Page 1

INSTALLATION AND OPERATING

MODELS:

HWS050

HWS100

INSTRUCTIONS

HWS SERIES HOT WATER SOFTENERS

Installer, please leave with homeowner.

3M is a trademark of 3M Company.

© 2012 3M Company. All rights reserved.

IN303 0912B

Please recycle. Printed in U.S.A.

3M Purification Inc.

400 Research Parkway

Meriden, CT 06450, USA

Toll Free: 866.990.9785

Worldwide: 203.237.5541

Fax: 203.238.8701

www.3Mfoodservice.com

www.3Mpurification.com

Page 2

SAFETY INFORMATION

Limited Warranty

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the 3M

HWS hot water softeners. Retain these instructions for future reference.

Intended use:

The HWS hot water softeners are intended for use in softening hot water in Foodservice installations. The system is intended

for indoor installations near the entry point of a foodservice water line, and must be installed by qualifi ed professional installers

according to these installation instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

WARNING

CAUTION

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious

injury and/or property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

WARNING

To reduce the risk associated with ingestion of contaminants due to use with water that is microbiologically unsafe or of

unknown quality:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the

system.

To reduce the risk associated with hazardous voltage:

• If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure

a suffi cient ground connection across the softener installation piping — refer installation to qualifi ed personnel.

• Do not use the softener if the wall-mounted power supply is damaged — contact qualifi ed service personnel for repair.

To reduce the risk associated with back strain:

• Follow safe lifting procedures.

3M Purification Inc. warrants HWS050 and HWS100 will be free from defects in material and manufacture for the following

periods from the date of purchase:

• One (1) year on the entire unit

• Five years on mineral tank only (does not include internal components)

• Five years on control valve body only (does not include internal or external components)

• Five years on salt storage container and components.*

This warranty does not cover failures resulting from abuse, misuse, alteration or damage not caused by 3M Purification Inc. or

failure to follow installation and use instructions. 3M PURIFICATION INC. MAKES NO OTHER WARRANTIES OR CONDITIONS,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTIBILITY

OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE OF

DEALING, CUTOMER OR USAGE OF TRADE. If this Product fails to satisfy this Limited Warranty during the warranty period, 3M

Purification Inc. will replace the Product or refund your Product purchase price. This warranty does do cover labor. The remedy

stated in this paragraph is the Customer’s sole remedy and 3M Purification’s exclusive obligation.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state, or country to country.

For any warranty questions, please call 855.3M.WATER (855.369.2837) or mail your request to: Warranty Claims, 3M Purification

Inc., 400 Research Parkway, Meriden, CT 06450. Proof of purchase (original sales receipt) must accompany the warranty claim,

along with a complete description of the Product, model number and alleged defect.

Limitation of Liability: 3M Purification Inc. will not be liable for any loss or damage arising from this 3M Purification Inc. product,

whether direct, indirect, special, incidental, or consequential, regardless of the legal theory asserted, including warranty, contract,

negligence or strict liability. Some states and countries do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

*water softeners only

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use Instructions before installation and use of this system;

• Installation must comply with existing state or local plumbing codes;

• Protect from freezing. Drain system when temperatures drop below 40°F (4.4°C);

• Do not install if water pressure exceeds 100 psi (689 kPa). If the system water pressure exceeds 100 psi, the installation must

use a pressure limiting valve. Contact a licensed plumbing professional if you are uncertain how to check your water pressure;

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum

prevention;

• When water supply is shut off, shut off fuel or electric power to water heater;

• Do not use torches or other heat sources near plastic plumbing, as damage may occur;

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur;

• On plastic fi ttings, use thread sealing tape only. Never use pipe sealant or pipe dope on plastic fi ttings, as damage may occur;

• Do not bend spring on fl oat assembly or damage to the vent may result;

• Do not install this system in direct sunlight or outdoors without protection from precipitation.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve

. The Inlet and

Outlet of other water treatment equipment products will vary depending on the control valve brand used.

IMPORTANT NOTES

• Failure to follow instructions may result in leakage and will void warranty.

WATER TREATMENT SYSTEM

PRODUCT REGISTRATION CARD

3M Purification Inc., 400 Research Parkway, Meriden, CT U.S.A.

PLEASE PRINT

THANK YOU

Model #

Where Purchased

Business Address

Equipment this system is used on

Model # (if known) Manufacturer

If the filter is used on more than one machine, please list below.

DATE OF

PURCHASE

Street

Mo. Yr.

Your Name

Business Name

Address

Telephone Number ( )

E-mail Address

NOTICE: Personal information collected in this card will only be used for 3M

Product Registration purposes.

Street

City State & Zip Code

edoC piZ & etatS ytiC

rerutcafunaM ledoM tnempiuqE

Page 3

TABLE OF CONTENTS

SECTION 7: MAINTENANCE

REPLENISHMENT OF SALT SUPPLY:

SECTION DESCRIPTION

1 BEFORE INSTALLATION

2 INSTALLATION

3 REGENERATION INSTRUCTIONS

(Timer Setting Instructions)

4 SERVICE INSTRUCTIONS

5 SPECIFICATIONS AND OPERATING DATA

6 PARTS

7 MAINTENANCE

SECTION 1: BEFORE INSTALLATION

Before starting the installation we suggest reading this manual all the way through for an overview, and then follow the installation steps

in the proper sequence. IMPROPER INSTALLATION could void the warranty. Installation should be completed by a qualifi ed plumber.

INSPECTING AND HANDLING THE WATER SOFTENER:

Inspect the equipment for shipping damage. If damaged, notify the transportation company and request a damage inspection.

Handle the equipment with care. Damage can result if dropped or if the brine tank is set on sharp, uneven projections on the fl oor. When

handling, do not turn the water softener unit upside down.

MAKE SURE YOUR WATER HAS BEEN THOROUGHLY TESTED:

The salt storage capacity of the brine tank is approximately 280 lbs. (127 kg). During each regeneration a specifi c amount of salt is

consumed, thus requiring its periodic replenishment (the frequency is dependent on the regeneration schedule). Always replenish salt

before the supply is exhausted to assure a continuous supply of softened water.

TYPE OF SALT TO USE:

Any type of water softener salt may be used. There are advantages and disadvantages to every type of salt. Please ask the local dealer

for his advice. The unit is designed to compensate for the disadvantages.

BRINE TANK CLEAN-OUT:

To prevent service problems the brine tank should be emptied and fl ushed out with a garden hose when dirt and other insolubles accumulate. The clean-out frequency depends on the type salt used and regeneration frequency. The clean-out should be done when the

salt level is low. Steps to follow:

1) Disconnect brine line at either end.

2) Turn brine tank upside down and discard old salt. Remove salt grid plate.

3) Rinse out with a garden hose.

4) Reconnect brine line.

5) Add enough water to brine tank to cover

year if rock salt is used; with other types of salt, approximately once every other year.

the air check in the brine well 1" before adding new salt. Perform approximately once a

PREVENTING IRON-FOULING OF MINERAL BED:

If iron is present in the water supply, the softener mineral bed will eventually become iron-fouled, resulting in reduced softening capacity and rust-stained fi xtures. Mixing one to two ounces of IRON-X Mineral Cleaner with every 80 lbs. of salt added to brine tank will

minimize these problems from occurring. IRON-X is available from the dealer.

An analysis of the water should be made prior to the selection of water conditioning equipment. The dealer will generally perform this

service, and may send a sample to the factory for analysis and recommendations. Enter the analysis below for a permanent record.

IMPORTANT NOTES

Hydrogen sulfi de (H2S) must be tested for at the well site. For accuracy, the sample must be drawn with the pump RUNNING, and the

test be completed within ONE minute after the sample is drawn.

Softeners are designed to remove hardness but can handle reasonable amounts of soluble iron if consideration is given to content when

selecting model and regeneration settings. To treat sulfur (hydrogen sulfi de), bacterial iron, precipitated iron or very high levels of soluble

iron requires special equipment in addition to a water softener. For best results, a Chem-Free Iron Reduction Filter is recommended for

use on waters containing more than 2 ppm of iron.

Analysis Of Your Water

CONTAMINANT YOUR WATER

gpg___________ssendraH

Iron (Fe) ___________ppm

Manganese (Mn) ___________ppm

___________Hp

Tannins (Humic Acid) ___________ppm

Hydrogen Sulfi de (H

Other____________________ ___________ppm

Other____________________ ___________ppm

S) ___________ppm

2

PERIODICALLY CHECK TIME OF DAY SETTING:

Power outages will cause TIME OF DAY timer setting to become incorrect. To reset, refer to appropriate HOW TO SET TIME CLOCK

REGENERATION CONTROL, Section 3.

MALFUNCTION OF UNIT:

The water softener, under normal conditions, should provide years of trouble-free service; however, since it is a mechanical device, it

can malfunction. (Refer to Section 4, SERVICE INSTRUCTIONS, if necessary).

CHANGE OF OPERATING CONDITIONS:

Should the daily water usage, or water quality change, the regeneration program settings may have to be adjusted. Consult the dealer

if any of the above occur.

1-1

7-1

Page 4

CHECK WATER PRESSURE AND PUMPING RATE:

Two water system conditions must be checked carefully to avoid unsatisfactory operation or equipment damage:

1) MINIMUM water pressure required at the softener tank inlet is 20 psi. IF PRESSURE IS OVER 100 PSI, A PRESSURE REDUCING VALVE MUST BE INSTALLED IN THE WATER SUPPLY LINE AHEAD OF THE WATER SOFTENER.

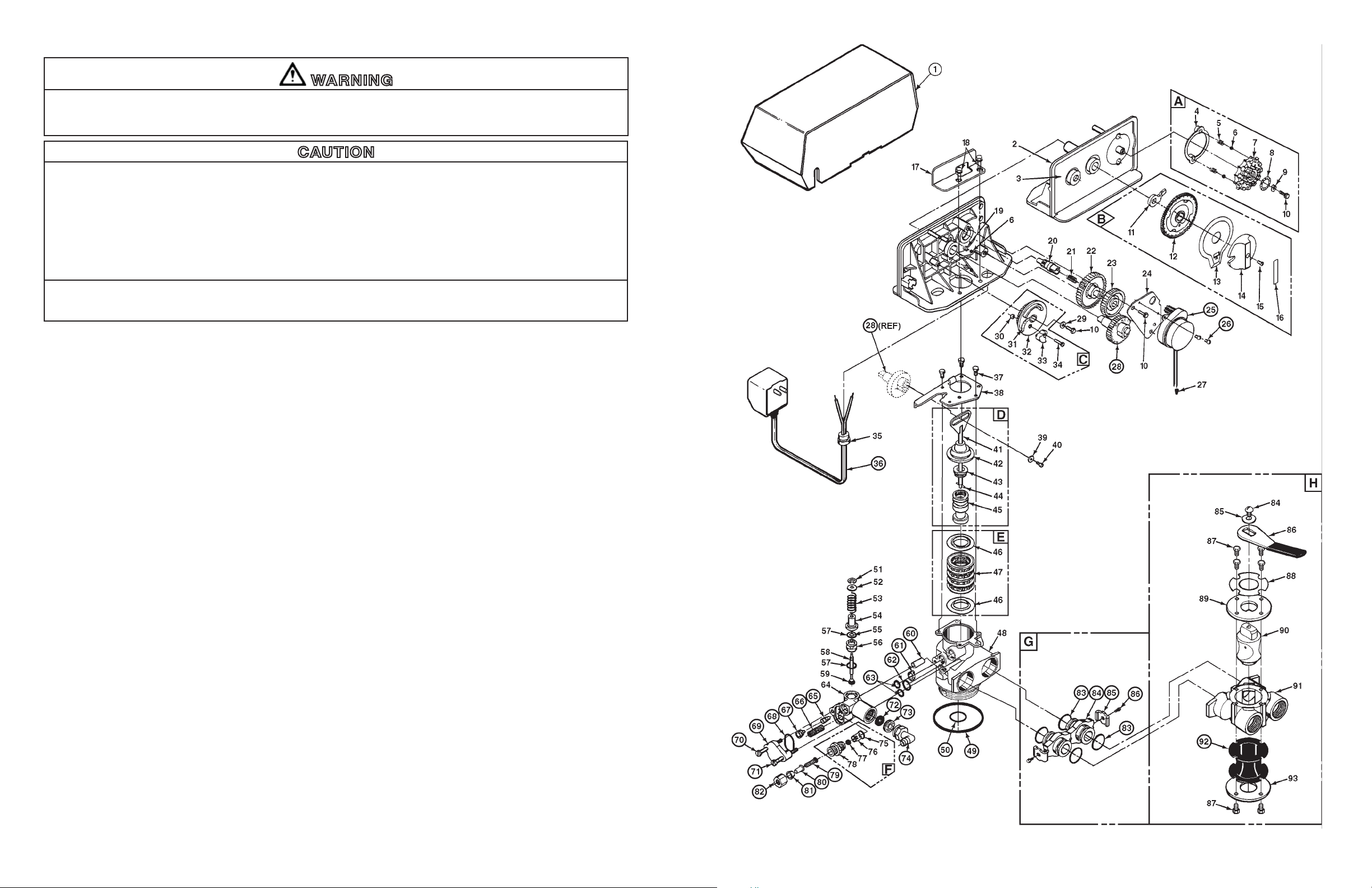

ONLY THOSE PARTS CIRCLED IN DRAWING AND/OR LISTED BELOW ARE STOCK ITEMS

ALL OTHERS ARE SPECIAL ORDER, NON-RETURNABLE

PARTS LIST - 12 DAY TIMER

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install if water pressure exceeds 100 psi (689 kPa). If the system water pressure exceeds 100 psi, the installation

must use a pressure limiting valve. Contact a licensed plumbing professional if you are uncertain how to check your water

pressure.

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum

prevention.

IMPORTANT NOTE

If the source is a municipal or a community water supply and daytime water pressure is 85 psi or more, nighttime pressure may

exceed 100 psi. Call the local water department or plant operator to obtain pressure readings. If the source is a private well, the

gauge on the pressure tank will indicate the high and low system pressure. Record water pressure data below:

WATER PRESSURE

Low _______ psi High _______ psi

2) If the source of water is a private well, the pumping rate of the well pump must be suffi cient for satisfactory operation and BACKWASHING of the WATER SOFTENER. (See SPECIFICATIONS AND OPERATING DATA, Section 5).

LOCATE WATER CONDITIONING EQUIPMENT CORRECTLY:

Select the location of the water softener with care. Various conditions which contribute to proper location are as follows:

1) Locate as close as possible to water supply source.

2) Locate as close as possible to a fl oor or other adequate drain.

3) Locate in correct relationship to other water conditioning equipment (Figure 1).

4) Temperatures above 150° F (66° C) will damage the softener and void the factory warranty.

5) Do NOT install the softener in a location where freezing temperatures occur. Freezing may cause permanent damage and will also

void the factory warranty.

6) Allow suffi cient space around the unit for easy servicing.

7) Provide a non-switched 110V, 60Hz power source for the control. (Ref

erence transformer to verify proper power supply voltage.)

REF.

A

B

C

D

E

F

G

H

1

25

26

28

36

50

49

60

61

62

63

65

66

67

68

69

70

71

72

73

74

79

80

81

82

83

84

85

86

92

14381X

13010XT

60514-02

60102-031

60125-05

60022-501

10090X

60040

22602

19659

11384

13170

U321

13304

10381-01

13361

13497

12638-01

13301-01

10226-1

10227

10225-1

13303-01

13166

13387

13315

12091

13173

12338

12767

10332

10330

10329

13305

13709

13255

13314

14105

DESCRIPTIONPART NO.

Skipper Wheel Assy. (Incl. Ref. Items 4-10)

24-Hour Gear Assy. (Incl. Ref. Items 11-16)

Brine Cam Assy. Minutes of Refi ll Salt (Incl. Ref. Items 30 - 34)

Piston Kit (Incl. Ref. Items 41-45)

Seal Kit, HW (Incl. Ref. Items 46 & 47)

Brine Line Flow Control Assy., 0.50 GPM, (Incl. Ref. Items 75-78)

Adapter Coupling Assy. (Incl. 2 ea. Ref. Items 84-86 & 4 ea. Item 83)

3/4" Bypass Valve, 316SS, Hot/Cold

Valve Cover, Specify Model

Motor, 24V/60 Hz

Motor Mtg. & Ground Screw

Main Gear

Transformer, 110V/60Hz - 24V/60Hz

Distributor Tube O-Ring

Tank O-Ring

Stand-off

Air Disperser

Drain O-Ring, HW

Injector O-Ring, HW

Injector Throat - Specify Size

Injector Screen

Injector Nozzle - Specify Size

Injector Cover O-Ring

Injector Cover

Screw, Injector Mounting

Injector Mounting Screw

Drain Line Flow Control Button:

4.0 GPM

Drain Line Flow Control Retainer

Drain Line Fitting

Brine Line Screen

Brine Line Tube Insert

Brine Line Ferrule

Brine Line Fitting Nut

Adapter Coupling O-Ring

Adapter Coupling

Adapter Clip (Incl. 2 ea. Ref. Item 83)

Adapter Coupling Screw

Seal, Bypass

1-2

6-4

Page 5

FACTS TO REMEMBER WHILE PLANNING THE INSTALLATION:

WARNING

To reduce the risk associated with hazardous voltage:

• If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a

suffi cient ground connection across the softener installation piping — refer installation to qualifi ed personnel.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Installation must comply with existing state or local plumbing codes.

• Do not install if water pressure exceeds 100 psi (689 kPa). If the system water pressure exceeds 100 psi, the installation must

use a pressure limiting valve. Contact a licensed plumbing professional if you are uncertain how to check your water pressure.

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum

prevention.

• Do not use torches or other heat sources near plastic plumbing, as damage may occur.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur.

• On plastic fi ttings, use thread sealing tape only. Never use pipe sealant or pipe dope on plastic fi ttings, as damage may occur.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and

Outlet of other water treatment equipment products will vary depending on the control valve brand used.

Remember that the fi lter INLET is

toward the water heater or other water treatment equipment device.

Before commencing the installation, it is advisable to study the existing piping system and to determine the size, number and type of

fi ttings required. Typical system schematics shown in Figure 1 will be of assistance.

attached to the pipe that supplies water (i.e. runs to the pump) and OUTLET is the line that runs

CONTROL VALVE

- 12 DAY TIMER

1-3

6-3

Page 6

SECTION 2: INSTALLATION

HOT WATER FILTER

SOFT

WATER

RAW

WELL

WATER

BRINE

MAKER

SOFTENER

Figure 1. INSTALLATION SCHEMATIC

CAUTION

To reduce the risk associated with property damage due to

water leakage:

• When water supply is shut off, shut off fuel or electric power to

water heater;

• Do not use torches or other heat sources near plastic plumb-

ing, as damage may occur;

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur;

• On plastic fi ttings, use thread sealing tape only. Never use pipe

sealant or pipe dope on plastic fi ttings, as damage may occur;

To reduce the risk associated with property damage due to

plugged water lines:

• Pay particular attention to correct orientation of control valve.

Water fl ow should match arrow on control valve. The Inlet and

Outlet of other water treatment equipment products will vary

depending on the control valve brand used.

Step 1

If not factory pre-installed, attach BYPASS VALVE using

ADAPTER COUPLINGS, CLIPS and SCREWS to CONTROL VALVE (Figure 2).

Step 2

Verify all packing materials have been removed from the

brine tank.

Step 3

Shut off water at supply valve. On a private well system,

turn off power to pump and drain pressure tank. Make certain pressure is relieved from complete system by opening

nearest faucet to drain system. SHUT OFF FUEL SUPPLY

TO WATER HEATER.

Step 4

Cut main supply line as required to fi t plumbing to INLET

and OUTLET of unit.

Step 5

Attach plumbing. DO NOT apply heat to any fi tting connected to BYPASS or CONTROL VALVE as damage may

result to internal parts or connecting adapters. Make certain water fl ow enters through inlet and discharges through

outlet.

SECTION 6: PARTS

COMPONENT PARTS LIST

REF

NO.

1

Control Valve, Time Clock Initiation, with

Cover, less Bypass (HWS Series)

2

Media Tank w/Base

3

Media

4

Distributor Assy.

5

Brine Line Tubing

6

Overfl ow Fitting

7

Brine Tank Shell w/Cover

8

Brine Well w/Cap

9

Grid Plate

10

Safety Brine Valve

11

Float Assembly

12

Air Check Assembly

NOTE: When ordering components, always specify model number.

DESCRIPTION

HWS050

B100407-5S1-2S

MTV1019B-BLU

H-050P

60795-10

13000X

BT16

BT1833BLU

BTCS11-28

Optional

60027-FFA

60028SAN

60003

HWS100

B100407-5S1-2S

MTV1040B-BLU

H-10P

60795-10

13000X

BT16

BT1833BLU

BTCS11-28

Optional

60027-FFA

60028SAN

60003

Figure 2. SOFTENER AND BRINE TANK ASSEMBLY, TOP VIEW

2-1

6-1

Page 7

Step 6

Attach DRAIN LINE to DRAIN LINE FITTING. To prevent back pressure from reducing fl ow

rate below minimum required for backwash, DRAIN LINE MUST be sized according to run

length and relative height. Be careful not to bend fl exible drain tubing sharply enough to

cause "kinking" (if kinking occurs DRAIN LINE MUST BE REPLACED). Typical examples

of proper DRAIN LINE diameters are:

(1) 1/2 in. ID up to 15 ft. when discharge is lower than INLET.

(2) 5/8 in. ID up to 15 ft. when discharge is slightly higher than INLET.

(3) 3/4 in. ID when drain is 25 ft. away and/or drain is installed overhead.

EQUIPMENT

DRAIN LINE

DRAIN

AIR GAP

2" REF.

SECTION 5 : SPECIFICATIONS AND OPERATING DATA

TIMER INITIATED MODELS:

ITEM

Nominal Media Volume, cu. ft. (cu. mtr.)

HWS050

0.50 (0.02)

HWS100

1.0 (0.03)

Step 7

Position DRAIN LINE over drain and secure fi rmly. To prevent backsiphoning of waste water, provide an air gap of at least 2 in. or 2 pipe diameters between end of drain hose and

drain (Figure 3). DO NOT raise DRAIN LINE more than 10 ft. above fl oor.

Figure 3. TYPICAL DRAIN

Step 8

Connect one end of the 3/8 in. poly line to BRINE VALVE located on the right side of CONTROL VALVE. Connect other end to ELBOW

inside of BRINE WELL. Brass insert sleeves and plastic ferrules must

PARTS Drawing, Section 6).

be used where necessary. (Figure 2 and CONTROL VALVE

Step 9

Install OVERFLOW LINE to brine tank OVERFLOW FITTING (Figure 2). Discharge of line must be lower than OVERFLOW FITTING.

DO NOT INTERCONNECT OVERFLOW LINE WITH VALVE DRAIN LINE.

Step 10

Make certain BYPASS VALVE IS IN "BYPASS" position. After all plumbing connections have

been completed, open main water shut-off valve or restore power to well pump. Check for

leaks and correct as necessary.

Step 11

Manually stage control to BACKWASH POSITION by turning "MANUAL REGENERATION

KNOB", clockwise to "BACKWASH" position, refer to HOW TO SET TIME CLOCK REGENERATION CONTROL (Section 3).

Figure 4. BYPASS VALVE

Step 12

Partially open (approximately 1/4 of the way) the INLET valve in plumbing or BYPASS VALVE (Figure 4). This will allow the unit to fi ll

slowly from the bottom up, eliminating air entrapment. Allow unit to fi ll slowly, failure to do so could result in loss of resin to the d

Once a steady stream of water, no air, is fl owing to drain, the INLET OR BYPASS VALVE can be fully opened. Manually advance control

to SERVICE POSITION. Plug transformer into a non-switched 110V, 60Hz power source. (Reference transformer to verify proper power

supply voltage.)

rain.

Salt dosage, lbs. (kg):

Factory Setting

Maximum Setting

Nominal Softening Capacity, grains (grams): (1)

At factory salt setting

At maximum salt setting

Operating Flow Rates, gpm (lpm): (2)

Service (10 minutes or less)

Pressure Loss @ Operating Flow Rates, psi (kPa):

Service

Regeneration Flow Rates, gpm (lpm):

Backwash (3)

Brine/Rinse

Rapid Rinse

Brine Refi ll

Inlet/Outlet Pipe Size, in. (cm)

Mineral Tank Dia. x Height, in. (cm)

Overall Depth & Height w/Control Valve, in. (cm)

Brine Tank, W x D x H, in. (cm)

Approx. Salt Storage, lbs. (kg)

Approx. Shipping Weight, lbs. (kg)

3.0 (1.4))

6.0 (2.7)

13,000 (842)

16,000 (1057)

5.0 (18.4)

2.0 (14)

4.0 (15.1)

0.6 (2.3)

4.0 (15.1)

0.5 (1.9)

3/4" FPT (1.9)

10x19 (40x76)

10x28 (25x112)

18x26 (46x66)

280 (127)

65 (30)

6.0 (2.7)

15.0 (6.8)

18,600(1205)

30,000(1944)

8.5 (32.2)

6.0 (42)

4.0 (15.1)

0.6 (2.3)

4.0 (15.1)

0.5 (1.9)

3/4" FPT (1.9)

10x40 (40x160)

10x49 (40x196)

18x26 (46x66)

280 (127)

100 (45)

Maximum operating temperature 150° F (66° C); Electrical requirements 110V/60Hz

(220V/50Hz); Operating pressure 20-100 psi (138 - 689 kPa). All types water softener salt

may be used (See MAINTENANCE). Specifi cations subject to change without notice.

Step 13

Set REGENERATION FREQUENCY. Refer to REGENERATION FREQUENCY SCHEDULES (Section 3) to determine correct frequency, then refer to HOW TO SET TIME CLOCK REGENERATION CONTROL (Section 3) for instructions on setting frequency.

IMPORTANT NOTE

Regeneration settings are factory preset for the most effi cient salt use and minimum water consumption used for regeneration (as

little as 50 gallons). REGENERATION FREQUENCY SCHEDULES are designed for use with factory regeneration settings (listed in

SPECIFICATIONS AND OPERATING DATA, Section 5).

The control valve design permits adjustment of the salt dosage. This adjustment may be necessary when unusual operating conditions exist, such as high concentrations of iron or hardness and/or high fl ow rates or daily water consumption. This adjustment is easily

performed by loosening the screw holding the white cam (on backside of timer) and adjusting the pointer to the desired refi ll time. Refi ll

rate is controlled by a fl ow control to 0.5 gpm. By adjusting the amount of time the unit is allowed to refi ll the brine tank, the salt dosage

can be adjusted. Each gallon of fresh water added to the brine tank will dissolve 3 lbs. of salt.

EXAMPLE: If a salt dosage of 6 lbs. is desired, the salt refi ll time should be set to 4 minutes.

4 minutes x 0.5 gpm = 2 gals.

2 gals. x 3 lbs/gal = 6 lbs.

2-2

NOTES:

1) Actual capacity may vary substantially depending on water analysis and operating conditions.

2) For satisfactory performance indicated fl ow rates and duration should not be exceeded. Flow rates specifi ed are adequate for

normal applications.

3) For system to operate properly, pumping rate of well pump ( if applicable) MUST be suffi cient to backwash unit at rate specifi ed.

5-1

Page 8

Step 14

Set TIME OF DAY (refer to appropriate HOW TO SET TIME CLOCK REGENERATION CONTROL, Section 3). When shifting to daylight

saving time (and back), you may wish to adjust TIME OF DAY accordingly.

IMPORTANT NOTE

TIME OF REGENERATION is pre-set for 2:00 a.m. because at this time water consumption is generally minimal (a built-in hard water

bypass does, however, permit water to be drawn during regeneration). Should the application require regular use of water during

the 2:00 to 3:00 a.m. regeneration period, or if other water treatment equipment is also set for 2:00 a.m. regeneration, the TIME OF

REGENERATION will need changing. To change, adjust time of day on 24-HOUR GEAR ahead or behind actual time of day. For

example, if 1:00 a.m. regeneration is desired and actual time of day is 10:00 a.m., advance 24-HOUR GEAR one hour to 11:00 a.m.;

or, should 3:00 a.m. regeneration be desired, set gear back one hour to 9:00 a.m.

Step 15

Before loading salt, using a pail or garden hose, add enough water to brine tank to cover the air check in the brine well by approx. one

(1) inch. Then add initial salt fi ll to brine tank, and one cup full of unscented laundry bleach to brine well.

Step 16

RESTORE FUEL SUPPLY OR POWER TO WATER HEATER. Put softener through complete regeneration to sanitize the system before

use (Refer to HOW TO SET TIME CLOCK REGENERATION CONTROL for instructions on manual regeneration).

Installation is now complete, and the water softener is now ready for service!

SECTION 4: SERVICE INSTRUCTIONS

noituloSesuaCmelborP

A. Electrical service to unit interrupted A. Assure permanent electrical service (check fuse, plug,

1. Hard water (unit not using salt; liquid

level in brine tank NOT too high)

D. Safety brine valve not opening D. Replace safety brine valve

T .B

2. Hard water (unit using salt; liquid level

in brine tank NOT too high)

C. Injector or Injector screen plugged C. Clean injector and screen

3. Liquid level in brine tank TOO high

4. System regenerates at wrong time

of day

5. Water continuously fl ows to drain

6. Water tastes salty

7. White spots on glassware and dark

surfaces

8. Low water pressure (low fl ow rate)

9. “Rotten egg” smell (from hot water only) A. Magnesium rod in water heater A. Replace with aluminum rod or remove

10. “Rotten egg” smell (from both hot and

cold water

11 Loss of resin through drain

D. Drain line frozen, plugged or restricted D. Free drain

E. Salt “mushed” or sand from salt plugging bottom

of brine tank

F. Incorrect brine line fl ow control (BLFC) F. Replace with correct

A. Power outage .A.derrucco Reset timer

A. Foreign material in control valve A. Remove piston assembly and inspect bore: remove

C. Control valve jammed in brine or backwash

position

B. Distributor tube ecalpeR .Btrohs oot

A. Sodium residual resulting from water having very

high hardness or total dissolved solids (TDS)

A. Iron build-up in line to water conditioner A. Clean line to water conditioner

B. Iron build-up in water conditioner B. Clean control and add Iron-X Mineral Cleaner to resin

A. Hydrogen sulfi de (“sulfur”) in water supply A. Install Sul-X Sulfur Reduction System

B. Incorrect Drain Line Flow Control (DLFC). B

C. Unit regenerating with cold water. C. Reinstall so unit uses hot water for regeneration.

pull chain, or switch)

. rotom remit ecalpeR .B.gnikrow ton remiT .B

tlas pukaerB .Eknat enirb ni ”degdirb“ tlaS .E

)yrassecen fi ecalper( ssapyb esolC .Anepo ssapyB .A

needed.

level retaw evoba niatniam ;tlas ddA .Cknat enirb ni tlas oN .C

(See HOW TO SET TIMER)

tinu llatsnieR .Esdrawkcab dellatsni tinU .E

tinu regral htiw ecalpeR .Fdezisrednu tinU .F

evlav enirb ecalpeR .Agnisolc ton evlav enirB .A

remit teseR .Bhgih oot gnittes tlaS .B

E. Clean out brine tank (see instructions)

fl ow control (see specifi cations)

foreign material and check control in various regeneration positions

C. Replace piston, seals and spacers

elcyc margorp teseR .Ahgih oot gnittes tlaS .A

A. Installation of additional water treatment equipment

such as reverse osmosis or demineralization

bed: increase frequency of regeneration

atsnI .Cdnas gnipmup lleW .C

well just before regeneration as frequently as necessary

trol: check for dry well condition

. Replace with correct DLFC.

part dnas ll

ecivres riaper pmup tcatnoC .Dyticapac gnisol pmuP .D

.gnittes tlas ro/dna noitareneger fo ycneuqerf esaercnI .Ctes ylreporpmi remiT .C

fi remit teser ro noitareneger fo ycneuqerf esaercnI .Btes ylreporpmi remi

gnittes tlas ro/dna noitareneger fo ycneuqerf esaercnI .Degasu retaw evissecxE .D

ylbmessa notsip ro/dna slaes ecalpeR .Bkael lortnoc lanretnI .B

metsyS noitcudeR norI eerF-mehC llatsnI .Bylppus retaw ni nori lairetcaB .B

enirb otni hcaelb yrdnual puc 2/1 yletamixorppa ruoP .Cylppus retaw ni eaglA .C

-noc rotanimile ria reporp sah metsys llew taht erussA .Ametsys retaw ni riA .A

2-3

4-1

Page 9

SECTION 3: REGENERATION INSTRUCTIONS

INSTRUCTIONS FOR USING REGENERATION FREQUENCY SCHEDULES:

1) Determine ADJUSTED HARDNESS by adding three (3) times the iron content in parts per million (ppm) to the hardness in grains

per gallon (gpg). The resulting number is ADJUSTED HARDNESS.

EXAMPLE: Hardness is 14 gpg and iron is 2 ppm. ADJUSTED HARDNESS is 20 gpg (14 plus 3 times 2).

2) Select REGENERATION FREQUENCY SCHEDULE corresponding to the model. Locate box intersected by DAILY WATER USE

and ADJUSTED HARDNESS (if ADJUSTED HARDNESS is between two numbers in schedule, use higher number). Number in

box represents FREQUENCY or NUMBER OF times per 12 DAYS timer should be set to regenerate. Refer to HOW TO SET TIME

CLOCK REGENERATION CONTROL to set correct frequency.

EXAMPLE: Rounding is always down. You have Model HWS050 (13,000 grain capacity at factory salt setting), 450 gpd usage and 5

gpg adjusted hardness. Refer to appropriate REGENERATION FREQUENCY SCHEDULE and locate box intersected by 450 gpd and

5 gpg adjusted hardness. The fi gure "3" in box indicates a REGENERATION frequency of THREE TIMES PER 12 DAYS

"4", etc. were in box, frequencies of once, twice and four times per twelve days, respectively, would be indicated.) This can be calculated

as 13,000/(5 x 450) = 5.8 days between regeneration, rounding down to every 4 days or 3 times in a 12 day cycle, as indicated.

REGENERATION FREQUENCY SCHEDULES

(TIMES PER 12 DAYS)

001SWH :LEDOM050SWH :LEDOM

(if a "1", "2",

HOW TO SET TIME CLOCK REGENERATION CONTROL

Gallons

Per

Day

50

100

150

200

250

300

350

400

450

500

5

10

1

1

1

1

1

2

1

2

2

3

2

3

2

3

2

4

2

4

3

4

NR - Not Recommended

HARDNESS - GPG

15

20

25

30

1

1

2

2

2

2

3

3

2

3

4

4

3

4

4

6

4

4

6

6

4

6

6

12

6

6

12

12

6

6

12

12

6

12

12

NR

6

12

12

NR

35

2

3

6

6

12

12

12

NR

NR

NR

40

2

4

6

6

12

12

NR

NR

NR

NR

Gallons

Per

Day

50

100

150

200

250

300

350

400

450

500

HARDNESS - GPG

5

10

15

20

25

30

1

1

1

1

1

1

1

1

1

2

2

2

1

1

2

2

3

3

1

2

2

3

3

4

1

2

3

3

4

4

1

2

3

4

4

6

2

2

3

4

6

6

2

3

4

4

6

6

2

3

4

6

6

12

2

3

4

6

6

12

35

12

12

12

40

2

2

3

2

4

3

4

4

6

6

6

6

12

6

12

12

NR

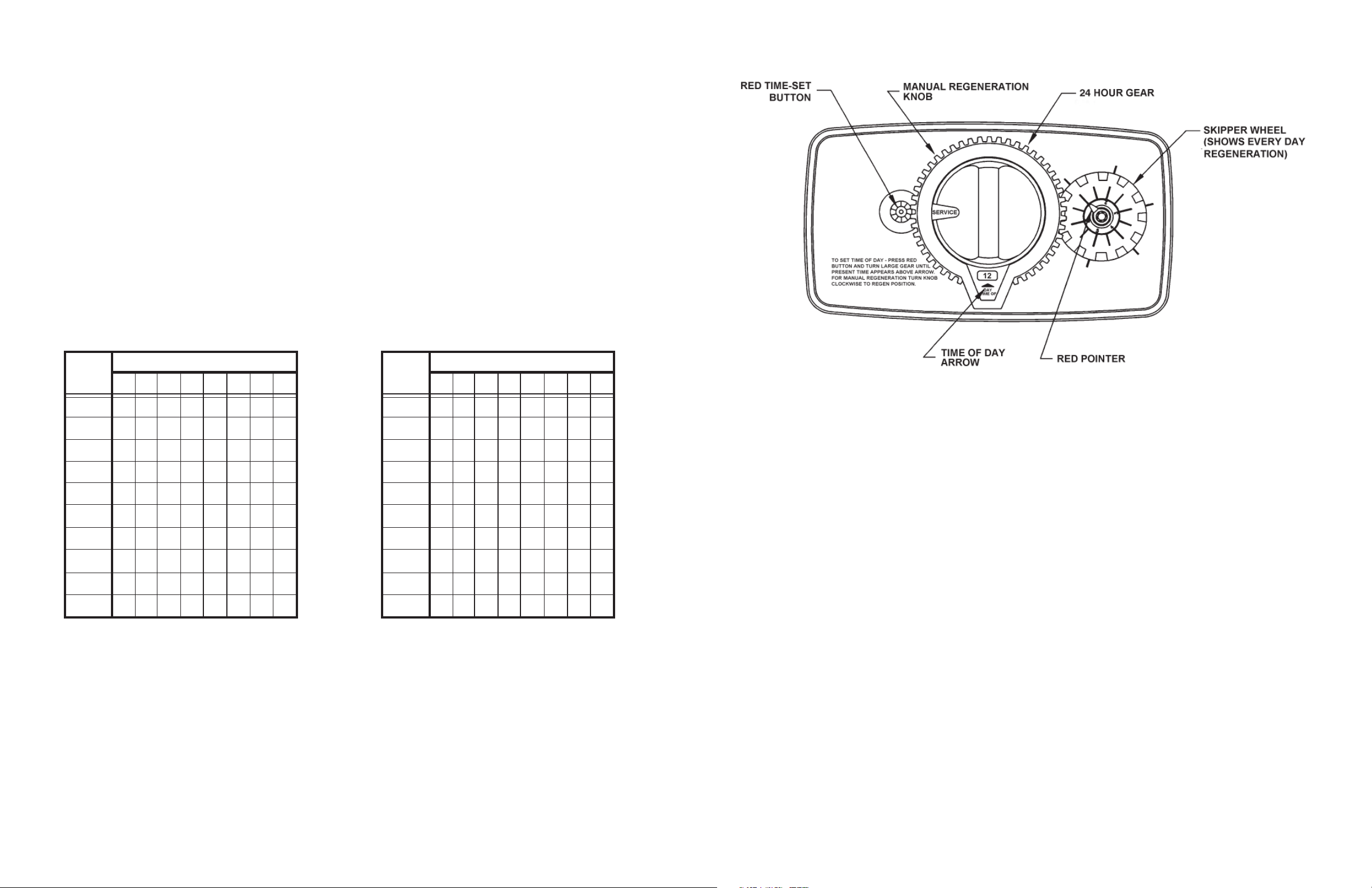

Rotate the skipper wheel until the number "1" is at the red pointer. Set the days that regeneration is to occur by sliding tabs on the skipper wheel outward to expose trip fi ngers. Each tab is one day. Finger at red pointer is tonight. Moving clockwise from the red pointer,

extend or retract fi ngers to obtain the desired regeneration schedule.

1) Press and hold the red button in to disengage the drive gear.

2) Turn the large gear until the actual time of day is opposite the time of day pointer.

3) Release the red button to again engage the drive gear.

4) Time of regeneration is preset for 2:00 a.m.

Turn the manual regeneration knob clockwise.

A slight, clockwise movement of the manual regeneration knob engages the program wheel and starts the regeneration program.

The black center knob will make one revolution in the following approximately three hours and stop in the position shown in the drawing

(SERVICE POSITION).

Even though it takes three hours for this center knob

one-third of this time.

In any event, conditioned water may be drawn after rinse water stops fl owing from the water softener drain line.

HOW TO SET DAYS ON WHICH WATER SOFTENER IS TO REGENERATE:

HOW TO SET THE TIME OF DAY:

HOW TO MANUALLY REGENERATE THE WATER SOFTENER AT ANY TIME.

to complete one revolution, the regeneration cycle of the unit might be set only

3-1

3-2

Loading...

Loading...