Page 1

Betapure™

Plasma Fractionation

Bacterial Fermentation

NT-P Series

The Next Generation in Pharmaceutical Depth Filter Technology

Enhanced flow. Lower pressure drop. Extended service life and lower total filtration

costs…these are the benefits of Betapure™ NT-P Series filter cartridges & capsules, the

latest advance in depth filtration technology. The all polypropylene filter is constructed

using a process that utilizes flow enhancing filter media and an innovative flow pattern.

The result is an absolute-rated filter with vastly superior life that provides more cost effective filtration than conventional polypropylene depth filters. Betapure NT-P Series filter

cartridges - the new leader in filtration performance.

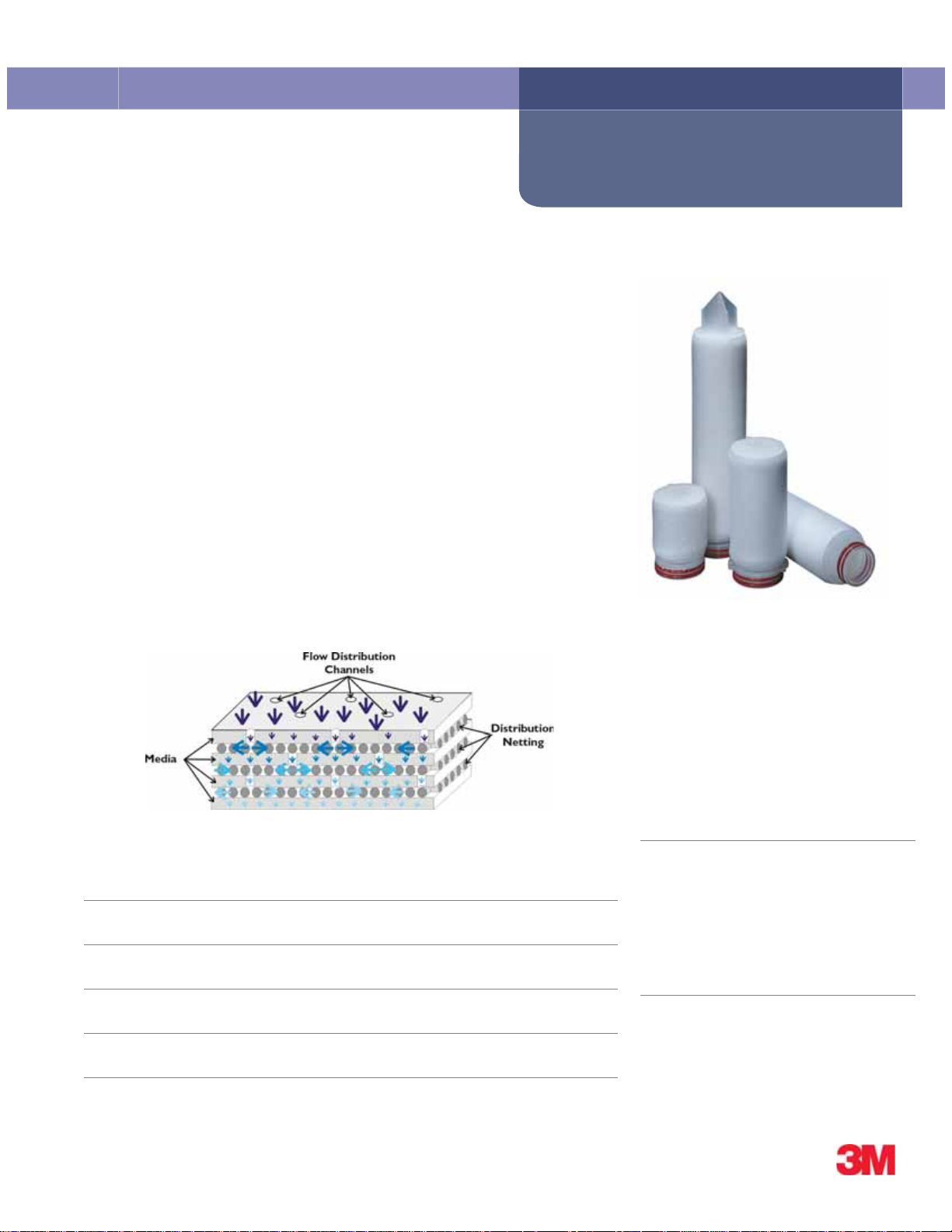

Betapure NT-P Series Filter Construction

Betapure NT-P Series cartridges and capsules are designed to provide significantly

superior service life while maintaining a consistent filtration efficiency. They achieve this

through an innovative design that allows uniform distribution of fluid flow and contaminant throughout the entire depth of the filter. Betapure NT-P Series filter construction

combines a unique polypropylene media with fluid distribution netting to form multiple

layers. Critically positioned media flow channels allow greater movement of fluid from

layer to layer. Three distinct media sections, made from multiple media/netting layers, are

combined to form the filter cartridge (see Figure 1).

Figure 1: Betapure NT-P Series Media Sections. Note that the actual fi lter sections contain multiple layers of media.

Features & Benefi ts

Superior Service Life.

■

As much as 4 times greater contaminant holding capacity than competitive fi lters.

All polypropylene depth fi lter cartridges.

■

Allow for broad chemical and temperature compatibility.

Ratings from 0.5 to 70 micron.

■

Suit a wide range of applications.

Absolute-Rated Performance.

■

Allows for consistent fi ltration quality.

Provided with Certifi cate of Quality documenting pharmaceutical testing & lot release criteria.

Pharmaceutical Grade Filters

Applications

Pharmaceutical Large and Small Volume

Parenterals (LVP/SVP)

Diagnostic Reagents & Buffers

Fine Chemical/Bulk Pharmaceutical

Chemical (BPC)

Orals & Topicals

Antibiotics

Vial & Stopper Washers

Ophthalmic

Solvent streams

Biologicals &

Bioprocessing

Vaccines

Downstream Protein Purifi cation

Animal Sera & Media Feeds

Pre-column clarifi cation (protection)

Mammalian Cell Culture

TFF Protection

Facilities & Deionized Water

Plant Services Water-for- Inj ect ion Sys tems ( WFI)

Air/Gas Pre-fi ltration

Solvent Streams

Plasma Fractionation

Bacterial Fermentation

Page 2

m

B

)

d

3.1

1.33

*

The outer and middle sections contain multiple layers of interleaved filter media and

fluid distribution netting. Within each media layer a portion of the fluid travels through

the media while the balance of the fluid is delivered directly to the next distribution

layer through the flow channels. The fluid distribution netting provides longitudinal and

latitudinal flow paths to evenly distribute fluid flow across the surface of each successive

media layer.

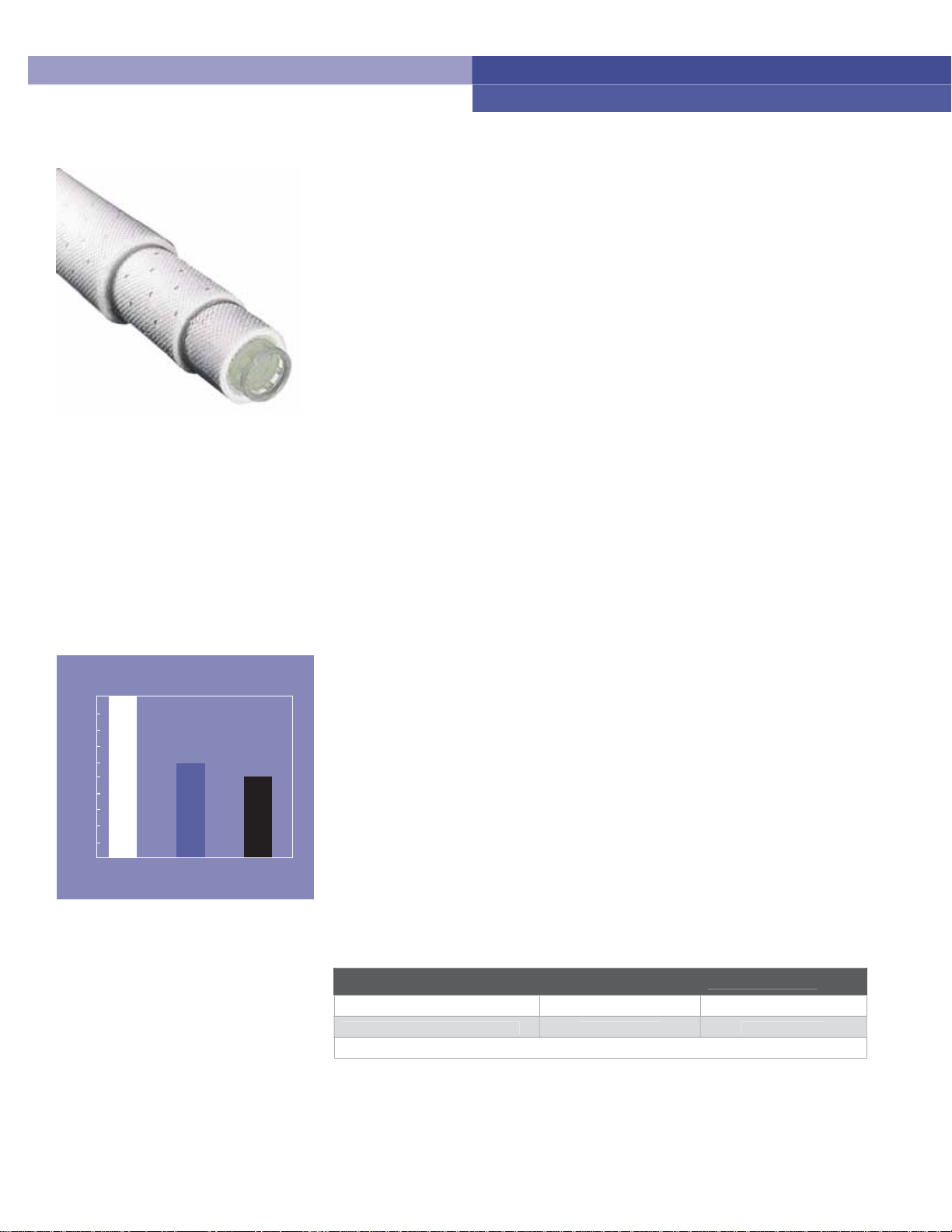

The Difference is Performance

Flow channels appear in the outer and middle sections of the filter matrix, as seen in the

cartridge cut-away. The size, number, and location of the flow channels combined with

the fluid distribution netting ensure that a uniform amount of contaminant is distributed

to each layer within these two sections, while maintaining a consistent flow .

Cut-away of the Betapure NT-P Series fi lter cartridge

showing the three sections of media layers and core

Graph 1: Betapure NT-P Series filters deliver

longer service life

Service Life Comparison of Betapure NT-P Series

to Competitive 5 μm Filter Cartridges

100

90

85

70

60

50

40

30

20

10

Percent of Betapure NT-P Series L ife

0

Betapure

NT-P Series

Competitor A

5 Micron Nominal

Competitor B

5 Micron Absolute

The number of media flow channels decrease from the outer to middle sections to ensure

even contaminant loading throughout the entire filter matrix. Extensive laboratory testing has demonstrated that 3M Purification Inc. has developed the optimal filter cartridge

design.

The inner section, supported by a rigid polypropylene core and equal to approximately

one third of the filter’s depth, contains no flow channels and is the final qualifying section

ensuring absolute rated performance.

The even distribution of contaminated fluid throughout the depth of the cartridge is the

key to the Betapure NT-P Series pharmaceutical grade filter’s exceptionally long service

life, low pressure drops, and increased cost effectiveness.

The Result

Superior Filter Service L if e

Extensive testing has demonstrated that competitive filters of equivalent removal ratings

subjected to the same contaminant load plug more quickly than Betapure NT-P Series

filters. The result is significantly shorter service life, and unpredictable filtration efficiencies. In this case, Betapure NT -P Series 5 micron filters provide a service life improvement of up to 2 times greater than competitive products. (Graph 1)

Lower Pr essur e Drop

The unique design and construction of the Betapure NT -P Series cartridge allows for significantly lower pressure drops compared to equivalently rated polypropylene depth filters. Based on published data, a 5 micron Betapure NT-P Series filter system with a given

flow would use up to 50% fewer cartridges than a 5 micron Pall® Profile. To underscore

the Betapure NT-P Series filter cost benefit, use the example in Table 1 as a guideline.

Table 1: Comparison of 5 Micron* Filters in a 110 GPM Syste

etapure NT-P Series FiltersPall Profile II (AB Style

Flow (gpm) / 10” cartridge @ 1 psi

Number of filters for a 110 gpm flow rate 12 / 30” cartridges 28 / 30” cartridges

Based on the manufacturer’s published rating.

2

Page 3

For the same initial cartridge differential pressure, a 110 gpm system using Betapure

G

g

()

(

)

()

P

*

P

1

P

2

P

3

P

5

P

10

P20020P

30

P

40

P50050P

0

NT-P Series 5 micron filters require significantly fewer, less than half, cartridges. This

results in lower capital investment for the filter housing and fewer cartridges to purchase.

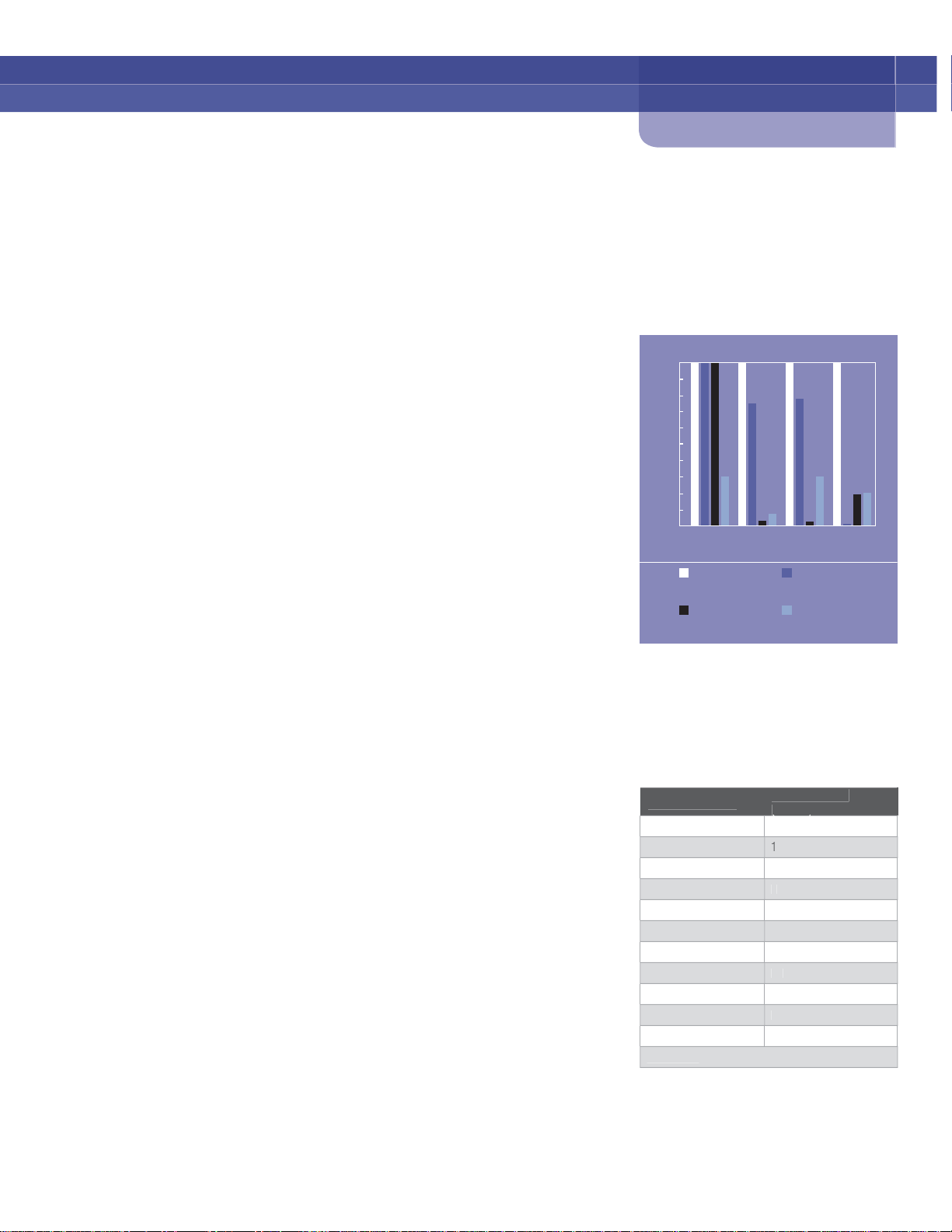

The Confi dence of Consistency

Betapure NT-P Series filters utilize advanced design and construction to achieve a

level of filtration consistency unattainable by competitive filters. Combined with an

exceptionally long service life, the Betapure NT-P Series filter’s consistent performance,

as illustrated by comparative Beta-Ratio vs. Differential Pressure (Graph 2), provides

predictable results throughout the filter’s usable life. F ilters A, B, and C show a degradation in the Beta-Ratio as the differential pressure increases. These filters exhibit a

pattern of either unloading previously held particles or a loss of filtration efficiency. The

result of this inconsistent performance is a reduction in finished product quality, product

yield, and an increase in total filtration cost.

Absolute Betapure NT-P Series

Consistent filtration performance, time after time, from start to finish - the goal of every

filter user, the solution provided by Betapure NT-P Series filters. Absolute removal

ratings for Betapure NT-P Series filters are determined using a filter performance test

developed by 3M Purification Inc. to comply with the general procedures outlined in

ASTM STP 97 5. 3M Purification Inc. defines absolute rating as the particle size (x)

providing an initial Beta Ratio (Bx) = 1000. At this Beta Ratio, the removal efficiency

is equal to 99.9%. Betapure NT -P Series filter ratings are specified in Table 2.

Your Benefi t - Total Filtration Cost Reduction

The Betapure NT-P Series filter’ s performance and superior life advantage allows direct

cost savings by reducing the number of filters used. In addition, the resulting reduction

in filter change-out frequency decreases direct labor and filter disposal costs. Betapure

NT-P Series filter cartridges - providing performance and value.

Betapure™

NT-P Series

Graph 2: Beta Ratios demonstrate the

Betapure NT-P Series filter’s ability to

perform consistently throughout its life

Beta Ratio Comparison of 20μm Filter Cartridges

1000

900

800

700

600

500

400

300

200

Beta Ratio

100

0

Betapure

NT-P Series

Competitor B

Gradient Pore Structure

Melt-Blown with Core

Pharmaceutical Grade Filters

0.5 1 10Initial

Differential Pressure (psid)

Competitor A

Gradient Pore Structure

Melt-Blown with Core

Competitor C

Graded Density Structure

Melt-Blown, Coreless

Pharmaceutical Testing and Optimization

Betapure NT-P Series filters undergo extensive quality testing prior to release, assuring safe and consistent performance in critical applications. Betapure NT-P Series

filter cartridges and capsules are manufactured and tested in accordance with an ISO

9001 :2 008 Quality Management Systems Standard. Betapure NT-P Series filter cartridges and capsules are supplied with a Certificate of Quality for traceability and documentation control. Filter cartridges and capsules are marked with a unique lot number

to provide full traceability through manufacturing records of raw material components.

A Regulatory Support File (70-0201-8826- 7) is available f or ease of compliance to regulatory requirements. Specific biosafety and effluent quality tests include the following:

• Meets USP Biological Reactivity,

• Non-pyrogenic per USP Bacterial Endotoxins Test (<0.25 EU/ml) .

• Meets oxidizable substances and pH test per USP Purified Water.

• Cleanliness - Meets USP Particulates in Injectables limits, microscopic examination of effluent particle counts serve to conform with requirements for non-fiber

releasing filter per CFR 21.

• Conductivity & Total Organic Carbon (TOC) - Meets requirements of USP Purified Water after flushing.

In Vi vo

, for Class VI 121°C Plastics.

Tab le 2: Betapu re NT-P Series Filter Ratings

rade Designation

005 0.5

010

020

030

050

100

300

400

700 7

* extrapolated

Absolute Ratin

Micron

3

Page 4

Betapure NT-P Series Filter Applications

Increasing emphasis on pharmaceutical process economies and end product purity are

driving today’s pharmaceutical and biotechnology industries to high technology filtration

products that offer tangible performance benefits. Betapure NT-P Series filters provide

high throughput, enabling reduced filter change-outs, longer on-stream service life, and

significant improvements in overall process economies.

Pharmaceutical

Betapure NT-P Series filters are ideally suited for general clarifying and prefiltration applications such as solvent streams, prefiltration of fermentation additives, and parenteral

prefiltration. Specific pharmaceutical process applications for Betapure NT-P Series

fil t ers in clud e:

• Large and Small Volume Parenterals (LVP/SVP )

• Fine Chemical/Bulk Pharmaceutical Chemical (BPC)

• Antibiotics

• Ophthalmic

• Diagnostic Reagents & Buffers

• Orals & T opi cals

• Vial & Stopper Washers

• Solvent Streams

Biologicals & Bioprocessing

In biological and bioprocess production, Betapure NT-P Series filters provide high capacity clarification of turbid biological solutions, including animal sera, vaccine broths, and

plasma fractions. Effective prefiltration with Betapure NT -P Series cartridges can avoid

costly oversized final filter systems. Specific biological and bioprocess applications for

Betapure NT-P Series filters include:

• Plasma Fractionation

• Vaccines

• Animal Sera & Media Feeds

• Mammalian Cell Culture

• Bacterial Fermentation

• Downstream Protein Purification

• Pre-Column Clarification (Protection)

• TFF Protection

Facilities & Plant Services

The Betapure NT-P Series filter’s unique construction provides longer service life in

general water filtration service, and in other continuous use applications. Polypropylene

depth media offers high contaminant capacity and low extractables in demanding solvent

fil t r a t ion a ppli c atio n s:

• Deionized Water

• Water-f or-Injection Systems (WFI)

• Air/Gas Prefiltration

• Solvent Streams

4

Page 5

Betapure™

s

g

g

s

e

s

)

5

g

e

)

I

n-situ

steam sterilization**

s

7

C)

ffere

essure

)

e

)

Ste

on

in-situ

S

M

A

5

Inside Diamete

1

3

/32” nominal

Outside

1/2

” nominal

Available Length

s

*

W

)

A

BCD

E

)

01

5

1/2

1/4

02

1/2

8

1/271/2

3

/

4

)

01302

)

01

2

3

/

4

0

g

e

NT-P Series

Table 3: Betapure NT-P Series Filter Specification

Materials of Construction, Cartridge & Capsules*

Filter Media, Netting, Core, End Connector & Capsule Body Polypropylene

Optional Support Rin

Gaskets & O-rin

Option

Operating Conditions, Cartridge

Maximum Operating Tempe ratur e 180 °F (82°C

Maximum Differential Pressure

Recommended Chan

e-Out Differential Pressur

Operating Conditions, Capsule

Maximum Operating Pressure

Maximum Forward Di

ntial Pr

Recommended Change-out Differential Pressur

rilizati

utoclave

Cartridge Dimensions

r

Diameter2

s 2.5, 5, 10, 20, 30, and 40 inches

Stainless Steel or Polysulfone

See ordering guid

0 psid at 86°F (3.4 bar at 30°C)

30 psid at 131°F (2.0 bar at 55°C)

15 psid at 180°F (1.0 bar at 82°C)

35 psid at 86°F (2.4 bar at 30°C

Maximum ten (10) 1 hour cycles at 259°F (126°C)

5 psig (5.2 bar) at 104°F (40°

35 psid at 104°F (2.4 bar at 40°C

35 psid at 86°F (2.4 bar at 40°C

DO NOT

TEA

cycles maximum for 30 minutes at 129°F (126°C)

Pharmaceutical Grade Filters

Nominal Capsule Dimension

ith End Connections*** (inches

5

555

7

Length (L

Nominal Length**

7

Diameter (D

Width to Vent (W

*** see Orderin

* All materials are FDA compliant per CFR 21

** For cartridges with support ring options (1 or 2) only. Capsules cannot be steam sterilized.

Guid

2

FLOW

7

Flow

D

L

W

5

Page 6

Cartridge Flow Rates

s

Grade

Absol

)

S

s

s

P005

0.5

4.5

81.9

P01012.5

45.5

P02020.8715.9

P03030.44

8.0

P05050.32

5.9

P100100.14

2.5P20020

0.065

1

P300300.05

0.91

P40040

0.0420.76

P500500.029

0.52

P700700.025

0.45

g

End Fitting

Maxi

)

H

id)

1

1/2

”

6.00

1.003/

8

”

T

6.00

1.001/

b

3.00

1.501/

4

” MNPT

1.50

2.40

T

b

0.50

2.20

Flow vs. differential pressure in water is calculated for each Betapure NT-P Series filter

grade using the formula below. Detailed information for calculating flows for fluids with

other viscosities is located in the following table. use the formula in conjunction with

the values from columns 3 or 4 in the table. The specific pressure drop values may be

effectively used when three of the four variables (viscosity , flow, differential pressure, and

cartridge grade) are set.

The specific aqueous pressure drop at ambient temperature is for a single length equivalent (10”) cartridge. For cartridge lengths OTHER than 10” , divide the total flow by the

number of equivalent lengths. For liquids other than water, multiply the specific pressure

drop value provided in the table by the viscosity in centipoise.

Table 4: Betapure NT-P Series Cartridge Flow Rate

ute Rating (μm

pecific Pressure Drop per 10” Cartridge

psid/gpm/cp

mbar/lpm/cp

.2

Table 5: Betapure NT-P Series Capsules - Maximum Recommended Flow by End Fittin

Sanitary Flange

FNP

” Hose Bar

mum Recommended Flow Rate (gpm

ousing Pressure Loss (ps

apered Hose Bar

Clean

Δ p

psi (mbar)

6

Total System gpm [lpm]

(

Viscosity in Cp

) (

) (

=

Number of Equivalent Single Length Cartridges in Housing

(

Value From Table

)

)

Page 7

Capsule Flow Rates

Model

D

n

of

f

C

ge

Maximu

Flow Rate*

Maxi

P

Temp

e

Literature

Reference

ZWB

T

h

bol

SO

O

s

0”

m

(

)

@

2

F

LITZRH106

S

ith clamp

closure

SO

O

gs

1

0”

26

m

(

)

200°FLITZRH10

S

Mini-

H

g

T-typ

cl

O

gs

1

2.5” or 5”

26

m

(

)

200°FL

S2

S

In-li

ith cl

cl

SO

O

gs

1

”

26

m

(

)

@

2

F

LITZRH

g

The following are typical water flow rates for Betapure NT-P Series capsules with

1 1/2” sanitary flange connections. Other end connections will affect maximum flow

rates, see the following table. Consult factory representative for flow rates for other

end connections.

3M Purifi cation Inc. Filter Housings

3M Purification Inc. provides a wide array of filter housings designed to meet the

sanitary requirements of the pharmaceutical and biological manufacturing industries.

Surface finishes of all sanitary housings are mirror polished 316L stainless steel, providing a high quality, lo w adhesion surface for full cleanability.

Table 6: Betapure NT-P Series Housing Specifications

escriptio

Cartridge

Style

Number

Cartridges

Length o

artrid

m

mum

ressure @

eratur

Betapure™

NT-P Series

Graph 3: Flow Rates for 2 1/2” capsules with

1 1/2” Sanitary Flanges @ 20°C

Pharmaceutical Grade Filters

-type wit

t closure

T-type

ZM

w

ZM

with clamp

ousin

osure

ne

ZV

amp

w

osure

* Flow rates are for housings only. Do not use to size an application. Actual process flow rates are determined by the recommended

flow rates of the installed cartrid

E - 226

-ring

E - 226

-rin

e

SOE - 226

-rin

E - 226

-rin

e and other process conditions.

3, 5, 7, 12 10” to 4

10” to 4

10” to 40

360 gp

1,3 60 lpm

gp

98 lpm

gp

98 lpm

gp

98 lpm

150 psi

00°

150 psi @

150 psi @

150 psi

00°

ITZRHZM

104

2.5

2.0

1.5

4

1.0

0.5

Differential Pressure (psid)

0.0

P030

P005

P010

P050

P020

1.0

P100

2.0

Fluid Flow (gpm)

Graph 4: Flow Rates for 5” capsules with

1 1/2” Sanitary Flanges @ 20°C

2.5

P005

P020

P010

2.0

1.5

1.0

0.5

Differential Pressure (psid)

0.0

2.0

1.0

Fluid Flow (gpm)

3.0

P030

P050

3.0

4.0

4.0

P200

P300 P400

P500 P700

5.0

P100

P200

P300 P400

P500 P700

5.0

6.0

6.0

7

Page 8

Betapure™ NT-P Series Cartridge Ordering Guide

Cartridge Type Length

Code Rating

(μm)

Grade

NT - Betapure NT-P Series

03 - 2.5” *

06 - 5” *

10 - 10”

20 - 20”

30 - 30”

40 - 40”

* 2.5” and 5” length cartridges available with “J” end modification only.

** Optional polysulfone support ring is available for applications requiring complete cartridge disposal or incineration.

*** Available for 2.5” and 5” cartridge lengths only.

P005 0.5

P010 1

P020 2

P030 3

P050 5

P100 10

P200 20

P300 30

P400 40

P500 50

P700 70

Packaging

Option

Z - Standard

Support Ring

Option

0 - None

1 - Polysulfone **

2 - Stainless Steel

Betapure NT-P Series Capsule Ordering Guide

Cartridge Type

Grade

Code Rating

(μm)

Confi guration

Nominal

Length

End Connection

End Modifi cation Gasket/O-ring Material

B - 226 O-Ring with Spear

C - 222 O-Ring with Spear

F - 222 O-Ring with Flat Cap

J - 226 O-Ring with Flat Cap***

Vent O-Ring

Option

A - Silicone

B - Fluorocarbon

C - EPR

D - Nitrile

K - PTFE Encapsulated

Fluorocarbon

Packaging Option

NT - Betapure NT-P Series

Important Notice: The information described in this literature is accurate to the best of our knowledge. A variet y of factors, however, can affect the performance of the Product(s) in a

particular application, some of which are uniquely within your knowledge and control. INFORMATION IS SUPPLIED UPON THE CONDITION THAT THE PERSONS RECEIVING THE SAME

WILL MAKE THEIR OWN DETERMINATION AS TO ITS SUITABILITY FOR THEIR USE. IN NO EVENT WILL 3M PURIFICATION INC. BE RESPONSIBLE FOR DAMAGES OF ANY

NATURE WHATSOEVER RESULTING FROM THE USE OF OR RELIANCE UPON INFORMATION.

It is your responsibility to determine if additional testing or information is required and if this product is fit for a particular purpose and suitable in your specific application.

3M PURIFICATION INC. MAKES NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OF ANY OTHER NATURE HEREUNDER WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH

INFORMATION REFERS.

Limitation of Liability: 3M Purification Inc. will not be liable for any loss or damage arising from the use of the Product(s), whether direct, indirect, special, incidental, or consequential,

regardless of the legal theory asserted, including warranty, contract, negligence or strict liability. Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation may not apply to you.

P005 0.5

P010 1

P020 2

P030 3

P050 5

P100 10

P200 20

P300 30

P400 40

P500 50

P700 70

C - Capsule

01 - 2 1/2”

02 - 5”

A - 1 1/2” Sanitary Flange

B - 1/2” (14 mm) Hose Barb

C - 1/4” MNPT

D - 3/8” FNPT

E - 1/4” - 5/16” - 3/8”

Tampered Hose Barb

A - Silicone

B - Fluorocarbon

C - EPR

01 - Single Pack

03 - 3 Pack

20 - 20 Pack

Your Local 3M Purifi cation Inc. Distributor:

3M Purifi cation Inc.

400 Research Parkway

Meriden, CT 06450

U.S.A.

(800) 243-6894

(203) 237-5541

Fax (203) 630-4530

www.3Mpurifi cation.com

3M is a trademark of 3M Company.

Betapure is a trademark of 3M Company used under license.

All other trademarks are the property of their respective owners.

© 2011 3M Company. All rights reserved.

70-0201-8721-0

REV 0411vb

Loading...

Loading...