Abb ACS880 User Manual

ABB industrial drives

Firmware manual

ACS880 primary control program

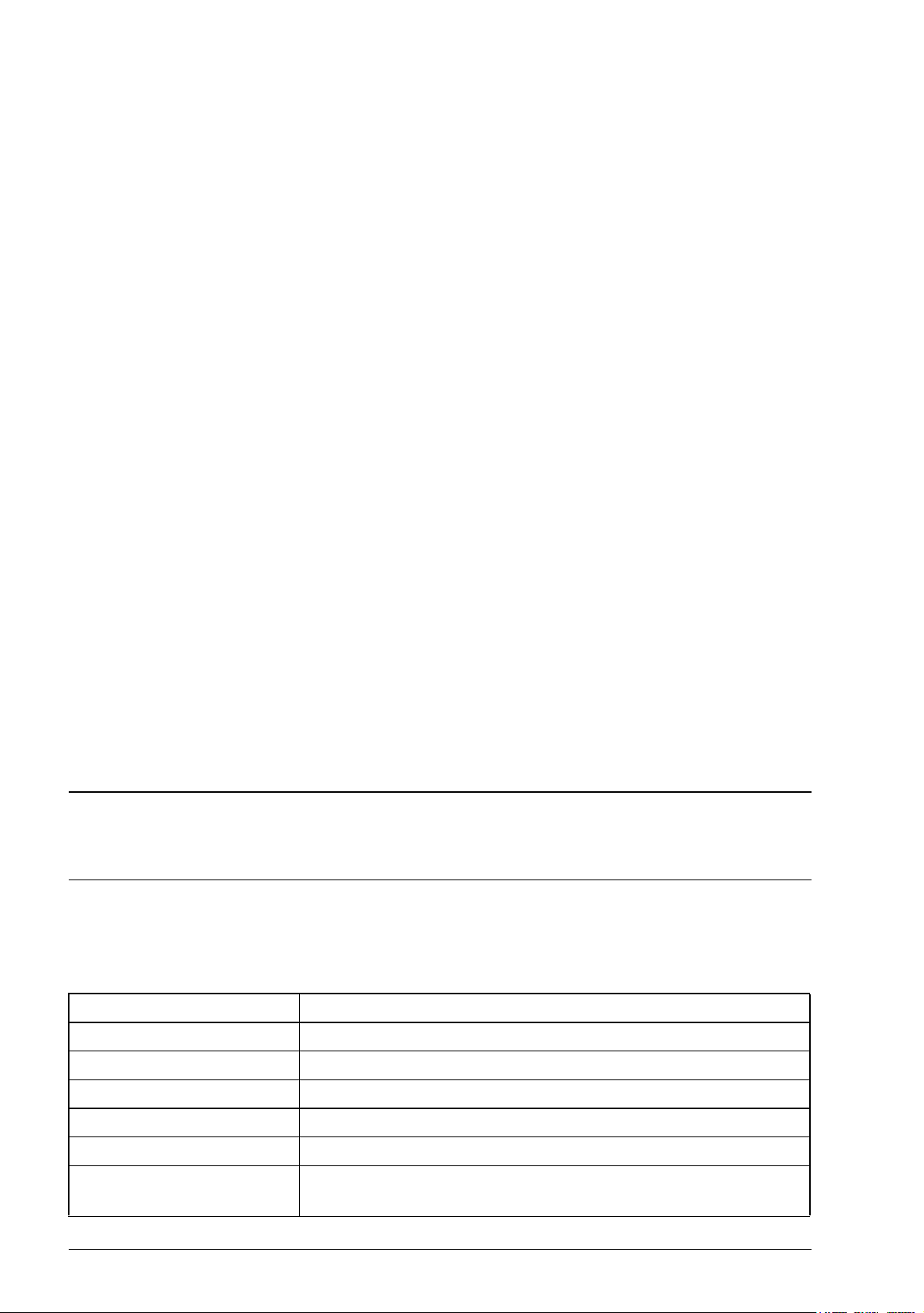

List of related manuals in English

ACS880-01 manuals

Drive hardware manuals and guides Code (English)

ACS880-01 hardware manual 3AUA0000078093

ACS880-01 quick installation guide for frames R1 to R3 3AUA0000085966

ACS880-01 quick installation guide for frames R4 and R5 3AUA0000099663

ACS880-01 quick installation guide for frames R6 to R9 3AUA0000099689

Drive firmware manuals and guides

ACS880 primary control program firmware manual 3AUA0000085967

ACS880 drives with primary control program, quick start-

up guide

Option manuals and guides

ACS-AP-I and ACS-AP-S assistant control panel user’s

manual

Drive composer Start-up and maintenance PC tool User’s

manual

Manuals and quick guides for I/O extension modules,

fieldbus adapters, encoder interfaces, etc.

3AUA0000098062

3AUA0000085685

3AUA0000094606

You can find manuals and other product documents in PDF format on the Internet. See section

Document library on the Internet on the inside of the back cover. For manuals not available in the

Document library, contact your local ABB representative.

Firmware manual

ACS880 primary control program

Table of contents

2012 ABB Oy. All Rights Reserved.

3AUA0000085967 Rev C

EN

EFFECTIVE: 2012-04-01

Table of contents 5

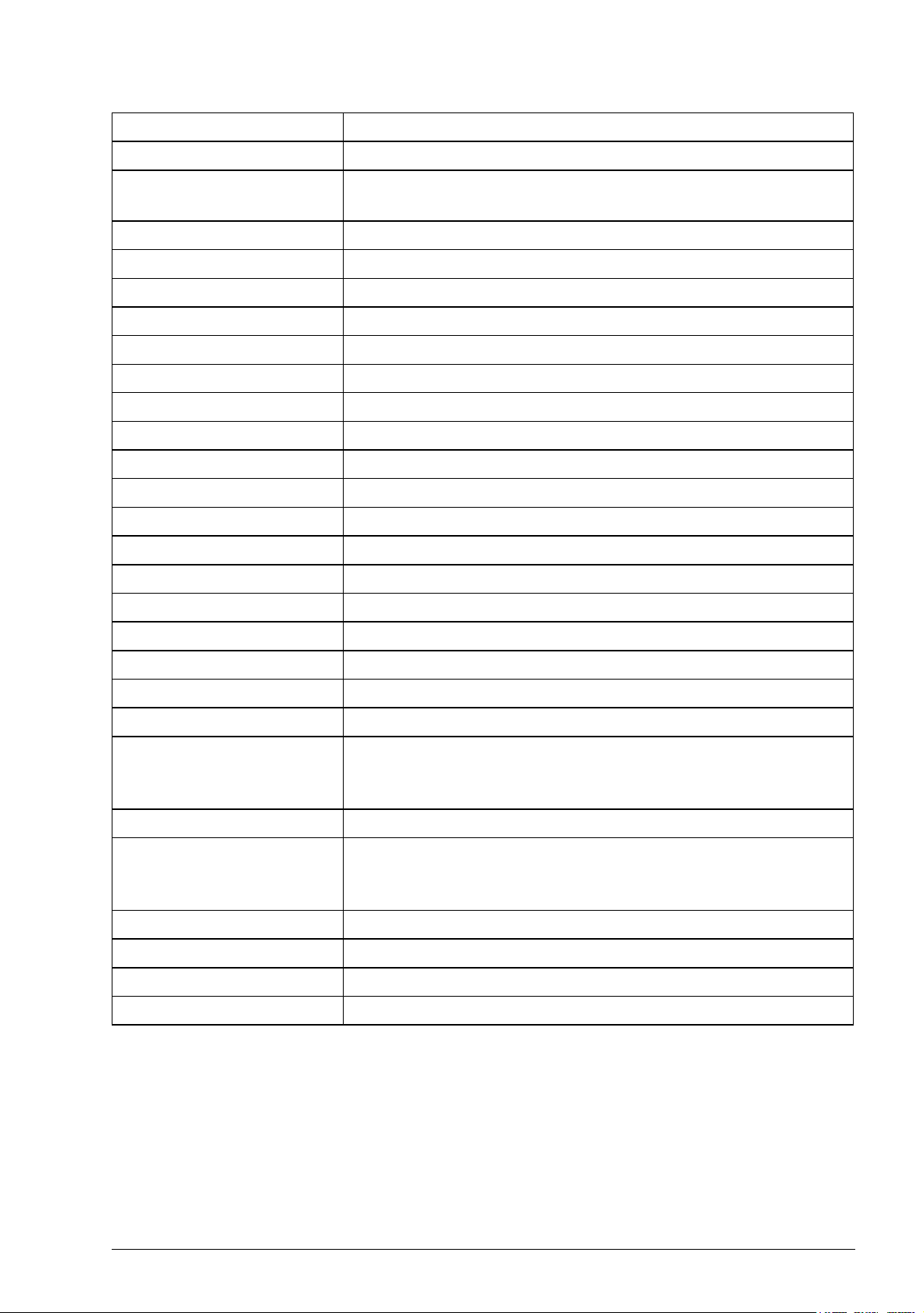

Table of contents

List of related manuals in English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. Introduction to the manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Contents of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2. Using the control panel

Safety

3. Control locations and operating modes

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Local control vs. external control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Local control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

External control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operating modes of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Speed control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Torque control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Frequency control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Special control modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Program features

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Drive configuration and programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Programming via parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Application programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Programmable analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Programmable analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Programmable digital inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Programmable relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Programmable I/O extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Direct torque control (DTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Reference ramping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Constant speeds (frequencies) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Critical speeds (frequencies) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Encoder support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Jogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Scalar motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6 Table of contents

Autophasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Flux braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DC magnetization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Application control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Application macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Process PID control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Mechanical brake control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

DC voltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Overvoltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Undervoltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Voltage control and trip limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Brake chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Safety and protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Motor thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Programmable protection functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Automatic fault resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Signal supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Maintenance timers and counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Energy savings calculator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Data storage parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5. Application macros

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Factory macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Default parameter settings for the Factory macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Default control connections for the Factory macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Hand/Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Default parameter settings for the Hand/Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Default control connections for the Hand/Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

PID control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Default parameter settings for the PID control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Default control connections for the PID control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Sensor connection examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Torque control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Default parameter settings for the Torque control macro . . . . . . . . . . . . . . . . . . . . . . . . . 66

Default control connections for the Torque control macro . . . . . . . . . . . . . . . . . . . . . . . . 67

Sequential control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Operation diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Selection of constant speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Default parameter settings for the Sequential control macro . . . . . . . . . . . . . . . . . . . . . . 69

Default control connections for the Sequential control macro . . . . . . . . . . . . . . . . . . . . . 70

Fieldbus control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table of contents 7

6. Parameters

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Summary of parameter groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Parameter listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

01 Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

03 Input references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

04 Warnings and faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

05 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

06 Control and status words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

07 System info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10 Standard DI, RO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11 Standard DIO, FI, FO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12 Standard AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

13 Standard AO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

19 Operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

20 Start/stop/direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

21 Start/stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

22 Speed reference selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

23 Speed reference ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

24 Speed reference conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

25 Speed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

26 Torque reference chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

28 Frequency reference chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

30 Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

31 Fault functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

32 Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

33 Maintenance timer & counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

35 Motor thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

36 Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

40 Process PID set 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

41 Process PID set 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

43 Brake chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

44 Mechanical brake control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

45 Energy efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

46 Monitoring/scaling settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

47 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

49 Panel port communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

50 Fieldbus adapter (FBA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

51 FBA A settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

52 FBA A data in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

53 FBA A data out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

90 Feedback selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

91 Encoder module settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

92 Encoder 1 configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

93 Encoder 2 configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

95 HW configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

96 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

97 Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

98 User motor parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

8 Table of contents

99 Motor data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

7. Additional parameter data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Fieldbus addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Parameter groups 1…9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Parameter groups 10…99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

8. Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

How to reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Warning/fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Parameters that contain warning/fault information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

9. Fieldbus control through the embedded fieldbus interface (EFB)

10. Fieldbus control through a fieldbus adapter

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Basics of the fieldbus control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Control word and Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Contents of the fieldbus Control word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Contents of the fieldbus Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

The state diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Setting up the drive for fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Parameter setting example: FPBA (PROFIBUS DP) . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

11. Drive-to-drive link

12. Control chain diagrams

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Speed reference source selection I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Speed reference source selection II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Speed reference ramping and shaping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Motor feedback configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Speed error calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Speed controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Torque reference source selection and modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Reference selection for torque controller I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Reference selection for torque controller II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Table of contents 9

Torque limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Frequency reference selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Frequency reference modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Process PID setpoint and feedback source selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Process PID controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

10 Table of contents

Introduction to the manual 11

1

Introduction to the manual

What this chapter contains

This chapter describes the contents of the manual. It also contains information on the

compatibility, safety and intended audience.

Applicability

This manual applies to the ACS880 primary control program (version 1.10 or later).

The firmware version of the control program is visible in parameter 07.05 Firmware

version.

Safety instructions

Follow all safety instructions delivered with the drive.

• Read the complete safety instructions before you install, commission, or use

the drive. The complete safety instructions are delivered with the drive as either

part of the Hardware manual, or, in the case of ACS880 multidrives, as a separate

document.

• Read the firmware function-specific warnings and notes before changing

parameter values. These warnings and notes are included in the parameter

descriptions presented in chapter Parameters.

Target audience

This manual is intended for people who design, commission, or operate the drive

system.

12 Introduction to the manual

Contents of the manual

This manual consists of the following chapters:

• Using the control panel provides the basic instructions for use of the control panel.

• Control locations and operating modes describes the control locations and

operating modes of the drive.

• Program features contains descriptions of the features of the ACS880 primary

control program.

• Application macros contains a short description of each macro together with a

connection diagram.

• Parameters describes the parameters of the drive.

• Additional parameter data contains further information on the parameters.

• Fault tracing lists the warning and fault messages with possible causes and

remedies.

• Fieldbus control through the embedded fieldbus interface (EFB) describes the

communication to and from a fieldbus network using the embedded fieldbus

interface of the drive.

• Fieldbus control through a fieldbus adapter describes the communication to and

from a fieldbus network using an optional fieldbus adapter module.

• Drive-to-drive link describes the communication between drives connected

together by the drive-to-drive (D2D) link.

• Control chain diagrams.

Related documents

Note: A quick start-up sequence for a speed control application is provided by

ACS880 drives with primary control program, Quick start-up guide

(3AUA0000098062), delivered with the drive.

A list of related manuals is printed on the inside of the front cover.

Terms and abbreviations

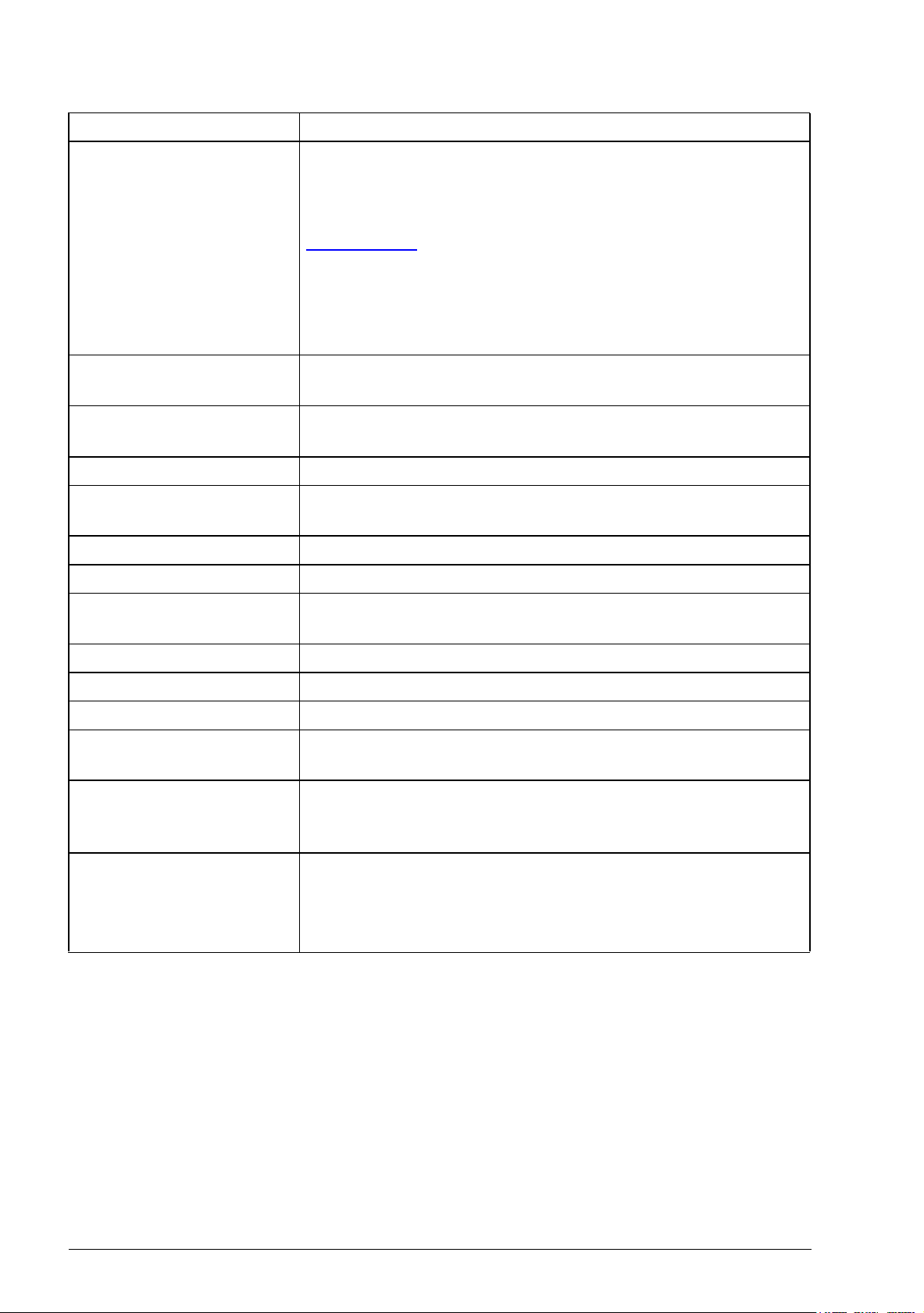

Term/abbreviation Definition

ACS-AP-I Type of control panel used with ACS880 drives

AI Analog input; interface for analog input signals

AO Analog output; interface for analog output signals

BCU Type of control unit used in ACS880 drives.

DC link DC circuit between rectifier and inverter

DDCS Distributed drives communication system; a protocol used in

optical fiber communication

Introduction to the manual 13

Term/abbreviation Definition

DI Digital input; interface for digital input signals

DIO Digital input/output; interface that can be used as a digital input

or output

DO Digital output; interface for digital output signals

DTC Direct torque control

EFB Embedded fieldbus

FBA Fieldbus adapter

FEN-01 Optional TTL encoder interface module

FEN-11 Optional absolute encoder interface module

FEN-21 Optional resolver interface module

FEN-31 Optional HTL encoder interface module

FIO-01 Optional digital I/O extension module

FIO-11 Optional analog I/O extension module

FCAN-0x Optional CANopen adapter

FDNA-0x Optional DeviceNet adapter

FECA-01 Optional EtherCAT® adapter

FENA-11 Optional Ethernet/IP adapter

FLON-0x Optional L

ONWORKS

®

adapter

FPBA-0x Optional PROFIBUS DP adapter

FSCA-0x Optional Modbus adapter

HTL High-threshold logic

IGBT Insulated gate bipolar transistor; a voltage-controlled

semiconductor type widely used in inverters due to their easy

controllability and high switching frequency

I/O Input/Output

ID run Motor identification run. During the identification run, the drive

will identify the characteristics of the motor for optimum motor

control.

LSB Least significant bit

LSW Least significant word

MSB Most significant bit

MSW Most significant word

14 Introduction to the manual

Term/abbreviation Definition

Network control With fieldbus protocols based on the Common Industrial

Protocol (CIP

TM

), such as DeviceNet and Ethernet/IP, denotes

the control of the drive using the Net Ctrl and Net Ref objects of

the ODVA AC/DC Drive Profile. For more information, see

www.odva.org

, and the following manuals:

• FDNA-01 DeviceNet adapter module User’s manual

(3AFE68573360 [English]), and

• FENA-01/-11 Ethernet adapter module User’s manual

(3AUA0000093568 [English]).

Parameter User-adjustable operation instruction to the drive, or signal

measured or calculated by the drive

PID controller Proportional–integral–derivative controller. Drive speed control

is based on PID algorithm.

PLC Programmable logic controller

Power unit Contains the power electronics and connections of the drive.

The drive control unit is connected to the power unit.

PTC Positive temperature coefficient

RFG Ramp function generator.

RO Relay output; interface for a digital output signal. Implemented

with a relay.

SSI Synchronous serial interface

STO Safe torque off

TTL Transistor-transistor logic

UPS Uninterruptible power supply; power supply equipment with

battery to maintain output voltage during power failure

ZCON Type of control board used in ACS880 drives. The board is

either integrated into the drive or fitted in a plastic housing (see

ZCU).

ZCU Type of control unit used in ACS880 drives that consists of a

ZCON board built into a plastic housing.

The control unit may be fitted onto the drive/inverter module, or

installed separately.

Using the control panel 15

2

Using the control panel

Refer to ACS-AP-I and ACS-AP-S assistant control panels user’s manual

(3AUA0000085685 [English]).

16 Using the control panel

Control locations and operating modes 17

3

Control locations and operating modes

What this chapter contains

This chapter describes the control locations and operating modes supported by the

control program.

18 Control locations and operating modes

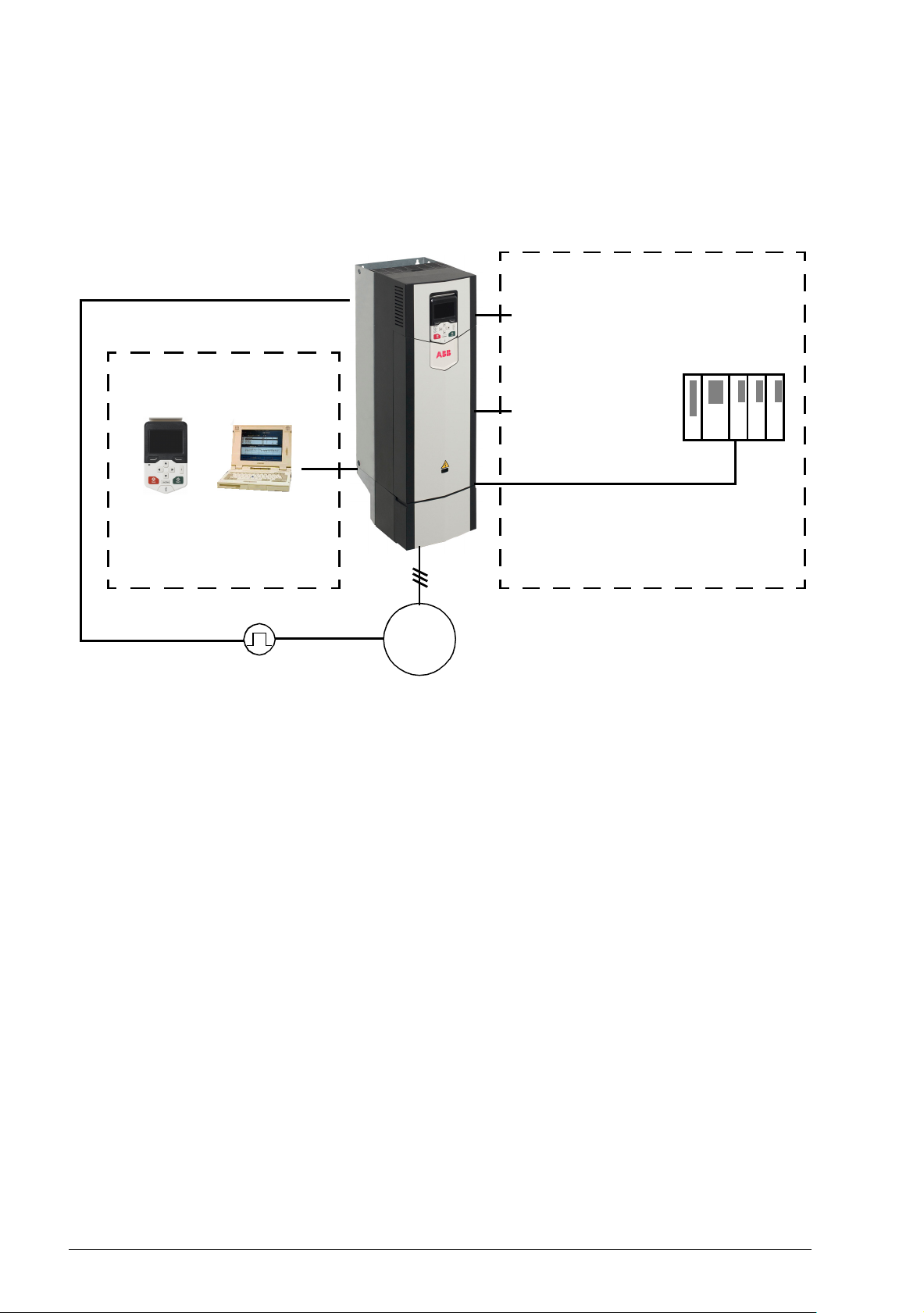

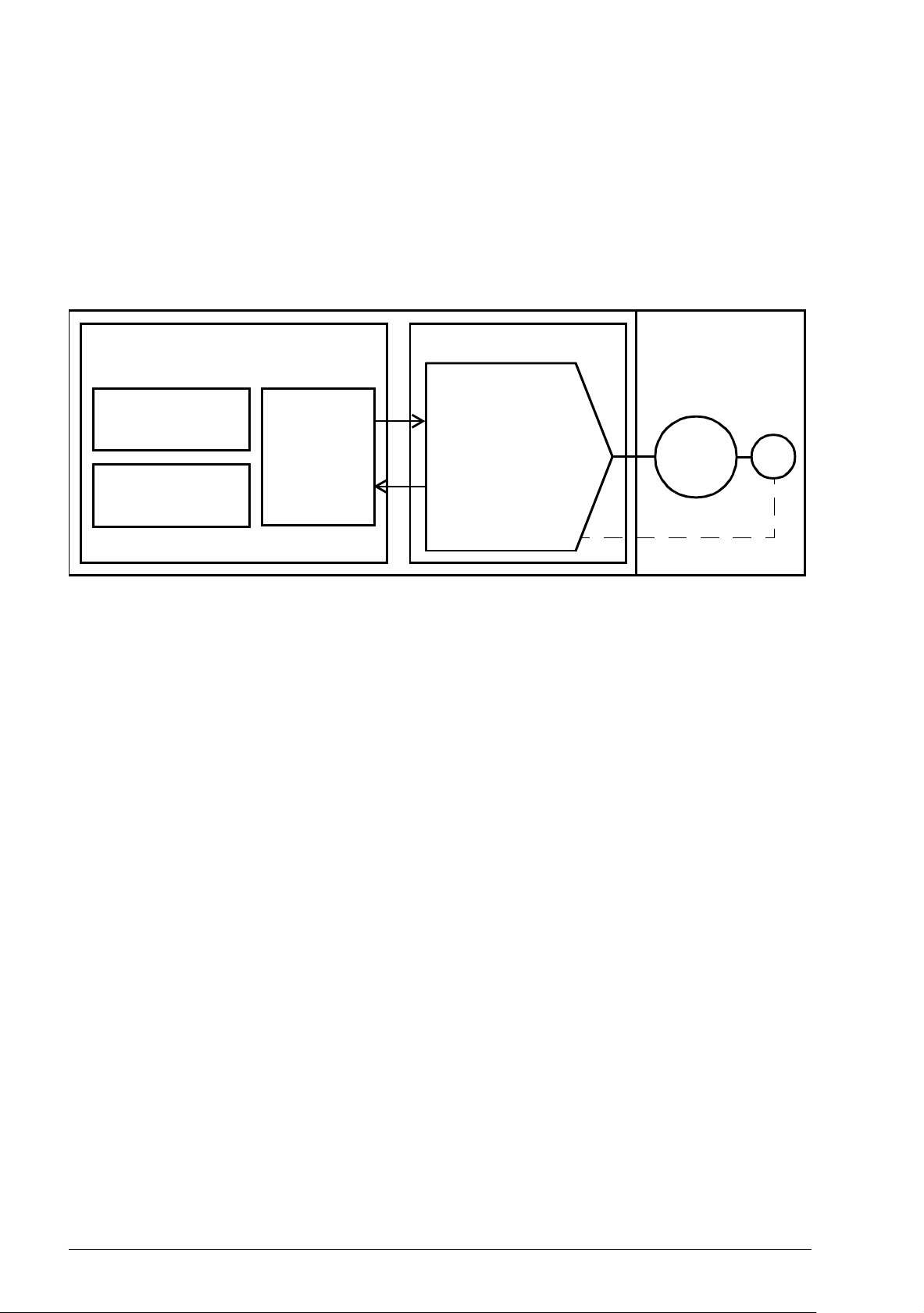

Control panel or Drive composer

PC tool (optional)

Fieldbus adapter or DDCS

communication module

Fxxx

1) Extra inputs/outputs can be added by installing optional I/O extension modules (FIO-xx) in

drive slots.

2) Encoder or resolver interface module(s) (FEN-xx) installed in drive slots.

MOTOR

PLC

(= Programmable

logic controller)

M

3~

I/O

1)

Drive-to-drive (D2D)

link or Embedded

fieldbus interface

External control

Local control

Encoder

2)

ACS880

Local control vs. external control

The ACS880 has two main control locations: external and local. The control location

is selected with the Loc/Rem key on the control panel or in the PC tool.

Local control

The control commands are given from the control panel keypad or from a PC

equipped with Drive composer when the drive is in local control. Speed and torque

control modes are available for local control; frequency mode is available when scalar

motor control mode is used (see parameter 19.16 Local control mode).

Local control is mainly used during commissioning and maintenance. The control

panel always overrides the external control signal sources when used in local control.

Changing the control location to local can be prevented by parameter 19.17 Local

control disable.

The user can select by a parameter (49.05 Communication loss action) how the drive

reacts to a control panel or PC tool communication break. (The parameter has no

effect in external control.)

Control locations and operating modes 19

External control

When the drive is in external control, control commands are given through the

fieldbus interface (via or an optional fieldbus adapter module), the I/O terminals

(digital and analog inputs), or optional I/O extension modules.

Two external control locations, EXT1 and EXT2, are available. The user can select

the sources of the start and stop commands separately for each location by

parameters 20.01…20.10. The operating mode can be selected separately for each

location, which enables quick switching between different operating modes, for

example speed and torque control. Selection between EXT1 and EXT2 is done via

any binary source such as a digital input or fieldbus control word (see parameter

19.11 Ext1/Ext2 selection). The source of reference is selectable for each operating

mode separately.

20 Control locations and operating modes

Motor feedback

configuration

(page 291)

Speed

reference

source selection

I

(page 288)

Speed controller

(page 293)

Speed reference

source selection

II

(page 289)

Speed reference

ramping and

shaping

(page 290)

Speed error

calculation

(page 292)

Torque

reference

source selection

and modification

(page 294)

Reference

modification for

torque controller

(page 296)

Frequency

reference

source selection

and modification

(page 298)

Reference

selection for

torque controller

(page 295)

Torque

controller

DTC motor

control mode

Scalar motor

control mode

Process PID

setpoint and

feedback source

selection

(page 300)

Process PID

controller

(page 301)

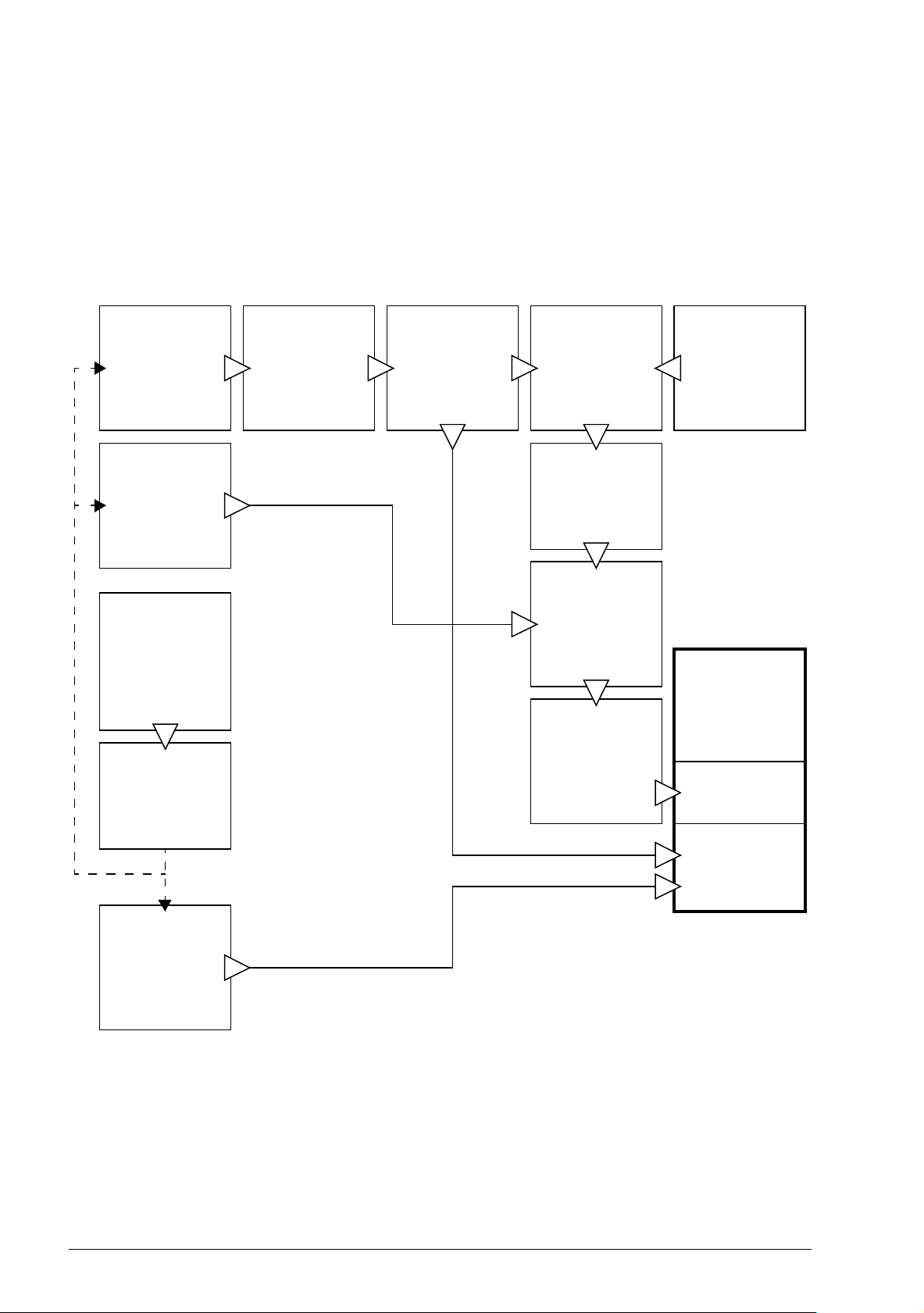

Operating modes of the drive

The drive can operate in several operating modes with different types of reference.

The mode is selectable for each control location (Local, EXT1 and EXT2) in

parameter group 19 Operation mode.

The following is a general representation of the reference types and control chains.

The page numbers refer to detailed diagrams in chapter Control chain diagrams.

Speed control mode

The motor follows a speed reference given to the drive. This mode can be used either

with estimated speed used as feedback, or with an encoder or resolver for better

speed control accuracy.

Control locations and operating modes 21

Speed control mode is available in both local and external control. It is also available

both in DTC (Direct Torque Control) and scalar motor control modes.

Torque control mode

Motor torque follows a torque reference given to the drive. This mode can be used

either with or without an encoder or resolver. When used with an encoder or resolver,

this mode provides for more accurate and dynamic motor control.

Torque control mode is available in both local and external control.

Frequency control mode

The motor follows a frequency reference given to the drive. Frequency control is only

available for scalar motor control.

Special control modes

In addition to the above-mentioned control modes, the following special control

modes are available:

• Process PID control. For more information, see section Process PID control (page

38).

• Emergency stop modes OFF1 and OFF3: Drive stops along the defined

deceleration ramp and drive modulation stops.

• Jogging mode: Drive starts and accelerates to the defined speed when the

jogging signal is activated. For more information, see section Jogging (page 31).

22 Control locations and operating modes

4

Program features

Program features 23

What this chapter contains

This chapter describes the features of the control program.

24 Program features

Application program

Firmware

Speed control

Torque control

Frequency control

Drive logic

I/O interface

Fieldbus interface

Protections

Feedback

Standard

block library

Function block

program

Drive control program

Parameter

interface

M

E

Drive configuration and programming

The drive control program is divided into two parts:

• firmware program

• application program.

The firmware program performs the main control functions, including speed and

torque control, drive logic (start/stop), I/O, feedback, communication and protection

functions. Firmware functions are configured and programmed with parameters.

Programming via parameters

Parameters can be set via

• the control panel, as described in chapter Using the control panel

• the Drive composer PC tool, as described in Drive composer user’s manual

(3AUA0000094606 [English]), or

• the fieldbus interface, as described in chapters Fieldbus control through the

embedded fieldbus interface (EFB) and Fieldbus control through a fieldbus

adapter.

All parameter settings are stored automatically to the permanent memory of the drive.

However, if an external +24 V DC power supply is used for the drive control unit, it is

highly recommended to force a save by using parameter 96.07 Parameter save

before powering down the control unit after any parameter changes.

If necessary, the default parameter values can be restored by parameter 96.06

Parameter restore.

Application programming

The functions of the firmware program can be extended with application

programming. (A standard drive delivery does not include an application program.)

Program features 25

Application programs can be built out of function blocks based on the IEC-61131

standard.

26 Program features

Control interfaces

Programmable analog inputs

The drive control unit has two programmable analog inputs. Each of the inputs can be

independently set as a voltage (0/2…10 V or -10…10 V) or current (0/4…20 mA)

input by a jumper on the drive control unit. Each input can be filtered, inverted and

scaled. The number of analog inputs can be increased by using FIO-xx I/O

extensions.

Settings

Parameter group 12 Standard AI (page 93).

Programmable analog outputs

The drive control unit has two current (0…20 mA) analog outputs. Each output can be

filtered, inverted and scaled. The number of analog outputs can be increased by

using FIO-xx I/O extensions.

Settings

Parameter group 13 Standard AO (page 95).

Programmable digital inputs and outputs

The drive has six digital inputs, a digital start interlock input, and two digital

input/outputs.

One digital input (DI6) doubles as a PTC thermistor input. See section Motor thermal

protection (page 49).

Digital input/output DIO1 can be used as a frequency input, DIO2 as a frequency

output.

The number of digital inputs/outputs can be increased by using FIO-xx I/O

extensions.

Settings

Parameter groups 10 Standard DI, RO (page 83) and 11 Standard DIO, FI, FO (page

88).

Programmable relay outputs

The drive control unit has three relay outputs. The signal to be indicated by the

outputs can be selected by parameters.

Relay outputs can be added by using FIO-0x I/O extensions.

Program features 27

Settings

Parameter group 10 Standard DI, RO (page 83).

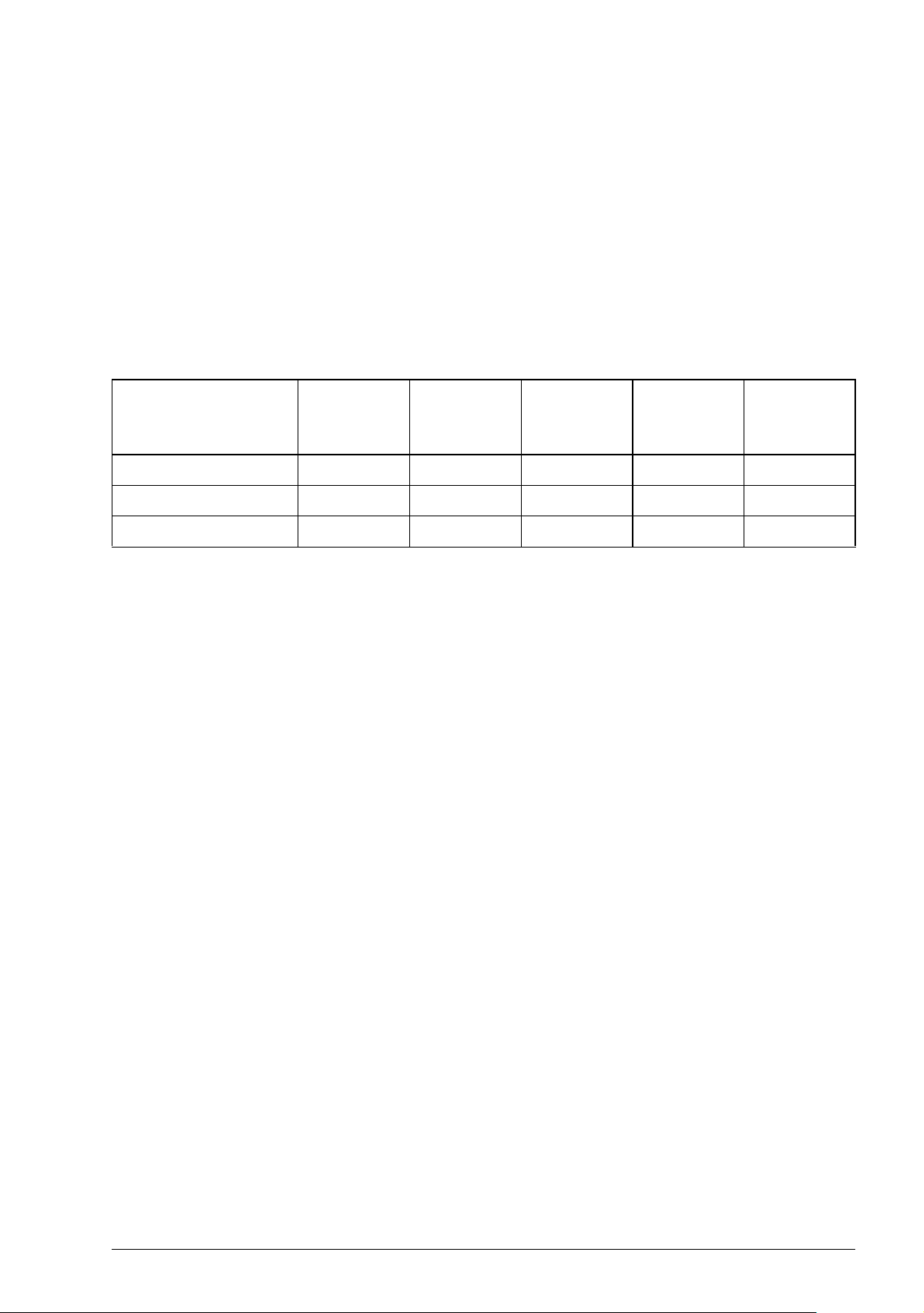

Programmable I/O extensions

The number of inputs and outputs can be increased by using FIO-xx I/O extensions.

The I/O configuration parameters (parameter groups 10…13) include the maximum

number of DI, DIO, AI, AO and RO that can be in use with different FIO-xx

combinations.

The table below shows the possible I/O combinations:

Digital

Location

Drive control unit72223

FIO-01 - 4 - - 2

FIO-11 -231 -

inputs

(DI)

Digital I/Os

(DIO)

Analog

inputs

(AI)

Analog

outputs

(AO)

Relay

outputs

(RO)

For example, with an FIO-01 and an FIO-11 connected to the drive, parameters

controlling DI1…7, DIO1…8, AI1…5, AO1…3 and RO1…5 are in use.

Settings

Parameter groups 10 Standard DI, RO (page 83), 11 Standard DIO, FI, FO (page 88),

12 Standard AI (page 93) and 13 Standard AO (page 95).

Fieldbus control

The drive can be connected to several different automation systems through its

fieldbus interfaces. See chapter Fieldbus control through a fieldbus adapter (page

273)

Settings

Parameter groups 50 Fieldbus adapter (FBA) (page 193), 51 FBA A settings (page

197), 52 FBA A data in (page 198), and 53 FBA A data out (page 199).

28 Program features

Motor control

Direct torque control (DTC)

The motor control of the ACS880 is based on direct torque control (DTC). The

switching of the output semiconductors is controlled to achieve the required stator

flux and motor torque. The switching frequency is changed only if the actual torque

and stator flux values differ from their reference values by more than the allowed

hysteresis. The reference value for the torque controller comes from the speed

controller or directly from an external torque reference source.

Motor control requires measurement of the DC voltage and two motor phase

currents. Stator flux is calculated by integrating the motor voltage in vector space.

Motor torque is calculated as a cross product of the stator flux and the rotor current.

By utilizing the identified motor model, the stator flux estimate is improved. Actual

motor shaft speed is not needed for the motor control.

The main difference between traditional control and DTC is that torque control has

the same time level as the power switch control. There is no separate voltage and

frequency controlled PWM modulator; the output stage switching is wholly based on

the electromagnetic state of the motor.

The best motor control accuracy is achieved by activating a separate motor

identification run (ID run).

See also section Scalar motor control (page 33).

Settings

Parameters 99.04 Motor ctrl mode (page 220) and 99.13 Identification run request

(page 222).

Reference ramping

Acceleration and deceleration ramping times can be set individually for speed, torque

and frequency reference.

With a speed or frequency reference, the ramps are defined as the time it takes for

the drive to accelerate or decelerate between zero speed or frequency and the value

defined by parameter 46.01 Speed scaling or 46.02 Frequency scaling. The user can

switch between two preset ramp sets using a binary source such as a digital input.

For speed reference, also the shape of the ramp can be controlled.

With a torque reference, the ramps are defined as the time it takes for the reference

to change between zero and nominal motor torque (parameter 01.30 Nominal torque

scale).

Program features 29

Special acceleration/deceleration ramps

The acceleration/deceleration times for the jogging function can be defined

separately; see section Jogging (page 31). Furthermore, a deceleration ramp can be

defined for emergency stop (“Off3” mode).

Settings

• Speed reference ramping: Parameters 23.11…23.19 and 46.01

(pages 119 and 189).

• Torque reference ramping: Parameters 01.30, 26.18 and 26.19

(pages 77 and 133).

• Frequency reference ramping: Parameters 28.71…28.75 and 46.02

(pages 139 and 189).

• Jogging: Parameters 23.20 and 23.21 (page 122).

• Emergency stop (“Off3” mode): Parameter 23.23 Emergency stop time

(page 122).

Constant speeds (frequencies)

It is possible to predefine up to 7 constant speeds. Constant speeds can be activated,

for example, through digital inputs. Constant speeds override the normal speed

reference.

For frequency control, seven constant frequencies can be defined in the same way.

Settings

Parameter groups 22 Speed reference selection (page 113 ) and 28 Frequency

reference chain (page 135).

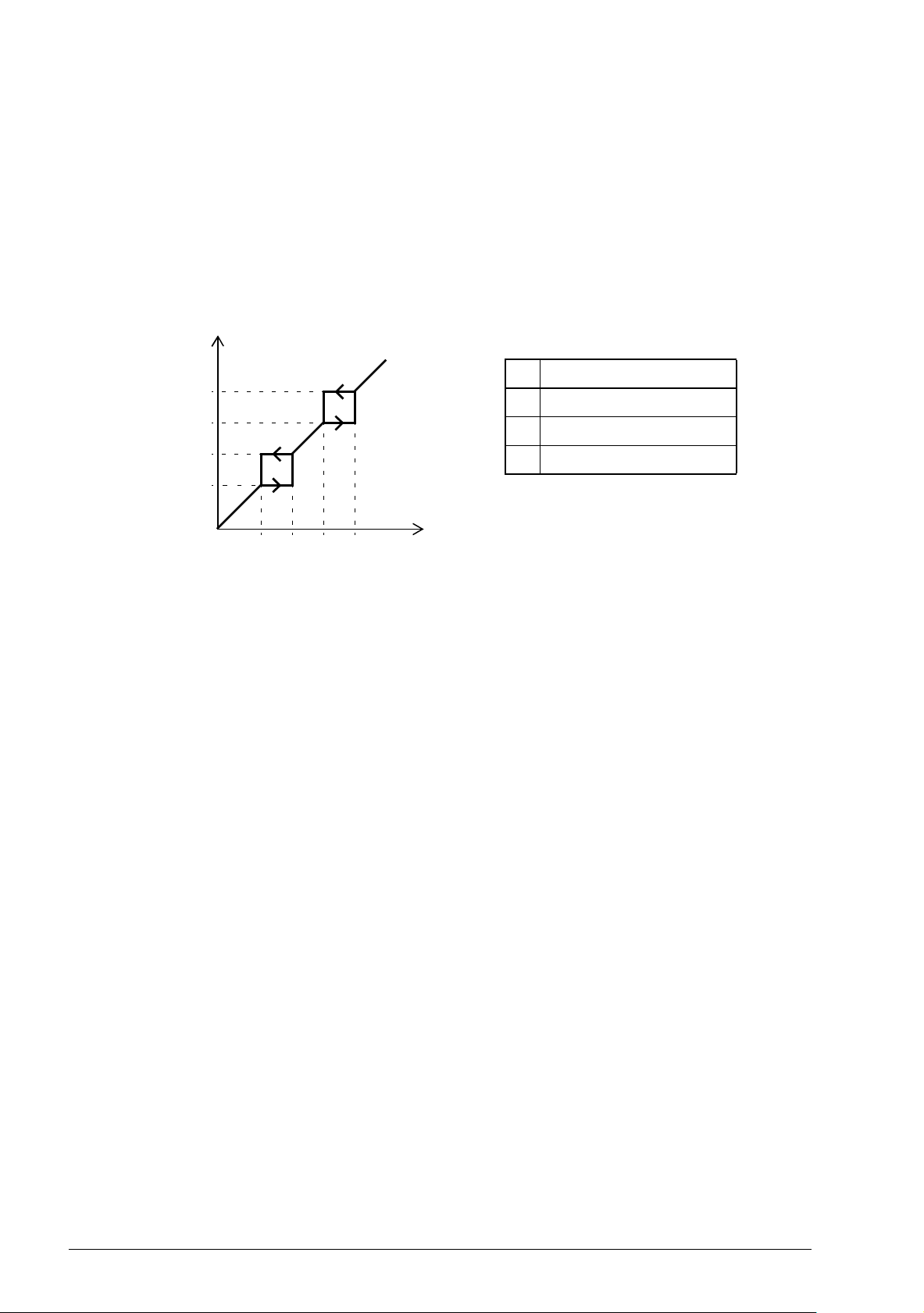

Critical speeds (frequencies)

A critical speeds function is available for applications where it is necessary to avoid

certain motor speeds or speed ranges because of, for example, mechanical

resonance problems.

A similar function is available for scalar motor control with a frequency reference.

30 Program features

540

690

1380

1560

1Par. 22.52 = 540 rpm

2Par. 22.53 = 690 rpm

3Par. 22.54 = 1380 rpm

4Par. 22.55 = 1560 rpm

1234

Motor speed

(rpm)

Speed reference

(rpm)

Example

A fan has vibrations in the range of 540 to 690 rpm and 1380 to 1560 rpm. To make

the drive jump over these speed ranges,

• enable the critical speeds function by turning on bit 0 of parameter 22.51 Critical

speed function, and

• set the critical speed ranges as in the figure below.

Settings

Parameter groups 22 Speed reference selection (page 113 ) and 28 Frequency

reference chain (page 135).

Encoder support

The program supports two single-turn or multiturn encoders (or resolvers). The

following optional interface modules are available:

• Absolute encoder interface FEN-11: absolute encoder input, TTL input, TTL

output (for encoder emulation and echo) and two digital inputs for position latching

• Resolver interface FEN-21: resolver input, TTL input, TTL output (for encoder

emulation echo) and two digital inputs for position latching

• HTL encoder interface FEN-31: HTL encoder input, TTL output (for encoder

emulation and echo) and two digital inputs for position latching.

The interface module is installed onto any option slot on the drive control unit, or onto

an FEA-xx extension adapter.

Quick configuration of HTL encoder feedback

1. Specify the type of the encoder interface module (parameter 91.11 Module 1 type

= FEN-31) and the slot the module is installed into (91.12 Module 1 location).

2. Specify the type of the encoder (92.01 Encoder 1 type = HTL). The parameter

listing will be re-read from the drive after the value is changed.

Loading...

Loading...