage control or active power

control). If the IGBT supply unit is at its current limit, reactive power is limited before active

power. Reactive power reference chain includes reference selection, limitation and

ramping.

The reactive power reference modifies the input reference to reactive current reference.

Possible input reference types are:

• Reactive current reference in Amperes

• Reactive current reference in percent of the nominal current

• Reactive power reference in kVAr

• Reactive power reference in percent of the nominal power

• Reactive power reference angle in degrees

• Reactive power reference in cosphi

• Voltage reference for the AC voltage control in Volts

• Voltage reference for the AC voltage control in percent.

The type of the reactive power reference is selected with parameter.

Main tasks of the reactive current ramping are:

• Reactive current reference limitation

• Reactive current reference ramping

• Ramp bypass in case of AC voltage control.

In reactive current reference limiting the incoming reference is limited between maximum

and minimum of the reactive current limits. If the incoming reference exceeds the defined

limits, the limit word is updated. The limited output is the input signal for the ramping

function.

The control program also contains a limitation feature for limiting the reactive power based

on ambient temperature or the temperature of the IGBTs. The user can tune the limitation

parameters.

Control chain diagram

See page 250.

Settings and diagnostics

Parameters: parameter groups 124 Reactive power reference and 130 Limits

Page 30

30 Program features

Net lost detection

The IGBT supply unit recognizes the loss of supply AC voltage and recovers automatically

when the AC voltage is connected again. The supply AC lost detection is based on fast

(about 0.2 s, 10 Hz) frequency change of the grid frequency. When the frequency goes

outside the frequency limits (+

activates the net lost state and generates a warning (AE78 Net lost). When the net lost is

detected, there are two options:

• If the grid measurements from external BAMU measuring board are not available,

after the delay (default 0.1 s) the IGBT supply unit tries to resynchronize to the grid. If

resynchronization is not successful and the net lost lasts too long (default 5 s), the

IGBT supply unit trips to a fault (8E07 Net lost).

• If the grid measurements from external BAMU measuring board are available, after

the delay (default 0.1 s) the IGBT supply unit tries to resynchronize to the grid when

the grid voltages are connected again and the frequency has been estimated to be

between allowed limits. If the maximum duration of the net lost is exceeded, the IGBT

supply unit trips to a fault (8E07 Net lost).

Settings and diagnostics

Warnings: AE78 Net lost

10 Hz of the nominal frequency), the control program

Faults: 3E05 DC link undervoltage, 8E07 Net lost

Reduced run function

Reduced run function is available for IGBT supply units consisting of parallel-connected

IGBT supply modules of frame size R8i. The function makes it possible to continue

operation with limited current even if one (or more) module is out of service, for example,

because of maintenance work. In principle, reduced run is possible with only one module,

but in practice, the modules in service must be able to provide enough current for running

the inverter modules.

The number of removed IGBT supply modules and LCL filter modules is restricted. The

following table lists the allowed configurations.

Original configuration Allowed configurations when using reduced run function

2×R8i + 1×LCL 1×R8i + 1×LCL

3×R8i + 2×LCL 2×R8i + 2×LCL

4×R8i + 2×LCL 2×R8i + 1×LCL or 1×R8i + 1×LCL

6×R8i + 3×LCL 4×R8i + 2×LCL or 2×R8i + 1×LCL or 1×R8i + 1×LCL

8×R8i + 4×LCL 6×R8i + 3×LCL or 4×R8i + 2×LCL or 2×R8i + 1×LCL or 1×R8i + 1×LCL

10×R8i + 5×LCL 8×R8i + 4×LCL or 6×R8i + 3×LCL or 4×R8i + 2×LCL or 2×R8i + 1×LCL or

1×R8i + 1×LCL

Note: When IGBT supply modules and LCL filter modules are removed, the corresponding

AC fuses need to be removed too.

Page 31

Program features 31

Activation of the reduced run function

Note: For cabinet-built drives, the wiring accessories and the air baffle needed during the

procedure are available from ABB, and are included in the delivery.

WARNING! Follow the safety instructions provided for the IGBT supply

unit in question.

1. Disconnect the supply voltage and all other sources that can supply the DC bus (eg,

DC/DC converter) from the IGBT supply unit.

2. If the control unit of the IGBT supply unit is powered from the faulty module, install an

extension to the wiring and connect it to one of the remaining modules.

3. Remove the module to be serviced from its bay. See the appropriate hardware manual

for instructions.

4. Install an air baffle to the top module guide to block the airflow through the empty

module bay.

5. Switch on the power to the IGBT supply unit.

6. Enter the number of IGBT supply modules present into parameter 195.13 Reduced

run mode.

7. Reset all faults and start the IGBT supply unit. The maximum current is now

automatically limited according to the new configuration. A mismatch between the

number of detected modules and the value set in 195.13 will generate a fault (5E0E

Reduced run).

After all modules have been reinstalled, parameter 195.13 Reduced run mode must be

reset to 0 to disable the reduced run function.

Settings and diagnostics

Parameters: 195.13 Reduced run mode, 195.14 Connected modules

Faults: 5E0E Reduced run

Page 32

32 Program features

Programmable protection functions

Emergency stop

The emergency stop signal is connected to the input selected by parameter 121.05

Emergency stop source. An emergency stop can also be generated through fieldbus

(parameter 106.01 Main control word, bits 1…2).

The way the IGBT supply unit is stopped when an emergency stop command is received,

is selected with parameter 121.04 Emergency stop mode. The following selections are

available:

• stop and warning,

• warning,

• fault.

Notes:

• The installer of the equipment is responsible for installing the emergency stop devices

and all additional devices needed for the emergency stop function to fulfill the required

emergency stop categories. For more information, contact your local ABB

representative.

• After an emergency stop signal is detected, the emergency stop function cannot be

canceled even though the signal is canceled.

Settings and diagnostics

Parameters: 121.04 Emergency stop mode, 121.05 Emergency stop source

Warnings: AE68 Emergency stop warning

Faults: 6E1C Emergency stop fault

External events

An external event signal can be connected to a selectable input which is not used for other

purposes. When the signal is lost, an external event (fault, warning, or a mere log entry) is

generated.

Settings and diagnostics

Parameters: 131.01 External event 1 source…131.10 External event 5 type

Warnings: AE51 External warning 1…AE55 External warning 5

Faults: 9E01 External fault 1…9E05 External fault 5

Earth fault detection

The earth fault detection function is based on sum current measurement. Note that

• in a grounded supply, the protection activates in 200 ms,

• in an ungrounded supply, the supply network capacitance should be 1 μF or more,

• the protection is deactivated when the supply unit is stopped.

Settings and diagnostics

Parameters: 131.20 Earth fault

Warnings: AE02 Earth leakage

Faults: 2E01 Earth leakage

Page 33

Program features 33

External earth leakage fault source selection

The parameter selects in which digital input or digital input/output external earth leakage

fault is connected.

Parameters: 131.28 Ext earth leakage signal source

Faults: 2E08 External earth fault

External earth leakage action selection

The parameter selects how the IGBT supply unit reacts when an external earth leakage is

detected.

Parameters: 131.29 Ext earth leakage action

Faults: 2E08 External earth fault

Warnings: AE87 Ext earth leakage

Supply phase loss detection

The parameter selects how the supply unit reacts whenever a supply phase loss is

detected.

Settings and diagnostics

Parameters: 131.21 Supply phase loss

Faults: 3E00 Input phase loss

Local control loss detection

The parameter selects how the supply unit reacts to a control panel or PC tool

communication break.

Settings and diagnostics

Parameters: 149.05 Communication loss action

Faults: 7E01 Panel loss

Automatic fault resets

The supply unit can automatically reset itself after overcurrent, DC overvoltage, DC

undervoltage, and external faults. The user can also specify a fault that is automatically

reset.

By default, automatic resets are off and must be specifically activated by the user.

Settings and diagnostics

Parameters: 131.12 Autoreset selection…131.16 Delay time

Warnings: AE57 Autoreset

Page 34

34 Program features

Thermal switch monitoring

The control program has a thermal switch monitoring function. The function monitors the

status of the switch through a digital input typically. By default, digital input DI1 is used for

monitoring the status of the thermal switch. Multiple switches must be connected in series.

The commissioning engineer can activate the function and define the monitored input by a

parameter. If the function receives an overtemperature indication (DI1 = 0), it trips the

supply unit to a fault.

Settings and diagnostics

Parameters: 131.33 Cabinet temperature fault source, 131.34 Cabinet temperature

supervision

Faults: 4E06 Cabinet or LCL overtemperature

Power limiting due to heat rise in the supply module

The control program has a supply module temperature monitoring function. The

commissioning engineer can define:

• the source for the coolant temperature measurement

• active and reactive power profile vs. temperature value

• warning and fault trip limits.

The function monitors the temperature of the coolant exiting the module. When the value

reaches the limit defined for the power limiting profile, the control program starts limiting

the power. If the temperature keeps rising despite of the power limiting, the control

program generates first a warning (at warning limit), and then trips to a fault (at fault limit).

User can activate and tune limitation in parameter group 130 Limits.

Example

Set parameter 130.50 Ext Tmp1 input selection with selection Other to 114.26 AI1 actual

value. Set parameter 114.77 AO1 source with selection Other to 130.54 Pt current. It is

possible to use groups 115 or 116 also.

Settings and diagnostics

Parameter groups: 130 Limits, 114 Extension I/O module 1…116 Extension I/O module 3

Warnings: AE10 Ext Tmp1 warning, AE11 Ext Tmp2 warning

Counting the number of charging attempts

The control program monitors charging attempts to prevent charging circuit overheating.

Settings and diagnostics

Parameters: 120.50 Charging overload event sel

Warnings: AE85 Charging count

Faults: 3E09 Charging count

Page 35

Program features 35

DC overvoltage and undervoltage protections

The control program defines the DC overvoltage and undervoltage limits on basis of the

supply voltage range given by the user with a parameter (195.01). The program monitors

the actual voltage level with an internal voltage measurement. When the measured value

exceeds the overvoltage limit or falls below the undervoltage limit, the control program

trips to a fault.

Trip limits

The trip limits of the intermediate DC link voltage are relative to the supply voltage range

selected with parameter 195.01 Supply voltage as well as supply unit type. The DC

voltage is displayed by parameter 101.01 DC voltage. The following table shows the

values of selected DC voltage levels in Volts.

Fault limit type

Overvoltage fault limit (R1i…R6i,

xxxxA-3)

Overvoltage fault limit (R1i…R6i,

xxxxA-5)

Overvoltage fault limit (R8i, xxxxA-3) 859.5 - - - -

Overvoltage fault limit (R8i, xxxxA-5) 859.5 895.5 895.5 - -

Overvoltage fault limit (R8i, xxxxA-7) - - - 1293 1293

Undervoltage fault limit (all types) 308 357 405 425 535

380…415 V 440…480 V 500 V 525…600 V 660…690 V

844----

880 880 880 - -

Supply voltage range (195.01)

Boost limits

Boost limit depends on the maximum voltage of the power module. Boost limits for DC

voltage are given in the table below.

DC voltage reference range

IGBT supply module type

xxxxA-3

xxxxA-5

xxxxA-7

Minimum

[V]

1)

1)

1)

Maximum

[V]

2)

663

2)

799

2)

110 2

1)

The control program limits the minimum value to sqrt(2) × Uac × (1.03…1.08).

2)

The maximum value is limited by parameter 123.06 DC voltage ref max.

Settings and diagnostics

Parameters: 101.01 DC voltage, 123.06 DC voltage ref max, 195.01 Supply voltage

Warnings: AE09 DC link overvoltage, AE0A DC link undervoltage

Faults: 3E04 DC link overvoltage, 3E05 DC link undervoltage

Page 36

36 Program features

Percentage of samples

0…10%

10…20%

20…30%

30…40%

40…50%

50…60%

60…70%

70…80%

80…90%

>90%

Amplitude ranges (parameters 136.40…136.49)

Diagnostics

Maintenance timers and counters

The program has six different maintenance timers or counters that can be configured to

generate a warning when a pre-defined limit is reached. The contents of the message can

be edited on the control panel by selecting Settings - Edit texts.

The timer/counter can be set to monitor any parameter. This feature is especially useful as

a service reminder.

There are three types of counters:

• On-time timers. Measures the time a binary source (for example, a bit in a status

word) is on.

• Signal edge counters. The counter is incremented whenever the monitored binary

source changes state.

• Value counters. The counter measures, by integration, the monitored parameter. A

warning is given when the calculated area below the signal exceeds a user-defined

limit.

Settings and diagnostics

Parameters: parameter group 133 Generic timer & counter

Load analyzer

Peak value logger

The user can select a signal to be monitored by a peak value logger. The logger records

the peak value of the signal along with the time the peak occurred, as well as supply unit

current, DC voltage and power at the time of the peak.

Amplitude loggers

The control program has two amplitude loggers.

For amplitude logger 2, the user can select a signal to be sampled at 200 ms intervals

when the IGBT supply unit is running, and specify a value that corresponds to 100%. The

collected samples are sorted into 10 read-only parameters according to their amplitude.

Each parameter represents an amplitude range 10 percentage points wide, and displays

the percentage of the collected samples that fall within that range.

Page 37

Program features 37

Amplitude logger 1 is fixed to monitor the converter current, and cannot be reset. With

amplitude logger 1, 100% corresponds to the maximum output current (I

distribution of samples is shown by parameters 136.20…136.29.

Settings

Parameters: parameter group 136 Load analyzer

max

). The

User parameter sets

The IGBT supply unit supports four user parameter sets that can be saved to the

permanent memory and recalled using parameters. It is also possible to use digital inputs

to switch between user parameter sets.

A user parameter set contains all editable values in parameter groups 110…199 except

• I/O extension module settings (groups 114…116)

• data storage parameters (group 147), and

• fieldbus communication settings (groups 151…156).

Settings and diagnostics

Parameters 196.10…196.13 (page 172).

User lock

For better cybersecurity, it is highly recommended that you set a master pass code to

prevent eg, the changing of parameter values and/or the loading of firmware and other

files.

WARNING! ABB will not be liable for damages or losses caused by the failure to

activate the user lock using a new pass code. See Cybersecurity disclaimer (page

12).

To activate the user lock for the first time, enter the default pass code, 10000000, into

196.02 Pass code. This will make parameters 196.100…196.102 visible. Then enter a new

pass code into 196.100 Change user pass code, and confirm the code in 196.101 Confirm

user pass code. In 196.102 User lock functionality, define the actions that you want to

prevent (we recommend you select all the actions unless otherwise required by the

application).

To close the user lock, enter an invalid pass code into 196.02 Pass code, activate 196.08

Control board boot, or cycle the power. With the lock closed, parameters

196.100…196.102 are hidden.

To reopen the lock, enter your pass code into 196.02 Pass code. This will again make

parameters 196.100…196.102 visible.

Settings

Parameters 196.02 (page 171) and 196.100…196.102 (page 175).

Page 38

38 Program features

Data storage parameters

Twenty-four (sixteen 32-bit, eight 16-bit) parameters are reserved for data storage. These

parameters are unconnected and can be used for linking, testing and commissioning

purposes. They can be written to and read from using other parameters’ source or target

selections.

Settings and diagnostics

Parameters: parameter group 147 Data storage

Page 39

Program features 39

Charging

The charging is always needed to power up the DC link capacitors smoothly. In other

words: you may not connect the discharged capacitors to full supply voltage but you must

increase the voltage gradually until the capacitors are charged and ready for normal use.

The control program has a function for controlling an additional charging circuit in the IGBT

supply unit. The charging function is active as standard, since the cabinet-installed ABB

drive which uses IGBT supply unit, needs the additional charging circuit typically.

Note: Some ABB supply and inverter module sizes have internal charging circuit as

standard. (Check from the appropriate supply and inverter module hardware manuals.) If

all supply and inverter modules connected to the common DC link of the drive have the

internal charging circuit, you do not need the common, additional circuit in the supply unit.

Then you can also inactivate the charging function of the supply unit (a parameter setting).

When the control program receives the start command (and Run enable and Start enable

are on), the control program controls the charging contactor on by a relay output. The

contactor connects the input power line to the drive DC link via charging resistors. The DC

capacitor charging starts. The DC voltage level in the DC link increases as the charging

continues. The charging resistors limit the charging current.

Charging is completed when:

• the actual DC voltage exceeds the predefined level (parameter 120.25 MCB closing

level)

• the actual DC voltage change rate is below the predefined level (parameter 120.26

Maximum dU/dt), and

• the pre-defined delay time has passed (parameter 120.27 Start delay).

The control program monitors the charging time. If charging takes more time than defined

by a parameter, the supply unit trips to a fault.

If the IGBT supply unit is used in a drive system where the charging must be done by the

IGBT supply unit, you must install an additional charging circuit, and activate and tune the

charging function in the IGBT supply control program. Consult ABB for more information

on tuning the parameters, and the components and wirings needed.

The control program checks that voltage rises after the charging contactor is closed. If the

voltage does not rise and the current stays below the level defined with parameter 120.22

Max current for MCB closing, the supply unit trips on fault 3E08 LSU charging (auxiliary

code 5). If the current is higher, the supply unit trips on fault 2E09 DC short circuit.

The control program monitors charging attempts to prevent charging circuit overheating. If

there are more than two attempts in five minutes to charge the DC link externally, start

inhibit is set (106.18 Start inhibit status word, bit 9). After five minutes from the first

charging attempt the start inhibit is removed. The supply unit also generates an event

selected with parameter 120.50 Charging overload event sel.

Page 40

40 Program features

1

3

1 2 3 4

1001h

1h

4

2

107h

3h

Udc 100% of nominal

120.25 MCB closing level

80% default, range

20…100%

Udc 0% of nominal

DC voltage and current

measurements are not active with

all power unit types on low DC

voltage levels in the beginning of

the charging sequence

DC voltage

Delay if 120.28 MCB relay

timing >0

0 s default, range -6…6 s

120.26 Maximum dU/dt

50.0 V/s default, range 0.0…200.0 V/s

Charging ready [conditions

passed]

Running on DC voltage control

120.22 Max current for

MCB closing

5% default, range 0…10%

106.11 Main status word

Only starting procedure related bits of the 106.11 Main

status word are shown in hexadecimal values here.

Other values of Main status word are possible

depending on control location etc. (eg, bit 9 Remote).

ON command and START

command from active control

location

110.24 RO1 source

Charging

Charging contactor closing command

Delay if 120.28 MCB relay timing <0

0 s default, range -6…6 s

110.30 RO3 source

MCB

MCB closing command

Delay if 120.28 MCB relay

timing >0

0 s default, range -6…6 s

If feedback is missing after

supervision delay, fault

5E06 Main contactor Fault is

generated.

Start delay for starting of

modulation begins after MCB

closing feedback (DI3 status is 1)

120.21 Delay for MCB DI3

supervision

1 s default, range 0…8 s

DI3 status

Running status

120.27 Start delay

0.5 s default, range 0…10 s

120.23 Max DC charging time

3 s default, range 0…10 s

Charging ready state can not be

reached before this time is

passed.

If charging ready state is not

reached before this time has

elapsed, fault 3E08 LSU

charging is generated. See

auxiliary code in chapter

Fault tracing.

Module current

4001h

Timing diagram

Settings and diagnostics

Signals: 101.01 DC voltage

Parameters: 106.18 Start inhibit status word, 110.24 RO1 source, 120.22 Max current for

MCB closing, 120.23 Max DC charging time, 120.25 MCB closing level, 120.26 Maximum

dU/dt, 120.27 Start delay, 120.28 MCB relay timing, 120.29 Diode mode, 120.30 External

charge enable, 120.50 Charging overload event sel

Warnings: AE85 Charging count

Faults: 2E09 DC short circuit, 3E08 LSU charging, 3E09 Charging count, 5E06 Main

contactor Fault

Page 41

Program features 41

DDCS communication with inverter unit

DDCS communication can be used for transferring data between IGBT supply unit and

inverter unit. The DDCS communication and the related transfer media (fiber optic link) are

in use in the single drives which consist of one supply unit and one inverter unit. The

DDCS link is not in use in multidrives, typically.

You can use the DDCS communication for these purposes:

• You can show and adjust the supply unit parameters in the inverter control program

(one interface for the control panel and commissioning engineer).

• You can show supply unit warnings and faults in the inverter control program.

• You can control both the inverter unit and the supply unit through one control interface

(for example one fieldbus adapter) in the inverter unit, and transfer the supply unit

control commands and references via the link to the supply unit.

For information on using DDCS communication, see section Setting up communication

through inverter unit on page 243.

Settings and diagnostics

Parameters: parameter groups 160 DDCS communication, 161 DDCS transmit,

162 DDCS receive

Warnings: AE56 INU-LSU comm loss

Faults: 7E0D FA2FA DDCS Com loss

Page 42

42 Program features

XD2D Drive-to-drive link

1 B

Drive-to-drive link (not in use by default)

2 A

3 BGND

4 Shield

D2D.TERM Drive-to-drive link termination

1)

X485 RS485 connection

5 B

Not in use (not in use by default)

6 A

7 BGND

8 Shield

XRO1…XRO3 Relay outputs

11 NC

XRO1: Charging

2)

(Energized = Closes charging contactor.)

250 V AC / 30 V DC / 2 A

12 COM

13 NO

21 NC

XRO2: Fault(-1)

3)

(Energized = Indicates no fault.)

250 V AC / 30 V DC / 2 A

22 COM

23 NO

31 NC XRO3: MCB ctrl

2)

(Energized = Closes main contactor/breaker.)

250 V AC / 30 V DC / 2 A

32 COM