Page 1

3M™ Hearing Protection Solutions

Detection Protection Validation

Hearing

Protection Solutions

Made Innovatively Easy

The power to protect your world.

SM

Page 2

We live in a world where people don’t always make the right choice. Health and safety professionals have a challenging job convincing

people to wear protective equipment for their own safety. You must combine compliance to standards and regulations and employee

safety, comfort, and even style. Everyone wants to look good, but they don’t always want to wear protective equipment. We know this

and it is why we continue to listen, test and add innovations to improve our products so people wear them longer.

We provide solutions for work situations requiring basic Personal Protective Equipment (PPE) through to environments that call for

the most sophisticated and comprehensive protection. Whether the customer is a single tradesperson, medium sized business or an

organisation employing thousands of workers, 3M has a workplace safety solution to meet your needs.

When job requirements call for special problem solving expertise, you can rely on 3M to use its diverse industry knowledge and

history of innovation to give you the confidence and power to protect your world.

The 3M range of solutions for worker safety includes:

• Respiratory Protection

• Hearing Protection

• Communications

• Eye, Head & Face Protection

• Welding Protection

• Spill Management

3M Safety brands you can trust:

TM

III

• Worker Visibility

• Detection & Monitoring

• Body Protection

Page 3

Training and Support

3M’s team of Specialist Representatives are available nationally, to provide support and training that meet the needs of our customers.

Furthermore, our qualified and highly experienced team are able to assist customers by:

• Conducting initial and ongoing assessments of the workplace.

• Recommending appropriate respiratory, hearing, eye protection, communication and spill management solutions required to maintain

a safe work environment

• Providing technical advice about the correct use and maintenance of the solution that has been selected

• Facilitate on-site fit testing for both respiratory and hearing protection solutions, as required

No matter how effective a piece of Personal Protective Equipment (PPE) is, it will offer little or no protection if it is not fitted and/or

worn correctly. Proper inspection, cleaning and storage is vital for safety equipment that protects a worker’s health and well-being.

That is why we offer training programs that explain the correct way to fit, inspect, clean and store the PPE designed and

manufactured by 3M.

Technical Assistance

3M TechAssist is the ideal point of contact for your questions, especially when you require a prompt answer. Supported by trained

staff, TechAssist is an immediate link to the worldwide resources of 3M.

Customers can contact TechAssist to answer questions on product information, technical advice, guidance with product selection,

Australia/New Zealand Standards and other important information they need to know on a day-to-day basis.

See back cover for Technical Assistance contact details.

ANZ Distributor network

3M distributes our wide range of workplace safety products through a network of distributors, resellers and retailers throughout

Australia and New Zealand.

IV

Page 4

Detection

Protection Validation

When it comes to protecting workers’ hearing, there is no one-size-fits-all solution.

Understanding the challenge requires accurate sound detection. Delivering the right solution

demands the right protection for the job. Verifying solutions calls for a validation system.

We deliver a complete set of tools needed to detect, protect and validate. It’s 3M hearing

protection solutions made innovatively easy.

1

Page 5

Table of

Contents

Introduction

Selection Chart 3

The Solution – Detection, Protection & Validation 5

Industry User Profiles 7

™

3M

E-A-Rfit™ Validation System 9

Technology & Support 10

3M™ Detection Solutions

3M™ Noise Indicator NI-100 12

™

3M

Sound Detector SD-200 12

3M™ Disposable Foam Earplugs

E-A-R™ Classic™ 14

™

E-A-R

Classic™ Platinum™ 14

™

E-A-R

Classic™ SuperFit™ 15

E-A-Rsoft

E-A-Rsoft

E-A-Rsoft

E-A-Rsoft

E-A-R

E-A-R

3M

3M

3M

3M

E-A-R

E-A-R

™

Yellow Neons™ 15

™

Yellow Neon Blasts™™ 16

™

SuperFit™ 16

™

FX™ 17

™

Tap erFit™ 2 17

™

Metal Detectable 18

™

Nitro™ 18

™

1120 Foam 19

™

1100 F oa m 19

™

One Touch™ 20

™

Vending Packs 20

™

Trade Packs 21

3M™ Passive Earmuffs

Peltor™ H10 37

™

Peltor

H9 37

™

Peltor

H7 38

™

Peltor

H6 38

™

Peltor

H31 39

™

Peltor

PLT™ 39

™

Peltor

H9A-02 Food Industry 40

™

Peltor

H505B Welding 40

™

Peltor

Bull's Eye 41

™

Peltor

X4 41

™

Peltor

X5 42

™

Peltor

Hygiene Tear Away Pads 42

™

Peltor

H510AK Kids 43

™

3M

1426 43

™

3M

1436 44

3M™ E-A-Rfit™ Validation System

E-A-Rfit™ Validation System 52

3M™ Push-to-Fit Earplugs

E-A-R™ Express™ Pod Plugs™ 23

™

E-A-R

Push-Ins™ 23

™

E-A-R

Push-Ins™ with Grip Rings 24

™

3M

Pistonz™ 24

™

3M

Skull Screws™ 25

3M

™

No-Touch

™

25

Support Materials 26

3M™ Reusable Earplugs

E-A-R™ UltraFit™ 28

™

E-A-R

UltraFit™ 27 28

™

E-A-R

UltraFit™ Plus 29

Tri-Flange

™

29

120 0 3 0

ClearE-A-R

E-A-R

E-A-R

™

20 30

™

Combat Arms™ Dual Ended 31

™

Combat Arms™ Single Ended 31

3M™ Banded Hearing Protectors

E-A-Rflex™ 33

™

E-A-R

Caboflex™ 33

E-A-Rcaps

E-A-R

3M

™

34

™

Swerve™ 34

™

1310 35

2

Page 6

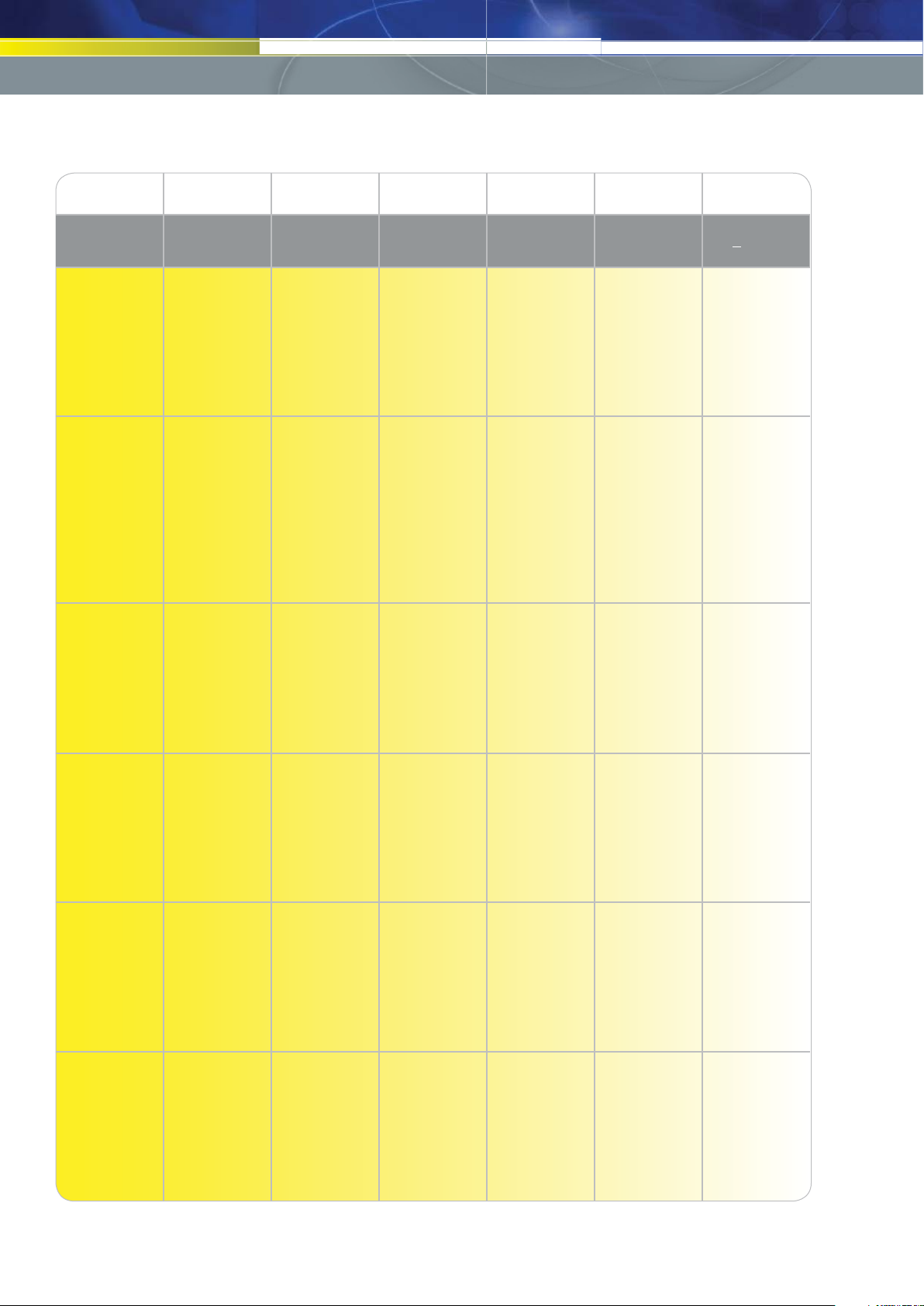

Selection Chart

AS/NZS Class Class 1 Class 2 Class 3 Class 4 Class 5

Exposure Levels

(LA eq 8hr)

No Roll Down

rplugs

Ea

Disposable

Earplugs

Reuseable

Earplugs

85 < 90dB 90 < 95dB 95

Ultrafit Metal

<

100dB 100 < 105dB 105 < 110dB

Express

Classic

(corded)

110 0

1110

Ultrafit

EZ-Ins

Detectable

Ultrafit Plus

Ultrafit Plus

Tri Flange

127 0

1290/1291

Push-Ins

Pistonz

No Touch

Classic

Classic Platinum

Classic Superfit 30

E-A-Rsoft Superfit

E-A-Rsoft Metal

Detectable

E-A-Rsoft Yellow

Neons

E-A-Rsoft Yellow

Neon Blast

1120

Ultrafit 27

Push-Ins with

Skull Screws

E-A-Rsoft FX,

Grip Rings

TaperF it 2

>

110dB

Seek advice

from your rep

Seek advice

from your rep

Seek advice

from your rep

Banded Earplugs

Earmuffs

Earmuffs with

Communications

3

Caboflex 600

E-A-R Caps

E-A-Rflex Foam

E-A-Rflex

Metal Detectable

Swerve with

FLEX 28 Tips

1310

Swerve with

Comfort Pods

H6 Series

H9 Series

H505B Series

SportTac

H10 Series,

H7 Series

H9A-02 Series

1426

143 6

Pro Tac II

Push-to-Listen

Worktunes Plus

Lite-Com III

Seek advice

from your rep

Seek advice

from your rep

Seek advice

from your rep

Page 7

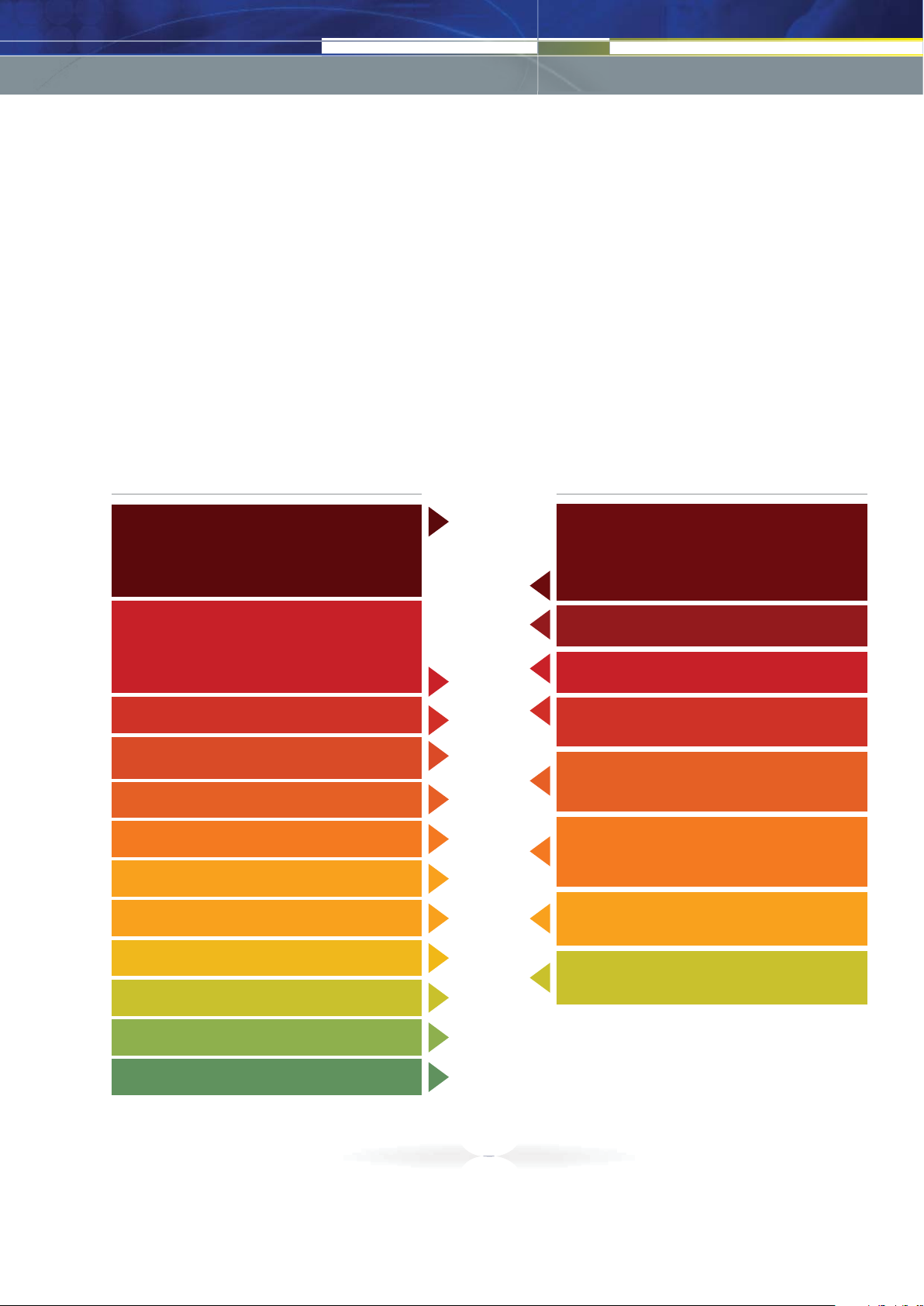

The Real World Concerns

of Hearing Protection

Variable Noise Levels: Every environment is different, and

workers can face a wide range of sound levels throughout the

day and in different areas at the same facility.

Employee Communication: Many employees need to be

able to communicate easily with co-workers and listen for

workplace warning sounds, while being protected from

hazardous noise levels.

What Types of Sounds

The Human Factor: Each person is physically unique, so

there is no one-size-fits-all hearing protection solution. The key

to achieving optimal protection is having the best fit possible.

12-Gauge Shotgun

Basketball Game Crowd Noise

Chainsaw 110

Rock Concert

Motorcycle 100

Lawn Mower 90

160

120

105

Require Hearing Protection?

At home and work, it’s important to understand which sounds

may cause hearing loss and require hearing protection:

Work Scale Decibels (dBA)*Home Scale Decibels (dBA)*

160

150

140

130

120

110

100

90

Jet Takeoff 140

Jackhammer

Pneumatic Riveter

Hammer Drill 114

Tractor / Hand Drill 97

Belt Sander 93

135

124

Vacuum Cleaner 80

Mid-Sized Auto Interior 70

Conversation 60

Floor Fan 50

Refrigerator Hum 40

Rustling Leaves 30

Watch Ticking 20

80

70

60

50

40

30

20

10

10

20

City Traffic 78

Air Conditioning Unit 60

Electrical Transformer 45

*As reported by Centers for Disease Control and Prevention:

www.cdc.gov/niosh/topics/noise/noisemeter.html

Other sources include: http://e-a-r.com/hearingconservation/faq-main.cfm,

http://www.cdc.gov/niosh/topics/noise/chart-carpenters.html,

http://www.nidcd.nih.gov/health/statistics/Pages/quick.aspx

4

Page 8

Detection Protection Validation

The Solution

3M Detection, Protection and Validation

As a global leader in sound and noise detection, hearing protection and fit test validation, 3M

delivers easy and comprehensive solutions to complex hearing protection challenges.

Accurate Noise Detection. The first step in solving the

challenge is to measure the noise levels facing your workers.

3M detection solutions make it easy to measure noise

hazards, so you can select the appropriate protection for the

job. Our detection instruments deliver accurate and reliable

measurements, and detection management software makes it

easy to report and share data.

Adaptable Hearing Protection. 3M delivers an unmatched

variety of innovative hearing protectors, making it easy to select

the right solution for the job. A variety of sizes and materials

are available, helping your team determine the right fit for

each person, and the right protection for the application. Our

innovative products are designed for comfortable, extended

wear, and they can help your team comply with your safety

program.

Fit Test Validation. Integrating hearing protector fit testing

into your hearing conversation program benefits everyone from

new hires to high-risk workers. The 3M

System makes it easier to fit, train and motivate workers and to

assess and manage the long-term performance of your hearing

conservation program.

™

E-A-Rfit™ Validation

5

Page 9

3M’s broad range of hearing protection devices in a

variety of styles and materials helps you solve many of the

challenges facing workers in various environments.

666

Page 10

Food Industry Worker

Susan works indoors at a food

processing plant in a damp,

refrigerated area. She leaves her

hearing protectors in throughout her

entire shift.

She needs metal detectable

earplugs or easy-to-clean earmuffs.

And they have to be comfortable.

“In my job, I don’t want

complicated hearing

protection. Just keep

it simple.”

Production Manager

John works indoors, and moves in

and out of noisy areas continuously

throughout the day. Most of the time he

is on the phone or a two-way radio.

He needs a hearing protection

sol

ution with wireless 2-way radio

communications and ambient

listening. In short, he needs to hear

and communicate in noisy areas to

do his job.

“ I need to be able to hear

my co-workers communicate

with me.”

7

Page 11

Iron Worker

Bill works in hot and humid

environments, and often in tight

spaces. He’s constantly moving and

takes his earplugs out frequently.

He needs large-sized earplugs that

’t have to be rolled down before

don

inserting. If he’s also wearing

earmuffs, they need to fit within

his welding helmet.

“ I don’t like boring products.

Give me some interesting

choices for my hearing

protection.”

Machine Operator

Julia works at the same station

every day and wears safety glasses

throughout her entire shift.

She needs small-sized earplugs

muffs that are comfortable

or ear

for extended wear.

“ My hearing protection

has got to be comfortable.

That’s my top priority.”

8

Page 12

Detection Protection Validation

9

3

3

AR 332

A

3

A 300

A 2

9

A

228

AAAA 2

2

Finding the Right Fit with the

™

3M

E-A-Rfit™ Validation System

The E-A-Rfit Validation System measures the level of employee

hearing protection by generating a Personal Attenuation Rating

(PAR) in just 10 seconds per ear. The PAR indicates a workers'

noise reduction levels for a given fitting and hearing protector.

The E-A-Rfit validation system assists employers in achieving

optimal fit through hearing protection selection and

employee training.

The 3M™ E-A-Rfit™

Validation System Helps You:

Fit, Train and Motivate

• Serves as a tool for training proper fitting techniques

and assessing fitting proficiency.

• Great for refitting or retraining after temporary threshold

shifts (TTSs) are detected.

• Motivates employees by helping them realise the control

they have in protecting their hearing.

Audit Your Team

• Establishes baseline values for new workers.

• Helps to identify workers receiving inadequate protection.

• Validates high protection levels required by workers in

high noise areas.

Assess and Manage

• Improves long-term performance of your hearing

conservation program.

The E-A-Rfit Validation System

An Integral Part of Your

Hearing Protection Program

Integrating hearing protector fit testing into your hearing

conservation program benefits everyone from new hires

to high-risk workers.

9

• Indicates which employees need further fit training

or alternative hearing protectors.

• After noise exposure data is input, the E-A-Rfit software can

help identify the most appropriate hearing protector(s) and

help minimize over/under protection.

PAR 28

Page 13

Technology and Support from

the Hearing Protection Experts

Employee Education and

Training. The 3M Hear Force

Training provides valuable

on-site training and seminars

throughout Australia and New Zealand, helping employers

and their workers achieve their hearing conservation goals.

This training is based on AS/NZS 1269.3 and is conveniently

performed on-site at no cost. Whether it’s explaining

attenuation ratings or regulations, or providing the motivation

workers need to comply, 3M Hear Force trainers are available

to help you achieve your hearing conservation program

objectives. They’re experts in hearing conservation training and

will work with your team to help ensure your employees are

protected with the right equipment for their jobs.

™

reduction. Many factors, such as the relationship between

the size of the wearer and size of the hearing protector, and

how it has been inserted or fitted, can impact how effective

that hearing protector will be. That’s why it is so important to

have the E-A-Rfit validation system as part of your hearing

conservation program and the support of a hearing protection

team with over 40 years of expertise.

Innovation from the Experts. At 3M, we understand

the challenges of the workplace, the complexities of fitting

protection devices, and the importance of creating adaptable

solutions for maximising hearing protection. Our innovations

in noise detection, protection and validation are designed to

solve real-world challenges, providing our customers with the

advanced and comprehensive solutions needed to help protect

workers.

Understanding Sound Level Conversion (SLC

). A SLC

80

rating is determined based on how well the hearing protector

performed in a laboratory. However, each hearing protector’s

SLC

is not always a good estimate for workplace noise

80

80

10

Page 14

Detection Protection Validation

Detection

Solutions

Detection is the first step in identifying where hearing protection may be needed.

3M delivers intuitive solutions for effective noise monitoring programs. Durable,

accurate, and easy-to-use instrumentation makes it simple to report and share

noise exposure data. 3M Detection products deliver innovatively simple solutions to

complex monitoring challenges.

11

Page 15

3M™

Detection Products

Noise Indicator NI-100

The 3M™ Noise Indicator NI-100 alerts the wearer to potentially dangerous noise

levels, helping identify areas where hearing protection may be needed. Users clip the

Noise Indicator to a shirt or jacket, and its LED light provides a clear indication when

noise levels exceed a potentially hazardous threshold. The NI-100’s small size and

lightweight design make it ideal for workers in a variety of industries.

• Affordable lightweight noise monitor with a durable, easy-to-use design

• Rechargeable battery that operates for up to 200 hours between charges

• Flashing green LED indicates if noise level is below 85 dBA

• Flashing red LED indicates noise level is above 85 dBA, indicating hearing

protection may be needed

Product Number Abbreviated General Description Packaging

NI-100 Noise Indicator 10 units/case

053-575

USB Cable Accessory for Battery Charging 10 units/case

Sound Detector SD-200

The 3M™ Sound Detector SD-200 is a compact, lightweight sound level meter designed

for measurement of workplace noise levels. Its intuitive design makes it easy for users

to measure sound levels and helps determine the attenuation of hearing protection that

may be required. The integrating feature computes the average sound pressure level,

allowing for more accurate assessment of intermittent sound levels.

• Simple, user-friendly interface; green, yellow and/or red LEDs flash when preset

noise levels are reached

• A rechargeable lithium polymer battery operates up to 50 hours between charges

• Average sound pressure level delivers a steady reading where noise levels are

highly variable

• Features a Class/Type 2 microphone

• Measures Sound Pressure Level (SPL), Average value (L

Maximum value (MAX), Minimum value (MIN), Run-Time, Overload (OL) and

Under-Range (UR)

• Display range is 40 to 130 dB (Dynamic Range)

EQ/LAVG

), LED alert,

Product Number Abbreviated General Description Packaging

SD-200 Sound Detector Kit, USB Cable, Windscreen 1 unit/case

053-575 USB Cable Accessory for Battery Charging 10 units/case

SD-WS Windscreen 1 unit/case

For more information on 3M's extensive range of detection products, please contact:

Air-Met Scientific on 1800 000 744 (AU) or Global Science New Zealand on 0800 734 100 (NZ)

12

Page 16

Detection Protection Validation

Disposable

Earplugs

3M™ Disposable Earplugs, made from expandable slow-recovery foam, provide

the best combination of comfort and protection for most users. Once in the ear,

foam earplugs expand to conform to the unique shape of each ear, providing

a comfortable, custom fit. 3M provides a wide range of disposable roll-down

earplugs so you can choose the best solution for your individual needs.

13

Page 17

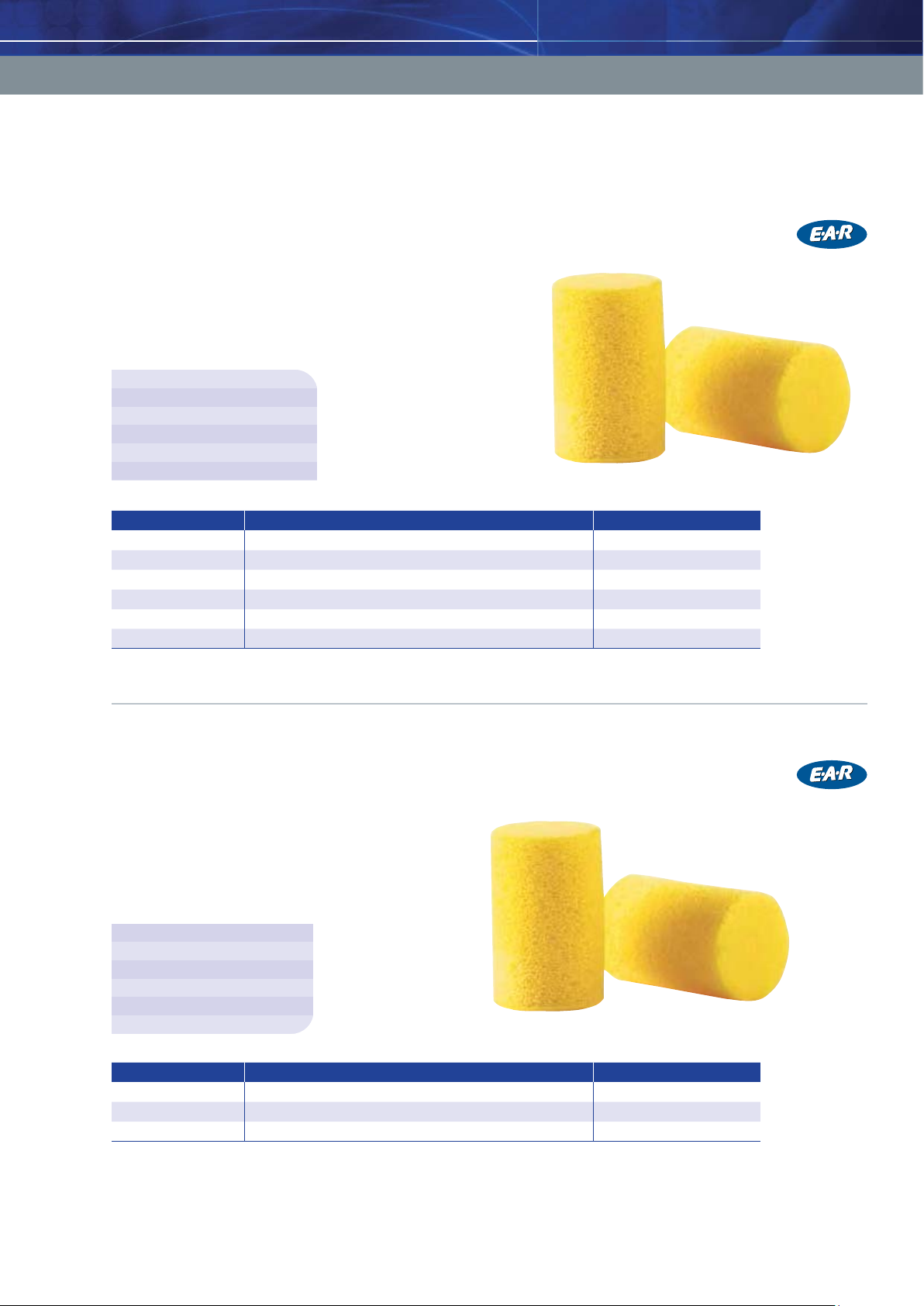

3M™ E-A-R™ Disposable

Foam Earplugs

E-A-R™ Classic™ Earplugs

Classic earplugs were the industry’s first foam earplugs, virtually revolutionising hearing

protection. Today, the revolution continues. It meets more wearer and environmental needs

with its proprietary foams, preferred cylindrical shape, and proven in-ear comfort.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

311-1101 Classic Earplug Corded, SLC

310-1001 Classic Earplug Uncorded, Pillow Pack 200 pairs/box, 10 boxes/case

312-1201 Classic Earplug Uncorded, Poly Bag 200 pairs/box, 10 boxes/case

391-1001 Classic One Touch Refill 500 pairs/bottle, 4 bottles/case

VP311-1101 Classic Earplug Corded, Vending Pack, SLC

VP312-1201 Classic Uncorded Earplug Vending Pack 5 pairs/bag, 100 bags/case

Ū

Ū

Ū

SLC

23dB (Class 4)

80

80

21dB (Class 3) 200 pairs/box, 10 boxes/case

80

21dB (Class 3) 5 pairs/bag, 100 bags/case

TM

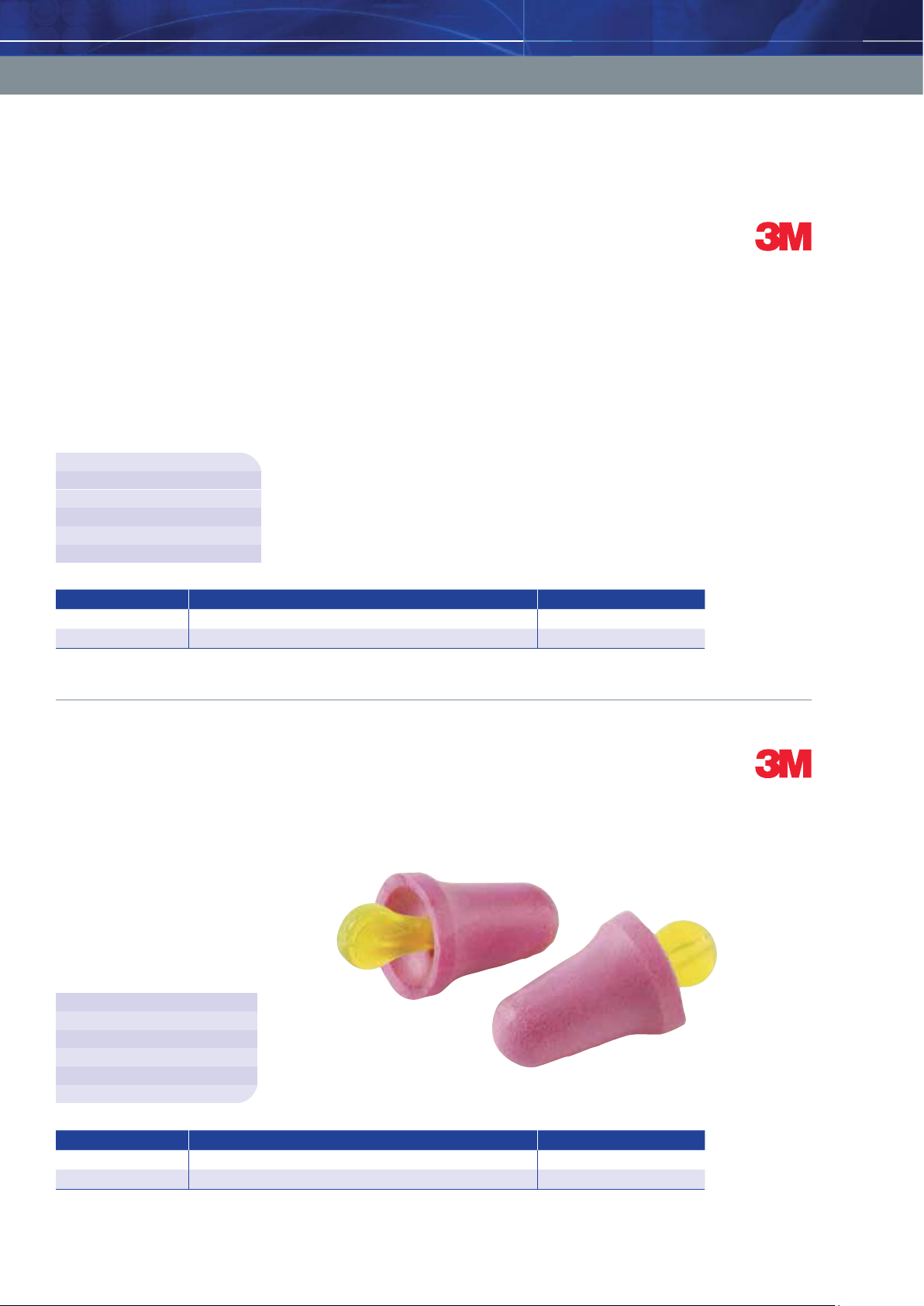

E-A-R™ Classic™

Platinum™ Earplugs

The diameter of a Classic Platinum earplug is smaller than the Classic

earplug (and the same length) to help provide optimum comfort and

protection in narrow ear canals.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

310-4002 Classic Platinum Earplug Uncorded, Pillow Pack 200 pairs/box, 10 boxes/case

310-4003 Classic Platinum Earplug Uncorded, Poly Bag 200 pairs/box, 10 boxes/case

391-1007 Classic Platinum One Touch Refill 500 pairs/bottle, 4 bottles/case

Ū

Ū

SLC

23dB (Class 4)

80

TM

14

Page 18

3M™ E-A-R™ Disposable

Foam Earplugs

E-A-R™ Classic™ SuperFit™

30 Earplugs

SuperFit earplugs are the only earplug model with a unique “fitting ring” to

easily see when the earplug is correctly fitted. When no orange color is visible,

the best fit is achieved.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

311-1126 Classic SuperFit 30 Earplug Corded, Poly Bag, SLC

312-4201 Classic SuperFit 30 Earplug Uncorded, Poly Bag 200 pairs/box, 10 boxes/case

391-1009 Classic SuperFit 30 One Touch Refill 500 pairs/bottle, 4 bottles/case

Ū

Ū

Ū

23dB (Class 4)

SLC

80

80

22dB (Class 4) 200 pairs/box, 10 boxes/case

TM

E-A-Rsoft™ Yellow Neons™ Earplugs

E-A-Rsoft Yellow Neons have a smooth texture for in-ear comfort and are made of an

advanced foam formulation for all-day wearabillity. Offered in two sizes to comfortably fit in a wide

range of ears, these high attenuation earplugs are ideal for many different noisy applications. Brightly

colored for hearing protection compliance sighting, E-A-Rsoft Yellow Neons earplugs are an excellent

choice for any hearing conservation program.

Available with Cord

Moisture Resistant

Reusable

Metal-Detectable (311-4106 only)

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

311-1250* E-A-Rsoft Yellow Neons Regular Earplug Corded, Pillow Pack 200 pairs/box, 10 boxes/case

312-1250

311-1251 E-A-Rsoft Yellow Neons Large Earplug Corded 200 pairs/box, 10 boxes/case

312-1251 E-A-Rsoft Yellow Neons Large Earplug Uncorded 200 pairs/box, 10 boxes/case

311-4106

310-1250* E-A-Rsoft Yellow Neons Uncorded, Pillow Pack 200 pairs/box, 10 boxes/case

391-1004 E-A-Rsoft Yellow Neons One Touch Refill 500 pairs/bottle, 4 bottles/case

* Only available in NZ

Ū

Ū

Ū

SLC80 23dB (Class 4)

E-A-Rsoft Yellow Neons Regular Earplug Uncorded 200 pairs/box, 10 boxes/case

E-A-Rsoft Yellow Neons Metal Detectable Earplug with Metal Detectable

Cord

200 pairs/box, 10 boxes/case

TM

15

Page 19

E-A-Rsoft™ Yellow Neon Blasts™ Earplugs

E-A-Rsoft Yellow Neon Blasts earplugs are made from a slowly expanding, polyurethane foam

material. They provide evenly distributed pressure, giving flexibility and a good seal with

optimum comfort. A red flame design adds fun to serious hearing protection.

TM

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

311-1252 E-A-Rsoft Yellow Neon Blasts Regular Earplug Corded 200 pairs/box, 10 boxes/case

312-1252 E-A-Rsoft Yellow Neon Blasts Regular Earplug Uncorded 200 pairs/box, 10 boxes/case

391-1010 E-A-Rsoft Yellow Neon Blasts Regular One Touch Refill 500 pairs/bottle, 4 bottles/case

E-A-Rsoft

E-A-Rsoft SuperFit earplugs have a smooth texture for in-ear comfort and are made of

an advanced foam formulation for outstanding softness. The exclusive orange fitting ring

design provides a built-in visual to help confirm proper fit.

Ū

Ū

SLC80 23dB (Class 4)

™

SuperFit™ Earplugs

TM

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

311-1254 E-A-Rsoft SuperFit Regular Earplug Corded 200 pairs/box, 10 boxes/case

312-1256 E-A-Rsoft SuperFit Regular Earplug Uncorded 200 pairs/box, 10 boxes/case

312-1255 E-A-Rsoft SuperFit Large Earplug Uncorded 200 pairs/box, 10 boxes/case

391-1254 E-A-Rsoft SuperFit Regular One Touch Refill 500 pairs/bottle, 4 bottles/case

Ū

Ū

SLC80 24dB (Class 4)

16

Page 20

3M™ E-A-R™ Disposable

Foam Earplugs

E-A-Rsoft™ FX™ Earplugs

FX earplugs feature a bell shape and super-soft, slow-recovery foam to

effectively seal the ear canal and provide reliable hearing protection. Flared end

helps make fitting and removal easier.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

312-1261 E-A-Rsoft FX Earplug Uncorded 200 pairs/box, 10 boxes/case

312-1260

Ū

Ū

SLC80 26dB (Class 5)

E-A-Rsoft FX Earplug Corded 200 pairs/box, 10 boxes/case

TM

E-A-R™ TaperFit™ II Earplugs

Soft, roll-down foam earplugs conform to the unique shape of each ear canal to

provide a low-pressure, comfortable seal. Offered in two sizes to fit most ears

comfortably.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

312-1219 E-A-R™ TaperFit™ II Regular Earplug Uncorded 200 pairs/box, 10 boxes/case

312-1221

312-1224 E-A-R™ TaperFit™ II Large Earplug Corded 200 pairs/box, 10 boxes/case

Ū

Ū

26dB (Class 5)

SLC

80

E-A-R™ TaperFit™ II Large Earplug Uncorded 200 pairs/box, 10 boxes/case

TM

17

Page 21

E-A-R™ Metal

Detectable Earplugs

All 3M™ Metal Detectable Earplugs have an integral stainless steel

ball encased in the earplug. Ideal for use in food manufacturing

industries, when contamination prevention is critical. Available

in a variety of comfortable earplug styles to meet most wearer

preferences and environmental needs.

TM

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

311-4106

340-4007

350-3101

Ū

Ū

Ū

SLC80 values included in the description box below.

E-A-Rsoft Yellow Neons Metal Detectable Earplug with Metal Detectable Cord

23dB (Class 4)

SLC

80

UltraFit Metal Detectable Earplug with Metal Detectable Cord SLC

(Class 3)

E-A-Rflex Metal Detectable Banded Earplug with Metal Detectable Arms

15dB (Class 2)

SLC

80

18dB

80

200 pairs/box, 10 boxes/case

100 pairs/box, 4 boxes/case

1 band/bag, 10 bags/case

3M™ Nitro™ Earplugs

With today’s louder lifestyles, younger workers are an even bigger

challenge when encouraging hearing protection compliance. Nitro

earplugs offer a variety of eye-popping colors in each dispenser box,

which promotes hearing protection compliance sighting. Advanced

foam formulation conforms to the unique shape of each earcanal for

enhanced comfort and fit.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

P1001 Nitro Earplug Corded, SLC

P1000 Nitro Earplug Uncorded 200 pairs/box, 10 boxes/case

Ū

Ū

SLC80 26dB (Class 5)

27dB (Class 5) 100 pairs/box, 10 boxes/case

80

18

Page 22

3M™ E-A-R™ Disposable

Foam Earplugs

3M™ 1120 Foam Earplugs

The unique articulated design reduces pressure inside the ear canal for

improved all day comfort. Soft hypo-allergenic foam provides greater comfort

and is less sensitive to temperature.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

1120 Foam Earplug Uncorded 200 pairs/box, 5 boxes/case

1130 Foam Earplug Corded 100 pairs/box, 5 boxes/case

1120-BT Foam Earplug One Touch Refill 500 pairs/bottle, 1 bottle/case

Ū

Ū

Ū

22dB (Class 4)

SLC

80

3M™ 1100 Foam Earplugs

Get the protection you need from the brand you can trust — at an affordable

price — with 3M 1100 and 1110 earplugs. Soft, hypoallergenic foam and a

tapered design provide a noise-reducing seal in the earcanal. 3M 1100 and

1110 earplugs are easy to roll down, and once fitted in the ear, soften with

body temperature for comfortable extended wear.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

1100 Foam Earplug Uncorded 200 pairs/box, 5 boxes/case

1110

1100-BT Foam Earplug One Touch Refill 500 pairs/bottle, 1 bottle/case

19

Ū

Ū

Ū

SLC80 21dB (Class 3)

Foam Earplug Corded 100 pairs/box, 5 boxes/case

Page 23

3M™ One Touch™

Dispenser

The One Touch dispenser offers convenient access to

workers on the move. The “No Waste Funnel” delivers

earplugs with each turn. The reusable, free-standing base

can be re-stocked with One Touch refills of our most popular

3M™ E-A-R™ Earplugs. The versatile design includes tabletop

or wall-mount options for convenient dispensing.

Refill Bottles

TM

™

Classic

Product Number Abbreviated General Description Packaging

391-1000 One Touch Dispensing Unit with Stand 1 dispenser/case

391-1001 Classic One Touch Refill 500 pairs/bottle, 4 bottles/case

391-1009 Classic SuperFit 30 One Touch Refill 500 pairs/bottle, 4 bottles/case

391-1004 E-A-Rsoft Yellow Neons One Touch Refill 500 pairs/bottle, 4 bottles/case

391-1008 E-A-Rsoft Yellow Neons Large One Touch Refill 500 pairs/bottle, 4 bottles/case

391-1010 E-A-Rsoft Yellow Neon Blasts Reg. One Touch Refill 500 pairs/bottle, 4 bottles/case

391-1254 E-A-Rsoft SuperFit Reg One Touch Refill 500 pairs/bottle, 4 bottles/case

391-1007 Classic Platinum One Touch Refill 500 pairs/bottle, 4 bottles/case

1100-BT 3M 1100 Foam Earplug One Touch Refill 500 pairs/bottle, 1 bottle/case

1120-BT 3M 1120 Foam Earplug One Touch Refill 500 pairs/bottle, 1 bottle/case

PN-01-011 3M Solar Foam Earplug One Touch Refill 500 pairs/bottle, 4 bottles/case

Yellow Neons

™

Yellow Neon Blasts

™

E-A-Rsoft

™

SuperFit

™

1100 Solar

E-A-R™ Vending

Packs

Earplugs conveniently packaged for vending purposes.

™

TM

™

Classic

Product Number Abbreviated General Description Packaging

VP311-1101 Classic Corded, Vending Pack, SLC

VP312-1201 Classic Uncorded Earplug, Vending Pack, SLC

VP318-1001 Push-Ins Corded, Vending Pack, SLC

VP340-4004 UltraFit Corded, Vending Pack, SLC

21dB (Class 3) 5 pairs/bag, 100 bags/case

80

23dB (Class 4) 5 pairs/bag, 100 bags/case

80

23dB (Class 4) 5 pairs/bag, 100 bags/case

80

18dB (Class 3) 5 pairs/bag, 100 bags/case

80

Push-Ins

™

UltraFit

™

20

Page 24

3M™ E-A-R™ Disposable

Dispensers

E-A-R™ Trade Packs

The Trade Packs are a convenient pocket sized pack designed to reduce

wastage and cost. They are ideal for small businesses such as contractors

and trades people looking to purchase quality PPE in a packout configuration

that suits their consumption.

Product Number Abbreviated General Description Packaging

TP391-1001 Classic Uncorded Trade Pack SLC

TP312-1261 FX Uncorded Trade Pack SLC

TP318-1009 Push Ins w/Grip Rings Corded Trade Pack SLC

TP340-4004 Ultrafit Corded Trade Pack SLC

23dB (Class 4) 10 pairs/pack, 12 packs/case

80

26dB (Class 5) 10 pairs/pack, 12 packs/case

80

26dB (Class 5) 5 pairs/pack, 12 packs/case

80

18dB (Class 3) 5 pairs/pack, 12 packs/case

80

TM

21

Page 25

Detection Protection Validation

Push-to-Fit

Earplugs

Simply hold 3M™ Push-to-Fit Earplugs by the stem then push them into place. There is

no roll-down required for a clean and comfortable fit. The soft foam tip quickly adjusts

to the shape of the earcanal to help create a noise-reducing seal. Since you don’t

touch the foam tip, they are easy to fit and keep clean, even when your hands are dirty

or you are wearing gloves.

22

Page 26

3M™ E-A-R™

Push-to-Fit Earplugs

E-A-R™ Express™ Pod Earplugs

The unique pod design of Express earplugs allows the foam to compress

easily so the earplug slides gently into the ear and expands slowly, making

an effective seal for most earcanals. A flexible stem makes fitting easy.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

321-2115 Express Assorted Earplug Corded, Pillow Pack 100 pairs/box, 4 boxes/case

321-3200

Ū

Ū

Ū

Express Assorted Earplug Uncorded, Pillow Pack 100 pairs/box, 4 boxes/case

SLC80 19dB (Class 3)

TM

E-A-R™ Push-Ins™ Earplugs

No roll-down is required with these earplugs. A gentle push is all it takes for

easy, consistent fitting. Blue stem makes fitting and removal easy and helps

keep the tips clean when the wearer’s hands are dirty. The unique, soft 3M

E-A-Rform™ Foam Tip is shaped and sized to mold comfortably to fit

most ear canals.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

318-1003 Push-Ins Earplug Corded 200 pairs/box, 10 boxes/case

318-1002

VP318-1001 Push-Ins Earplug Corded, Vending Pack 5 pairs/bag, 100 bags/case

Ū

Ū

Ū

Push-Ins Earplug Uncorded 200 pairs/box, 10 boxes/case

23dB (Class 4)

SLC

80

™

TM

23

Page 27

E-A-R™ Push-Ins™ with

Grip Rings

Push-Ins earplugs with proprietary Grip Rings gently seal the ear canal to

enhance fit. The flexible stem makes insertion and removal easy and helps

keep the tips clean when the wearer’s hands are dirty. Foam tips made of soft

polyurethane foam.

TM

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

318-1009 Push-Ins with Grip Rings Earplug Corded 200 pairs/box, 10 boxes/case

318-1008

3M™ Pistonz

These earplug tips look like metal, but feel ultra-soft. They are made of

a specially formulated foam that is so soft and comfortable the earplugs

can be worn all day long. The cylindrical shape is designed to fit and

seal most size ear canals. The stem is stiff enough to insert yet is

designed to flex sideways if impacted during wear. No need to

roll foam tips before fitting. Just grip the stem and insert

tip into the ear canal — right out of the package.

Ū

Ū

Ū

Push-Ins with Grip Rings Earplug Uncorded 200 pairs/box, 10 boxes/case

™

SLC80 26dB (Class 5)

Earplugs

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

P1401 Pistonz Earplug Corded 100 pairs/box, 4 boxes/case

P1400 Pistonz Earplug Uncorded 100 pairs/box, 4 boxes/case

Ū

Ū

Ū

SLC80 25dB (Class 4)

24

Page 28

3M

™

E-A-R

™

Push-to-Fit Earplugs

3M™ Skull Screws™ Earplugs

Skull Screws earplugs perform as tough as they look by providing excellent

protection for noisy environments. The metallic colour makes the earplugs look solid,

but they are made from ultra-soft foam that provides day long comfort. Grab the

attention of your young workers with these radically designed, push-to-fit earplugs

and help boost hearing protection and compliance at the same time.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

P1300 Skull Screws Earplug Uncorded 120 pairs/box, 4 boxes/case

P1301 Skull Screws Earplug Corded 120 pairs/box, 4 boxes/case

Ū

Ū

Ū

26dB (Class 5)

SLC

80

3M™ No-Touch™ Earplugs

Soft, purple No-Touch push-to-fit foam earplugs create a hygienic, noise-reducing seal in the

ear canal with soft foam, a smooth tapered shape and paddle stems. Push-to-fit design makes

fitting hearing protection easy, with no roll-down required. Available with or without cord.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

P2001 No-Touch Earplug Corded 100 pairs/box, 4 boxes/case

P2000

25

Ū

Ū

Ū

No-Touch Earplug Uncorded 100 pairs/box, 4 boxes/case

SLC

25dB (Class 4)

80

Page 29

Support Materials

The perfect tools to enhance your hearing conservation

training.

www.e-a-r.com/hearingconservation/booklet_main.cfm

Product Number Abbreviated General Description Packaging

319-1002 Clear Ear 1 unit/case

319-1003 Roll Model 1 unit/case

85099-00000 Ear Gauge ear canal Sizing Tool 50 units/case

26

Page 30

Detection Protection Validation

Reusable

Earplugs

These durable, long-lasting earplugs are made from soft, flexible materials that

are washable and reusable. The tapered tips are pre-molded to fit a wide range of

earcanal sizes comfortably. Available in a variety of styles and protection levels.

27

Page 31

™

3M™ E-A-R

Reusable Earplugs

E-A-R™ UltraFit™ Earplugs

A proven triple-flange design and pliable, premolded material make UltraFit

earplugs a more comfortable fit for most ear canals. These durable, reusable

earplugs are easy to use again and again, reducing waste. They can be cleaned

easily with soap and water. Since there is no need to roll them down before

fitting, simply push them into the ear canal for clean and comfortable noise

reduction.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable (340-4007 only)

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

340-4002 UltraFit Earplug Corded, with Case 50 pairs/box, 4 boxes/case

340-4004 UltraFit Earplug Corded 100 pairs/box, 4 boxes/case

VP340-4004 UltraFit Earplug Corded, 5-Pair Vending Pack 5 pairs/bag, 100 bags/case

340-4001 UltraFit Earplug Uncorded, with Case 50 pairs/box, 4 boxes/case

340-4007 UltraFit Metal Detectable Earplug Corded 100 pairs/box, 4 boxes/case

Ū

Ū

Ū

Ū

Ū

18dB (Class 3)

SLC

80

TM

E-A-R™ UltraFit™ 27

Earplugs

Soft, flexible triple-flange tips provide enhanced fitting and noise

reduction. Pistol-grip stems provide fingertip control for easy fitting.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

340-8002 UltraFit 27 Earplug Corded 100 pairs/box, 4 boxes/case

340-8001 UltraFit 27 Earplug Uncorded 100 pairs/box, 4 boxes/case

Ū

Ū

Ū

Ū

SLC80 22dB (Class 4)

TM

28

Page 32

3M

™

E-A-R

™

Reusable Earplugs

E-A-R™ UltraFit™ Plus™ Earplugs

UltraFit Plus earplugs offer quick, hygienic and easy fitting with paddle-style stems. A variety

of stem colors are available. An optional storage case keeps earplugs clean when not in use.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

340-6002* UltraFit Plus Earplug Corded, with Case 50 pairs/box, 4 boxes/case

* Only available in NZ

Ū

Ū

Ū

Ū

SLC80 19dB (Class 3)

TM

3M™ Tri-Flange™ Earplugs

Soft, flexible flanges adapt to the shape of the ear canal to comfortably reduce

exposure to noise. The plastic stem allows the wearer to fit the earplugs quickly

and easily without touching the premolded tips. Choose from a vinyl or cloth

cord.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

P3000 Tri-Flange Earplug Corded 100 pairs/box, 4 boxes/case

P3001

Ū

Ū

Ū

Ū

Tri-Flange Earplug with Cloth Cord 100 pairs/box, 4 boxes/case

SLC80 19dB (Class 3)

NRR 26 dB*

29

Page 33

3M™ 1200 Earplugs

This ear plug is lightweight, comfortable and easy-to-use

for workers in a wide variety of industrial and commercial

applications.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

1270 1270 Corded 100 pairs/box, 5 boxes/case

1271 1271 Cased Corded 50 pairs/box, 5 boxes/case

1290* 1290 Cloth Corded 100 pairs/box, 5 boxes/case

1291* 1291 Cased Cloth Corded 50 pairs/box, 5 boxes/case

*Only available in NZ

Ū

Ū

Ū

Ū

18dB (Class 3)

SLC

80

SLC80 21dB (Class 3)

ClearE-A-R™ 20 Earplugs

The ClearE-A-R 20 has been designed to offer optimum attenuation and is

ideally suited in medium noise risk areas without affecting vital communication

with your colleagues or customers. The high precision filter controls the flow of

sound to maintain a connection with the outside world.

TM

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

UF-01-021 ClearE-A-R 20 Earplug Uncorded 1 pair/box, 12 boxes/case

*Only available via firm order

Ū

Ū

Ū

SLC80 18dB (Class 3)

NRR 26 dB*

30

Page 34

3M

™

E-A-R

™

Reusable Earplugs

E-A-R™ Combat Arms™ 4.1

3M Combat Arms™ Earplugs – Generation 4.1 meet the demanding hearing protection needs of those

serving in the armed forces defense markets. The 3M™ Combat Arms™ Earplugs – Generation 4.1

contain a housing assembly featuring a rocker switch. When the tab featuring the 3M logo is pressed,

the device is in the Closed Mode and acts as a conventional earplug. The Closed Mode provides

protection against all types of noise, and should be the only mode used for steady noise such as

aircraft, vehicle, generator and watercraft.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

370-1040 Combat Arms™ Earplug 4.1–Small 500 PR/CS

370-1041 Combat Arms™ Earplug 4.1–Medium 500 PR/CS

370-1042 Combat Arms™ Earplug 4.1–Large 500 PR/CS

*Only available via firm order

Ū

Ū

Ū

Open/Weapons Fire Mode SLC80 9dB (Class 1)

Closed/Constant Protection Mode SLC80 12dB (Class)

NRR 26 dB*

TM

E-A-R™ Combat Arms™

Earplugs Single Ended

If the rocker cover is in Open/Weapons Fire mode, sound travels

into the earplug and down the sound channel to the special

filter. The filter allows lower-level sounds to pass with limited

interruption but high-level impulsive noises are restricted. The

more intense the impulse, the more it is limited.

Available with Cord

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

370-1030 CAE Earplug Small 1 pair/box, 50 boxes/case

370-1031 CAE Earplug Regular 1 pair/box, 50 boxes/case

370-1032 CAE Earplug Large 1 pair/box, 50 boxes/case

*Only available via firm order

Ū

Ū

Ū

Ū

Open/Weapons Fire Mode SLC

Closed/Constant Protection Mode SLC

80

13dB (Class 1)

80

22dB (Class 4)

TM

31

Page 35

Detection Protection Validation

Banded

Hearing Protectors

Banded hearing protectors are an easy-to-use, convenient alternative to insert earplugs

and earmuffs. They are quick to put on and take off and may be stored around the neck

in between uses, making them ideal for intermittent use. Banded hearing protectors offer

simplicity to help ensure your workers are receiving the right level of protection. Most

models are available with replacement tips, which make them a very cost-effective option.

32

Page 36

™

3M™ E-A-R

Banded Hearing Protectors

E-A-Rflex™

Hearing Protectors

A comfortable, effective, lightweight alternative to earmuffs.

Ideal for people who fit and remove their hearing protection

frequently. Soft tips pivot to help maintain a comfortable,

noise-blocking seal. Multi-position wearing with conical tips.

Moisture Resistant

Reusable

Metal Detectable (350-3101 only)

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

350-3001 E-A-Rflex Hearing Protector 1 band/bag, 10 bags/case

350-3002 E-A-Rflex Replacement Tips 50 pairs/box, 10 boxes/case

350-3101 E-A-Rflex Metal Detectable Hearing Protector 1 band/bag, 10 bags/case

Ū

Ū

Ū

Ū

15dB (Class 2)

SLC

80

TM

Replacement Tips Available

™

E-A-R™ Caboflex

Hearing Protectors

This lightweight, banded hearing protector is ideal when moving in

and out of noisy areas, fitting comfortably around the neck when

not in use. Each cone-shaped tip pivots to align with the ear canal,

providing comfortable protection against noise.

Band may be worn under the chin or behind the head.

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

320-2001 Caboflex Model 600 Hearing Protector 1 band/bag, 10 bags/case

Ū

Ū

Ū

Ū

SLC

11dB (Class 1)

80

TM

33

Page 37

E-A-Rcaps™

Hearing Protectors

One of the lightest banded hearing protectors on the market,

E-A-Rcaps banded hearing protectors feature comfortable

foam caps on a flexible band to block the ear canal opening.

Ideal for visitors to a noisy facility or people who need hearing

protection for short periods of time.

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

321-2101 E-A-Rcaps Model 200 Hearing Protector 1 band/bag, 10 bags/case

Ū

Ū

Ū

SLC80 11dB (Class 1)

TM

E-A-R™ Swerve™ Banded

Hearing Protector

Comfort meets performance as the unique Swerve banded earplugs incorporate a cutting-edge

band design with the effectiveness of E-A-R foam earplugs. The ergonomic design minimises

interference, and the neckband shape helps eliminate contact with collars and headgear,

which reduces band sound transmission. The band slides forward and backward for

custom neck and ear positioning. It is also supplied with a removable cotton lanyard.

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

322-2000 Swerve Banded Hearing Protector 1 band/bag, 10 bags/case

322-2001

320-1001 E-A-RFlex 28 Replacement Tips 5 pairs/bag, 10 bags/case

Ū

Ū

Comfort Pods: SLC

Ū

Flex 28 Tips: SLC80 20dB (Class 3)

Replacement Comfort Pod Tips 5 pairs/bag, 10 bags/case

23dB (Class 4)

80

TM

Replacement Tips Available

34

Page 38

™

3M™ E-A-R

Banded Hearing Protectors

3M™ 1310 Hearing Protector

3M Banded Earplugs are easy to use, convenient and extremely comfortable. They are

quick to put on and off and to store around the neck when not required, making them

ideal for intermittent use. Banded earplugs offer simplicity to help your workers receive

protection from hazardous noise. The flexible band for allows for easy manipulation

and constant low pressure in the ear. The soft round foam ear plugs also reduce

pressure and provide a comfortable seal.

Moisture Resistant

Reusable

Metal Detectable

Slow-Recovery Foam

No Roll-Down Required

Product Number Abbreviated General Description Packaging

1310 1310 Banded Hearing protector 10 bands/box, 5 boxes/case

1311

Ū

Ū

SLC

Ū

Ū

1311 Replacement Tips 20 pairs/box, 5 boxes/case

18 dB (Class 3) - when worn under chin

80

13dB (Class 1)- when worn behind the neck.

SLC

80

*Note: Wearing banded hearing protectors in ways other than as per the fitting instructions can lead to different attenuation results.

35

Page 39

Detection Protection Validation

Passive

Earmuffs

Earmuffs are a popular choice in hearing protection due to their ease of

use and consistent fit. Available in headband, neckband, hard hat attached,

and folding models, earmuffs help meet hearing protection needs in many

common applications.

36

Page 40

™

3M™ Peltor

Passive Earmuffs

Peltor™ Extreme Performance

Earmuffs - H10 Series

The H10 Series is a high performance hearing protector and has been developed for use in extremely noisy

environments. The protection is based on a technology with a double casing minimising resonance in the casing

giving optimum high-frequency attenuation. An acoustic connection between the inner and outer casings provides

maximum low-frequency attenuation. The sealing rings are broad and filled with soft plastic foam for the best fit and

low contact pressure.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

H10A Over-the-Head Dual Cup Earmuff SLC

H10A HV Hi-Viz Over-the-Head Green Dual Cup Earmuff SLC

H10B Behind-the-Head Dual Cup Earmuff SLC

H10P3E Hard Hat Attached Dual Cup Earmuff SLC

H10P3G Hard Hat Attached Dual Cup Earmuff SLC

H10P3M* Hard Hat Attached Dual Cup Earmuff SLC

H10P3E-01* Hard Hat Attached Dual Cup Electrically Insulated (Dielectric) Earmuff SLC

HY54 Hygiene Kit 1 Pr Cushions/1 Pr Foam Inserts for H10 Series 1 kit/bag, 20 bags/case

*Only available in NZ *Firm order only

Ū

Ū

Ū

Ū

Ū

Ū

33dB (Class 5)

33dB (Class 5) 1 pair/box, 10 boxes/case

80

33dB (Class 5) 1 pair/box, 10 boxes/case

80

34dB (Class 5) 1 pair/box, 10 boxes/case

80

33dB (Class 5) 1 pair/box, 10 boxes/case

80

33dB (Class 5) 1 pair/box, 10 boxes/case

80

33dB (Class 5) 1 pair/box, 10 boxes/case

80

1 pair/box, 10 boxes/case

80

Peltor™ Select Performance

Earmuffs - H9 Series

The H9 Series offers versatile protection and is very lightweight providing high wearer comfort. It combines a

low profile with generous inner depth which makes it easy to combine with other equipment, allowing

the ear to rest comfortably. It is ideal for use in environments with moderate industrial noise, such as

workshops, sheetmetal shops and printing works, but also suitable for outdoors, such as lawn mowing or in

connection with hobbies and leisure activities.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Ū

Ū

Ū

Ū

Product Number Abbreviated General Description Packaging

H9A Over-the-Head Yellow Earmuff SLC

H9B Behind-the-head Yellow Earmuff SLC

H9P3E Hard Hat Attached Yellow Earmuff SLC

H9P3G Hard Hat Attached Yellow Earmuff SLC

H9P3M* Hard Hat Attached Yellow Earmuff SLC

37

*Only available in NZ

HY5

Replacement Hygiene Kit 1 Pr Cushions/1 Pr Foam Inserts for H6 and H9

Series

24dB (Class 4) 1 pair/box, 10 boxes/case

80

24dB (Class 4) 1 pair/box, 10 boxes/case

80

24dB (Class 4) 1 pair/box, 10 boxes/case

80

24dB (Class 4) 1 pair/box, 10 boxes/case

80

24dB (Class 4) 1 pair/box, 10 boxes/case

80

1 kit/bag, 20 bags/case

Page 41

Peltor™ Deluxe Earmuffs - H7 Series

The H7 Series has been developed for demanding noisy environments with increased low frequency

attenuation. The sealing rings are filled with a unique combination of liquid and foam. The result is an

optimum seal with low contact pressure, which provides agreeable comfort even during long-term

use. The H7 Series is a suitable choice for typical environments with substantial industrial noise or

construction machinery, airports and agricultural work.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

H7A Over-the-Head Green Earmuff SLC

H7B Behind-the-Head Green Earmuff SLC

H7P3E Hard Hat Attached Green Earmuff SLC

H7P3G Hard Hat Attached Green Earmuff SLC80 30dB (Class 5)

H7P3M* Hard Hat Attached Green Earmuff SLC80 30dB (Class 5)

H7F Folding Green Earmuff SLC80 31dB (Class 5)

H7F HV HV Hi Vis Folding Green Earmuff SLC80 31dB (Class 5)

HY3 Replacement Hygiene Kit for H7 Type Hearing Protectors 1 kit/bag, 20 bags/case

*Only available in NZ

Ū

Ū

Ū

Ū

Ū

Ū

30dB (Class 5) 1 pair/box, 10 boxes/case

80

28dB (Class 5) 1 pair/box, 10 boxes/case

80

30dB (Class 5) 1 pair/box, 10 boxes/case

80

1 pair/box, 10 boxes/case

1 pair/box, 10 boxes/case

1 pair/box, 10 boxes/case

1 pair/box, 10 boxes/case

Peltor™ Low Profile Earmuffs -

H6 Series

The H6 Series is specially engineered for high comfort and continuous wear. They provide effective noise

protection for daily exposures up to 104dB. The foam sealing rings provide a quality noise seal with low

pressure for all day wearer comfort.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

H6A Low Profile Over-the-Head Beige Earmuff SLC

H6B Low Profile Behind-the-Head Beige Earmuff SLC

H6F Low Profile Folding Beige Earmuff SLC

H6P3G Low Profile Hard Hat Attached Beige Earmuff SLC

HY5

Ū

Ū

Ū

Ū

Ū

22dB (Class 4) 1 pair/box, 10 boxes/case

80

22dB (Class 4) 1 pair/box, 10 boxes/case

80

23dB (Class 4) 1 pair/box, 10 boxes/case

80

22dB (Class 4) 1 pair/box, 10 boxes/case

80

Replacement Hygiene Kit 1 Pr Cushions/1 Pr Foam Inserts for H6, H9 and

H31 Type Hearing Protectors

1 kit/bag, 20 bags/case

38

Page 42

™

3M™ Peltor

Passive Earmuffs

Peltor™ H31 Earmuff

This earmuff is ultra light and features orange cups for added visibility. This

versatile, over-the-head earmuff has a stainless steel headband that resists

bending and warping. The earcups provide optimum comfort with pivot points

that tilt and liquid/foam-filled earmuff cushions.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

H31P3E Deluxe Hard Hat Attached Orange Earmuff SLC

H31P3AF

H31P3BB H31P3BB Airstream Series Hard Hat Attached Orange Earmuff SLC

HY3 Replacement Hygiene Kit for H31 Type Hearing Protectors 1 kit/bag, 20 bags/case

Ū

Ū

Ū

Ū

28dB (Class 5) 1 pair/box, 10 boxes/case

80

M-Series Hard Hat Attached Orange Earmuff M-100: SLC

3)/M-300: SLC80 25dB (Class 4) 6 EA

(Class 4)

20dB (Class

80

23dB

80

1 pair/box, 6 boxes/case

1 pair/box, 1 box/case

Peltor™ PTL™ Earmuff

Push-to-Listen earmuffs allow workers to listen safely without removing their

earmuffs. Listeners simply press the button to boost the volume of conversation and

other sounds for 30 seconds. Ideal for workers in environments where intermittent

ambient listening is required.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

H7A-PTL* PTL Over-the-Head Earmuff SLC

H7P3E-PTL* PTL Hard Hat Attached Earmuff SLC

HY3 Replacement Hygiene Kit for H7 Type Hearing Protectors 1 kit/bag, 20 bags/case

*Firm order only

39

Ū

Ū

Ū

27dB (Class 5) 1 pair/box, 10 boxes/case

80

27dB (Class 5) 1 pair/box, 10 boxes/case

80

Page 43

Peltor™ Food Industry

Earmuff H9A-02

Engineered to meet the stringent hygiene demands of the food industry, these comfortable

lightweight earmuffs feature a smooth, non-porous headband designed to help prevent food

particle accumulation. The lightweight ear cups have washable, replaceable inserts designed

to help reduce moisture absorption.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

H9A-02 H9A-02 Food Industry Earmuff SLC

HY55 H9A-02 Earmuff Hygiene Replacement Kit (cushions and inserts) 1 kit/bag, 10 bags/case

Ū

Ū

26dB (Class 5) 1 pair/box, 10 boxes/case

80

Peltor™ Welding Earmuff

H505B

The 3M™ Peltor™ Welding Helmet Earmuff H505B features a low-profile design

that fits comfortably under most welding helmets, as well as a semi-soft cup

surface that minimises scratch sound transmission. With a two-point suspension

for balanced pressure distribution, this advanced earmuff delivers the comfortable

protection that professionals need in a wide range of welding environments.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

H505B Welding Earmuff SLC

HY505 Hygiene Kit 1 kit/bag, 10 bags/case

Ū

Ū

Ū

22dB (Class 4) 1 pair/box, 10 boxes/case

80

40

Page 44

™

3M™ Peltor

Passive Earmuffs

Peltor™ Bull's Eye Earmuff

This passive range of foldable earmuffs are available in three different colours,

military green, black and red. These hearing protectors are designed to

provide a moderate to high level of protection that meet the needs of sport

shooters and hunters. The bevelled cup increased compatibility with hunting/

shooting weapons.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

H515FB-516-RD* Bull's Eye Red Earmuff 1 pair/box, 20 boxes/case

H515FB-516-GN* Bull's Eye Green Earmuff 1 pair/box, 20 boxes/case

H515FB-516-SV* Bull's Eye Black Earmuff 1 pair/box, 20 boxes/case

*Firm order only

Ū

Ū

26dB (Class 5)

SLC

80

Peltor™ Premium Earmuff X4 Series

The X-Series earmuffs are 3M’s latest advancement in hearing conservation. New technologies in

comfort, design and protection all come together in this groundbreaking earmuff line. The X4A utilises

a newly designed spacer, specially formulated foam liners and innovative ear cushions to help improve

attenuation. This lightweight, lower-profile earmuff helps with compatibility with other personal

protective equipment and is designed for protection against moderate-to-high level industrial noise and

other loud sounds. It features an electrically insulated wire headband, often referred to as “dielectric”.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

X4A X4A Over The Head Green Premium Earmuff SLC

X4P3E X4P3E Hard Hat Attached Green Premium Earmuff SLC

HYX4 X4 Hygiene Kit 1 kit/bag, 20 bags/case

41

Ū

Ū

Ū

Ū

31dB (Class 5) 1 pair/box, 10 boxes/case

80

27dB (Class 5) 1 pair/box, 10 boxes/case

80

Page 45

Peltor™ Premium Earmuff

X5 Series

The X5A earmuffs offer 3M's highest SLC (35 dB) which makes them ideal for very high

noise situations. The high attenuation delivered by X5A earmuffs is possible as a result

of a combination of advanced technologies including: newly designed spacers, specially

formulated earcup liners and innovative foam contained in the cushions. It also features an

electrically insulated wire headband, often referred to as “dielectric”.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

X5A X5A Over The Head Black Premium Earmuff SLC

X5P3E X5P3E Hard Hat Attached Black Premium Earmuff SLC

HYX5 X5 Hygiene Kit 1 kit/bag, 20 bags/case

Ū

Ū

Ū

Ū

35dB (Class 5) 1 pair/box, 10 boxes/case

80

31dB (Class 5) 1 pair/box, 10 boxes/case

80

Peltor™ Hygiene Tear Away Pads

The disposable hygiene pads are an easy way to improve hygiene and comfort. Effective and practical

use in dirty and hot environments to keep cushions hygienically clean. Also useful when several

persons are using the same hearing protector i.e. visitors' earmuffs.

Product Number Abbreviated General Description Packaging

HY100A Hygiene Tear Away Pads 100 pairs/box, 10 boxes/case

42

Page 46

™

3M™ Peltor

Passive Earmuffs

Peltor™ Kids Earmuff H510AK

Peltor Kid hearing protectors can attenuate harmful noise levels without completely

shutting out other ambient sounds. These muffs are recommended for use by children up

to age seven. Peltor Kid comes in two characteristic colours – neon pink and neon green –

for high visibility and fun.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

H510AK-442-GB Kids Neon Green Earmuff 1 pair/box, 6 boxes/case

H510AK-442-RE Kids Neon Fink Earmuff 1 pair/box, 6 boxes/case

Ū

SNR 27 dB

3M™ Earmuff 1426

An entry level earmuff with high level attenuation. Super economical, the over the head

design for use with other PPE.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

1426 1426 Economy Earmuff 1 pair/bag, 20 bags/case

43

Ū

SLC80 26dB (Class 5)

Page 47

3M™ Earmuff 1436

Designed for moderate to high noise exposure. The versatile 1436 foldable earmuff offers

an economical, lightweight yet durable earmuff. The 1436 provides a high degree of

comfort to the wearer at an affordable price.

Electrically Insulated (Dielectric)

Neckband

Folding Headband

Hard Hat Attached

Hi-Viz

Liquid/Foam-Filled Cushions

Hygiene Kit

Product Number Abbreviated General Description Packaging

1436 1436 Foldable Economy Earmuff 1 pair/bag, 20 bags/case

*Peltor Helmet Attachments Guide

Helmet Manufacturer Helmet Model Peltor Product Codes Retrofit Codes

MSA Super V-Gard II P3E (Z3E)

MSA V-Gard P3E (Z3E)

Protector Elite 300 P3E (Z3E)

Protector Tuffmaster II P3E or P3G (Z3E or Z3G)

Protector HC600V P3G (Z3G)

Protector Tuffmaster Lite P3G (Z3G)

Unisafe Unilite P3G (Z3G)

NZ Safety 410 P3M (Z3M)

NZ Safety 620V P3M (Z3M)

3M G2000 P3K (Z3K)

3M Peltor hard hat attachments were tested in combination with the following industrial helmets and may give different levels of protection if fitted to

different helmets: 3M G22 MSA V-Guard.

Ū

SLC80 27dB (Class 5)

Z3E

Z3M

Z3G

Z3K

44

Page 48

Detection Protection Validation

Fit Testing

Made Easy

The 3M™ E-A-Rfit™ Validation System measures the level of employee hearing

protection by generating a personal attenuation rating (PAR) in just 10 seconds per

ear. This simple, in-the-field test system can enhance your hearing conservation

program by assisting with the selection of appropriate protectors for workers and

their environments. It also serves as a tool for training proper insertion techniques.

Make E-A-Rfit testing a key part of your comprehensive hearing protection program.

45

Page 49

™

3M

Validation Products

3M™ E-A-Rfit™ Validation System

E-A-Rfit is a comprehensive fit validation system to test the actual protection workers receive from their hearing protectors.

For more information on this service, please contact your 3M Personal Safety Sales Representative. NOTE: If your customers

wish to have someone at their company trained to become a certified E-A-Rfit Technician so they can service their own

employees, please contact a 3M Personal Safety Sales Representative for more information.

These earplug styles cover fit validation testing for over 80 different 3M earplug products.

E-A-Rsoft™ Yellow Neons

Classic™ Platinum Express

Product Number Abbreviated General Description Packaging

393-1100 E-A-Rfit Kit – Validation System includes the Software, Speaker and Impact

393-2000-50 E-A-Rsoft Yellow Neons Probed Test Plugs 10 pairs/bag, 5 bags/case

393-2001-50

393-2002-50

393-2003-50

393-2004-50

393-2006-50

393-2007-50

393-2008-50

393-2010-50

393-2011-50

393-2012-50

393-2013-50

393-2014-50

393-2015-50

393-3005-2 Peltor X4/X5 Test Probe Kits 1 pair/case

™

™

UltraFit

™

Resistant Carrying Case

UltraFit Probed Test Plugs

Push-Ins Probed Test Plugs

Classic Probed Test Plugs

E-A-Rsoft FX Probed Test Plugs

TaperFit Probed Test Plugs

Classic Platinum Probed Test Plugs

Express Probed Test Plugs

1100 Probed Test Plugs

Tri-Flange Probed Test Plugs

Skull Screws Probed Test Plugs

No Touch Probed Test Plugs

E-A-Rsoft Yellow Neons Large Probed Test Plugs

E-A-R Push Ins with Grip Rings Probed Test Plugs

1100 Tri-Flange

Push-Ins

™

™

Classic

™

E-A-Rsoft™ FX

™

™

E-A-Rsoft™ Yellow Neons™ Lrg Taperfit 2

E-A-R™ Push Ins™ w/Grip RingsSkull Screws

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

10 pairs/bag, 5 bags/case

1 kit/case

Tri-Flange

™

X Series Earmuffs

™

No Touch

™

46

Page 50

Attenuation Data

No Roll Down Earplugs

Push-Ins™ with Grip Rings (Corded & Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 24.4 24.3 25.7 28.6 33.8 37.0 39.8

Standard Deviation dB 5.9 5.0 6.0 6.5 3.4 5.7 8.8

80

: 26dB Class 5

SLC

Push-Ins™ (Corded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 25.4 24.0 24.7 25.9 34.2 36.0 37.0

Standard Deviation dB 9.1 8.2 8.4 7.4 4.8 4.7 5.7

80

: 23dB Class 4

SLC

Express™ (Corded & Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 19.3 19.2 19.6 21.4 30.6 32.3 35.4

Standard Deviation dB 8.3 7.6 8.4 5.0 5.3 4.5 5.0

80

: 19dB Class 3

SLC

3M™ No-Touch™ (Corded & Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 25.9 27.3 29.3 30.6 34.9 43.3 45.0

Standard Deviation dB 7.1 7.7 8.7 9.3 7.4 8.6 9.3

80

: 25dB Class 4

SLC

3M™ Skull Screws™ (Corded & Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 26.7 26.6 28.5 32.5 37.3 40.5 43.4

Standard Deviation dB 8.9 8.8 9.2 7.8 4.6 5.4 8.1

80

: 27dB Class 5

SLC

3M™ Pistonz™ (Corded & Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 24.3 24.8 26.5 26.0 31.5 41.2 44.4

Standard Deviation dB 19.6 20.1 21.8 20.3 26.7 35.3 39.0

80

: 25dB Class 4

SLC

Disposable Earplugs

Taperfit™ 2 Uncorded

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 23.6 24.6 28.2 29.7 34.9 44.2 45.3

Standard Deviation dB 6.9 8.8 8.7 7.3 4.5 5.2 7.7

Taperfit™ 2 Lrg Corded

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 26.2 26.2 28.2 27.9 35.5 46.6 46.9

Standard Deviation dB 5.9 6.1 6.8 6.2 3.4 5.5 3.5

E-A-Rsoft™ FX (Corded & Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 28.5 27.3 28.3 28.5 36.0 45.2 46.7

Standard Deviation dB 6.5 5.3 6.7 6.8 4.8 6.5 6.4

Classic™ Uncorded

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 19.8 20.6 27.8 27.4 31.0 38.7 41.2

Standard Deviation dB 9.2 8.6 7.3 8.7 6.3 6.1 9.2

80

: 26dB Class 5

SLC

80

: 26dB Class 5

SLC

80

: 26dB Class 5

SLC

80

: 23dB Class 4

SLC

Disposable Earplugs (continued)

Classic™ (Corded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 19.0 19.0 25.1 23.9 30.7 37.0 39.3

Standard Deviation dB 6.7 5.1 7.9 7.5 6.9 5.5 9.0

Classic™ Platinum

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 19.8 20.5 27.0 28.5 30.4 38.1 40.9

Standard Deviation dB 6.3 6.6 8.8 7.9 6.6 5.5 5.6

Classic™ Superfit™30 (Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 21.7 22.9 25.2 25.2 31.9 40.6 39.4

Standard Deviation dB 7.8 7.3 7.8 6.5 4.8 5.5 8.9

Classic™ Superfit™30 (Corded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 19.4 21.2 23.6 23.6 30.9 39.4 40.3

Standard Deviation dB 6.9 5.5 5.6 5.7 4.8 4.9 8.5

E-A-Rsoft™ Superfit™ (Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 25.9 25.9 28.1 28.1 33.8 46.3 46.3

Standard Deviation dB 8.2 8.7 9.8 8.1 5.2 5.4 5.7

E-A-Rsoft™ Superfit™ (Corded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 27.3 27.0 28.8 28.0 33.2 46.2 46.6

Standard Deviation dB 8.7 9.5 9.5 8.9 5.8 4.0 4.4

E-A-Rsoft™ Yellow Neons (Corded & Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 21.9 22.2 24.5 25.7 31.3 42.7 42.5

Standard Deviation dB 8.1 7.4 7.7 6.2 4.8 5.5 7.9

E-A-Rsoft™ Yellow Neon Blast (Corded & Uncorded)

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 11.1 13.4 20.4 26.0 31.7 37.8 36.2

Standard Deviation dB 8.1 7.4 7.7 6.2 4.8 5.5 7.9

E-A-Rsoft™ Metal Detectable

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 21.9 22.2 24.5 25.7 31.3 42.7 42.5

Standard Deviation dB 8.1 7.4 7.7 6.2 4.8 5.5 7.9

3M™ Disposable Earplugs 1120/1130

Frequency 125 250 500 1000 2000 4000 8000

Mean Attenuation dB 17.6 19.6 23.6 25.1 32.3 35.7 39.2

Standard Deviation dB 6.0 5.7 5.8 6.3 6.7 7.1 5.9

3M™ Disposable Earplugs 1100/1110