ABB ACS880 Catalog

Low voltage AC drives

ABB industrial drives

ACS880, single drives

0.75 to 4250 hp (0.55 to 3200 kW)

Catalog

ACS880 series drives

Uncompromised productivity

Contents

4 Simplifying your world without limiting your possibilities

6 What does all-compatible mean for you?

8 Cost and time savings with drive-based functional safety

9 Drive-based application programming

10 Save time, ease troubleshooting and improve drive performance with

ABB smartphone apps

12 How to select a drive

12 Technical data

13 Wall-mounted single drives, ACS880-01

14-15 Ratings, types and voltages, ACS880-01

16 Cabinet-built single drives, ACS880-07

17-19 Ratings, types and voltages, ACS880-07

20 Cabinet-built regenerative single drives, ACS880-17

21 Ratings, types and voltages, ACS880-17

22 Cabinet-built ultra-low harmonic single drives, ACS880-37

23 Ratings, types and voltages, ACS880-37

24 Standard interface and extensions for comprehensive connectivity

25 Standard software for scalable control and functionality

26-27 Application control programs

29 Designed to control virtually any type of AC motor

30 SynRM packages

31 Intuitive human-machine interface

31 PC tool for easy startup and maintenance

32 Integrated safety simplifies configuration

33 Drive application programming based on IEC standard 61131-3

34 Flexible connectivity to automation networks

35 Input/output extension modules for increased connectivity

35 Speed feedback interfaces for precise process control

35 I/O option extension adapter

35 DDCS communication option modules

35 Remote monitoring access worldwide

36 EMC – electromagnetic compatibility

37-39 Sine filters, ACS880-01, ACS880-07 and ACS880-17/-37

40 Brake options

41 Brake options, ACS880-01

42-43 Brake options, ACS880-07

44 Brake options, ACS880-37

45-46 du/dt filters

47 Dimensioning tool for selecting the optimal drive

49-51 Summary of features and options

52-53 Drive services

2 ABB industrial drives ACS880 single drives | Catalog

When your electric motor-driven application requires dependable capability and

scalability to meet your exact requirements for variable speed operation, you need

our ACS880 industrial drives. Our drives are built to truly understand and refi ne your

business and cover every possible application. We make your opportunities work

with our strong drives series that covers all your process control needs no matter

what your industry. These are our ACS880 industrial drives, our benchmark of

uncompromising productivity, serving you locally on a global scale.

Catalog | ABB industrial drives ACS880 single drives 3

Simplifying your world

without limiting your possibilities

Multidrives

The all-compatible drives are designed to provide customers

across industries and applications with unprecedented

levels of compatibility and flexibility. Our ACS880 single

drives are stand alone drives. They are customized to meet

the precise needs of industries such as oil and gas, mining,

metals, chemicals, cement, power plants, material handling,

pulp and paper, sawmills, marine, water and wastewater,

food and beverage and automotive. They control a wide

range of applications such as cranes, extruders, winches,

winders, conveyors, mixers, compressors, centrifuges, test

bences, elevators, extruders, pumps and fans.

Direct torque control (DTC)

ABB’s signature motor control technology

provides precise speed and torque control

for all applications and virtually any type of

AC motor.

See page 24

Application control programs

A range of ready-made programs to optimize

productivity and usability in applications such as

cranes, winches and artificial lifting.

See page 25

Removable memory unit

Stores all the software and parameter

configurations in an easily replaceable

and simple-to-install module.

See page 24

Energy effi ciency

The drive provides features such as an energy optimizer

and energy efficiency information that help you monitor

and save the energy used in the processes.

See page 24

Remote monitoring

With a built-in Web server, NETA-21

makes worldwide access easy for

industry applications.

See page 34

Drive-to-drive link

Allows fast communication between drives

including master-follower configurations as

standard.

See page 34

4 ABB industrial drives ACS880 single drives | Catalog

Wide range of

safety features

Safe torque off is built-in

as standard. An optional

safety functions module

provides extended safety

functions, simplifying the

configuration and reducing

installation space.

See page 31

Drive application

programming

Customizable to meet

the precise application

needs based on IEC

61131-3. Uses the same

programming environment

and is also easy to integrate

with other ABB components

such as PLCs and HMIs.

See page 32

te

ts

Drives going

mobile

We offer several

smartphone applications

to ease and enhance the

use of ABB drives. These

tools provide a user-friendly

and easy-to-use approach

for the commissioning,

servicing and use of ABB

drives.

See page 10

Intuitive human-machine

interface

Intuitive, high-contrastand high-resolution

displayenabling easy navigation in multiple

languages.

See page 30

Startup and maintenance tool

Drive composer PC tool for drive startup,

configuration and daily use and process

tuning. PC tool is connected to the drive via

Ethernet or USB interface.

See page 30

Communication with all

major automation networks

Fieldbus adapters enable connectivity with all

major automation networks.

See page 33

Flexible product

confi gurations

Drives are built to order with a wide range of

options such as braking options and different

enclosure variants.

See product variant pages

Extended connectivity

In addition to the standard interfaces, the

drive has three built-in slots for additional

input/output extension modules and speed

feedback interfaces.

See page 34

Catalog | ABB industrial drives ACS880 single drives 5

dri

vesACS88

0

What does all-compatible

mean for you?

Business all-compatible

The all-compatible drives are not just equipment – they are part of your

business strategy. Providing better control over your processes, our

drives mean lower energy consumption, improved productivity, flexibility

and ease of use. In addition to drives, we offer a wide range of products

and services to support your business. With offices in over 90 countries

and a global technical partner network, we are in a good position to offer

technical advice and local support, worldwide.

6 ABB industrial drives ACS880 single drives | Catalog

Process all-compatible

The drives are compatible with all kinds of processes. They control

virtually any type of AC motor, provide extensive input/output

connectivity and support all major fieldbus protocols. The drives cover

a wide voltage and power range. Control performance is scalable from

basic to demanding applications, delivered by direct torque control

(DTC). The flexibility and scalability of the drives enable one drive

platform to control virtually any application or process, making your

drive selection easy.

Environment all-compatible

There is increased demand for industries to reduce their impact on the

environment. Our drives can help you reduce energy consumption in a

wide range of applications. Our drives have an energy optimizer feature

that ensures maximum torque per ampere, reducing energy drawn from the

supply. The built-in energy efficiency calculators help you to analyze and

optimize your processes. We can help you to investigate the energy-saving

potential of selected applications with our six-step energy appraisal.

Our wall-mounted ACS880 industrial drives fulfill the highest IE2 drive (EN

50598-2) energy efficiency class, further reducing environmental impact.

In addition, all ACS880 industrial drives are compatible with high-efficiency

IE4 motors.

Human all-compatible

All our drives share easy-to-use interfaces, saving you time during drive

commissioning and maintenance. When you have learned it once, you can use it

with all the drives in our all-compatible drives portfolio.

The control panel supports over 20 languages. With the PC tool, you get extensive

drive monitoring capabilities and quick access to the drive settings. Integrated and

certified safety features provide safety for machine operators.

To further improve the user experience, we have developed mobile apps that can be

utilized in interacting with the drive. These apps give you an easy graphical interface for

management, maintenance and service of your drives.

Catalog | ABB industrial drives ACS880 single drives 7

Cost and time savings

with drive-based functional safety

With our ACS880 drive, you can achieve SIL 3/PL e safety level with certifi ed safety

functions modules. The safety module is easy to integrate inside the drive and

offers you several safety functions. Integration with automation systems is quick

and reliable using PROFIsafe connectivity. ACS880 drives have a safe torque off

(STO) function as a standard.

Scalable safety with

PROFIsafe and Safety PLC

The safety functionality can be scaled

to your needs. From a safety module

integrated into a single relay to a complete

safety system with a PROFIsafe and a

safety PLC, eg, AC500-S.

Safely limited speed

without encoders

The SIL 3/PL e certified safely-limited speed

(SLS) function prevents the motor from

exceeding a defined speed limit with no

encoders. This allows machine interaction

to be performed at a safe speed without

stopping the process.

TÜV-certifi ed safety

design tool

Functional safety design tool

(FSDT-01) is used for machinery

safety. It helps to increase the safety of

users in the vicinity of machines. You can

perform functional safety modeling, design,

calculations and verification for machine

functional safety.

8 ABB industrial drives ACS880 single drives | Catalog

Drive-based

application programming

The built in PLC capability of the ACS880 provides you a possibility to customize

the drive for your application without the cost of extra hardware. As programming

is based on the IEC 61131-3 standard used in AC500 PLCs and by many other

PLC vendors, you do not need to retrain your staff. By decentralizing your machine

control closer to the process, you achieve better control performance.

Adaptive programming

Adaptive programming is ideal for

creating simple control programs for

various applications. It does not require

expertise in programming and is offered

as a standard in All-compatible drives.

Application programming

Application programming makes it possible for

system integrators and machine builders to integrate

their desired functionality and know-how directly

into the drive. It utilizes standard IEC 61131-3

programming used by many PLCs like the AC500.

This means that programs can be easily moved

from the drive to a PLC and extended into a larger

system.

Automation builder

Automation Builder is a software

suite for automation engineering,

which makes programming industry

devices such as drives, PLCs, robots

and human-machine interfaces (HMIs)

easy using one integrated engineering

suite. Automation builder is used both

for engineering devices and entire

automation projects.

Catalog | ABB industrial drives ACS880 single drives 9

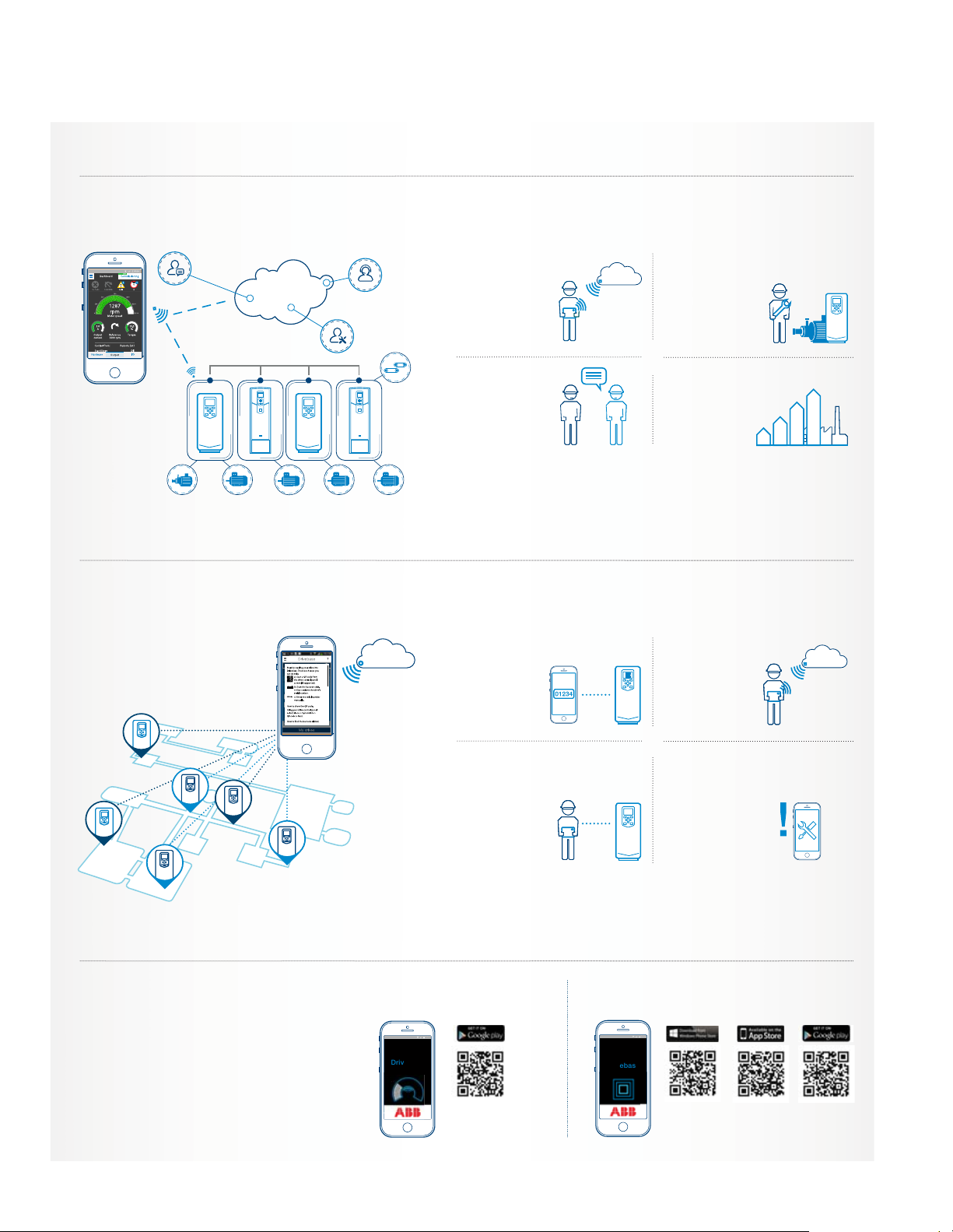

Save time, ease troubleshooting and improve drive performance

3

3

with ABB smartphone apps

Better connectivity and user experience with Drivetune

Easy and fast access to product information

and support

Manage your drives and the process lines and

machines they control

Easy access to

cloud-based

drive and process

information

from anywhere

via an online

connection

Simplified user

guidance with

instant access to

drive status and

configuration

Services and support on the go with Drivebase

Search for support documents and contacts

Maintain and service all your installed drives on

one or multiple sites

Get 6 months

extra warranty

for free by

registering

your drive with

the Drivebase

app

Start up,

commission and

tune your drive

and application

Performance

optimization

via drive

troubleshooting

features and

fast support

Access your product

and service

information

in the cloud

from anywhere

Access information anywhere

Download the apps using the

QR codes below

10 ABB industrial drives ACS880 single drives | Catalog

or directly from the app stores

Access

your drive‘s

diagnostics data

Drivetune for commissioning

and managing drives

12:

Drivetune

Push notifications

for critical product

and service

updates

Drivebase for ensured reliability and reduced

downtime on production sites

12:

Drivebase

Catalog | ABB industrial drives ACS880 single drives 11

How to select a drive

Many of the features for the ACS880 single drives are built-in

as standard, making selection easy. A wide range of options

are available to optimize the drive for different requirements.

To choose the right drive for your application, please refer to

the rating tables on page 12, 13, 15, 16, 18 and 20 or use

ABB’s DriveSize dimensioning tool (page 43). The selected drive

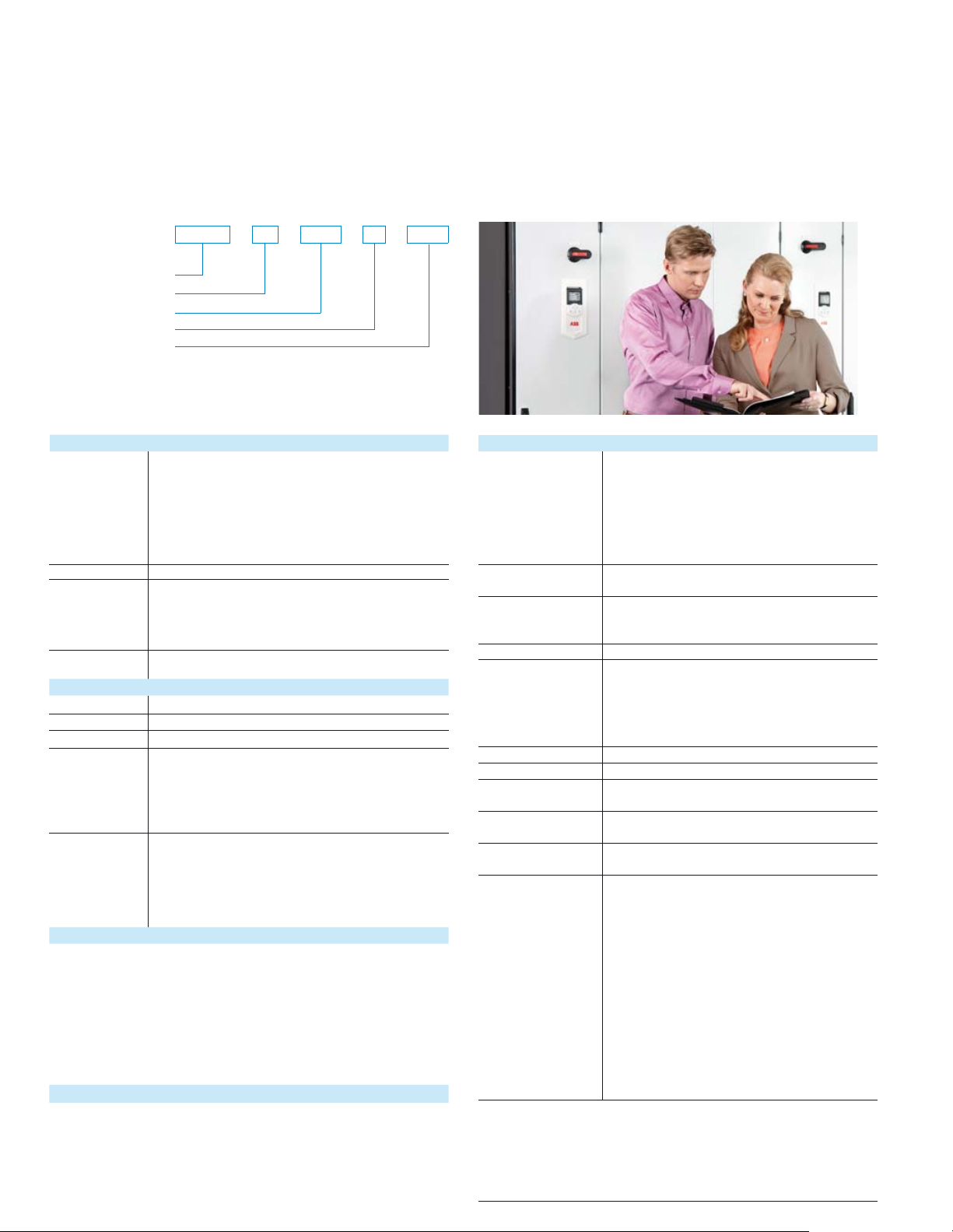

Type designation:

Product series

Types and construction

Ratings

Voltages

Options

ACS880 – XX – XXXX – X + XXXX

Technical data

Mains connection

Voltage and

power range

Frequency 50/60 Hz ±5%

Power factor

(ACS880-01, -07)

Power factor

(ACS880-17, -37)

Effi ciency (at

nominal power)

Motor connection

Voltage 3-phase output voltage 0 to U

Frequency 0 to ±500 Hz

Motor control Direct torque control (DTC)

Torque control:

Open loop

Closed loop

Open loop

Closed loop

Speed control:

Open loop

Closed loop

Open loop

Closed loop

Product compliance

- CE

- Low Voltage Directive 2006/95/EC

- Machinery Directive 2006/42/EC

- EMC Directive 2004/108/EC

- Quality assurance system ISO 9001 and Environmental system ISO 14001

- RoHS

-

UL, cUL 508A or cUL 508C and CSA C22.2 NO.14-10, C-Tick, EAC

- Functional safety: STO TÜV Nord certificate

- ATEX-certified Safe Disconnection Function, Ex II (2) GD

- Marine type approvals for -01

EMC according to EN 61800-3:2004 + A1:2012

Categories C3 and C2 with internal option

12 ABB industrial drives ACS880 single drives | Catalog

3-phase, UN2 = 208 to 240 V, +10/-15% (-01)

3-phase, U

±10% (-07,-17,-37)

3-phase, U

±10% (-07,-17,-37)

= 380 to 500 V, +10/-15% (-01),

N5

= 525 to 690 V, +10/-15% (-01),

N7

0.75 to 350 hp (0.55 to 250 kW) (-01)

50 to 3000 hp (45 to 2800 kW) (-07)

250 to 4250 hp (250 to 3200 kW) (-17, -37)

cosϕ

= 0.98 (fundamental)

1

cosϕ = 0.93 to 0.95 (total)

cosϕ

= 1 (fundamental)

1

98% (-01,-07)

97% (-17,-37)

/UN3 /UN5 /UN7

1) 2)

N2

Torque step rise time:

<5 ms with nominal torque

<5 ms with nominal torque

Non-linearity:

± 4% with nominal torque

± 3% with nominal torque

Static accuracy:

10% of motor slip

0.01% of nominal speed

Dynamic accuracy:

0.3 to 0.4% seconds with 100% torque step

0.1 to 0.2% seconds with 100% torque step

5)

4)

has a unique type designation, which identifies the drive by

construction, power and voltage range. The options are added

to the type designation with a “plus” code. Build up your own

ordering code using the type designation key or contact your

local ABB drives sales office and let them know your needs/

requirements.

Environmental limits

Ambient

temperature

Transport

Storage

Operation (air-cooled)

Cooling method

Air-cooled Dry clean air

Altitude

0 to 1,000 m

1,000 to 4,000 m

Relative humidity 5 to 95%, no condensation allowed

Degree of protection

IP20

IP21

IP22

IP42, IP54

IP55

Paint color RAL 9017/9002 (-01), RAL 9017/7035 (-07, -17, -37)

Contamination levels No conductive dust allowed

Storage IEC 60721-3-1, Class 1C2 (chemical gases),

Transportation IEC 60721-3-2, Class 2C2 (chemical gases),

Operation IEC 60721-3-3, Class 3C2 (chemical

Functional safety

Standard

With internal safety

option safety functions

module

Fieldbus

communication

C = Chemically active substances

S = Mechanically active substances

1)

For higher operational output frequencies please contact your local ABB offi ce

2)

Operation above 120 Hz might require type specific derating, please contact your

local ABB office

3)

Please see pages 12 to 13 for further details

4)

EAC has replaced GOST R

5)

Codes +L513/+L514, +Q971 for -07, -17,- 37

6)

Derating reduced by lower than 40 oC ambient temperature

-40 to +70 °C

-40 to +70 °C

-15 to +55 °C, no frost allowed (-01)

0 to +50 °C, no frost allowed (-07, -17, -37)

+40 to 55 °C with derating (-01)

3)

+40 to 50 °C with derating of 1%/1 °C (-07,-17,-37)

Without derating

With derating of 1%/100 m

6)

Option (-01)

Standard (-01)

Standard (-07, -17, -37)

Option (-07, -17, -37)

Option (-01)

Class 1S2 (solid particles)

Class 2S2 (solid particles)

gases), Class 3S2 (solid particles)

Safe torque off (STO according EN/IEC 61800-5-2)

IEC 61508 ed2: SIL 3, IEC 61511: SIL 3,

EN/IEC 62061: SIL CL 3, EN ISO 13849-1: PL e

Safe stop 1 (SS1), safely-limited speed (SLS), safe

stop emergency (SSE), safe brake control, (SBC)

and safe maximum speed (SMS), prevention of

unexpected startup (POUS), Safe direction (SDI),

Safe speed monitor (SSM), EN/IEC 61800-5-2,

IEC 61508 ed2: SIL 3, IEC 61511: SIL 3,

EN/IEC 62061: SIL CL 3, EN ISO 13849-1: PL e

TÜV Nord certified

PROFIsafe over profinet, certified

Wall-mounted single drives, ACS880-01

Our wall-mounted drives are designed on ABB’s common

drives architecture. They are customized to the precise needs

of industries such as oil and gas, mining, metals, chemicals,

cement, power plants, material handling, pulp and paper,

sawmills and marine. They are designed to control a wide

range of applications including cranes, extruders, winches,

winders, conveyors, mixers, compressors, pumps and fans.

The drive comes in nine different frame sizes (R1 to R9) for

easy installation and commissioning.

At the heart of the drive is direct torque control (DTC), ABB’s

premier motor control technology. The extensive range of

options include EMC filters, encoder and resolver interfaces,

du/dt filters, sine filters, chokes and brake resistors, as well

as application specific software. Built-in safety features

reduce the need for external safety components. Multiple

drives can be daisy-chained for synchronized drive-to-drive

communication.

The drives offering includes enclosure classes IP20, IP21 and

IP55 for dusty and wet environments. Our offering also covers

an option for flange mounting with IP55 back side protection.

In flange mounting the control electronics are separated from

the cooling airflow for better thermal management.

ABB provides an extensive selection of support documentation

for planning including dimension drawings in different formats,

EPLAN P8 macros and line apparatus selection tool for

selecting external components on the line side and motor side

of the drive.

Main features

− Enclosure classes IP20, IP21 and IP55 for different

environments

− Compact design for easy installation, commissioning and

maintenance

− Integrated safety including safe torque off (STO) as

standard and the optional safety functions module,

(TÜV Nord certified)

− Supports various motor types including synchronous

reluctance motors

− Intuitive control panel with USB connection

− Removable memory unit for easy maintenance

− Drive composer PC tool for commissioning and confi guration

− Primary control program - common software used

throughout the ACS880 drive series

− Control unit supporting a wide range of fieldbuses,

feedback devices and input/output options

− Coated boards as standard

− Controllable cooling fan

− Incoming air temperature measurement for protecting the

drive from different temperature related failure mechanisms

− Built-in braking chopper, option for frame sizes R5 to R9

− EMC filter option

− du/dt filter option for motor protection

− Built-in choke

− Supporting optimized cabinet mounting with option

(P940, +P944)

− Flange mounting option

The type approved ACS880-01 marine drive, provides

advanced reliability and availability at sea. The drive fulfills

marine and offshore requirements and the design and

operations have been tested according to marine type

approval requirements. ACS880-01 comes with marine type

approval from various key classification bodies.

ACS880-01,

frame sizes R1 to R9, IP21

ACS880-01,

frame sizes R1, R8 and R5, IP20

ACS880-01,

frame sizes R1, R8 and R5, IP55

Catalog | ABB industrial drives ACS880 single drives 13

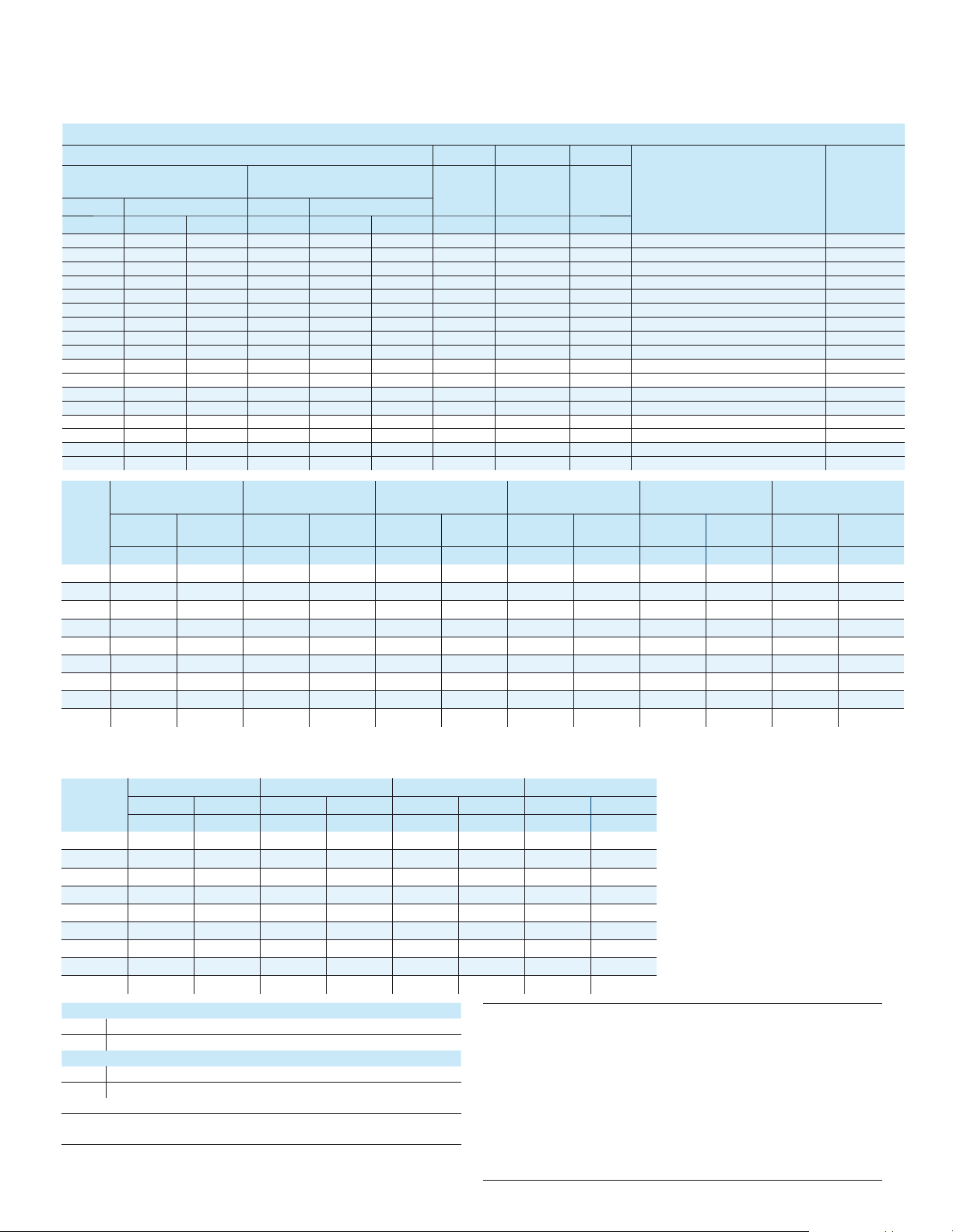

Ratings, types and voltages

Wall-mounted drives, ACS880-01

UN = 230 V (range 208 to 240 V). The power ratings are valid at nominal voltage 230 V (0.75 to 100 Hp).

Nominal ratings Type designation Frame

Light-duty use

(10% overload for 1 min)

I

Ld

PLd I

A Hp kW A Hp kW dB(A) W cfm

4.4 1 0.75 3.7 0.75 0.55 46 73 26 ACS880-01-04A6-2 R1

6.3 1.5 1.1 4.6 1 0.75 46 94 26 ACS880-01-06A6-2 R1

7.1 2 1.5 6.6 1.5 1.1 46 122 26 ACS880-01-07A5-2 R1

10.1 3 2.2 7.5 2 1.5 46 172 26 ACS880-01-10A6-2 R1

16 5 4 10.6 3 3 51 232 52 ACS880-01-16A8-2 R2

23.1 7.5 5.5 16.8 5 4 51 337 52 ACS880-01-24A3-2 R2

29.3 10 7.5 24.3 7.5 5.5 57 457 79 ACS880-01-031A-2 R3

44 15 11 38 10 7.5 62 500 79 ACS880-01-046A-2 R4

58 20 15 45 15 11 62 630 165 ACS880-01-061A-2 R4

71 25 18.5 61 20 15 62 680 165 ACS880-01-075A-2 R5

83 30 22 72 25 18.5 62 730 165 ACS880-01-087A-2 R5

109 40 30 87 30 22 67 840 256 ACS880-01-115A-2 R6

138 50 37 105 40 30 67 940 256 ACS880-01-145A-2 R6

162 60 45 145 50 37 67 1260 265 ACS880-01-170A-2 R7

196 75 55 169 60 45 67 1500 265 ACS880-01-206A-2 R7

260 100 75 213 75 55 65 2100 324 ACS880-01-274A-2

UN = 500 V (range 380 to 500 V). The power ratings are valid at nominal voltage 480 V (0.75 to 350 Hp).

Nominal ratings Type designation Frame

Light-duty use

(10% overload for 1 min)

I

Ld

PLd I

A Hp kW A Hp kW dB(A) W cfm

2.1 1 0.75 1.7 0.75 0.55 46 30 26 ACS880-01-02A1-5 R1

3 1.5 1.1 2.1 1 0.75 46 40 26 ACS880-01-03A0-5 R1

3.4 2 1.5 3 1.5 1.1 46 52 26 ACS880-01-03A4-5 R1

4.8 3 2.2 3.4 2 1.5 46 73 26 ACS880-01-04A8-5 R1

7.6 5 4 5.2 3 3 46 122 26 ACS880-01-07A6-5 R1

11 7.5 5.5 7.6 5 4 46 172 26 ACS880-01-11A0-5 R1

14 10 7.5 11 7.5 5.5 51 232 52 ACS880-01-014A-5 R2

21 15 11 14 10 7.5 51 337 52 ACS880-01-021A-5 R2

27 20 15 21 15 11 57 457 79 ACS880-01-027A-5 R3

34 25 18.5 27 20 15 57 562 79 ACS880-01-034A-5 R3

40 30 22 34 25 18.5 62 667 79 ACS880-01-040A-5 R4

52 40 30 40 30 22 62 907 165 ACS880-01-052A-5 R4

65 50 37 52 40 30 62 1117 165 ACS880-01-065A-5 R5

77 60 45 65 50 37 62 1120 165 ACS880-01-077A-5 R5

96 75 55 77 60 45 67 1295 256 ACS880-01-096A-5 R6

124 100 75 96 75 55 67 1440 256 ACS880-01-124A-5 R6

156 125 90 124 100 75 67 1940 265 ACS880-01-156A-5 R7

180 150 110 156 125 90 67 2310 265 ACS880-01-180A-5 R7

240 200 132 180 150 110 65 3300 324 ACS880-01-240A-5

302 250 187.5 260 200 132 68 4200 677 ACS880-01-302A-5

361 300 200 302 250 188 68 4800 677 ACS880-01-361A-5

1)

414

350 250 361

Heavy-duty use

(50% overload for 1 min)

2Hd

P

Hd

Heavy-duty use

(50% overload for 1 min)

2Hd

2)

P

Hd

300 200 68 6000 677 ACS880-01-414A-5

Noise

level

Noise

level

Heat

dissipation

Heat

dissipation

Air flow

3

Air flow

4

3

6

5

size

R8

size

R8

R9

R9

R9

Continuous rms output current allowing 10% overload for

I

Ld

1 minute every 5 minutes.

Typical motor power in light-overload use.

P

Ld

Heavy-duty use

Light-duty use

I

Continuous rms output current allowing 50% overload for

2HD

1 minute every 5 minutes.

Typical motor power in heavy-duty use.

P

Hd

Ratings apply at an ambient temperature of 40 °C (104 °F) unless otherwise noted.

To achieve the rated motor power given in the table, the rated current of the drive

must be higher than or equal to the rated motor current.

14 ABB industrial drives ACS880 single drives | Catalog

1)

For drives with enclosure class UL type 1 (IP21), the ratings apply at 30 °C (86 °F)

ambient temperature. At ambient temperature 40 °C (104oF), rating is 393A

2)

125% overload for 1 minute, every 5 minutes.

3)

For drives with enclosure class UL type 12 (IP55), the ratings apply at 40 °C

ambient temperature. At higher temperature the derating is 1%/1°C from 40 to

45 °C and 2.5%/1°C from 45 to 55 °C.

4)

For drives with enclosure class UL type 12 (IP55), the ratings apply at 40 °C

ambient temperature. At higher temperature the derating is 1%/1°C from 40 to

50 °C and 2.5%/1 °C from 50 to 55 °C.

5)

For drives with enclosure class UL type 12 (IP55), the maximum ambient

temperature is 35 °C (95 °F).

6)

For drives with enclosure class UL type 12 (IP55), the ratings apply at 40 °C

ambient temperature. At higher temperature the derating is 1%/1 °C from 40 to

45 °C, 2.5%/1 °C from 45 to 50 °C, and 5%/1 °C from 50 to 55 °C.

Ratings, types and voltages

Wall-mounted drives, ACS880-01

UN = 690 V (range 525 to 690 V). The power ratings are valid at nominal voltage 575 V (5 to 250 Hp)

Nominal ratings Type designation Frame

Light-duty use

(10% overload for 1 min)

I

Ld

PLd I

A Hp kW A Hp kW dB(A) W cfm

9 7.5 5.5 6.1 5 4 62 217 165 ACS880-01-07A3-7 R5

11 10 7.5 9 7.5 5.5 62 284 165 ACS880-01-09A8-7 R5

17 15 11 11 10 7.5 62 399 165 ACS880-01-14A2-7 R5

22 20 15 17 15 11 62 490 165 ACS880-01-018A-7 R5

27 25 18.5 22 20 15 62 578 165 ACS880-01-022A-7 R5

32 30 22 27 25 18.5 62 660 165 ACS880-01-026A-7 R5

41 40 30 32 30 22 62 864 165 ACS880-01-035A-7 R5

52 50 37 41 40 30 62 998 165 ACS880-01-042A-7 R5

52 50 37 41 40 30 62 1120 165 ACS880-01-049A-7 R5

62 60 45 52 50 37 67 1295 256 ACS880-01-061A-7 R6

77 75 55 62 60 45 67 1440 256 ACS880-01-084A-7 R6

99 100 75 77 75 55 67 1940 265 ACS880-01-098A-7 R7

125 125 90 99 100 75 67 2310 265 ACS880-01-119A-7 R7

144 150 110 125 125 90 65 3300 324 ACS880-01-142A-7 R8

180 200 132 144 150 110 65 3900 324 ACS880-01-174A-7

242 250 160 192 200 132 68 4200 677 ACS880-01-210A-7

271 250 200 2421 250 160 68 4800 677 ACS880-01-271A-7

Frame

Height (H1) Height (H2) Width Depth

size

UL type 1 IP21 UL type 1

(in) (mm) (in) (mm) (in) (mm) (in) (mm) (lbs) (kg) (lbs) (kg)

R1 16 405 14.6 370

R2

R3

R4

R5

R6

R7

R8

R9

H1 = Height with cable entry box

H2 = Height without cable entry box

8)

Comes with main power clamp (Note: IP20 variant only)

Frame

size

16 405 14.6 370

18.5 471 16.5 420

22.9 580 18.2 462

28.8 732 23.5 596

28.6 727 21.6 548 9.9 252 14.1 357 14.1 357 99 70

34.6 880 23.6 600 11.2 284 14.4 365 14.4 365 121 55

38.0 965 26.8 680 11.8 300 15.2 386 15.2 386 155 70

37.6 955 26.7 680 15.0 380 16.3 413 16.3 413 216 98

Height (H) Width (W) Depth (D) Weight

UL type 12 IP55 UL type 12 IP55 UL type 12 IP55 UL type 12 IP55

(in) (mm) (in) (mm) (in) (mm) (lbs) (kg)

R1 17.6 450 6.3 162 12.0 295 13 6

R2

R3

R4

R5

R6

R7

R8

R9

17.6 450 6.3 162 12.0 315 18 8

20.5 525 7.0 180 13.0 327 22 10

29.0 735 9.3 236 14.0 344 41 18.5

34.9 886 9.3 236 14.0 344 51 23

34.8 884 11.5 291 16.0 417 99 45

40.9 1038 12.8 324 16.5 418 121 55

44.3 1123 13.8 350 17.8 452 159 72

46.8 1188 17.0 431 18.8 477 220 100

Light-overload use

Continuous current allowing 10% ILd for 1 min/5 min at 40 °C.

I

Ld

Typical motor power in light-overload use.

P

Ld

Heavy-duty use

Continuous current allowing 50% IHd for 1 min/5 min at 40 °C.

I

Hd

P

Typical motor power in heavy-duty use.

Hd

The ratings apply at 40 °C ambient temperature. At higher temperatures (up to 55 °C)

the derating is 1%/1 °C.

Heavy-duty use

(50% overload for 1 min)

2Hd

P

IP20 UL type 1 IP21 UL type 1

open

8)

8)

8)

8)

8)

Noise

level

Hd

Heat

dissipation

Air flow

3

7

5

Depth

(+P940)

IP20 UL type

open

(+P944)

IP21 UL type 1 IP21

open

6.1 155 8.9 226 8.9 226 13 6

6.1 155 9.8 249 10.0 249 18 8

6.7 172 10.1 256 10.3 261 22 10

8.2 203 13.1 333 10.8 274 41 18.5

8.2 203 13.1 333 10.8 274 51 23

3)

For drives with enclosure class IP55 the ratings apply at 40 °C ambient temperature.

At higher temperature the derating is from 40 to 45 °C 1%/1 °C and 45 to 55 °C

2.5%/1 °C.

4)

For drives with enclosure class IP55 the ratings apply at 40 °C ambient temperature.

At higher temperature the derating is from 40 to 50 °C 1%/1 °C and 50 to 55 °C

2.5%/1 °C.

5)

For drives with enclosure class IP55 the maximum ambient temperature is 35 °C.

6)

For drives with enclosure class IP55 the ratings apply at 40 °C ambient temperature.

At higher temperatures the derating is from 40 to 45 °C 1%/1 °C and 45 to 50 °C

2.5%/1 °C and 50 to 55 °C 5%/1 °C.

7)

For drives with IP55 enclosure class the ratings apply at 40 °C ambient temperature.

At higher temperatures the derating is from 40 to 45 °C 3.5%/1 °C. Note: Maximum

ambient temperature is 45 °C.

size

R8

R9

R9

Weight

Catalog | ABB industrial drives ACS880 single drives 15

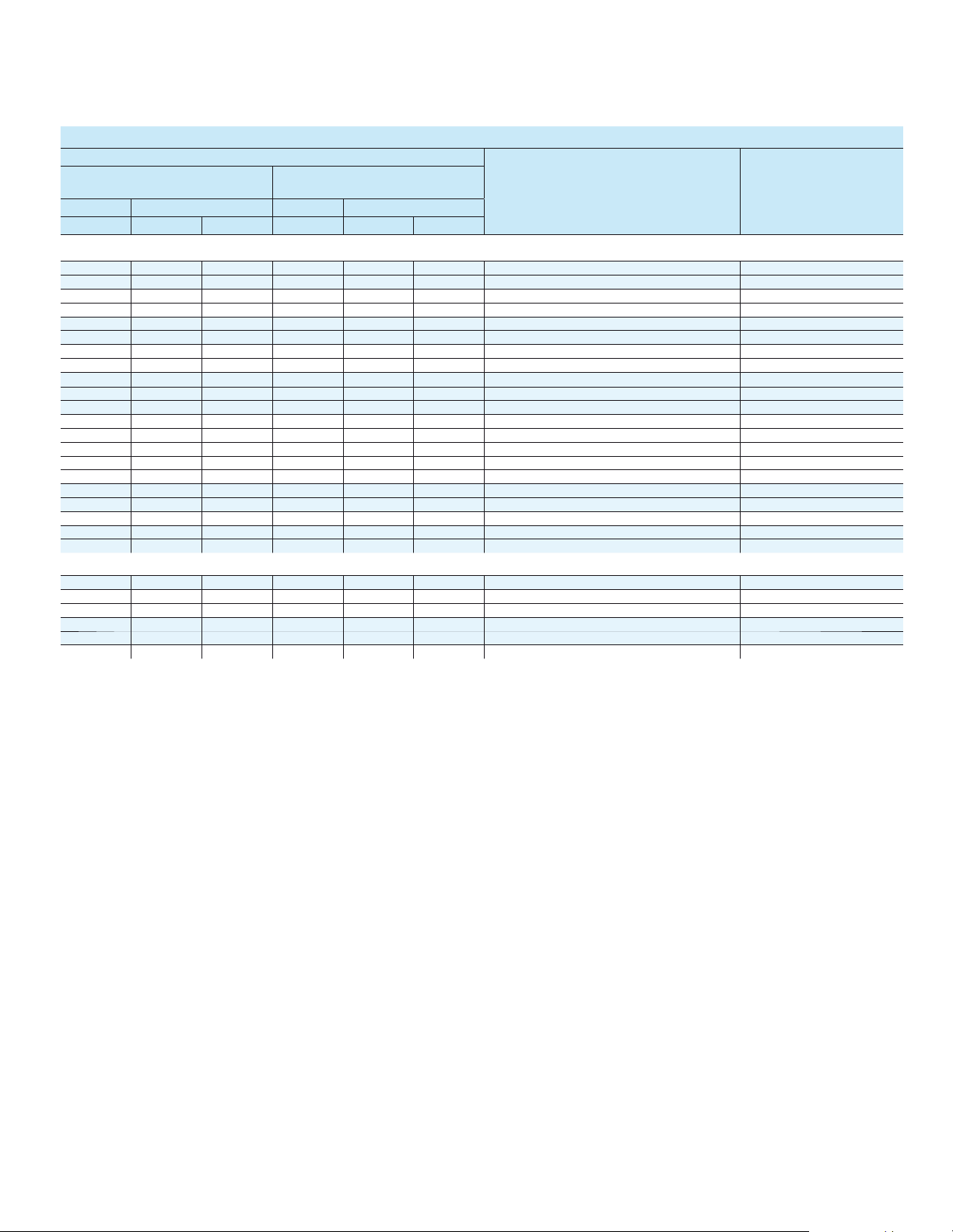

Cabinet-built single drives, ACS880-07

Our cabinet-built single drives are built to order, meeting

customer needs despite any technical challenges. Designed on

ABB's common drives architecture, this compact drive comes in

different sizes for easy assembly and commissioning.

These single drives are customized to the precise needs of

industries such as oil and gas, mining, metals, chemicals,

cement, power plants, material handling, pulp and paper,

woodworking and marine. Typical applications include cranes,

extruders, winches, conveyors, mixers, compressors, pumps

and fans. The drive configuration contains a rectifier, DC link,

inverter, fuses and a main switch, all built into a compact

cabinet. The features and options include extended inputs and

outputs, fieldbus options, du/dt filtering, EMC filtering and a

brake resistor.

Induction motors, synchronous motors and induction servo

motors are all supported as standard without the need for

additional software. The drive can control the motors in either

open loop or closed loop, through its high precision motor

control platform, direct torque control (DTC). Built-in safety

features reduce the need for external safety components.

Main features

− Compact design for easy cabinet assembly and maintenance

− Main switch and fuses

− Cabling solutions include bottom and top entry and exit

− Enclosure classes IP22, IP42 and IP54 for different

environments, with option for air intake through bottom of the

cabinet and channeled air outlet on the top of the cabinet

− Integrated safety including safe torque off (STO) as standard

and the optional safety functions module, FSO-12 (TÜV Nord

certified)

− Supports various motor types including synchronous

reluctance motors

− Drive composer PC tool for commissioning and configuration

− Intuitive and easy to operate control panel with USB

connection

− Device panel for optional switches and pilot lights

− Primary control program – common software used throughout

the ACS880 drive series

− Control unit supporting a wide range of fieldbuses, feedback

devices and input/output options

− Removable memory unit for easy maintenance

− Coated boards as standard

− Extensive, programmable digital and analog inputs and outputs

− Line choke

− Long lifetime capacitors

− Cooling fans with speed control or on-off control

− Braking option inside the module or cabinet

− EMC filter option

− du/dt and common mode filter options for motor protection

− Cabinet light and heater option

− Marine construction option

ACS880-07, frame sizes R6 to R8 and R11, IP22 ACS880-07, frame size 1×D8T+2×R8i, IP22

16 ABB industrial drives ACS880 single drives | Catalog

Ratings, types and voltages

Cabinet-built drives, ACS880-07

UN = 500 V AC (range 380 to 500 V AC). Power ratings are valid at nominal voltage 480 V AC, 60 Hz

Nominal ratings Type designation Frame size

Light-duty use

(10% overload for 1 min)

I

Ld

PLd I

A Hp kW A Hp kW

= 500 V (range 380 to 500 V). Power ratings are valid at nominal voltage 480 V 60 Hz

U

N

96 75 55 77 60 45 ACS880-07-0096A-5+C129 R6

124 100 75 96 75 55 ACS880-07-0124A-5+C129 R6

156 125 90 124 100 75 ACS880-07-0156A-5+C129 R7

180 150 110 156 125 90 ACS880-07-0180A-5+C129 R7

240 200 132 180 150 110 ACS880-07-0240A-5+C129 R8

302 250 200 260 200 132 ACS880-07-0302A-5+C129 R9

361 300 200 302 250 200 ACS880-07-0361A-5+C129 R9

1)

414

350 250 361

450 375 315 330 275 200 ACS880-07-0460A-5+C129 R10

483 400 315 361 300 250 ACS880-07-0503A-5+C129 R10

573 450 400 414 350 250 ACS880-07-0583A-5+C129 R10

623 500 450 477 400 315 ACS880-07-0635A-5+C129 R10

705 600 500 566 450 400 ACS880-07-0715A-5+C129 R11

807 700 560 625 500 450 ACS880-07-0820A-5+C129 R11

857 725 560 697

1027 900 710 800 700 560 ACS880-07-1070A-5+C129+H359

1267 1100 900 987 850 710 ACS880-07-1320A-5+C129+F255+H359

1392 1200 900 1085 900 710 ACS880-07-1450A-5+C129+F255+H359

1517 1350 1000 1182 1000 800 ACS880-07-1580A-5+C129+F255+H359

1728 1500 1200 1346 1200 900 ACS880-07-1800A-5+C129+F255+H359

1901 1700 1300 1481 1300 1000 ACS880-07-1980A-5+C129+F255+H359

12-pulse connection

3)

950 800 630 741 600 500 ACS880-07-0990A-5+A004+H359

1267 1100 900 987 850 710 ACS880-07-1320A-5+A004+H359

1392 1200 900 1085 900 710 ACS880-07-1450A-5+A004+H359

1517 1300 1000 1182 1000 800 ACS880-07-1580A-5+A004+H359

1728 1500 1200 1346 1200 900 ACS880-07-1800A-5+A004+H359

1901 1700 1300 1481 1300 1000 ACS880-07-1980A-5+A004+H359

Heavy-duty use

(50% overload for 1 min)

2Hd

2)

4)

P

300 200 ACS880-07-0414A-5+C129 R9

600 500 ACS880-07-0880A-5+C129 R11

Hd

1

2

2

2

2

2

1,3

1,3

1,3

1,3

1,3

1,3

D8T+2×R8i

2×D8T+2×R8i

2×D8T+2×R8i

2×D8T+2×R8i

2×D8T+3×R8i

2×D8T+3×R8i

2×D7T+2×R8i

2×D8T+2×R8i

2×D8T+2×R8i

2×D8T+2×R8i

2×D8T+3×R8i

2×D8T+3×R8i

1)

130% overload

2)

125% overload

3)

140% overload

4)

144% overload

Catalog | ABB industrial drives ACS880 single drives 17

Loading...

Loading...