Page 1

Instructions for the following series products:

SYNTHETIC ROPE HORIZONTAL LIFELINE

See the last pages for specic model numbers

User Instruction Manual Synthetic Rope

Horizontal Lifeline System

This manual is intended to be used as part of an employee training program as

required by OSHA.

Form: 5902179 Rev: F

© 3M 2018

Page 2

SAFETY INFORMATION

ENENENEN

Please read, understand, and follow all safety information contained in these

instructions, prior to the use of this product. FAILURE TO DO SO COULD RESULT IN

SERIOUS INJURY OR DEATH.

These instructions must be provided to the user of the equipment. Retain these

instructions for future reference.

Intended Use:

This product is used as part of a complete Fall Protection system.

Use in any other application including, but not limited to, material handling, recreational

or sports-related activities, or other activities not described in these instructions, is not

approved by 3M and could result in serious injury or death.

This product is only to be used by trained users in workplace applications.

! WARNING

This product is used as part of a complete Fall Protection system. All users must be fully

trained in the safe installation and operation of their complete Fall Protection system.

Misuse of this product could result in serious injury or death. For proper selection,

operation, installation, maintenance, and service, refer to all instruction manuals and

manufacturer recommendations. For more information, see your supervisor or contact 3M

Technical Services.

To reduce the risks associated with using a Horizontal System which, if not

avoided, could result in serious injury or death:

- Inspect the product before each use and after any fall event, in accordance with

the procedures specied in these instructions.

- If inspection reveals an unsafe or defective condition, remove the product from

service immediately and clearly tag it “DO NOT USE”. Destroy or repair the product

as required by these instructions.

- Any product that has been subject to fall arrest or impact force must be

immediately removed from service. Destroy or repair the product as required by

these instructions.

- Ensure that Fall Protection systems assembled from components made by dierent

manufacturers are compatible and meet all applicable Fall Protection regulations,

standards, or requirements. Always consult a Competent or Qualied Person before

using these systems.

- The product must only be installed as described in its instruction manuals.

Installations and use outside the scope of these instruction manuals must be

approved in writing by 3M.

- Before installing, ensure that the installation methods and the product will not

interfere with electric lines, gas lines, or other critical materials or systems.

- Ensure the product is congured and installed properly for safe operation as

described in these instructions.

- Do not exceed the number of allowable users specied in these instructions.

- Do not twist, tie, knot, or allow slack in the lifeline.

- Do not connect to the system while it is being transported or installed.

- Use caution when installing, using, or moving the product as moving parts may

create pinch points.

FORM NO: SIT 5908279

REV: B

2

Page 3

• To reduce the risks associated with working at height which, if not avoided,

could result in serious injury or death:

- Your health and physical condition must allow you to safely work at height and to

withstand all forces associated with a fall arrest event. Consult your doctor if you

have questions regarding your ability to use this equipment.

- Never exceed allowable capacity of your Fall Protection equipment.

- Never exceed the maximum free fall distance specied for your Fall Protection

equipment.

- Do not use any Fall Protection equipment that fails inspection, or if you have

concerns about the use or suitability of the equipment. Contact 3M Technical

Services with any questions.

- Some subsystem and component combinations may interfere with the operation of

this equipment. Only use compatible connections. Contact 3M Technical Services

before using this equipment in combination with components or subsystems other

than those described in these instructions.

- Use extra precautions when working around moving machinery, electrical hazards,

extreme temperatures, chemical hazards, explosive or toxic gases, sharp edges,

abrasive surfaces, or below overhead materials that could fall onto you or your Fall

Protection equipment.

- Ensure use of your product is rated for the hazards present in your work

environment.

- Ensure there is sucient fall clearance when working at height.

- Never modify or alter your Fall Protection equipment. Only 3M, or persons

authorized in writing by 3M, may make repairs to 3M equipment.

- Before using Fall Protection equipment, ensure a written rescue plan is in place to

provide prompt rescue if a fall incident occurs.

- If a fall incident occurs, immediately seek medical attention for the fallen worker.

- Only use a full body harness for Fall Arrest applications. Do not use a body belt.

- Minimize swing falls by working as directly below the anchorage point as possible.

- A secondary Fall Protection system must be used when training with this product.

Trainees must not be exposed to an unintended fall hazard.

- Always wear appropriate Personal Protective Equipment when installing, using, or

inspecting the product.

- Never work below a suspended load or worker.

- Always maintain 100% tie-o.

FORM NO: SIT 5908279

REV: B

3

Page 4

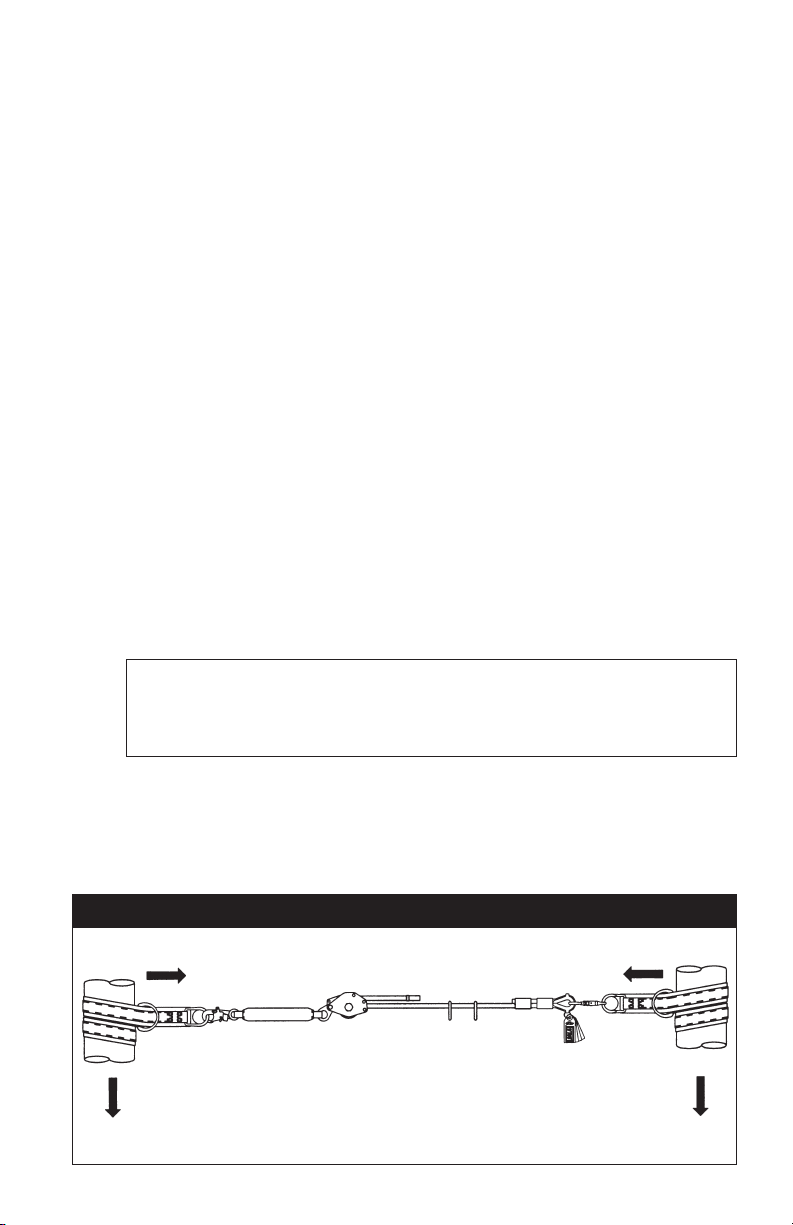

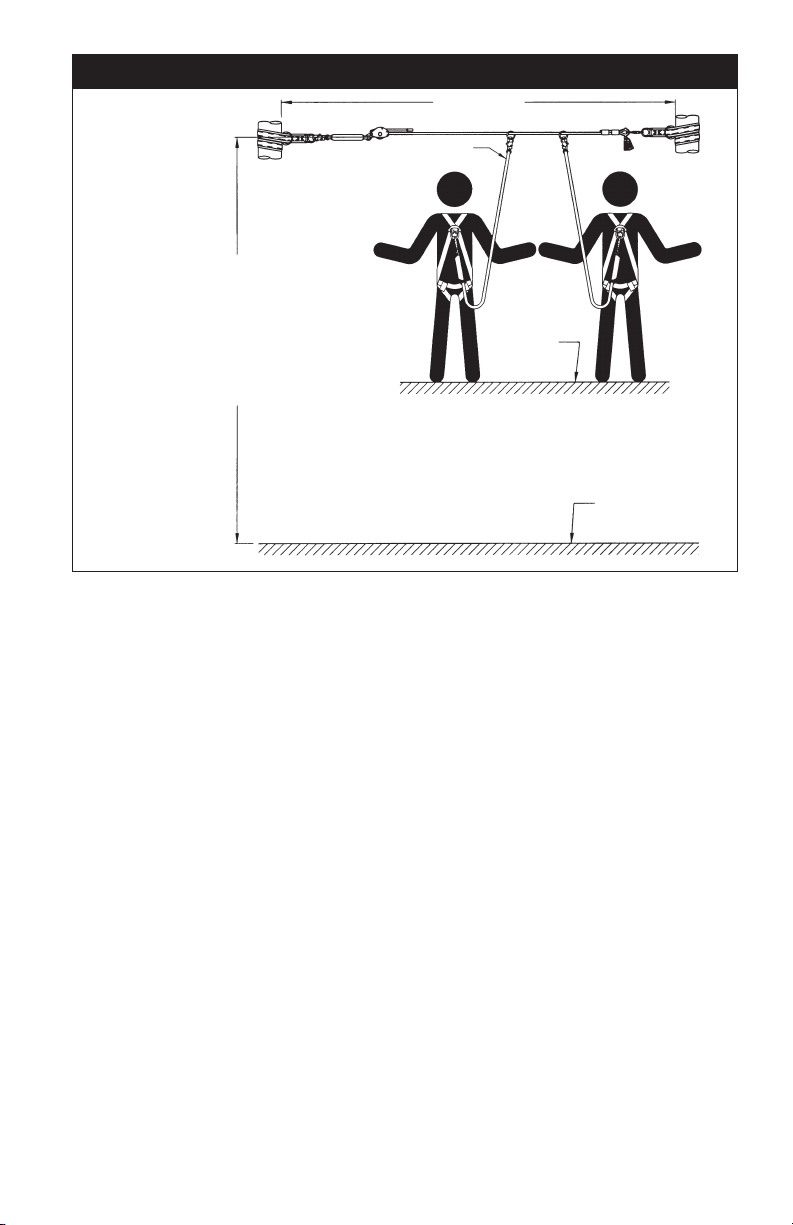

Figure 1 - Typical Installation

Snap Hook

Span length 100 ft (30.m) Max.

In-line Energy Absorber

Labels

Attachment O-ring for User

(Lanyard)

Typical Horizntal Lifeline Installation

Rope Tensioner

Tie-off Adapter

(Anchorage Connector)

Anchorage

4

Page 5

WARNING: This product is part of a personal fall arrest system. The

user must follow the manufacturer’s instructions for each component

of the system. These instructions must be provided to the user of this

equipment. The user must read and understand these instructions

before using this equipment. Manufacturer’s instructions must be

followed for proper use and maintenance of this equipment. Alterations

or misuse of this equipment, or failure to follow instructions, may

result in serious injury or death.

IMPORTANT: If you have questions on the use, care, or suitability of

this equipment for your application, contact 3M Fall Protection.

IMPORTANT: Record the product identication information from the

ID label in the inspection and maintenance log in section 9.0 of this manual.

1.0 APPLICATION

1.1 PURPOSE: The Sayine Synthetic Rope Horizontal Lifeline System

is designed for use as an anchoring means for one or two persons.

Use the Sayine Horizontal Lifeline System where horizontal

mobility and fall protection are required.

1.2 LIMITATIONS: The following limits apply to the installation and

use of the Sayine Synthetic Rope Horizontal Lifeline System.

Other limitations may apply:

IMPORTANT: The employer must ensure that each horizontal lifeline is

designed, installed, and used under the supervision of a qualied person;

and is part of a complete personal fall arrest system that maintains a

safety factor of at least two. Reference OSHA 1010.140 (c) (11). See

also OSHA 1926.502 (d)(8).

QUALIFIED PERSON: Qualied describes a person who, by possession

of a recognized degree, certicate, or professional standing, or who

by extensive knowledge, training, and experience has successfully

demonstrated the ability to solve or resolve problems relating to the

subject matter, the work, or the project. Reference OSHA 1910.140 (b).

See also OSHA 1926.32 (m).

A. HORIZONTAL LIFELINE SPAN: The maximum span distance

is 100 feet. The span length must be reduced when clearance

is limited. See section 3.2 for clearance information.

B. ANCHORAGES: The Sayfline horizontal lifeline must be

installed on anchorages that meet the requirements specified

in section 2.4.

C. SYSTEM CAPACITY: The maximum capacity of the Sayfline

horizontal lifeline is two persons. The maximum weight of each

person, including tools and clothing, is 310 lbs. (141kg).

D. CONNECTING SUBSYSTEM: Each person’s connecting

subsystem must limit fall arrest forces to 900 lbs. (4kN) or

less. See section 2.5.

5

Page 6

E. FREE FALL: Rig and use the personal fall arrest system

such that the maximum potential free fall does not exceed

Government regulatory and subsystem manufacturer’s

requirements. See section 3.0 and subsystem manufacturer’s

Instructions for more information.

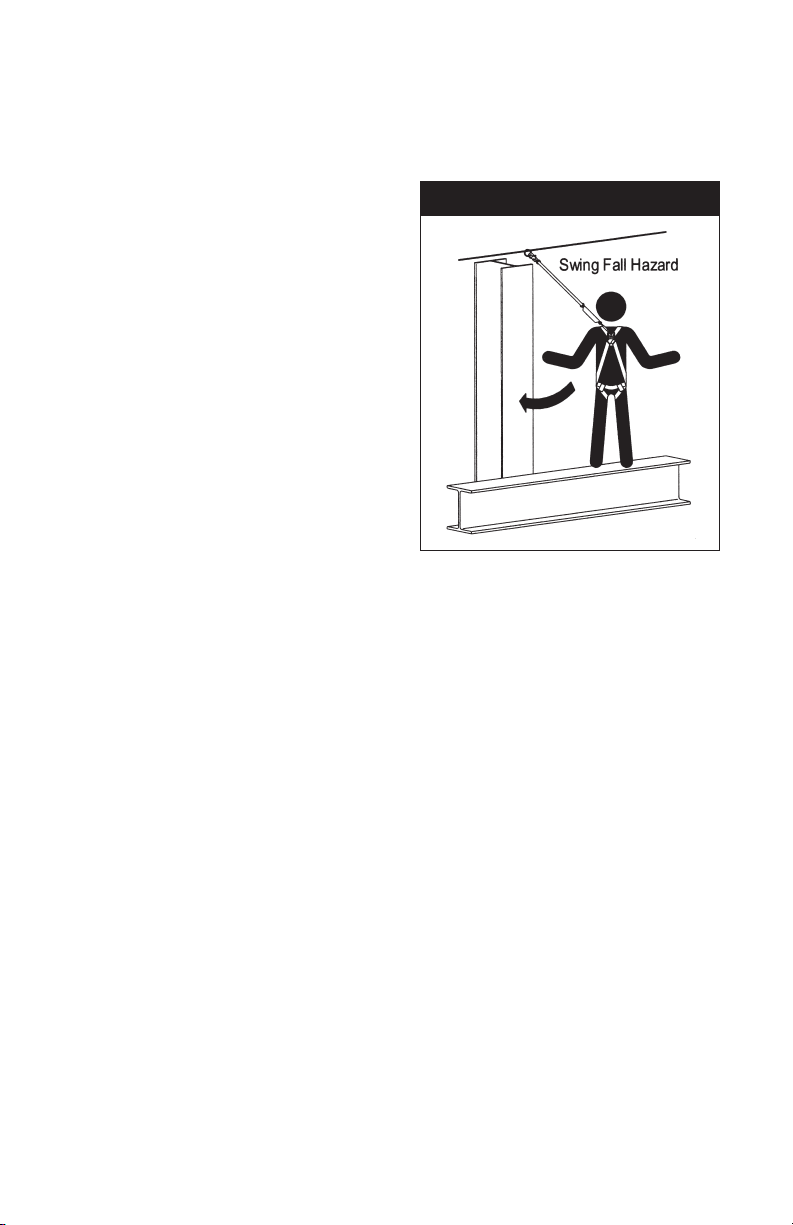

F. SWING FALLS: See Figure

2. Swing falls occur when

the anchorage point is not

directly overhead. The force

of striking an object in a

swing fall may cause serious

injury or death. Minimize

swing falls by working as

directly below the anchorage

point as possible. Do not

permit a swing fall if injury

could occur. Swing falls will

significantly increase the

clearance required when a

self retracting lifeline or other

variable length connecting

subsystem is used. If a swing

fall situation exists in your

application, contact 3M Fall

Protection before proceeding.

G. FALL CLEARANCE: There must be sufficient clearance below

the worker to arrest a fall before striking the lower level or

obstruction. See section 3.2 for required clearance information.

H. BODY SUPPORT: A full body harness must be used with the

Synthetic Rope Horizontal Lifeline System.

Figure 2 - Swing Fall

I. ENVIRONMENTAL HAZARDS: Use of this equipment in areas

with environmental hazards may require additional precautions

to reduce the possibility of injury to the user or damage to the

equipment. Hazards may include, but are not limited to; heat,

chemicals, corrosive environments, high voltage power lines,

gases, moving machinery, and sharp edges. Contact 3M Fall

Protection if you have questions about using this equipment

where environmental hazards exist.

J. TRAINING: This equipment must be installed and used by

persons trained in its correct application and use. See section 4.0.

1.3 APPLICABLE STANDARDS: Refer to national standards, including

ANSI Z359.1, local, state, and federal (OSHA 1910.66 and

1926.502) requirements for more information on personal fall

arrest systems and associated components. In Canada, see the

Z259 group of CSA standards.

6

Page 7

2.0 SYSTEM REQUIREMENTS

2.1 PERSONAL FALL ARREST SYSTEM COMPONENTS: The Sayine

horizontal lifeline must be used with 3M Fall Protection approved

components and subsystems. Non-approved components may

be incompatible, and could affect the safety and reliability of the

complete system. Personal fall arrest components used with this

system must meet all applicable OSHA and ANSI requirements. A

full body harness must be used with this system.

2.2 PERSONAL FALL ARREST SYSTEM CONNECTORS: Connectors

used to attach to the attachment O-ring on the horizontal lifeline

(hooks, carabiners, D-rings) must support at least

kN).

Connectors and attachment elements must be compatible

in size, shape, and strength. Non-compatible connectors may

unintentionally disengage (roll-out). Do not use non-locking

connectors with this system.

2.3 ANCHORAGE CONNECTORS: Connectors used to attach the

horizontal lifeline to end anchors must be compatible with the

connection point. The connection must be positive; and, with

connecting elements, capable of sustaining a

load without failure.

2.4 STRUCTURE LOAD: Structural anchorage points must be rigid,

and capable of supporting at least 5000 lbf (22.2 kN) along the axis

of the horizontal lifeline. Anchorages must also support at least 3600

lbf (16 kN) applied in all potential directions of fall arrest that are

perpendicular to the axis of the horizontal lifeline. See Figure 3.

WARNING: Anchorages must be rigid. Large deformations of

the anchorage will affect system performance, and may increase

the required fall clearance below the system, which could result

in serious injury or death.

5000 lbf (22.2

5000 lbf (22.2 kN)

2.5 CONNECTING SUBSYSTEM: The connecting subsystem is the

portion of the personal fall arrest system that is used to connect

between the horizontal lifeline subsystem and harness fall arrest

attachment element. The connecting subsystem must limit forces

applied to the horizontal lifeline to 900 lbf (4kN) or less.

Figure 3 - Strength Requirements

Anchorage Strength Requirements

5000 lbf (22.2 kN) Minimum 5000 lbf (22.2 kN) Minimum

3600 lbf (16 kN) Minimum in all potential directions of fall

arrest that are perendicular to the axis of the lifeline

7

Page 8

3.0 OPERATION AND USE

WARNING: Do not alter or intentionally misuse this equipment. Consult

3M Fall Protection when using this equipment in combination with

components or subsystems other than those described in this manual.

Some subsystem and component combinations may interfere with the

operation of this equipment. Use caution when using this equipment

around moving machinery, electrical hazards, chemical hazards, and

sharp edges.

WARNING: Consult your doctor if there is reason to doubt your

tness to absorb the impact from a fall arrest. Age and tness can

affect your ability to withstand fall arrest forces. Pregnant women and

minors must not use this system.

3.1 BEFORE EACH USE inspect this equipment according to section

5.0. Do not use this equipment if inspection reveals an unsafe or

defective condition. Plan your use of the fall protection system

prior to exposing workers to dangerous situations. Consider all

factors affecting your safety before using this system.

A. Read and understand all manufacturer’s instructions for each

component of the personal fall arrest system. All 3M Fall

Protection harnesses and connecting subsystems are supplied

with separate user instructions. Keep all instructions for future

reference.

B.

Review sections 1.0 and 2.0 to ensure system limitations and

other requirements have been adhered to. Review applicable

information regarding system clearance criteria, and ensure

changes have not been made to the system installation (i.e.

length) or occurred at the job site that could affect the required

fall clearance. Do not use the system if changes are required.

3.2 SYSTEM INSTALLATION: Figure 1 shows a typical Sayine

horizontal lifeline installation. When using an energy absorbing

lanyard to connect to the system, the end anchorages must be

located at a height which will limit the free fall to 6 feet (1.8m).

When using a self retracting lifeline (SRL) to connect to the

system, the end anchorages must be located above the user. The

SRL, when fully retracted, must be above the harness attachment

level. The horizontal lifeline system should be positioned at a

level that will minimize free fall while allowing ease of use. The

horizontal lifeline should be positioned near the work location to

minimize swing fall hazards. The connecting subsystem length

should be kept as short as possible to reduce the potential free

fall and required clearance distance. Both anchorages must

be installed at approximately the same elevation, so that the

horizontal lifeline system is not sloped more than 5°.

Step 1. Determine the locations of the end anchorages and

evaluate their strengths in accordance with section 2.4.

Determine the span length and evaluate the required

clearance using Figures 4, 5, or 6 and Tables 1, 2 or 3.

8

Page 9

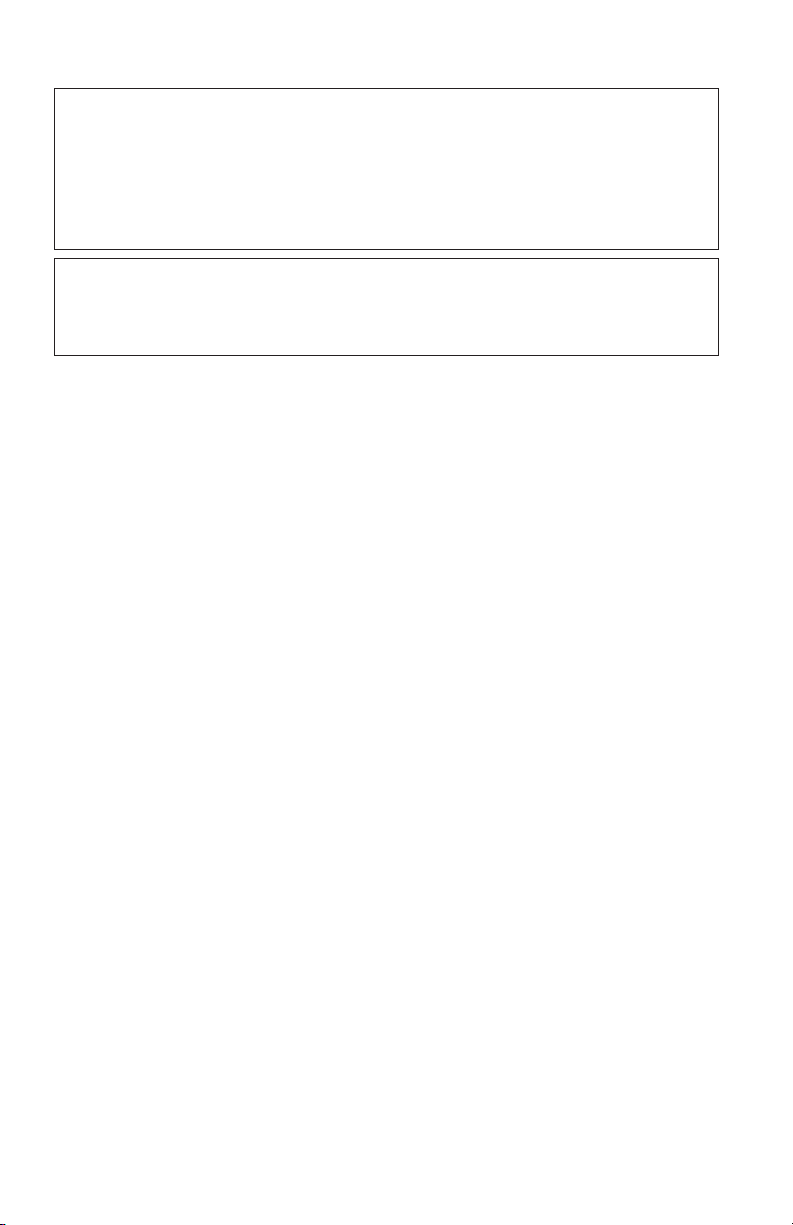

Figure 4 - Clearance: Single Worker with Energy Absorbing Lanyard

Span Length

Energy

Absorbing

Clearance Evaluation for One Worker

Connected to the HLL with a 3M Fall

Protection Energy Absorbing Lanyard

Required clearance from nearest lower level or

obstruction to HLL system height

1) Find your system span length in the rows of

Table 1.

2) Find your lanyard length in the columns of

Table 1.

3) The requied clearance is where the span

length row and lanyard length column intersect.

Lanyard

Lower Level or

Obstruction

Working Level

9

Page 10

Table 1 - Required Clearance for One Worker Connected to the System

with a 3M Fall Protection Energy Absorbing Lanyard (See Figure 4)

Span length

in feet

0-10

(0-3.05)

10-15

(3.05-4.57)

15-20

(4.57-6.10)

20-25

(6.10-7.62)

25-30

(7.62-9.14)

30-35

(9.14-10.67)

35-40

(10.67-12.19)

40-45

(12.19-13.72)

45-50

(13.72-15.24)

50-55

(15.2-16.76)

55-60

(16.76-18.29)

60-65

(18.29-19.81)

65-70

(19.81-21.34)

70-75

(21.34-22.86)

75-80

(22.86-24.38)

80-85

(24.38-25.91)

85-90

(25.91-27.43)

90-95

(27.43-28.96)

95-100

(28.96-30.48)

3

(.91)4 (1.22)5 (1.52)6 (1.83)7 (2.13)8 (2.44)9 (2.74)

16’-1”

(4.90)

16’-3”

(4.95)

16’-5”

(5.00)

16’-7”

(5.06)

16’-9”

(5.11)

17’-6”

(5.33)

18’-3”

(5.56)

18’-11”

(5.77)

19’-6”

(5.94)

20’-2”

(6.15)

20’-10”

(6.35)

21’-5”

(6.53)

22’-1”

(6.73)

22’-8”

(6.91)

23’-4”

(7.11)

24’-0”

(7.32)

24’-7”

(7.49)

25’-3”

(7.70)

25’-10”

(7.87)

Length of Energy Absorbing Lanyard in feet

17’-1”

(5.20)

17’-3”

(5.26)

17’-5”

(5.31)

17’-7”

(5.36)

17’-9”

(5.41)

18’-6”

(5.64)

19’-3”

(5.87)

19’-11”

(6.07)

20’-6”

(6.25)

21’-2”

(6.45)

21’-10”

(6.66)

22’-5”

(6.83)

23’-1”

(7.04)

23’-8”

(7.21)

24’-4”

(7.42)

25’-0”

(7.62)

25’-7”

(7.80)

26’-3”

(8.00)

26’-10”

(8.18)

18’-1”

(5.51)

18’-3”

(5.56)

18’-5”

(5.61)

18’-7”

(5.66)

18’-9”

(5.72)

19’-6”

(5.94)

20’-3”

(6.17)

20’-11”

(6.38)

21’-6”

(6.55)

22’-2”

(6.76)

22’-10”

(6.96)

23’-5”

(7.14)

24’-1”

(7.34)

24’-8”

(7.52)

25’-4”

(7.72)

26’-0”

(7.93)

26’-7”

(8.10)

27’-3”

(8.31)

27’-10”

(8.48)

19’-1”

(5.82)

19’-3”

(5.87)

19’-5”

(5.92)

19’-7”

(5.97)

19’-9”

(5.97)

20’-6”

(6.25)

21’-3”

(6.48)

21’-11”

(6.68)

22’-6”

(6.86)

23’-2”

(7.06)

23’-10”

(7.26)

24’-5”

(7.44)

25’-1”

(7.65)

25’-8”

(7.82)

26’-4”

(8.03)

27’-0”

(8.23)

27’-7”

(8.41)

28’-3”

(8.61)

28’-10”

(8.79)

20’-1”

(6.12)

20’-3”

(6.12)

20’-5”

(6.27)

20’-7”

(6.27)

20’-9”

(6.33)

21’-6”

(6.55)

22’-3”

(6.78)

22’-11”

(6.99)

23’-6”

(7.16)

24’-2”

(7.37)

24’-10”

(7.57)

25’-5”

(7.75)

26’-1”

(7.95)

26’-8”

(8.13)

27’-4”

(8.33)

28’-0”

(8.53)

28’-7”

(8.71)

29’-3”

(8.92)

29’-10”

(9.09)

Meters are shown in parenthesis

21’-1”

(6.43)

21’-3”

(6.48)

21’-5”

(6.53)

21’-7”

(6.58)

21’-9”

(6.63)

22’-6”

(6.86)

23’-3”

(7.09)

23’-11”

(7.29)

24’-6”

(7.47)

25’-2”

(7.67)

25’-10”

(7.87)

26’-5”

(8.05)

27’-1”

(8.26)

27’-8”

(8.43)

28’-4”

(8.64)

29’-0”

(8.84)

29’-7”

(9.02)

30’-3”

(9.22)

30’-10”

(9.40)

22’-1”

(6.73)

22’-3”

(6.78)

22’-5”

(6.83)

22’-7”

(6.88)

22’-9”

(6.93)

23’-6”

(7.16)

24’-3”

(7.39)

24’-11”

(7.60)

25’-6”

(7.77)

26’-2”

(7.98)

26’-10”

(8.18)

27’-5”

(8.36)

28’-1”

(8.56)

28’-8”

(8.74)

29’-4”

(8.94)

30’-0”

(9.14)

30’-7”

(9.32)

31’-3”

(9.53)

31’-10”

(9.70)

10

(3.1)

23’-1”

(7.04)

23’-3”

(7.09)

23’-5”

(7.14)

23’-7”

(7.19)

23’-9”

(7.24)

24’-6”

(7.47)

25’-3”

(7.70)

25’-11”

(7.90)

26’-6”

(8.08)

27’-2”

(8.28)

27’-10”

(8.48)

28’-5”

(8.66)

29’-1”

(8.87)

29’-8”

(9.04)

30’-4”

(9.25)

31’-0”

(9.45)

31’-7”

(9.63)

32’-3”

(9.83)

32’-10”

(10.01)

10

Page 11

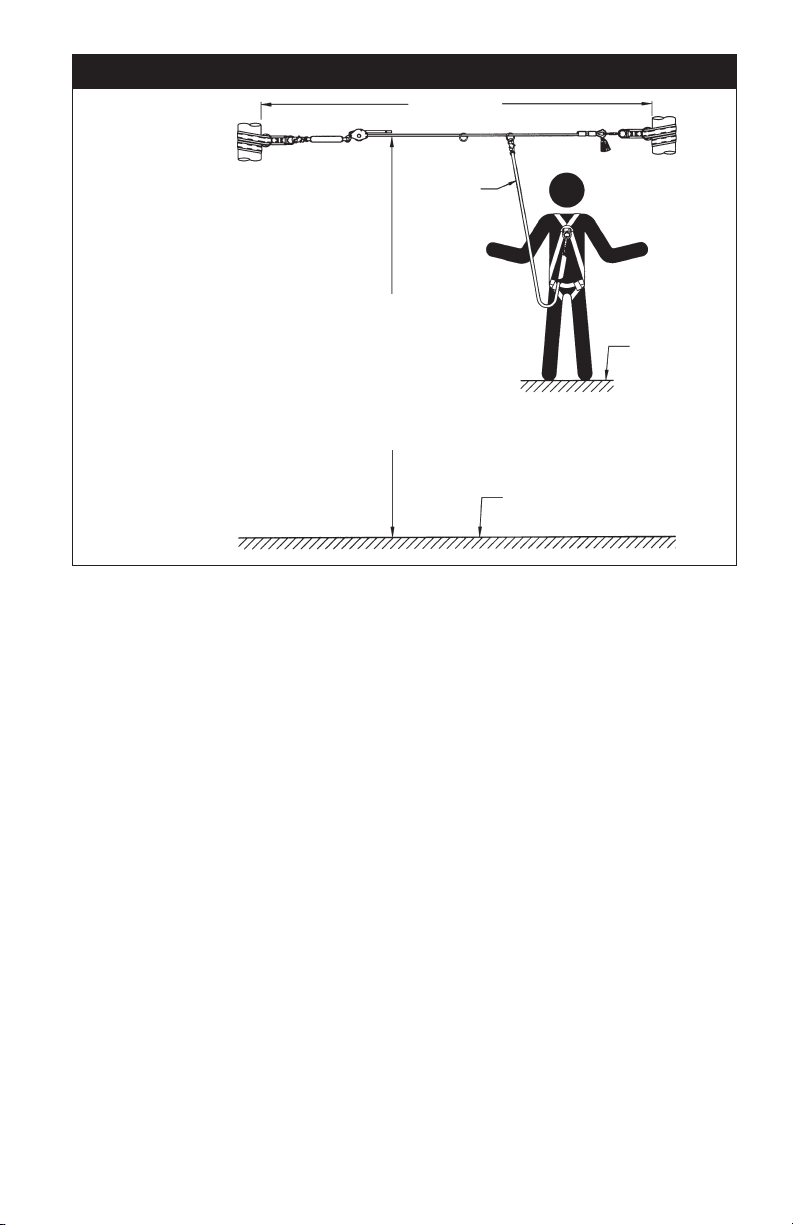

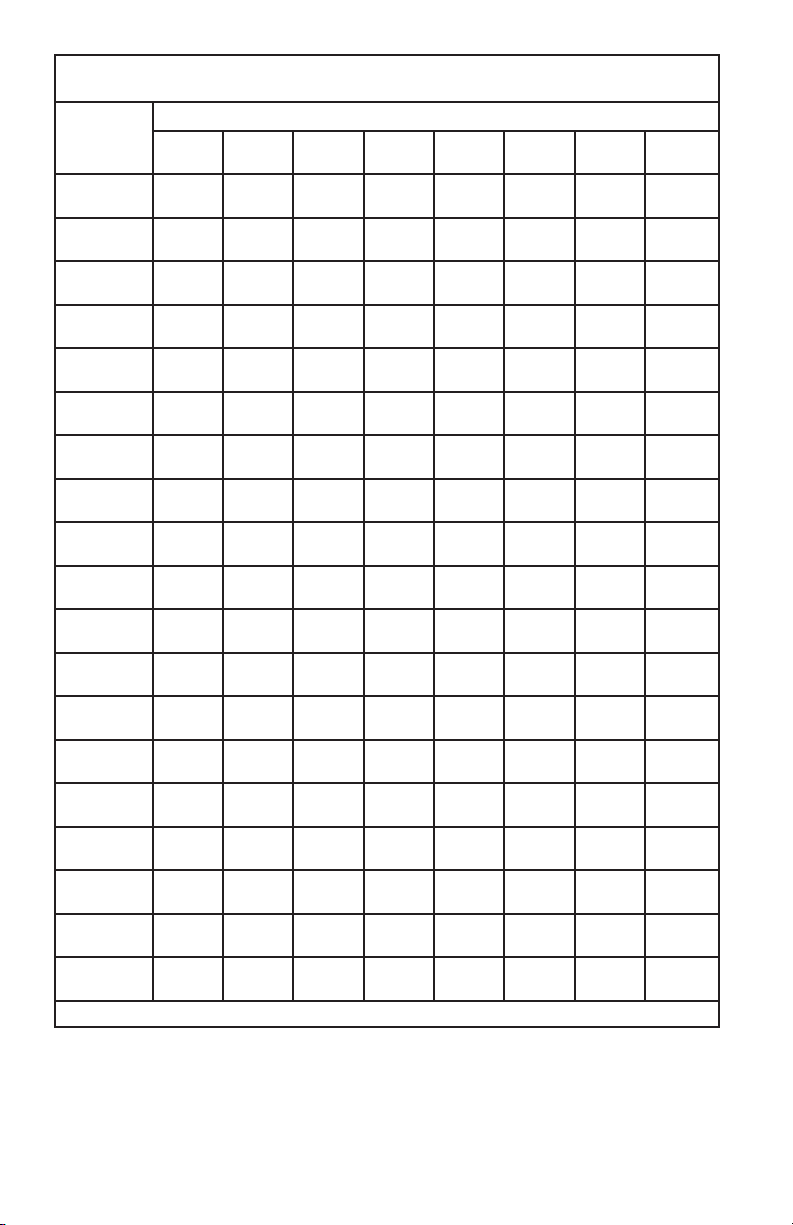

Figure 5 - Clearance: Two Workers with Energy Absorbing Lanyards

Span Length

Energy Absorbing

Lanyard

Required clearance from nearest lower level or

obstruction to HLL system height

1) Find your system span length in the rows of

Table 2.

2) Find your lanyard length in the columns of

Table 2.

3) The requied clearance is where the span

length row and lanyard length column intersect.

Clearance Evaluation for One or Two

Workers Connected to the HLL with a

3M Fall Protection Energy Absorbing

Lanyard

Working

Level

Lower Level or

Obstruction

11

Page 12

Table 2 - Required Clearance for Two Workers Connected to the System

with a 3M Fall Protection Energy Absorbing Lanyard (See Figure 5)

Span

length

in

feet

0-10

(0-3.05)

10-15

(3.05-4.57)

15-20

(4.57-6.10)

20-25

(6.10-7.62)

25-30

(7.62-9.14)

30-35

(9.14-10.67)

35-40

(10.67-12.19)

40-45

(12.19-13.72)

45-50

(13.72-15.24)

50-55

(15.2-16.76)

55-60

(16.76-18.29)

60-65

(18.29-19.81)

65-70

(19.81-21.34)

70-75

(21.34-22.86)

75-80

(22.86-24.38)

80-85

(24.38-25.91)

85-90

(25.91-27.43)

90-95

(27.43-28.96)

95-100

(28.96-30.48)

3

(.91)4 (1.22)5 (1.52)6 (1.83)7 (2.13)8 (2.44)9 (2.74)

16’-5”

(5.00)

17’-5”

(5.31)

18’-5”

(5.61)

19’-4”

(5.89)

20’-4”

(6.20)

21’-7”

(6.58)

22’-9”

(6.93)

23’-10”

(7.26)

24’-11”

(7.60)

26’-0”

(7.93)

27’-2”

(8.28)

28’-3”

(8.61)

29’-4”

(8.94)

30’-5”

(9.27)

31’-6”

(9.60)

32’-7”

(9.93)

33’-8”

(10.26)

34’-9”

(10.59)

35’-10”

(10.92)

Length of Enerrgy Absorbing Lanyard in feet

17’-5”

(5.31)

18’-5”

(5.61)

19’-5”

(5.92)

20’-4”

(6.20)

21’-4”

(6.50)

22’-7”

(6.88)

23’-9”

(7.24)

24’-10”

(7.57)

25’-11”

(7.90)

27’-0”

(8.23)

28’-2”

(8.59

29’-3”

(8.92)

30’-4”

(9.25)

31’-5”

(9.58)

32’-6”

(9.91)

33’-7”

(10.24)

34’-8”

(10.57)

35’-9”

(10.90)

36’-10”

(11.23)

18’-5”

(5.61)

19’-5”

(5.92)

20’-5”

(6.27)

21’-4”

(6.50)

22’-4”

(6.81)

23’-7”

(7.19)

24’-9”

(7.54)

25’-10”

(7.87)

26’-11”

(8.20)

28’-0”

(8.53)

29’-2”

(8.89

30’-3”

(9.22)

31’-4”

(9.55)

32’-5”

(9.88)

33’-6”

(10.21)

34’-7”

(10.54)

35’-8”

(10.87)

36’-9”

(11.20)

37’-10”

(11.54)

19’-5”

(5.92)

20’-5”

(6.27)

21’-5”

(6.53)

22’-4”

(6.81)

23’-4”

(7.11)

24’-7”

(7.49)

25’-9”

(7.85)

26’-10”

(8.18)

27’-11”

(8.51)

29’-0”

(8.84)

30’-2”

(9.20

31’-3”

(9.53)

32’-4”

(9.86)

33’-5”

(10.19)

34’-6”

(10.52)

35’-7”

(10.85)

36’-8”

(11.18)

37’-9”

(11.51)

38’-10”

(11.84)

20’-5”

(6.27)

21’-5”

(6.53)

22’-5”

(6.83)

23’-4”

(7.11)

24’-4”

(7.42)

25’-7”

(7.80)

26’-9”

(8.15)

27’-10”

(8.48)

28’-11”

(8.81)

30’-0”

(9.14)

31’-2”

(9.50

32’-3”

(9.83)

33’-4”

(10.16)

34’-5”

(10.49)

35’-6”

(10.82)

36’-7”

(11.15)

37’-8”

(11.48)

38’-9”

(11.81)

39’-10”

(12.14)

Meters are shown in parenthesis

21’-5”

(6.53)

22’-5”

(6.83)

23’-5”

(7.14)

24’-4”

(7.42)

25’-4”

(7.72)

26’-7”

(8.10)

27’-9”

(8.46)

28’-10”

(8.79)

29’-11”

(9.12)

31’-0”

(9.45)

32’-2”

(9.80

33’-3”

(10.14

34’-4”

(10.47)

35’-5”

(10.80)

36’-6”

(11.13)

37’-7”

(11.46)

38’-8”

(11.79)

39’-9”

(12.12)

40’-10”

(12.45)

22’-5”

(6.83)

23’-5”

(7.14)

24’-5”

(7.44)

25’-4”

(7.72)

26’-4”

(8.03)

27’-7”

(8.41)

28’-9”

(8.76)

29’-10”

(9.09)

30’-11”

(9.42)

32’-0”

(9.75)

33’-2”

(10.11

34’-3”

(10.44

35’-4”

(10.77)

36’-5”

(11.10)

37’-6”

(11.43)

38’-7”

(11.76)

39’-8”

(12.09)

40’-9”

(12.42)

41’-10”

(12.75)

10 (3.1)

23’-5”

(7.14)

24’-5”

(7.44)

25’-5”

(7.75)

26’-4”

(8.03)

27’-4”

(8.33)

28’-7”

(8.71)

29’-9”

(9.07)

30’-10”

(9.40)

31’-11”

(9.73)

33’-0”

(10.06)

34’-2”

(10.41

35’-3”

(10.74

36’-4”

(11.07)

37’-5”

(11.41)

38’-6”

(11.74)

39’-7”

(12.07)

40’-8”

(12.40)

41’-9”

(12.73)

42’-10”

(13.06)

12

Page 13

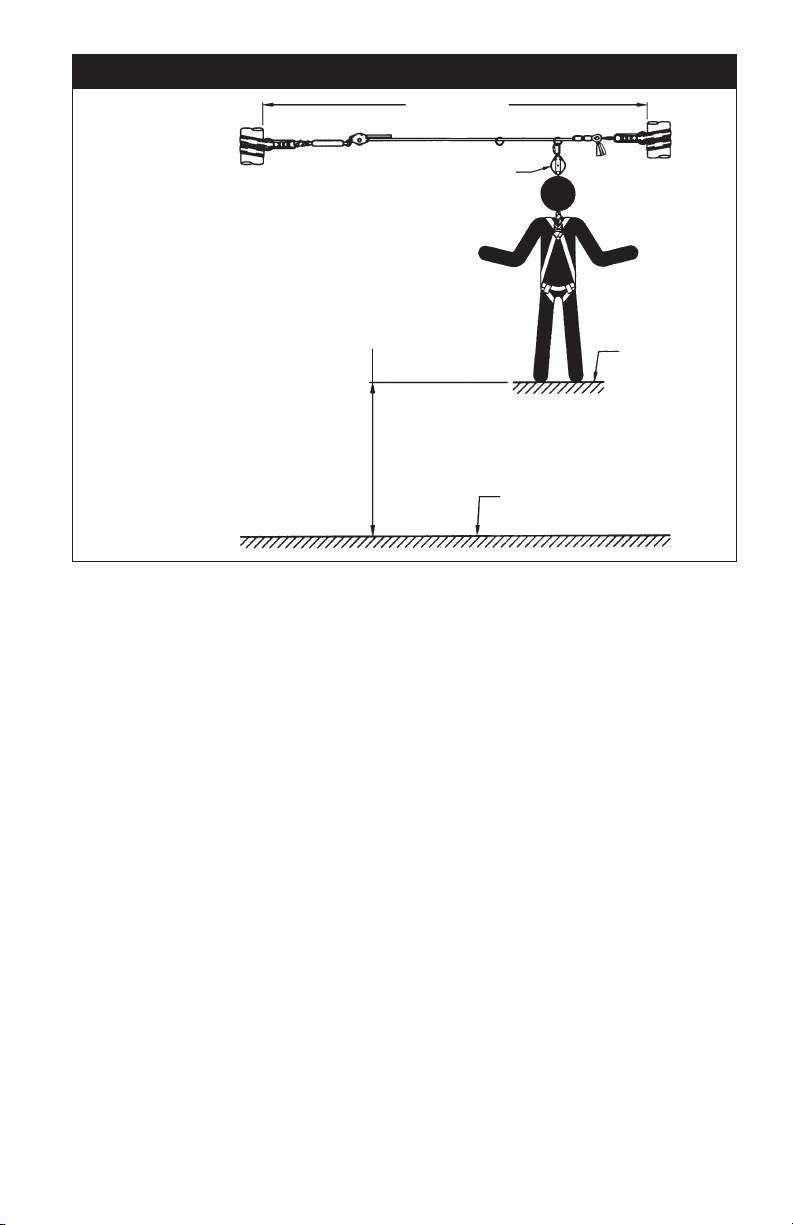

Figure 6 - Clearance: One or Two Workers with SRLs

Span Length

Self Retracting

Lifeline

Required clearance from nearest lower level or

obstruction to working level

1) Find your system span length in the rows of

Table 3.

2) Find the number of workers to be connected to

the system in the columns of Table 3.

3) The requied clearance is where the span length

row and number of workers column intersect.

Clearance Evaluation for One or

Two Workers Connected to the

HLL with a 3M Fall Protection Self

Retracting Lifeline

WARNING: This information only applies

when the SRL is directly overhead and above

the level of the harness attachment point and

the user is standing.

Lower Level or

Obstruction

Working Level

13

Page 14

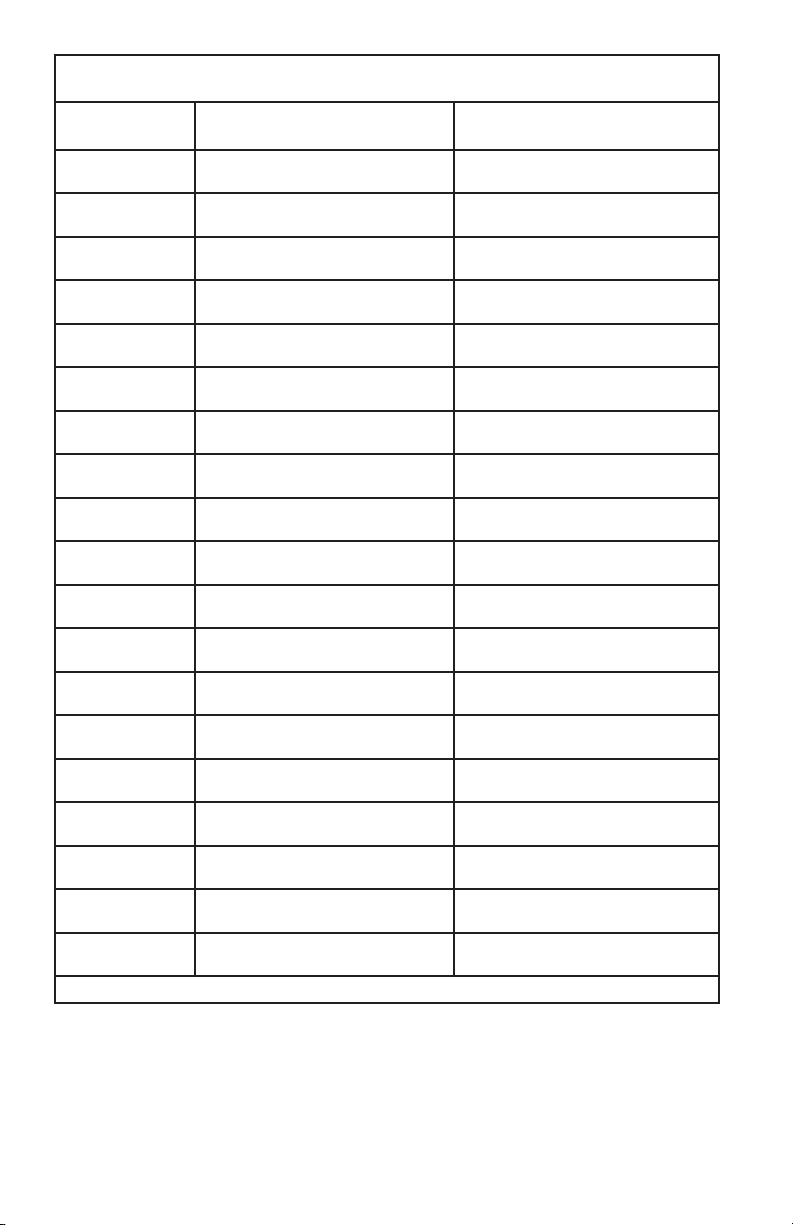

Table 3 - Required Clearance for One or Two Workers Connected to the

System with a 3M Fall Protection Self Retracting Lifeline (See Figure 6).

Span Lenght

in feet

0-10

(0-3.05)

10-15

(3.05-4.57)

15-20

(4.57-6.10)

20-25

(6.10-7.62)

25-30

(7.62-9.14)

30-35

(9.14-10.67)

35-40

(10.67-12.19)

40-45

(12.19-13.72)

45-50

(13.72-15.24)

50-55

(15.2-16.76)

55-60

(16.76-18.29)

60-65

(18.29-19.81)

65-70

(19.81-21.34)

70-75

(21.34-22.86)

75-80

(22.86-24.38)

80-85

(24.38-25.91)

85-90

(25.91-27.43)

90-95

(27.43-28.96)

95-100

(28.96-30.48)

Required Clearance Below

Working Level for One Worker

7’-11”

(2.41)

8’-2”

(2.49)

8’-5”

(2.57)

8’-8”

(2.64)

8’-10”

(2.69)

9’-1”

(2.77)

9’-4”

(2.84)

10’-3”

(3.12)

11’-3”

(3.43)

12’-2”

(3.71)

13’-2”

(4.01)

14’-2”

(4.32)

15’-1”

(4.60)

16’-1”

(4.90)

17’-0”

(5.18)

18’-0”

(5.49)

19’-0”

(5.79)

19’-11”

(6.07)

20’-11”

(6.38)

Meters are shown in parenthesis

Required Clearance Below

Working Level for Two Workers

8’-11”

(2.72)

9’-7”

(2.92)

10’-3”

(3.12)

10’-10”

(3.30)

11’-6”

(3.51)

12’-2”

(3.71)

12’-9”

(3.89)

14’-2”

(4.32)

15’-6”

(4.72)

16’-11”

(5.16)

18’-3”

(5.56)

19’-8”

(5.99)

21’-0”

(6.40)

22’-5”

(6.83)

23’-9”

(7.24)

25’-2”

(7.76)

26’-6”

(8.08)

27’-11”

(8.51)

29’-3”

(8.92)

14

Page 15

Step 2. Install the

anchorage

connectors.

Some

Figure 7 - Tie-off Adapter

Installing Tie-Off Adaptor to Vertical

or Sloped Anchorage Structure.

Sayine

horizontal

lifeline

systems

include

Vertical or Sloped

Anchorage Structure

Tie-Off Adaptor

two tie-off

adaptor

anchorage

Wrap Tie-Off Adaptor twice

around Anchorage Structure

connectors.

To ensure

the tie-off adaptor does not slide down a vertical or

sloped anchorage, the tie-off adaptor must be wrapped

twice around the structure as shown in Figure 7.

Refer to the tie-off adaptor instructions for complete

installation information. The horizontal lifeline may be

secured directly to the anchorage when the anchorage

incorporates a compatible attachment

element that

meets the requirements specied in section 2.3.

WARNING: For applications where the HLL cannot be located

overhead, contact 3M Fall Protection for application-specic clearance.

For use in accordance with CSA Z259 technical standards, the HLL may

not be installed at a height lower than 1 ft. below the user’s D-ring.

Step 3. Secure each end of the horizontal lifeline to the

anchorage connectors with the snap hook or carabiner.

Loosen and reposition the rope tensioner as required.

Step 4. Remove the slack from the horizontal lifeline by pulling

the rope through the tensioner by hand. To tension the

horizontal lifeline, use a pointed bar or a 1 1/4 in (32

mm) wrench and turn the tensioning nut clockwise until

the tensioner slips. Do not modify the rope tensioner to

achieve greater lifeline tension. See Figure 8. The nal

tension will be 300 to 450 lbs. (1.3 to 2.0 kN).

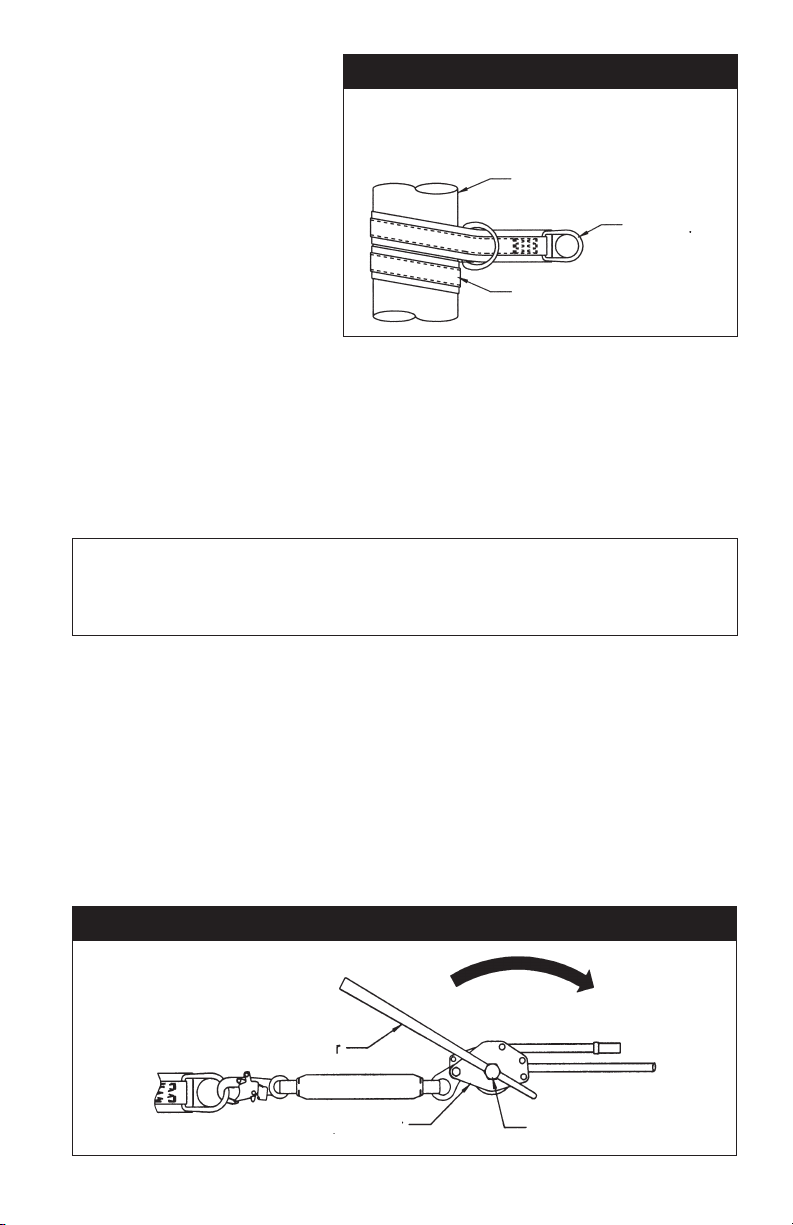

Figure 8 - Tensioning the Horizintal Lifeline

Tensioning the

Horizontal Lifeline

Pointed Bar

Rope Tensioner

Tensioning Nut

15

Page 16

3.3 OPERATION:

A. PERSONAL FALL ARREST SYSTEM COMPONENTS: Inspect

and don the full body harness according to manufacturer’s

instructions. Attach the connecting subsystem (energy

absorbing lanyard or SRL) to the dorsal connection on the

harness.

B. CONNECTING TO THE HORIZONTAL LIFELINE SYSTEM:

Approach the work area using the appropriate access

equipment. Connect your personal fall arrest system to one of

the attachment O-rings on the horizontal lifeline. Connectors

must meet all compatibility and strength requirements.

C. HAZARDOUS SITUATIONS: Do not take unnecessary risks,

such as jumping or reaching too far from the edge of the

working surface. Do not allow the connecting subsystem

to pass under arms or between feet. To avoid inadequate

clearance, do not climb above the horizontal lifeline. To avoid

swing fall hazards, do not work too far from either side of the

horizontal lifeline.

D. TWO (2) PERSONS CONNECTED TO THE HLL: When a

person falls while connected to the horizontal lifeline, the

system will deflect. If two (2) persons are connected to

the same horizontal lifeline, and one (1) person falls, the

second person may be pulled off the working surface due to

deflection. The potential for the second person falling increases

as the horizontal lifeline span length increases. The use of

independent horizontal lifeline systems for each person, or

shorter span length, is recommended to minimize the potential

of the second person falling.

E. FREE FALL: The personal fall arrest system must be rigged to

limit free falls to 6 feet (1.8m) or less when using an energy

absorbing lanyard, or such that the SRL is overhead without

slack, according to OSHA requirements.

F. SHARP EDGES: Avoid working where the connecting

subsystem or other system components will be in contact with,

or abrade against, unprotected sharp edges. If working around

sharp edges is unavoidable, a protective cover must be used to

prevent cutting of the personal fall arrest system components.

G. IN THE EVENT OF A FALL: The responsible party must have

a rescue plan and the ability to implement a rescue. Tolerable

suspension time in a full body harness is limited, so a prompt

rescue is critical.

H. RESCUE: With the number of potential scenarios for a

worker requiring rescue, an on-site rescue team is beneficial.

The rescue team is given the tools, both in equipment and

technique, to perform a successful rescue. Training should be

provided on a periodic basis to ensure rescuers’ proficiency.

16

Page 17

Figure 9 - Releasing Tension from the Horizontal Lifeline

Pointed Bar

Releasing Tension on

the Horizontal Lifeline

Locking Lever

Rope Tensioner

Tensioning Nut

3.4 SYSTEM REMOVAL: When no longer required, the horizontal

lifeline system should be removed from the job site.

A. RELEASE TENSION ON THE HORIZONTAL LIFELINE:

Step 1. Lift the locking lever and position the pointed bar under

the locking lever as shown in Figure 9.

Step 2. Push the pointed bar in a upward motion to unlock the

lever.

Step 3. Loosen the tensioning nut by inserting the pointed bar

through the hole in the nut, or use a 1 1/4 in (32 mm)

wrench, and turn the tensioning nut counterclockwise.

Step 4. Remove all knots and kinks in the rope before storage.

4.0 TRAINING

4.1 It is the responsibility of all users of this equipment to understand

these instructions, and to be trained in the correct installation,

use, and maintenance of this equipment. These individuals must

be aware of the consequences of improper installation or use

of this equipment. This user manual is not a substitute for a

comprehensive training program. Training must be provided on a

periodic basis to ensure prociency of the users.

5.0 INSPECTION

5.1 INSPECTION FREQUENCY: The Sayine Synthetic Rope

Horizontal Lifeline System shall be inspected by the user before

each use and, additionally, by a competent person1 other than the

user after installation and at intervals of no more than one year2.

Results of the Competent Person inspection should be recorded in

the “Inspection and Maintenance Log” at the back of this manual.

17

Page 18

5.2 INSPECTION STEPS:

Step 1. Inspect all metal components (hooks, O-rings, rope

tensioner, etc.) for cracks, deformities, corrosion,

or other damage that may affect their strength or

operation.

Step 2. Inspect rope for concentrated wear; especially those

portions of the rope that contact the Rope Tensioner.

Material must be free of frayed strands, broken yarns,

cuts, abrasions, burns, and discoloration. The rope

must be free of knots, excessive soiling, paint build-up,

and rust staining. Inspect ferrules for cracks or other

damage. Thimble must be held rmly by the ferrule.

Check for chemical or heat damage; indicated by brown,

discolored, or brittle areas. Check for ultraviolet damage;

indicated by discoloration, splinters, and slivers along

the rope surface. All of the above factors are known to

reduce rope strength.

ROPE CORE: Concentrated wear, cuts,

abrasion, or burns may expose the white inner

core of the rope. Any time the white inner core

of the rope is visible, excluding the cut ends

of the rope, the rope shall be removed from

service and no longer used. If the braided

black cover must be pulled, spread apart, or

separated by hand to expose the white core,

the rope is still acceptable for use. Frayed or

broken strands that give the rope a “fuzzy”

appearance are acceptable, provided the white

inner core is not visible.

Acceptable:

White inner core

is not exposed.

Unacceptable:

White inner core

is exposed.

Step 3. Inspect system labels. The labels must be present and

fully legible. See section 8.0.

IMPORTANT: If this equipment is subjected to the forces of a

fall arrest, it must be removed from service and destroyed, or

returned to 3M Fall Protection for inspection or repair.

5.3 If inspection reveals an unsafe or defective condition, remove unit

from service and destroy, or contact 3M Fall Protection for possible

repair.

IMPORTANT: Only 3M Fall Protection or parties authorized in

writing may make repairs to this equipment.

5.4 USER EQUIPMENT: Inspect harness and energy absorbing

lanyard or SRL according to manufacturer’s instructions.

5.5 RFID TAG: If your equipment has an

Figure 10 - RFID

Radio Frequency Identication (RFID) tag

(Figure 10), the RFID tag can be used with

a reading device to simplify inspection

and provide records for your equipment.

Contact 3M Fall Protection for more

information.

18

Page 19

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 CLEANING AND MAINTENANCE: Clean the horizontal lifeline

system with water and a mild detergent. Wipe dry with a clean,

dry cloth and hang to air dry. Do not force dry with heat. An

excessive build-up of dirt, paint, etc. may prevent the system

from working properly, and in severe cases, weaken the rope. A

lubricant may be applied to the moving parts of the rope tensioner.

Do not allow lubricant to contact the rope tensioner teeth.

6.2 STORAGE: Store this horizontal lifeline system in a clean, dry

environment, out of direct sunlight. Avoid areas where chemical

vapors are present. Thoroughly inspect the system after extended

storage.

6.3 USER EQUIPMENT: Maintain, service, and store user equipment

according to manufacturer’s instructions.

7.0 SPECIFICATIONS

7.1 MATERIALS:

• Rope Tensioner: Steel, plated

• O-rings: Alloy steel, plated

• Lifeline Rope: 11/16 in. nylon, static kernmantle, breaking

strength: 12,000 lb.

• Rope Tensioner Strap: Polyester/Nylon

• Snap Hooks: Alloy steel, plated

• Carabiners: High tensile alloy steel, plated

• Tie-off Adaptor: Polyester web, plated alloy steel hardware

19

Page 20

8.0 LABELING

8.1 The following labels must be present and fully legible:

This product is RFID enabled, and contains an electronic

tag that can be read by compatible readers - providing

inspection logs, inventory management and other safety

information.

Ce produit est validé dans RFID et contient une rondelle

d'identication électronique qui peut être lue par des

lecteurs compatibles - en assurant des registres

d'inspection, de l'information sur la gestion des stocks et

d'autre information relative à la protection.

20

Page 21

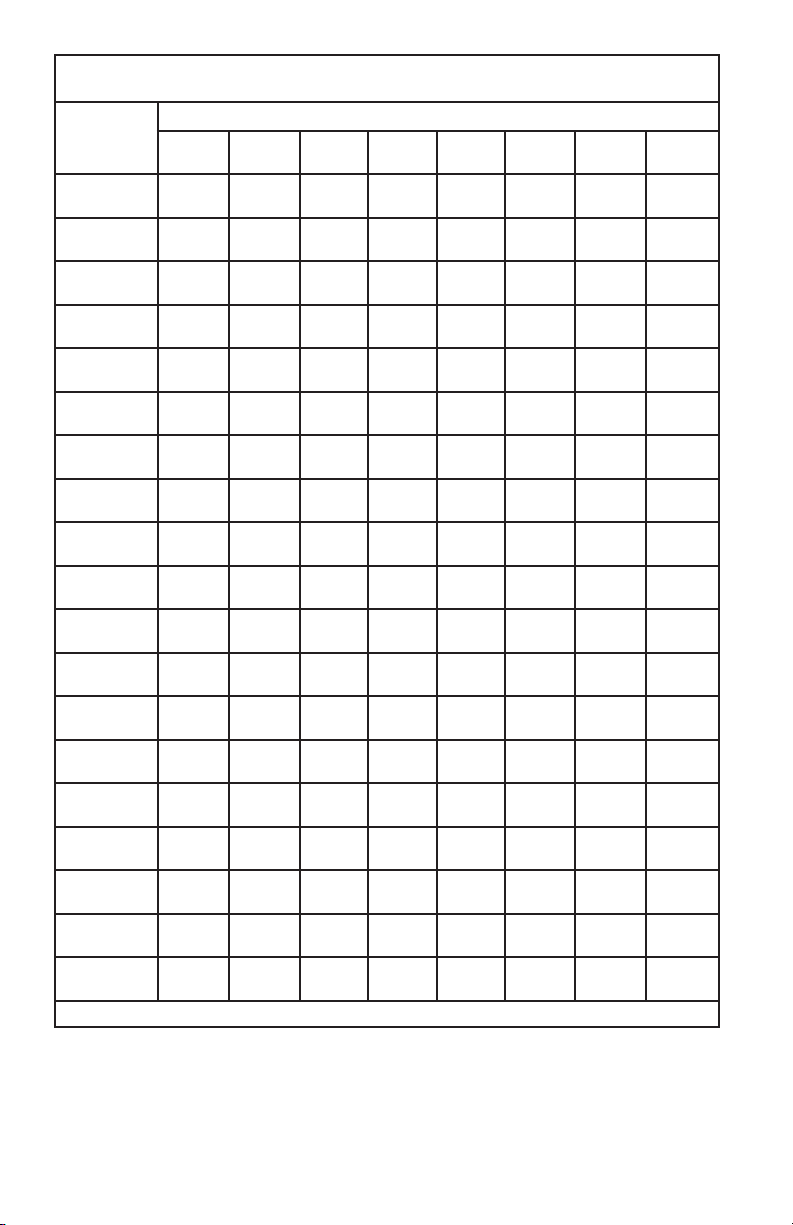

INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Page 22

Page 23

This instruction applies to the following models:

5908549

7600008

7600009

7600501

7600502

Additional model numbers may appear on the next printing of these instructions

7600503

7600504

7600505

7600506

7600507

7600508

7600509

7600510

7600511

7600512

7600513

7600514

7600515

7600516

7600517

7600518

7600519

7600520

7600521

7611904

Page 24

Page 25

Instruções para os seguintes

produtos de série:

CABO DE SEGURANÇA HORIZONTAL

COM TRAMA EM CORDA SINTÉTICA

Ver números de modelo especícos

nas últimas páginas

Manual de Instruções do usuário do sistema de cabo de

segurança horizontal com trama em corda sintética

Este manual deve ser usado como parte de um programa de treinamento de

funcionários, conforme os requisitos da OSHA.

Formulário: 5902179, Rev: F

© 3M 2018

Page 26

INFORMAÇÕES DE SEGURANÇA

PTPTPTPT-B

Favor ler, compreender e seguir todas as informações de segurança contidas nestas

instruções, antes do uso deste produto. O NÃO CUMPRIMENTO DESTAS EXIGÊNCIAS

PODERÁ CAUSAR LESÕES GRAVES OU MORTE.

Estas instruções devem ser fornecidas ao usuário do equipamento. Guarde estas

instruções para referência futura.

Utilização prevista:

Este produto é utilizado como parte de um sistema completo de proteção contra quedas.

O uso em qualquer outra aplicação incluindo, mas não limitado a, manuseio de materiais, atividades

recreativas ou esportivas, ou outras atividades não descritas nestas instruções, não é aprovado pela

3M e pode resultar em ferimentos graves ou morte.

Este produto deve ser usado somente por usuários treinados em aplicações no local de trabalho.

! AVISO

Este produto é utilizado como parte de um sistema completo de proteção contra quedas. Todos

os usuários devem ser totalmente treinados para a instalação e operação segura de seu sistema

completo de proteção contra quedas. O mau uso deste produto pode resultar em lesões

graves ou morte. Para uma seleção, operação, instalação, manutenção e serviço adequados,

consulte todos os manuais de instruções e recomendações do fabricante. Para mais informações,

consulte seu supervisor ou entre em contato com os serviços técnicos da 3M.

Para reduzir os riscos associados ao uso de um Sistema Horizontal, os quais, quando não

evitados, podem resultar em ferimentos graves ou morte:

- Inspecione o produto antes de cada uso e após qualquer evento de queda, de acordo com

os procedimentos especicados nestas instruções.

- Se a inspeção revelar uma condição insegura ou defeituosa, retire o produto de

serviço imediatamente e marque claramente "NÃO UTILIZAR". Destrua ou repare o

produto, conforme exigido por estas instruções.

- Qualquer produto que tenha sido sujeito a queda ou força de impacto deve ser

imediatamente removido de serviço. Destrua ou repare o produto, conforme exigido por

estas instruções.

- Certique-se de que os sistemas proteção de queda montados a partir de componentes

fabricados por diferentes fabricantes sejam compatíveis e atendam a todos os

regulamentos, normas ou exigências aplicáveis de proteção de queda. Consulte sempre

um indivíduo qualicado ou competente antes de utilizar estes sistemas.

- O produto só deverá ser instalado conforme descrito em seus manuais de instruções.

Modalidades de instalação e uso fora do escopo destes manuais de instruções devem ser

aprovadas por escrito pela 3M.

- Antes de instalar, certique-se de que os métodos de instalação e o produto não

interferirão nas linhas elétricas, nas tubulações de gás ou em outros materiais/sistemas

críticos.

- Certique-se de que o produto esteja congurado e instalado corretamente para uma

operação segura, conforme descrito nestas instruções.

- Não exceda o número de usuários permitidos especicado nestas instruções.

- Não torça, amarre, dê nó, ou permita folga na corda de segurança.

- Não se conecte ao sistema enquanto ele estiver sendo transportado ou instalado.

- Tenha cuidado ao instalar, usar ou mover o produto, pois peças móveis podem criar

pontos de aperto.

Nº DO FORMULÁRIO SIT 5908279,

REV: B

26

Page 27

• Para reduzir os riscos associados ao trabalho em altura que, se não forem evitados,

poderão resultar em lesão grave ou morte:

- Sua saúde e condição física devem permitir-lhe trabalhar com segurança em altura e

resistir a todas as forças associadas a um evento de parada de queda. Consulte seu

médico se você tiver dúvidas quanto à sua capacidade de usar este equipamento.

- Nunca exceda a capacidade permitida de seu equipamento de proteção contra queda.

- Nunca exceda a distância máxima de queda livre especicada para seu equipamento de

proteção contra quedas.

- Não utilize nenhum equipamento de proteção contra quedas que falhe a inspeção, ou

se você tiver preocupações sobre o uso ou a adequação do equipamento. Em caso de

dúvidas, entre em contato com o suporte técnico da 3M.

- Algumas combinações de subsistemas e componentes podem interferir na operação deste

equipamento. Utilize apenas conexões compatíveis. Contate o suporte técnico da 3M antes

de utilizar este equipamento em combinação com outros componentes ou subsistemas

além daqueles descritos nestas instruções.

- Use precauções extras ao trabalhar perto de máquinas em movimento, perigos elétricos,

temperaturas extremas, perigos químicos, gases explosivos ou tóxicos, bordas aadas,

superfícies abrasivas ou abaixo de materiais que possam cair sobre você ou sobre seu

equipamento de proteção contra quedas.

- Certique-se de que o uso de seu produto seja classicado para os perigos presentes em

seu ambiente de trabalho.

- Certique-se de que haja espaço suciente para queda quando se trabalha em altura.

- Nunca modique ou altere seu equipamento de proteção contra queda. Somente a 3M, ou

pessoas autorizadas por escrito pela 3M, podem fazer reparos em equipamentos 3M.

- Antes de usar o equipamento de proteção contra quedas, certique-se de que haja um

plano de resgate por escrito para proporcionar resgate imediato caso ocorra um incidente

de queda.

- Caso ocorra um incidente de queda, procure imediatamente atenção médica para o

trabalhador caído.

- Usar somente um cinturão tipo paraquedista de corpo inteiro para aplicações de detenção

de queda. Não use um cinturão abdominal.

- Para minimizar quedas pendulares, trabalhe o mais próximo possível da área abaixo do

ponto de ancoragem.

- Um sistema secundário de proteção contra quedas deve ser usado quando se treina com

este produto. Estagiários não devem ser expostos a um risco de queda não intencional.

- Sempre use Equipamento de Proteção Individual apropriado ao instalar, usar ou

inspecionar o produto.

- Nunca trabalhe abaixo de uma carga ou trabalhador suspenso.

- Manter sempre 100% de amarração.

Nº DO FORMULÁRIO SIT 5908279,

REV: B

27

Page 28

Figura 1 - Instalação típica

Anel O de conexão para o

usuário (talabarte)

Etiquetas

Mosquetão automático

Absorvedor de

energia em linha

Comprimento máximo de expansão de 30 m (100 pés)

Instalação típica do cabo de segurança horizontal

Tensor da corda

Fita cruzada

(Conector de ancoragem)

Ancoragem

28

Page 29

AVISO: Este produto faz parte de um sistema de trava-queda

individual. O usuário deve seguir as instruções do fabricante de cada

componente do sistema. Estas instruções deverão ser fornecidas ao

usuário deste equipamento. O usuário deverá ler e compreender estas

instruções antes de usar o equipamento. As instruções do fabricante

devem ser seguidas para utilização e manutenção correta deste

equipamento. Alterações no equipamento, erro em sua utilização ou

a não observância dessas instruções podem resultar em ferimentos

graves ou morte.

IMPORTANTE: Se você tiver dúvidas sobre o uso, cuidado ou

a adequação deste equipamento para a sua aplicação, entre em

contato com a 3M Fall Protection.

IMPORTANTE: registre as informações de identicação do produto

que estão na

etiqueta de identicação no Registro de Inspeção e

Manutenção na seção 9.0 deste manual.

1.0 APLICAÇÃO

1.1 FINALIDADE: O sistema de cabo de segurança horizontal com

trama de corda sintética Sayine foi desenvolvido para ser usado

como um recurso de ancoragem para uma ou duas pessoas.

Utilize o sistema de cabo de segurança horizontal com trama

Sayine em lugares onde a mobilidade horizontal e a proteção

contra quedas sejam necessárias.

1.2 LIMITAÇÕES: As seguintes limitações se aplicam à instalação

e ao uso do sistema de cabo de segurança horizontal com trama

em corda sintética Sayine. Outras limitações podem se aplicar:

IMPORTANTE: o empregador deve garantir que cada cabo de

segurança horizontal seja projetado, instalado e utilizado sob a

supervisão de um indivíduo qualicado; e que faça parte de um

sistema individual completo contra quedas que mantenha um fator de

segurança de pelo menos dois. Referência OSHA 1010.140 (c) (11).

Consulte também OSHA 1926.502 (d)(8).

INDIVÍDUO QUALIFICADO: alguém que, por possuir um diploma,

certicado ou posição prossional reconhecida, ou que, por meio de

amplo conhecimento, treinamento e experiência, tenha demonstrado

com sucesso a capacidade de resolver ou sanar problemas relacionados

ao assunto, ao trabalho ou ao projeto. Referência OSHA 1910.140 (b).

Consulte também OSHA 1926.32 (m).

A. EXPANSÃO DO CABO DE SEGURANÇA HORIZONTAL:

A distância de expansão máxima é de 30,48 m (100 pés).

O comprimento do vão deve ser menor quando a zona livre

de queda for limitada. Consulte a seção 3.2 para obter

informações sobre a zona livre de queda.

B. ANCORAGEM: o sistema de cabo de segurança horizontal

Sayfline deve ser instalado em ancoragens que atendam aos

requisitos especificados na seção 2.4.

C. CAPACIDADE DO SISTEMA: A capacidade máxima do

cabo de segurança horizontal Sayfline é de duas pessoas.

O peso máximo de cada pessoa, incluindo ferramentas e

roupa, é de 141 quilos (310 lbs).

29

Page 30

D. SUBSISTEMA DE CONEXÃO: O subsistema de conexão

de cada pessoa deve limitar as forças de prevenção contra

quedas em 4 kN (900 lb) ou menos. Consulte a Seção 2.5.

E. QUEDA LIVRE: ajuste e use o sistema de trava-queda

individual para que a

possível queda livre

máxima não exceda as

exigências do fabricante

do subsistema e as

normas governamentais.

Consulte a seção 3.0 e as

instruções do fabricante do

subsistema para obter mais

informações.

F. QUEDAS PENDULARES:

Consulte a Figura 2.

As quedas pendulares

ocorrem quando o ponto

de ancoragem não está

diretamente acima da

cabeça. A força ao atingir

um objeto em uma

queda pendular pode

provocar lesões graves

ou morte. Para minimizar

quedas pendulares, trabalhe o mais próximo possível da

área abaixo do ponto de ancoragem. Evite uma queda

pendular se houver possibilidade de ocorrer lesões. As

quedas pendulares aumentam significativamente a zona

livre de queda exigida quando um trava-queda retrátil ou

outro subsistema de conexão de comprimento variável é

utilizado. Se existir uma situação de queda pendular em sua

aplicação, entre em contato com a 3M Fall Protection antes

de prosseguir.

G. ZONA LIVRE DE QUEDA: deve haver zona livre de queda

suficiente abaixo do trabalhador para impedir uma queda

antes que ele atinja o nível mais baixo ou outro obstáculo.

Consulte a seção 3.2 para obter as informações necessárias

sobre a zona livre de queda.

H. SUPORTE CORPORAL: Um cinturão tipo paraquedista de

corpo inteiro deve ser usado com o sistema de cabo de

segurança horizontal com trama de corda sintética.

I. RISCOS AMBIENTAIS: O uso desse equipamento em

áreas onde há riscos ambientais pode exigir precauções

adicionais para reduzir a possibilidade de ferimentos

ao usuário ou danos ao equipamento. Os riscos podem

incluir, entre outros: alta temperatura, produtos químicos,

ambientes corrosivos, linhas de transmissão de alta tensão,

gases, máquinas em movimento e bordas afiadas. Entre em

contato com a 3M Fall Protection em caso dúvidas sobre o

uso deste equipamento quando houver riscos ambientais.

J. TREINAMENTO: este equipamento deve ser instalado e

utilizado por

corretas. Consulte a seção 4.0.

pessoas treinadas na sua aplicação e utilização

Figura 2 - Queda

pendular

Risco de queda

pendular

30

Page 31

1.3 NORMAS APLICÁVEIS: Consulte as normas dos Estados

Unidos, incluindo ANSI Z359.1 e os requisitos locais, estaduais

e federais (OSHA 1910.66 e 1926.502) para obter mais

informações sobre sistemas pessoais de prevenção contra

quedas e componentes associados. No Canadá, consulte o grupo

Z259 de normas da CSA.

2.0 REQUISITOS DO SISTEMA

2.1 COMPONENTES DO SISTEMA INDIVIDUAL DE

TRAVAMENTO DE QUEDA: O cabo de segurança horizontal

Sayine deve ser usado com componentes e subsistemas

aprovados pela 3M Fall Protection. Os componentes não

aprovados podem ser incompatíveis e poderão afetar a

segurança e a conabilidade de todo o sistema. Os componentes

pessoais de prevenção contra quedas usados com esse sistema

devem atender a todos os requisitos aplicáveis da OSHA e do

ANSI. É preciso usar um cinturão tipo paraquedista de corpo

inteiro com esse sistema.

2.2 CONECTORES DO SISTEMA INDIVIDUAL DE TRAVAMENTO

DE QUEDA: Os conectores usados para xar o anel O

de conexão no cabo de segurança horizontal (ganchos,

mosquetões, argolas em D) devem suportar pelo menos

(5000 lbf).

compatíveis em tamanho, formato e resistência. Conectores não

compatíveis podem provocar desengate involuntário (roll-out).

Não use conectores sem trava com este sistema.

2.3 CONECTORES DE ANCORAGEM: Conectores usados para

engatar o cabo de segurança horizontal em âncoras de

extremidades devem ser compatíveis com o ponto de conexão.

A conexão deve ser positiva e dispor de elementos de conexão

capazes de sustentar, sem falhas, uma carga de

(5000 lbf)

2.4 CARGA DA ESTRUTURA: Os pontos de ancoragem estrutural

devem ser rígidos

(5000 lbf) ao longo do eixo do cabo de segurança horizontal. As

ancoragens devem também suportar no mínimo 16 kN (3.600 lbf)

aplicados em todas as direções possíveis para prevenção contra

quedas que sejam perpendiculares ao eixo do cabo de segurança

horizontal. Consulte a Figura 3.

AVISO: as ancoragens devem ser rígidas. Grandes

deformações na ancoragem afetarão o desempenho do

sistema e podem aumentar a zona livre de queda necessária

para quedas abaixo do sistema, o que poderia resultar em

lesões graves ou morte.

2.5 SUBSISTEMA DE CONEXÃO: o subsistema de conexão é a

parte do sistema individual de travamento de queda usada

para fazer a conexão entre o subsistema do cabo de segurança

horizontal e o elemento de conexão de travamento de queda

do cinturão tipo paraquedista. O subsistema de conexão deve

limitar as forças aplicadas ao cabo de segurança horizontal a

4 kN (900 lbf) ou menos.

Os conectores e elementos de engate devem ser

22,2 kN

,

e capazes de suportar pelo menos 22,2 kN

22,2 kN

31

Page 32

Figura 3 - Exigências de resistência

Requisitos de resistência para ancoragem

Mínimo de 22,2 kN (5000 lbf) Mínimo de 22,2 kN (5000 lbf)

Mínimo de 16 kN (3600 lbf) em todas as direções possíveis de retenção

de queda que sejam perpendiculares ao eixo do cabo de segurança

3.0 OPERAÇÃO E USO

AVISO: Não altere este equipamento nem o use intencionalmente

de forma inadequada. Consulte a 3M Fall Protection quando utilizar

este equipamento em combinação com componentes ou subsistemas

que não sejam os descritos neste manual. Algumas combinações

de subsistemas e componentes podem interferir na operação deste

equipamento. Tenha cuidado ao usar este equipamento perto de

locais com máquinas em movimento, risco elétrico, risco causado por

substâncias químicas e bordas aadas.

AVISO: consulte seu médico se tiver qualquer razão para duvidar

de sua condição física para absorver o impacto do travamento de

queda. A idade e a condição física podem inuenciar na capacidade

de resistência de um trabalhador a forças de travamento de queda.

Mulheres grávidas ou menores de idade não devem usar esse sistema.

3.1 ANTES DE CADA UTILIZAÇÃO, inspecione este equipamento

de acordo com a seção 5.0. Não use este equipamento se

a inspeção detectar que há alguma condição insegura ou

defeituosa. Planeje o uso do sistema de prevenção contra

quedas antes de expor os trabalhadores a situações de perigo.

Considere todos os fatores que afetam sua segurança antes de

usar esse sistema.

A. Leia e entenda todas as instruções do fabricante de cada

componente do sistema individual de travamento de queda.

Todos os cinturões tipo paraquedista e subsistemas de

conexão da 3M Fall Protection são fornecidos com instruções

de usuário separadas. Guarde todas as instruções em local

seguro para futuras consultas.

B.

Reveja as seções 1.0 e 2.0 para garantir que as limitações do

sistema e outros requisitos tenham sido observados. Reveja as

informações aplicáveis relativas aos critérios de zona livre de

queda do sistema e assegure-se de que não tenham sido feitas

mudanças na instalação do sistema (ou seja, comprimento) ou

que estas não tenham ocorrido no local de trabalho, no caso

de poderem afetar a folga necessária para queda. Não utilize o

sistema se for necessário efetuar mudanças.

3.2 INSTALAÇÃO DO SISTEMA: A Figura 1 mostra uma instalação

típica do cabo de segurança horizontal Sayine. Ao usar um

talabarte de absorção de energia para conexão com o sistema,

as ancoragens de extremidades devem estar localizadas em uma

32

Page 33

altura que limitará a queda livre a 1,8 m (6 pés). Ao usar uma

trava-queda retrátil (self retracting lifeline, SRL) para conexão

com o sistema, as ancoragens de extremidades devem estar

localizadas acima do usuário. Quando totalmente retraído, o

trava-queda retrátil deve estar acima do nível de conexão do

cinturão tipo paraquedista. O sistema de cabo de segurança

horizontal deve estar posicionado em um nível que minimize a

queda livre, ao mesmo tempo permitindo a facilidade de uso.

A trava-queda horizontal deve estar posicionada próximo ao

local de trabalho para minimizar os riscos de queda pendular.

O comprimento do subsistema conector deve permanecer o

mais curto possível para reduzir a possibilidade de queda livre

e a distância necessária para zona livre de queda. Ambas as

ancoragens devem ser instaladas aproximadamente na mesma

elevação para que o sistema do cabo de segurança horizontal

não tenha inclinação de mais de 5°.

Etapa 1. Determine a localização das ancoragens de

extremidades e avalie sua resistência de acordo com

a seção 2.4. Determine o comprimento de expansão

e avalie a zona livre de queda necessária, usando as

Figuras 4, 5 ou 6 e as Tabelas 1, 2 ou 3.

Figura 4 - Zona Livre de Queda: Um trabalhador

com talabarte de absorção de energia

Comprimento do vão

Talabarte de

absorção de

Avaliação de zona livre de queda

para um trabalhador conectado ao

HLL com um talabarte de absorção

de energia da 3M Fall Protection

energia

Zona livre de queda necessária do nível inferior mais

próximo ou obstrução até a altura do sistema HLL

1) Encontre o comprimento de expansão de seu sistema

nas linhas da Tabela 1.

2) Encontre o comprimento de seu talabarte nas colunas

da Tabela 1.

3) A zona livre de queda necessária está onde a linha do

comprimento do vão e a coluna com o comprimento do

talabarte se cruzam.

33

Nível inferior ou

obstrução

Nível de

trabalho

Page 34

Tabela 1 - Zona livre de queda exigida para um trabalhador

conectado ao sistema com um talabarte de absorção de energia da

3M Fall Protection (consulte a Figura 4)

Compri-

mento de

expansão

pés (metros)

0–10

(0-3,05)

10–15

(3,05-4,57)

15–20

(4,57-6,10)

20–25

(6,10-7,62)

25–30

(7,62-9,14)

30–35

(9,14-10,67)

35–40

(10,67-12,19)

40–45

(12,19-13,72)

45–50

(13,72-15,24)

50–55

(15,2-16,76)

55–60

(16,76-18,29)

60–65

(18,29-19,81)

65–70

(19,81-21,34)

70–75

(21,34-22,86)

75–80

(22,86-24,38)

80–85

(24,38-25,91)

85–90

(25,91-27,43)

90–95

(27,43-28,96)

95–100

(28,96-30,48)

Comprimento do talabarte de absorção de energia em pés (metros)

em

3

(0,91)

16'-1"

(4,90)

16'-3"

(4,95)

16'-5"

(5,00)

16'-7"

(5,06)

16'-9"

(5,11)

17'-6"

(5,33)

18'-3"

(5,56)

18'-11"

(5,77)

19'-6"

(5,94)

20'-2"

(6,15)

20'-10"

(6,35)

21'-5"

(6,53)

22'-1"

(6,73)

22'-8"

(6,91)

23'-4"

(7,11)

24'-0"

(7,32)

24'-7"

(7,49)

25'-3"

(7,70)

25'-10"

(7,87)

4

(1,22)5 (1,52)6 (1,83)7 (2,13)

17'-1"

(5,20)

17'-3"

(5,26)

17'-5"

(5,31)

17'-7"

(5,36)

17'-9"

(5,41)

18'-6"

(5,64)

19'-3"

(5,87)

19'-11"

(6,07)

20'-6"

(6,25)

21'-2"

(6,45)

21'-10"

(6,66)

22'-5"

(6,83)

23'-1"

(7,04)

23'-8"

(7,21)

24'-4"

(7,42)

25'-0"

(7,62)

25'-7"

(7,80)

26'-3"

(8,00)

26'-10"

(8,18)

18'-1"

(5,51)

18'-3"

(5,56)

18'-5"

(5,61)

18'-7"

(5,66)

18'-9"

(5,72)

19'-6"

(5,94)

20'-3"

(6,17)

20'-11"

(6,38)

21'-6"

(6,55)

22'-2"

(6,76)

22'-10"

(6,96)

23'-5"

(7,14)

24'-1"

(7,34)

24'-8"

(7,52)

25'-4"

(7,72)

26'-0"

(7,93)

26'-7"

(8,10)

27'-3"

(8,31)

27'-10"

(8,48)

19'-1"

(5,82)

19'-3"

(5,87)

19'-5"

(5,92)

19'-7"

(5,97)

19'-9"

(5,97)

20'-6"

(6,25)

21'-3"

(6,48)

21'-11"

(6,68)

22'-6"

(6,86)

23'-2"

(7,06)

23'-10"

(7,26)

24'-5"

(7,44)

25'-1"

(7,65)

25'-8"

(7,82)

26'-4"

(8,03)

27'-0"

(8,23)

27'-7"

(8,41)

28'-3"

(8,61)

28'-10"

(8,79)

20'-1"

(6,12)

20'-3"

(6,12)

20'-5"

(6,27)

20'-7"

(6,27)

20'-9"

(6,33)

21'-6"

(6,55)

22'-3"

(6,78)

22'-11"

(6,99)

23'-6"

(7,16)

24'-2"

(7,37)

24'-10"

(7,57)

25'-5"

(7,75)

26'-1"

(7,95)

26'-8"

(8,13)

27'-4"

(8,33)

28'-0"

(8,53)

28'-7"

(8,71)

29'-3"

(8,92)

29'-10"

(9,09)

Metros são exibidos em parênteses

8

(2,44)

21'-1"

(6,43)

21'-3"

(6,48)

21'-5"

(6,53)

21'-7"

(6,58)

21'-9"

(6,63)

22'-6"

(6,86)

23'-3"

(7,09)

23'-11"

(7,29)

24'-6"

(7,47)

25'-2"

(7,67)

25'-10"

(7,87)

26'-5"

(8,05)

27'-1"

(8,26)

27'-8"

(8,43)

28'-4"

(8,64)

29'-0"

(8,84)

29'-7"

(9,02)

30'-3"

(9,22)

30'-10"

(9,40)

9

(2,74)

22'-1"

(6,73)

22'-3"

(6,78)

22'-5"

(6,83)

22'-7"

(6,88)

22'-9"

(6,93)

23'-6"

(7,16)

24'-3"

(7,39)

24'-11"

(7,60)

25'-6"

(7,77)

26'-2"

(7,98)

26'-10"

(8,18)

27'-5"

(8,36)

28'-1"

(8,56)

28'-8"

(8,74)

29'-4"

(8,94)

30'-0"

(9,14)

30'-7"

(9,32)

31'-3"

(9,53)

31'-10"

(9,70)

10

(3,1)

23'-1"

(7,04)

23'-3"

(7,09)

23'-5"

(7,14)

23'-7"

(7,19)

23'-9"

(7,24)

24'-6"

(7,47)

25'-3"

(7,70)

25'-11"

(7,90)

26'-6"

(8,08)

27'-2"

(8,28)

27'-10"

(8,48)

28'-5"

(8,66)

29'-1"

(8,87)

29'-8"

(9,04)

30'-4"

(9,25)

31'-0"

(9,45)

31'-7"

(9,63)

32'-3"

(9,83)

32'-10"

(10,01)

34

Page 35

Figura 5 - Zona Livre de Queda: Dois trabalhadores

com talabartes de absorção de energia

Comprimento do vão

Talabarte de absorção

Zona livre de queda necessária do nível inferior

mais próximo ou obstrução até a altura do

sistema HLL

1) Encontre o comprimento de expansão de

seu sistema nas linhas da Tabela 2.

2) Encontre o comprimento de seu talabarte

nas colunas da Tabela 2.

3) A zona livre de queda necessária está onde

a linha do comprimento do vão e a coluna com

o comprimento do talabarte se cruzam.

Avaliação de zona livre de queda

para um ou dois trabalhadores

conectados ao HLL com um

talabarte de absorção de energia

da 3M Fall Protection

de energia

Nível de

trabalho

Nível inferior

ou obstrução

35

Page 36

Tabela 2 - Zona livre de queda exigida para dois trabalhadores

conectados ao sistema com um talabarte de absorção de energia da

3M Fall Protection (consulte a Figura 5)

Compri-

Comprimento do talabarte de absorção de energia em pés (metros)

mento de

expansão

em pés

(metros)

0–10

(0-3,05)

10–15

(3,05-4,57)

15–20

(4,57-6,10)

20–25

(6,10-7,62)

25–30

(7,62-9,14)

30–35

(9,14-10,67)

35–40

(10,67-12,19)

40–45

(12,19-13,72)

45–50

(13,72-15,24)

50–55

(15,2-16,76)

55–60

(16,76-18,29)

60–65

(18,29-19,81)

65–70

(19,81-21,34)

70–75

(21,34-22,86)

75–80

(22,86-24,38)

80–85

(24,38-25,91)

85–90

(25,91-27,43)

90–95

(27,43-28,96)

95–100

(28,96-30,48)

3

(0,91)

16'-5"

(5,00)

17'-5"

(5,31)

18'-5"

(5,61)

19'-4"

(5,89)

20'-4"

(6,20)

21'-7"

(6,58)

22'-9"

(6,93)

23'-10"

(7,26)

24'-11"

(7,60)

26'-0"

(7,93)

27'-2"

(8,28)

28'-3"

(8,61)

29'-4"

(8,94)

30'-5"

(9,27)

31'-6"

(9,60)

32'-7"

(9,93)

33'-8"

(10,26)

34'-9"

(10,59)

35'-10"

(10,92)

4

(1,22)

17'-5"

(5,31)

18'-5"

(5,61)

19'-5"

(5,92)

20'-4"

(6,20)

21'-4"

(6,50)

22'-7"

(6,88)

23'-9"

(7,24)

24'-10"

(7,57)

25'-11"

(7,90)

27'-0"

(8,23)

28'-2"

(8,59)

29'-3"

(8,92)

30'-4"

(9,25)

31'-5"

(9,58)

32'-6"

(9,91)

33'-7"

(10,24)

34'-8"

(10,57)

35'-9"

(10,90)

36'-10"

(11,23)

5

(1,52)

18'-5"

(5,61)

19'-5"

(5,92)

20'-5"

(6,27)

21'-4"

(6,50)

22'-4"

(6,81)

23'-7"

(7,19)

24'-9"

(7,54)

25'-10"

(7,87)

26'-11"

(8,20)

28'-0"

(8,53)

29'-2"

(8,89)

30'-3"

(9,22)

31'-4"

(9,55)

32'-5"

(9,88)

33'-6"

(10,21)

34'-7"

(10,54)

35'-8"

(10,87)

36'-9"

(11,20)

37'-10"

(11,54)

6

(1,83)

19'-5"

(5,92)

20'-5"

(6,27)

21'-5"

(6,53)

22'-4"

(6,81)

23'-4"

(7,11)

24'-7"

(7,49)

25'-9"

(7,85)

26'-10"

(8,18)

27'-11"

(8,51)

29'-0"

(8,84)

30'-2"

(9,20)

31'-3"

(9,53)

32'-4"

(9,86)

33'-5"

(10,19)

34'-6"

(10,52)

35'-7"

(10,85)

36'-8"

(11,18)

37'-9"

(11,51)

38'-10"

(11,84)

Metros são exibidos em parênteses

7

(2,13)

20'-5"

(6,27)

21'-5"

(6,53)

22'-5"

(6,83)

23'-4"

(7,11)

24'-4"

(7,42)

25'-7"

(7,80)

26'-9"

(8,15)

27'-10"

(8,48)

28'-11"

(8,81)

30'-0"

(9,14)

31'-2"

(9,50)

32'-3"

(9,83)

33'-4"

(10,16)

34'-5"

(10,49)

35'-6"

(10,82)

36'-7"

(11,15)

37'-8"

(11,48)

38'-9"

(11,81)

39'-10"

(12,14)

8

(2,44)

21'-5"

(6,53)

22'-5"

(6,83)

23'-5"

(7,14)

24'-4"

(7,42)

25'-4"

(7,72)

26'-7"

(8,10)

27'-9"

(8,46)

28'-10"

(8,79)

29'-11"

(9,12)

31'-0"

(9,45)

32'-2"

(9,80)

33'-3"

(10,14)

34'-4"

(10,47)

35'-5"

(10,80)

36'-6"

(11,13)

37'-7"

(11,46)

38'-8"

(11,79)

39'-9"

(12,12)

40'-10"

(12,45)

9

(2,74)

22'-5"

(6,83)

23'-5"

(7,14)

24'-5"

(7,44)

25'-4"

(7,72)

26'-4"

(8,03)

27'-7"

(8,41)

28'-9"

(8,76)

29'-10"

(9,09)

30'-11"

(9,42)

32'-0"

(9,75)

33'-2"

(10,11)

34'-3"

(10,44)

35'-4"

(10,77)

36'-5"

(11,10)

37'-6"

(11,43)

38'-7"

(11,76)

39'-8"

(12,09)

40'-9"

(12,42)

41'-10"

(12,75)

30'-10"

31'-11"

(10,06)

(10,41)

(10,74)

(11,07)

(11,41)

(11,74)

(12,07)

(12,40)

(12,73)

42'-10"

(13,06)

10

(3,1)

23'-5"

(7,14)

24'-5"

(7,44)

25'-5"

(7,75)

26'-4"

(8,03)

27'-4"

(8,33)

28'-7"

(8,71)

29'-9"

(9,07)

(9,40)

(9,73)

33'-0"

34'-2"

35'-3"

36'-4"

37'-5"

38'-6"

39'-7"

40'-8"

41'-9"

36

Page 37

Figura 6 - Zona Livre de Queda: Um ou dois

trabalhadores com SRLs

Comprimento do vão

Zona livre de queda necessária do nível inferior

mais próximo ou obstrução até o nível de trabalho

1) Encontre o comprimento de expansão de seu

sistema nas linhas da Tabela 3.

2) Encontre o número de trabalhadores que estão

conectados ao sistema, nas colunas da Tabela 3.

3) A zona livre de queda necessária está onde a linha

do comprimento de expansão e a coluna com o número

de trabalhadores se cruzam.

Avaliação de zona livre de

queda para um ou dois

trabalhadores conectados ao

HLL com um trava-queda retrátil

da 3M Fall Protection

AVISO: Essas informações se aplicam

somente quando o SRL estiver diretamente

acima da cabeça e acima do nível do ponto

de conexão do cinturão tipo paraquedista,

e o usuário estiver de pé.

Trava-queda

retrátil

Nível inferior

ou obstrução

Nível de

trabalho

37

Page 38

Tabela 3 - Zona livre de queda exigida para um ou dois

trabalhadores conectados ao sistema com um trava-queda

retrátil da 3M Fall Protection (consulte a Figura 6).

Comprimento

de expansão

em pés

Zona livre de queda

necessária abaixo do nível de

trabalho para um trabalhador

Zona livre de queda necessária

abaixo do nível de trabalho

para dois trabalhadores

(metros)

0–10

(0-3,05)

10–15

(3,05-4,57)

15–20

(4,57-6,10)

20–25

(6,10-7,62)

25–30

(7,62-9,14)

30–35

(9,14-10,67)

35–40

(10,67-12,19)

40–45

(12,19-13,72)

45–50

(13,72-15,24)

50–55

(15,2-16,76)

55–60

(16,76-18,29)

60–65

(18,29-19,81)

65–70

(19,81-21,34)

70–75

(21,34-22,86)

75–80

(22,86-24,38)

80–85

(24,38-25,91)

85–90

(25,91-27,43)

90–95

(27,43-28,96)

95–100

(28,96-30,48)

7'-11"

(2,41)

8'-2"

(2,49)

8'-5"

(2,57)

8'-8"

(2,64)

8'-10"

(2,69)

9'-1"

(2,77)

9'-4"

(2,84)

10'-3"

(3,12)

11'-3"

(3,43)

12'-2"

(3,71)

13'-2"

(4,01)

14'-2"

(4,32)

15'-1"

(4,60)

16'-1"

(4,90)

17'-0"

(5,18)

18'-0"

(5,49)

19'-0"

(5,79)

19'-11"

(6,07)

20'-11"

(6,38)

Metros são exibidos em parênteses