ABB ACS880-01 Installation Manual

ABB AC Drives

ACS880-01…+C212 Extension Box,

1 – 60 HP at 230V

1 – 150 HP at 480V

7.5 – 125 HP at 575V

Document No. 3AXD50000043508 Rev. 0

ACS880-01…+C212 Extension Box Installation Quick Guide

The ACS880-01…+C212 Extension Box is an ACS880-01 wall-mounted

variable frequency AC drive on a back panel with an electrical box for

additional devices. Standard devices include line fuses to protect the drive

and a power distribution block. Optional devices includes a line disconnect switch, control power transformer, switches and pilot lights as well as

ACS880-01 options for eldbus, input/output adapters, special software,

etc.

1. Safety in installation and maintenance

Electrical safety

These warnings are intended for all who work on the drive, motor cable or

motor.

WARNING! Ignoring the following instructions can cause physical injury or

death, or damage to the equipment:

– Only qualied electricians are allowed to install and maintain the drive.

– Never work on the drive, motor cable or motor when main power

is applied. After disconnecting the input power, always wait for 5

minutes to let the intermediate circuit capacitors discharge before you

start working on the drive, motor or motor cable.

– Always ensure by measuring with a multimeter (impedance at least 1

Mohm) that:

– Voltage between drive input phases L1, L2 and L3 and the frame

is close to 0 V

– Voltage between terminals UDC+ and UDC- and the frame is

close to 0 V.

– Do not work on the control cables when power is applied to the drive

or to the external control circuits. Externally supplied control circuits

may cause dangerous voltages inside the drive even when the main

power on the drive is switched off.

– Do not make any insulation or voltage withstand tests on the drive.

– Do not connect the drive to a voltage higher than what is marked

on the type designation label. Higher voltage can activate the brake

chopper and lead to brake resistor overload, or activate the overvolt-

age controller what can lead to motor rushing to maximum speed.

Note:

– The motor cable terminals on the drive are at a dangerously high

voltage when the input power is on, regardless of whether the motor

is running or not.

– The DC terminals (UDC+, UDC-) carry a dangerous DC voltage (over

500 V) when internally connected to the intermediate DC circuit.

– Depending on the external wiring, dangerous voltages (115 V, 220

V or 230 V) may be present on the terminals of relay outputs (XRO1,

XRO2 and XRO3).

– The Safe torque off function does not remove the voltage from the

main and auxiliary circuits. The function is ineffective against deliber-

ate sabotage or misuse.

IMPORTANT: Other Safety Information

Before handling the equipment or connecting voltage to the drive, see

ACS880 Hardware Manual (3AUA0000078093) Chapter 1 Safety instructions for additional information on grounding, lifting, starting up and

operating the equipment.

This guide instructs briey how to install the drive. For more detailed

instructions, engineering guide lines, technical data and complete safety

instructions, see the ACS880 Hardware Manual in the accompanying CD

or available here: www.abb.com/drives: Select Document Library and

search for document number 3AUA0000078093 [English].

2. List of related manuals

Drive hardware manuals and guides Code (English)

ACS880-01 hardware manual 3AUA0000078093

ACS880-01 quick installation guide for frames R1 to R3 3AUA0000085966

ACS880-01 quick installation guide for frames R4 and R5 3AUA0000099663

ACS880-01 quick installation guide for frames R6 to R9 3AUA0000099689

ACS880-01 drives for cabinet installation (option +P940,

+P944) supplement 3AUA0000145446

ACS880-01 assembly drawings for cable entry boxes of

P21 frames R5 to R9 3AUA0000119627

ACS-AP-x assistant control panels user’s manual 3AUA0000085685

Vibration dampers for ACS880-01 drives (frames R4, R5,

option +C131) installation 3AXD50000010497

Vibration dampers for ACS880-01 drives (frames R6, R9,

option +C131) installation 3AXD50000013389

ACS880-01 marine type-approved drives (option +C132)

supplement 3AXD50000010521

Drive rmware manuals and guides

ACS880 standard control program rmware manual 3AUA0000085967

Quick start-up guide for ACS880 drives with primary

control program 3AUA0000098062

Option manuals and guides

FDIO-01 digital I/O extension module user’s manual EN 3AUA0000124966

Other manuals and quick guides for I/O extension modules,

eldbus adapters, etc. Multiple

You can nd manuals and other product documents in PDF format on

the Internet. See section manuals not available in the Document library,

contact your local ABB representative

The QR code below opens an online listing of the manuals applicable to

this product.

ACS880-01 manuals

3. Packing List

The following items are included in the box:

1. ACS880 Extension Box drive unit (See ratings chart for size and

variants)

2. ACS880 Extension Box Quick Guide (this document)

3. ACS880 Quick Start Guide

4. ACS880 Manuals on CD

5. ACS880 Extension Box schematic diagram and layout drawing

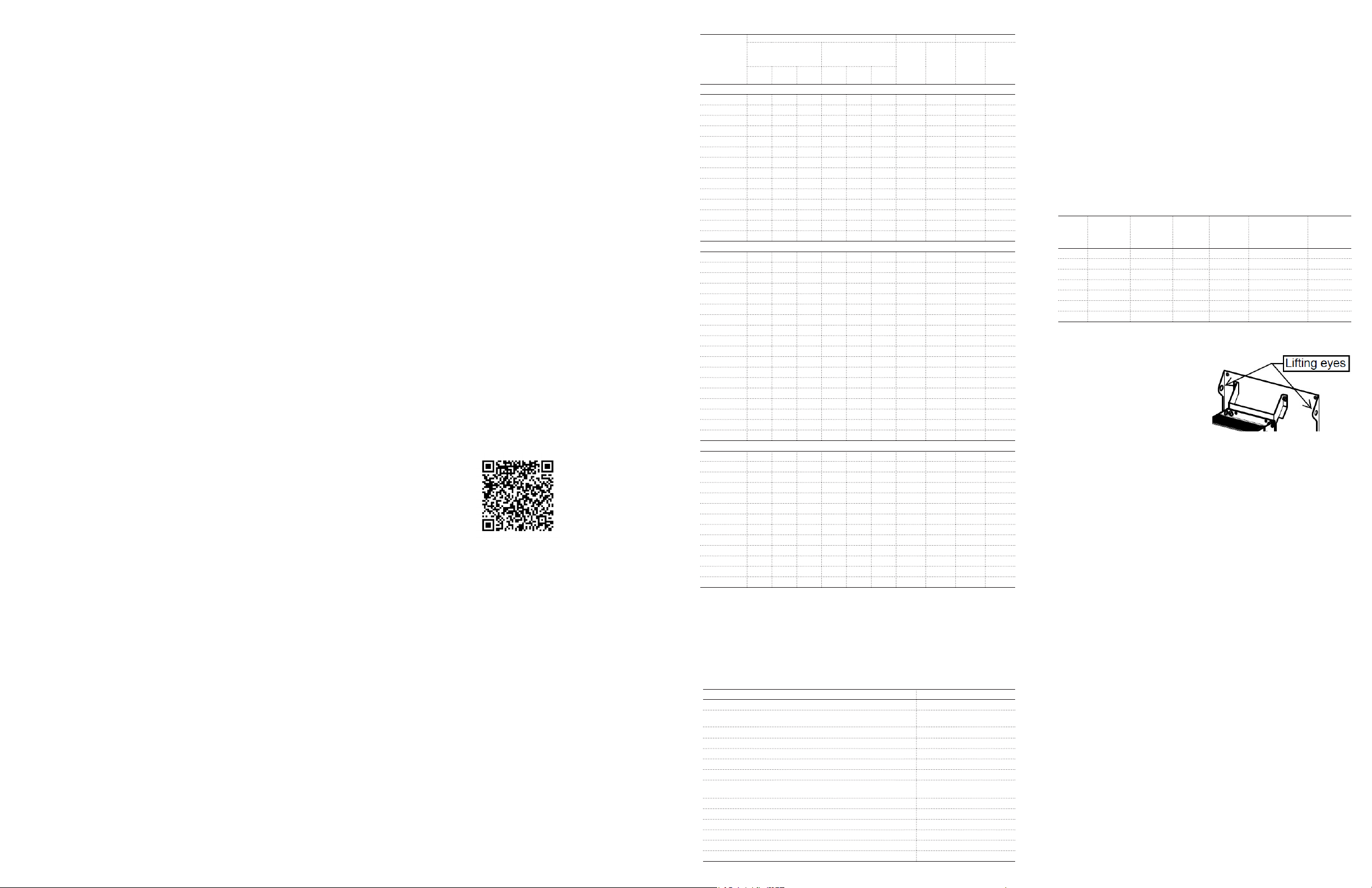

4. Drive Ratings Table and Plus Code Variants

Type code

(110% overload for

ACS880-01-

240 VAC (range 208 to 240 VAC); Power ratings are valid at nominal voltage 230 VAC, 60 Hz

04A6-2+C212 4.4 1 0.75 3.7 0.75 0.55 F2-R1 57 F12-R1 88

06A6-2+C212 6.3 1.5 1.1 4.6 1 0.75 F2-R1 57 F12-R1 88

07A5-2+C212 7.1 2 1.5 6.6 1.5 1.1 F2-R1 57 F12-R1 88

10A6-2+C212 10.1 3 2.2 7.5 2 1.5 F2-R1 57 F12-R1 88

16A8-2+C212 16 5 4 10.6 3 3 F2-R2 62 F12-R2 93

24A3-2+C212 23.1 7.5 5.5 16.8 5 4 F3-R2 54 F12-R2 93

031A-2+C212 29.3 10 7.5 24.3 7.5 5.5 F3-R3 58 F12-R3 97

046A-2+C212 44 15 11 38 10 7.5 F4-R4 82 F12-R4 116

061A-2+C212 58 20 15 45 15 11 F4-R4 84 F12-R4 116

075A-2+C212 71 25 18.5 61 20 15 F5-R5 118 --- ---

087A-2+C212 83 30 22 72 25 18.5 F5-R5 118 --- ---

115A-2+C212 109 40 30 87 30 22 F5-R6 166 --- ---

145A-2+C212 138 50 37 105 40 30 F5-R6 166 --- ---

170A-2+C212 162 60 45 145 50 37 F6-R7 210 --- ---

500 VAC (range 380 to 500 VAC); Power ratings are valid at nominal voltage 460 VAC, 60 Hz

02A1-5+C212 2.1 1 0.75 1.7 0.75 0.55 F2-R1 57 F12-R1 88

03A0-5+C212 3 1.5 1.1 2.1 1 0.75 F2-R1 57 F12-R1 88

03A4-5+C212 3.4 2 1.5 3 1.5 1.1 F2-R1 57 F12-R1 88

04A8-5+C212 4.8 3 2.2 3.4 2 1.5 F2-R1 57 F12-R1 88

07A6-5+C212 7.6 5 4 5.2 3 3 F2-R1 57 F12-R1 88

11A0-5+C212 11 7.5 5.5 7.6 5 4 F2-R1 57 F12-R1 88

014A-5+C212 14 10 7.5 11 7.5 5.5 F2-R2 62 F12-R2 93

021A-5+C212 21 15 11 14 10 7.5 F3-R2 54 F12-R2 93

027A-5+C212 27 20 15 21 15 11 F3-R3 58 F12-R3 97

034A-5+C212 34 25 18.5 27 20 15 F3-R3 58 F12-R3 97

040A-5+C212 40 30 22 34 25 18.5 F4-R4 84 F12-R4 116

052A-5+C212 52 40 30 40 30 22 F4-R4 84 F12-R4 116

065A-5+C212 65 50 37 52 40 30 F5-R5 118 --- ---

077A-5+C212 77 60 45 65 50 37 F5-R5 118 --- ---

096A-5+C212 96 75 55 77 60 45 F5-R6 166 --- ---

124A-5+C212 124 100 75 96 75 55 F6-R6 188 --- ---

156A-5+C212 156 125 90 124 100 75 F6-R7 210 --- ---

180A-5+C212 180 150 110 156 125 90 F6-R7 210 --- ---

600 VAC (range 525 to 690 VAC); Power ratings are valid at nominal voltage 575 VAC, 60 Hz

07A3-7+C212 9 7.5 5.5 6.1 5 4 F5-R5 118 --- ---

09A8-7+C212 11 10 7.5 9 7.5 5.5 F5-R5 118 --- ---

14A2-7+C212 17 15 11 11 10 7.5 F5-R5 118 --- ---

018A-7+C212 22 20 15 17 15 11 F5-R5 118 --- ---

022A-7+C212 27 25 18.5 22 20 15 F5-R5 118 --- ---

026A-7+C212 32 30 22 27 25 18.5 F5-R5 118 --- ---

035A-7+C212 41 40 30 32 30 22 F5-R5 118 --- ---

042A-7+C212 52 50 37 41 40 30 F5-R5 118 --- ---

049A-7+C212 52 50 37 41 40 30 F5-R5 118 --- ---

061A-7+C212 62 60 45 52 50 37 F5-R6 166 --- ---

084A-7+C212 77 75 55 62 60 45 F5-R6 166 --- ---

098A-7+C212 99 100 75 77 75 55 F6-R7 210 --- ---

119A-7+C212 125 125 90 99 100 75 F6-R7 210 --- ---

Notes:

Ratings apply at an ambient temperature of 40°C (104°F) unless otherwise noted.

To achieve the rated motor power given in the table, the rated current of the drive must be higher than or

equal to the rated motor current.

Denitions:

ILD Continuous rms output current allowing 110% overload for 1 minute every 5 minutes.

PLD Typical motor power in light-overload use.

IHD Continuous rms output current allowing 150% overload for 1 minute every 5 minutes.

PHD Typical motor power in heavy-duty use.

Back panel and electrical box below the drive with line fuses and power

distribution block

CPT and digital I/O extension; provides 115 VAC digital inputs and

outputs. Field wiring required.

ILd APLd HPP

Nominal ratings UL Type 1 UL Type 12

Light duty

1 min)

(150% overload for

kWI

A PHd HPP

Ld

2Hd

Heavy duty

1 min)

kW

Frame

Weight

size

(lb)

Hd

Frame

size

+B055

Plus CodeVariant

B055UL Type 12 (IP54)

C212

E205Drive output (dV/dt) lter (10 hp max)

F253Input disconnect switch and handle (replaces power distribution block)

G302Hand-off-auto (HOA) switch

G303Speed potentiometer

G304Control power transformer (CPT)

G304+L526

G327Ready pilot light, white

G328Run pilot light, green

G329Fault pilot light, red

G331Emergency stop push button

G401Start/ Stop push buttons

G404Fault reset push button

Weight

(lb)

+B005

5. Installation

1. Unpacking the unit

Detach the protective wrapping from the shipping pallet.

Remove the unit by unscrewing the four bolts.

2. Mounting:

a. See Technical Specications section for environmental conditions.

b. The unit must be installed in an upright position with the back panel

against a wall.

c. The mounting wall must be vertical, non-ammable and strong

enough to hold the weight of the unit. The material below and

above the unit should be non-ammable.

d. Unit has four (4) mounting holes. (Frame F3 has ve (5).) The

recommended method is to mount the units on horizontal strut

channel. The table below shows mounting dimensions.

Frame Horizontal

Distance

between

Holes

F2 11-1/4 29-3/8 12-3/4 30-1/4 10-1/8 12

F3* 12-1/2 29-1/8 14 30 10-1/8 12

F4 12-1/2 32-1/8 14 33 12-3/8 13

F5 18-1/2 43-1/8 20 44 14-1/4 15-3/8

F6 18-1/2 47-3/8 20 48-1/4 17-3/8 18-1/2

F12 14-1/2 50 16 51 12-1/2 to 13-1/2 14-5/8

Recommended hardware: Four (4) bolts, 3/8 in. (10mm) diameter

* F3 has 3rd hole at top center

** Slots at bottom

(in) (in) (in) (in) (in) (in)

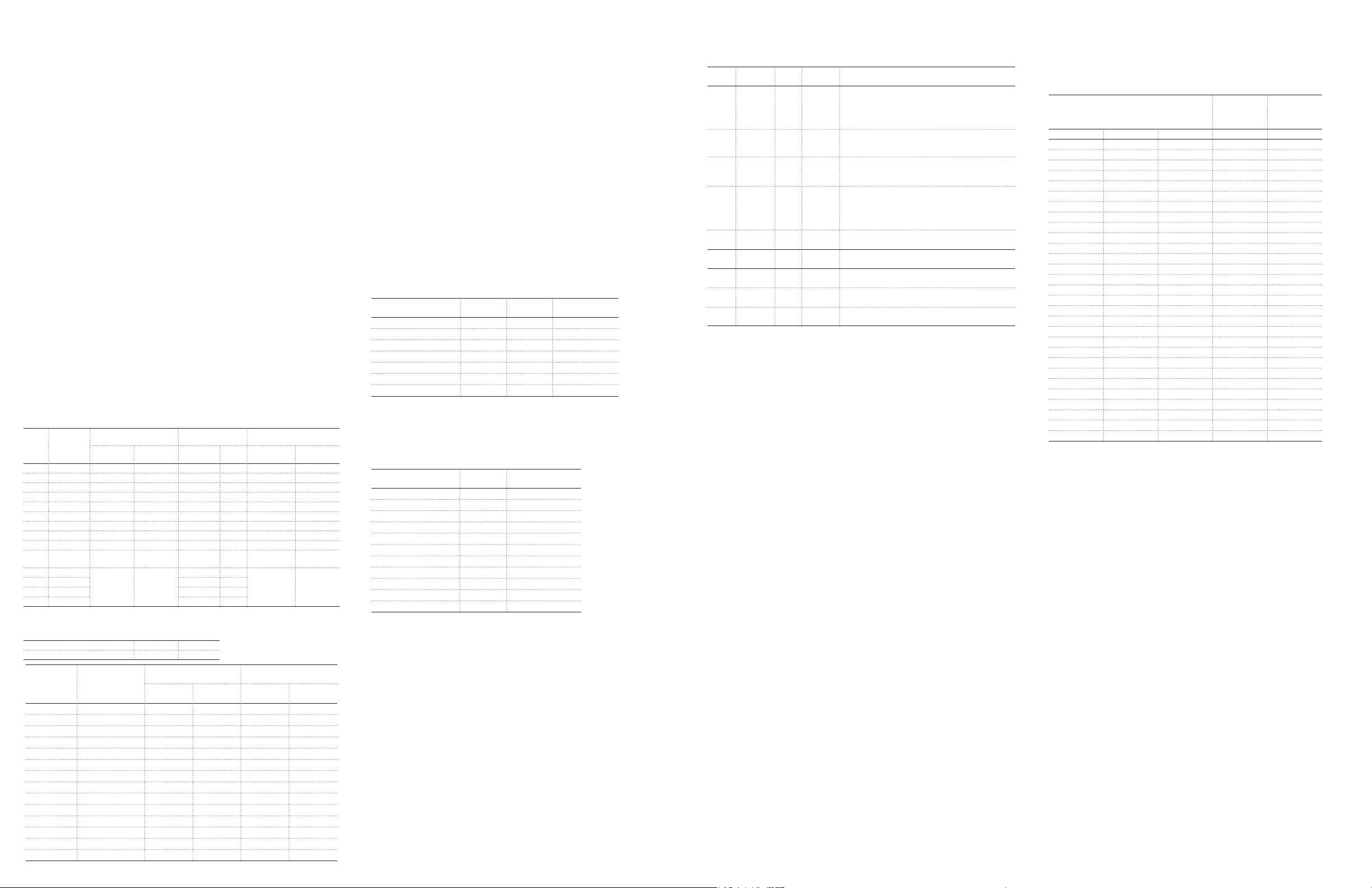

3. Lifting

Lift the unit into place. See ratings

table for weight. Lifting equipment

may be required. Use the back pan-

el lifting eyes which are on units F5

and above. Do NOT use the base

drive lifting eyes which are not rated

for the additional weight of the back panel.

4. Minimum Clearance

a. Above unit: 8 inches (area becomes hot!)

b. Below unit: 12 inches

c. Left side: 0 inches

d. Right side: 2 inches to allow for door swing

e. Between units: 2 inches to allow for door swing

5. Additional Clearance

a. Air ows from bottom to top. Allow enough free space above and

below the drive for cooling air ow, service and maintenance.

b. Allow enough free space in front of the drive for operation, service

and maintenance.

6. Cable entry and exit connections

a. The unit is designed for connection to the top and/or the bottom

of the box for both the motor and the line connections. Conduit

knockouts are provided for this purpose. There are four (4) knocks

on the top and four (4) on the bottom.

b. Knockout Dimensions:

F2 – F5: Suitable for (QTY 2) ½” conduit and (QTY 2) ¾” conduit

F6: Suitable for (QTY 2) ½” conduit and (QTY 2) 1” conduit

F12: Suitable for (QTY 2) ½” conduit and (QTY 2) ¾” conduit

Vertical

Distance

between

Holes**

Overall

Width

Overall

Height

Depth without

Disconnect

Switch

Depth with

Disconnect

Switch

7. Internal wiring connections

a. Line: Phases L1, L2, and L3 bolt to the power distribution block

or the disconnect switch (if equipped). IMPORTANT: When not

equipped with the disconnect switch, the unit must be protected

with class J fuses to provide a 100 kA short circuit current rating

(SCCR). Fuses to be installed upstream of the unit; supplied by

others. See fuse table below.

b. Motor (no lter): Motor leads bolt to terminals T1U, T2V, and T3W

located on the base drive. Remove the base drive cover for easier

access using a Torx screwdriver. See ACS880 Quick Guide and

Hardware Manual for more information.

c. Motor (dV/dt lter): Motor leads bolt to terminals A2, B2 and C2

located on the dV/dt lter.

d. Control: Connect control wires to the colored terminal blocks on

the base drive as needed. See ACS880 Quick Guide and Hardware Manual for more information.

e. Control Power Transformer: If equipped, the secondary of the

control power transformer will be wired to the white 10-position

terminal block. Terminals 1 & 2: L1 (hot); Terminals 3 & 4: L2

(neutral)

f. Digital I/O Extension, FDIO-01: See the FDIO-01 user manual

(3AUA0000124966).

8. Prior to power up

a. IMPORTANT: Prior to power up, carefully review the ACS880

Quick Guide and the ACS880 Hardware Manual.

6. Wire Size and Tightening Torque

1. The list below shows the minimum and maximum wire size each terminal is designed to hold.

2. For cable size recommendations, see ACS880-01 Hardware Manual, chapter: Planning the Electrical Installation, Section: Selecting the

Power Cables.

Power Distribution Block

Frame

Rating @

Size

480 V

F2-R1 1 - 7.5 HP 14 to 2 40 in-lb 18 to 8 7 in-lb 18 to 10* 5 in-lb

F2-R2 10 HP 14 to 2 40 in-lb 18 to 8 7 in-lb 18 to 10** 5 in-lb

F3-R2 15 HP 14 to 2 40 in-lb 18 to 8 7 in-lb 18 to 10 5 in-lb

F3-R3 20 - 25 HP 14 to 2 40 in-lb 14 to 4 18 in-lb 20 to 6 15 in-lb

F4-R4 30 - 40 HP 14 to 2 40 in-lb 14 to 4 18 in-lb 20 to 2 28 in-lb

F5-R5 50 - 60 HP 14 to 2 40 in-lb M8 x 25 bolt 11 ft-lb 10 to 2/0 4 ft-lb

F5-R6 75 HP 14 to 2/0 10 ft-lb M8 x 25 bolt 11 ft-lb 4 to 300 MCM 22 ft-lb

F6-R6 100 HP 14 to 2/0 10 ft-lb 4 to 300MCM 23 ft-lb 4 to 300 MCM 22 ft-lb

F6-R7 125 - 150 HP 4 to 500 MCM 31 ft-lb 4 to 300MCM 23 ft-lb 3/0 to 400 MCM 29 ft-lb

100 - 125 HP

F6-R7

@ 575V

F12-R1 1 - 7.5 HP

F12-R2 10 - 15 HP 14 to 4 35 in-lb

F12-R3 20 - 25 HP 14 to 4 35 in-lb

F12-R4 30 - 40 HP 8 to 1/0 55 in-lb

* with lter, 14 - 12 ga, 10 in-lb

** with lter 12 - 4 ga, 20 in-lb

Control

10-position terminal block 22 - 10 ga 4.5 in-lb

base drive terminal blocks 24 - 12 ga 5.3 in-lb

Frame Size Rating @ 480 V

F2-R1 1 - 7.5 HP 14 to 2 35 - 50 in-lb 18 to 10 5 in-lb

F2-R2 10 HP 14 to 2 35 - 50 in-lb 18 to 10 5 in-lb

F3-R2 15 HP 14 to 2 35 - 50 in-lb 18 to 10 5 in-lb

F3-R3 20 - 25 HP 14 to 2 35 - 50 in-lb 20 to 6 15 in-lb

F4-R4 30 - 40 HP 14 to 2 35 - 50 in-lb 20 to 2 28 in-lb

F5-R5 50 - 60 HP 14 to 2 35 - 50 in-lb 10 to 2/0 4 ft-lb

F5-R6 75 HP 14 to 2 35 - 50 in-lb 4 to 3/0 14 ft-lb

F6-R6 100 HP 14 to 2 35 - 50 in-lb 4 to 3/0 14 ft-lb

F6-R7 125 - 150 HP 14 to 2 35 - 50 in-lb 4 to 300 MCM 22 ft-lb

F6-R7 100 - 125 HP @ 575V 14 to 2 35 - 50 in-lb 4 to 300 MCM 22 ft-lb

F12-R1 1 - 7.5 HP 8 to 14 40 in-lb 18 to 10 5 in-lb

F12-R2 10 - 15 HP 8 to 14 40 in-lb 18 to 10 5 in-lb

F12-R3 20 - 25 HP 8 to 14 40 in-lb 20 to 6 15 in-lb

F12-R4

30 - 40 HP

(L1, L2, L3)

Wire Size

allowed (ga)

4 to 500 MCM 31 ft-lb 4 to 300MCM 23 ft-lb 4 to 300 MCM 22 ft-lb

14 to 2

Torque

14-10: 35 in-lb

8: 40 in-lb

6-4: 45 in-lb

2: 50 in-lb

allowed (ga)

Disconnect Switch

(L1, L2, L3)

Wire Size

allowed (ga)

14 to 4 35 in-lb

Panel Ground Terminal

Wire Size

8 to 14 40 in-lb 20 to 2 28 in-lb

Torque

Torque Wire Size Torque

Motor Terminals

(T1/U, T2/V, T3/W)

Wire Size

allowed (ga)

14 to 2

DB Resistor

(R-, R+)

Torque

14-10: 35 in-lb

8: 40 in-lb

6-4: 45 in-lb

2: 50 in-lb

7. Control Power Transformer (G304)

1. Optional control power transformer ratings

a. Input voltage: 208*, 230, 480, 575 Vac 1ph.

*for 208V, convert a 240V unit by changing the

wiring to the transformer primary as indicated below.

b. Output voltage: 115 Vac

c. Rated power: 100 VA

d. Available power: 100 VA (drive control power is not fed from

this device)

e. Heat dissipation: 21 Watts

2. Primary wiring connections: 230V and 480V units using Micron

B100MBT13RK

a. 480 Volt: H1 and H4

b. 230 Volt: H2 and H4

c. 208 Volt: H3 and H4

3. Primary wiring connections: 575V units using Micron B150WZ13RKF

a. 575 Volt: H1 and H4 (diagram not shown)

8. Drive Output (dV/dt) Filter (E205) -

UL Type 1 only

1. Optional output (dV/dt) lter heat dissipation

Type Code

ACS880-01-02A1-5+C212 1 75 TCI - V1K3A00

ACS880-01-03A0-5+C212 1.5 75 TCI - V1K3A00

ACS880-01-03A4-5+C212 2 75 TCI - V1K4A00

ACS880-01-04A8-5+C212 3 80 TCI - V1K6A00

ACS880-01-07A6-5+C212 5 95 TCI - V1K12A00

ACS880-01-11A0-5+C212 7.5 95 TCI - V1K12A00

ACS880-01-014A-5+C212 10 95 TCI - V1K16A00

Rating at

480 V (HP)

2. External output (dV/dt) lter: Below are recommendations for a lter

located outside the extension box. Filters shown are for 480V motors.

230V motors typically do not require lters. Filters are not readily avail-

able for 575V motors.

Type Code

ACS880-01-021A-5+C212 15 TCI - V1K21A01

ACS880-01-027A-5+C212 20 TCI - V1K27A01

ACS880-01-034A-5+C212 25 TCI - V1K35A01

ACS880-01-040A-5+C212 30 TCI - V1K45A01

ACS880-01-052A-5+C212 40 TCI - V1K55A01

ACS880-01-065A-5+C212 50 TCI - V1K80A01

ACS880-01-077A-5+C212 60 TCI - V1K80A01

ACS880-01-096A-5+C212 75 TCI - V1K110A01

ACS880-01-124A-5+C212 100 TCI - V1K130A01

ACS880-01-156A-5+C212 125 TCI - V1K160A01

ACS880-01-180A-5+C212 150 TCI - V1K200A01

Rating at

480 V (HP)

Filter Loss

(Watts)

Recommended Filter

Replacement Part

9. Switches and Pilot Lights (G3xx, G4xx) -

UL Type 12 only

Variant

G302

G303

G331 Estop

G401

G404 Fault Reset DI-3 Reset

Variant

G327

G328

G329 Fault (red) XRO-3 Faulted Illuminates when the drive has generated a fault

Code

Code

Switch

Hand/Off/

Auto

Speed

Potentiometer

Start/

Stop Push

Button

Pilot Light

Ready

(white)

Run

(green)

Signal

No.

DI-1

DI-3

AI-1

IN1

IN2

DI-1

DI-2

Signal

No.

DIO-1

DIO-2

Signal

Name

Stop (0) /

Start (1)

Hand (0) /

Auto (1)

Speed

Reference

Safe

Torque

Off

Start

Stop

Signal

Name

Output:

Ready

Output:

Running

Description

Three-position selector switch for selecting between hand

(manual), off and automatic mode. IMPORTANT: Must be

congured. Select the hand/auto macro with parameter

96.04. Refer to the ACS880 Firmware Manual, chapter

Application Macros.

Used to select the motor speed while in hand (manual)

mode. Parameter 22.81 shows the actual value.

Red mushroom pushbutton for de-energizing the motor

when the button is pressed. Refer to the ACS880 Hard-

ware Manual, chapter Safe Torque Off Function.

Two (2) push buttons for energizing and de-energizing the

motor. IMPORTANT: Must be congured. Change

parameter 20.01 to (4) “In1P Start; In2 Stop.” Reassign

DI01 or DI02 as Fault Reset input when G302 and hand/

auto macro are used.

Black ush push button for resetting a fault. (Not

compatible with hand/auto macro.)

Description

Illuminates when the drive is able to control the motor

illuminates when the motor is energized by the drive

10. Technical Specications

1.In addition to the following, see ACS880-01 Hardware Manual, chapter:

Technical Specications.

a. Environment: -15 to 40°C (5 to 104°F). -15 to 55°C (5 to 131°F) w/

derate. No frost allowed.

b. Cooling, UL Type 1 (IP21): 3 - 10 HP: forced air via VFD;

15 HP and above: non-ventilated

c. Cooling, UL Type 12 (IP54): non-ventilated

d. Input voltage range – standard: 208-240 V; 380-500 V; 525-690 V

e. Input voltage range – with optional control power transformer

(G304): 208 V, 240 V; 480 V; 575 V

f. Short circuit rating (UL 508c) – standard: 100,000 rms

symmetrical Amperes up to 600 V when protected by class J

fuses. Fuses to be installed upstream of the supplied drive;

supplied by others.

g. Short circuit rating (UL 508c) – with optional input disconnect

(F253): 100,000 rms symmetrical amperes up to 600 V

h. Frequency – standard: 0 - 500 Hz

i. Frequency – with optional dV/dt lter (E205): 0 - 60 Hz

j. Approvals – The ACS880 Extension Box is cULus Listed per

UL508A

11. Fuses

1. Control power transformer

a. Primary: (2) FNQR-1-½

b. Secondary: (1) FNM-2

2. Drive input fuses and overload protection fuses

ACS880 Extension Box

Drive Rating

ACS880-01…

230 V 480 V 575 V UL Class J UL Class T

04A6-2 07A6-5 200 JJS-15

06A6-2 200 JJS-15

07A5-2 07A3-7 200 JJS-15

10A6-2 11A0-5 09A8-7 200 JJS-20

16A8-2 014A-5 200 JJS-25

24A3-2 027A-5 018A-7 200 JJS-40

031A-2 034A-5 022A-7 200 JJS-50

046A-2 052A-5 042A-7 200 JJS-80

061A-2 200 JJS-100

075A-2 200 JJS-125

087A-2 200 JJS-125

115A-2 096A-5 084A-7 200 JJS-150

145A-2 124A-5 119A-7 200 JJS-200

170A-2 600 JJS-250

1. Only needed when disconnect switch option is omitted, the table shows the maximum

Amperage rating of branch circuit fuses to be installed upstream of the supplied drive.

Required to maintain 100 kA SCCR. Fuses supplied and installed by others.

2. Line fuses are included inside the Extension Box

02A1-5 200 JJS-3

03A0-5 200 JJS-6

03A4-5 200 JJS-6

04A8-5 200 JJS-10

05A2-5 200 JJS-10

14A2-7 200 JJS-30

021A-5 200 JJS-35

026A-7 200 JJS-50

040A-5 035A-7 200 JJS-60

049A-7 200 JJS-80

065A-5 200 JJS-90

077A-5 061A-7 200 JJS-110

098A-7 200 JJS-150

156A-5 600 JJS-225

180A-5 600 JJS-300

Maximum

Overcurrent

Protection Fuse

(Amps)

1

Internal Line

2

Fuses

12. Main Cooling Fan Replacement

1. R1 to R5: The main cooling fan is located on the top of the

base drive. Removal and replacement can be done without

removing the base drive from the back panel. Follow the instructions in the ACS880-01 Hardware Manual, chapter: Fans.

2. R6 & R7: The main cooling fan is located on the bottom of the

base drive.

a. Disconnect the drive from the power line. Lock the main

disconnecting device and ensure by measuring that there

is no voltage.

b. Method 1: Remove the fan mounting screws (2) with a

screwdriver by reaching behind the extension box from

below.

c. Method 2: After disconnecting the wires, remove the base

drive from the back panel by removing only the two mounting nuts at the top. (Nuts at the bottom should not be

removed.) Use the lifting eyes on the base drive to remove

and lift the unit to gain access to the cooling fan at the

bottom. To remount the base drive, slide the slots at the

bottom over the two lower studs and drop the base drive

onto the top two studs. Reattach the two nuts. Reconnect the wires.

d. For fan replacement, follow the instructions in the ACS880-

01 Hardware Manual, chapter: Fans.

13. Drive Removal Procedure

Use the same procedure as Method 2 above to remove

the base drive for all of the frames.

3AXD50000043508 REVB Effective: 04/20/2017. Subject to change without notice.

Loading...

Loading...