A2A Cessna 182 User Manual

A2ASIMULATIONS

C182

ACCU-SIM C182 SKYLANE

ACCU-SIM C182

© 2014 A2A Simulations Inc. All rights reserved.

Published by A2A Simulations Inc.

ATTENTION!

Accu-Sim C182, including sounds, aircra, and all content is under strict,

and enforceable copyright law. If you suspect anyone has pirated any part

of Accu-Sim C182, please contact piracy@a2asimulations.com

RISKS & SIDE EFFECTS

Ergonomic Advice

▶ Always maintain a distance of at least 45cm to

the screen to avoid straining your eyes.

▶ Sit upright and adjust the height of your chair so that

your legs are at a right angle. The angle between your

upper arm and forearm should be larger than 90º.

▶ The top edge of your screen should be at eye level or

below, and the monitor should be tilted slightly backwards, to prevent strains to your cervical spine.

▶ Reduce your screen’s brightness to lower the contrast

and use a flicker-free, low-radiation monitor.

▶ Make sure the room you play in is well lit.

▶ Avoid playing when tired or worn out and take

a break (every hour), even if it’s hard…

Epilepsy Warning

Some people experience epileptic seizures when viewing flashing lights or

patterns in our daily environment. Consult your doctor before playing computer games if you, or someone of your family, has an epileptic condition.

Immediately stop the game, should you experience any of the following

symptoms during play: dizziness, altered vision, eye or muscle twitching,

mental confusion, loss of awareness of your surroundings, involuntary

movements and/or convulsions.

A2ASIMULATIONS

C182

ACCU-SIM

C182 SKYLANE

4

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

CONTENTS

6 THE CESSNA 182

16 DESIGNER’S NOTES

18 FEATURES

20 QUICK START GUIDE

24 ACCU-SIM AND THE COMBUSTION ENGINE

30 SPECIFICATIONS

34 CHECKLISTS

40 PROCEDURES EXPLAINED

46 PERFORMANCE

62 EMERGENCY PROCEDURES

68 EMERGENCIES EXPLAINED

72 AIRPLANE & SYSTEMS DESCRIPTION

86 AIRPLANE HANDLING, SERVICE & MAINTENANCE

98 ACCU-SIM AND THE C182 SKYLANE

102 CREDITS

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

5

THE CESSNA 182

The Jack of All Trades and Master of All

6

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

HE MASTER OF ALL TRADES? WELL, PERHAPS THAT IS A BIT

elaborate; however, the Cessna 182 is the proven master of a great

T

many aeronautical “trades”, indeed. So, what are the “trades” that

we want a General Aviation (GA) aeroplane to be the master of? Well, we

want it to be fast, carry lots of fuel, people and baggage, climb well, stall

gently, be easy to land and fly, be economical to operate and maintain,

and generally be a safe and pleasant ride for us and our passengers -that’s a lot to ask of one aeroplane. Aer all, the physical world is based

upon compromise and give and take; what is gained here is lost there, etc.

Because of this necessary compromise, when it comes to mastering all

of these “trades”, virtually every aeroplane fails to make the grade. Some

exhibit very high performance but are a handful to fly for the average

pilot and others are as gentle as a puppy, but do not perform so well.

That ubiquitous physical compromise is present in most instances.

NOW CONSIDER THE CESSNA 182:

It has a light and simple fixed gear but it can cruise as

fast, or nearly so, as many retractable gear aircra. It

can haul over 1,200 pounds of passengers, fuel and/or

cargo. It will climb at nearly 1,000 fpm fully loaded and

has an excellent ceiling and higher altitude performance even without turbocharging due to its generous

supply of power. Due to very large and eective flaps,

its slow speed and departed flight regimes are excellent, predictable and better in most circumstances

than other aircra in its class. Accordingly, a pilot may

get it in and out of very small fields with confidence.

Its engine is reliable, easily maintained and not unduly

thirsty for fuel or oil. While it has a constant speed

propeller, it is a simple and basic aeroplane to operate

that may be quickly mastered by even relatively lowtime pilots. It possesses a large and comfortable cabin

for four plus a capacious baggage compartment. While

it is maneouverable and quick on the controls, it is also

stable around all axes and possesses no dangerous or

surprising traits. It is an excellent IFR aeroplane. The

C-182 and feels substantial and robust; it is well-made

and can operate in and out of fairly rough airstrips.

Its high wing allows unlimited downward visibility.

Its rear cabin window gives a pilot increased visibility

and grants a more spacious and open feeling to rear

passengers.

The C-182T will cruise at 140KTAS at 10,000 while

burning only 12 gallons an hour or so and this while

carrying full fuel (88 U. S. gallons), four adults and

some baggage and being a gentle and predictable

aeroplane for the weekend pilot to confidently fly with

his family. Since 2005 the Garmin G1000 Glass Cockpit

has been available in the C-182. This makes instrument

and low visibility flying easier and safer.

While practical and simple to operate, many consider

the high-performance capability of Cessna 182 to be

the ultimate aeroplane for the casual, sportsman flyer.

The Master of all trades? Well, almost all. It cannot

break the sound barrier or reach 40,000. However, it is

the master of so many trades that really matter, that no

one could reasonably ask for more.

HOW?

By now you ought to have the feeling that there is very

little that the C-182 cannot do - without ease, grace

and élan. So, how did Cessna achieve this aeronautical

superlative?

As any dog breeder will tell you, ancestry makes

a great deal of dierence. The C- 182’s immediate

ancestor is the Cessna 180, the 182 being essentially

the tricycle gear version of the 180. In creating the

C-180, the first thing Cessna did was to borrow what

was an already proven wing design from the all metal

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

7

THE CESSNA 182

C-170/172. Below its high wing, however, the C-180/182

is an entirely new aeroplane.

The C-182’s cowling is larger and fuselage is longer

than the C-172’s, and the cabin does not taper rearwards adding a good deal of useful space. The C-182’s

undercarriage is sturdier and more robust to handle its

heavier weight. The C-182’s six cylinder 230 h. p. engine

is almost 60% more powerful than that of the C-172’s

but its gross weight is only 30% greater. This gives the

C- 182 a very respectable power- loading of 13.52 lb./

hp. While the C-172 and the C-182 share the same wing,

that wing is more than large enough to give the C-182

a relatively light wing- loading of 17.8 lb./sq.. It is

this combination of high power and low weight which

produces the excellent performance that the C-182

demonstrates.

Greater power and a larger propeller produce more

P-eect and torque which require appropriately sized

tail surfaces to counter them. Accordingly, the C-182’s

tail surfaces (fin/rudder and stabilizer/elevators) were

made larger to accommodate the additional power up

front. While this results in a somewhat heavy feeling

elevator whilst on the ground and at slow speeds, in

the air the elevator is not disproportionately heavy as

compared to other aircra in its class.

Taking all of these design elements together,

pound for pound the C-182 emerges as one of the

most capable GA aircra of all time, a true Master of

All Trades. Superlative performance has been justly

rewarded, with over 23.000 having been built, the

C-182 is the second most popular and numerously

produced high performance GA aeroplane of all time,

just aer the C-172.

WHY?

So, why did Cessna go to so much trouble to create an

aeroplane with all of the ability that the C-182 possesses? As usual, there is more than one answer. One

reason was due to market conditions. Aer the end of

World War II, there was a fast growing demand for the

so-called bush plane. The simplest definition of a bush

plane is one which will be primarily operated in and

out of rough, short and remote fields and waterways;

those which could not in any real way be considered to

be airports or airfields.

It has been long established that high -wing, tailwheel aeroplanes are best for bush flying. High wings

sit well above the sometimes tall brush and far from

stones and other debris which might be kicked up.

The sturdy main gear of a tailwheel aeroplane is best

suited for rough landings in fields which might actually

damage a more delicate nosewheel strut. Also, a

tailwheel aeroplane’s propeller is higher o the ground

when taking o, landing and taxiing than the propeller

of a nosewheel aeroplane, putting it farther away from

stones, etc.

Cessna’s high wing aeroplanes, with a suicient amount

of power and a tailwheel are ready-made for bush flying.

The 170 had almost all of the features required for a bush

aeroplane. What was wanted was a larger, more robust

airframe and an increase in power. Thus came the C-180,

which, with a nose wheel is the C-182.

BUSH LEAGUE

Contrary to popular belief, bush flying did not begin

aer W.W. II.; it began in Canada in 1919. Ellwood Wilson

was a Canadian forester who was employed by the

Laurentide Company located in Quebec. Laurentide

trained foresters whom they hired out to large lumber

companies. Of forester Wilson’s many duties, surely

very high in importance was the hopefully early detection and reportage of forest fires. One day Mr. Wilson

had a brilliant idea: The forests were too vast for even

hundreds of foresters like himself to properly patrol and

map; however, from an aeroplane the entire forest could

be well-patrolled and mapped and any sign of smoke

that might indicate a burgeoning fire could be instantly

detected and reported.

He obtained two surplus Curtiss HS-2L flying boats

from the Canadian government. Between 4 and 8 June,

1919, the first aerial fire-patrol and photography missions were piloted by RCAS Captain Stuart Graham and

engineer Walter Kahre. One of their cross-country flights

of 645 miles to Lac-àla- Tortue, was at that time, the

longest cross-country flight in Canada.

This and subsequent forest patrol flights of the Curtiss

JS-2Ls are considered to be the very first bush aircra

operations. Laurentide Company initially financed these

flights which received tremendous publicity in Canada.

Soon thereaer a new subsidiary was formed, Laurentide

Air Services, Ltd., the first exclusively bush operator in

Eastern Canada.

Curtiss HS-2L

in military use

during W. W. I.

A Curtiss HS-2L

of Laurentide

Air Services

in the early

1920s.

8

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

An Airco DH-4

which was

used in Air

Mail service

in the 1920’s.

Piper J-3

“Grasshopper”.

Very popular

for bush ying

is the Piper

Super Cub

with oversized

tundra tires for

rough elds.

Curtiss JN-4 “Jenny”

Meanwhile, in Western Canada, in Edmonton, Wilfred

May and his brother Court began the first commercial

bush flying business in that area, called May Airplanes,

Ltd. Flying a surplus Curtiss JN- 4 “Jenny” they,

along with pilot George Gorman and mechanic Peter

Derbyshire flew newspapers and small packages to

outlying towns and villages.

Soon, these nascent companies were recognized to

be successfully providing a vital service in the rugged

and oen isolated area of central Canada. In 1919, Carl

Ben Eielson, an Alaskan originally from North Dakota,

began flying passengers in a surplus “Jenny” from

Fairbanks to and from outlying villages. In 1924 the U.S.

Post Oice granted Eielson a license to deliver mail in

and around the Fairbanks area, but now in a far more

powerful DH-4.

From these humble beginnings, bush flying in

Canada, Alaska and the northern continental United

States quickly blossomed into a major industry with

thousands of aeroplanes connecting what were

formerly remote and wild places with the rest of the

world. Food, medicine, doctors and other vital commodities and people were, for the first time, now able

to be delivered to so many remote regions which had

been formerly bere of these necessities.

Aer W. W. II, aircra manufactures recognised that

bush flying companies would be operating again without the restrictions upon civilian aviation that the war,

out of necessity, had applied. It was not long before

many of the Piper Cubs and Super Cubs, Stinsons,

Aeroncas, all of the so -called “Grasshoppers” of the U.

S. and Canadian Air Services began to show their age

-- rough field and water flying taking its inevitable toll

on them. New aircra to replace these noble veterans

were wanted.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

9

THE CESSNA 182

THE CESSNA “AIRMASTER” - WHERE

IT ALL BEGINS — FOR A WHILE

In 1935 Cessna introduced what was to be a very useful

bush and cargo single-engine aeroplane- the C-145/165

‘Airmaster”. These were rugged, substantial aircra

made of wood and steel tubing with fabric covering.

The wing was cantilever and did not require any external struts. Like virtually all aircra of that era it had a

tail wheel. It was ideal for rough country operations.

With its capacious fuselage and an excellent useful load

of 970 lbs. and later well over 1,100 lbs, with the 165 hp

(123 kW) Warner engine installed. It was a very capable

rough country aeroplane.

While Cessna’s production of civilian Airmasters

ended at the U. S. ’s entry on to W.W. II on December

8, 1941, a few Airmasters, now called UC-77B, UC-77C,

and UC-94 entered the into the military services of the

U.S. A number of them were also used by the Air Forces

of Australia and Finland.

The powerful and rugged 4-place, high wing

Airmaster is the direct ancestor of all post- war Cessna

single –engine aircra.

Civilian 1938 Cessna

C-165 “Airmaster”

Cessna C-37 Airmaster set up for

bush operations with removed

wheel pants and large tyres.

THE END OF THE WAR AND A

NEW BEGINNING FOR CESSNA

In 1945, Cessna produced its only post-war radialengined, five place aeroplane, the C-190/195. While

Cessna had first designed and flown the 190 in 1945, it

was not until 1947 that it was introduced it to the public.

This is possibly because Cessna was hesitant to jump

back into the post-war general aviation market with

such an expensive aeroplane (which apparently did

not at all daunt Beechcra). Instead, the first Cessna

introduced aer the war was the modest, two-place, 65

hp C-120 which was available to the public in 1946.

The sole dierence between a C-190 and a C-195

is its engine: the C-190 having a 240 h. p. Continental

W670-23 radial engine, and a C-195 a 300 h. p. Jacobs

R-755 radial engine. Both engines have a diameter of

42” which makes the 190/195’s forward fuselage quite

large and most capacious. With seating for five (two

up front, three a) the 195’s useful load is 1,250 lbs.

permitting full 75 gallon tanks plus four - 200 lb. or five

- 160 lb. souls on board. Its published cruise is 170mph

(148k; 274km/h) at 70% power at 7, 500’. This was

remarkable performance for a light aeroplane in 1947

and quite similar to the modern C-182.

While the 190/195’s wing is, as with the pre-war

“Airmaster”, a cantilever design, unlike the “Airmaster”

the C-190/195 is of all- metal construction. Cessna

apparently came to the understanding (as would Piper

later in the decade) that manufacturing fabric-covered

aeroplanes is highly labor intensive and therefore

more costly to build than an all-metal aircra. The

C-190/195’s airfoil is the familiar NACA 2412 as used by

Cessnas’ 170, 150, 172 and 182 to this day.

An expensive “luxury” type, the C-190/195 was not

intended or expected to greatly fuel the post-war private

General Aviation market. These large, 5-place aircra

were intended primarily to be used for commercial charter and business transportation rather than as a light

aeroplane for personal use. Many of the 190/195s were

converted to floatplanes which made them very useful

commuter aircra in areas where there were few or no

airports. In this sense it could be said that the C-190/195

was a bush plane, although bush planes are generally

not so well-appointed nor so elegant.

As impressive as its performance may be, the massive C-190/195 was too costly, its thirsty radial engine

required a good deal of maintenance, and its general

appearance, while sleek and attractive, was a definite

throwback to aircra of the thirties. Cessna understood

that something new was wanted in the brave new era

of peace.

10

A2ASIMULATIONS

SOMETHING NEW

Introduced in 1946, the basic and aordable 2-place

Cessna 120 was an instant success. It spawned the

C-140 which was then slightly stretched and in 1948

became the four-place 170. The 170 eventually

:::

C182 MANUAL www.a2asimulations.com

A Cessna C-195 on

amphibious oats. A very

capable bush aeroplane.

1949 Cessna 195. Sleek,

powerful …and expensive.

morphed into the all-metal, tricycle undercarriage

Cessna 172 in 1956, which is where the modern era of

Cessna aircra begins.

The whole story of the how the C-172 came to be and

how it evolved may be found in the A2A C-172 Manual

and, accordingly, will not be repeated here. I do commend it to you, dear reader, even though I must admit

that I wrote it. Nevertheless, you still may find it worthy

of a glance or two, as therein is discussed the genesis

and early development of the post- W.W. II Cessna line

of light aircra.

All went swimmingly well for a while, but Cessna

became inundated by the pleas of those who loved

the C-170 but wanted to go faster and carry more load.

Some of those were bush pilots who operated in and

out of the most primitive places on earth and who

required aeroplanes with lots of power, load capacity,

high performance and strength. Others simply wished

to take their families on trips without having to land for

fuel so oen.

While the C-170 was an excellent, relatively inexpensive personal aeroplane for use in relatively civilized

places, it did not have suicient power, load carrying

capability and overal performance necessary for

serious bush flying (and it is all serious). As of 1952,

except for the C-190/195, Cessna did not produce an

aeroplane that could be inexpensively used as a bush

plane.

Surely tired and frustrated at hearing how rival Piper

Cubs and Super Cubs were hauling goods and people

all around the remote northern regions, in 1952 Cessna

decided to satisfy these clamouring requests and

began to design the C-180.

THE CESSNA 180 - A RUGGED,

HEAVY HAULER

The first thing that Cessna did in designing the 180

was to slightly increase the size of the fuselage to

accommodate a new, more powerful engine, the 225h.

p. Continental O-470-A, O-470-J, and later a 230h. p.

Continental O-470-K engine. Some 180s have engines

up to 300 h.p. The 180’s larger fuselage also gave

the cabin a bit more room, particularly in width, and

tail surfaces were re-designed to accommodate the

increase in power.

On 26 May, 1952, with Cessna’s chief engineering

test pilot William D. Thompson at the controls, the

first Cessna 180, N41697, made its maiden flight. It

was certified by the FAA’s predecessor, the CAA (Civil

Aeronautics Authority), on 23 December of that year;

a nice Christmas present indeed for Cessna to give

itself. During 1953, the C-180 was made available to the

public. This was the “Golden Year” of aviation, in that

it was 50 years since the Wright Brothers made what

is considered to be the first powered flight; something

Cessna did not fail to mention in its advertisements for

the 180.

C-170 tail

surfaces were

originally

round-shaped.

The more

powerful C-180

tail surfaces are

square- shaped

and larger.

This was later

adopted for

the C-170.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

11

THE CESSNA 182

Even though the Cessna 180 has the same wing as

the later model all-metal Cessna 170, the 180 is a very

dierent aeroplane. It is heavier, more powerful and

more capable in every way. Unlike the C-170, C-180

with its 1,100 lb. useful load can comfortably carry four

adults and full fuel. Here is a basic comparison:

Cessna 170 Cessna 180

Empty Weight 1,205 lbs. 1,700 lbs.

Useful Load 950 lbs. 1,100 lbs.

Power 145 h.p. 230 h.p.

Cruise 105 K 142 K

Stall (Full flaps at MGW) 43 K 48 K

Range (Statute miles) 590 1,024

Absolute Ceiling 15,500 . 17,700 .

Rate of Climb at MGW 590 fpm 1,100 fpm

Without question the Cessna 180 performed very

well with its six- cylinder horizontally opposed 230 h.

p. Continental engine. It was just what the bush pilots

were looking for: an economical but hardy, heavy

loader that could go long distances quickly without

having to re-fuel. This was a much better deal than

the larger C- 190/195, which was far more expensive

to purchase, maintain and operate. It was even more

capable and rugged than the excellent C-37 Airmaster.

FOLLOW THE MONEY

All of this was just fine; however, Cessna was not only

in the business of selling aeroplanes to bush pilots,

as commercially sound as that was. The really plush

market in the burgeoning and prosperous middle

1950’s was private pilots who wanted a fast aeroplane

that could carry themselves and their families for long

distances and not cost the Earth to do so. The C-170

was fine but its performance was, to be charitable, not

spectacular.

However, the C-180 could do all that the C-170 could

not. Cessna tried to sell the C-180 to private pilots but

universally met with strong resistance over one matter

in particular - the C-180 has a tail wheel. In the middle

of the 1950’s new aeroplanes had nosewheels.

More and more private pilots of that era were no

longer content nor comfortable with an aeroplane with

a tail wheel with its inherent instability on the ground,

the high possibility of a groundloop at landing and the

poor visibility over the nose when taxiing. Once a pilot

had experienced flying an aeroplane with a nosewheel,

he or she was not willing to go back to the tailwheel.

Accordingly, Cessna had no good argument regarding

this when pilots baulked at the C-180. The solution was

more than obvious and Cessna, with yawning empty

coers anxiously awaiting to be filled with the loot to

be gained by new purchases, went to work to remedy

the deficiency.

IT LOOKS SO EASY, BUT…

Sometime during 1954, Cessna’s Board of Directors

were convinced that it would be in Cessna’s best

Piper PA-22

Tri-Pacer. Notefully steerable

nosewheel

interest for the future to put nosewheels on their two

top selling aeroplanes. They likely did not consider

that this was going to be a big problem. Aer all,

they were already manufacturing two very popular

prime candidates for this modification, the C-170

and the newer C-180. It is likely that the Board had

for some time resisted this rather expensive and

extensive change until it was painfully pointed out to

them that Cessna had indeed fallen far behind their

competitors in this regard, particularly Piper with its

prescient tricycle undercarriage Tri-Pacer which was

introduced to the public in early 1951. Not having

produced any single engine aircra with a nosewheel

by 1954 was certainly a major concern for Cessna.

Ultimately convinced to go ahead, the Board directed

Cessna’s engineers to go to the drawing board and

come up with a satisfactory solution. However, putting a nosewheel on an existing tailwheel aircra is

much easier said than done.

SO, WHAT’S THE BIG DEAL?

First, the main gear must be moved back behind the

centre of gravity (C. G.) so that the aeroplane will firmly

sit forward on its new nosewheel. This may sound at

first blush to be a simple and obvious matter, but it is

more of a problem than it might appear with respect

to a high wing aeroplane such as the Cessna 180. One

reason (of many) for the complication is because the

main undercarriage is necessarily attached to the

bottom of the C-180’s fuselage and that fuselage has

already been designed to absorb and transfer the

stresses of taxiing and landing at the former, more forward attachment point of its main undercarriage legs.

Low-wing, tailwheel aeroplanes which are re-designed

for a nosewheel have many of the same problems as

those of high-wing aeroplanes, however moving the

main undercarriage attachment point farther a on the

wing is a simpler matter.

Of course, there are a few exceptions to the

bottom of fuselage location for main undercarriage

attachment on a high-wing, nosewheel aeroplane,

particularly with regard to some twin engine,

high-wing aeroplanes such as the Aero Commander,

the Mitsubishi MU-2 and the Britten-Norman BN-2

12

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

Islander. In each of these examples, the main gear

assembly is located in the engine nacelles. Highwing singles such as the C-180 do not have such a

convenient place to attach the main gear as do those

aeroplanes. Accordingly, the internal structure of the

fuselage of the formerly “standard” undercarriage

C-180 had perforce to be altered. It required that

the new stress points, created by the relocated main

gear, adequately transfer and distribute rough-field

taxiing and landing forces into the fuselage struc

ture; forces which in the real world are not always

perfectly gentle and benign.

The exact placement rearward of the main gear must

also be resolved. This is a complicated matter of balance and compromise that involves the consideration

of a number of matters such as:

1. The location of the C. G. within a useable range

after the nosewheel is installed. This must

take into account the weight of the nosewheel

assembly, since its position is well forward with

respect to the aircraft datum or fuselage station.

While the main undercarriage sits slightly behind

the C.G. and having two wheels and legs, etc. is

heavier, it does not necessarily offset the forward

moment arm of the new nosewheel assembly.

2. The balance of the aeroplane when on the

ground. The main undercarriage legs must

be placed far enough aft to provide a stable

platform for the aeroplane to sit upon. It

must also be far enough aft to prevent the

aeroplane from tending to easily tip back

onto its tailskid under normal operating,

load and wind conditions; however…

3. The main undercarriage legs must not be so far

aft so as to prevent rotation or create too high a

load for the elevator to lift the nose on takeoff. A

certain aft placement of the main undercarriage

legs might make for a very stable aeroplane

whilst on the ground, but if it is placed too far

aft the resulting geometry may cause a situation in which the elevator may not be powerful

enough to lift the nose during the takeoff.

LEFT: Aero

Commander

note- main

undercarriage in

engine nacelle

CENTER:

Britten-Norman

BN-2 Islander.

Note- main

undercarriage

attached to

engine nacelle

RIGHT: Grumman

AA-5B “Tiger”note simple

non-steerable,

castering

nosewheel

Other considerations include:

1. The nosewheel assembly’s added mass

and drag below the data line which

will likely cause pitch – down.

2. The additional weight of the nosewheel

which reduces the aeroplane’s useful load.

3. The new tri-cycle geometry must allow for

precise and positive braking, taxiing.

4. The placement of the main undercar-

riage legs must not prevent and ought

to aid entry into the aeroplane.

5. The transfer of forces during taxi-

ing and landing must not unduly disturb the pilot and passengers.

There are probably a few more considerations as

well, but I presume that the point has been made.

Once these many thorny problems are resolved to

the best of the design engineers’ ability, the matter

of the nose wheel assembly itself and its placement

must be addressed. The area beneath the engine

and its accessories where there was little to no space

must now house the nosewheel assembly attachment. This includes a strut of suicient strength

and robustness to withstand rough field taxiing

and less than gentle landings. Not only that, but the

nosewheel’s steering mechanism and its linkages

must also be considered. In some nosewheel aircra

such as the Grumman AA-5A “Cheetah” and the

AA-5B “Tiger”, the Tecnam P Twenty-Ten and many

homebuilt aircra, this particular problem at least

has been simplified by installing a free- castering

nosewheel whereby all ground steering is achieved

by dierential braking and not by a direct link to the

nosewheel. Additionally, free-castering nosewheel

permits a very tight turning circle and many pilots

report that they like it better than a steerable

nosewheel. Cessna desired to provide a fully steering

nosewheel as did Piper’s Tri-Pacer and many other

aircra, so the complex linkages from the rudder

pedals to the nosewheel had to be designed and

space for all of this had to be found.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

13

THE CESSNA 182

PRESENTING: (APPROPRIATE

FANFARE) THE CESSNA 182

In November 1955 the C-172 was introduced to the public,

albeit as a 1956 model. Within a few months, in early 1956,

the C-182 took its opening bow. It was an instant suc

cess in the GA market. The following year the C-182 was

upgraded and became the “Skylane”. Bush pilots, how

ever, continued and continue to date to operate C-180s as

even the best nose wheel system is considered to be too

delicate for operations in rough country. With over 23,000

C-182/Skylanes having been produced to date the C-182/

Skylane has certainly proven to be a popular ride.

IT KEEPS GETTING BETTER, BUT

THE ’PLANE REMAINS THE SAME

The C-182/Skylane did not sit dormant for very long before

improvements and modifications were incorporated by

Cessna. Engines, landing gear material, larger windows,

and cabin appointments have changed and its useful load

has steadily increased. However, even with all of these

changes, the Cessna 182 remains the same simple, fast,

heavy hauling, comfortable, easy to fly aeroplane that it

was when it was first introduced in November, 1955.

Sure, over the years there have been a few modifications to the airframe, the vertical fin and rudder being

swept back with “D” model in 1960, and the most

dramatic and obvious change being the cut down rear

fuselage and the installation of “Omni-Vision” (a rear

cabin window) with “E” model in 1961. In 1996, with

the “S” model, the familiar Continental O-470-U engine

was replaced by the fuel injected Lycoming IO-540 of

similar power. Other than that the 182’s changes have

been modest and subtle, updated radios, fancier cabin

appointments and such.

The retractable gear R182 was introduced in 1977,

and a turbocharged T182 was introduced in 1980.

Both retractable gear and a turbocharged engine were

available in the TR182 in 1978. In 2001, a turbocharged

-

-

The very rst Cessna 182 (N4966E)

ABOVE RIGHT:

1956 C-182 panel

with a few radios,

etc. added.

BELOW RIGHT:

1956 C-182. Even

with a nosewheel

ip- overs are

possible.

and fuel injected engine was available in the T182T. The

introduction of the Garmin G1000 “Glass Cockpit” was

introduced as standard equipment in 2004. A diesel

engined 182, the T182JT-A, was tested in 2012 and set for

delivery to its first customer this year.

TH E C-18 2T

With each new model the Cessna 182 shows thoughtful improvements which enhance its usefulness and

convenience, sometimes in large gulps, sometime in

smaller ones. The “T” model 182 is no exception and

displays a number of changes from the previous “S”

model.

Cockpit” (not modelled) there are other electronic

enhancements. Recognizing that the electrical system

of the 182 had become more sophisticated as well as

more capacious. The avionics master switch now controls a split electrical bus. Also, there is an additional

main bus with a standby battery position. For safety in

the event that there should occur an electrical system

malfunction the avionics are divided onto two discrete,

separately switchable busses. Should a particular

component or group of components malfunction and it

becomes necessary to shed electrical load on the main

system, basic navigation and/or communication capability may be preserved by shutting down power to Nav

I or II and/or Com I or II while leaving the other radios

operational. Bus #1 switches the Honeywell Bendix/

King KLN 94, if so equipped, plus the #1 Nav/Com. Bus

#2 switches the Bendix/King KMD 550 multifunction

display (MFD), if so equipped, the #2 Nav/Com and the

transponder.

practice of dividing the most important instruments

between electric and hydraulic power, so that if one

system should fail, at least half of the instruments

would still operate.The Directional Gyro (or HSI if one

Aside from the optional Garmin G1000 “Glass

The “T” model continues Cessna’s safe and wise

14

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

is installed) is powered by the electrical system while

the Attitude Indicator (Artificial Horizon) is driven by

the vacuum system. There are two constantly working

vacuum pumps in C-182T’s with Nav I and Nav II equipment and one vacuum pump in Nav III 182s.

Cosmetically the 182”T” continues the practice

of painting on the trim over the white base colour.

Previously, and prior to 2003 the trim stripes were

decals which were clear coated to preserve them from

the weather, etc. Not surprisingly, this did not work

out so well in all instances and more than a few decaltrimmed 182Ts are showing a bit of ragged wear. Since

2003 the 182 has painted on trim.

The 182T’s seats are available covered in either

fabric or leather, at no cost dierence (A2A opted for

the leather). The control yokes are leather bound for

better traction when hauling back that heavy elevator. The LED interior lighting makes aer dark flying a

pleasure. Unlike former 182’s painted spinners the “T”

model’s spinner is a spiy polished aluminium.

The “T” model also underwent a thorough aerodynamic drag reduction program that added four knots

over the “S” model under the same power:

1. Sleeker undercarriage leg and

wheel-pants fairing.

2. Improved wingtips with internally

mounted navigation lights.

3. Improved cowling promoting more

efficient air movement within.

4. Draggy wire antennae on the vertical fin replaced

with flat plate antennae aligned with the airflow.

5. Sleeker cockpit entry steps on the

main undercarriage legs.

Also, the 230-horsepower Lycoming IO-540 has been

de-rated to operate at 2,400 rpm max. which will surely

tend to increase the practical TBO (time between overhaul) and reduce maintenance costs. The “S” model’s

three-blade McCauley prop with curved leading and

trailing edges is standard equipment on the “T’.

Over the years pilot ergonomics has not been

ignored by Cessna. In the 182’s cockpit everything

is where you might expect it to be and all controls,

switches and buttons fall nicely to hand. Flap, gear

and trim controls feel like what they control, and

operate intuitively. However, the optional electric

elevator trim button on the pilot’s control yoke is

highly recommended being that the 182’s high wing

and generous quotient of power on a thrust line

some distance below it makes this aeroplane want

trim and plenty of it upon every change of power

and/or airspeed. While the C-182T has a 24 volt

electrical system, in keeping up with the times for

the pilot’s and passengers’ convenience, for the first

time there is now a 12 volt outlet plug for an outboard electrical device such as a GPS, laptop, IPad,

or whatever.

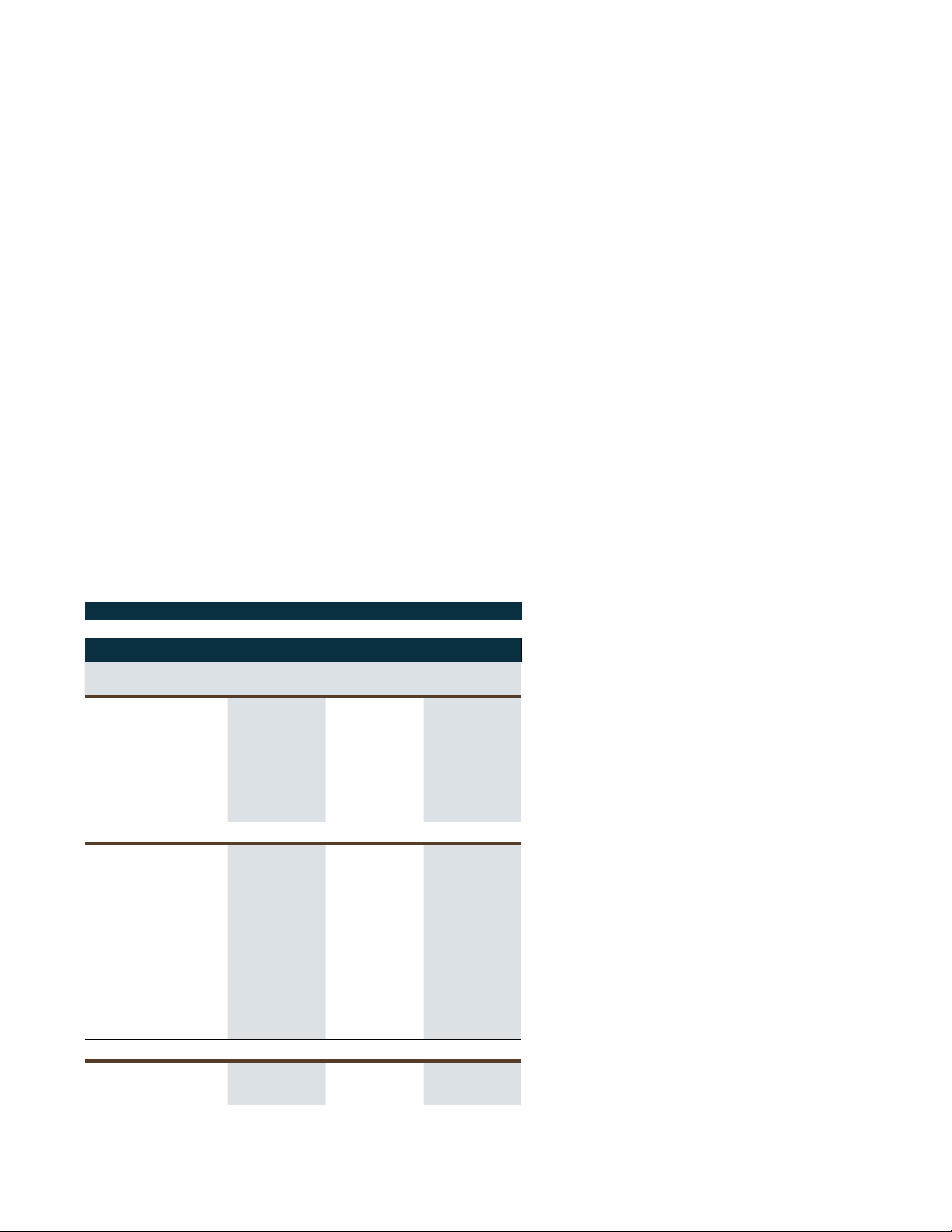

PERFORMANCE COMPARISON

Cessna 182S

SKYLANE

Engine

Horsepower 230 230 235

Top Speed 146 KTS. 150 KTS. 148 KTS.

Cruise speed 142 KTS. 145 KTS. 143 KTS.

Stall Speed (full flaps) 49 KTS. 49 KTS. 56 KTS.

Ground Roll 805 . 795 . 795 .

Over 50 obstacle 1,515 . 1,514 . 1,216 .

Rate Of Climb 865 fpm 924 fpm 1,010 fpm.

Ceiling 14,900 . 18,100 . 18,100 .

Gross Weight 3,100 lbs. 3,100 lbs. 3,000 lbs.

Empty Weight 1,775 lbs. 1,897 lbs. 1,608 lbs.

Useful load 1,213 lbs. 1,382 lbs.

Fuel Capacity 92 gal. 88 gal. 72 gal.

Range 817 nm. 968 nm. 650 nm.

Ground Roll 590 . 590 . 825 .

Over 50 obstacle 1,350 . 1,350 . 1,725 .

Lycoming

IO-540-AB1A5

Takeo

Landing

Cessna 182T

SKYLANE

Lycoming

IO-540-AB1A5

PIPER 235

DAKOTA

Lycoming

O-540-J3A5D

LIKE AN OLD, COMFORTABLE

PAIR OF SHOES

From its inception the Cessna 182 filled a need in

the GA industry that it still fills, and with distinction.

Steadily evolving since its introduction 1955 it has

never strayed far from its original incarnation. If a

pilot who flew the very first C-182 were to fly the latest

model, he or she would still find the cockpit to be a

familiar environment; and with the exception, perhaps,

of the flap control, originally manual and now electric,

everything would still essentially be where it always

had been and operate as it always did. He or she would

find it just as satisfying to fly as it always has been, like

putting on an old, comfortable pair of shoes; and that

quality, in the end, may be the Cessna 182’s greatest

achievement.

The Cessna 182 flies and operates like a basic,

simple aeroplane that any low-time Private Pilot could

easily check out in within an hour or two at most, while

it constantly delivers the high performance of a more

complex and demanding aeroplane. No doubt, as time

passes, continuing improvements will be made to the

venerable Cessna 182 that will surely enhance it in

many ways. But the basic aeroplane, that master of

virtually all aeronautic trades, will remain a familiar old

friend and perhaps the greatest of all GA aeroplanes.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

15

DESIGNER’S NOTES

16

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

HE 182 TO ME, MEANS BUSINESS.

It’s large, comfortable, and tough.

T

Upon first entering the cabin, you are greeted with

an expansive, wide, and especially long interior. My

initial thought was, “wow, four people would be

very comfortable in here, even for long cross country

flights.” The rear baggage is also easily accessible just

behind the rear seat, making the entire lengthy interior

accessible in flight.

If you are familiar with it’s smaller brother, the

Skyhawk, your eyes should catch some additional

gauges including a CHT (cylinder head temp), a large

fuel gallons per hour gauge, manifold pressure, a blue

prop handle, a cowl flaps lever, and rudder trim. And in

general, the panel is wider and more expansive.

If you are like me, when you first step into a cockpit,

you will grab the yoke or stick to get a feel for the

controls and linkage. When I first pulled back on the

yoke in the Skylane, I thought “who put sand bags on

the elevator?” It’s that heavy, and by my own measurements, a Skyhawk requires 6 lbs to li the elevator while

the Skylane requires a whopping 25lbs. Having spoken

with several 182 owners and pilots, this heavy elevator is

a “love – hate” relationship, with most loving it.

Starting the powerful Lycoming 540 engine, you are

greeted by a throaty exhaust note. This plane sounds

mean. However, when you start to taxi, it reminds me

of an old 1970’s American car power steering. While the

rudders feel just as light as a feather, you’re aware that

these delicate forces are moving a large and powerful

vehicle.

At takeo, a 3-bladed prop has a distinctly strong

pull o the line and reaches 60 mph almost twice

as fast as the Skyhawk or Cherokee. As soon as you

li o into a climb, you will see climb rates between

1,000-2,000 / min. And being a high performance

airplane, aer takeo you will want to pull the throttle

back to 23” of manifold pressure, which is about 2/3rds

throttle. As you climb higher into thinner air, you can

slowly increase the throttle to maintain 23”. If you are

planning for a higher altitude cruise, you are in for a

treat because with it’s high li wing, drooping wing

tips, and 541 cu engine, it will continue to climb strong

right to your desired height.

Once you settle, and begin trimming for cruise, you

will see a nice increase of 15-20 KTS over the smaller

GA planes and the entire time you will also enjoy a

smoother ride from the higher wing loading.

Being a high wing airplane with power, any significant power or speed changes will require a strong pull

or push on the yoke until you adjust trim. This can get

especially heavy on final, if you don’t dial in enough

nose up trim. To quote Dudley Henriques, “If someone

told me they just bought a 182, my first question

When you start to slow down for your approach, you

need to be mindful of the trim at all times. Because if

you don’t have enough trim dialed in as you cross the

threshold, you may not be able to flare this properly.

This is not an airplane you fly with a thumb and finger;

you fly and especially land a Skylane with a tightly

clenched fist and a strong fore arm.

However, once in the flare (assuming you have it

properly trimmed), the heavy elevator really counters

any instinct to over flare. I find the Skylane to be one of

the easiest planes to land (again, if properly trimmed)

as the wing continues to fly well even at high angles of

attack. If you don’t have it trimmed properly, however,

you will be in for a hard touchdown.

When you do finally touch down, the feel of the

wheels digging into the pavement tells you just how

tough this bird’s landing gear is. Even if you did land

it very hard, the feeling is this plane could take a

lot more. The large tires dig into the pavement, and

the gear flexes beautifully. This is no doubt a plane

originally designed for some very tough terrain.

Once you have slowed down and exit the runway,

the feather light taxi forces feel as if someone laid a red

carpet out for you aer your flight. It’s just the easiest,

most pleasurable airplane to taxi. I cannot imagine

improving on this aspect.

No question, the Cessna 182 Skylane is an airplane

that can do everything you ask it too, and I can see

how owners can become quite attached and loyal to

their Skylane. It’s also no surprise why the Skylane is

the world’s most produced high performance general

aviation airplane of all time. I hope you enjoy your

Accu-Sim Skylane, as we have certainly enjoyed

making (and flying) it.

THE AIR TO AIR SIMULATIONS TEAM

would be “does it have

electric trim?” if not, I would

recommend they stop what

they are doing and get one

installed immediately.”

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

17

FEATURES

18

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

A true propeller simulation.

Interactive pre-flight inspection system.

Gorgeously constructed aircra, inside

and out, down to the last rivet.

Physics-driven sound environment.

Persistent airplane even when the

computer is o.

Four naturally animated passengers that

can sit in any seat.

3D Lights ‘M’ (built directly into the

model).

Complete maintenance hangar internal

systems and detailed engine tests

including compression checks.

Visual Real-Time Load Manager.

Piston combustion engine modeling.Air

comes in, it mixes with fuel and ignites,

parts move, heat up, and all work in

harmony to produce the wonderful

sound of a Lycoming 540 engine. Now

the gauges look beneath the skin of your

aircra and show you what Accu-Sim is

all about.

Authentic Bendix King Avionics stack

including the KMA 26 Audio Panel, two

KX 155A NAV/COMMS, KR 87 ADF, KT 76C

Transponder, KN 62A DME, and KAP 140

Two Axis Autopilot with altitude preselection. Optional KI 525 HSI.

Three in-sim avionics configurations

including no GPS, GPS 295, or the GNS

400. Built-in, automatic support for 3rd

party GNS 430 and 530, GTN 650 and 750.

Pure3D Instrumentation.

In cockpit pilot’s map.

Authentic fuel delivery includes priming

and proper mixture behavior. Mixture can

be tuned by the book using the EGT or by

ear. It’s your choice.

A2A specialized materials with authentic

metals, plastics, and rubber.

Oil pressure system is aected by oil

viscosity (oil thickness). Oil viscosity is

aected by oil temperature. Now when

you start the engine, you need to be

careful to give the engine time to warm.

Eight commercial aviation sponsors have

supported the project including Phillips

66 Aviation, Champion Aerospace, and

Knots2u speed modifications.

And much more …

Electric starter with accurate cranking

power.

Dynamic ground physics including both

hard pavement and so grass modeling.

Primer-only starts.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

19

QUICK START GUIDE

20

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

HANCES ARE, IF YOU ARE

reading this manual, you

C

have properly installed

the A2A Accu-Sim C182 Skylane.

However, in the interest of

customer support, here is a brief

description of the setup process,

system requirements, and a quick

start guide to get you up quickly

and eiciently in your new aircra.

SYSTEM REQUIREMENTS

The A2A Simulations Accu-Sim C182

Skylane requires the following to run:

▶ Requires licensed copy of

Lockheed Martin Prepar3D

OPERATING SYSTEM:

▶ Windows XP SP2

▶ Windows Vista

▶ Windows 7

PROCESSOR:

2.0 GHz single core processor (3.0GHz and/or multiple

core processor or better recommended)

HARD DRIVE:

250MB of hard drive space or better

VIDEO CARD:

DirectX 9 compliant video card with at least 128 MB

video ram (512 MB or more recommended)

OTHER:

DirectX 9 hardware compatibility and audio card with

speakers and/or headphones

INSTALLATI ON

Included in your downloaded zipped (.zip) file, which

you should have been given a link to download aer purchase, is an executable (.exe) file which, when accessed,

contains the automatic installer for the soware.

To install, double click on the executable and follow

the steps provided in the installer soware. Once complete, you will be prompted that installation is finished.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

21

CHAPTER NAME

IMPORTANT: If you have Microso

Security Essentials installed, be sure

to make an exception for Lockheed

Martin Prepar3D as shown right.

REALISM SETTINGS

The A2A Simulations Accu-Sim

C182 Skylane was built to a

very high degree of realism and

accuracy. Because of this, it was

developed using the highest realism settings available in Lockheed

Martin Prepar3D.

The following settings are

recommended to provide the most

accurate depiction of the flight

model. Without these settings,

certain features may not work

correctly and the flight model will

not perform accurately. The figure

below depicts the recommended

realism settings for the A2A AccuSim C182 Skylane.

FLIGHT MODEL

To achieve the highest degree of

realism, move all sliders to the

right. The model was developed in

this manner, thus we cannot attest

to the accuracy of the model if

these sliders are not set as shown

above. The only exception would

be “Crash tolerance.”

INSTRUMENTS AND LIGHTS

Enable “Pilot controls aircra

lights” as the name implies

for proper control of lighting.

Check “Enable gyro dri” to

provide realistic inaccuracies

which occur in gyro compasses

over time.

“Display indicated airspeed”

should be checked to provide a

more realistic simulation of the

airspeed instruments.

ENGINES

Ensure “Enable auto mixture” is

NOT checked. The C182 has a fully

working mixture control and this

will interfere with our extensively

documented and modeled mixture

system.

FLIGHT CONTROLS

It is recommended you have

“Auto-rudder” turned o if you

have a means of controlling the

rudder input, either via side

swivel/twist on your specific

joystick or rudder pedals.

ENGINE STRESS DAMAGES ENGINE

(Acceleration Only). It is

recommended you have this

UNCHECKED.

22

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

QUICK FLYING TIPS

To Change Views Press A or SHIFT + A.

Keep the engine at or above 800 RPM. Failure to do

so may cause spark plug fouling. If your plugs do foul

(the engine will sound rough), try running the engine

at a higher RPM. You have a good chance of blowing

them clear within a few seconds by doing so. If that

doesn’t work, you may have to shut down and visit the

maintenance hangar.

Reduce power aer takeo. This is standard procedure

with high performance aircra.

On landing, raise your flaps once you touch down to

settle the aircra, pull back on the stick for additional

elevator braking while you use your wheel brakes.

Be careful with high-speed dives, as you can lose

control of your aircra if you exceed the max allowable

speed.

For landings, take the time to line up and plan your

approach. Keep your eye on the speed at all times.

Using in-sim accelerated time may cause

odd system behavior.

Keep throttle above when flying at high RPM to avoid

fouling plugs.

A quick way to warm your engines is to use auto start

(CTRL-E) or re-load your aircra while running.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

23

ACCU-SIM AND THE

COMBUSTION ENGINE

The piston pulls

in the fuel / air

mixture, then

compresses the

mixture on its

way back up.

24

A2ASIMULATIONS

The spark plug

ignites the

compressed air

/ fuel mixture,

driving the piston

down (power),

then on it’s way

back up, the

burned mixture

is forced out

the exhaust.

:::

C182 MANUAL www.a2asimulations.com

HE COMBUSTION ENGINE IS BASICALLY AN AIR PUMP. IT CREATES

power by pulling in an air / fuel mixture, igniting it, and turning the

T

explosion into usable power. The explosion pushes a piston down

that turns a cranksha. As the pistons run up and down with controlled

explosions, the cranksha spins. For an automobile, the spinning

cranksha is connected to a transmission (with gears) that is connected

to a drivesha, which is then connected to the wheels. This is literally

“putting power to the pavement.” For an aircra, the cranksha is

connected to a propeller sha and the power comes when that spinning

propeller takes a bite of the air and pulls the aircra forward.

The main dierence between an engine designed

for an automobile and one designed for an aircra is

the aircra engine will have to produce power up high

where the air is thin. To function better in that high,

thin air, a supercharger can be installed to push more

air into the engine.

OVERVIEW OF HOW THE ENGINE

WORKS AND CREATES POWER

Fire needs air. We need air. Engines need air. Engines

are just like us as – they need oxygen to work. Why?

Because fire needs oxygen to burn. If you cover a fire, it

goes out because you starved it of oxygen. If you have

ever used a wood stove or fireplace, you know when

you open the vent to allow more air to come in, the

fire will burn more. The same principle applies to an

engine. Think of an engine like a fire that will burn as

hot and fast as you let it.

Look at these four images on the le and you will

understand basically how an engine operates.

The piston pulls in the fuel / air mixture, then

compresses the mixture on its way back up.

The spark plug ignites the compressed air / fuel

mixture, driving the piston down (power), then on

it’s way back up, the burned mixture is forced out

the exhaust.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

25

ACCU-SIM AND THE COMBUSTION ENGINE

AIR TEMPERATURE

Have you ever noticed that your car engine runs

smoother and stronger in the cold weather? This is

because cold air is denser than hot air and has more

oxygen. Hotter air means less power.

Cold air is

denser and so

provides more

WEAK

oxygen to your

engine. More

oxygen means

more power.

STRONG

MIXTURE

Just before the air enters the combustion chamber it is

mixed with fuel. Think of it as an air / fuel mist.

A general rule is a 0.08% fuel to air ratio will produce

the most power. 0.08% is less than 1%, meaning for

every 100 parts of air, there is just less than 1 part fuel.

The best economical mixture is 0.0625%.

Why not just use the most economical

mixture all the time?

Because a leaner mixture means a hotter running

engine. Fuel actually acts as an engine coolant, so the

richer the mixture, the cooler the engine will run.

However, since the engine at high power will be

nearing its maximum acceptable temperature, you

would use your best power mixture (0.08%) when you

need power (takeo, climbing), and your best economy

mixture (.0625%) when throttled back in a cruise when

engine temperatures are low.

So, think of it this way:

▶ For HIGH POWER, use a RICHER mixture.

▶ For LOW POWER, use a LEANER mixture.

THE MIXTURE LEVER

Most piston aircra have a mixture lever in the

cockpit that the pilot can operate. The higher you

fly, the thinner the air, and the less fuel you need

to achieve the same mixture. So, in general, as you

climb you will be gradually pulling that mixture lever

backwards, leaning it out as you go to the higher,

thinner air.

How do you know when you have the right mixture?

The standard technique to achieve the proper mixture in

flight is to lean the mixture until you just notice the engine

getting a bit weaker, then richen the mixture until the

engine sounds smooth. It is this threshold that you are

dialing into your 0.08%, best power mixture. Be aware, if

you pull the mixture all the way back to the leanest posi

tion, this is mixture cuto, which will stop the engine.

-

26

A2ASIMULATIONS

Just before the

air enters the

combustion chamber

it is mixed with

fuel. Think of it as

an air / fuel mist.

When you push the

throttle forward, you

are opening a valve

allowing your engine

to suck in more

fuel / air mixture.

:::

C182 MANUAL www.a2asimulations.com

INDUCTION

As you now know, an engine is an air pump that runs

based on timed explosions. Just like a forest fire, it

would run out of control unless it is limited. When you

push the throttle forward, you are opening a valve

allowing your engine to suck in more fuel / air mixture.

When at full throttle, your engine is pulling in as much

air as your intake system will allow. It is not unlike a

watering hose – you crimp the hose and restrict the

water. Think of full power as you just opening that

water valve and letting the water run free. This is 100%

full power.

In general, we don’t run an airplane engine at full

power for extended periods of time. Full power is only

used when it is absolutely necessary, sometimes on

takeo, and otherwise in an emergency situation that

requires it. For the most part, you will be ‘throttling’

your motor, meaning you will be be setting the limit.

MANIFOLD PRESSURE = AIR PRESSURE

You have probably watched the weather on television

and seen a large letter L showing where big storms are

located. L stands for LOW BAROMETRIC PRESSURE

(low air pressure). You’ve seen the H as well, which

stands for HIGH BAROMETRIC PRESSURE (high air

pressure). While air pressure changes all over the

world based on weather conditions, these air pressure

changes are minor compared to the dierence in air

pressure with altitude. The higher the altitude, the

much lower the air pressure.

On a standard day (59°F), the air pressure at sea

level is 29.92 in. Hg BAROMETRIC PRESSURE. To keep

things simple, let’s say 30 in. Hg is standard air pressure. You have just taken o and begin to climb. As you

reach higher altitudes, you notice your rate of climb

slowly getting lower. This is because the higher you fly,

the thinner the air is, and the less power your engine

can produce. You should also notice your MANIFOLD

PRESSURE decreases as you climb as well.

Why does your manifold pressure

decrease as you climb?

Because manifold pressure is air pressure, only it’s

measured inside your engine’s intake manifold. Since

your engine needs air to breath, manifold pressure is

a good indicator of how much power your engine can

produce.

Now, if you start the engine and idle, why

does the manifold pressure go way down?

When your engine idles, it is being choked of air. It is

given just enough air to sustain itself without stalling.

If you could look down your carburetor throat when an

engine is idling, those throttle plates would look like they

were closed. However if you looked at it really closely,

you would notice a little space on the edge of the throttle

valve. Through that little crack, air is streaming in. If you

turned your ear toward it, you could probably even hear

a loud sucking sound. That is how much that engine is

trying to breath. Those throttle valves are located at the

base of your carburetor, and your carburetor is bolted

on top of your intake manifold. Just below those throttle

valves and inside your intake manifold, the air is in a near

vacuum. This is where your manifold pressure gauge’s

sensor is, and when you are idling, that sensor is reading

that very low air pressure in that near vacuum.

As you increase power, you will notice your manifold

pressure comes up. This is simply because you have

used your throttle to open those throttle plates more,

and the engine is able to get the air it wants. If you

apply full power on a normal engine, that pressure

will ultimately reach about the same pressure as the

outside, which really just means the air is now equal

ized as your engine’s intake system is running wide

open. So if you turned your engine o, your manifold

pressure would rise to the outside pressure. So on a

standard day at sea level, your manifold pressure with

the engine o will be 30”.

IGNITION

The ignition system provides timed sparks to trigger timed explosions. For safety, aircra are usually

equipped with two completely independent ignition

systems. In the event one fails, the other will continue

to provide sparks and the engine will continue to run.

This means each cylinder will have two spark plugs

installed.

An added advantage to having two sparks instead

of one is more sparks means a little more power.

The pilot can select Ignition 1, Ignition 2, or BOTH by

using the MAG switch. You can test that each ignition

is working on the ground by selecting each one and

watching your engine RPM. There will be a slight drop

when you go from BOTH to just one ignition system.

This is normal, provided the drop is within your pilot’s

manual limitation.

The air and fuel

are compress

by the piston,

then the ignition

system adds the

spark to create

a controlled

explosion.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

27

ACCU-SIM AND THE COMBUSTION ENGINE

ENGINE TEMPERATURE

All sorts of things create heat in an engine, like friction, air temp, etc., but nothing produces heat like

COMBUSTION. The hotter the metal, the weaker its

strength.

Aircra engines are made of aluminum alloy, due

to its strong but lightweight properties. Aluminum

maintains most of its strength up to about 150°C. As

the temperature approaches 200°C, the strength starts

to drop. An aluminum rod at 0°C is about 5× stronger

than the same rod at 250°C, so an engine is most

prone to fail when it is running hot. Keep your engine

temperatures down to keep a healthy running engine.

LUBRICATION SYSTEM (OIL)

An internal combustion engine has precision machined

metal parts that are designed to run against other metal

surfaces. There needs to be a layer of oil between those

surfaces at all times. If you were to run an engine and pull

the oil plug and let all the oil drain out, aer just minutes,

the engine would run hot, slow down, and ultimately

seize up completely from the metal on metal friction.

There is a minimum amount of oil pressure required

for every engine to run safely. If the oil pressure falls

below this minimum, then the engine parts are in

danger of making contact with each other and incurring

damage. A trained pilot quickly learns to look at his oil

pressure gauge as soon as the engine starts, because if

the oil pressure does not rise within seconds, then the

engine must be shut down immediately.

Without the layer of oil between

the parts, an engine will

quickly overheat and seize.

Above is a simple illustration of a cranksha that is

located between two metal caps, bolted together. This

is the very cranksha where all of the engine’s power

ends up. Vital oil is pressure-injected in between these

surfaces when the engine is running. The only time the

cranksha ever physically touches these metal caps is at

startup and shutdown. The moment oil pressure drops

below its minimum, these surfaces make contact. The

cranksha is where all the power comes from, so if you

starve this vital component of oil, the engine can seize.

However, this is just one of hundreds of moving parts

in an engine that need a constant supply of oil to run

properly.

28

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

MORE CYLINDERS, MORE POWER

The very first combustion engines were just one or

two cylinders. Then, as technology advanced, and the

demand for more power increased, cylinders were

made larger. Ultimately, they were not only made

larger, but more were added to an engine.

Below are some illustrations to show how an

engine may be configured as more cylinders are

added.

The more cylinders you add to an engine, the more

heat it produces. Eventually, engine manufacturers started to add additional “rows” of cylinders.

Sometimes two engines would literally be mated

together, with the 2nd row being rotated slightly so the

cylinders could get a direct flow of air.

THE PRATT & WHITNEY R4360

Pratt & Whitney took this even further, creating the

R4360, with 28 Cylinders (this engine is featured in the

A2A Boeing 377 Stratocruiser). The cylinders were run

so deep, it became known as the “Corn Cob.” This is the

most powerful piston aircra engine to reach production. There are a LOT of moving parts on this engine.

TORQUE VS HORSEPOWER

Torque is a measure of twisting force. If you put a foot

long wrench on a bolt, and applied 1 pound of force at the

handle, you would be applying 1 foot-pound of torque to

that bolt. The moment a spark triggers an explosion, and

that piston is driven down, that is the moment that piston

is creating torque, and using that torque to twist the

cranksha. With a more powerful explosion, comes more

torque. The more fuel and air that can be exploded, the

more torque. You can increase an engine’s power by either

making bigger cylinders, adding more cylinders, or both.

Horsepower, on the other hand, is the total power that

engine is creating. Horsepower is calculated by combin

ing torque with speed (RPM). If an engine can produce

500 foot pounds of torque at 1,000 RPM and produce the

same amount of torque at 2,000 RPM, then that engine is

producing twice the horsepower at 2,000 RPM than it is

at 1,000 RPM. Torque is the twisting force. Horsepower is

how fast that twisting force is being applied.

If your airplane has a torque meter, keep that engine

torque within the limits or you can break internal components. Typically, an engine produces the most torque

in the low to mid RPM range, and highest horsepower in

the upper RPM range.

-

The “Corn Cob,”

the most powerful

piston aircraft

engine to reach

production.

www.a2asimulations.com C182 MANUAL

:::

A2ASIMULATIONS

29

SPECIFICATIONS

30

A2ASIMULATIONS

:::

C182 MANUAL www.a2asimulations.com

Loading...

Loading...